3D printing method of integrated encapsulating luminous device

A 3D printing, light-emitting device technology, applied in semiconductor devices, electrical components, ceramic molding machines, etc., can solve the problems of accelerated LED photoaging, reduced service life, hindered heat transfer, etc., to achieve good thermal conductivity, reduce Volume and weight, the effect of improving the performance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

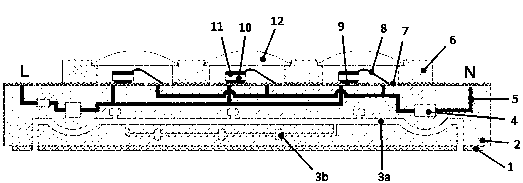

[0035] as attached figure 1 Shown, a kind of 3D printing method of integrated package light-emitting device, comprises the following steps:

[0036] S1, draw the model with 3D drawing software according to the design requirements, and convert it into a file format that can be recognized by the 3D printing equipment.

[0037] S2, use metal copper as the material to print the copper substrate 1 with the heat dissipation channel interface, the interface of the heat dissipation channel 3 is provided with threads for easy connection, print the ceramic substrate 2 with the heat dissipation channel 3 on the copper base 1, and the port of the heat dissipation channel 3 is facing The heat dissipation channel interface on the copper substrate 1, and the ceramic substrate is made of aluminum nitride. The direction of the heat dissipation channel is a composite structure of curved and straight lines, and may have a transverse heat dissipation channel 3a and a longitudinal heat dissipatio...

Embodiment 2

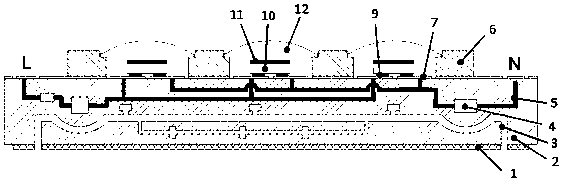

[0046] as attached figure 2 As shown, the printing steps are basically the same as in Example 1, including copper substrate 1, ceramic substrate 2, heat dissipation channel 3, electronic components 4, conductive circuit 5, bowl cup 6, power supply external pad 7, solder 9, LED chip 10 , phosphor glue 11, lens 12. The difference is that flip-chip LED chips are used. At this time, there is no need to print bonding wires, and the electrical connection is directly achieved through solder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com