Ultrasonic vibration assisted 3D printing method

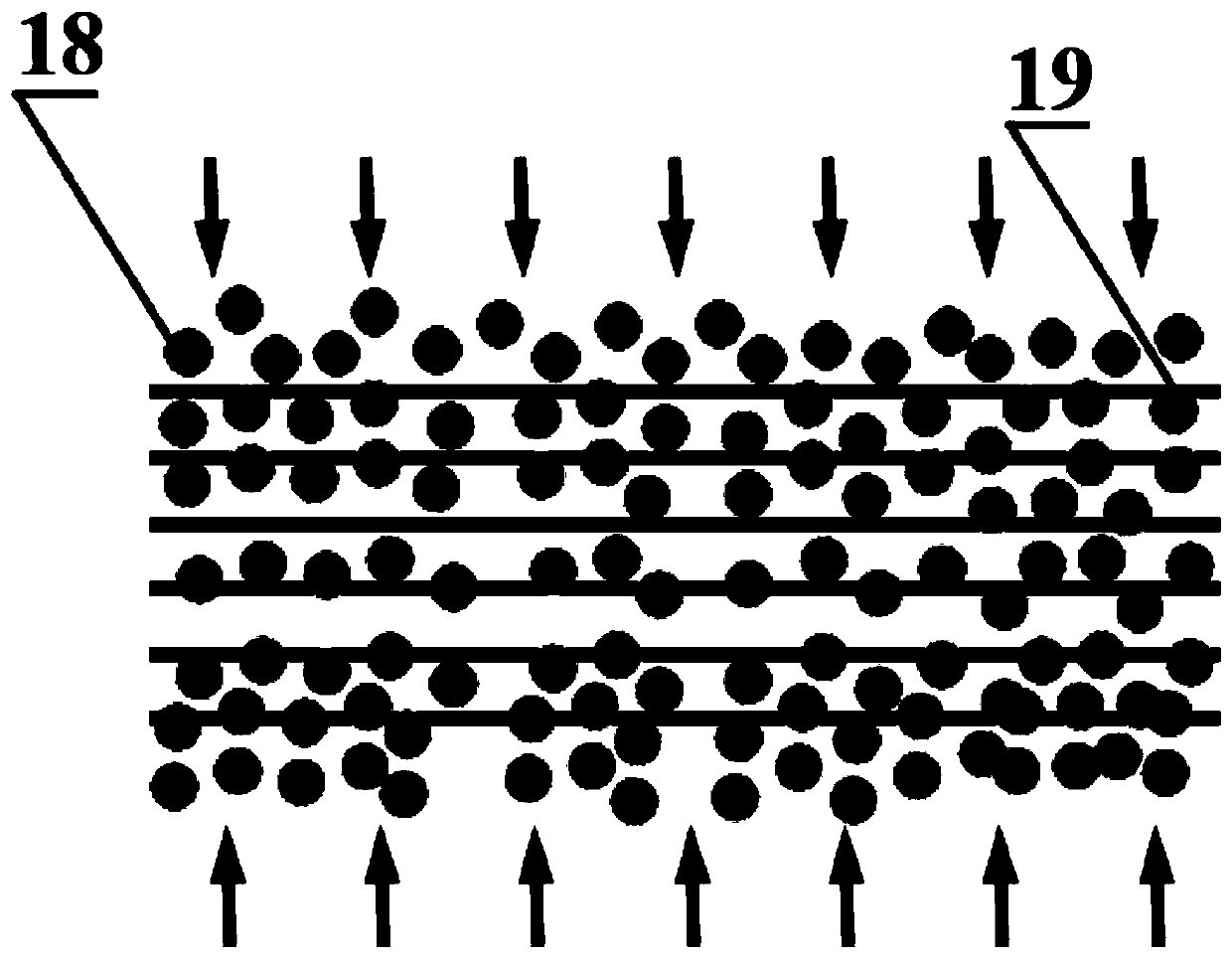

A 3D printing and ultrasonic vibration technology, applied in the field of 3D printing, can solve the problems of uneven Z-axis vibration and unsatisfactory actual effect, and achieve the effect of firm bonding, reduction of internal void defects, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

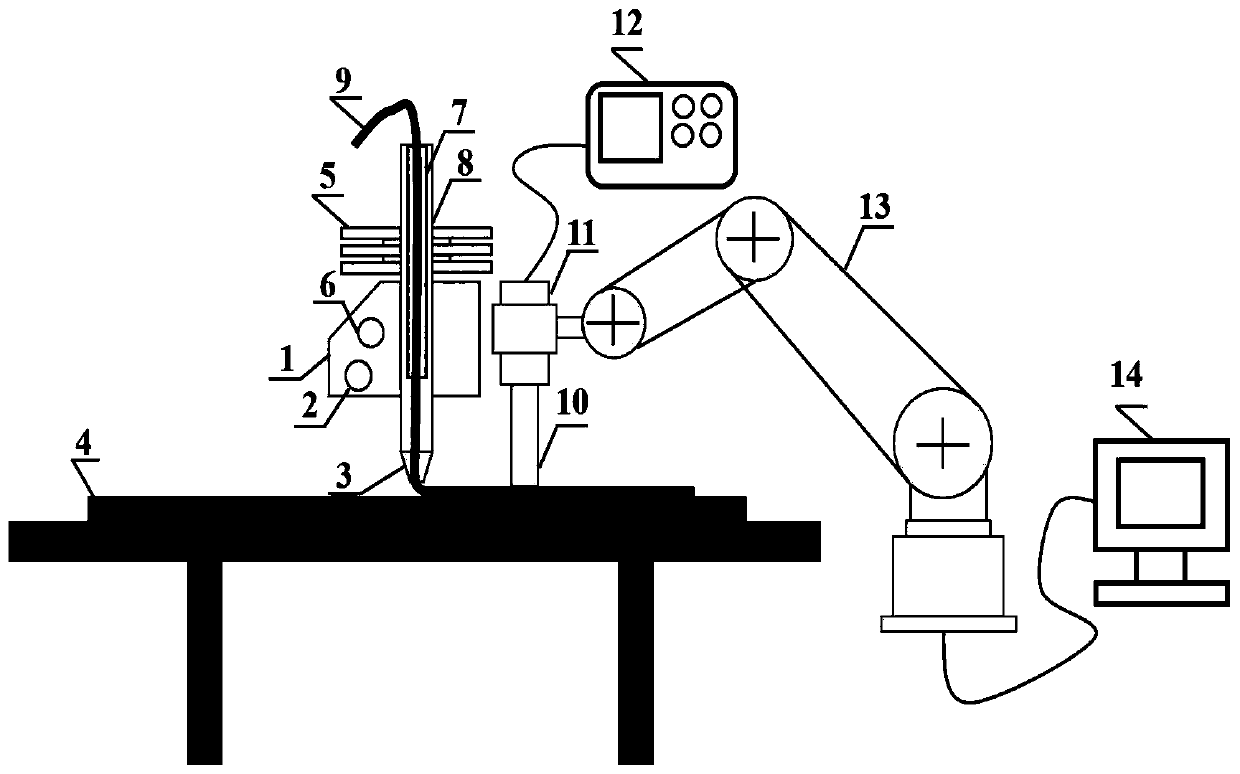

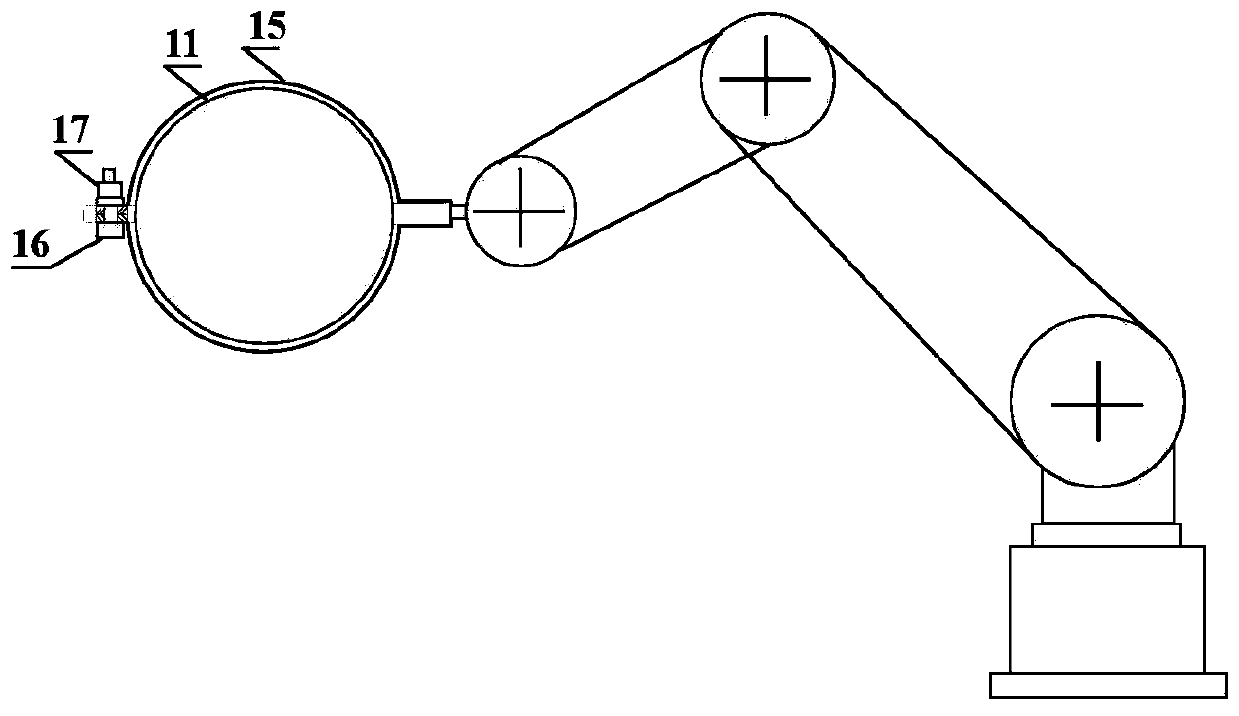

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0022] The ultrasonic-assisted 3D printing device of the embodiment includes a 3D printing mechanism and an ultrasonic vibration structure. The printing parameters are selected as follows: printing speed 200-350mm / min; printing temperature 200-210°C; printing layer height 0.15-0.35mm; printing line spacing 0.5-1mm; nozzle outlet diameter 1-2mm; printing material 9 is carbon fiber prepreg .

[0023] The specific steps of the ultrasonic vibration-assisted 3D printing method are as follows:

[0024] Step 1 Assemble the Ultrasonic Assisted 3D Printing Device

[0025] The ultrasonic-assisted 3D printing device is composed of a 3D printing mechanism and an ultrasonic vibration structure. In the ultrasonic-assisted 3D printing device, the outer ring of the throat pipe 8 is threaded from top to bottom to connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com