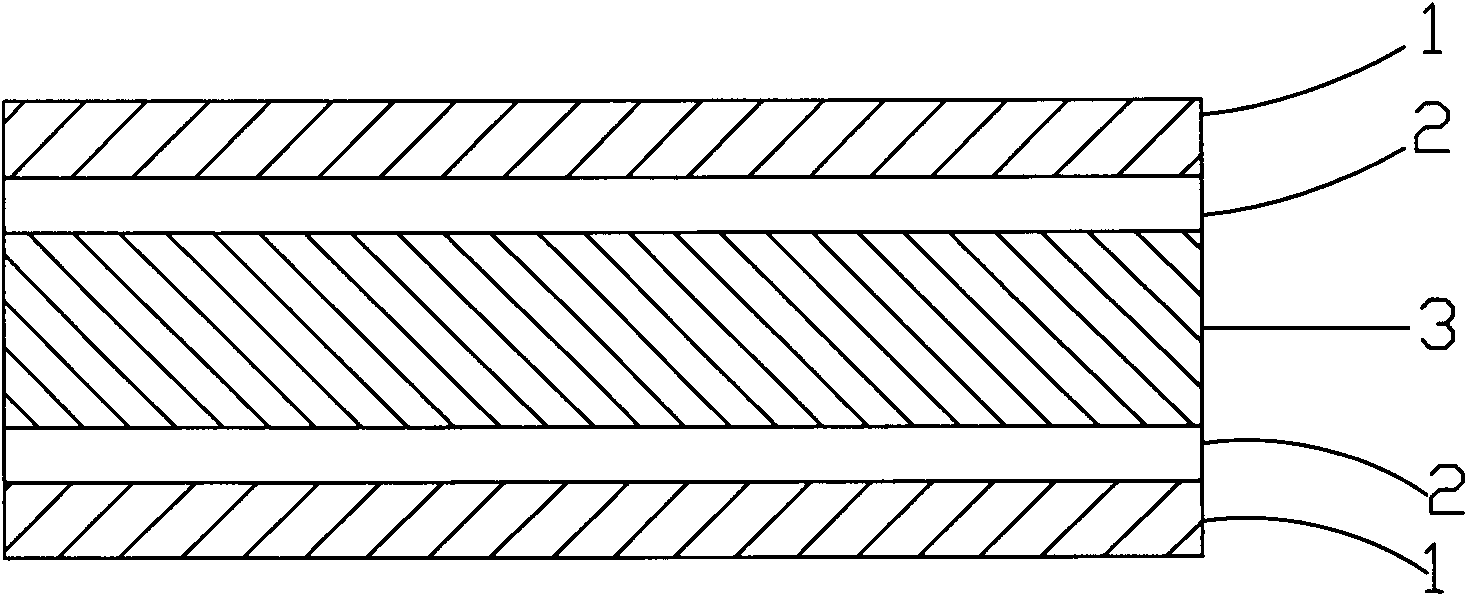

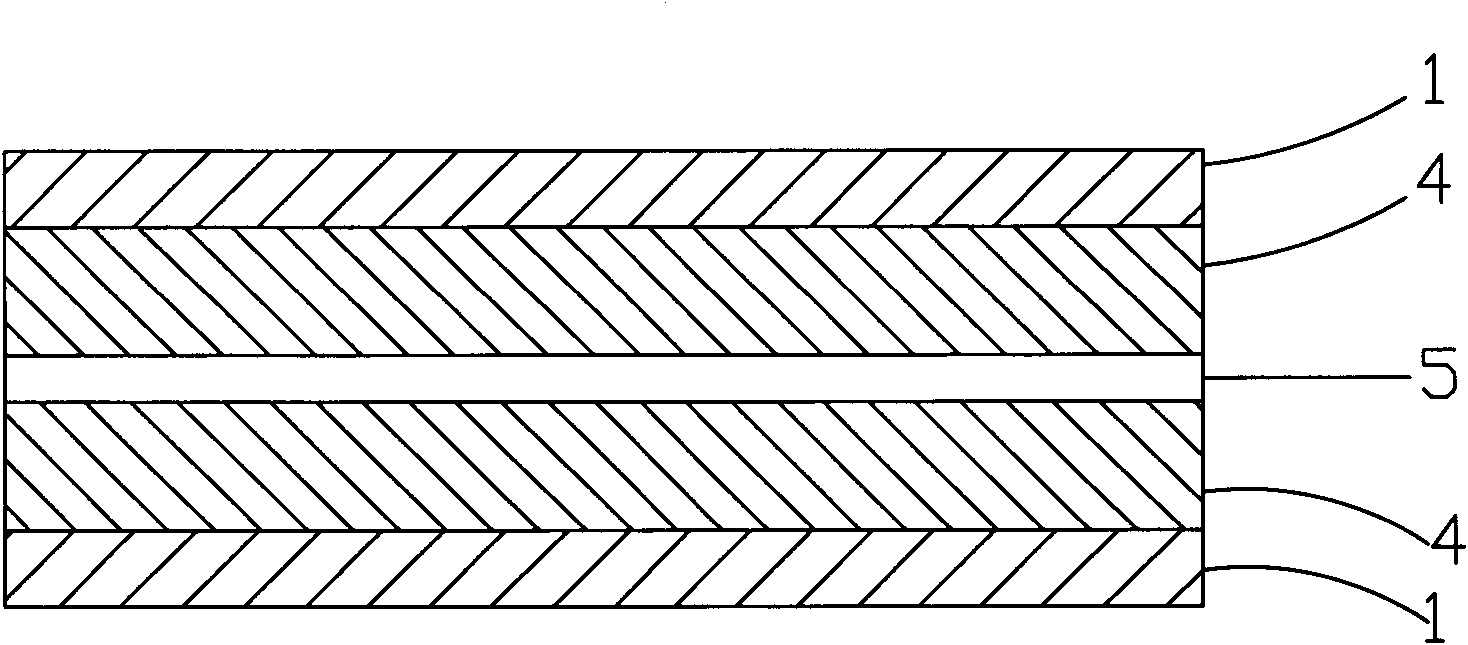

Double-surface flexible copper-clad plate and manufacturing method thereof

A technology of flexible copper clad laminate and manufacturing method, which is applied in the directions of chemical instruments and methods, layered products, metal layered products, etc., can solve the problem that filler filling is not explained, and it is difficult to meet the requirements of good bendability of flexible copper clad laminates , The mechanical properties of the insulation substrate of the copper clad laminate are reduced, so as to improve the heat resistance, reduce the water absorption rate and cost, and reduce the coating amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

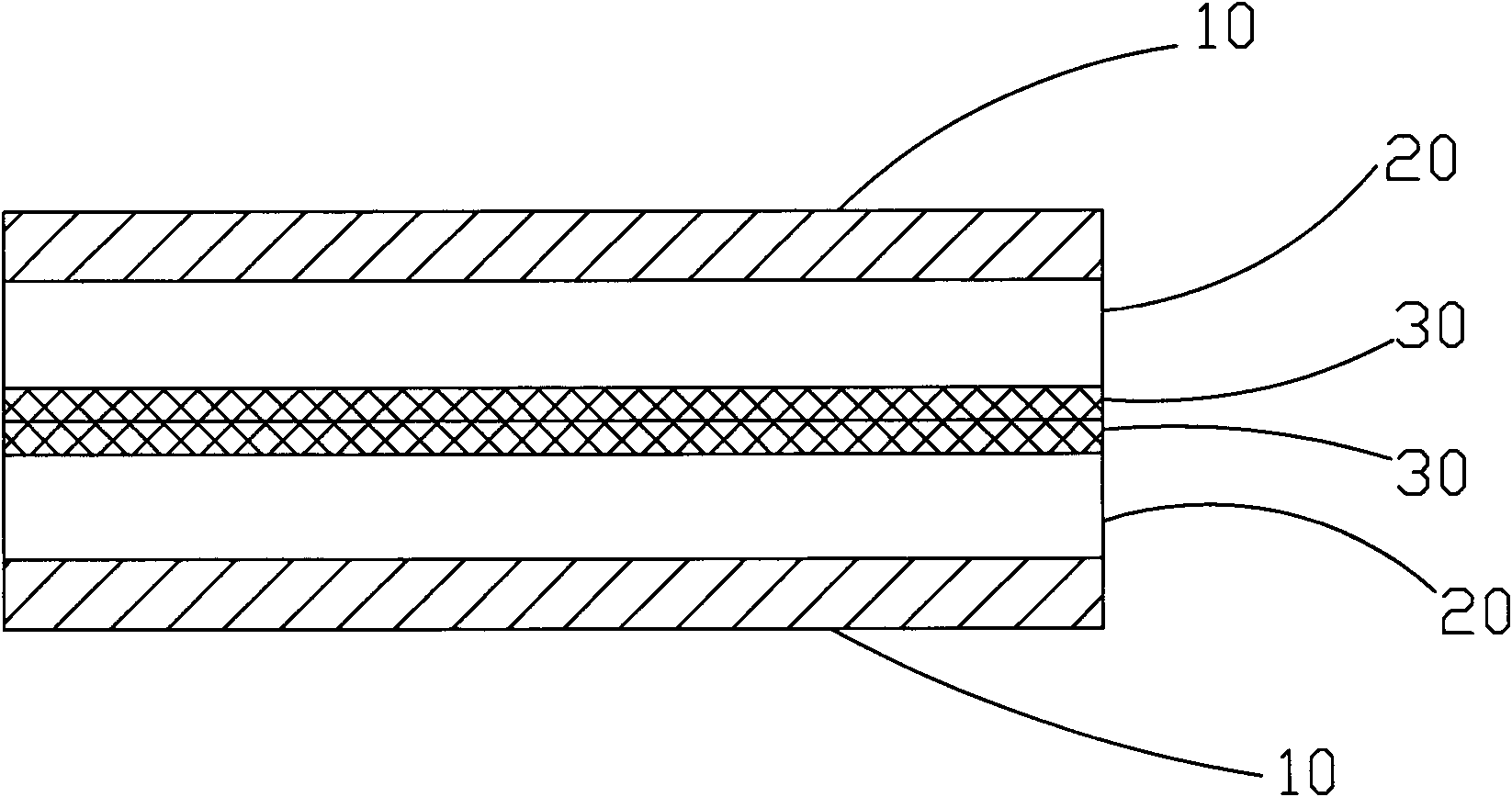

[0033] In the preparation process of flexible printed circuit boards, repeated water absorption and heating processes such as etching and hot pressing are likely to cause delamination of copper clad laminates. Therefore, improving the heat resistance of the substrate as much as possible and reducing the water absorption of the substrate as much as possible are issues of great concern to the circuit board industry. As we all know, the heat resistance of thermoplastic polyimide resin is much lower than that of thermosetting polyimide resin, so the heat resistance of the entire copper clad laminate depends on the heat resistance of thermoplastic polyimide resin, with the filler Adding, especially the addition of high heat-resistant fillers, the heat resistance of filler-filled thermoplastic polyimide resins is significantly improved compared with pure thermoplastic polyimide resins, so that the heat resistance of the entire copper clad laminate has a significant improvement. Ano...

Synthetic example 1

[0046] Add 440g of NMP (N-methylpyrrolidone) in a 500ml three-necked flask, add 18.16g of p-PDA, dissolve in the solution, cool the solution in a water bath, add 49.42g of BPDA under nitrogen flow, and then dissolve the solution Return to room temperature, continue to stir for 3 hours, and carry out polymerization reaction to prepare a viscous polyamic acid solution of thermosetting polyimide resin.

Synthetic example 2

[0048] Add NMP440g in a 500ml three-necked flask, add 30gSiO 2 , add 18.16g of p-PDA, dissolve in the solution, cool the solution in a water bath, add 49.42g of BPDA under nitrogen flow, then return the solution to room temperature, continue to stir for 3 hours, and carry out polymerization reaction to prepare viscous Thick polyamic acid solution of thermosetting polyimide resin. The amount of filler added to the polyamic acid solution accounts for 30% of the total solid weight.

[0049] Synthesis of Filler-Filled Thermoplastic Polyimide Resin

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com