UV (Ultra Voilet) light curing transfer printing coating sizing agent and transfer printing coating

A technology of coating slurry and photocuring, which is applied in the direction of coating, can solve the problems of organic solvent environmental pollution and other problems, and achieve the effect of less equipment investment, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

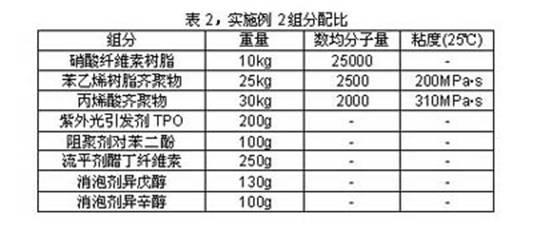

[0038] Step 1, prepare UV transfer printing coating slurry according to the equipment in Table 1;

[0039]

[0040] The initiator 184 in the table is 1-hydroxycyclohexyl phenyl ketone.

[0041] According to the distribution ratio of each component in Table 1, the cellulose resin is blended with the free radical resin oligomer, and then a polymerization inhibitor, an ultraviolet photoinitiator, a leveling agent and a defoamer are added to form a UV photocurable transfer coating slurry.

[0042] In step 2, coating is carried out, and at the same time light curing is performed to prepare a transfer coating.

[0043] The glass transition temperature Tg of the transfer printing coating prepared in Example 1 of the present invention is 130° C., which has good heat resistance; at the same time, the transfer printing coating prepared by the present invention has a hardness of 3H and has relatively high mechanical strength; and the coating The layer peeling performance is excellen...

Embodiment 2

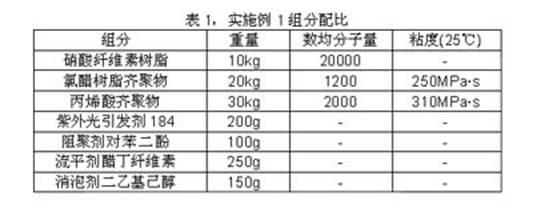

[0045] Step 1, prepare UV transfer printing coating slurry according to the equipment in Table 2;

[0046]

[0047] The initiator TPO in the table is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide.

[0048] According to the distribution ratio of each component in Table 2, the cellulose resin is blended with the free radical resin oligomer, and then a polymerization inhibitor, an ultraviolet photoinitiator, a leveling agent and a defoamer are added to form a UV photocurable transfer coating slurry.

[0049] In step 2, coating is carried out, and at the same time light curing is performed to prepare a transfer coating.

[0050]The glass transition temperature Tg of the transfer printing coating prepared in Example 2 of the present invention is 135° C., which has good heat resistance; at the same time, the transfer printing coating prepared by the present invention has a hardness of 4H and has relatively high mechanical strength; and the coating The layer peeling performance...

Embodiment 3

[0052] Step 1, prepare UV transfer printing coating slurry according to the equipment in Table 3;

[0053]

[0054] According to the distribution ratio of each component in Table 3, the cellulose resin is blended with the free radical resin oligomer, and then a polymerization inhibitor, an ultraviolet photoinitiator, a leveling agent and a defoamer are added to form a UV photocurable transfer coating slurry.

[0055] In step 2, coating is carried out, and at the same time light curing is performed to prepare a transfer coating.

[0056] The glass transition temperature Tg of the transfer printing coating prepared in Example 3 of the present invention is 140° C., which has good heat resistance; at the same time, the transfer printing coating prepared by the present invention has a hardness of 6H and has relatively high mechanical strength; and the coating The layer peeling performance is excellent, which meets the requirements of thermal transfer printing process.

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com