Environment-friendly coated white board

A technology for coating paperboard and white paperboard, applied in the field of pulp and paper making, can solve problems such as increasing the manufacturing cost of coated whiteboard, and achieve the effects of beautiful appearance, reduction of bleaching pollution, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

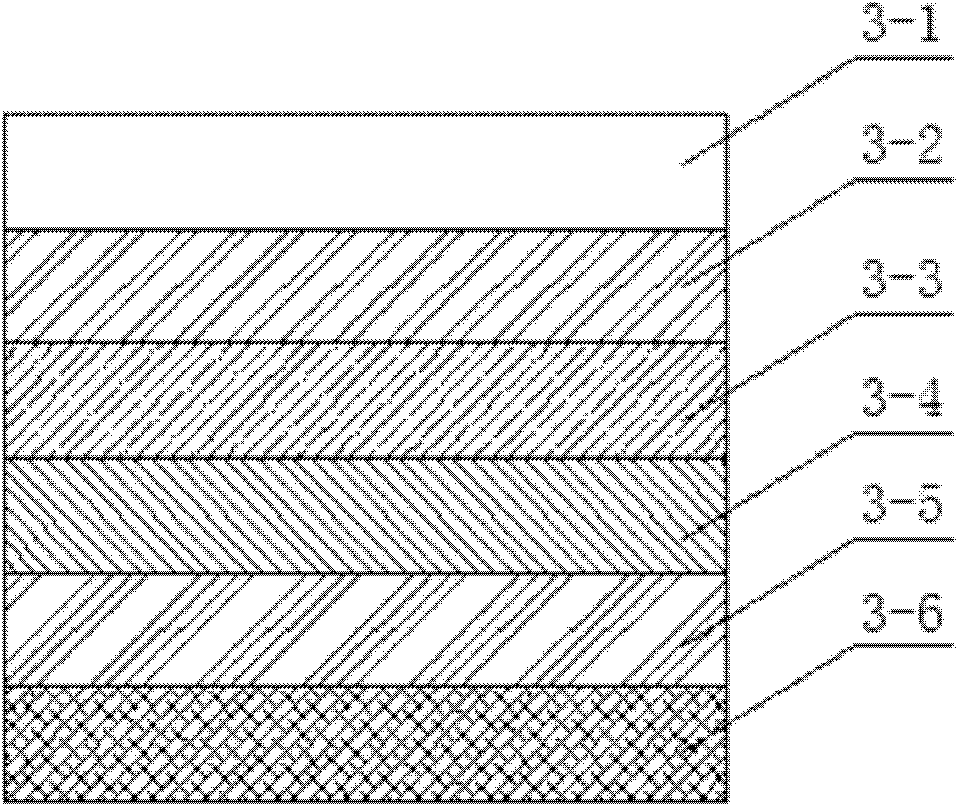

[0035] Production of 250 g / m for coated base paper with 3 ply unbleached board 2 Coated white cardboard:

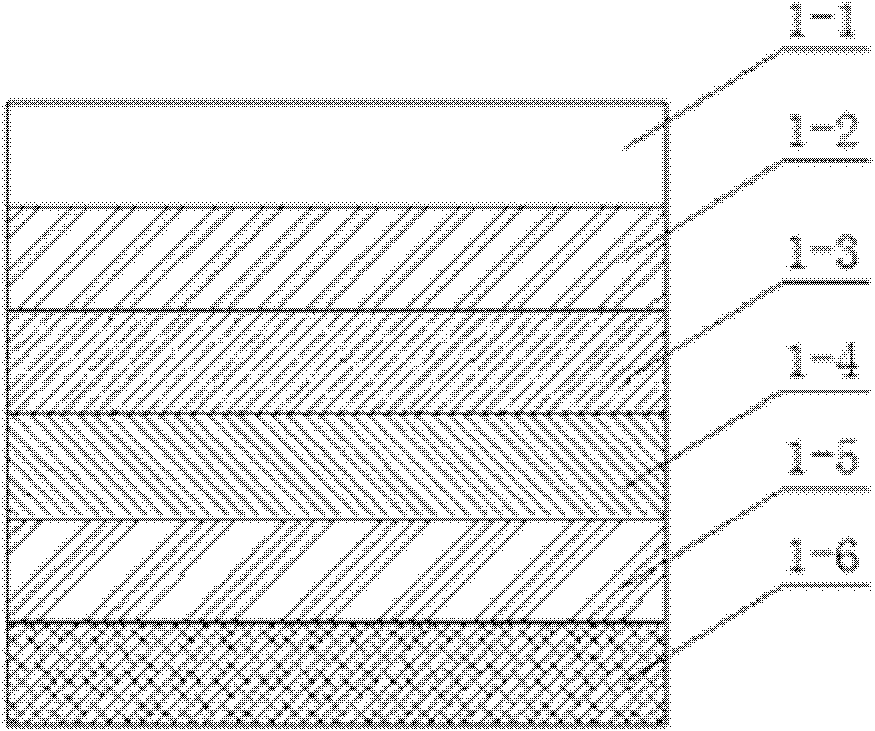

[0036] Figure-2 is the coated white paperboard produced by the present invention with 3 layers of paperboard without bleaching pulp as the coated base paper. The adopted process scheme is:

[0037] (1) The weight is 215g / m by triple-fold wire forming equipment 2 Coated base paper without bleached pulp, of which:

[0038] Surface layer: 20% unbleached softwood chemical pulp, 80% old carton OCC waste paper recycled pulp, basis weight 60g / m 2 ;

[0039] Core layer: composed of 45% old newspaper recycled pulp, 40% mixed waste paper recycled pulp, 15% old carton OCC waste paper recycled pulp, basis weight 95g / m 2 ;

[0040] Bottom layer: Composed of 100% old newspaper deinked recycled pulp, basis weight 60g / m 2 .

[0041] (2) Carry out sizing treatment to the cardboard front with sizing equipment, sizing liquid is made up of starch and sizing aid alkyl succinic anhydrid...

Embodiment 2

[0049] 350g / m produced with 4 layers of coated base paper without bleached pulp 2 Coated white cardboard

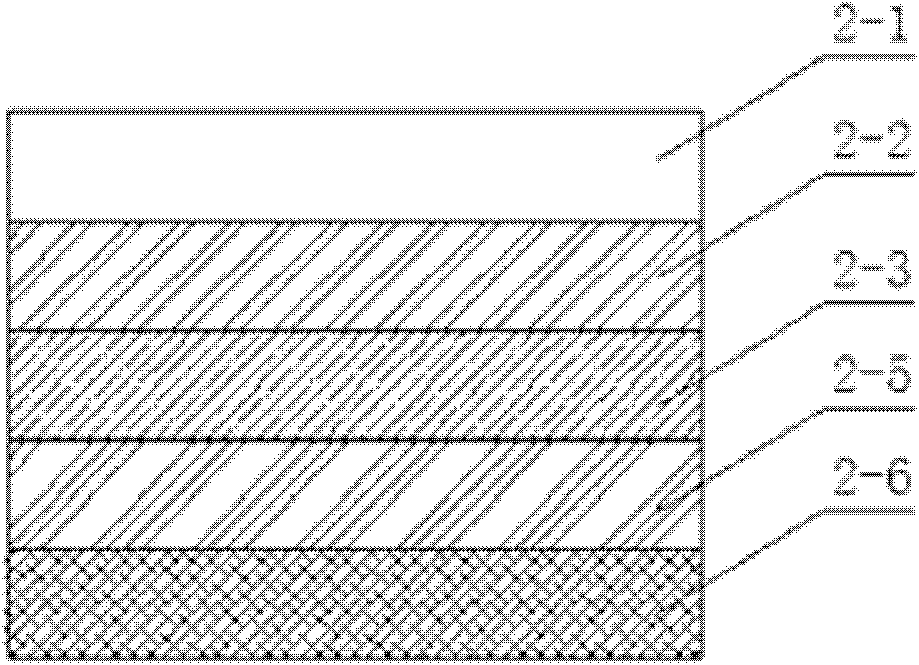

[0050] Figure-3 is the coated white cardboard produced with 4-layer coated base paper of the present invention, and the adopted process scheme is:

[0051] (1) Use four-fold wire forming equipment to make quantitative 315g / m 2 Coated base paper without bleached pulp, of which:

[0052] Surface layer: 20% unbleached softwood chemical pulp, 80% old carton OCC waste paper recycled pulp, basis weight 60g / m 2 ;

[0053] Lining: 80% old newspaper recycled pulp, 20% OCC waste paper recycled pulp, basis weight 95g / m 2 ;

[0054] Core layer: composed of 50% old newspaper recycled pulp, 40% mixed waste paper recycled pulp, 10% OCC waste paper recycled pulp, basis weight 100g / m 2 ;

[0055] Bottom layer: Composed of 100% old newspaper deinked recycled pulp, basis weight 60g / m 2 ,

[0056] (2) Carry out sizing treatment to the cardboard front with sizing equipment, sizing li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com