Fat composition

A kind of oil and fat composition, the technology of the composition, applied in the direction of edible oil/fat, food science, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

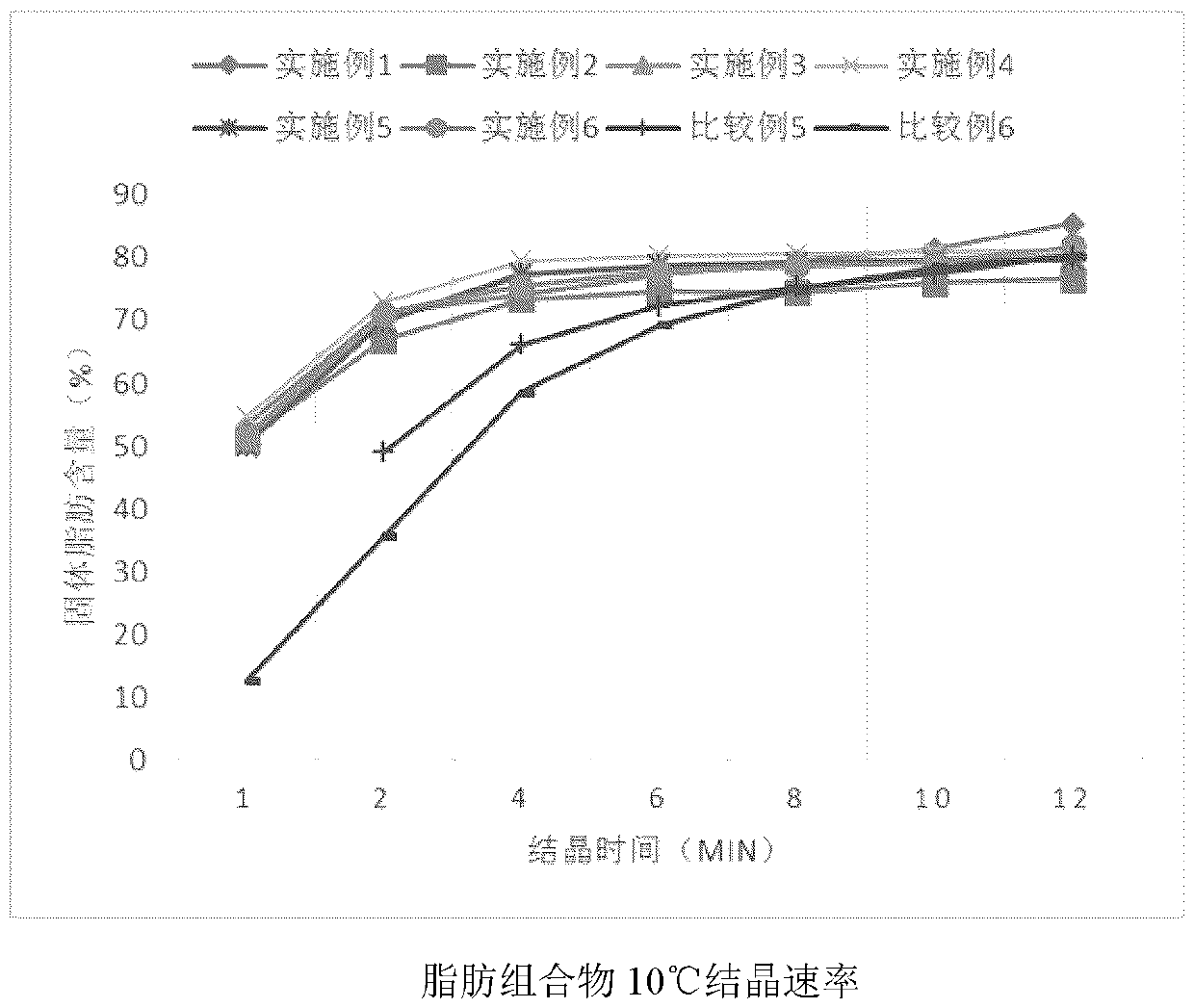

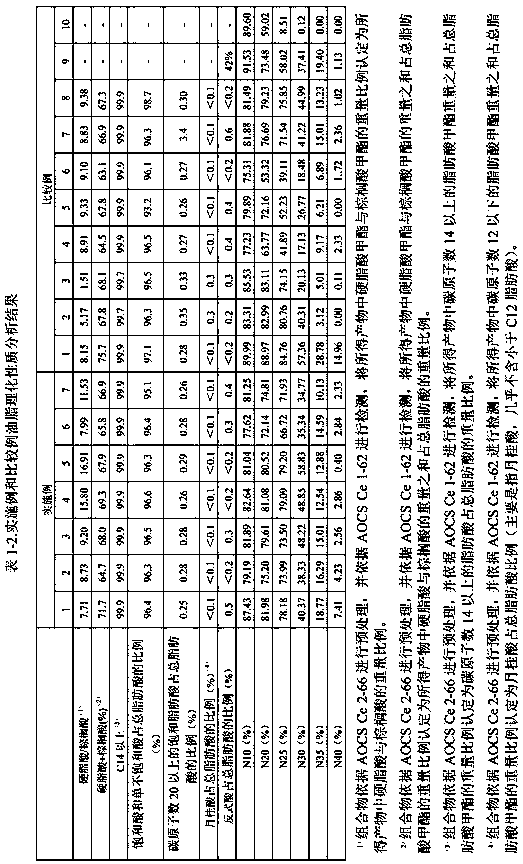

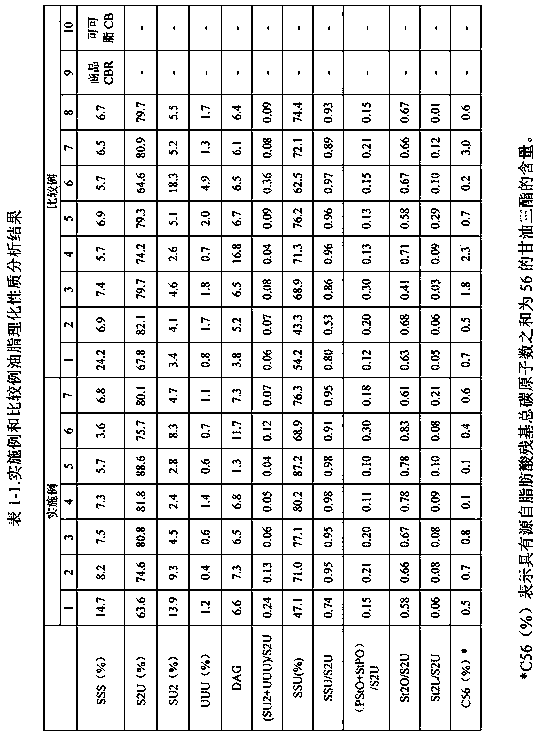

Image

Examples

preparation example Construction

[0136] Preparation method of oil composition

[0137] The grease composition of the present invention can be prepared by the preparation method of following grease composition, and described method comprises:

[0138] (1) Contacting and esterifying at least one fatty acid or its derivatives with at least one extremely hydrogenated oil; (2) Purifying the product obtained in step (1) by molecular distillation; (3) Purifying the product obtained in step (2) product.

[0139] The esterification step is chemical transesterification or enzymatic transesterification. The esterification step is carried out in the presence of immobilized lipase. The esterification step can be carried out by conventional methods.

[0140] In the enzymatic transesterification process, the lipase can be lipase D (Rhizopus oryzae) concentrate, purchased from Japan Amano Enzyme Co., Ltd.; or purchased from Novozymes’ Lipozyme RM IM or NS40086 (rice black Rhizomucor miehei, NS40086 Lot No. PKG211117-02),...

Embodiment 1

[0168] Enzymatic transesterification

[0169] 2.4kg of extremely hydrogenated soybean oil and 1.6kg of high oleic sunflower oil were heated and mixed at a mass ratio of 1.5:1 and placed in a 5L stainless steel jacketed reaction kettle, and TL enzyme (Lipozyme TL IM(Lipozyme TL IM( Aspergillus oryzae, Thermomyceslanuginosus, batch number LA331045)), react with 70°C, 80r / min at 80r / min for 3 hours, after the reaction is completed, the material liquid is collected by filtering through a 200-mesh stainless steel screen at the bottom of the reactor, while the immobilized enzyme remains in the reactor to continue For use, the crude reaction product was collected and mixed for purification.

[0170] Purification of triglycerides by molecular distillation

[0171] The crude product of the above reaction is molecularly distilled, and the distillation temperature is set at 210°C, the rotation speed is 300r / min, and the vacuum degree is 1×10 - 3 mbar, to remove substances such as fatt...

Embodiment 2

[0177] Enzymatic transesterification

[0178] 2.0kg of extremely hydrogenated soybean oil and 2.0kg of oleic acid were heated and mixed at a mass ratio of 1:1 and placed in a 5L stainless steel jacketed reaction kettle, and TL enzyme (Lipozyme TL IM (Lipozyme TL IM (Aspergillus oryzae, Thermomyces lanuginosus, batch number LA331045)), reacted with 70°C and 80r / min at 80r / min for 3 hours, and filtered the feed liquid through a 200-mesh stainless steel screen at the bottom of the reactor after the reaction, while the immobilized enzyme remained in the reactor for continued use. The crude reaction products were pooled for purification.

[0179] Purification of triglycerides by molecular distillation

[0180] The crude product of the above reaction is molecularly distilled, and the distillation temperature is set at 210°C, the rotation speed is 300r / min, and the vacuum degree is 1×10 - 3 mbar, to remove substances such as fatty acids, monoglycerides, or diglycerides.

[0181] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com