Patents

Literature

453results about "Luminescent/fluorescent substance addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whitened fluff pulp

InactiveUS6893473B2Luminescent/fluorescent substance additionPaper/cardboardWhitening AgentsFluff pulp

Whitened fluff pulp and methods for making whitened fluff pulp. The whitened pulp is a fluff pulp that has been treated with one or more of a white pigment, a colorant, or a fluorescent whitening agent.

Owner:WEYERHAEUSER CO

Process of manufacturing authenticatable paper products

InactiveUS6054021AConvenient verificationEasy to manufactureSpecial paperPaper after-treatmentFiberWhitening Agents

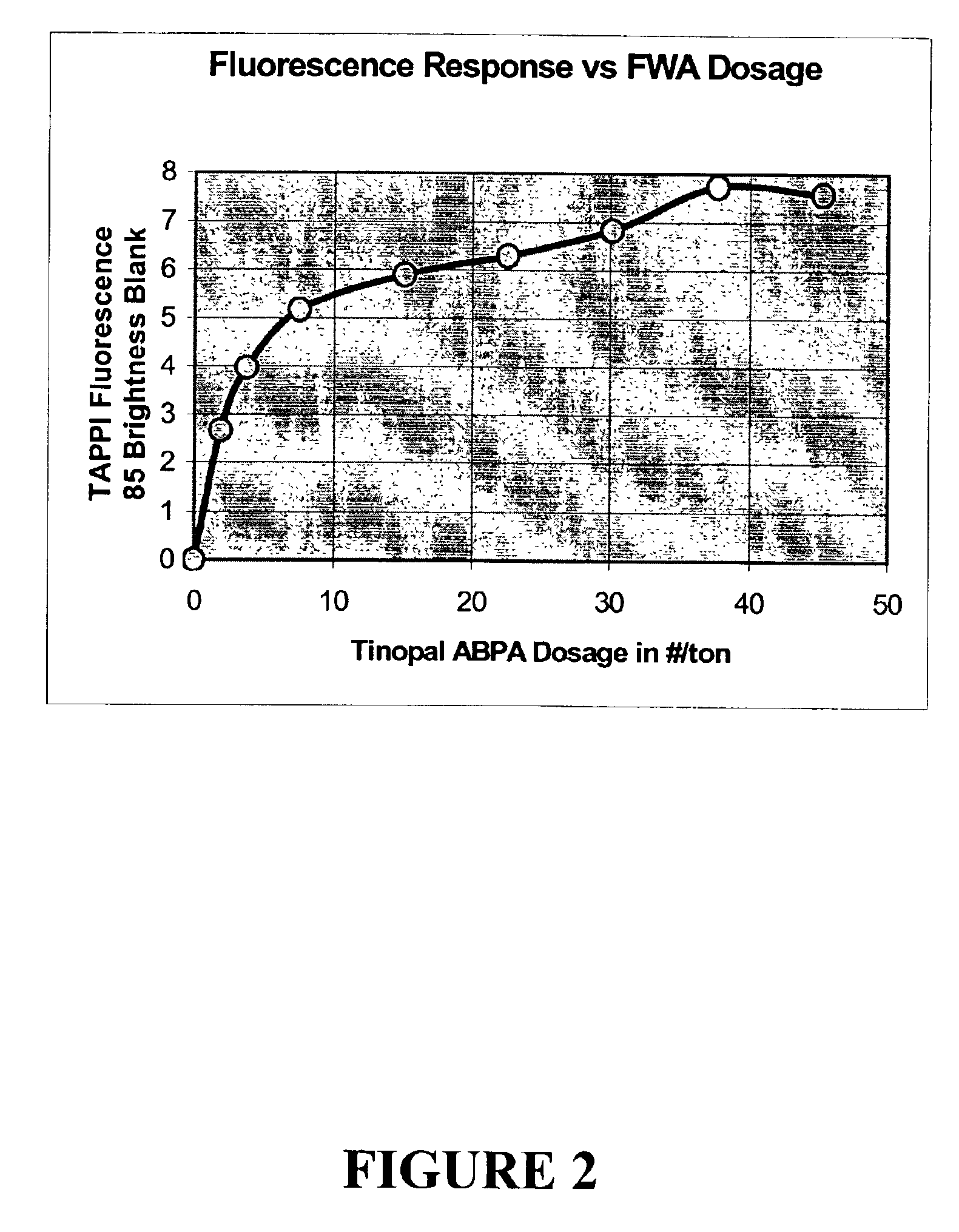

An authenticatable paper product is prepared by adding to a papermaking furnish fibers treated with from about 50-200 lb / ton of a fluorescent whitening agent (FWA). The paper made from the papermaking furnish will include fluorescent cellulosic fibers in an amount ranging from between 0.1-4.0 lb / ton to achieve FWA concentrations within the range of 1-20 ppm.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC

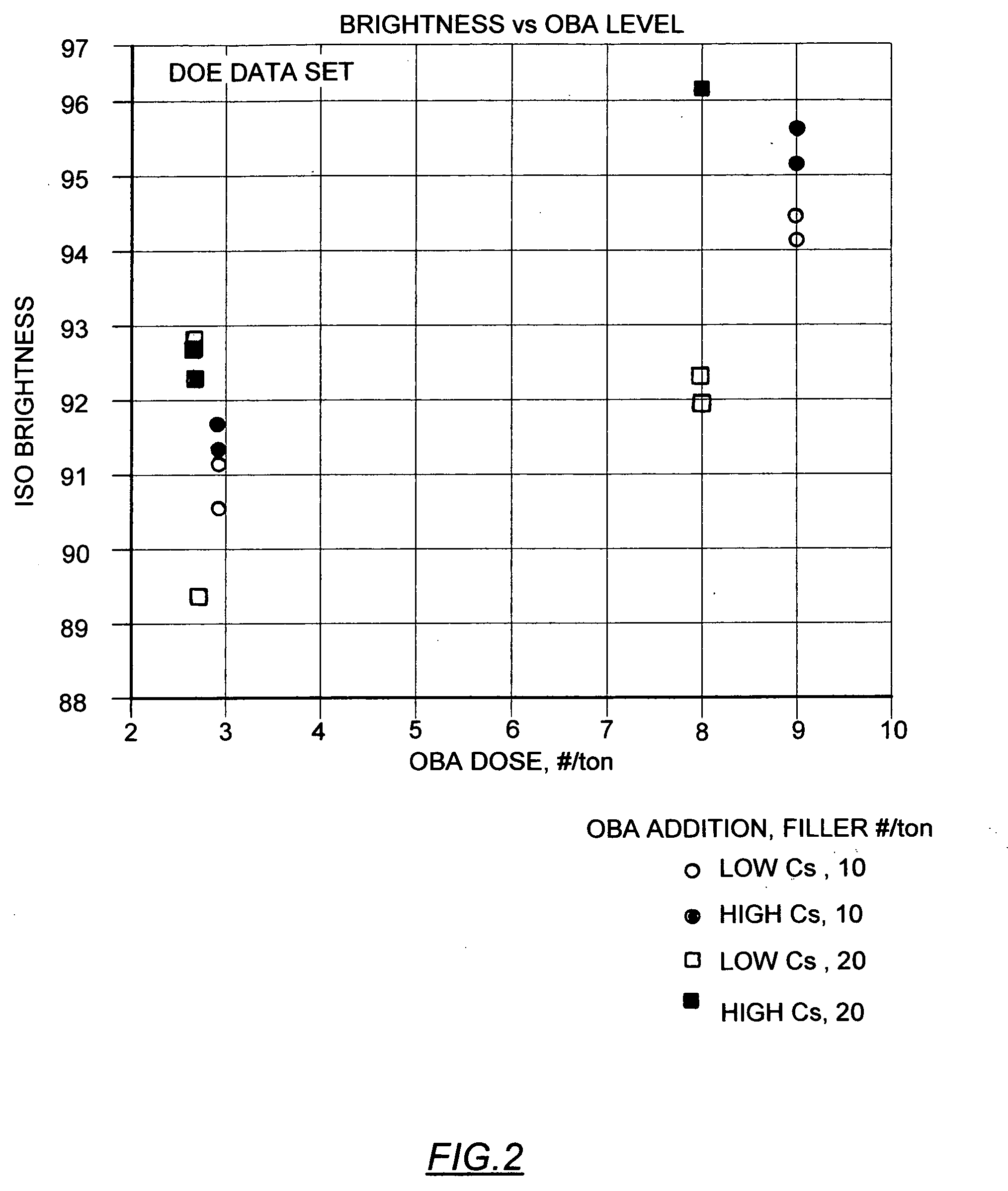

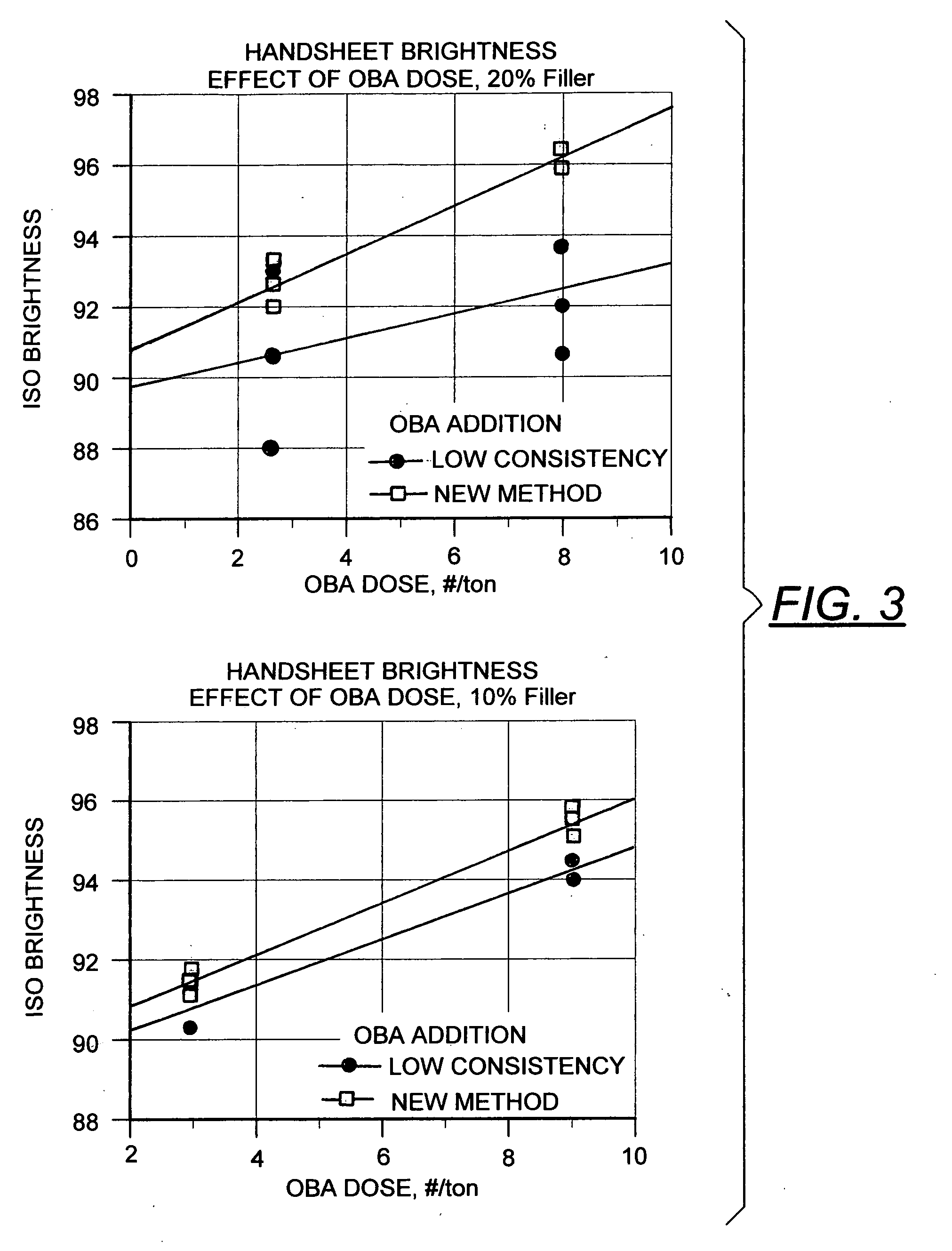

Pulp and paper having increased brightness

InactiveUS20070193707A1Natural cellulose pulp/paperSpecial paperPulp and paper industryBrightness perception

Owner:INT PAPER CO

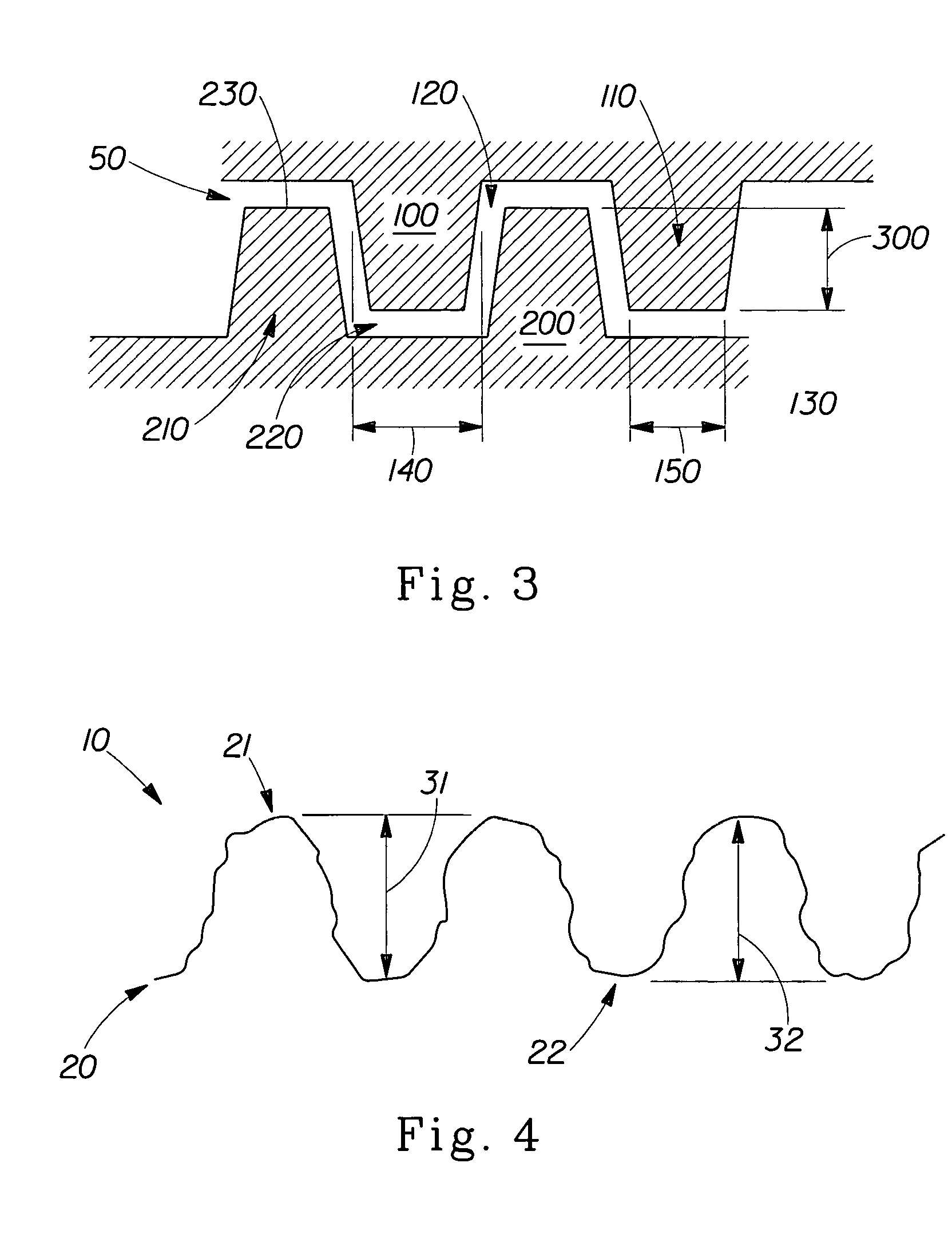

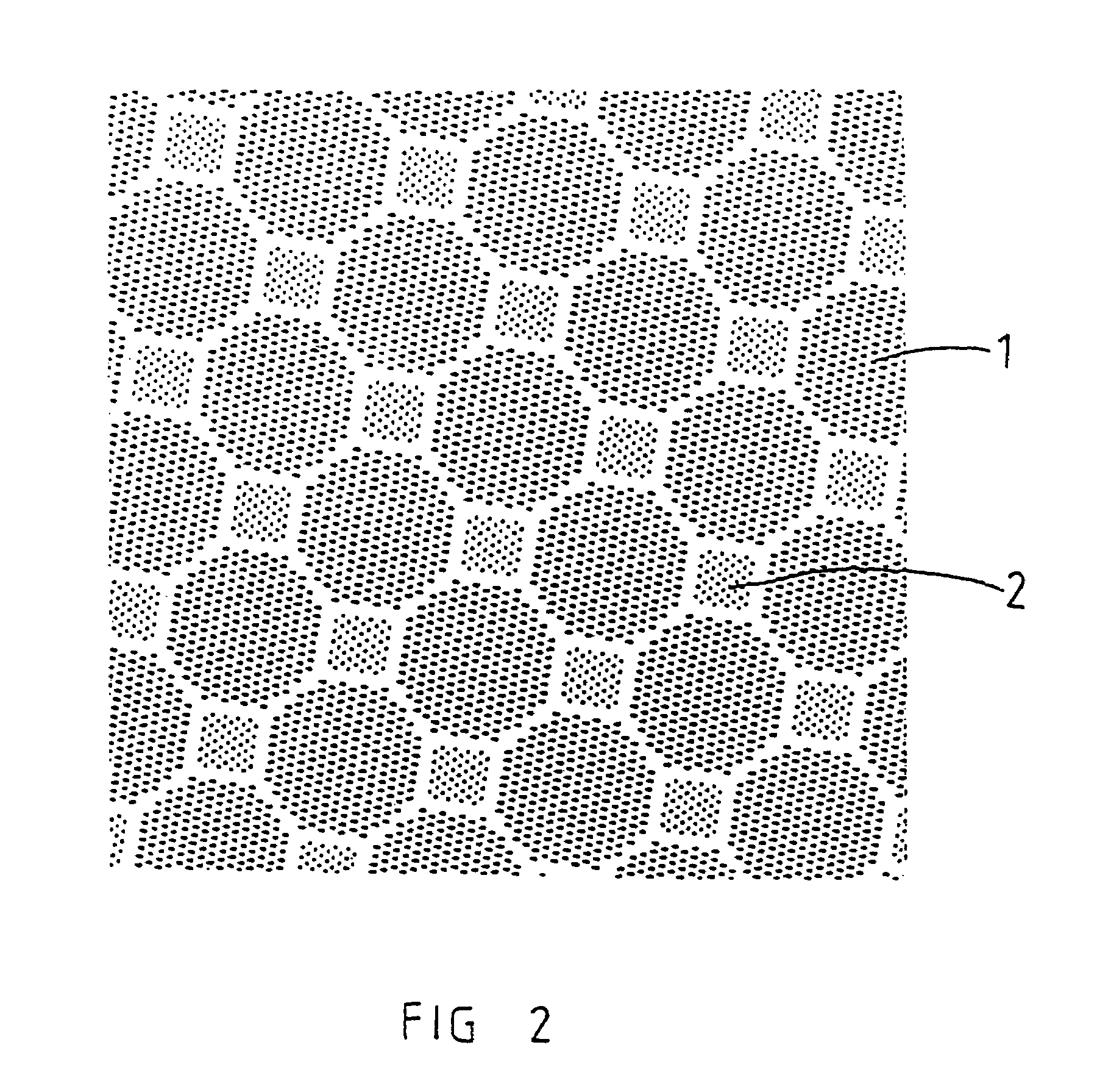

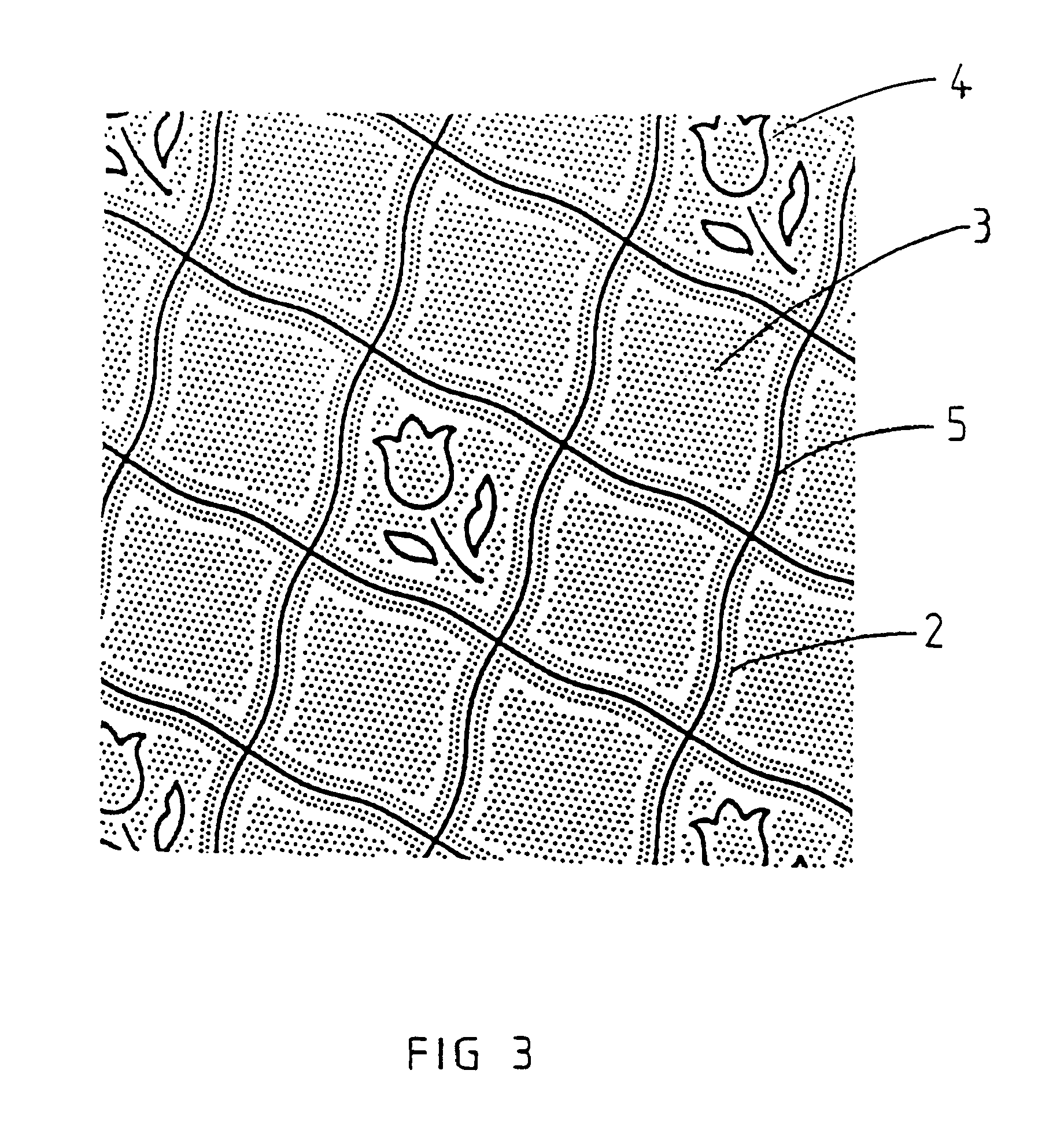

Deep-nested embossed paper products

The present invention relates to embossed tissue-towel paper products comprising one or more plies of tissue paper wherein at least one of the plies of tissue paper comprises a plurality of embossments wherein the at least one embossed plies have a total embossed area less than or equal to about 15% and an average embossment height of at least about 650 μm and E factor of between about 0.0150 to about 1.0000 inches4 per number of embossments.

Owner:THE PROCTER & GAMBLE COMPANY

Process for making abrasion resistant paper and paper and paper products made by the process

InactiveUS20050155731A1Improve optical brightnessLow friction surfacePaper after-treatmentPaper coatingPapermakingPaper sheet

In this papermaking process, a first strength agent is added to a stock suspension containing pulp and optionally other additives prior to its being formed into a web at the wet end of a papermaking machine. The web is then formed and processed into paper. A second strength agent is then applied to the surface of the paper. The strength agents may be selected to have opposite charge.

Owner:NAT GYPSUM PROPERTIES

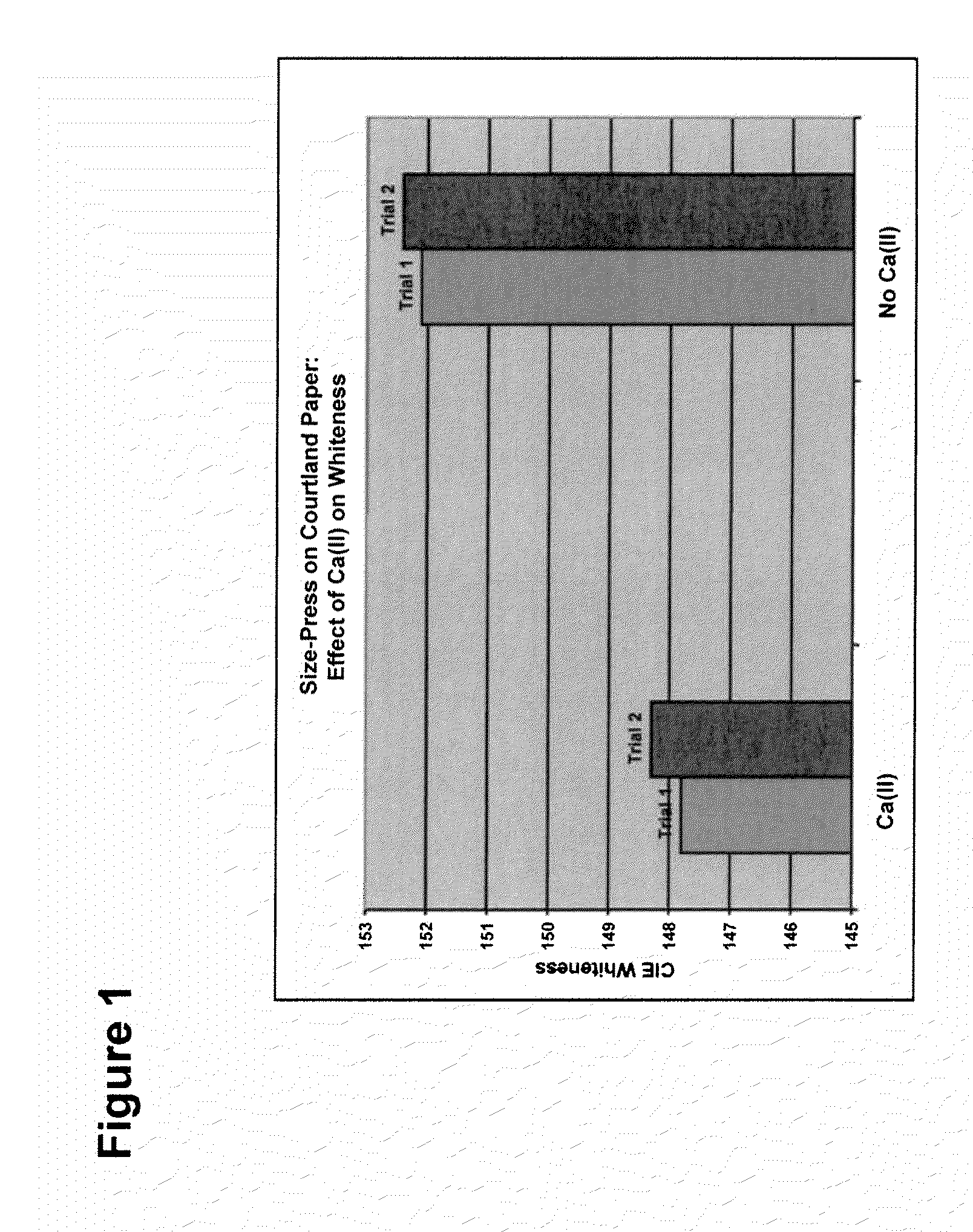

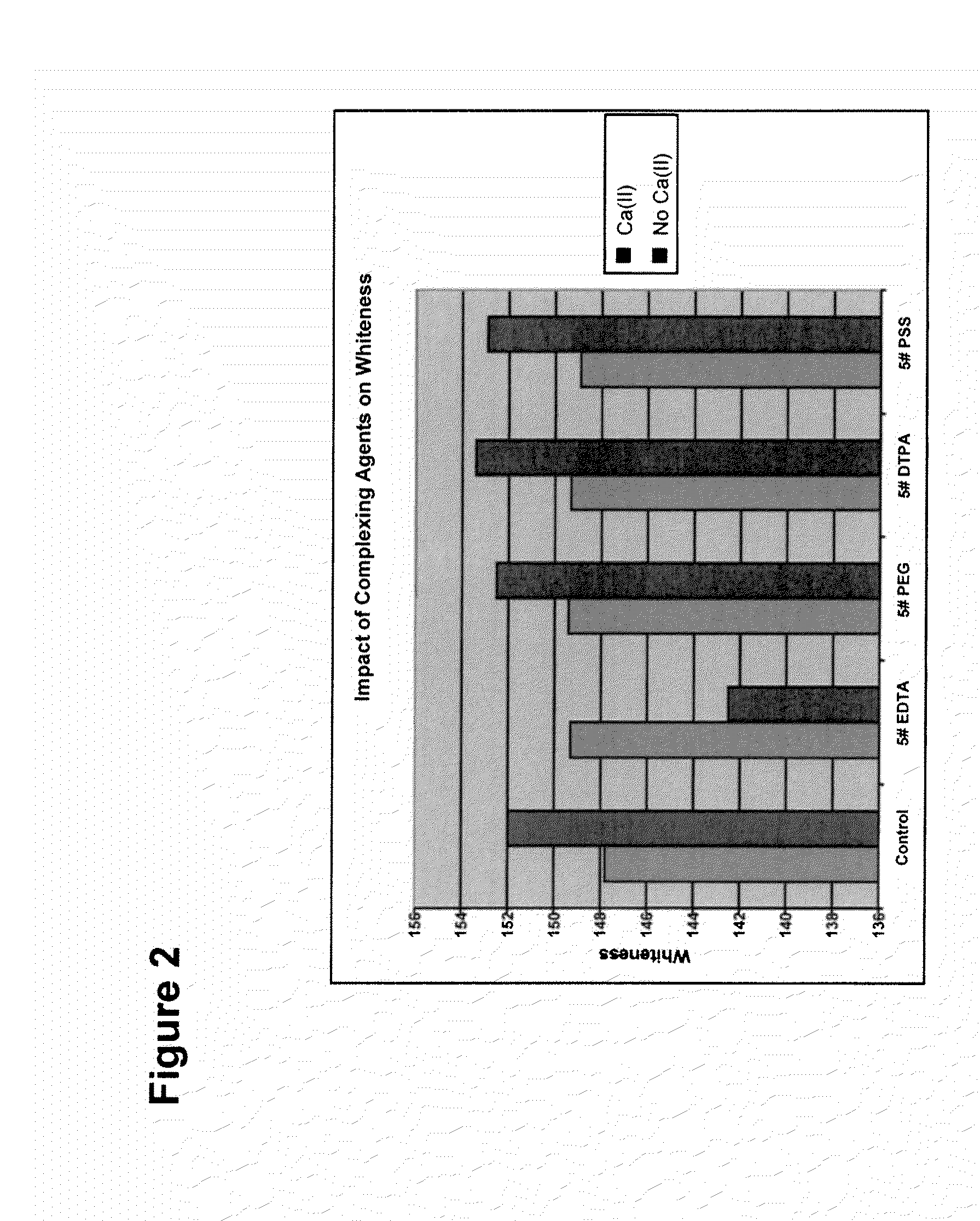

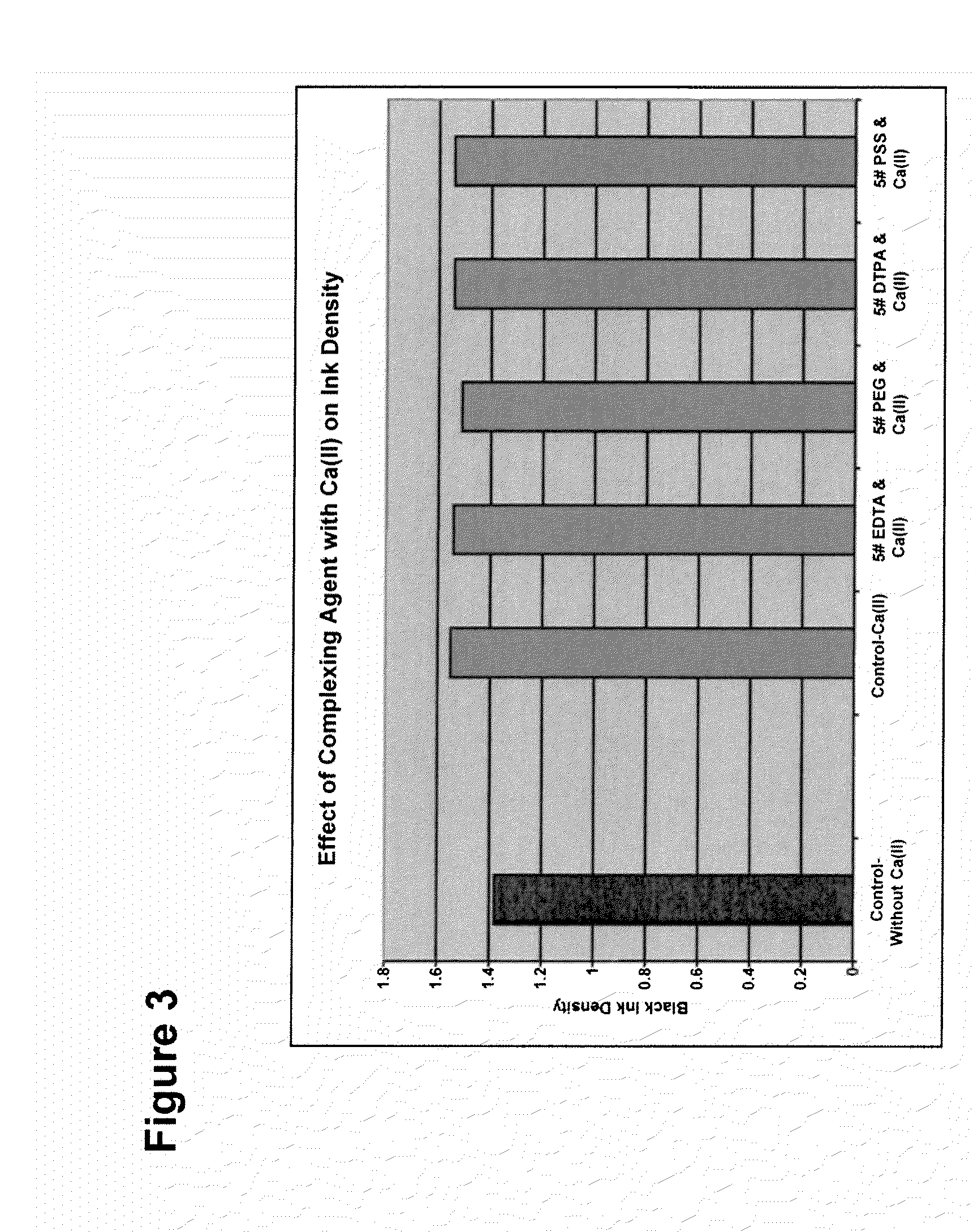

Composition and recording sheet with improved optical properties

ActiveUS20090317549A1Good optical performanceImprove printing effectNatural cellulose pulp/paperSpecial paperOptical propertyDivalent metal

Owner:GLOBAL HLDG II INC

Novel whitening agents for cellulosic substrates

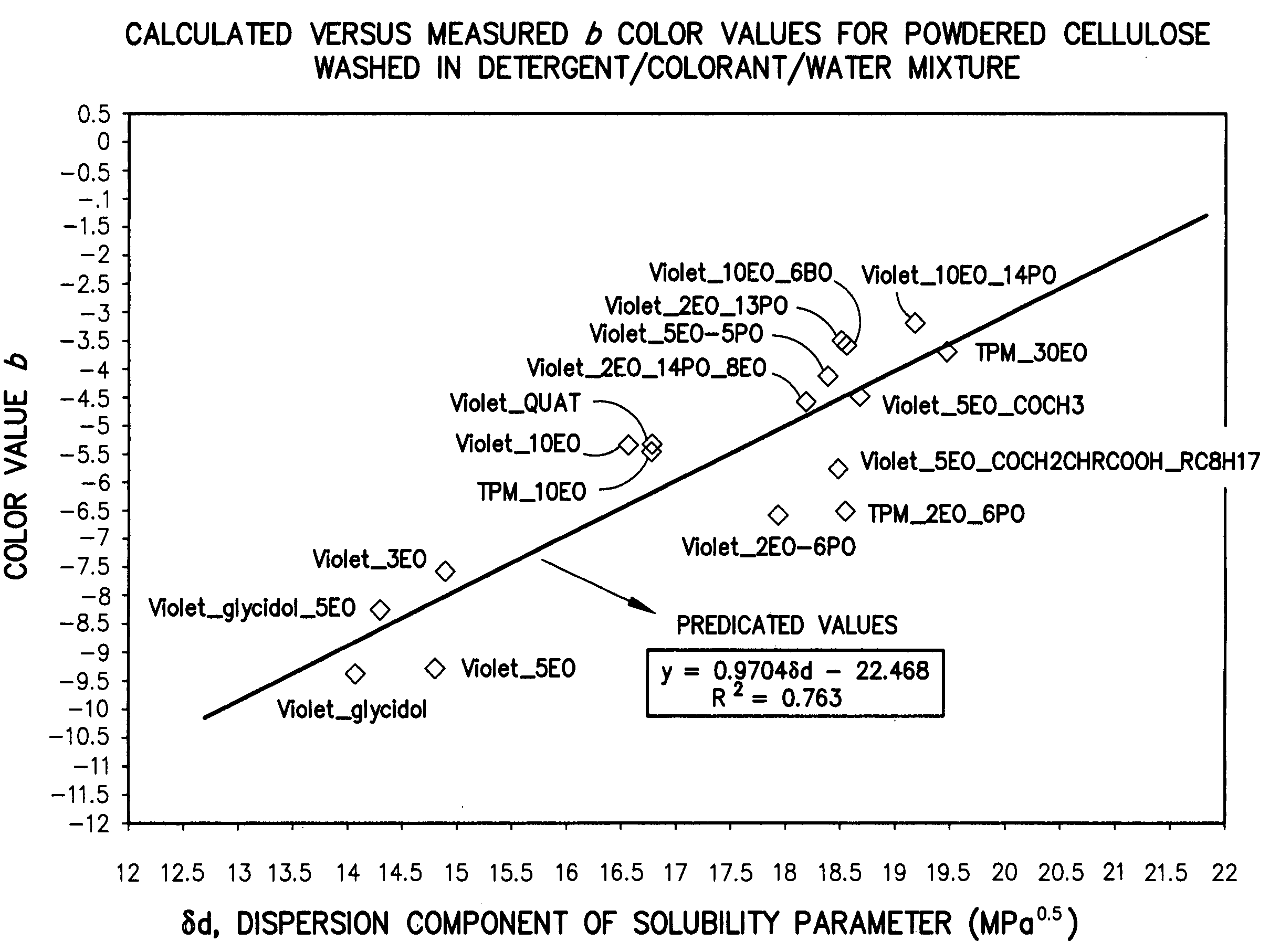

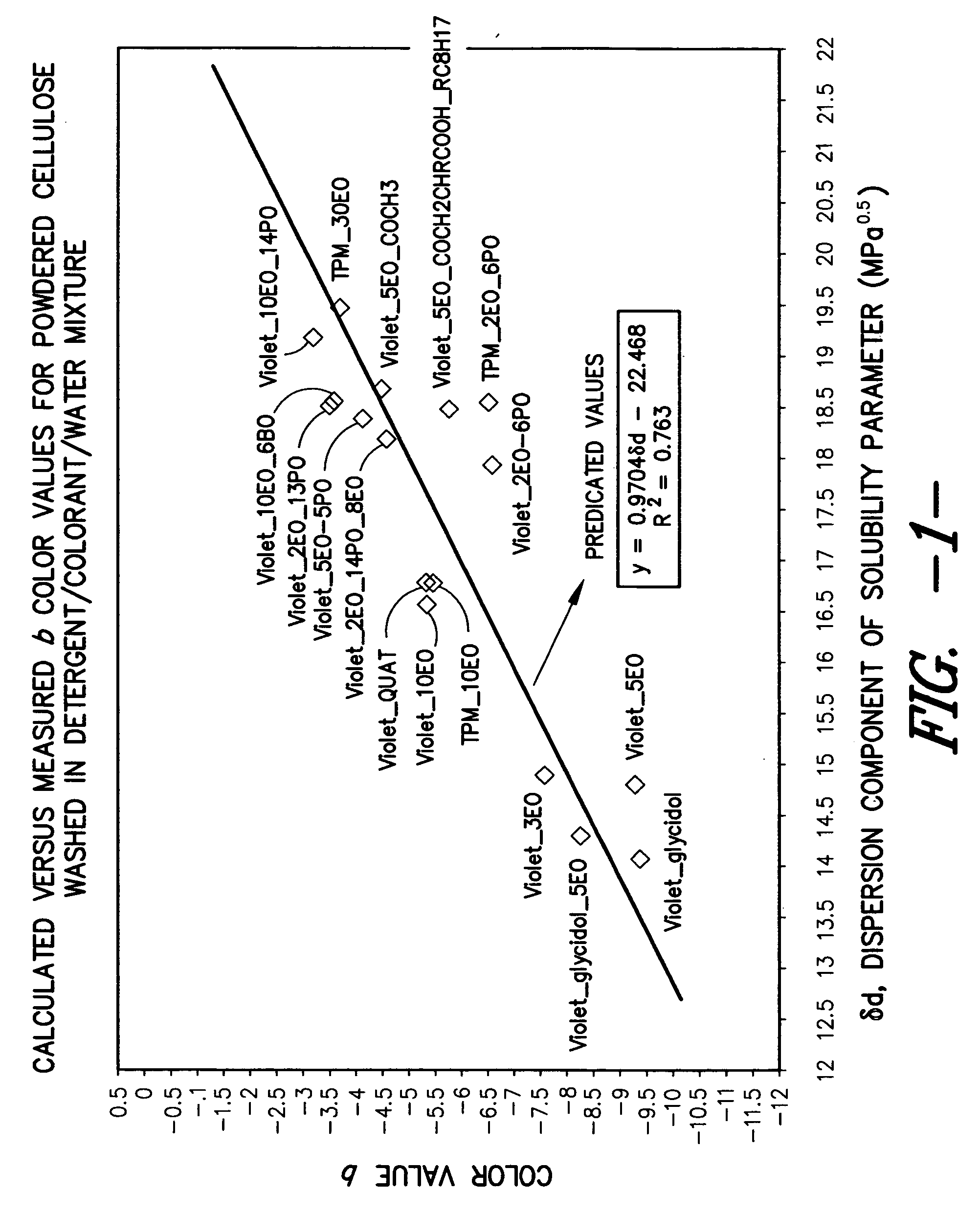

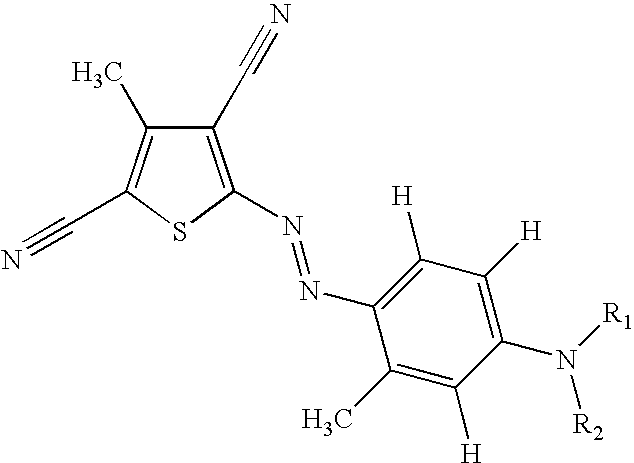

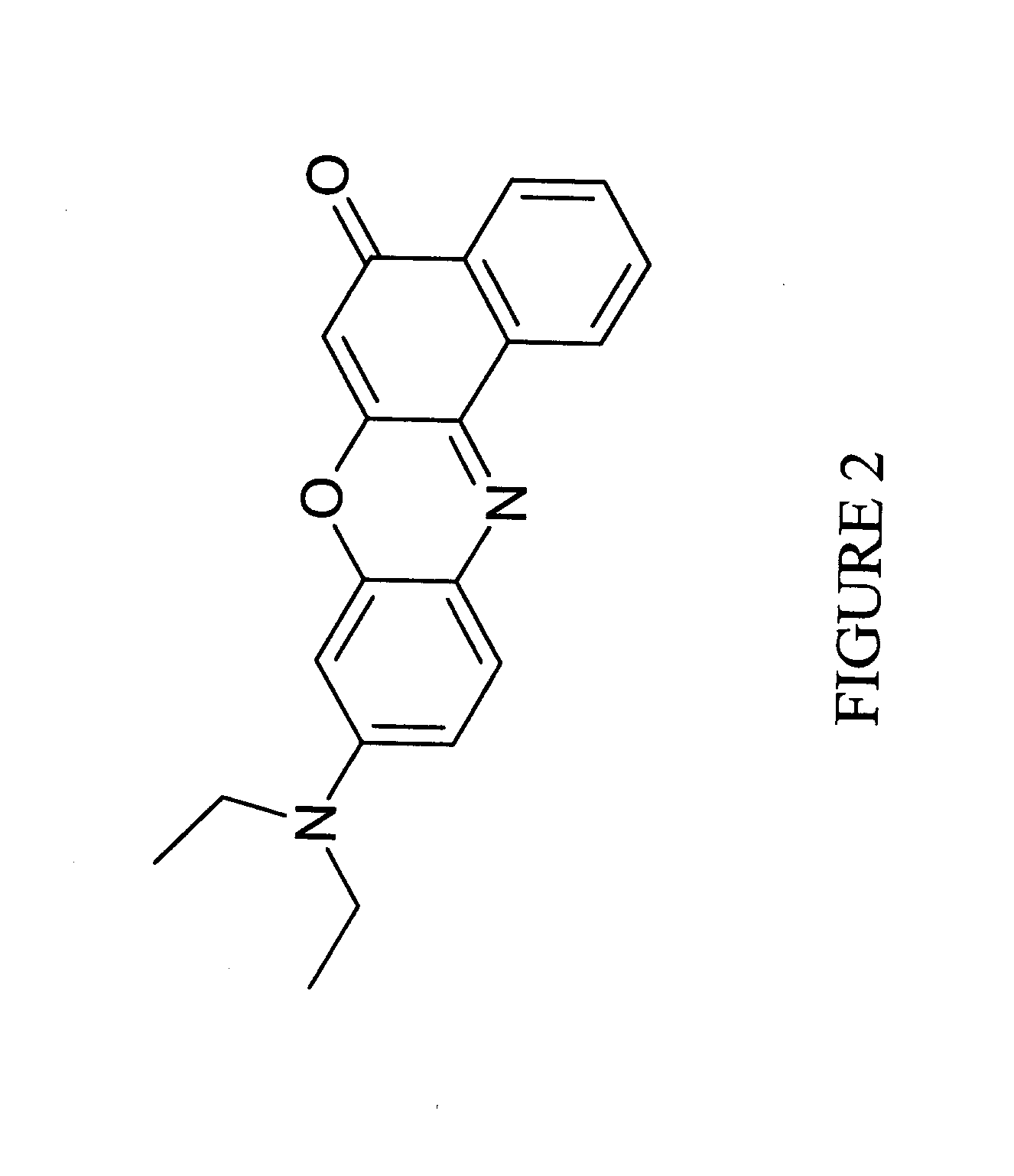

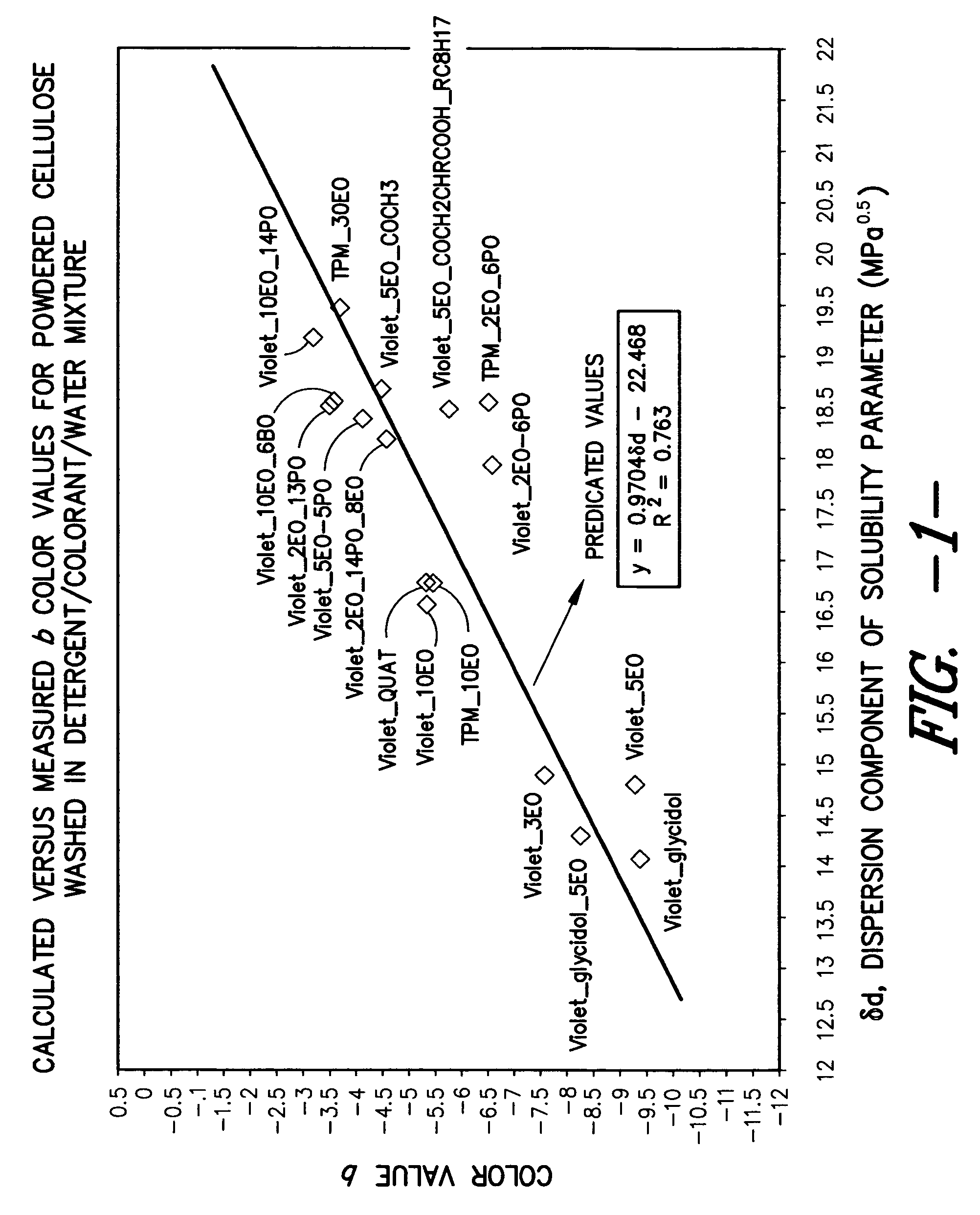

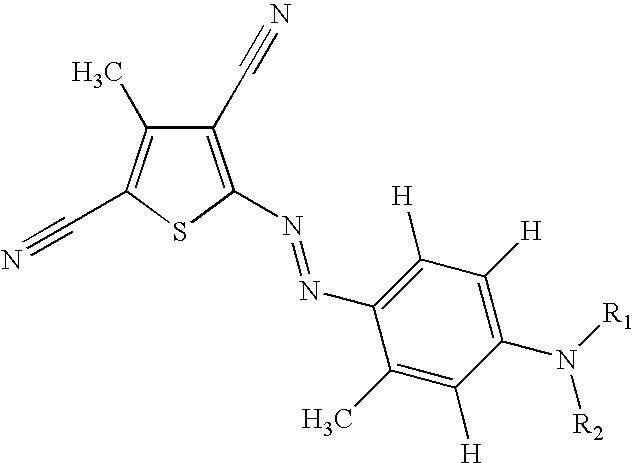

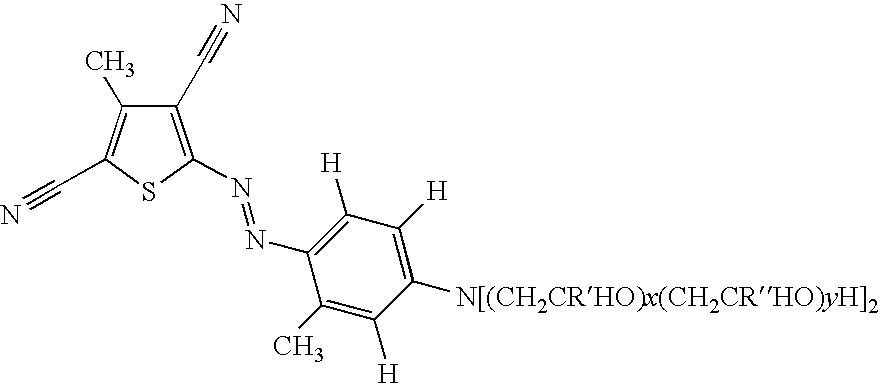

This invention relates to novel whitening agents for cellulosic substrates. The whitening agents are comprised of at least two components: at least one chromophore component and at least one polymeric component. Suitable chromophore components generally fluoresce blue, red, violet, or purple color when exposed to ultraviolet light, or they may absorb light to reflect these same shades. The whitening agents are further characterized by having a dispersion component value of the Hansen Solubility Parameter of less than or equal to about 17 MPa0.5. This invention also relates to laundry care compositions including but not limited to liquid and / or powder laundry detergent formulations and rinse added fabric softening (RAFS) compositions that comprise such whitening agents.

Owner:MILLIKEN & CO

Compositions and processes for paper production

ActiveUS20080017337A1Avoid brightness lossIncrease brightnessNatural cellulose pulp/paperSpecial paperPaper productionPapermaking

Oxidative compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The oxidative composition and method maintains and / or enhances brightness, prevents yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the oxidative agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

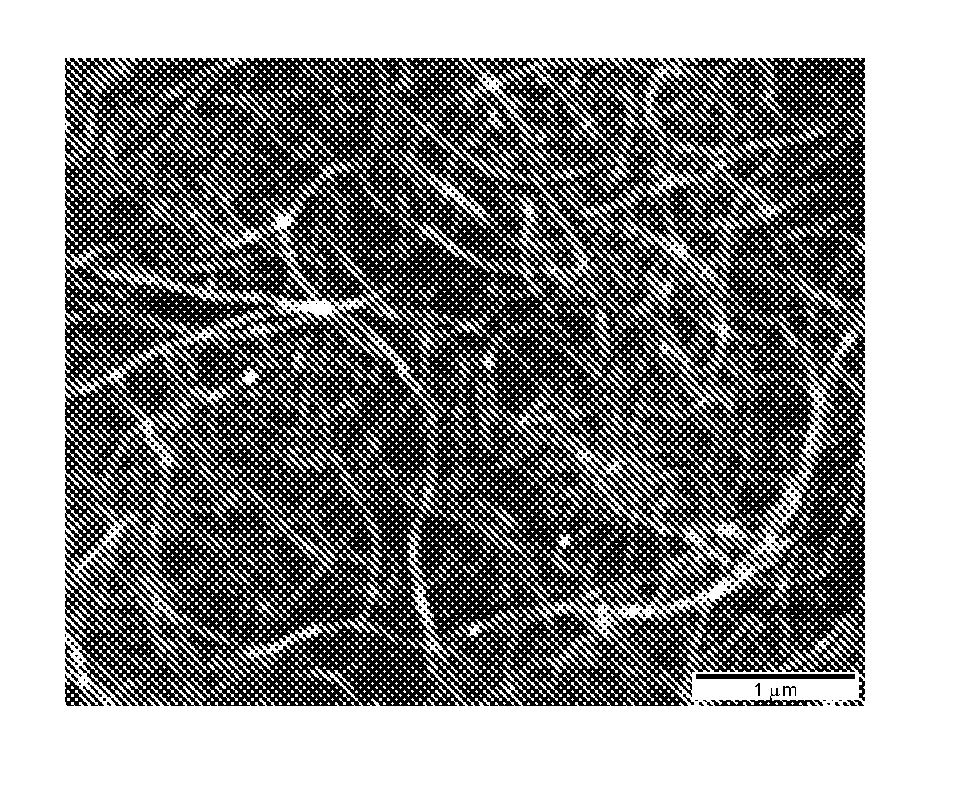

Method for manufacturing nanofibrillated cellulose pulp and use of the pulp in paper manufacturing or in nanofibrillated cellulose composites

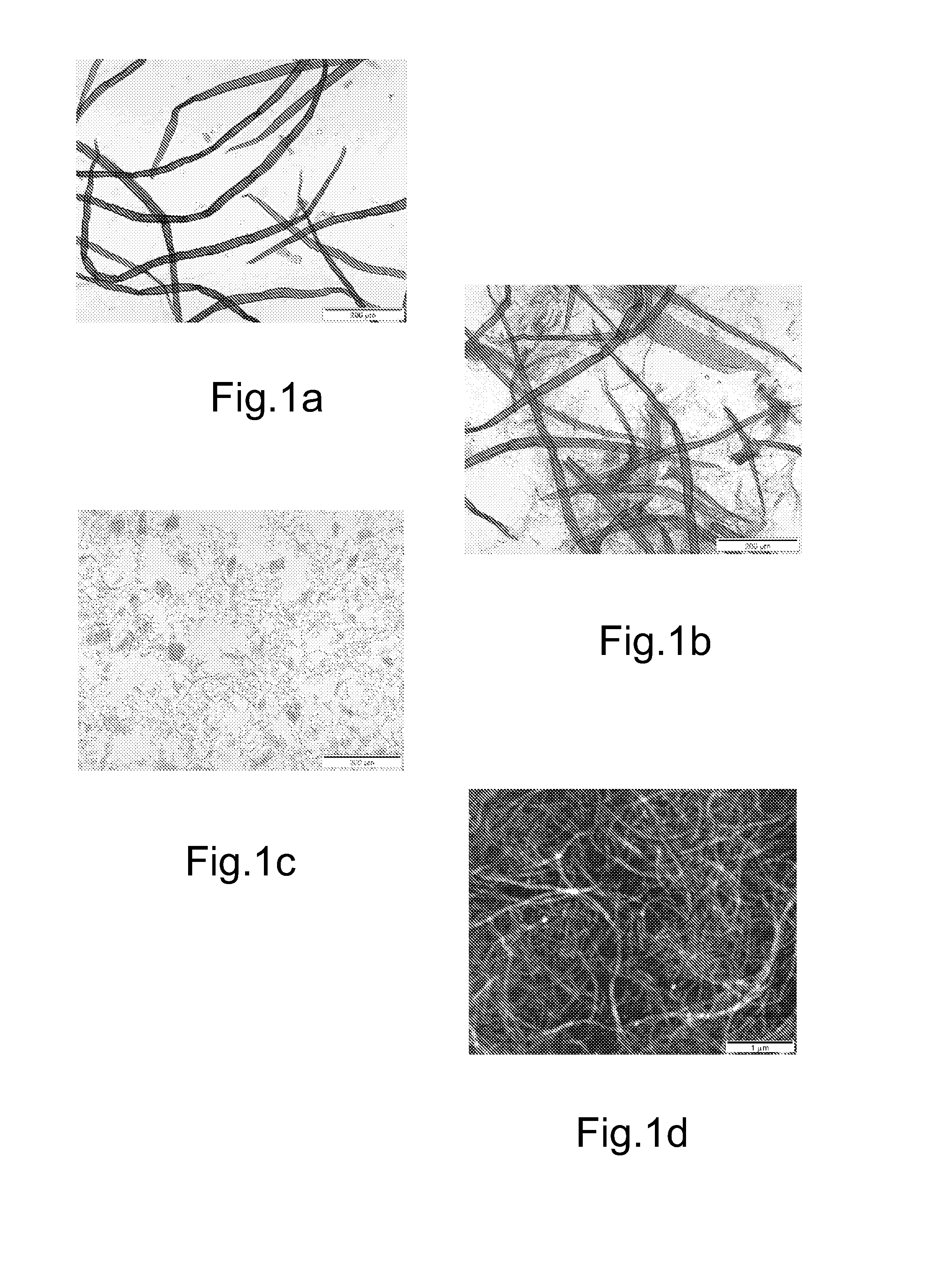

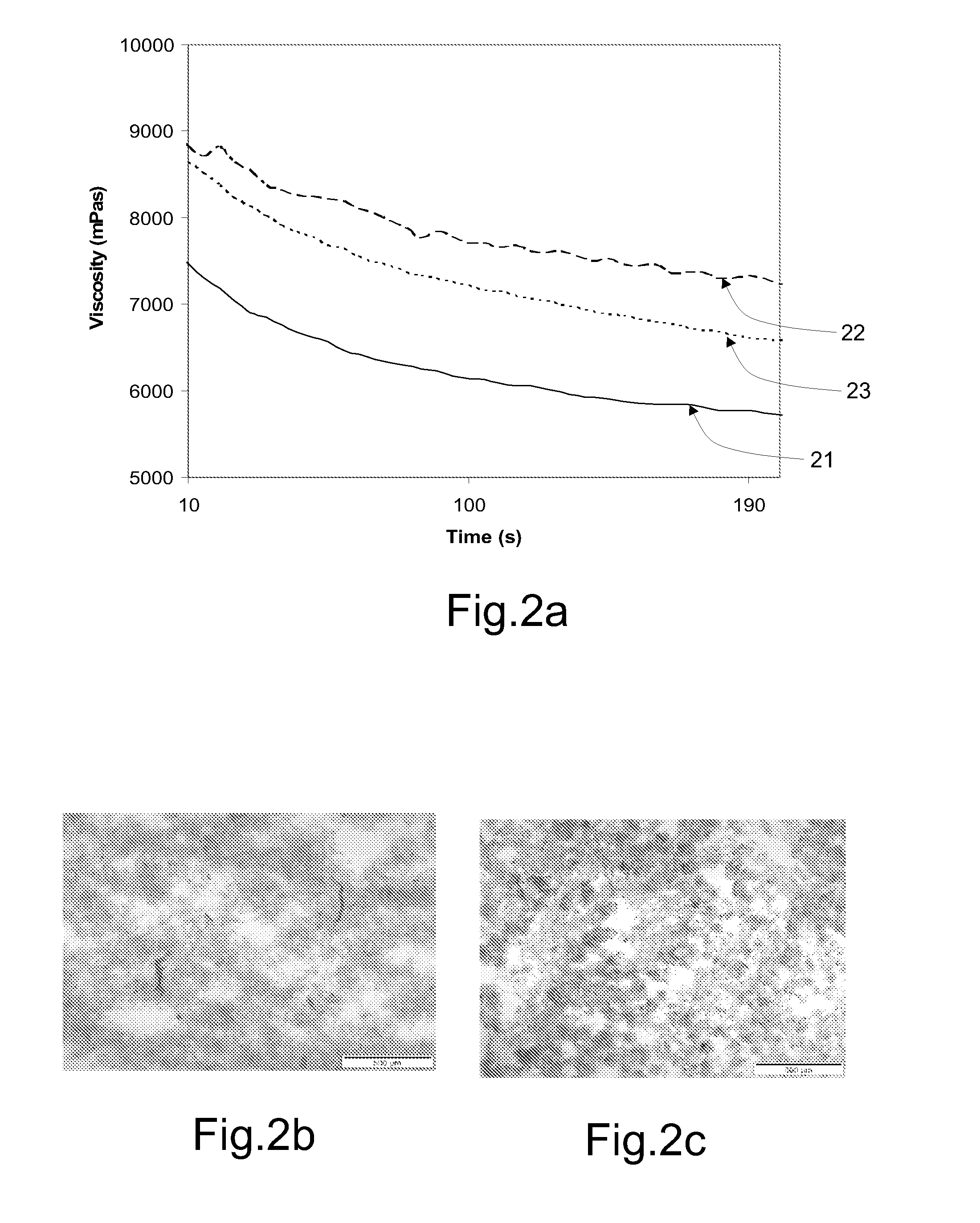

InactiveUS20130000855A1Increase productivityPrevents hydrogen bondPulp properties modificationLuminescent/fluorescent substance additionPaper manufacturingPulp and paper industry

Owner:UPM-KYMMENE OYJ

Multiple reversible color change microcapsule anti-counterfeiting material and preparation method and application thereof

InactiveCN101724392AHigh-speed emulsification and dispersionGood weather resistanceOther chemical processesLuminescent/fluorescent substance additionInfraredWater based

The invention discloses a multiple reversible color change microcapsule anti-counterfeiting material and a preparation method and applications thereof. The preparation method comprises the following steps: dissolving at least one of temperature-sensitive material, humidity sensitive material, ultraviolet excited fluorescence material and infrared excited fluorescence material in high boiling point solvent containing UV resistant agent and antioxidant, then adding emulsifier and protective colloid to obtain emulsion solution, and adopting the in-situ polymerization method to obtain the anti-counterfeiting material with microcapsule structure. The microcapsule structure of the invention can isolate the air and the wall of the microcapsule can reduce the light transmission, thus improving the weather resistance and light resistance of the anti-counterfeiting material and prolonging the use validity of the product. The material is a microcapsule aqueous solution so that the material is completely applicable to the coating method of the currently existing water-based paint, removes apprehensions in areas of safety, health and environmental protection, thoroughly solves the defect of the complicated solvent-based (oily material) coating and processing method, satisfies the anti-counterfeiting demand and can be applied in papers, cloth and film materials in large.

Owner:张世智

Compositions and processes for paper production

ActiveUS20070062653A1Increase brightnessIncrease resistanceCellulosic pulp after-treatmentNatural cellulose pulp/paperPapermakingPaper production

Compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The composition and method maintains and / or enhances brightness, prevent yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the described agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

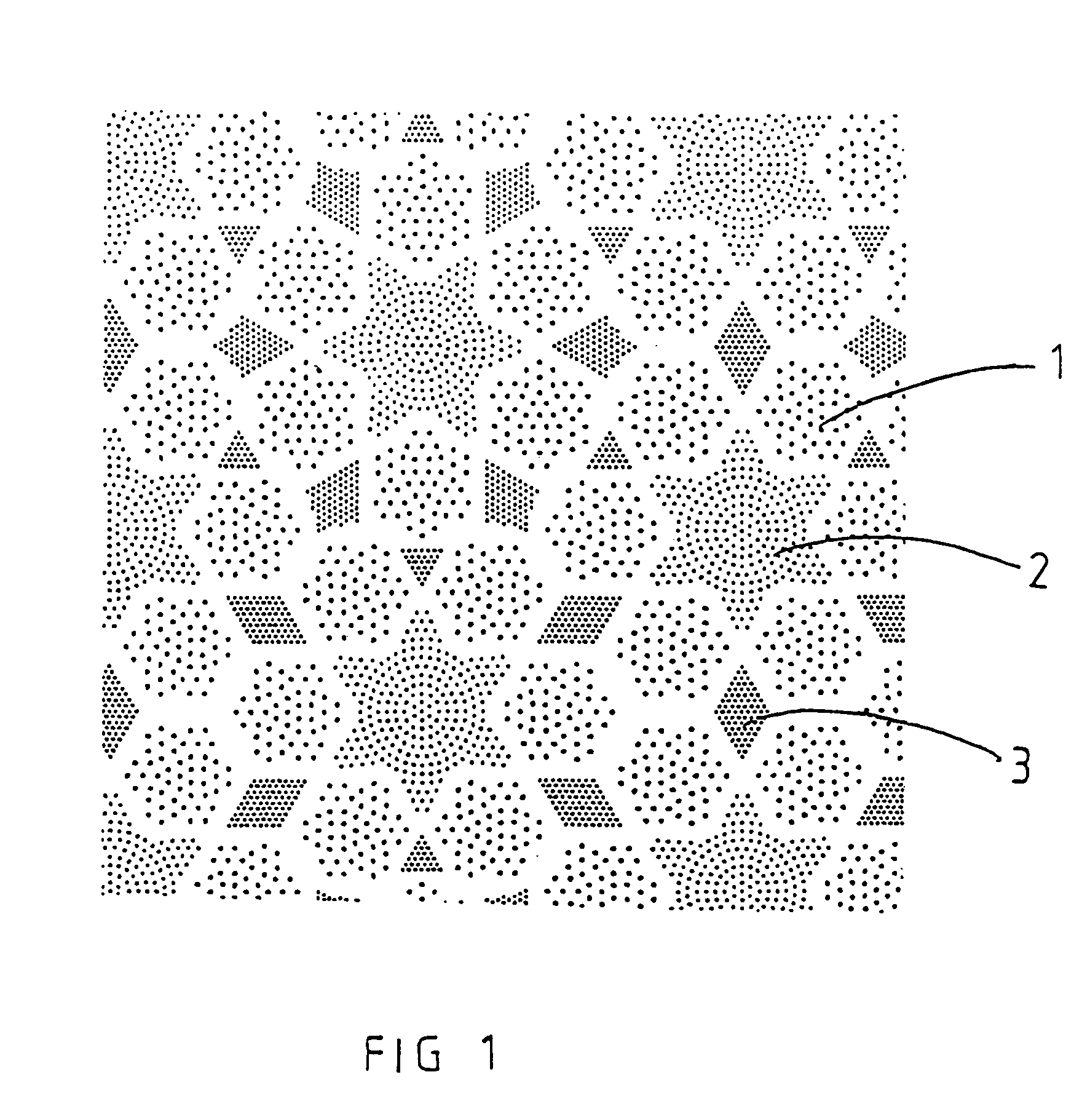

Absorbent paper product having improved embossing

InactiveUS7494564B2Natural cellulose pulp/paperMechanical working/deformationVolumetric Mass DensityMechanical engineering

The invention relates to an absorbent paper product, made in particular of tissue paper, that includes at least two plies, at least one of which is embossed according to an embossing pattern that includes projections (1, 2, 3) with a density of 30 or more per cm2. According to the invention, the embossing patterns include at least two adjacent zones whose projections (1, 2, 3) have, respectively, a different density and / or a different surface area at the peak so as to produce a relief effect on the product.

Owner:ESSITY OPERATIONS FRANCE

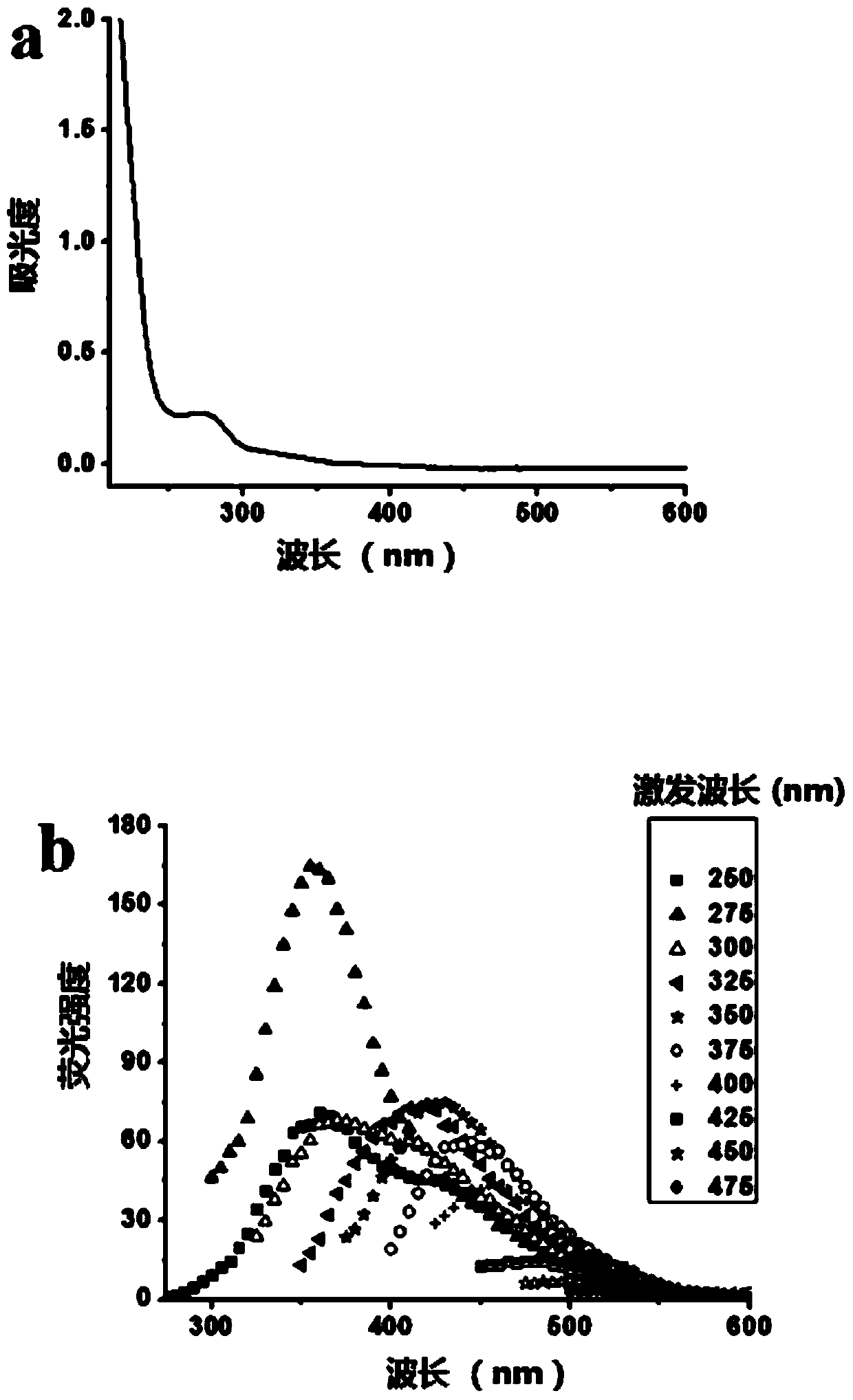

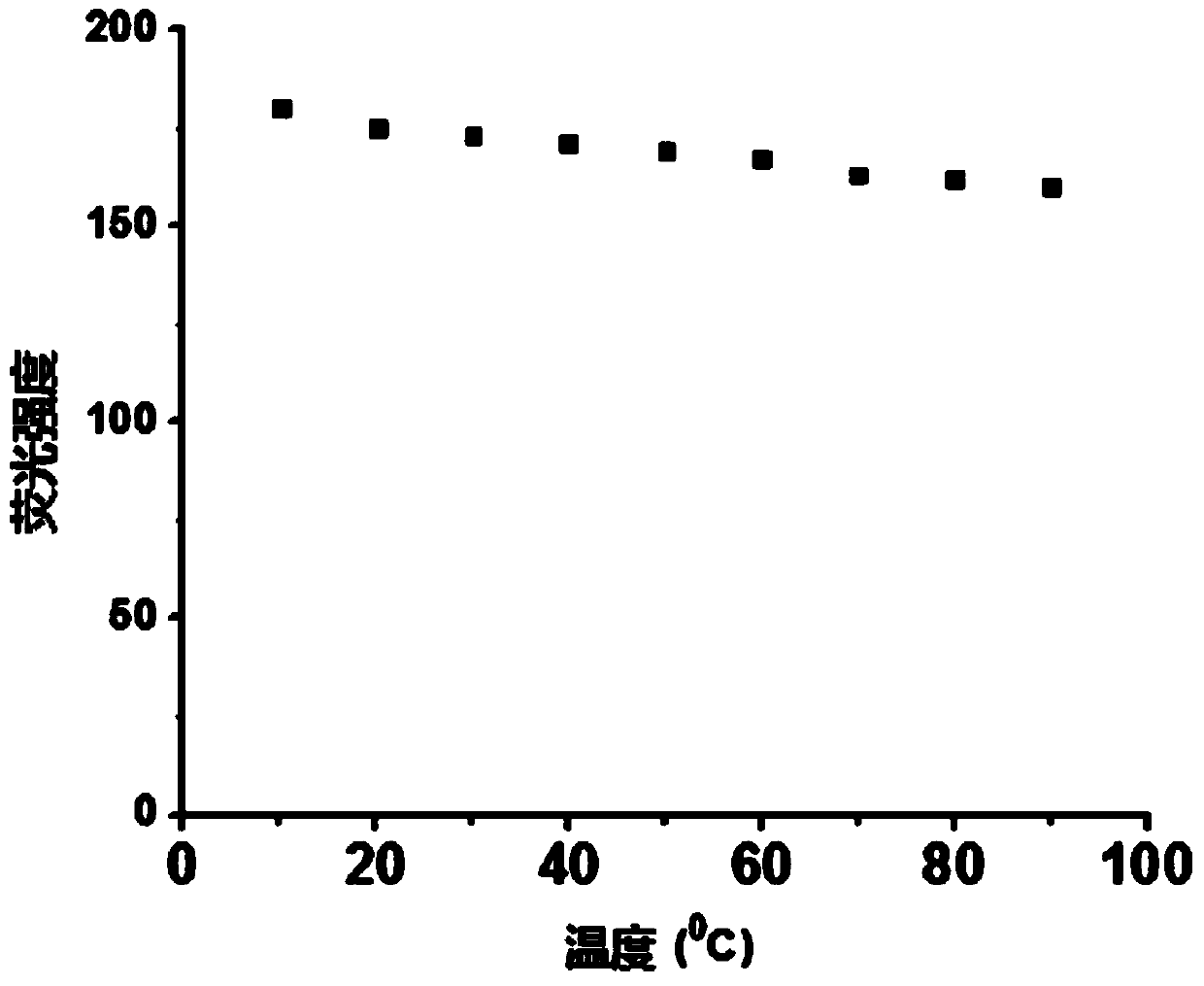

Application of multifunctional carbon quantum dot taken as fluorescent whitening agent

ActiveCN103993504AAvoid it happening againThe synthesis method is simpleLuminescent paintsFibre treatmentWhitening AgentsReactive oxygen radicals

The invention discloses application of a multifunctional carbon quantum dot taken as a fluorescent whitening agent in the fields of spinning printing and dyeing, washing agents, papermaking, plastics, leathers or coatings and the like. The carbon quantum dot disclosed by the invention has the advantages of wide application field, good whitening effect and good light resistance, is innoxious and environmentally friendly, can be applied to the fields of spinning printing and dyeing, washing agents, papermaking, plastics, leathers or coatings and the like, and can generate unforeseeable technical effect because the carbon quantum dot can generate active oxygen free radicals under the condition of illumination, wherein the unforeseeable technical effect is as follows: the bacteria attached to the surfaces of spinning printing and dyeing materials, the washing agents, paper sheets, the plastics, the leathers or the coatings and the like can be effectively killed after the spinning printing and dyeing materials, the washing agents, paper sheets, the plastics, the leathers or the coatings and the like which are doped with the carbon quantum dot absorb ultraviolet light.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

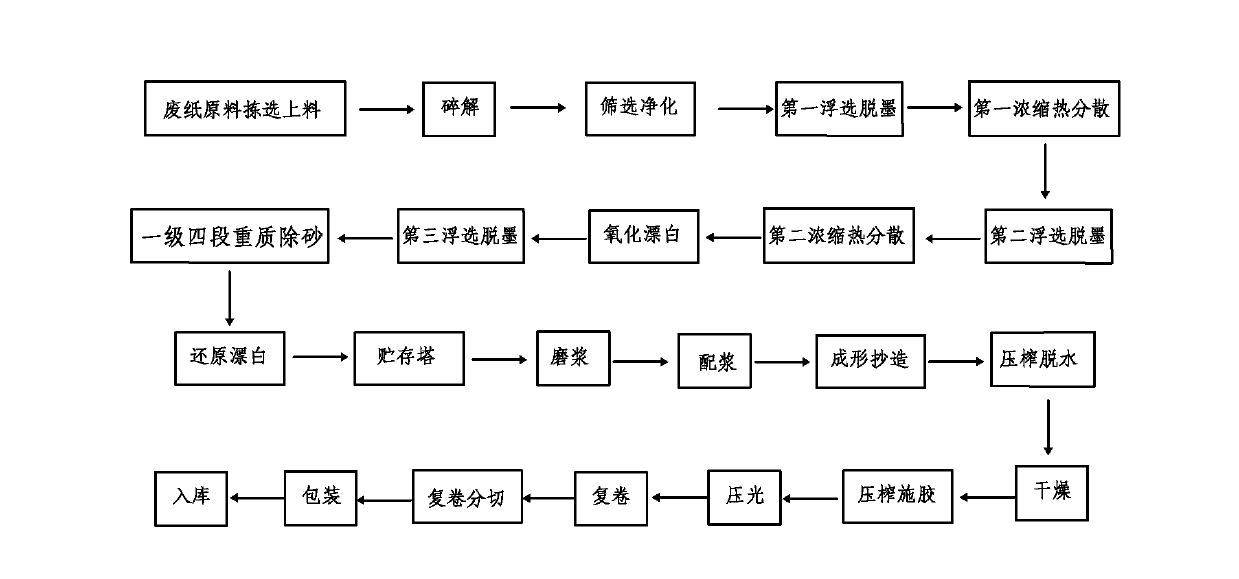

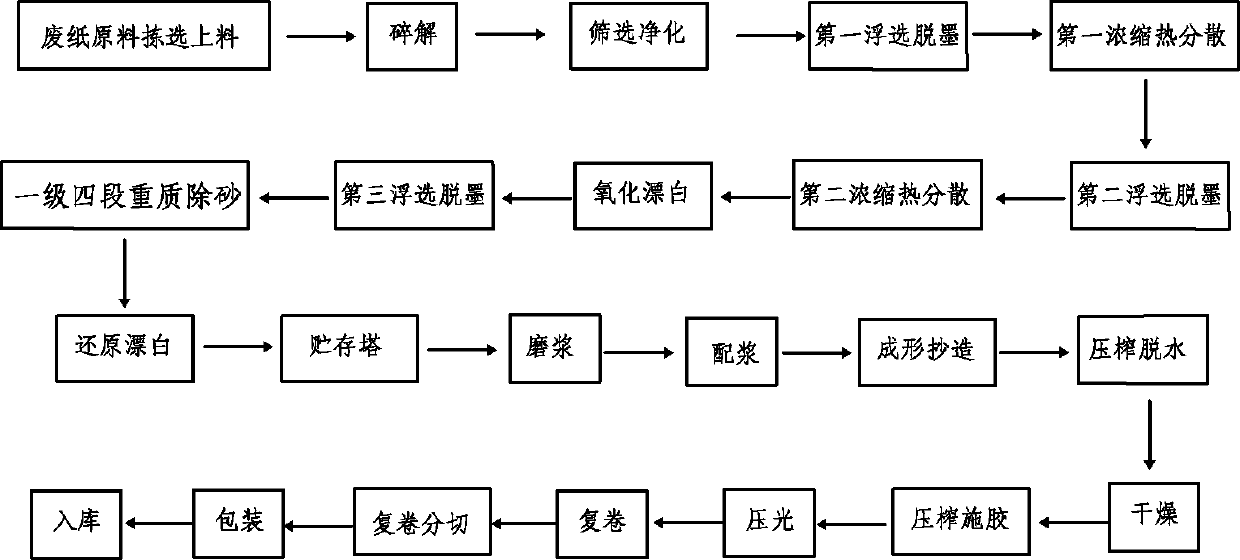

Process for preparing cultural paper by utilizing full-recovered pulp

InactiveCN102677532AQuality improvementImprove cleanlinessPaper recyclingLuminescent/fluorescent substance additionPapermakingSizing

The invention belongs to the technical field of a papermaking process and particularly relates to a process for preparing cultural paper by utilizing full-recovered pulp. The process for preparing the cultural paper by utilizing the full-recovered pulp comprises the following preparation steps of: a step A of sorting and loading waste paper raw materials; a step B of beating; a step C of screening and purifying; a step D of carrying out primary floatation deinking; a step E of carrying out primary concentration and heat dispersion; a step F of carrying out secondary floatation deinking; a step G of carrying out secondary concentration and heat dispersion; a step H of carrying out oxidation bleaching; a step I of carrying out reduction bleaching; a step J of storing in a tower; a step K of milling pulp; a step L of preparing the pulp; a step M of forming and manufacturing the paper with the pulp; a step N of squeezing and dehydrating; a step O of drying; a step P of squeezing and sizing; and a step Q of carrying out press polishing and then completing processing of a finished product by the working sections of reeling, rewinding, packaging and warehousing. According to the process disclosed by the invention, the high-quality cultural paper of which the appearance quality and the physical indexes all reach the domestic and overseas standards is produced by utilizing the low-price waste paper raw materials; the production cost is reduced; the production environment is clean and environmental-friendly; and the production efficiency is high.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Papermaking processes using coagulants and optical brighteners

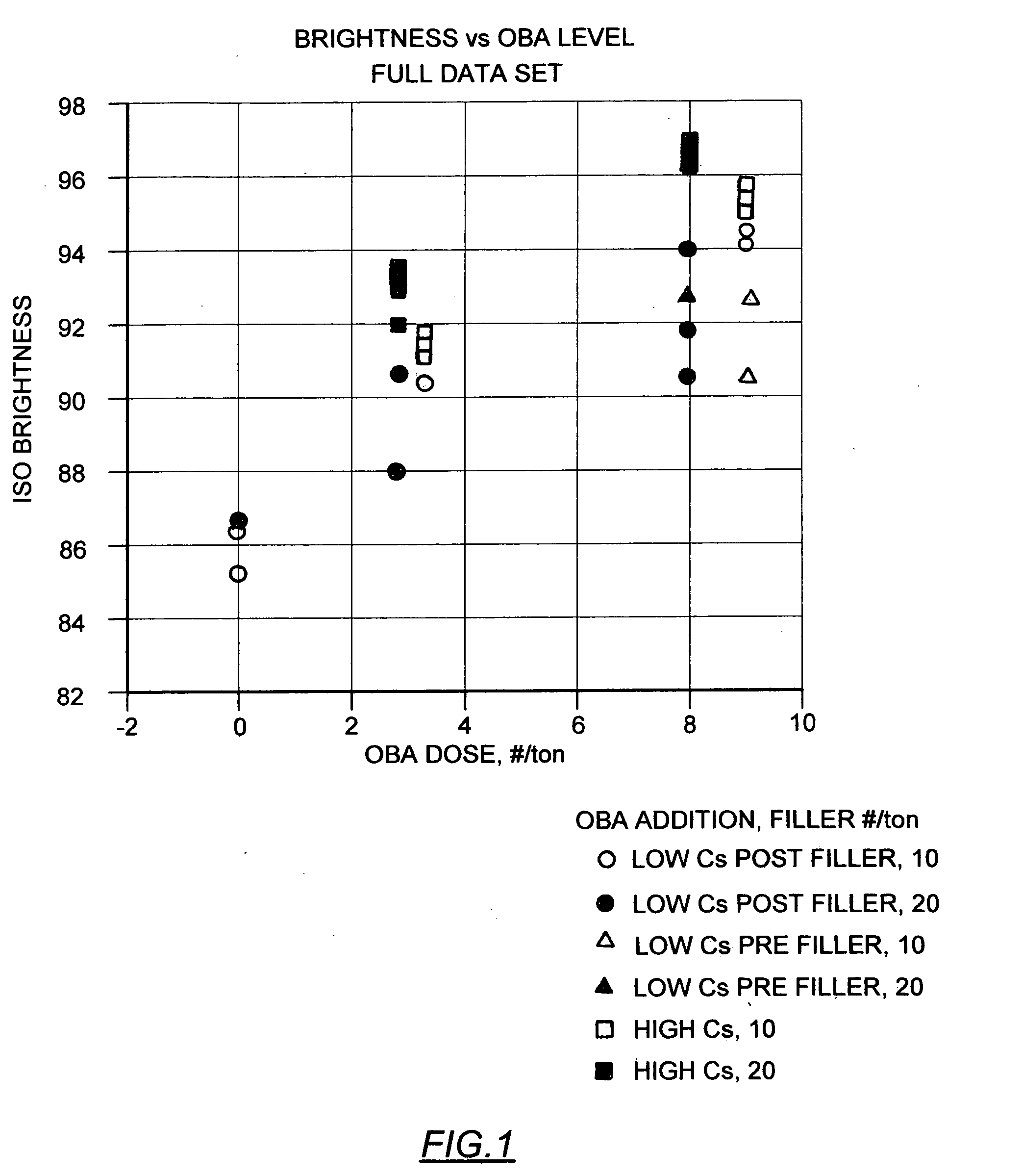

InactiveUS20070169903A1Reduce the amount requiredSatisfactory brightnessNatural cellulose pulp/paperSpecial paperPaperboardEngineering

A method of making paper or paperboard is described, which includes introducing at least one charged starch, preferably having a degree of substitution greater than 0.045, and at least one optical brightening agent to a papermaking pulp and then forming the pulp into paper or paperboard. The present invention further describes methods of improving optical brightener performance.

Owner:BUCKMAN LAB INT INC

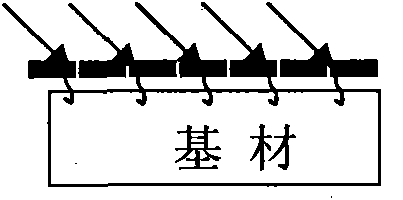

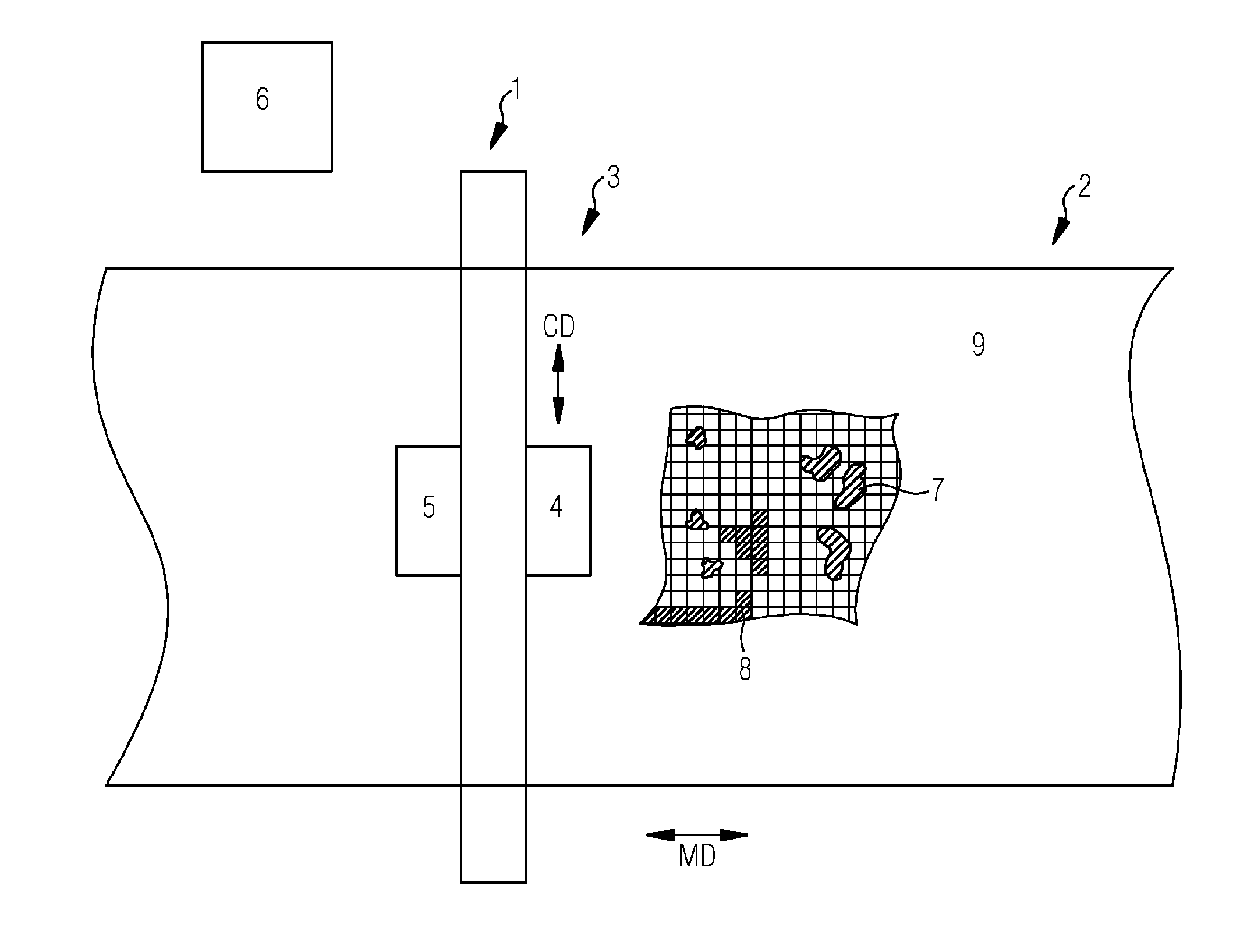

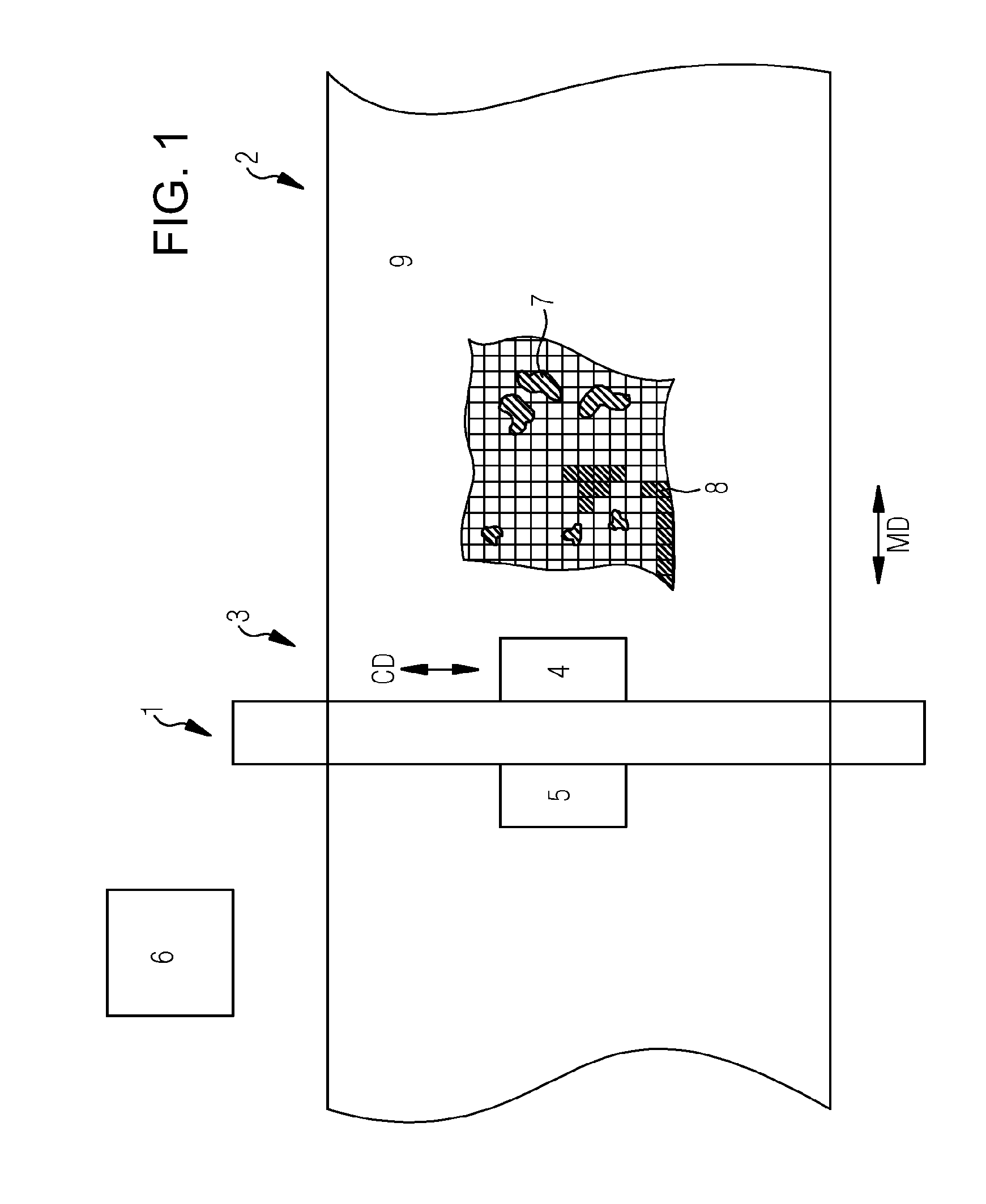

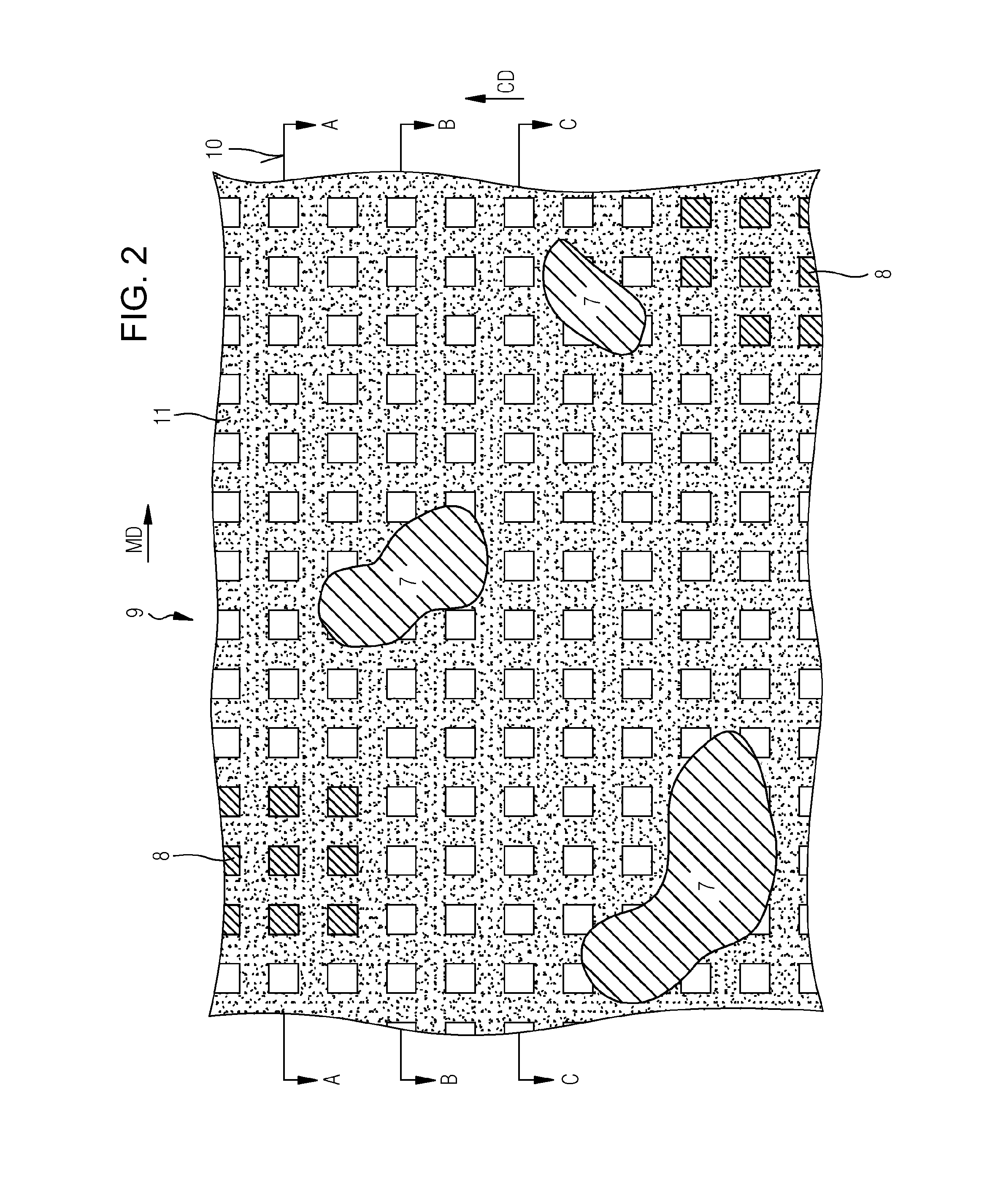

Method for detecting soiling of paper machine clothing and paper machine clothing

The invention relates to a method for detecting soiling of clothing providing a contact surface and a cavity volume in a machine for producing and / or treating a material web, in particular a fibrous web such as for example, paper, cardboard or tissue web, on which the soiling is detected and evaluated using a detection and evaluation unit. A detection and evaluation unit categorizes the soiling according to the soiling, distinguishing at least between soiling on the contact surface of the clothing and soiling within the clothing.

Owner:VOITH PATENT GMBH

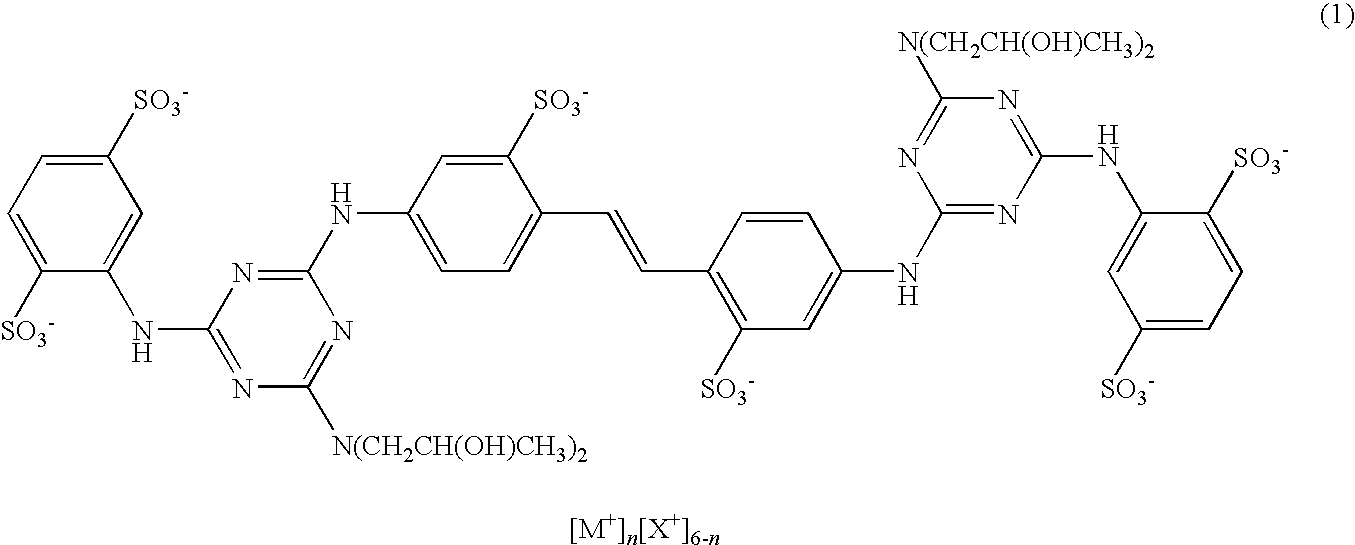

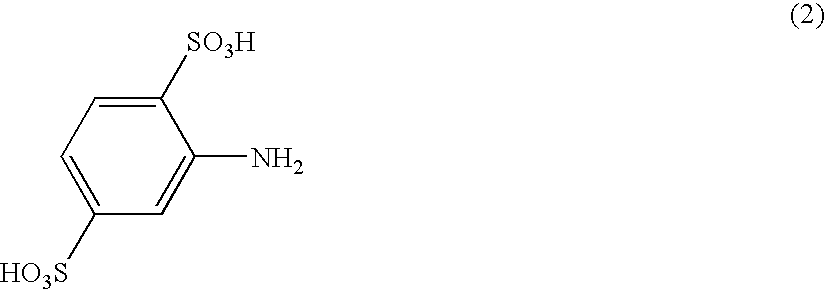

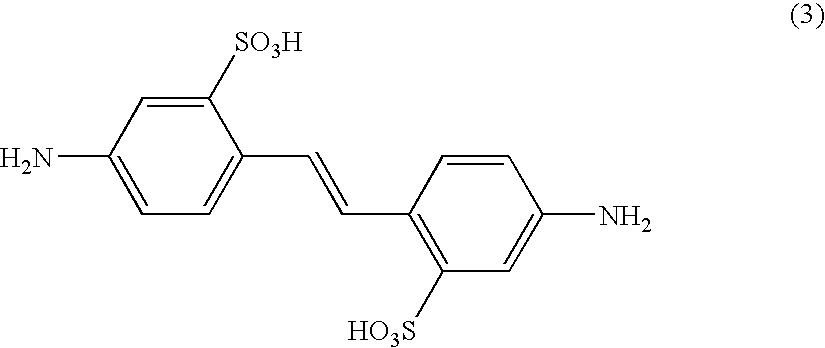

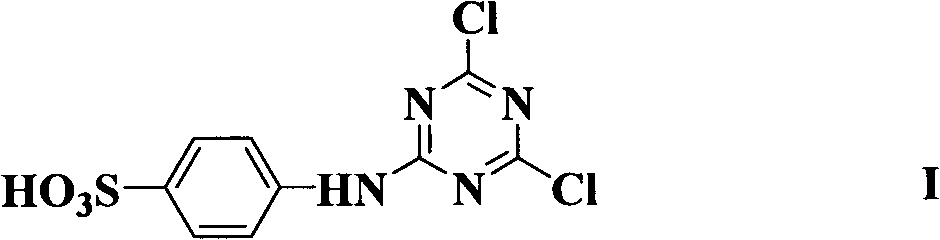

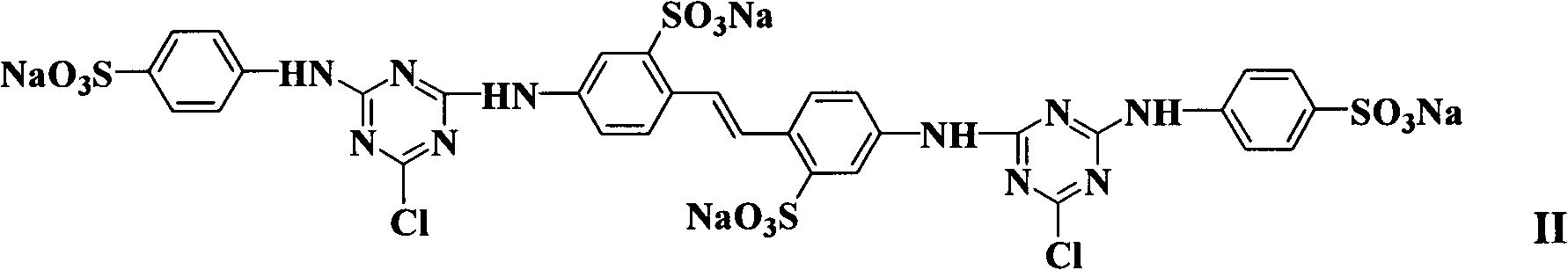

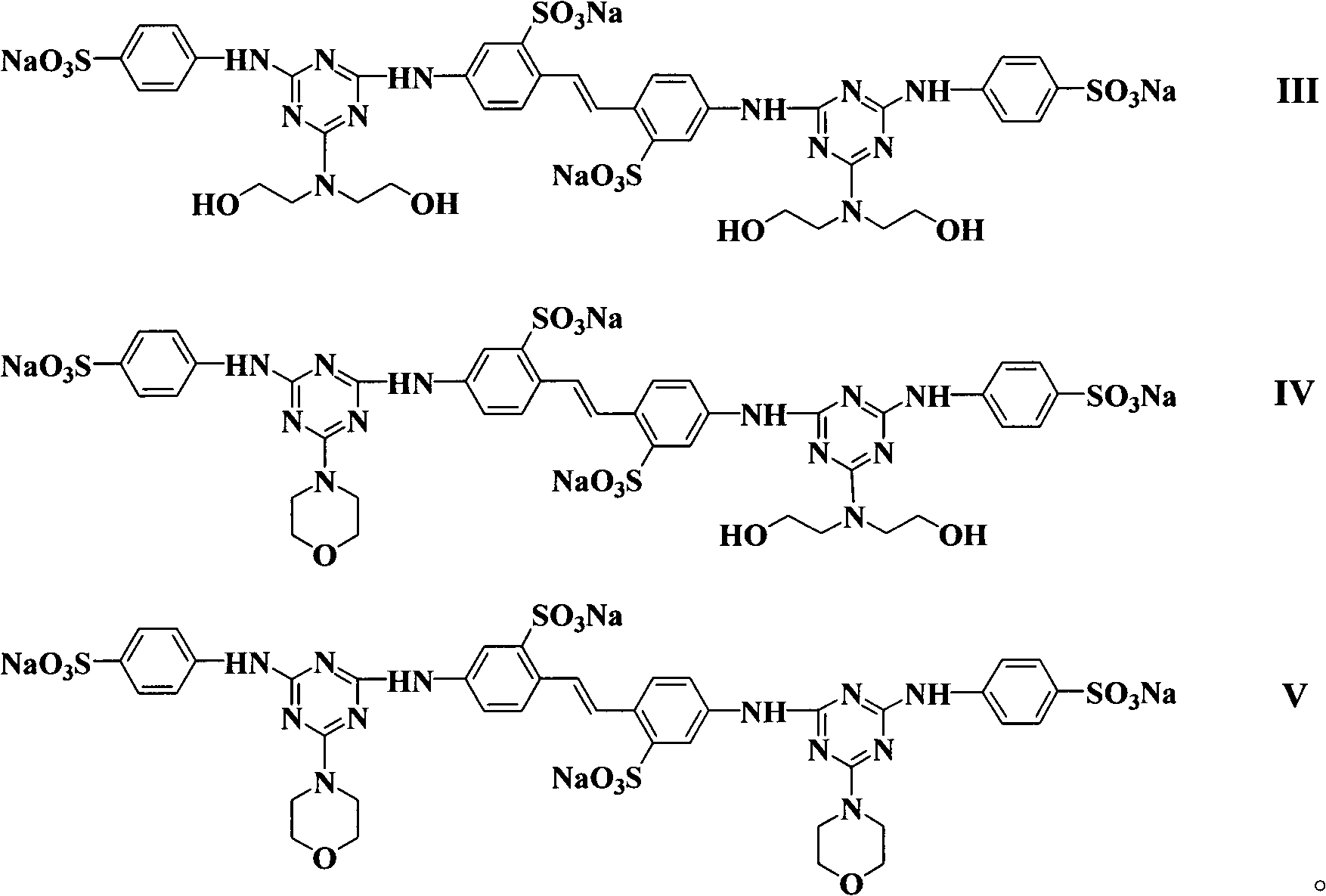

Highly effective environment friendly triazine amino stilbene fluorescent bleachng agent

The related synthesis technique for environment-protective triazinylamino diphenyl ethylene fluorescer in paper-making, paint and ink comprises: with ANSD acid as initial reactant, composing asymmetric fluorescer; designing a new synthesis path for the composite mixed and quaternary fluorescers; solves the pollution problem basically, and spreads application range. Wherein, the substituents of R1 and R2 are independent amino acid residues with hydrogen atoms on amido removed, such as, the aminobenzenesulfonic residue (I) and o-aminobenzenesulfonic residue (II); the R3 and R4 are independent alkamine residues or aminoalkyl residues with hydrogen atoms on amido removed, such as, morpholinyl(III), phenylamimo(IV), diethanolamimo(-N(CH2CH2OH)2), diacetylamino(-N(C2H5)2), ethanolamimo(-NCH2CH3OH), triethanolamimocation(V), triethylaminocation(VI).

Owner:SHANDONG UNIV

Methods To Detect Organic Contaminants In Pulp and Fiber

InactiveUS20090084510A1Accurate readingFats/resins/pitch/waxes removal in pulpDigestersFiberFluorescence

A method to detect organic contaminants in pulp and fiber is described which uses hydrophobic dyes, such as fluorescent dyes.

Owner:BUCKMAN LAB INT INC

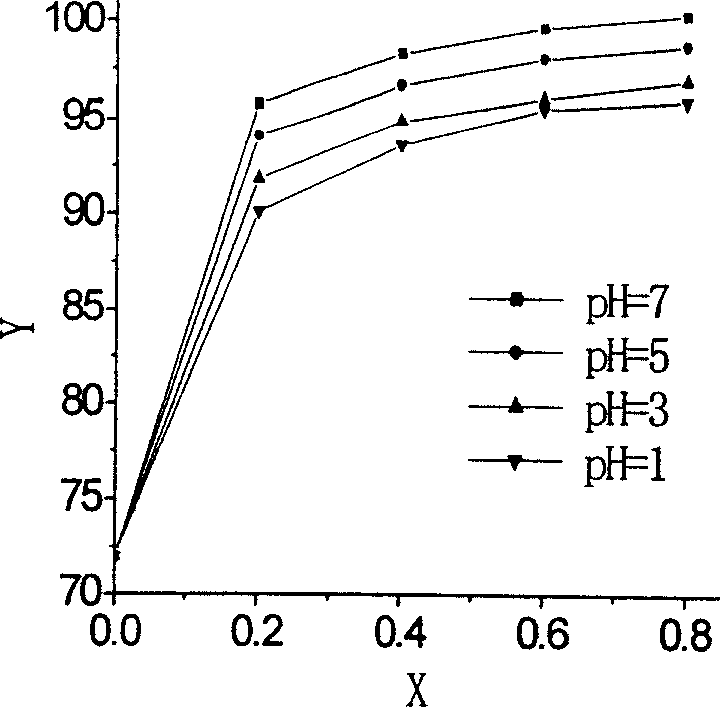

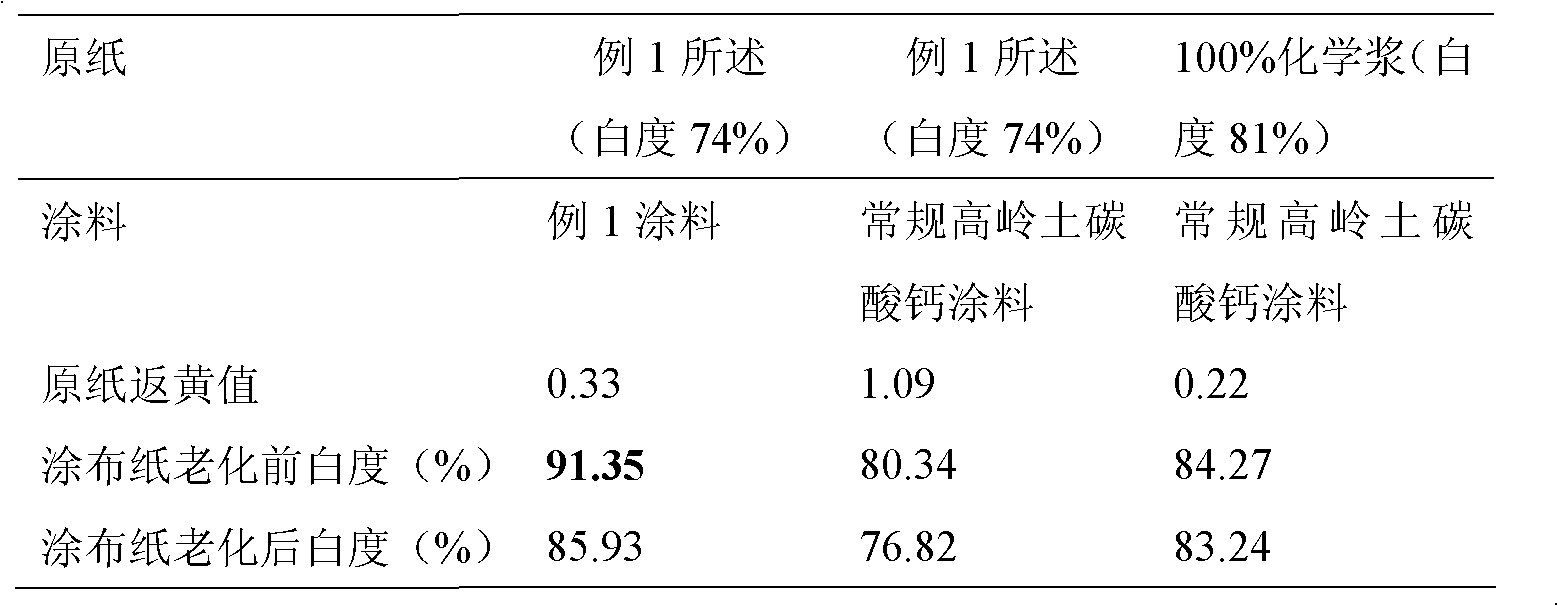

High-whiteness coated paper coated by using raw paper with medium whiteness, coating method and coating

InactiveCN102199897AReduce whitenessFulfil requirementsCoatings with pigmentsReinforcing agents additionCardboardManufacturing technology

The invention relates to high-whiteness coated paper coated by using raw paper with medium whiteness, a coating method and a coating. The coating method is mainly characterized by greatly reducing the whiteness of the raw paper for producing conventional high-grade coated paper such as copper plate paper and coated white cardboards. The coating mode is a common single-side or double-side two-layer (double-coating) or multi-layer coating mode in a papermaking plant. By using the mechanical property of the raw paper, the printing property of coatings and the synergetic whitening effect between the coatings, yellowing of the raw paper is inhibited, and the whiteness of the coated paper is improved to over 86 percent so as to meet the requirements of national standards on the high-grade copper plate paper. The raw paper of the high-grade coated paper can be made by using various kinds of environment-friendly and resource-saving pulp of medium whiteness more widely, and is favorable for promoting the development of the low-carbon manufacturing technology of the pulping papermaking industry. The newly invented coated paper can substitute the traditional high-grade paper such as the copper plate paper, the coated white cardboards and the like in the fields of printing and packing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of toluylene triazine liquid fluorescent brightener composite

InactiveCN101654894AReduce salt contentGood storage stabilityOrganic chemistryNon-macromolecular organic additionSulfanilic acidMorpholine

The invention provides a preparation method of symmetric and asymmetric toluylene triazine liquid fluorescent brightener composite expressed by the structural formulas (III), (VI) and (V), comprisingthe following steps: taking cyanuric chloride, sulfanilic acid, 4, 4-diaminobenzil-2, 2-disulfonic acid, morpholine and diethanol amine as raw materials; synthesizing by the three steps of reaction; and desalinating and filtering by means of nanofiltration membrane filtration. The liquid fluorescent brightener composite has a built synergistic effect and better brightening effect than a single composite; and the method not only can improve the quality of the fluorescent brightener, but also can reduce the consumption of amounts of raw materials, and greatly elevates product yield and quality.

Owner:山西晋光化工有限公司

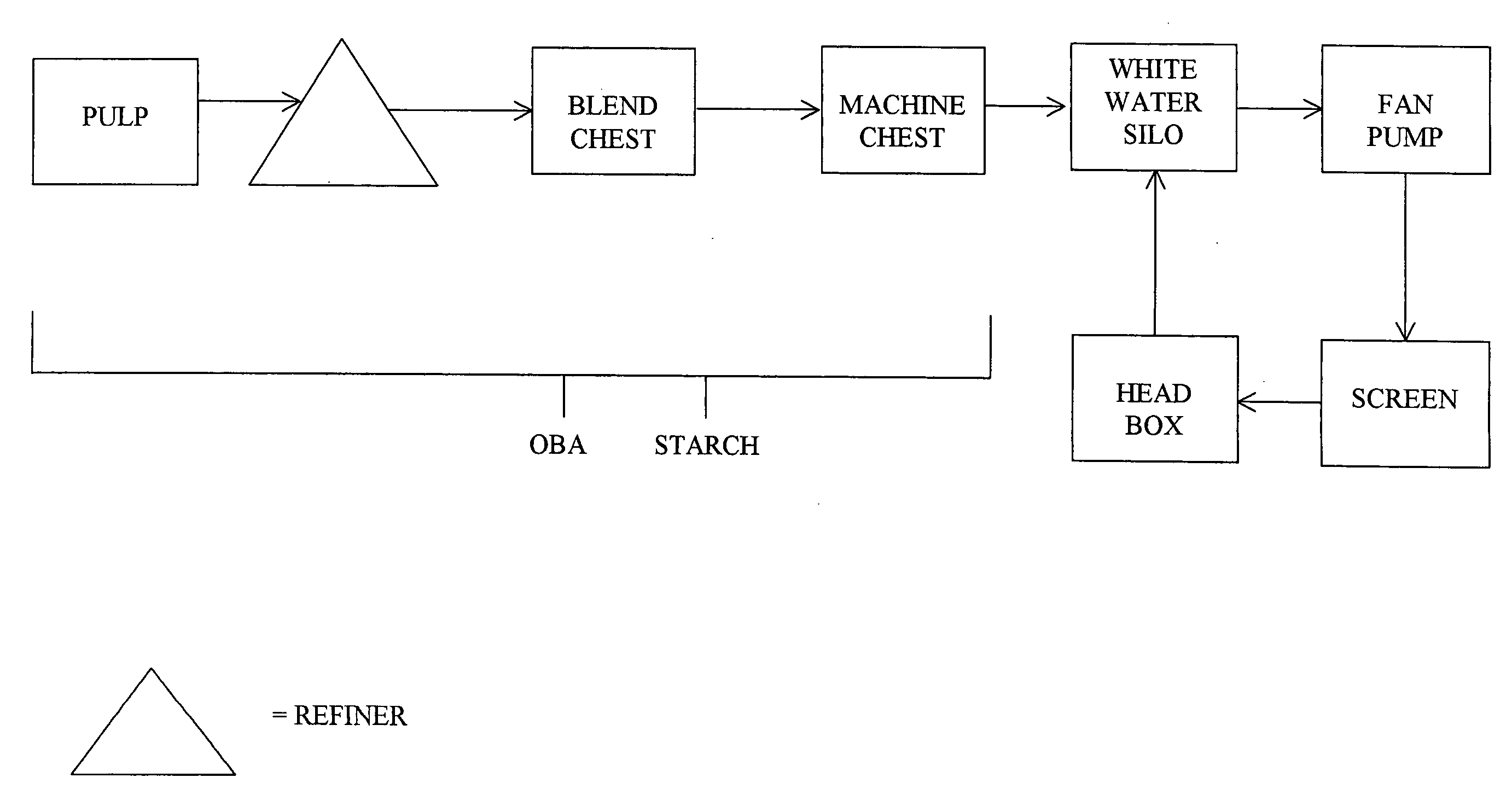

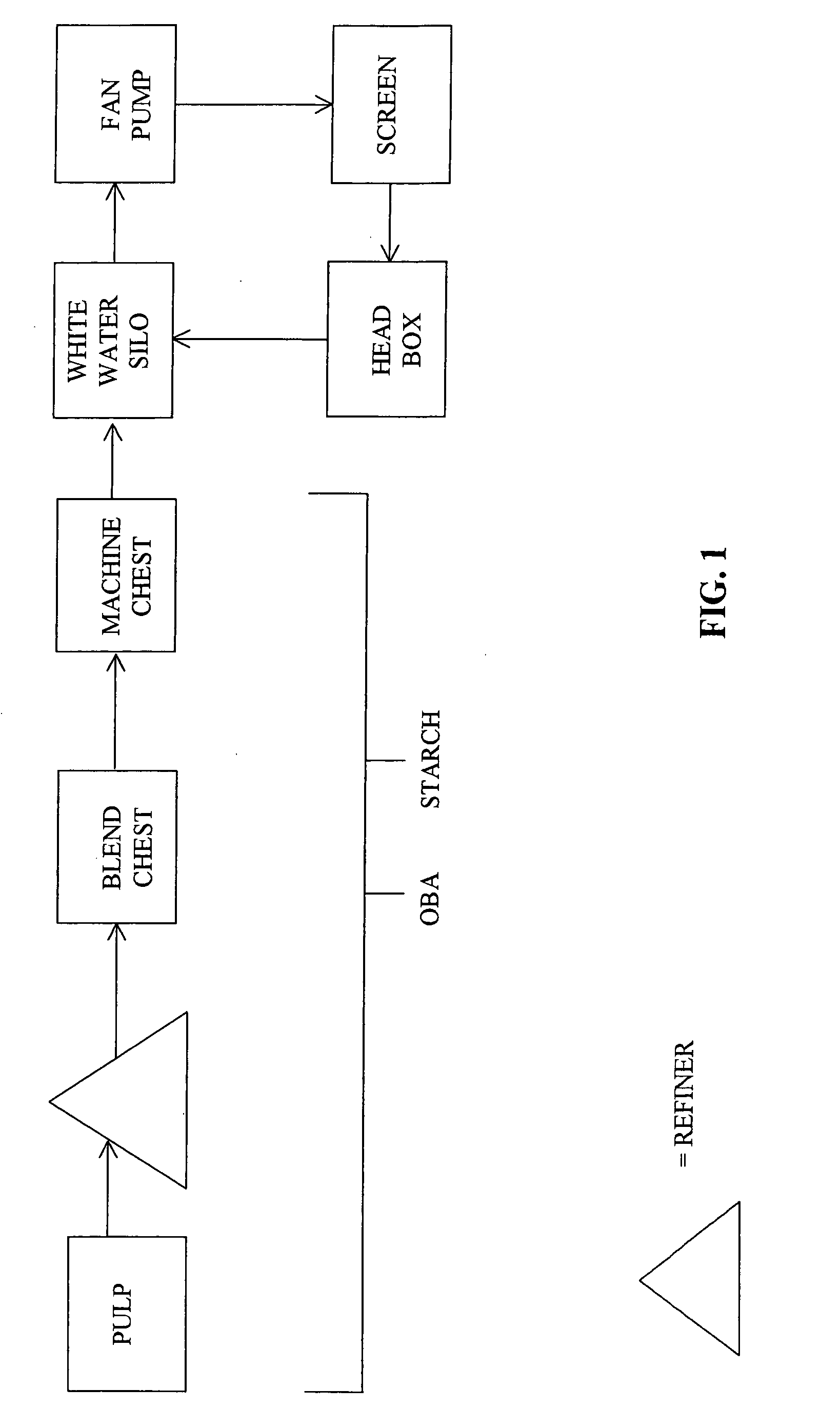

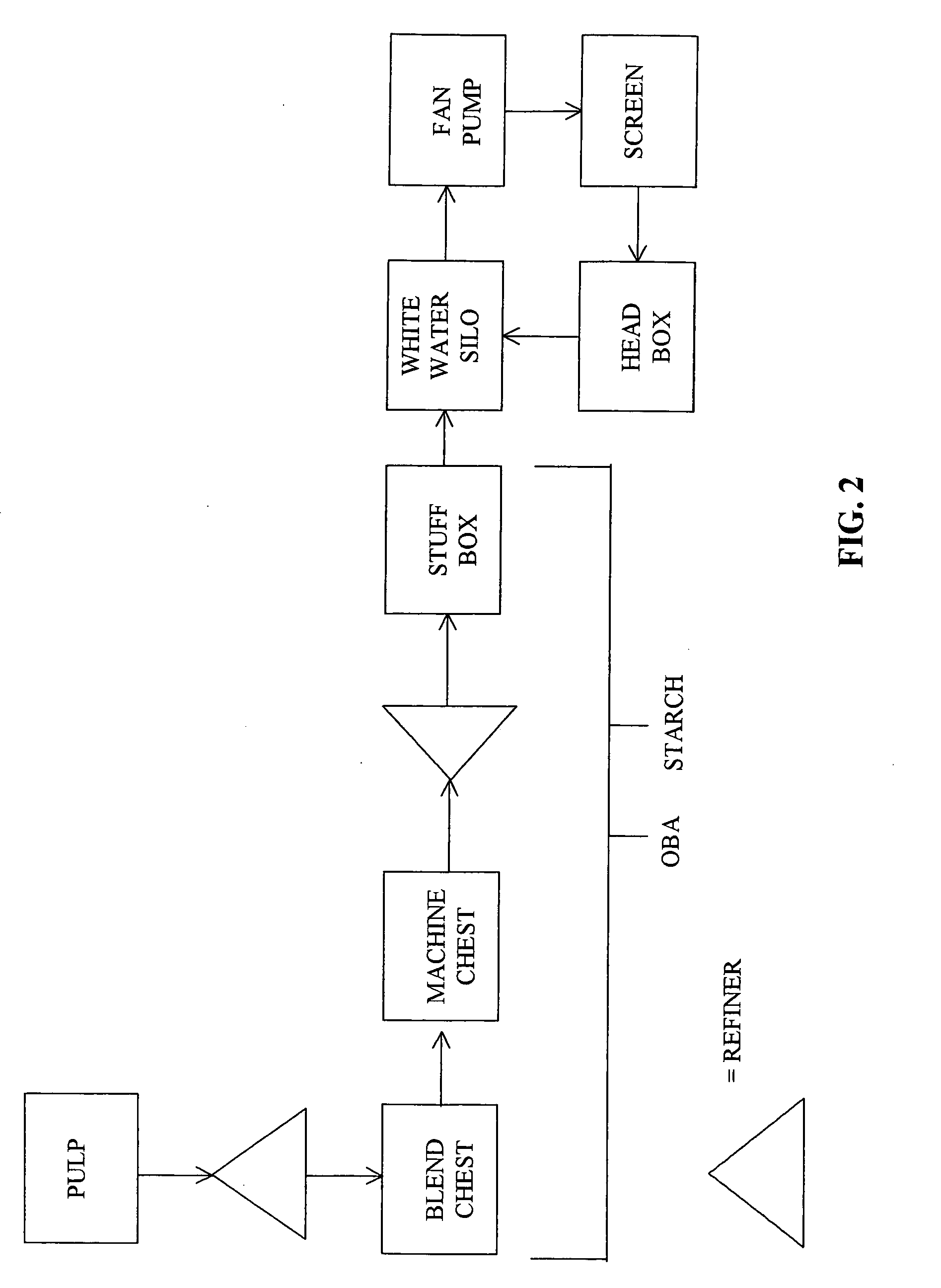

Process for improving optical properties of paper

InactiveUS20100132901A1Increase brightnessHigh whitenessNatural cellulose pulp/paperSpecial paperOptical propertyCellulose fiber

The present invention is directed to a method of efficiently maintaining or increasing brightness and whiteness of refined paper. In one aspect, the invention is directed to a method for substantially maintaining (or even increasing) brightness and / or whiteness of paper with increased pulp refining, the method including refining the pulp down to reduce the freeness at least about 100 CSF and adding a combination of an OBA and a carrier polymer to the paper surface in the size press in amounts sufficient to increase brightness and / or whiteness of the final paper. In another aspect, the invention is directed to a method of making paper from refined pulp that includes refining a cellulosic fiber suspension to reduce the freeness at least about 100 CSF and contacting the cellulosic fibers with at least one optical brightening agent (OBA) during or after the refining step prior to adding any additional wet end chemicals.

Owner:AKZO NOBEL NV

Method for Measuring Hydrophobic Contaminants in Paper Pulp

ActiveUS20080308241A1High fluorescence intensityNatural cellulose pulp/paperSpecial paperFiberFluorescence

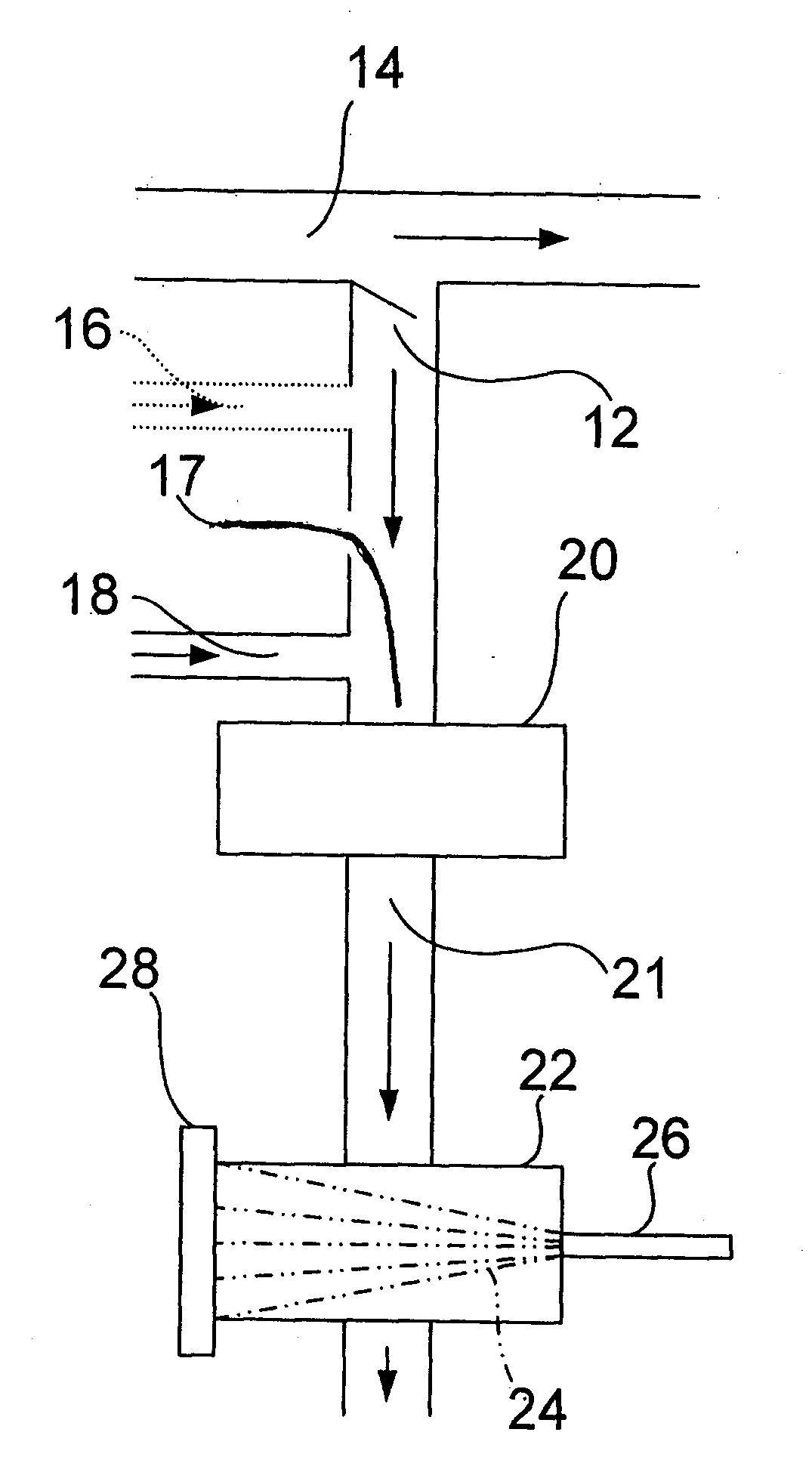

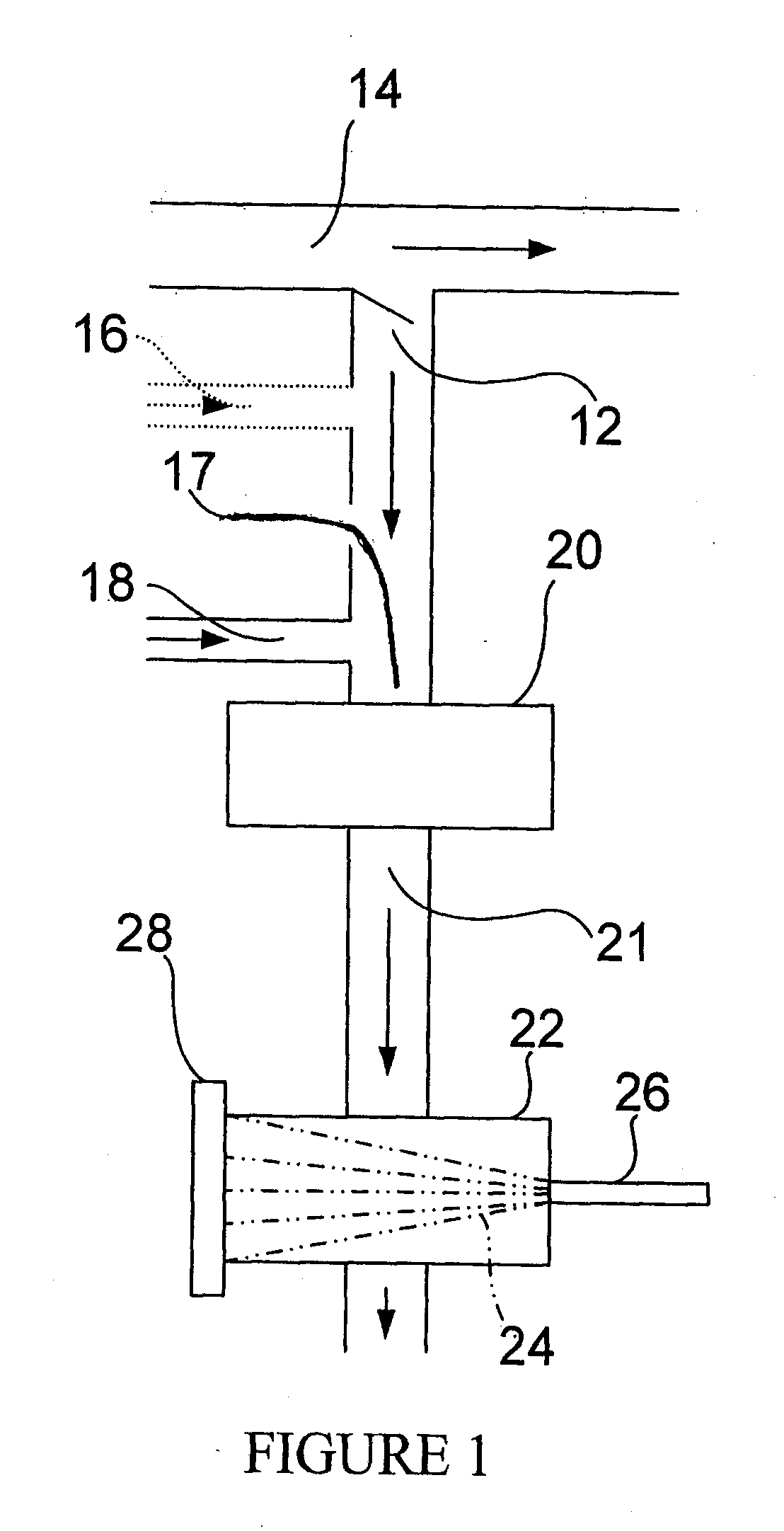

A method is provided for measuring hydrophobic contaminants distributed in paper pulp suspension. The method comprises: adding a fluorescent dye (18) to the paper pulp suspension (12) including fibers and hydrophobic contaminants, the dye (18) interacting with the hydrophobic contaminants of the paper pulp suspension (12); submitting the paper pulp suspension (12) including the fibers, the hydrophobic contaminants, and the dye (18) to light characterized by a wavelength exciting the dye (18) to produce light emission signals; and detecting the light emission signals and evaluating the signals to measure the hydrophobic contaminants.

Owner:CASCADES CANADA INC

Methods for enhancing brightness and resistance to thermal yellowing of bleached kraft pulp and paper

ActiveUS8246780B2Improve the immunityImproving and stabilizing brightnessCellulosic pulp after-treatmentSpecial paperFluorescencePapermaking

Compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The composition and method maintains and / or enhances brightness, prevent yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the described agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

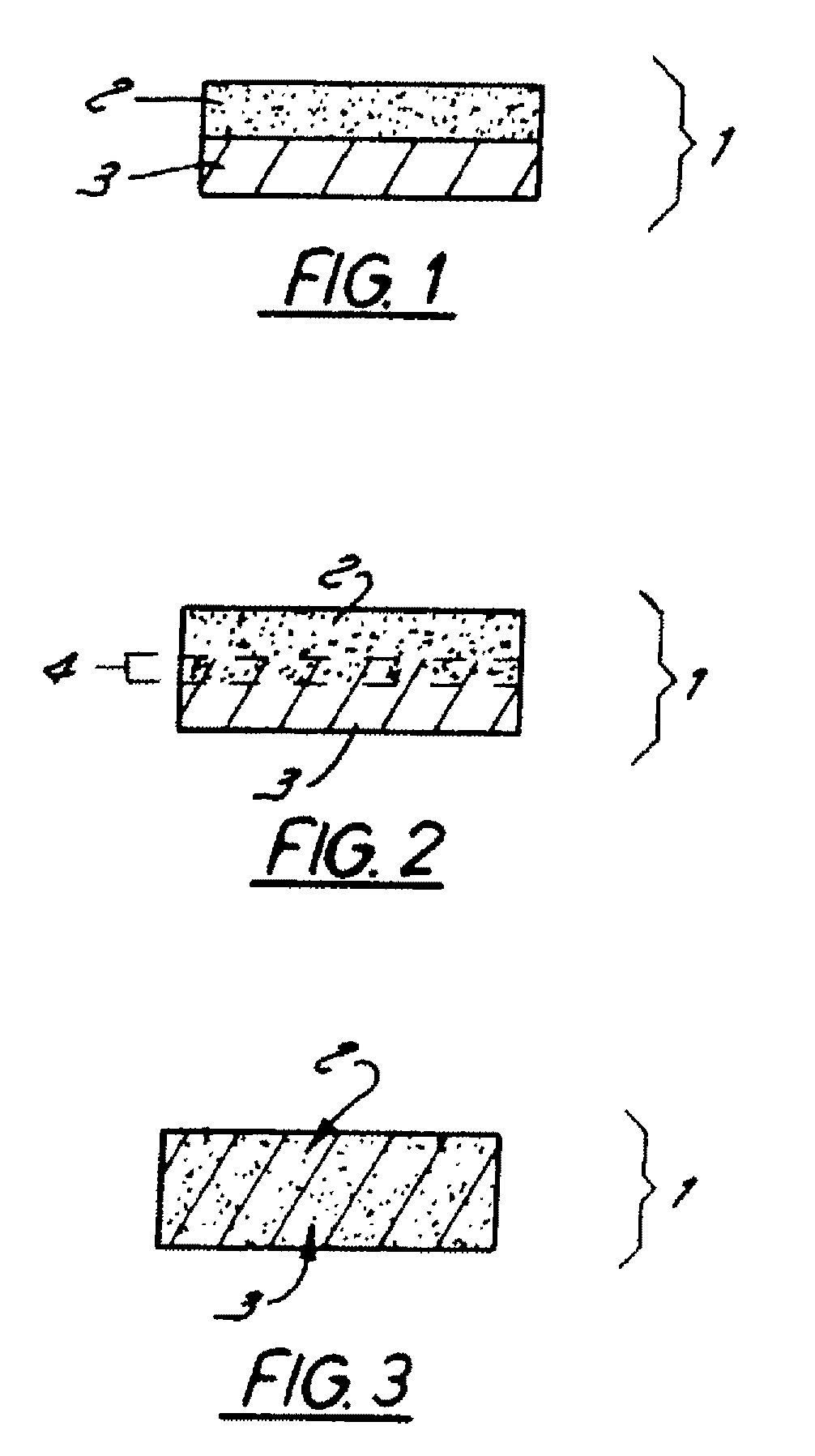

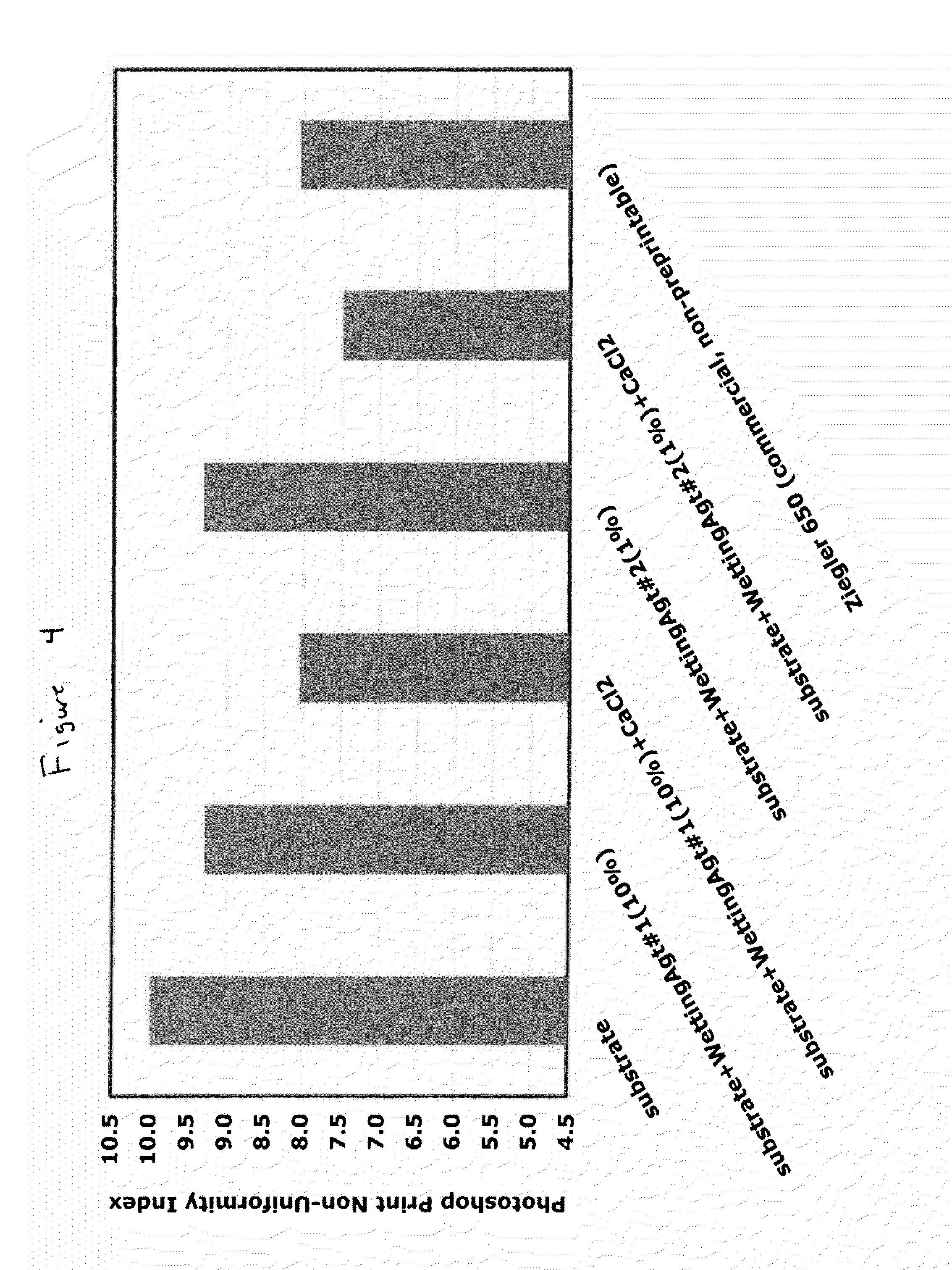

Paper substrate containing a wetting agent and having improved printability

The present invention relates to a sizing composition that, when applied to paper substrate, creates a substrate, preferably suitable for inkjet printing, having increased print density, and print mottle, as well as print sharpness, low HST, and / or image dry time, the substrate preferably having high brightness and reduced color-to-color bleed as well. In addition, the present invention relates to a method of reducing the HST of a paper substrate by applying the sizing composition to at least one surface thereof. Further, the application relates to methods of making and using the sizing composition, as well as methods of making and using the paper containing the sizing composition.

Owner:GLOBAL HLDG II INC

Whitening agents for cellulosic substrates

This invention relates to novel whitening agents for cellulosic substrates. The whitening agents are comprised of at least two components: at least one chromophore component and at least one polymeric component. Suitable chromophore components generally fluoresce blue, red, violet, or purple color when exposed to ultraviolet light, or they may absorb light to reflect these same shades. The whitening agents are further characterized by having a dispersion component value of the Hansen Solubility Parameter of less than or equal to about 17 MPa0.5. This invention also relates to laundry care compositions including but not limited to liquid and / or powder laundry detergent formulations and rinse added fabric softening (RAFS) compositions that comprise such whitening agents.

Owner:MILLIKEN & CO

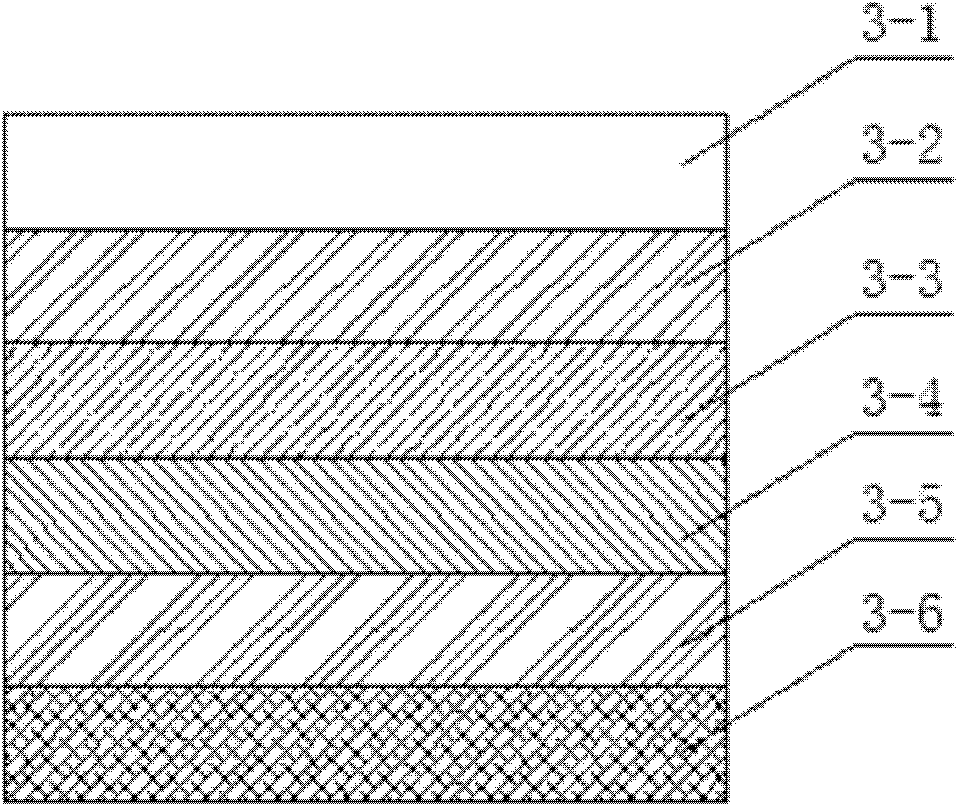

Coated natural kraft and manufacturing method thereof

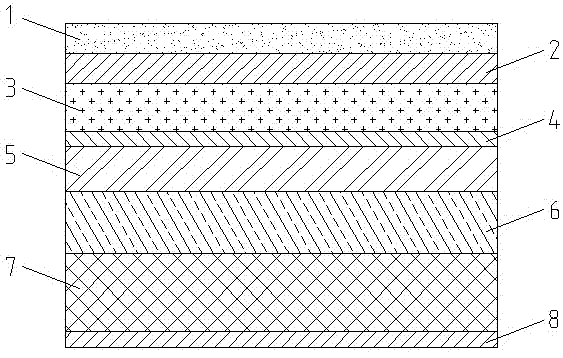

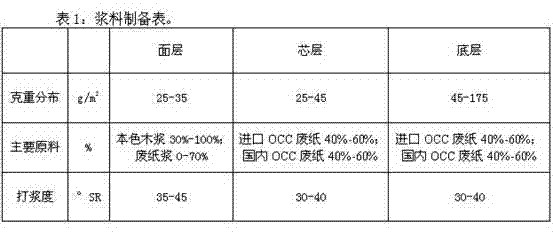

ActiveCN102199898AHigh strengthIncreased ring compressive strengthDefoamers additionWater-repelling agents additionSurface layerPulp and paper industry

The invention relates to coated natural kraft and a manufacturing method thereof. The traditional coated kraft does not have the advantages of attractive appearance, environment friendliness, high strength and good printing performance. The coated natural kraft disclosed by the invention comprises natural kraft, a surface sizing layer and a surface coating layer and is characterized in that a bottom layer comprises OCC (Old Corrugated Case) waste paper pulp and a core layer comprises waste paper; a surface layer comprises natural wood pulp and waste paper pulp, wherein the weight percentage of the natural wood pulp is 30% to 90% and the balance is the waste paper pulp; the surface sizing layer comprises a front sizing layer and a back sizing layer; and the surface coating layer comprises a bottom coating layer, a middle coating layer and a surface coating layer. The manufacturing method for the coated natural kraft sequentially comprises a natural kraft preparing working procedure, a sizing working procedure, a coating working procedure and a molding working procedure. The coated natural kraft has the advantages of reasonable structure design, attractive appearance, environment friendliness, high strength, good printing performance, simple preparation technology, low production cost and good quality.

Owner:JIAN GRP

Dullish coated paper for printing

InactiveUS20050016701A1Good flexibilityImprove surface smoothnessNatural cellulose pulp/paperSpecial paperFiberAdhesive

A dull coated printing paper that is bulky (low in density) having a density of 0.90 to 1.15 g / cm3 and yet offers excellent pliability, superior surface smoothness, high degree of print gloss and minimal small-scale gloss variations in the image area are obtained by forming a coating layer comprising a pigment and an adhesive on a base paper which contains an organic compound having an action to inhibit binding between pulp fibers and then carrying out calender treatment at a line pressure for the treatment of 50 to 150 kg / cm.

Owner:NIPPON PAPER IND CO LTD

Environment-friendly coated white board

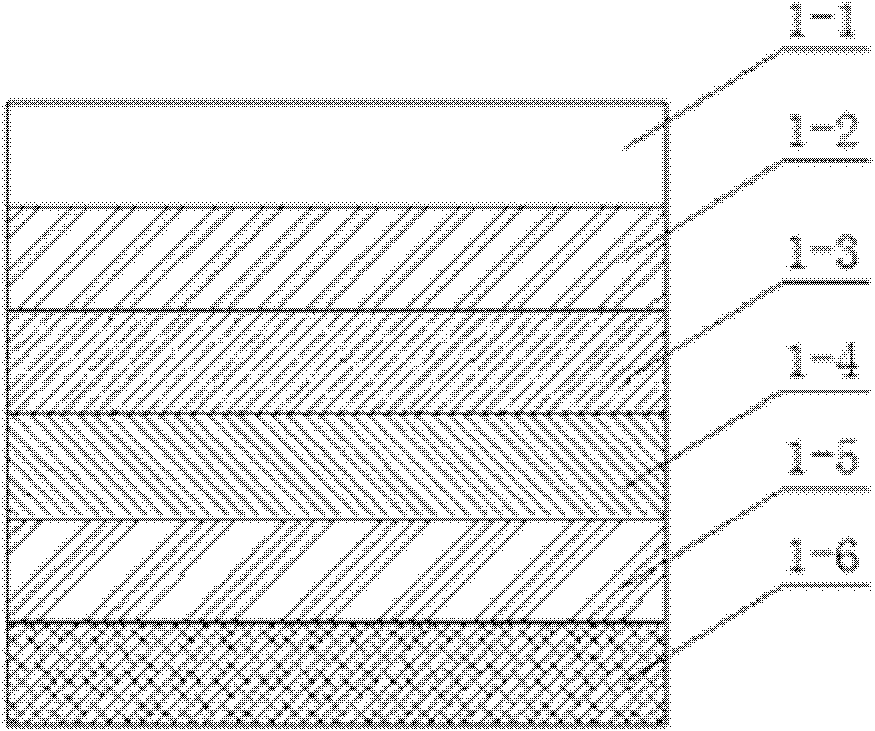

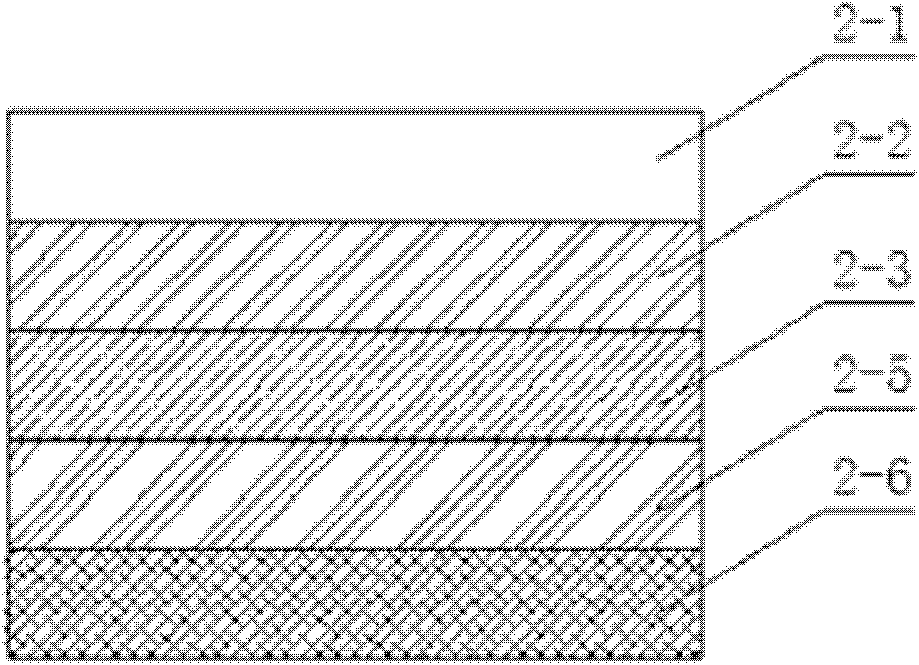

InactiveCN102677549AGood optical performanceGood printabilityCoatings with pigmentsSpecial paperCardboardWhiteboard

The invention discloses an environment-friendly coated white board which sequentially comprises a board body paper bottom layer, a core layer, a surface layer, a bottom coated layer and a surface coated layer from bottom to top. The whiteness of the coated white board ranges from 78% to 88%, and the quantification of the coated white board ranges from 200g / m<2> to 450g / m<2>. The environment-friendly coated white board is characterized in that the board surface layer is made of recycled pulp from waste paper of old corrugated cartons OCC and uncolored wood pulp which are mixed, or is made of one of the recycled pulp from the waste paper of old corrugated cartons OCC and the uncolored wood pulp, the quantification of the board surface layer ranges from 40g / m<2> to 80g / m<2>, the quantification of each of the bottom coated layer and the surface coated layer ranges from 6g / m<2> to 20g / m<2>, and the total coating quantity ranges from 12g / m<2> to 40g / m<2>. The coated white board is mainly made of the unbleached recycle pulp of the waste paper, has the advantages of capabilities of saving wood resources and reducing beaching pollution, low production cost, fine printability, attractive appearance, high strength and the like, and can replace traditional coated kraft card boards and coated white-surface white boards to manufacture packaging cartons and folded cartons such as wine boxes, boxes for articles for daily life, healthcare product boxes, electronic product boxes and high-grade clothing boxes.

Owner:臧永华

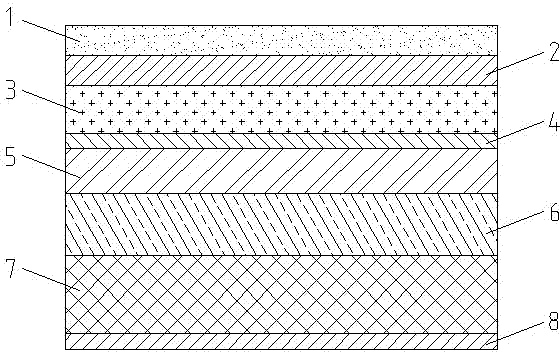

Flame-retardant wallpaper base paper and preparation method thereof

ActiveCN103614951AHigh activityPlay the role of wrappingSpecial paperReinforcing agents additionCelluloseFiber

The invention relates to flame-retardant wallpaper base paper and a preparation method thereof and belongs to processing of flame-retardant nonwoven wallpaper base paper. The flame-retardant wallpaper base paper is prepared through the following components in parts by weight: 65 to 70 parts of wood pulp cellulose, 15 to 20 parts of chemical fibers, 10 to 15 parts of rubber latex, 1 to 3 parts of fire retardant, 1 to 3 parts of modifier, 0.1 to 0.5 parts of dry strength agent, 0.1 to 0.5 parts of wet strength agent and 0.05 to 0.2 parts of fluorescent agent. The preparation method comprises the following steps: uniformly mixing the flame retardant and the modifier at a mass ratio, thereby obtaining a modified flame-retardant solution; immediately adding the modified flame-retardant solution into crylic acid rubber latex, and uniformly mixing, thereby obtaining an a glue applying solution; soaking a base paper semifinished product in the glue applying solution, thereby obtaining the flame-retardant wallpaper base paper with stable flame-retardant property and low cost. The flame-retardant wallpaper base paper is high in whiteness and good in flame-retardant property, the flame-retardant property of the flame-retardant wallpaper base paper can reach a B1 fire-retardant standard, the high flame-retardant property can be maintained after the base paper is used for a long time, and the base paper unlikely turns yellow after being used for a long time.

Owner:ZIBO OU MU SPECIAL PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com