Additive manufacturing and subtractive manufacturing integrated numerical control machining machine tool

A technology for CNC machining machine tools and material addition and subtraction. It is applied in the direction of additive processing, manufacturing tools, and other manufacturing equipment/tools. It can solve the problems of wasting processing time, affecting the quality of material reduction, and difficulty in material reduction, so as to reduce equipment costs. , save working space, print fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

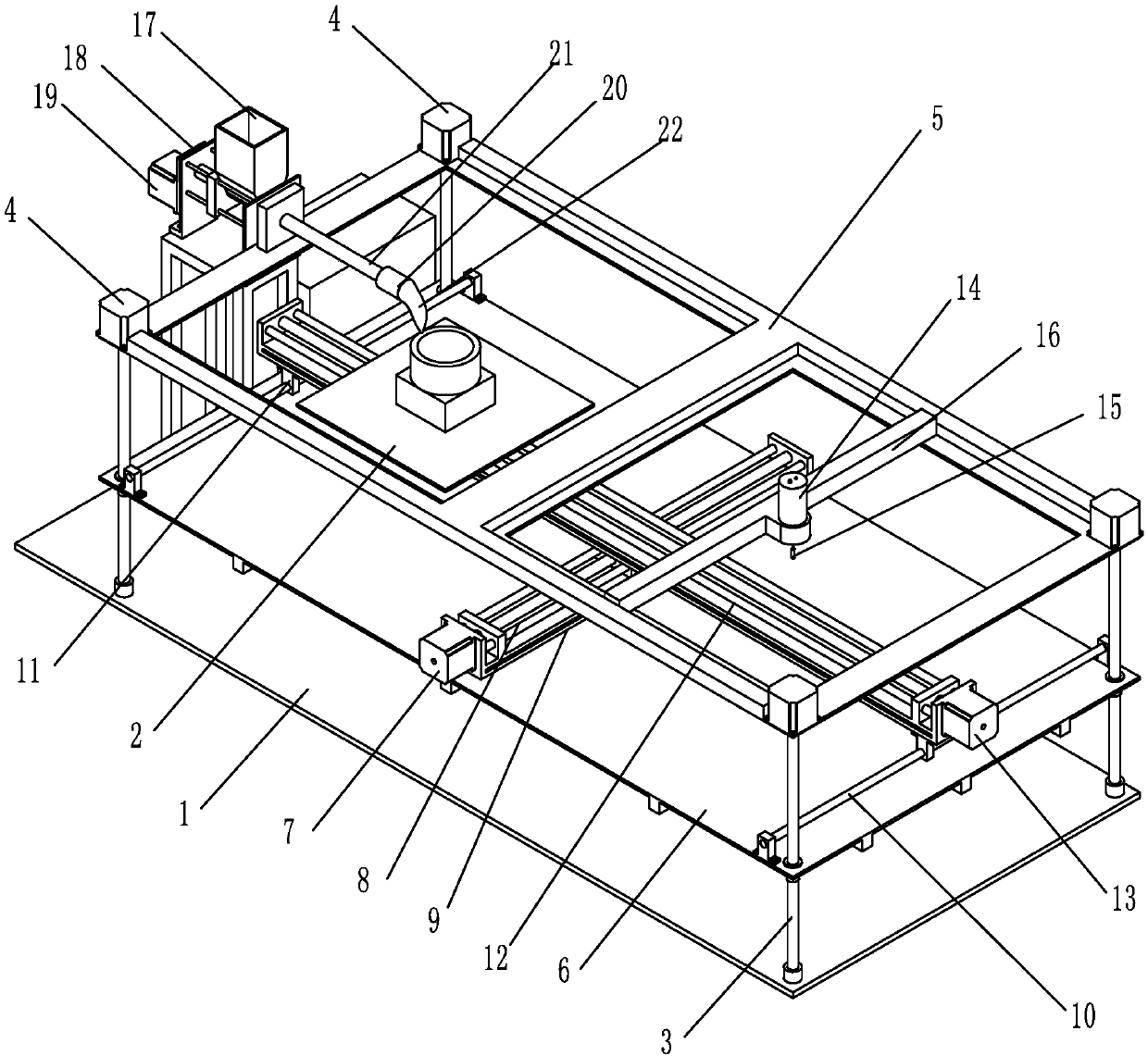

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of numerical control processing machine tool that adds and subtracts materials in this embodiment, includes base plate 1 and moving device, and moving device is installed on base plate 1, and it also includes milling device, feeding device, printing nozzle assembly and printing Platform 2, the feeding device is installed on one side of the mobile device, the printing nozzle assembly is connected with the feeding device and extends into the mobile device, the printing platform 2 is installed on the mobile device, and the milling device is installed on the other side of the mobile device and aligns the printing platform 2. The additive material on 2 is milled and cut.

[0017] The bottom plate 1 of this embodiment is made of sheet metal material and is located at the bottom of the machine tool. The working space is supported by four Z-axis screw slide table columns 3 and is used as the Z c...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 Describe this embodiment, the moving device of this embodiment includes four Z-axis screw slide table columns 3, four Z-axis motors 4, support brackets 5, Z-axis printing platform 6, Y-axis motor 7, Y-axis screw slide Table 8, Y-axis sliding platform 9, two X-axis carriages 10, two X-axis sliders 11, X-axis screw slide table 12 and X-axis motor 13, bottom plate 1 is a rectangular bottom plate, four Z-axis wires The bar slider column 3 is installed on the four corners of the bottom plate 1 by vertical rotation respectively, the support bracket 5 is installed on the upper part of the four Z-axis screw slide column columns 3, and the four Z-axis motors 4 are installed on the four corners of the support bracket 5, each Z The upper end of the screw slide table column 3 is connected to a Z-axis motor 4, and the four corners of the Z-axis printing platform 6 are respectively set on a Z-axis screw slide table column 3, and ...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 To describe this embodiment, a plurality of positioning holes are opened on the upper end of the printing platform 2 of this embodiment. Such a setting makes it easy to print the base of the product on the printing platform 2, and mill it after the product is added or subtracted. The positioning on the positioning hole can ensure the stability of the product positioning and prevent the product from being loosely clamped during milling. The problem of large product processing errors. Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com