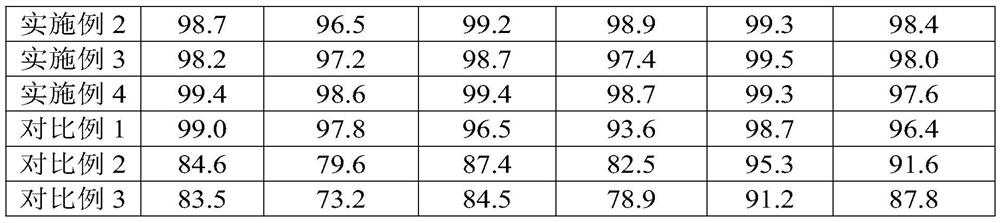

Patents

Literature

59results about How to "Achieve quick drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corundum-silicon nitride-silicon carbide composite pouring material

The invention discloses a corundum-silicon nitride-silicon carbide compound castable used for a blast tuyere zone of an ironmaking blast furnace. The corundum, the silicon nitride, the silicon carbide, aluminate cement, aluminum powder, silicon metal, ultrafine silica powder, alumina powder and polypropylene fiber are mixed to form the castable. Residual brick of compound brown corundum refractory brick can be fast poured and repaired at the blast tuyere zone of the ironmaking blast furnace. When building a blast furnace, residual brick can be direct poured and formed to replace the compound brown corundum refractory forming brick and no high temperature is needed to fire during the production process; therefore, the invention is also an energy saving refractory for the blast tuyere zone of the ironmaking blast furnace and cast-place construction is not limited by space; fast pouring masonry is carried out and fast drying method is adopted, thereby being an inorganic nonmetal refractory applied to fast-drying quick furnace building and repairing during the blast furnace repairing and the tuyere zone of the newly-built blast furnace. The invention can normally furnace dry with the blast furnace.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Quick-drying explosion-proof castable and producing process thereof

The invention discloses a castable used for an industrial furnace lining and a producing process thereof, and particularly relates to a quick-drying explosion-proof castable used for an industrial furnace lining and a producing process thereof. The producing process comprises four steps of raw material purchasing and testing, burdening, mixing and packaging. The producing process of the invention has the advantages of realizing quick-drying (rapid hardening) and fast stripping of the castable, and rapid baking without burst or explosion. With greatly shortened construction time and baking time, production pace is speeded up, a large quantity of energy is saved, emission of carbon dioxide and nitrogen oxide is significantly reduced and economic and social benefits are prominent.

Owner:LUOYANG KECHUANG NEW MATERIAL CO LTD

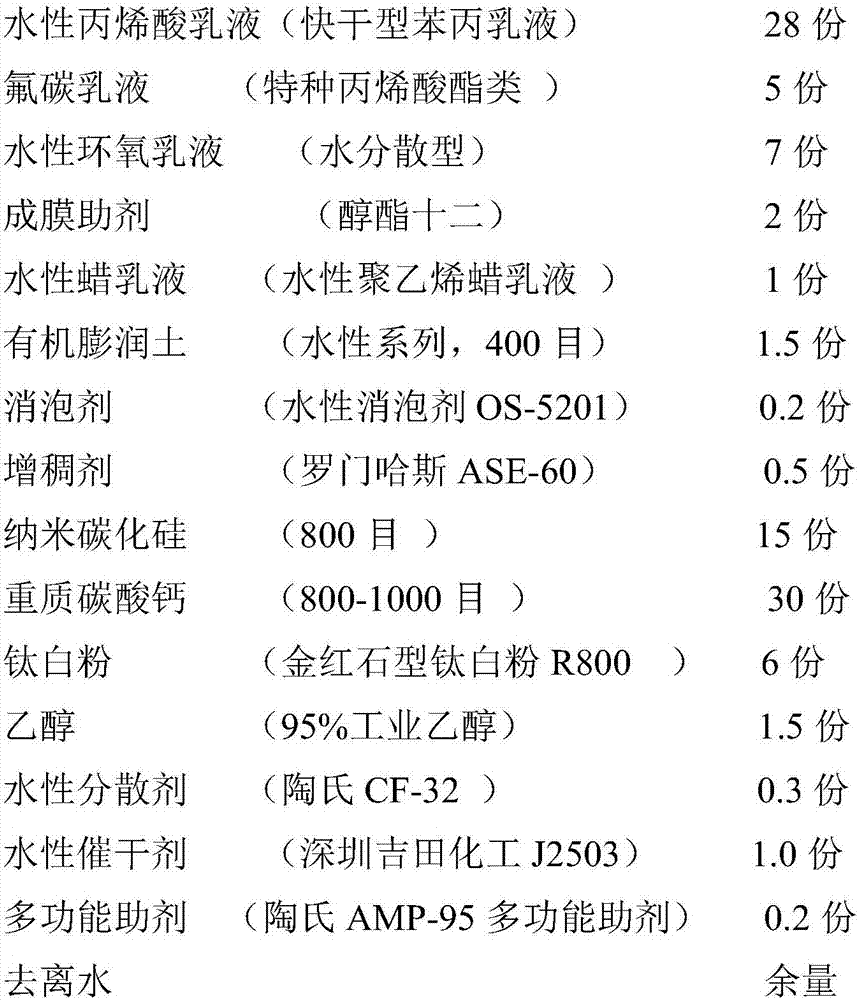

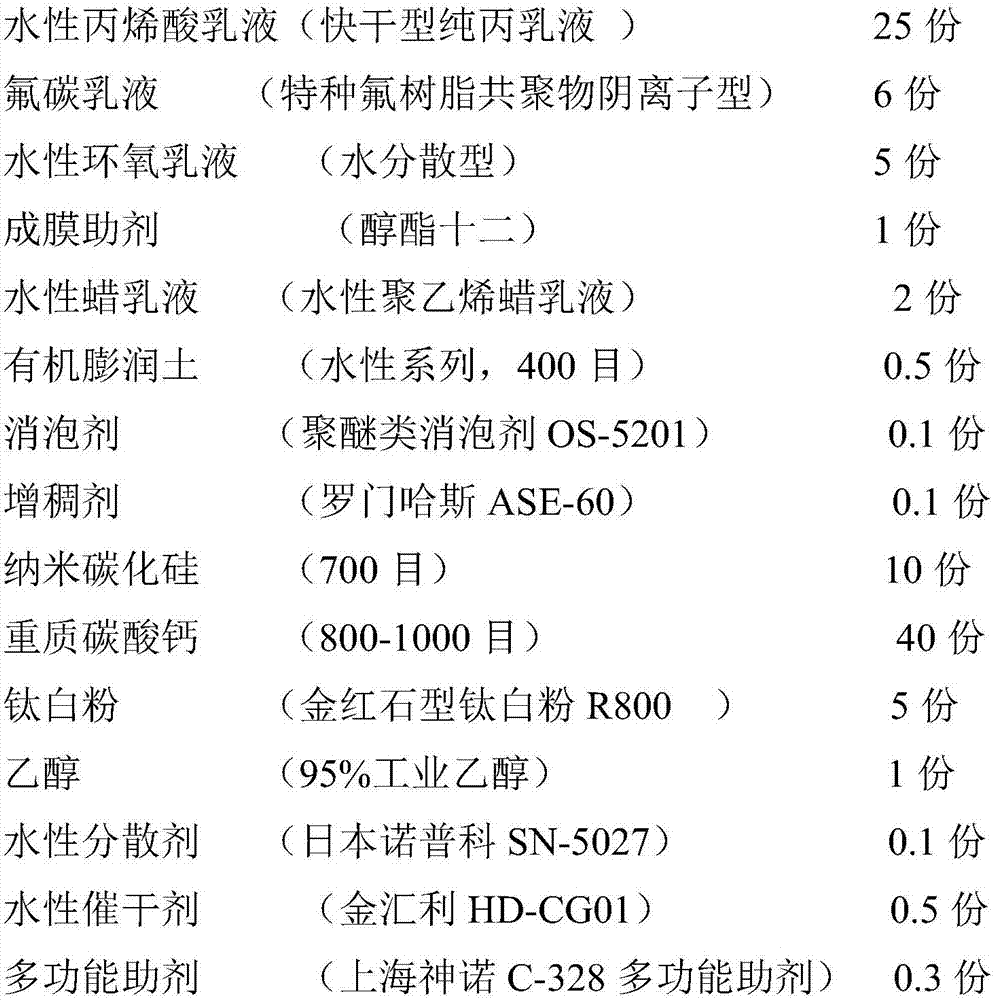

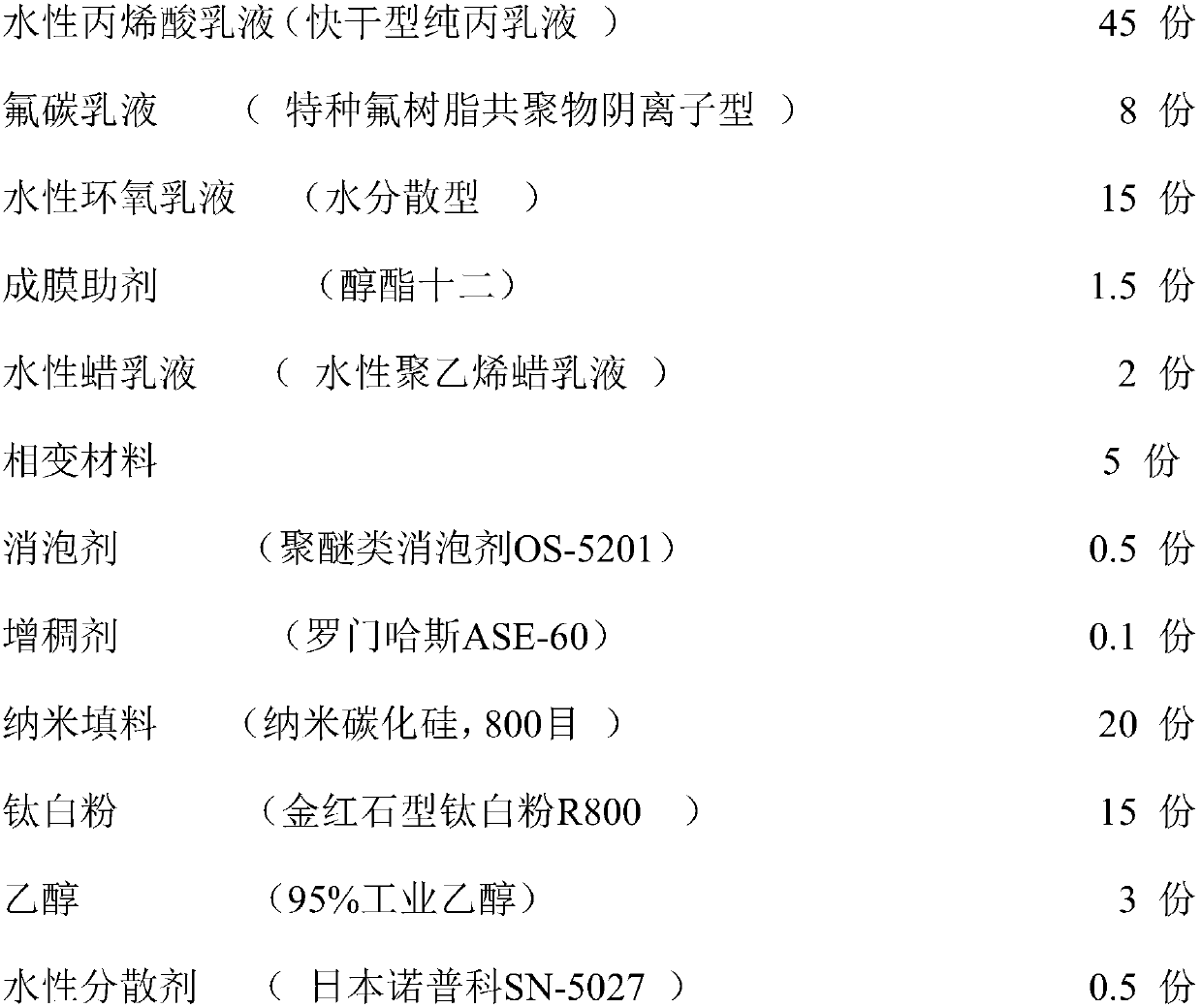

Waterborne marking paint and preparation method and construction method thereof

ActiveCN108003713AGood quick dryingImprove wear resistanceAntifouling/underwater paintsPaints with biocidesWaxWeather resistance

The invention provides waterborne marking paint and a preparation method and construction method thereof. The waterborne marking paint is prepared from, by weight, 15-35wt% of waterborne acrylic emulsion, 5-10wt% of fluorocarbon emulsion, 5-10wt% of waterborne epoxy emulsion, 1-3wt% of coalescing agent, 1-3wt% of waterborne wax emulsion, 0.5-5wt% of organic bentonite, 0.1-0.5wt% of antifoaming agent, 0.1-0.5wt% of thickener, 10-20wt% of nano-silicon carbide, 15-40wt% of heavy calcium carbonate, 5-10wt% of titanium dioxide, 1-3wt% of ethanol, 0.1-0.5wt % of waterborne dispersing agent, 0.5-1.5wt% of waterborne drier, 0.2-0.5wt% of multifunctional auxiliary agent and the balance deionized water; the particle size of silicon carbide is 600-900 nm. The waterborne marking paint has excellent quick-drying performance, abrasion resistance, weather resistance and stain resistance.

Owner:SUZHOU TOPOLINE TECH

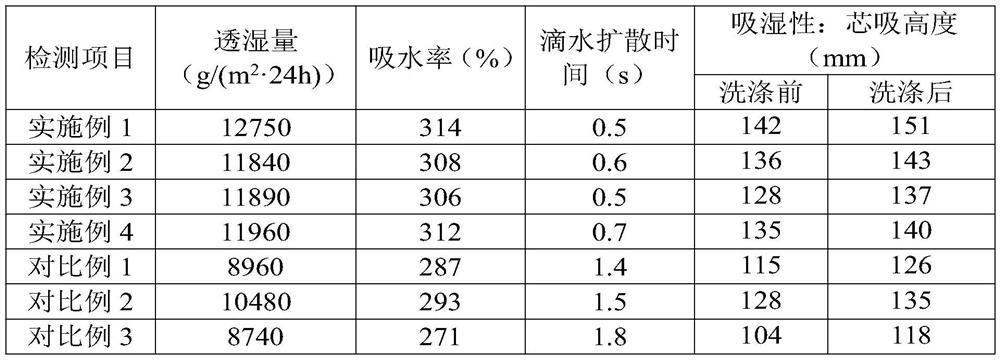

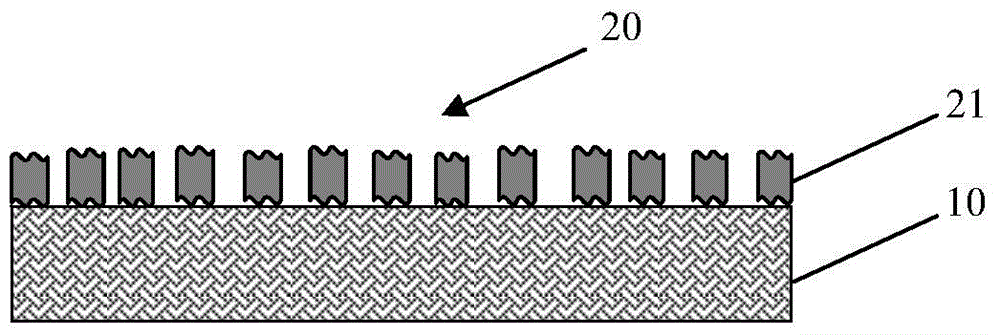

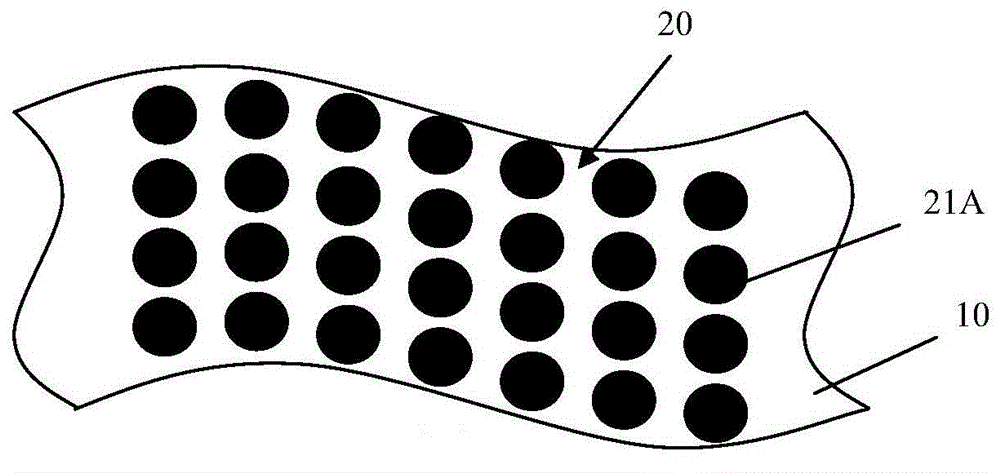

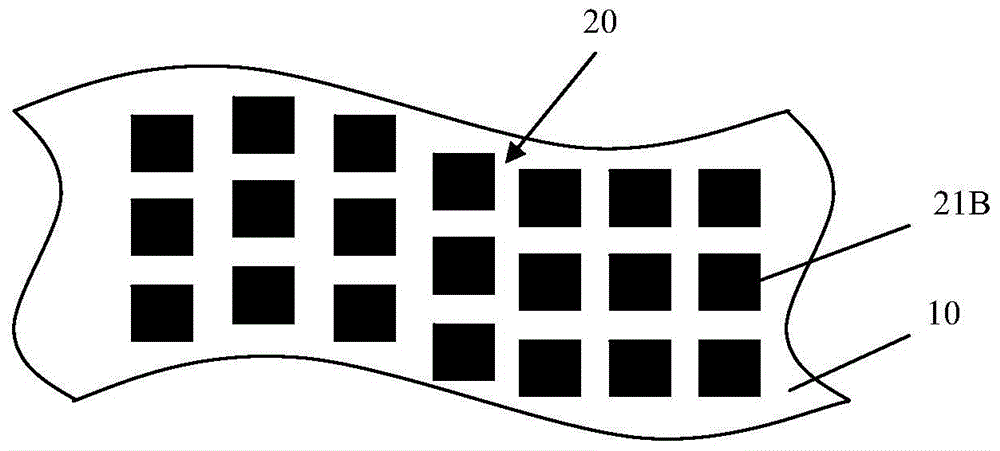

Moisture-conducting quick-drying weft-knitted fabric and processing technology thereof

PendingCN107354564AStable moisture-wicking functionLow raw material costWeft knittingTextile/flexible product manufactureChemistryProcess engineering

The invention provides a moisture-conducting quick-drying weft-knitted fabric. The fabric can solve the problems that an existing moisture-conducting quick-drying fabric is not washable when treated with a functional additive, is not resistant to high temperature when water-repellent fibers serve as the inner layer, and is expensive and not easy to process when waterproof yarn serves as the inner layer. A grey fabric of the fabric is formed through weft knitting of at least two kinds of yarn different in DPF, wherein the looping area of the yarn, with the minimum DPF, in the at least two kinds of yarn different in DPF on the front side of the grey fabric accounts for 60-100% of the total area of the front side; the looping area or the floating thread area of the yarn, with the maximum DPF, in the at least two kinds of yarn different in DPF on the reverse side of the grey fabric accounts for 60-100% of the total area of the reverse side; the DPF value of the yarn with the maximum DPF is at least 0.3 larger than that of the yarn with the minimum DPF. The invention provides a processing technology of the moisture-conducting quick-drying weft-knitted fabric. The technology comprises the following steps of grey cloth weaving, pre-treatment, dyeing, reduction washing, high-temperature setting, reduction washing and finished product shaping.

Owner:WUXI HANUO TEXTILE TECH

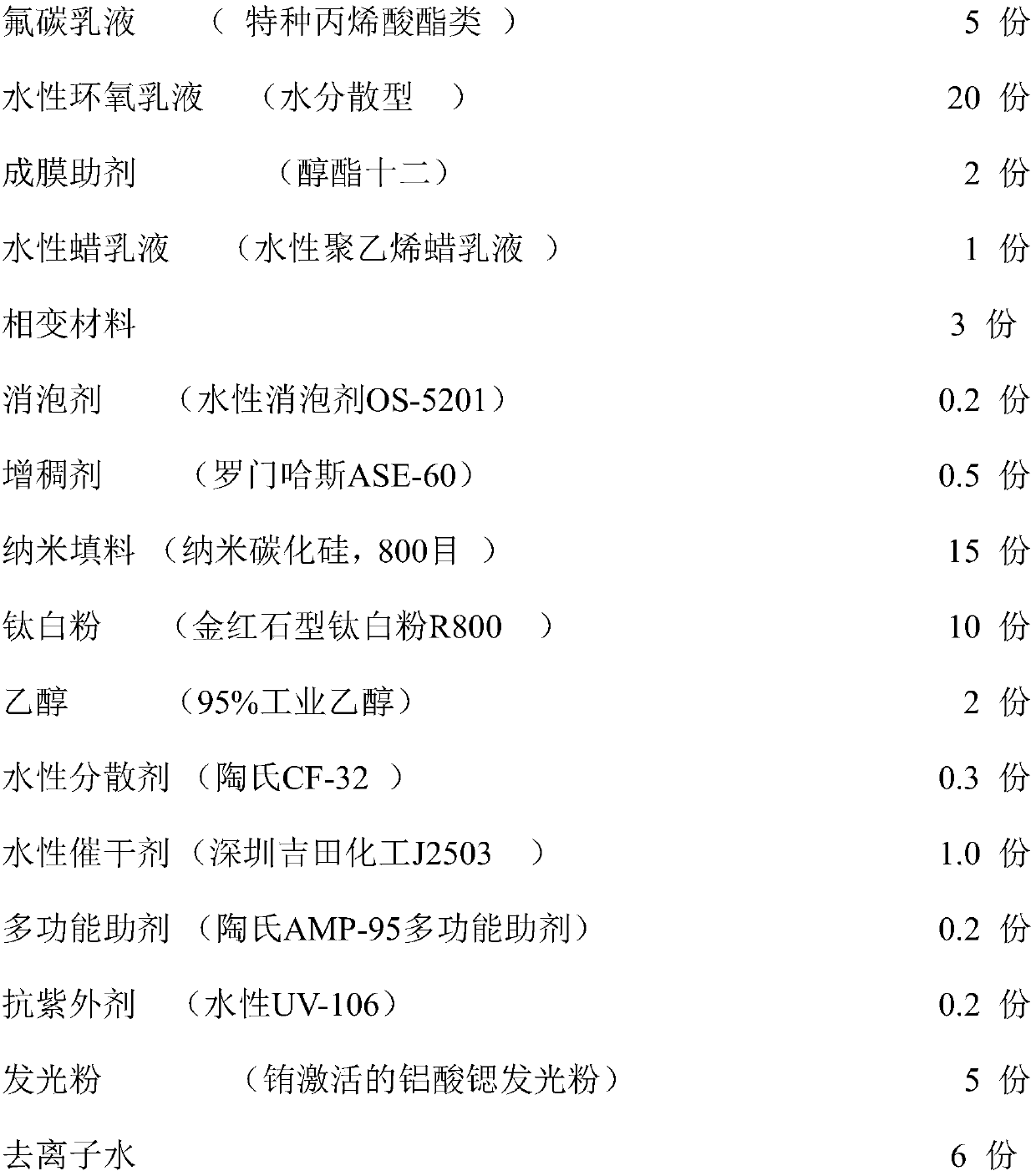

Water-based self-luminous marking coating and preparing method thereof

InactiveCN109651898AAlkali resistantGood weather resistanceAntifouling/underwater paintsLuminescent paintsEpoxyWater based

The invention relates to the technical field of chemical coatings, and particularly discloses a water-based self-luminous marking coating and a preparing method thereof. The water-based self-luminousmarking coating is prepared from 35-50 parts of water-based acrylic emulsion, 5-10 parts of fluorine-carbon emulsion, 10-20 parts of water-based epoxy emulsion, 1-3 parts of a film-forming auxiliary,1-3 parts of water-based wax emulsion, 3-7 parts of a phase-change material, 10-20 parts of a nanofiller, 10-20 parts of titanium dioxide, 1-3 parts of ethyl alcohol, 0.1-0.5 part of a water-based dispersing agent, 5-10 parts of luminescent powder and 4-6 parts of deionized water. By means of the water-based self-luminous marking coating, the quick dryness, weather resistance, abrasion resistance,fouling resistance, adhesion, crack resistance and other advantages of the water-based marking coating are improved, the marking identification degree at night is improved, and traffic driving safetyis ensured.

Owner:SUZHOU TOPOLINE TECH

Ceramic adhesive and preparation method thereof

InactiveCN107353872AImprove adhesionMaterials are readily availableMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveHigh carbon

The invention relates to a ceramic adhesive and a preparation method thereof. The ceramic adhesive is prepared from raw materials in parts by weight as follows: 20-35 parts of quartz sand, 10-13 parts of synthetic resin, 10-15 parts of butanediol, 5-9 parts of amino resin, 3-6 parts of phenolic resin, 6-8 parts of a polyvinyl acetate emulsion, 8-11 parts of butyl p-hydroxybenzoate, 5-10 parts of high-carbon alcohol aliphatic ester composition and 3-5 parts of titanium dioxide. The materials are easy to obtain, the preparation method is simple, the ceramic adhesive is low in cost, small in density, light in mass, high in adhesion, high in bonding force, good in permeability, waterproof, moisture-proof and high-temperature resistant, has certain fireproof effect and insulativity and good defoaming or non-foaming effect, realizes rapid drying, can effectively bond hard materials such as ceramic, metal and the like and is wide in application range, safe, non-poisonous and good in environment-friendly effect.

Owner:方碧水

Quick-drying concrete

The invention relates to a quick-drying concrete, comprising hydrophobic perlite, crushed stone, mica powder, calcium fluoride, zinc sulfate, sodium silicate, montmorillonite, dickite and diatomite. By weight, 15-19 parts of the hydrophobic perlite, 30-47 parts of crushed stone, 20-24 parts of mica powder, 10-14 parts of calcium fluoride, 5-8 parts of zinc sulfate, 3-8 parts of sodium silicate , 15-19 parts of montmorillonite, 18-22 parts of dickite and 18-25 parts of diatomite. The invention can effectively realize the quick-drying of concrete, at the same time improve the flexural strength and toughness of concrete, limit the crack width, resist concrete surface cracking and anti-explosion fire resistance, and can be widely used in the fields of civil engineering, water conservancy, municipal transportation, marine military industry and the like concrete structure.

Owner:周淑华

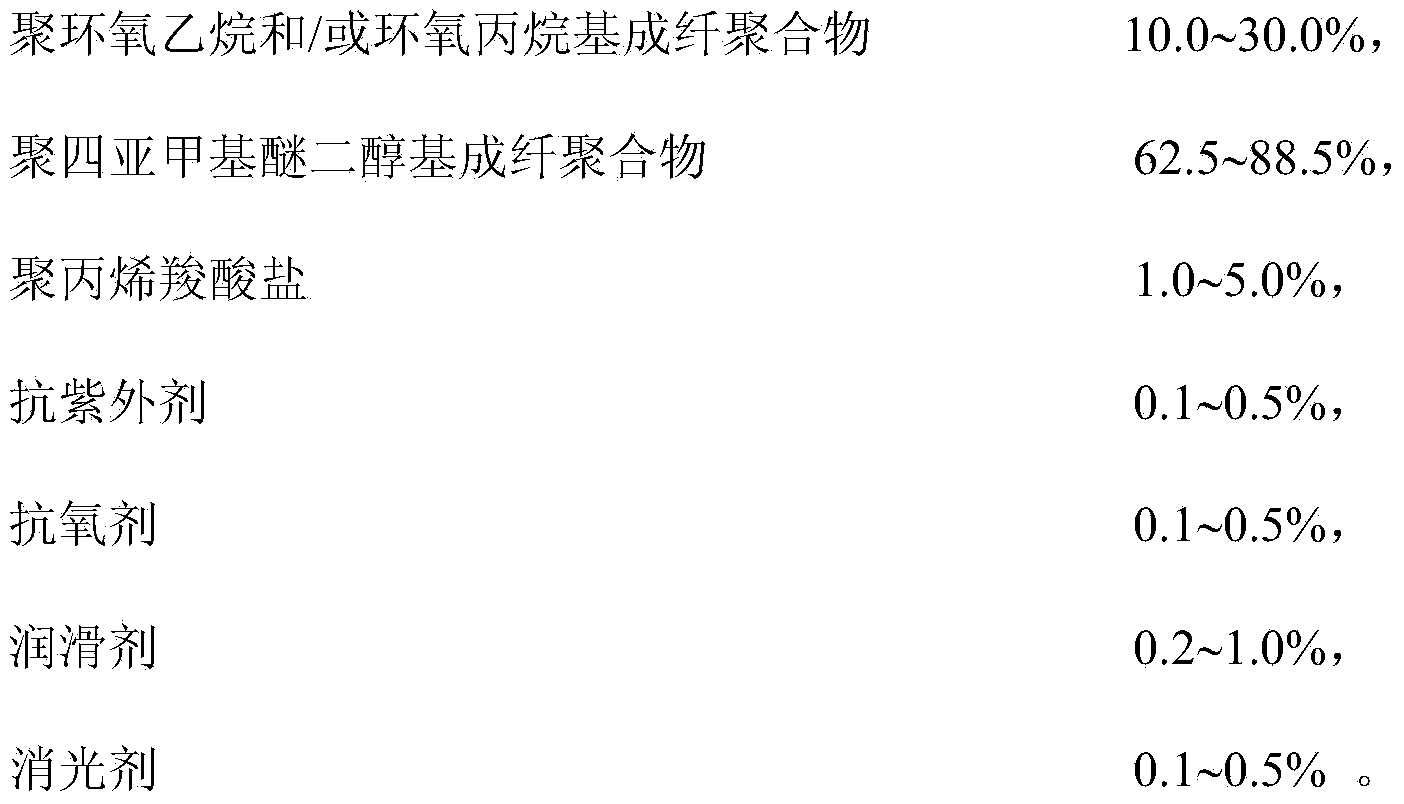

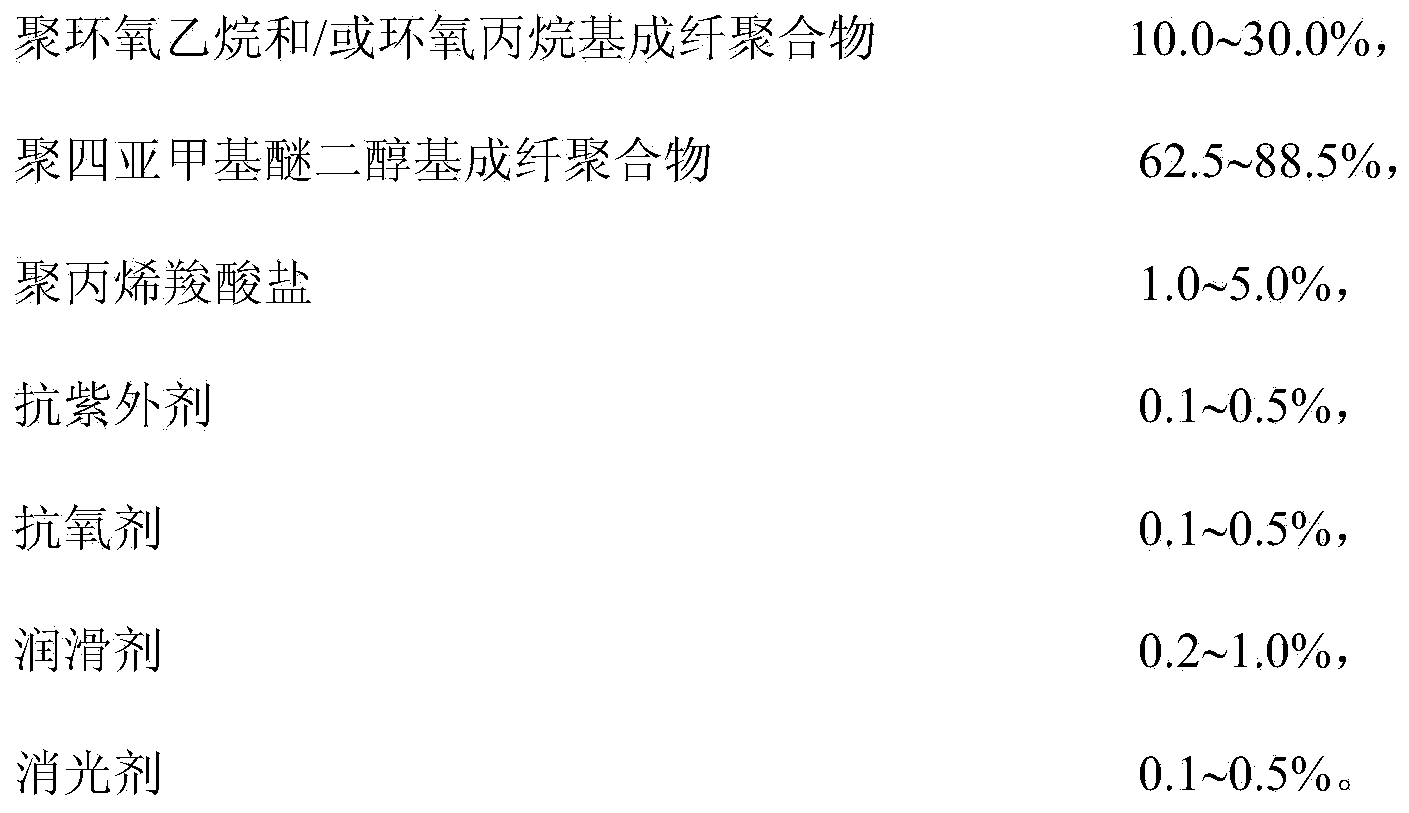

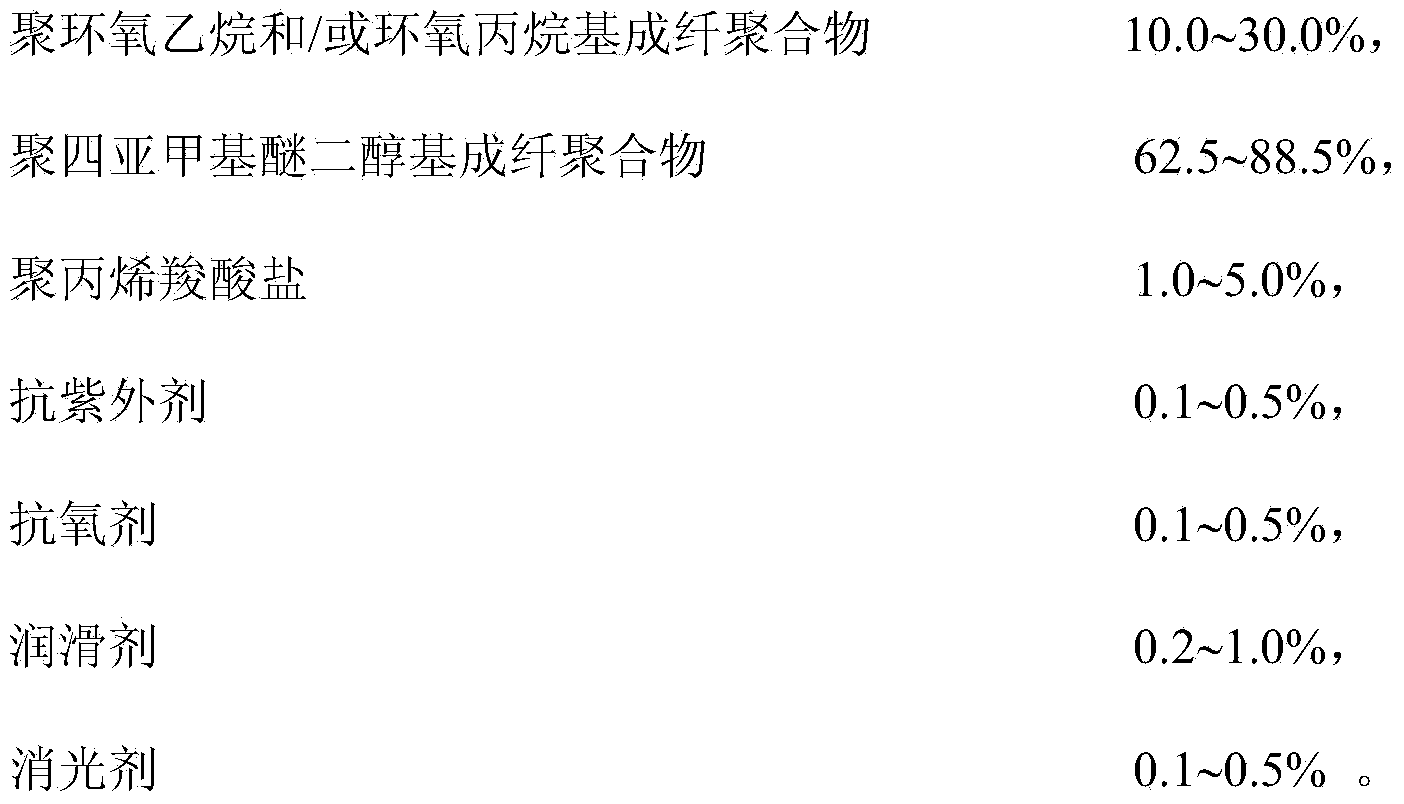

Hydroscopic and fast dry spandex fiber and preparation method thereof

ActiveCN104073913AGood hygroscopicityDimensionally stableMonocomponent synthetic polymer artificial filamentDry spinning methodsFiberPolyethylene oxide

The invention relates to a hydroscopic and fast dry spandex fiber and a preparation method thereof. The preparation method comprises the following steps: (1) mixing polytetramethylene ether glycol and 4,4'-diphenylmethane diisocyanate for reacting to obtain a prepolymer 1, mixing polyethylene oxide and / or epoxypropane and 4,4'-diphenylmethane diisocyanate in N,N-dimethylacetamide for reacting to obtain a prepolymer 2, uniformly blending the prepolymer 1 and the prepolymer 2, and rapidly adding N,N-dimethylacetamide into the prepolymer mixture to form a solution; (2) performing a reaction on the prepolymer solution and a mixed diamine chain extender to obtain a polymer solution; (3) adding special auxiliary slurry into the polymer solution, stirring and curing, thereby obtaining a spinning solution; and (4) carrying out spinning by spinning equipment, thereby obtaining the hydroscopic and fast dry spandex fiber. The hydroscopic and fast dry spandex fiber has a hydroscopic and fast dry function and the comfort of a spandex fiber fabric is greatly improved.

Owner:ZHEJIANG HUAFENG SPANDEX

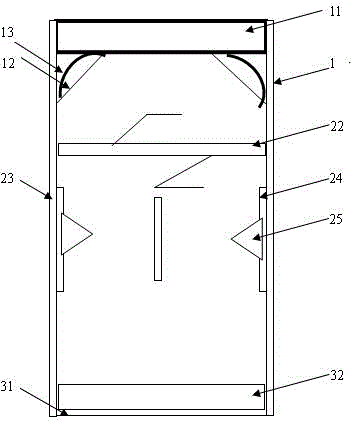

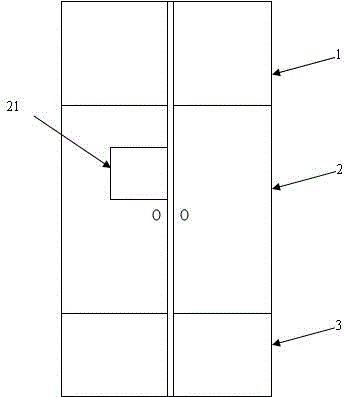

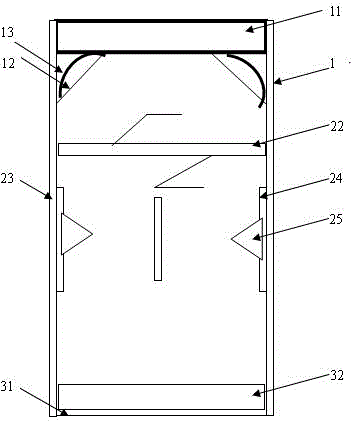

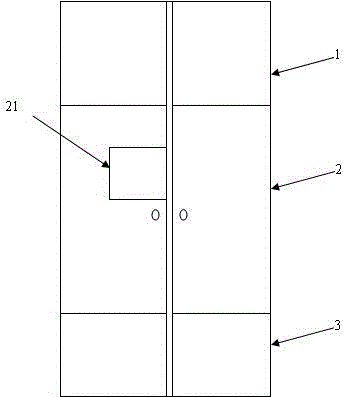

Clothes airing cabinet

ActiveCN104452230AImprove sterilization efficiencyImprove the bactericidal effectOther drying apparatusTextiles and paperMechanical engineeringIndustrial engineering

The invention discloses a clothes airing cabinet which is composed of an upper cabinet, a middle cabinet and a lower cabinet from top to bottom. The upper cabinet comprises a top cover, a condensing device and a disinfecting device. The middle cabinet comprises an outer control part, a clothes hanging device, a side wall, a drying device and an air drying device, wherein the clothes hanging device, the side wall, the drying device and the air drying device are arranged inside the middle cabinet. The lower cabinet comprises a bottom plate and a bearing device. The clothes airing cabinet achieves multiple technical effects of attractiveness of clothes airing, clothes drying and sterilization.

Owner:ZHEJIANG HOOEASY SMART TECH

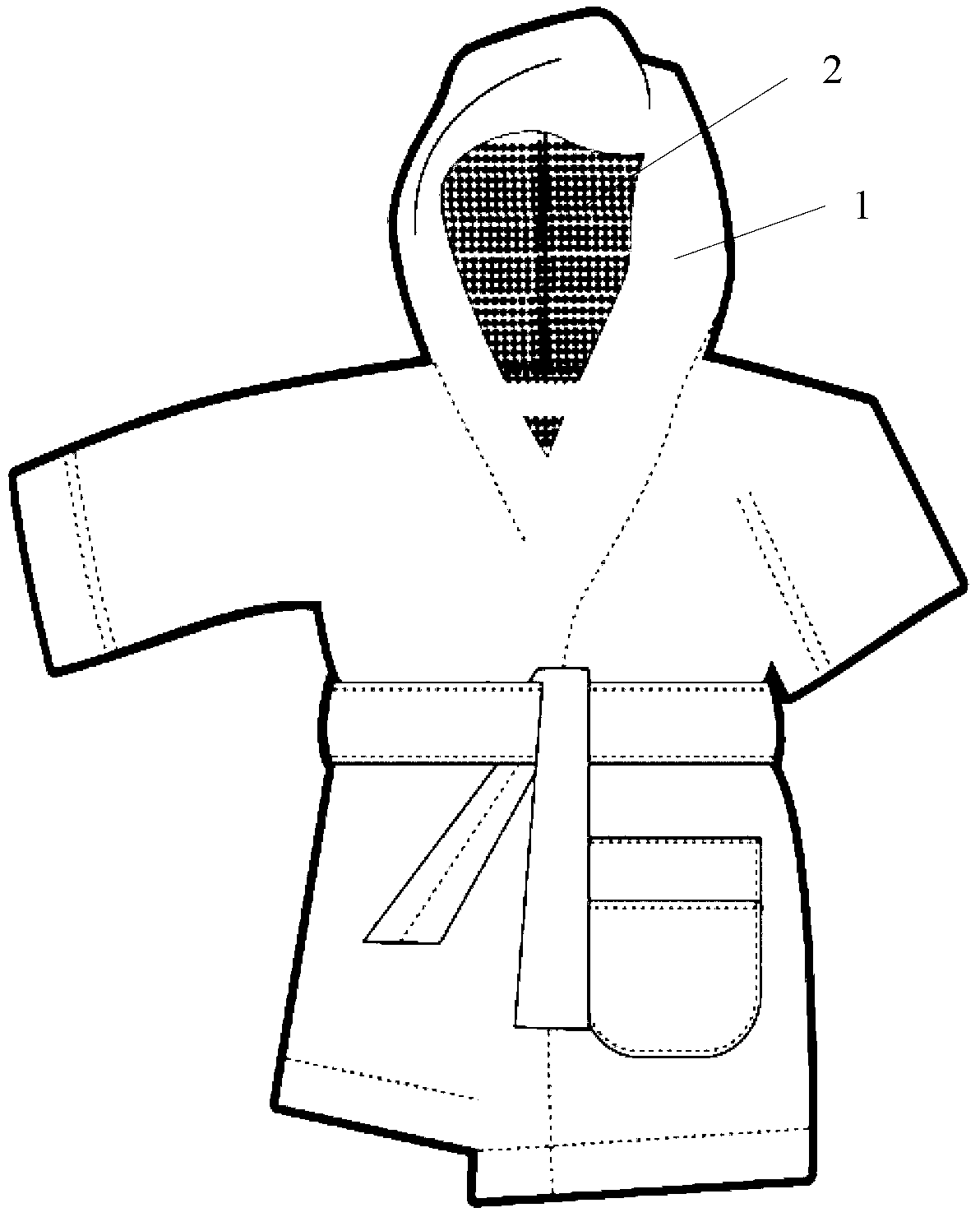

Hygroscopic and quick-dry night dress

The invention provides a hygroscopic and quick-dry night dress which comprises a night dress body and a hat. The hygroscopic and quick-dry night dress is characterized in that a layer of ultrafine fiber towel cloth is sewn on the inner surface of the hat or adhered on the inner surface of the hat by hook-and-loop fasteners. Uniform, compact, soft and high-elastic fine woolen masses are arranged on the surface of the ultrafine fiber towel cloth and have high decontamination and water absorption performances. The fiber surface area of the ultrafine fiber towel cloth is greatly increased, a large number of gaps are reserved in a fabric to form a capillary wicking effect, water absorption effects are greatly enhanced, and the water absorptivity of the ultrafine fiber towel cloth is 4 to 7 times that of common towel cloth. Therefore, after the ultrafine fiber towel cloth is arranged on the inner surface of the hat of the night dress, water on hair can be quickly absorbed when a user wears the night dress, the hair can be quickly dried, and the night dress is particularly suitable for pregnant women and children as electric hair driers are unsuitable for the pregnant women and the children.

Owner:WUXI HODOHOME GARMENT

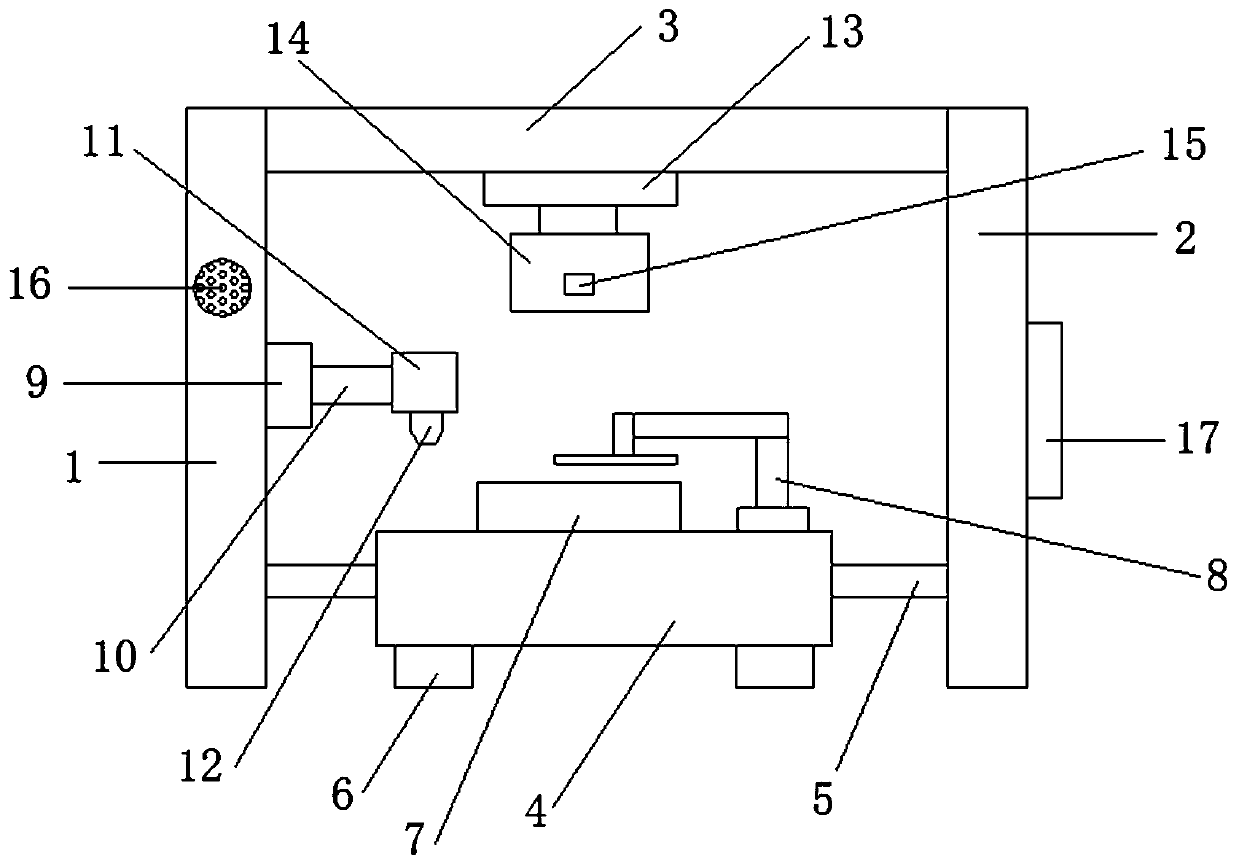

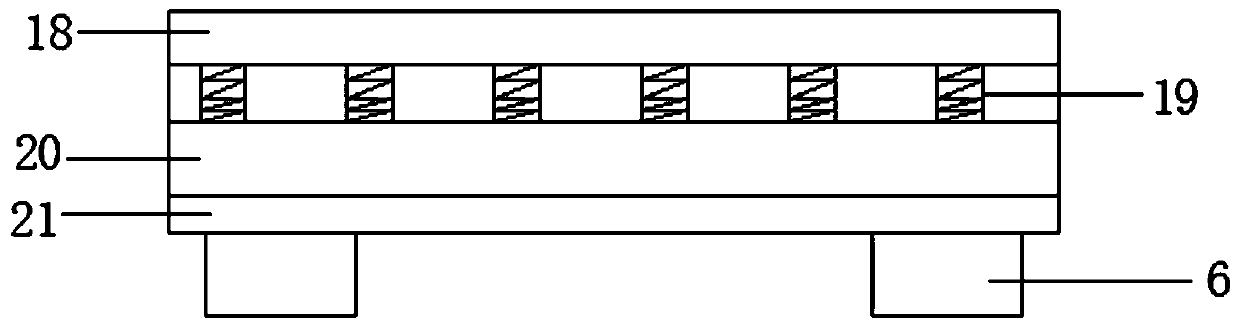

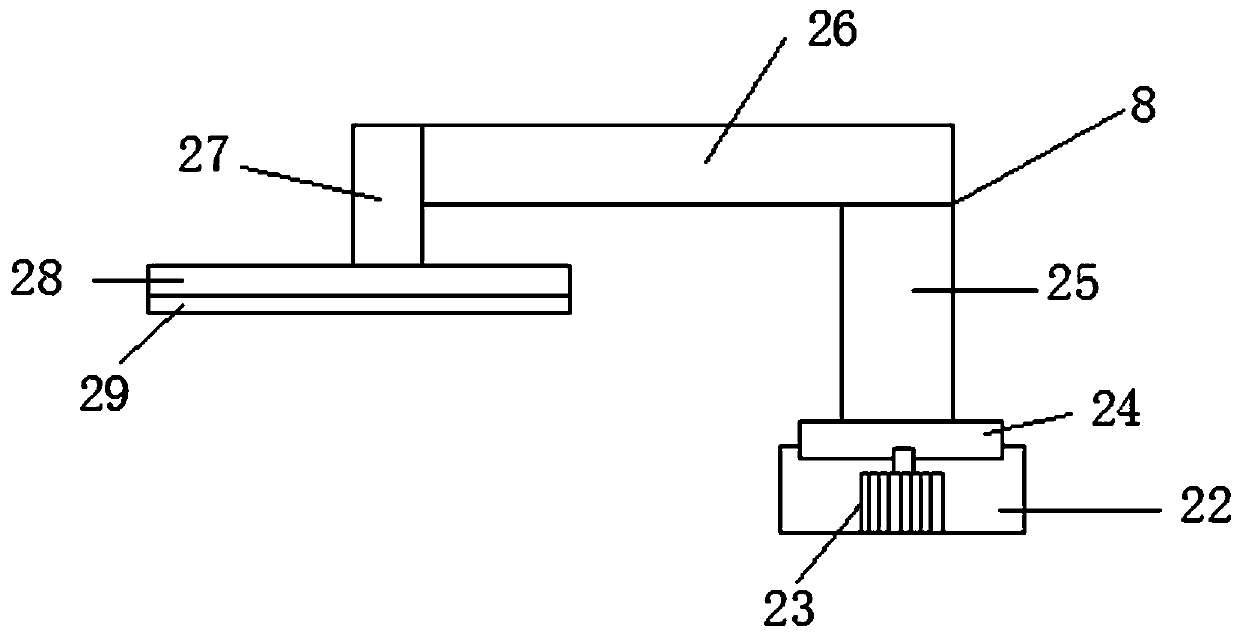

Composite material forming equipment

InactiveCN110815845AImprove securityEasy unloadingLiquid surface applicatorsCoatingsAdhesive glueManufacturing engineering

The invention relates to composite material forming equipment. The composite material forming equipment comprises a first supporting frame and a second supporting frame; the first supporting frame isarranged on the left side of the second supporting frame; a cross beam is fixedly connected between the first supporting frame and the second supporting frame, and is fixedly connected to the tops ofthe first supporting frame and the second supporting frame; the first supporting frame and the second supporting frame are fixedly connected with a supporting table through a reinforcing rod; supporting feet are fixedly connected to the bottom of the supporting table; the top of the supporting table is fixedly connected with a punching die table; a uniform applying device is arranged on the rightside of the punching die table; the right end of the first supporting frame is fixedly connected with a first hydraulic cylinder; the output end of the first hydraulic cylinder is fixedly connected with a first telescopic rod; and the right end of the first telescopic rod is fixedly connected with a glue storage box. The whole composite material forming equipment facilitates uniformly applying glue, rapid drying of the glue is facilitated, the automation degree of composite plate production is improved, the discharging after plate forming is facilitated, and the production efficiency is improved.

Owner:户玉珠

High-solid-content low-viscosity odorless alkyd resin as well as preparation method and application thereof

ActiveCN113201124ALarge space three-dimensional structureAccelerate evaporationPolyurea/polyurethane coatingsXylylenePolymer science

The invention discloses high-solid-content low-viscosity odorless alkyd resin as well as a preparation method and application thereof, and the high-solid-content low-viscosity odorless alkyd resin is prepared from the following raw materials in parts by mass: 29.5 to 33.5 parts of vegetable oil fatty acid, 18.5 to 21.5 parts of anhydride, 2.5 to 4.9 parts of monobasic acid, 20.3 to 24.1 parts of polyhydric alcohol, 2 to 5 parts of aldehyde resin, 3 to 5 parts of xylene and 14 to 15 parts of organic solvent. The structure and performance of the prepared resin are easy to control and adjust, the prepared resin is used for preparing a two-component polyurethane wood lacquer coating, the hardness reaches up to H or above, the adhesive force is grade 0, the residual VOC is lower than 5g / L after a paint film is dried for 2 days, and the resin is odorless and environmentally friendly and has excellent chemical resistance and thermal stability.

Owner:SOUTH CHINA UNIV OF TECH

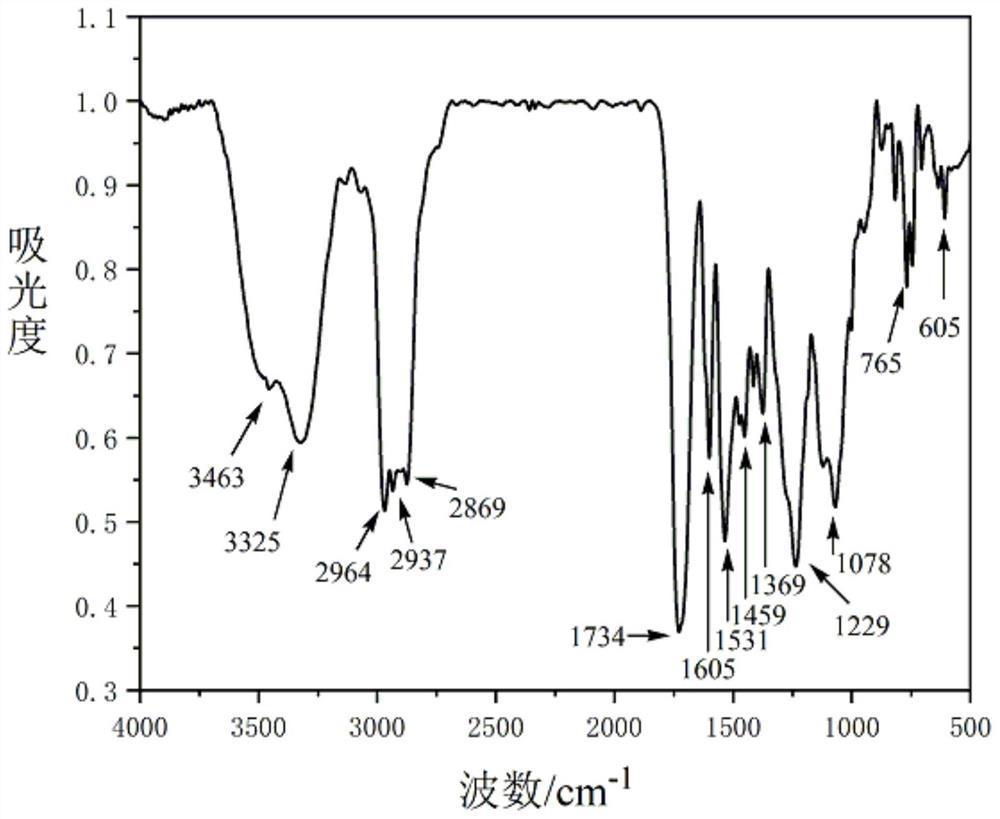

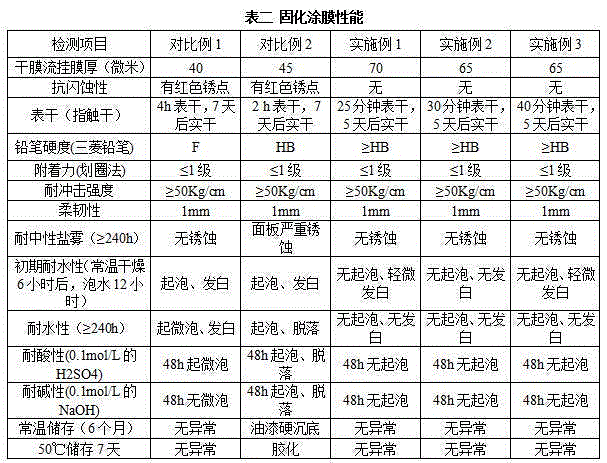

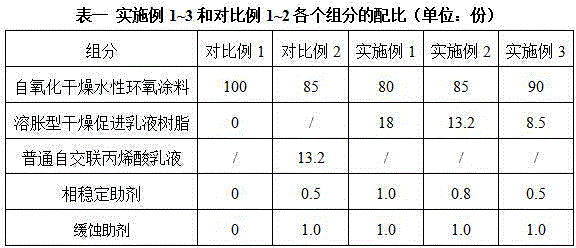

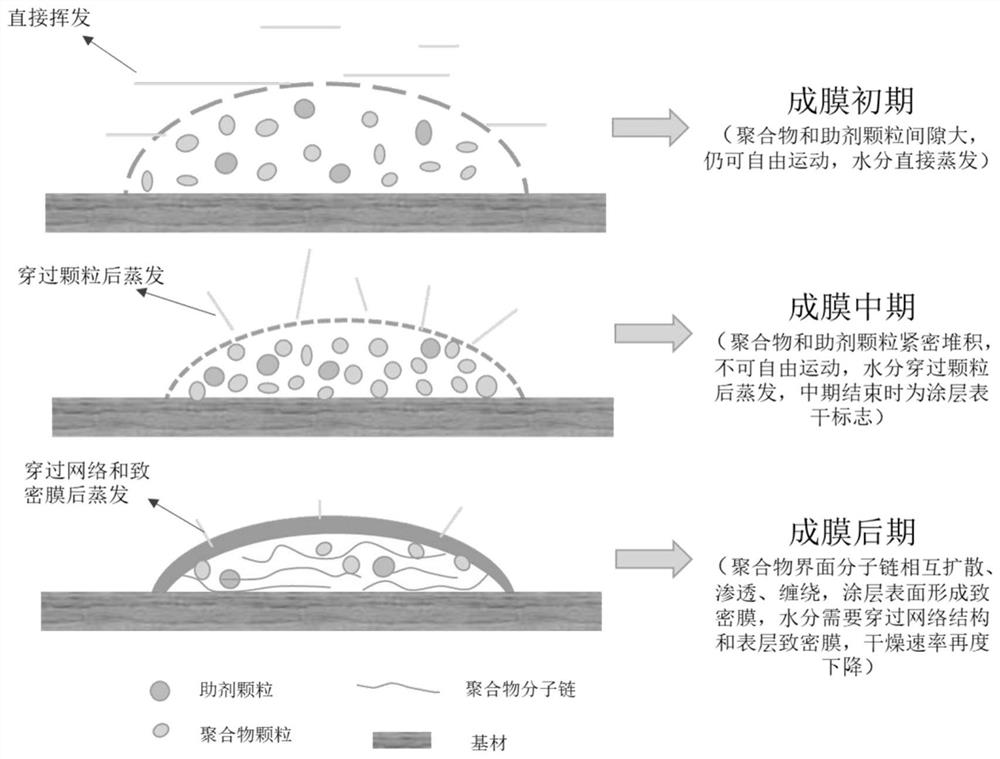

Water-based air-drying protective coating for escalator and coating process of water-based air-drying protective coating in humid environment

ActiveCN105199531AAchieve quick dryingAchieving flash rust resistanceAnti-corrosive paintsCorrosion resistantCoating

The invention discloses a water-based air-drying protective coating for an escalator. The water-based air-drying protective coating comprises the following components in parts by weight: 80-100 parts of a self-oxidation-drying water-based epoxy coating, 0-20 (except 0) parts of swelling type drying promoting emulsion resin, 0.5-2 parts of a phase stabilizing aid and 1-2 parts of a corrosion inhibition aid. The invention further discloses a coating process of the water-based air-drying protective coating in a humid environment. The water-based air-drying protective coating is applicable to the flow line production of oily coating lines of escalators in the prior art, and the rapid-drying capacity, the flash-rust resistance, the once thick-coating sagging resistance and the corrosion resistance of the coating are achieved under humid conditions.

Owner:GUANGZHOU KINTE IND

Liquid film quick-coating air knife quick-drying creep suppression in-situ crystallization continuous preparation method for textured uniform perovskite film

ActiveCN109524551AReduced crawl timeAchieve quick dryingSolid-state devicesSemiconductor/solid-state device manufacturingIn situ crystallizationMicrometer scale

The invention discloses a liquid film quick-coating air knife quick-drying creep suppression in-situ crystallization continuous preparation method for a textured uniform perovskite film, comprising afirst step of uniform coating of a perovskite liquid film; a second step of rapid drying of the profiling perovskite liquid film: drying the profiling perovskite liquid film by using 5 to 20 airflow channels of a multi-flow air knife; a third step of hot gas annealing treatment of the perovskite liquid film: performing a heat treatment on the perovskite film for 10 to 30 minutes by using a gas having a temperature of 80 to 160 degrees centigrade and by using 30 to 50 airflow channels of the multi-flow air knife to remove a residual solvent and growing the grains, and obtaining a full-covered pyramid-like textured uniform perovskite film. The method realizes the preparation of the full-covered uniform profiling perovskite film on the pyramid textured substrate having micrometer scale protrusions by a solution deposition method under the condition that the silicon pyramid textured is not polished and smoothed, and maintains the high efficiency of a silicon solar cell.

Owner:XI AN JIAOTONG UNIV

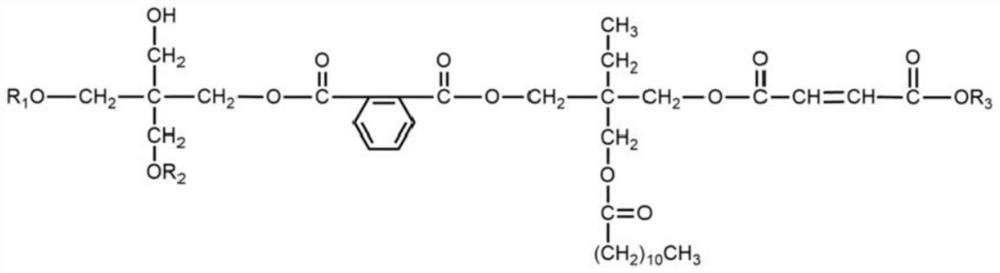

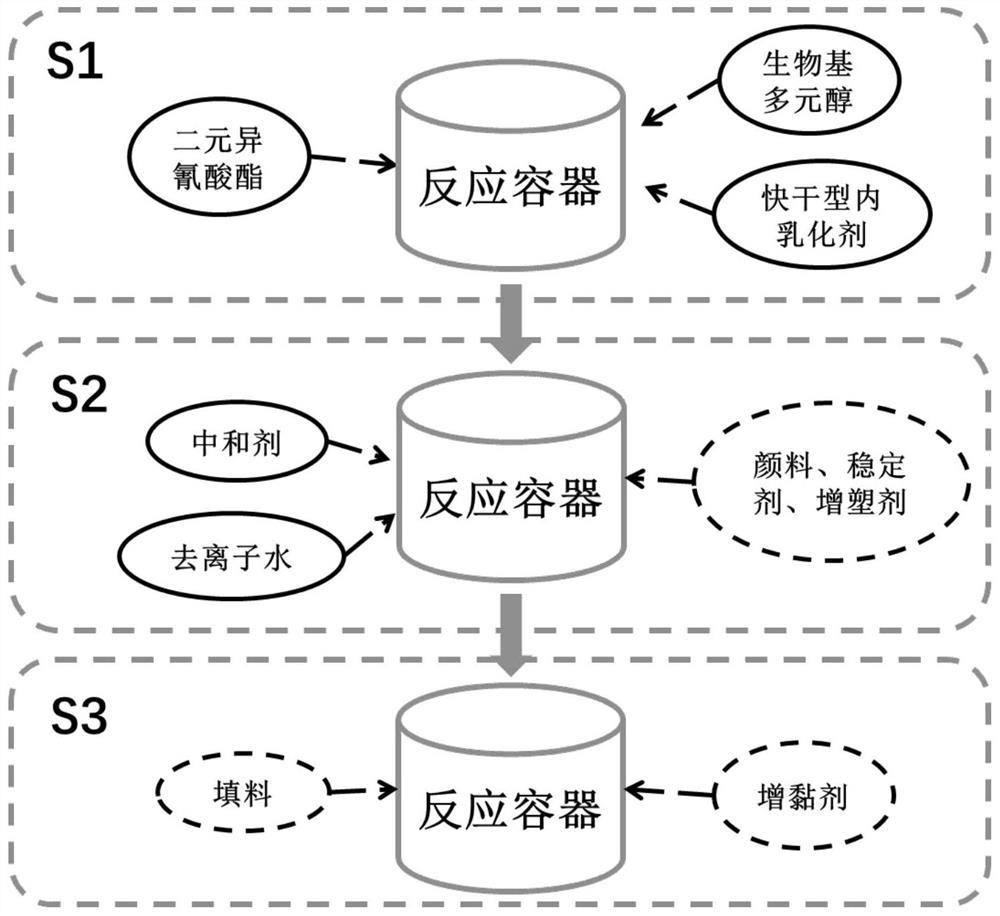

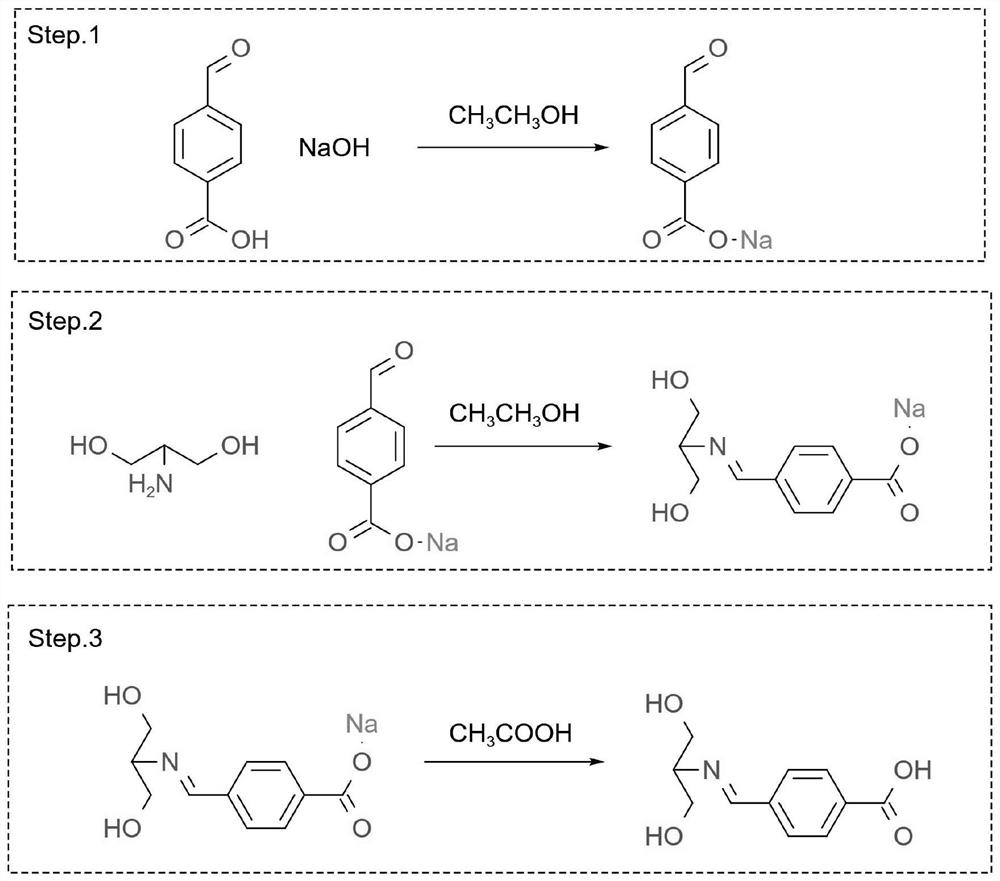

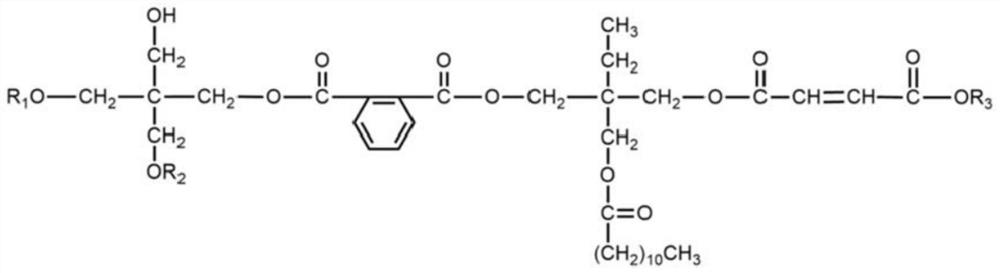

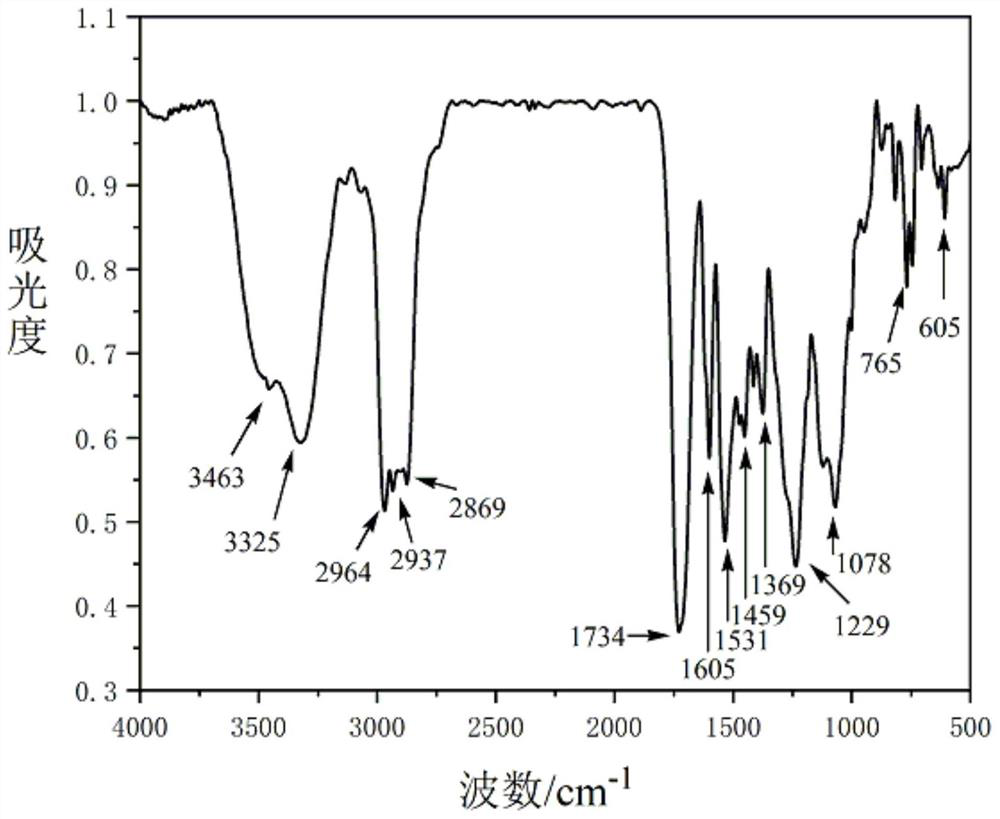

Quick-drying bio-based waterborne polyurethane coating based on stimulus response mode and preparation method of quick-drying bio-based waterborne polyurethane coating

ActiveCN114350250AExcellent low-temperature quick-drying performanceGuarantee personal safetyPolyurea/polyurethane coatingsPolymer sciencePolyol

The invention discloses a low-temperature quick-drying bio-based waterborne polyurethane coating based on a stimulus response mode and a preparation method thereof, and the low-temperature quick-drying bio-based waterborne polyurethane coating comprises the following raw materials by mass: 33-46 parts of bio-based polyol; 25 to 36 parts of binary isocyanate; 16 to 26 parts of a quick-drying internal emulsifier; 1-2 parts of a catalyst; 5-8 parts of a neutralizer; 0-4 parts of a pigment; 2-3 parts of a stabilizer; 0-5 parts of a filler; 0-2 parts of a plasticizer; and 0-1 part of a tackifier. The water-based polyurethane coating obtained in the invention is a bio-based water-based polyurethane coating based on a stimulus-responsive internal emulsifier, under a certain stimulus condition, the internal emulsifier can generate a response behavior, and the hydrophilicity of the emulsifier is broken under regulation, so that polyurethane particles in an emulsion are promoted to settle from an aqueous solution; the volatilization of water molecules is not influenced by polymer particle aggregation and diffusion, permeation and winding among polymer chains any more, the aim of quickly drying the coating at low temperature is achieved, and the coating has excellent low-temperature quick-drying performance under the strategy and can fully meet various application occasions.

Owner:CENT SOUTH UNIV

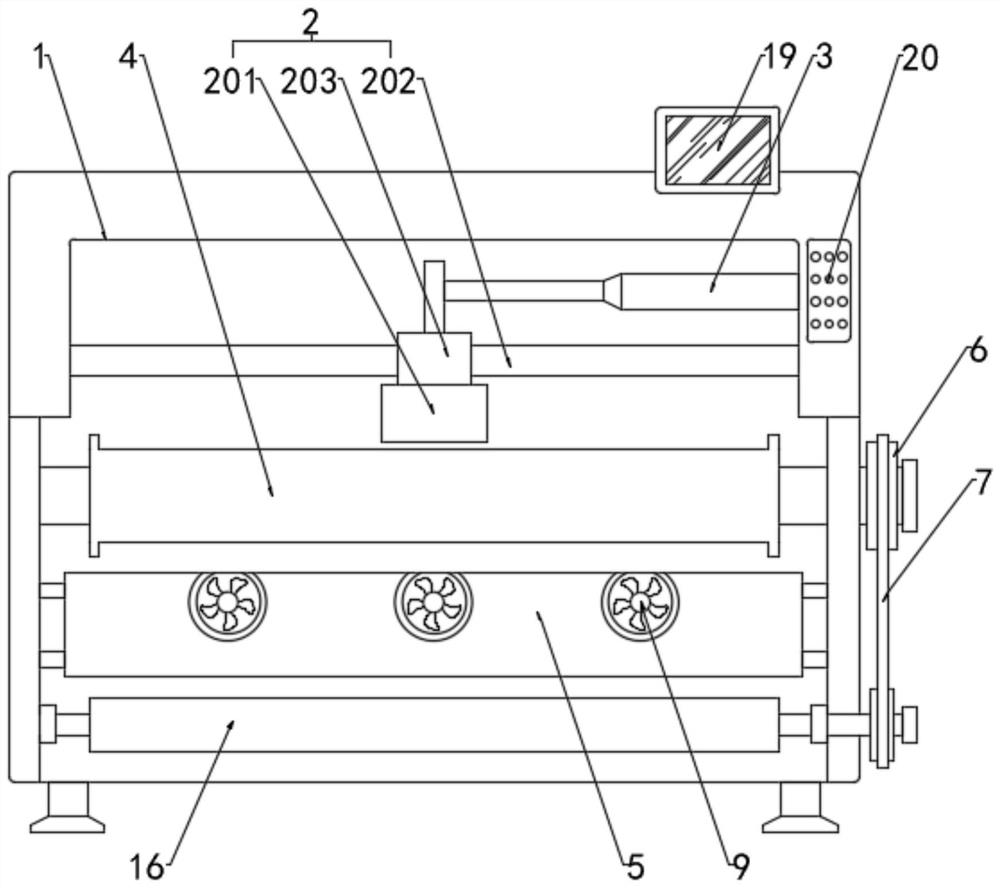

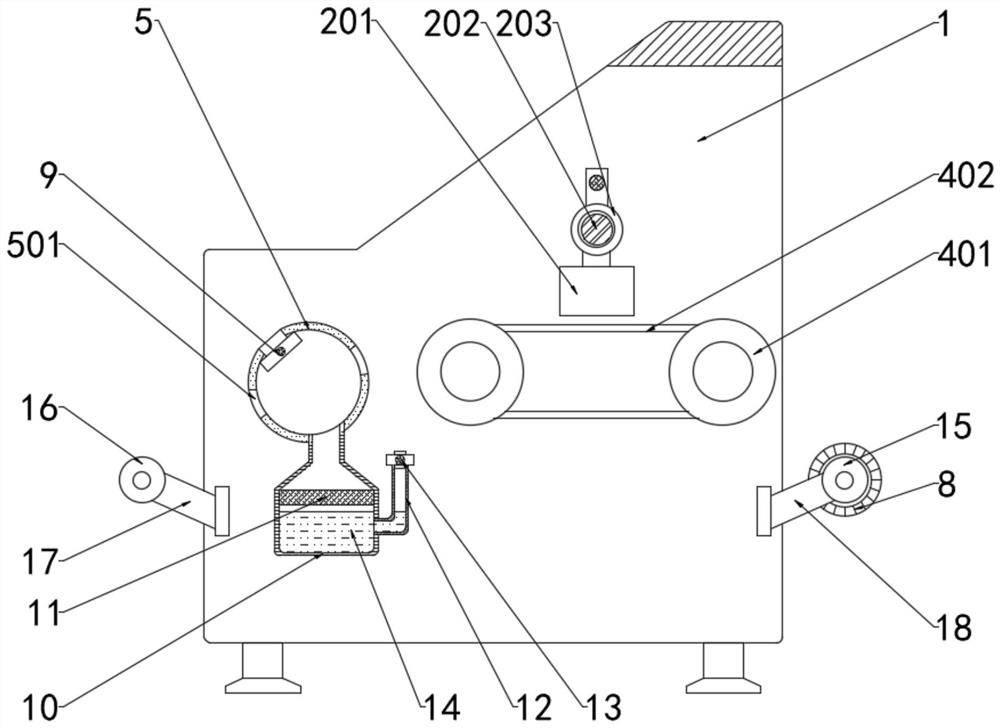

Water-resistant garment fabric printing method and device

InactiveCN112428663ARewind in timeAchieve quick dryingPlaten pressesDispersed particle separationTextile printerActivated carbon

The invention discloses a water-resistant garment fabric printing device which comprises a rack, a display terminal, a controller and a printing mechanism. The display terminal and the controller arearranged on the rack, and the printing mechanism is arranged in the rack. An air cylinder is arranged on one side of the top of the printing mechanism, and a conveying mechanism is arranged below theprinting mechanism. A drying cylinder is arranged at the position, located in front of the conveying mechanism, in the rack. According to the device, when printed gold stamping fabric penetrates through the interior of the drying cylinder, hot air flow generated by an air heater dries printing ink marks, quick drying of ink is achieved, the printed fabric can be conveniently rolled in time, meanwhile, gas in the drying cylinder enters a purification box under the action of an induced draft fan, an activated carbon adsorption core firstly adsorbs and filters particulate matter in waste gas, then pollutants in the waste gas are in contact reaction with cleaning liquid for secondary purification, and the purified gas is exhausted through an exhaust pipe, so that the emission diffusion of thepolluted gas is greatly reduced, and the environmental protection property of the fabric printing device is favorably improved.

Owner:泉州我宜纺织有限公司

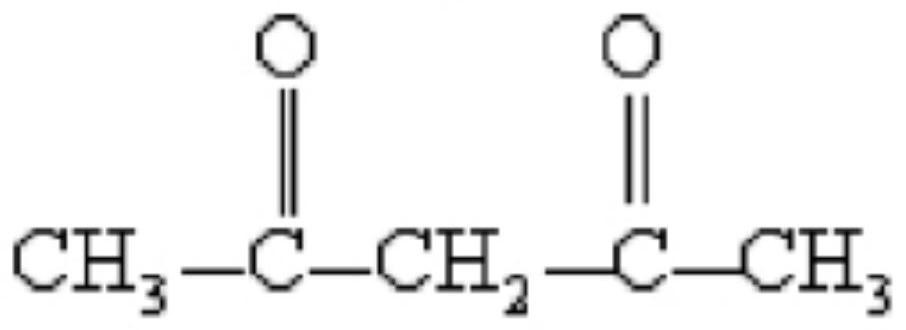

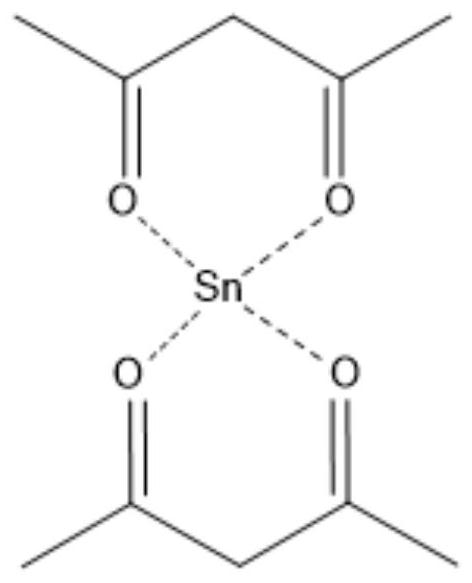

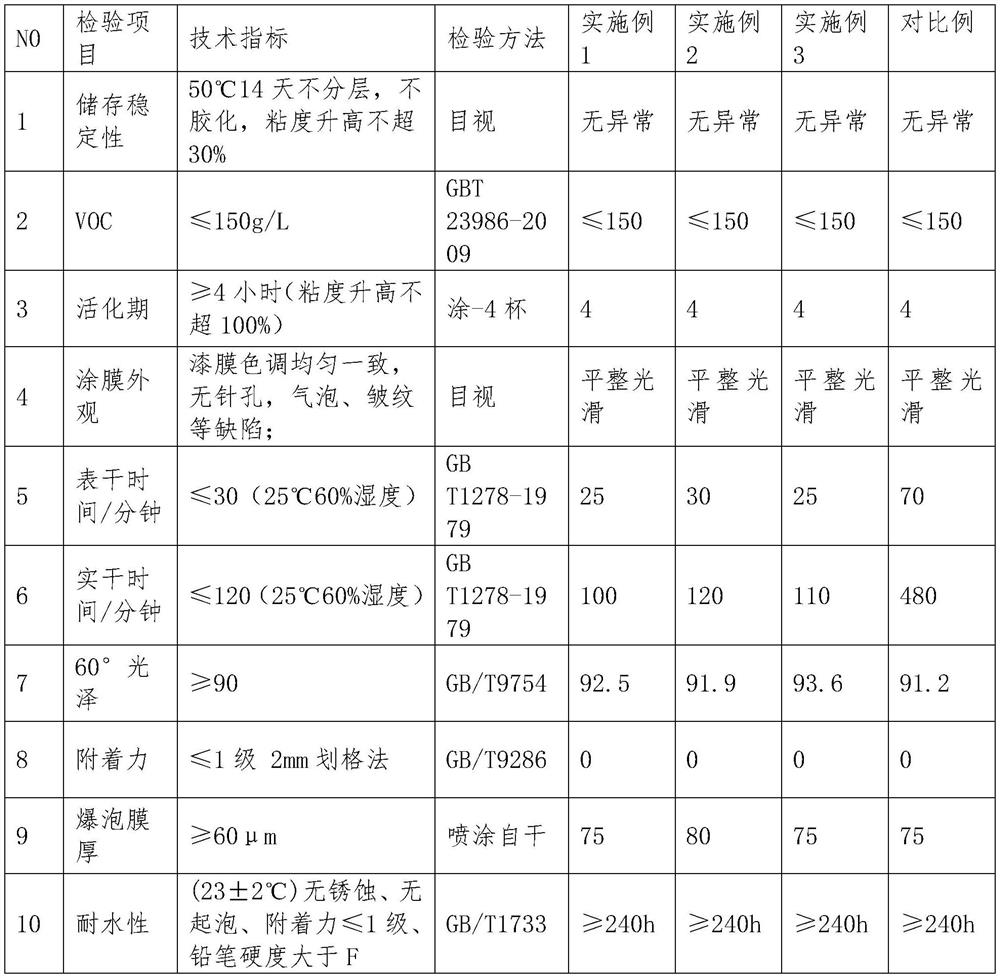

Preparation method of ultra-quick-drying water-based two-component acrylic acid refinishing paint

The invention relates to a preparation method of ultra-quick-drying water-based two-component acrylic acid refinishing paint. The ultra-quick-drying water-based two-component acrylic acid refinishing paint comprises a component A and a component B. The method comprises the steps: mixing the component A and the component B according to the mass ratio of 6: 1. then adding the organic tin drier into the polyurethane curing agent, uniformly stirring, filtering by using a 200-mesh filter screen, spraying on the original finishing coat with defects polished by a 320 # abrasive paper machine by using an air spray gun with the caliber of 1.3 mm, and naturally drying to obtain the repair coating with the thickness of 30-50 [mu] m. The organic tin drier is introduced to catalyze the reaction between hydroxyl and the polyurethane curing agent, and the solvent with high volatilization speed is adopted to dilute the curing agent so as to achieve a quick-drying effect. Acetylacetone is introduced to chelate tin ions in the organic tin drier so that the problems of paint film blistering, low bubble film thickness, short activation period and the like caused by too fast reaction between water and a polyurethane curing agent due to too fast early reaction are avoided.

Owner:三棵树(上海)新材料研究有限公司

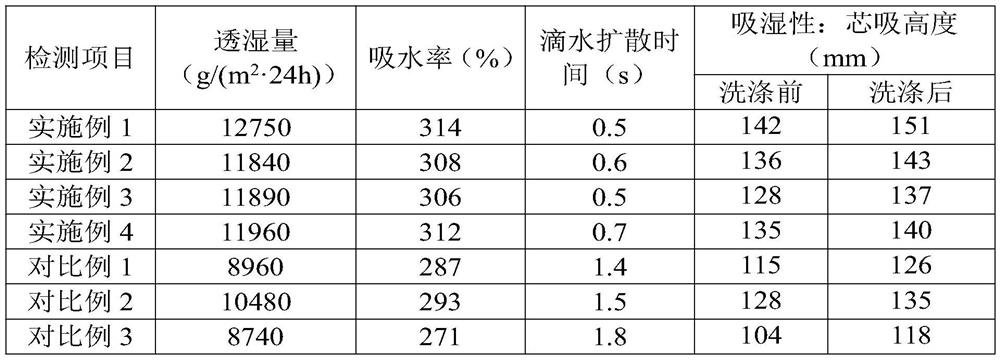

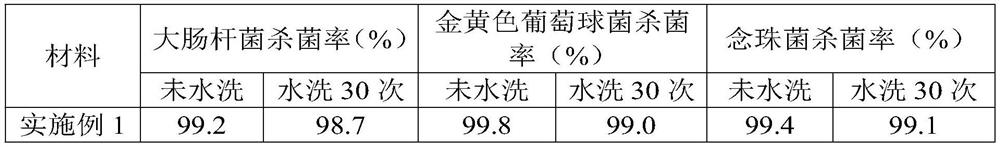

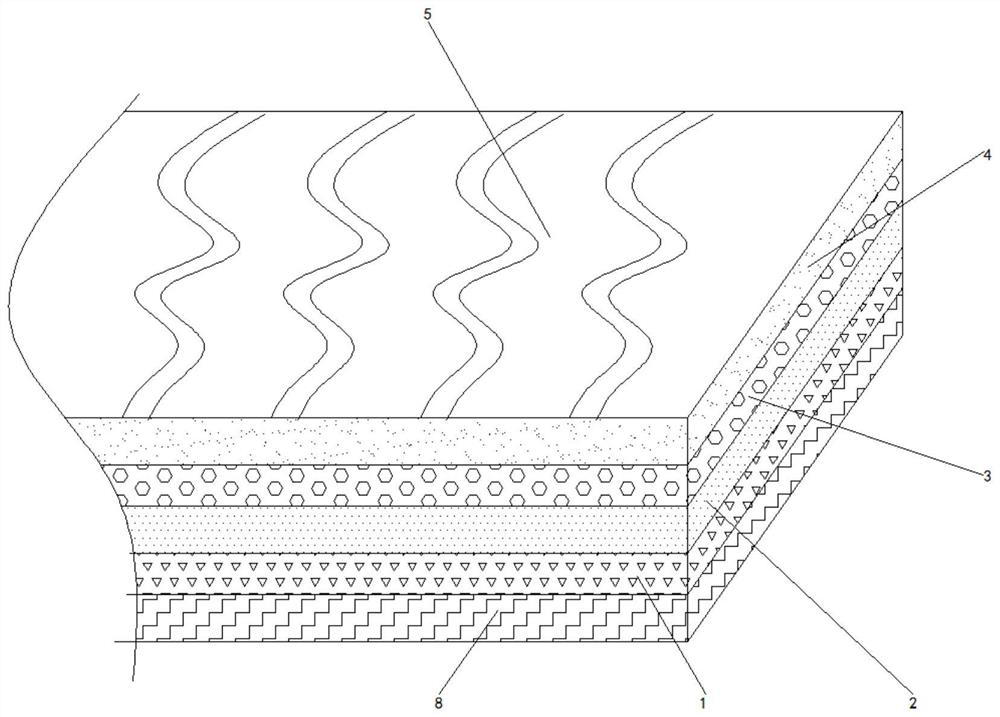

Long-acting moisture-absorbing and sweat-releasing antibacterial knitted fabric and preparation method thereof

ActiveCN113249858AFast absorptionGood moisture absorption and perspirationWeft knittingLiquid/gas/vapor removalYarnPolyester

The invention discloses a long-acting moisture-absorbing and sweat-releasing antibacterial knitted fabric and a preparation method thereof. The preparation method comprises the following steps that modified polyester fibers are prepared; a single sisal fiber yarn and a single kapok fiber yarn form parallel double yarns in a parallel mode, and a single modified polyester fiber untwisted yarn and a single cotton fiber untwisted yarn are spirally wound with each other according to the spiral ratio of 1: 1 to obtain intertwined double yarns; the parallel double yarns are used as inner-layer raw materials, the intertwined double yarns are used as outer-layer raw materials, a double-sided circular knitting machine is adopted for knitting, the inner layer is completely looped, the outer layer is partially tucked to form a mesh structure with a concave-convex appearance, and gray fabric is obtained; and the gray fabric is put into a moisture-absorbing antibacterial microsphere finishing liquid at normal temperature, two-time soaking and two-time rolling are carried out, then drying, washing twice, and then drying again are carried out. The prepared long-acting moisture-absorbing and sweat-releasing antibacterial knitted fabric is excellent in moisture-absorbing and sweat-releasing effect and outstanding in antibacterial property, the preparation method is simple, the preparation process is easy to operate, practicability is high, and excellent economic effects are achieved.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Internal circulation multifunctional clothes-airing cabinet

ActiveCN105696289AImprove the bactericidal effectAchieve quick dryingOther drying apparatusTextiles and paperMechanical engineeringAir drying

The invention discloses an internal circulation multifunctional clothes-airing cabinet which comprises an upper cabinet, a middle cabinet and a lower cabinet from top to bottom. The upper cabinet comprises a top cover, a condensing device and a sterilization device. The middle cabinet comprises an external control part, an internal clothes-hanging device, a side wall, a drying device and an airing device. The lower cabinet comprises a base plate and an undertaking device. The internal circulation multifunctional clothes-airing cabinet has the advan tages of clothes airing attractiveness, clothes drying and sterilization.

Owner:ZHEJIANG HOOEASY SMART TECH

Urine separating cushion and preparation method thereof

ActiveCN102764183AGood hygroscopicityWith quick-drying functionAbsorbent padsBandagesFiberAntibiosis

The invention provides an urine separating cushion, comprising a surface layer and a waterproof layer located below the surface layer, wherein the surface layer is detachably connected with the waterproof layer; the surface layer is made of moisture-absorption quick-drying shell fabric; the moisture-absorption quick-drying shell fabric is prepared by selected Supplex fiber or a mixture of the Supplex fiber and lycra elastic fiber; a preparation method for the urine separating cushion is also provided by the invention; the urine separating cushion of the invention has functions such as moisture absorption, quick drying, antibiosis, easy decontamination and the like; the urine separating cushion is characterized by simple structure and convenient cleanness and improves problems of poor air permeability of original urine separating cushions, easy bacterium growth and the like; in addition, the urine separating cushion can be cleaned in an emphasizing manner directly at different demands; and the urine separating cushion can be used as maternal and child supplies and also can be used for a patient who lies in bed.

Owner:SHANGHAI SHUIXING HOME TEXTILE

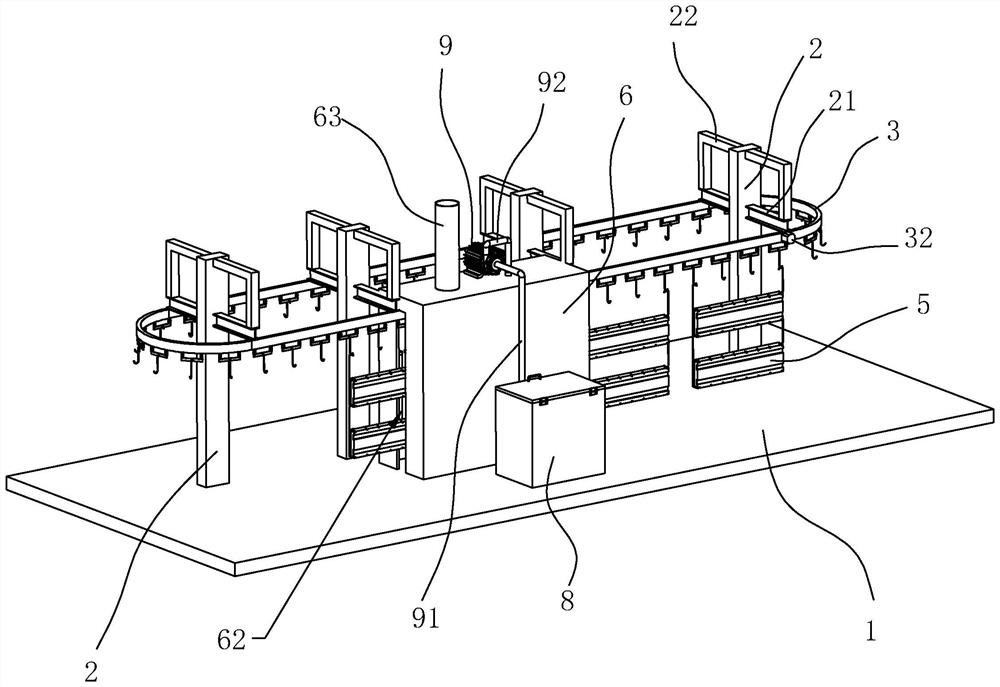

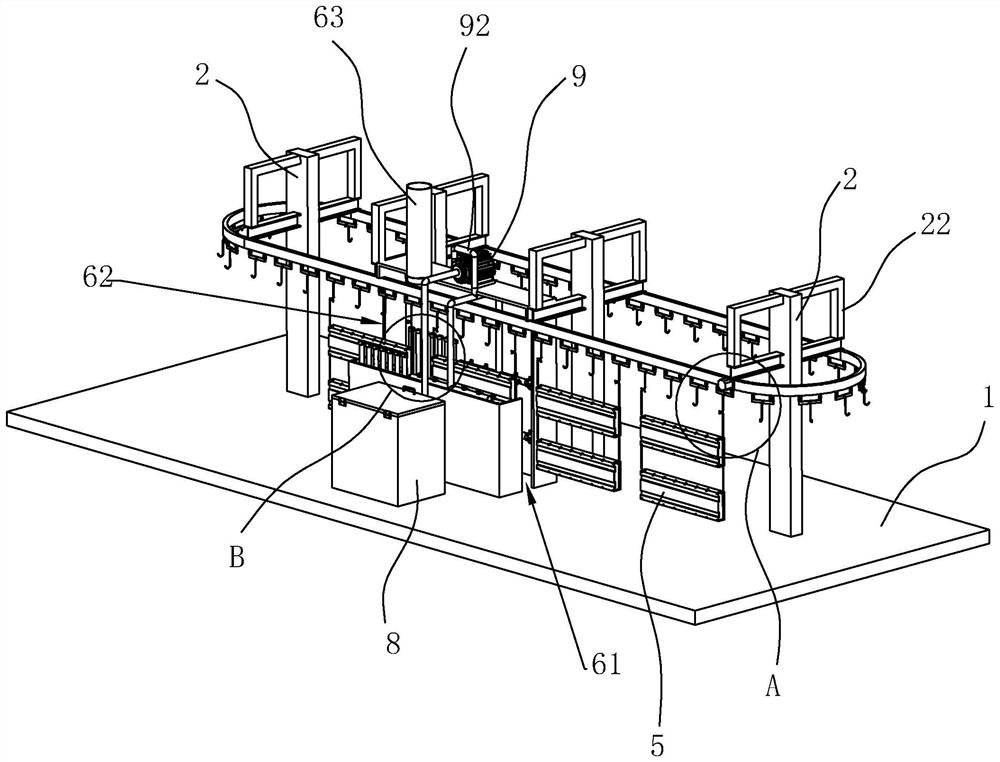

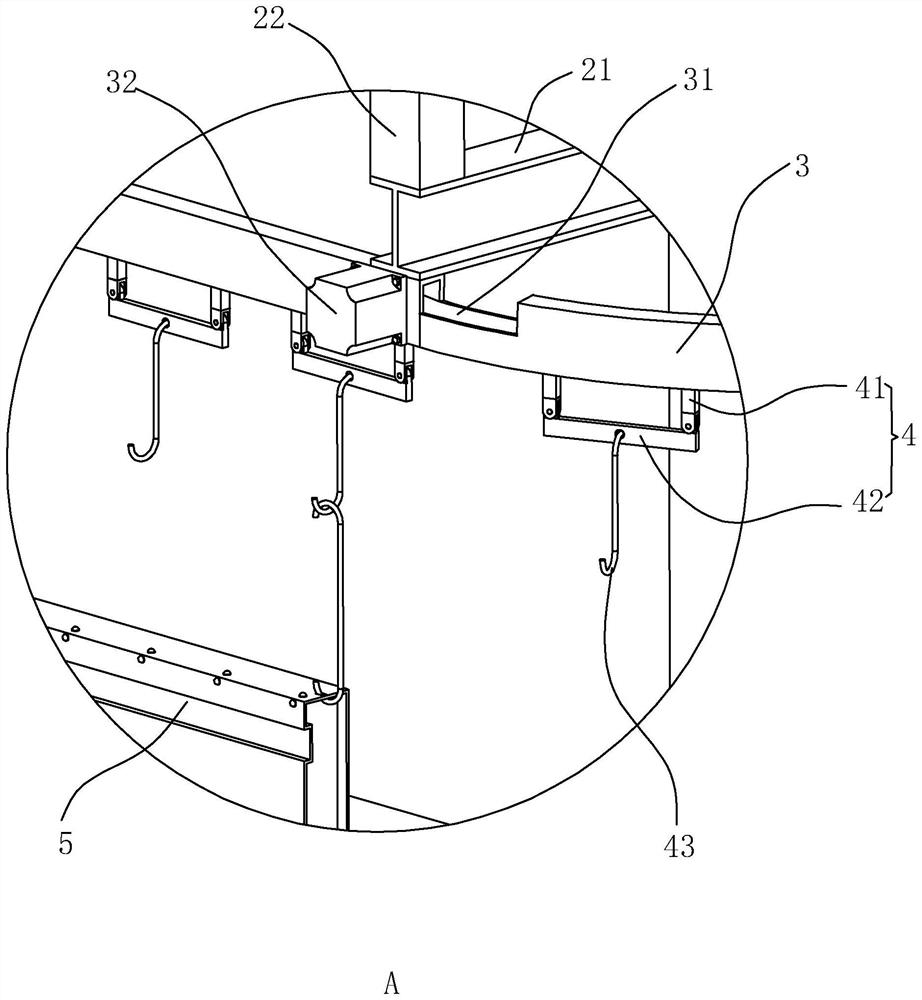

Expressway sound barrier production line

PendingCN114273117AIncrease productivityAchieve quick dryingPretreated surfacesCoatingsElectric machineryNoise barrier

The expressway sound barrier production line comprises a plurality of sets of steel structure supports, a rail is jointly hoisted on the steel structure supports, a belt is inserted into the rail in a rotating mode, and motors for driving the belt to rotate are installed on the steel structure supports; a plurality of groups of hangers are mounted at the lower end of the belt, hooks are hung at the lower end parts of the hangers, and a sound insulation barrier is hung at the lower end parts of the two groups of hooks; a cover body is installed on the ground, a first opening and a second opening are formed in the two sides of the cover body respectively, and a rail is horizontally inserted into the cover body from the first opening and moves out of the second opening. The inner walls of the two sides, close to the first opening, of the cover body are each provided with a plurality of sprayers, a paint box used for containing paint is placed on the ground, an oil pump is installed on the upper end face of the cover body, an inlet of the oil pump is connected with a feeding pipe inserted into the cover body, and an outlet of the oil pump is connected with discharging pipes inserted into the cover body and connected with the sprayers. The paint spraying efficiency of the sound insulation barrier is improved.

Owner:广东晟虹交通科技有限公司

High-strength light composite building material

InactiveCN107266118AAchieve quick dryingImprove flexural strengthCeramicwarePolyvinyl chlorideStearate

The invention relates to a high-strength light composite building material. The high-strength light composite building material is prepared from the following components in parts by weight: 15 to 19 parts of hydrophobic pearlite, 30 to 47 parts of barium stearate, 20 to 24 parts of graphite powder, 10 to 14 parts of cadmium stearate, 5 to 8 parts of calcium stearate, 3 to 8 parts of polyvinyl chloride, 15 to 19 parts of foaming material, 18 to 22 parts of limestone and 18 to 25 parts of diatomite. By adopting the high-strength light composite building material, the rupture strength and toughness of the composite building material can be enhanced effectively, the crack width is limited, and surface cracking of the composite building material is resisted; the high-strength light composite building material can be widely applied to composite building material structures in the fields of civil engineering, water conservation, municipal transportation, marine military industry and the like.

Owner:钱小平

A kind of long-term moisture absorption and perspiration antibacterial knitted fabric and preparation method thereof

ActiveCN113249858BFast absorptionGood moisture absorption and perspirationWeft knittingLiquid/gas/vapor removalYarnPolyester

The invention discloses a long-lasting moisture-absorbing, sweat-wicking and antibacterial knitted fabric and a preparation method thereof, comprising the following steps: preparing modified polyester fibers; forming parallel lines with a single sisal fiber yarn and a single kapok fiber yarn in a parallel manner Double yarn, a single modified polyester fiber untwisted yarn and a single cotton fiber untwisted yarn are spirally wound with each other at a helical ratio of 1:1 to obtain an intertwined double yarn; the parallel double yarn is used as the inner layer raw material, and the intertwined double yarn is obtained. As the raw material for the outer layer, it is woven with a double-sided circular knitting machine, the inner layer is completely formed into a circle, and the outer part of the tuck is in a mesh structure with a concave-convex appearance to obtain a grey fabric; at room temperature, the grey fabric is placed in a hygroscopic antibacterial microsphere finishing solution for two Dip two tie, then dry, wash twice and then dry again. The long-acting moisture-absorbing and sweat-wicking antibacterial knitted fabric prepared by the invention has excellent moisture-absorbing and sweat-wicking effect, high antibacterial property, simple preparation method, easy operation, strong practicability and excellent economic effect.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Corundum-silicon nitride-silicon carbide composite pouring material

The invention discloses a corundum-silicon nitride-silicon carbide composite castable for iron-making blast furnace tuyeres. The castable is composed of corundum, silicon nitride, silicon carbide, aluminate cement, metal aluminum powder, metal Silica, silica micropowder, alumina micropowder, and polypropylene fiber are mixed, which realizes rapid pouring and repairing of the remaining bricks with composite brown corundum refractory bricks at the tuyere of the blast furnace. Corundum refractory shaped bricks do not need to be fired at high temperatures during the production process, so they are also an energy-saving refractory material for blast furnace tuyere belts. The pouring construction is not limited by the construction space, and can be poured and masonry quickly. Normal furnace is an inorganic non-metallic refractory material for quick-drying and rapid furnace construction and repair for blast furnace repair and new blast furnace tuyere belt.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

A kind of high solid content low viscosity clean taste alkyd resin and its preparation method and application

ActiveCN113201124BLarge space three-dimensional structureAccelerate evaporationPolyurea/polyurethane coatingsXylylenePolymer science

The invention discloses a high-solids and low-viscosity clean alkyd resin and a preparation method and application thereof. In parts by mass, the raw materials of the high-solids and low-viscosity clean alkyd resins are composed of: 29.5-33.5 parts of vegetable oil fatty acids, acid anhydrides 18.5-21.5 parts, 2.5-4.9 parts of unit acid, 20.3-24.1 parts of polyol, 2-5 parts of polyacetal resin, 3-5 parts of xylene, 14-15 parts of organic solvent; the resin prepared by the invention has easy structure and performance Controlled and adjustable, etc., used to prepare two-component polyurethane wood paint coatings, with hardness up to H above, adhesion level 0, residual VOC less than 5g / L after the paint film is dried for 2 days, clean and environmentally friendly, with excellent chemical resistance and thermal stability.

Owner:SOUTH CHINA UNIV OF TECH

Continuous preparation method of uniform perovskite film on suede surface by liquid film quick-coating air knife quick-drying method to inhibit climbing and in-situ crystallization

ActiveCN109524551BReduced crawl timeAchieve quick dryingSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneSilicon solar cell

The invention discloses a liquid film rapid coating air knife quick-drying method for inhibiting creep and in-situ crystallization continuous preparation method of a uniform perovskite film on a suede surface. The method includes: first step, uniform coating of perovskite liquid film; second The first step is the rapid drying of the profiled perovskite liquid film: the drying of the profiled perovskite liquid film is completed by using 5 to 20 airflow channels of the multi-flow air knife; the third step is the hot gas annealing treatment of the perovskite liquid film: Using multi-flow air knife with 30 to 50 gas flow channels, the perovskite film is heat-treated with gas at a temperature of 80 to 160°C for 10 to 30 minutes to remove residual solvent and make the crystal grains grow, and obtain a pyramid-like fleece with full coverage Uniform perovskite thin films. Under the condition that the silicon pyramid textured surface is not polished and flattened, the present invention adopts the solution deposition method to realize the preparation of a fully covered and uniform profiled perovskite film on the micron-scale undulating pyramid textured substrate, maintaining the silicon solar cell The advantage of high efficiency.

Owner:XI AN JIAOTONG UNIV

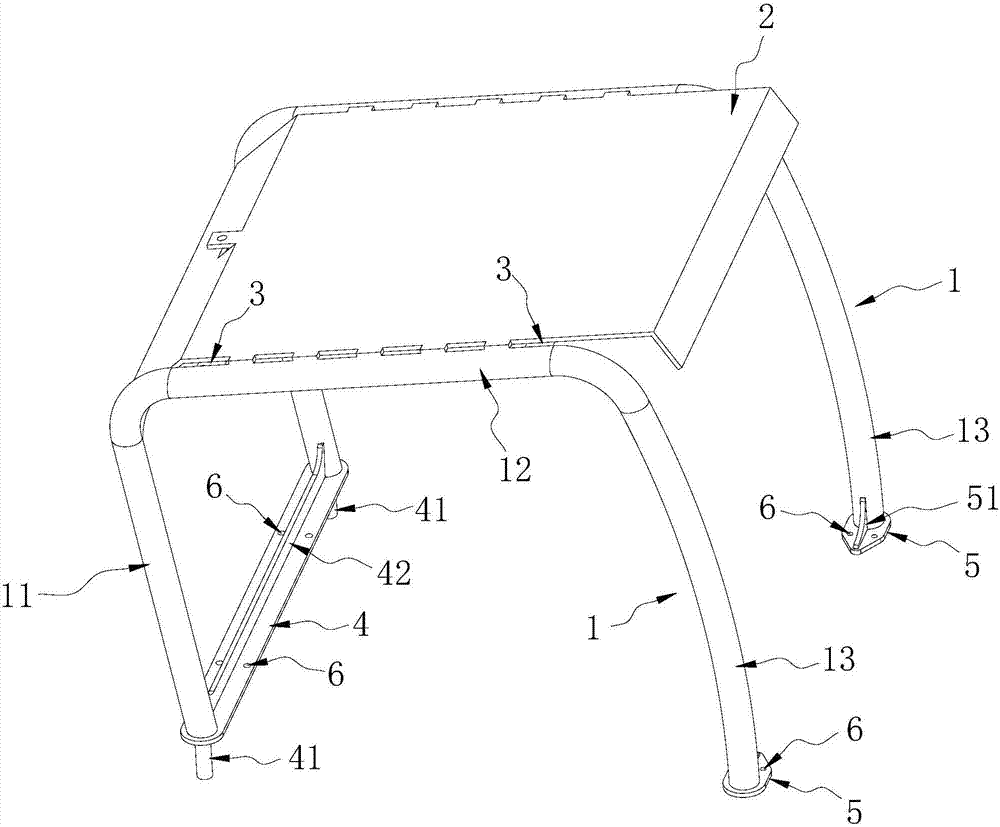

Safety protection device on road roller

PendingCN107237240AReasonable structureAvoid the problem of easy oxidation and corrosionRoads maintainenceUltimate tensile strengthCorrosion

The invention discloses a safety protection device on a road roller. The safety protection device comprises a supporting frame and a shield, wherein the supporting frame is composed of two bilaterally symmetrically arranged supporting tubes and a plurality of connecting tube for connecting the two supporting tubes, the upper part of the supporting frame is covered with the shield, the left and right sides of the shield are respectively correspondingly welded with the supporting tubes on the left and right sides, each supporting tube is of a U-shaped structure composed of a back tube section, an upper tube section and a front tube section, a connecting plate is welded between the back tube sections of the two supporting tubes, a plurality of insert columns are also arranged below the connecting plate, a backing plate is welded at the bottom of the front tube section of each of the two supporting tubes, and connecting holes are formed in both the connecting plate and the backing plate. The supporting tubes on two sides and the shield of the safety protection device are in an integrated structure instead of being formed by welding, so the safety protection device has high strength, avoids the problem of easy oxidation corrosion at the connections resulted from the traditionally adopted welding manner, is difficult to accumulate liquid, has high structural strength and has high connection firmness with an outer casing on the road roller.

Owner:浙江奥桑机械设备有限公司

Temperature adjusting cloth

ActiveCN105019102AHeat storage hasImprove insulation effectLayered productsWoven fabricsHuman bodyEngineering

The invention discloses a temperature adjusting cloth. The temperature adjusting cloth comprises a base material and a temperature adjusting layer, wherein the temperature adjusting layer is formed on at least part of a surface of the base material and is provided with at least one temperature adjusting unit, and each temperature adjusting unit comprises puzzolana. The temperature adjusting cloth has the effects of heat storage, warming, quick drying and deodorization through the inherent heat storage and adsorption capabilities of the puzzolana, and the puzzolana which is a natural material does not produce adverse effect on human body. Users feel more comfortable when clothes, sleeping bags, tents and the like made of the temperature adjusting cloth are used.

Owner:FORMOSA TAFFETA CO LTD

Quick-drying cotton knitted printed cloth

PendingCN113580710AFast absorptionAchieve quick dryingSynthetic resin layered productsYarnTextile printer

The invention relates to quick-drying cotton knitted printed cloth, which comprises base cloth, a quick-drying part is arranged on the outer side of the base cloth, an antibacterial layer is fixedly connected to the outer side of the quick-drying part, a flame-retardant layer is fixedly connected to the outer side of the antibacterial layer, a printing layer is fixedly connected to the outer side of the flame-retardant layer, and a wear-resistant layer is fixedly connected to the outer side of the printing layer. The quick-drying piece comprises a moisture guide layer and a moisture absorption layer, the moisture guide layer is made of Coo lmax fibers with four grooves, a cotton fiber layer is arranged between the moisture guide layer and the moisture absorption layer, the moisture absorption layer is made of heavy-twist combed yarn knitted fibers, and the heavy-twist combed yarn knitted fibers are heavy-twist combed yarns. According to the quick-drying cotton knitted printed cloth, the moisture guiding layer and the moisture absorbing layer in the quick-drying piece are used in cooperation, so that moisture can be quickly absorbed, the quick-drying effect is achieved, and through the arrangement of the antibacterial layer, the flame-retardant layer and the wear-resistant layer, the knitted printed cloth has good antibacterial, flame-retardant and wear-resistant properties.

Owner:YANCHENG WANDALI KNITTING MACHINERY

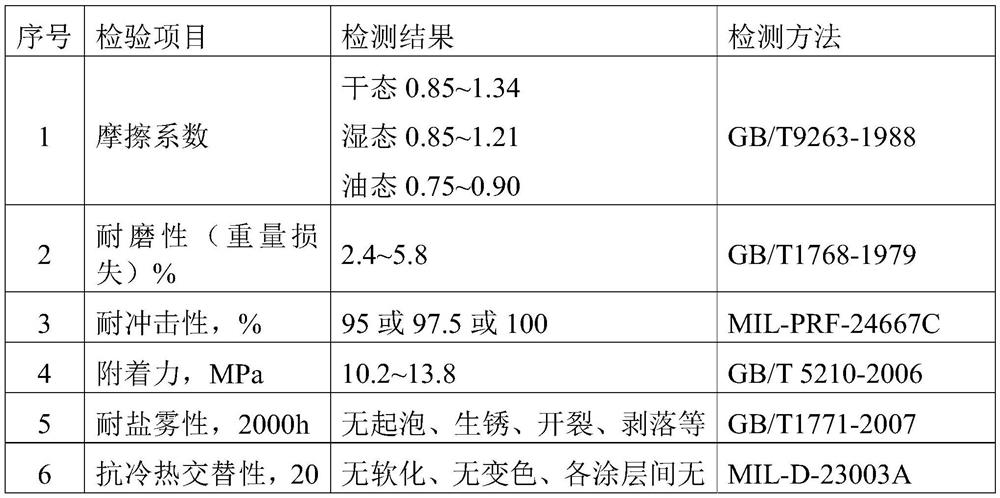

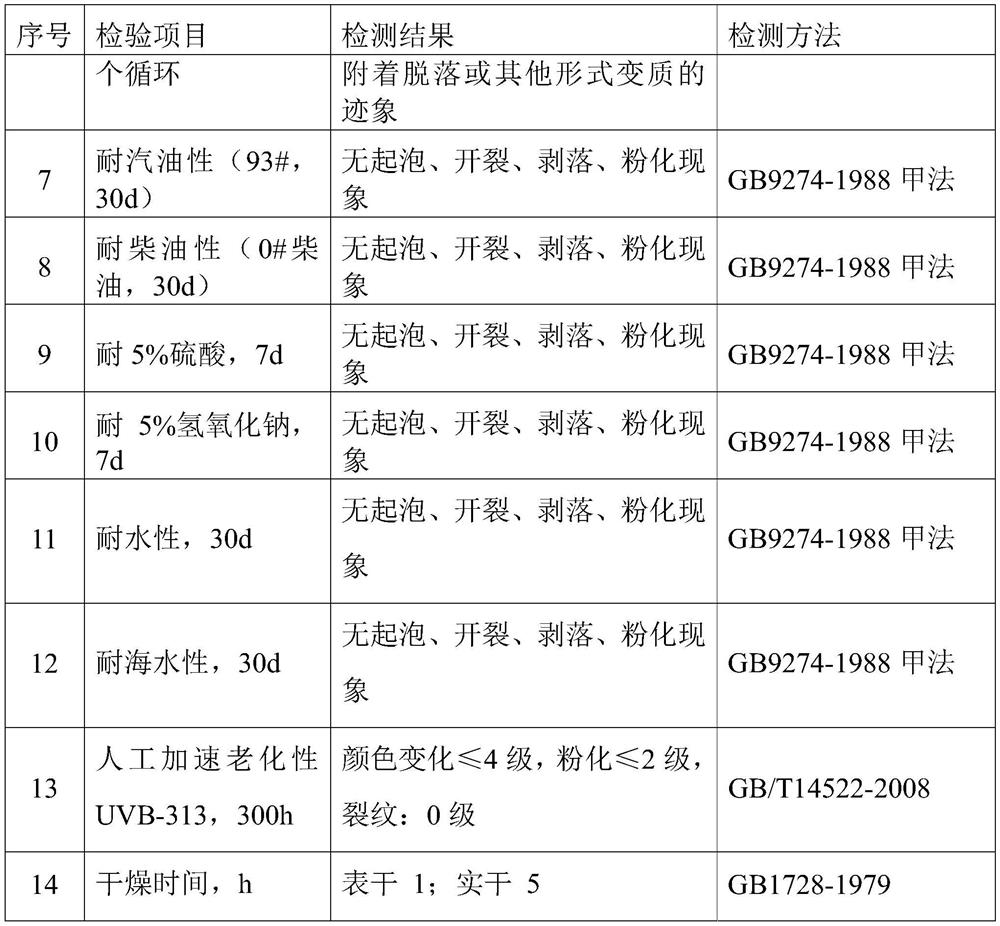

Composite anti-skid coating for heavy-load track and preparation method of composite anti-skid coating

ActiveCN114316729ALow viscosityQuick responseAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidSolid content

The invention relates to an anti-skid coating for a heavy-load track and a preparation method thereof, and the composite anti-skid coating for the heavy-load track comprises an anti-corrosion primer, a first anti-skid finishing coat and a second anti-skid finishing coat, wherein the anti-corrosion primer is epoxy anti-corrosion primer; the first anti-skid finish paint is epoxy anti-skid finish paint; and the second anti-skid finish paint comprises a polyaspartic acid ester finish paint and anti-skid particles. The selected resin has the characteristics of high solid content, low viscosity, high reaction speed and the like, and the special composition of the first anti-skid finishing coat and the second anti-skid finishing coat is adopted, so that the excellent adhesive force with the anti-corrosion primer is ensured, and the properties of quick drying, aging resistance, wear resistance and the like of the coating are realized.

Owner:MARINE CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com