A method for producing coated linerboard or coated kraftboard at low cost and the coated linerboard or coated kraftboard produced by the method

A kraft cardboard, low-cost technology, applied in the field of pulp and papermaking, can solve the problems of whitening effect of raw pulp, reduced mechanical properties, high production cost, etc., to achieve the goal of increasing added value, reducing consumption, and reducing negative impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

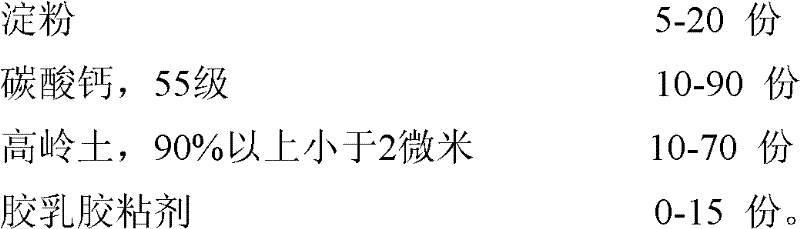

[0026] A method for producing coated linerboard or coated kraftboard at low cost, the steps are as follows:

[0027] (1) Using the applicator, the primer is applied at a quantitative rate of 141g / m 2 On recycled cardboard paper with a whiteness of 15.8%, the primer coating includes: 60 parts of kaolin (more than 90% less than 2 microns), 40 parts (grade 55) of calcium carbonate, 7 parts of styrene-butadiene latex, 10 parts of starch, and others Coating additives include: dispersant (sodium polyacrylate), 0.2 part; defoamer (polyethylene glycol), 0.02 part; water-resistant agent (polyamide polyurea resin), 0.5 part; lubricant (calcium stearate) , 0.5 parts.

[0028] Coating amount is 10±1g / m 2 , the solid content of the coating is 50-68% (the same below).

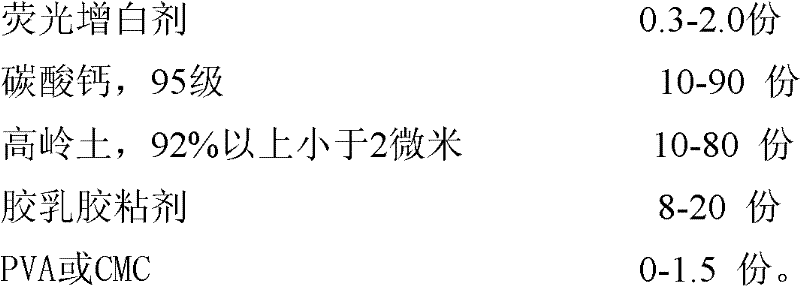

[0029] (2) Using an applicator, apply the top coating on the primed recycled cardboard, wherein the top coating includes: 60 parts of fine-grained kaolin (more than 92% less than 2 microns), 40 parts of 95 grade calcium c...

Embodiment 2

[0033] A method for producing coated linerboard or coated kraftboard at low cost, the steps are as follows:

[0034] (1) Using a coating device, the primer is applied at a quantitative rate of 141g / m 2 On recycled cardboard paper, the coating includes 60 parts of kaolin (more than 90% less than 2 microns), 40 parts of calcium carbonate (grade 55), 7 parts of styrene-butadiene latex, 10 parts of starch, and other commonly used coating additives such as: dispersion agent, anti-water agent, defoamer, lubricant. Coating amount is 10±1g / m 2 .

[0035] (2) Using a coating device, the top coating is coated on the primed recycled cardboard, wherein the coating includes 60 parts of fine-grained kaolin (more than 92% is less than 2 microns), 40 parts of 95 grade calcium carbonate, 12 1 part of styrene-butadiene latex, 1 part of polyvinyl alcohol (PVA, as OBA carrier), 0.6 part of 4S type fluorescent whitening agent, and other commonly used coating additives such as: dispersant, water...

Embodiment 3

[0038] A method for producing coated linerboard or coated kraftboard at low cost, the steps are as follows:

[0039](1) Using a coating device, apply the primer coating at a quantitative rate of 141g / m 2 On recycled cardboard paper, the coating includes 60 parts of kaolin, 40 parts of 55-grade calcium carbonate, 8 parts of styrene-butadiene latex, 6 parts of starch, and other commonly used coating additives such as: dispersant, water-resistant agent, defoamer, lubricant. Coating amount is 10±1g / m 2 .

[0040] (2) Using a coating device, the top coating is coated on the primed recycled cardboard, wherein the coating includes 60 parts of kaolin (more than 92% is less than 2 microns), 40 parts of 95 grade calcium carbonate, 12 parts of butyl Benzene latex, 1 part of sodium carboxymethyl cellulose (CMC), 0.6 part of 4S type fluorescent whitening agent, other commonly used coating additives such as: dispersant, water resistant agent, defoamer, lubricant. Coating amount is 17±1g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com