Cocoa butter equivalents produced by the enzymatic interesterification process and method for preparing the same

A technology of exchange reaction and reactant, applied in the field of cocoa butter substitute and its preparation, can solve the problems of high cost, no application, etc., and achieve the effects of convenient and simple process steps, improved yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 selects enzyme

[0055] Lipase TLIM derived from Thermomyces lanuginosus (Lipozyme TLIM; Novozymes, Denmark) was immobilized in porous silica particles and was insoluble in oil.

[0056] In this example, in order to compare the properties of the lipase TLIM enzyme and the widely used lipase RMIM (Lipozyme RMIM, Novozymes, Denmark), the same substrate was reacted for 24 hours.

[0057] Table 1 (area ratio: %)

[0058]

DG

SOO

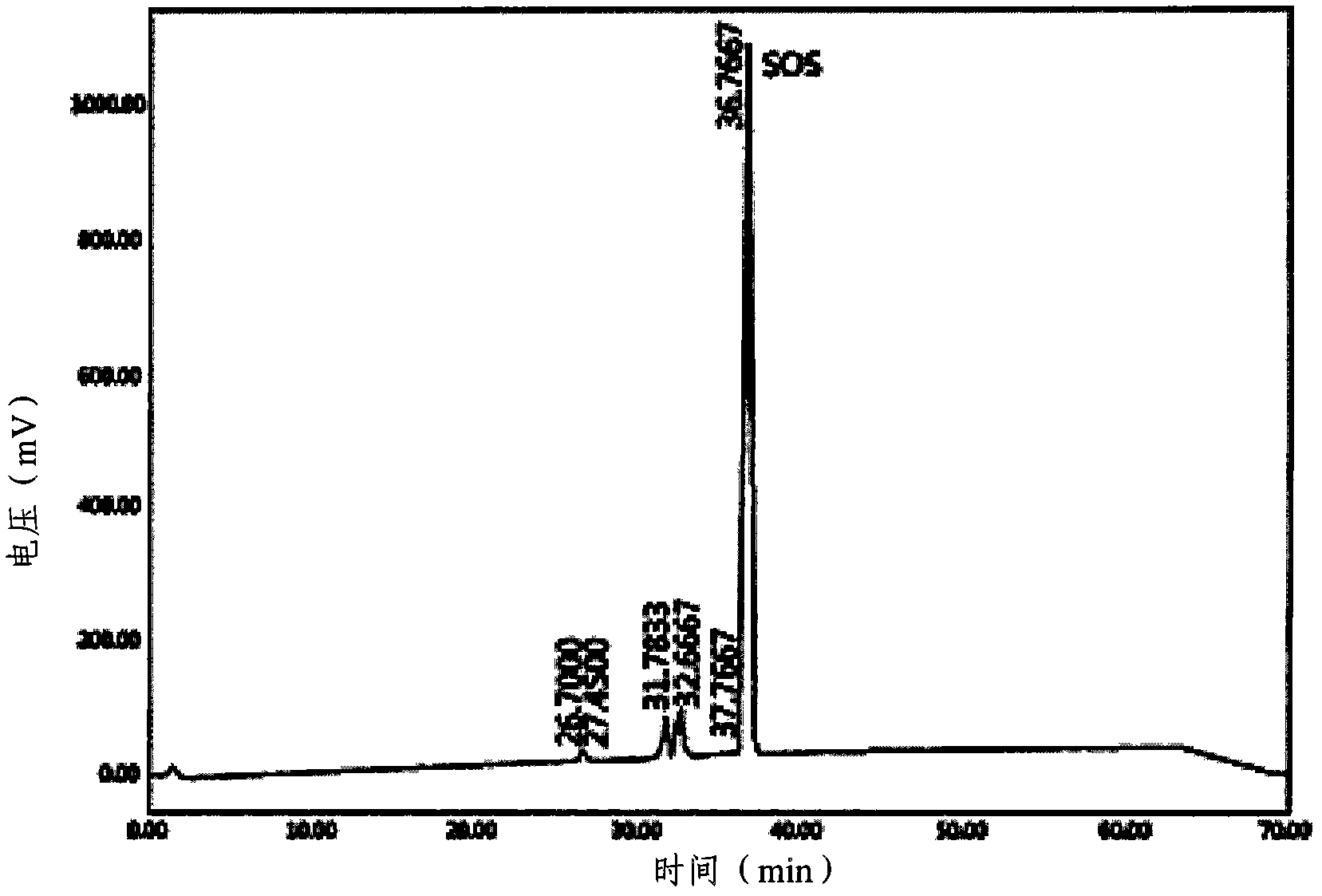

SOS

TLIM

1.4

32.4

49

3.7

RMIM

14.4

34.2

39

2.3

[0059] DG: diglyceride, S: stearic acid, O: oleic acid

[0060] The reaction result is that the activity of RMIM is lower than the activity of TLIM. As shown in the above table 1, after 24 hours of reaction, the composition of the triglyceride of the reactant is: the content of diglyceride in RMIM is high, thus it can be seen that the present invention Conditions of enzymatic transesterification re...

Embodiment 2

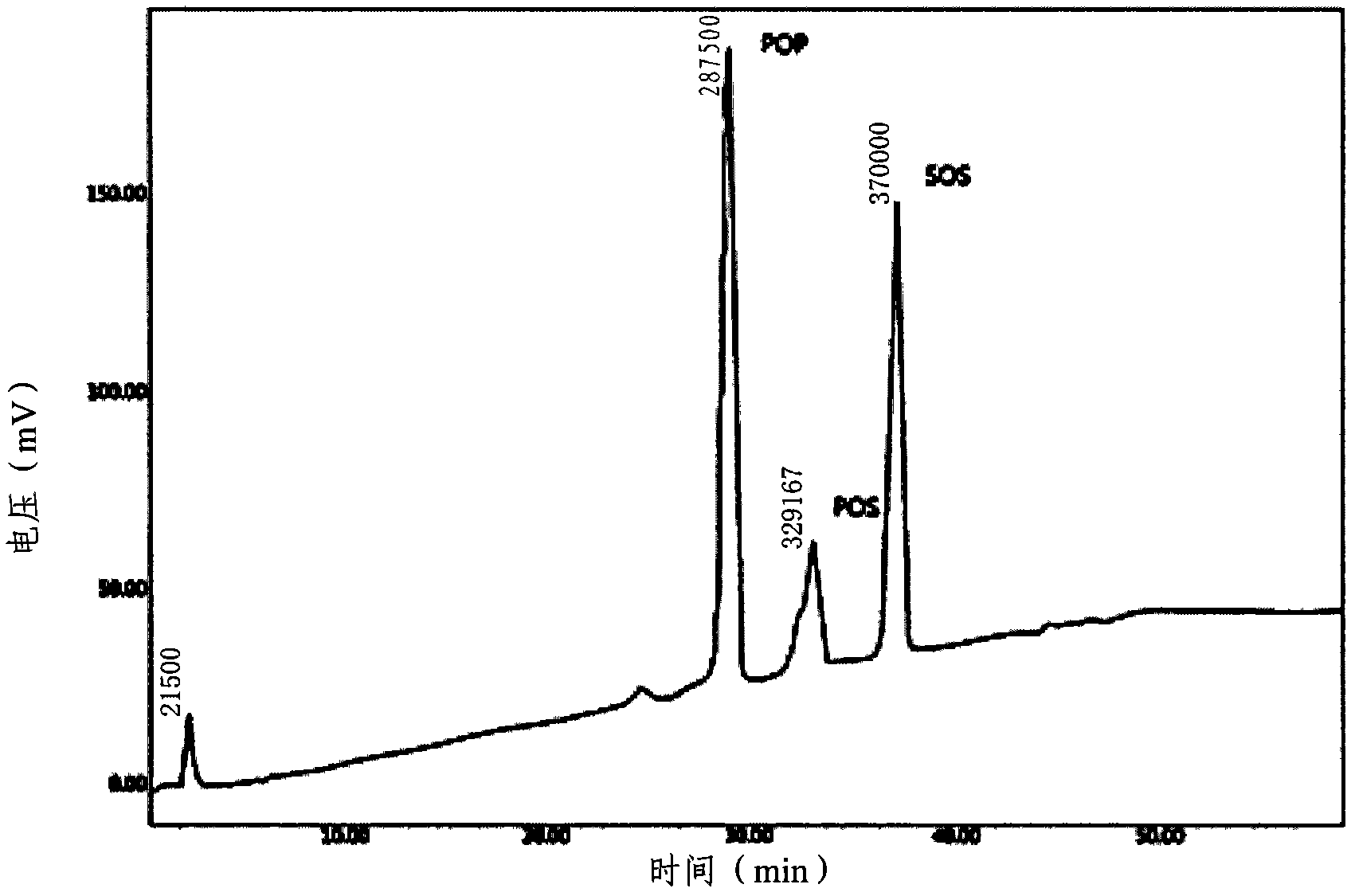

[0061] Embodiment 2 is to the research of whether the selected enzyme can carry out transesterification reaction

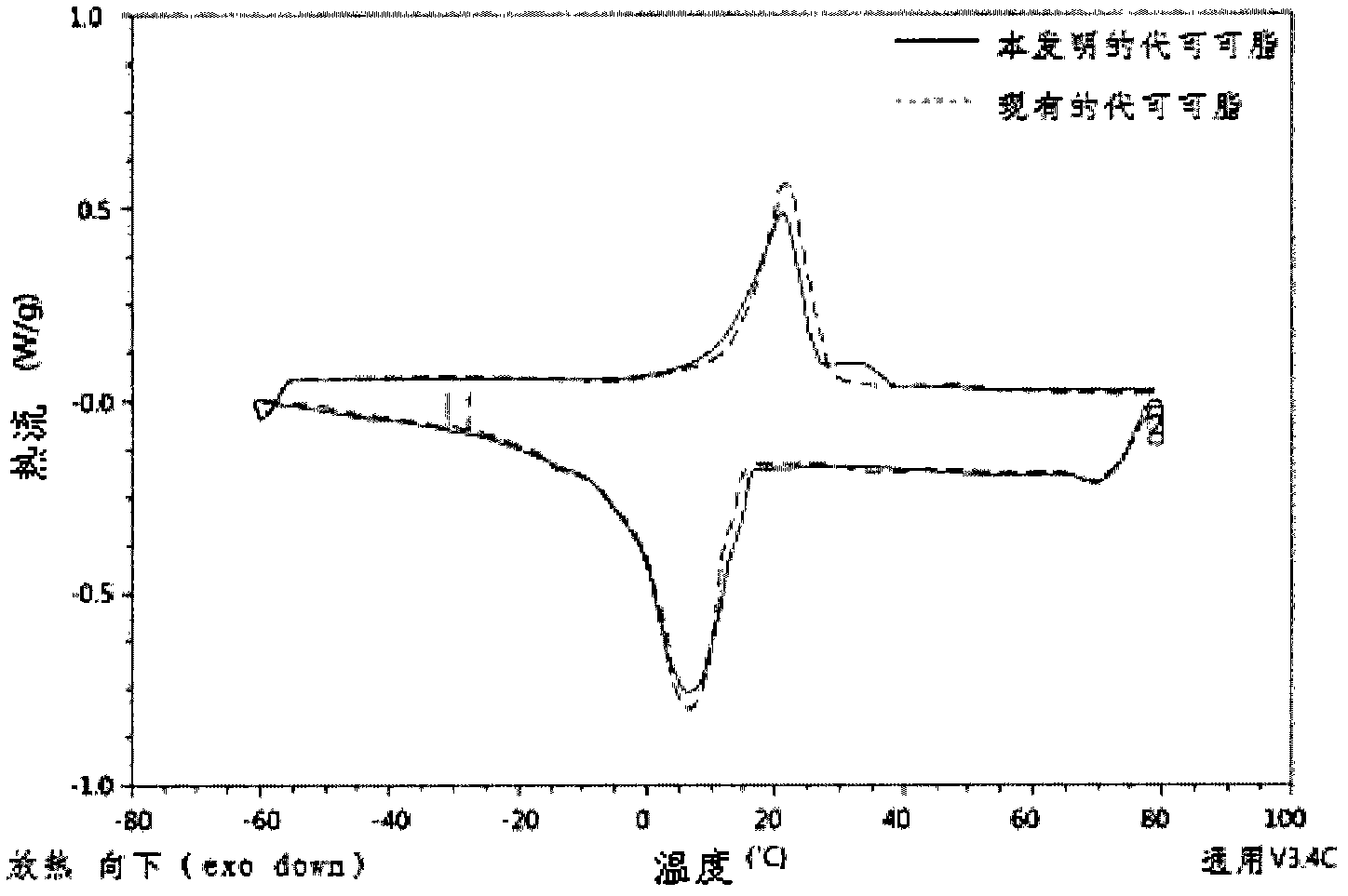

[0062]In this example, in order to determine whether the lipase TLIM enzyme selected in the above example 1 can carry out transesterification reaction, high oleic oil and stearic acid are mixed in a molar ratio of 1:2-6, and then the above Mixed oils were used for batch reactions. At this time, the reaction temperature is 45-50°C. In order to detect the degree of reaction in hexane solvent, it is divided into two types: adding solvent and not adding solvent. analyze. Melting points before and after transesterification by enzymes were measured using an automatic rising melting point measuring device, and the content of SOS triglyceride structures in fats and oils was measured using reversed-phase liquid chromatography-evaporative light scattering detectors. The melting melting point of the mixed oil before the reaction is about 25-28°C, and the melting melting po...

Embodiment 3

[0065] Example 3 Removal of Fatty Acids, Monoglycerides and Diglycerides by Distillation

[0066] In this embodiment, a molecular distillation device is used to remove unreacted fatty acid, ethyl acetate, and monoglyceride and diglyceride produced after the reaction from the reaction oil prepared by enzymatic transesterification. The reaction condition is 1×10 -3 mbar, 200°C, the amount of monoglycerides and diglycerides in the reaction oil after distillation shall not exceed 1%. And the distilled fatty acid, ethyl acetate, etc. can be reused in the enzymatic transesterification reaction through the hydrogenation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com