Water paint for paper materials and preparation method thereof

A technology for water-based paint and paper materials, applied in the field of water-based paint for paper materials and its preparation, can solve the problems of lack of corrosion resistance and wear resistance, reduce the adhesion of substrates, and poor water resistance, and achieve outstanding moisture-proof and mildew-proof capabilities. Less amount of cloth, good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

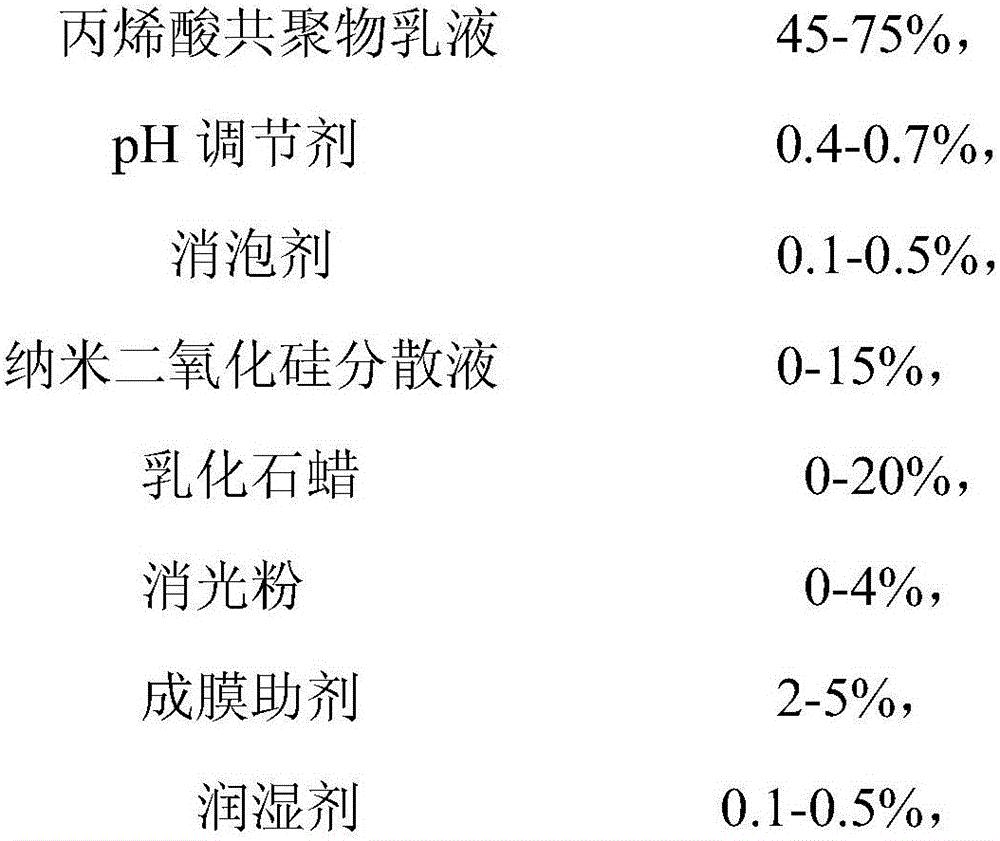

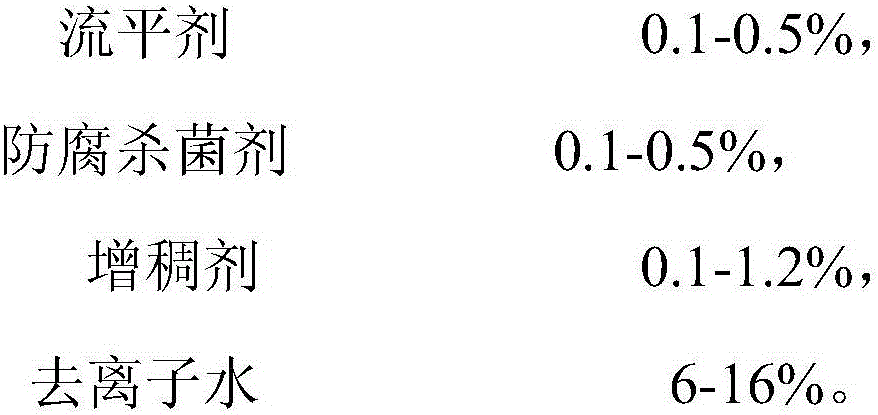

[0032] A kind of water-based paint for paper of the present invention, said water-based paint for paper comprises the following components in the following percentages by weight:

[0033]

[0034]

[0035] The acrylic acid copolymer emulsion is a pure acrylic acid copolymer emulsion. Like Germany WPA5812;

[0036] The pH regulator is multifunctional amine AMP-95.

[0037] The defoamer is a silicone defoamer. Such as BYK028.

[0038] The film-forming aid is Alcohol Fat-12.

[0039] Described emulsified paraffin is oxidatively modified polyethylene hard wax; Described wetting agent is polyether modified organosilicon compound, described leveling agent is Tego270 of Tego Company, and described anticorrosion bactericide is Isothiazoline antiseptic and fungicide.

[0040] Described anticorrosion bactericide is YN-188 of Rufa Chemical Company.

[0041] The thickener is a hydrophobically modified alkali-swellable thickener.

[0042] The preparation method of water-based ...

Embodiment 2

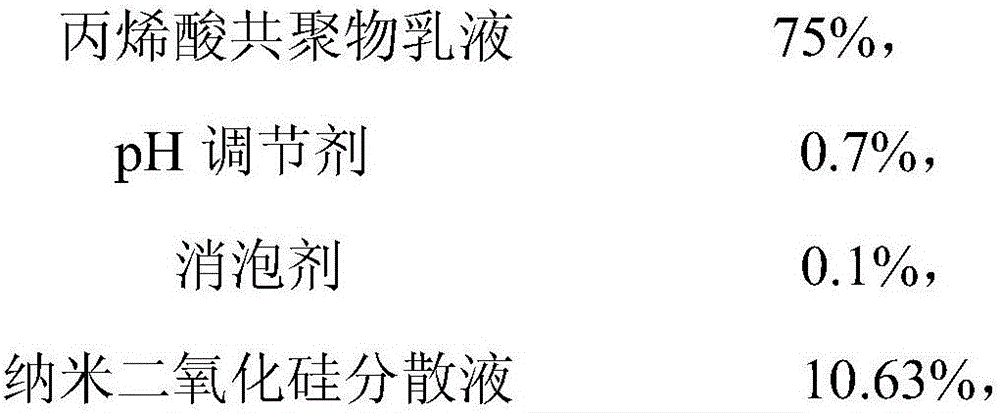

[0048] The difference between embodiment 2 and embodiment 1 is: a kind of water-based paint for paper of the present invention, described water-based paint for paper comprises the following components in the following percentages by weight:

[0049]

[0050]The acrylic acid copolymer emulsion is a combination of pure acrylic acid copolymer emulsion and phenylacrylic acid copolymer emulsion. Like Germany WPA5812;

[0051] The pH regulator is dimethylethanolamine. Described film-forming aid is propylene glycol methyl ether. The thickener is a polyurethane thickener. Described anticorrosion bactericide is the K9N of Troy company.

[0052] The preparation method of water-based paint for paper of the present invention comprises the steps:

[0053] (1) Accurately weigh each component according to the ratio;

[0054] Preparation of matting slurry: add part of deionized water to the tank, add matting powder at a stirring speed of 400r / min, prepare the matting powder into a 16w...

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 1 is: a kind of water-based paint for paper of the present invention, described water-based paint for paper comprises the following components in the following percentages by weight:

[0059]

[0060]

[0061] The acrylic acid copolymer emulsion is a phenylacrylic acid copolymer emulsion. Like Germany WPA5812;

[0062] The film-forming aid is a combination of three of propylene glycol methyl ether, dipropylene glycol methyl ether, and dipropylene glycol butyl ether.

[0063] The thickener is a combination of hydrophobically modified alkali-swellable thickener or polyurethane thickener.

[0064] The preparation method of water-based paint for paper of the present invention comprises the steps:

[0065] (1) Accurately weigh each component according to the ratio;

[0066] Prepare matting slurry: add part of deionized water to the container, add matting powder at a stirring speed of 600r / min, prepare the matting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com