Patents

Literature

1081results about "Manufacturing auxillary operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

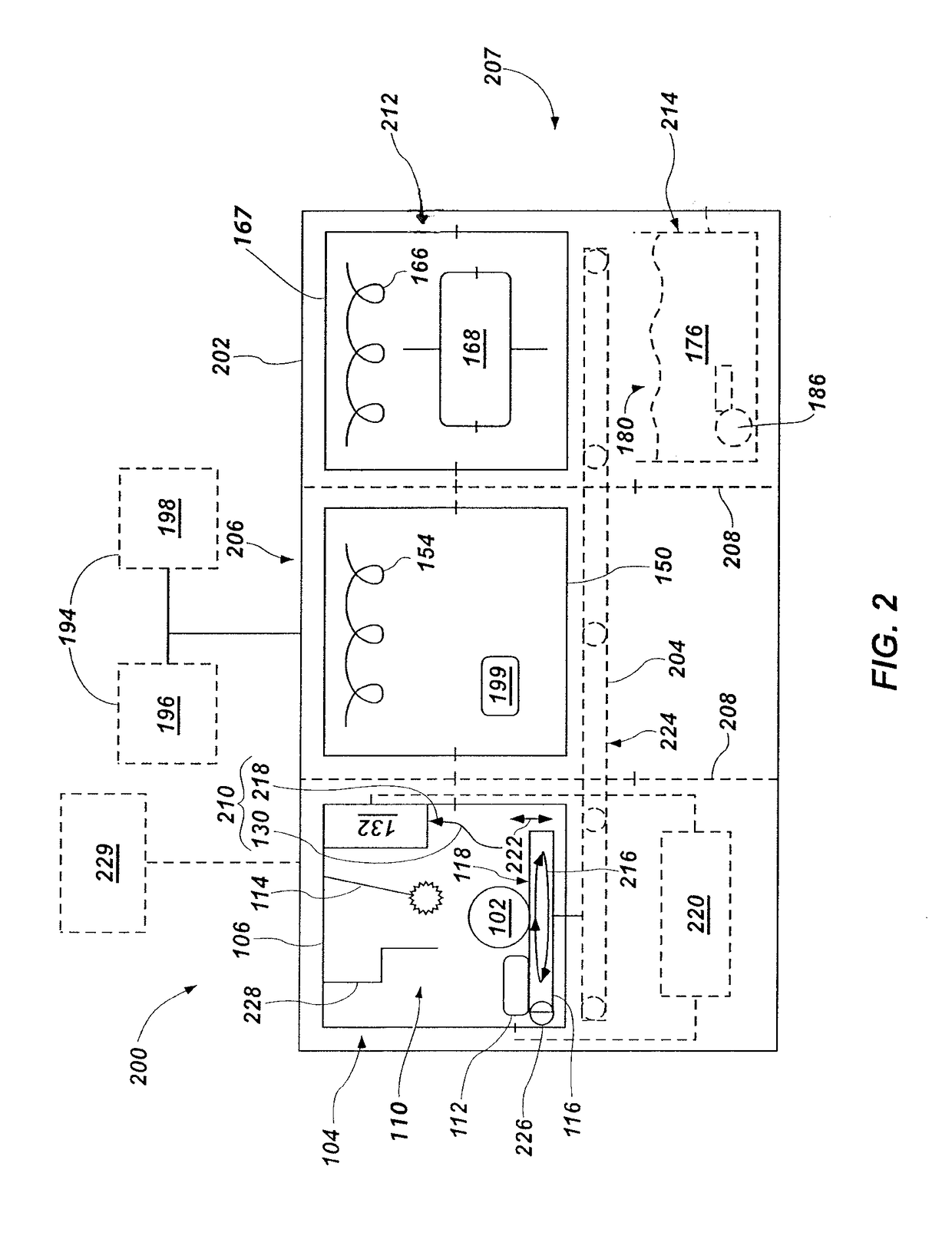

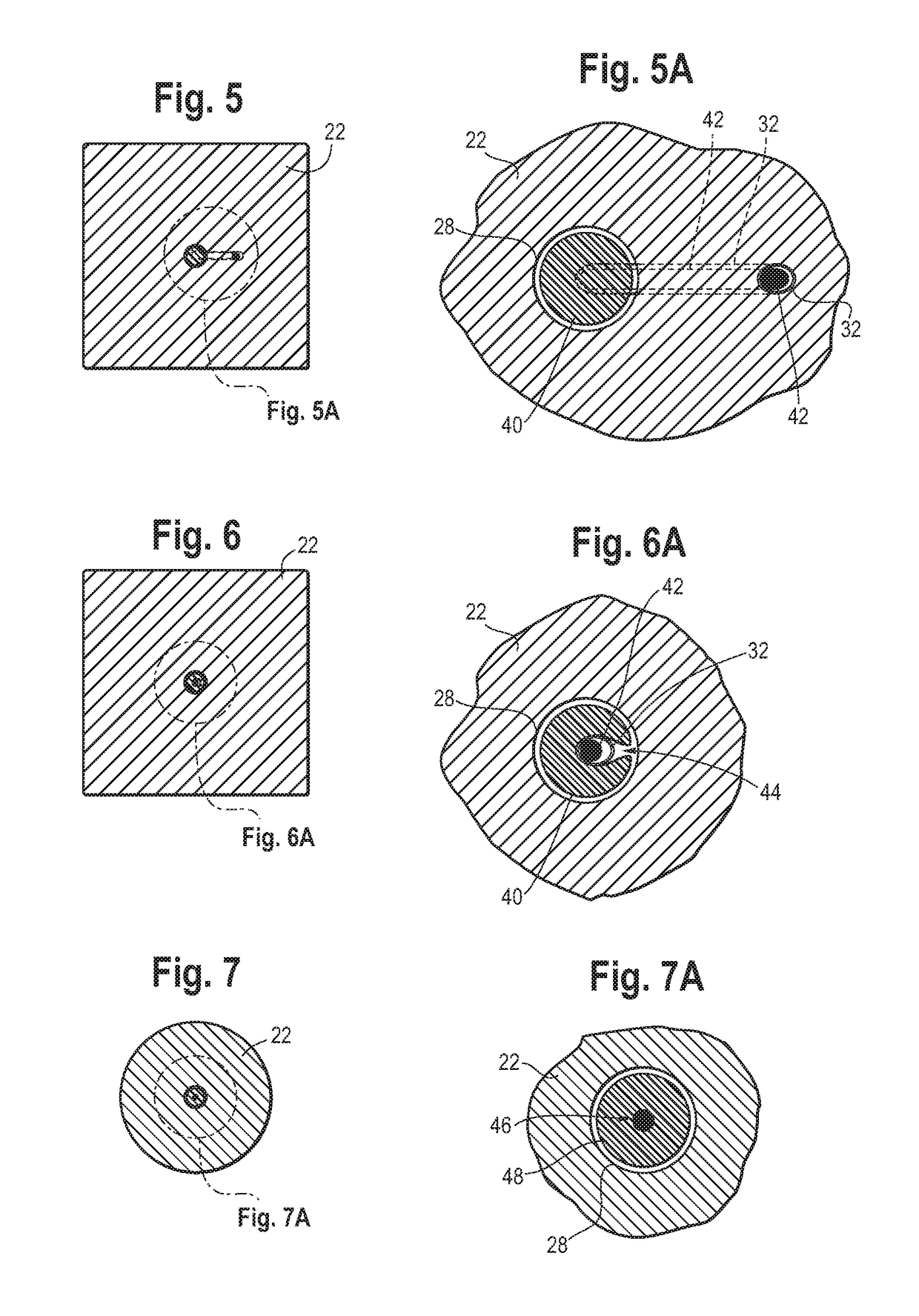

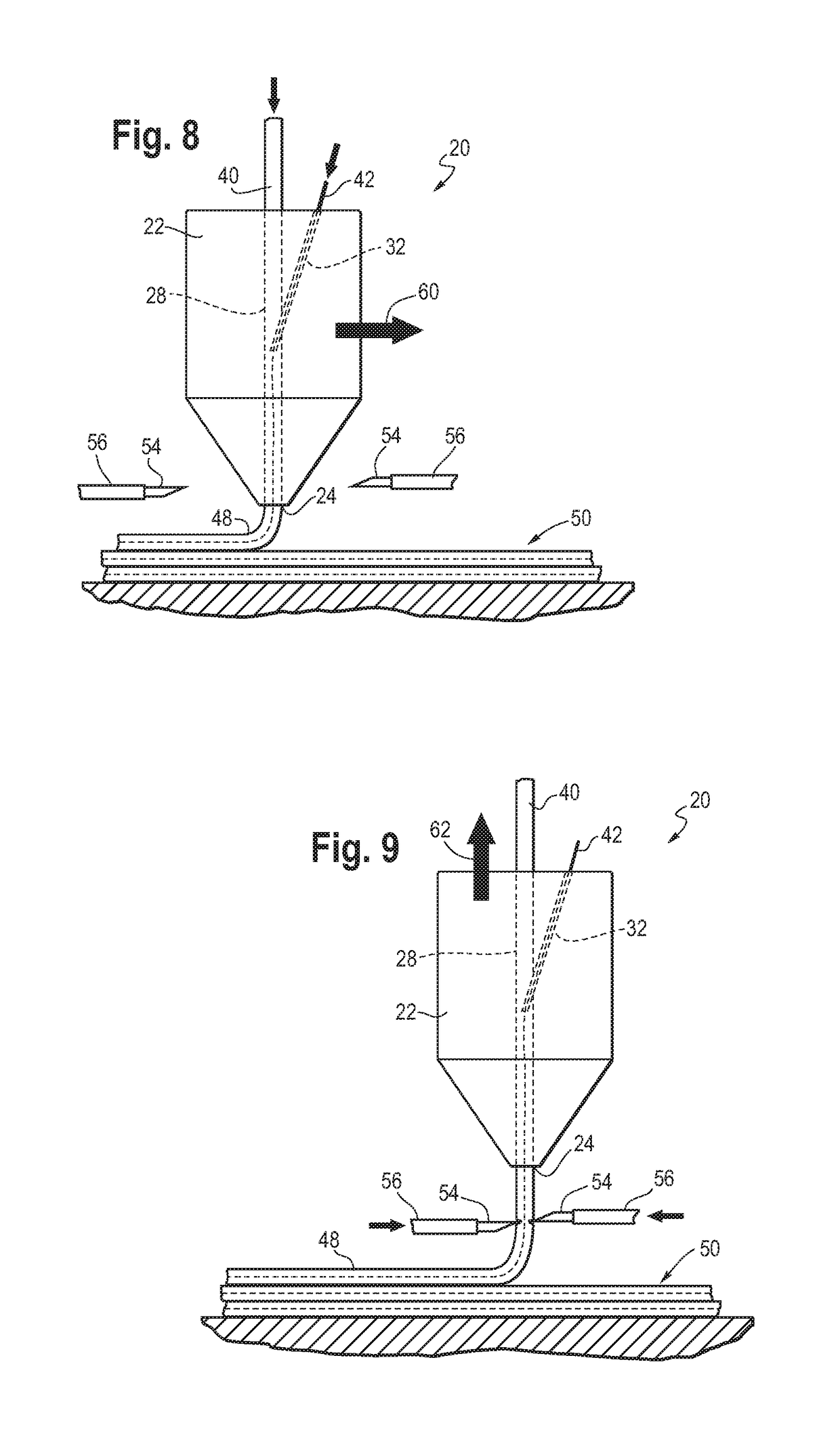

Method and apparatus for computer-aided tissue engineering for modeling, design and freeform fabrication of tissue scaffolds, constructs, and devices

ActiveUS20060105011A1Clear processProgramme controlAnimal cellsData processing systemProcess systems

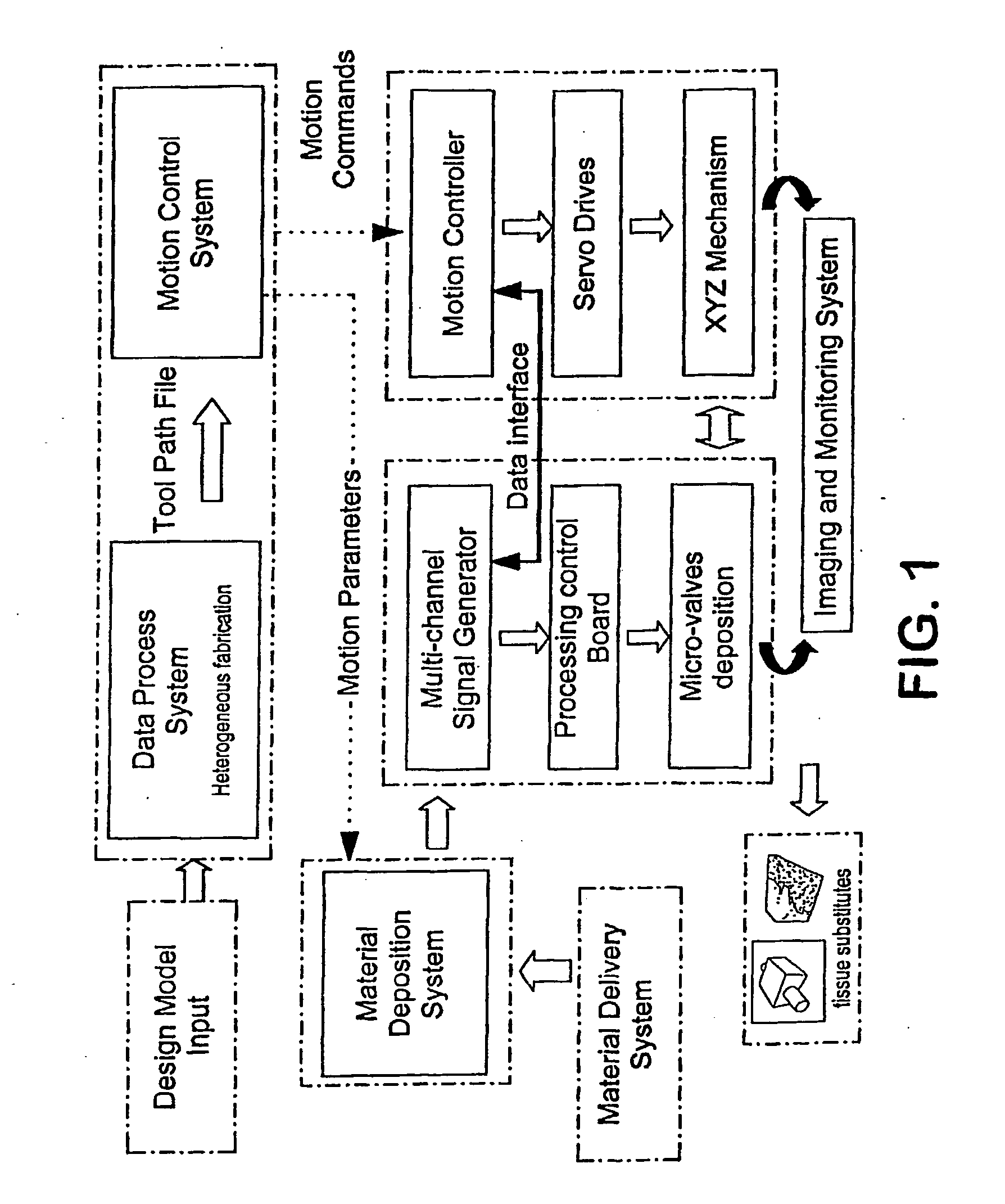

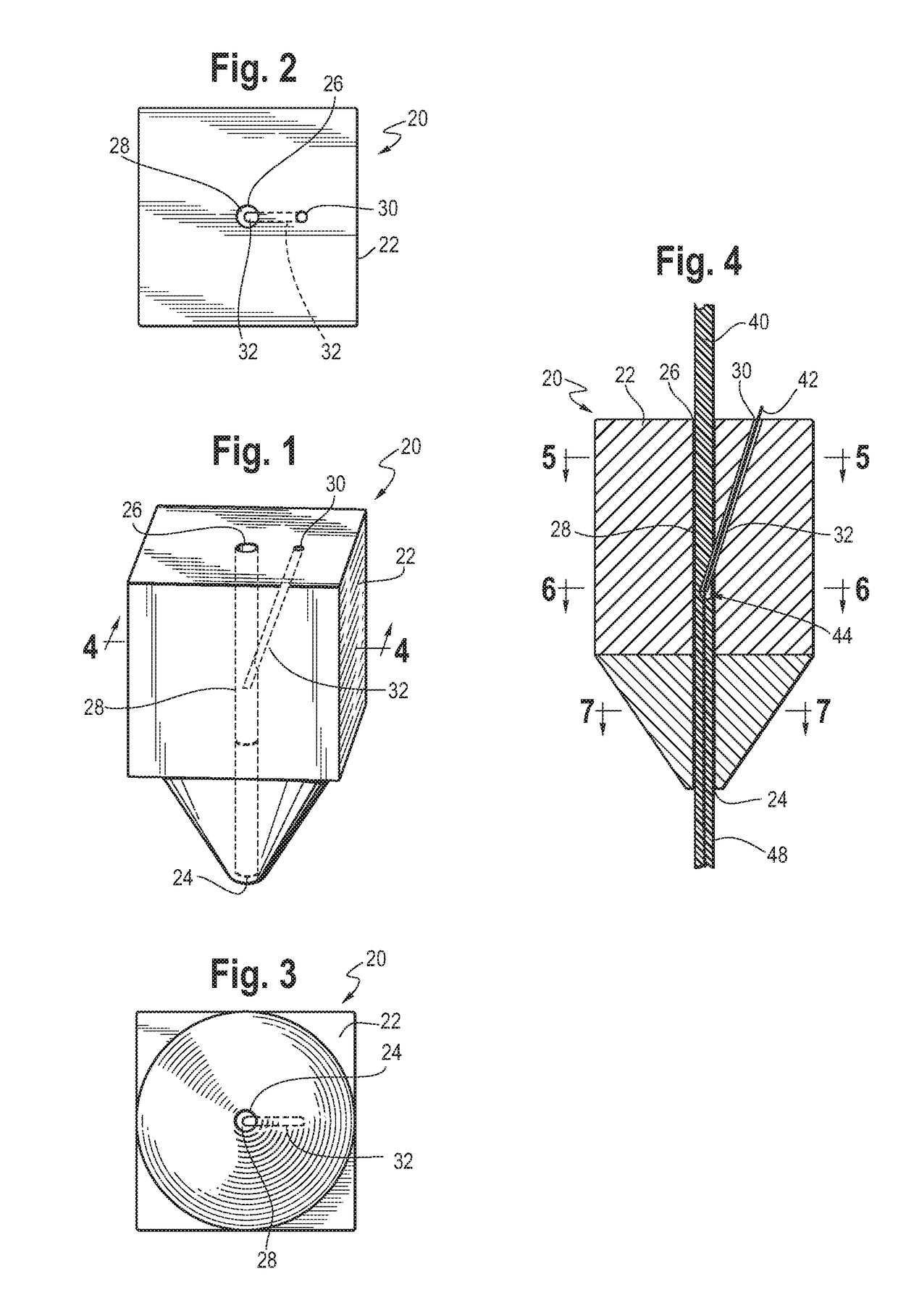

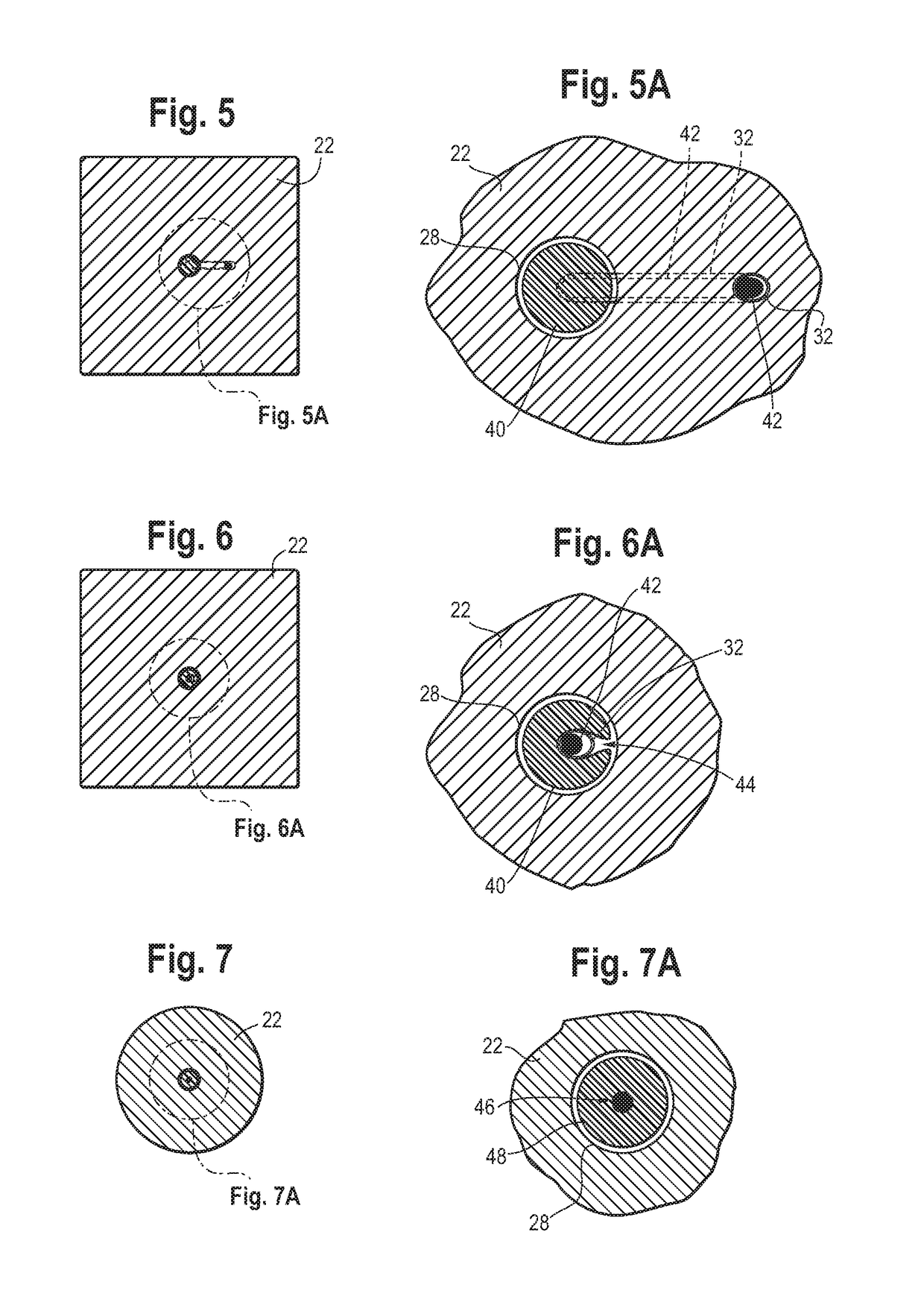

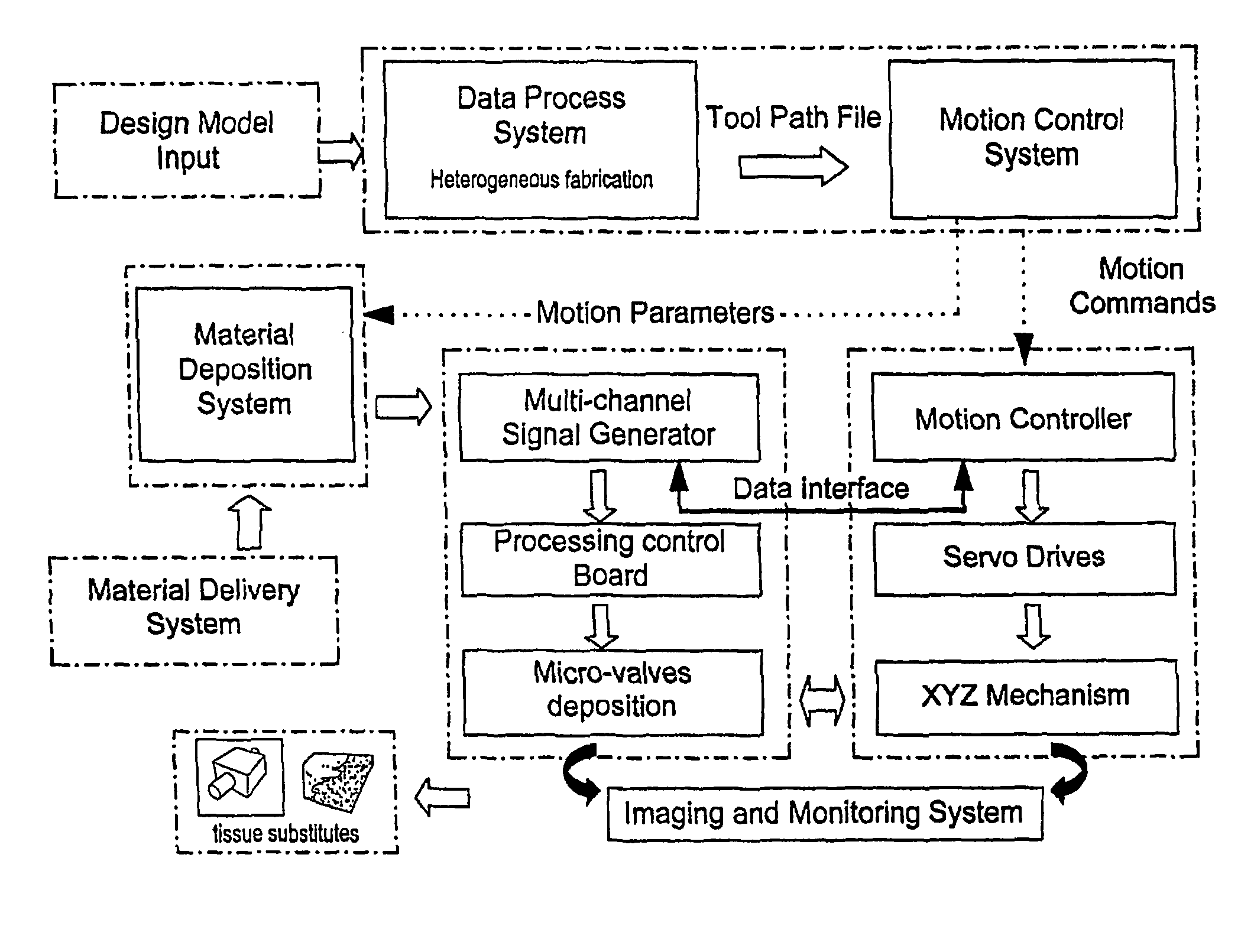

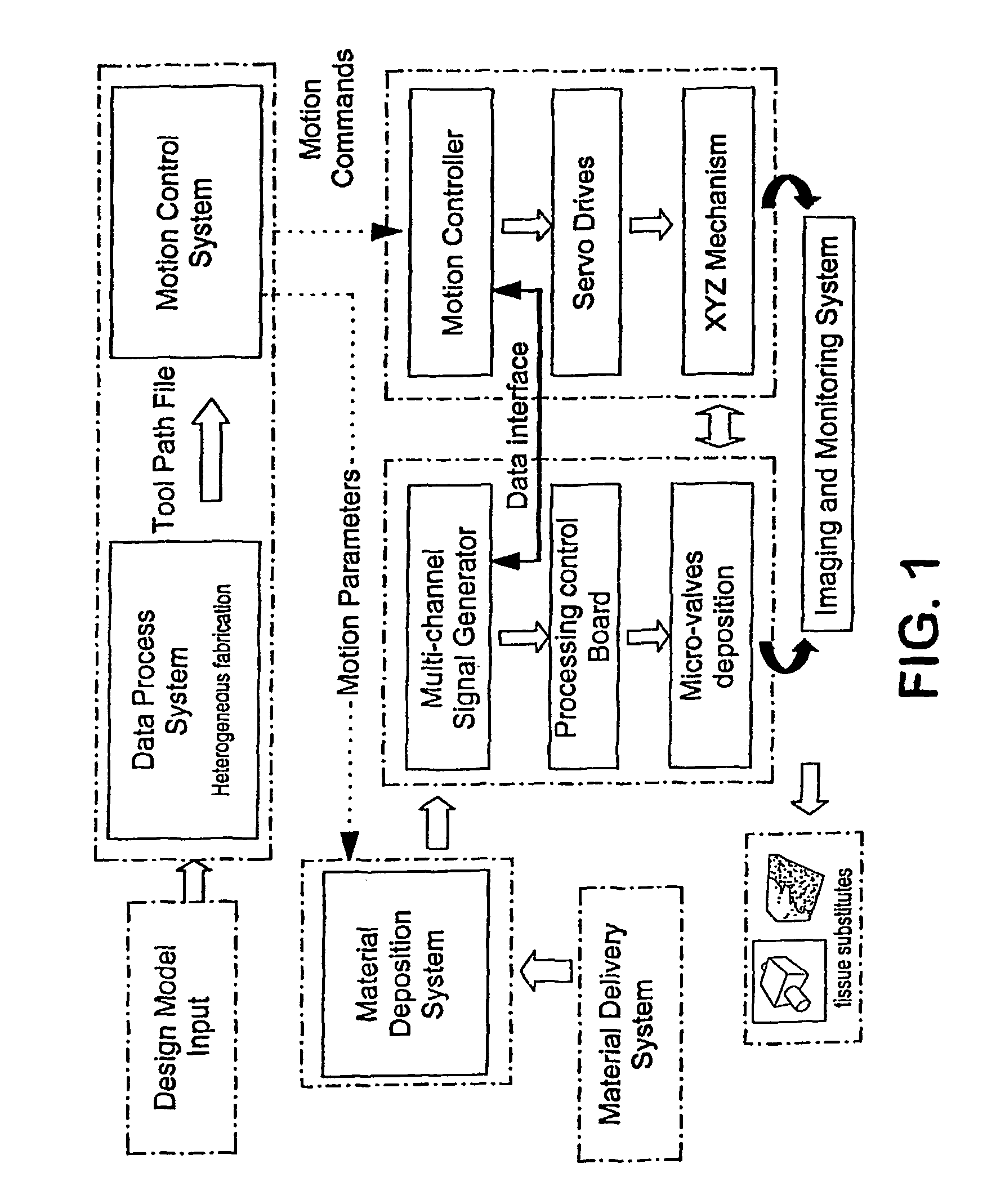

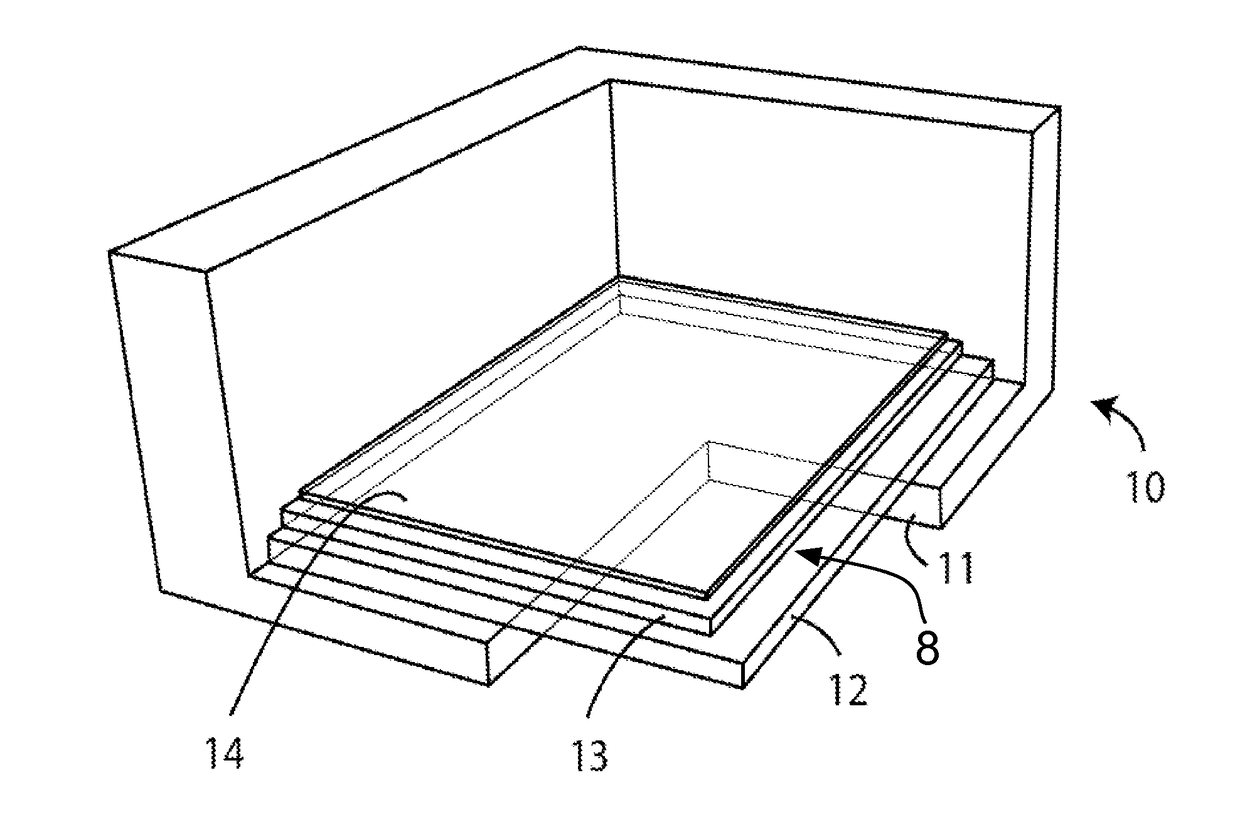

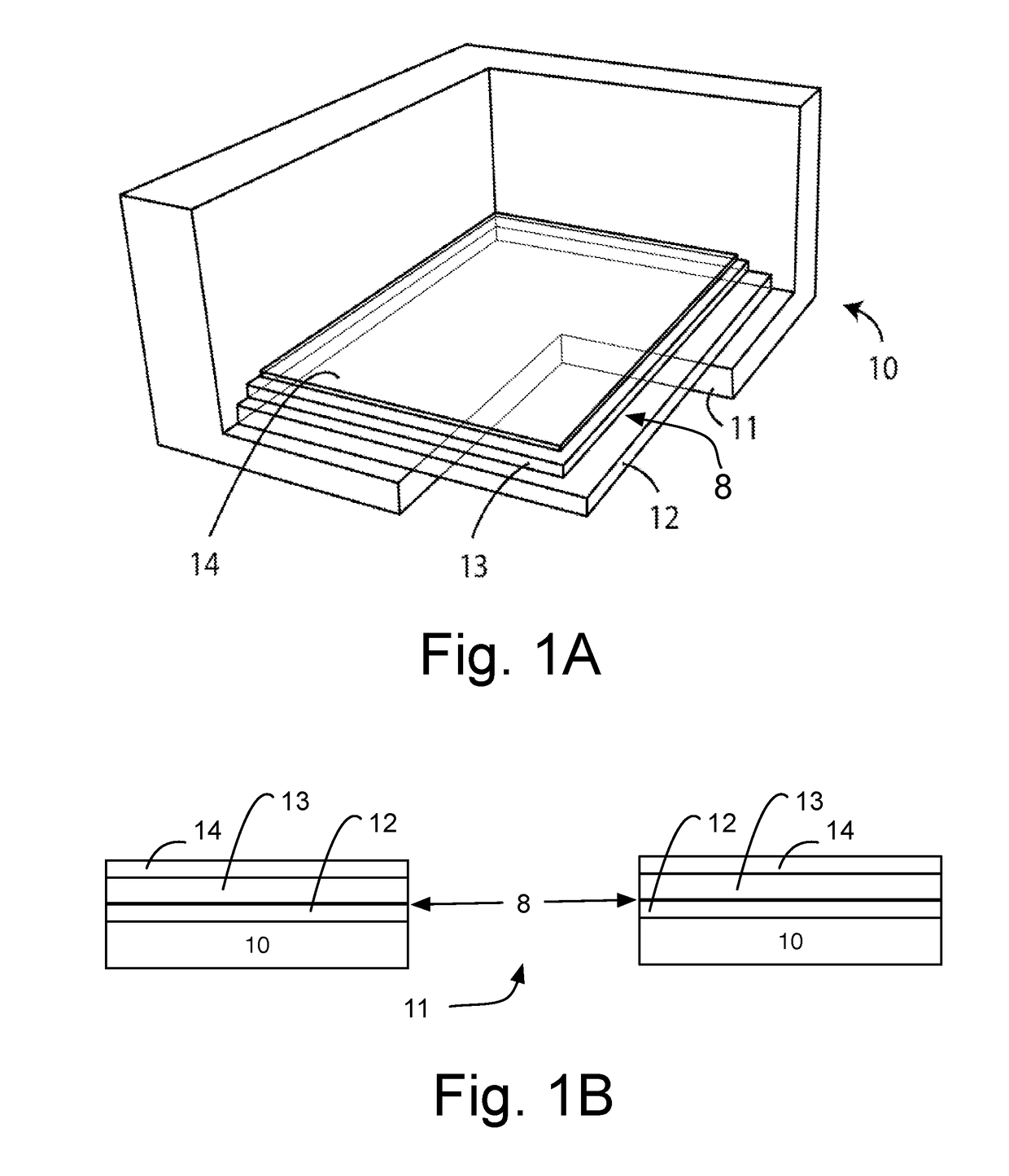

A process and apparatus are provided for manufacturing complex parts and devices which utilize a CAD environment to design a part or device to be created (FIG. 1); Boolean, scaling, smoothing, mirroring, or other operations to modify the CAD design; a software interface to convert the CAD designed part (Data Process System) or device into a heterogeneous material and multi-part assembly model (Design Input Model) which can be used for multi-nozzle printing; and a multi-nozzle system to print the designed part or device using different, specialized nozzles (Tissue substitutes).

Owner:DREXEL UNIV

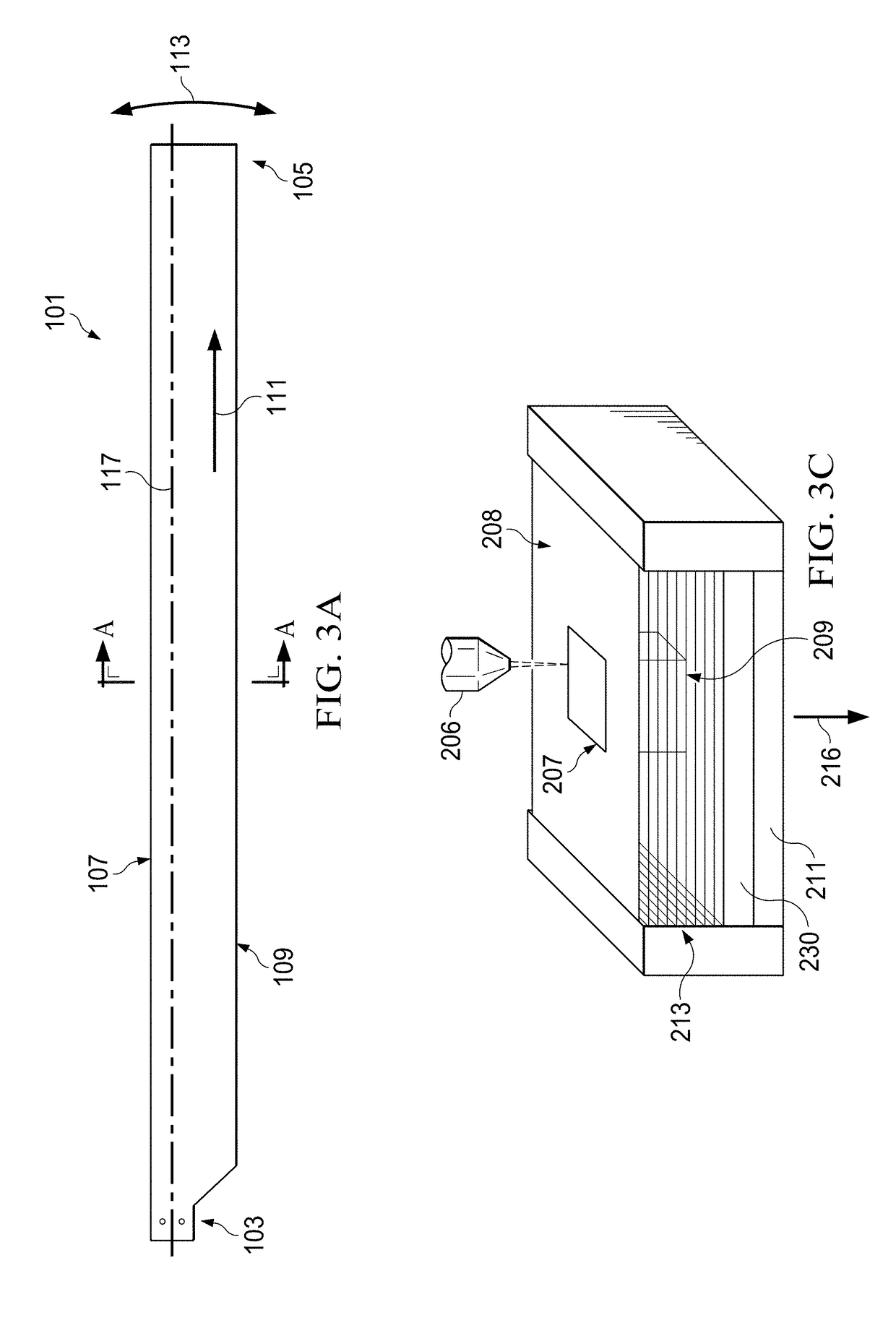

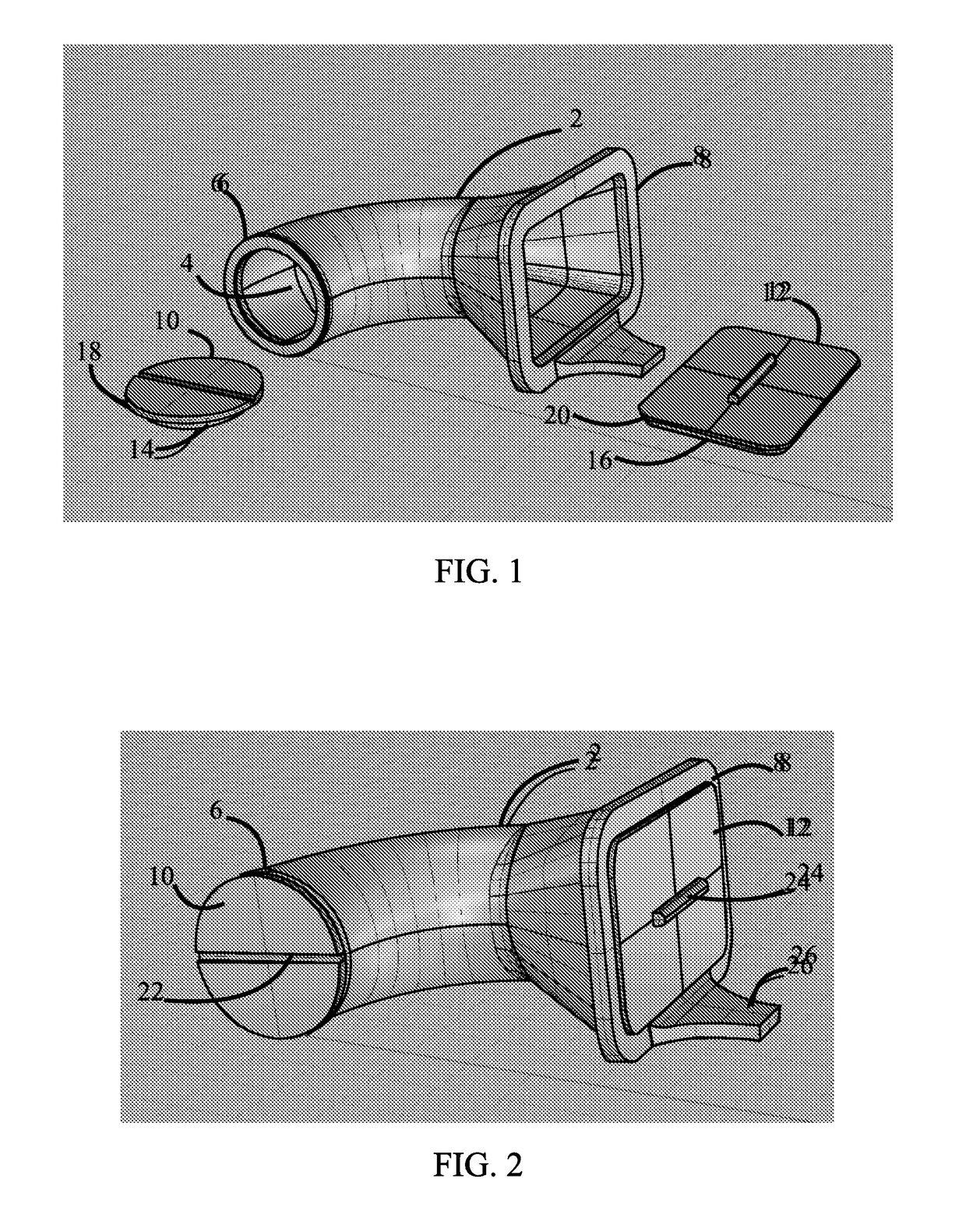

Device and method for 3D printing with long-fiber reinforcement

ActiveUS20170157851A1Eliminate point3D object support structuresAdditive mnaufacturing with solid and fluidAdvanced composite materialsPolymer

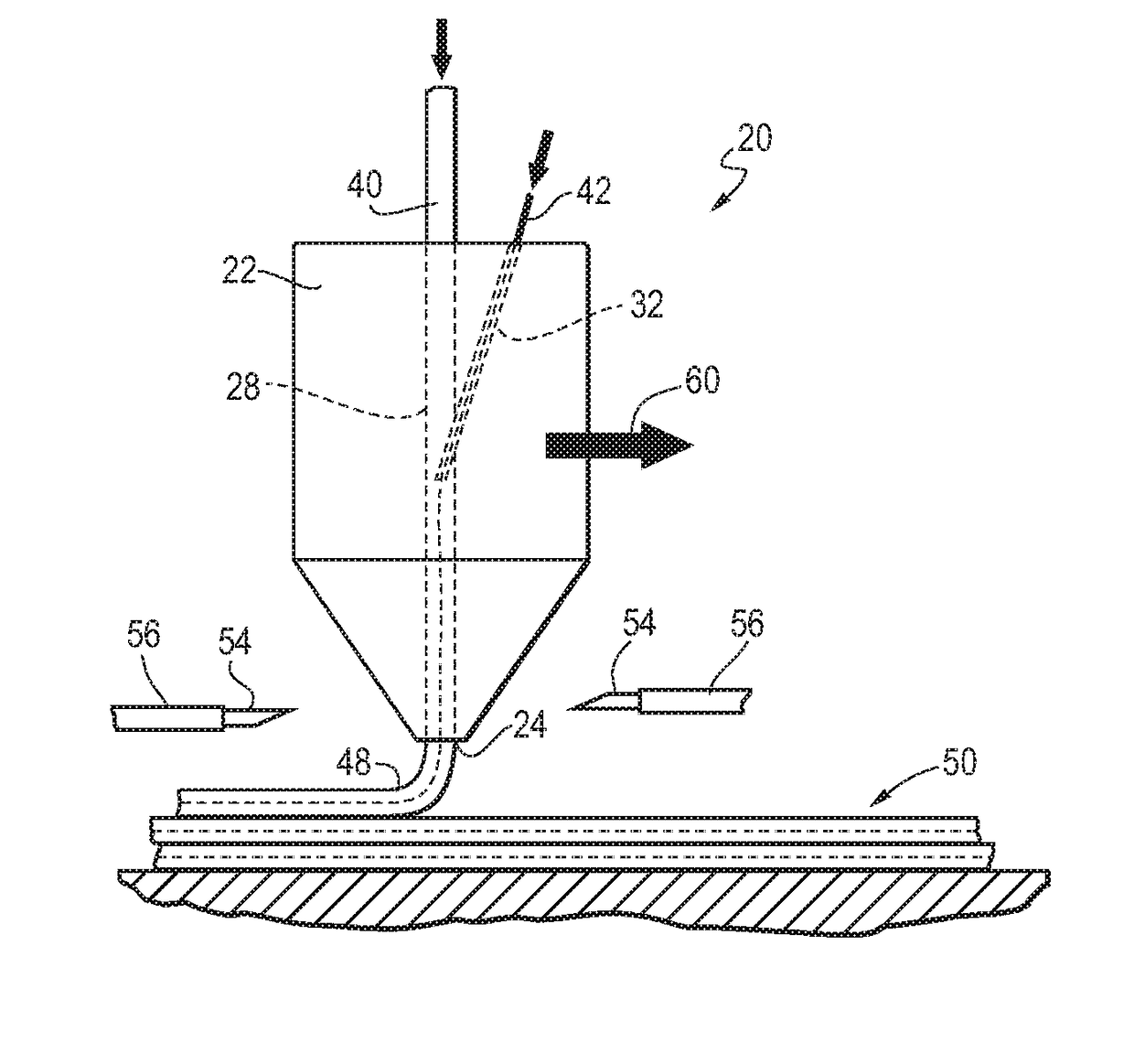

A process and device for 3D printing parts incorporating long-fiber reinforcements in an advanced composite material is disclosed. A nozzle for a 3D printing device receives a polymer material and a reinforcing fiber through separate inlets. A passage from the reinforcing fiber inlet cleaves the passage containing the polymer material, creating an interstitial cavity into which the reinforcing fiber is introduced. The polymer material closes back on itself and encapsulates the reinforcing fiber, then drags the fiber along with the flow and exits nozzle to be deposited on a work surface or part being manufactured.

Owner:NORTHROP GRUMMAN SYST CORP

Method and apparatus for computer-aided tissue engineering for modeling, design and freeform fabrication of tissue scaffolds, constructs, and devices

A process and apparatus are provided for manufacturing complex parts and devices which utilize a CAD environment to design a part or device to be created (FIG. 1); Boolean, scaling, smoothing, mirroring, or other operations to modify the CAD design; a software interface to convert the CAD designed part (Data Process System) or device into a heterogeneous material and multi-part assembly model (Design Input Model) which can be used for multi-nozzle printing; and a multi-nozzle system to print the designed part or device using different, specialized nozzles (Tissue substitutes).

Owner:DREXEL UNIV

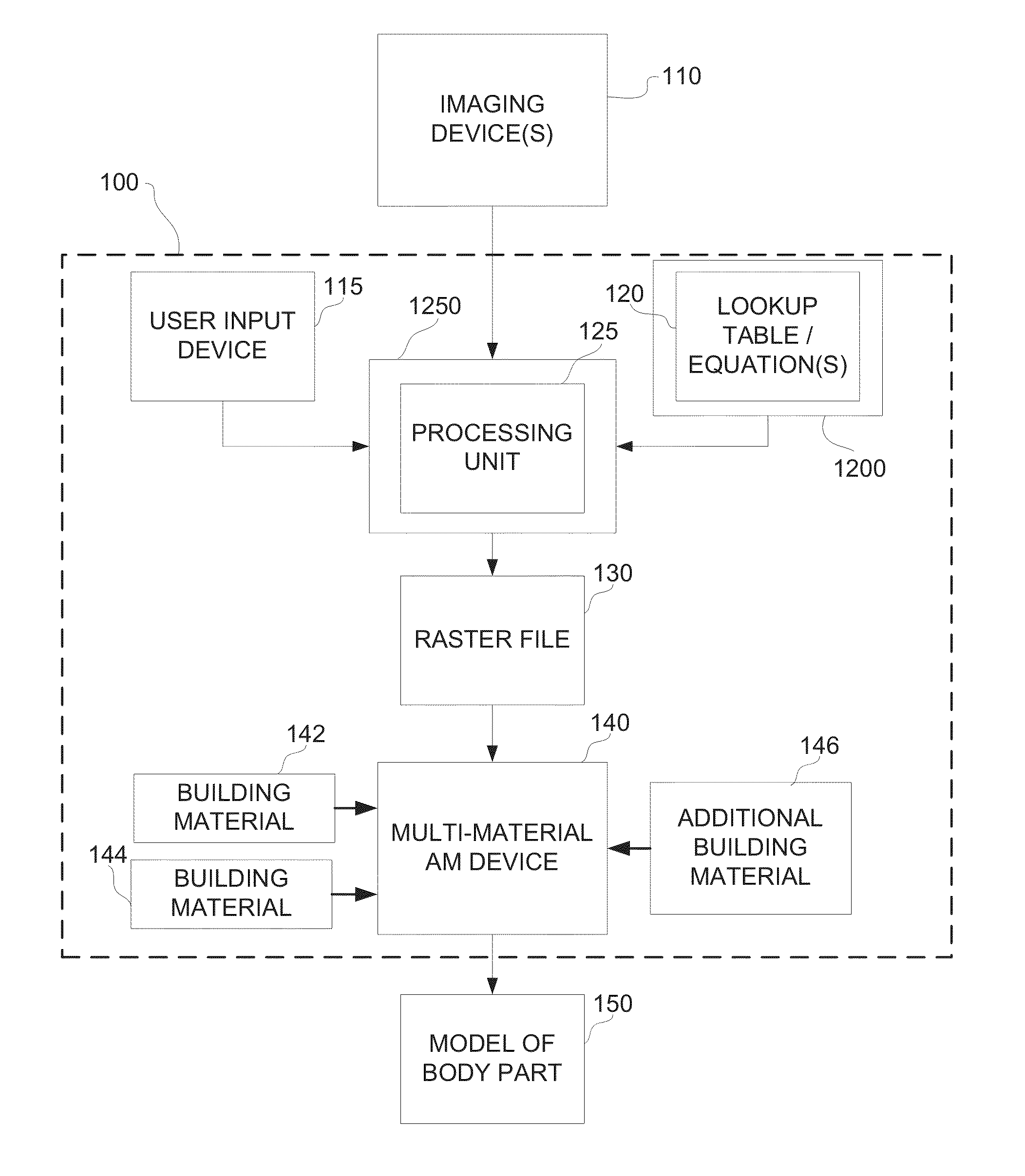

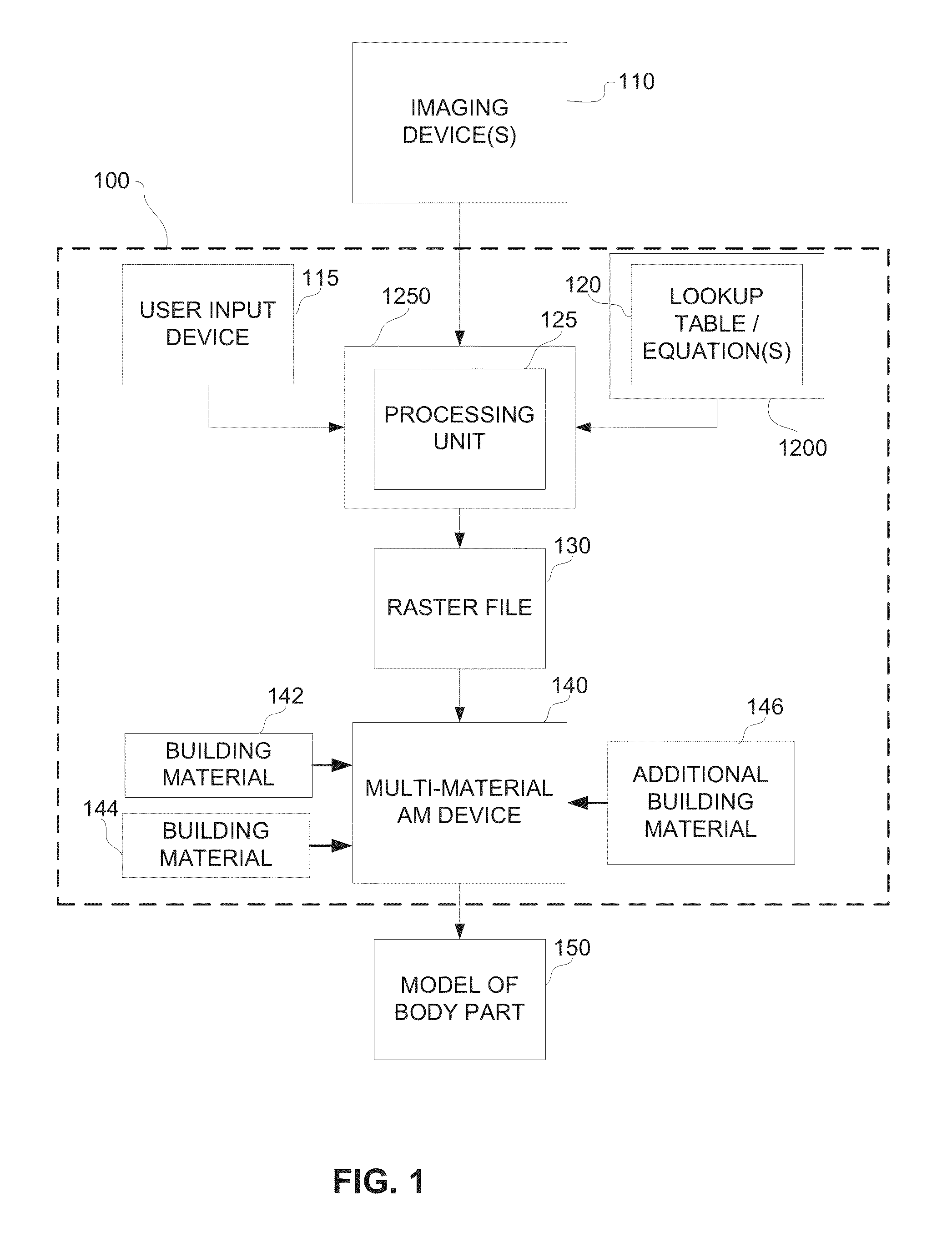

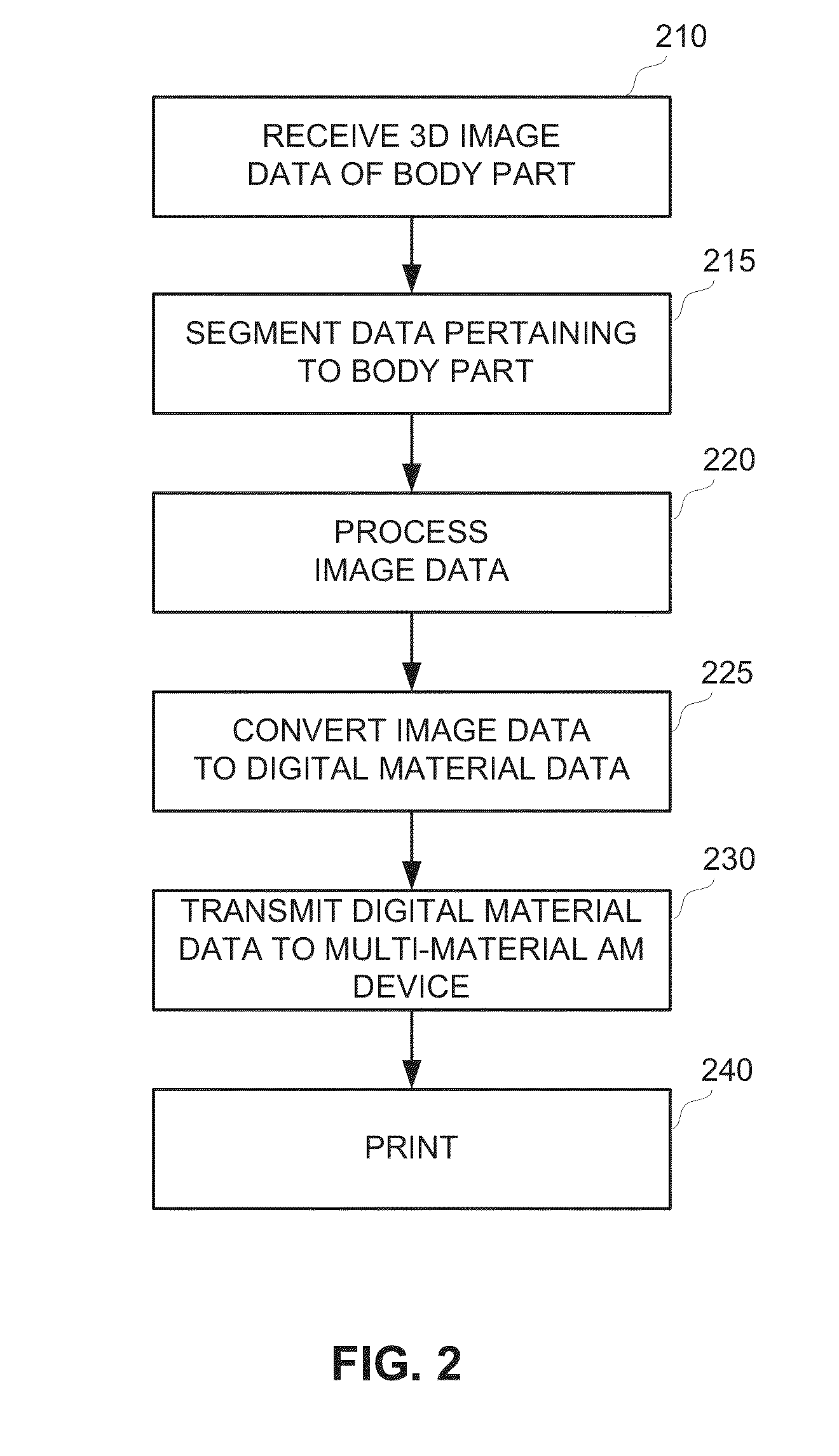

System and method for fabricating a body part model using multi-material additive manufacturing

ActiveUS20140312535A1Improve representationTurning machine accessoriesJoint implantsMulti materialVoxel

A method for physically reconstructing a body part using multi-material additive manufacturing includes receiving image data of the body part in the form of arrays of voxels, each array of voxels representing image data pertaining to cross-section of the body part, translating the image data in the arrays of voxels to printable bitmap images representing combinations of modeling materials for reconstructing the body part, and dispensing the combinations of modeling materials responsive to the bitmap images in a layerwise manner.

Owner:STRATASYS LTD

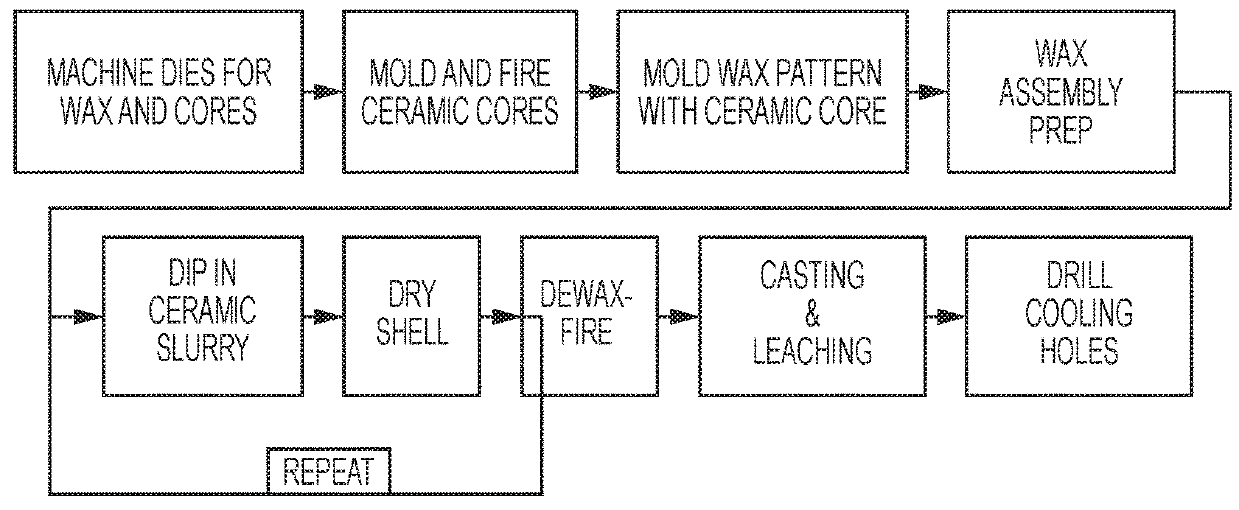

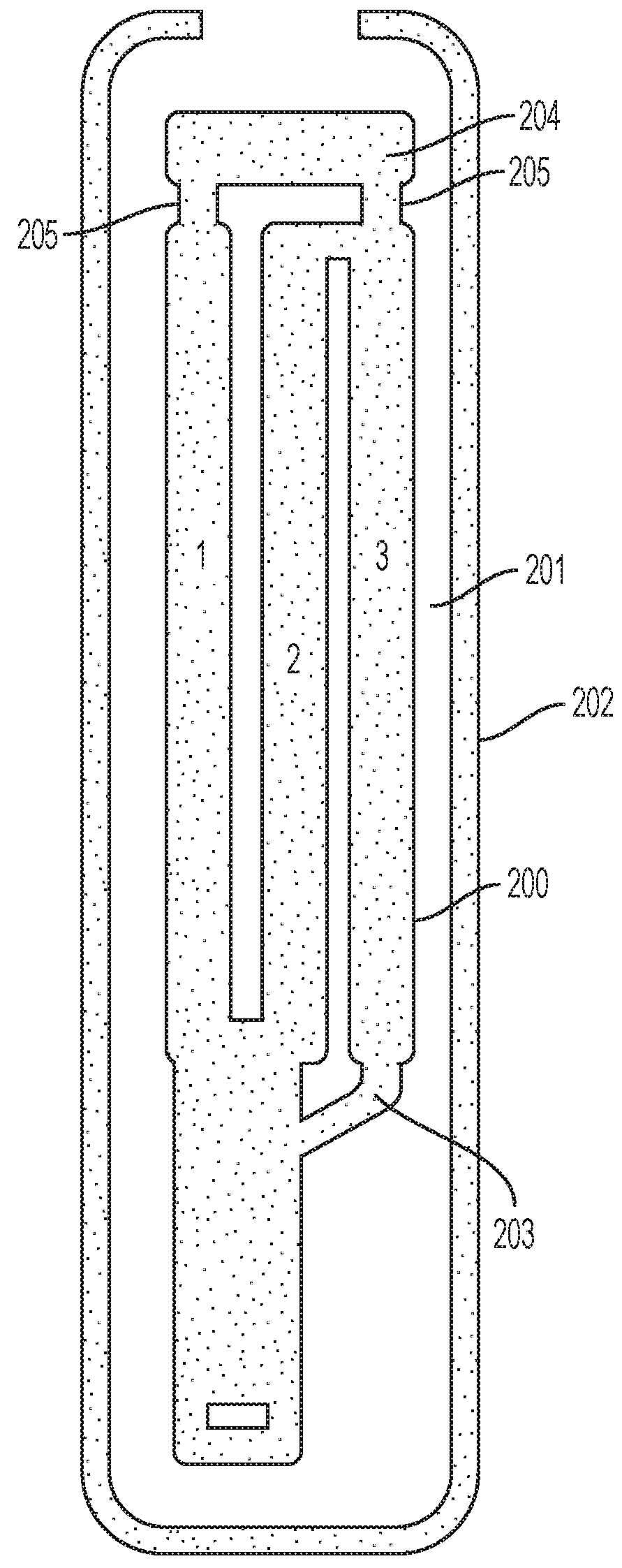

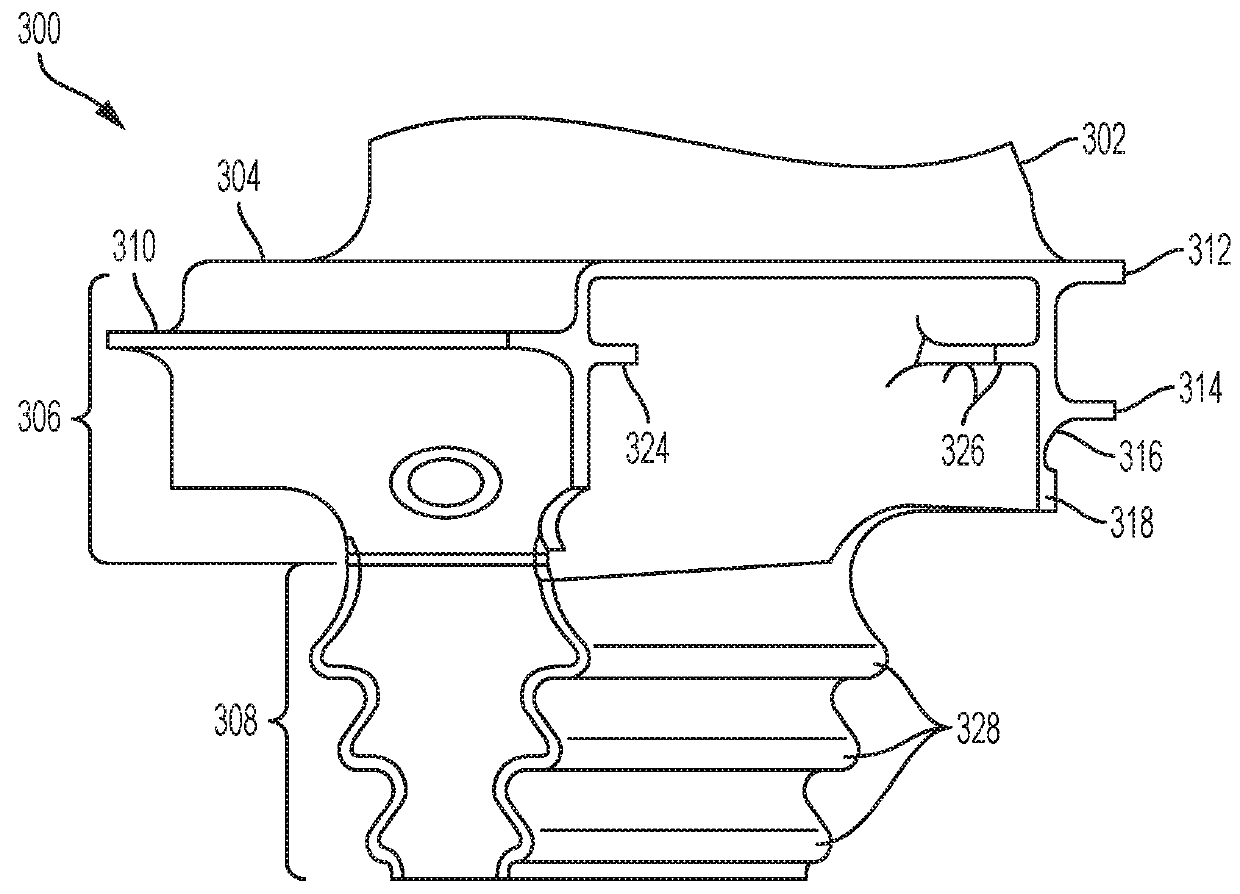

Integrated casting core-shell structure for making cast components having thin root components

The present disclosure generally relates to integrated core-shell investment casting molds that provide an indentation structure corresponding to a thin root component of the turbine blade or vane (i.e. angel wing, skirt, damper lug).

Owner:GENERAL ELECTRIC CO

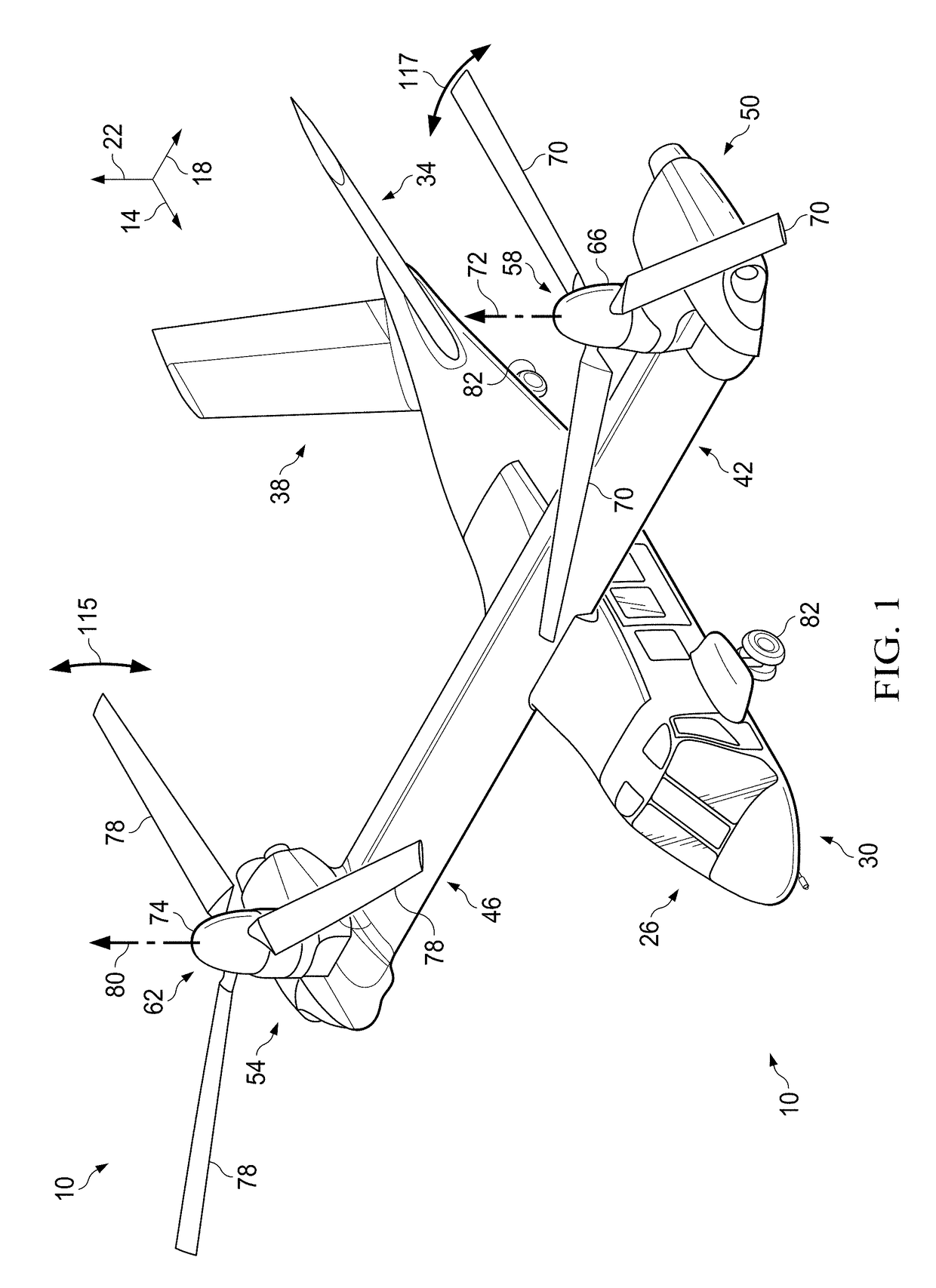

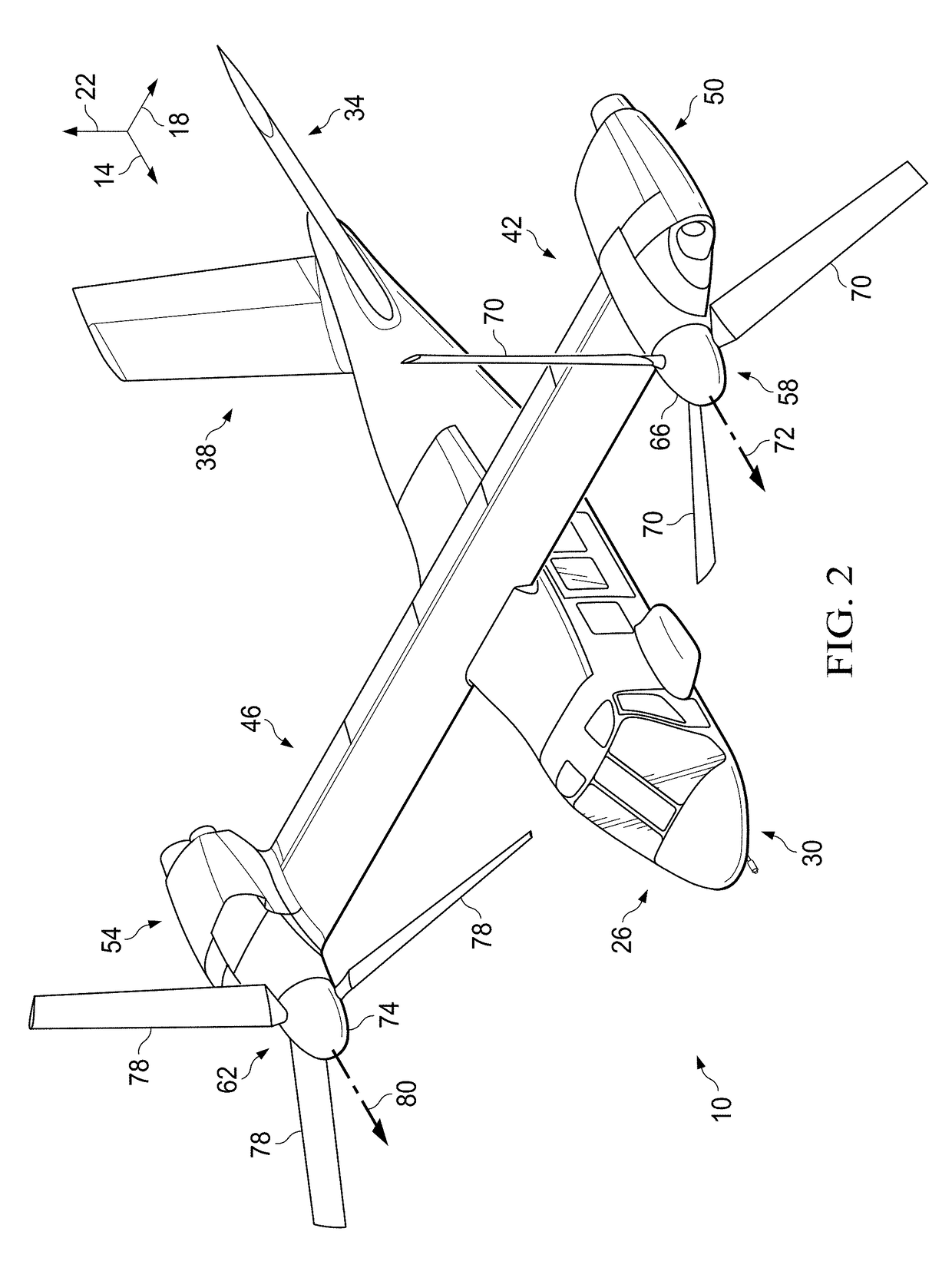

Methods of customizing, manufacturing, and repairing a rotor blade using additive manufacturing processes and a rotor blade incorporating the same

In a first aspect, there is a method of making a rotor blade, including designing at least one of an upper skin, a lower skin, a support network, and components therefor; and forming at least one of the upper skin, the lower skin, a support network, and components therefor using an additive manufacturing process. In a second aspect, there is an airfoil member having a root end, a tip end, a leading edge, and a trailing edge, the airfoil member including an upper skin; a lower skin; and a support network having a plurality of interconnected support members in a lattice arrangement and / or a reticulated arrangement, the support network being configured to provide tailored characteristics of the airfoil member. Also provided are methods and systems for repairing an airfoil member.

Owner:BELL HELICOPTER TEXTRON INC

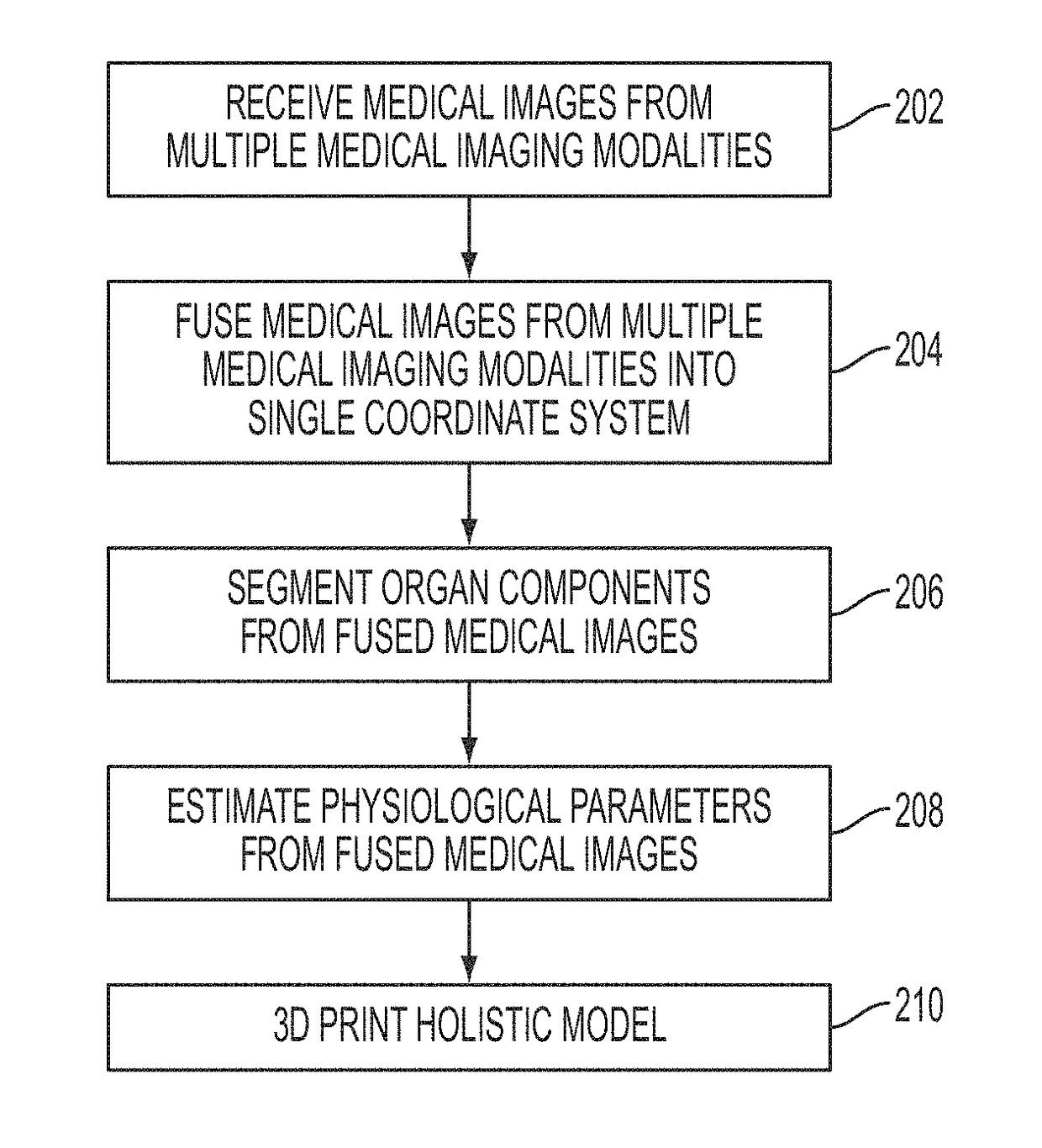

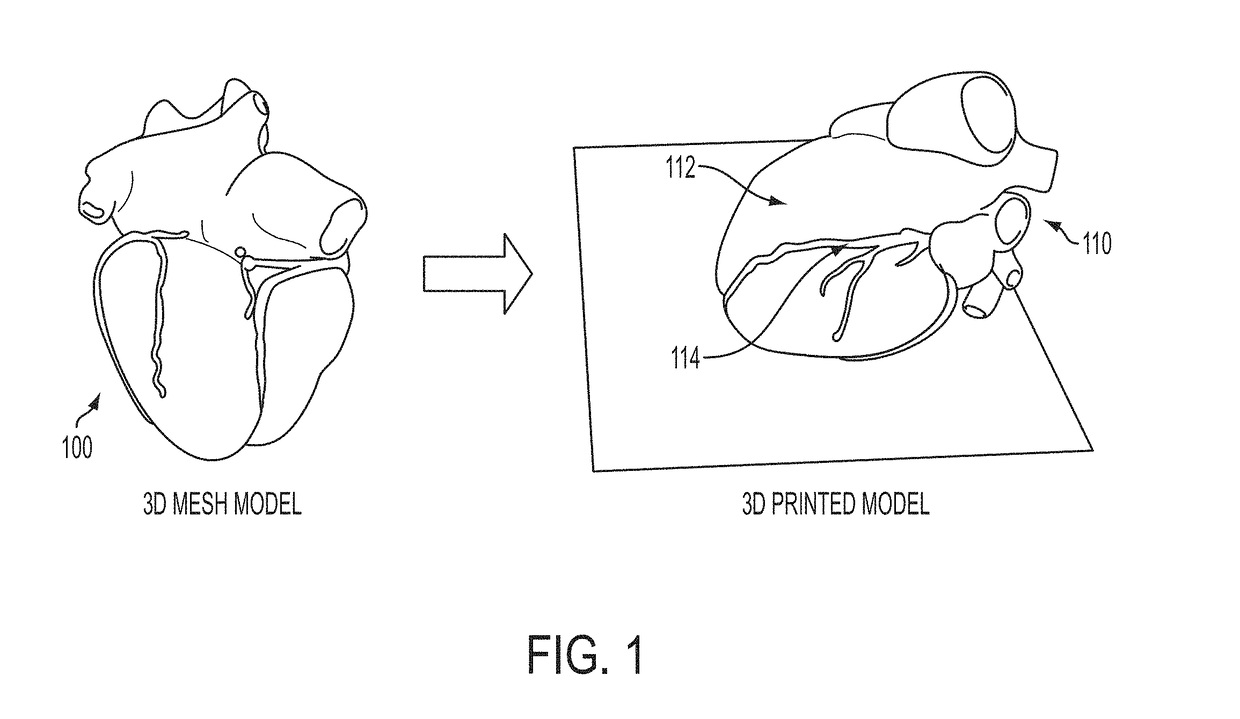

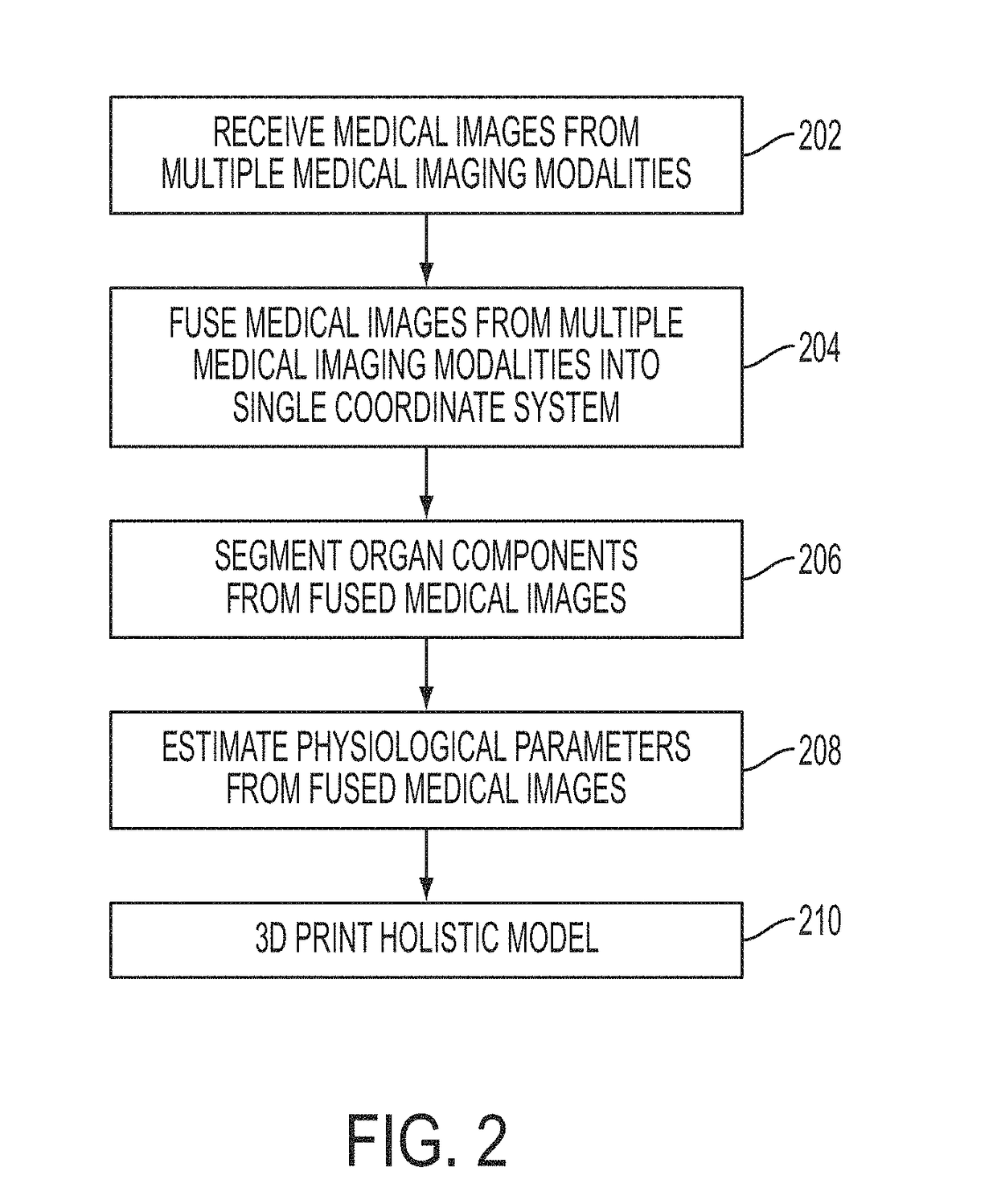

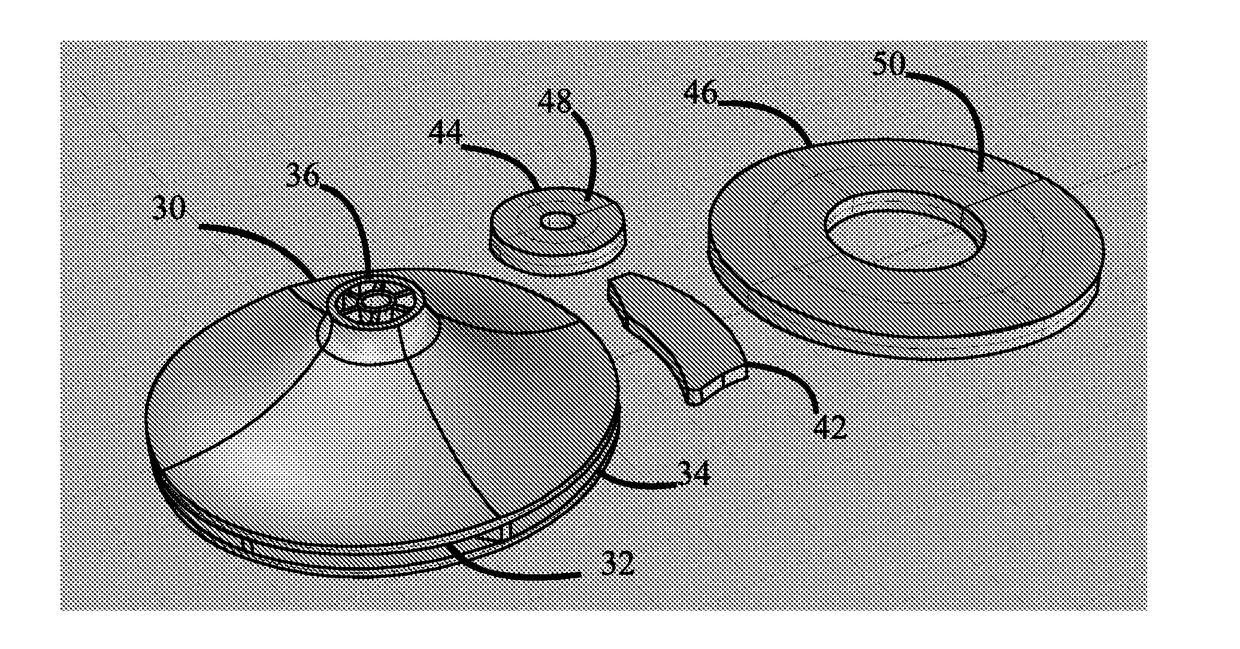

Multi-Modality Image Fusion for 3D Printing of Organ Morphology and Physiology

A system and method for multi-modality fusion for 3D printing of a patient-specific organ model is disclosed. A plurality of medical images of a target organ of a patient from different medical imaging modalities are fused. A holistic mesh model of the target organ is generated by segmenting the target organ in the fused medical images from the different medical imaging modalities. One or more spatially varying physiological parameter is estimated from the fused medical images and the estimated one or more spatially varying physiological parameter is mapped to the holistic mesh model of the target organ. The holistic mesh model of the target organ is 3D printed including a representation of the estimated one or more spatially varying physiological parameter mapped to the holistic mesh model. The estimated one or more spatially varying physiological parameter can be represented in the 3D printed model using a spatially material property (e.g., stiffness), spatially varying material colors, and / or spatially varying material texture.

Owner:SIEMENS HEALTHCARE GMBH

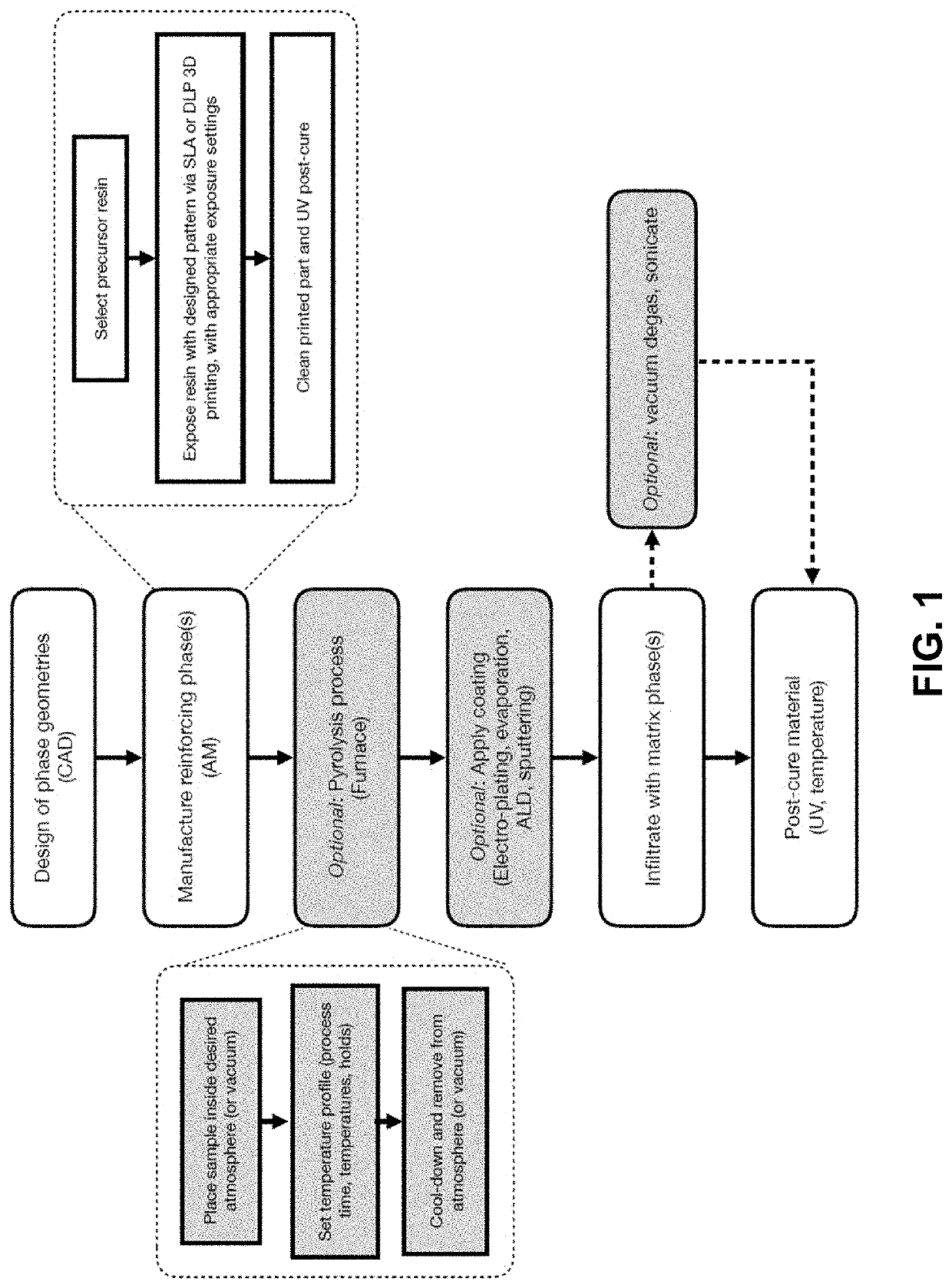

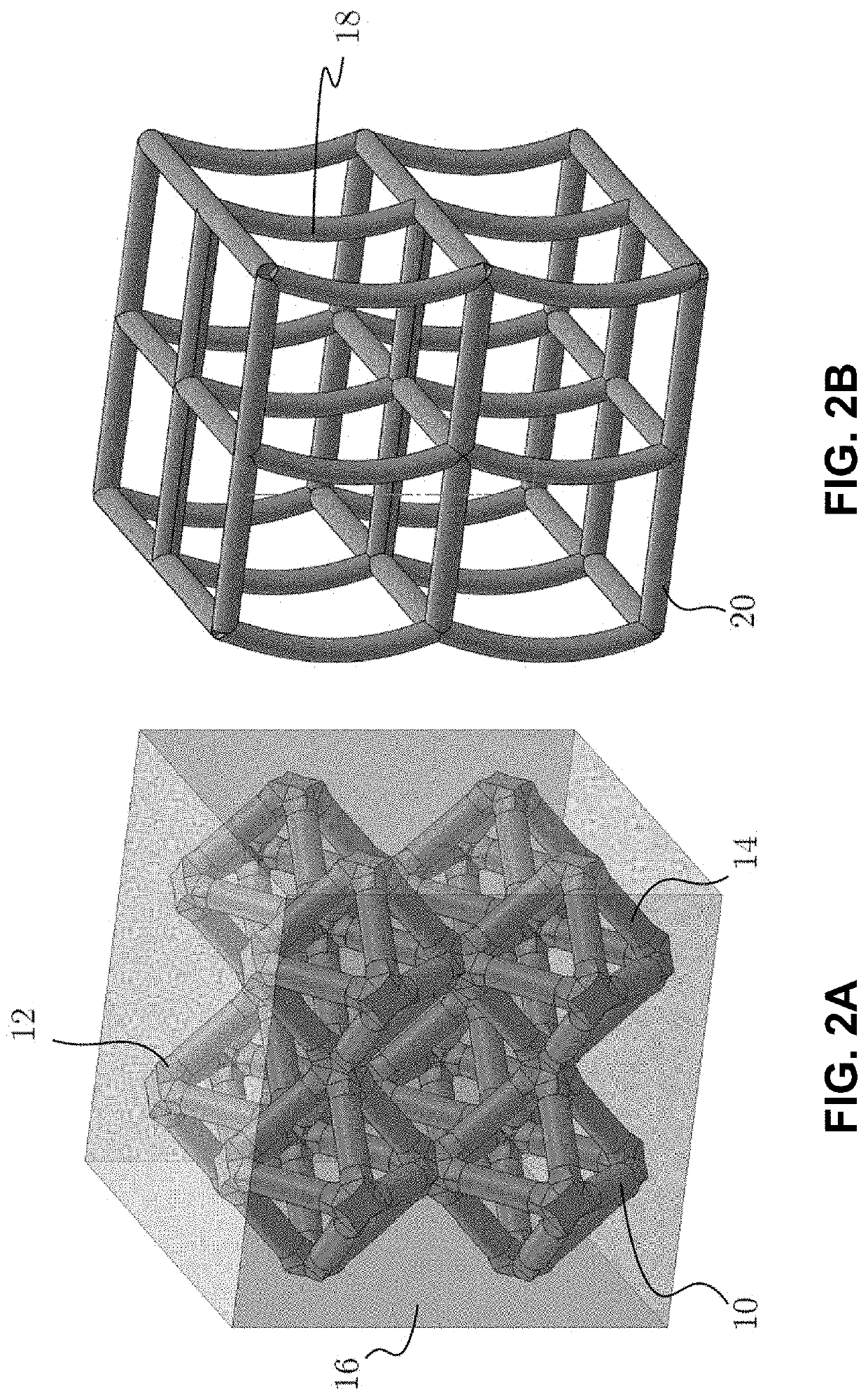

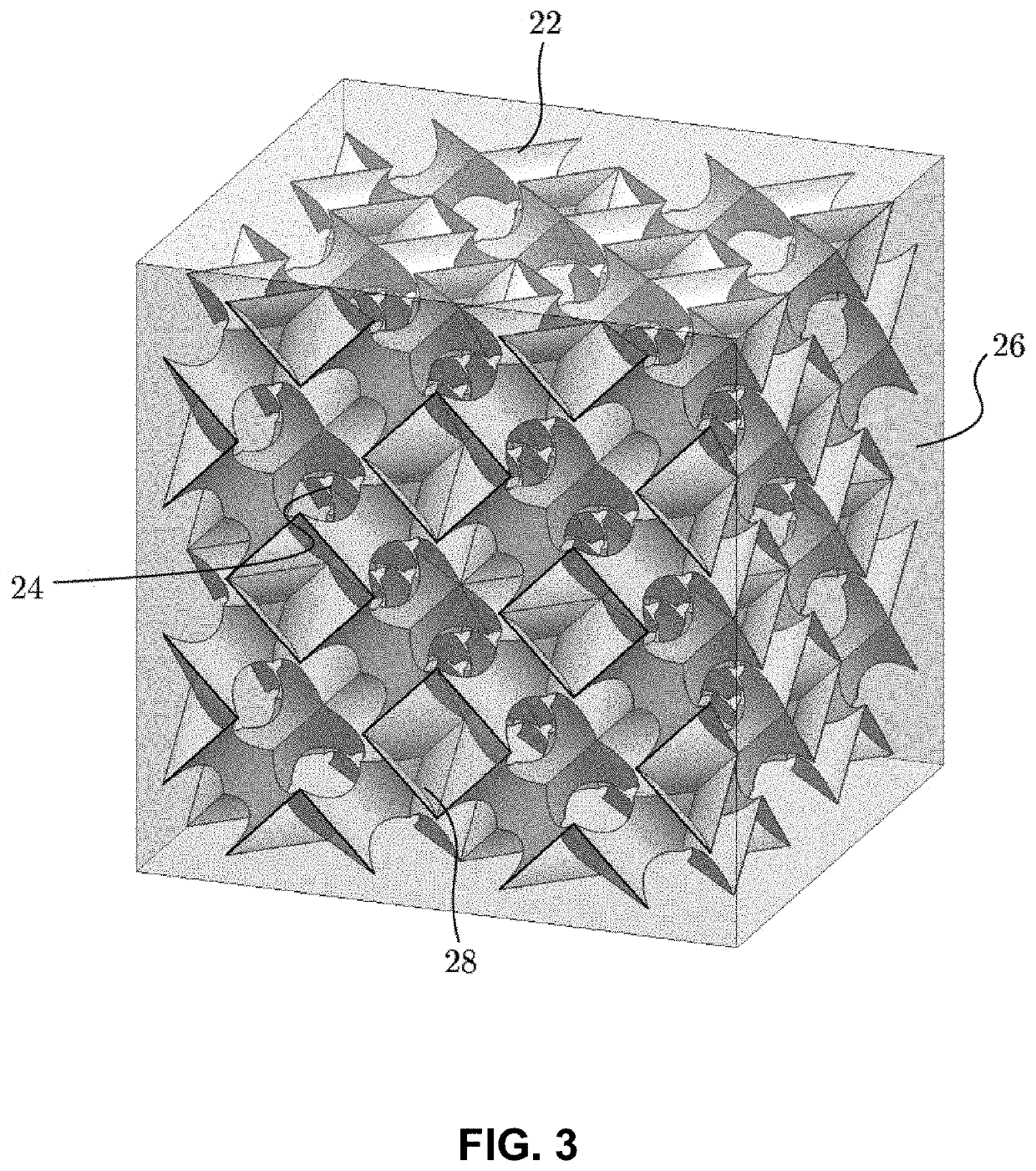

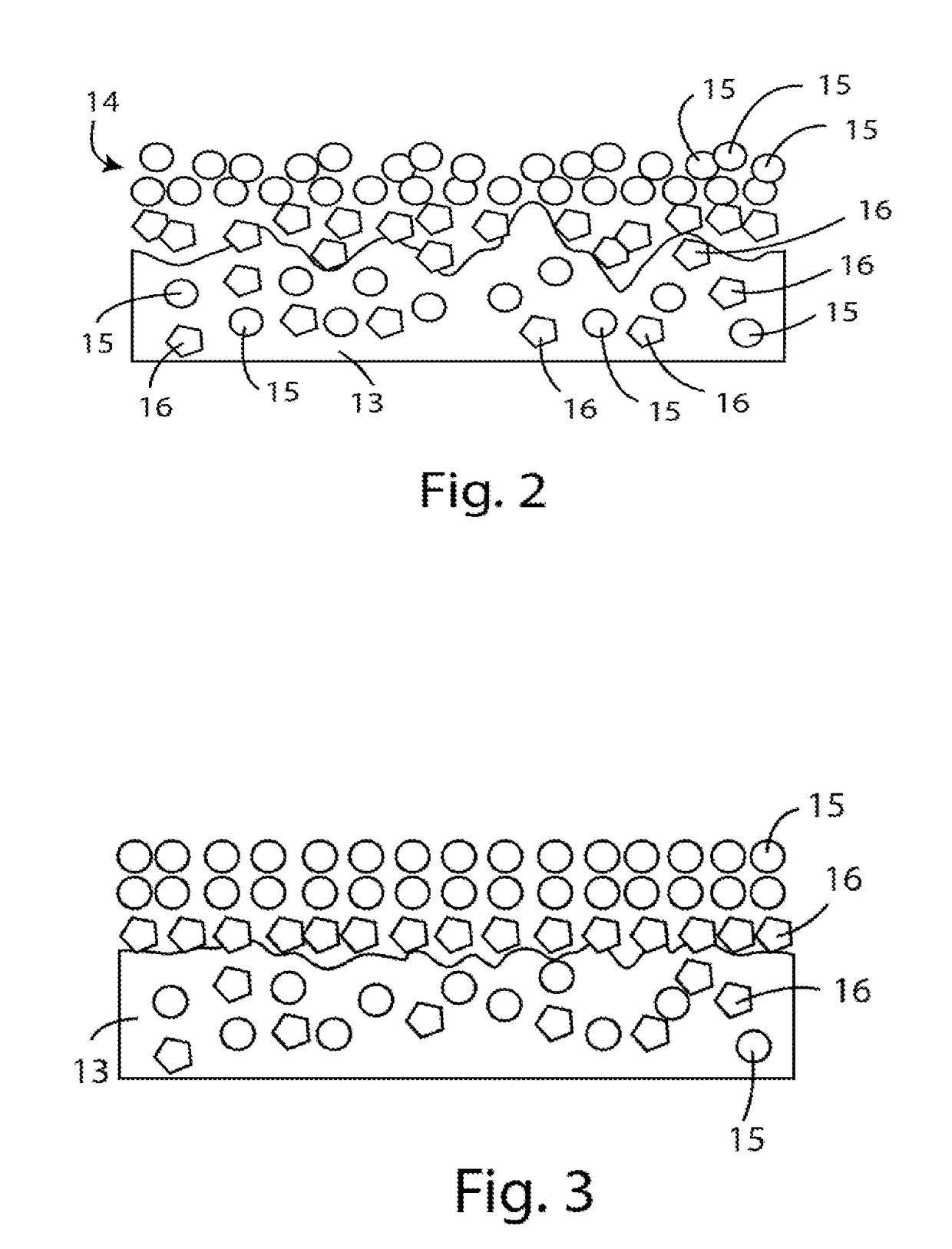

Fabrication and design of composites with architected layers

PendingUS20200023584A1Improve adhesionAdditive manufacturing apparatusSpringsEngineeringMechanical engineering

In an aspect, a composite material system comprises: a structure having an architected three-dimensional geometry; wherein said three-dimensional geometry is monolithic and deterministic; and a matrix phase; wherein said matrix phase at least partially infiltrates said structure. In some embodiments, the three-dimensional geometry is a nano- or micro-architected three-dimensional geometry.

Owner:CALIFORNIA INST OF TECH

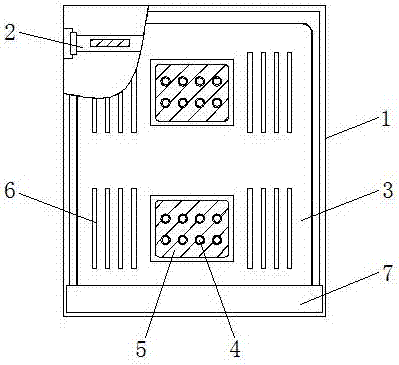

3D printing method for embedded electronic product and 3D printer

ActiveCN106493939AEfficient integrated manufacturingLow costAdditive manufacturing apparatus3D object support structuresComputer printingHemt circuits

The invention discloses a 3D printing method for an embedded electronic product and a 3D printer. After each layer of structure material is printed, a layer of release material is arranged around a support reserved position in a jet printing manner, support printing is conducted, and when the set of structure layers are printed, supports of reserved holes and grooves are removed, an electronic component is embedded, printing of the set of electric conduction layer structure, jet printing of electric conduction circuits and jet printing of dielectric materials between the electric conduction circuits are sequentially conducted, the process is repeatedly conducted till the last set of electric conduction layer structure is printed, and the electronic product is packaged through printing structure materials. The release material is introduced between the structure material and a support material, the support material is easy to remove, on one hand, removal of the supports through an ultrasonic alkaline solution is avoided (a traditional support removing technology is not allowed to be adopted in the embedded electronic product), and on the other hand, influences on a printed electric conduction circuit from support removal are avoided. The problem about support removal in the embedded electronic product manufacturing process is effectively solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

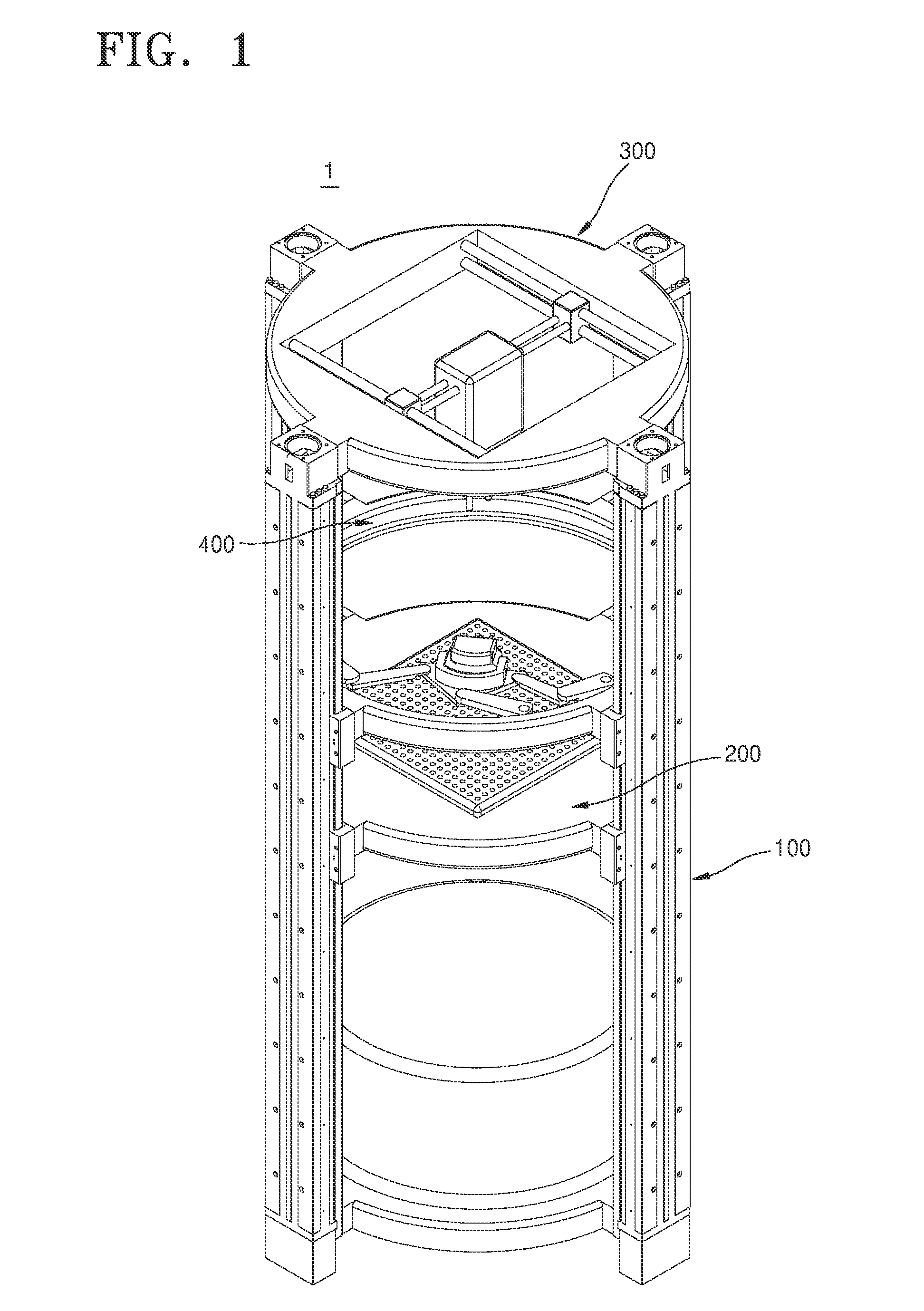

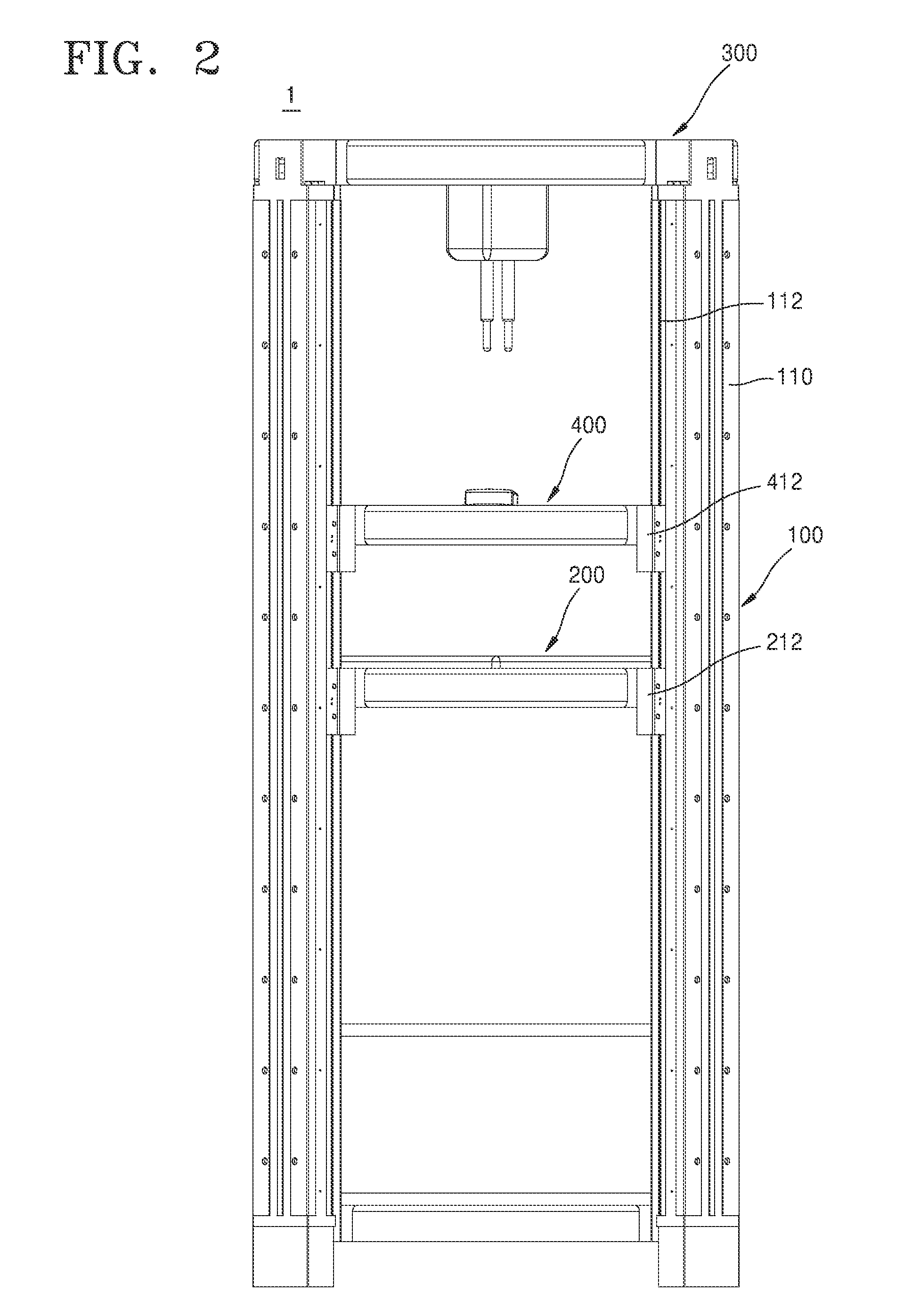

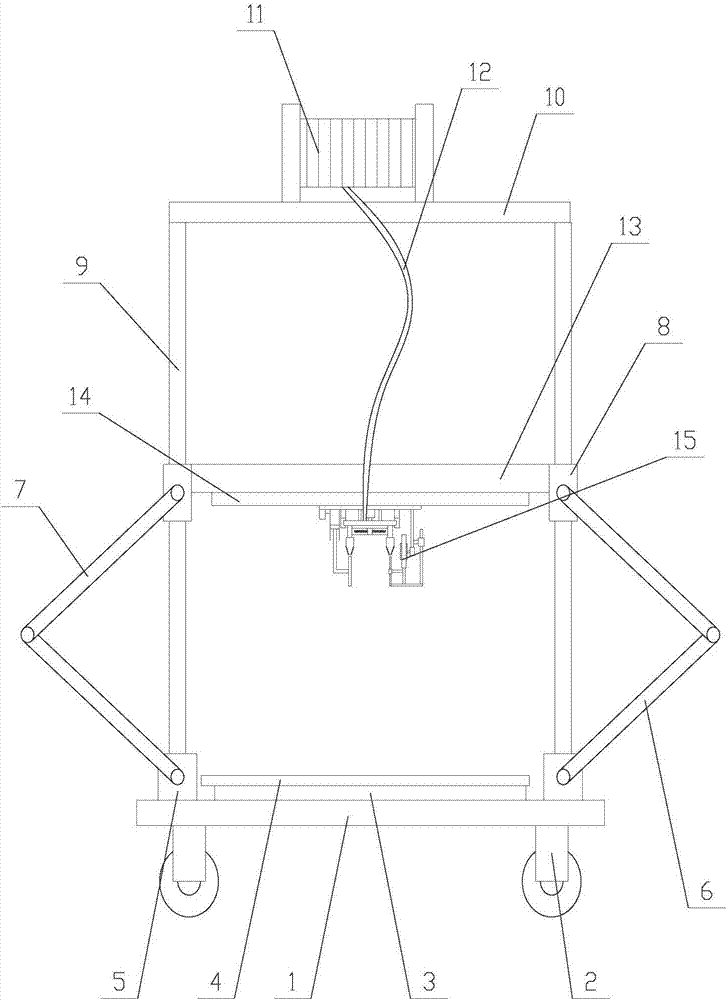

3D printer having dual stage structure

InactiveUS20160207260A1Manufacturing platforms/substratesManufacturing driving meansDual stageSpray nozzle

A 3D printer has a dual stage structure and includes: a frame; an extrusion unit having a nozzle configured to extrude a raw material; a stacking base unit positioned under the extrusion unit and configured to receive the raw material on a surface thereof so that an object is formed in a layer-by-layer manner on the surface; and a cutting unit positioned between the stacking base unit and the extrusion unit and configured to grind or cut the object formed on the surface of the stacking base unit, wherein the frame is configured to be connected to outer sides of the stacking base unit, the extrusion unit, and the cutting unit, the stacking base unit and the cutting unit are configured to be vertically movable along the frame, and the nozzle is configured to be movable on a plane.

Owner:FOUND OF SOONGSIL UNIV IND COOP

Methods for Controlling Warpage of Cavities of Three-Dimensionally Printed Articles During Heat Treament

InactiveUS20170252973A1Avoid bondingAdditive manufacturing apparatusCeramic shaping apparatusPolymer scienceHeat treated

Methods are presented for controlling warpage during heat treatment of a 3DPBJ article having a cavity extending inwardly from an outside surface wherein a 3DPBJ article is 3DPBJ printed from a build powder as is a 3DPBJ object which is adap ted to be contactingly insertable into the cavity of the 3DP BJ article. At least a portion of the 3DPBJ article cavity surface and / or at least a portion of the surface of the 3DPBJ object is treated to prevent the 3DPBJ object from becoming bonded to the 3DPBJ article during the heat treatment. The 3DPBJ object is inserted into the 3DPBJ article cavity and the 3DPBJ article and the 3DPBJ object are heat treated to transform the 3DPBJ article into the intended article itself and the 3DPBJ object into a heat treated 3DPBJ object. The heat treated 3DPBJ object is removed from the article.

Owner:THE EX ONE

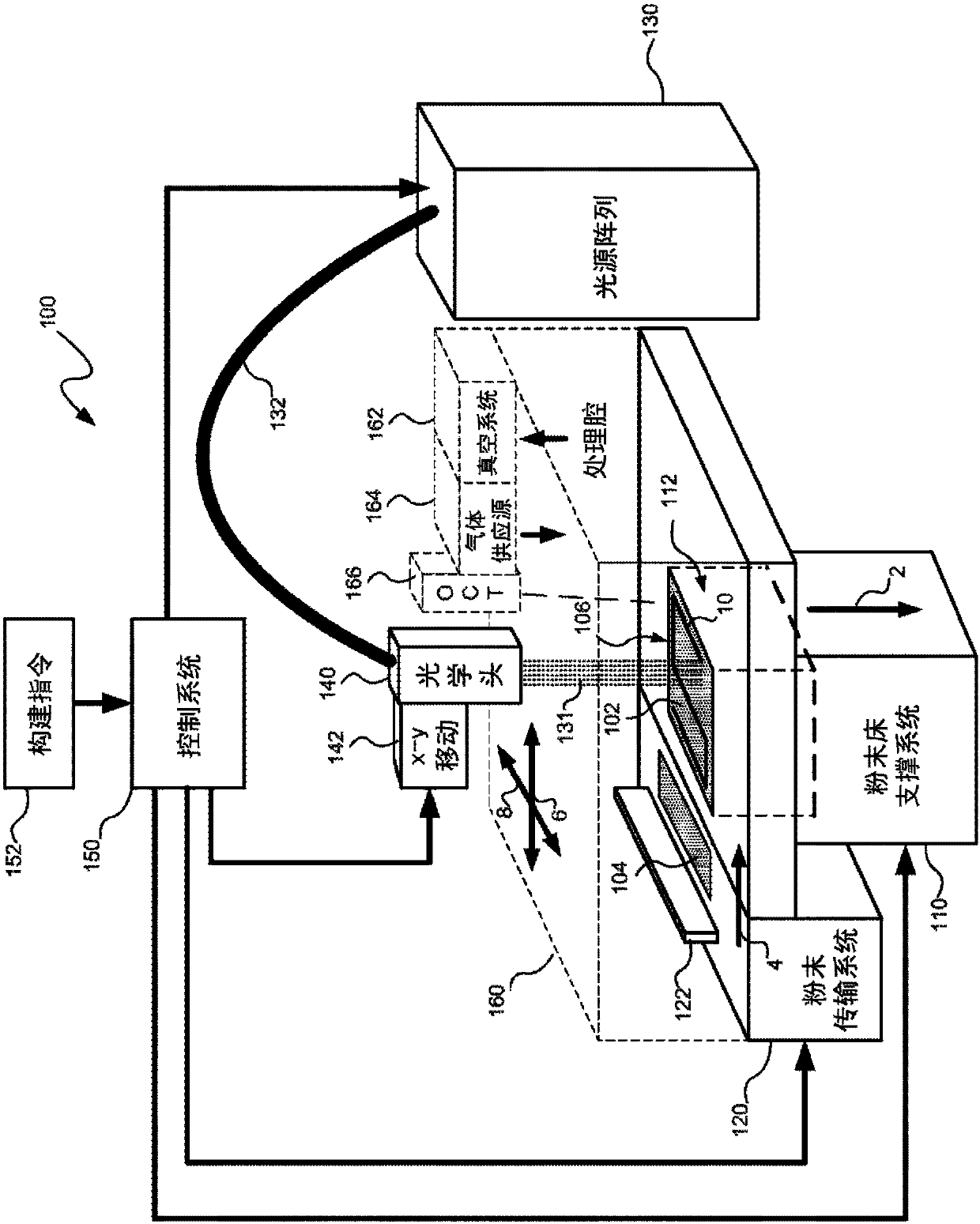

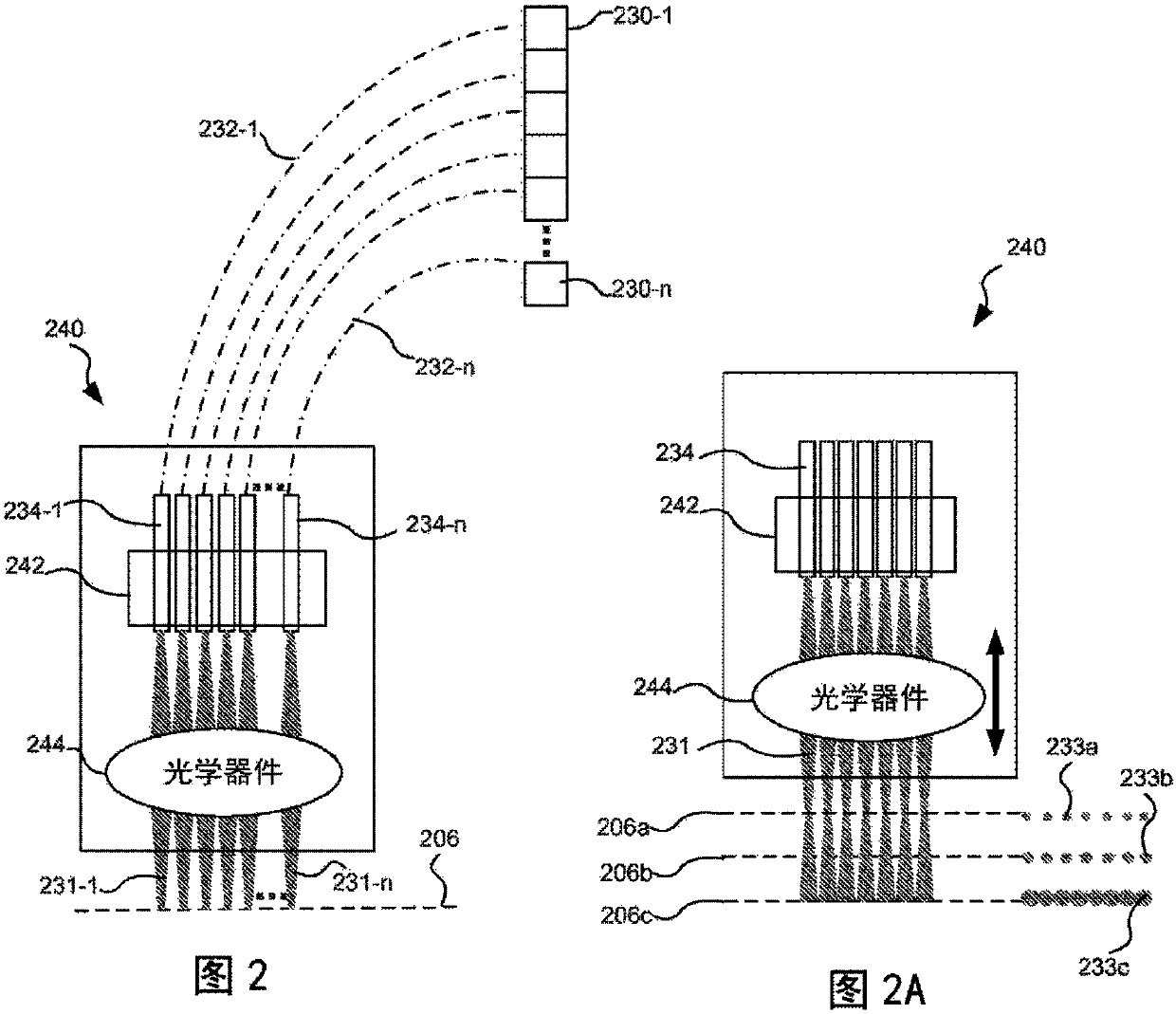

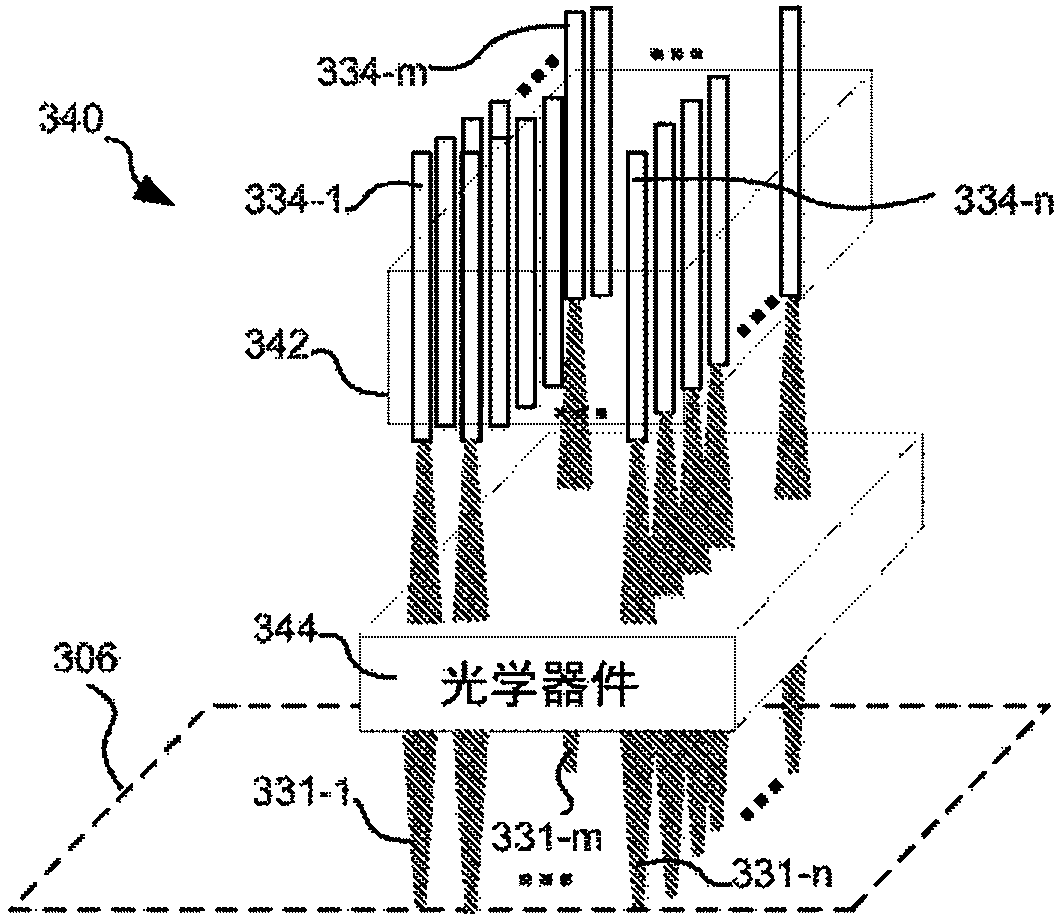

Multiple beam additive manufacturing

Systems and methods for multiple beam additive manufacturing use multiple beams of light (e.g., laser light) to expose layers of powder material in selected regions until the powder material fuses toform voxels, which form build layers of a three-dimensional structure. The light may be generated from selected light sources and coupled into an array of optical fibers having output ends arranged inan optical head in at least one line such that multiple beams are sequentially directed by the optical head to the same powder region providing multiple beam sequential exposures (e.g., with pre-heating, melting and controlled cool down) to fuse the powder region. The multiple sequential beams may be moved using various techniques (e.g., by moving the optical head) and according to various scan patterns such that a plurality of fused regions form each build layer.

Owner:IPG PHOTONICS CORP

Method and apparatus for photo-curing photo-sensitive materials for the formation of three-dimensional objects in a tank with a flexible, self-lubricating substratum

InactiveUS20180207867A1Manufacturing platforms/substrates3D object support structuresMembrane configurationLubricant

Methods and apparatus for forming three-dimensional objects by photo-curing a photo-curing liquid polymer exposed to a radiation. The three-dimensional objects form by growth, due to the progressive curing of the photo-curing liquid polymer within the tank, in the space between a transparent base and a supporting plate. On the side of the transparent base facing towards the photo-curing liquid polymer, a membrane is arranged, said membrane being transparent to said radiation and being covered by a layer of liquid lubricant, which is released gradually by said membrane. The membrane is flexible, allowing it to bend or arch during formation of the three-dimensional objects when the supporting plate is raised.

Owner:NEXA3D INC

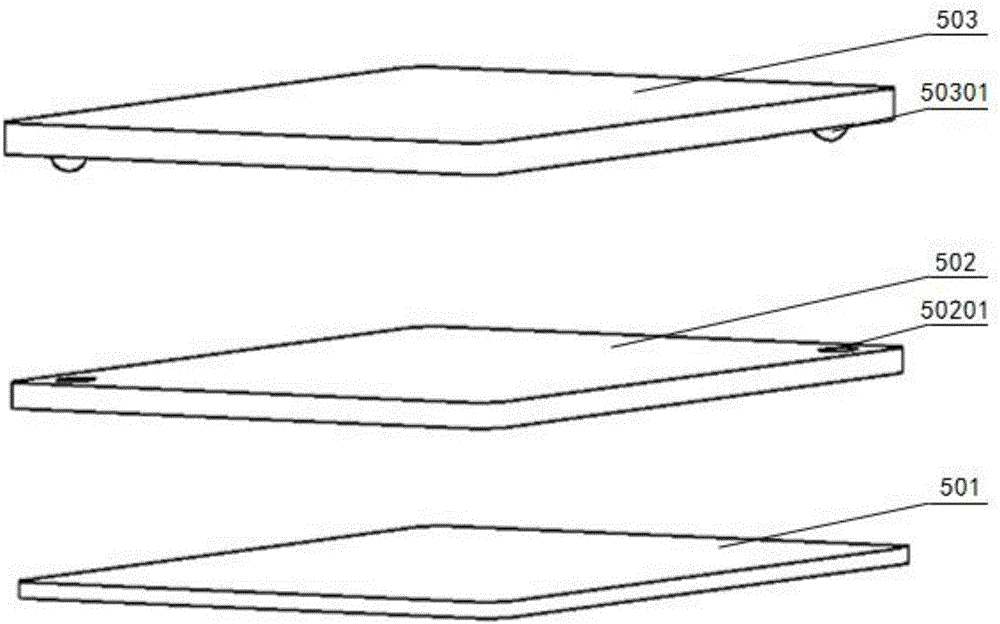

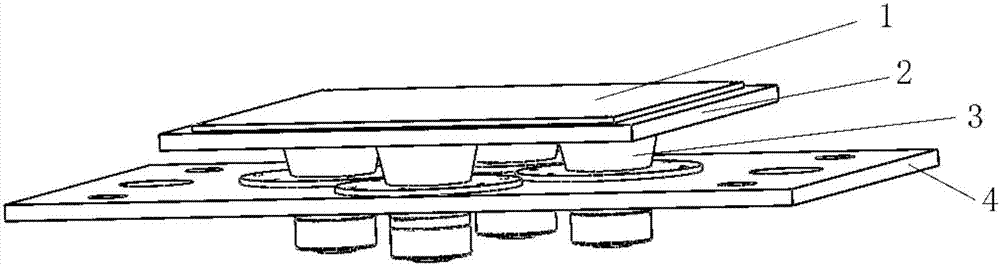

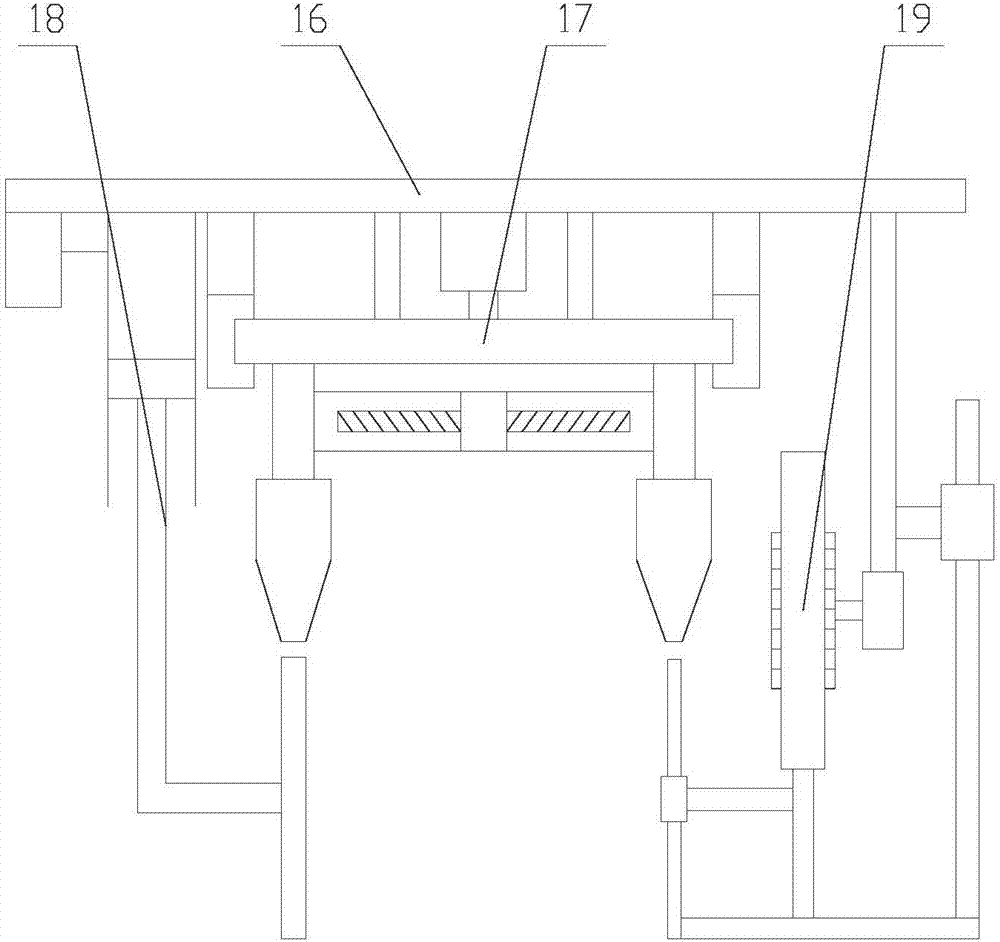

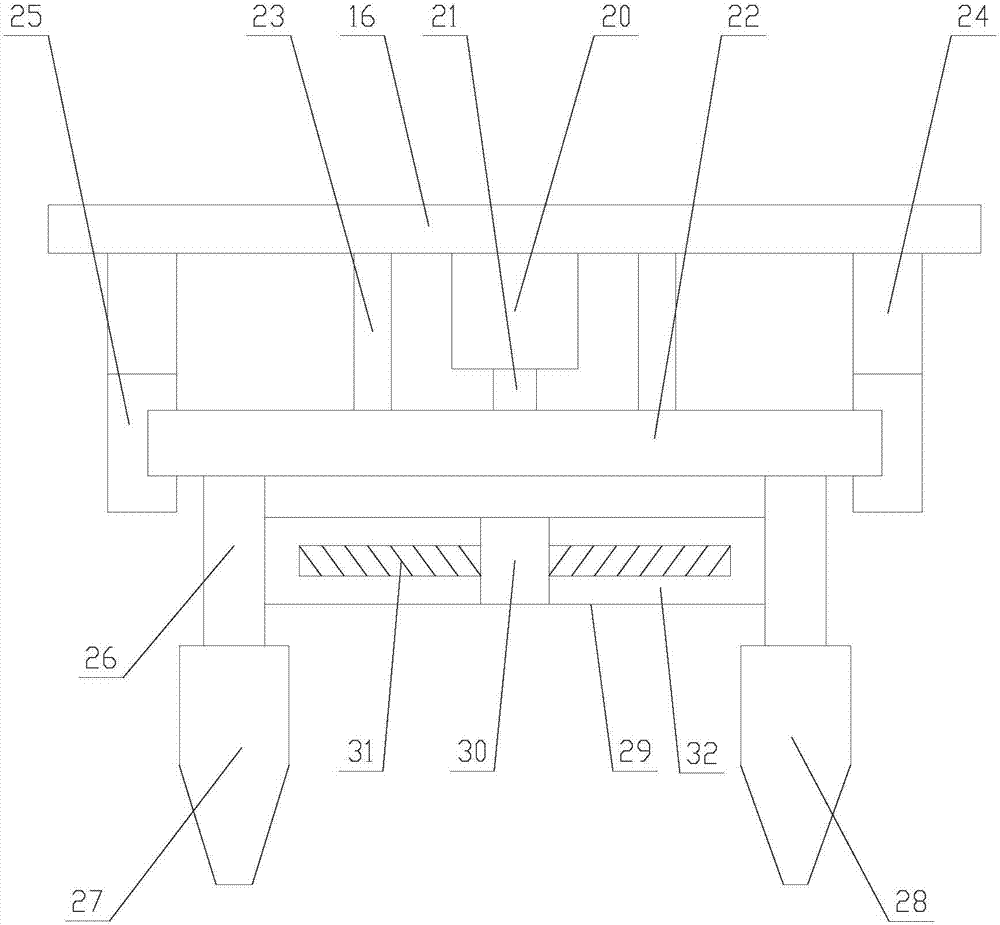

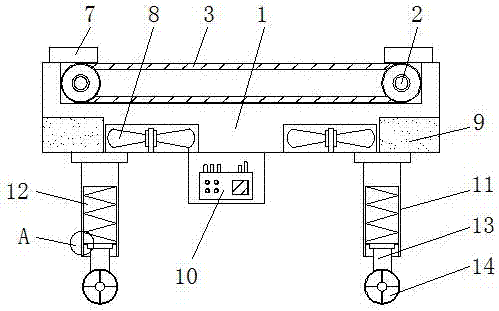

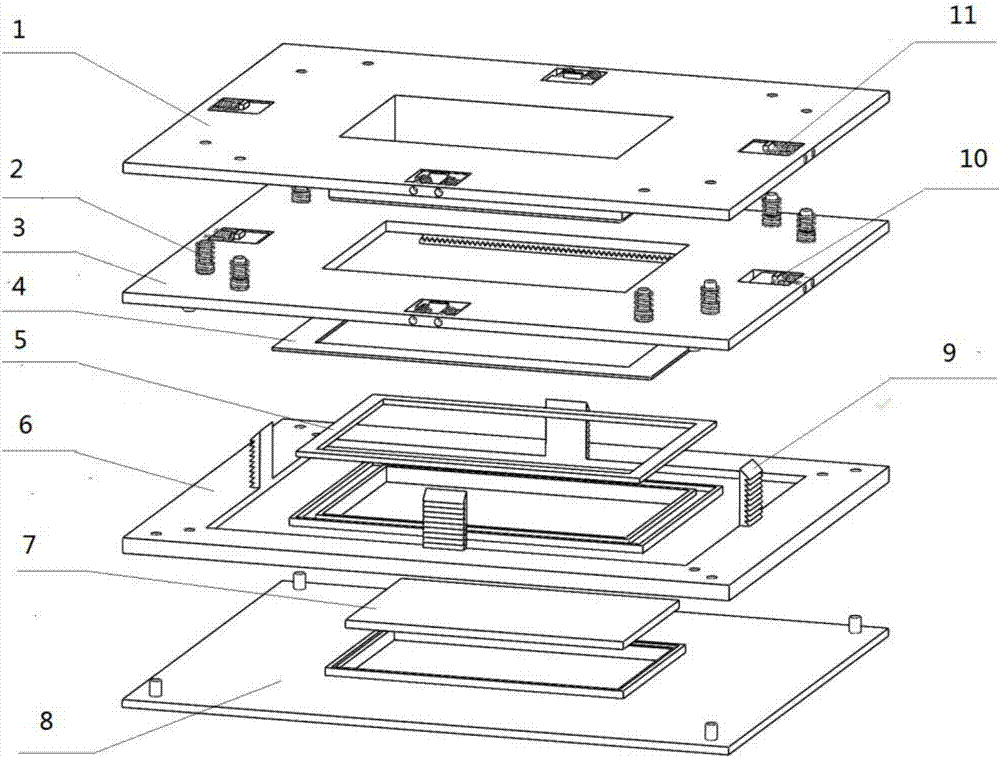

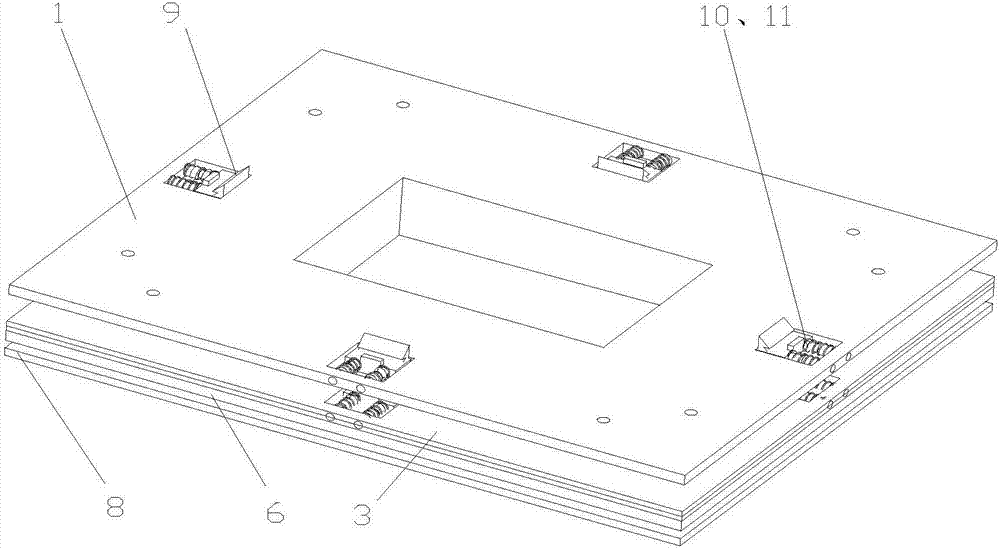

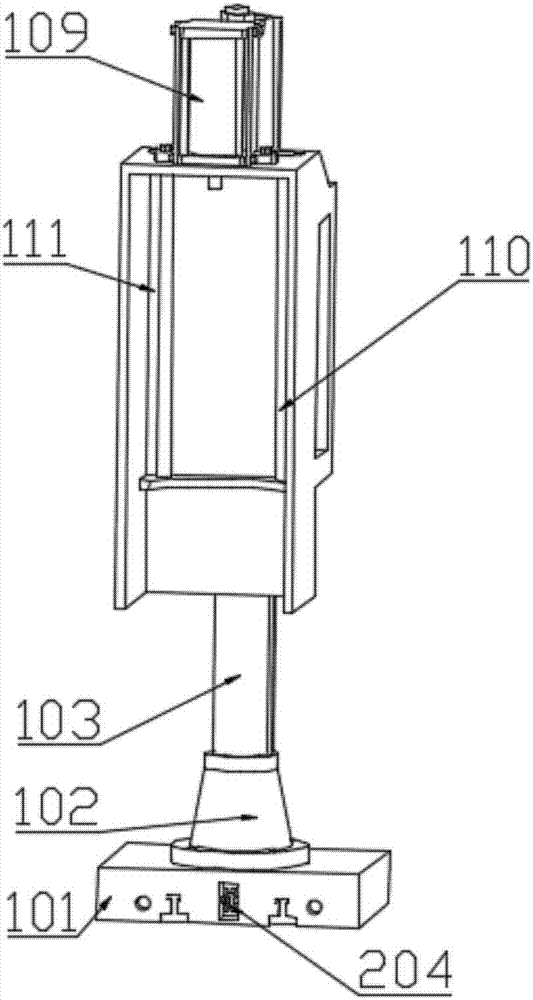

Ultrasonic-assisted vibration FDM type 3D printing platform

InactiveCN107042628AIncreased corrugated microstructureTightly boundManufacturing heating elementsMechanical vibrations separationUltrasonic assistedMicrowave

The invention discloses an ultrasonic-assisted vibration FDM type 3D printing platform which comprises a hot bed arranged on a supporting plate. Ultrasonic transducers are fixed to the lower portion of the supporting plate. The ultrasonic-assisted vibration FDM type 3D printing platform is used for making the hot bed generate ultrasonic vibration during 3D printing, and the ultrasonic transducers are fixed to a fixing plate through flanges on amplitude changing poles. By means of the above ultrasonic-assisted vibration FDM type 3D printing platform, the microwave-shaped microscopic structure of a printing product can be improved, the mechanical performance is higher, combination of printing layers is more compact, and the surface roughness of the printing products is lowered.

Owner:GUANGDONG UNIV OF TECH

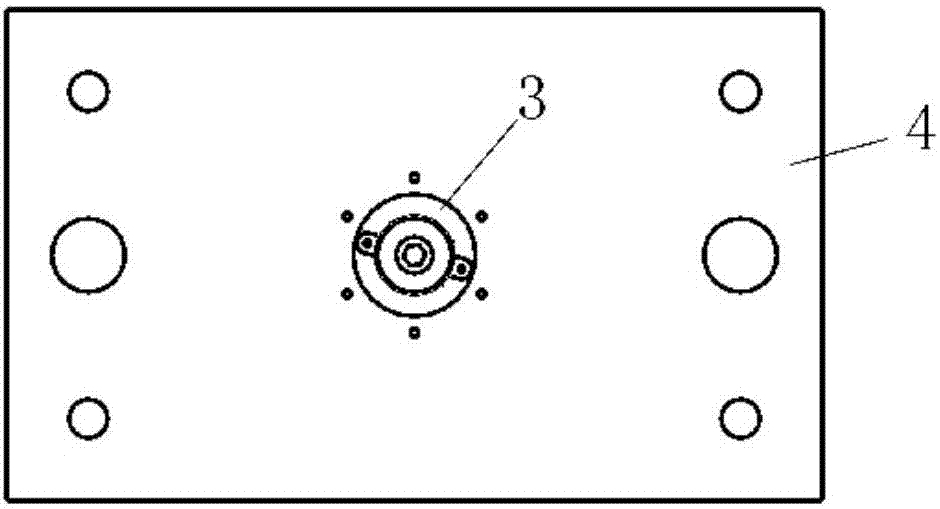

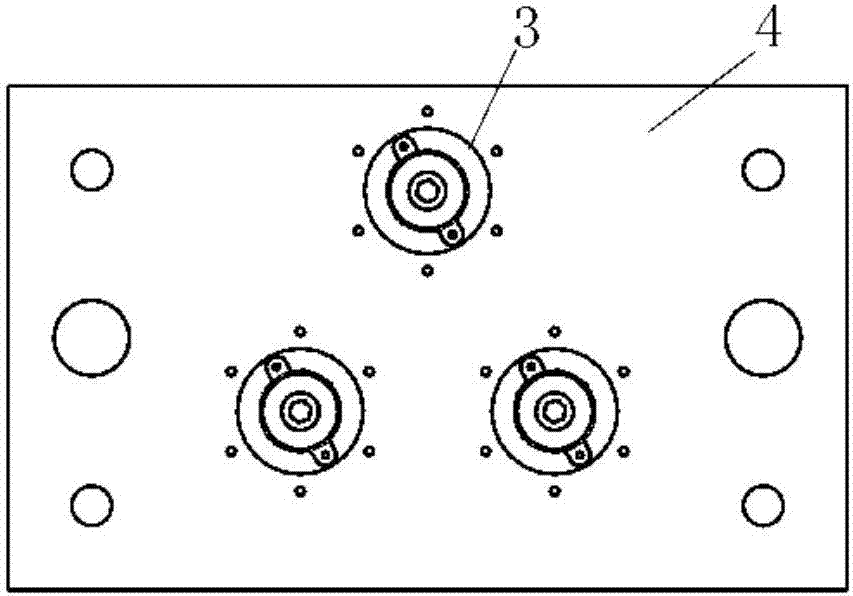

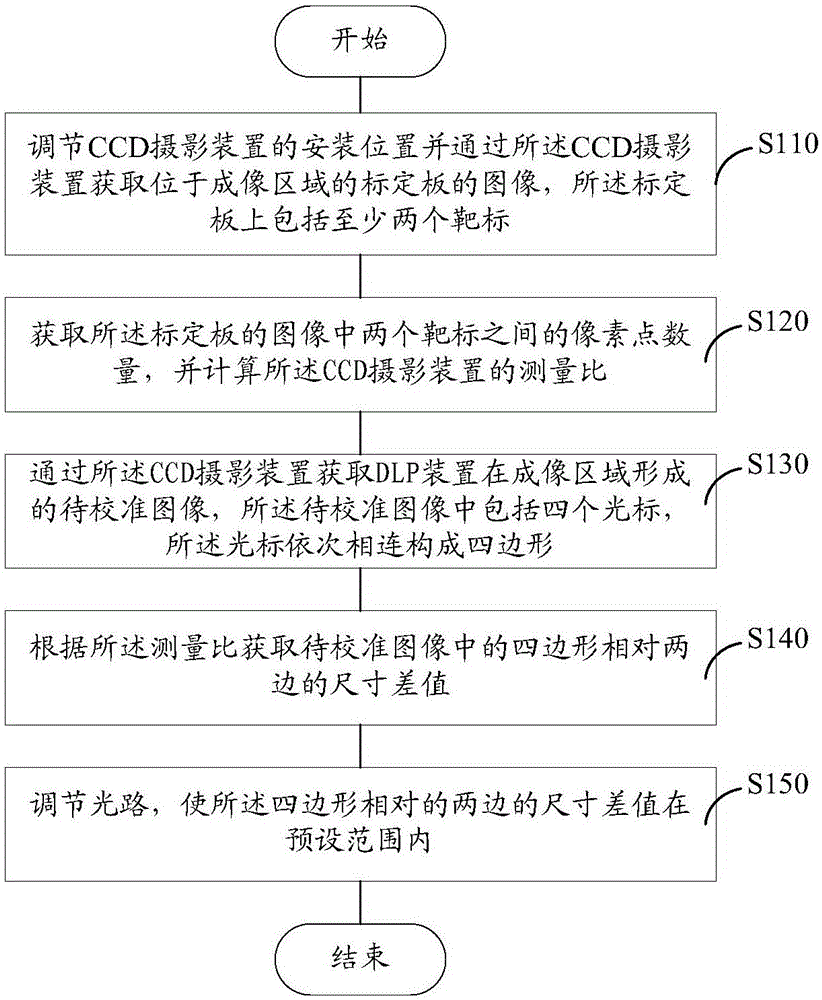

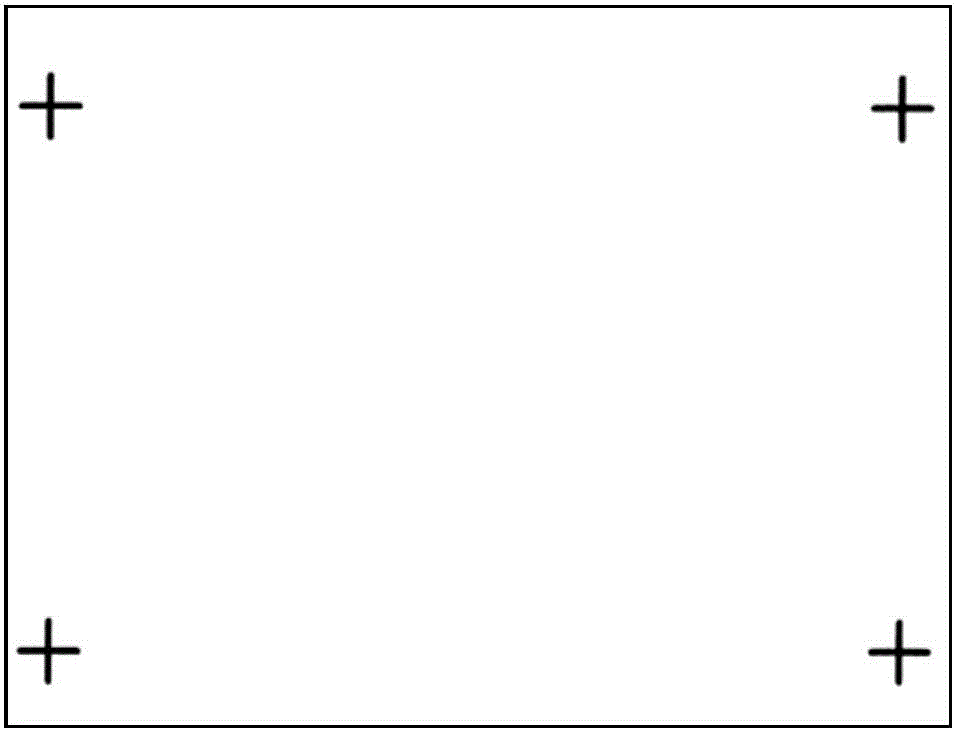

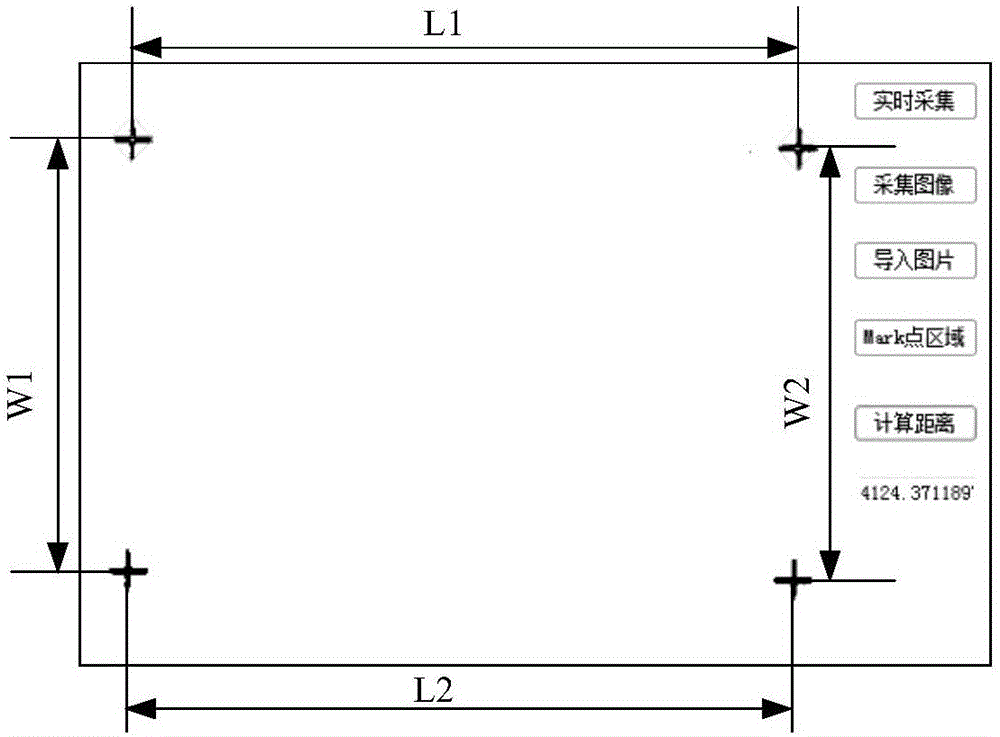

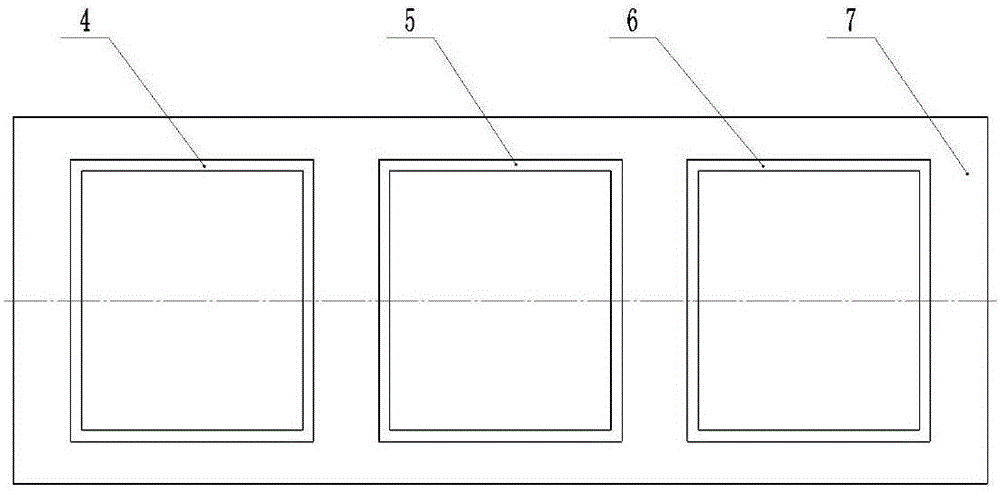

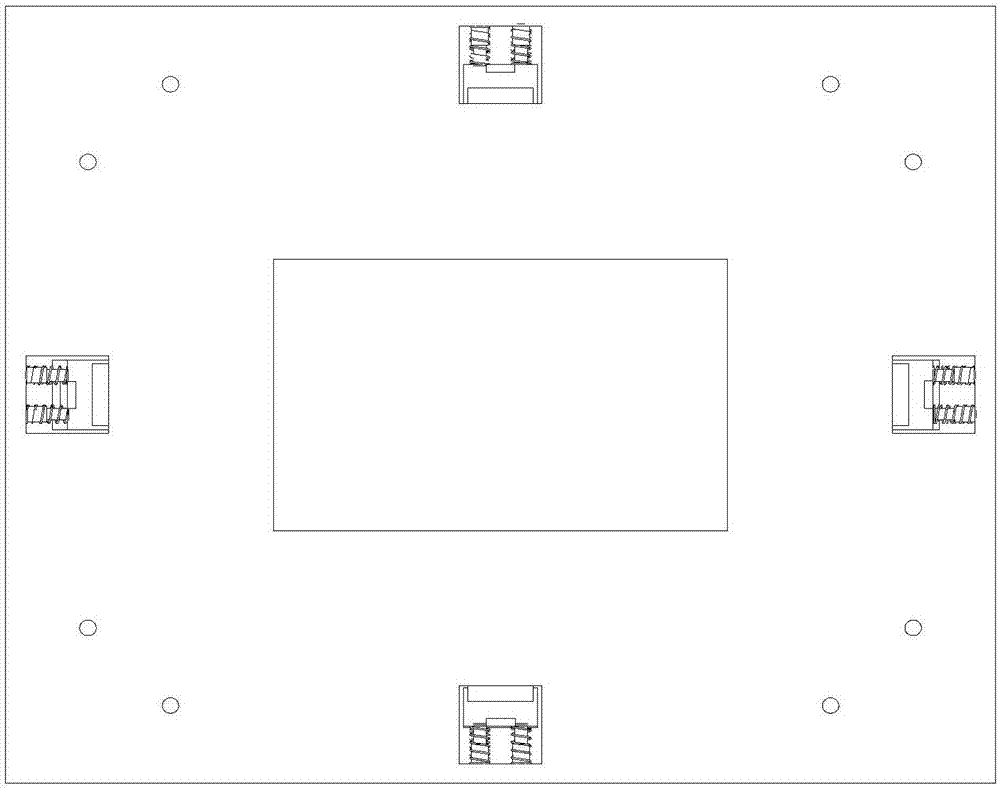

3D printing imaging calibration method and 3D printing imaging calibration system

ActiveCN106827515AAdditive manufacturing apparatus3D object support structuresSize differenceGraphics

The present invention relates to a 3D printing imaging calibration method and a 3D printing imaging calibration system. According to the 3D printing imaging calibration method, the image of a calibration plate positioned in an imaging region is acquired through a CCD imaging device; the measurement ratio of the CCD imaging device is calculated according to the acquired image of the calibration plate; according to the measurement ratio of the CCD imaging device, the size difference between the two opposite edges of a quadrilateral formed by four cursors of a DLP device in the imaging region is calculated; and by adjusting an optical path, the size difference between the two opposite edges of the quadrilateral formed by the four cursors of the DLP device in the imaging region is adjusted. With the 3D printing imaging calibration method of the present invention, the size of the projecting image of the imaging plane (exposure plane) of the DLP device can be quickly and accurately calibrated in a non-contact manner. In addition, the invention provides the 3D printing imaging calibration system.

Owner:HANS LASER TECH IND GRP CO LTD

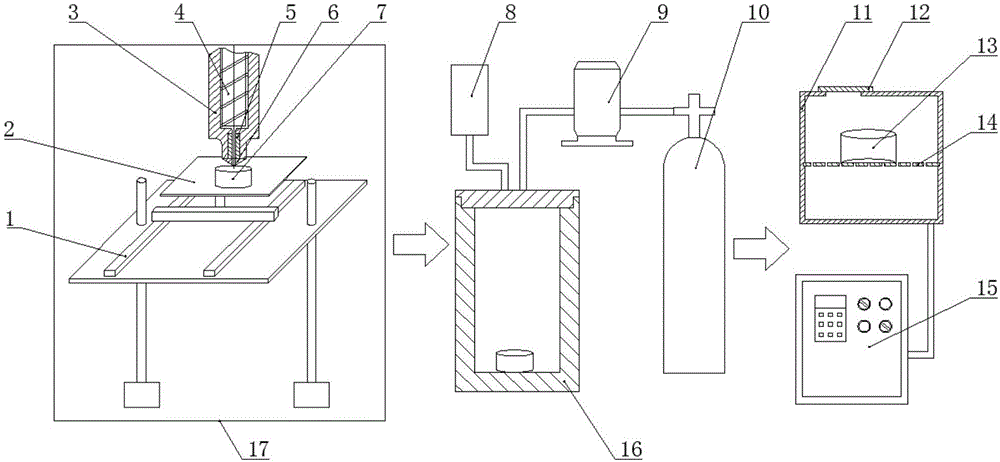

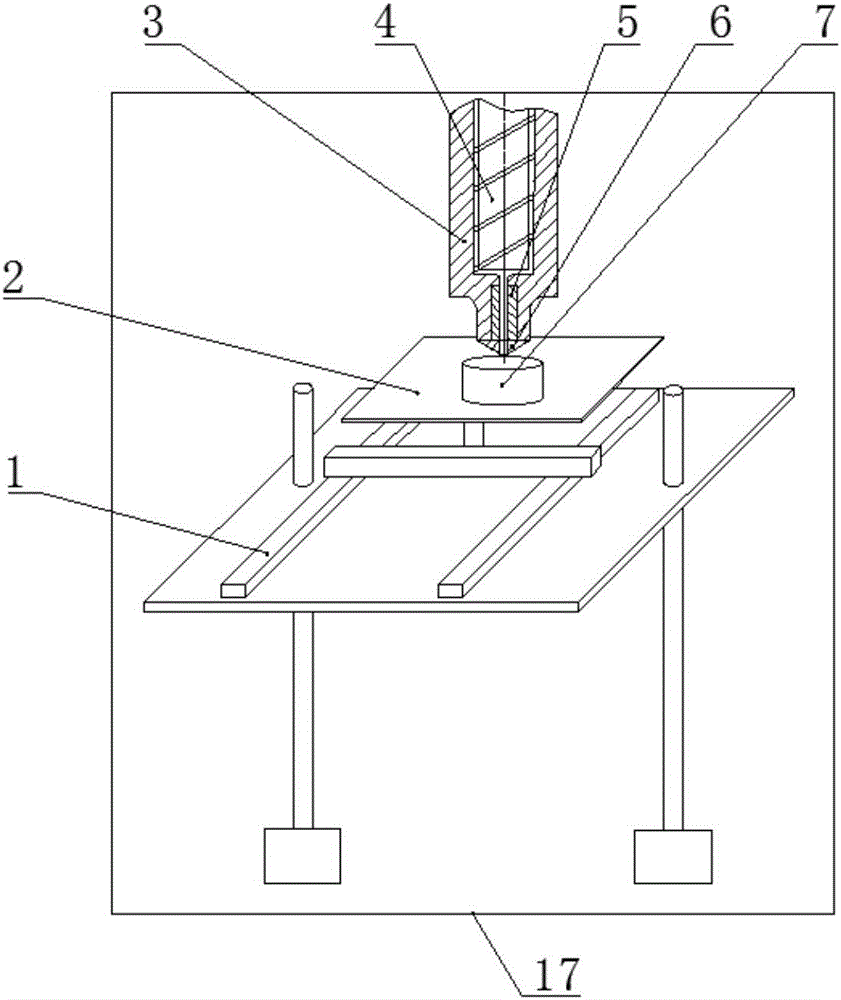

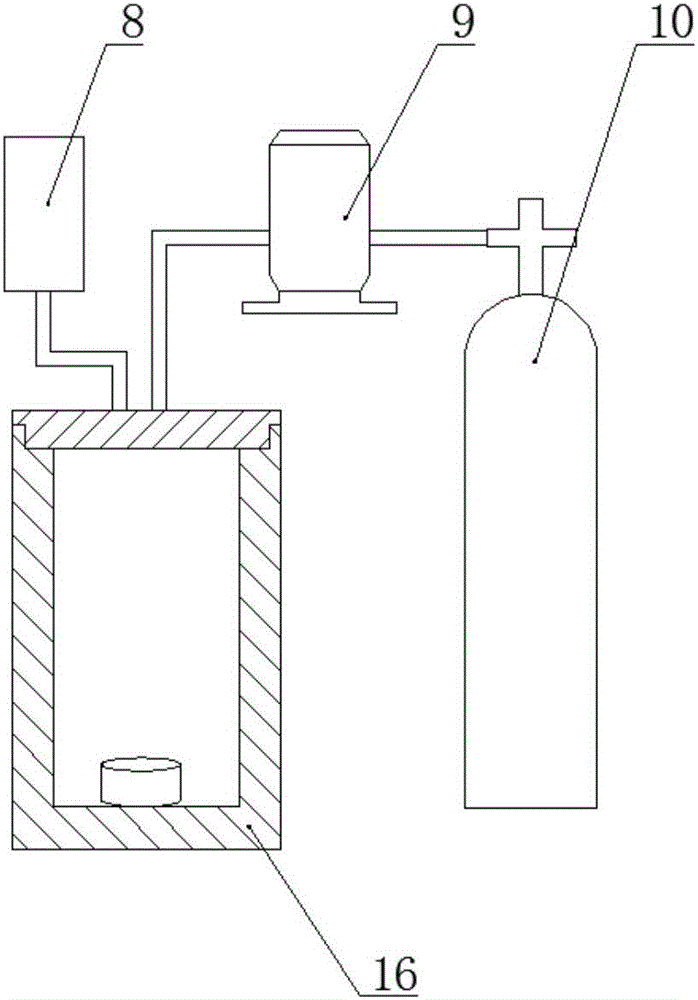

Method and apparatus for producing foamed product based on 3D printing

InactiveCN106493968AHigh forming precisionEasy to produceAdditive manufacturing apparatus3D object support structuresCo2 storageProduct base

The invention discloses a method and apparatus for producing a foamed product based on 3D printing. The apparatus mainly comprises a molding unit, a supercritical infiltration unit and a foaming unit, wherein the molding unit is a 3D printer and mainly comprises a three-dimensional ball screw sliding table, a molding platform, a 3D printer case, a plasticizing screw, a heating ring and a nozzle; the supercritical infiltration unit is mainly composed of a preheater, a booster pump, a CO2 storage tank and an infiltration vessel; and the foaming unit is mainly composed of a steam generator, a foaming case and a cover plate. The method comprises the following steps: printing a three-dimensional model via the molding unit according to product needs; then putting the three-dimensional model into the infiltration vessel in the supercritical infiltration unit and carrying out infiltration by using supercritical CO2; and carrying out steam foaming in the foaming case so as to obtain the foamed product. According to the method and apparatus provided by the invention, production stages are simplified to three production stages, so production cost and process complexity are reduced, and simplified production of foamed products with any complex structures can be realized.

Owner:BEIJING UNIV OF CHEM TECH

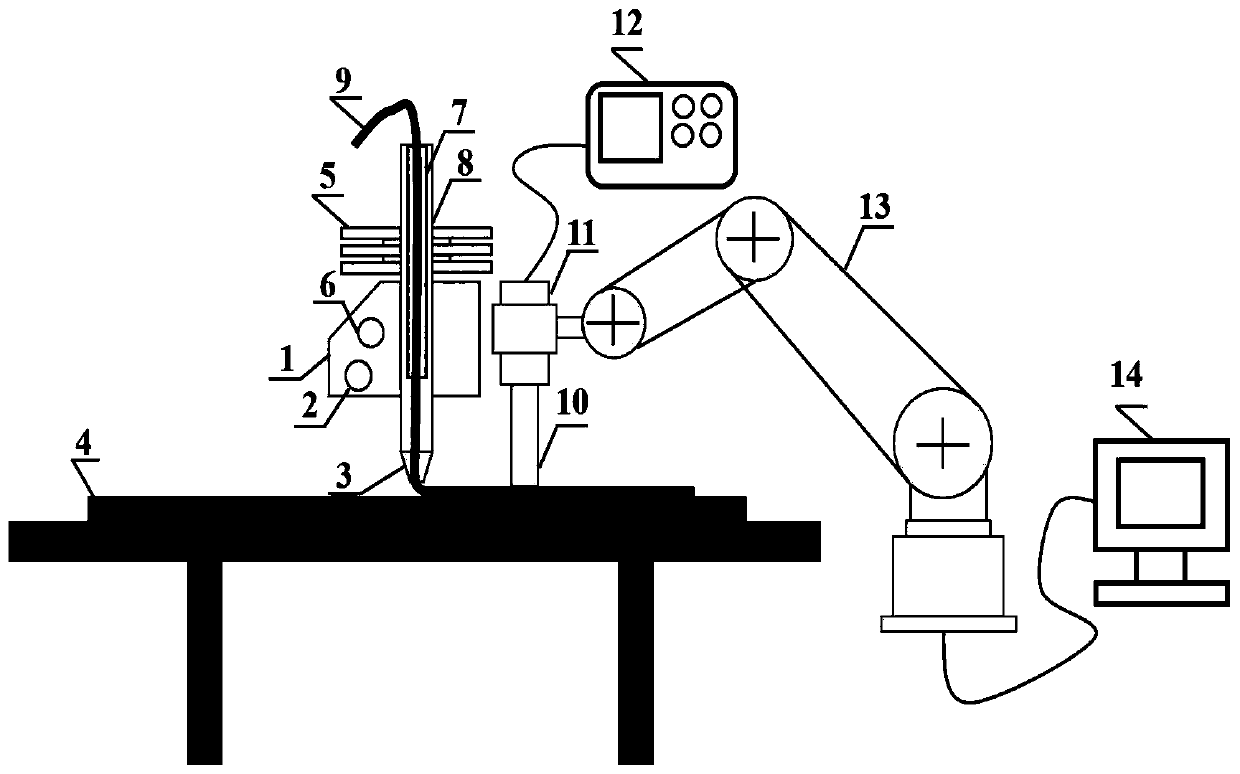

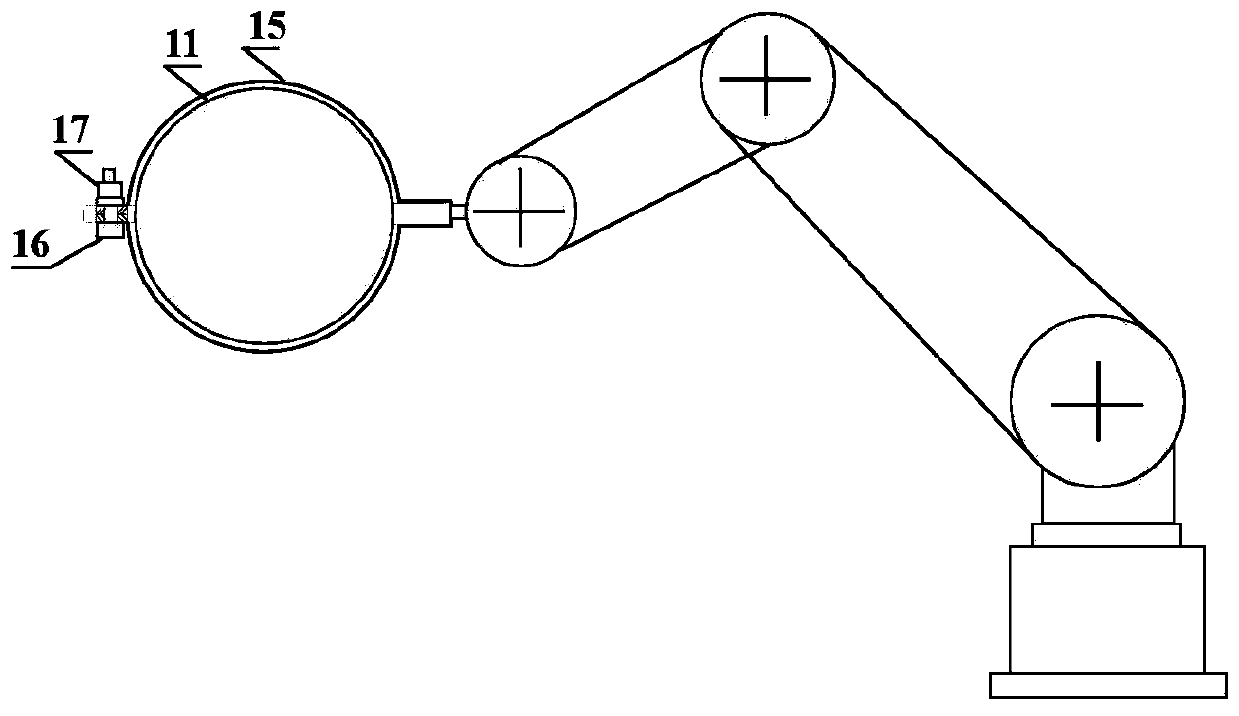

Ultrasonic vibration assisted 3D printing method

InactiveCN110481003AUniform and fine tissueGood adhesionManufacturing heating elements3D object support structuresMolten stateEngineering

The invention discloses an ultrasonic vibration assisted 3D printing method, belongs to the technical field of 3D printing, and relates to a device and method based on ultrasonic vibration assisted 3Dprinting. According to the method, the specially-made ultrasonic-assisted 3D printing device is adopted, and the device is composed of a 3D printing mechanism and an ultrasonic vibration structure. According to the ultrasonic vibration assisted 3D printing method, the 3D printing device is assembled firstly, and when ultrasonic vibration is assisted for 3D printing, firstly, a printing material is fed into a printing nozzle through a stepping motor; the printing material in the nozzle is converted into a molten state from a solid state under the action of a high temperature and is extruded toa printing bottom plate through the nozzle; and at the moment, under the control of a six-degree-of-freedom mechanical arm and an ultrasonic generator, an ultrasonic amplitude-variable rod carries out the ultrasonic vibration on the material which is not completely solidified, so that a high-performance 3D printing part with few pores and good interphase, interline and interlayer combination is formed after repeated layer by layer printing. The method has the advantages of being high in material adaptability and wide in application prospects and the like.

Owner:DALIAN UNIV OF TECH

Nano-scale high-precision additive manufacturing equipment

PendingCN108748975AImprove printing accuracyChange stressManufacturing platforms/substratesAdditive manufacturing with liquidsHigh fluxSpray nozzle

The invention discloses nano-scale high-precision additive manufacturing equipment. The nano-scale high-precision additive manufacturing equipment comprises a printing platform and a printing nozzle,wherein a high-voltage pulse power supply is applied between the printing platform and a conductive nozzle of the printing nozzle; and a uniform-intensity magnetic field perpendicular to the printingplatform is further arranged between the printing platform and the printing spray head, and the distance between the printing platform and the printing nozzle meets the characteristic requirements. According to the nano-scale high-precision additive manufacturing equipment, nano-scale 2D and 3D additive manufacturing is achieved, high-voltage pulse electric fluid dynamic jetting, a nano-scale printing head and a constraint magnetic field are benefited, and the problem that high-precision nano-scale materials cannot be constructed in the prior art is solved, and particularly relates to the insufficiency and restrictions in the field of electronic circuit board printing, nano energy storage, solar cells and biomedicine, flexible electronic materials, high-flux preparation and the like.

Owner:CENT SOUTH UNIV

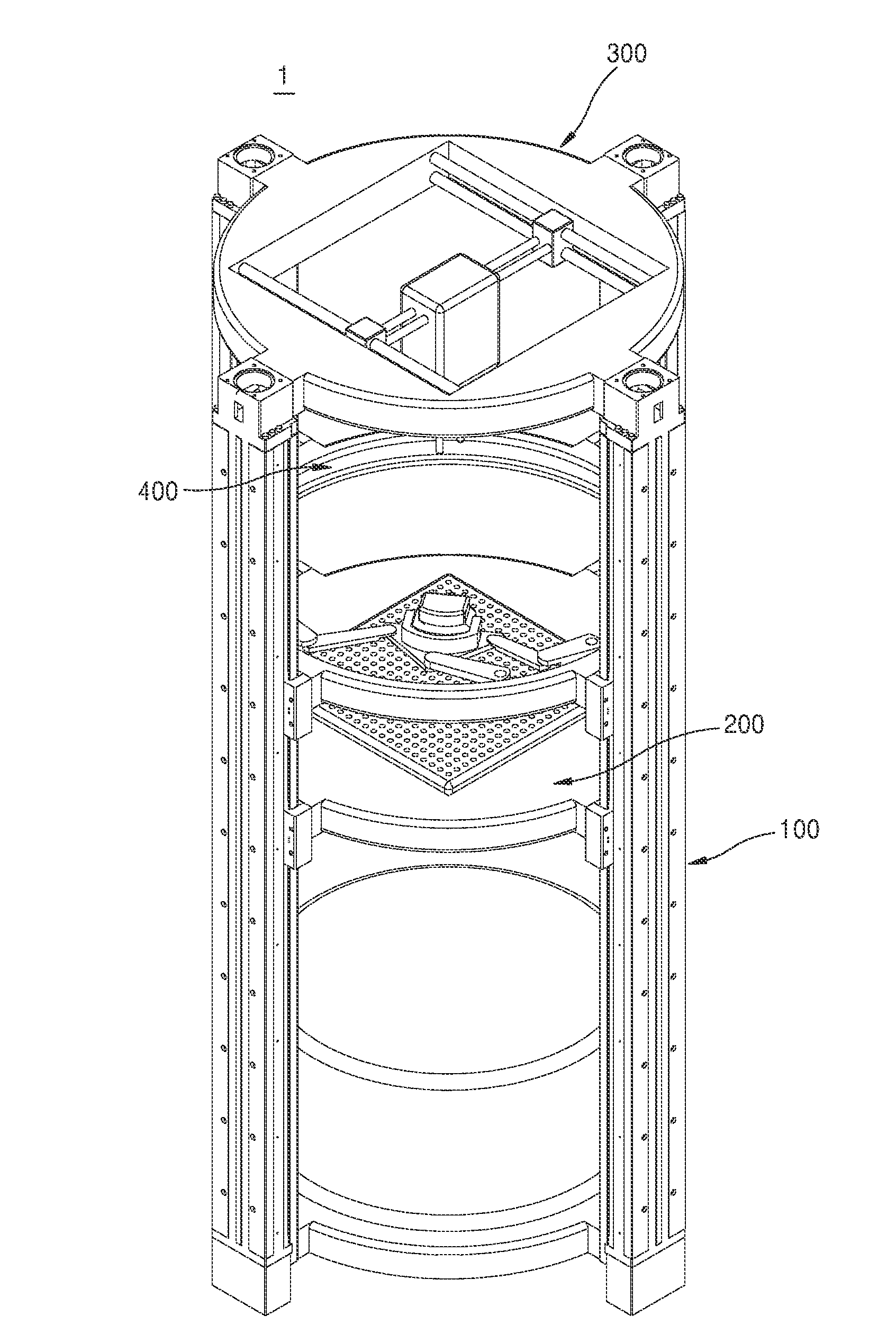

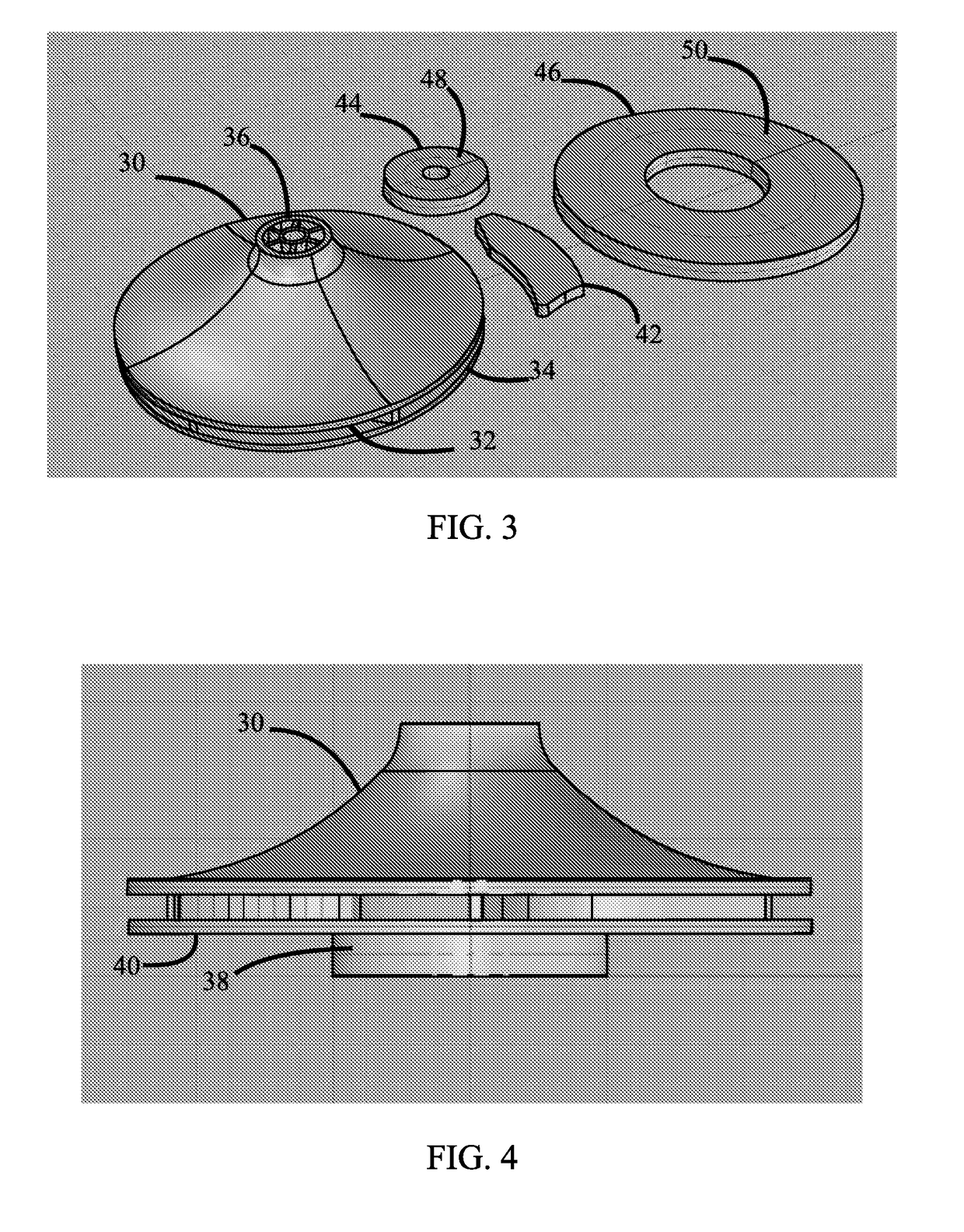

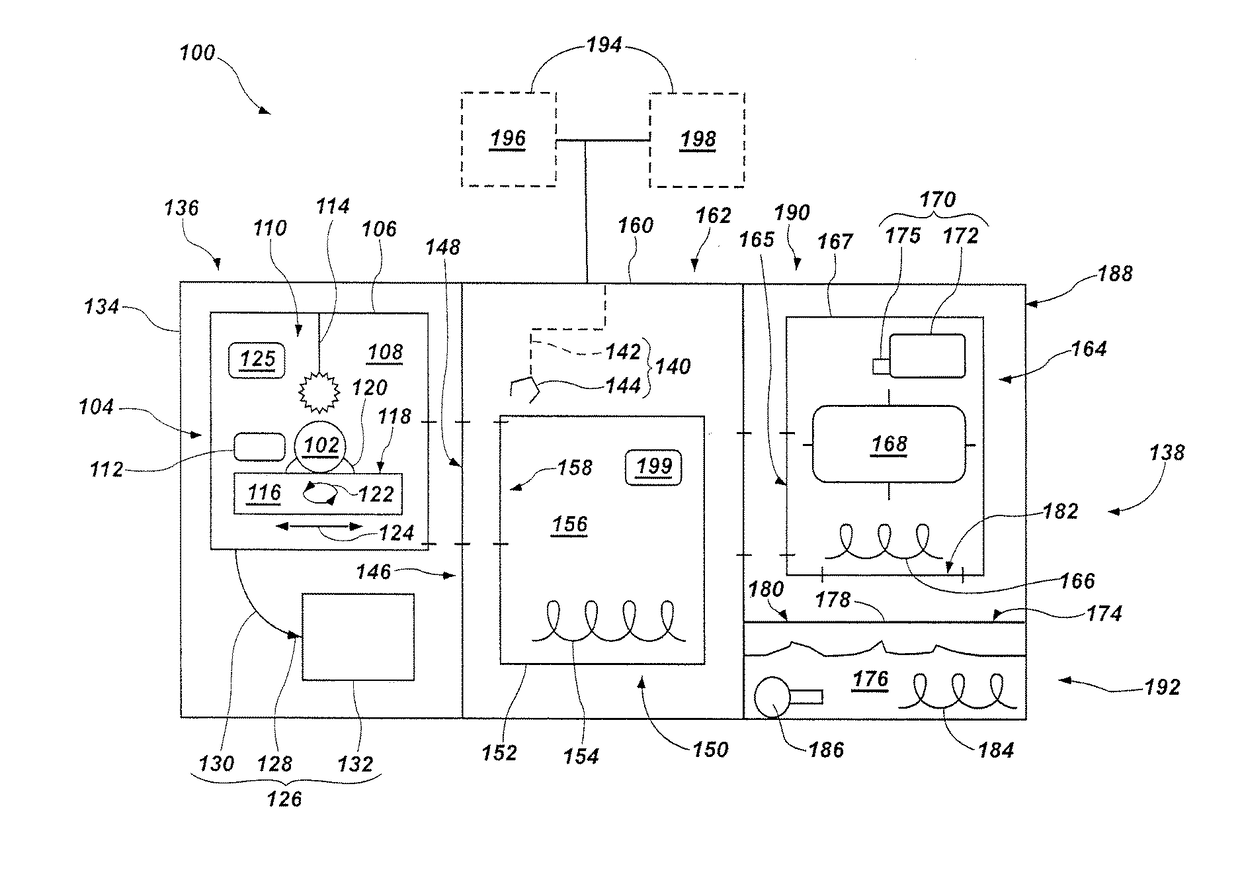

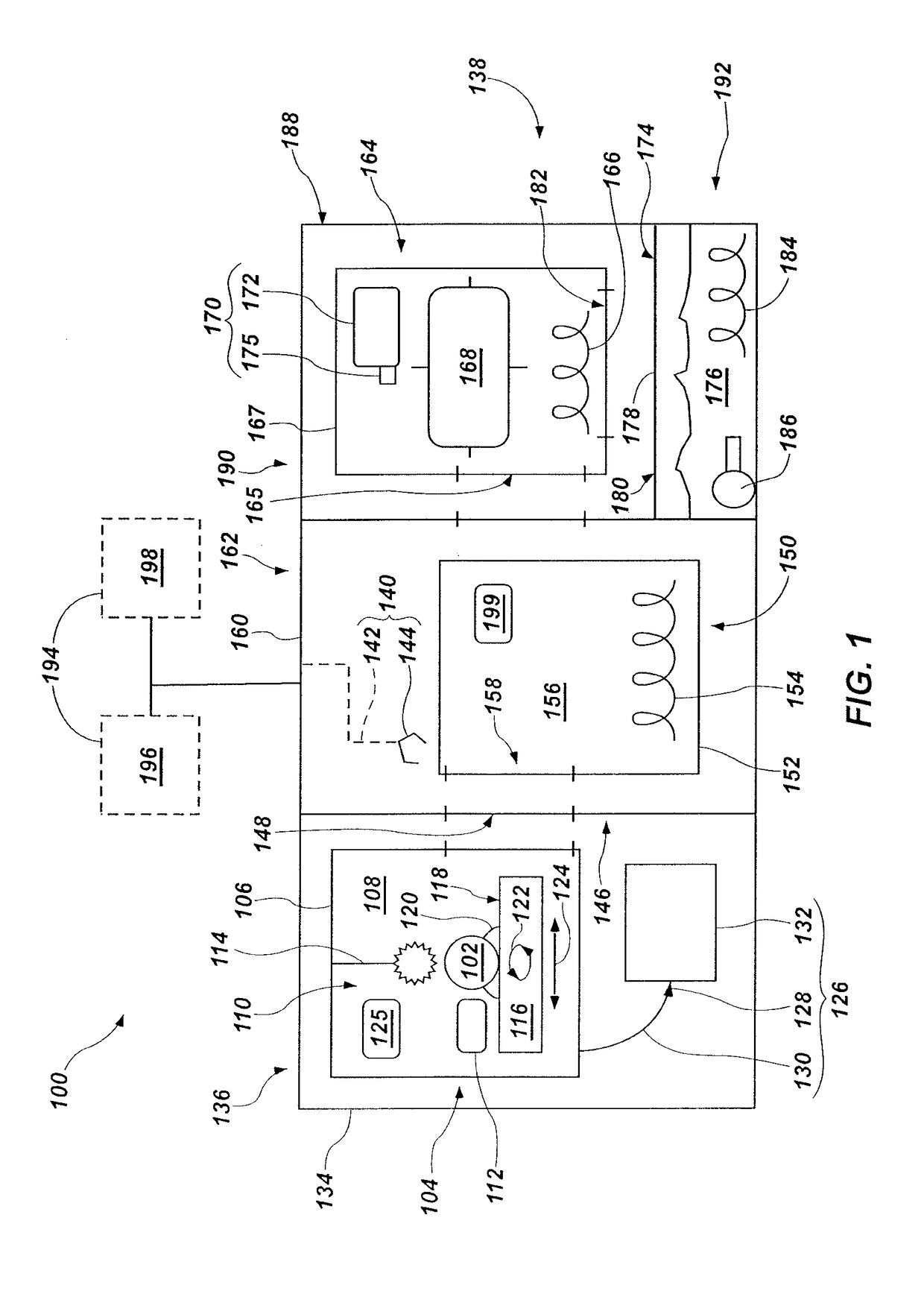

3d-printing systems configured for advanced heat treatment and related methods

ActiveUS20170282457A1Additive manufacturing apparatusManufacturing auxillary operationsPressure transmissionEngineering

In some embodiments, systems for creating and heat-treating 3D-printed objects may include a 3D printer configured to create the object. A heat-treatment apparatus may be operatively connected to the 3D printer. The heat-treatment apparatus may be configured to expose the object to an elevated temperature to heat-treat the object. A pressure-transmission medium of the heat-treatment apparatus may be configured to apply pressure to the object during heat treatment. The 3D printer and heat-treatment apparatus may be incorporated into a unified process flow volume. Methods of creating and heat-treating 3D-printed objects may involve creating an object utilizing a 3D printer. The object may be moved from the 3D printer to a heat-treatment apparatus. The object may be exposed to an elevated temperature and pressure may be applied to the object utilizing a pressure-transmission medium of the heat-treatment apparatus. The 3D printer and heat-treatment apparatus may in a unified process flow volume.

Owner:BAKER HUGHES INC

Efficient 3D printer with anti-blocking and automatic adjusting functions

ActiveCN107053656AWith automatic adjustment functionImprove printing efficiencyManufacturing driving means3D object support structuresSprayerAir pump

The invention relates to an efficient 3D printer with anti-blocking and automatic adjusting functions. The efficient 3D printer comprises a base, a printing platform, a top plate, a material disc, a wire feeding pipe and two lifting units. A printing mechanism comprises a movable plate, a printing unit, a flow guiding unit and a dredging unit. The printing unit comprises a rotating unit, a first sprayer, a second sprayer, a blocking pipe and two material conveying pipes. A blocking mechanism is arranged in the blocking pipe. The dredging unit comprises a fixing rod, a driving unit, an inserting rod, a lifting rod and a bottom rod. The flow guiding unit comprises an air pump, an air pipe, an air cylinder, a piston and a heating pipe. According to the efficient 3D printer with the anti-blocking and automatic adjusting functions, the first sprayer and the second sprayer are flexibly switched through the rotating unit, the printing efficiency can be improved, the printing precision can be guaranteed, more than that, the driving unit drives a lifting frame and the inserting rod to move in the vertical direction back and forth, the first sprayer and the second sprayer are dredged, and the blocking phenomenon generated during printing is avoided.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

3D printing equipment having air purification function

InactiveCN106945284AAvoid pollutionAvoid damageCombination devicesAdditive manufacturing apparatusFiltrationProtection mechanism

The invention relates to 3D printing equipment having an air purification function. The 3D printing equipment comprises a main body, a spray head, a printing table, a material conveying mechanism and a power mechanism; the main body further comprises an air purification mechanism and a protection mechanism; the air purification mechanism comprises a purification chamber, a fan, a filtration component and a sterilization component; and the protection mechanism comprises a first connecting rod, a second connecting rod, a protection cover and a driving component. According to the 3D printing equipment having the air purification function, air in the 3D printing equipment is filtered through the air purification mechanism, and then the purified air is exhausted, so that harmful gas is prevented from harming human health, and air pollution is avoided; in addition, when the 3D printing equipment does not work, a winding reel and a material wire are protected through the protection mechanism, so that a situation that the material wire is wound due to the fact that the winding reel is exposed out is prevented, and the material wire is prevented from being damaged.

Owner:福建省速卖通电子商务有限公司

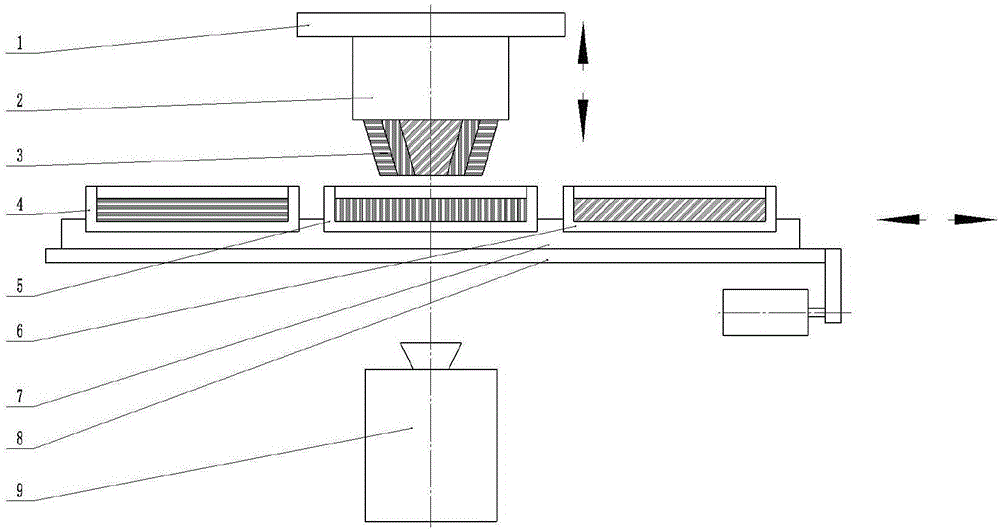

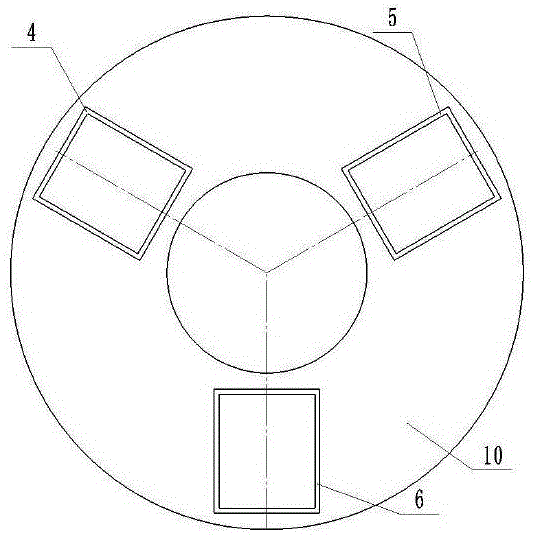

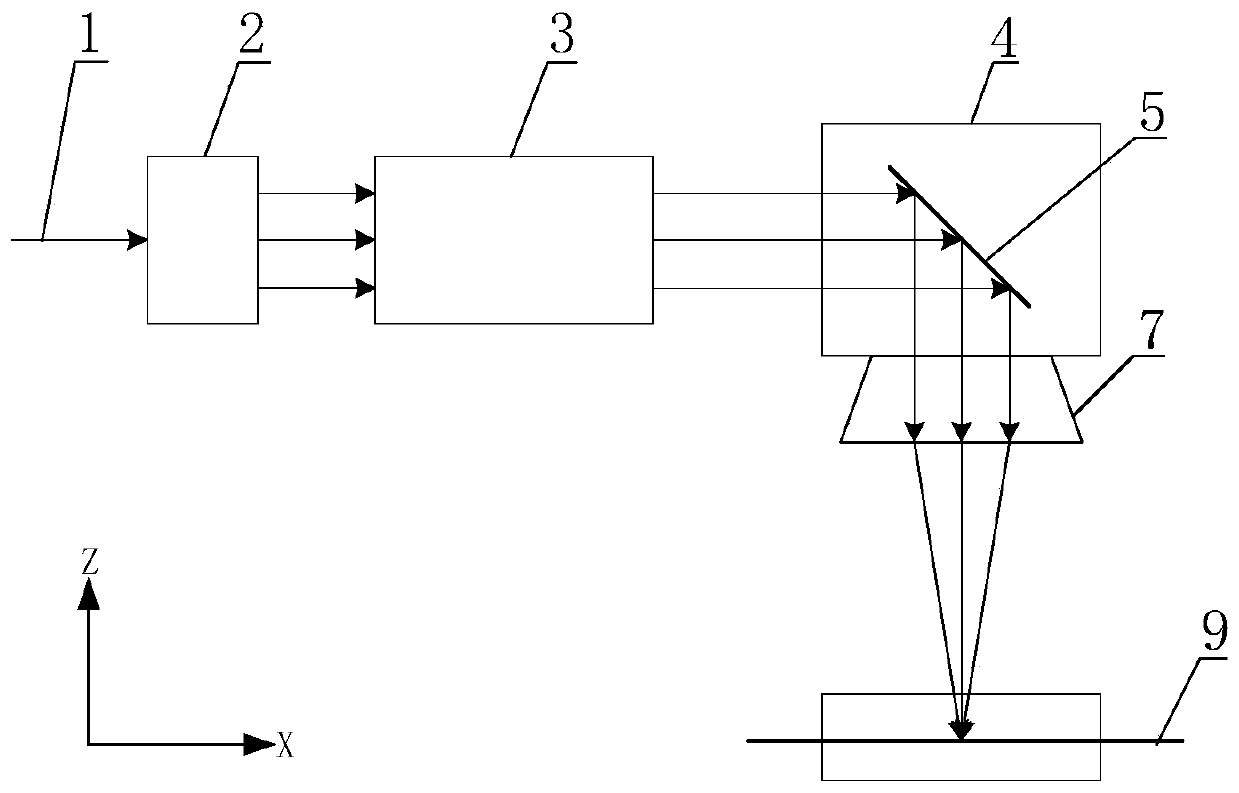

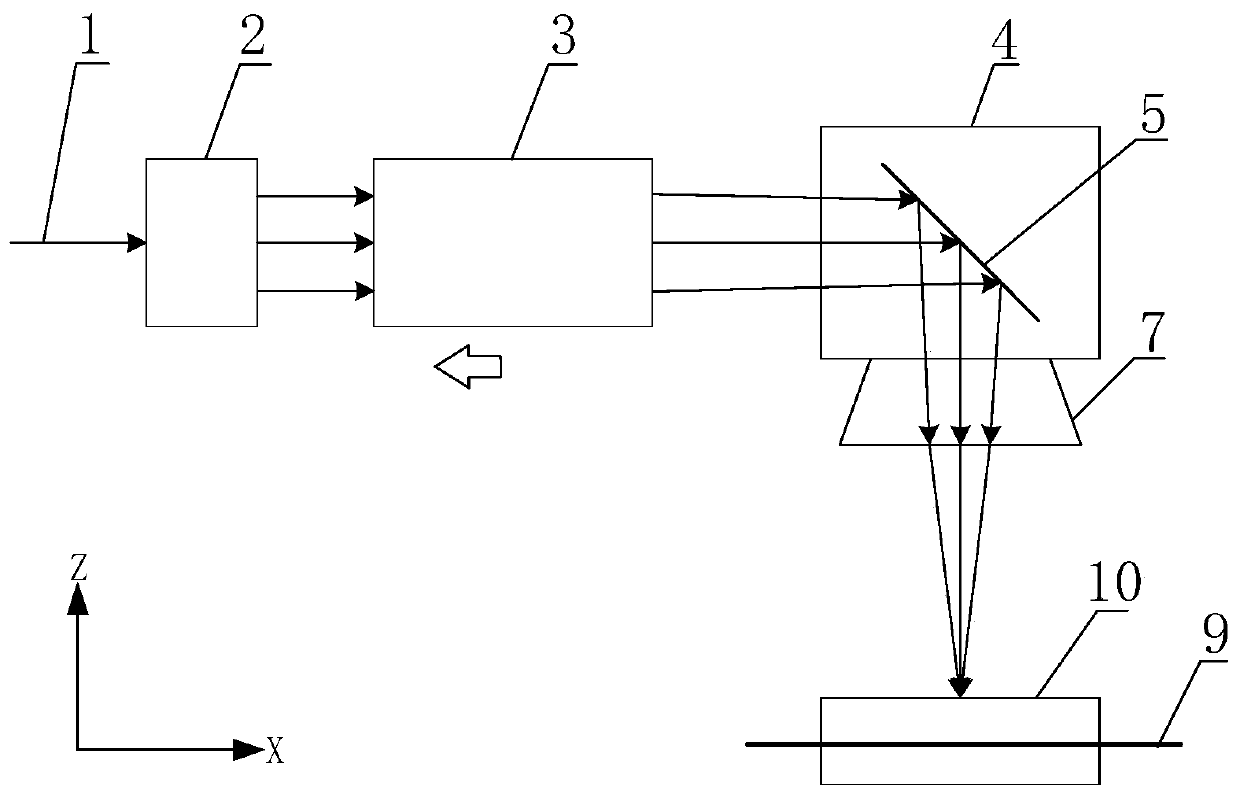

Multi-material digital light processing (DLP) three-dimensional printing method and printing equipment thereof

InactiveCN106363906AMeet individual needsAdditive manufacturing apparatus3D object support structuresMulti materialIrradiation

The invention provides a multi-material digital light processing (DLP) three-dimensional printing method and printing equipment thereof. The core of the multi-material DLP three-dimensional printing method lies in the multi-trough switching technique, that is, two or more resin troughs containing different kinds of photosensitive resin are arranged below a model building table, and the resin troughs are installed on a horizontal motion mechanism controlled by a motor. Each resin trough can be directly moved to the position below the building table when needed. After printing of one material is completed, the resin trough containing another material is horizontally moved to the position below the building table, the material replaces the original material to continue to receive irradiation of a projector, and thus printing operation can be continued. The overall arrangement of the multi-material DLP three-dimensional printer is conducted according to a lower exposure type three-dimensional printing system, the single trough structure and the motion mode of existing DLP three-dimensional printing equipment are converted into a multi-trough structure, printing of various resin materials can be conducted so that individual requirements of models can be met, and accordingly the application range of the DLP three-dimensional printing technology is broadened.

Owner:BEIJING HENGCHUANG ADVANCED MATERIALS & ADDITIVE MFG INST CO LTD

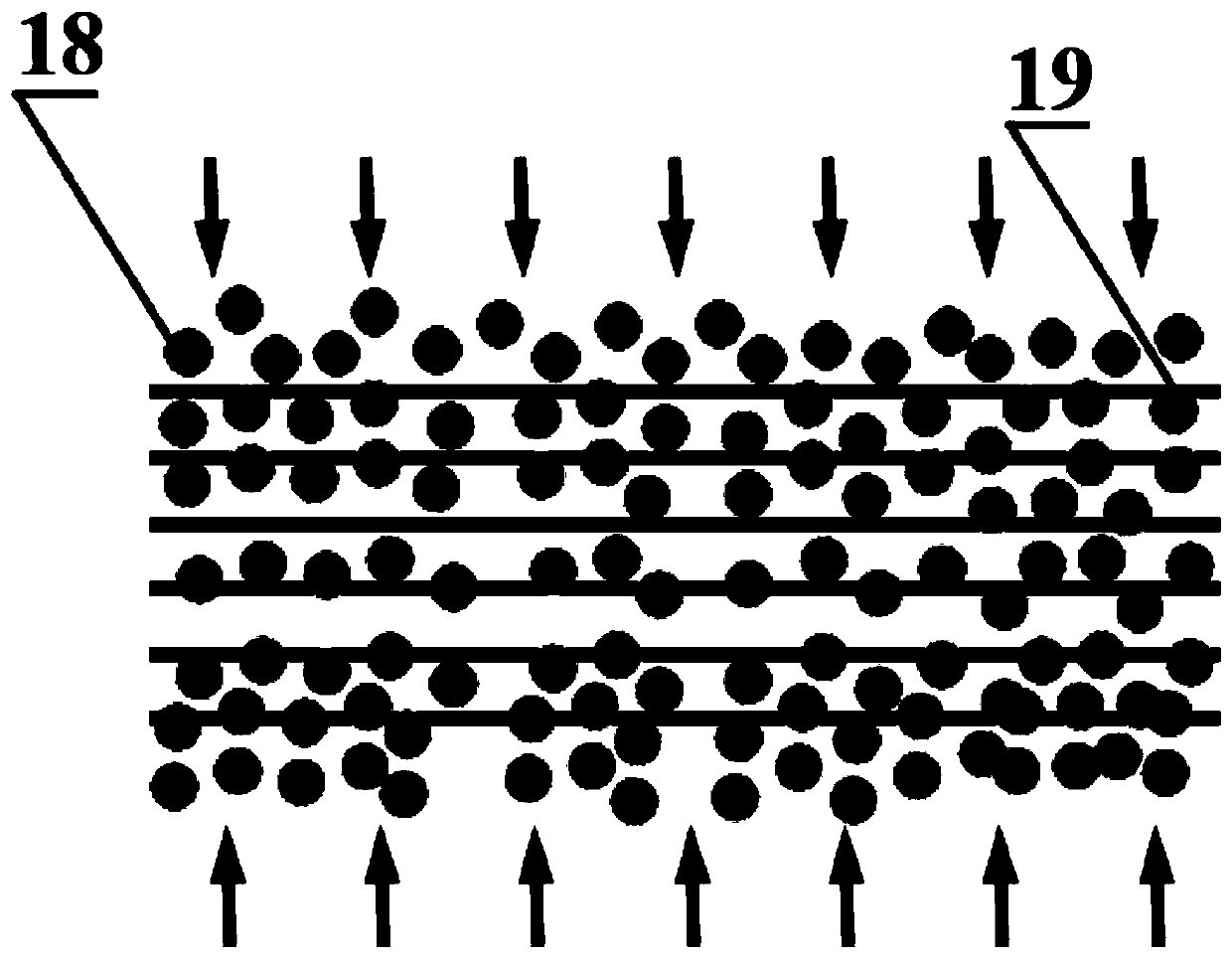

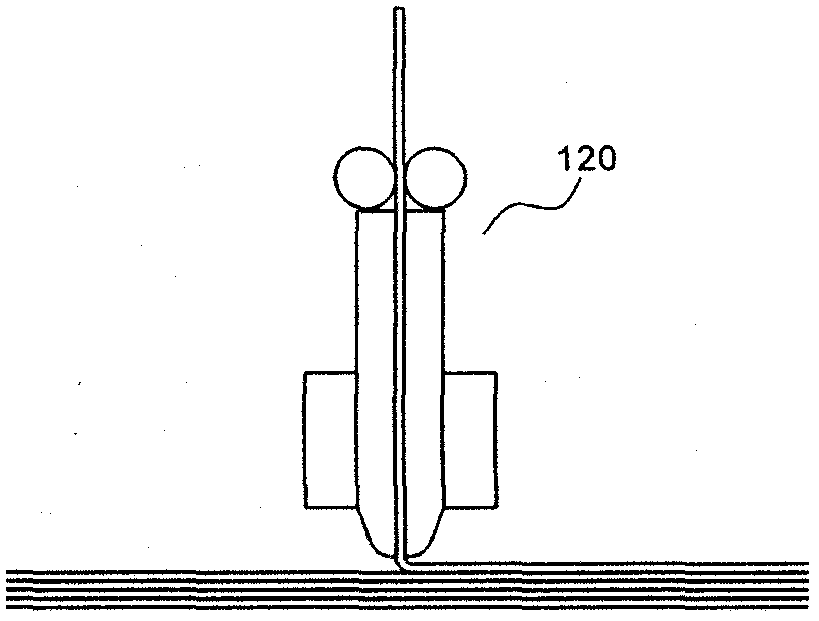

Interlayer reinforcement technology for 3D printing of fiber reinforced composite

InactiveCN108790144AImprove the status quo of weak interlayer performanceGood internal performanceAdditive manufacturing apparatus3D object support structuresIn planeResin matrix

The invention relates to an interlayer reinforcement technology for 3D printing of a fiber reinforced composite and belongs to the technical field of interlayer reinforcement technologies for 3D printing of continuous fiber reinforced thermoplastic resin matrix composites. 3D printing equipment involved in the interlayer reinforcement technology comprises at least two printing nozzles, namely a fiber reinforced thermoplastic resin printing nozzle (an in-plane nozzle) and an interlayer reinforcement nozzle. The interlayer reinforcement technology comprises the following working steps: firstly,printing certain layers of an in-plane material by using the in-plane nozzle till the thickness reaches 0.5 mm to 30 mm; secondly, according to the design space, implanting a thin bar into a multi-point position of the printed layered area by using the interlayer reinforcement nozzle so as to complete the one-layer reinforcement operation; and thirdly, repeating step 1 to step 2 so as to completethe multi-layer printing and reinforcement operation till a product is printed. The interlayer reinforcement technology provided by the invention has the beneficial effects that the cost is low; the degree of automation is high; and the weak interlayer performance of a 3D printing product can be greatly improved.

Owner:TIANJIN POLYTECHNIC UNIV

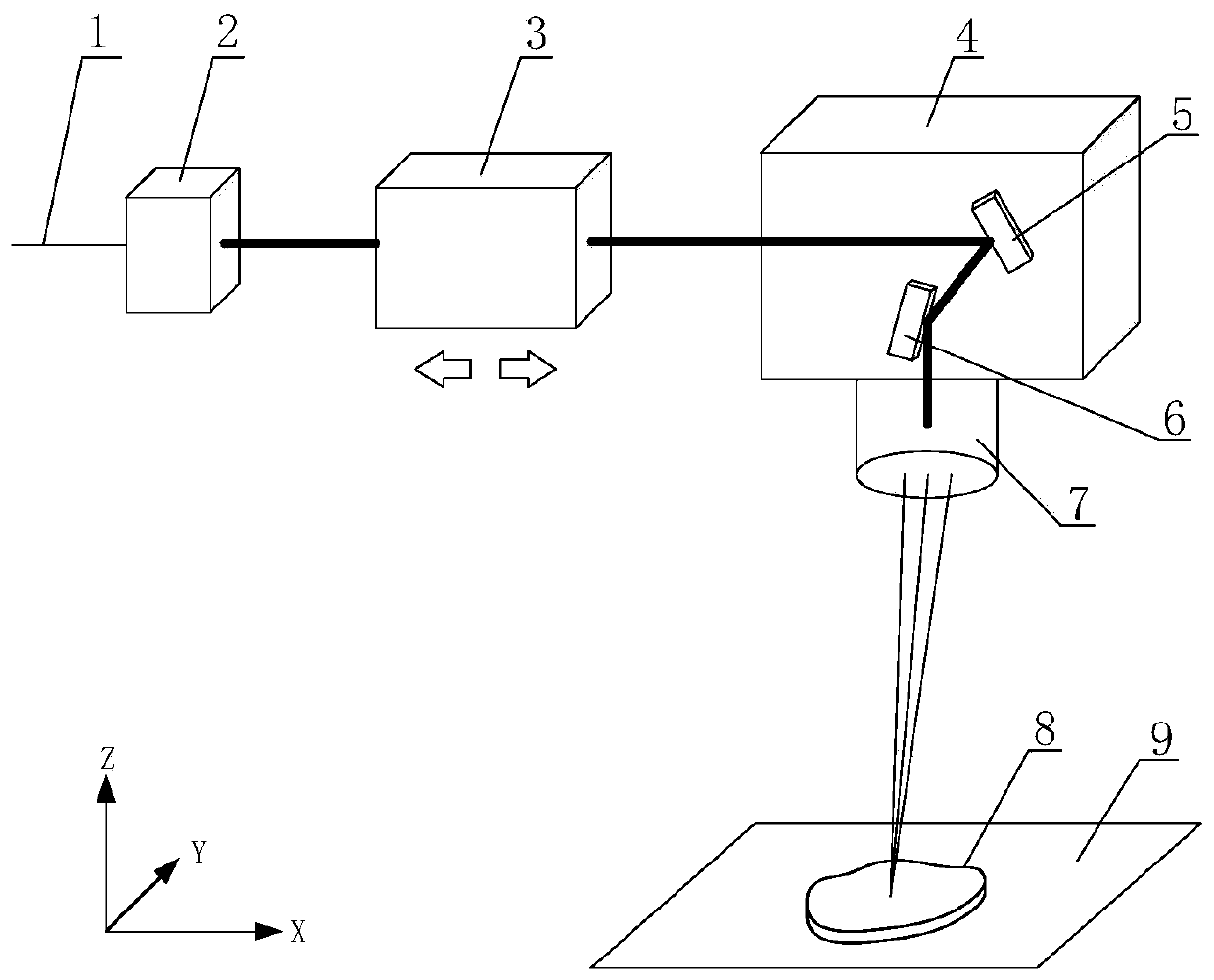

Three-dimensional scanning forming device and method based on laser forming

InactiveCN109940880AAvoid errorsImprove printing efficiencyAdditive manufacturing apparatus3D object support structuresBeam expanderThree-dimensional space

The invention discloses a three-dimensional scanning forming device and method based on laser forming. A collimating beam expander, an adjusting lens and a galvanometer are installed on a straight line. The collimated beam expander is used for diverging small light spots output by a laser device, parallel light after beam expanding enters the adjusting mirror, the transmission distance of a lightbeam is adjusted by the adjusting lens, namely an optical path is changed, the diameter and focal length of focused light spots are adjusted, the light beam deflects optionally by the galvanometer, finally, the light beam deflected by the galvanometer is focused through a field lens, a small light spot high-energy light beam is formed and moves on a printing platform, and a forming material on theprinting platform is printed and formed by the focused light spots focused by the field lens. According to the device, the focusing height of the light beam in the height direction is adjusted by theadjusting lens, meanwhile, in cooperation with the galvanometer, movement of a light beam focus on a plane is adjusted, thus, forming and movement of the focused light spots in a three-dimensional space are realized, continuous forming in a three-dimensional space can be realized, and the printing precision, scanning efficiency and printing precision are improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

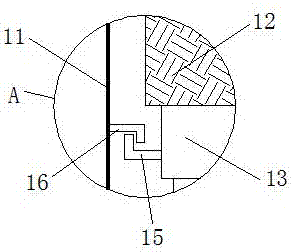

Cooling and damping movable base of 3D printer

PendingCN107351403APlay a buffer roleChange the condition of wear and tearAdditive manufacturing apparatusNon-rotating vibration suppressionComputer printingTransmission belt

The invention discloses a cooling and damping movable base of a 3D printer. The cooling and damping movable base comprises a fixed base, a transmission belt, a protection baffle and a damping spring. A rotating shaft is installed in the fixed base. The transmission belt is connected with the fixed base through the rotating shaft. Vent holes are formed in the surface of the transmission belt. Filter screens are installed outside the vent holes. Antiskid strips are arranged on the two sides of each filter screen. The protection baffle is located above the fixed base. A sound absorbing sponge is installed in the fixed base. A limiting clamping block is installed on the left side of a supporting rod. A safety pin is installed on the right side of a bearing column. According to the cooling and damping movable base, the printer is pulled to rotate together with the transmission belt, the position of the printer can be conveniently moved, the abrasion of the bottom of the printer is avoided, when external pressure suddenly increases, the safety pin is broken, the damping spring absorbs impact of the supporting rod, and the overall stability is improved.

Owner:王保锋

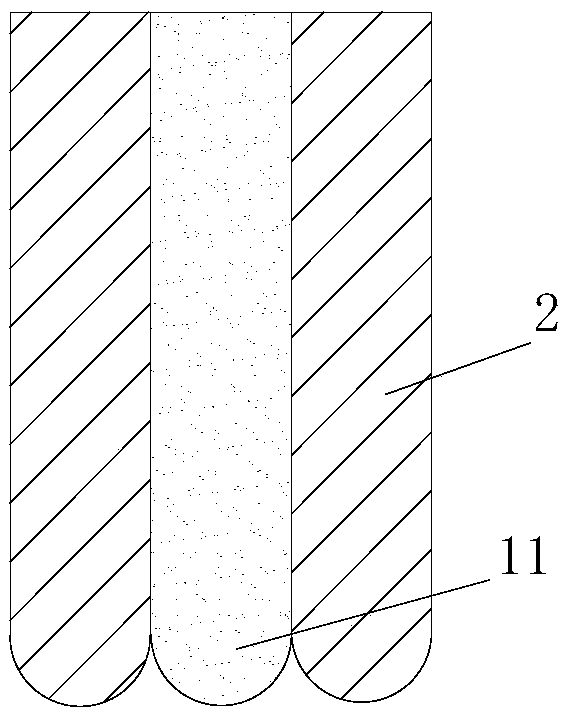

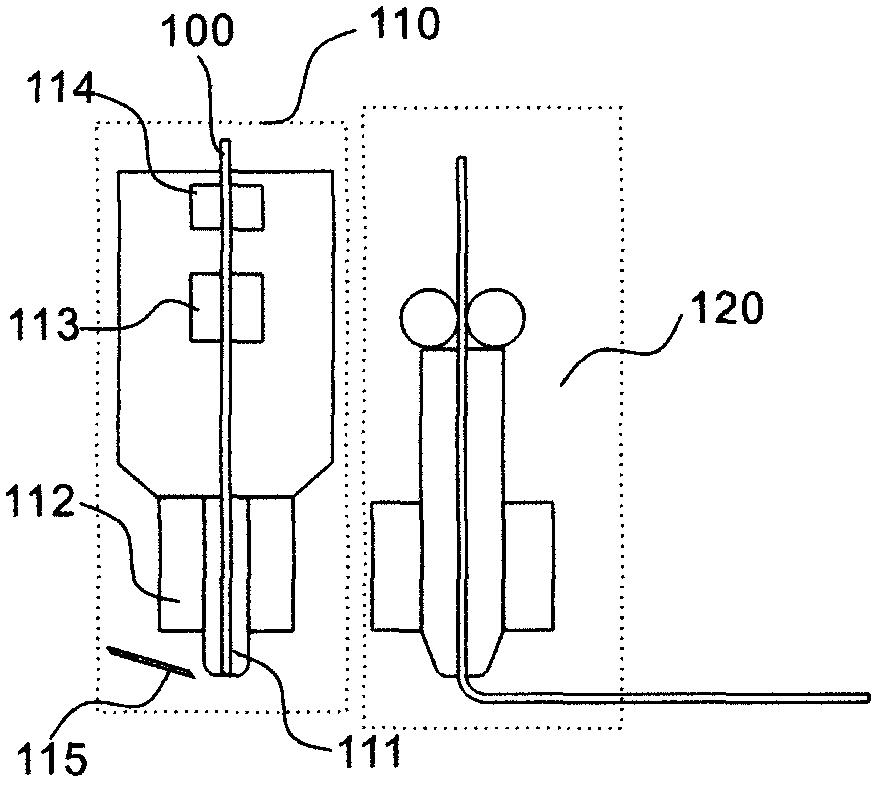

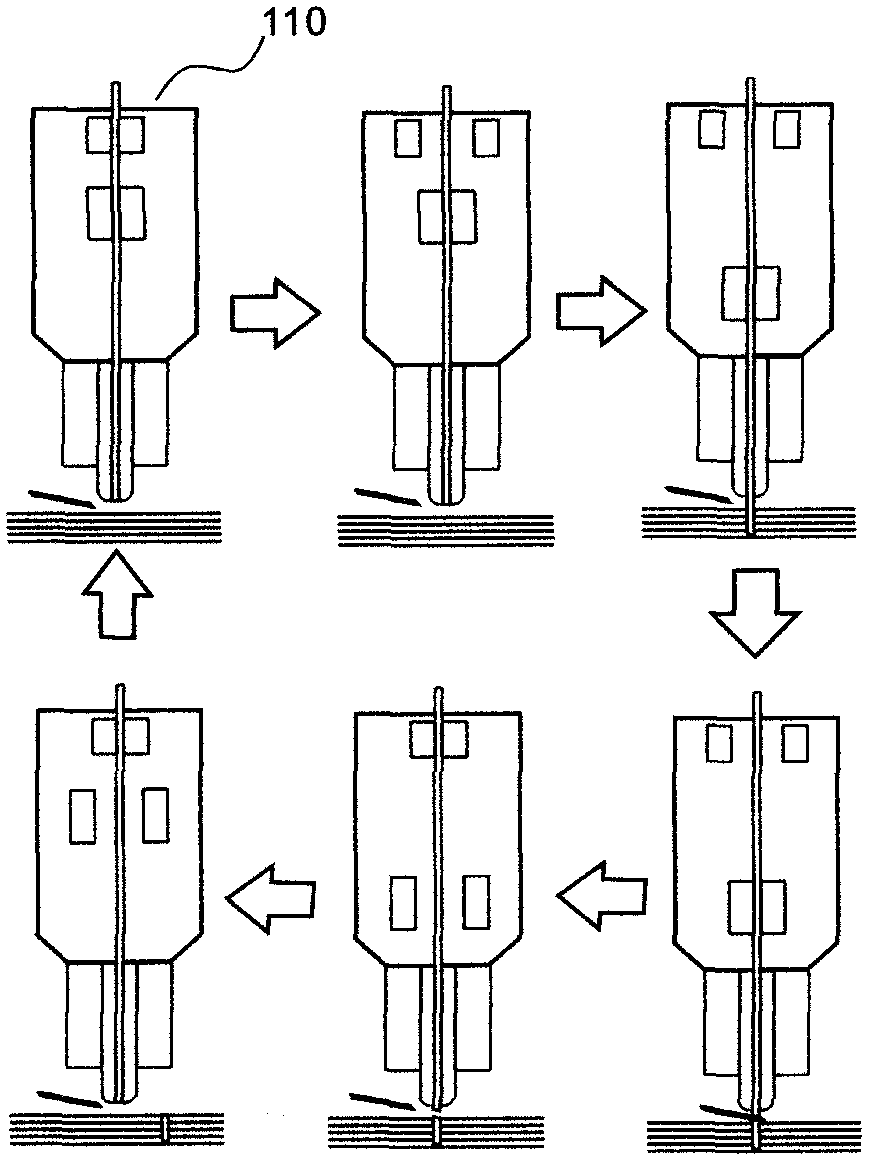

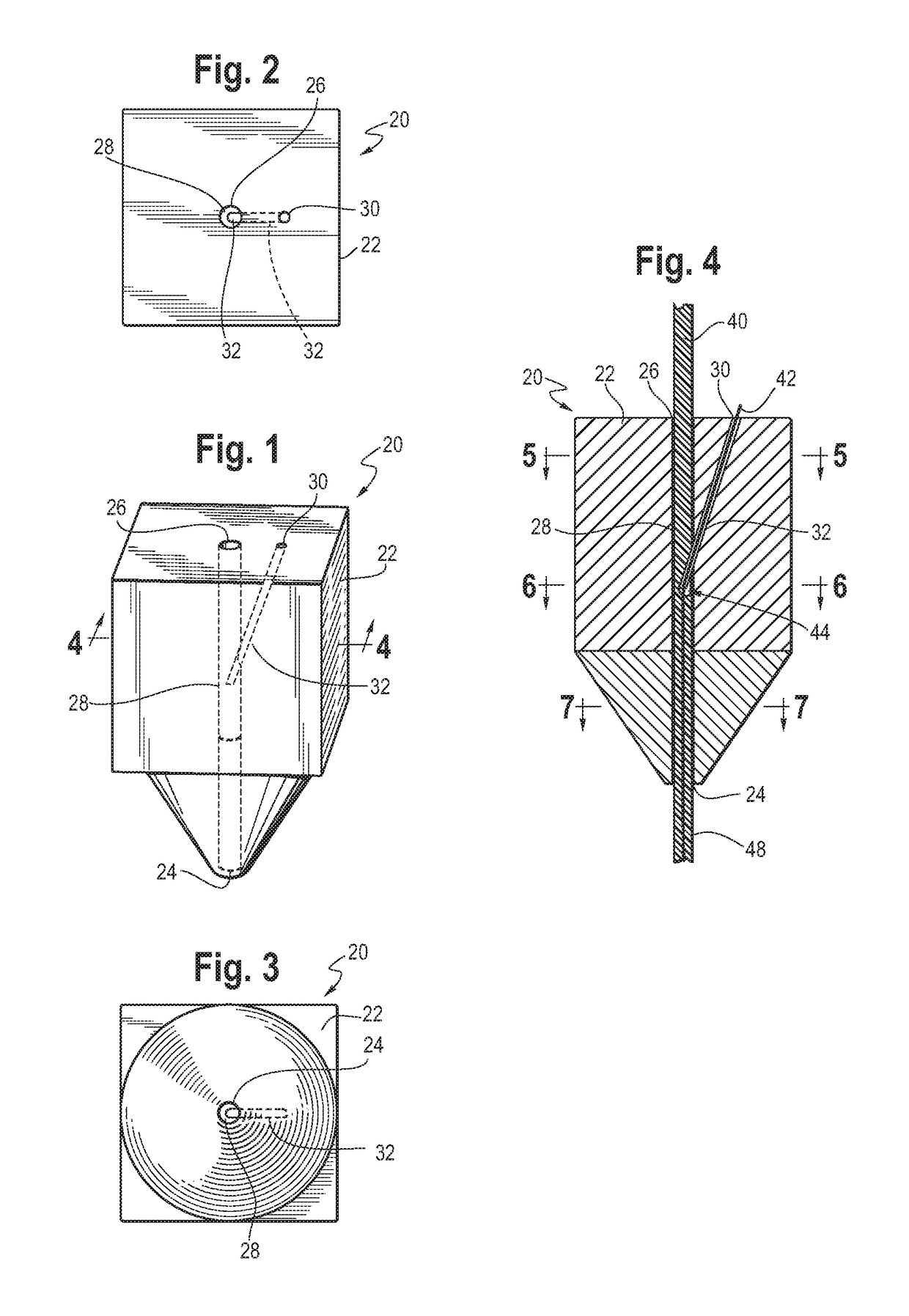

Device and method for 3D printing with long-fiber reinforcement

ActiveUS10173410B23D object support structuresAdditive mnaufacturing with solid and fluidEngineeringAdvanced composite materials

A process and device for 3D printing parts incorporating long-fiber reinforcements in an advanced composite material is disclosed. A nozzle for a 3D printing device receives a polymer material and a reinforcing fiber through separate inlets. A passage from the reinforcing fiber inlet cleaves the passage containing the polymer material, creating an interstitial cavity into which the reinforcing fiber is introduced. The polymer material closes back on itself and encapsulates the reinforcing fiber, then drags the fiber along with the flow and exits nozzle to be deposited on a work surface or part being manufactured.

Owner:NORTHROP GRUMMAN SYST CORP

Resin tank for DLP photocuring 3D printer capable of achieving quick film replacement and assembling method thereof

ActiveCN107336438AEasy to replaceAdjust the tensionManufacturing enclosures3D object support structuresEngineering3d printer

The invention discloses a resin tank for a DLP photocuring 3D printer capable of achieving quick film replacement and an assembling method thereof. The resin tank mainly comprises four parts including an upper end cover, an upper clamping plate, a lower clamping plate and a base; a polyperfluorinated ethylene propylene film is clamped between the upper clamping plate and the lower clamping plate and ejected into square through holes formed in the upper clamping plate and the lower clamping plate through a pressing frame of the upper end cover to be tensioned, the tensioned film can be well released from cured resin through the elasticity of the film in the printing process, and different printing precision requirements can be met by adjusting the tensioning degree of the film. According to the resin tank, a threaded fastener is not used in design, the polyperfluorinated ethylene propylene film can be quickly replaced and adjusted to the film tensioning degree, operation is more convenient, and the efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

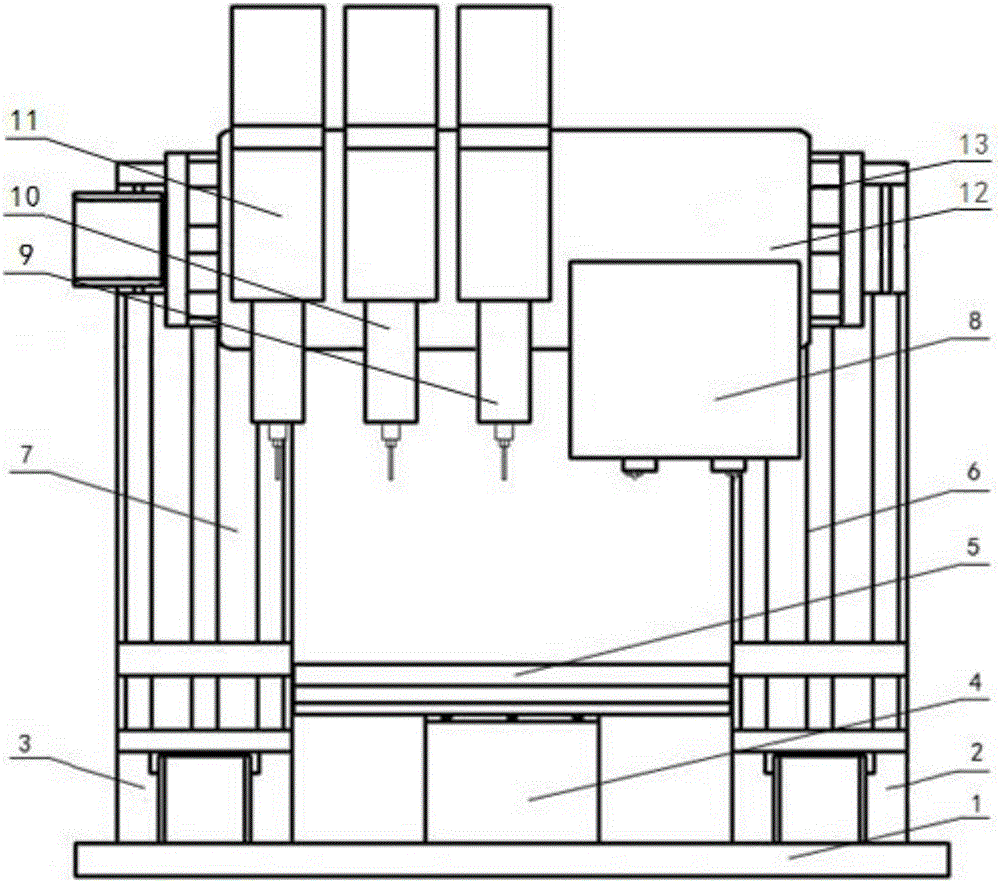

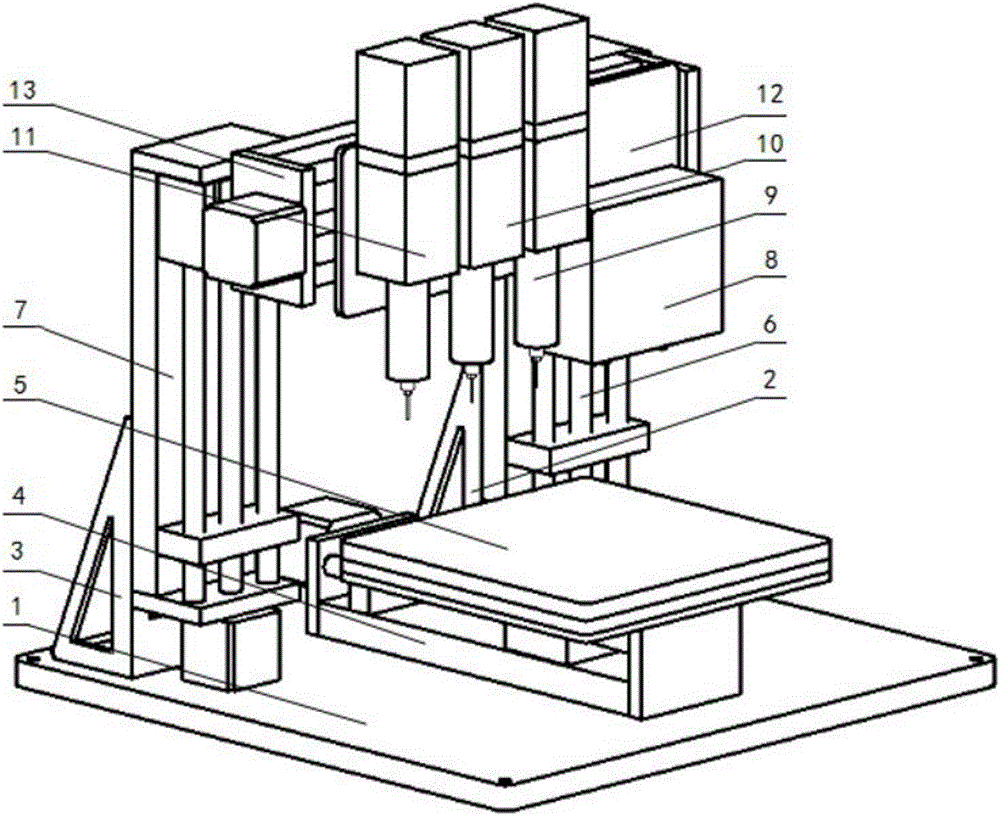

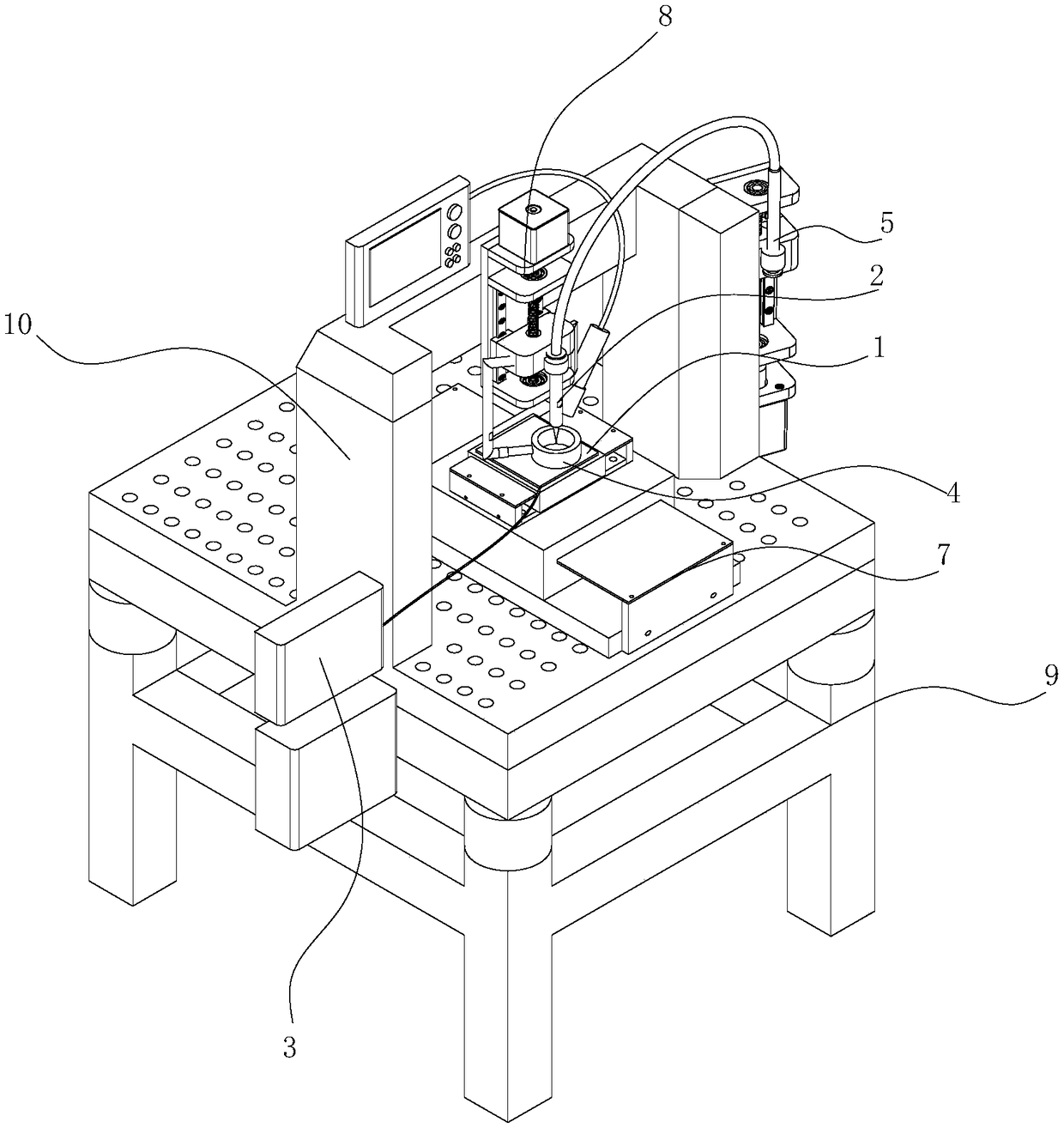

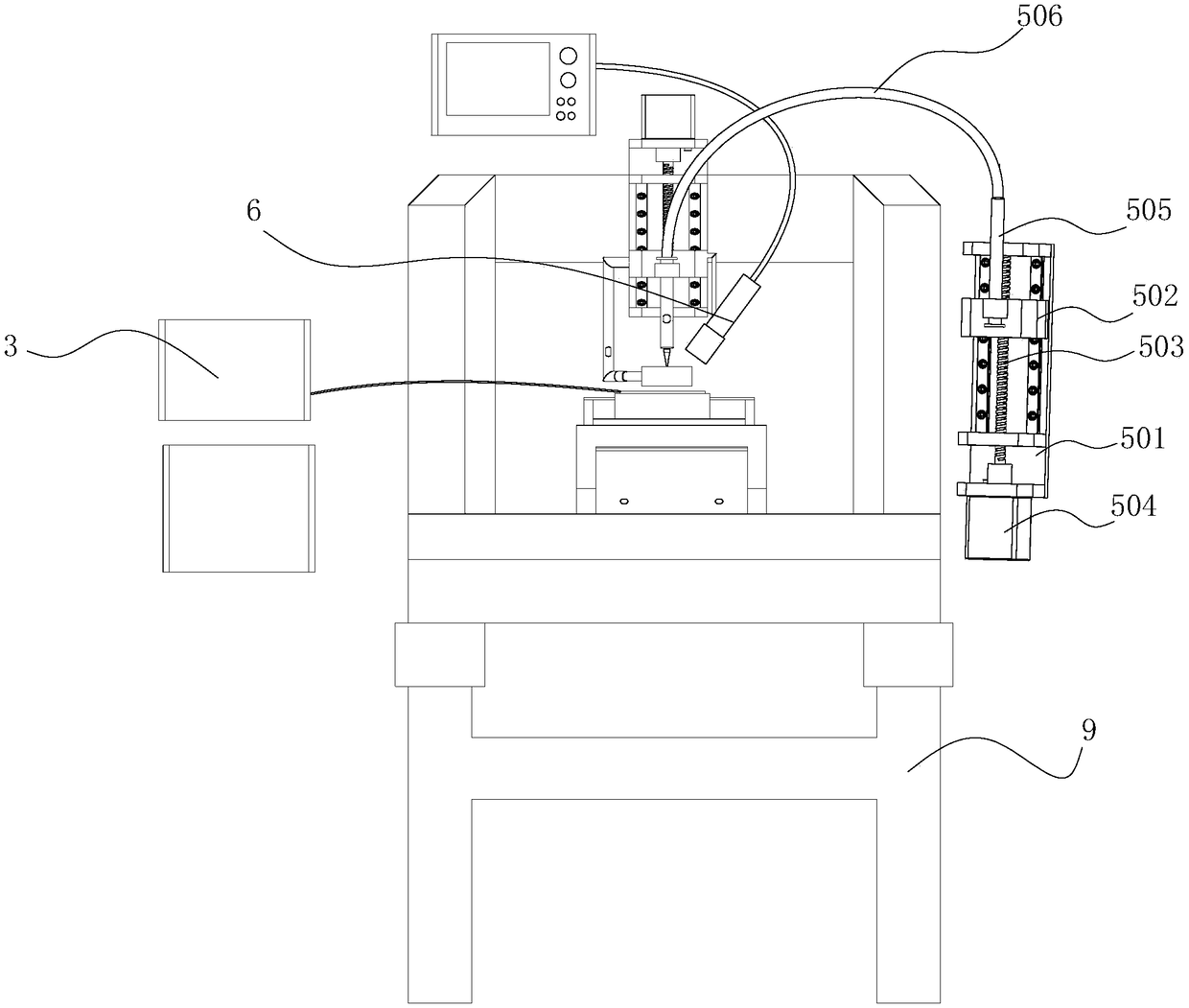

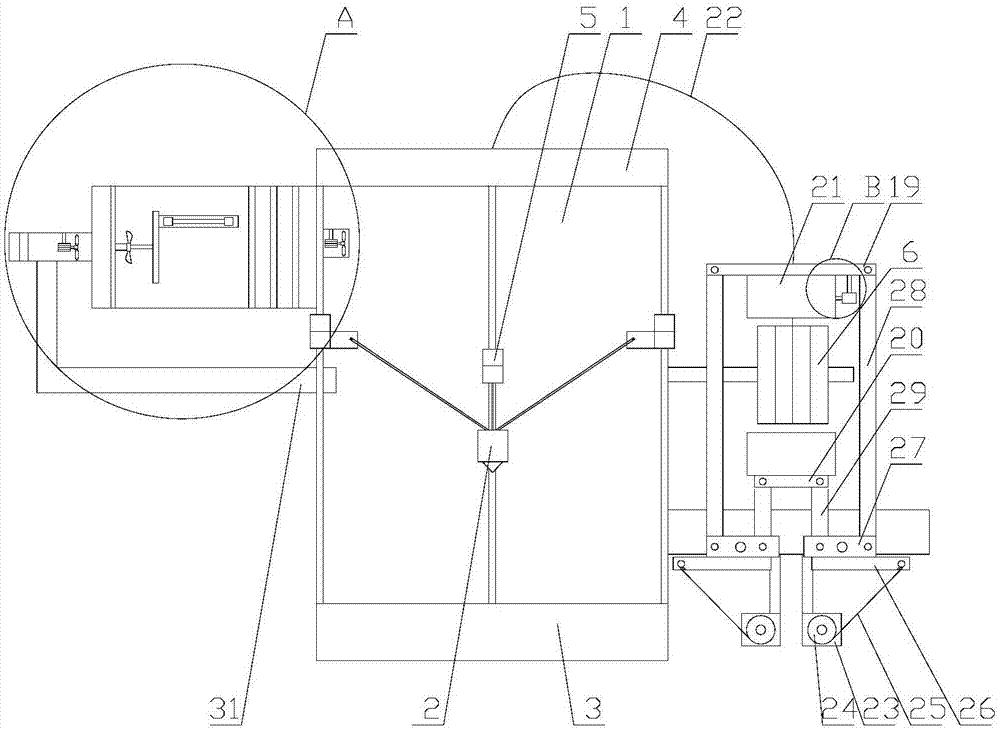

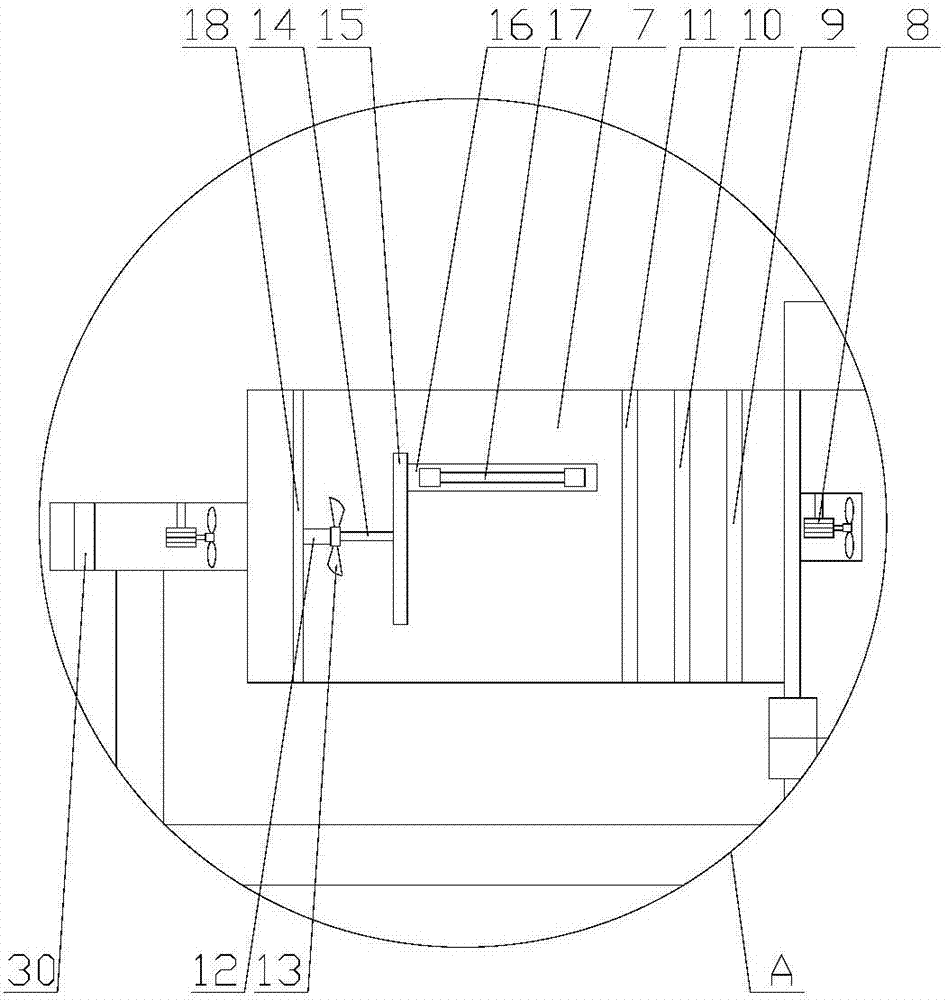

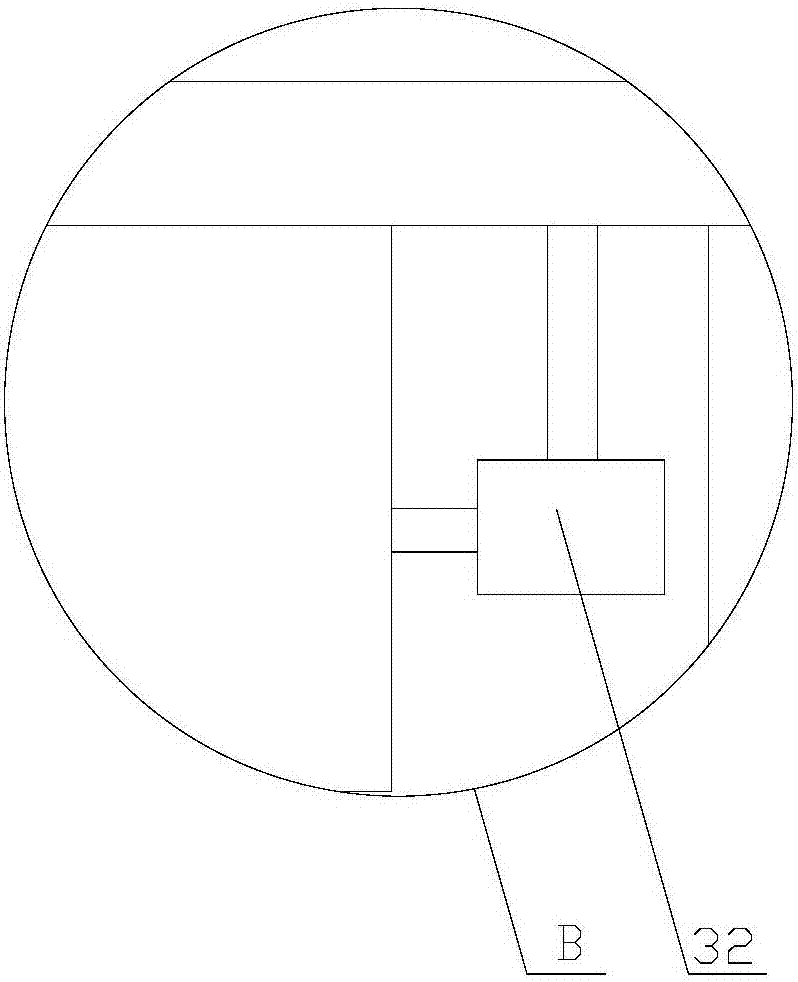

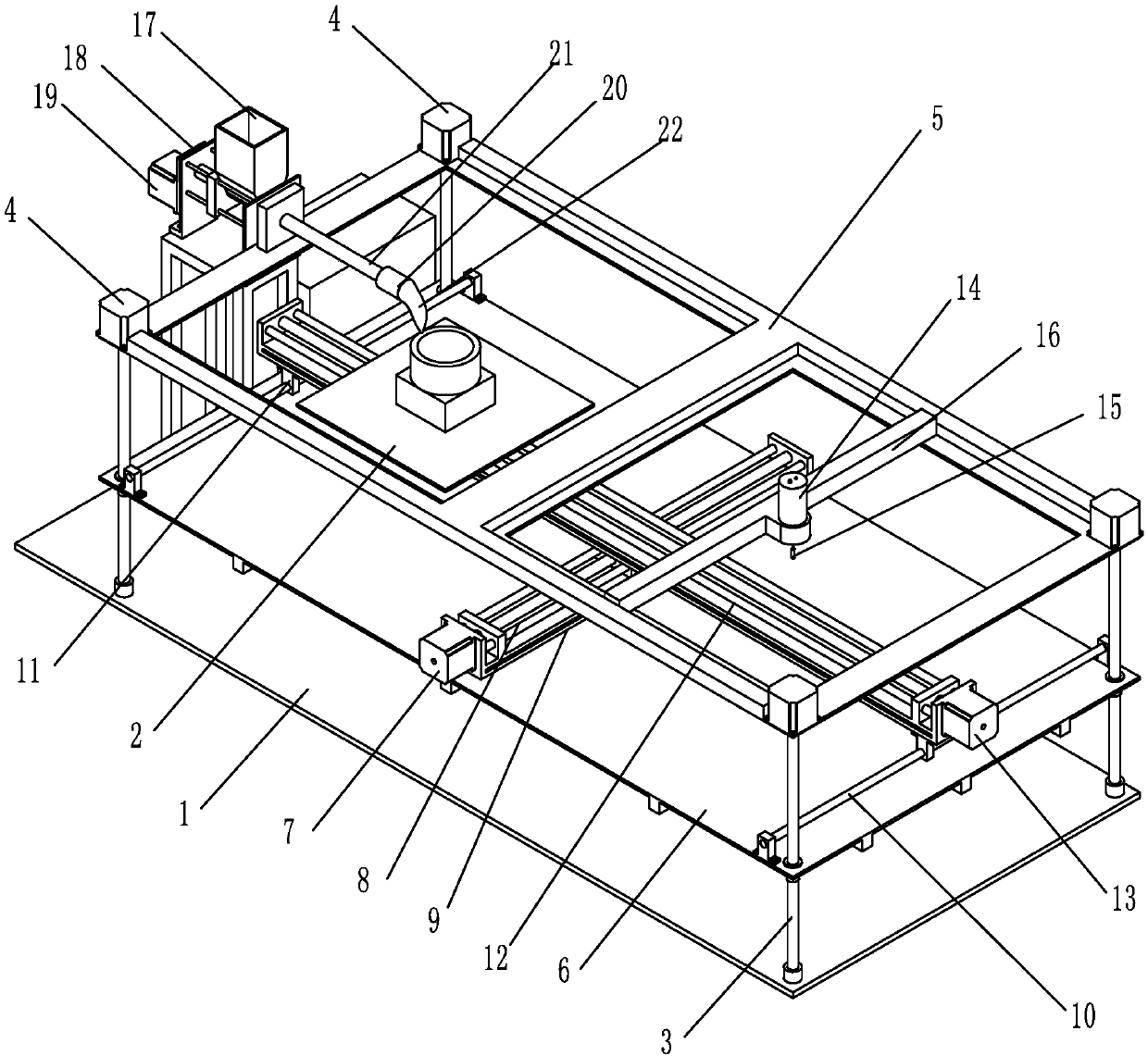

Additive manufacturing and subtractive manufacturing integrated numerical control machining machine tool

PendingCN107745258AIncrease profitLow costAdditive manufacturing apparatusOther manufacturing equipments/toolsNumerical controlEngineering

The invention relates to a numerical control machining machine tool, in particular to an additive manufacturing and subtractive manufacturing integrated numerical control machining machine tool. The problems that existing additive manufacturing and subtractive manufacturing are treated through different devices, thus subtractive manufacturing is difficult, the subtractive manufacturing quality isaffected through secondary clamping, and the whole machining period is prolonged are solved. The additive manufacturing and subtractive manufacturing integrated numerical control machining machine tool comprises a bottom plate (1) and a moving device and further comprises a milling device, a feeding device, a printing nozzle assembly and a printing platform (2). The moving device is mounted on thebottom plate (1), and the feeding device is mounted on one side of the moving device. The printing nozzle assembly is connected with the feeding device and extends into the moving device. The printing platform (2) is mounted on the moving device, and the milling device is mounted on the other side of the moving device and conducts milling subtractive manufacturing on additive manufacturing materials on the printing platform (2). The additive manufacturing and subtractive manufacturing integrated numerical control machining machine tool is used for wood plastic composite extrusion printing.

Owner:NORTHEAST FORESTRY UNIVERSITY

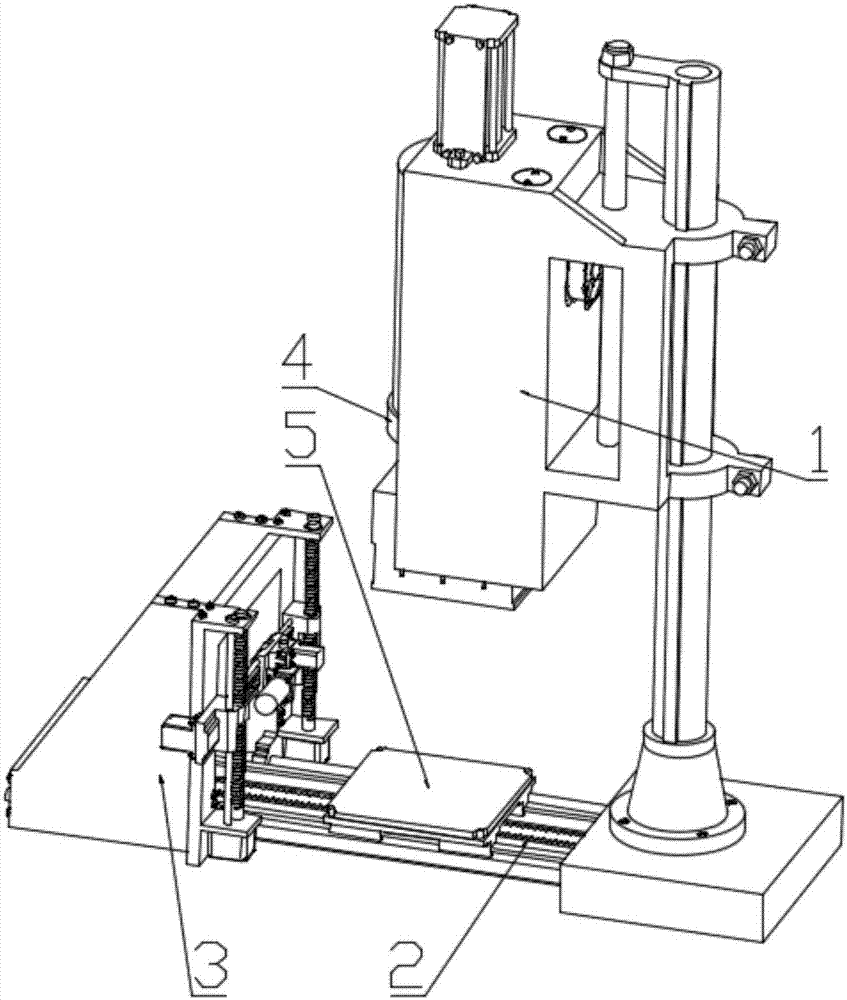

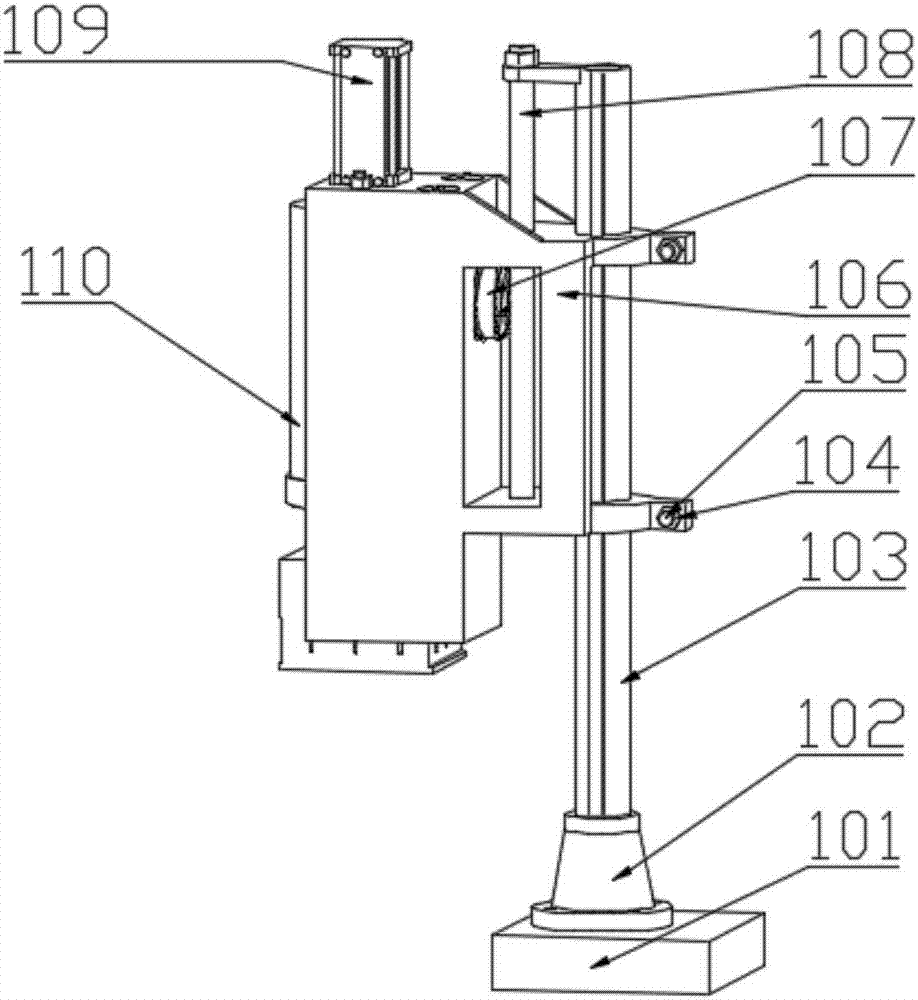

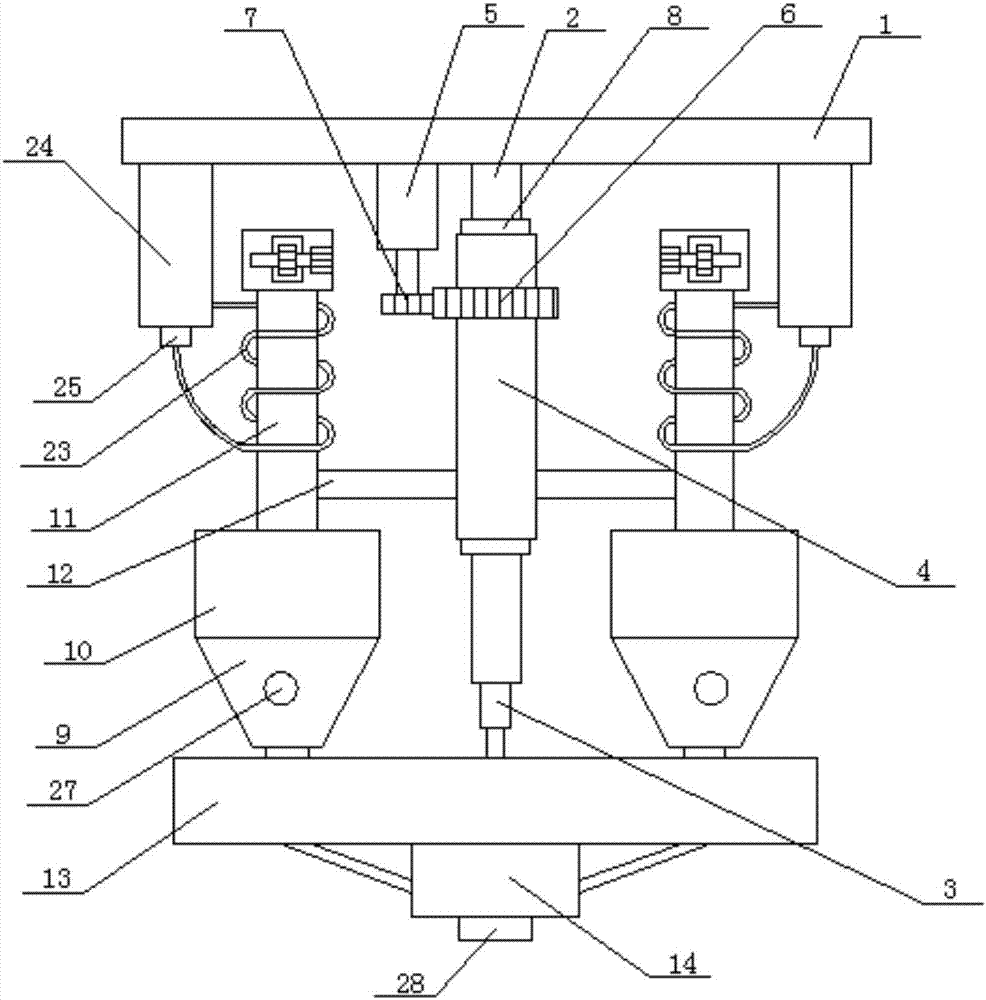

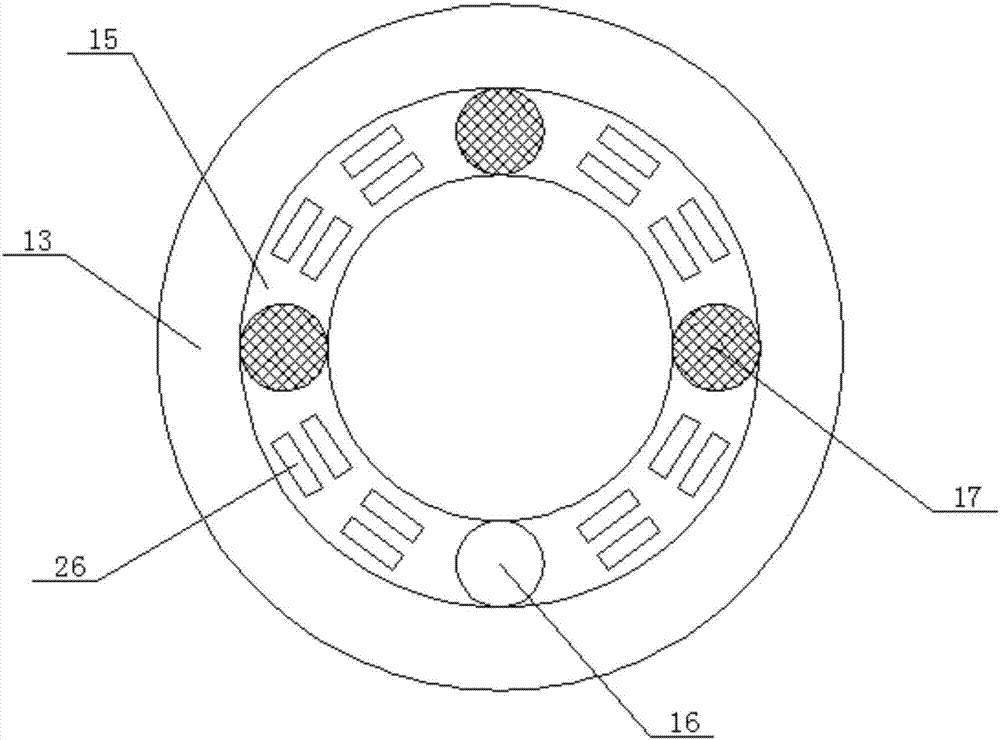

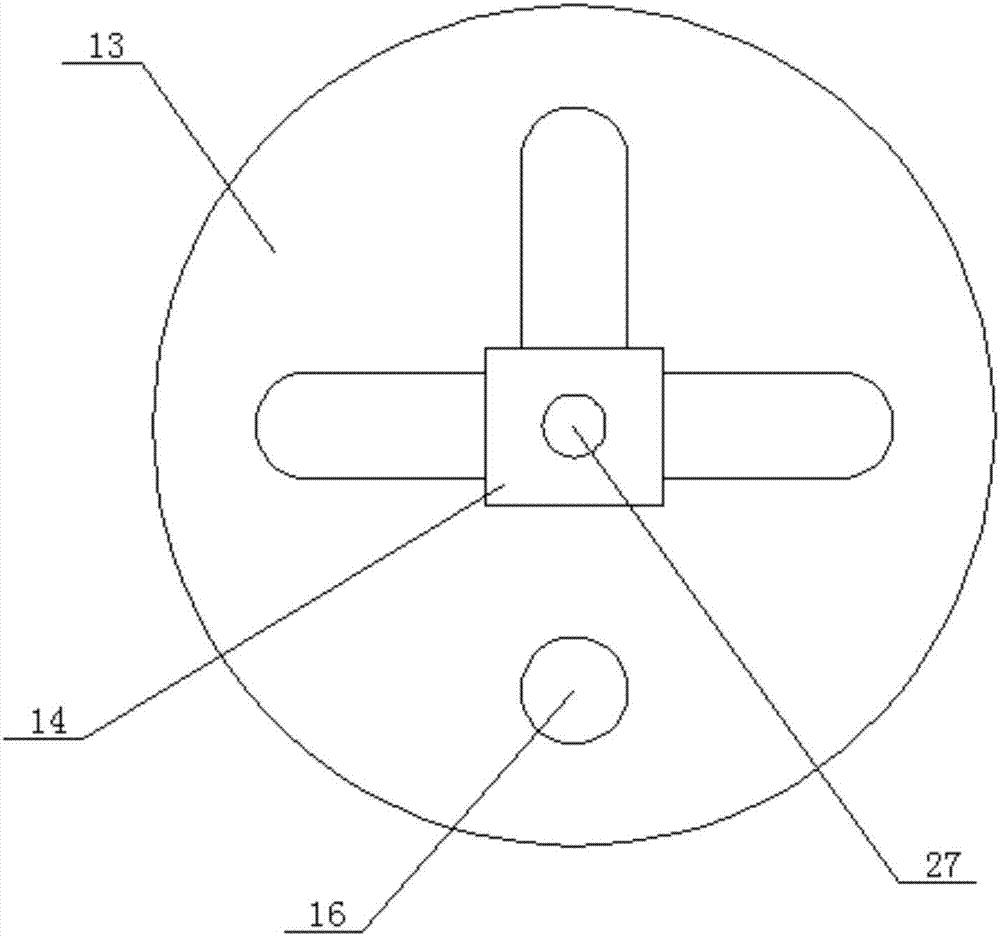

Compound ultrasonic fusion deposition additive-manufacturing device and compound ultrasonic fusion deposition additive-manufacturing method

ActiveCN107244072AHigh mechanical strengthImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringUltrasonic vibration

The invention relates to a compound ultrasonic fusion deposition additive-manufacturing device and a compound ultrasonic fusion deposition additive-manufacturing method, and belongs to the technical field of additive manufacturing. An ultrasonic enhancement device is fixed to a guide rod I and a guide rod II of an ultrasonic support platform; a moving base plate is installed on a guide rail I and a guide rail II of an X-directional guide connection system, and fixed to a synchronous belt simultaneously; the moving base plate is driven to move through an X-directional motor; and a fusion deposition additive-manufacturing system and the ultrasonic support platform are connected through a connection rod I and a connection rod II in the X-directional guide connection system. Parts with poor adhesion among fusion deposition wire materials and between the deposition wire materials and a deposition layer can be re-melted by virtue of ultrasonic vibration, and the deposition wire materials in formed parts are compounded into one piece, so that the comprehensive mechanical property of fusion deposition additive-manufactured parts, and in particular, the mechanical strength in the vertical direction of a forming axis, is remarkably improved.

Owner:李桂伟

Rotary type 3D printing head

InactiveCN106853680AIngenious designHigh feasibilityManufacturing heating elements3D object support structuresSpray nozzleEngineering

The invention relates to a rotary type 3D printing head which comprises a supporting mechanism, a rotating mechanism, spray nozzle mechanisms and a shading mechanism, wherein the supporting mechanism comprises a supporting plate, a supporting rod and a cylinder; the rotating mechanism comprises a sleeve, a first motor, a first circular gear, a second circular gear and limiting rings; the spray nozzle mechanisms comprise spray nozzles, heating blocks, material feeding pipes and connection rods; the shading mechanism comprises a baffle and a collection chamber; a material feeding mechanism comprises a material feeding plate, a second motor and a third circular gear; a heat dissipation mechanism comprises a coil pipe, a water tank and a water pump. The rotary type 3D printing head is provided with four spray nozzle mechanisms, so that four raw materials can be put into the printing head at the same time; during printing, switching of the different raw materials can be realized; during switching of the different raw materials, the raw materials leaking from the spray nozzles can be led into the collection chamber, so that the printing quality is guaranteed; furthermore, a water cooling heat dissipation mechanism is arranged outside the material feeding pipes, so that noise is reduced, and interference of air to the printing head during heat dissipation of a conventional fan is further prevented.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com