Patents

Literature

125results about How to "Realize full recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

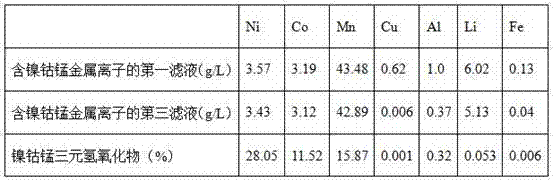

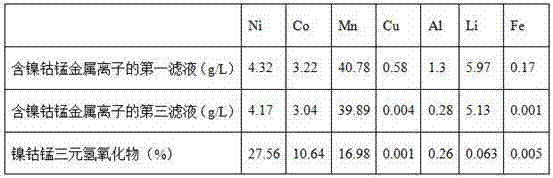

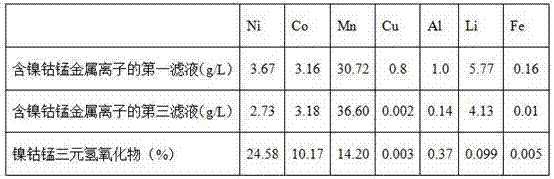

Method for preparing ternary hydroxide from nickel cobalt manganese recycled from waste lithium ion batteries through liquid phase method

ActiveCN107117661ALabor savingEasy to industrializeWaste accumulators reclaimingNickel oxides/hydroxidesManganeseSlurry

The invention discloses a method for preparing ternary hydroxide from nickel, cobalt and manganese in waste lithium ion batteries recovered by a liquid phase method, belonging to the technical field of metallurgical recovery of valuable metals, and solves the increasingly prominent problem of recycling waste lithium ion batteries. question. The invention uses waste lithium ion batteries as raw materials, and the main production steps include: dismantling and crushing, pulping, leaching, copper removal by extraction, iron and aluminum removal by precipitation, and preparation of nickel-cobalt-manganese ternary hydroxide. In the invention, the whole battery is crushed and then processed, no harmful gas is generated in the whole process of recovery and preparation, and green recovery is realized from the root. Raw material requirements, the entire production process is more convenient to operate, and the product is more pure, suitable for industrialization.

Owner:JINCHUAN GROUP LIMITED

Eco-friendly self-compacting concrete prepared through complete recycling of waste concrete

InactiveCN104788054AWorkability is goodExcellent and workability (liquiditySolid waste managementSuperplasticizerFly ash

The invention discloses eco-friendly self-compacting concrete prepared through complete recycling of waste concrete. The eco-friendly self-compacting concrete comprises components in parts by weight as follows: 100 parts of cement, 10-25 parts of fly ash, 10-25 parts of mineral powder, 20-40 parts of recycled micro-powder, 1-2 parts of a polycarboxylate superplasticizer, 230-380 parts of recycled fine aggregate, 240-400 parts of recycled coarse aggregate and 45-60 parts of water which are mixed. The coarse aggregate only adopts the recycled coarse aggregate, the fine aggregate only adopts the recycled fine aggregate, the recycled micro-powder formed by grinding waste materials produced in production of the recycled aggregate is blended into a mineral admixture, so that complete recycling of the waste concrete is realized, and the eco-friendly self-compacting concrete has a very good eco-friendly effect.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

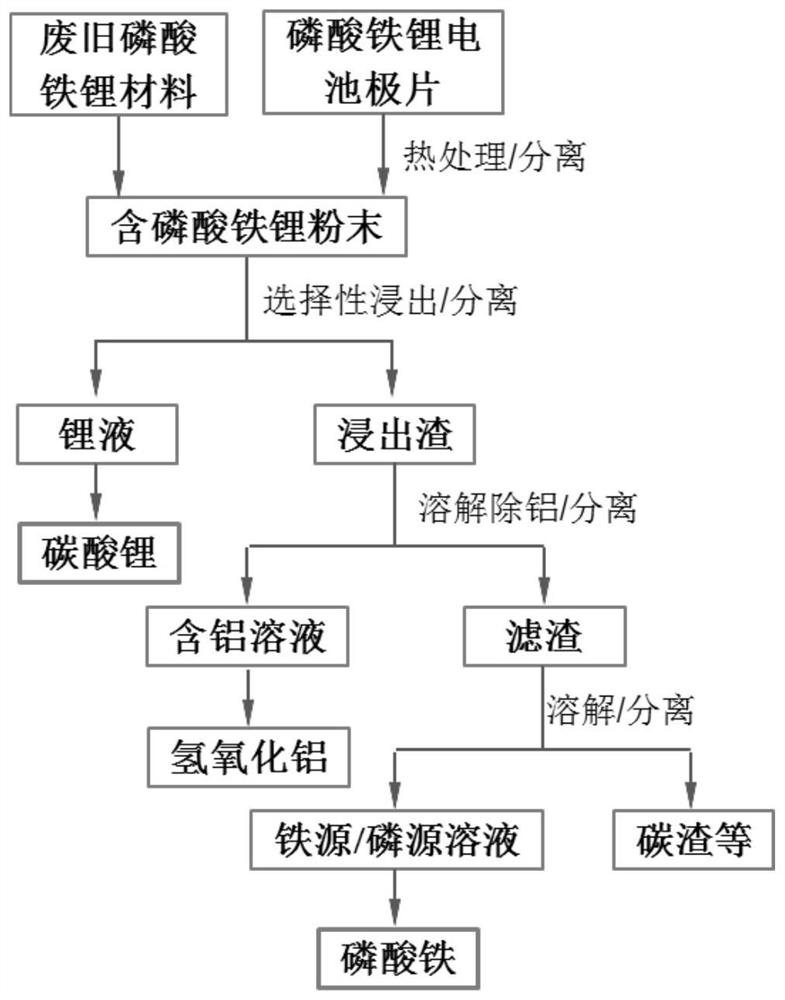

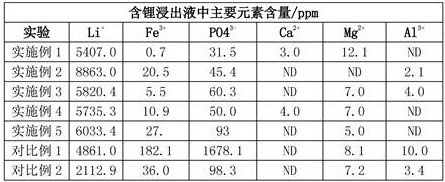

Recovery method of waste lithium iron phosphate positive electrode material

ActiveCN112441572AImprove leaching rateRealize full recyclingAluminium oxide/hydroxide preparationWaste accumulators reclaimingPregnant leach solutionO-Phosphoric Acid

The invention provides a recovery method of a waste lithium iron phosphate positive electrode material. The method comprises the following steps: S1, adding waste lithium iron phosphate powder to a leaching agent A, slowly adding a leaching agent B, adjusting the pH value to be more than or equal to 2, and carrying out solid-liquid separation to obtain a lithium-containing leaching agent and a leaching residue; S2, adding a precipitator into the lithium-containing leachate to obtain lithium carbonate; S3, adding a first alkaline solution into the leaching residues, and filtering to obtain an aluminum-containing solution and filter residues; S4, adjusting the pH value of the aluminum-containing solution to obtain an aluminum hydroxide precipitate; S5, adding the filter residue into a firstacidic solution, performing filtering, adding a second alkaline solution into the obtained filtrate, adjusting the pH value to 2.0-2.7 to obtain basic iron phosphate, and adding phosphoric acid to obtain iron phosphate. The leaching agent A comprises a mixed solution of at least one of a weak base solution or a weak acid solution and a first oxidizing agent; and the leaching agent B comprises a mixed solution of a second acidic solution and a second oxidant. By the adoption of the method, the leaching rate of lithium is high, impurities are few, the purification and wastewater treatment cost during lithium carbonate preparation is reduced, and meanwhile iron phosphate can be efficiently recycled.

Owner:BYD CO LTD +1

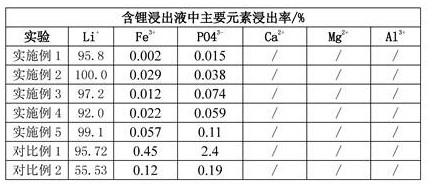

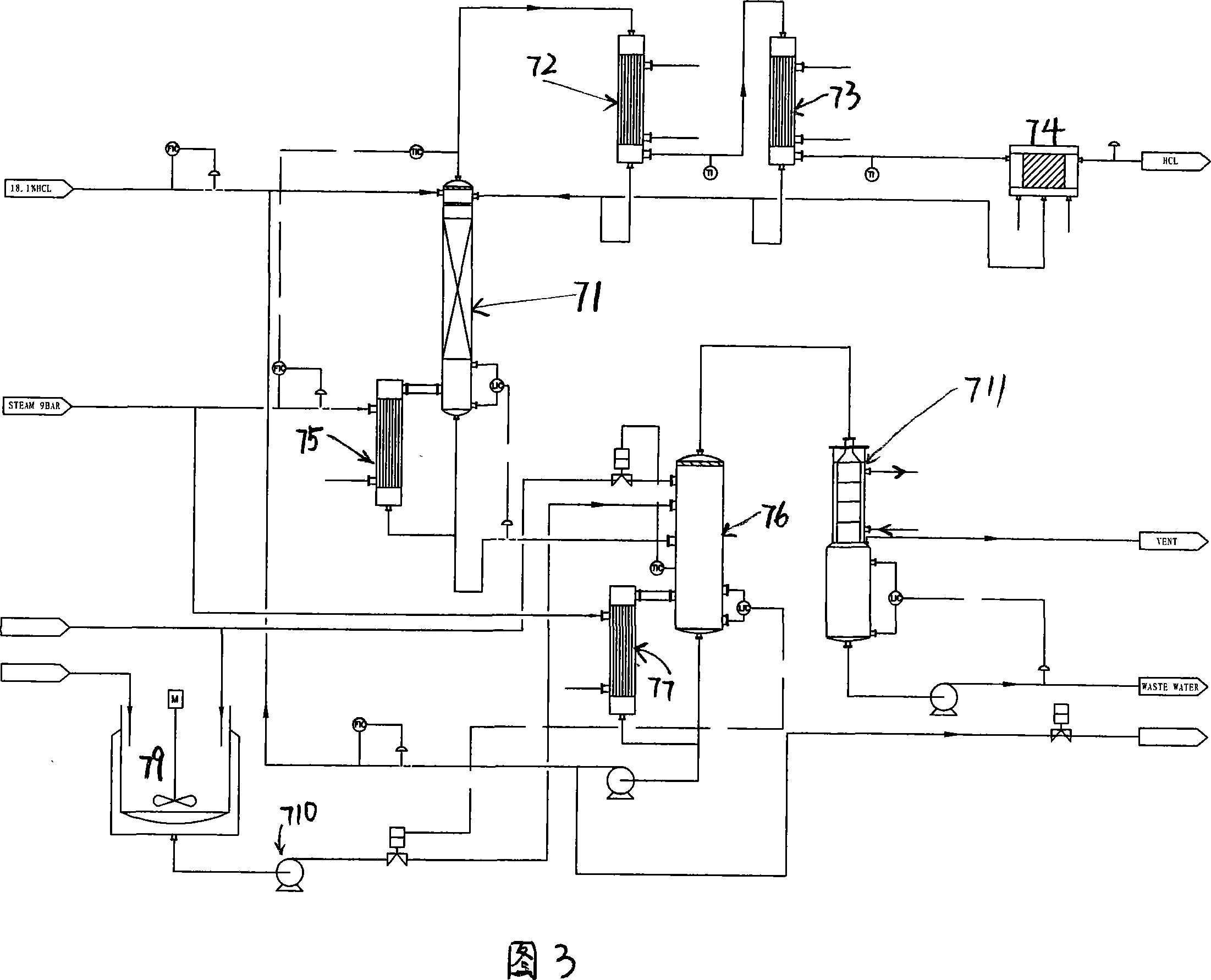

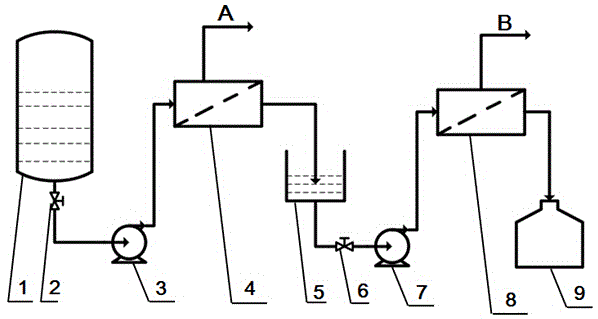

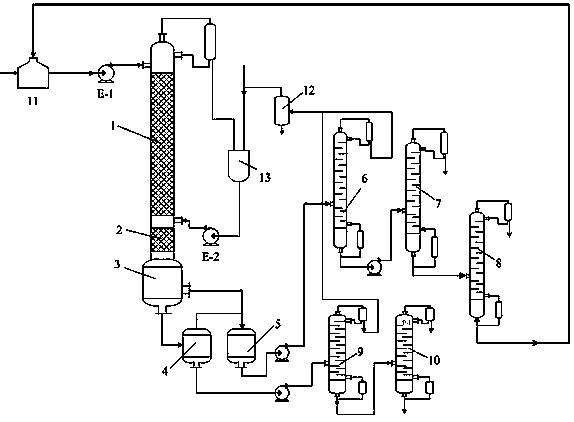

Hydrogen chloride whole reclaiming zero discharging technique and device for PVC producing process

ActiveCN101235160AReduce manufacturing costRealize full recyclingPreparation by halogen halide additionDesorptionSmall footprint

The invention discloses a hydrochloride total-recover zero-discharge method in PVC production and a relative equipment, which uses a new absorber as hydrochloride combination adsorption tower, an alcaine desorption equipment and a dilute hydrochloric acid deep desorption equipment as main equipments, uses the combination adsorption tower to absorb the over hydrochloride in the chloroethylene production and uses the alcaine desorption equipment and dilute hydrochloric acid deep desorption equipment to convert into the synthesis gas material of chloroethylene. The invention can directly convert the low-density alcaine generated in traditional method into the synthesis gas material of chloroethylene, to save production cost, avoid environment pollution and simplify hydrochloride recovery, with few equipments, small volume, thereby saving investment.

Owner:仇晓丰

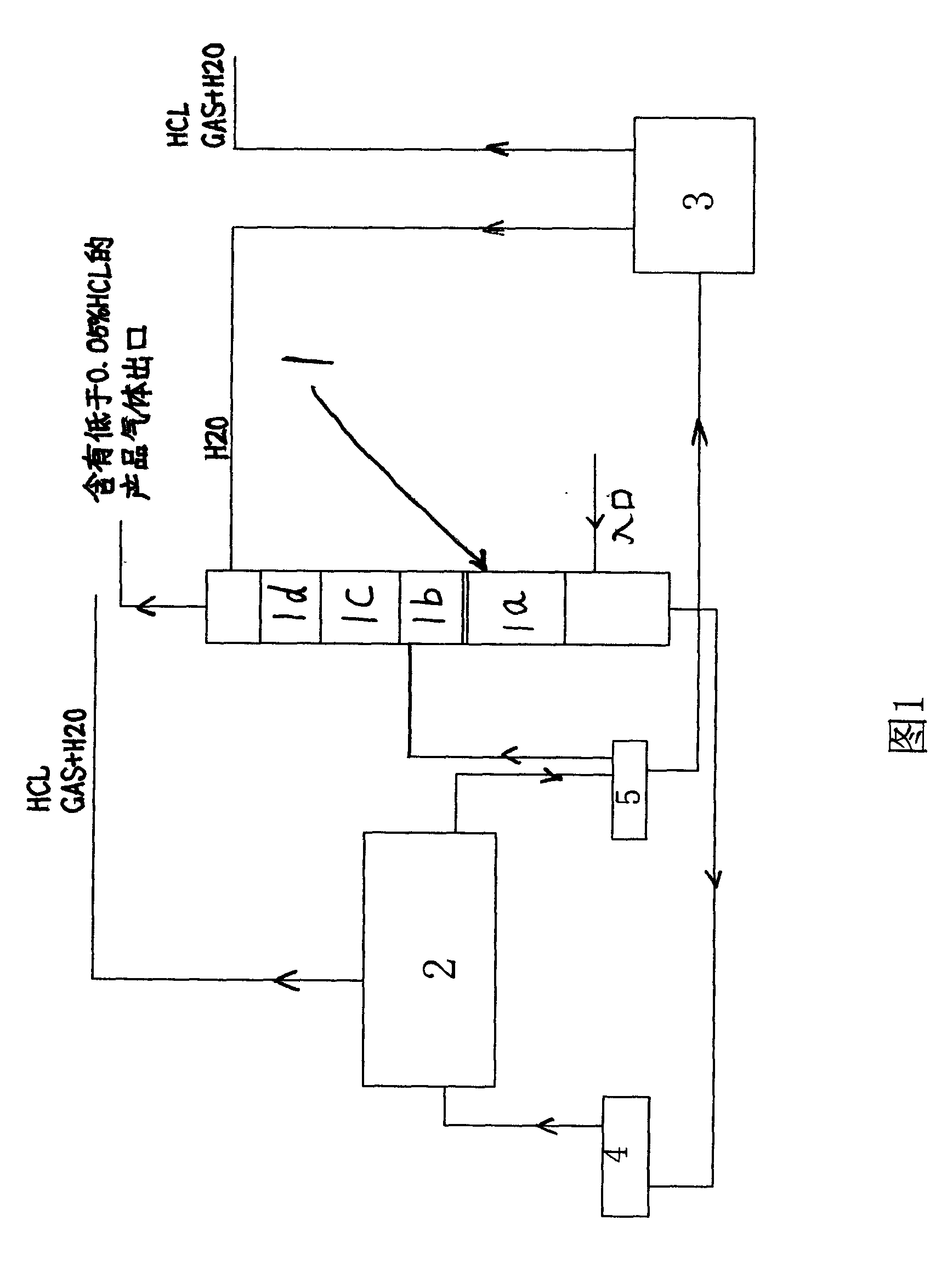

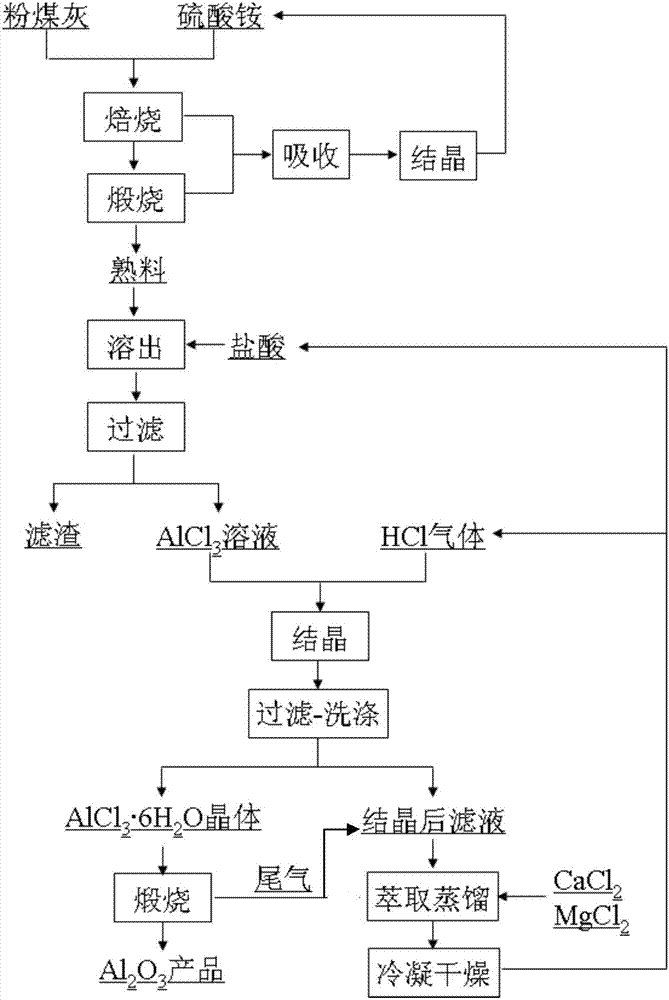

Process method for extracting aluminum oxide in coal ash of pulverized coal furnace by using acid method

InactiveCN106966415ARealize direct recyclingEasy roasting operationAluminium oxides/hydroxidesExtractive distillationBiological activation

The invention relates to a process method for extracting aluminum oxide in coal ash of a pulverized coal furnace by using an acid method. The process method comprises the following steps; adding ammonium sulfate into the coal ash of the pulverized coal furnace for activating, and performing the high-temperature calcination to obtain activated coal ash clinker, adding hydrochloric acid, heating and dissolving out, to obtain aluminum chloride digesting liquor; pumping hydrogen chloride gas into the digesting liquor for crystallizing, performing the solid-liquid separation and washing to obtain high-purity aluminum chloride hexahydrate crystal and waste acid solution, calcining the crystal to generate metallurgy-level aluminum oxide; adding inorganic salt chloride, such as calcium chloride or magnesium chloride, into the waste acid, heating, extractive-distilling and recycling the hydrochloric acid and the hydrogen chloride gas for the dissolving out and crystallization working procedures, performing the absorption-crystallization to tail gas generated in the roasting-calcining activation to generate ammonium sulfate, and realizing the cyclic utilization of materials, wherein the obtained solid residue with abundant silicon dioxide can be used for generating white carbon black or the materials for building. The process method is capable of realizing the reduced recycling of the coal ash of the pulverized coal furnace, and realizing the full cyclic utilization of the materials. The purity of the obtained aluminum oxide product is the first level, the quality of the metallurgy-level aluminum oxide is standard, and the extraction efficiency is up to 84.6%-90.4%.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

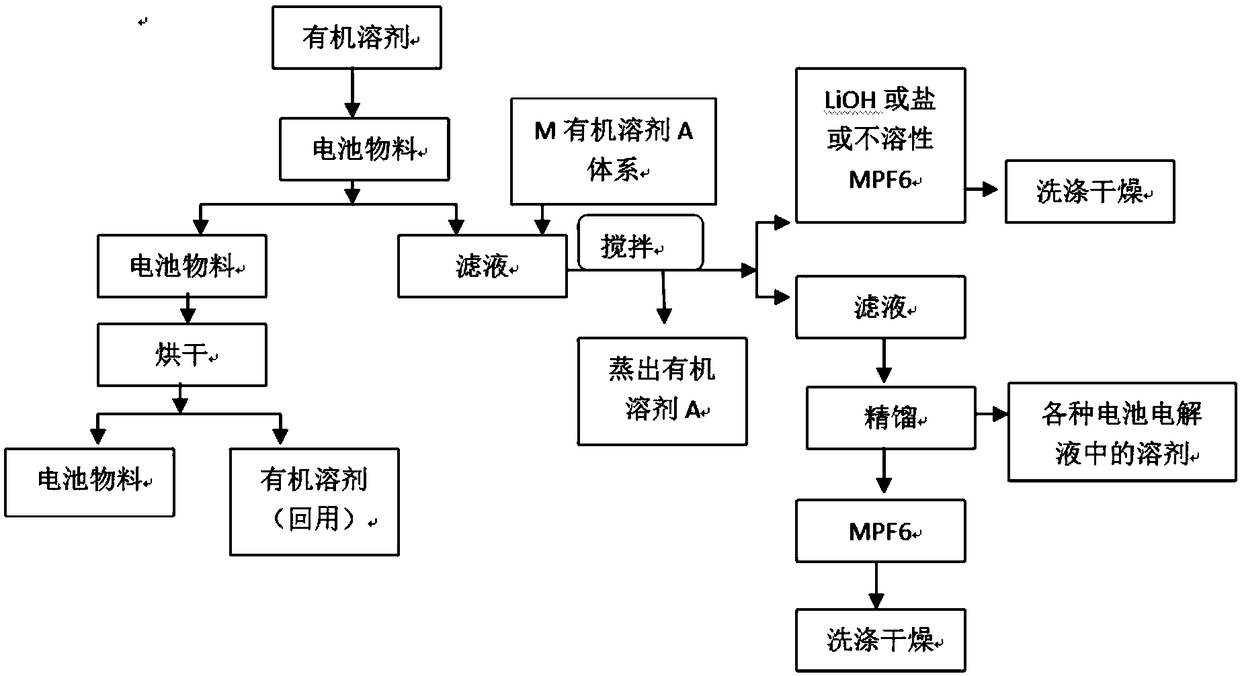

A method for recycle that electrolyte of waste battery

ActiveCN109193062AAchieve recyclingRealize full recyclingWaste accumulators reclaimingBattery recyclingSolventPotassium ions

A method for recover and utilizing waste power battery electrolyte includes leaching crushed battery material with organic leaching solvent, filter after leaching to obtain clarified leaching solutionand filter residue, recovering electrolyte from crushed battery material with organic leaching solvent, recovering electrolyte from crushed battery material with organic leaching solvent, recoveringelectrolyte from crushed battery material with organic leaching solvent. Dropping an organic solvent A solution of a potassium ion compound or a metal ion compound into the leaching solution until thereaction is completed to obtain a reaction mixture; Separating an organic solvent A in the reaction mixture, and filtering to obtain a filtrate and crystals of lithium hydroxide or lithium salt; Separating the organic solvent from the filtrate to obtain potassium hexafluorophosphate or other hexafluorophosphate crystals. The invention fully considers the composition of the electrolyte and the physico-chemical characteristics of the electrolyte lithium hexafluorophosphate, by introducing the solvent leaching-lithium hexafluorophosphate conversion-rectification separation technology and the like, the recycling of electrolyte in waste batteries is realized. The technical process can realize the full recovery of electrolyte without any discharge and has the advantages of environmental protection and high efficiency.

Owner:山西根复科技有限公司

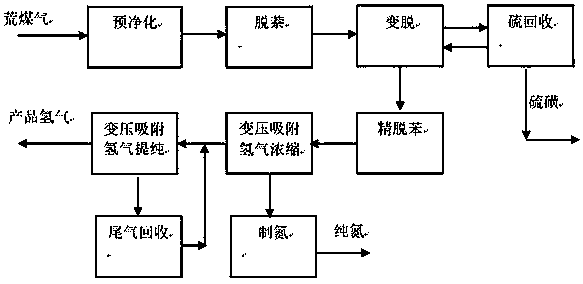

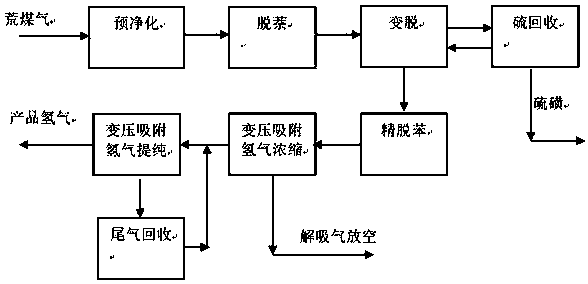

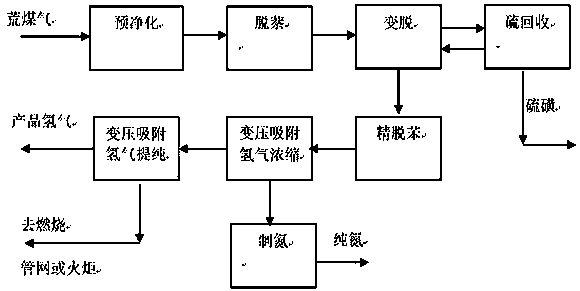

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

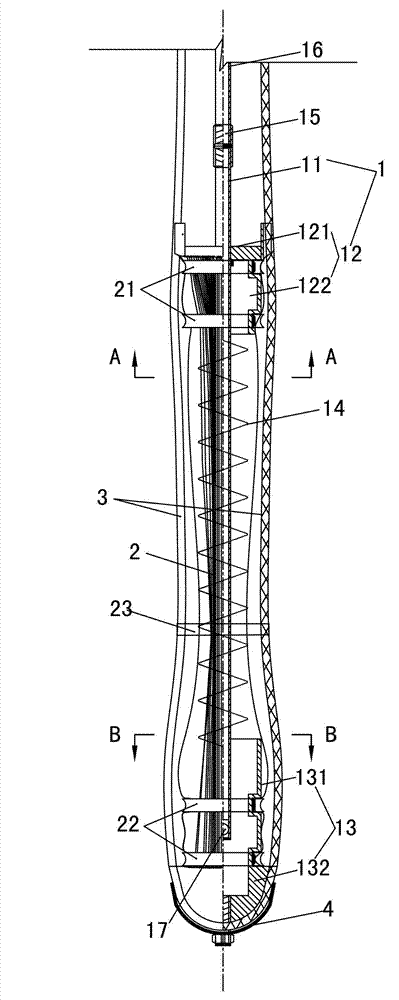

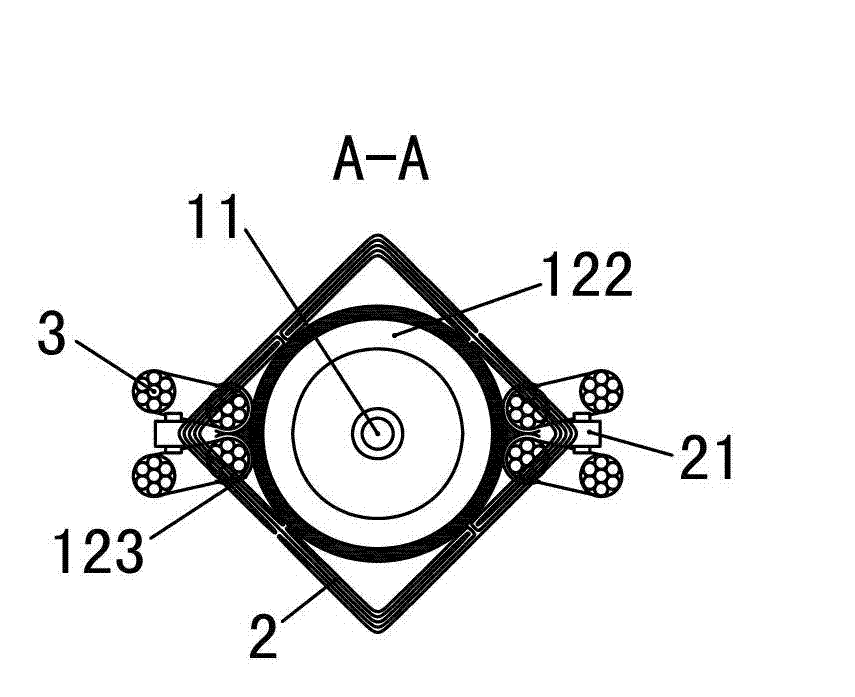

Fully-recycled body expanding anchor rod and construction method for anchoring ground using same

ActiveCN102733385AReduce underground pollutionImprove bearing capacityExcavationsBulkheads/pilesPollutionArchitectural engineering

The invention provides a fully-recycled body expanding anchor rod and a construction method for anchoring ground using the same. The fully-recycled body expanding anchor rod comprises a main machine rack, a sealed cladding bag and a non-adhesive steel strand, wherein the main machine rack comprises a grouting core pipe, an upper assembly, a lower assembly and a spiral stirrup; the top of the grouting core pipe is connected with a grouting recycled pipe, and the bottom of the grouting core pipe is provided with a one-way valve; the sealed cladding bag is sleeved outside the grouting core pipe and the spiral stirrup of the main machine rack; the both ends of the sealed cladding bag are respectively fixed on the upper assembly and the lower assembly; the non-adhesive steel strand is wounded outside the sealed cladding bag; the both ends of the non-adhesive steel strand extend outside the grouting core pipe; the middle part of the non-adhesive steel strand is adhered to the bottom of the lower assembly; and the positions of the non-adhesive steel strand, which are close to the upper assembly, are slidably connected with the both sides of the outer wall of the upper assembly. With the adoption of the fully-recycled body expanding anchor rod and the construction method thereof, the grouting recycled pipe and steel wires in the non-adhesive steel strand of an anchor beam body can be entirely recycled and reused, so that the construction cost is reduced, and the pollution of the underground soil can be reduced. Thus, the fully-recycled body expanding anchor rod and the construction method are beneficial to energy conversation and emission reduction.

Owner:CHINA JINGYE ENG +1

Stainless steel pickling waste water resource recycling method

ActiveCN105060599AReduce dosageImprove recycling efficiencyWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodEvaporation

The invention discloses a stainless steel pickling waste water resource recycling method. The method includes the steps of firstly, conducting reduced pressure evaporation on mixed acid of hydrofluoric acid and nitric acid so that acid recycling can be achieved; secondly, separating out and recycling iron in the solution; thirdly, gathering diluted acid, nickel and chromium in a circulating mode; fourthly, recycling diluted acid through a film method; fifthly, conducting neutralization and iron recycling; sixthly, separating nickel and chromium and recycling nickel; seventhly recycling chromium. By means of the method, efficient recycling of valuable metal resources such as nitric acid, hydrofluoric acid, iron, chromium and nickel is achieved, purified water can stably reach the standard, and the method is remarkable in economic benefit.

Owner:CENT SOUTH UNIV

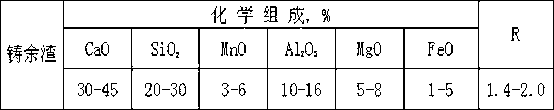

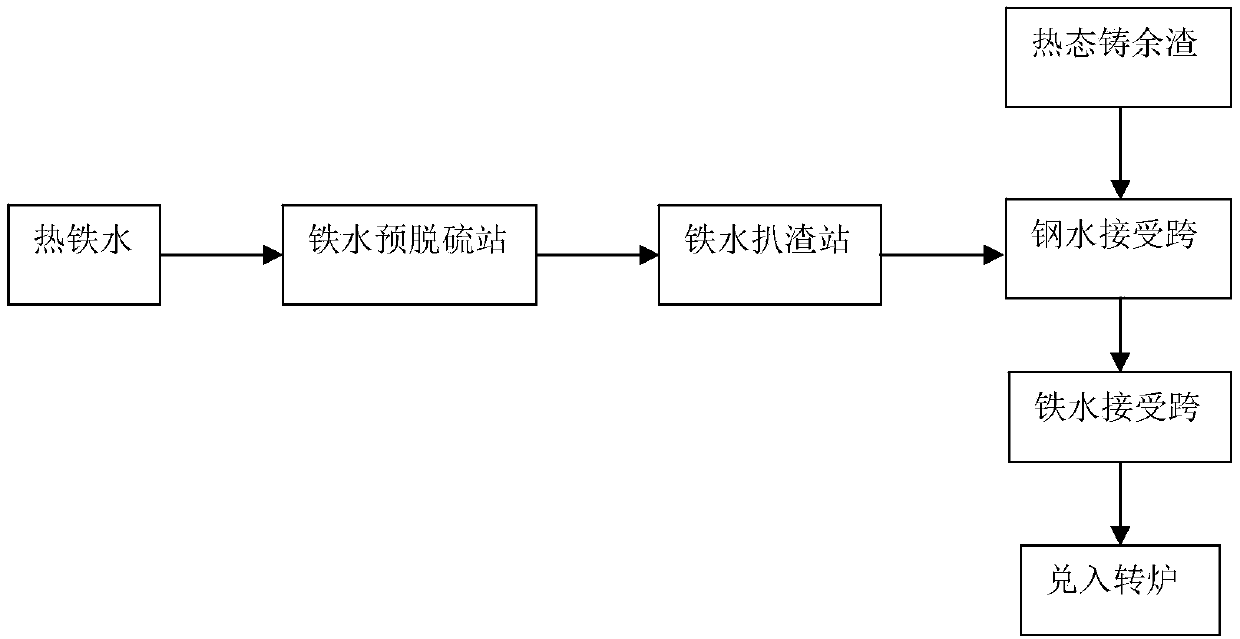

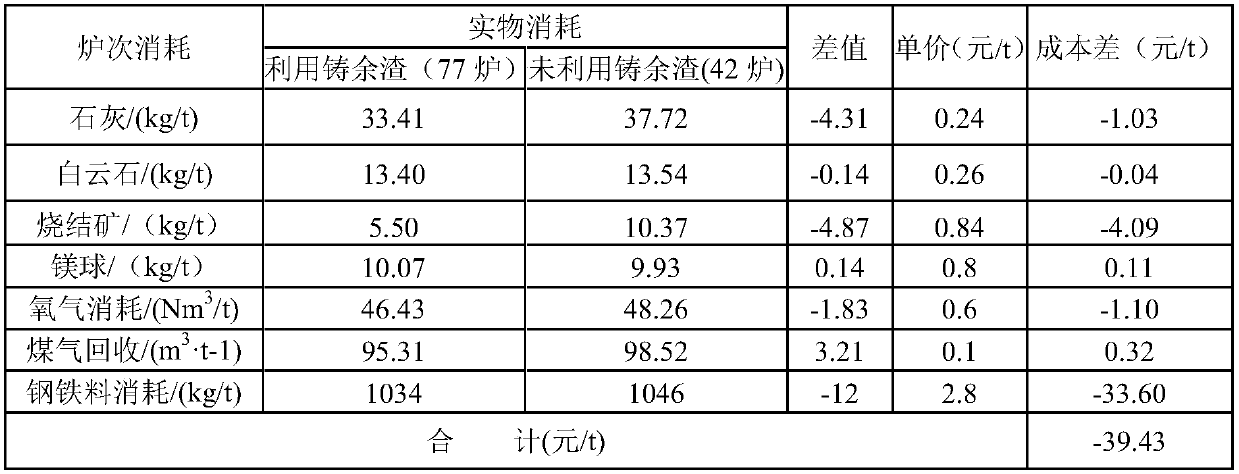

Method for heat application of low-alkalinity casting residue in steel-making

ActiveCN102994689ALow production costRealize full recyclingManufacturing convertersProcess efficiency improvementSteelmakingAlkalinity

The invention provides a method for heat application of low-alkalinity casting residue in steel-making. The method comprises the following steps that: 5 to 7kg / t of low-alkalinity casting reside of steel slag is added to a converter along with semi-steel under a hot steel state in order to fully utilize the heat of the molten casting residue, and the slag can be quickly generated by blowing for 2 minutes. By adopting the method, the complex slag forming constituent and heating agent requested in a conventional semi-steel smelting process are saved, and the production cost is reduced; the high-alkalinity slag can be quickly formed at low temperature in accordance with the slag formation system; the content of phosphorus of 0.35 to 0.80% in the molten ion can be quickly removed within the normal smelting period, and the final requirement of steel grade can be met; all casting residues in steel making are basically recycled, so that the pressure of residue discharge to the environment and the handling cost can be reduced, and remarkable environment protection benefit is brought. The method brings no change to original requirement, is high in dephosphorization efficiency, and little in influence on the converter melting furnace and the capacity, can expand the steel-making capacity, is high in storage capacity and low in cost, and can be used for expanding the application of phosphorite, and reducing the production cost.

Owner:WUKUN STEEL

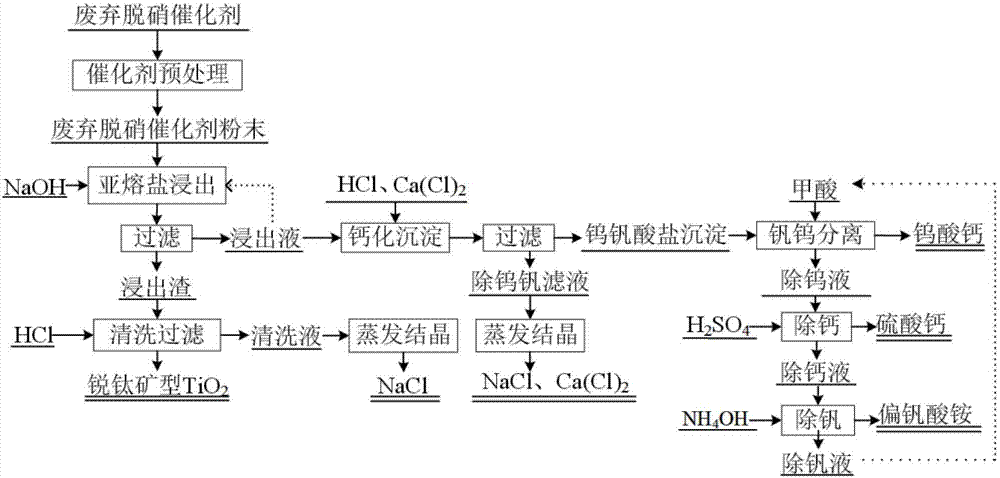

Sub-molten salt method for totally recycling vanadium, tungsten and titanium from waste denitration catalyst

ActiveCN106884090ARealize full recyclingAvoid pollutionProcess efficiency improvementResource utilizationCalcification

The invention belongs to the field of solid waste resource utilization, and relates to a sub-molten salt method for totally recycling vanadium, tungsten and titanium from a waste denitration catalyst. The sub-molten salt method mainly comprises the processes of pretreatment, sub-molten salt leaching, titanium dioxide recycling, lixivium cyclic utilization, calcification sedimentation, vanadium and tungsten separation, calcium removing, vanadium removing and the like. Compared with the prior art, a sub-molten salt treatment process is adopted, reaction energy consumption can be effectively reduced, green recycling and zero exhaust gas emission can be achieved, and the recycling economic value can be increased; and meanwhile, the recycling treatment process is simpler and easier to operate, waste residues and waste liquid in the process are fully recycled, economic input is reduced, and secondary pollution is prevented from being generated to the environment.

Owner:BEIJING UNIV OF TECH

Method for fully recycling yellow water in white spirit production process

ActiveCN104312881AImprove recycling efficiencyEfficient separationBy-product recoveryAlcoholic beverage preparationAlcoholEnergy consumption

The invention discloses a method for fully recycling yellow water in a white spirit production process. The method comprises the following steps: firstly, separating yellow water in a raw material tank by virtue of a porous separating membrane system; feeding yellow water clean liquor permeating a porous separating membrane into a pervaporation membrane for further separation; enriching most alcohol, aldehyde and ester matters through the pervaporation membrane on the other side of the membrane in the form of gas state; recovering the matters which are condensed by using a condenser of a pervaporation membrane system to a product storage tank for blending white spirit; increasing fragrant component and the like in original spirit; and further recovering intercepted porous separating membrane permeating liquor and pervaporation membrane permeating liquor. The method disclosed by the invention has the remarkable characteristic that the yellow water recovery efficiency is improved by virtue of two membrane separating and integrating methods including the porous separating membrane and the pervaporation membrane, so that the effective matters of the yellow water are utilized to a maximum extent, thereby thoroughly solving the outlet problem of the yellow water. In addition, the method further has the advantages of being simple in equipment and low in separating energy consumption and has strong practicality.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

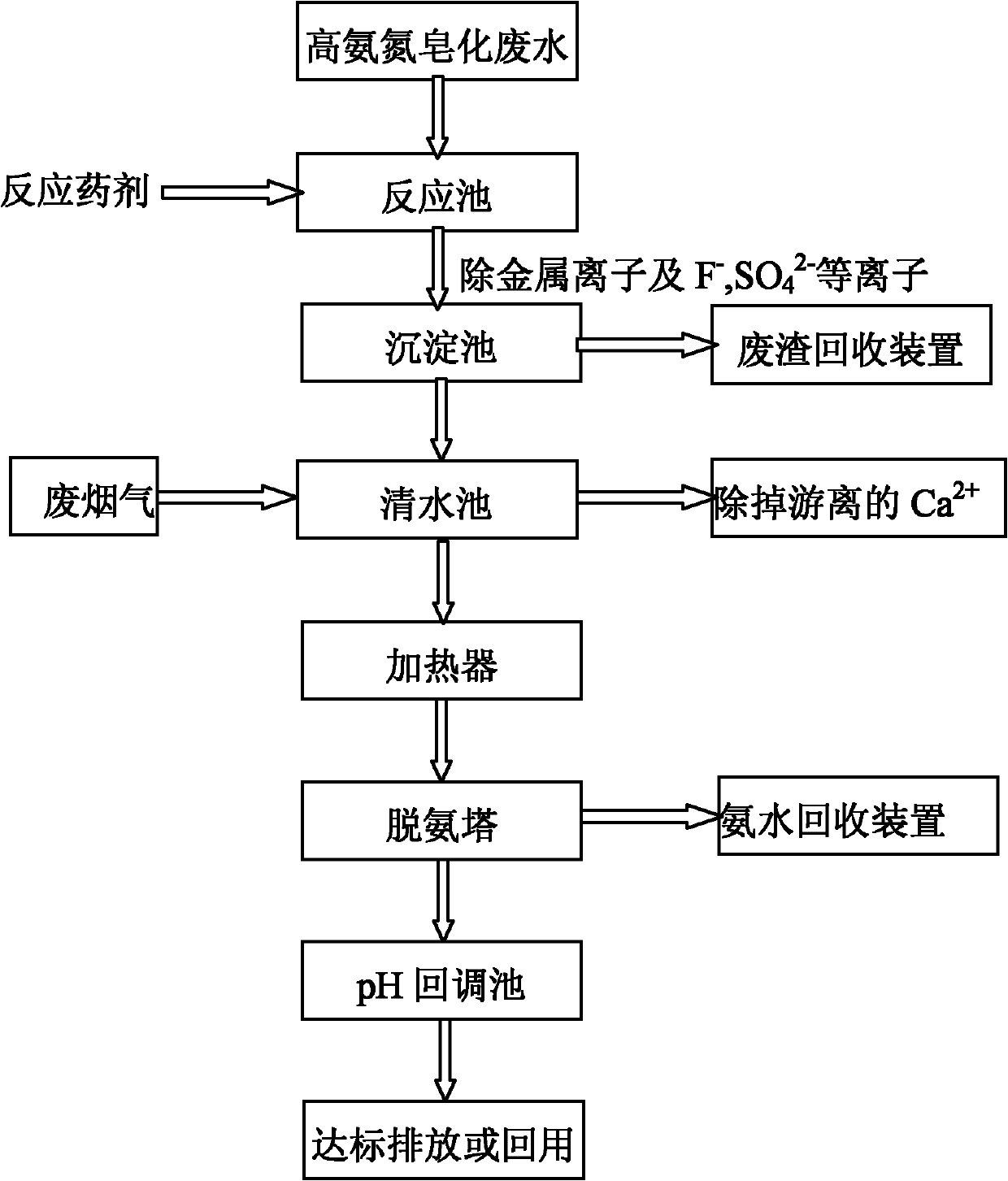

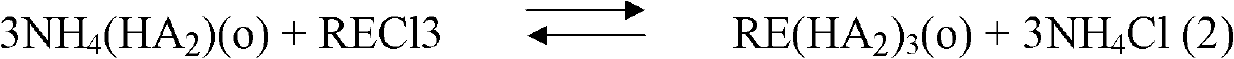

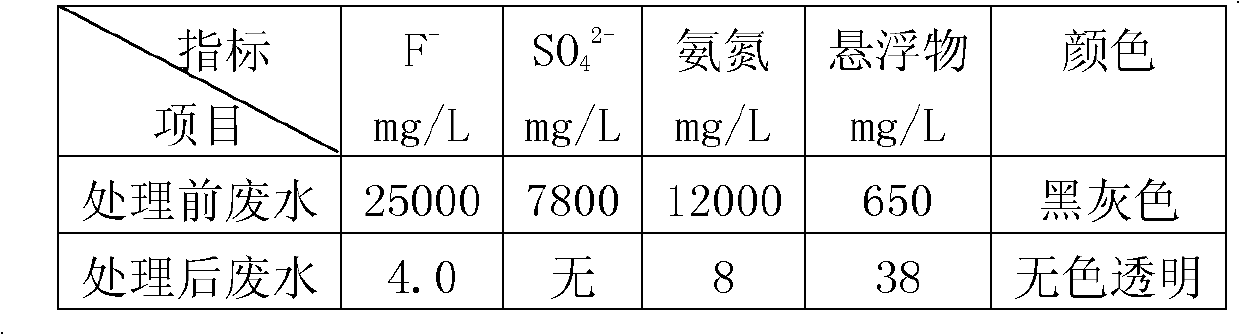

Deep treatment technology of high-ammonia nitrogen rare earth wet process-smelted saponifying wastewater

ActiveCN102167467ASolve processing problemsEliminate scaling problemsProductsReagentsRare earthTower

The invention discloses a deep treatment technology of high-ammonia nitrogen rare earth wet process-smelted saponifying wastewater. The technology is characterized by comprising the steps of: adding a reaction medicament into rare earth wet process-smelted extract liquor saponifying wastewater for reacting; precipitating after the reacting; separating out solid waste residue; feeding CO2-containing waste gas into clean water; leading the Ca2+ content in the wastewater to be less than 0.01mol / L; filtering; adjusting the PH value of the wastewater to be 10.5-11.0, and heating to be 55-65DEG C; feeding the adjusted wastewater into a deaminizing tower for performing negative pressure ammonia stilling type deamination; and adjusting the PH value of the wastewater to be 6-9 after the deaminizing. By matching the unslaked lime, the waste gas with the negative pressure stilled ammonia, the method can be used for removing not only various metal plasmas in the rare earth wet process-smelted extract liquor saponifying wastewater, such as F1<-> and SO4<2-> and the like, but also ignored calcium ions, so that the scaling problem of follow-up equipment is avoided, and the waste gas generated by a boiler is further treated.

Owner:JIANGSU HUASHAN ENVIRONMENTAL PROTECTION TECH

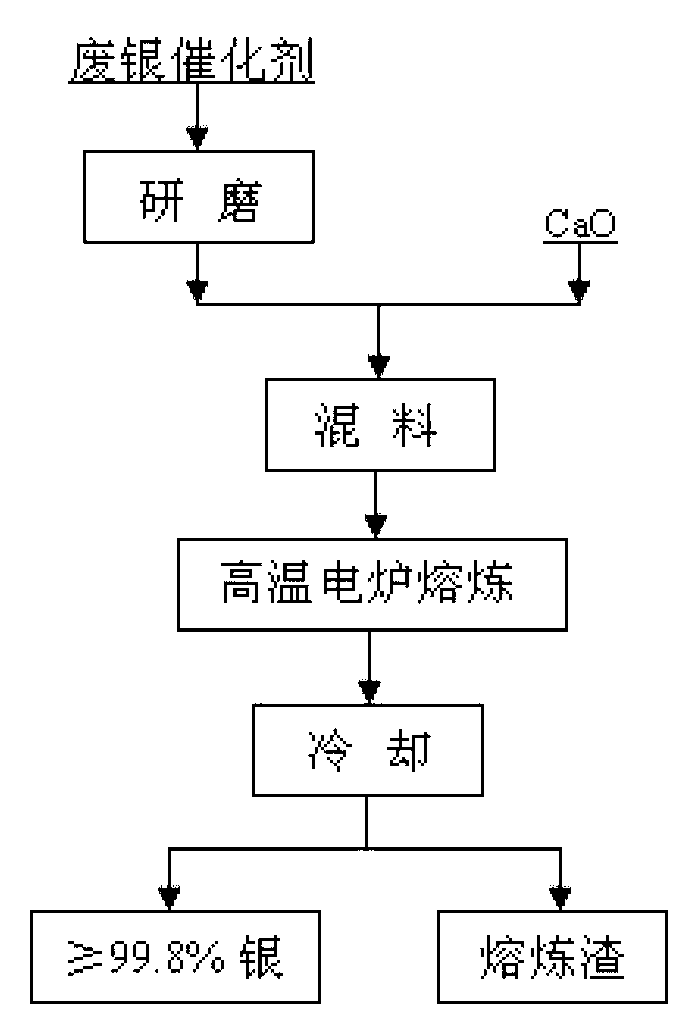

Method for recovering silver from waste silver catalyst

ActiveCN103276216ALow melting pointReduce operating proceduresProcess efficiency improvementSlagSilver catalyst

The invention discloses a method for recovering silver from a waste silver catalyst. The method is technically characterized in that CaO is added in the ground waste silver catalyst, and smelting is performed in a high-temperature electric resistance furnace to form a CaO-Al2O3 binary slag system. Silver is a good trapping agent, so that the trapping agent is not required to be added to introduce other impurities, and silver with higher purity is obtained. The method comprises the steps as follows: (1), material grinding: the waste silver catalyst is ground to 40-200 meshes; (2), material mixing: the ground waste silver catalyst powder is completely mixed with a slag forming agent CaO in a specific ratio; (3), smelting: a uniformly mixed material is placed in a graphite crucible and smelted in the high-temperature electric resistance furnace, the temperature ranges from 1,450 DEG C to 1,700 DEG C, and the time is 5-8 hours; and (4), cooling: the smelted material is naturally cooled, specific gravity of silver is larger, so that silver is deposited at the bottom of the crucible, and a slag phase and a metal phase are separated to obtain pure silver. The method disclosed by the invention can effectively shorten operation procedures and reduce production cost, and is more environment-friendly.

Owner:GUIYAN RESOURCE YIMEN

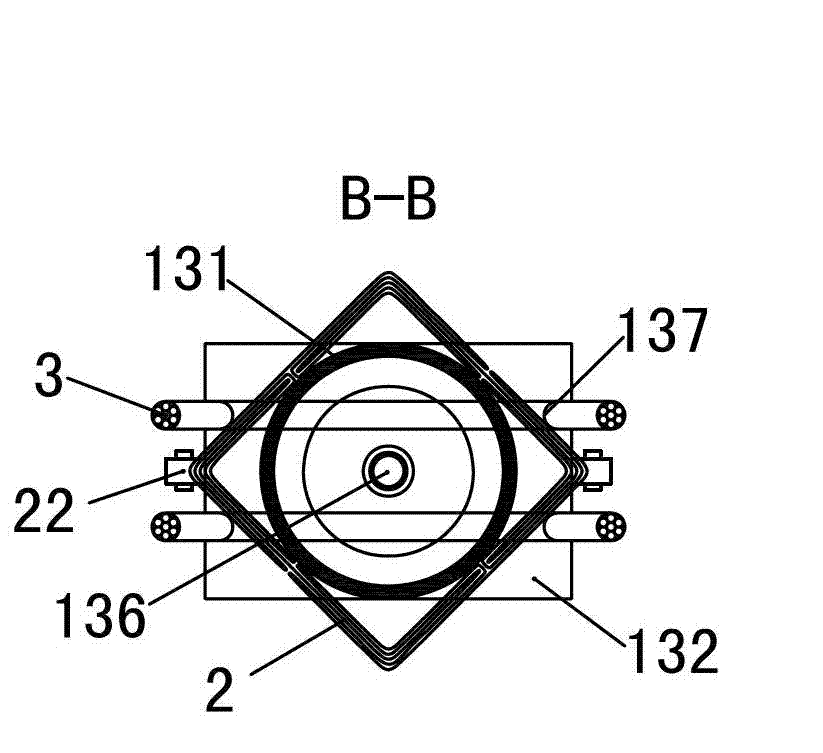

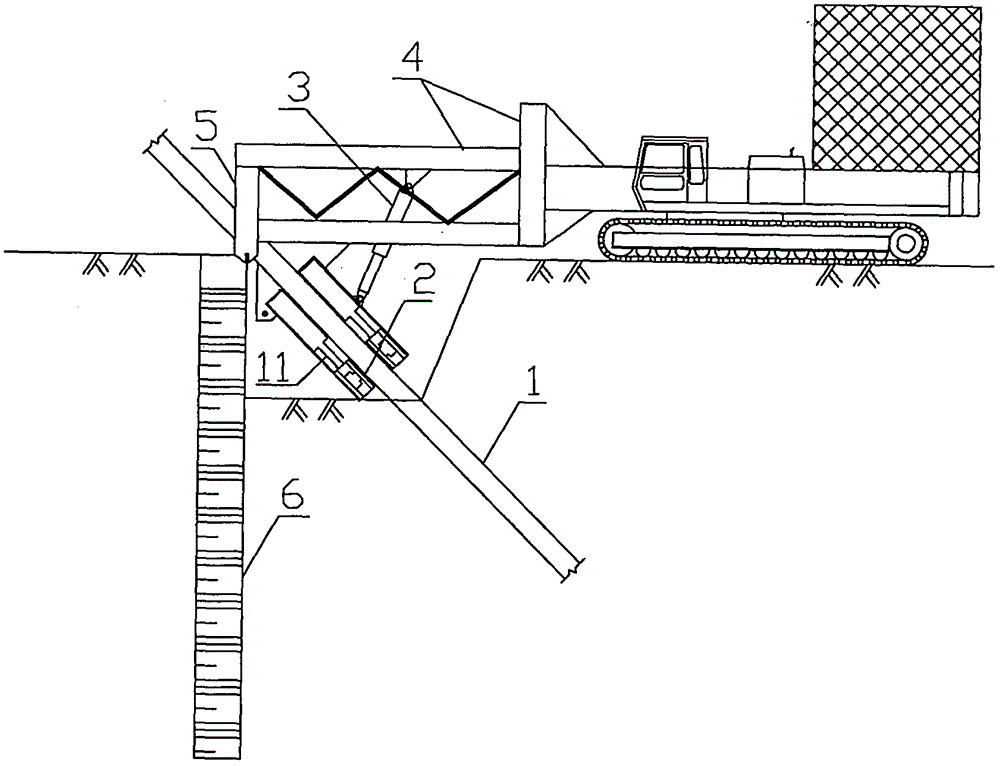

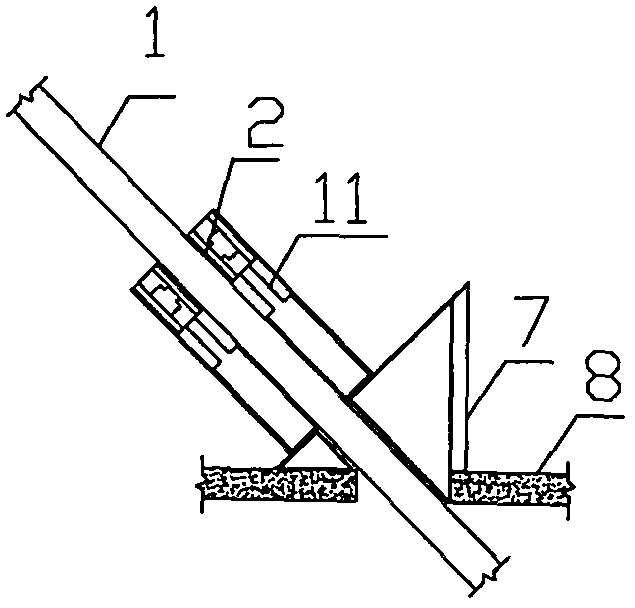

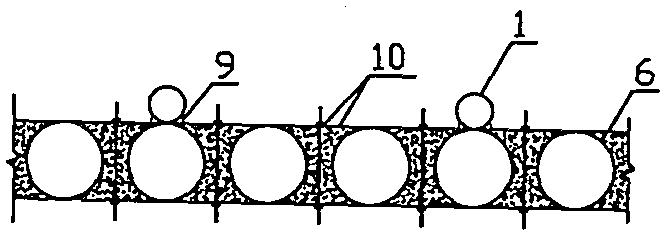

Inclined pile construction device and inclined pile foundation pit supporting construction method

InactiveCN106759345ARealize plug-in constructionRealize full recyclingExcavationsBulkheads/pilesEngineeringCounterforce

The invention relates to an inclined pile construction device and a construction method, and belongs to the field of foundation pit support projects. The inclined pile construction device comprises a pile sinking device and a pile pulling device. The pile sinking device comprises a guard pile connector (5), a mechanical base (4), a sleeve clamp (2), a power device (11) and an inclined pile angle adjusting device (3). The pile pulling device comprises the sleeve clamp (2), the power device (11) and a counter-force base (7). The pile sinking device provides pile sinking counterforce through ground and a guard pile constructed firstly, and the pile pulling device provides pile pulling counterforce through a foundation base board. The invention further provides an insertion and extraction construction step and method of an inclined pile (1). According to the inclined pile construction device and the construction method, the problem of insertion and extraction construction of the inclined pile (1) in the foundation fit support projects is well solved, the construction efficiency is high, the manufacturing cost is low, quality is reliable, and application of prestress can be finished while construction is conducted.

Owner:张继红

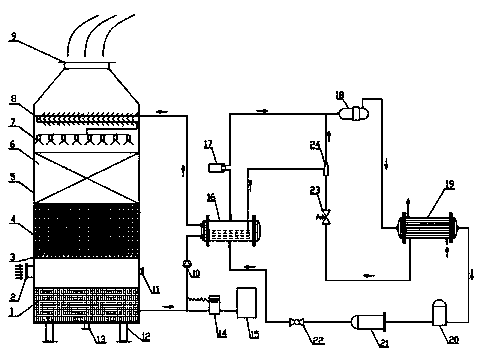

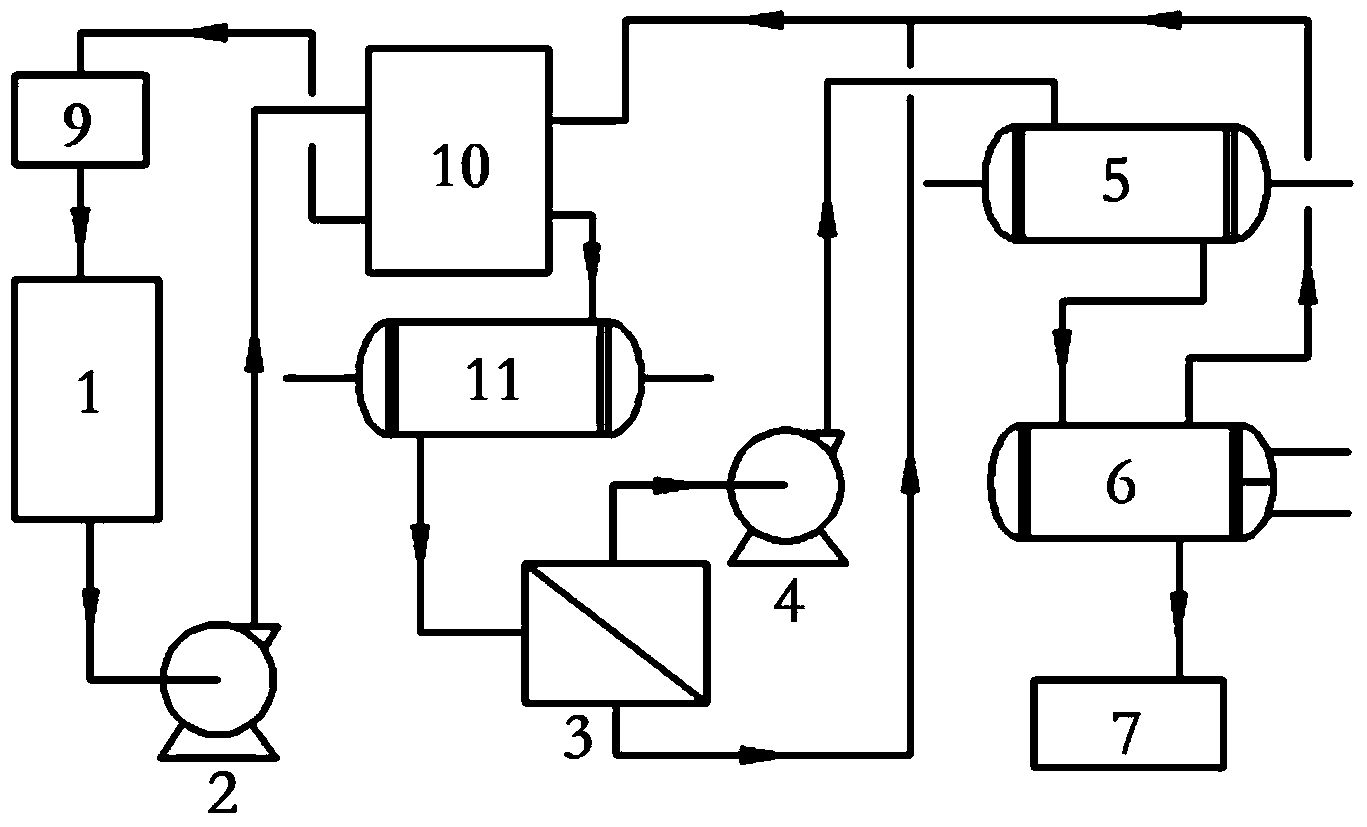

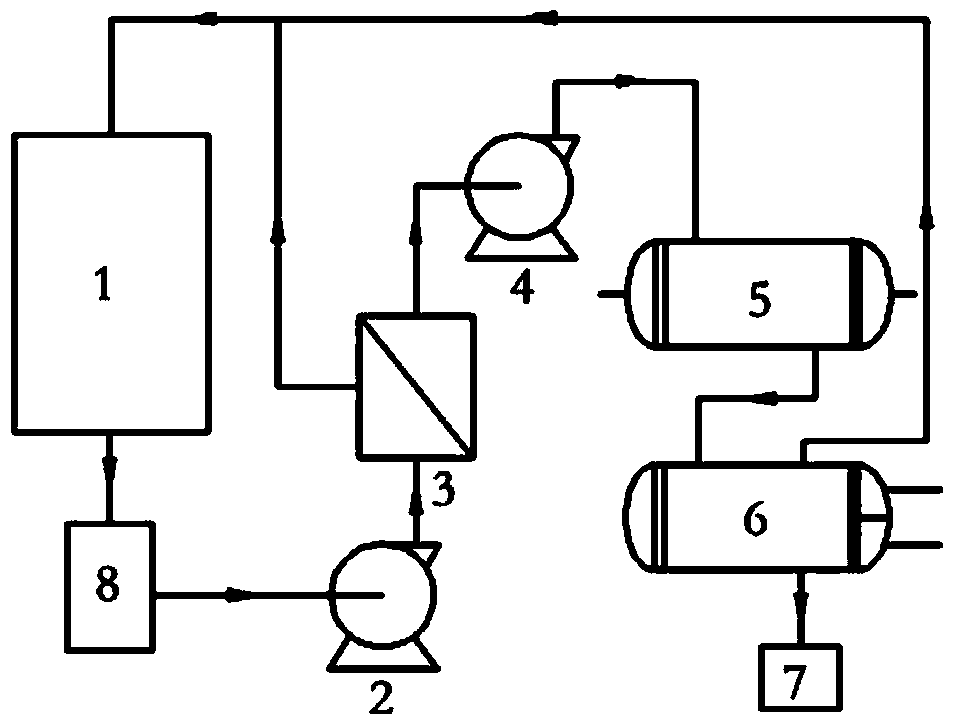

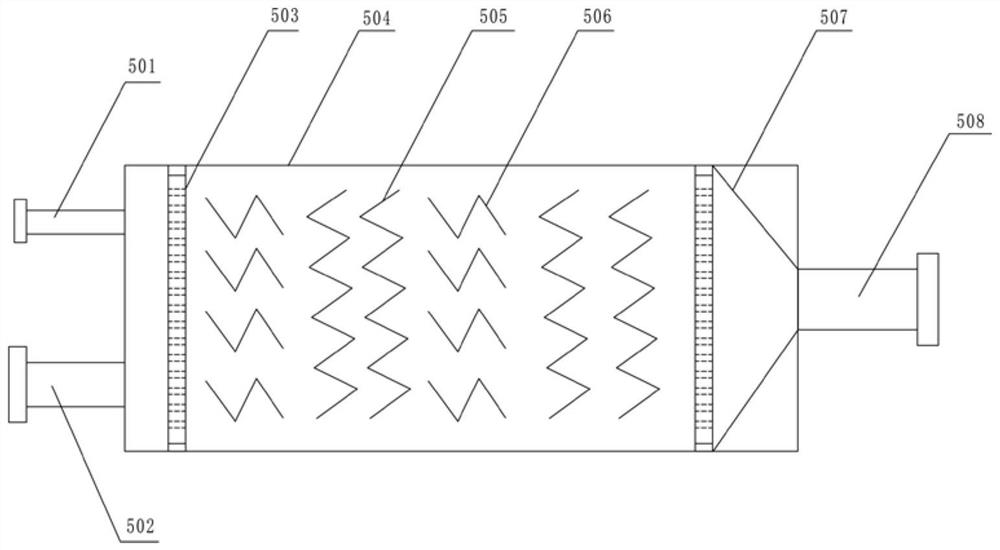

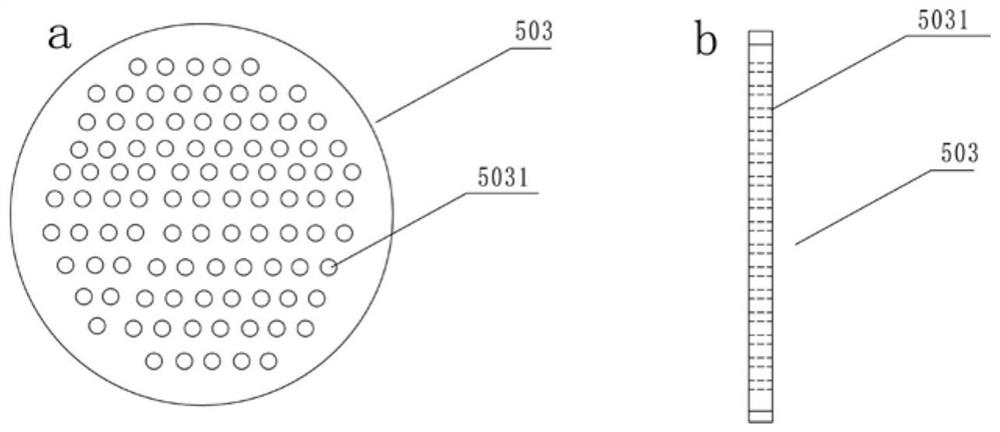

Heat pump system with smoke waste heat full-recovery function and method for preparing high-temperature hot water

InactiveCN104279794ALow flow resistanceIncrease heat exchange spaceFluid heatersHeat pumpsWater source heat pumpWater source

The invention discloses a heat pump system with a smoke waste heat full-recovery function and a method for preparing high-temperature hot water. The heat pump system comprises a waste heat recovery device and a water source heat pump device. The waste heat recovery device comprises a spraying type waste heat recoverer, a circulating water pump and a circulating water pipeline. The water source heat pump device comprises a flooded evaporator and a petal pore plate type condenser. The circulating water pipeline of the waste heat recovery device is connected with the flooded evaporator of the water source heat pump device to enable the waste heat recovery device and the water source heat pump device to form the heat pump system. An automatic monitoring and controlling system is applied to operation of the heat pump system. The method for preparing the high-temperature hot water includes fully recovering sensible heat and latent heat of smoke by the spraying type waste heat recoverer, transmitting the recovered heat to the flooded evaporator through the circulating water pipeline, increasing the grade of the recovered heat by the water source heat pump device, and transmitting the high-grade heat to tap water by the petal pore plate type condenser to produce the high-temperature hot water. The heat pump system can fully recover smoke waste heat, and has a smoke purification function.

Owner:ZHENGZHOU UNIV +1

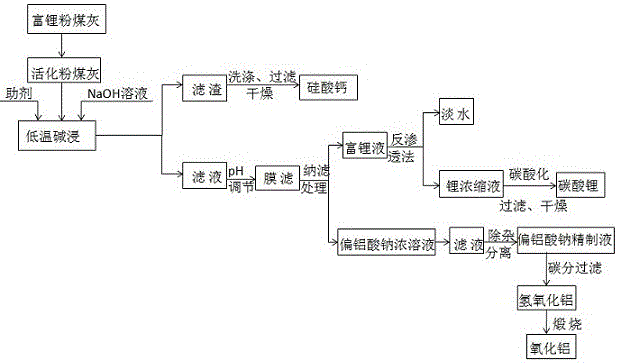

Method for separating and enriching lithium, aluminum and silicon from fly ash

ActiveCN106745016AEasy to recycleImprove leaching rateAlkaline-earth metal silicatesLithium carbonates/bicarbonatesCalcium silicateReverse osmosis

The invention discloses a method for separating and enriching lithium, aluminum and silicon from fly ash. The method comprises the following steps: (1) pretreating fly ash; (2) carrying out low-temperature alkali dip reaction on the treated fly ash, aids and a sodium hydroxide solution, and filtering; (3) washing the filter residue, removing the impurities, filtering, and drying to obtain calcium silicate; (4) regulating the pH value of the filtrate to alkalinity, separating the lithium / aluminum-containing filtrate to obtain a sodium metaaluminate concentrated solution and a lithium-rich solution, carrying out reverse osmosis on the lithium-rich solution to obtain a lithium concentrated solution, and mixing the sodium metaaluminate concentrated solution with the lithium / aluminum-containing filtrate to obtain a refined solution; (5) precipitating the sodium metaaluminate refined solution, filtering to obtain aluminum hydroxide, and calcining to obtain the aluminum oxide finished product; (6) treating the lithium-rich solution to obtain a lithium-rich concentrated solution and fresh water; and (7) carrying out carbonating precipitation on the lithium-rich concentrated solution, filtering, and drying to obtain the lithium carbonate finished product. The method is a short-stage extraction process, reduces the lithium loss, and implements separation, enrichment and extraction of calcium silicate, aluminum oxide and lithium carbonate.

Owner:HEBEI UNIV OF ENG

Production device and method of biodiesel

ActiveCN104031747AEfficient responseImprove conversion rateFatty acid esterificationBiofuelsProcess engineeringMethanol

The invention discloses a production device and method of biodiesel and belongs to the technical field of preparation of biodiesel. The production device comprises a tower-kettle integrated device, a rectifying tower, a flash tower and a separation tower. The production method comprises the following steps: carrying out a countercurrent contact reaction on grease which flows downward through a catalyst reaction layer and gas phase methanol; recovering unreacted methanol; introducing reaction products through a temperature raising layer to a layering kettle to further separate polar products and coarse oil products; and rectifying or separating and purifying to obtain multifunctional biodiesel. According to the production device and method disclosed by the invention, solid-liquid-gas phase catalytic reactions are carried out in the catalytic reaction layer of a reaction tower, so that the reactants and the catalyst fully contact for efficient reaction, and the conversion ratio is increased by 10-25% than that in the prior art. The production device is reasonable in design, high in product purity and complete in cyclic utilization and suitable for market promotion and has a very good application prospect.

Owner:TAIYUAN UNIV OF TECH

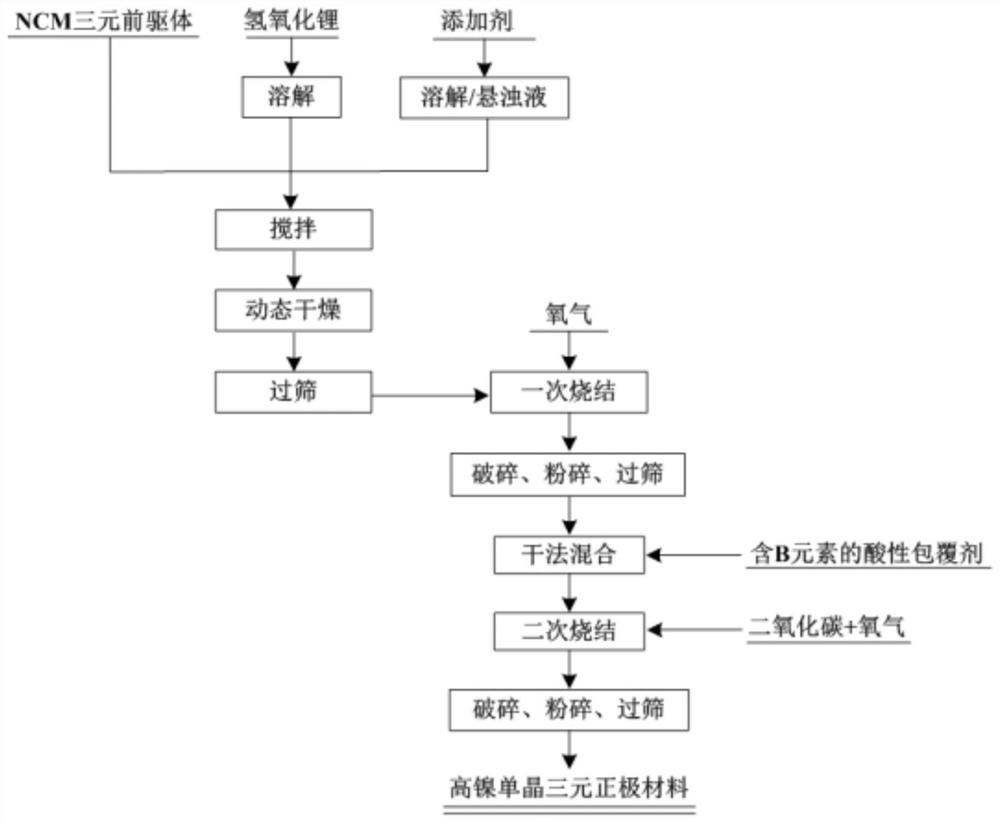

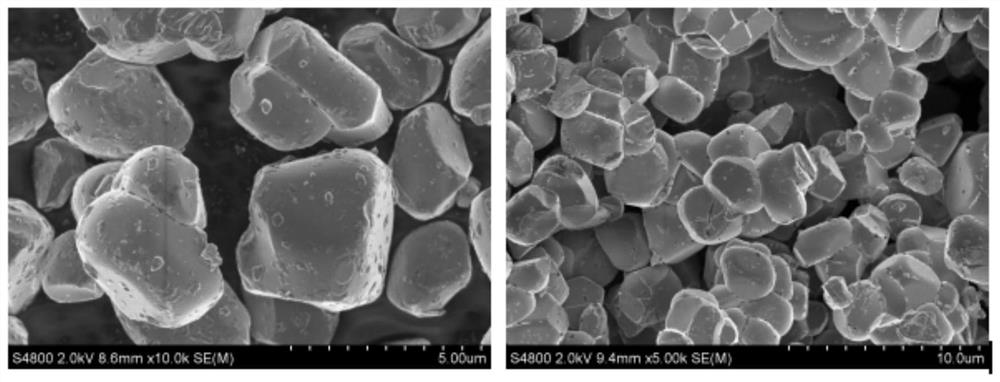

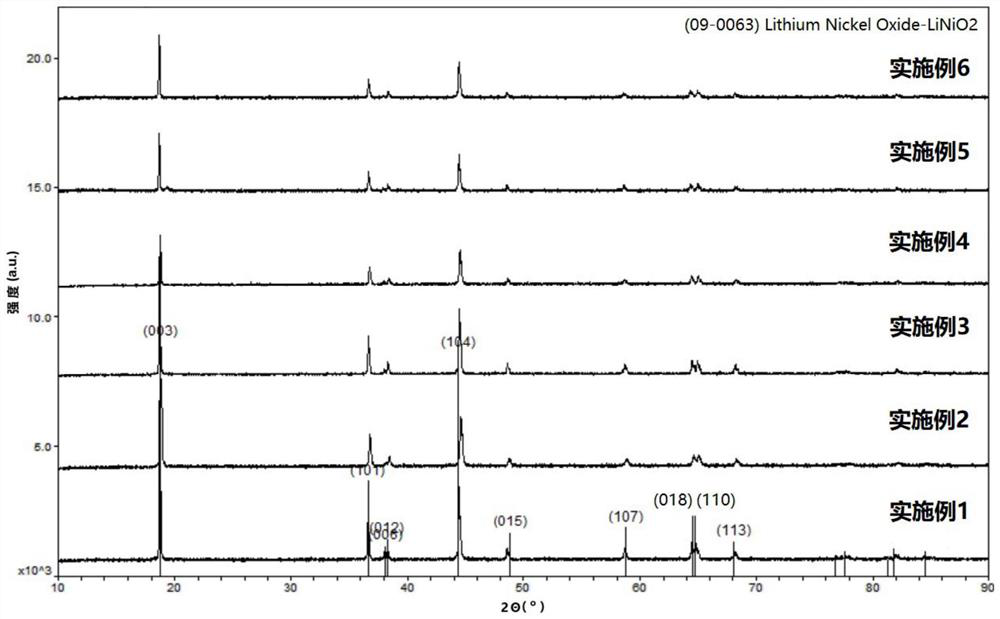

Preparation method and application of no-clean high-nickel single-crystal lithium nickel cobalt manganate positive electrode material

InactiveCN111916724ARealize full recyclingAchieve hybridCell electrodesSecondary cellsLithium hydroxideNew energy

The invention relates to the technical field of lithium ion power batteries for new energy vehicles, in particular to a preparation method of a nickel cobalt lithium manganate positive electrode material of a high-nickel single crystal lithium ion battery. The preparation method comprises the following steps: (1) dissolving lithium hydroxide and an additive in deionized water, adding a granular and spherical NCM ternary precursor after the lithium hydroxide and the additive are completely dissolved, and performing stirring; (2) dynamically evaporating the slurry stirred in the step (1) to dryness, and performing sieving to obtain a powder material with better dispersity; (3) carrying out primary sintering under an oxygen-enriched atmosphere condition, and carrying out jaw crushing, rolleraligning, air flow crushing and sieving on the sintered material to obtain a single crystal primary sintering base material; (4) mixing the single crystal primary sintering base material with an acidic coating agent containing an element B, sintering again under the condition of a composite atmosphere of carbon dioxide and oxygen, and then carrying out jet milling and sieving to obtain the product.

Owner:浙江格派钴业新材料有限公司

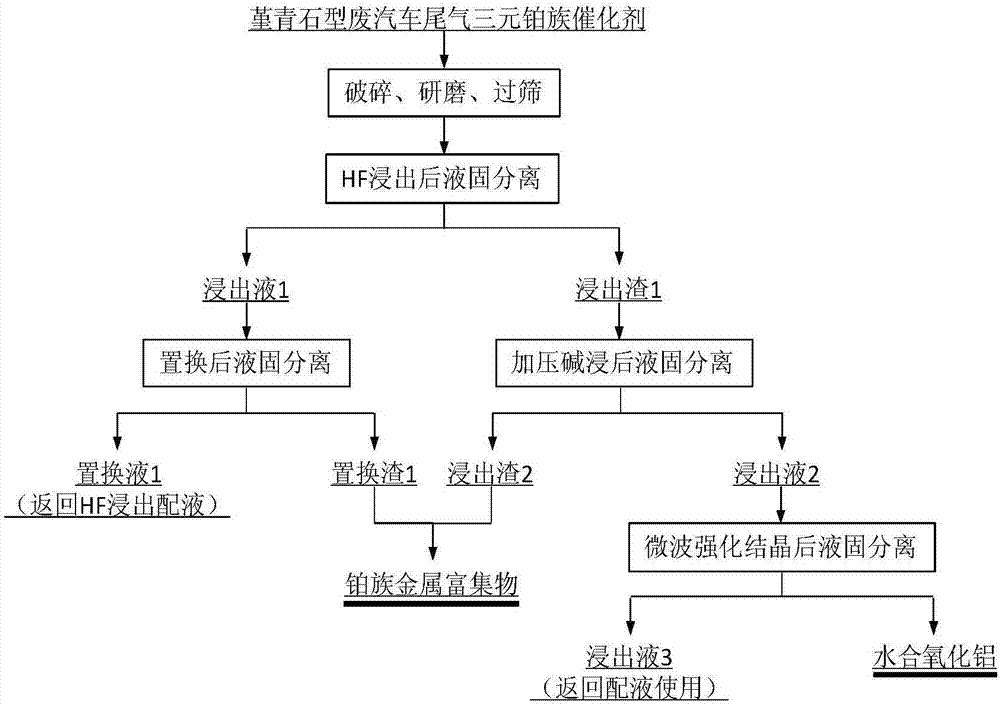

Rough extraction method for cordierite type waste automobile tail gas three-way catalyst

ActiveCN107287438AReduce enrichment rateSpeed up decompositionProcess efficiency improvementAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHydrated aluminaMicrowave

The invention discloses a rough extraction method for a cordierite type waste automobile tail gas three-way catalyst. According to the method, under the specific condition of a proper amount of HF liquid, the SiO2-Al2O3 bond in the waste automobile tail gas three-way catalyst is opened, gamma-Al2O3 and part of cordierite structures (2MgO.2Al2O3.5SiO2) are destroyed, and part of Si in the waste automobile tail gas three-way catalyst is separated in a differentiation manner; then, the waste automobile tail gas three-way catalyst is further treated under the specific condition through the pressurizing alkaline leaching technology, part of Al, Si and the like in the waste automobile tail gas three-way catalyst are selectively dissolved out, finally, a platinum group metal enriched body is obtained, a sodium aluminate solution obtained through pressurizing alkaline leaching is subjected to enhanced decomposition through microwaves, hydrated alumina is obtained, and recycling of aluminum in the waste automobile tail gas three-way catalyst is achieved.

Owner:YIYANG SHENGLI CHEM IND

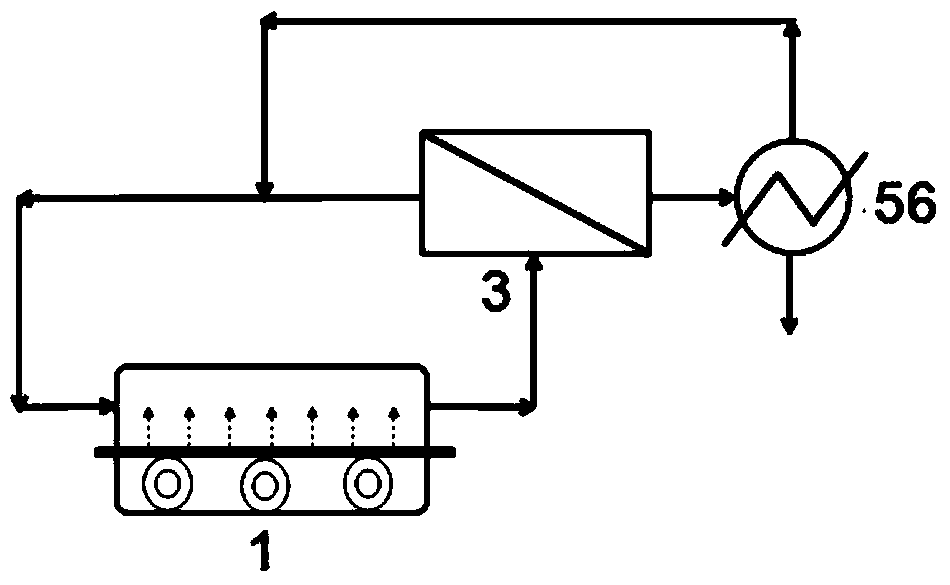

Membrane-method recovery process for realizing zero emission of volatile organic compound

ActiveCN103706224AAchieve emissionsRealize full recyclingDispersed particle separationMembrane methodOrganic solvent

The invention discloses a membrane-method recovery process for realizing the zero emission of a volatile organic compound. Waste gas which is generated by an organic compound generation system and contains the volatile organic compound directly enters a membrane separation system or is cooled and then enters the membrane separation system. A membrane can be separated by using the difference between the pressures of the upstream and downstream sides of the membrane as impelling force. Gas with high content of the volatile organic compound is obtained on the permeation side of the membrane through enrichment. Gas with low content of the volatile organic compound is obtained on the non-permeation side of the membrane. The gas with the high content of the volatile organic compound on the permeation side of the membrane enters a condensation system to directly obtain part of the organic compound. Meanwhile, uncondensed gas returns to the organic compound generation system, and the gas with the low content of the volatile organic compound on the non-permeation side of the membrane returns to the organic compound generation system. The two flows of returned gas pass through the organic compound generation system, are mixed with a part of the volatile organic compound, and re-enter the membrane separation system for next circulation. According to the process, any emitted gas is eliminated, and the zero emission is realized. The process plays an important role in recovery of an organic solvent.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

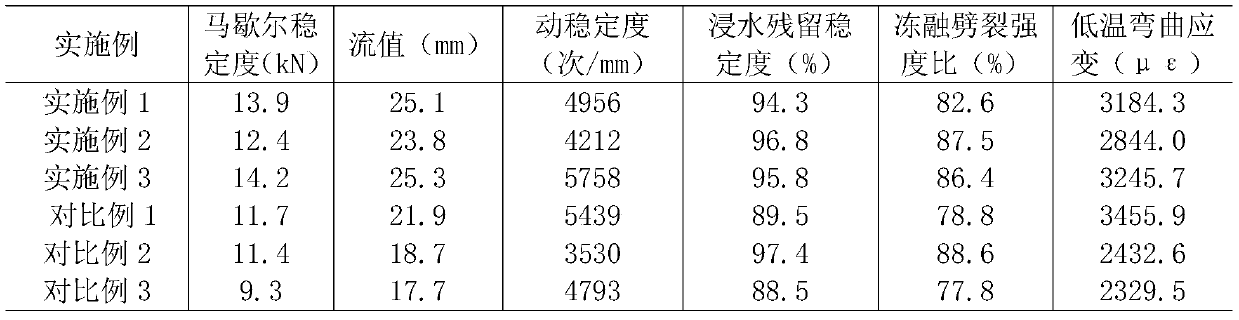

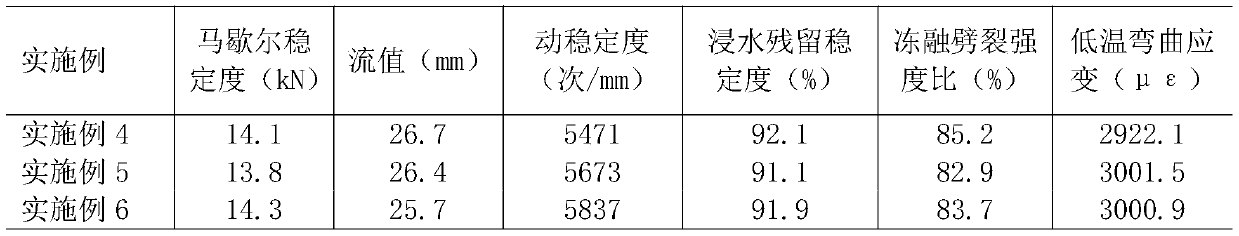

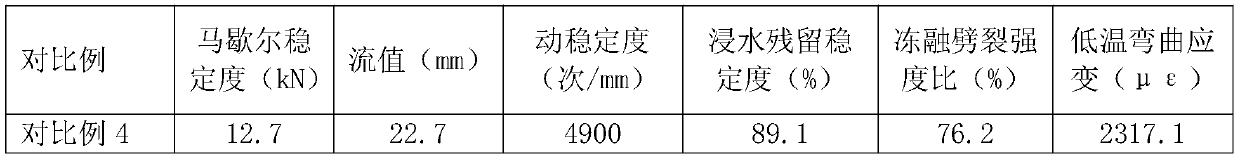

Stone mastic asphalt mixture using recycled fan blade waste as filler

ActiveCN111233374ASolve the low recovery rateLow costSolid waste managementStone mastic asphaltAsphalt

The invention relates to a stone mastic asphalt mixture using recycled fan blade waste as a filler. The mixture comprises the following components in parts by weight: 6-9 parts of SBS modified asphalt, 8-12 parts of lignin fibers and fan fibrous waste, 100-150 parts of crushed stones, 4-6 parts of fan powder waste and 1-5 parts of fan blocky waste. In the mixture, the particle size of the fan powder waste is smaller than 0.075 mm, the particle size of the fan fiber waste is larger than or equal to 0.075 mm and smaller than 9.5 mm, the length-width ratio of the fan fiber waste is larger than 10, the particle size of the fan block waste is greater than or equal to 9.5 mm, aggregate except asphalt in the stone mastic asphalt mixture meets the grading requirement of the national stone mastic asphalt mixture, and the SBS modified asphalt adopts No.90 matrix asphalt. By means of the size synergistic effect of the fan fiber waste materials of various sizes, the fan blade waste materials, thelignin fibers and the crushed stone aggregates form a better interlocking framework structure and dense filling in the stone mastic asphalt mixture, and the anti-cracking performance and the anti-rutting performance of the material are improved.

Owner:河北安恕朗晴环保设备有限公司 +1

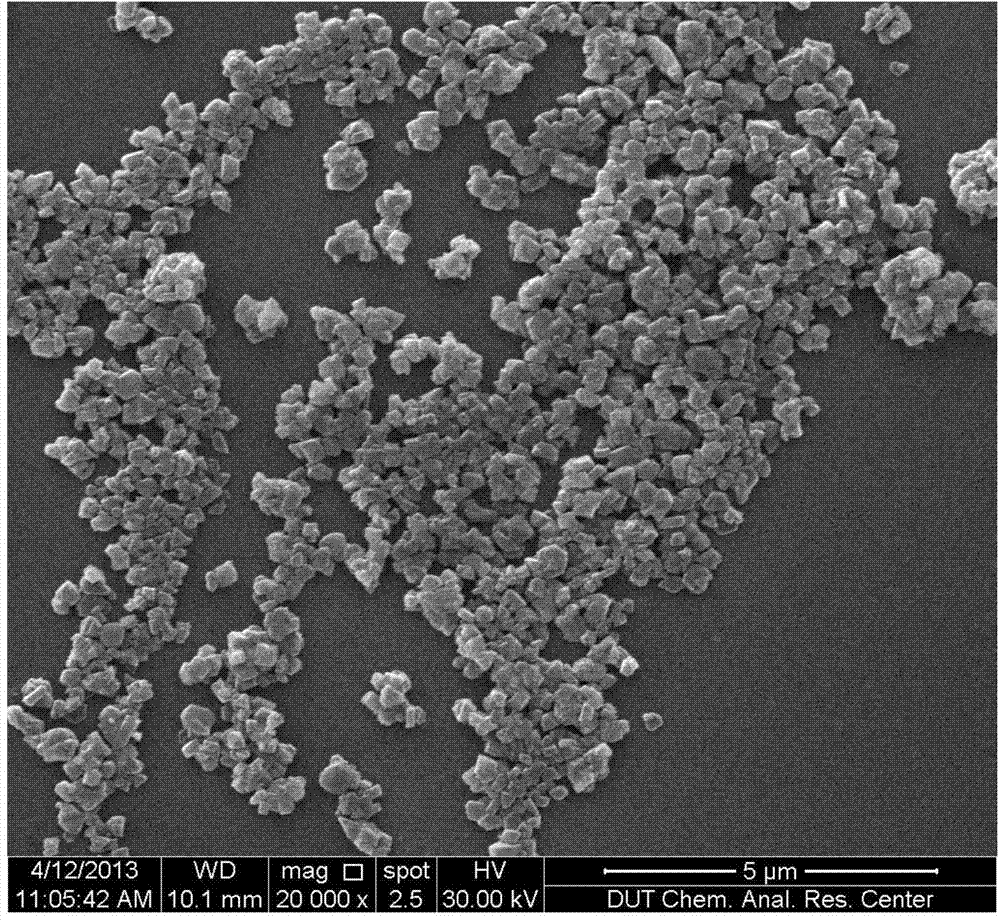

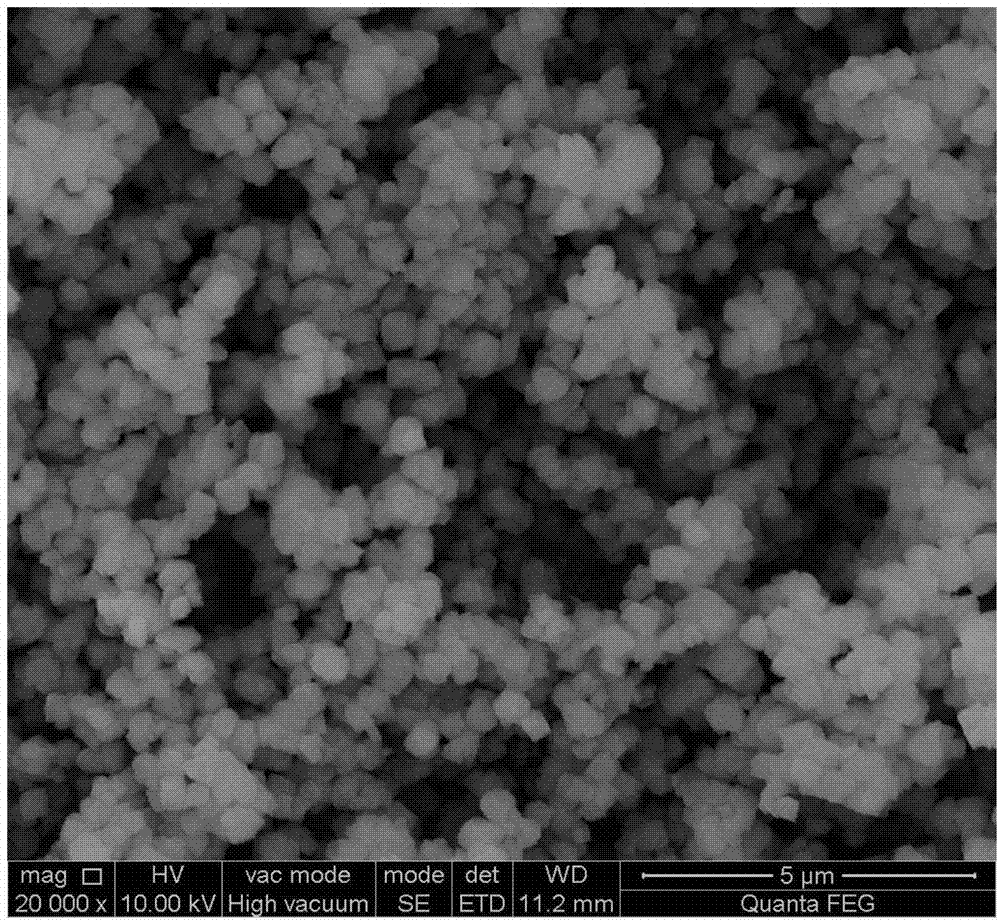

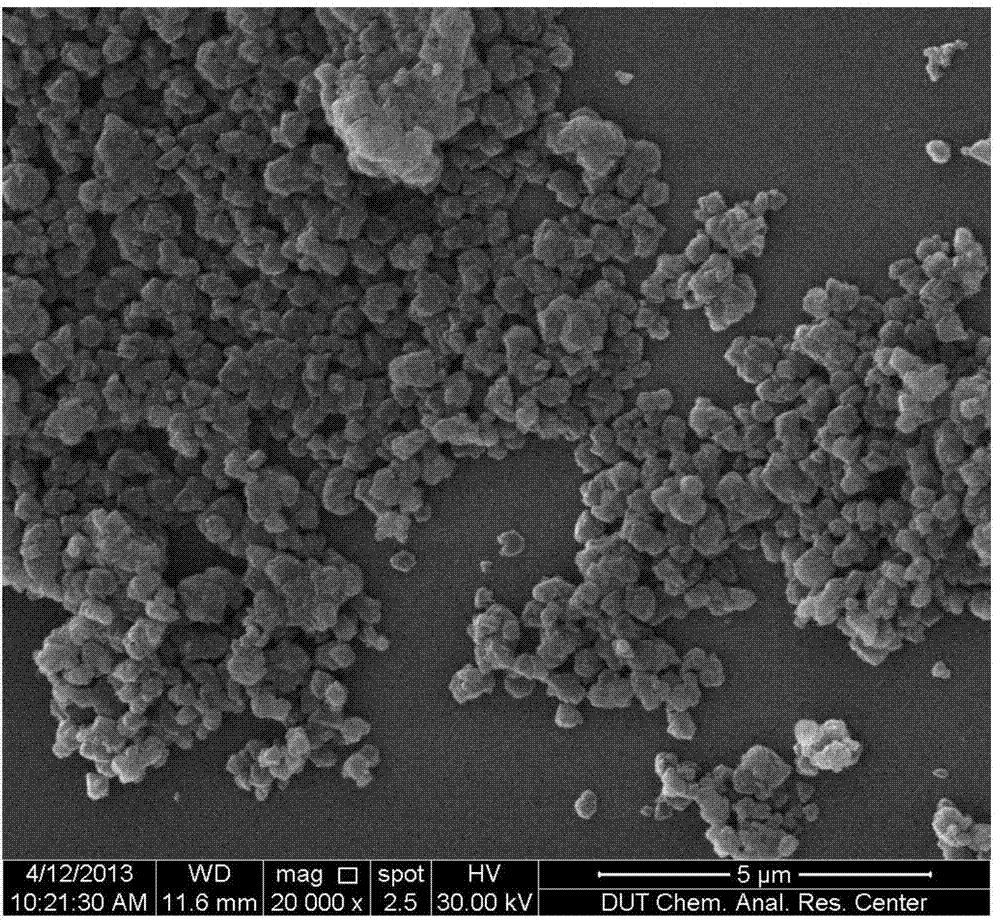

Method for synthesis of high silica-alumina ratio ultrafine NaY molecular sieve

ActiveCN104743572ARealize full recyclingReduce consumptionFaujasite aluminosilicate zeoliteMolecular sieveHigh silica

The invention discloses a method for synthesis of a high silica-alumina ratio ultrafine NaY molecular sieve. The method comprises the following steps of collecting a crystallization mother liquor of a high silica-alumina ratio ultrafine NaY molecular sieve, adding inorganic acid and soluble aluminum salt solution into the crystallization mother liquor so that pH is adjusted and silica-alumina gel precipitates are formed, filtering the precipitates to obtain silica-alumina gel filter cake with a SiO2 / Al2O3 ratio of 17-85, preparing a guiding agent from a part of or all the filter cake, adding reaction gel with a silicon source, an aluminum source and water into the guiding agent, and carrying out at least three programming calefactive control crystallization processes under full dynamic conditions. The NaY molecular sieve has average crystal grain sizes of 100-500nm and a skeleton silica-alumina ratio (SiO2 / Al2O3) higher than 6.7. The method realizes silicon source complete cycle utilization.

Owner:陕西煤化工技术工程中心有限公司 +1

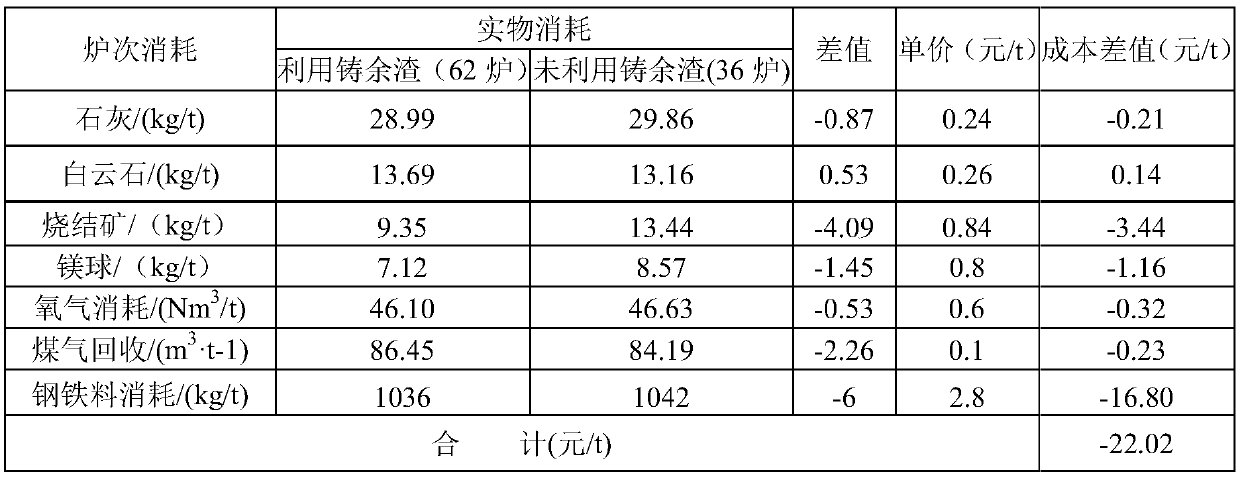

Method for recycling steel-ladle hot-state casting residues by means of converter

ActiveCN109609721AReduce steel consumptionUse efficientlyManufacturing convertersFerrous metallurgySmelting

The invention discloses a method for recycling steel-ladle hot-state casting residues by means of a converter, and belongs to the technical field of ferrous metallurgy. The problem that the casting residues and self waste heat of the casting residues cannot be effectively utilized in the prior art is solved. The method comprises the following steps that the hot-state casting residues remaining inthe steel ladle after molten steel pouring are returned to the converter steelmaking process for recycling and utilization, and the alkalinity of the hot-state casting residues ranges from 6 to 8. According to the method, the liquid-state continuous casting residues are used in an energy-saving, environment-friendly, effective and stable manner for realizing the heat-state recycling of the castingresidues; and the consumption of steel materials can be reduced, the sensible heat of furnace slag can be effectively utilized, the smelting efficiency can be improved, the steelmaking production cost is reduced, the quality of molten steel is improved, and the environment-friendly benefit is obvious.

Owner:CENT IRON & STEEL RES INST

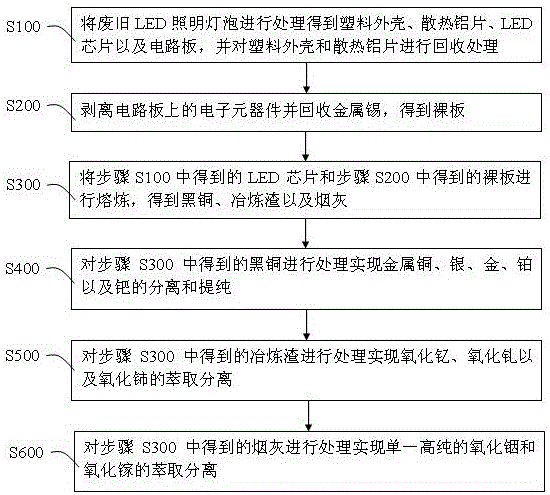

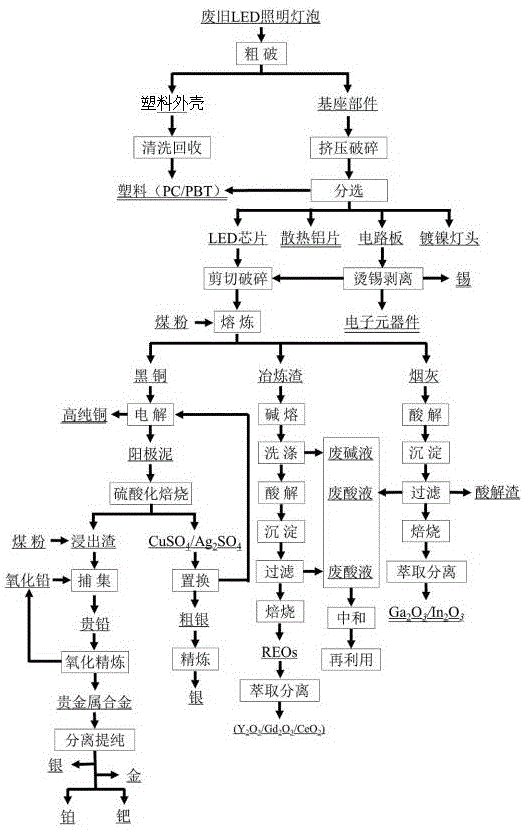

Waste LED lighting bulb recycling method

ActiveCN106381390ARealize full recyclingImprove recycling efficiencyPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention provides a waste LED lighting bulb recycling method comprising the steps of treating waste LED lighting bulbs to obtain plastic shells, heat radiating aluminum sheets, LED chips and circuit boards, and recycling the plastic shells and the heat radiating aluminum sheets; stripping electronic components on the circuit boards, and recovering metal tin to obtain bare boards; smelting the LED chips and the bare boards to obtain black copper, smelting slag and sooth; treating the black copper to realize the separation and purification of metal copper, silver, gold, platinum and palladium; treating the smelting slag to realize extraction separation of yttrium oxide, gadolinium oxide and cerium oxide; and treating the soot to realize extraction separation of single high-purity indium oxide and gallium oxide. By using the waste LED lighting bulb recycling method, the aim of completely recycling metals in the waste LED lighting bulbs is effectively realized; and the waste LED lighting bulb recycling method is high in recycling efficiency, good in comprehensive utilization compatibility and suitable for industrial production.

Owner:DELTA ALUMINUM IND

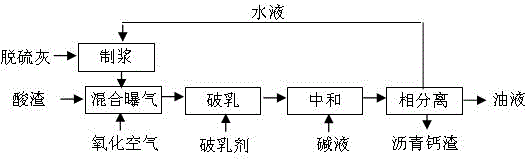

Combined treatment method for acid sludge and desulfurization ash

InactiveCN104415963ARealize harmless disposalSimple processSolid waste disposalActivated sludgeEconomic benefits

The invention relates to the field of comprehensive utilization of industrial wastes and particularly relates to a combined treatment method of waste acid sludge in the lubricating oil recycling industry and desulfurization ash in the dry-process / semidry process flue gas desulfurization industry. The combined treatment method of the acid sludge and the desulfurization ash comprises the following steps: after pulping the desulfurization ash, mixing and aerating with the acid sludge, and performing phase separation by virtue of emulsion-breaking and neutralizing effects, wherein an oil phase is utilized as fuels, a water phase is returned to a desulfurization ash pulping system for recycling, and a solid phase is utilized as a building material. The combined treatment method disclosed by the invention is simple in process, environmentally friendly, and capable of realizing innocent treatment of harmful wastes and developing a new way for recycling the harmful wastes, and has good economic benefits and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD +1

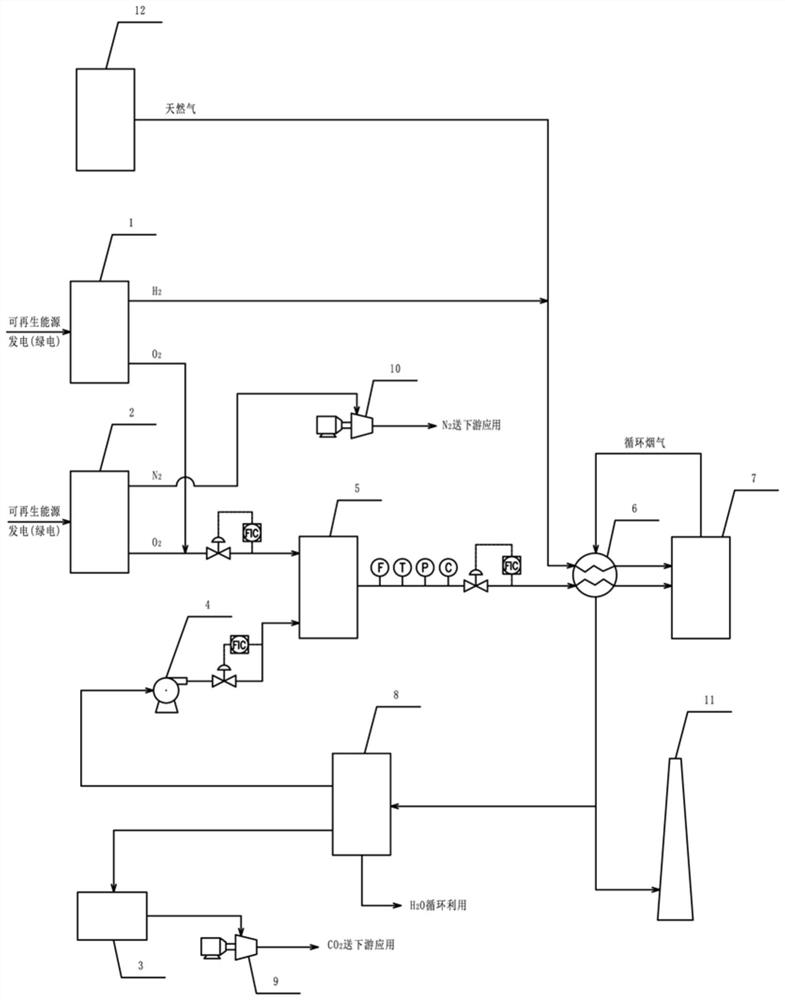

Nitrogen-insulating combustion and CO2 capture and utilization process for gas-fired boiler

The invention discloses a gas-fired boiler nitrogen-insulating combustion and CO2 capture and utilization process. A system required by the process comprises a natural gas supply device, a water electrolysis hydrogen production device, an oxygen preparation device, a nitrogen compressor, a carbon-based nitrogen-insulating gas mixer, a gas heat exchanger, a gas-fired boiler, a chimney, a flue gas dehydration device, an air blower, a CO2 recovery device and a CO2 compressor. The method has excellent performance in the aspects of yield increase, energy conservation and emission reduction, the unit consumption of per ton of steam and natural gas can be reduced by 10% or above, the yield can be improved by 10% or above, the flue gas emission is reduced, and ultralow emission of NOx is achieved.

Owner:SHANGHAI YUANHAN ENERGY&CHEM TECH CO LTD +1

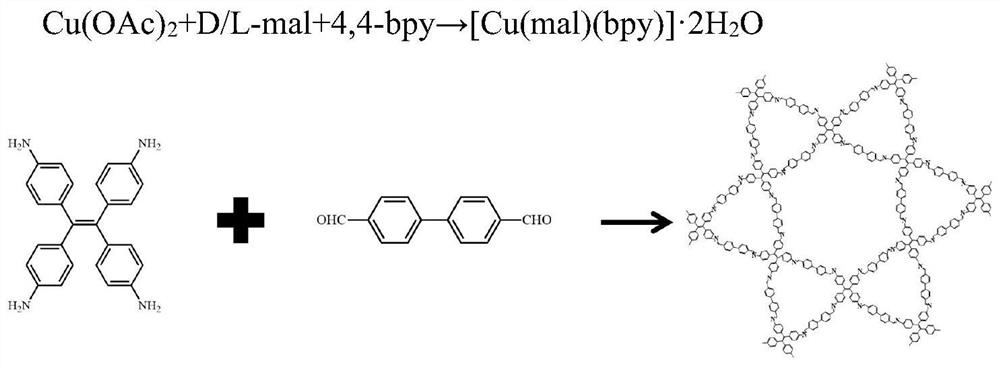

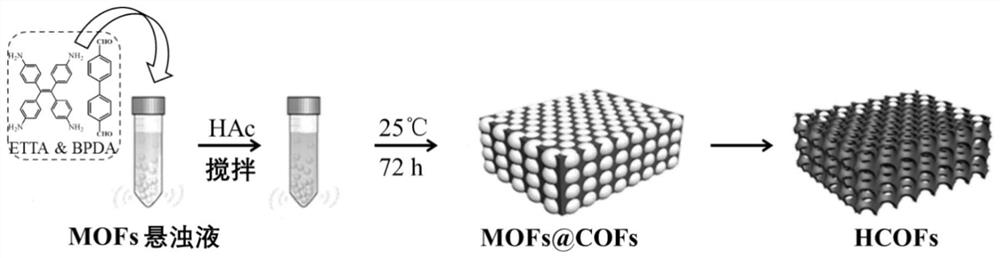

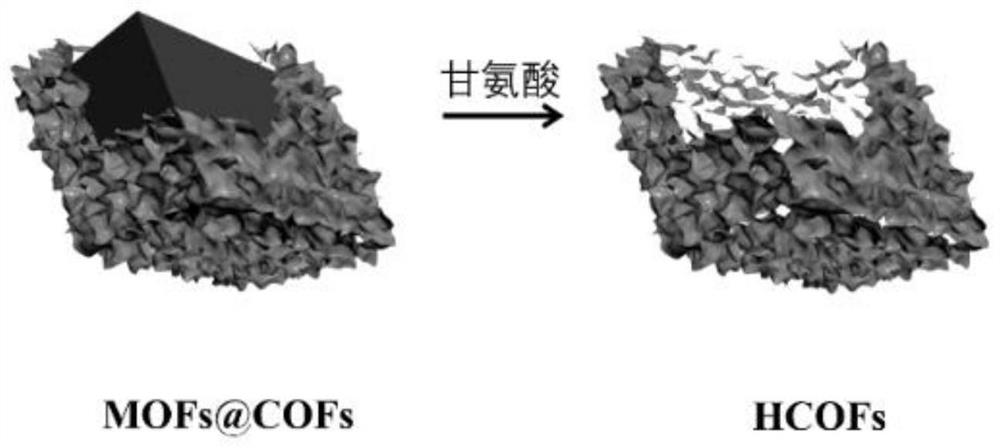

Hierarchical heterogeneous covalent organic framework material, preparation method and application thereof

ActiveCN112705179AReduce distractionsRealize full recyclingComponent separationOther chemical processesSoil sciencePesticide residue

The invention provides a hierarchical different-pore covalent organic framework material, a preparation method and application thereof. According to the invention, a composite material is prepared through the physical coating effect of a different-pore covalent organic framework and a metal organic framework, and takes the metal organic framework as a sacrificial template, and the metal organic framework is dissolved with a dissolving agent to synthesize the hierarchical heterogeneous covalent organic skeleton material; the hierarchical heterogeneous covalent organic framework material has excellent rapid purification ability on pigment molecules in food and agricultural products; and the pesticide residue content of food and agricultural product samples is detected and analyzed by combining a liquid chromatography or mass spectrometry analysis technology, so that the chemical hazard factors can be completely recycled.

Owner:NANKAI UNIV

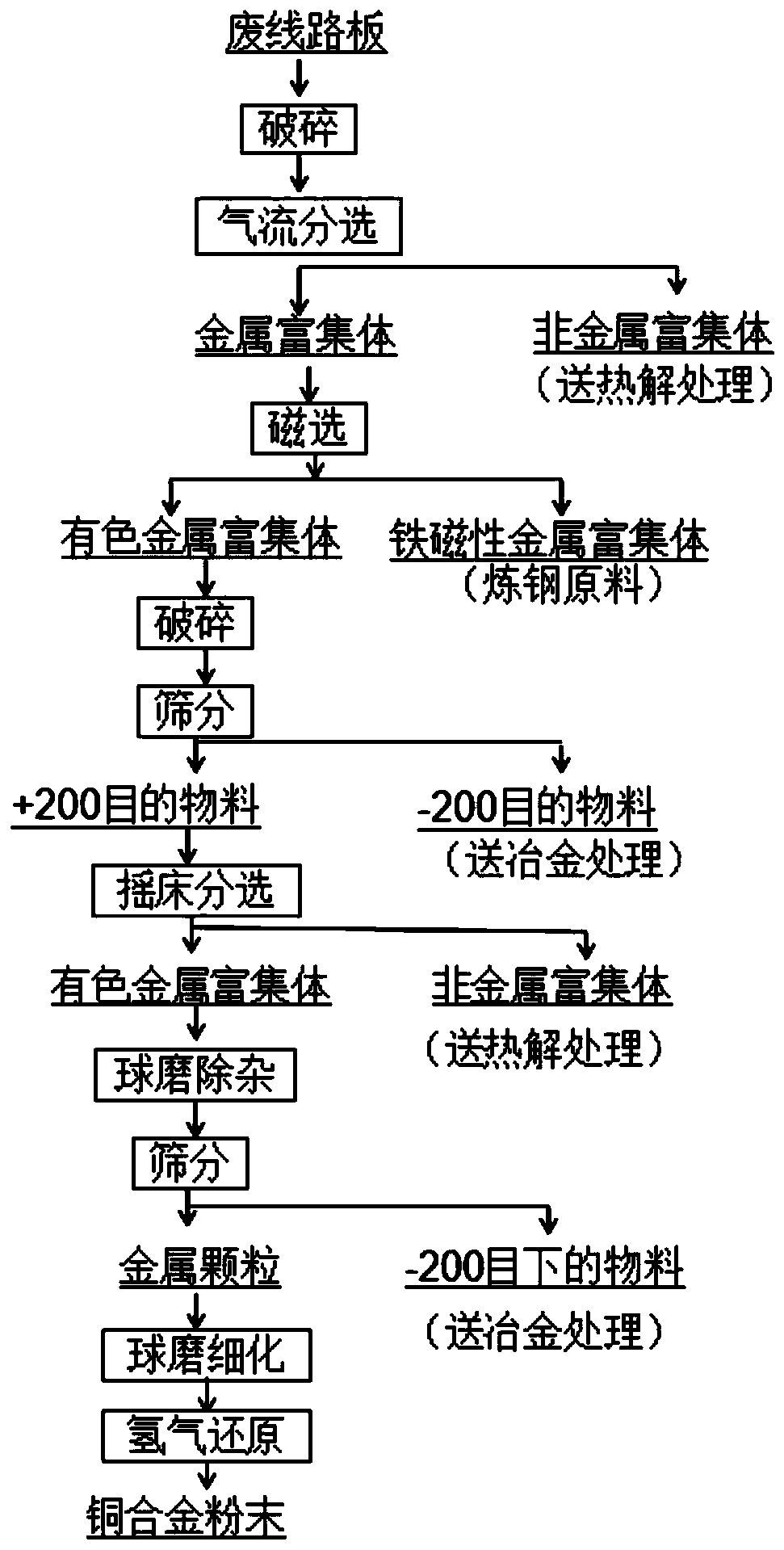

Process for processing waste circuit boards to prepare copper alloy powder by mechanical physical method

ActiveCN110434158AShort processReduce energy consumptionSolid waste disposalSolid separationAirflowEnergy consumption

The invention discloses a process for processing waste circuit boards to prepare copper alloy powder by a mechanical physical method. The process comprises the steps of waste circuit board crushing pretreatment, airflow separation, magnetic separation iron removal, mechanical pulverization, screening, shaking table sorting, ball-milling impurity removing, ball-milling refining, powder purificationtreatment and other procedures, and the copper alloy powder is finally obtained. The process has the following advantages that the obtained copper alloy powder mainly contains Cu, Sn, Pb and Fe, theingredient and content of the obtained copper alloy powder is within the range required by a copper base friction material, the obtained copper alloy powder can be directly applied to prepare the copper base friction material, a small amount of tailings generated in the whole process is easy to process, and full recovery of metal can be realized; and compared with other methods capable of realizing cyclic regeneration of valuable metals in the waste circuit boards, the process adopts the mechanical physical method without a metallurgical process, direct materialization of waste metallic coppercan be realized, and the process is simple, low in production cost and energy consumption and less in pollution.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing polyferric chloride by using wastewater produced in pickling of steel with hydrochloric acid

InactiveCN109250762AIncrease concentrationSimple processIron halidesWater/sewage treatment by flocculation/precipitationPhosphateReaction temperature

The invention relates to a method for preparing polyferric chloride by using wastewater produced in pickling of steel with hydrochloric acid. The method comprises the following steps: pretreating hydrochloric acid pickling wastewater, and quantitatively feeding the filtered hydrochloric acid pickling wastewater into a reaction kettle; adding a phosphate buffer in batches, wherein 0.03 to 0.04 tonof the phosphate buffer is added for per ton of the concentrated hydrochloric acid pickling wastewater; carrying out sufficient stirring to completely dissolve the phosphate buffer; and adding an oxidizing agent under the conditions of stirring and constant-temperature heating for an oxidative polymerization reaction, wherein the concentration of the oxidizing agent is 120-150 mg / L, 0.7 to 1.1 kg / h of the oxidizing agent is added for per ton of the concentrated hydrochloric acid pickling wastewater, the rotating speed of an agitator in a reaction vessel is 200 to 400 rpm, a reaction temperature is 40 to 60 DEG C, and after sufficient reaction for 14 to 26 h, the polyferric chloride is obtained. The method has the following advantages: process flow is simple; only one reaction kettle is needed in a core production procedure; and the oxidative polymerization reaction is implemented in the reaction kettle.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com