Waterborne marking paint and preparation method and construction method thereof

A kind of marking paint, water-based technology, applied in anti-fouling/underwater paint, epoxy paint, coating and other directions, to achieve good fast drying, enhanced adhesion, enhanced wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Second aspect, the present invention also provides a kind of preparation method of water-based marking paint, comprises steps:

[0039] S10, mixing the water-based acrylic emulsion, the fluorocarbon emulsion, the water-based epoxy emulsion, the water-based dispersant, and the defoamer and stirring at a low speed until they are evenly mixed to obtain a first mixed solution;

[0040] S20. After slowly adding titanium dioxide, heavy calcium carbonate, and nano-silicon carbide into the first mixed solution, stir until uniform to obtain a second mixed solution;

[0041] S30, adding the aqueous wax solution, thickener, organic bentonite, and aqueous drier to the second mixed solution;

[0042] S40, adding ethanol, deionized water and multifunctional additives to the third mixed solution, stirring evenly, after filtering, leaving the filtrate to stand to obtain a water-based marking paint;

[0043] Wherein, based on the total weight of the water-based marking paint, the conte...

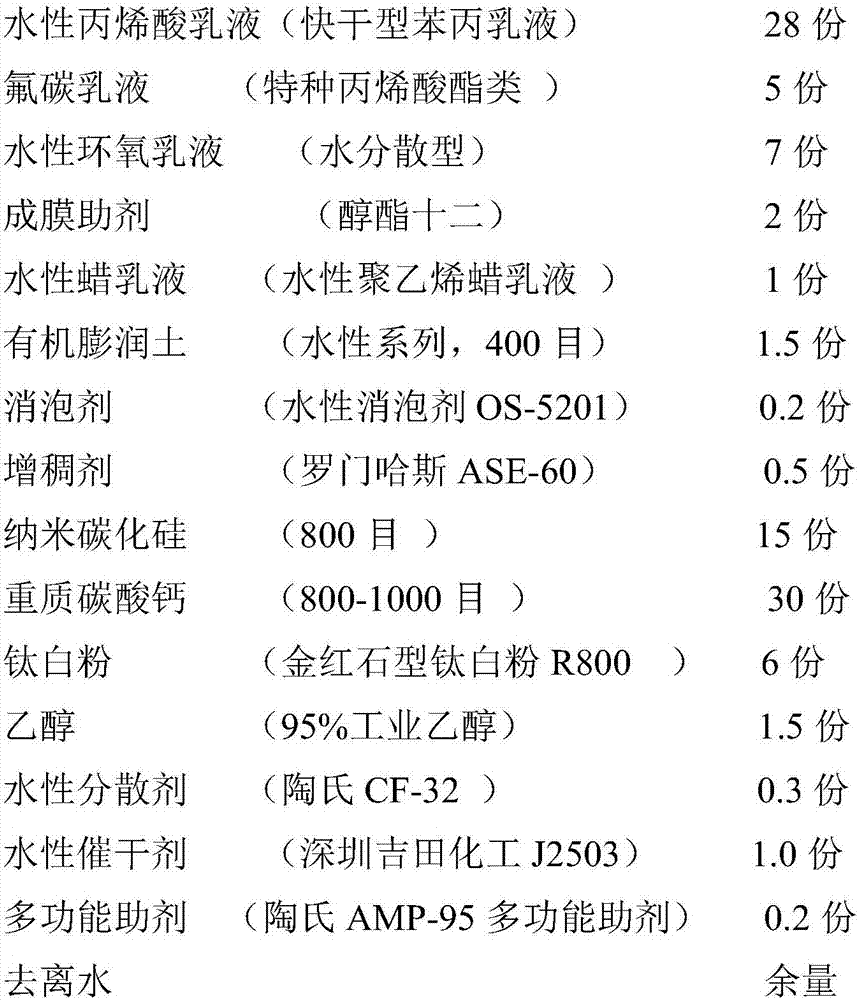

Embodiment 1

[0070] Water-based marking paint D1 formula:

[0071]

[0072] The water-based epoxy emulsion also includes a water-based epoxy curing agent, the ratio of the water-based epoxy emulsion:water-based epoxy curing agent is 55:45-45:55, and the curing agent is the water-based epoxy curing agent GCA02.

[0073] 1) Material preparation: Accurately weigh the required raw materials according to the formula, and reserve

[0074] 2) Add the weighed water-based acrylic emulsion, fluorocarbon emulsion, water-based epoxy emulsion, water-based dispersant, and defoamer into the dispersion tank, and stir at a low speed (200r / min) for 5 minutes, and stir evenly

[0075] 3) Increase the stirring speed to 400r / min, slowly and evenly add the weighed titanium dioxide, heavy calcium carbonate, and nano-silicon carbide, after adding, increase the stirring speed to 1000r / min, stir for 15 minutes, and stir evenly

[0076] 4) Add the weighed water-based wax emulsion, thickener, organic bentonite, and...

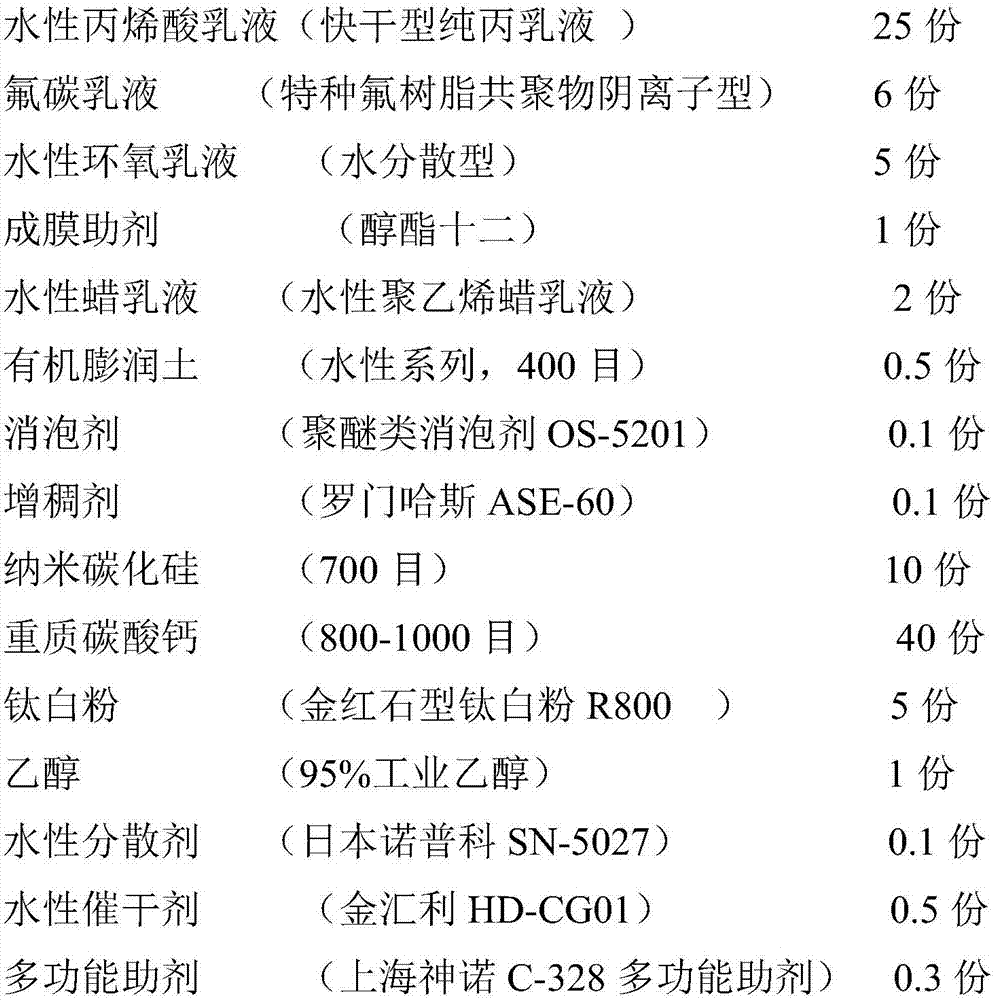

Embodiment 2

[0080] Waterborne marking paint D2 formula:

[0081]

[0082]

[0083] The water-based epoxy emulsion also includes a water-based epoxy curing agent, the ratio of the water-based epoxy emulsion:water-based epoxy curing agent is 55:45-45:55; the curing agent is the water-based epoxy curing agent HTW208.

[0084] 1) Material preparation: Accurately weigh the various raw materials required according to the formula, and set them aside;

[0085] 2) Add the weighed water-based acrylic emulsion, fluorocarbon emulsion, water-based epoxy emulsion, water-based dispersant, and defoamer into the dispersion tank, and stir at a low speed (200r / min) for 5 minutes, and stir evenly;

[0086] 3) Increase the stirring speed to 400r / min, slowly and evenly add the weighed titanium dioxide, heavy calcium carbonate, and nano-silicon carbide, after adding, increase the stirring speed to 1000r / min, stir for 15 minutes, and stir evenly;

[0087] 4) Add the weighed water-based wax emulsion, thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Coefficient of retroreflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com