3D printing method for embedded electronic product and 3D printer

A technology for 3D printers and electronic products, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve the problems of support removal and inability to realize integrated manufacturing of embedded electronic products, and achieve easy removal, convenient suspension of disassembly and The effect of high installation positioning and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

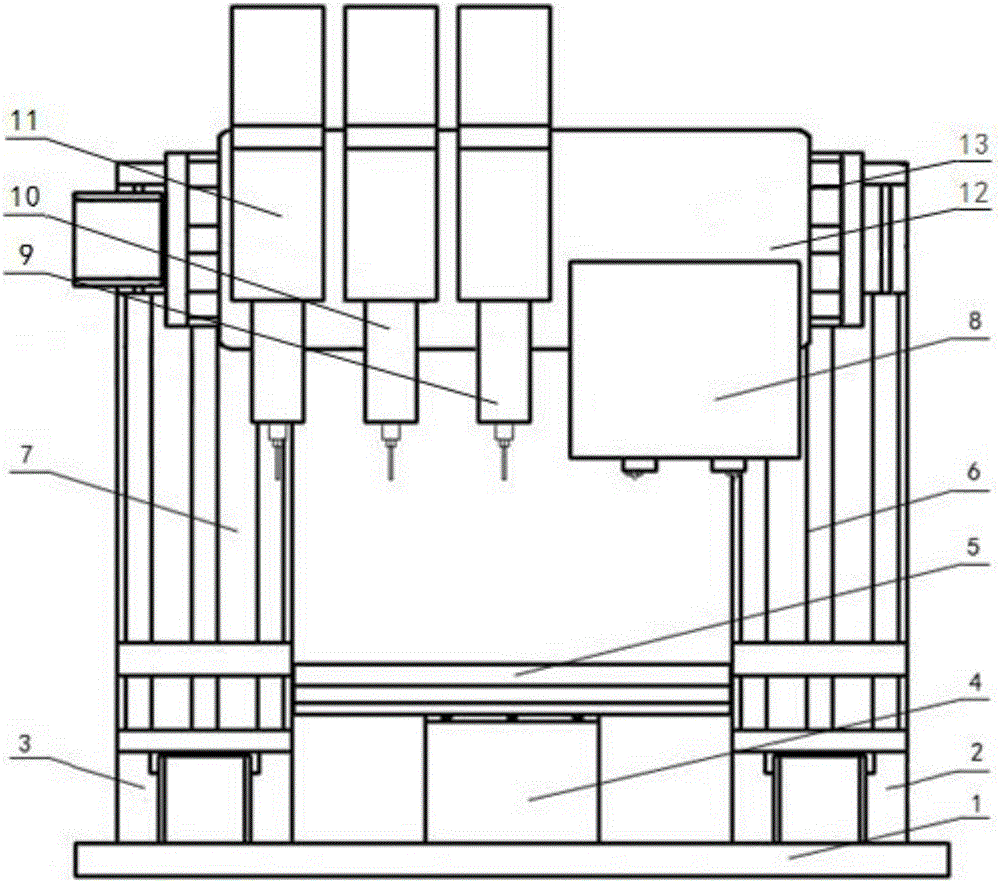

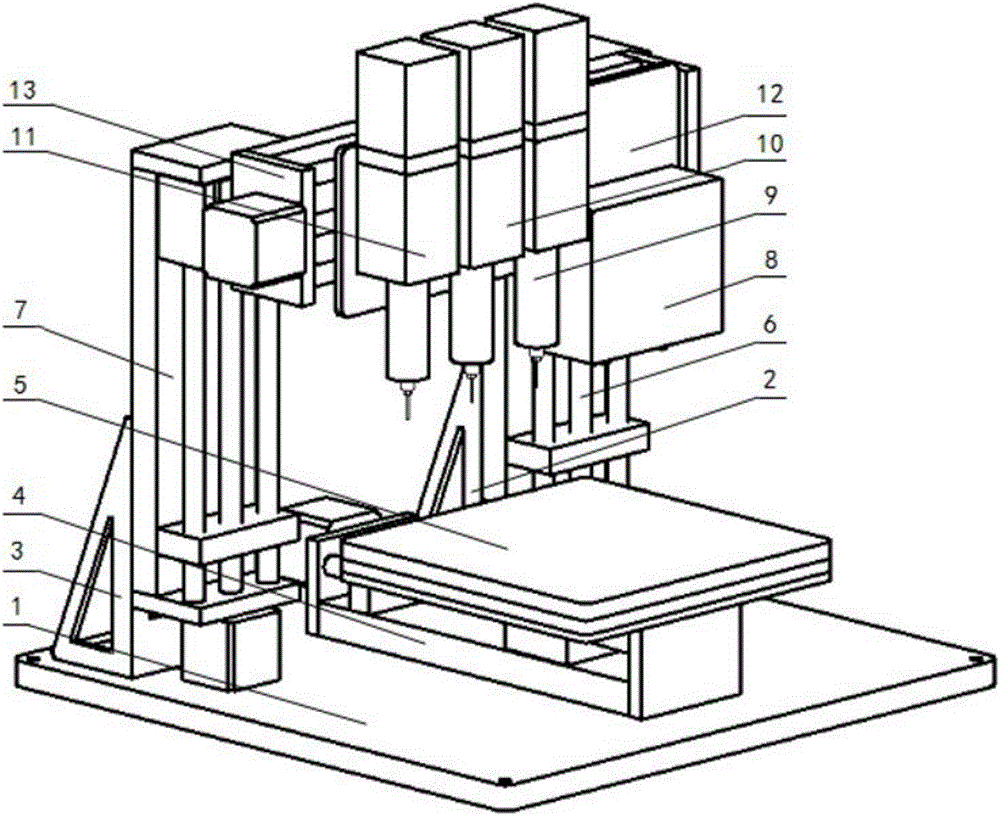

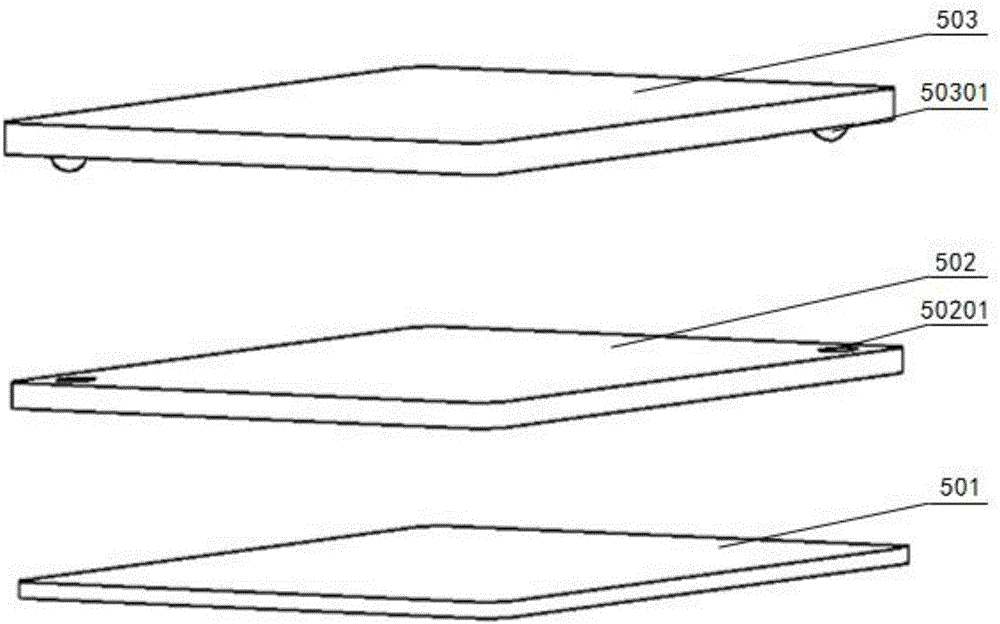

[0045] figure 1 It is a schematic diagram of the structure and principle of the 3D printer used to manufacture embedded electronic products in Embodiment 1 of the present invention, figure 2 It is a perspective view showing the structural principle of a 3D printer for manufacturing embedded electronic products according to Embodiment 1 of the present invention. Embodiment 1 The 3D printer used to manufacture embedded electronic products includes: base 1, support I2, support II3, Y-direction workbench 4, printing bed 5, Z-direction workbench I6, Z-direction workbench II7, first nozzle 8 , the second nozzle 9, the third nozzle 10, the fourth nozzle 11, the nozzle mounting plate 12, and the X-direction workbench 13. Among them, the Y-direction workbench 4 is fixed on the base 1 and is located in the center of the base 1; the printing bed 5 is composed of a support plate 501, a hot bed aluminum substrate 502 and a magnetic printing platform 503 and placed on the Y-direction work...

Embodiment 2

[0067] Embodiment 2 The schematic diagram of the structure and principle of the printer is as follows Figure 7 As shown, the electrojet printing technology is used to print conductive lines. Connecting the third spray head 10 and the printing bed 5 to the high-voltage power supply 14 can achieve higher precision of the conductive circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com