Patents

Literature

63results about How to "Low in trans fatty acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moderately processed vegetable oil and preparation method thereof

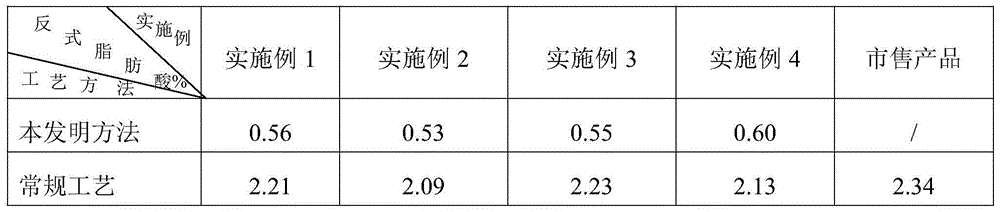

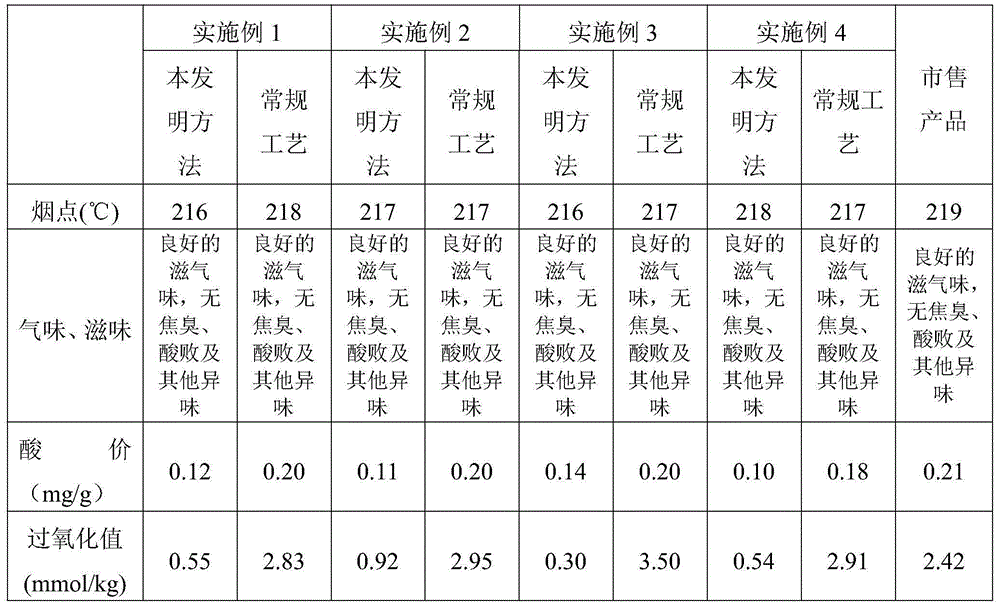

The invention provides a moderately processed vegetable oil and a preparation method thereof. The preparation method comprises the following steps: carrying out degumming twice (first deep degumming and then combining the secondary degumming) to realize efficient degumming and remove high boiling impurities as many as possible, so as to carry out alkali refining and neutralization at low temperature; then pre-decoloring with waste clay used for recycling, adding clay, decoloring under vacuum condition, and removing residual soap, phosphorus, pigment, metal, and the like; and finally carrying out combined deodorization of the plate column and the packed column, carrying out thermal decoloration, and removing fatty acid and micro-molecular stinking material, so as to reduce the generation of trans fatty acid, reduce the loss of vitamin E, save energy, reduce consumption, and improve the oil quality. According to the invention, vegetable oil products with low content of trans fatty acid (less than 1.0 %) and low loss rate of vitamin E can be produced.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

Zero trans-fatty acid multi-vitamin first-grade soybean oil and preparation method thereof

ActiveCN102517142ALow in trans fatty acidsIncrease contentFatty-oils/fats refiningFatty-oils/fats productionLow activitySOYBEAN SEED OIL

The invention provides zero trans-fatty acid multi-vitamin first-grade soybean oil and a preparation method thereof. The zero trans-fatty acid multi-vitamin first-grade soybean oil is produced by screening of soybean raw materials, a soybean peeling and instantaneous high-pressure wet-hot enzyme inactivation technology, a double-enzyme degumming / super degumming and washing-free long-time mixing and de-acidifying coupling technology, a two-step decolorization technology with low-activity decolorizing agent, a low-temperature short-time / two-stage catching, refluxing and deodorization technology, a ''nitrogen charging fresh-keeping'' technology and the like. In the zero trans-fatty acid multi-vitamin first-grade soybean oil, the trans-fatty acid content is less than or equal to 0.5 percent, the natural vitamin E content is more than or equal to 1,200ppm, the plant sterol content is more than or equal to 2,200ppm, and the squalene content is more than or equal to 60ppm; the soybean oil is packed by charging nitrogen, and any chemically synthesized antioxidant is not added; and compared with the commercially available first-grade soybean oil, the soybean oil is more safe, nutritional and healthy.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

Deodorizing method for reducing trans-fatty acid content in vegetable oil

InactiveCN101536711ALower trans fatty acidsReduced trans isomerizationEdible oils/fatsOil and greaseVegetable oil

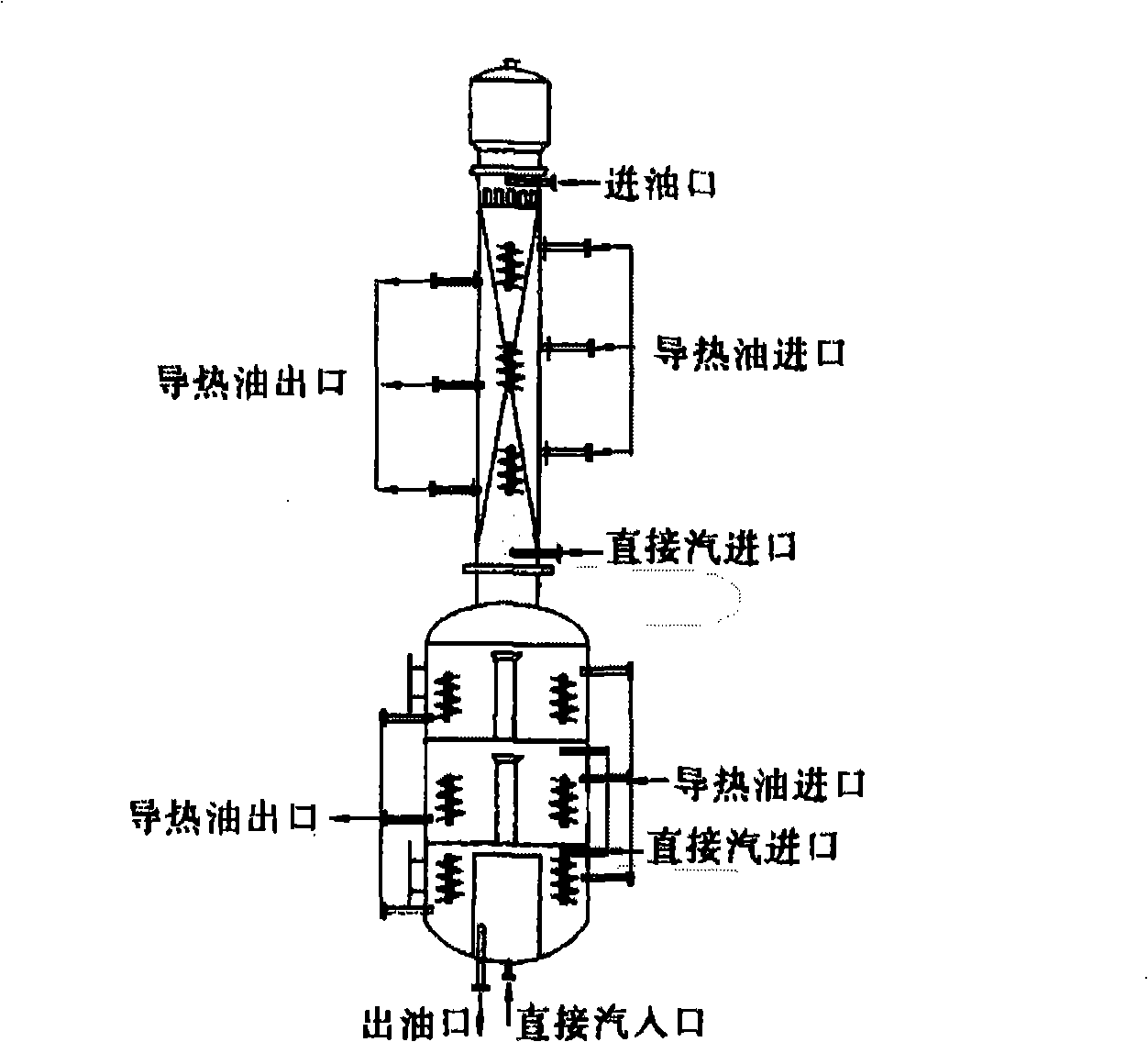

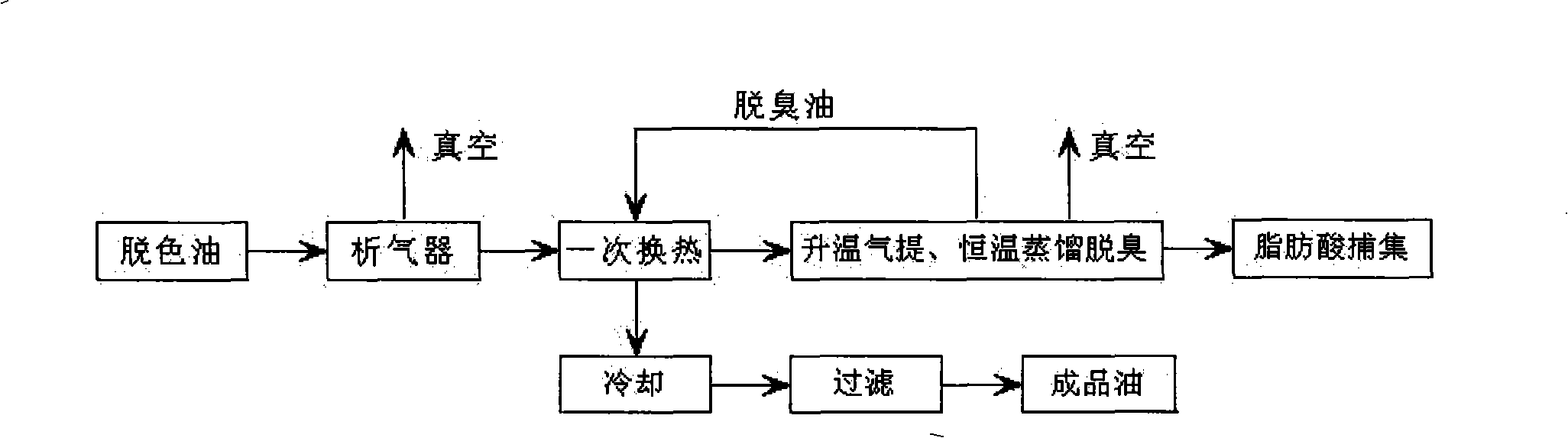

The invention relates to a deodorizing method for reducing trans-fatty acid content in vegetable oil, belonging to the technical field of oil refining and deodorization and food safety. In the deodorizing method, discolored vegetable oil is used as the raw material, and a packing-plate combined stripping-distilling deodorizing tower is selected; on the one hand, the structure of the deodorizing tower is improved to realize the deodorization mode of temperature increase stripping and constant distilling and to reduce the high temperature heated time of oil; and on the other hand, the deodorizing technology of low trans-fatty acid content is obtained by controlling the parameters such as deodorization temperature, deodorization time and the like and integrally considering the content of trans-fatty acid and deodorization effect in oil. The invention reduces the content of trans-fatty acid during deodorization, builds up the deodorizing technology of low trans-fatty acid, and provides a whole new approach for the development of green, safe and nutrition vegetable oil.

Owner:JIANGNAN UNIV

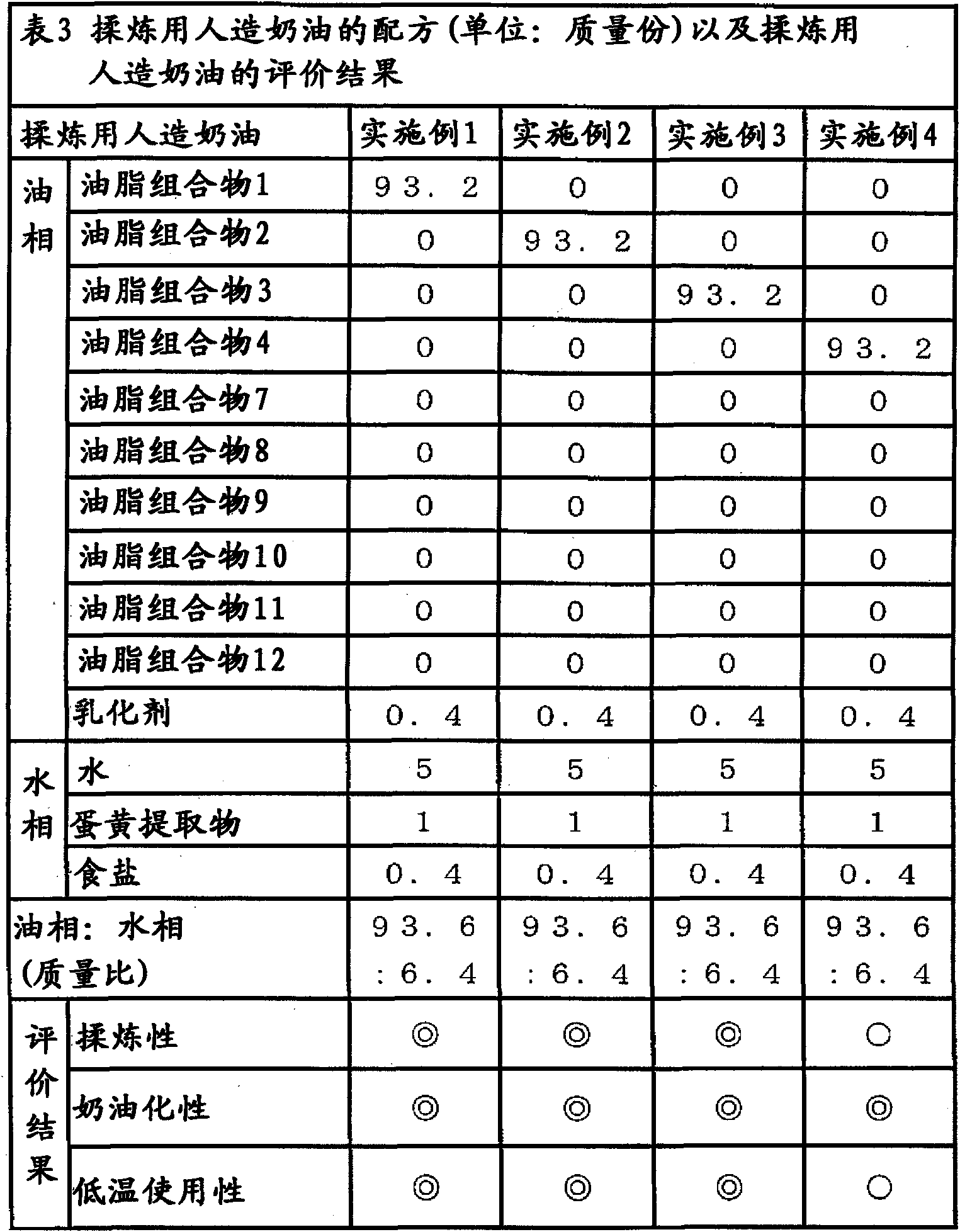

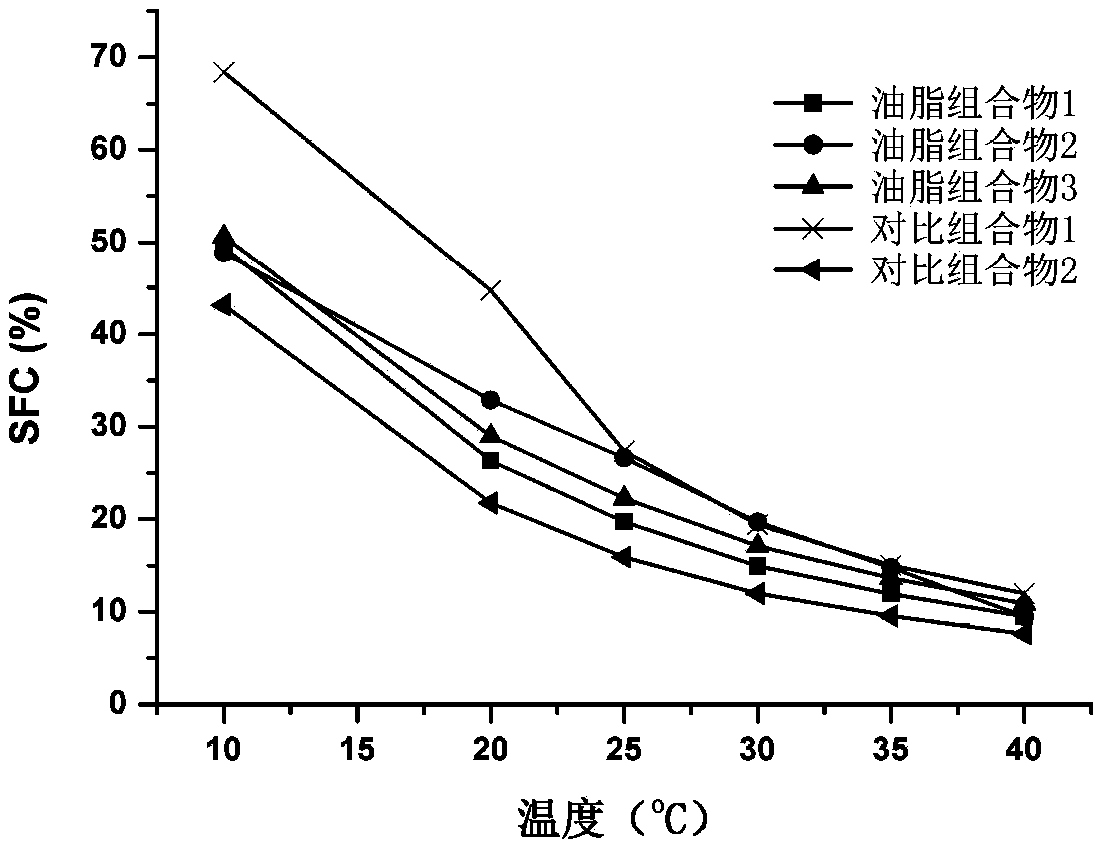

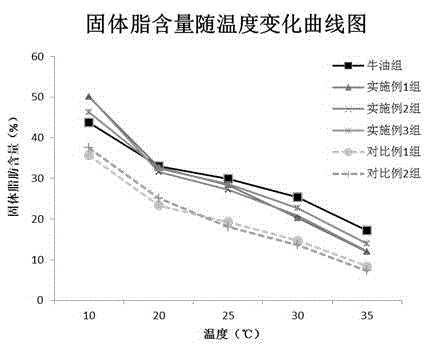

Oil-and-fat composition and plastic oil-and-fat composition

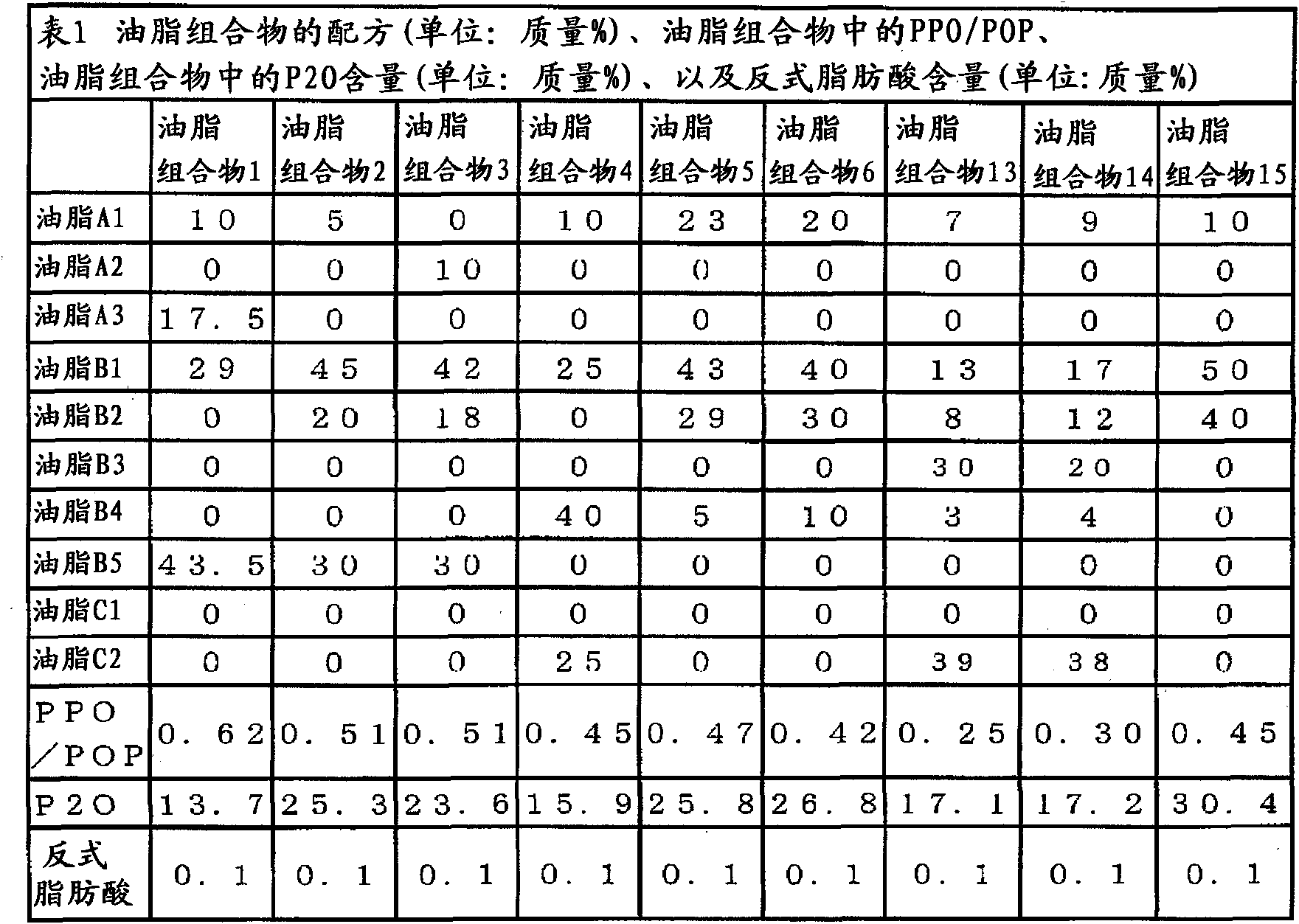

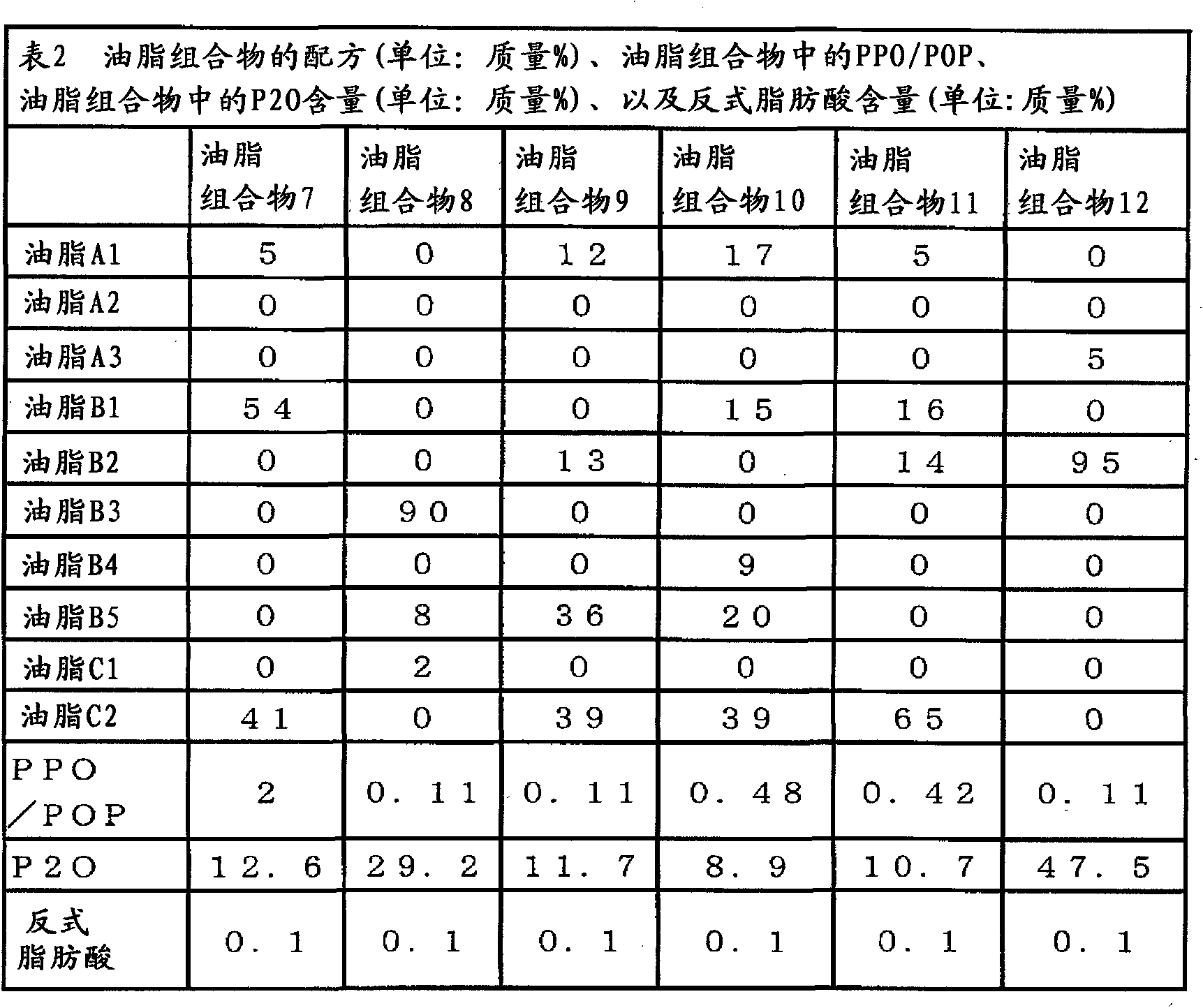

ActiveCN102137595AEasy to operateGood formabilitySpread compositionsFatty acid esterificationOil and greaseStearic acid

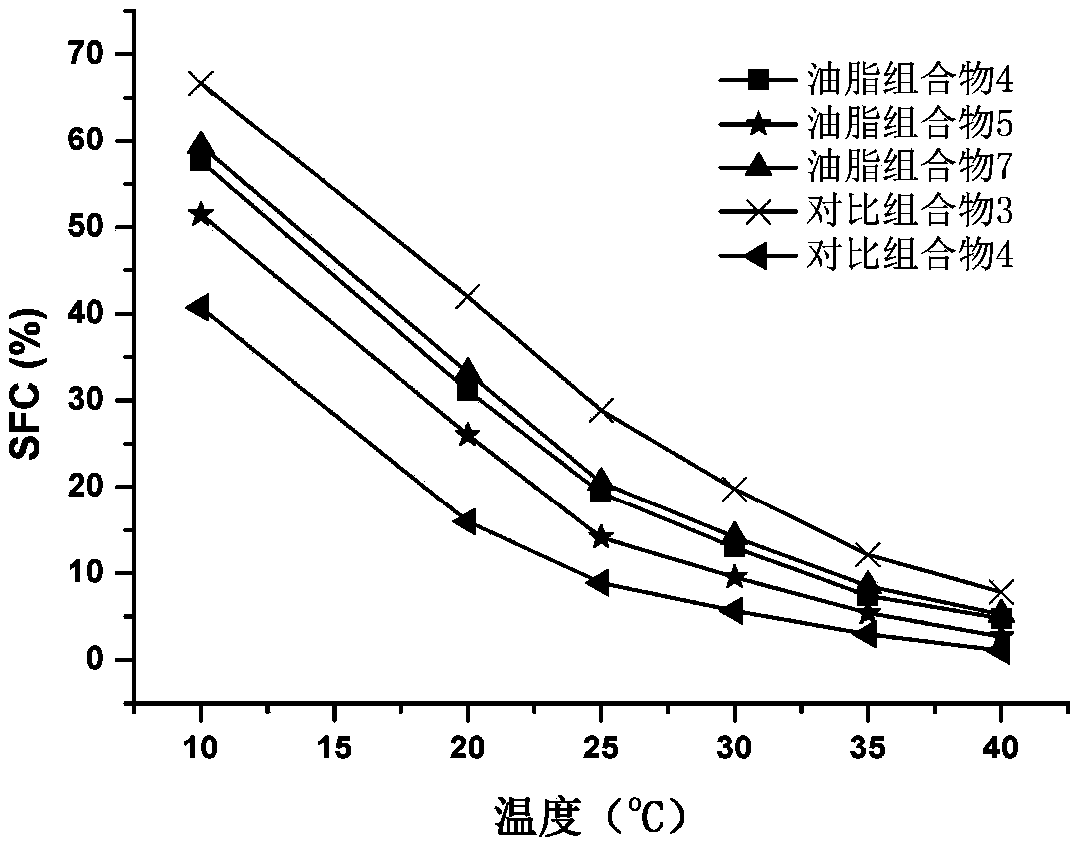

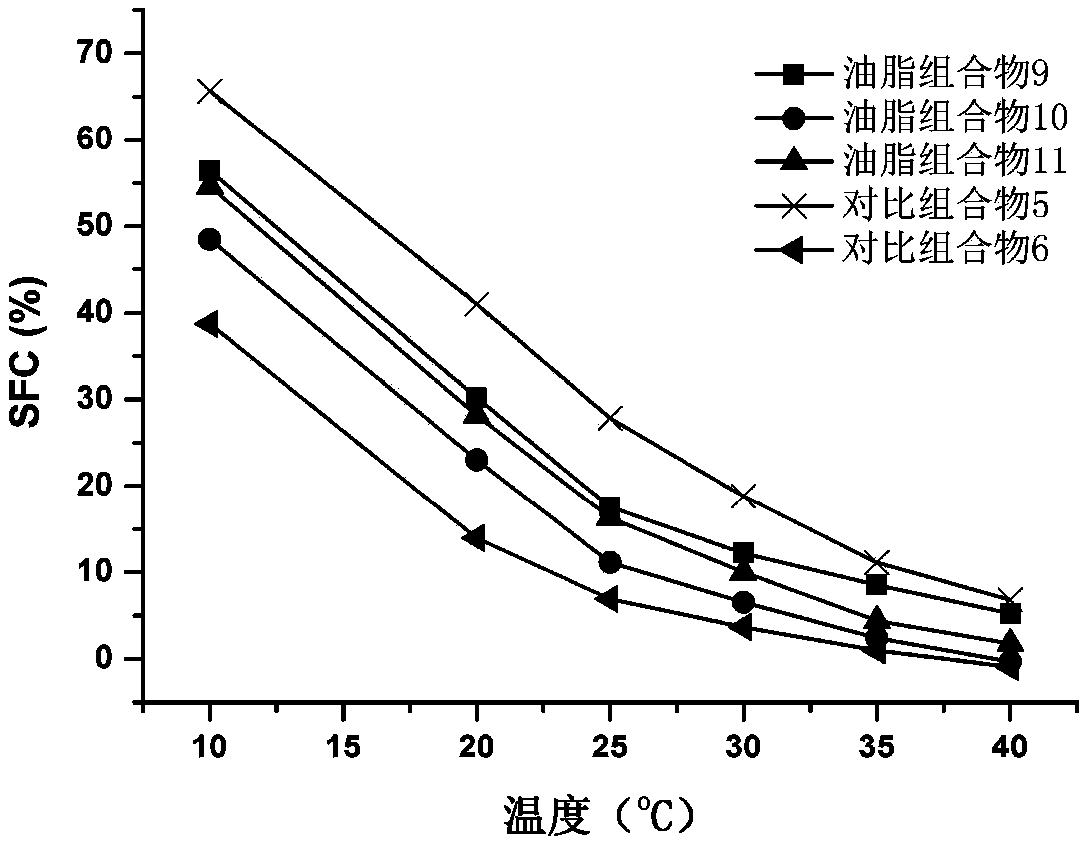

Disclosed is a plastic oil-and-fat composition which is suitable for use applications such as kneading, a spread, a coating cream, a sand cream or the like and contains a trans fatty acid at a low content. Also disclosed is an oil-and-fat composition for use in the plastic oil-and-fat composition. The oil-and-fat composition comprises the oil-and-fats (A) and (B) shown below and meets the requirements (a) and (b) shown below. Oil-and-fat (A): an oil-and-fat containing a saturated fatty acid having 12 to 14 carbon atoms in an amount of 20 to 70 mass% relative to the total amount of all of the constituent fatty acids. Oil-and-fat (B): an oil-and-fat containing palmitic acid in an amount of 20 to 69.5 mass%, stearic acid in an amount of 0.5 to 6 mass% and oleic acid in an amount of 30 to 60 mass% all relative to the total amount of all of the constituent fatty acids. (a) The content of P2O in the oil-and-fat composition is 12 to 45 mass%. (b) The ratio of PPO to POP (PPO / POP) in the oil-and-fat composition is 0.15 to 1.00.

Owner:THE NISSHIN OILLIO GRP LTD

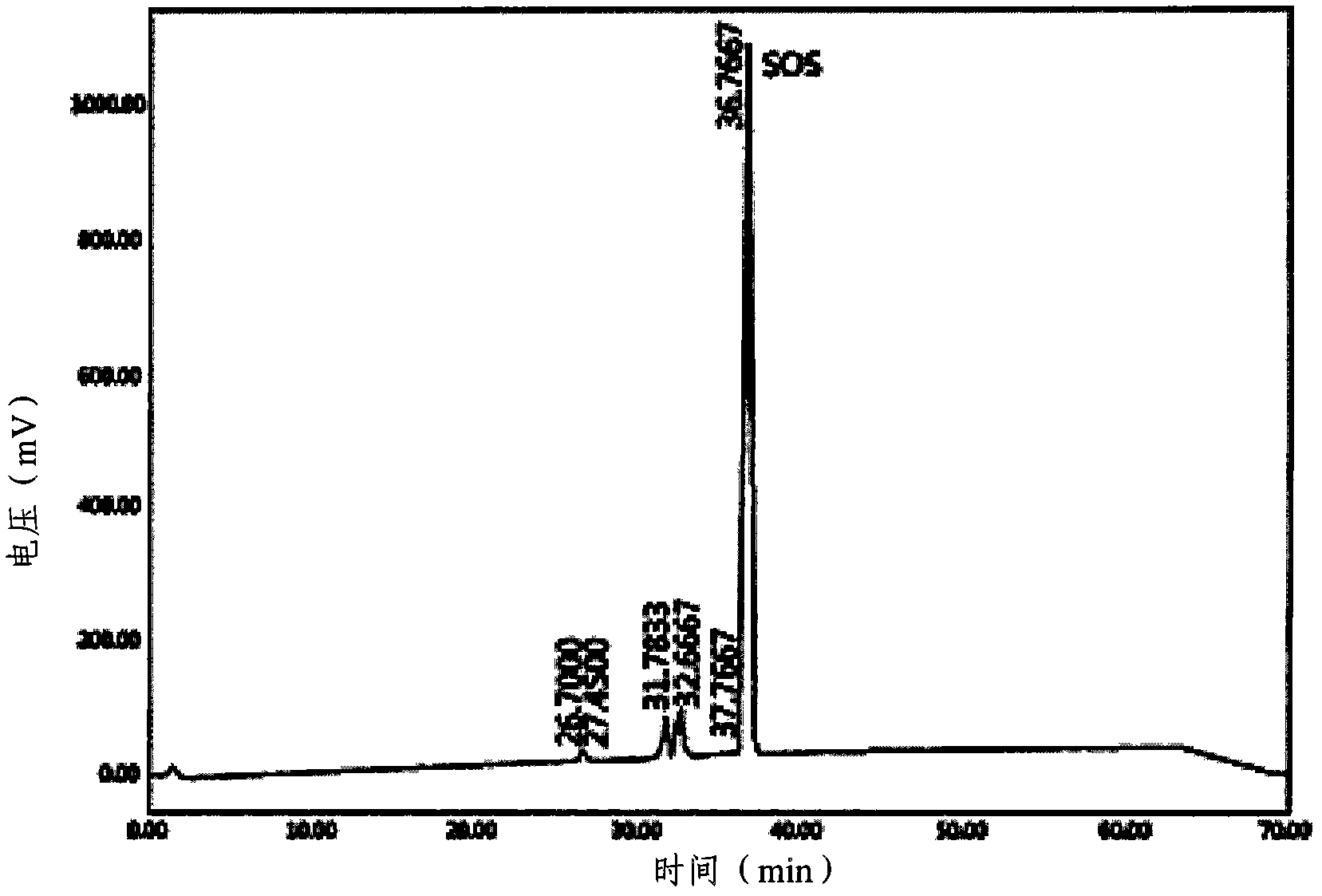

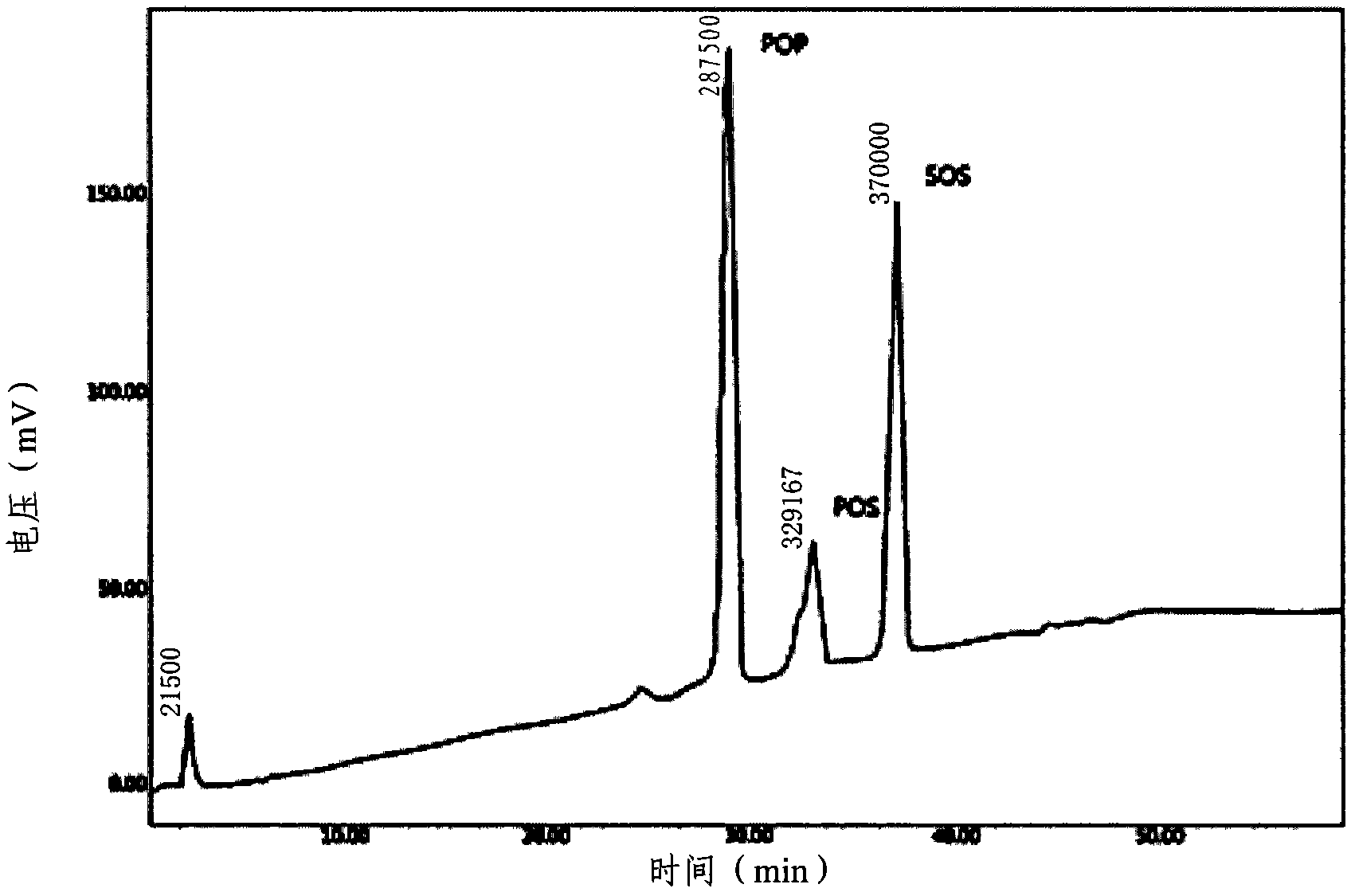

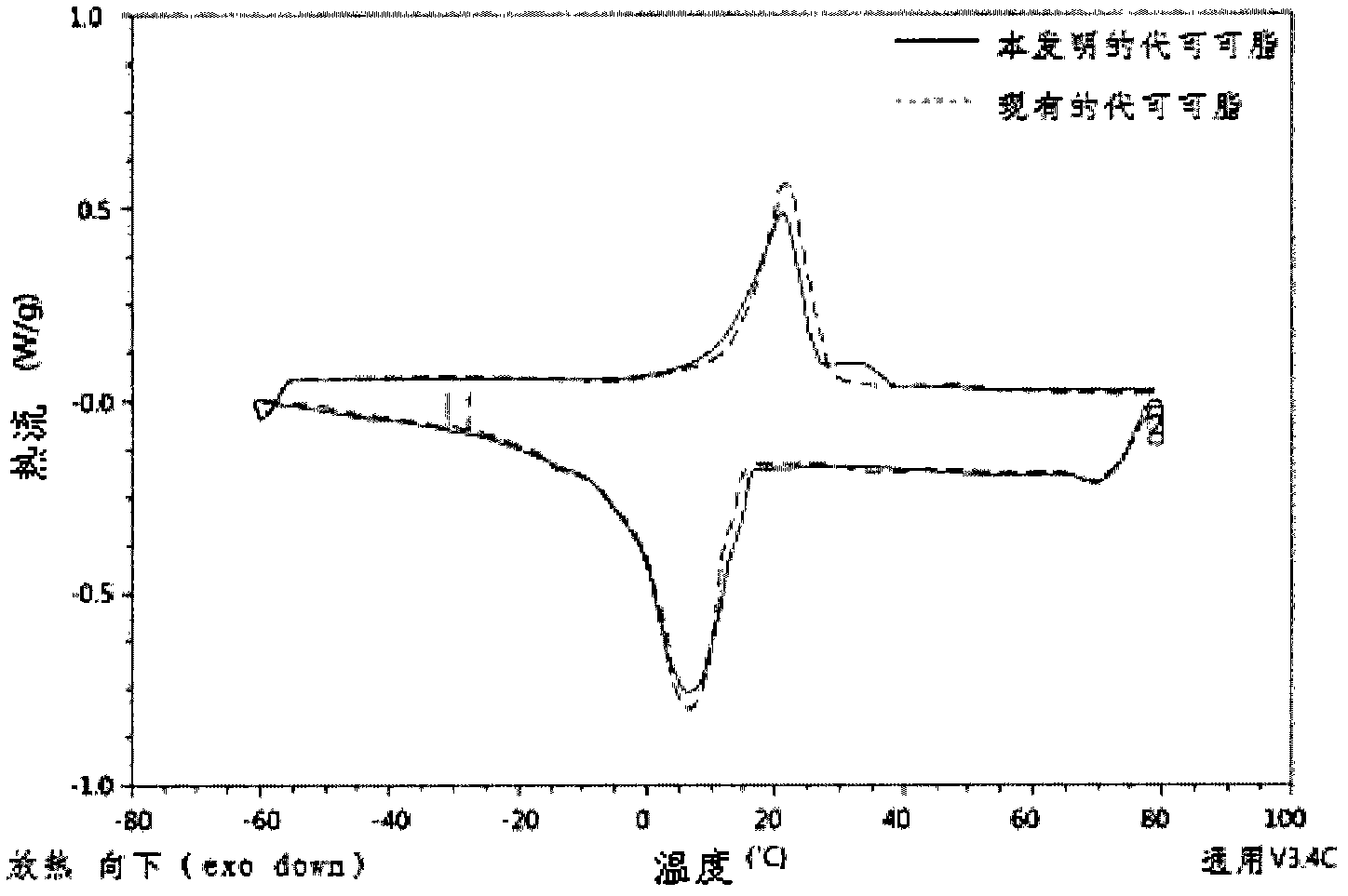

Cocoa butter equivalents produced by the enzymatic interesterification process and method for preparing the same

InactiveCN102215696ALow in trans fatty acidsFatty acid esterificationFatty-oils/fats refiningButter cocoaMonoglyceride

The present invention relates to a process for preparing hard butter having high SOS content by mixing oil for preparing butter with fatty acid or fatty acid ester, adding 1,3 regio-specific enzymes to the obtained mixture to carry out interesterification, distilling the obtained reactants to remove fatty aicd, ethyl ester, and monoglyceride and diglyceride formed after the reaction and fractionally extracting the obtained reactants to separate a solid phase, and to cocoa butter equivalents prepared by the hard butter and a process for preparing the same in which the cocoa butter equivalents can replace existing import cocoa butter equivalents with 1 : 1 because of its equivalent chemical properties, and have no difference in taste and properties with natural cocoa butter and also have lower trans fatty acid. Hard butter according to the present invention can make desired triglyceride structure in oil based on the reaction conditions and have a improved purity and yield in the whole process by recycling all of byproduct other than major product in the distillation and fractional distillation process and is eco-friendly matter by using the enzymatic interesterification reaction, and also cocoa butter equivalents made by the hard butter is characterized in replacing existing import cocoa butter equivalents with 1 : 1 because of its equivalent chemical composition and properties in the production of chocolate with no difference in taste.

Owner:CJ CHEILJEDANG CORP

A kind of lower trans fatty acid edible vegetable oil and refining method thereof

InactiveCN102273522ALight colorHigh smoke pointFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The invention relates to fully refined edible vegetable oil with lower trans fatty acid and a refining method thereof. The vegetable oil is rapeseed oil, soybean oil, corn oil or blending oil with any ratio; the trans fatty acid content of the vegetable oil is less than or equal to 1 weight percent; and the oil smoke point is more than or equal to 210 DEG C. The refining method comprises the steps of selecting crude oil, degumming, deacidifying, removing saponin, dehydrating, decoloring, removing impurities, deoxidizing, deodorizing, cooling and obtaining finished products. The refining method is characterized in that: at the decoloring state, the removing grain size of the impurities is reduced from 25 mu m to 10 mu m; and at the deodorizing stage, the deodorizing temperature is controlled to be between 230 and 245 DEG C and the vacuum degree is controlled to be within 2 tau. Oil is refined at lower temperature and a lowest trans fat structure is realized by controlling the grain size of the impurities and the vacuum degree; after being refined, the vegetable oil has good quality, namely the trans fatty acid is reduced to be lower than 60 percent of the normal level; and the refined vegetable oil has light color, high smoke point, high purity and storage resistance and is beneficial to people's long-term health.

Owner:SHENZHEN NANSHUN GREASE

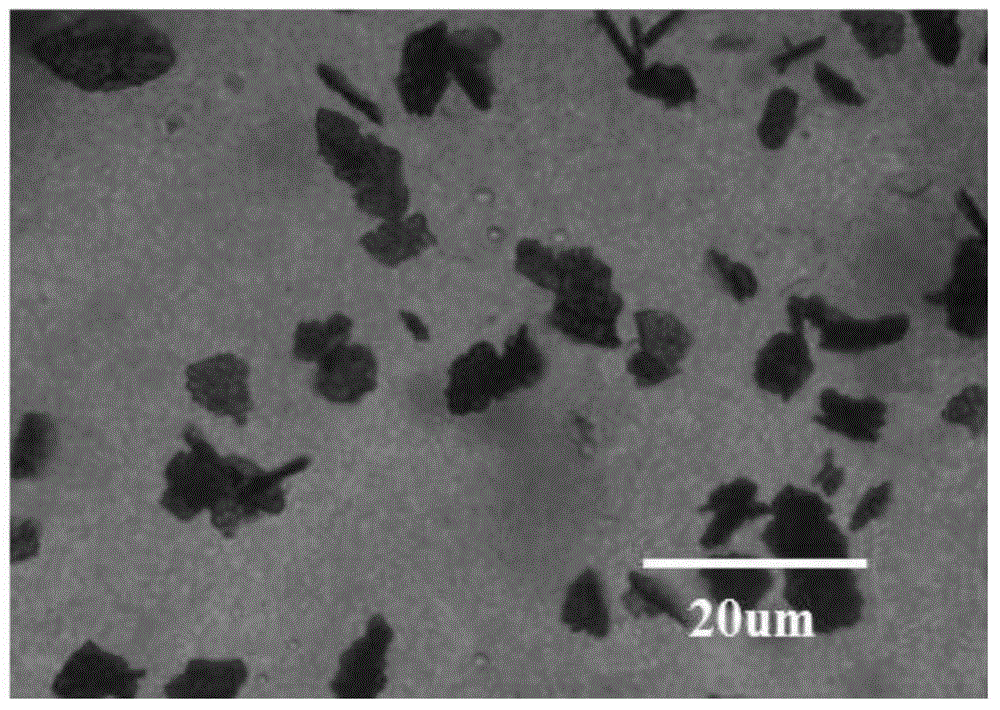

Preparation method of fat gel capable of loading carotene

ActiveCN104855548AStable in natureImprove antioxidant capacityEdible oils/fatsBiotechnologyNutritive values

The invention relates to a preparation method of fat gel capable of loading carotene. The method comprises the steps of adding 8-12% of food-grade ceramide to maize oil, performing heating at 85 DEG C, stirring for 30min at a revolution speed of 200-400rPm, allowing ceramide to be uniformly dissolved in the oil, adding 0.5-5wt% of carotene to a mixture, continuing to react for 10-15min, cooling to 5-25 DEG C at a cooling rate of 1-10 DEG C / min, storing for 24h at a constant temperature, and obtaining the fat gel capable of highly loading the carotene. The preparation method is simple, mild in condition and low in cost; the obtained fat gel is stable in property and good in oxidation resistance; a load rate of the carotene reaches above 90%; and the fat gel can serve as a high-quality carotene carrying system and can be compounded with other stearin for preparing food shaping fat with high nutritive value.

Owner:SOUTH CHINA UNIV OF TECH

Grease composition for margarine and shortening and preparing method thereof

InactiveCN104247783AReduce accumulationLow in trans fatty acidsEdible oils/fatsTriglycerideCompound (substance)

The invention relates to a medium-carbon-chain triglyceride fatty acid, long-carbon-chain triglyceride fatty acid and / or medium- and long-carbon-chain triglyceride fatty acid containing grease composition for margarine and shortening and a preparing method thereof. Relative to the total weight of the composition, the grease composition contains more than 80 wt% of triglycerides; relative to the total weight of all the fatty acids forming the grease composition, the medium-carbon-chain fatty acid accounts for 8-15 wt%; the grease composition is obtained through physical mixing or an ester exchange reaction, wherein the ester exchange reaction can be a chemical ester exchange reaction or an enzymatic ester exchange reaction.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Preparation method of moderately processed DHA (Docosahexaenoic acid) microalgae grease

ActiveCN103351947ARetain functional ingredientsQuality improvementFatty-oils/fats refiningEdible oils/fatsFree acidChemistry

The invention provides a preparation method of moderately processed DHA (Docosahexaenoic acid) microalgae grease. The method comprises the following steps of: first, degumming to remove colloid and impurities in microalgae grease; after degumming, refining alkali and neutralizing at low temperature to remove free acids; then, decoloring in a low temperature vacuum condition to remove residual soap, phosphorus, pigments and the like; and finally, deodorizing through combination of a packed tower and a plate tower, and thermosensitively decoloring to remove fatty acid and small molecular stink substances, wherein the generation amount of trans-fatty acids can be reduced, the loss of vitamin D is reduced, the energy is saved and the consumption is reduced, and the quality of grease products is improved. Due to the adoption of the method, the DHA microalgae grease with low content of trans-fatty acids (less than 1.0%) and low loss ratio of vitamin D can be prepared.

Owner:青岛海智源生命科技有限公司

Multigrain biscuit with blood fat-lowering and slimming effects and preparation method thereof

InactiveCN102293230ALow in trans fatty acidsAvoid absorptionDough treatmentModified nutritive productsAlcohol sugarsRapeseed

The invention discloses a miscellaneous grain biscuit with the effects of lowering blood fat and reducing body weight and a preparation method thereof, belonging to the technical field of food processing. The multigrain biscuit includes flour, sugar alcohol, rapeseed oil, phytosterol, oat powder, lotus leaf powder, motherwort powder, blueberry powder, functional oligosaccharide, emulsifier composition and thickener. On the one hand, the product of the present invention reduces the amount of oil and sugar used in bread through technical means, and introduces ingredients that have the effect of reducing blood lipids; value. The multigrain biscuit of the invention has a simple preparation method and is suitable for industrial production.

Owner:CHINA AGRI UNIV

Preparation method of moderately processed ARA (Arachidonic acid) microalgae grease

ActiveCN103351946ALow in trans fatty acidsImprove quality and qualityFatty-oils/fats refiningEdible oils/fatsFree acidChemistry

The invention provides a preparation method of moderately processed ARA (Arachidonic acid) microalgae grease. The method comprises the following steps of: first, degumming to remove colloid and impurities in microalgae grease; after degumming, refining alkali and neutralizing at low temperature to remove free acids; then, decoloring in a low temperature vacuum condition to remove residual soap, phosphorus, pigments and the like; and finally, deodorizing through combination of a packed tower and a plate tower, and thermosensitively decoloring to remove fatty acid and small molecular stink substances, wherein the generation amount of trans-fatty acids can be reduced, the energy is saved and the consumption is reduced, and the quality of grease products is improved. Due to the adoption of the method, the ARA microalgae grease with low content of trans-fatty acids (less than 1.0%) can be prepared.

Owner:青岛海智源生命科技有限公司

Refining method of low trans-fatty acid compound oil

InactiveCN104970115ASuppression of trans-formation of essential fatty acidsSuppression of trans-formationFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The invention relates to a refining method of low trans-fatty acid compound oil. According to a formula, various raw oil in a nutrition compound oil is compounded in the corresponding proportion, and then the refining working procedures of a hydration degumming working procedure, a deacidifying working procedure, a decoloring working procedure, a deodorizing working procedure, a dewaxing working procedure, a degreasing working procedure, a filtering working procedure, a nitrogen-filled packaging working procedure and the like are performed, and in the processing of refining, the temperature of the deodorizing step is controlled to be 210-225 DEG C, the degree of vacuum is maintained to be 0-10mmbar, and the deodorizing time is 15-20 minutes, so that the trans-fatty acid in finished products is ensured to be lower than 1%, and each index conforms to the standard of international first-class oil of a corresponding oil product. The refining method disclosed by the invention has the benefits that in accordance with the nutritional requirements of different crowds of mid-aged people and aged people, pregnant women, babies, and the like, the components in different fat in the formula are regulated, so that the composition of fatty acid in the products is regulated; therefore, the concoction of vegetable oil, with a certain specific function, can ensure that the trans-fatty acid in products is low in content.

Owner:HARBIN PURUN GREASE

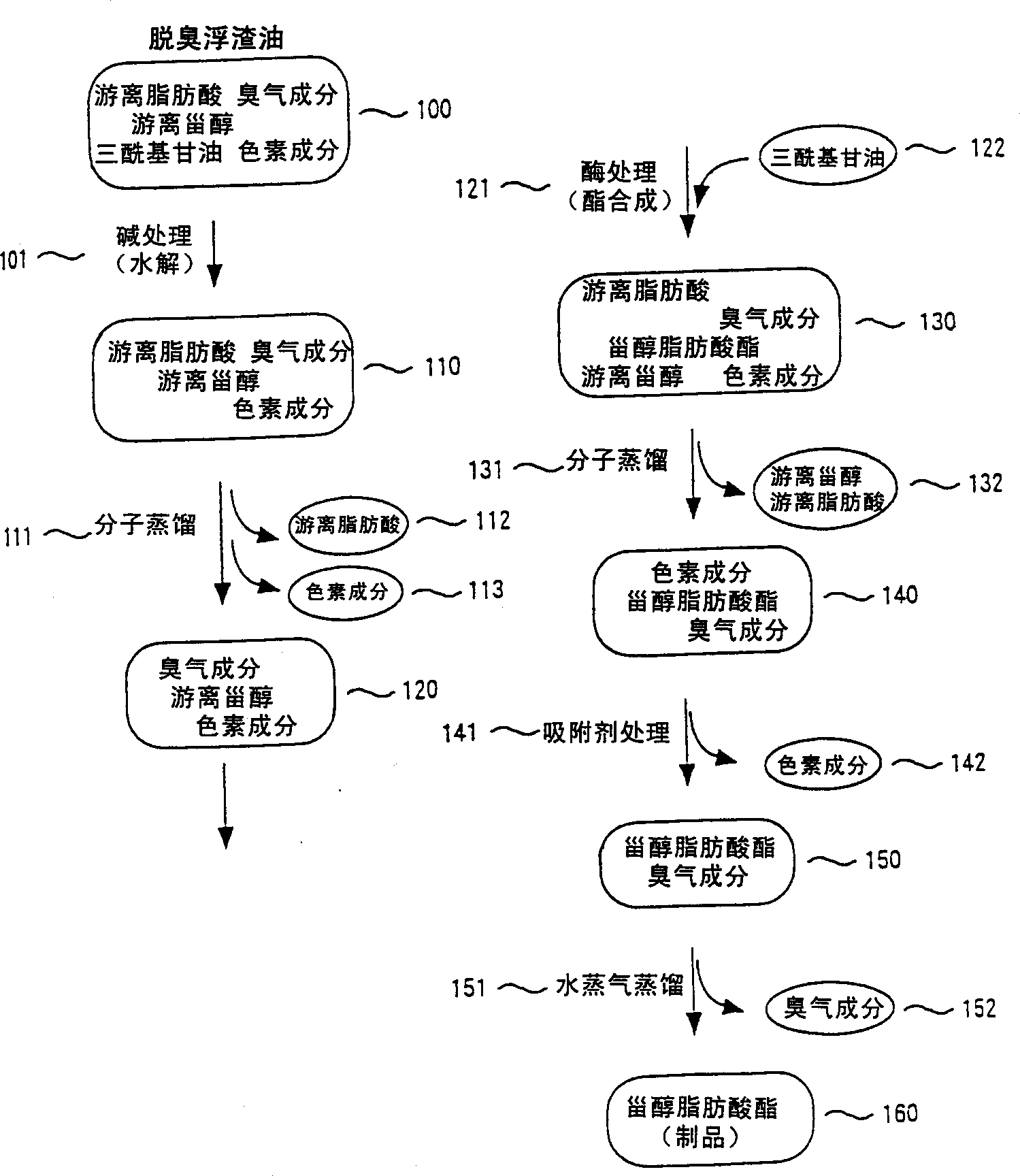

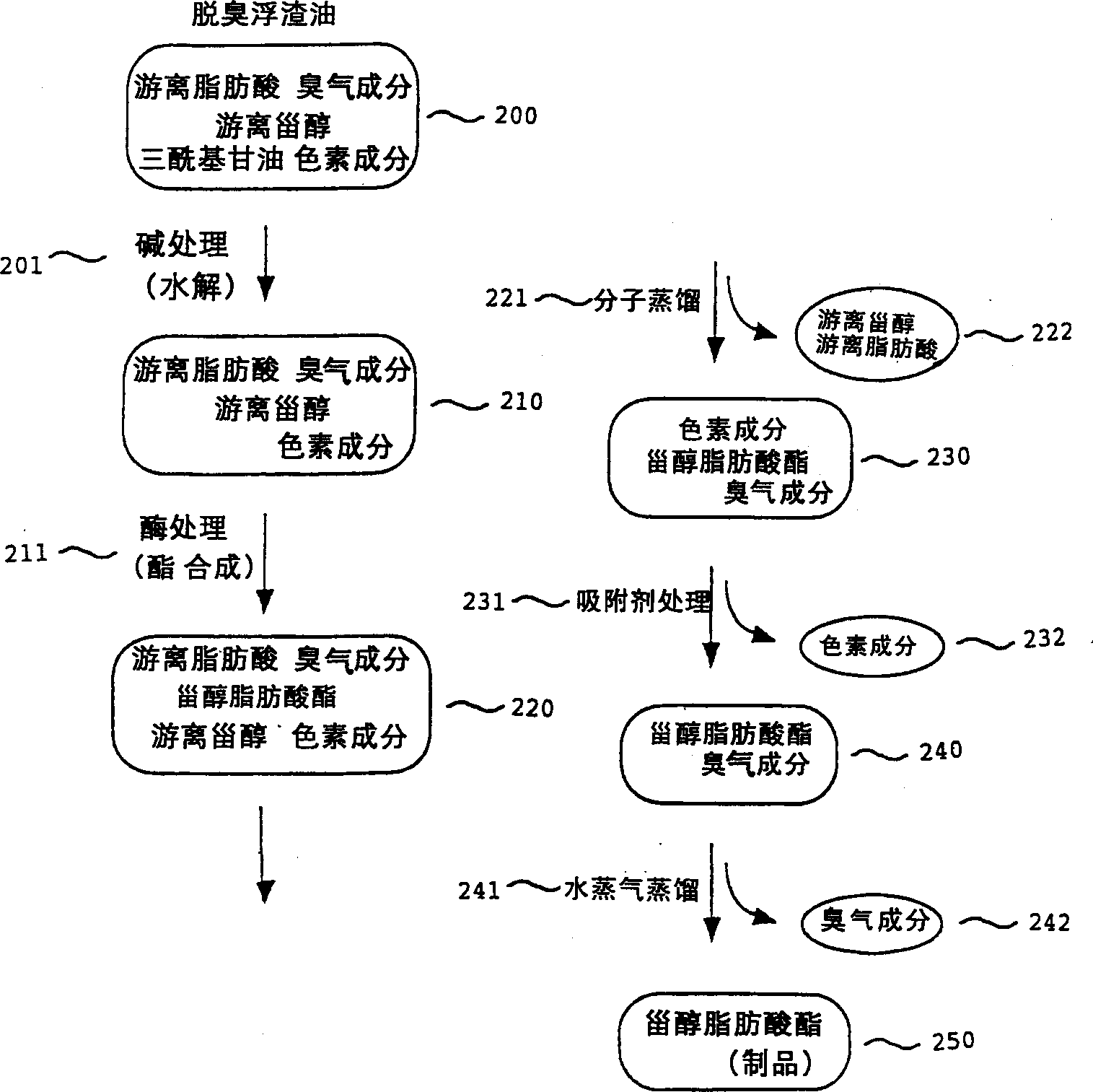

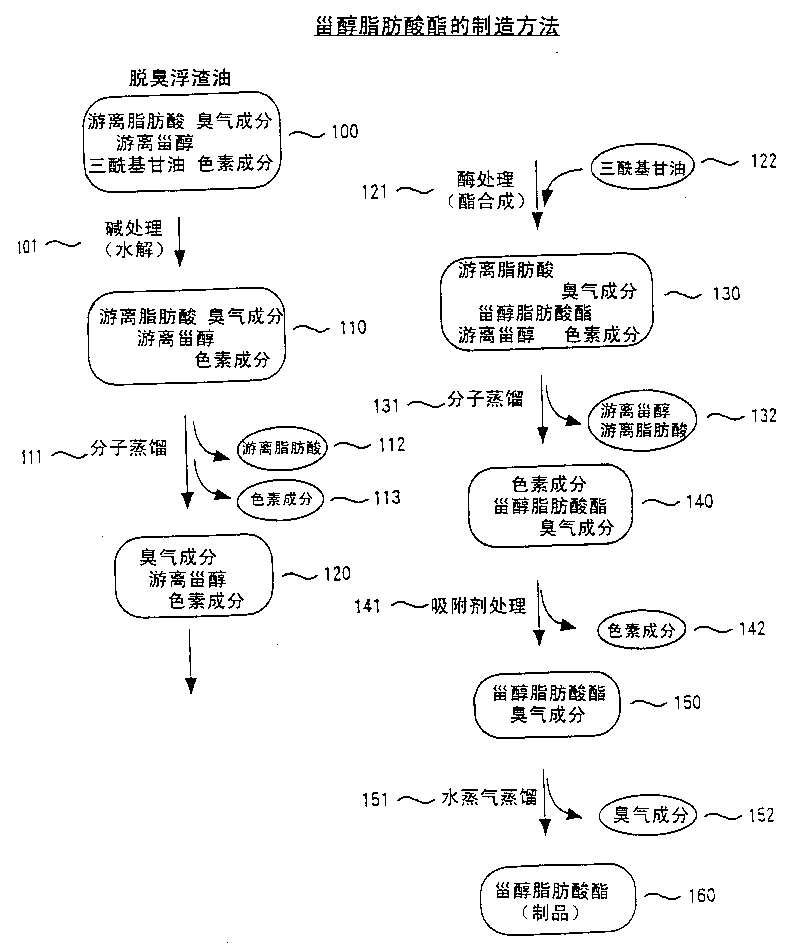

Process for preparing sterol ester of fatty acid for food

InactiveCN1356394ALow in trans fatty acidsLower cholesterol lowering effectFatty acid esterificationFatty-oils/fats refiningIodo fatty acidWater vapor

Disclosed is a method for enzymatically producing sterol fatty acid ester for food, this method comprises: reaction for synthesizing the sterol fatty acid ester by deodorizing scum oil, in the presence of the enzyme which is active in fat decomposing as a catalyst, an enzyme deactivation treatment, dehydration treatment and enzymatic protein removal treatment, the impurity is removed by molecular distillation treatment, adsorbent treatment, and steam distillation treatment, thus obtaining the sterol fatty acid ester for foods excellent in terms of both appearance and safety.

Owner:IKEDA SHOKKEN KK

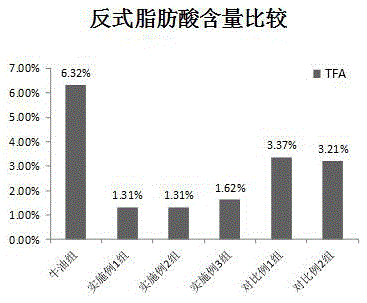

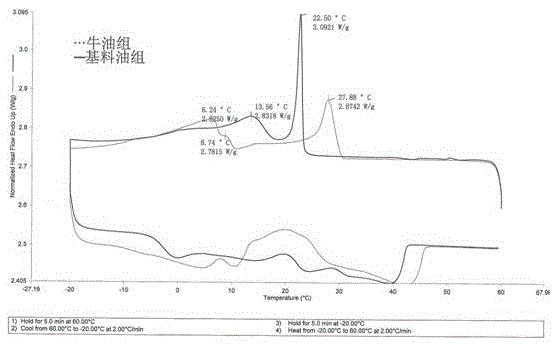

Butter character like low-trans-fatty acid base material oil and preparation method thereof

ActiveCN105638932AImprove oxidation stabilityFulfil requirementsEdible oils/fatsOil and greaseCoconut oil

The invention belongs to the field of foods, and in particular relates to a butter character like low-trans-fatty acid base material oil and a preparation method thereof. The base material oil mainly comprises butter, stearin palm oil, palmitin and coconut oil; the preparation method is as follows: adding the components in a reaction kettle, and then adding an alkali solution to react, adding an acid solution to stop the reaction, and then carrying out washing and de-saponifying, decoloring, and deodorizing to obtain the finished product. The butter character like low-trans-fatty acid base material oil prepared by the invention is rich in middle melting point triglyceride, and compared with the butter, the trans-fatty acid content is reduced by about 80%; and meanwhile, the pure butter wide plasticity range character is maintained; the product prepared from the vegetable shortening or margarine blended through the base material oil cannot produce tissue cracking, crystalline transition and granulation phenomena in the package, storage or transportation process or under the temperature fluctuation condition; and the stability of the lipid product can be greatly improved, the method is in favor of the popularization and application of the butter character like low-trans-fatty acid base material oil.

Owner:GUANGZHOU NANQIAO FOOD +1

Discoloring method for reducing trans-fatty acid content of vegetable oil

InactiveCN101538508ALower trans fatty acidsLow in trans fatty acidsFatty-oils/fats refiningIsomerizationVegetable oil

The invention relates to a Discoloring method for reducing trans-fatty acid content of vegetable oil, belonging to the technical field of vegetable oil refining and discoloring. In the discoloring method, activated clay and neutralized vegetable oil are used as the raw material; on the one hand, discoloring earth is selected; and on the other hand, the discoloring technology of reducing fatty acid trans-isomer is obtained by controlling the discoloring temperature, the clay usage amount, the discoloring time and the stirring rate and integrally considering the trans-isomerization of discoloring effect and fatty acid. The invention reduces the content of trans-fatty acid formed during discoloring, builds up the discoloring technology of low trans-acid, plays a role of good guiding for improving the refining processing technology of vegetable oil and lays a foundation for constructing the processing technology of healthy vegetable oil.

Owner:SHANGHAI RONGS HEALTH IND CO LTD

Method for reducing trans fatty acid content in vegetable oil grease by two-stage type deodorization tower

InactiveCN101993779AReduce high temperature heating timeLow in trans fatty acidsFatty-oils/fats refiningKetoneSOYBEAN SEED OIL

The invention relates to a method for reducing trans fatty acid content in vegetable oil grease by a two-stage type deodorization tower, belonging to the technical field of food safety. The method comprises the following steps of: using decolored soybean oil as a raw material, selecting a heating-type stripping distillation deodorization tower, using the two-stage deodorization process so that most materials with higher vapour pressure of ketone, aldehydes, and the like are removed in an upper-segment plate-type tower, and heating the oil grease to high temperature under the limited vacuum state so that the fatty acid and hydrocarbon with high boiling point are removed in a lower-segment plate-type tower. Compared with the traditional plate-type decoloration tower, the invention reduces the heating time of the oil grease under the condition of not reaching limited vacuum state, reduces the content of trans fatty acid, decreases the transisomer, improves the quality of refined oil product and ensures that the content of trans fatty acid in the refined oil product is controlled below 1.0%.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Refined plant oil and preparation method thereof

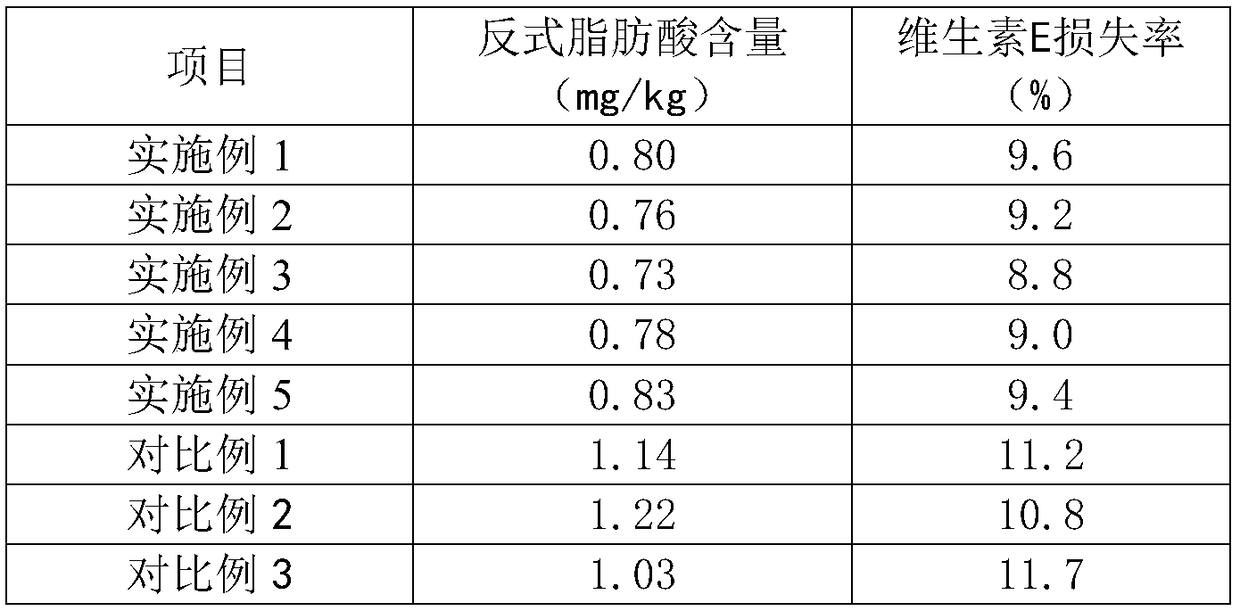

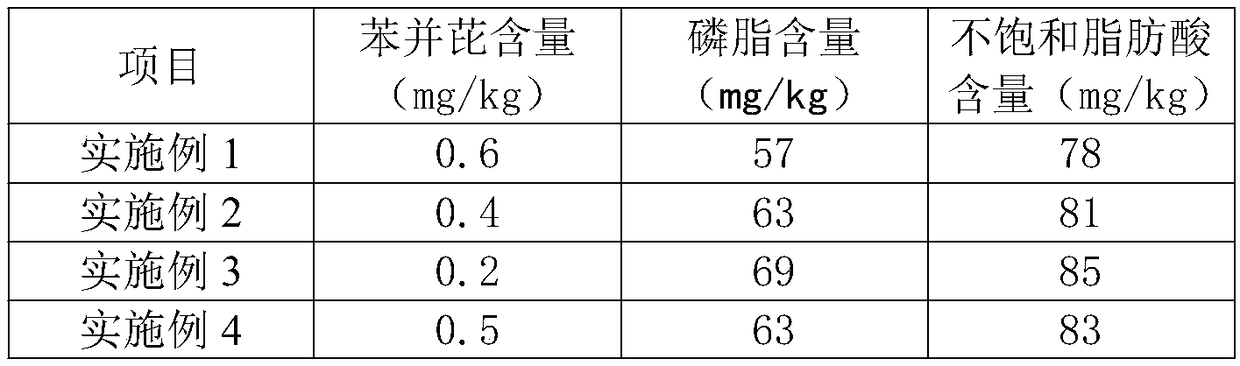

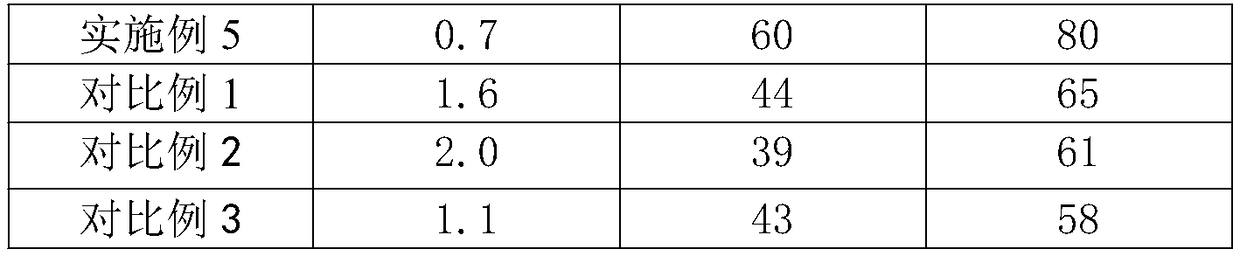

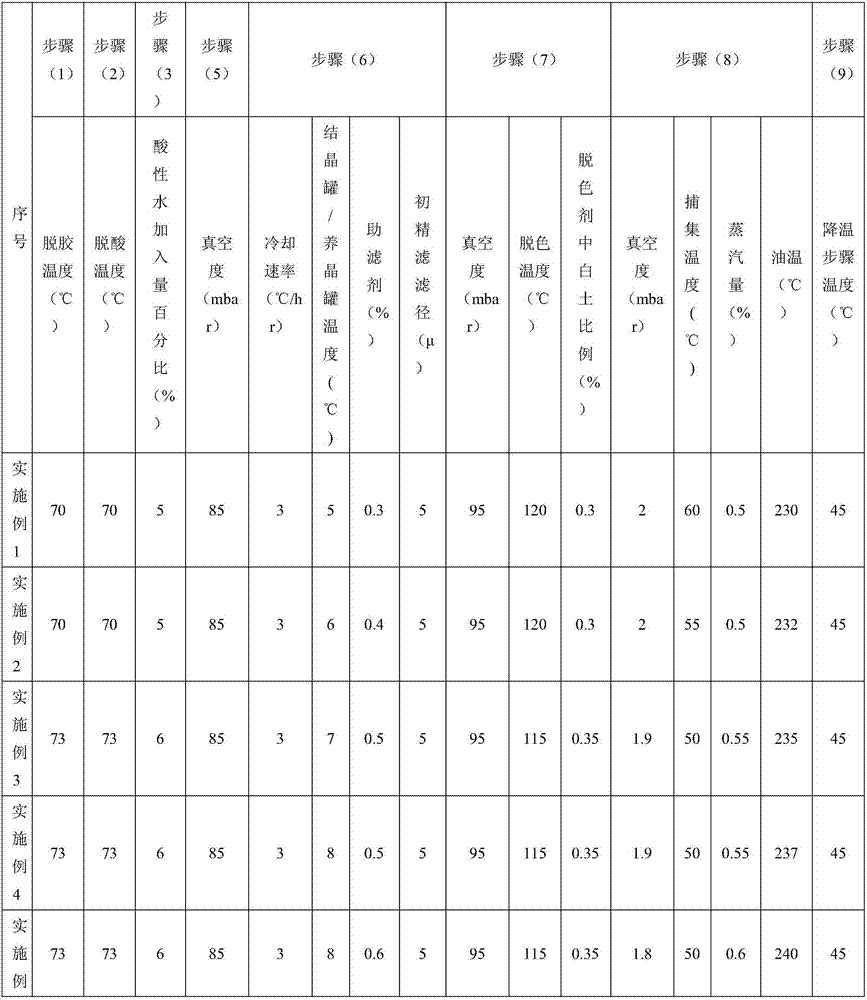

The invention relates to the technical field of grease refining and particularly relates to refined plant oil and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out decontamination; (2) degumming, namely carrying out a primary degumming neutralization reaction and a secondary degumming neutralization reaction; (3) removing soap; (4) decoloring, namely carrying out pre-decoloring and activated clay decoloring; (5) carrying out deodorization. By adopting the refined plant oil and the preparation method thereof, the refining method is simple in procedure and low in cost, impurities such as colloid and benzopyrene in plant oil can be effectively removed, the prepared plant oil has the advantages of being low in trans-fatty acid content and lowin vitamin E loss rate, in addition, the refined plant oil is thick in fragrance, good in taste, high in quality and rich in nutrition.

Owner:JIXI COUNTY HANHUI AGRI DEV

Production process of low-oil-fume sunflower seed oil

PendingCN107299001AReduce the amount of sootQuality improvementFatty-oils/fats refiningEdible oils/fatsFiltrationTrapping

The invention discloses a production process of low-oil-fume sunflower seed oil. The production process of the low-oil-fume sunflower seed oil comprises the following steps: degumming, deacidifying, washing with water, centrifuging, performing vacuum drying, performing winterization, decoloring, deodorizing, cooling and performing refined filtration, wherein the deodorizing process comprises the following steps: vacuumizing until the vacuum degree is not more than 2.0 mbar, performing heating circulation on a plate type tower, opening stripped vapor in the plate type tower when the oil temperature in the plate type tower reaches 180 DEG C, stirring and trapping fatty acid, wherein the trapping temperature is 40 to 60 DEG C; and when the oil temperature in the plate type tower reaches 220 to 260 DEG C, pumping the sunflower seed oil into a filling tower, entering the plate type tower and performing deodorization. Through improvements on the process condition, particularly on the deodorizing process, the quality of the obtained sunflower seed oil is greatly improved. The quantity of the oil fume generated when the sunflower seed oil produced by the production process is heated at high temperature is small; in the sunflower seed oil, the nutrient content is high and the trans-fatty acid content is extremely low.

Owner:佳格投资(中国)有限公司

Processing method of organic tea oil

InactiveCN112226274ALow in trans fatty acidsHigh in squaleneFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyNutrition

The invention discloses a processing method of organic tea oil. The method specifically comprises the following steps: collecting and drying organic raw materials, controlling the moisture content, purifying the dried raw materials, separating shells and kernels, performing crushing by a crusher after color sorting, performing multiple squeezing by a double-screw spiral oil press, performing refining by degumming, deacidifying, decolorizing, deodorizing and dewaxing, and filling finished oil. According to the method, the organic raw materials are subjected to collection, drying, sorting, husking, color sorting, crushing and refining to obtain the organic camellia oleosa seed oil, and compared with commercially available first-grade camellia oleosa seed oil at present, the organic camelliaoleosa seed oil is low in trans-fatty acid content, high in vitamin E content, phytosterol content and squalene content, safer, nutritional, healthy, high in nutrient content, free of artificially synthesized substances such as pesticides, fertilizers and hormones, and good in health care effects.

Owner:霍山知行信息科技有限公司

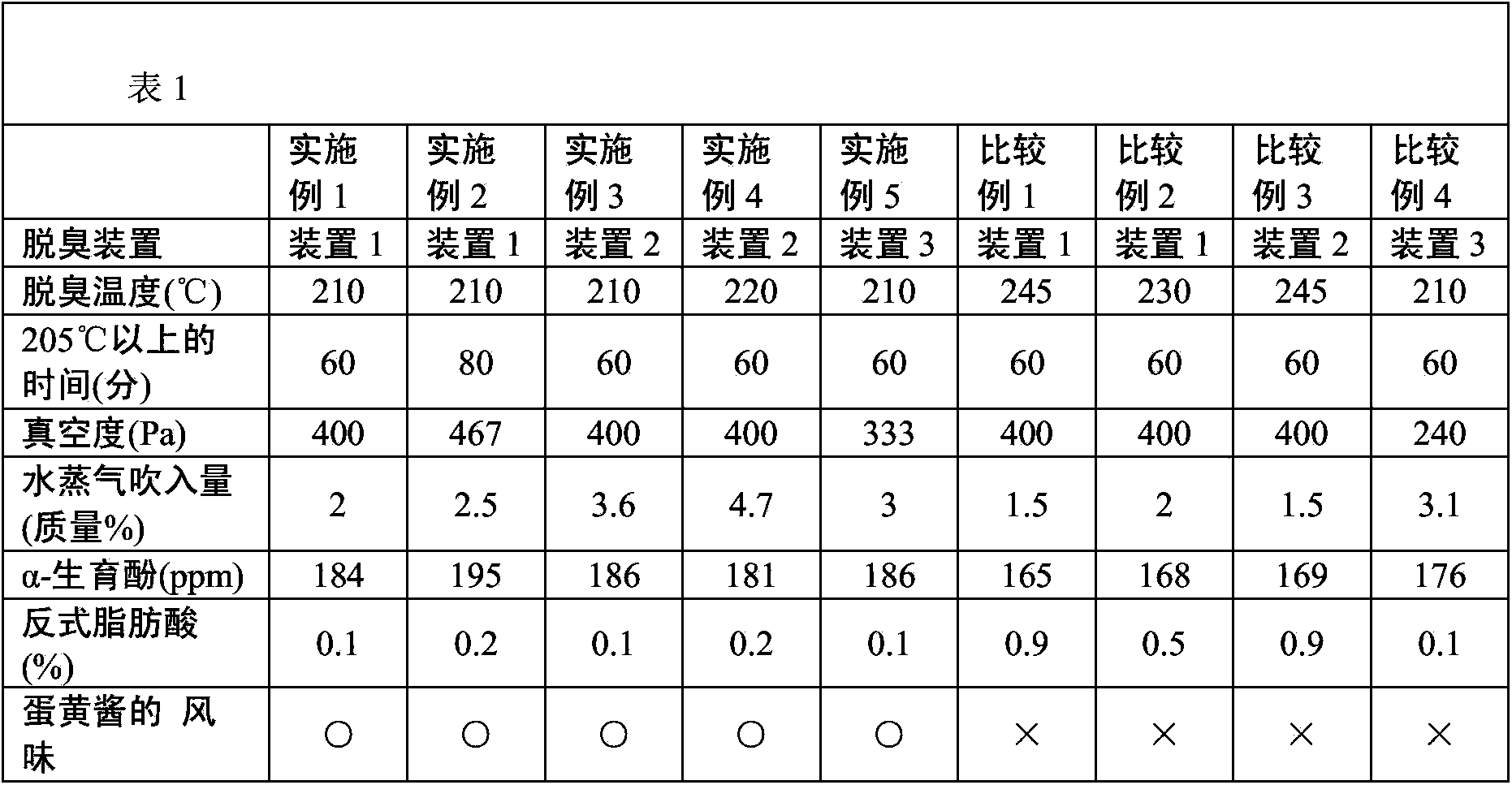

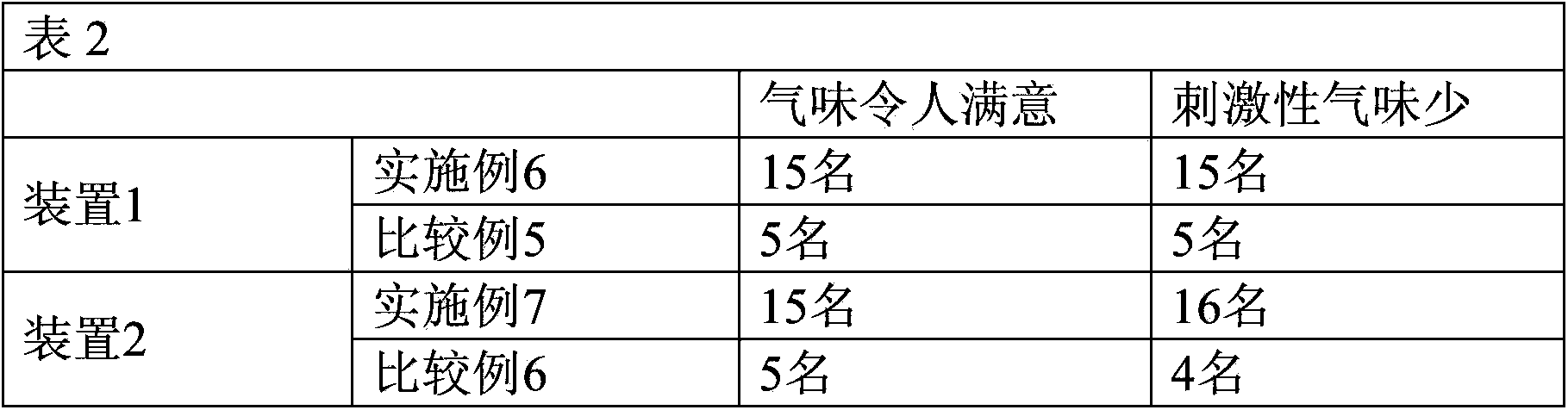

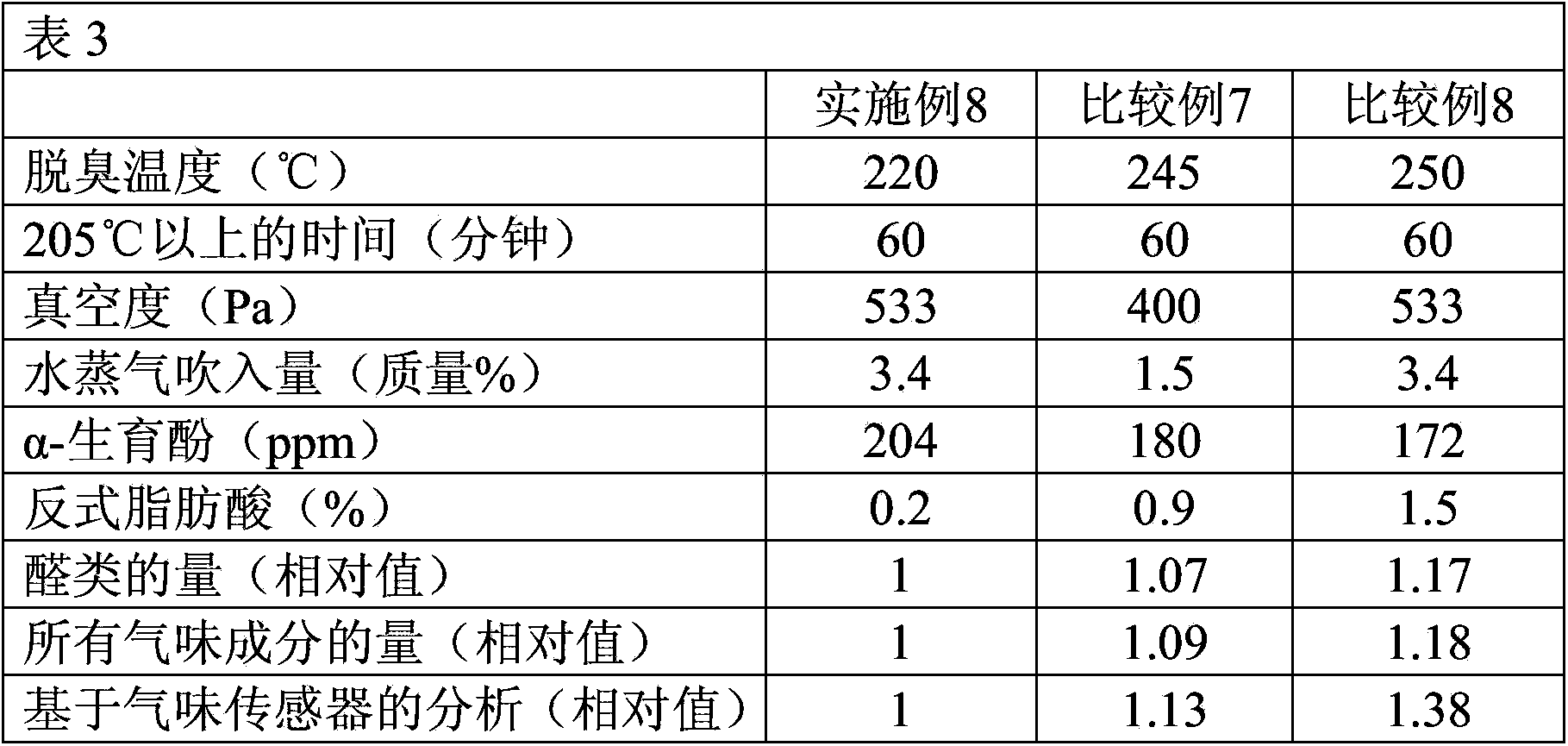

Production method of refined colza oil, refined colza oil produced by using the method, and acid emulsion food containing the above mentioned colza oil

InactiveCN103451016ALow in trans fatty acidsAdd flavorFatty-oils/fats refiningEdible oils/fatsFlavorEmulsion

The invention provides a production method of refined colza oil, a refined colza oil produced by using the method, and an acid emulsion food containing the above mentioned colza oil, and a method of reducing the aldehydes in the refined colza oil. The refined colza oil can be used to inhibit the reduction of the alfa- tocopherol, and can be used to reduce the trans-fatty acids, and the flavor is good. The production method provided by the invention comprises a deodorization process, and the deodorization process is characterized in that the deodorization process comprises a contact process, namely the colza oil is contacted with the vapor for 53-100min under the temperature condition in a range from 205 to 225 DEG C and the vacuum degree in a range from 300 to 800 Pa. The content of the vapor can be 1.0-5.0 wt% by comparing with the colza oil. The above mentioned deodorization process can be carried out by using the tray-type deodorization device.

Owner:THE NISSHIN OILLIO GRP LTD

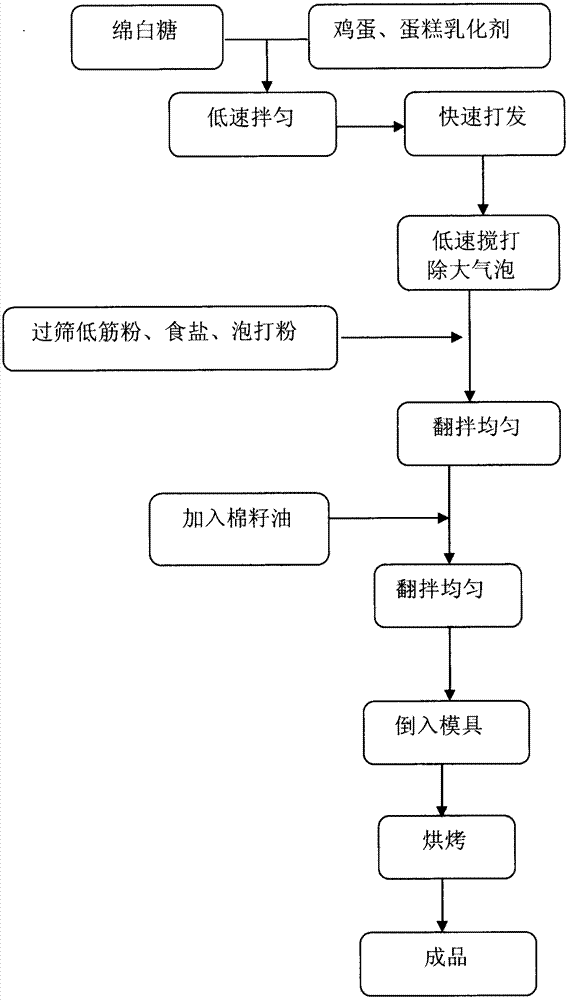

Method for producing sponge cake by using cottonseed oil

InactiveCN102919321ALow in trans fatty acidsImprove qualityDough treatmentBakery productsCottonseed oilSponge cake

The invention relates to an application of cottonseed oil to a sponge cake and belongs to the field of food processing. The sponge cake is made by the following processing steps of fully agitating soft sugar, cake emulsifying agents and eggs in a stirrer to be white, adding sieved flour, salt and baking powders, continuing agitating the mixture to be pasty, pouring the cottonseed oil into the mixture, stirring the mixture to be uniform, and pouring the cake paste into a mold for baking to obtain the sponge cake. According to the application of the cottonseed oil to the sponge cake, cottonseed oil resources are fully used, trans-fatty acid contents in the cake are obviously reduced, and simultaneously, qualities of the cake are obviously improved so that the obtained cake is large in size, delicate and uniform in structure, spongy and soft and tastes wet.

Owner:黄卫宁

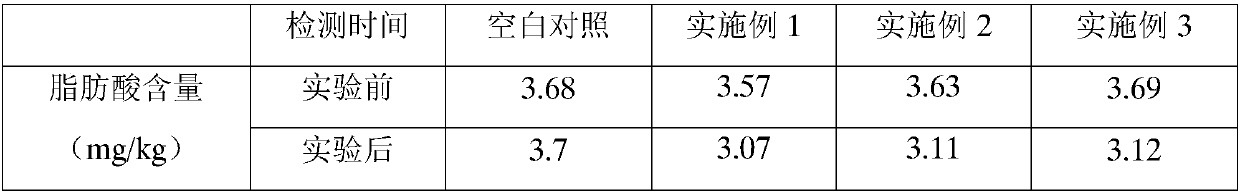

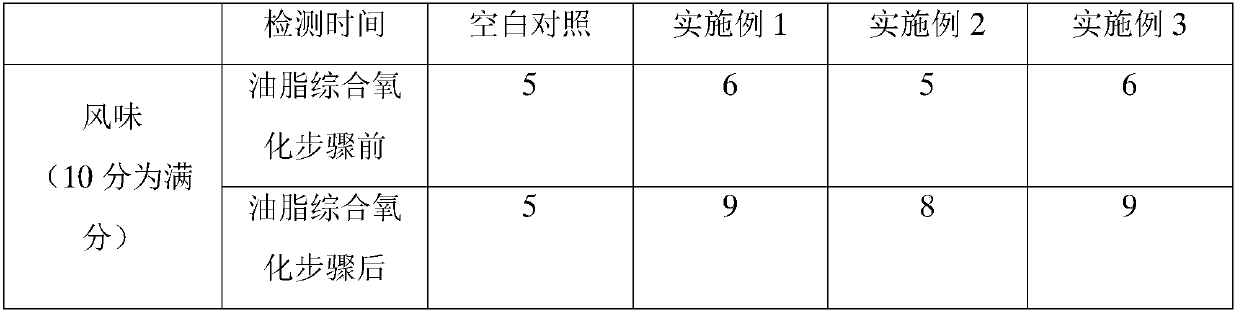

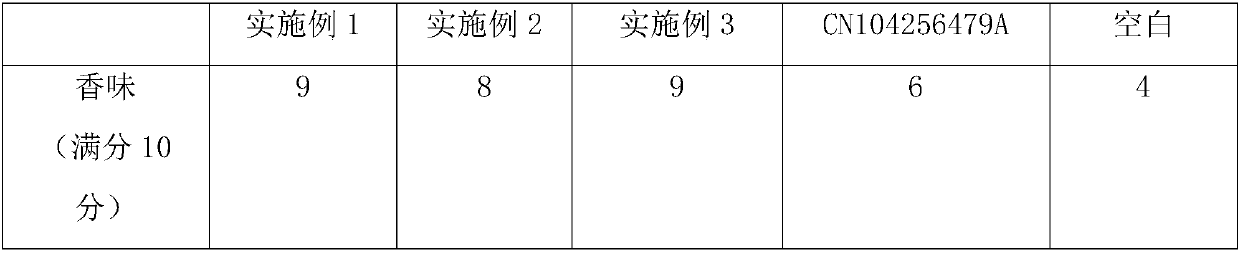

Fresh shrimp flavor sauce and preparation method thereof

The invention provides a fresh shrimp flavor sauce and a preparation method thereof. The preparation method includes the steps of using the processing residual materials of shrimp skins, shrimp heads,fish bones and the like as raw materials, combining comprehensive grease oxidation, biological enzymolysis, Maillard reaction and the like technology, upgrading products to increase product added value, reduce or even eliminate bad odors such as bitterness and smelling of fish, and researching and developing a fresh shrimp special sauce with obvious fresh shrimp special favor, rich and smooth taste. The preparation method of the fresh shrimp flavor sauce has the advantages of combining the comprehensive grease oxidation and biological enzymolysis to improve the content of trans fatty acids insauces, using the Maillard reaction to provide flavor degree of products and being applicable to various types products such as hotpot seasoning, traditional cuisine cooking ingredients, pickling material, canned food, instant food, ready-to-eat products and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Moderately processed vegetable oil and preparation method thereof

The invention provides a moderately processed vegetable oil and a preparation method thereof. The preparation method comprises the following steps: carrying out degumming twice (first deep degumming and then combining the secondary degumming) to realize efficient degumming and remove high boiling impurities as many as possible, so as to carry out alkali refining and neutralization at low temperature; then pre-decoloring with waste clay used for recycling, adding clay, decoloring under vacuum condition, and removing residual soap, phosphorus, pigment, metal, and the like; and finally carrying out combined deodorization of the plate column and the packed column, carrying out thermal decoloration, and removing fatty acid and micro-molecular stinking material, so as to reduce the generation of trans fatty acid, reduce the loss of vitamin E, save energy, reduce consumption, and improve the oil quality. According to the invention, vegetable oil products with low content of trans fatty acid (less than 1.0 %) and low loss rate of vitamin E can be produced.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

Zero trans-fatty acid multi-vitamin first-grade soybean oil and preparation method thereof

ActiveCN102517142BLow in trans fatty acidsHigh in squaleneFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyPlant sterol

The invention provides zero trans-fatty acid multi-vitamin first-grade soybean oil and a preparation method thereof. The zero trans-fatty acid multi-vitamin first-grade soybean oil is produced by screening of soybean raw materials, a soybean peeling and instantaneous high-pressure wet-hot enzyme inactivation technology, a double-enzyme degumming / super degumming and washing-free long-time mixing and de-acidifying coupling technology, a two-step decolorization technology with low-activity decolorizing agent, a low-temperature short-time / two-stage catching, refluxing and deodorization technology, a ''nitrogen charging fresh-keeping'' technology and the like. In the zero trans-fatty acid multi-vitamin first-grade soybean oil, the trans-fatty acid content is less than or equal to 0.5 percent, the natural vitamin E content is more than or equal to 1,200ppm, the plant sterol content is more than or equal to 2,200ppm, and the squalene content is more than or equal to 60ppm; the soybean oil is packed by charging nitrogen, and any chemically synthesized antioxidant is not added; and compared with the commercially available first-grade soybean oil, the soybean oil is more safe, nutritional and healthy.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

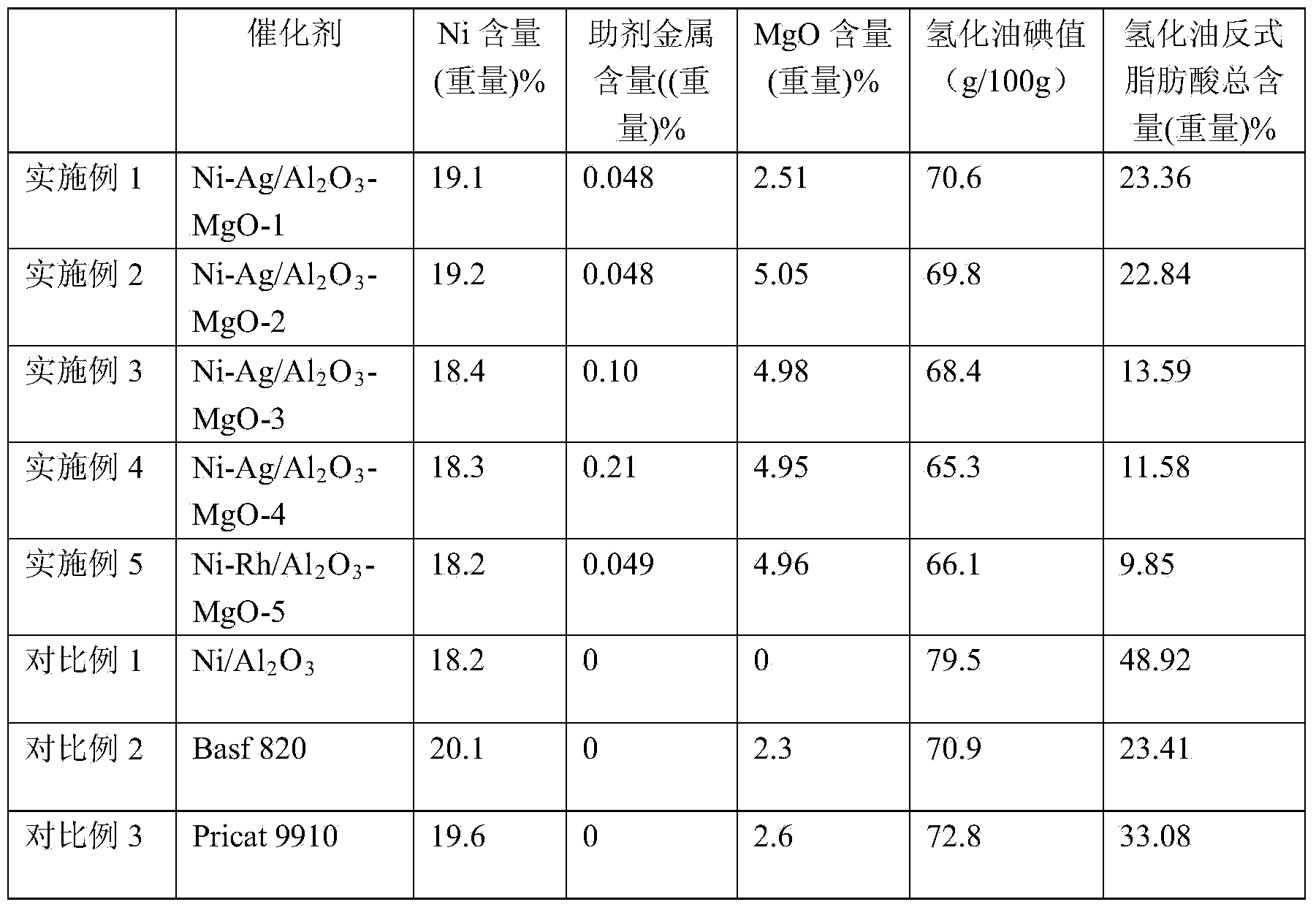

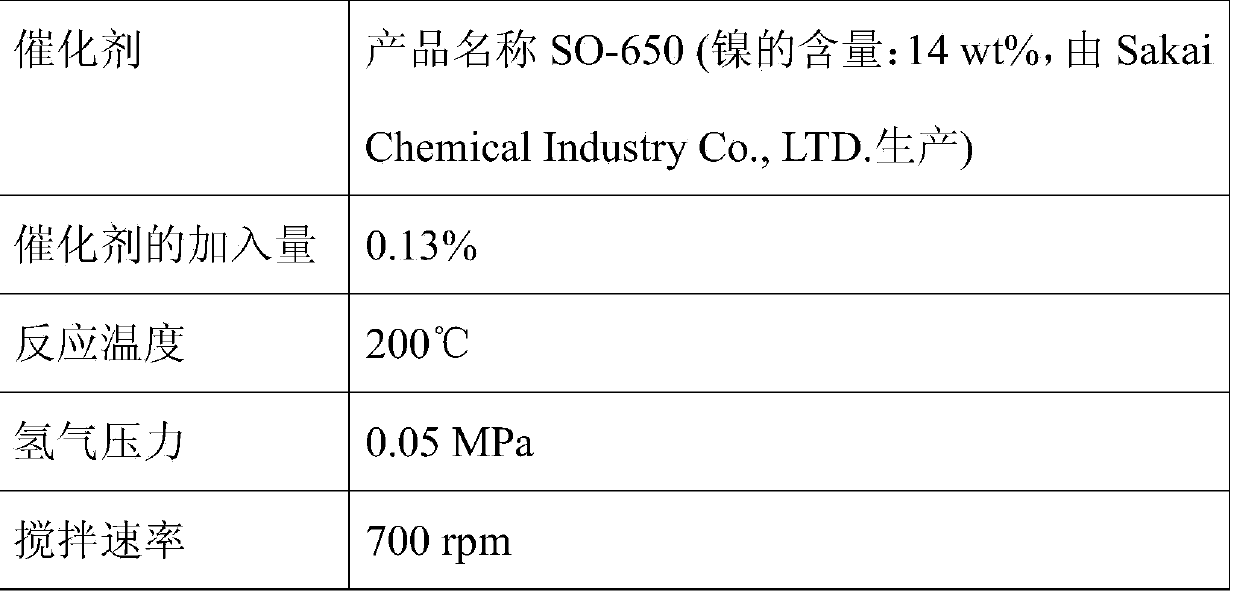

Hydrogenation catalyst with low trans-acid grease and preparation method thereof

ActiveCN104368391AImprove hydrogenation activityAvoid uneven loadOrganic-compounds/hydrides/coordination-complexes catalystsActive componentHydrogenation reaction

The invention discloses a hydrogenation catalyst with low trans-acid grease and a preparation method thereof. The hydrogenation catalyst consists of four parts, i.e., a main active component (nickel), an additive, a composite carrier Al2O3-MgO and stearic acid. The structural formula is Ni-M / Al2O3-MgO / stearic acid; the content of the main active component (nickel) is 5.0-20wt%; M is one of Ru, Rh, Pd and Ag, and the content of the M is 0.01-0.05wt%; the content of the composite carrier Al2O3-MgO is 20-50wt%; the remaining is stearic acid. The preparation method of the hydrogenation catalyst comprises the following steps of: loading the metal nickel and the additive onto the carrier by adopting a step-by-step impregnation method, then drying, roasting, reducing and forming the hydrogenation catalyst with low trans-acid grease. The hydrogenation catalyst disclosed by the invention has the advantages that the preparation operation is simple, the repeatability for batch preparation is good, the cost is low; the activity is high, the content of trans-fatty acid as a hydrogenation product is low, the use is safe, so that the hydrogenation catalyst is especially suitable for hydrogenation reaction of edible grease.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

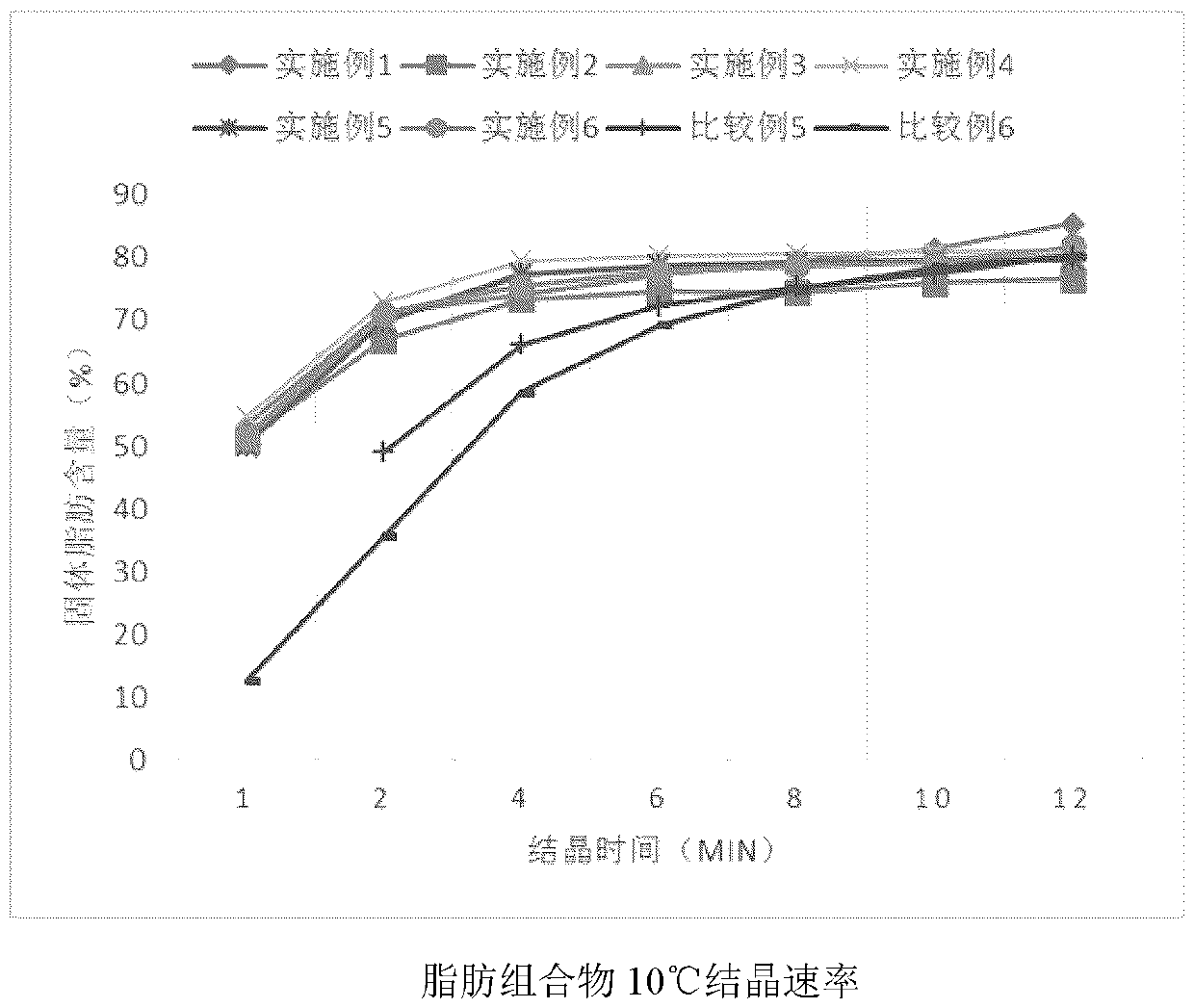

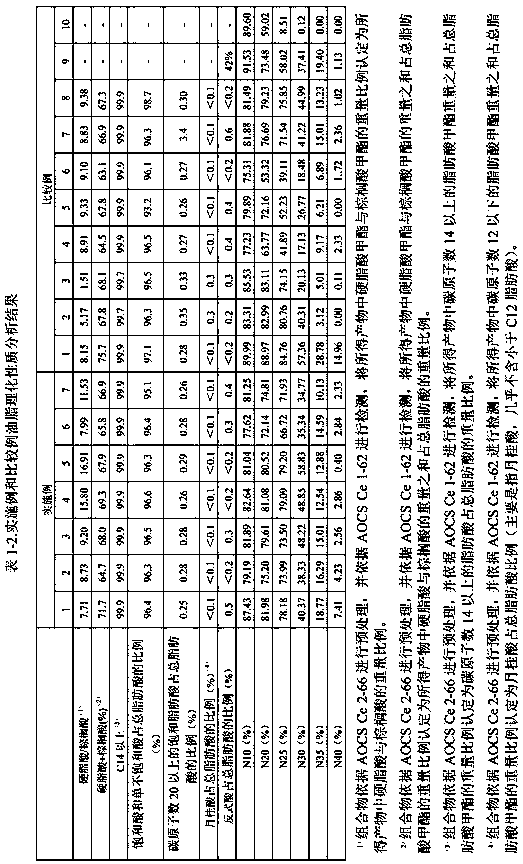

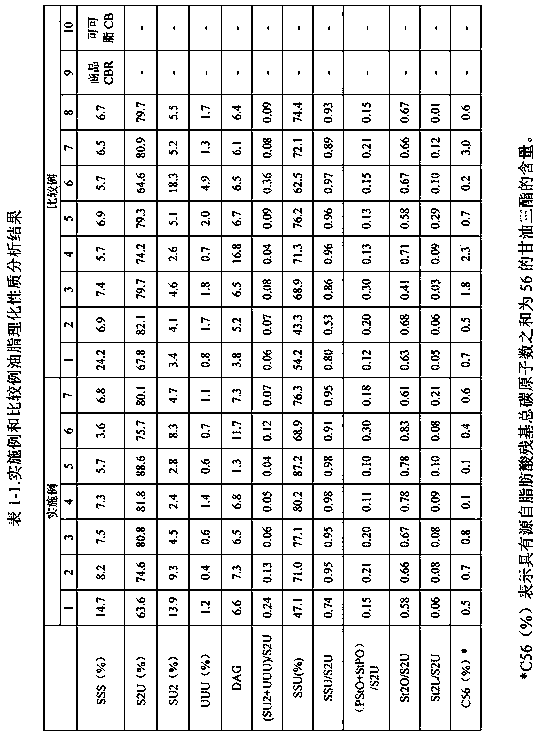

Fat composition

PendingCN109984208AFast crystallization rateGreat tasteEdible oils/fatsTriglycerideOrganic chemistry

The invention relates to a fat composition. The fat composition of the invention contains triglyceride, the composition meets a condition that SSU / S2U is greater than 0.6 in weight ratio, wherein S represents the same or different saturated fatty acid residues with 12-30 carbon atoms; U represents the same or different unsaturated fatty acid residues with 16-30 carbon atoms; SSU represents the triglyceride of which the first and second positions are S and the third position is U; S2U represents the triglyceride combined with 2 molecules S and 1 molecule U. The grease composition of the invention is a grease composition of non lauric acid type, non trans-acid, non temperature adjustment and high DAG content, and has excellent properties.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

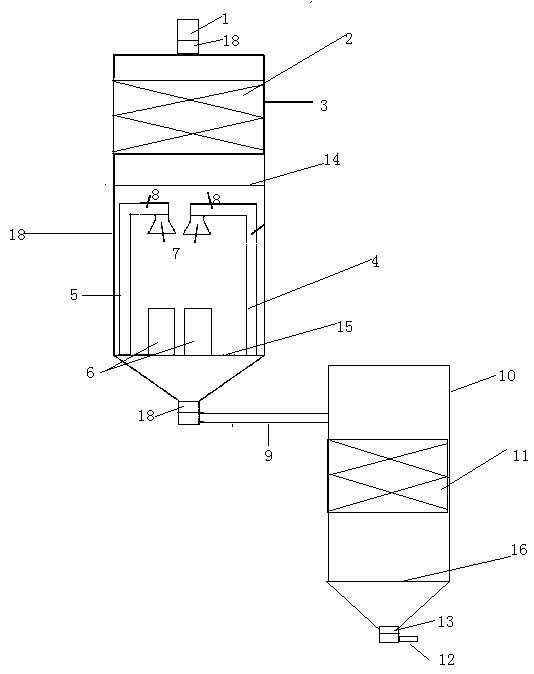

Equipment for reducing content of trans-fatty acids in corn oil and process of equipment

The invention discloses equipment for reducing the content of trans-fatty acids in corn oil. The equipment includes a deodorization tower (18), a pre-deacidification tower located at the upper part ofthe deodorization tower, and a post-deacidification tower connected with the deodorization tower through a deodorization tower oil outlet pipe; the upper part of the pre-deacidification tower is provided with an oil inlet pipe, the interior of the pre-deacidification tower is provided with a stainless steel mesh, and a first partition plate is arranged between the pre-deacidification tower and the deodorization tower; a second partition plate is arranged in the deodorization tower, and a vertical liquid conveying tube, two oil receiving cups, and a vertical liquid conveying tube are sequentially arranged on the second partition plate, the vertical liquid conveying tubes are vertically connected to the second partition plate, and the upper end of each vertical liquid conveying tube communicates with one spray nozzle through one corresponding horizontal oil conveying tube; and a stainless steel mesh is installed in the post-deacidification tower, the lower part of the post-deacidification tower is provided with a third partition plate, and the bottommost part is provided with a deacidification tower oil outlet pipe. The invention also discloses a process for deacidification and deodorization by using the equipment. The equipment and process provided by the invention control the generation of the trans-fatty acids.

Owner:SHANDONG XINGQUAN GREASE CO LTD +1

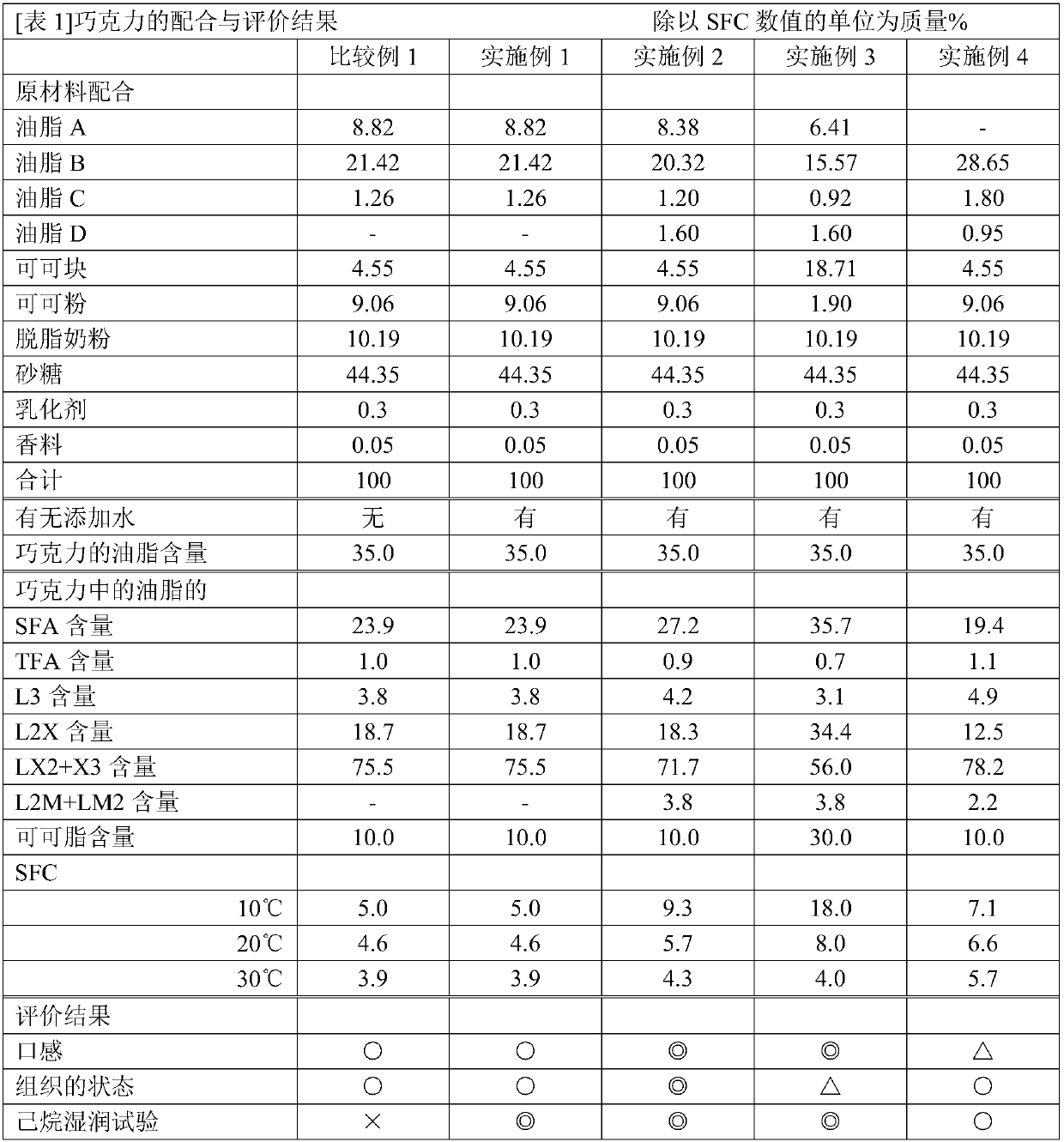

Oily food

PendingCN107708428ALow in saturated fatty acidsLow in trans fatty acidsCocoaEdible oils/fats with aqeous phaseFlavorButter cocoa

The present invention addresses the problem of providing an oily food that contains a low amount of saturated fatty acids and trans-fatty acids and has a good shape retention and a low adhesion, and,in particular, an oily food that contains cocoa butter and has a good flavor. Provided is an oily food that contains a fat / oil and a saccharide such that saturated fatty acids account for 45 mass% orless of the total fatty acids constituting the fat / oil, and trans-fatty acids account for 5 mass% or less of the total fatty acids constituting the fat / oil. The oily food has a sugar backbone. The L3content of the oily food accounts for 10 mass% or less of the fat / oil.

Owner:THE NISSHIN OILLIO GRP LTD

Decoloration method for producing edible vegetable oil with low content of trans fatty acid at CO2 supercritical state

The invention relates to a decoloration method for producing edible vegetable oil with low content of trans fatty acid at a supercritical CO2 state. The decoloration method of the invention controls the decoloration pressure of the supercritical CO2, the temperature, the carclazyte adding amount, the time and the stirring speed, takes the content of the trans fatty acid as an indicator, and regulates and controls each main parameter to obtain the edible vegetable oil with low content of trans fatty acid finally. In the method of the invention, the decolored carclazyte is utilized to decolor the oil at a supercritical liquid CO2 state; as the active decolored carclazyte has stronger Van der Waals' force at the supercritical liquid CO2 state, the triglyceride polarity is extremely small, and the pigment is larger relative to the polarity, the decolored carclazyt has stronger acting force on the pigment matters in the oil; and at the supercritical liquid state, the liquidity of the pigment is better, reactions, such as oxidation and addition reaction and the like are not easy to occur the oil; and the trans fatty acid content is low.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

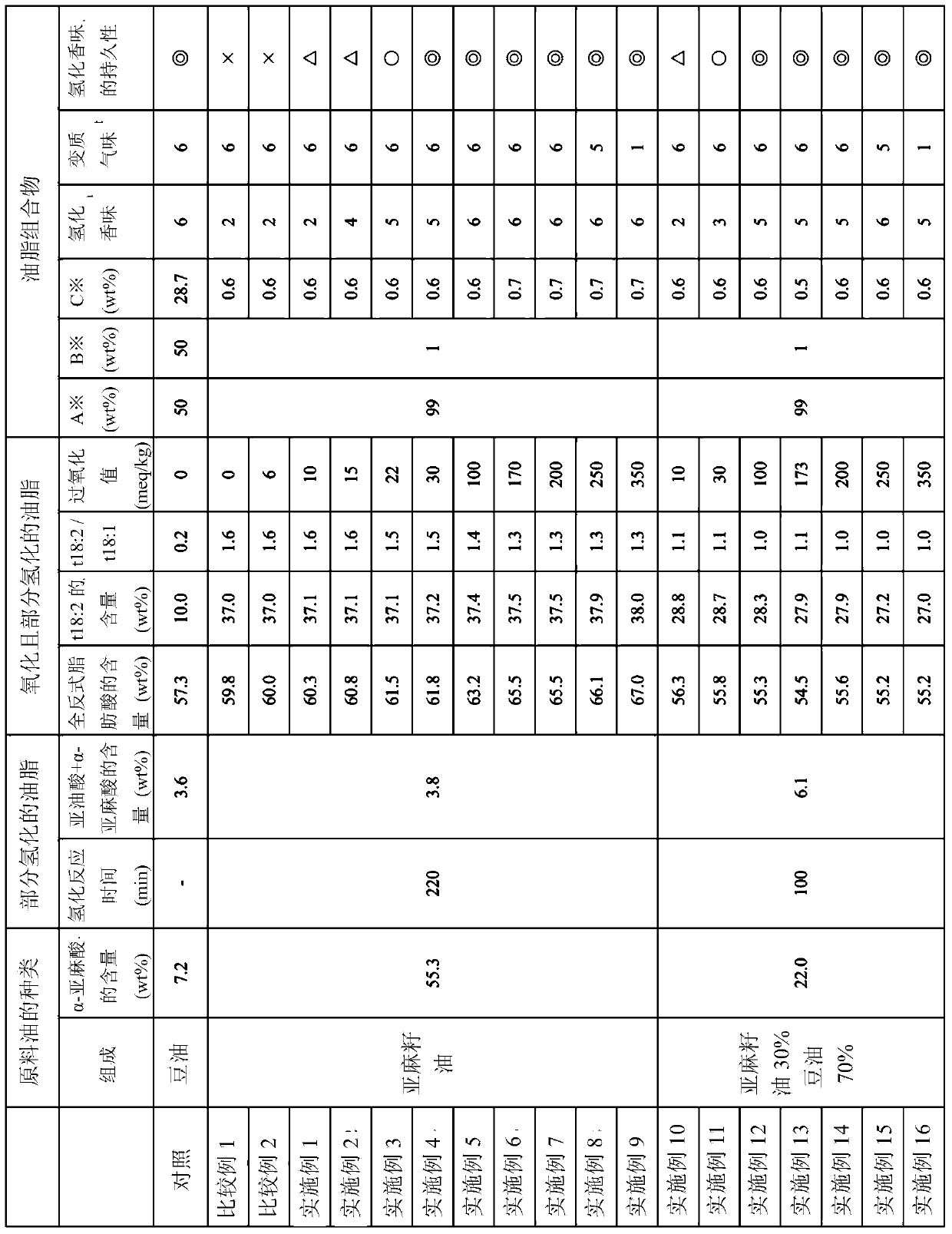

Oxidized partially hydrogenated oil

ActiveCN103748200ARich flavorImprove durabilityFatty acid hydrogenationSpread compositionsChemical compositionPartial hydrogenation

The invention is to provide an oil composition having a hydrogenated aroma and flavor as in the past and having persistence of a hydrogenated aroma, while holding the trans fatty acid content to that of conventional salad oil, as well to provide the starting material thereof. The oxidized partially hydrogenated oil of the invention has a C18:2 trans isomer content that is between 10 and 60 wt% of the total structural fatty acid content and a peroxide value that is between 8 and 350 mEq / kg. The weight ratio of the C18:2 trans isomer content to the C18:1 trans isomer content of the total structural fatty acids is preferably between 0.3 and 1.8.

Owner:J OIL MILLS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com