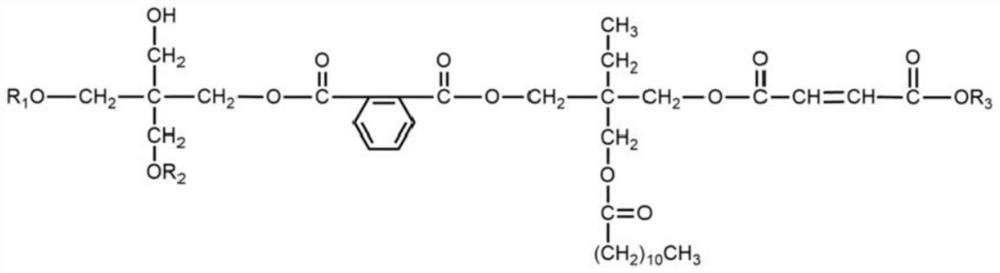

High-solid-content low-viscosity odorless alkyd resin as well as preparation method and application thereof

A clean-odor alkyd resin, low-viscosity technology, used in coatings, polyurea/polyurethane coatings, etc., can solve problems such as residual odor, and achieve the effects of increasing cross-linking density, stable and controllable reaction process, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of a high-solid low-viscosity net-taste alkyd resin

[0052] In parts by mass, the raw material components and consumption are as follows in Table 1

[0053] Table 1

[0054]

[0055] The preparation process comprises the following steps:

[0056] Add soybean oleic acid, ricinoleic acid, phthalic anhydride, pentaerythritol, 1,4-butanediol, benzoic acid, polyaldehyde resin KR-A81, maleic anhydride, p-tert-butyl Base benzoic acid, 3 parts of xylene, keep warm at 170°C for 3h, keep warm at 215°C for 3h, when the acid value is lower than 15mgKOH / g, and the viscosity reaches the preset viscosity, add 10 parts of xylene and 5 parts of butyl acetate to dilute, Obtain high solid content and low viscosity net taste alkyd resin.

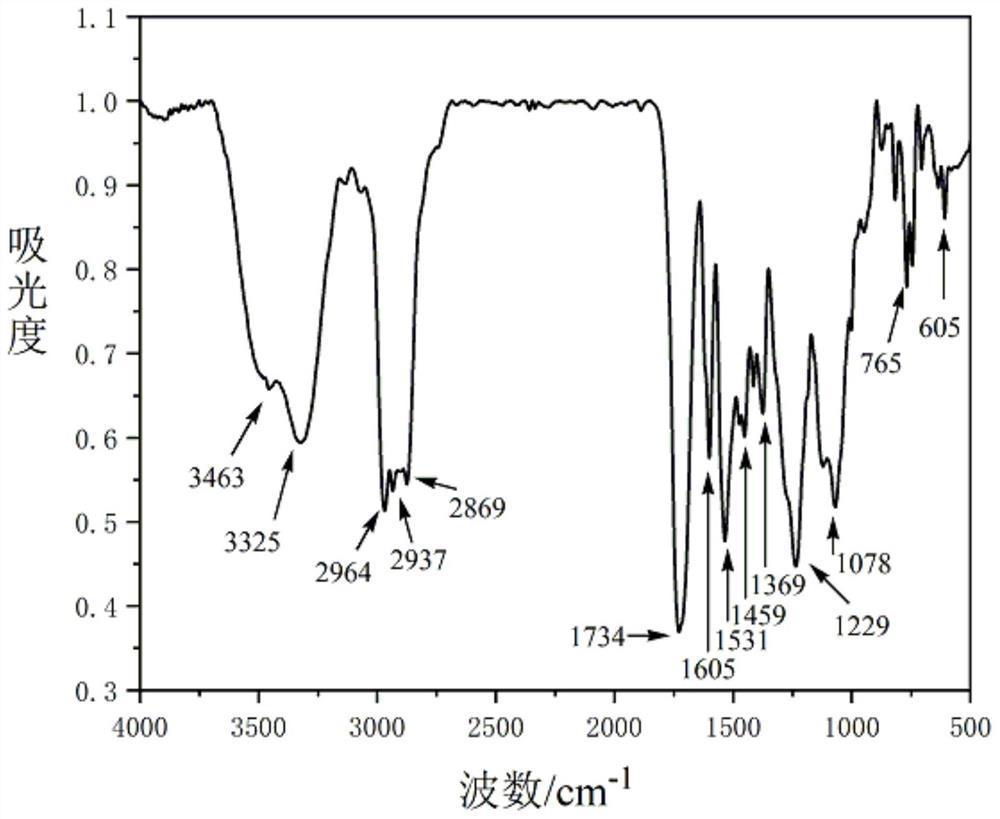

[0057] (2) The properties of the high-solid low-viscosity net-odor alkyd resin are shown in Table 2.

[0058] Table 2

[0059]

[0060]

[0061] (3) Preparation and properties of two-component polyurethane wood coatings

...

Embodiment 2

[0076] (1) Preparation of a high-solid low-viscosity net-taste alkyd resin

[0077] In parts by mass, the raw material components and consumption are as shown in Table 5

[0078] table 5

[0079]

[0080]

[0081] The preparation process comprises the following steps:

[0082] Add soybean oleic acid, coconut oil acid, phthalic anhydride, pentaerythritol, trimethylolpropane, ethylene glycol, diethylene glycol, tannic acid, polyaldehyde resin KR-80F, Maleic anhydride, 5 parts of xylene, keep warm at 190°C for 2 hours, slowly raise the temperature, keep warm at 200°C for 5 hours, wait until the acid value is lower than 15mgKOH / g, the viscosity reaches the preset viscosity, cool down to 80°C, add 5 parts of xylene, 4 parts of butyl acetate and 4 parts of ethyl acetate are diluted to obtain a high-solid low-viscosity net-odour alkyd resin.

[0083] (2) The properties of the high-solid low-viscosity net-odour alkyd resin are shown in Table 6.

[0084] Table 6

[0085] ...

Embodiment 3

[0096] (1) Preparation of a high-solid low-viscosity net-taste alkyd resin

[0097] In parts by mass, the raw material components and consumption are as shown in Table 9

[0098] Table 9

[0099]

[0100]

[0101] The preparation process comprises the following steps:

[0102] Add coconut oil acid, ricinoleic acid, phthalic anhydride, pentaerythritol, ditrimethylolpropane, 1,4-butanediol, 2-butyl-2-ethyl- 1,3-propanediol, benzoic acid, polyaldehyde resin KR-A101, rosin, succinic anhydride, 5 parts xylene, keep warm at 180°C for 2.5h, slowly heat up, keep warm at 210°C for 4h, until the acid value is lower than 15mgKOH / g, the viscosity reaches the preset viscosity, lower the temperature to 80°C, add 5 parts of xylene, 5 parts of ethyl acetate, and 4 parts of propylene glycol methyl ether acetate to dilute to obtain a high solid content and low viscosity net odor alkyd resin.

[0103] (2) The properties of the high-solid low-viscosity net-odour alkyd resin are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com