Device and method for denitrification of single stage autotroph in low-cellulose nitrate (CN) high-ammonia nitrogen waste water

A technology for autotrophic biological denitrification and high ammonia nitrogen, applied in the field of autotrophic biological denitrification of high ammonia nitrogen wastewater, can solve the problems of insufficient ammonia oxidizing bacteria substrate, limit denitrification performance, and reduced nitrification activity, so as to reduce pollution Sludge production, reduced sludge treatment cost, reduced inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

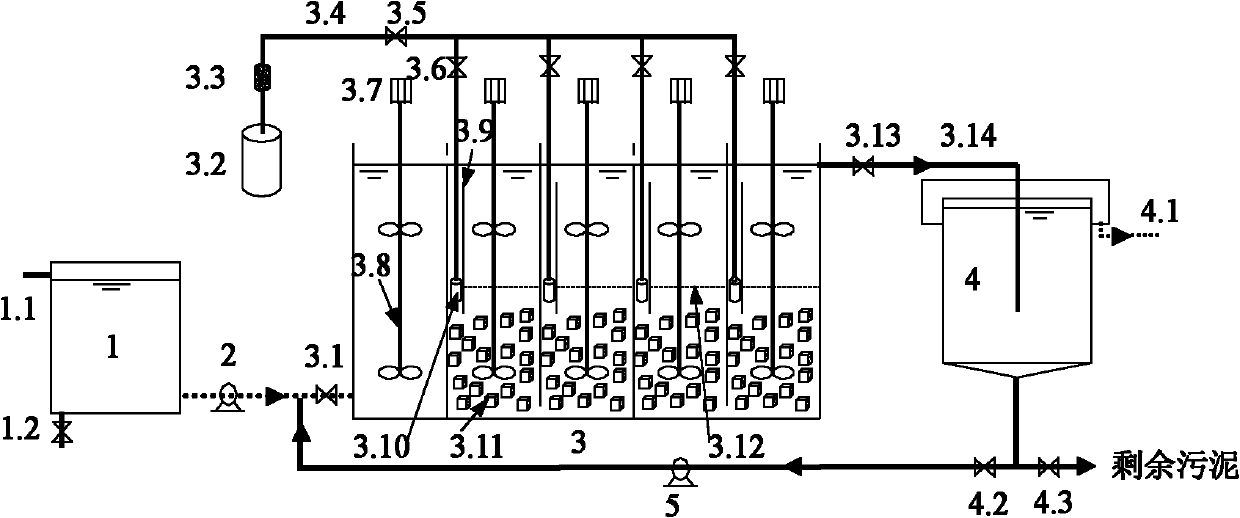

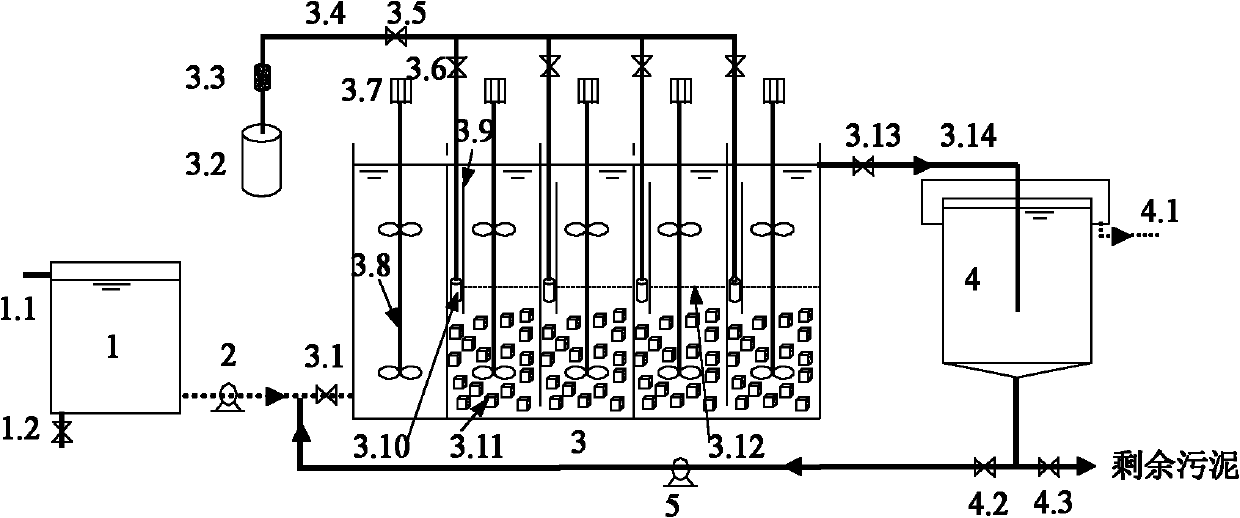

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples: as shown in the figure, a device and method for single-stage autotrophic biological denitrification of low-CN high-ammonia-nitrogen wastewater is characterized in that: a raw water tank 1, an inlet pump are provided. 2. Reactor 3, secondary sedimentation tank 4, sludge return pump 5. The raw water tank 1 is an open tank body with an overflow pipe 1.1 and a vent pipe 1.2; the reactor 3 is an open tank body, the inner cavity of which is divided into several compartments, which are staggered up and down according to the direction of water flow Set flow holes to connect each cell, the front end is the anoxic zone cell, the rear end is the aerobic zone cell, the anoxic zone cell is provided with a stirrer 3.7 and a stirring paddle 3.8, and the aerobic zone cell is provided with a stirrer. 3.7 and stirring paddle 3.8, there are also air compressor 3.2, gas flow me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com