3D printing method for embedded electronic product

An electronic product, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems that restrict the development and wide application of embedded electronic products, cannot meet the engineering needs of embedded electronic products, and difficult to print submicroscale/nanoscale graphics , to achieve the effect of various types of printing materials, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as figure 2 As shown, the 3D printing method for embedded electronic products consists of the following steps:

[0034] Step 1: Carry out integrated design and optimization according to the structure of the electronic product, the position of the embedded electronic components, the function and actual requirements of the connecting circuit between the electronic components, and output the design results to the file format required by the fused deposition 3D printer;

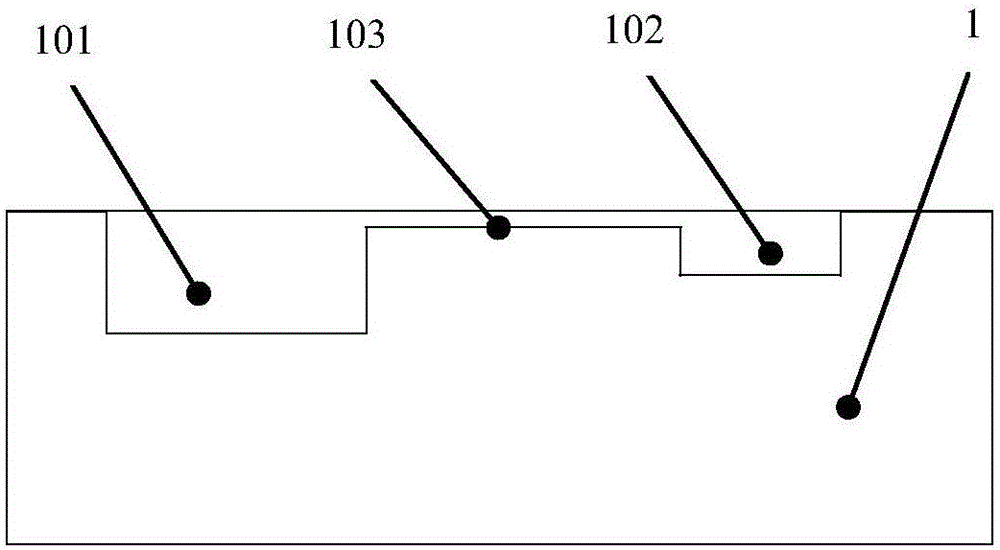

[0035] Step 2: Use a fused deposition 3D printer to manufacture electronic product structures (including basic functional structures, reserved hole structures for embedded electronic components, and reserved groove structures for connecting electronic components and connecting circuits, etc.);

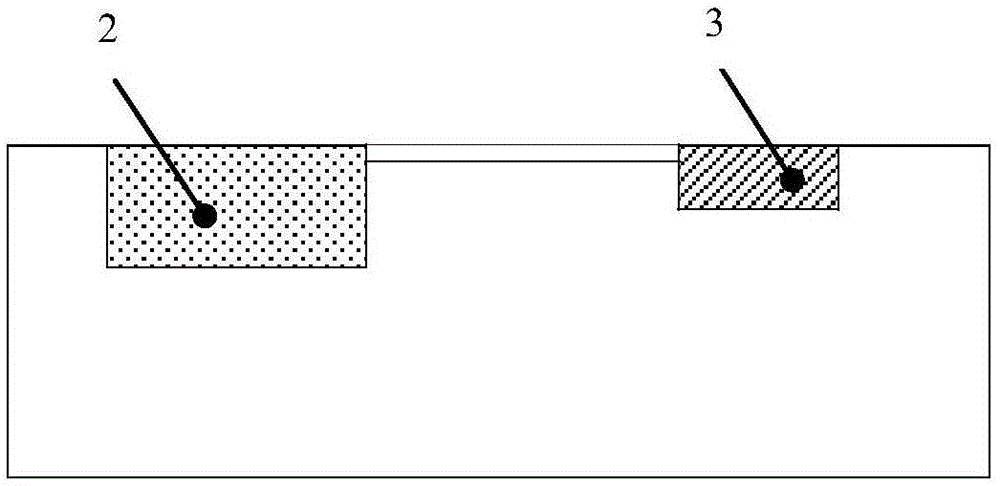

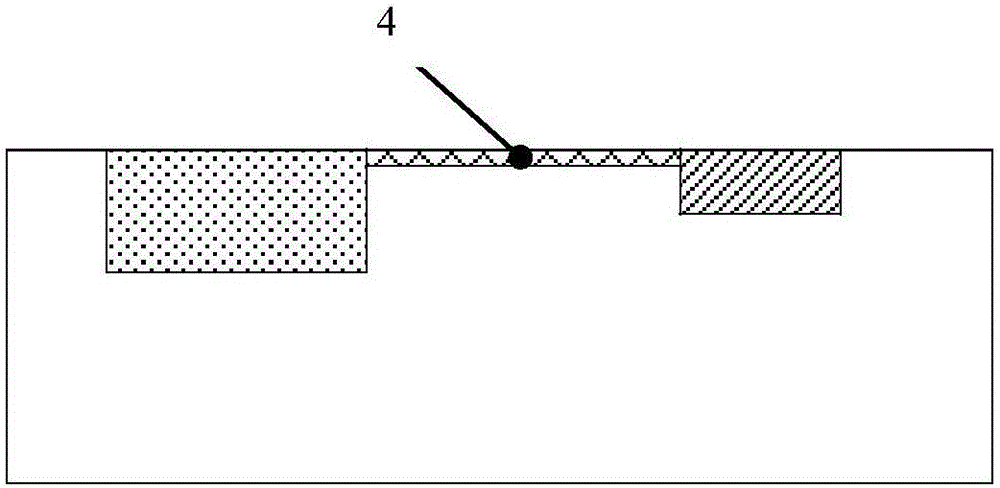

[0036] Step 3: Stop and pause the 3D printer according to the preset pause positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com