Patents

Literature

97results about How to "Control hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

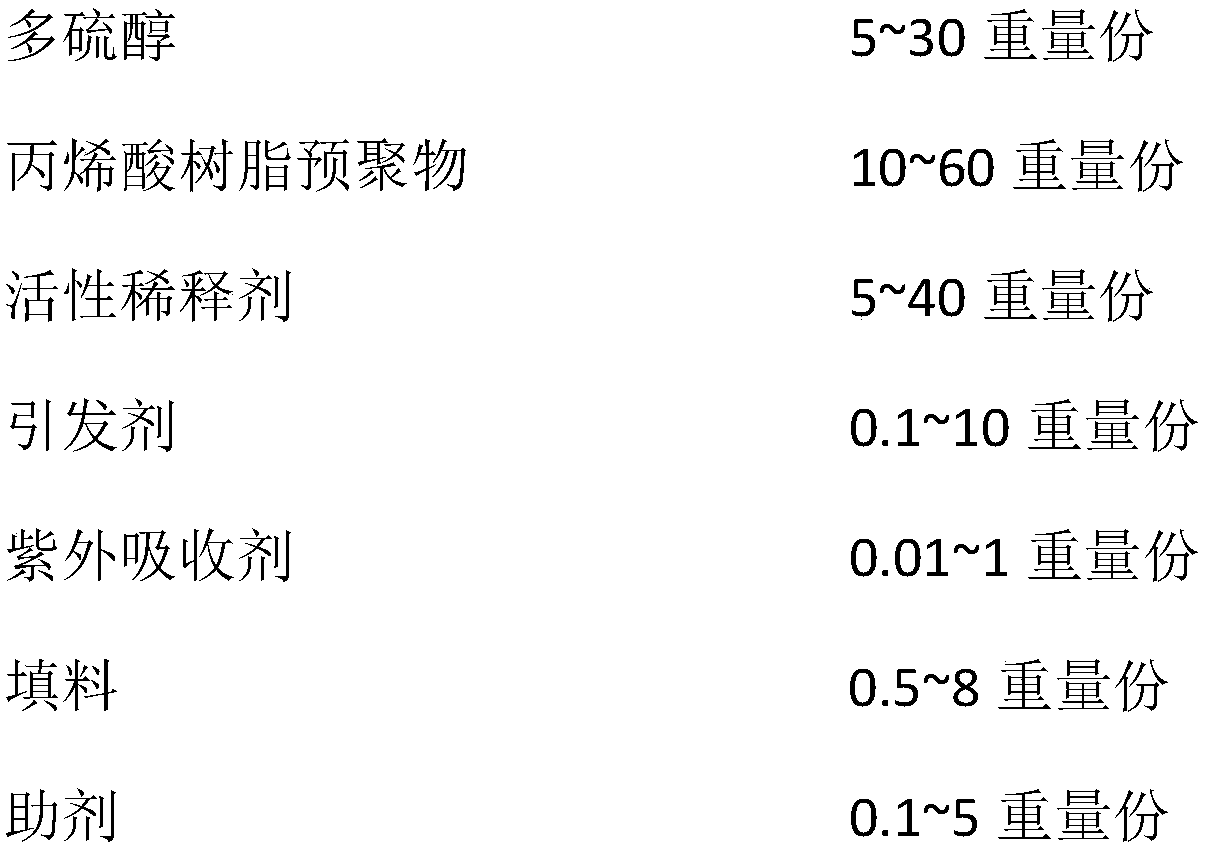

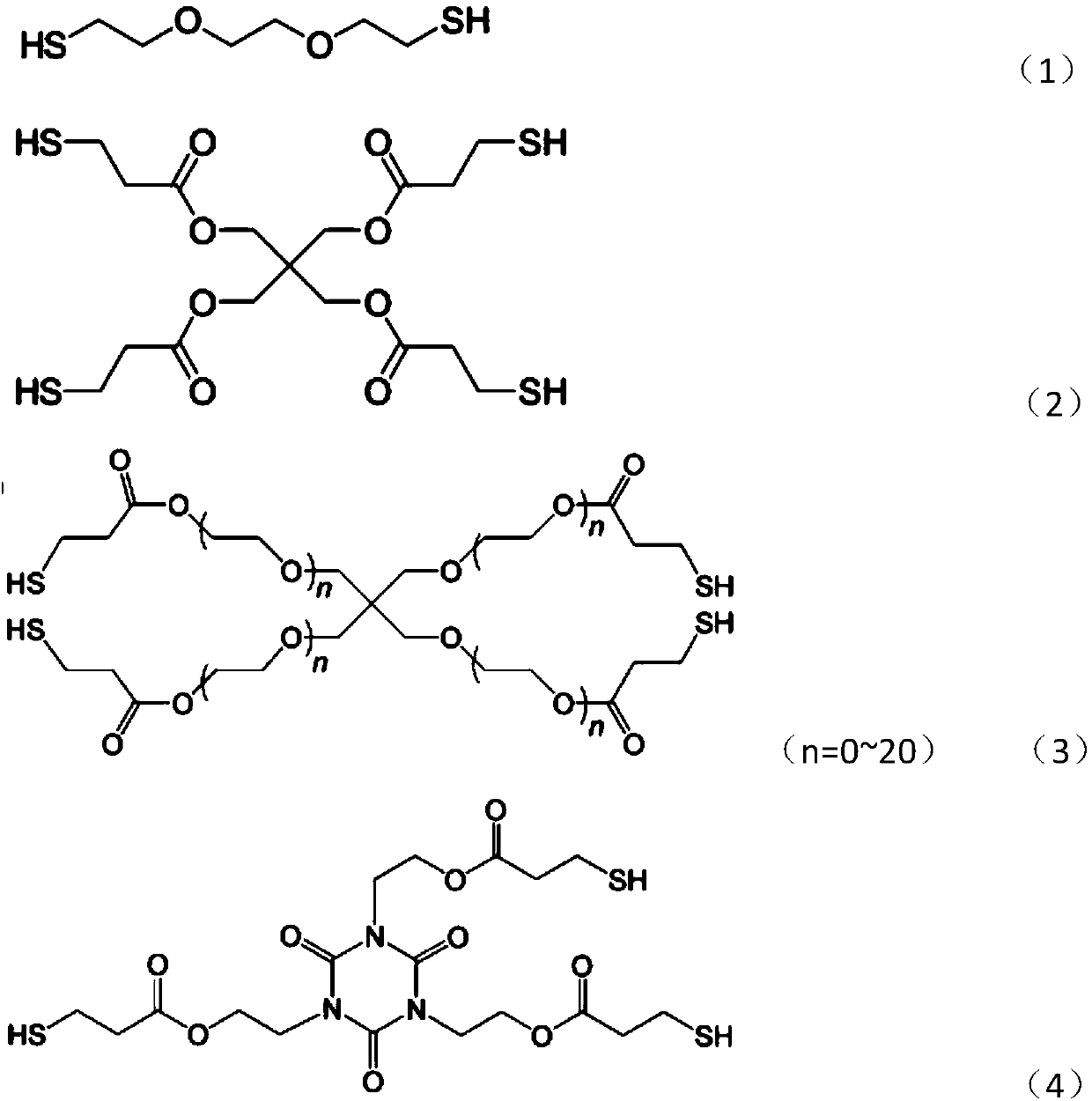

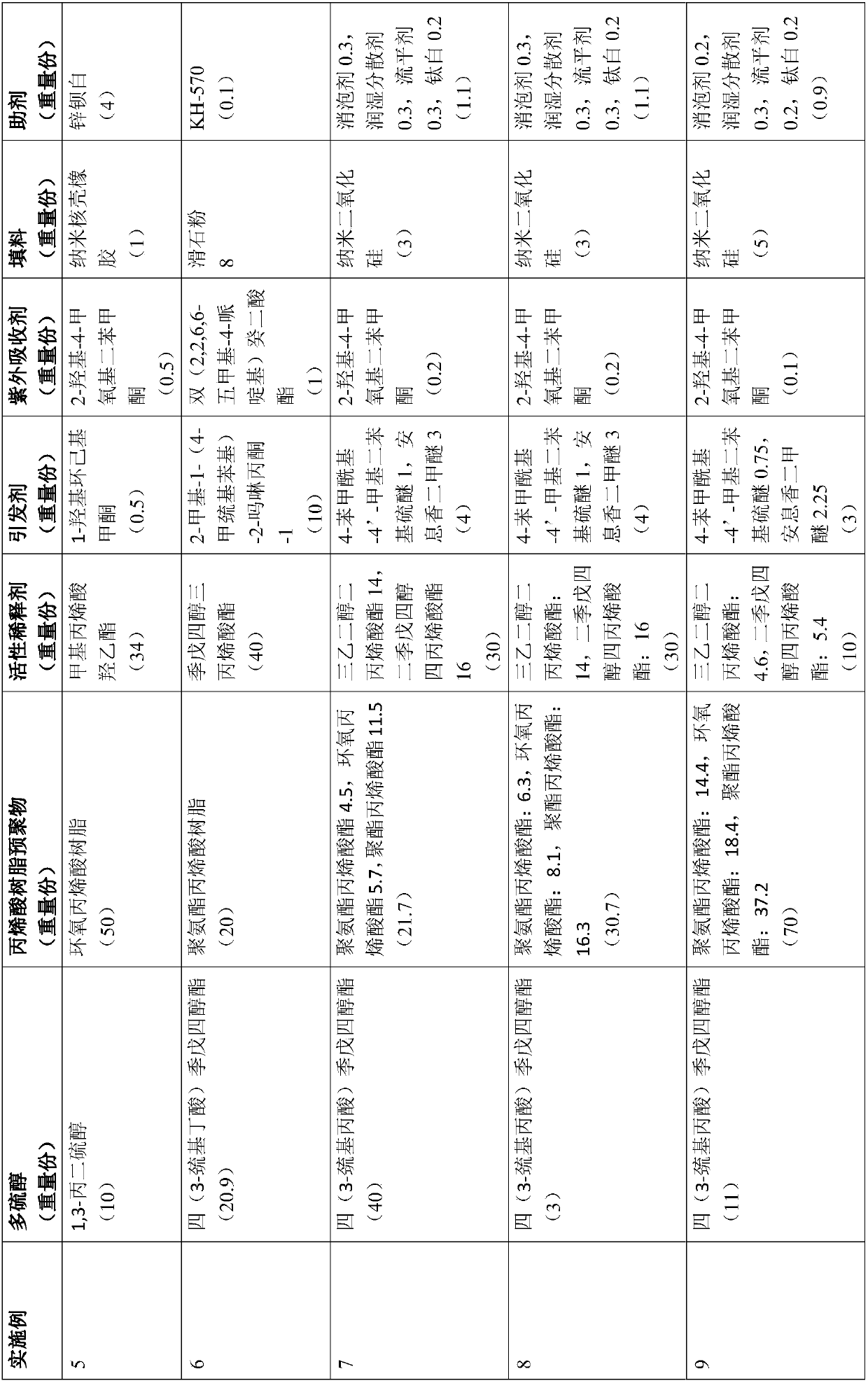

Mercaptan-alkene light-cured resin for 3D printing and preparation method of mercaptan-alkene light-cured resin for 3D printing

ActiveCN107641200ASimple applicationControl hardnessAdditive manufacturing apparatusIncreasing energy efficiencyPrepolymerDouble bond

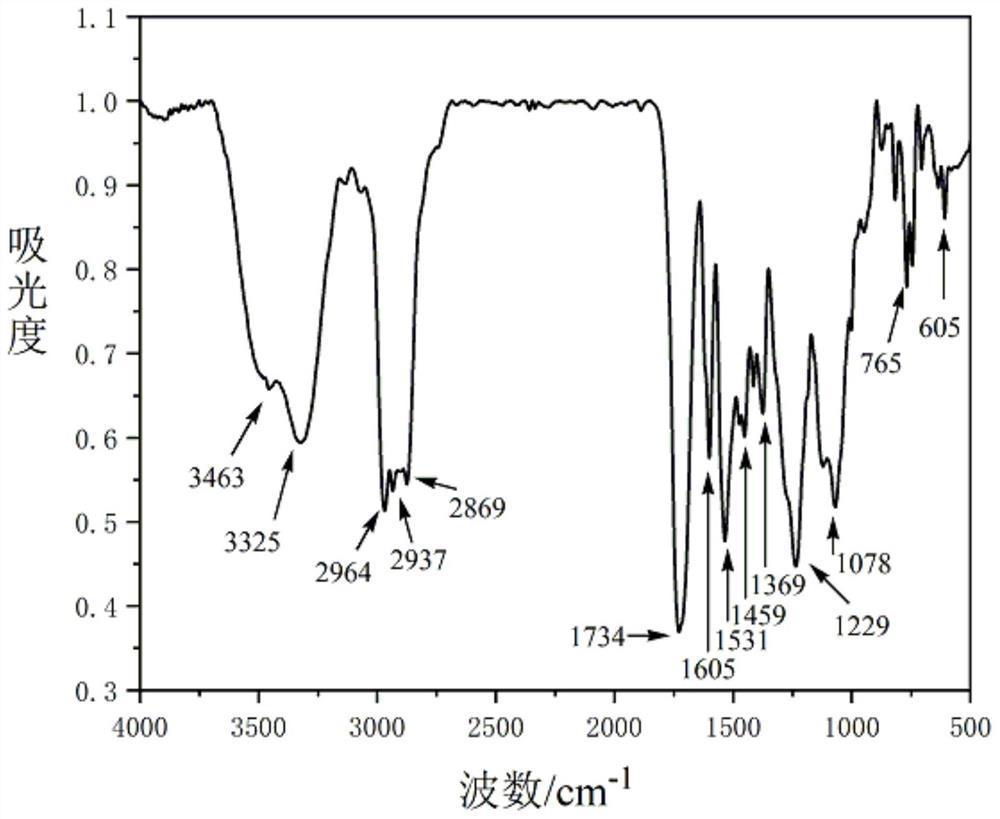

The invention relates to the technical field of 3D printing, in particular to mercaptan-alkene light-cured resin for 3D printing and a preparation method of the mercaptan-alkene light-cured resin for3D printing. The mercaptan-alkene light-cured resin for 3D printing is prepared from multi-mercaptan, an acrylic resin prepolymer, a reactive diluent, an initiator, an ultraviolet absorbent, a fillerand an auxiliary raw material. According to the 3D printing light-cured resin, under the existence of a photoinitiator, during printing polymerization forming, a chain transfer reaction between doublebonds and sulfydryl occurs to reduce the volume of a polymer, so that the mercaptan-alkene light-cured resin has the advantages that oxygen-free polymerization inhibition is realized, the crosslinking degree and the reaction speed can be controlled according to different vinyl monomers, and a small number of the photoinitiators are used. By introduction of mercaptan-alkene click reaction into the3D printing resin, the curing time can be shortened, the toughness and the hardness of a 3D printing material can be improved, the production efficiency is improved, and the energy utilization rate is greatly increased.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

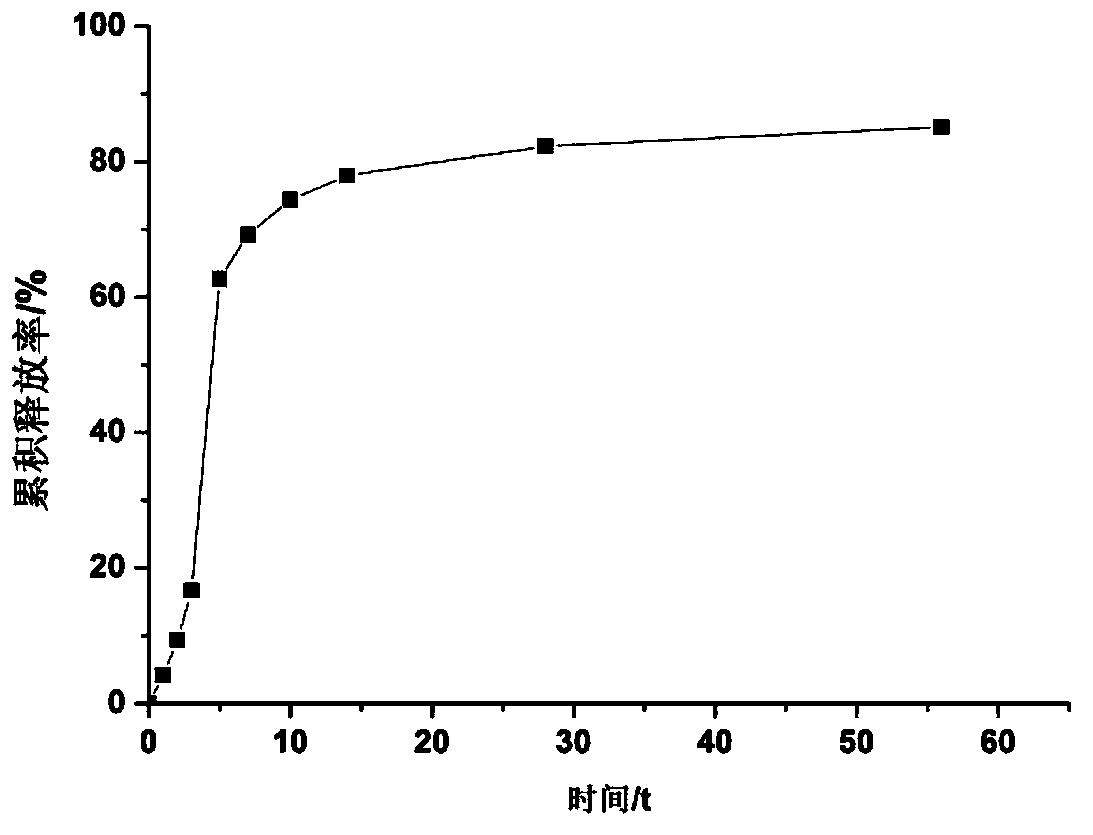

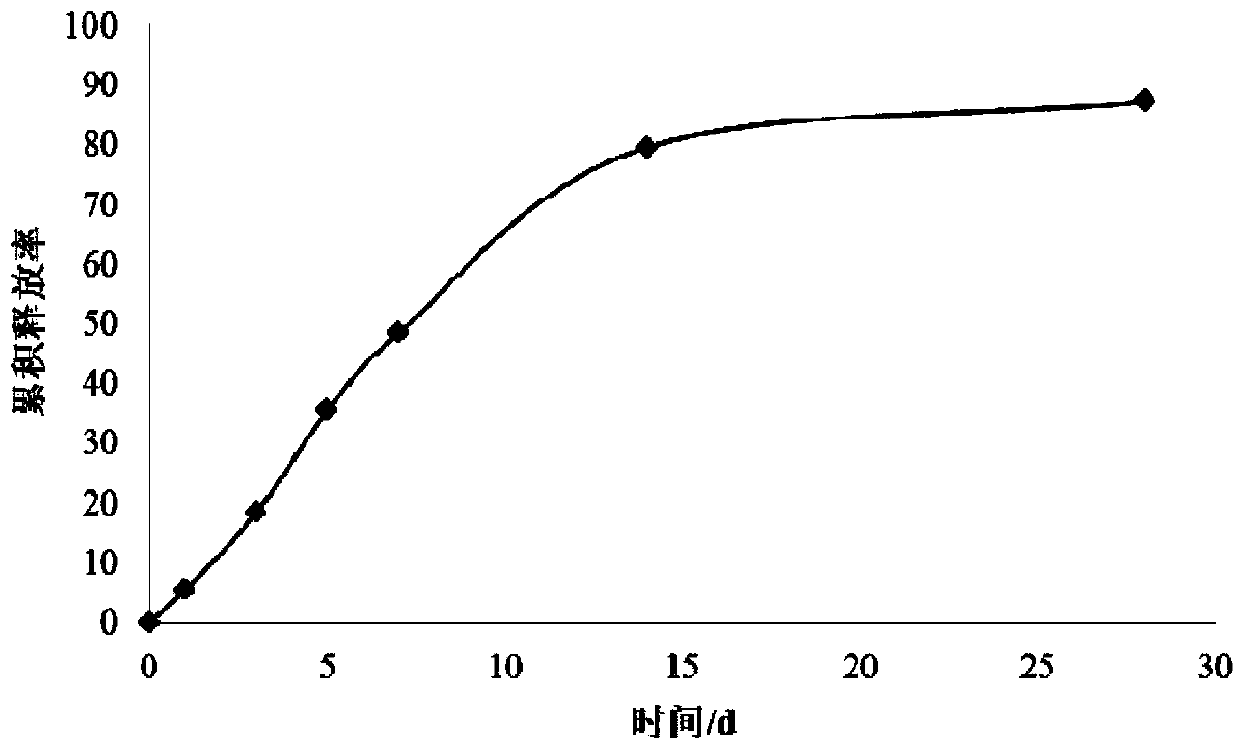

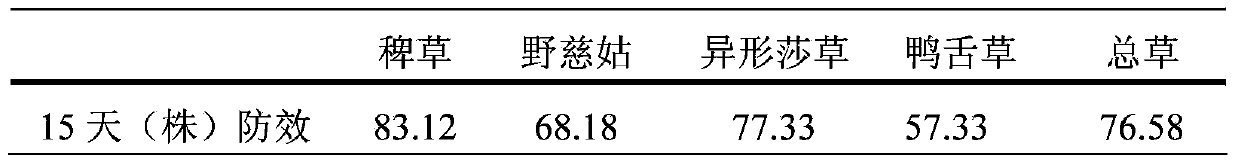

Polymer-coated controlled release pesticide granule and preparation method thereof

ActiveCN103387456AImprove water resistanceImprove targetingFertilizer mixturesWater basedPolyurethane membrane

The invention discloses a polymer-coated controlled release pesticide granule and a preparation method thereof. The polymer-coated controlled release pesticide granule comprises a pesticide granule and a polymer layer, wherein the pesticide granule is coated by the polymer layer; the pesticide granule contains one or more effective pesticide components; the polymer layer is a hydrophobic membrane layer and comprises a water-based polyacrylate membrane material or a polyurethane membrane material; the mass of the polymer layer accounts for 3%-15% of the weight of the polymer-coated controlled release pesticide granule. The effective pesticide components are acted on the peripheries of crop roots after the polymer-coated controlled release pesticide granule disclosed by the invention is applied along with a base fertilizer. The polymer-coated controlled release pesticide granule has good prevention and control effects on farmland weeds, soil insects and soil-borne diseases, and the coating material synthesis and preparation process is advanced and the polymer-coated controlled release pesticide granule has good controlled release property. The polymer-coated controlled release pesticide granule provided by the invention has the advantages of pesticide utilization ratio improvement, environment pollution reduction, sustainable development and wide application prospect.

Owner:BEIJING BOYICHENG SCI & TECH

Water polymer integument and method for preparing integument controlled-release fertilizer thereof

InactiveCN101182269AImprove water resistanceImprove targetingFertiliser formsFertilizer mixturesWater basedChemical industry

The invention discloses a water-based polymer coated film and a preparation method of a film-coated controlled release fertilizer thereof, which belongs to the agricultural controlled release fertilizer preparation technical field and relates to using a novel water-emulsion type polymer. The polymer film-coated controlled release fertilizer is coating a layer of novel degradable latex polymer film layer on the surface of granular fertilizer. The granular fertilizer with the diameter of 2 to 5mm is packed inside a film coating device of a rotating drum or a fluidized bed, and the granular fertilizer flows inside the film coating device to be heated to 80 DEG C to 100 DEG C. Organic matter is sprayed on the surface of the granular fertilizer, then complex polymer latex is sprayed on the facial surface of the organic matter film layer of the granular fertilizer to be dried continuously, the water of the film layer is removed by complete drying, and the polymer latex film-coated controlled release fertilizer is obtained. The invention conquers the problem that organic solvent leaks to cause the environmental pollution during the process of the production and avoids the problems of solvent recycling; the manufacturing process is easy for realizing the large scale chemical industry production; the investment cost is low; the production cost is reduced greatly.

Owner:吉林省沃野生态环境治理有限公司

Method for recycling waste polyurethane

InactiveCN101376718AControl hardnessLow densityPlastic recyclingMechanical material recoveryPolyesterPolyol

The invention relates to a recycling method of a wasted polyurethane material. In the method, the recycled wasted polyurethane after decontamination is cracked; then the cracked particles are fed into a high mixer; then chemical inhibitor, vesicant, thermoplastic styrene-butadiene rubber, polyether or polyester polyol, isocyanate and lubricant are added in turn and uniformly mixed; the uniformly mixed materials are fused, extruded, cooled and pulled into strips by an extruding machine, and then are cut into polyurethane particles by a granulator; the obtained polyurethane particles are injected and shaped by an injection machine or is shaped by the mould pressing of a block press. The invention aims at providing a recycling method of wasted polyurethane which can carry out regulation and control on the density and rigidity of the recycled polyurethane. Compared with the prior art, the recycling method has the advantages of high operating factors on the recycled materials, low production cost, high recycling and utilization value, simple recycling technique, and the like.

Owner:WENZHOU ZHENGUANG SHOES MATERIAL

Method for processing lactic acid bacteria-fermented rice-flour noodles

The invention discloses a method for processing lactic acid bacteria-fermented rice-flour noodles, and belongs to the technical field of food processing. The method comprises the following steps: jordaning, spreading pulp and steaming, extruding and boiling, steaming, washing and cooling, wherein the selected raw material is rice or broken rice of which the straight-chain starch content is greater than 20%; compound lactobacillus is added before or after a pulping process to carry out constant-temperature fermentation; the quantity of the compound lactobacillus is10*<6> to 10*<11>cfu / ml; the fermentation temperature is 35-45 DEG C; the fermentation time is 10-20 hours. The harm of latent mixed bacteria is eliminated by using pure enrichment fermentation, the toughness effect is better, the sanitation and the health of the rice-flour noodles are ensured, and the quality and the flavor of the product are improved.

Owner:QINGDAO ANBEIKANG BIOLOGICAL MEDICINE TECH CO LTD

Unique ballistic composition

InactiveUS20070010151A1Control hardnessControl stiffnessSynthetic resin layered productsPersonal protection gearYarnGram

A ballistic composite comprises multiple layers of a fabric having unidirectional ballistic resistant yarns in at least two layers and a resin layer between each pair of such multiple layers adhered to the ballistic resistant yarns but not encapsulation the same and not penetrating the layer of fabric. The ballistic yarn layers are at 90°±5° with respect to each other and the ballistic resistant yarns are stabilized by being woven in a second fabric. The second fabric is formed of yarns having a substantially lower tenacity and tensile modulus than the ballistic resistant yarn. The ballistic resistant yarns have a tenacity of at least about 15 grams per denier and a modulus of at least about 40 grams per denier. The resin in the resin layer has a modulus of at least about 7000 psi.

Owner:BARRDAY

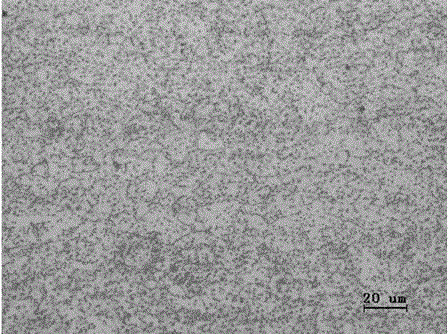

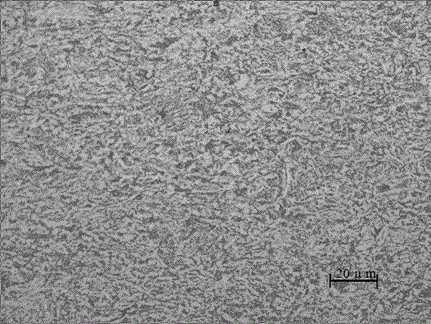

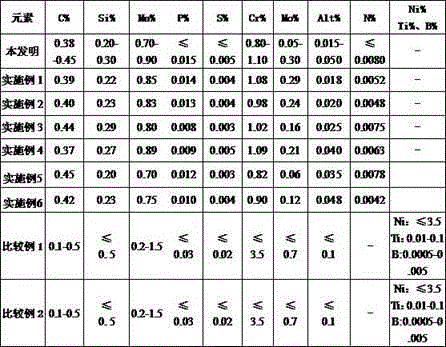

Cold-rolled steel sheet for automobile-seat-adjusting toothed plate produced through precision stamping and manufacturing method of cold-rolled steel sheet

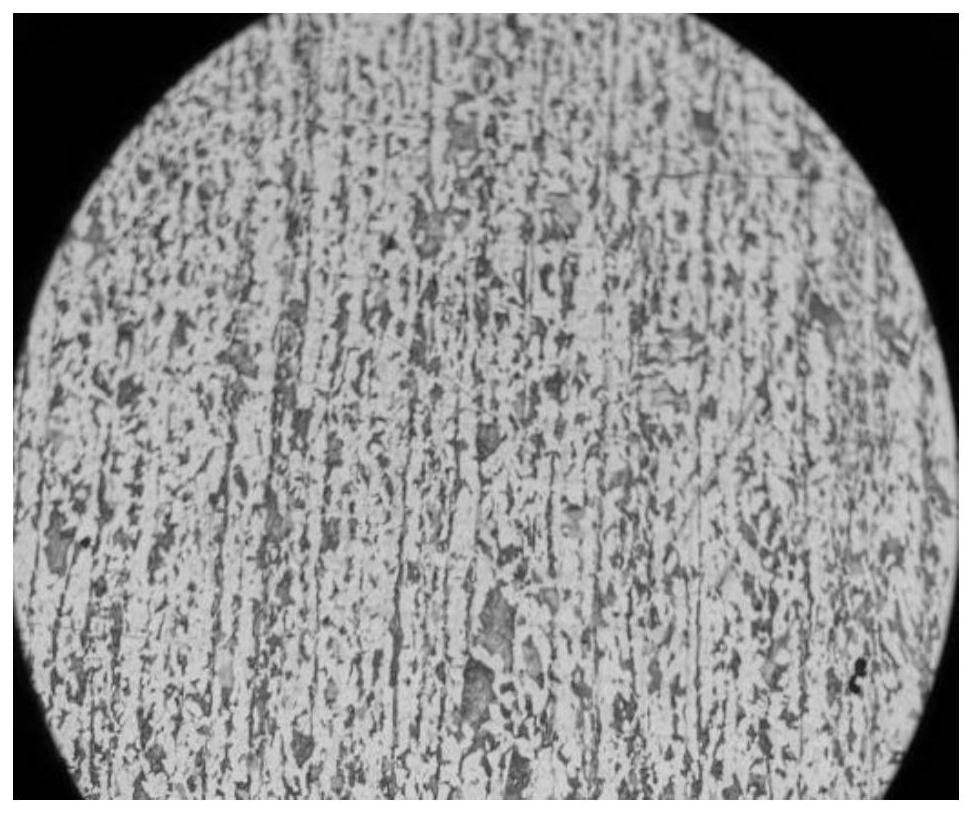

The invention relates to a cold-rolled steel sheet for an automobile-seat-adjusting toothed plate produced through precision stamping and a manufacturing method of the cold-rolled steel sheet, and solves the technical problem that a cold-rolled steel sheet for an automobile-seat-adjusting toothed plate prepared through precision stamping in the prior art is low in size precision and relatively low in spheroidization rate, and is not suitable for high-speed precision stamping. The cold-rolled steel sheet comprises chemical components, by weight: 0.38-0.45% of C, 0.20-0.30% of Si, 0.70-0.90% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.80-1.10% of Cr, 0.05-0.30% of Mo, 0.015-0.050% of Alt, and no more than 0.0080% of N, with the balance being iron and inevitable impurities. The cold-rolled steel sheet is used for high-speed precision stamping to produce components, such as an automobile-seat-adjusting toothed plate.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Sub-micro grain hard alloy anvil and preparation method thereof

ActiveCN103572136AEffective control of flexural strengthAdjust the flexural strengthTemperingVitamin C

The invention discloses a sub-micro grain hard alloy anvil and a preparation method thereof. The sub-micro grain hard alloy anvil comprises the following alloy components: WC (Wolfram Carbide), 10% of Co, 0.4-0.6% of Cr3C2 and 0.2-0.3% of VC (Vitamin C); the particle size of an alloy crystal is 0.8-0.9mum; the porosity of an alloy is A00B00C00; the hardness of the alloy is 90.5-91.5HRA; the coercive force of the alloy is 205-245Oe. The preparation method comprises the steps: with WC powder with the Fisher particle size of 1.0-1.2mum and Co powder with the Fisher particle size of 0.8-1.0mum as raw materials, adding Cr and V additives in the alloy in the preparation process of the WC powder; preparing an alloy mixture by using a rolling wet grinding process, wherein the wet grinding time is 55-60h, and the mass ratio of a ball material is 4:1; drying and granulating the wet ground mixture by using a spray drying granulation method; and sintering a pressed anvil blank at the temperature of 1400-1410 DEG C by using a pressure sintering process, wherein the pressed anvil blank is obtained through cold isostatic compaction; and carrying out copious cooling treatment on the sintered pressed anvil blank by using liquid nitrogen with the temperature of 180 DEG C below zero to 190 DEG C below zero, and then, carrying out subsequent reinforcement treatment on a refined anvil by using a 350-400 DEG C medium-temperature tempering treatment process.

Owner:DALIAN FAR EASTERN CARBIDE

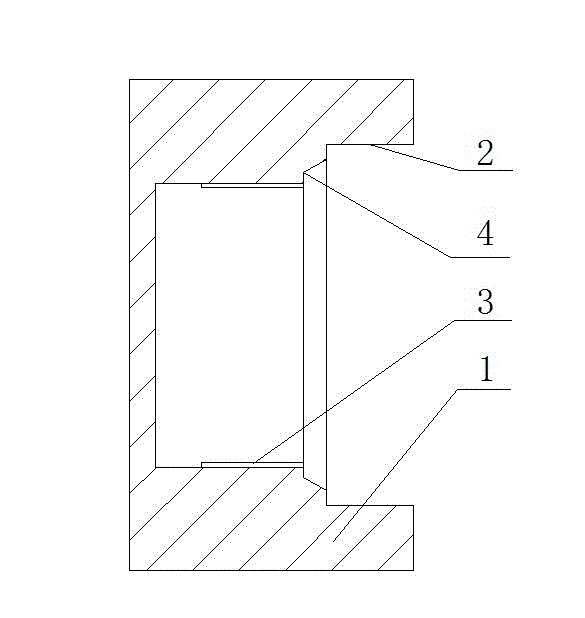

Anti-seepage sleeve of gear shaft

InactiveCN102864405AEasy to installImprove the quality of anti-seepageSolid state diffusion coatingFurnace typesBiochemical engineeringQuenching

The invention discloses an anti-seepage sleeve of a gear shaft. The anti-seepage sleeve comprises a sleeve body (1), wherein a circle (2) is arranged at an opening of the sleeve body (1); the bottom of the sleeve body (1) is provided with a thread (3); and a step (4) is arranged between the thread (3) and the circle (2). The anti-seepage sleeve of the gear shaft, which is used in quenching, has the advantages of being convenient to mount and improved in anti-seepage quality, increasing the production efficiency and saving energy.

Owner:江国辉

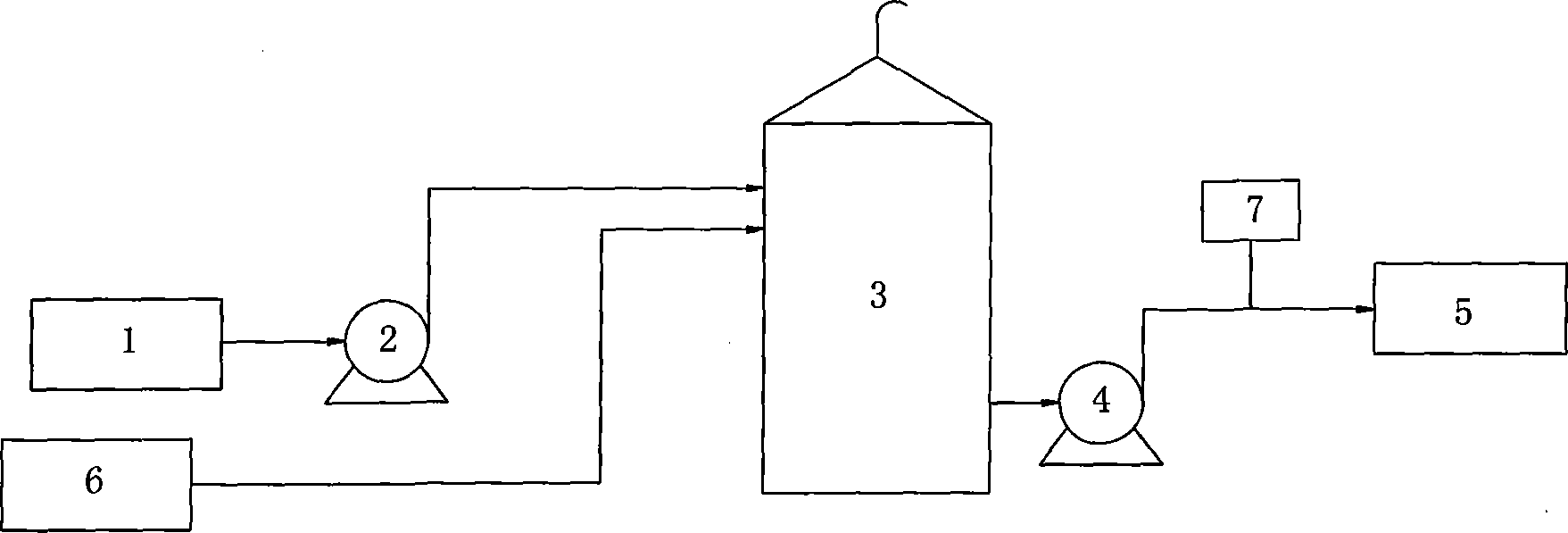

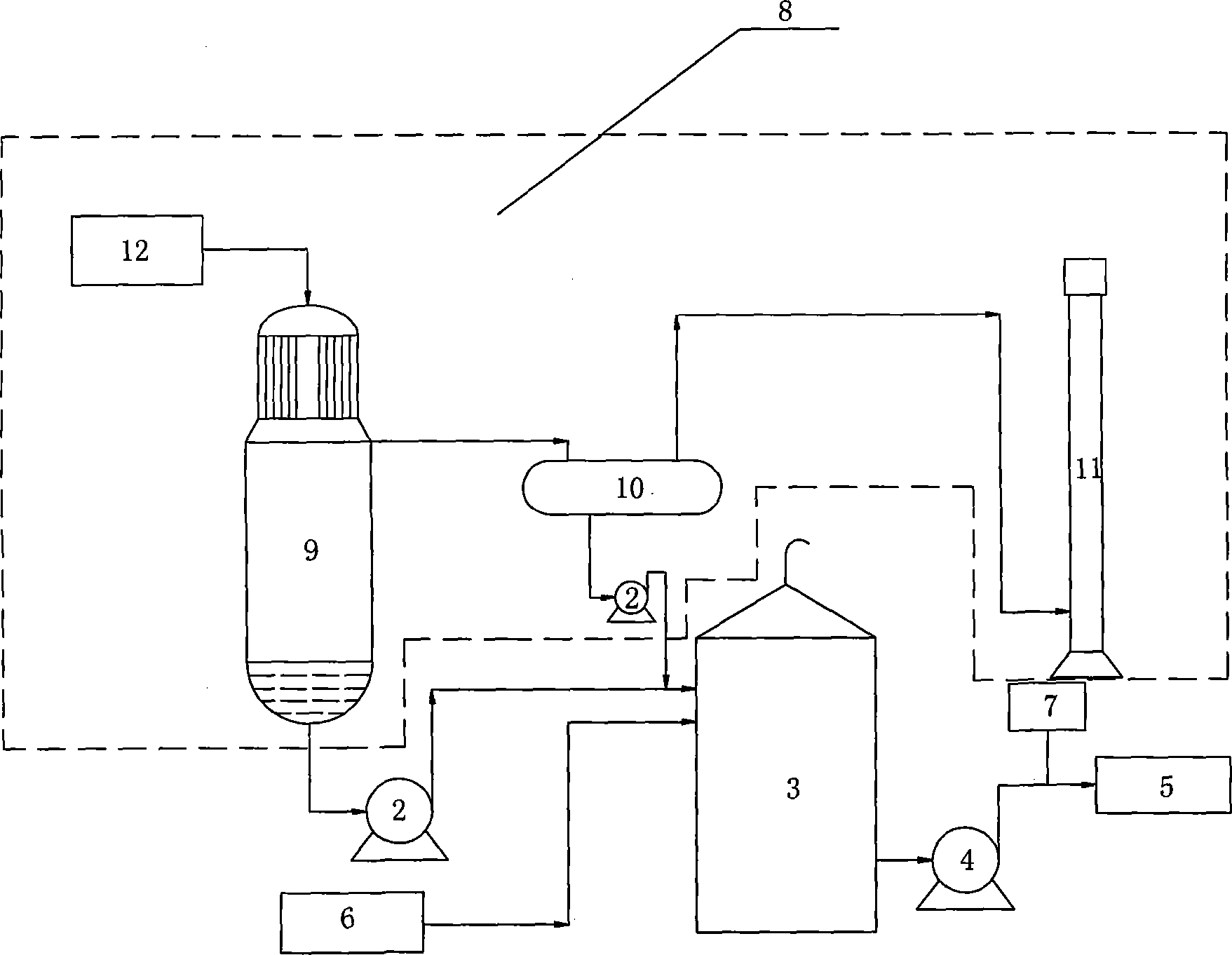

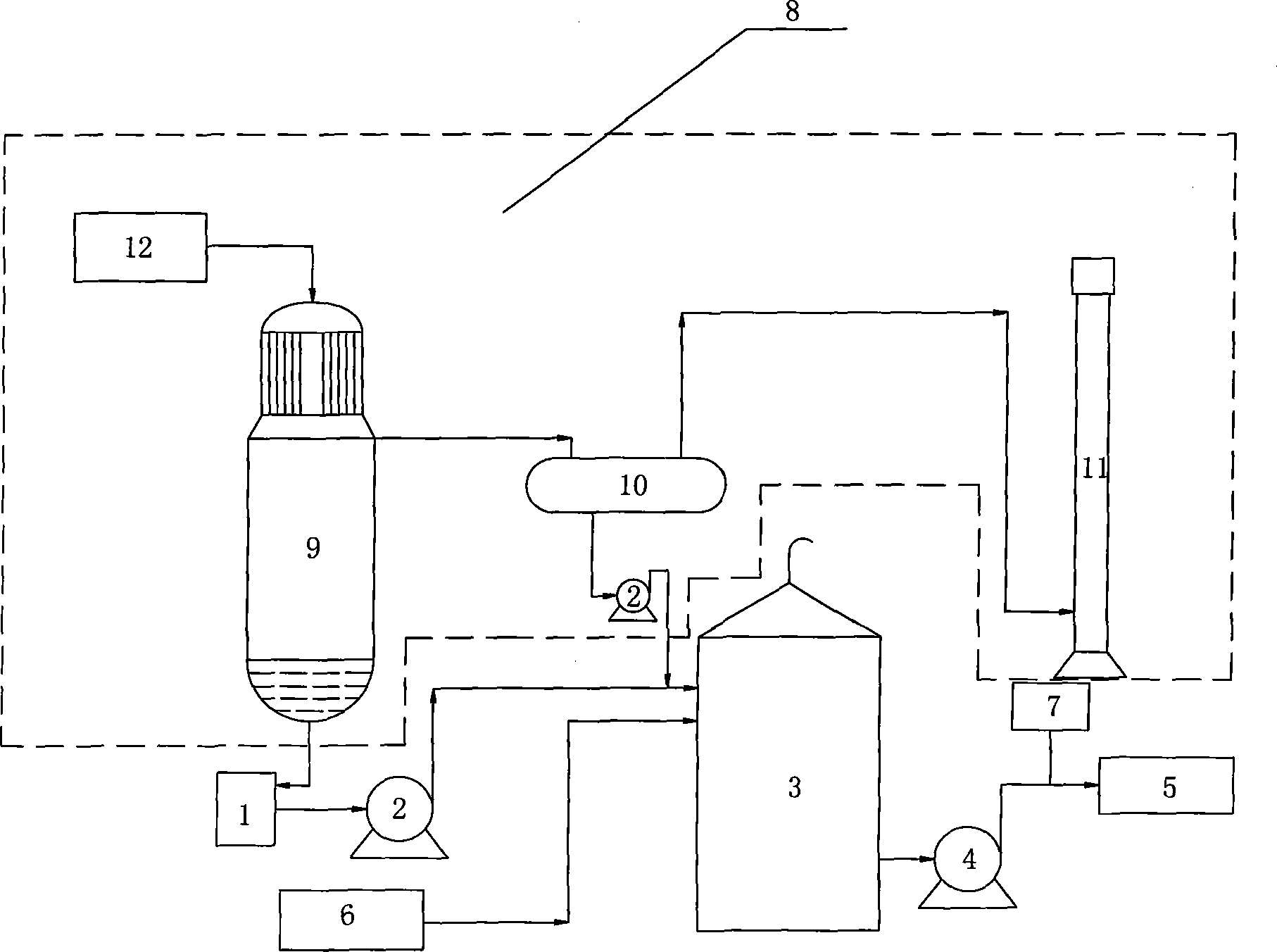

System and method for recycling Fischer-Tropsch synthetic wastewater in indirect coal liquefaction production

ActiveCN103011373BWeak alkalineReduce the burden onWater/sewage treatment by neutralisationChemical industryWater storage

Owner:INNER MONGOLIA YITAI CTO

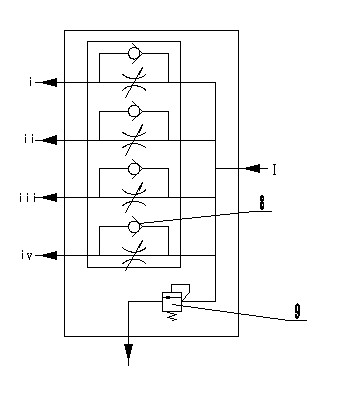

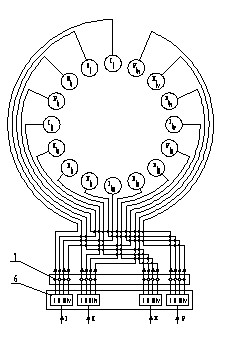

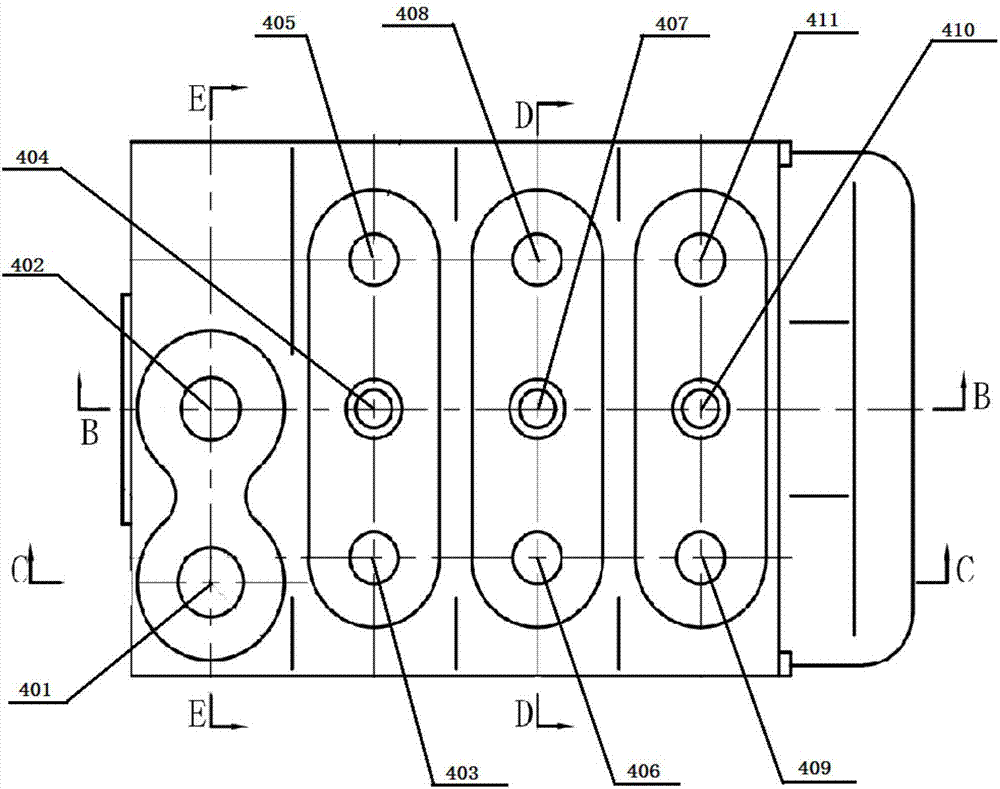

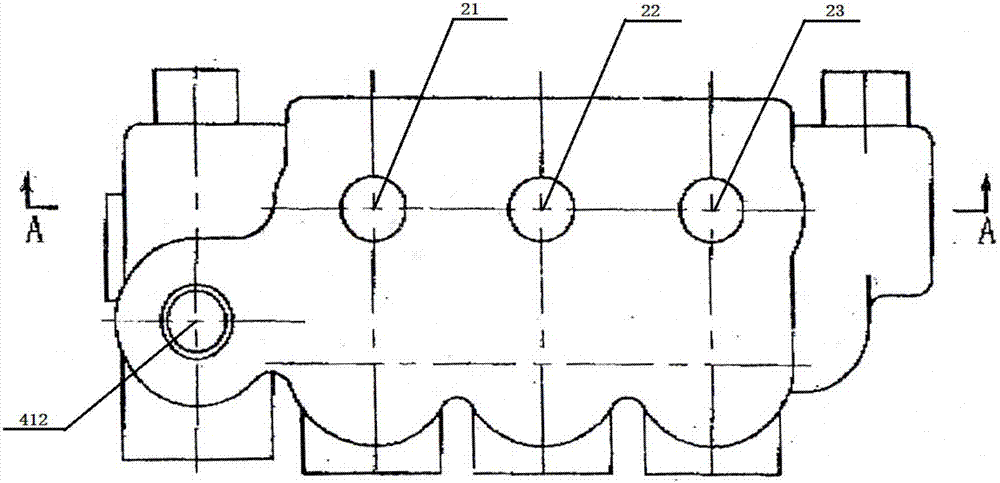

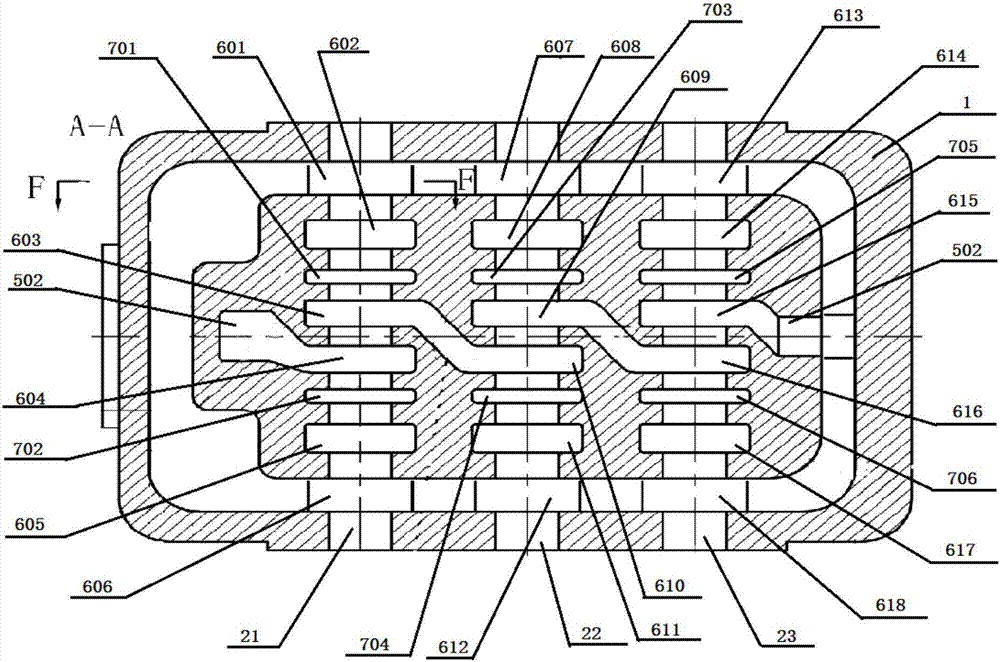

Adaptive variable working condition cylindrical spherical pressure bearing system

ActiveCN101907133AGuaranteed reliabilityGuaranteed durabilityGrain treatmentsBearingsEngineeringHigh pressure

The invention discloses an adaptive variable working condition cylindrical spherical pressure bearing system. The system comprises 12 to 16 independent spherical hydrostatic bearings, wherein every 4 to 8 independent spherical hydrostatic bearings form a group; the spherical hydrostatic bearings in each group share a high-pressure valve block; each spherical hydrostatic bearing is connected with the high-pressure valve blocks through own independent oil passages; each oil passage is also provided with a one-way valve; and each group of spherical hydrostatic bearings are uniformly distributed on the same circular plane in a sequential staggering way. The system can automatically swing to perform adjustment along with the change of the action direction of a load, also prevent the change of an oil supply flow along with pressure or temperature fluctuation and ensure stable oil supply to ensure that a stable working oil film is formed.

Owner:CHONGQING GEARBOX

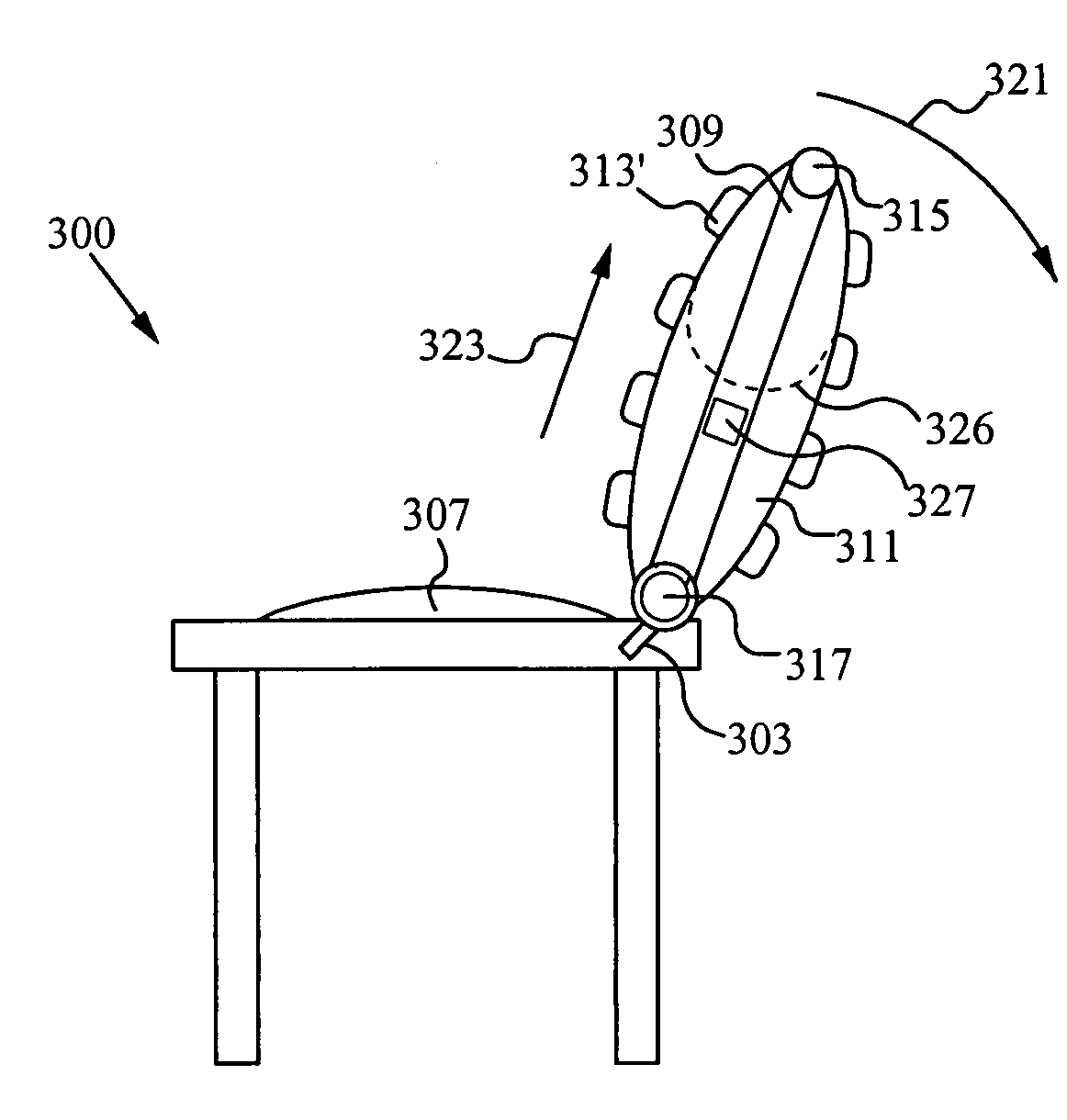

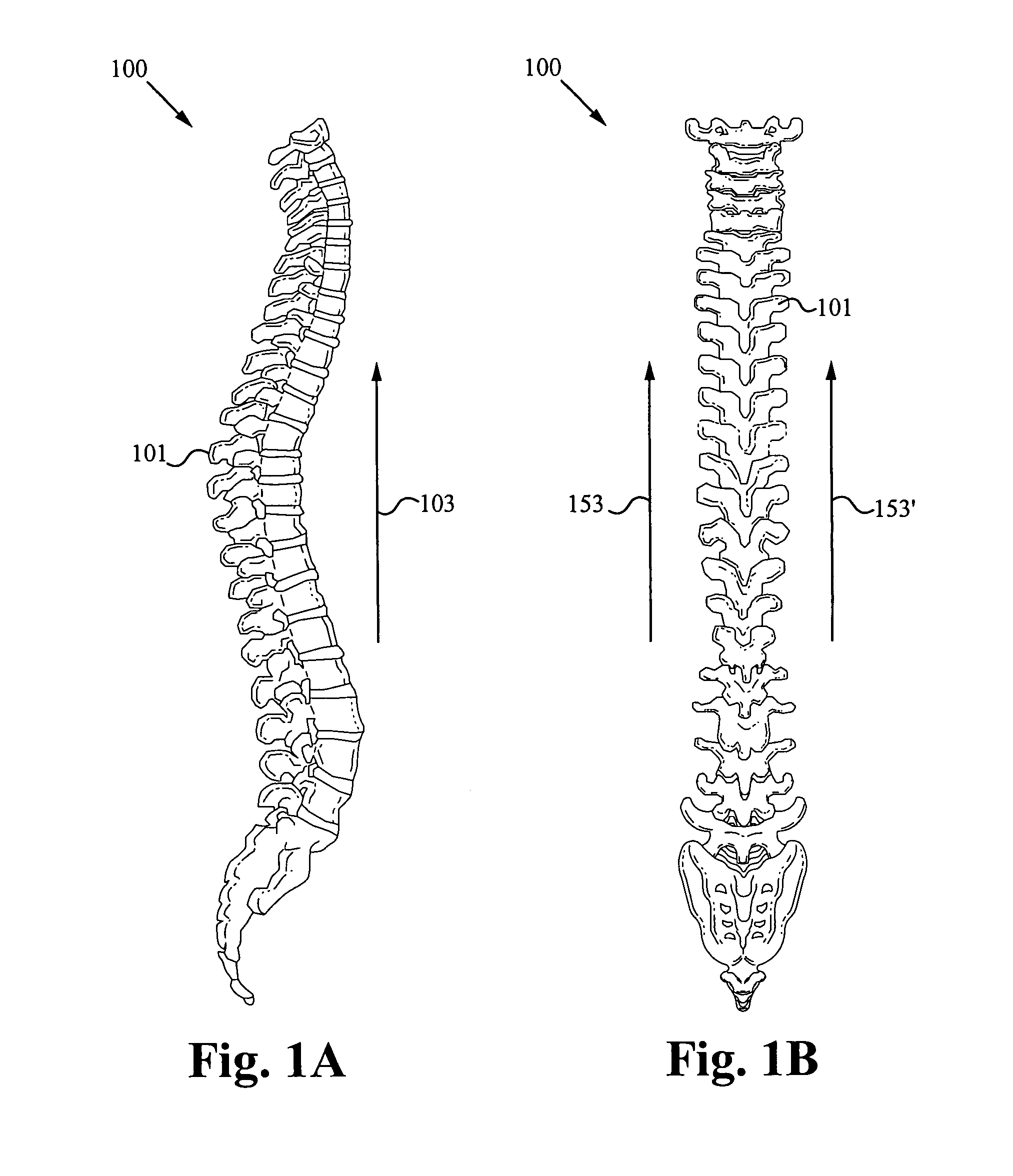

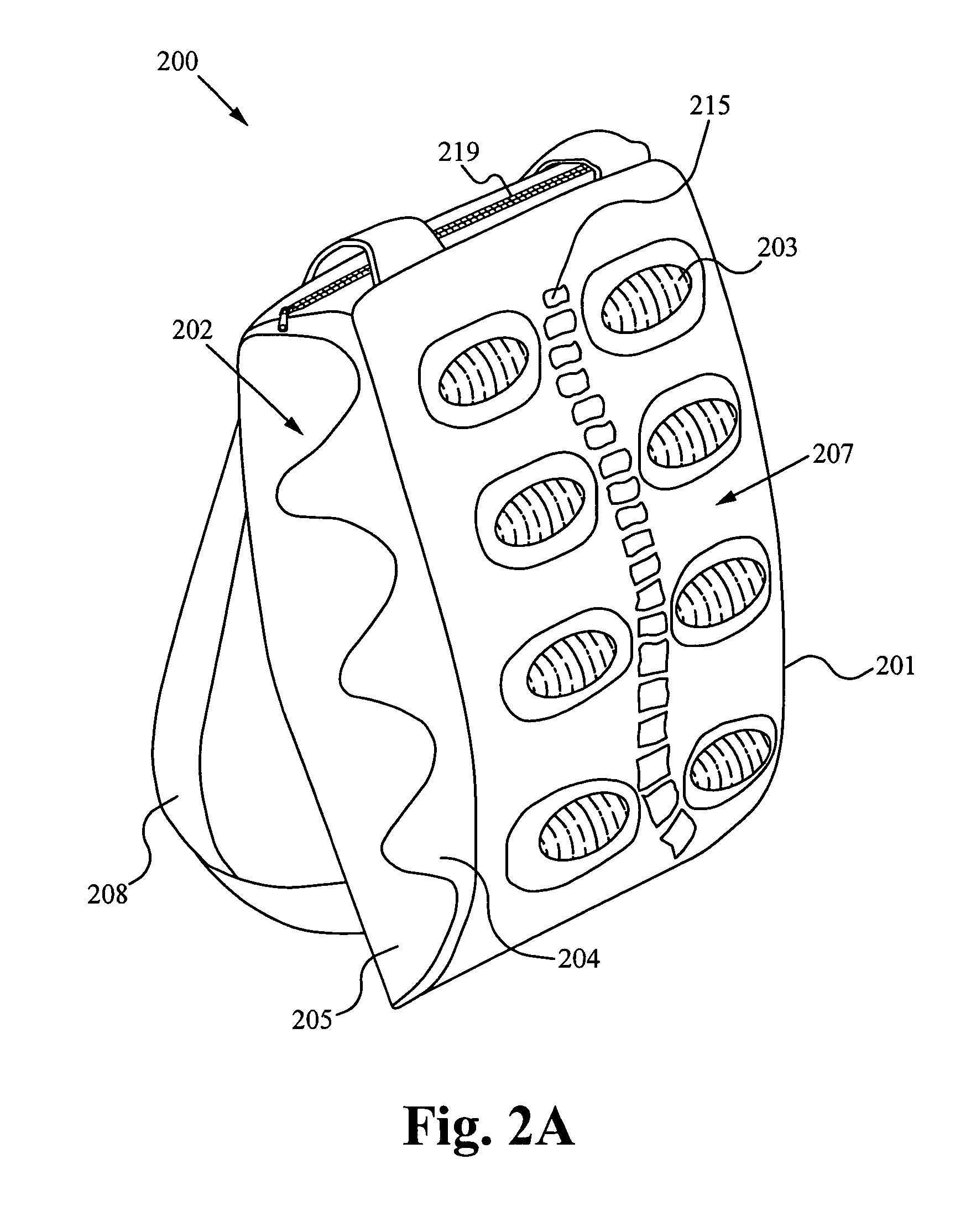

Ergonomic systems and devices

InactiveUS7540564B2Improve postureLow compressibilityStoolsAdjustable chairsBiomedical engineeringCushion

Ergonomic systems and devices are disclosed. In accordance with the embodiments of the invention, a system or device includes a traction surface that provides traction and / or support through contact with a portion of a user's body. For example, an ergonomic system includes a backrest cushion. The backrest cushion has a traction surface with a plurality of protruding traction pads for resting against a user's back and pulling along the user's back. The traction pads help stretch or decompress the user's spine through contact at multiple positions on the back and flanking the spine. In alternative embodiments of the invention, a chair, resting table, bed or other article of furniture includes one or more traction surfaces that provide traction through contact with one or more corresponding portions of a user's body.

Owner:GOKHALE ESTHER

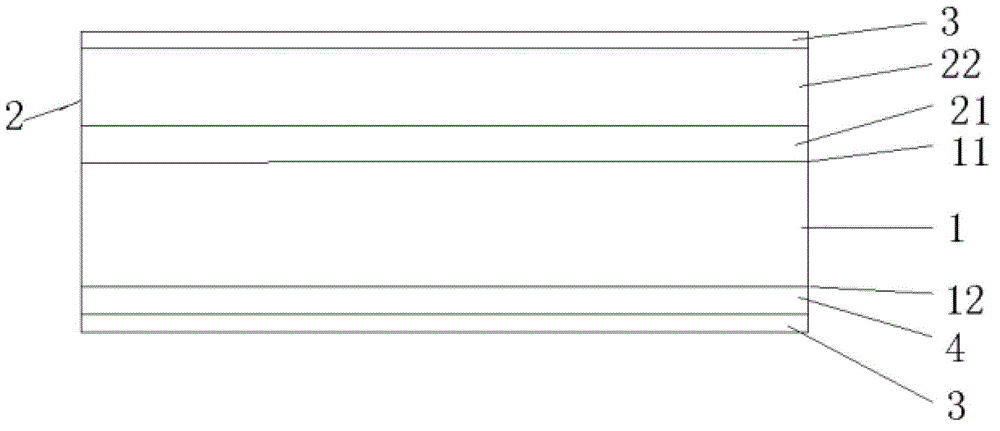

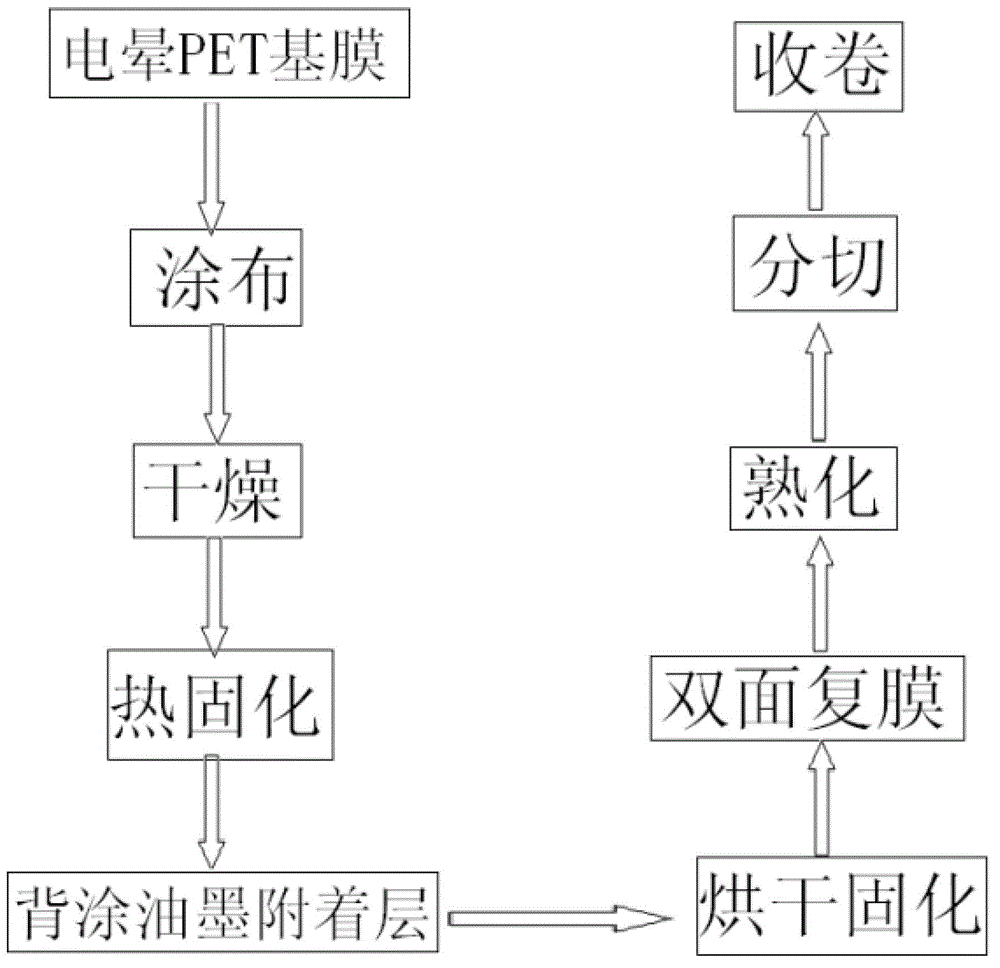

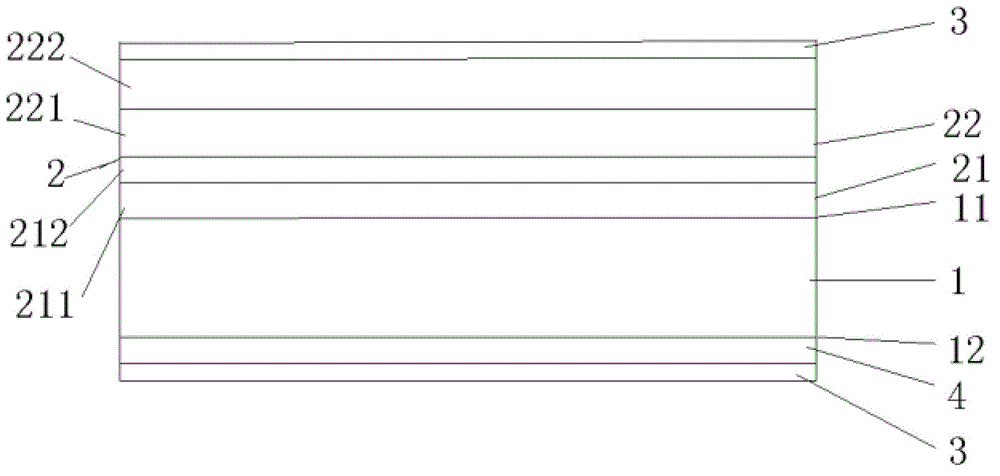

Thermosetting type IMD film and preparation method thereof

InactiveCN102744939AGood light transmissionGood flexibilitySynthetic resin layered productsPolyesterEngineering

The invention provides a thermosetting type IMD film and a preparation method thereof. The IMD film comprises a PET (polyester) base film, wherein an anti-scraping coating layer is arranged on the upper surface of the PET base film; a film layer is arranged on the anti-scraping coating layer; an ink adhesion layer is arranged on the lower surface of the PET base film; the film layer is arranged on the ink adhesion layer; and the anti-scraping coating layer is a thermosetting coating layer. The preparation method comprises the following steps of performing corona on the PET base film; coating the PET base film; drying the coated PET base film; drying and curing the dried PET base film; coating the ink adhesion layer on the back of the thermoset PET base film; and drying and curing the PET base film of which the back is coated with the ink adhesion layer, coating the film on the two surfaces, and curing, rolling and cutting the film. The thermosetting type IMD film has the characteristics of high transmittance, flexibility and adhesion. The process of strengthening the coating is a progressive temperature raising process, the cross-linking of the coating is fuller, and the requirements of high transmittance, flexibility and adhesion are met.

Owner:南京市江亚数码科技有限公司

Integral triple valve and casting technology thereof

ActiveCN107052265AAssembly positioning is accurateHighly integratedFoundry mouldsFoundry coresSpatial structureMechanical engineering

The invention relates to a metal valve, in particular to an integral triple valve and a casting technology thereof. The triple valve casting comprises a valve body, valve element through holes, a main flowing channel, through holes, auxiliary flowing channels, circular-ring-shaped oil grooves and small circular-ring-shaped oil grooves are formed in the valve body, the auxiliary flowing channels and the internal main flowing channel are used for connecting the valve element through holes with the through holes, the circular-ring-shaped oil grooves and the small circular-ring-shaped oil grooves are formed in the valve element through holes, the through holes and the auxiliary flowing channels, and openings of the through holes are located on the surfaces of the valve body and communicate with the auxiliary flowing channels of the valve body. The casting technology comprises the steps of shell-shaped mold making, clay core making, clay core assembling, clay core coating, clay core and shell-shaped mold assembling, molding operating, smelting operating, pouring operating and casting cleaning and inspecting. The integral triple valve has the advantages of being high in integration level, small in spatial structure, precise in internal flowing channel size, long in life, high in inner surface cleanliness and the like and is wide in application range.

Owner:南通华东油压科技有限公司

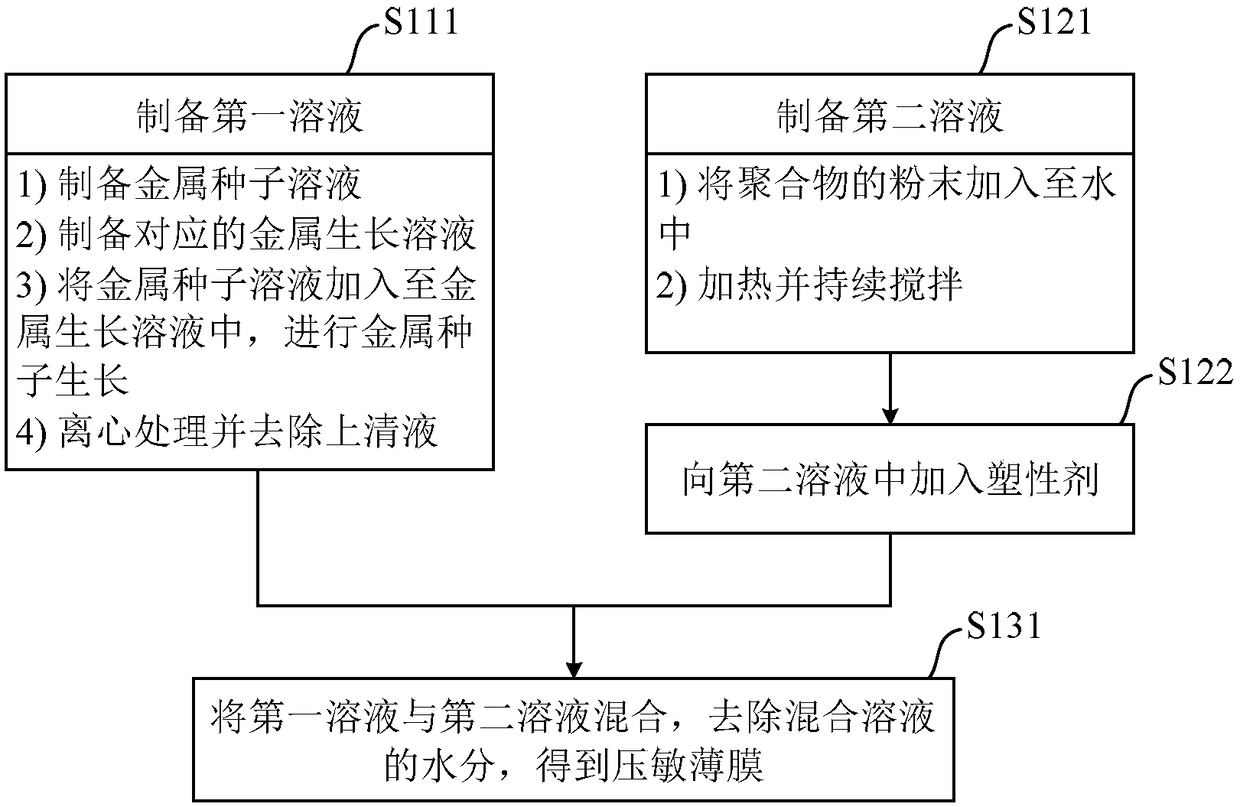

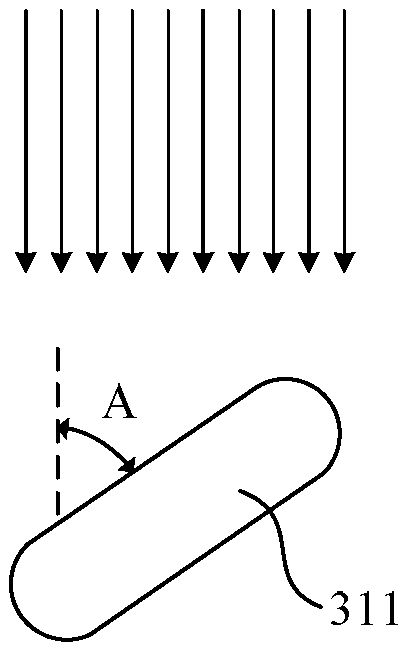

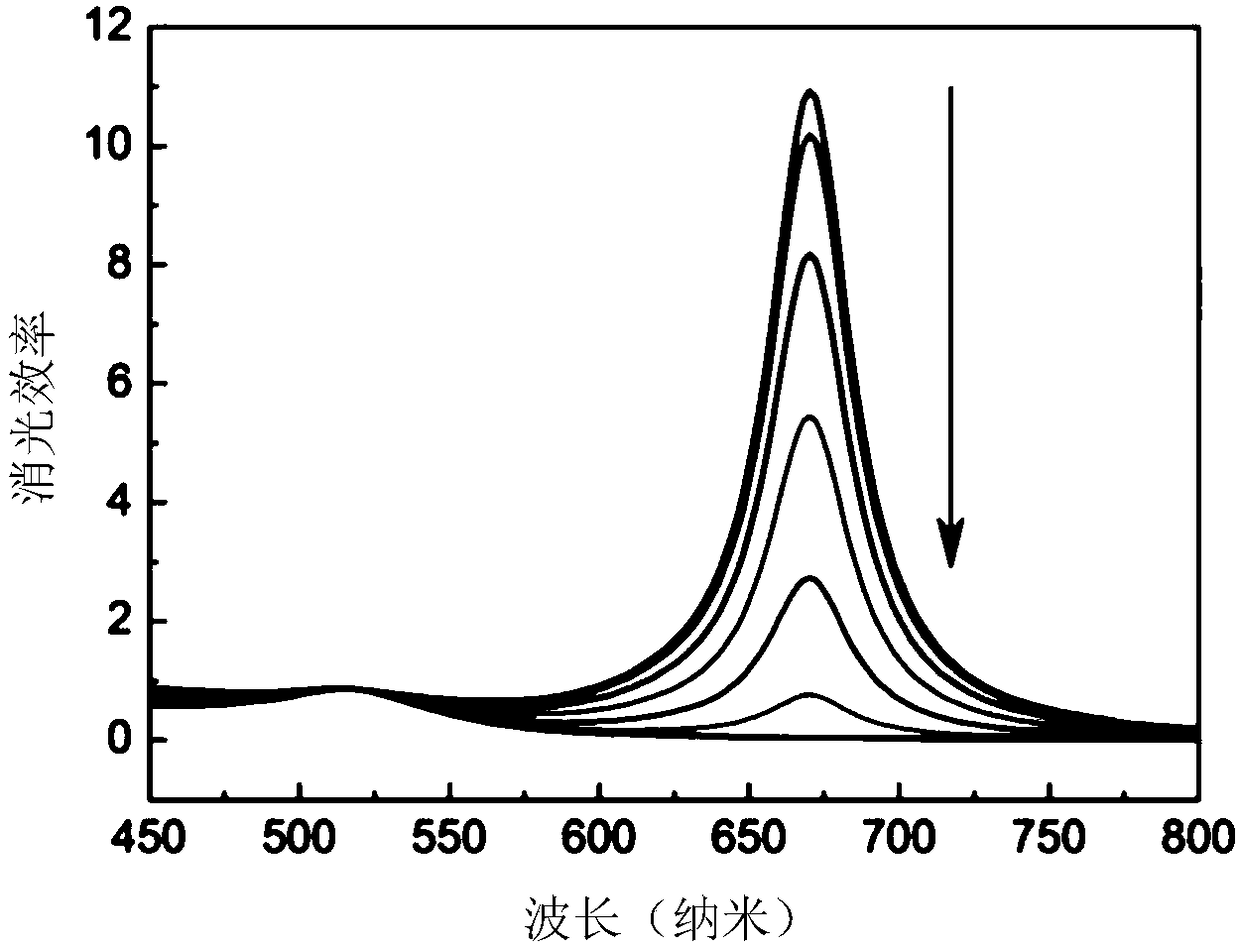

Pressure-sensitive film, preparation method of pressure-sensitive film and pressure sensor

InactiveCN108663152AAvoid interferenceImprove accuracyFluid pressure measurement using elastically-deformable gaugesElectromagnetic interferenceMoisture

The invention discloses a pressure-sensitive film, a preparation method of the pressure-sensitive film and a pressure sensor. The preparation method of the pressure-sensitive film comprises the stepsof preparing a first solution comprising one-dimensional or two-dimensional metal nanoparticles; preparing a second solution comprising a polymer compatible with the metal nanoparticles; mixing the first solution with the second solution to remove moisture from the mixed solution, so as to obtain the pressure-sensitive film. Before the first solution is mixed with the second solution, a plastic agent is added into the second solution. According to the preparation method of the pressure-sensitive film, the pressure-sensitive film sensitive to pressure and capable of absorbing spectrum can be prepared. The pressure-sensitive film can be used in a pressure sensor, and the electromagnetic interference resistance of the sensor is improved.

Owner:KUANG CHI INST OF ADVANCED TECH +1

Method for preparing micro-arc oxidation ceramic film layer on surface of magnesium alloy

InactiveCN103789810AControl hardnessAdjust porosity contentCellsAnodisationMicro arc oxidationCeramic membrane

The invention relates to a method for preparing a micro-arc oxidation ceramic film layer on the surface of a magnesium alloy. By controlling the duty cycle and the frequency of a micro-arc oxidation power supply, the pore content and the pore size of the micro-arc oxidation ceramic film layer can be effectively adjusted, and furthermore the hardness of the micro-arc oxidation ceramic film layer is controlled; in addition, the heat in the micro-arc oxidation process can be dissipated through a compressed air stirring system, and a solution is prevented from being partially overheated. The method ensures that the appearance of the micro-arc oxidation ceramic film layer is uniform, continuous and consistent, the hardness of a film layer is controlled to be more than HV400, the salt mist resistance time is longer than 1,000 hours, and meanwhile the binding force of the film layer and a substrate is higher than 40MPa.

Owner:HARBIN DONGAN ENGINE GRP

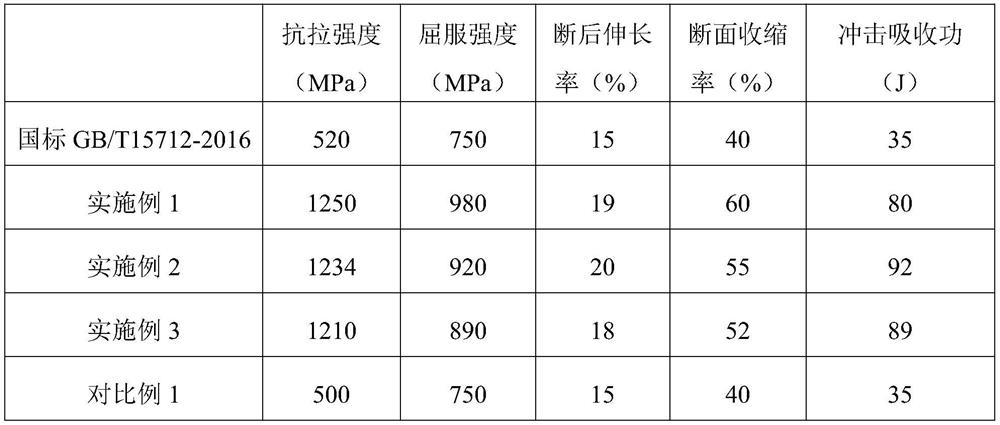

High-forming nitrogen-containing austenitic stainless steel and manufacturing method thereof

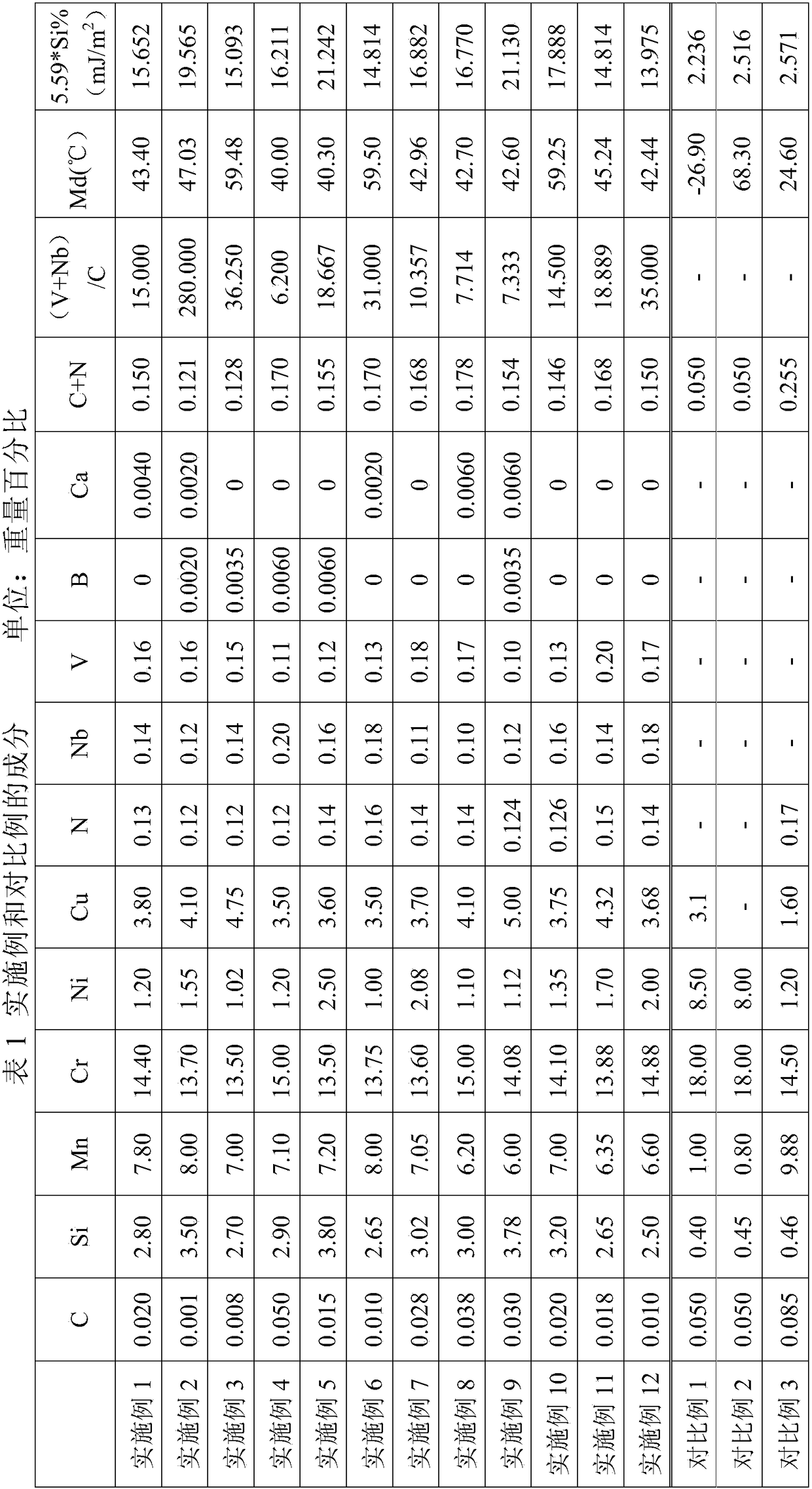

The invention discloses a high-forming nitrogen-containing austenitic stainless steel and a manufacturing method thereof. The composition of the steel comprises the following components of, by weight,0.001-0.05% of C, 2.50-3.80% of Si, 6.0-8.0% of Mn, 13.5-15.0% of Cr, 1.0-2.5% of Ni, 0.12-0.15% of N, 3.5-5.0% of Cu, less than or equal to 0.004% of S, 0.1-0.2% of V, 0.1-0.2% of Nb, and the balance Fe and inevitable impurities, wherein C+N is less than or equal to 0.18% , (V + Nb) / C is larger than or equal to 5, the content of Si multiplied by 5.59 mJ / m<2> is greater than or equal to 14 mJ / m<2>, Md30 / 50 is 40-70 DEG C, the average grain size is larger than or equal to 90 microns, and the hardness is less than or equal to HV180. According to the preparation method disclosed by the invention, the Ni is replaced with nitrogen alloying, and the Mn, the Cu and the like which obtain austenite structures are added; the Si and the like are added, so that lower stacking fault energy is remarkably reduced; the initial hardness of a material is reduced, and the temperature of the MD30 / 50 is controlled, so that the martensite phase changes slowly in the strain process; the erishen value is larger than or equal to 14.5, LDR is larger than or equal to 2.4, the requirements of complex forming is met, and the performance is close to 304 DDQ with high forming and high cost, so that the steel can be widely applied to industries such as electronics, instruments and apparatus, products and the like.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

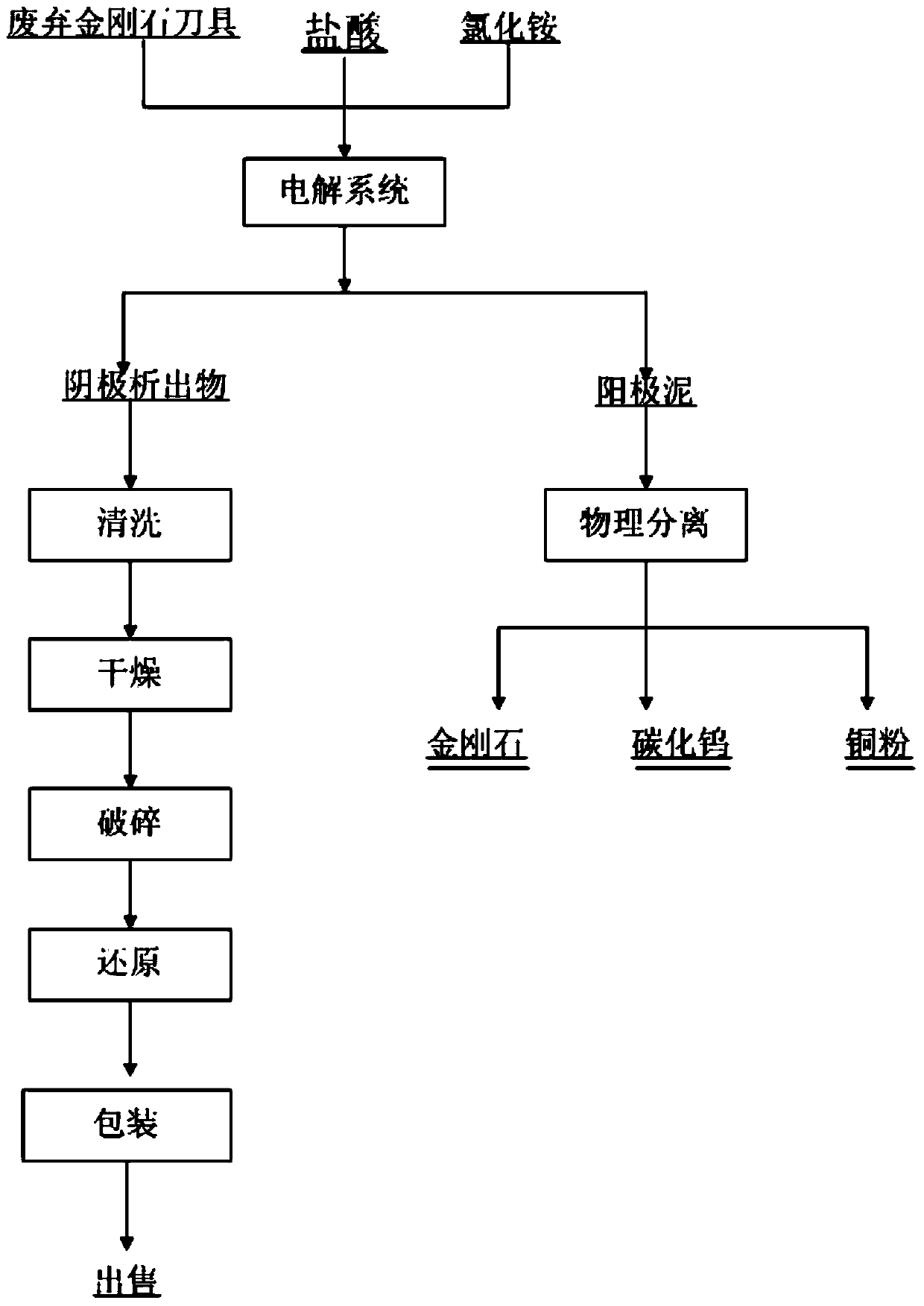

Comprehensive recovery method for waste iron-based diamond tool

InactiveCN104195591AImprove protectionShorten the timePhotography auxillary processesProcess efficiency improvementRecovery methodMaterials science

The invention relates to a comprehensive recovery method for a waste iron-based diamond tool, and belongs to the technical field of comprehensive utilization of resources. The method comprises the following steps: using the waste iron-based diamond tool as an anode, using an inert material as a cathode, and using a solution containing ferrous ions as an electrolyte; carrying out recycling and electrolyzation under the condition that the pH value is 3-6; during the recycling and electrolyzation, obtaining a cathode sediment containing hydrogen and iron in a cathode area and obtaining anode mud containing diamond in an anode area, wherein the concentration of the ferrous ions in the electrolyte is 20-50 g / L, during the recycling and electrolyzation, the cathode-current density is controlled to be 200-500 A / m <2>, the cell voltage is controlled to be 2.0-4.5V, and the current efficiency is controlled to be 80-95%, the cathode sediment is directly utilized after being dried, smashed and restored, and the anode mud is directly utilized after being dried and separated. The comprehensive recovery method has the advantages of simple technology, easy operation, environmental protection, low cost, high product value and the like, and is suitable for popularization and application.

Owner:陈忠

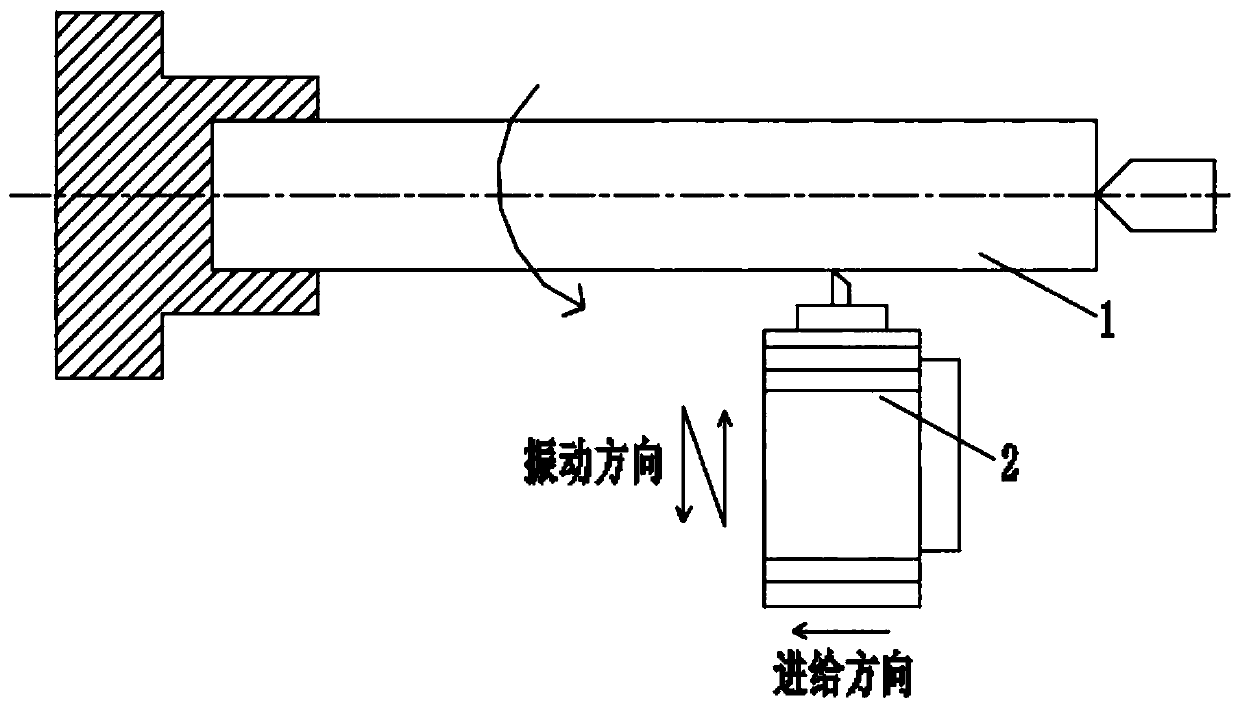

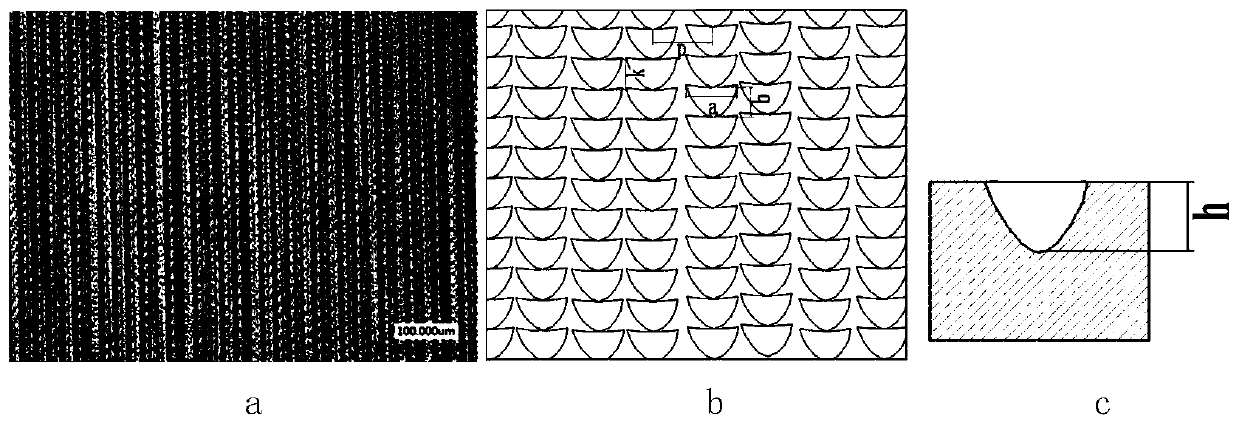

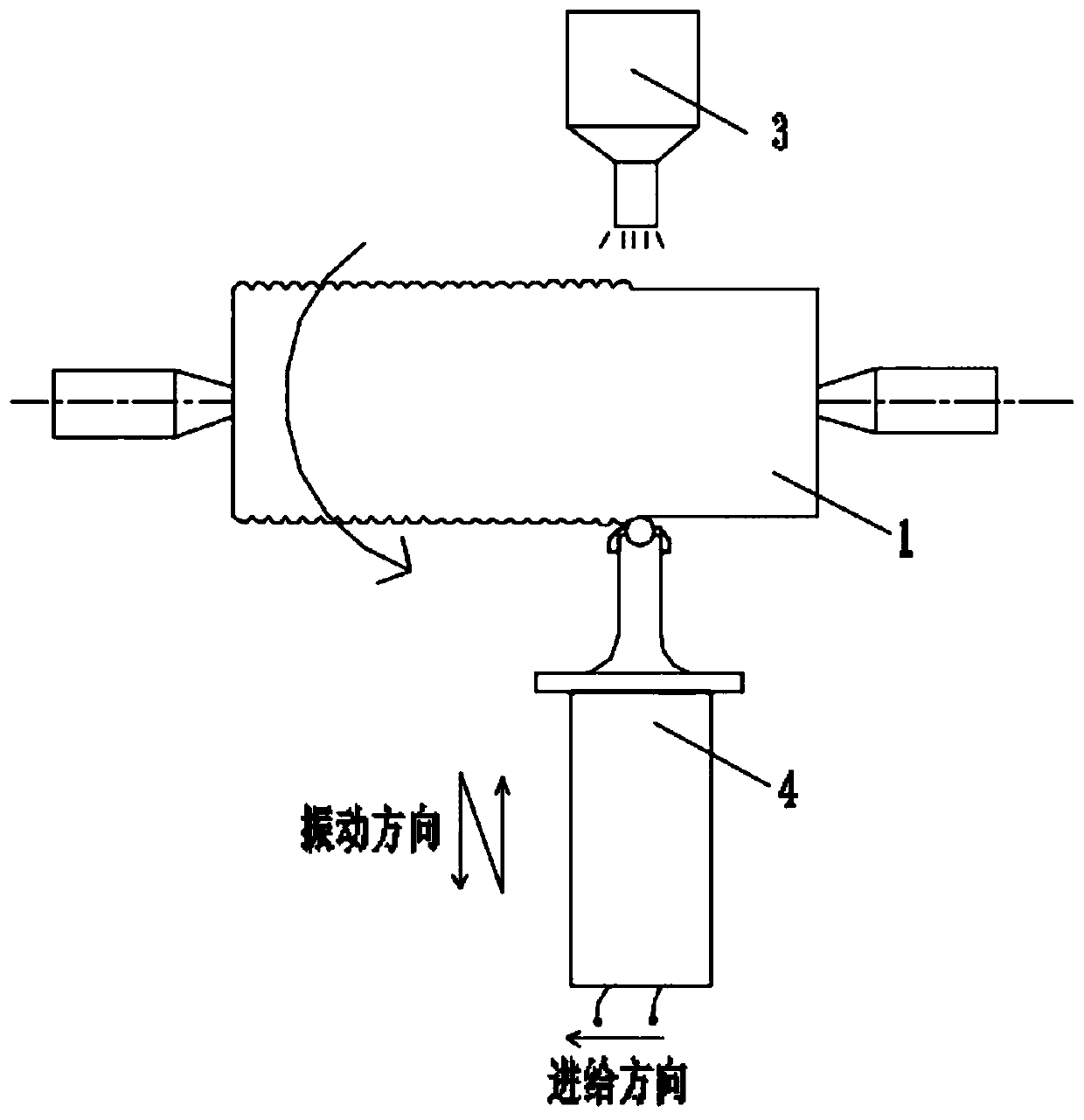

High-performance surface composite strengthening method for shaft parts

The invention discloses a high-performance surface composite strengthening method for shaft parts, and belongs to the field of surface machining of metal materials. The surface composite strengtheningmethod comprises the following steps that S1, carrying out radial vibration turning on the shaft parts, and forming a specific regular distributed micron scale / nano scale microcosmic geometrical morphology on the surfaces of the shaft parts; S2, coating the surfaces; and S3, carrying out mechanical reinforcement treatment on the coating surfaces by adopting an ultrasonic rolling processing technology. Compared with the prior art, the high-performance surface composite strengthening method for the shaft parts can greatly improve the bonding strength of a bonding interface of a base material and a coating layer, meanwhile, the hardness, the fatigue strength and the wear-resistant and corrosion-resistant shaft parts of the final forming surfaces are improved, and the method has good popularization and application values.

Owner:QILU UNIV OF TECH

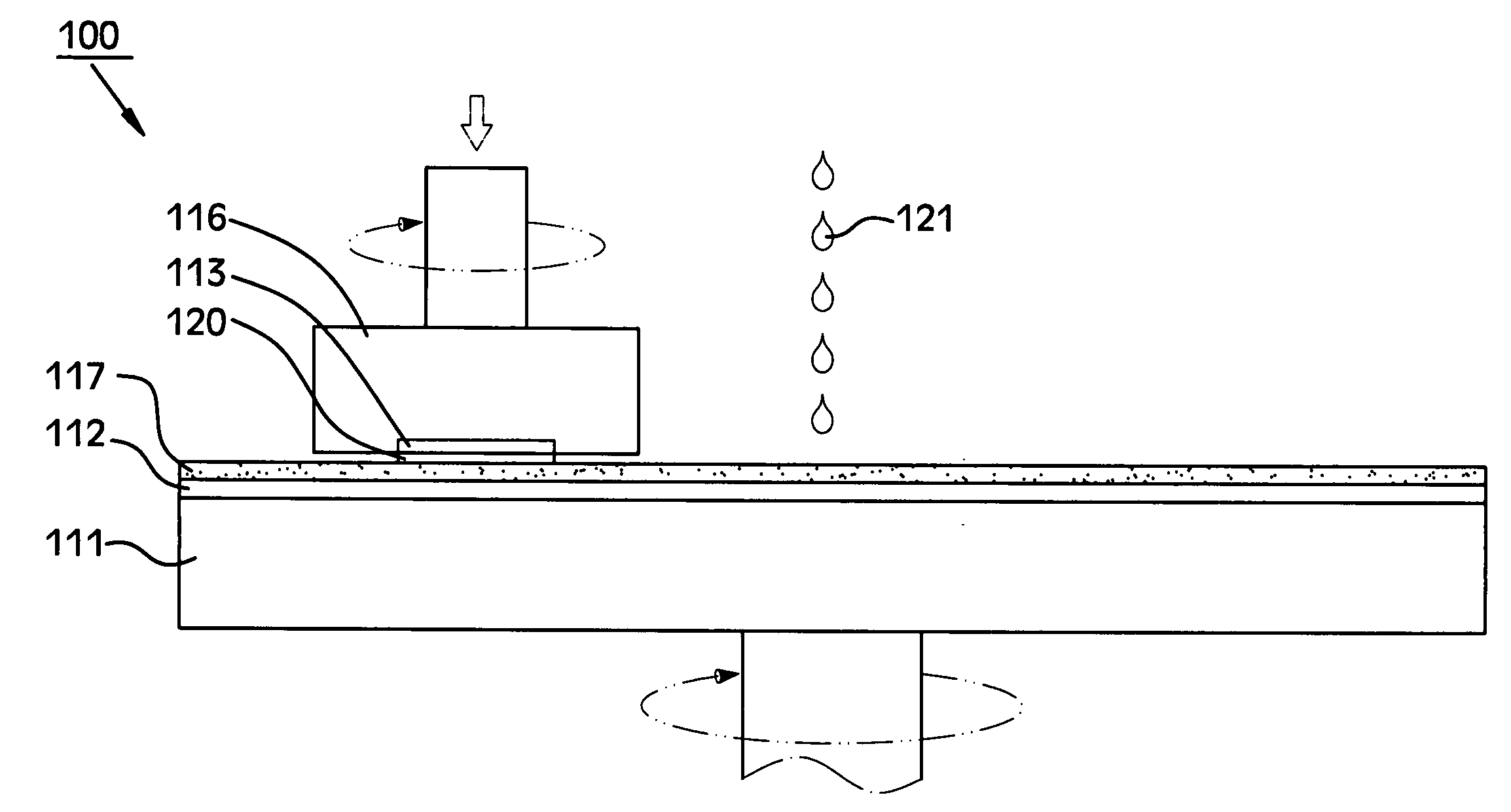

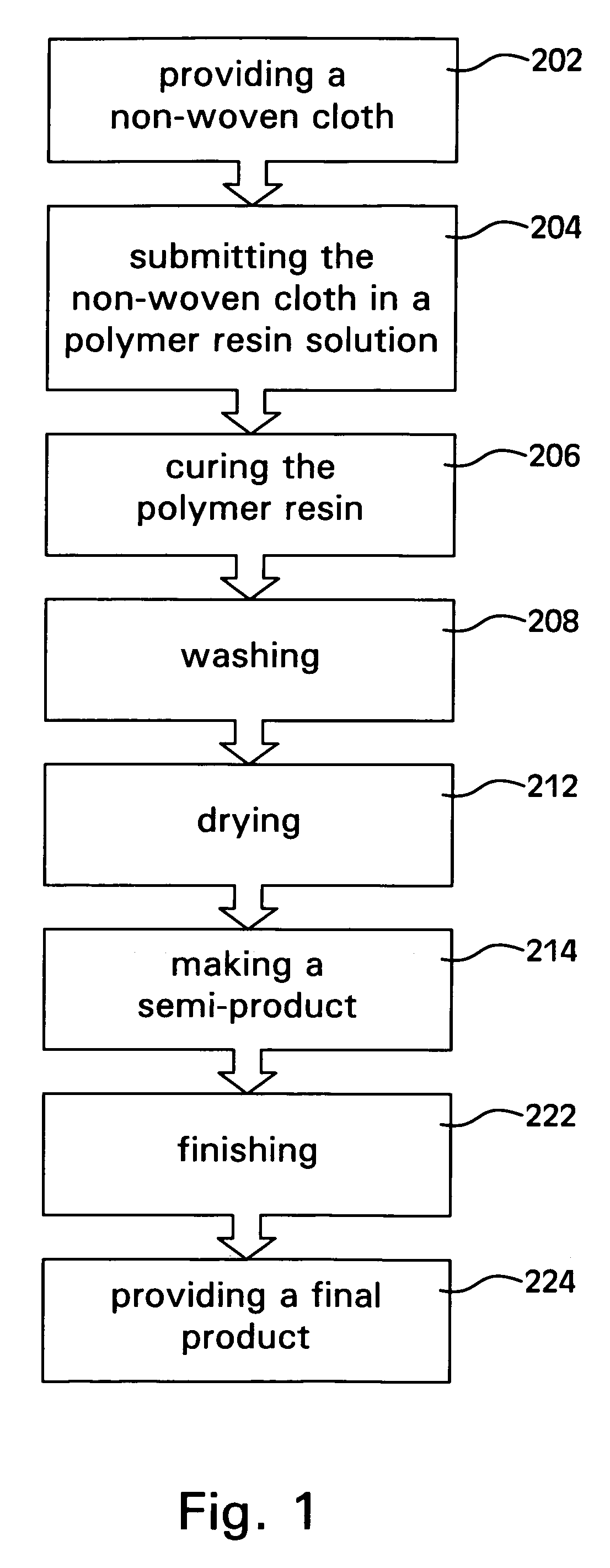

Polishing pad and method for manufacturing the polishing pad

InactiveUS20070155268A1Speed up the flowDifferenceSynthetic resin layered productsCleaning equipmentNonwoven fabricMechanical engineering

A polishing pad includes a non-woven cloth and a continuous porous polymer. The non-woven cloth includes fibers. The polymer includes a plurality of holes communicated with one another. The polymer is cured in and bonded to the non-woven cloth. A surface of the polishing pad is constituted by the fibers of the non-woven cloth and the polymer.

Owner:SAN FANG CHEM IND

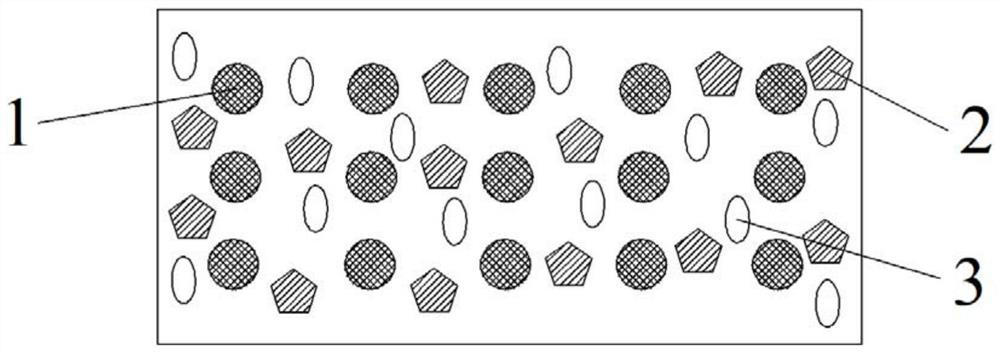

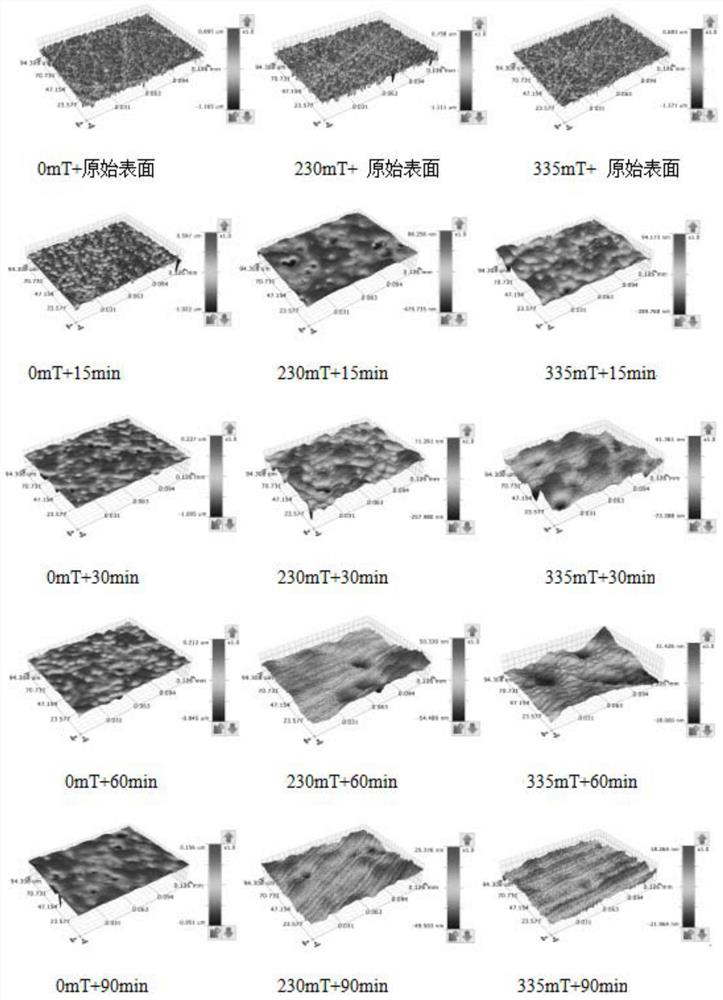

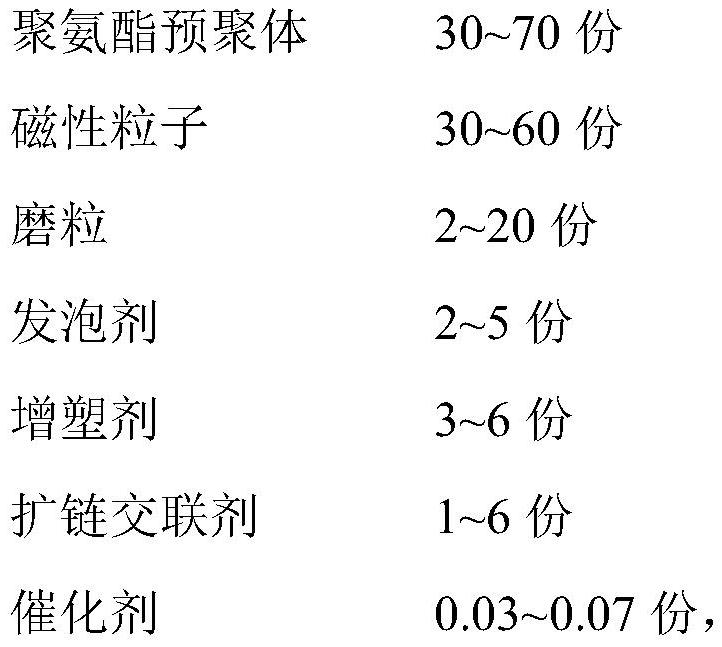

Magnetorheological elastomer as well as preparation method and application thereof

ActiveCN113770816AExcellent magnetorheological propertiesModulation of mechanical removalEdge grinding machinesPolishing machinesElastomerPolymer science

The invention discloses a magnetorheological elastomer as well as a preparation method and application thereof. The magnetorheological elastomer comprises the following components of, in parts by weight, 30-70 parts of a polyurethane prepolymer, 30-60 parts of magnetic particles, 2-20 parts of abrasive particles, 2-5 parts of a foaming agent, 3-6 parts of a plasticizer, 1-6 parts of a chain extension cross-linking agent and 0.03-0.07 part of a catalyst, and the magnetic particles are carbonyl iron powder and / or ferroferric oxide. According to the magnetorheological elastomer, the magnetic particles serve as carriers, a magnetic chain string consistent with a magnetic field line in direction is formed under the action of a directional magnetic field in the pre-structuring process, an abrasive material, a foaming agent and other substances are clamped in the magnetic chain string, and after vulcanization, the magnetorheological elastomer with the magnetic particles, the abrasive particles and air holes in directional arrangement and capable of being subjected to a solid-phase Fenton reaction is finally formed; and the magnetorheological elastomer can be applied to grinding and polishing of hard and brittle photoelectric materials, the machining efficiency is effectively improved, coarse polishing and fine polishing can be synchronously achieved, and a high-quality machined surface is obtained.

Owner:GUANGDONG UNIV OF TECH

NM300XT steel band with great formability and production method thereof

The invention relates to a NM300XT steel band with great formability. The NM300XT steel band consists of the following chemical components in a percent by mass: 0.14-0.22% of C, 0.40-0.70% of Si, 1.2-1.5% of Mn, smaller than or equal to 0.016% of P, smaller than or equal to 0.006% of S, 0.012-0.050% of Als, 0.006-0.030% of Nb and 0.0009-0.002% of B. The invention further provides a production method of the NM300XT steel band with great formability. A two-stage laminar cooling technology is adopted at a cooling procedure, the first-stage cooling speed is 45-50DEG C / S, the second-stage cooling speed is 30-50DEG C / S, and the coiling temperature is 250-300DEG C. The NM300XT steel band with great formability has stable coiling property and uniform crystal grains, and the deformation evenness ofthe NM300XT steel band is greatly improved.

Owner:HANDAN IRON & STEEL GROUP +1

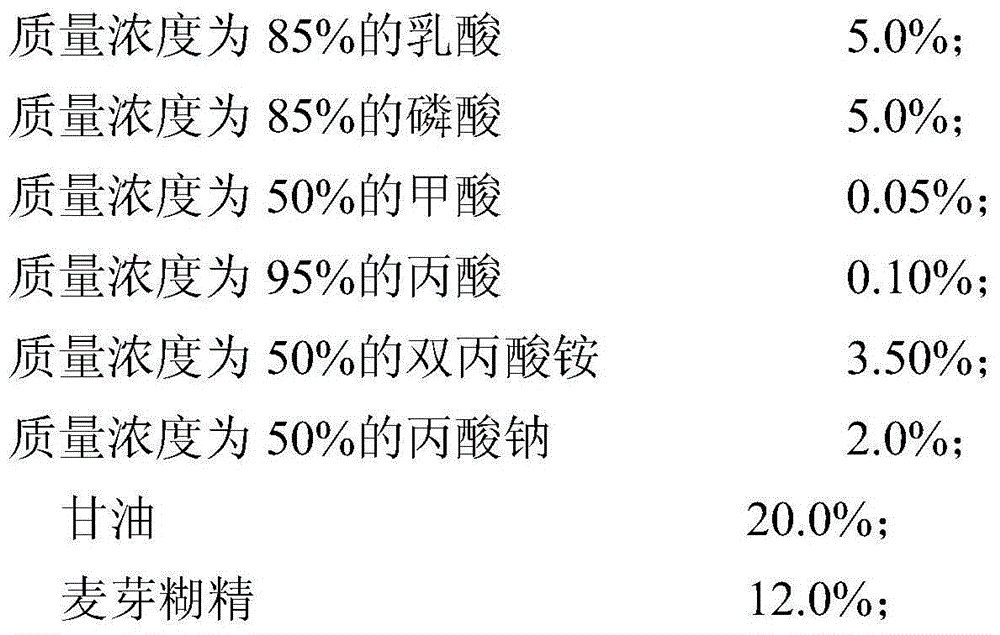

Composite liquid acidification and mildew resistance agent and preparation method thereof

InactiveCN104686796AAvoid negative effectsImprove ripenessAnimal feeding stuffPropanoic acidGlycerol

The present invention discloses a composite liquid acidification and mildew resistance agent and a preparation method thereof. The composite liquid acidification and mildew resistance agent includes the following raw materials in parts by mass: 5.0-9.50% of 85% lactic acid, 5.0-9.50% of 85% phosphoric acid, 0.05-0.10% of 50% formic acid, 0.10-0.20% of 95% propionic acid, 3.50-4.50% of 50% dipropylene ammonium, 2.0-3.5% of 50% sodium propionate, 10.0-20.0% glycerin, 10.0-20.0% maltodextrin and 50.0-60.0% of water. The preparation method includes the following steps: evenly mixing six solutions of the 85% lactic acid, the 85% phosphoric acid, the 50% formic acid, the 95% propionic acid, the 50% dipropylene ammonium and the 50% sodium propionate to obtain a mixer; dissolving the maltodextrin in the water completely and then adding the glycerin and carrying out even mixing to obtain another mixer; finally mixing the two mixers and obtaining the composite liquid acidification and mildew resistance agent. The composite liquid acidification and mildew resistance agent prepared by the preparation method in the present invention can overcome the negative effects which are caused by silica carrier on feed intake when using a solid acidifying agent and a solid mildew resistance agent. Therefore, palatability of pig feed can be greatly increased, and the feed intake can be improved.

Owner:WUHAN XINNONGXIANG FEED

Machining technique for valve seat ring

The invention discloses a machining technique for a valve seat ring. The machining technique comprises the following machining steps that (1) preparation is carried out: raw materials are fed and pressurized on an oil press in cooperation with a semi-automatic formwork; (2) pressing is carried out: a base layer is pressed, and the height of the base layer is controlled; then an infiltration layer is pressed, and finally demolding is carried out; (3) firing is carried out: after demolding, a sintering furnace is used for sintering and infiltration, and a blank is formed through pre-firing, sintering and infiltration; (4) finish machining is carried out: the blank is directly machined, finish turning of the inner face and the outer face is carried out, and the outer circle and a cross section are finally ground; (5) detection is carried out: a finished product is subjected to quenching, then defective items are removed, and the finished product is polished. According to the machining method of the valve seat ring, the valve seat ring is made of powered metal materials; the strength of the valve seat ring can be improved through pressing preparation on the two sides, and the density and the hardness of the base layer can be controlled when the base layer is pressed; heat resistance and thermal impact resistance of the valve seat ring can also be improved, and machining performance is improved.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

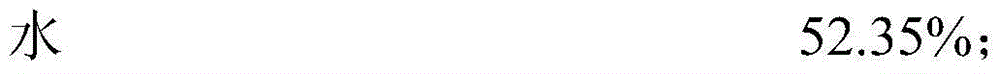

Silica gel film plating windshield wiper rubber strip and preparation method thereof

The invention relates to a silica gel film plating windshield wiper rubber strip and a preparation method thereof. The silica gel film plating windshield wiper rubber strip is prepared from the following ingredients in parts by weight: 30 to 50 parts of 70-DEG C silicon rubber raw materials, 10 to 30 parts of 60-DEG C silicon rubber raw materials, 20 to 40 parts of 60-DEG C powder rubber raw materials, 7 to 14 parts of talcum powder, 1 to 1.5 parts of simethicone, 1 to 1.7 parts of color masterbatch and 2 to 4 parts of vulcanizing agents. The silica gel film plating windshield wiper rubber strip has the advantages that the formula is simple; the preparation cost is low; the excellent mechanical intensity, ozone resistance and atmosphere aging resistance performance are realized; the friction coefficient is low; the use temperature is wide; the long-time use can be realized at -40 DEG C (or lower temperature) to +100 DEG C (or higher temperature).

Owner:XIAMEN METO AUTO PARTS IND

Rolling production method for improving toughness of steel on line

ActiveCN113245365AReduce heating energy consumptionReduce manufacturing costWork heating devicesMetal rolling arrangementsTemperingContinuous rolling

The invention discloses a rolling production method for improving the toughness of steel on line. A continuous casting billet is taken as a raw material. The rolling production method sequentially comprises the following working procedures of billet heating, descaling, rough rolling, continuous rolling, through-water cooling, finish rolling through a bar reducing and sizing mill and cooling through a cooling bed, and finally a finished product bar is obtained; wherein a rolled material subjected to continuous rolling is subjected to through-water cooling to 650-850 DEG C, after through-water cooling, the rolled material is subjected to self-tempering to obtain the finish rolling temperature of the bar reducing and sizing mill, the finish rolling temperature is 500-700 DEG C, and the temperature of the bar on the cooling bed is 480-650 DEG C. According to the method, KOCKS rolling is adopted for finish rolling of the bar reducing and sizing mill, proeutectoid ferrite in a non-required form is eliminated by controlling the finish rolling temperature and the cooling temperature after rolling, the toughness of the steel is improved, and the grain size, hardness and mechanical performance of the non-quenched and tempered steel can be controlled by adopting the rapid cooling technology after rolling.

Owner:DAYE SPECIAL STEEL CO LTD

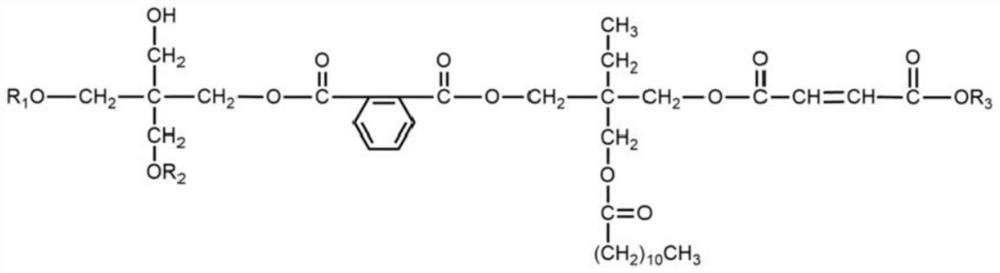

High-solid-content low-viscosity odorless alkyd resin as well as preparation method and application thereof

ActiveCN113201124ALarge space three-dimensional structureAccelerate evaporationPolyurea/polyurethane coatingsXylylenePolymer science

The invention discloses high-solid-content low-viscosity odorless alkyd resin as well as a preparation method and application thereof, and the high-solid-content low-viscosity odorless alkyd resin is prepared from the following raw materials in parts by mass: 29.5 to 33.5 parts of vegetable oil fatty acid, 18.5 to 21.5 parts of anhydride, 2.5 to 4.9 parts of monobasic acid, 20.3 to 24.1 parts of polyhydric alcohol, 2 to 5 parts of aldehyde resin, 3 to 5 parts of xylene and 14 to 15 parts of organic solvent. The structure and performance of the prepared resin are easy to control and adjust, the prepared resin is used for preparing a two-component polyurethane wood lacquer coating, the hardness reaches up to H or above, the adhesive force is grade 0, the residual VOC is lower than 5g / L after a paint film is dried for 2 days, and the resin is odorless and environmentally friendly and has excellent chemical resistance and thermal stability.

Owner:SOUTH CHINA UNIV OF TECH

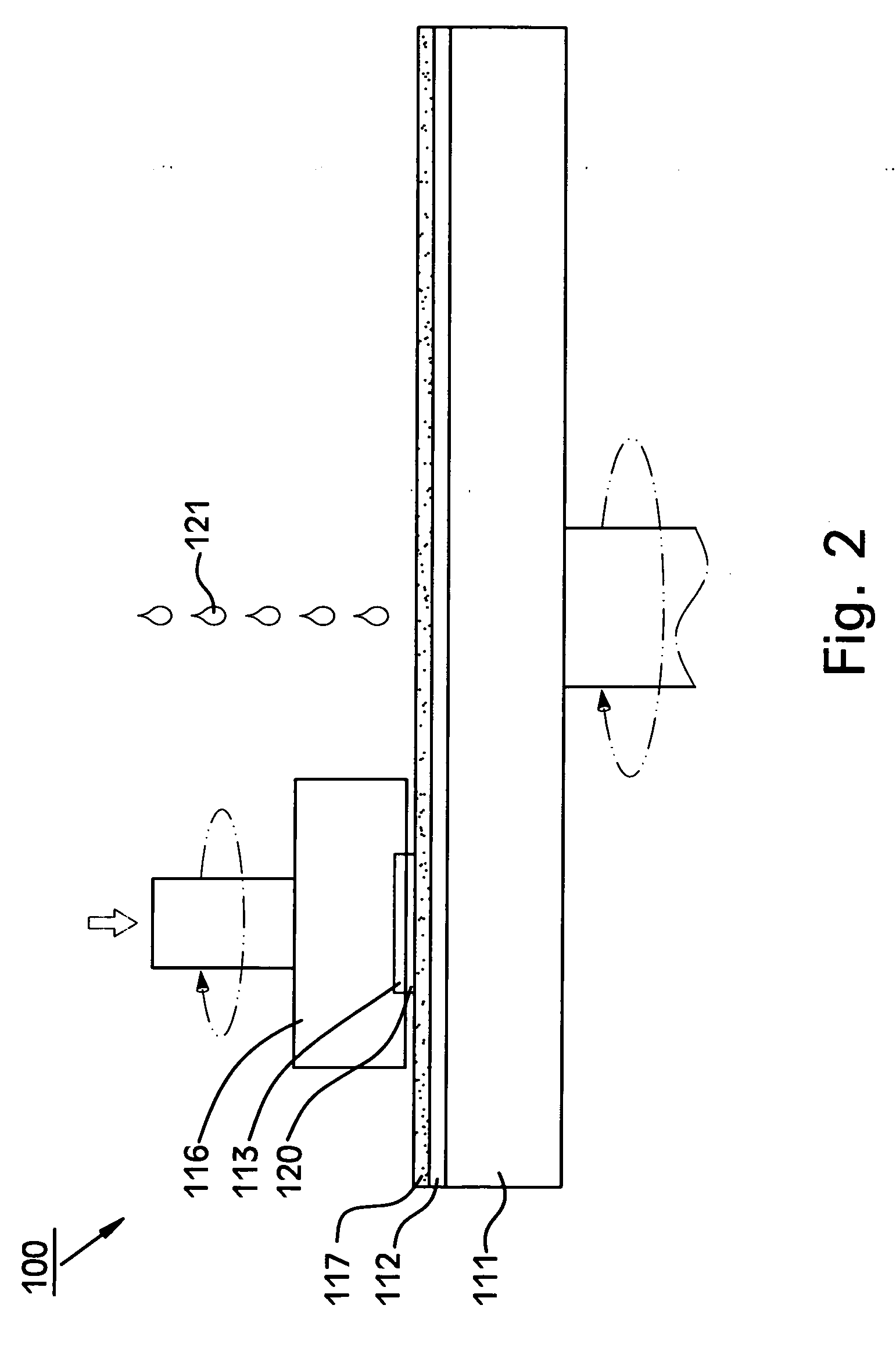

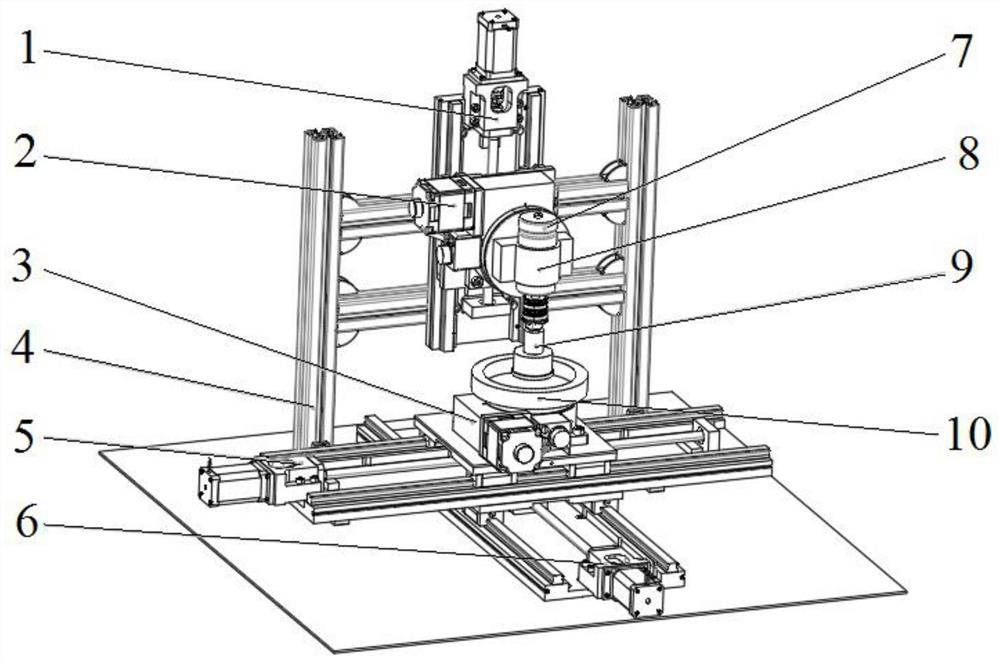

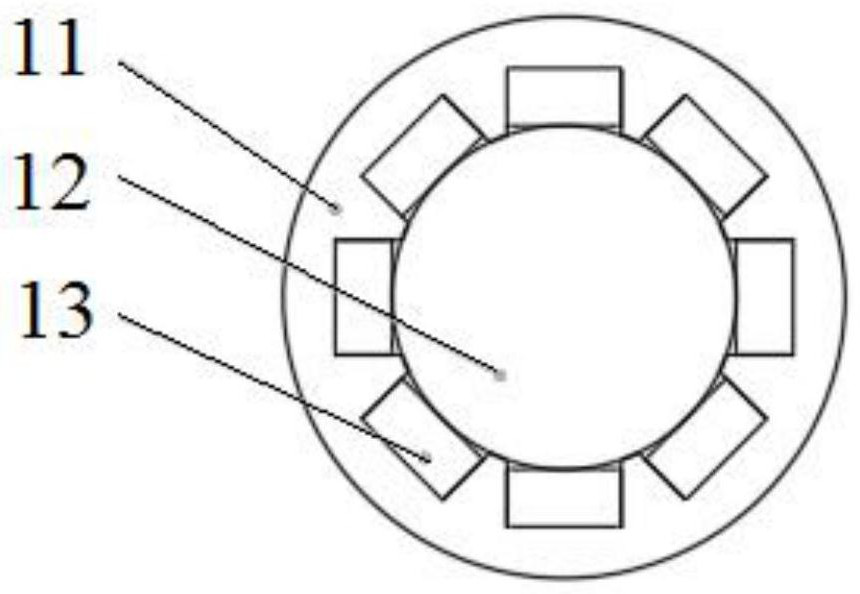

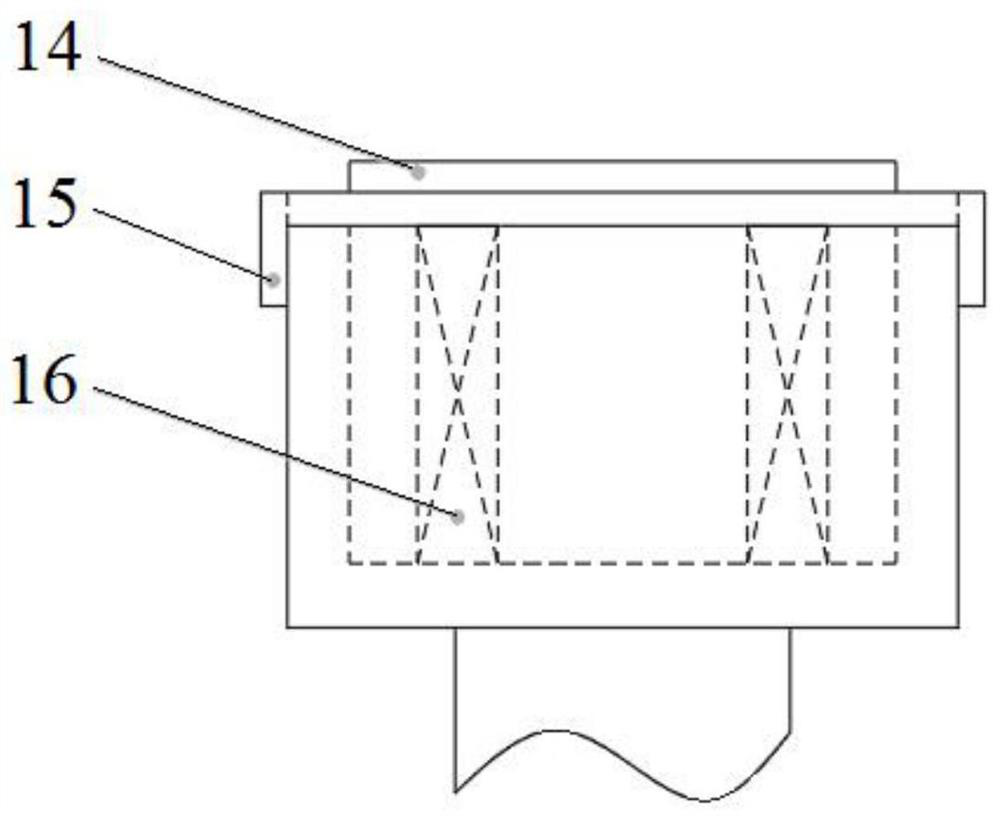

Magnetic control modulus plane polishing device and method

ActiveCN113664698AImproves flexibilityHigh polishing precisionPolishing machinesGrinding drivesPhysicsMagnetic field magnitude

The invention relates to a magnetic control modulus plane polishing device and method. The polishing device comprises a rack, an X-axis movement module, a Y-axis movement module, a Z-axis movement module, a spindle motor, a polishing head, a workbench and a controller. The X-axis movement module is installed above the Y-axis movement modules, the Y-axis movement module is installed on a rack bottom plate, the spindle motor is installed on the Z-axis movement module, the polishing head is installed at the output end of the spindle motor, and the workbench is installed on the X-axis movement module and located below the polishing head. The polishing head comprises a magnetic field generator and a pre-structured elastomer polishing sheet. The controller is connected with the X-axis movement module, the Y-axis movement module, the Z-axis movement module, the spindle motor and the magnetic field generator. The magnetic field generator is used for adjusting the elastic modulus and the shear modulus when the pre-structured elastomer polishing sheet is used for polishing the surface of a workpiece to be polished, and the controller is used for controlling the magnetic field intensity of the magnetic field generator. According to the magnetic control modulus plane polishing device and method, the polishing precision is improved.

Owner:ZHEJIANG NORMAL UNIVERSITY

Nb-containing Cr-Ni carburizing steel for cold forming and cold forming method of part

ActiveCN113373382ALow costControl hardnessSolid state diffusion coatingFurnace typesCold formedCrazing

The invention discloses a Nb-containing Cr-Ni carburizing steel for cold forming and a cold forming method of a part. The content of C is reduced and the content of spherical pearlite obtained after spheroidizing annealing is reduced, so that the hardness of a blank is effectively controlled; high-content Ni is added, so that plasticity and toughness of ferrite in the blank are improved, and deformation micro-cracks are not prone to occurring in the interior and on the surface of the part during cold forming; by means of the solid solution characteristic of Nb, N and C in steel, part of Nb, N and C are separated out at an austenitizing temperature of 1100-1250 DEG C, and steel grains can be prevented from being coarsened at a forging temperature; and nbN / NbC is completely separated out, so that the grain size is guaranteed to be smaller than 7 grades, and intermediate cooling treatment is not needed. Pre-oxidation adopts sectional control, the surface of a workpiece is activated, the inside and outside temperature difference is reduced, the inside and outside heating is more uniform, and the internal structure of the part starts repeated crystallization, so that the internal and external structures are more uniform, and thermal treatment deformation aggravation caused by rapid temperature rise is avoided; and residual austenite on the surface of a Ni-containing steel quenching part is reduced, so that the surface hardness is improved to be not smaller than HRC61.

Owner:DONGFENG COMML VEHICLE CO LTD

Gelling composition and food containing the same

PendingUS20170347694A1Reduce syneresisEasily orally takenFood shapingFood ingredient as gelling agentMethyl celluloseSolvent

Provided is a gelling composition capable of keeping a gel state in a food even when the food heated at 75° C. is cooled to around 45° C. at which the food can be eaten in a warm state. Specifically provided is a gelling composition comprising methyl cellulose, a 2.0% by weight aqueous solution of which has a storage modulus G′ (75° C.) at 75° C. of 3,000 to 5,500 Pa, the 2.0% by weight aqueous solution of which has a return temperature storage modulus G′ (75 to 45° C.) of 2,000 to 3,600 Pa when the temperature of the aqueous solution is returned from 75° C. to 45° C., and a 2.0% by weight aqueous solution of which has a viscosity at 20° C. of 3,000 to 10,000 mPa·s; a low temperature gelling agent; and a solvent. A food comprising the gelling composition is also provided.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com