Production device and method of biodiesel

A technology for biodiesel and production equipment, which is applied in the fields of biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of insufficient catalyst, incompatibility of oil and methanol, contact of reactants, etc., and achieves reasonable design and product quality. The effect of high purity and efficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

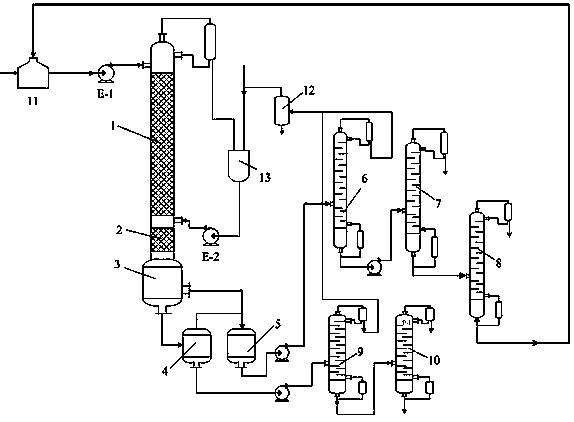

[0036]0.72kg / h soybean oil enters the (0.1MPa) reaction tower from the top of the tower through pump E-1, and flows down into the CaO catalyst reaction layer 1 at a temperature of 82°C. 1kg / h methanol enters from the tower waist through pump E-2 , the temperature is 120°C, the gaseous methanol enters the CaO catalyst reaction layer upwards, and reacts with soybean oil in countercurrent contact, the reaction temperature is 94°C, and the unreacted methanol rises to the top of the tower (temperature 83.2°C) through the reflux ratio of 1.1:1, part of which returns to the reaction The other part enters the methanol storage tank 13. The reaction product flows down the bed to the temperature raising layer 2 (temperature 135°C), and the miscible methanol is gasified again in the temperature raising layer 2 and enters the CaO catalyst reaction layer 1 for reaction, and other products continue to flow down to the static layered kettle 3 for standing layered. The lower layer is glycerin...

Embodiment 2

[0038] 1kg / h of pretreated waste oil (acid value 3.2mgKOH / g) enters from the top of the tower (0.2MPa) by pump E-1 and flows down into the Zr-SBA-15 catalyst reaction layer 1 at a temperature of 138°C, 3.56kg Methanol / h enters from the tower waist by pump E-2, the temperature is 180°C, the gaseous methanol enters the Zr-SBA-15 catalyst reaction layer upwards, and reacts with the pretreated waste oil countercurrently, the reaction temperature is 160°C, the unreacted Methanol rises to the top of the tower (temperature 140.4°C) and passes through a reflux ratio of 1.2:1, part of which returns to the reaction tower, and the other part enters the methanol storage tank 13. The reaction product flows down the bed to the temperature raising layer 2 (temperature 205°C), and the miscible methanol is vaporized again in the temperature raising layer 2 and enters the Zr-SBA-15 catalyst bed 1 for reaction, and other products continue to flow down to the static layered kettle 3. Let it stand...

Embodiment 3

[0040] 1kg / h pretreated kitchen waste oil (acid value 4.4mgKOH / g) enters the (0.15MPa) reaction tower from the top of the tower through the pump E-1, and flows down into the H β Catalyst reaction layer 1, the temperature is 138°C, 1.45kg / h methanol enters from the tower waist through the pump E-2, the temperature is 190°C, and the gas phase methanol enters the H β Catalyst bed, countercurrent contact reaction with the pretreated kitchen waste oil, the reaction temperature is 150°C, the unreacted methanol rises to the top of the tower (temperature 139.5°C), through the reflux ratio of 1.0:1, part of it returns to the reaction tower, and the other part Enter the methanol storage tank 13. The reaction product flows down the bed to the heating layer 2 (temperature 230°C), and the miscible methanol is gasified again in the heating layer 2 and enters the H β The catalyst reaction layer 1 reacts, and other products continue to flow down into the static stratification kettle 3 for st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com