Heavy metal-contaminated soil solidifying agent and application method thereof

A technology of heavy metal contaminated soil and curing agent, applied in chemical instruments and methods, applications, solid waste management and other directions, can solve the problems of accelerated heavy metal ion leaching, pollution of human living environment, large amount of curing agent added, etc., to reduce porosity , the effect of reducing environmental pollution and solving treatment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

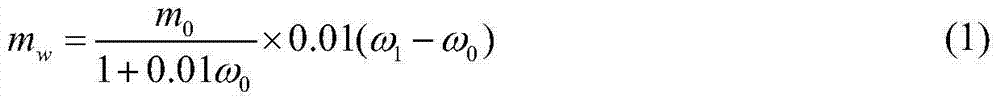

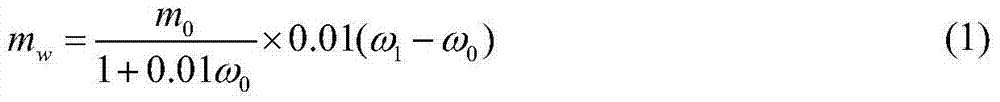

[0053] The moisture content of the heavy metal-contaminated soil to be treated was measured by drying method to be 15%, and the weight of the heavy metal-contaminated soil was 300kg. When solidified, the moisture content of the heavy metal-contaminated soil slurry was 100%. According to the formula (1), the amount of water added was calculated as 182.61kg, according to the formula (2), the dry weight of heavy metal-contaminated soil is 260.87kg. Mix 182.61kg of weighed water with heavy metal-contaminated soil, stir for 5 minutes to form heavy metal-contaminated soil slurry, then dissolve 2.61kg of sodium sulfide in the heavy metal-contaminated soil slurry, and stir for 5 minutes; add 13.04kg of biological Carbon, stir again for 5 minutes; after 30 minutes, add 26.09kg bagasse fiber and 26.09kg cement, and stir vigorously for 20 minutes.

Embodiment example 2

[0055] The moisture content of the heavy metal-contaminated soil to be treated was measured by the drying method to be 18%, and the weight of the heavy metal-contaminated soil was 300kg. When solidified, the moisture content of the heavy metal-contaminated soil slurry was 110%. According to the formula (1), the amount of water added was calculated as 188.14kg, according to the formula (2), the dry weight of heavy metal-contaminated soil is 254.24kg. Mix the weighed 188.14kg of water with the heavy metal contaminated soil, stir for 7 minutes to form a heavy metal contaminated soil slurry, then dissolve 2.54kg of potassium dihydrogen phosphate in the heavy metal contaminated soil slurry, and stir for 7 minutes; add 12.71 kg of biochar, and stir again for 7 minutes; after 30 minutes, add 25.42kg of straw fiber and 25.42kg of lime, and stir vigorously for 20 minutes.

Embodiment example 3

[0057] The moisture content of the heavy metal-contaminated soil to be treated was measured by the drying method to be 21%, and the weight of the heavy metal-contaminated soil was 300kg. When solidified, the moisture content of the heavy metal-contaminated soil slurry was 120%. According to the formula (1), the amount of water added was calculated as 193.39kg, according to the formula (2), the dry weight of heavy metal-contaminated soil is 247.93kg. Mix the weighed 193.39kg of water with the heavy metal contaminated soil, stir for 8 minutes to form a heavy metal contaminated soil slurry, then dissolve 2.48kg of sodium sulfide in the heavy metal contaminated soil slurry, and stir for 8 minutes; add 12.40kg of biological Carbon, stir again for 8 minutes; after 30 minutes, add 24.79kg bagasse fiber and 24.79kg gypsum, and stir vigorously for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com