Patents

Literature

191 results about "Folding carton" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

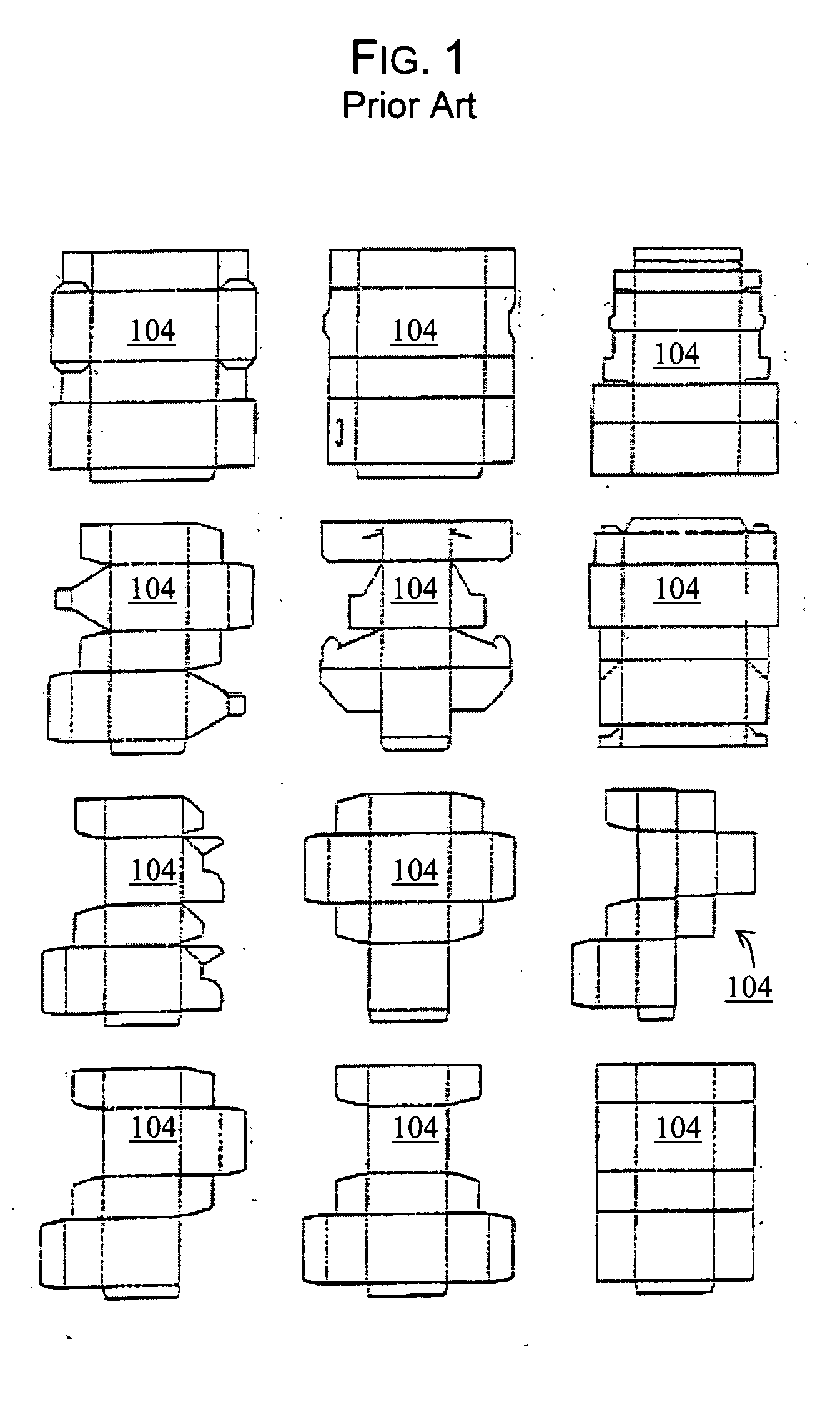

The folding carton created the packaging industry as it is known today, beginning in the late 19th century. The process involves folding carton made of paperboard that is printed, laminated, cut, then folded and glued before transport to packagers. The cartons are shipped flat to a packager, which has its own machinery to fold the carton into its final shape as a container for a product. The classic example of such a carton is a cereal box.

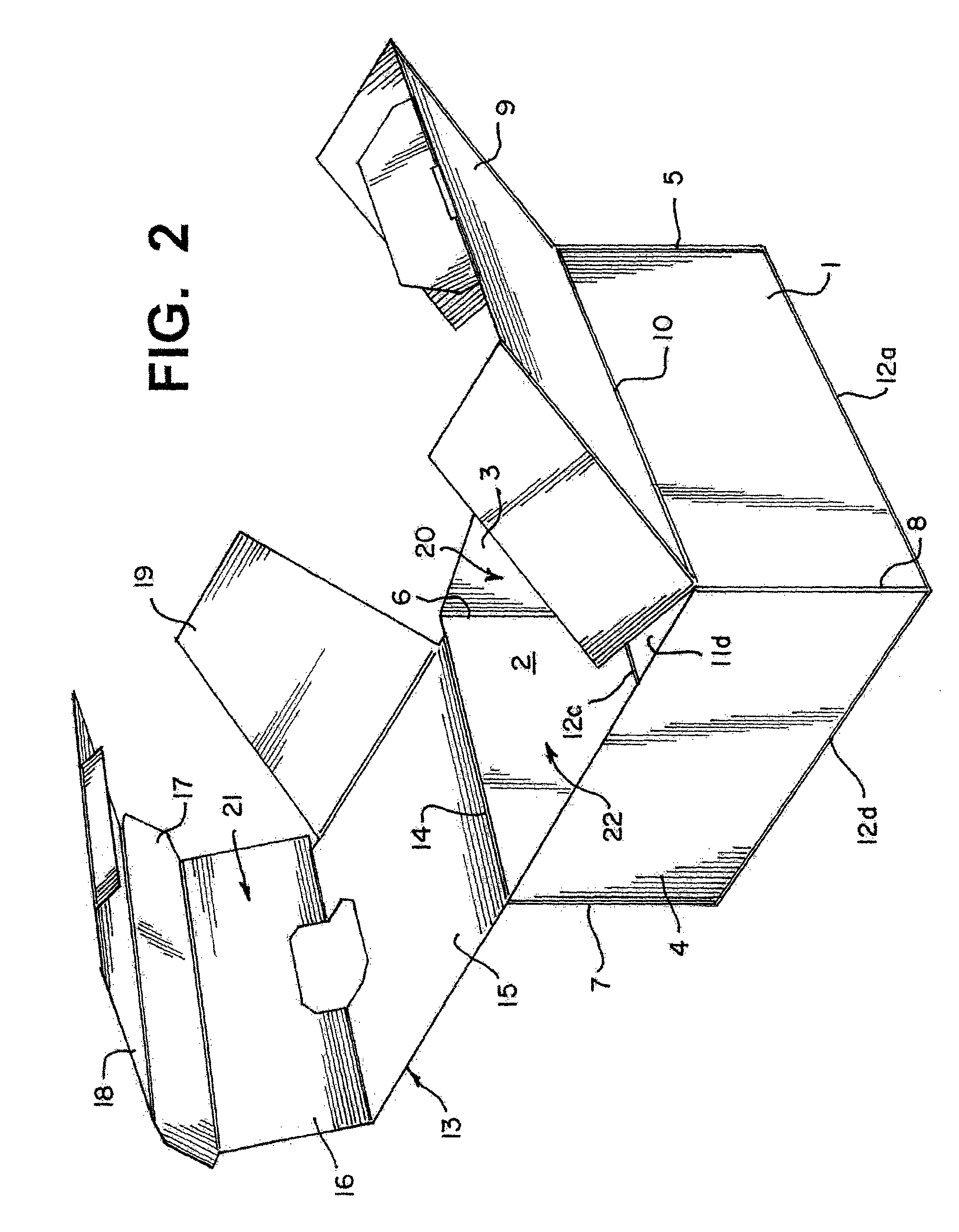

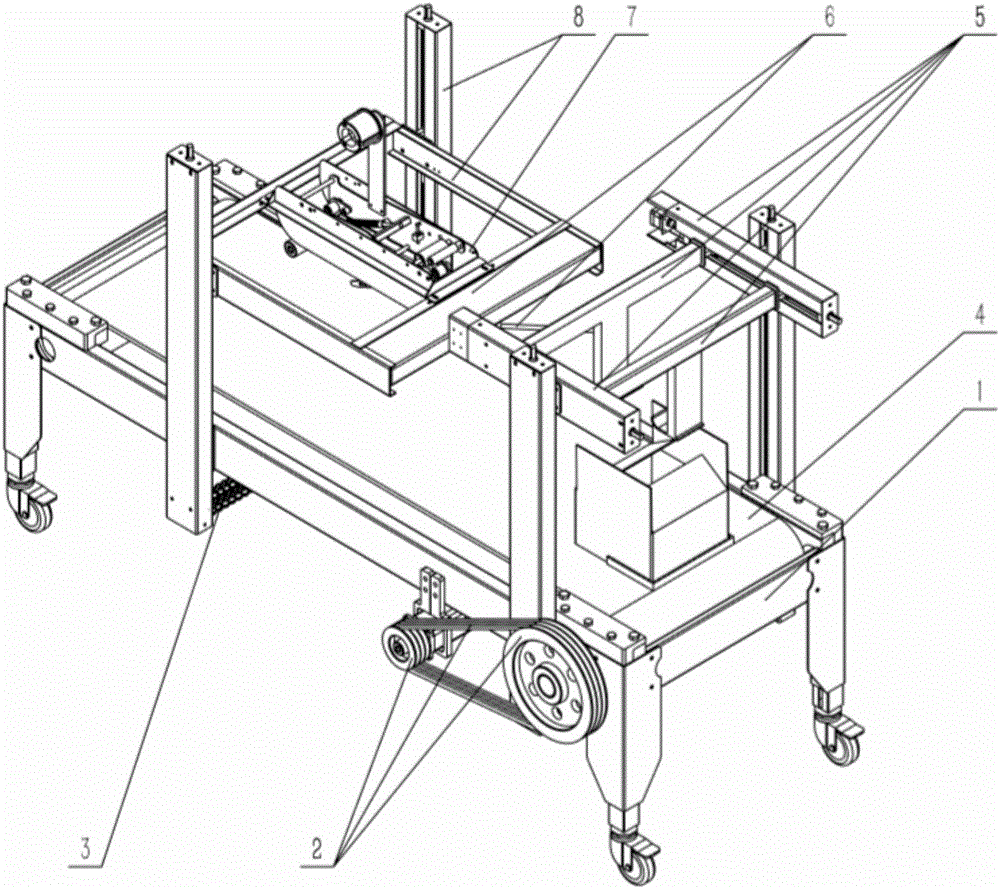

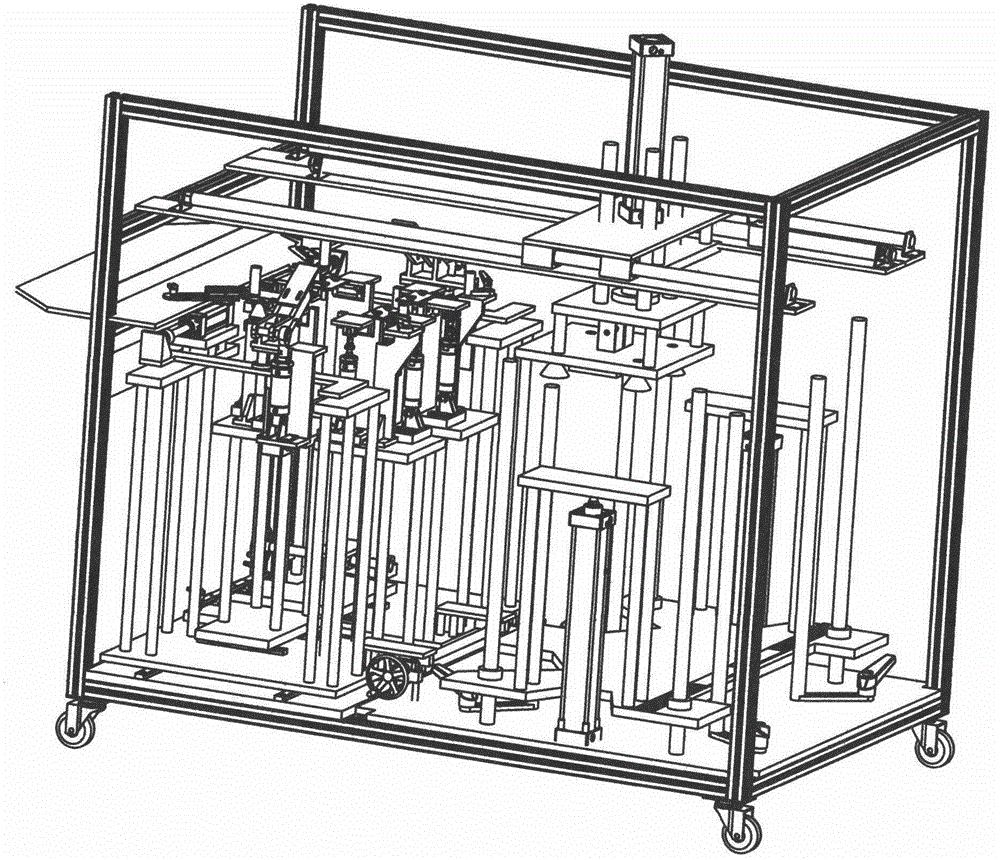

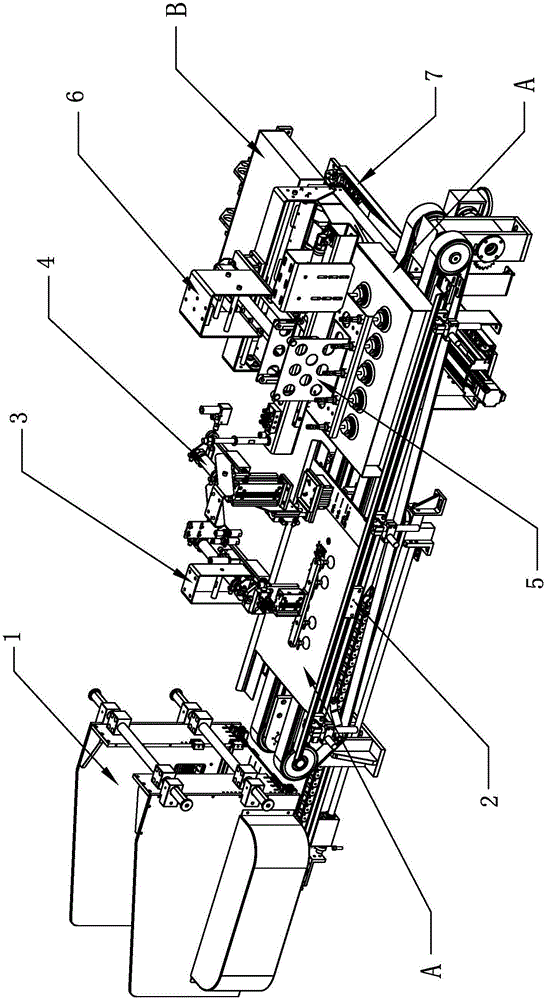

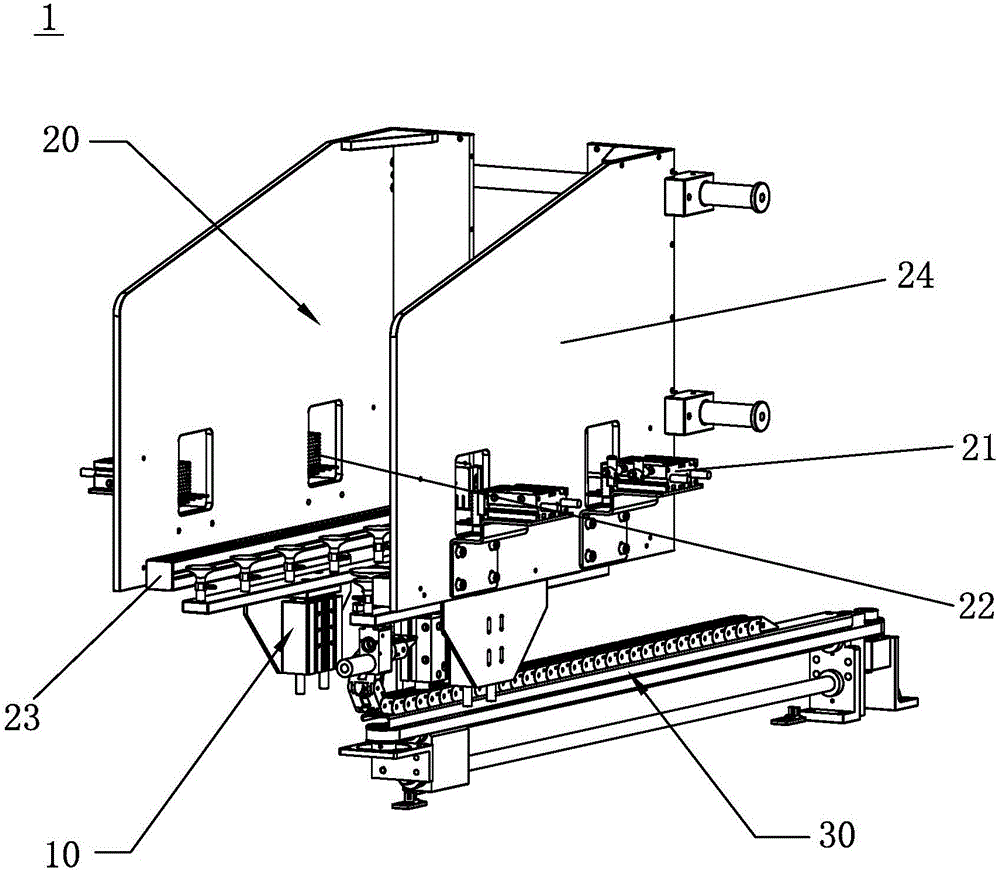

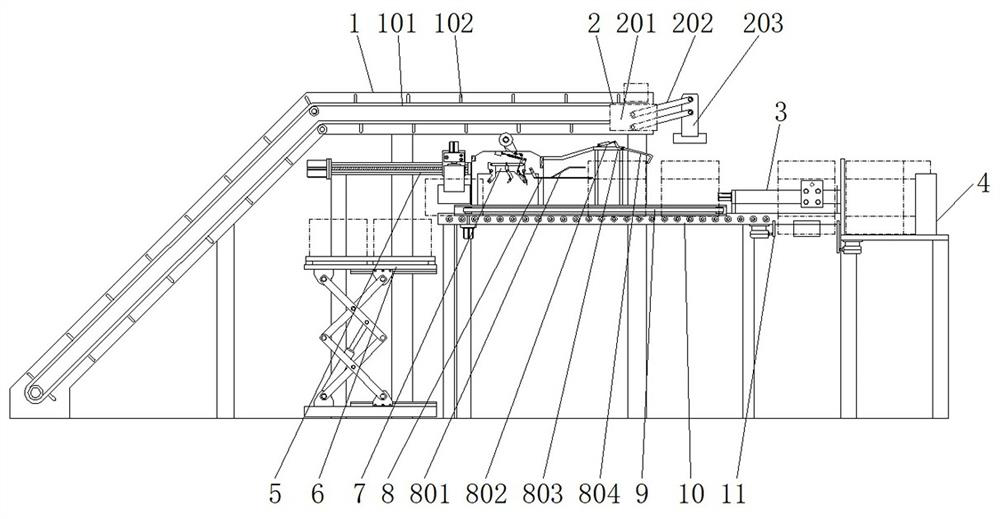

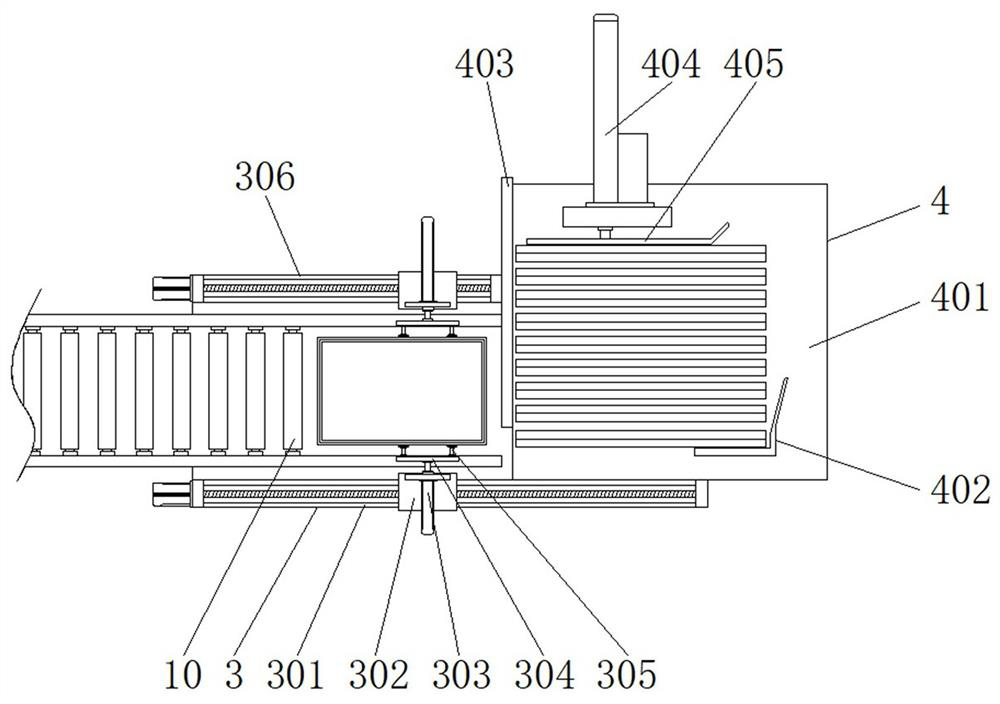

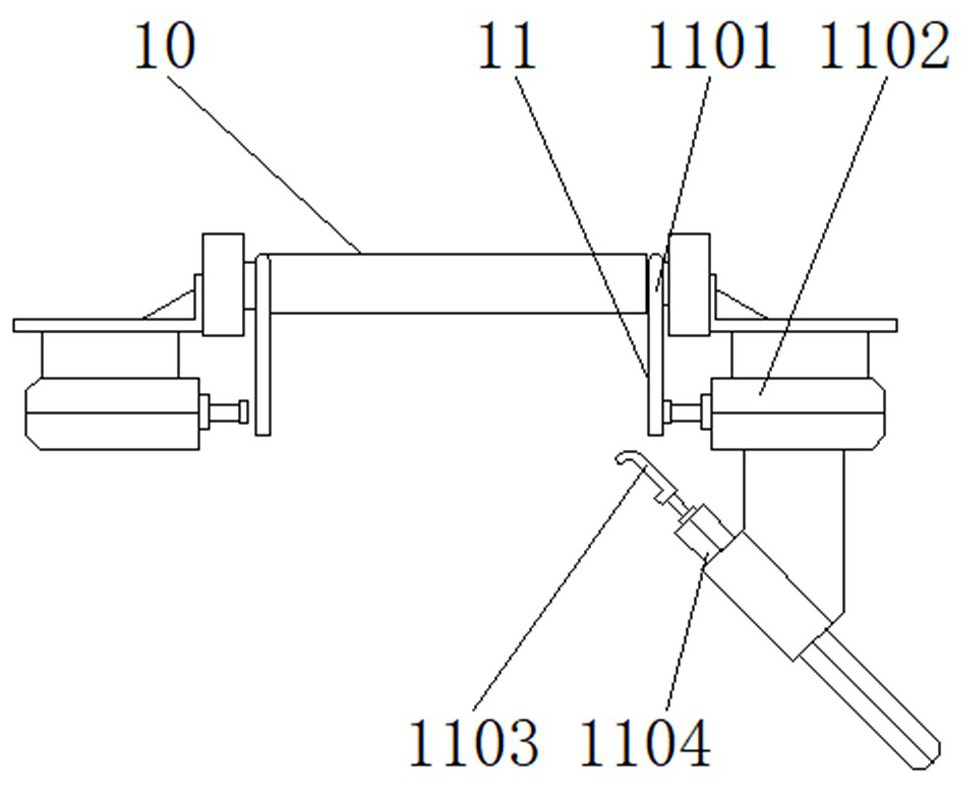

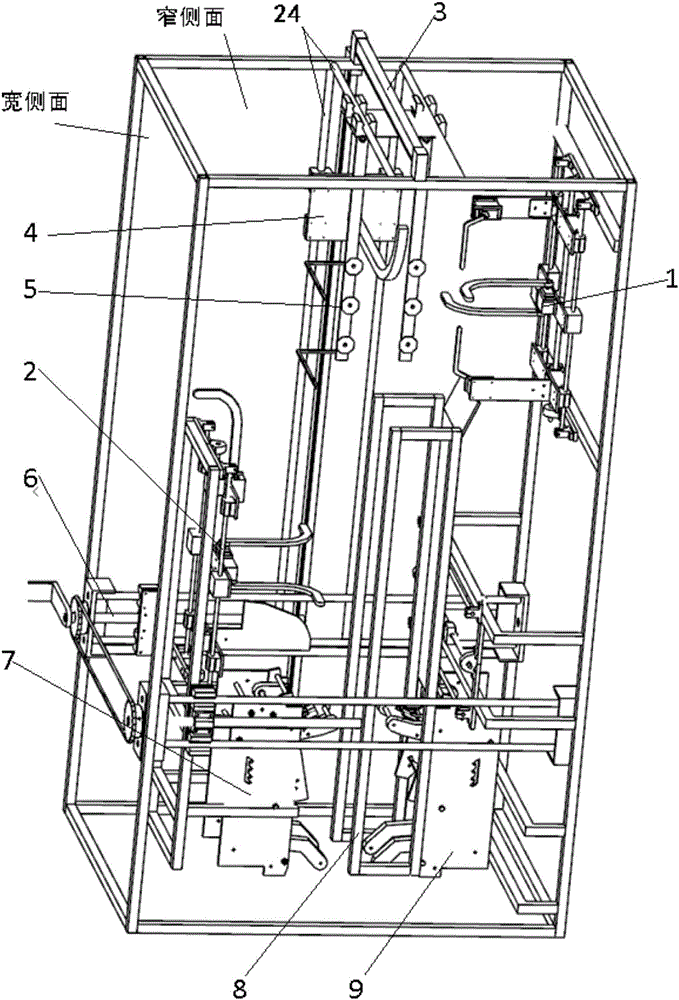

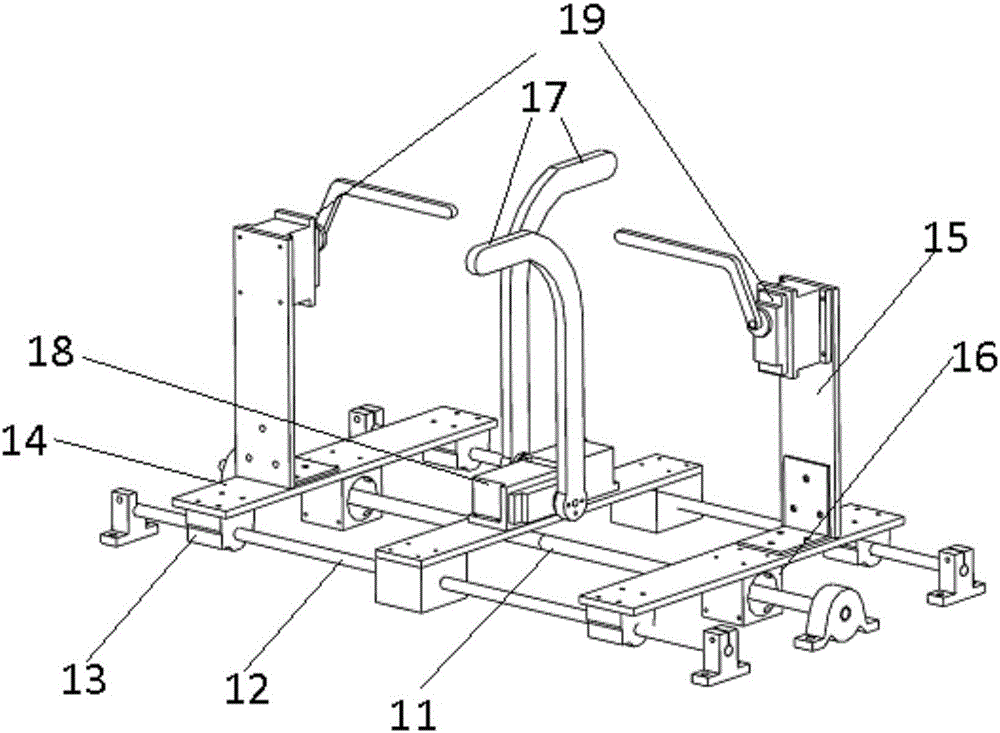

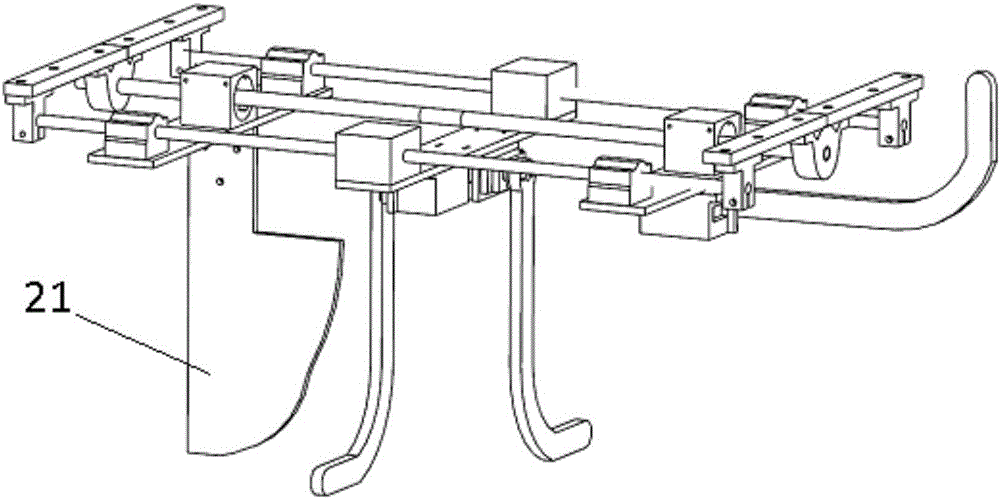

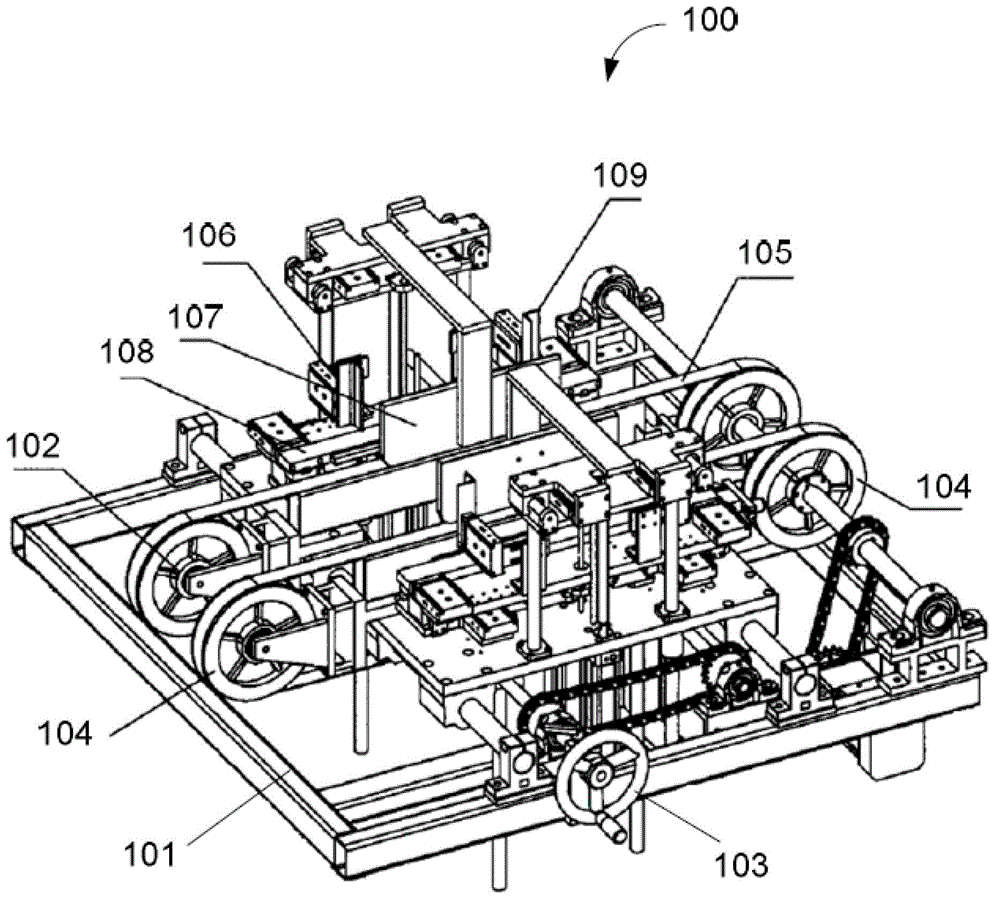

Automatic molding device of carton box

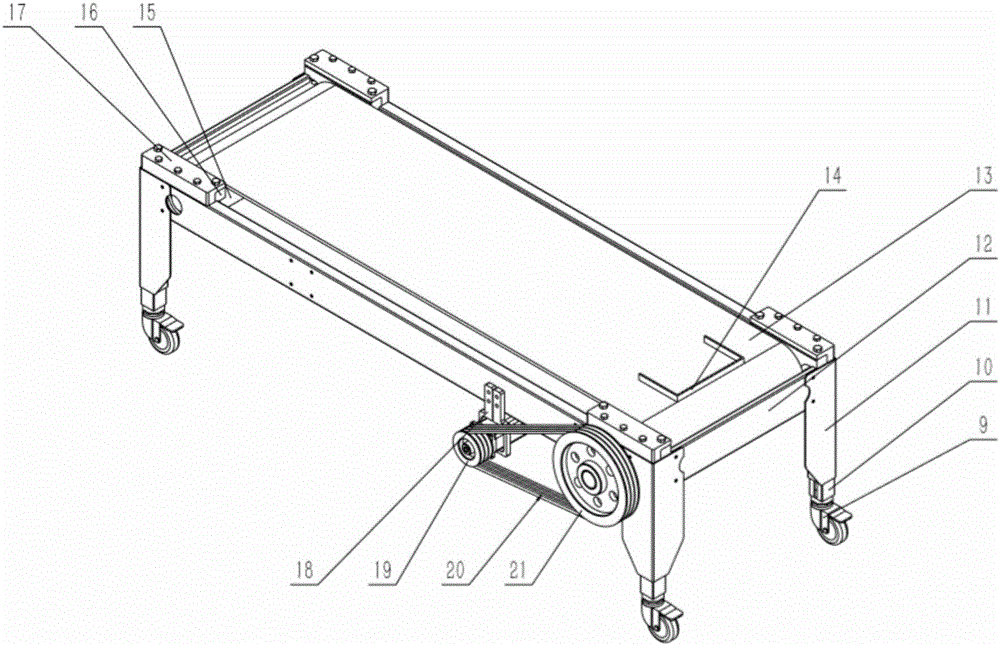

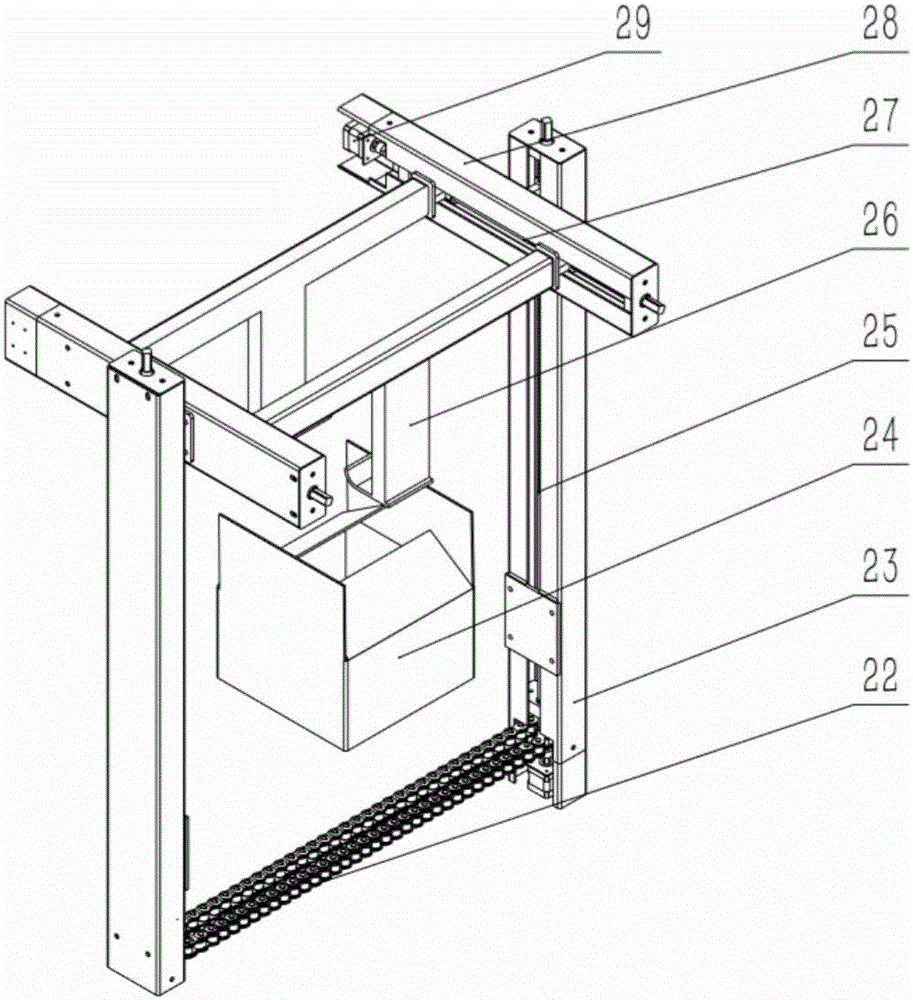

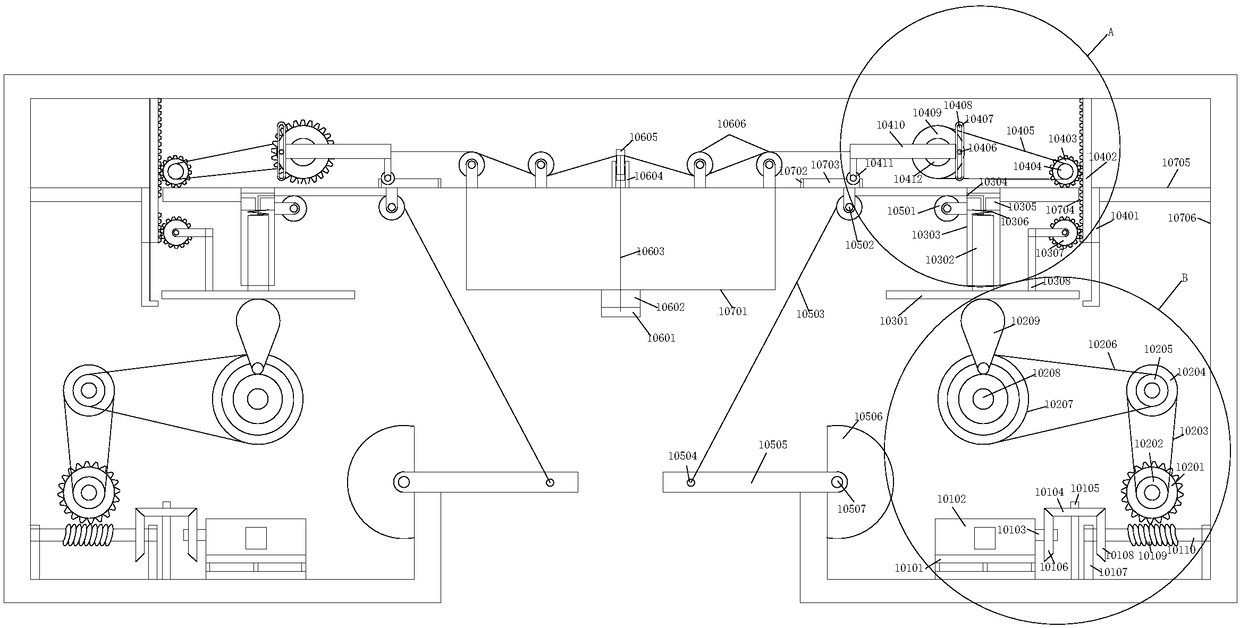

The invention provides an automatic molding device of a carton box. The device comprises a transmission device for moving the carton box along the transmission direction, a feeding device for gradually feeding the folded carton box, an initial forming device for raising one side surface of the folded carton box to form an opened carton box, a folding dispensing device for folding and molding a front cover, a rear cover, an upper cover and a rear cover of the opened carton box and dispensing to adhere to form a molded carton box, a rack and a control device; the feeding device, the initial molding device and the folding dispensing device are sequentially arranged on the rack in a sequence along the transmission direction; the control device is respectively connected with the feeding device, the initial molding device, the folding dispensing device and the transmission device through signals. With the adoption of the device, the carton box can be automatically molded, thus the labor intensity of a worker can be reduced, the labor cost can be saved, and the production efficiency can be raised.

Owner:刘银庭

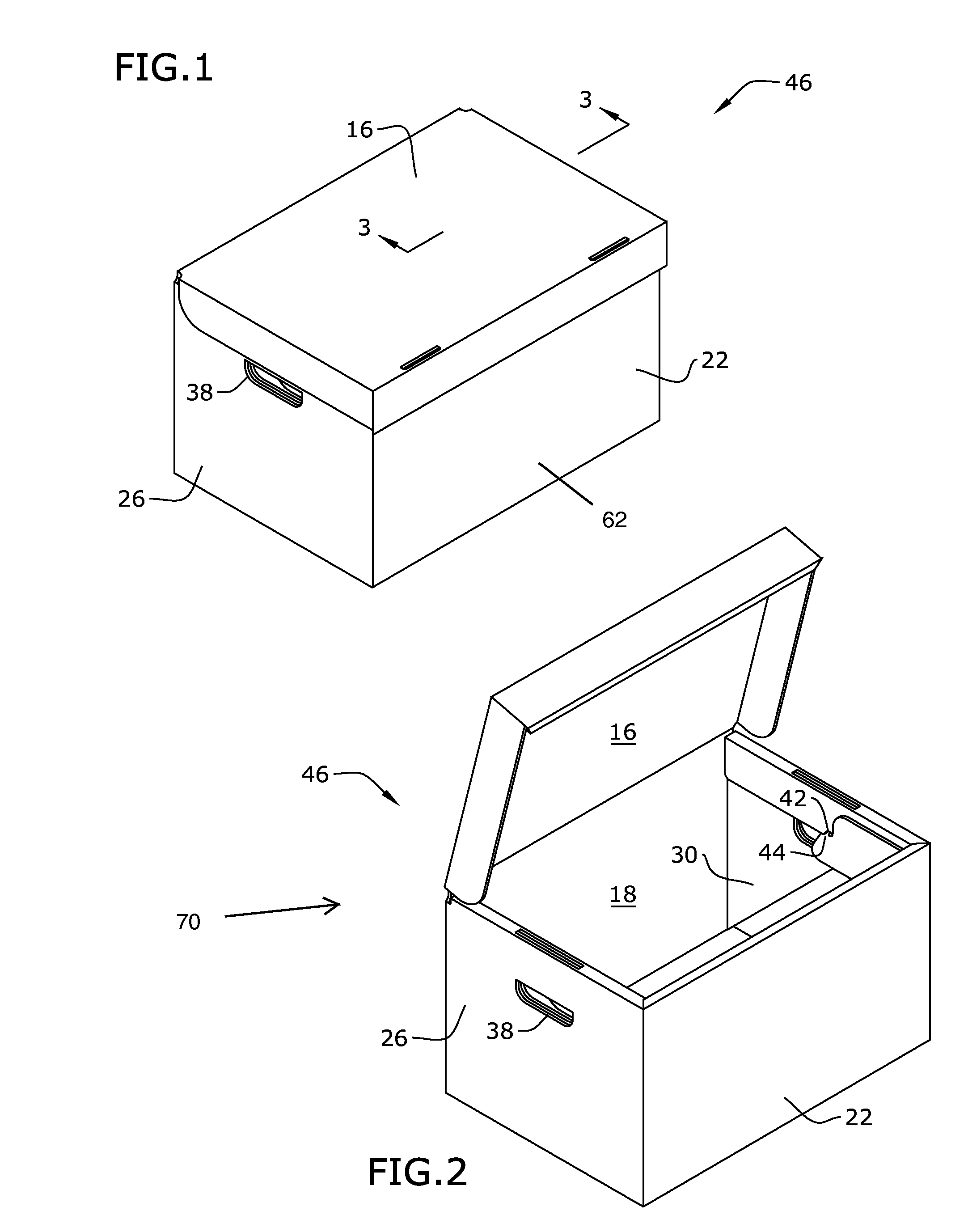

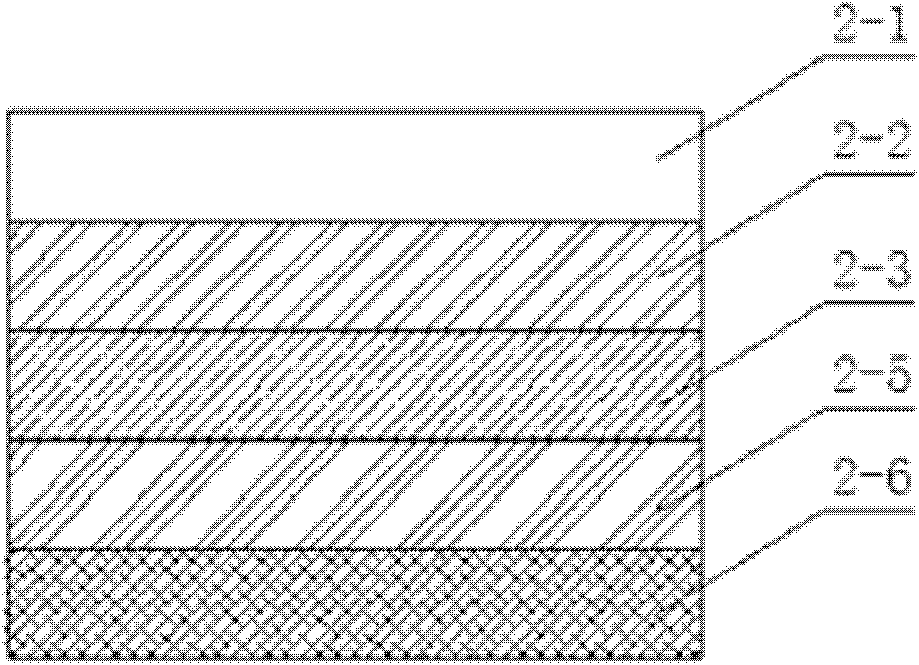

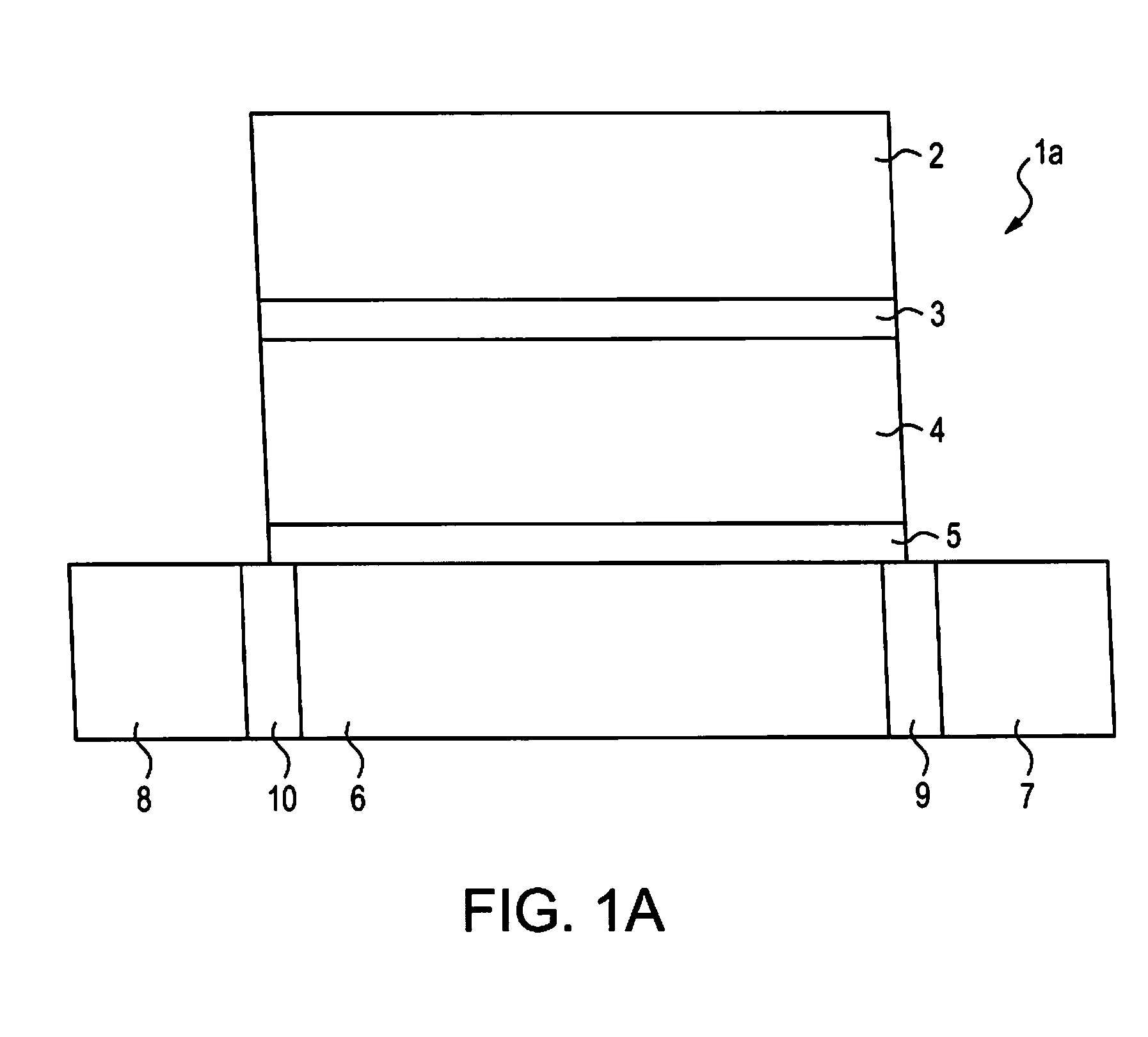

Paper-based thermal insulated container and method of manufacturing the same

InactiveUS20150336730A1Boxes/cartons making machineryDomestic cooling apparatusInter layerPaper based

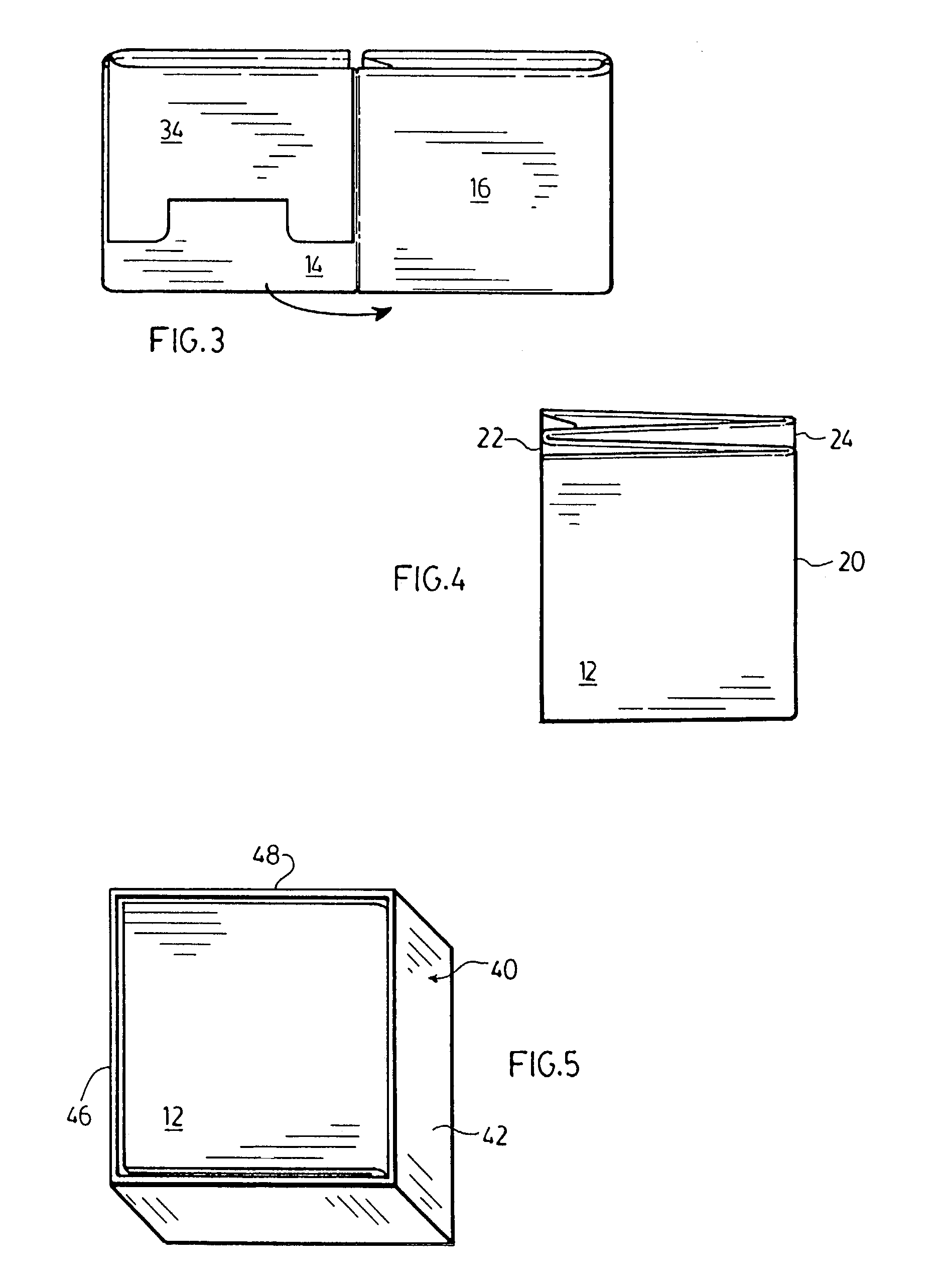

A thermal insulating container and a method of making the same is provided. The thermal insulating container may include a folded carton and a cooperating lid pivotably connected thereto by a living hinge. The thermal insulating container may be deployed by folding a flat configuration container cut-out into a three-dimensional configuration, forming the thermal insulated container. The container cutout may be die-cut from a unitary construction material formed by adhering together a paper-based interior layer, a paper-based intermediate layer and a paper-based exterior layer. The interior and intermediate layer may be coated with water-resistant coating. The paperboard outside liner may be treated with a UV-coating as well as provided with predetermined graphic printing.

Owner:SHIELDS DOUGLAS ARTHUR

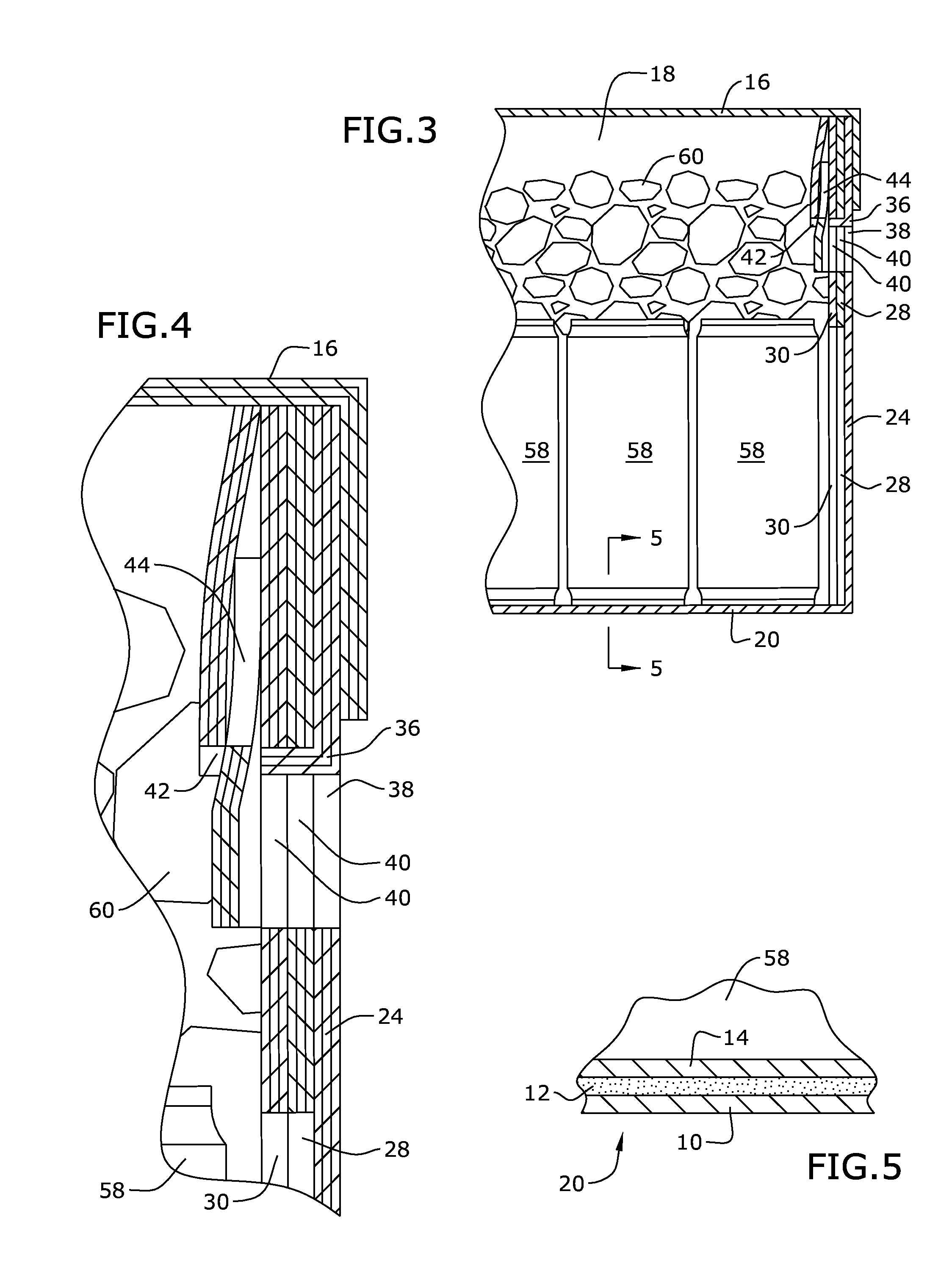

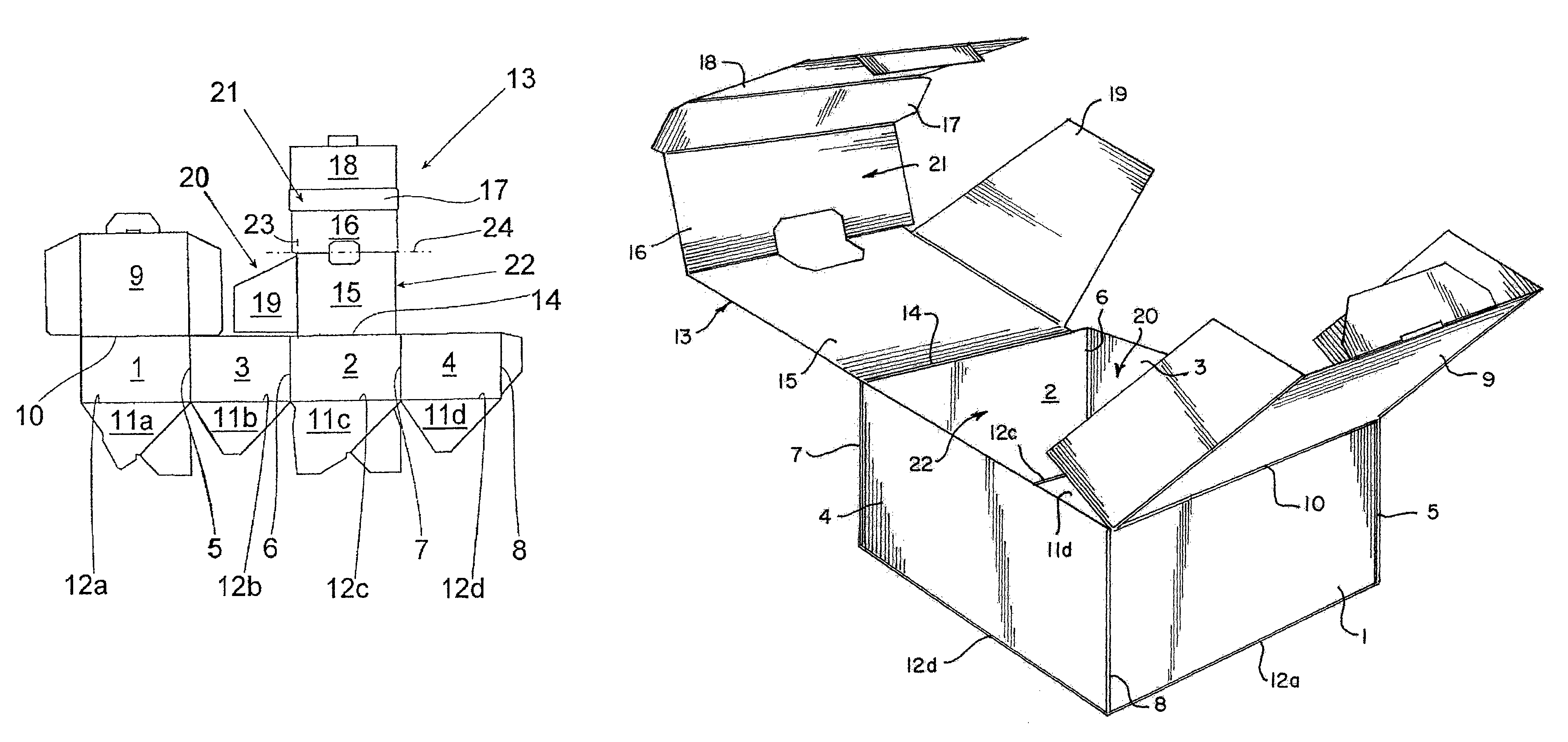

Folding carton and corresponding manufacturing machine

InactiveUS7992764B2Reduce complexityBox making operationsRigid containersEngineeringMechanical engineering

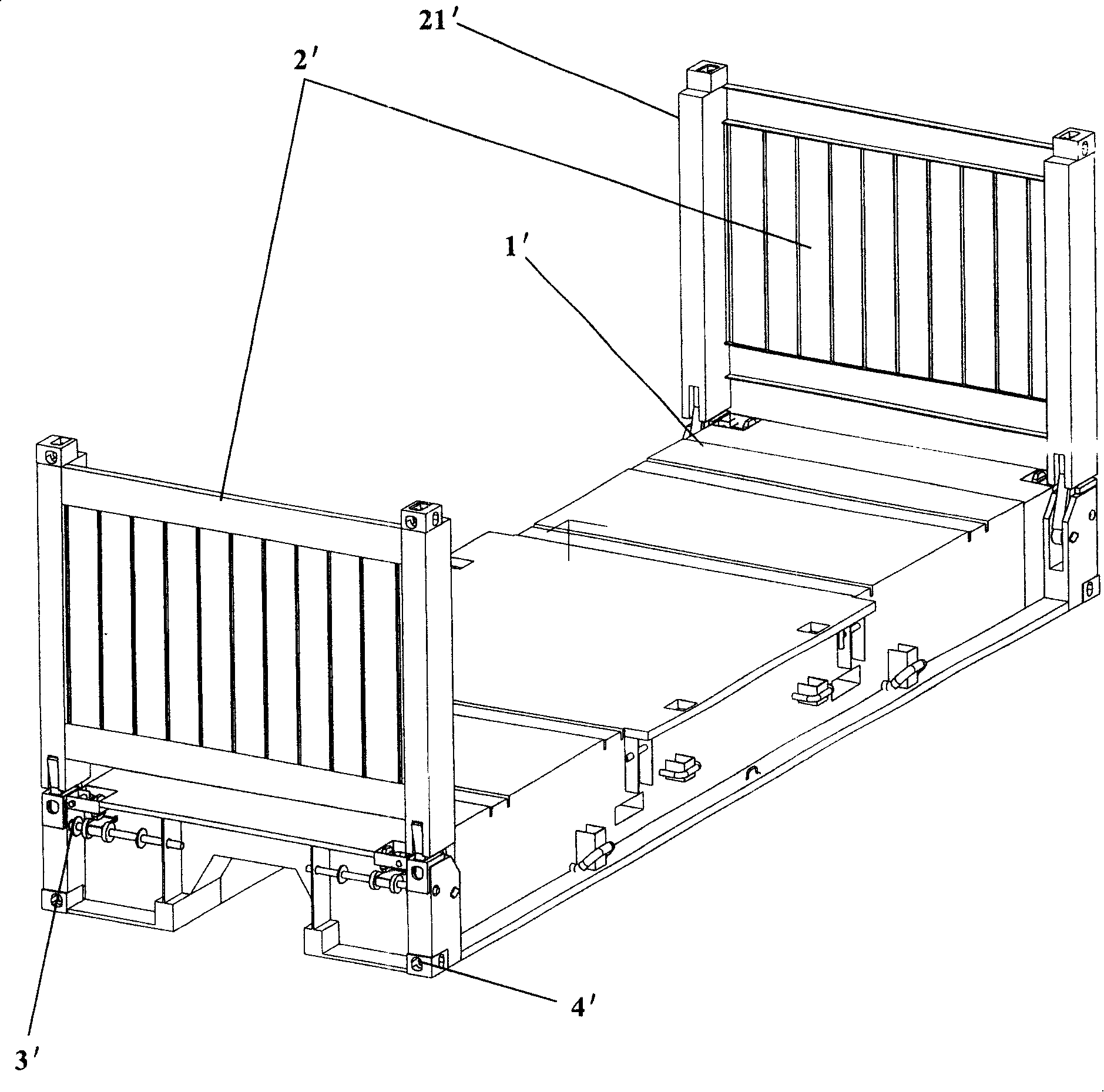

The invention relates to a folding carton for the preservation and for the transport of goods with a reduced complexity, comprising a front wall element, a rear wall element, side wall elements connected to the front wall element and to the rear wall element by fold lines, a lid connected to the front wall element by a fold line, a base connected to at least one of the front wall element, the rear wall element and the side wall elements by a fold line and a separation flap element connected to one of the rear wall element and the side wall elements by a fold line, wherein the separation flap element comprises a plurality of flap sections, the flap sections by folding being arranged relative to each other in such a way that at least three compartments are formed.

Owner:RPX CORP

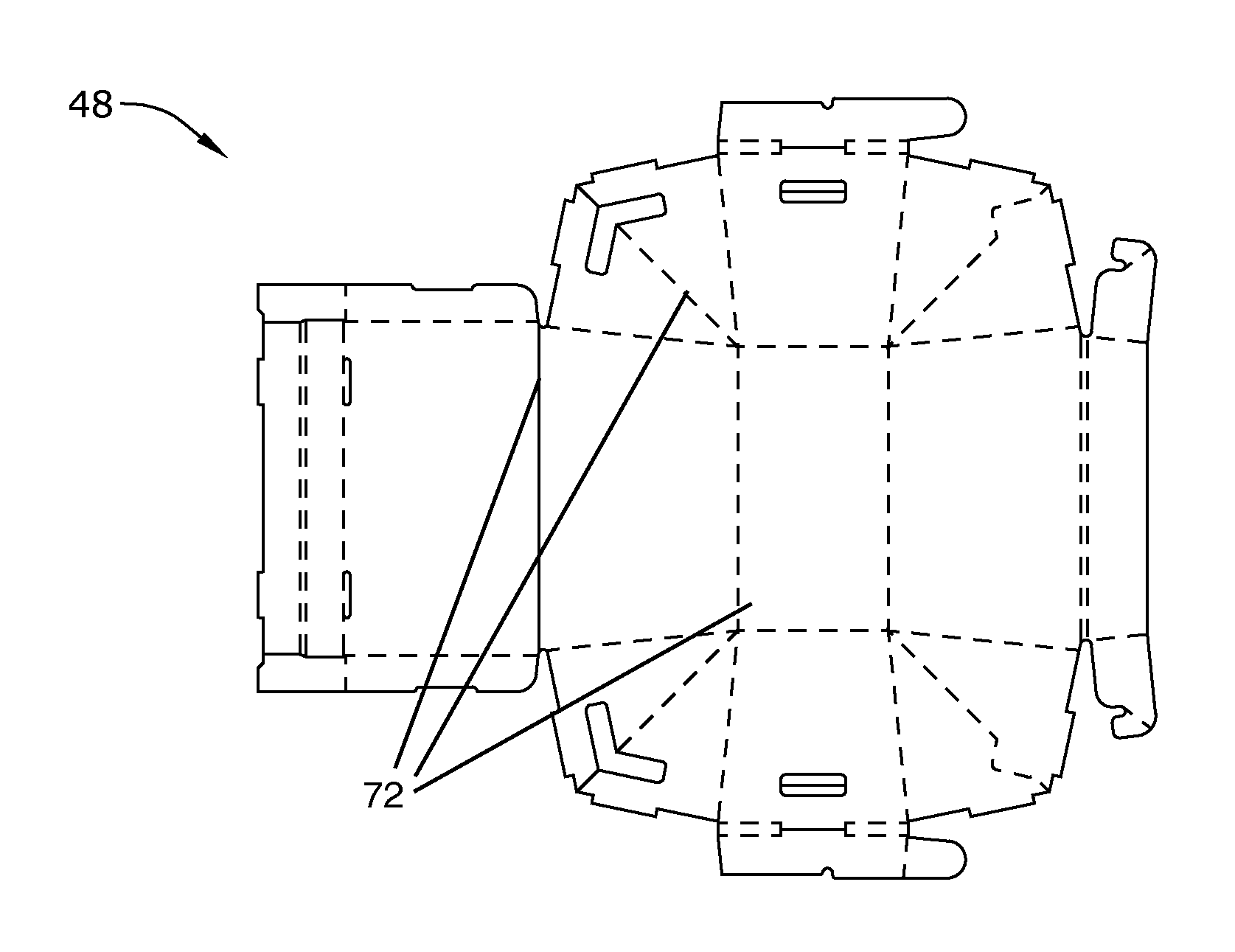

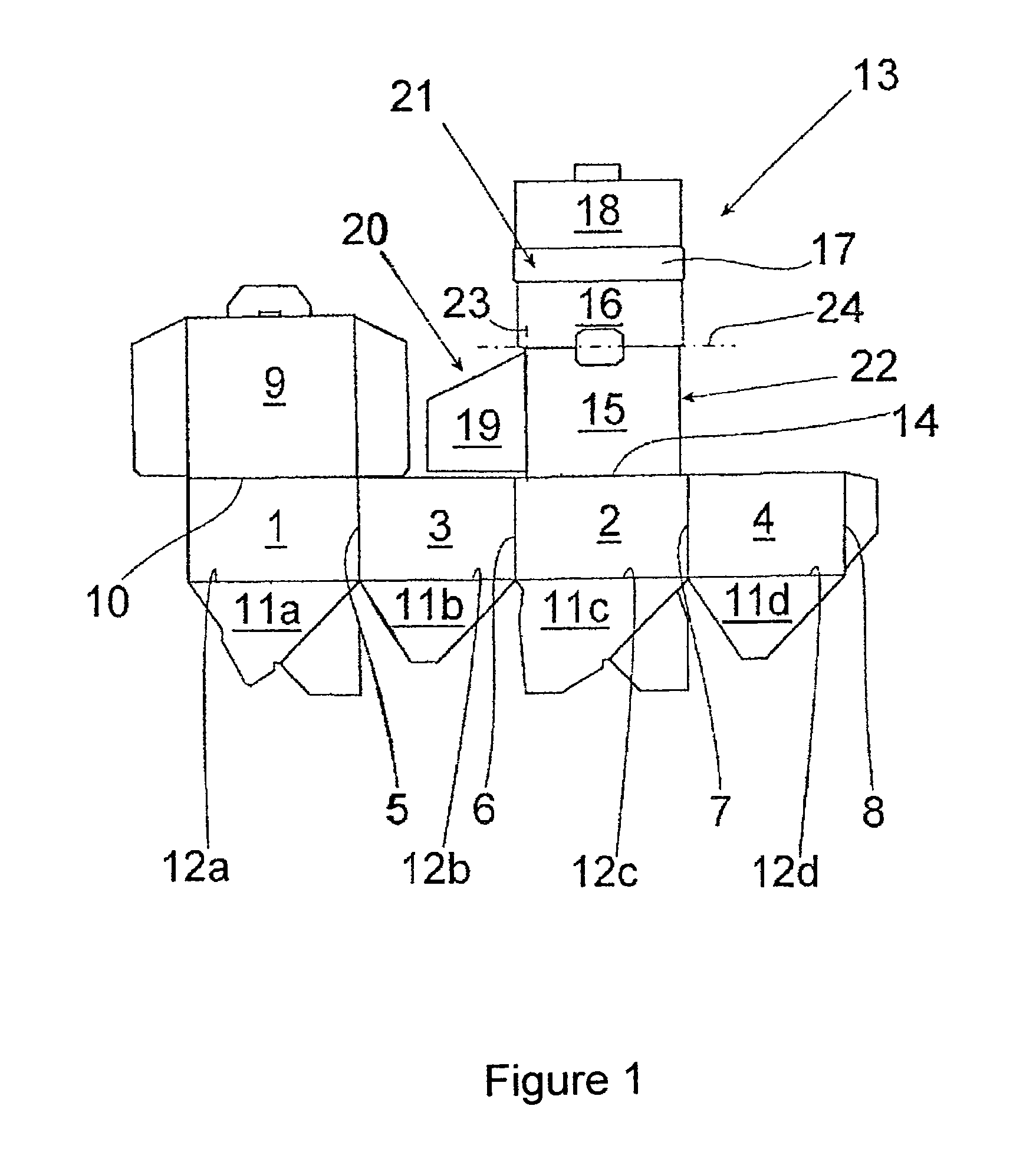

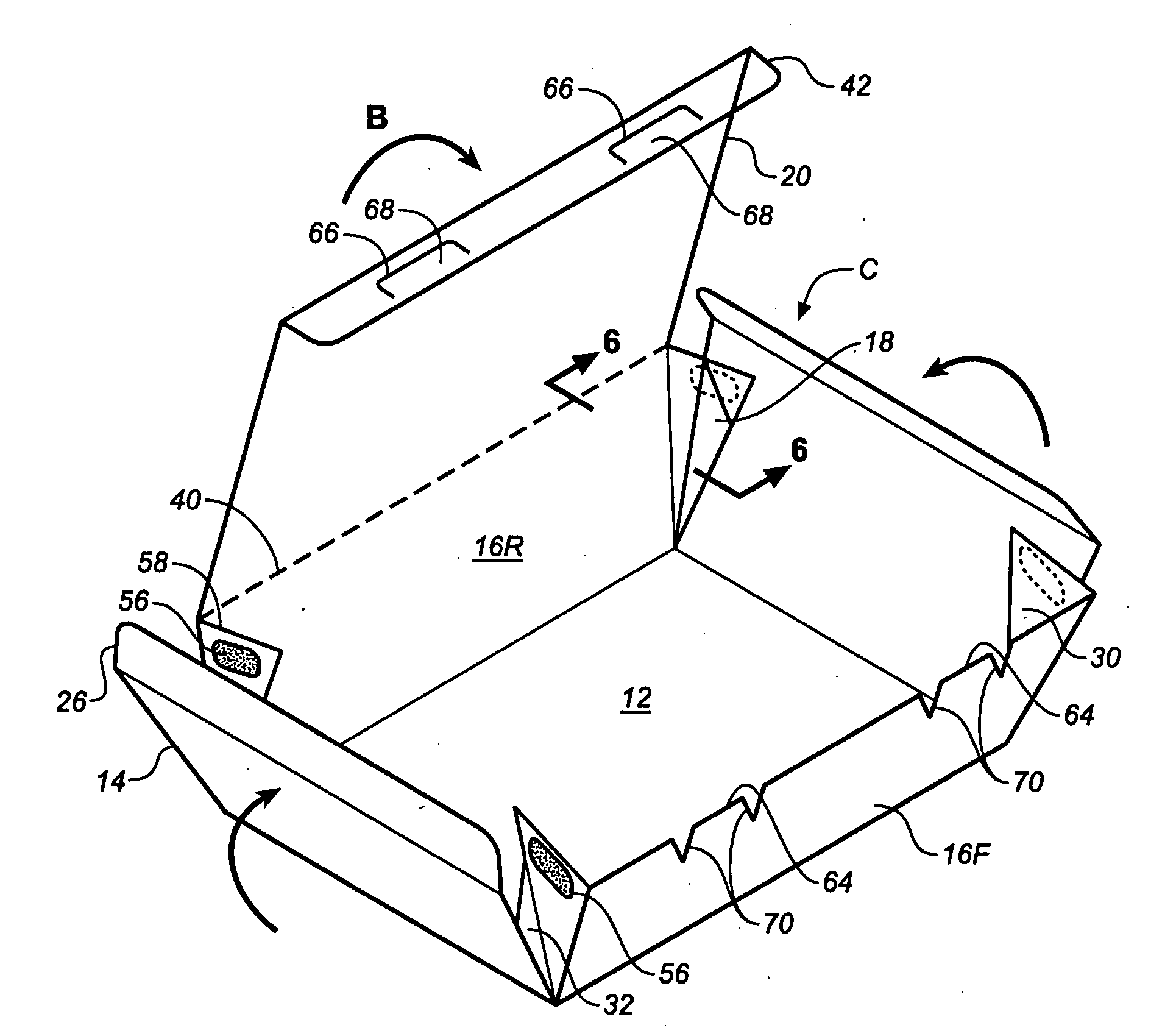

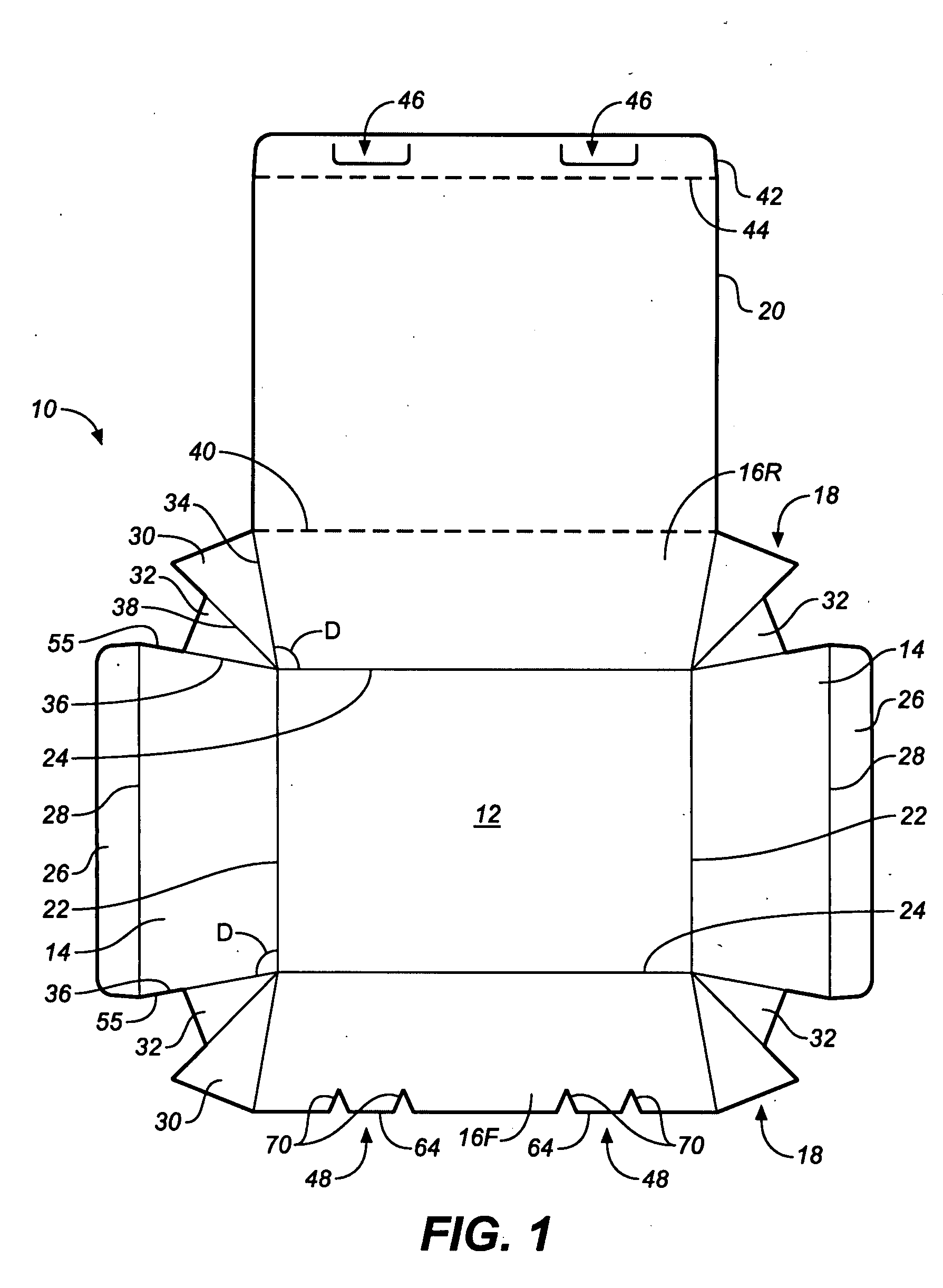

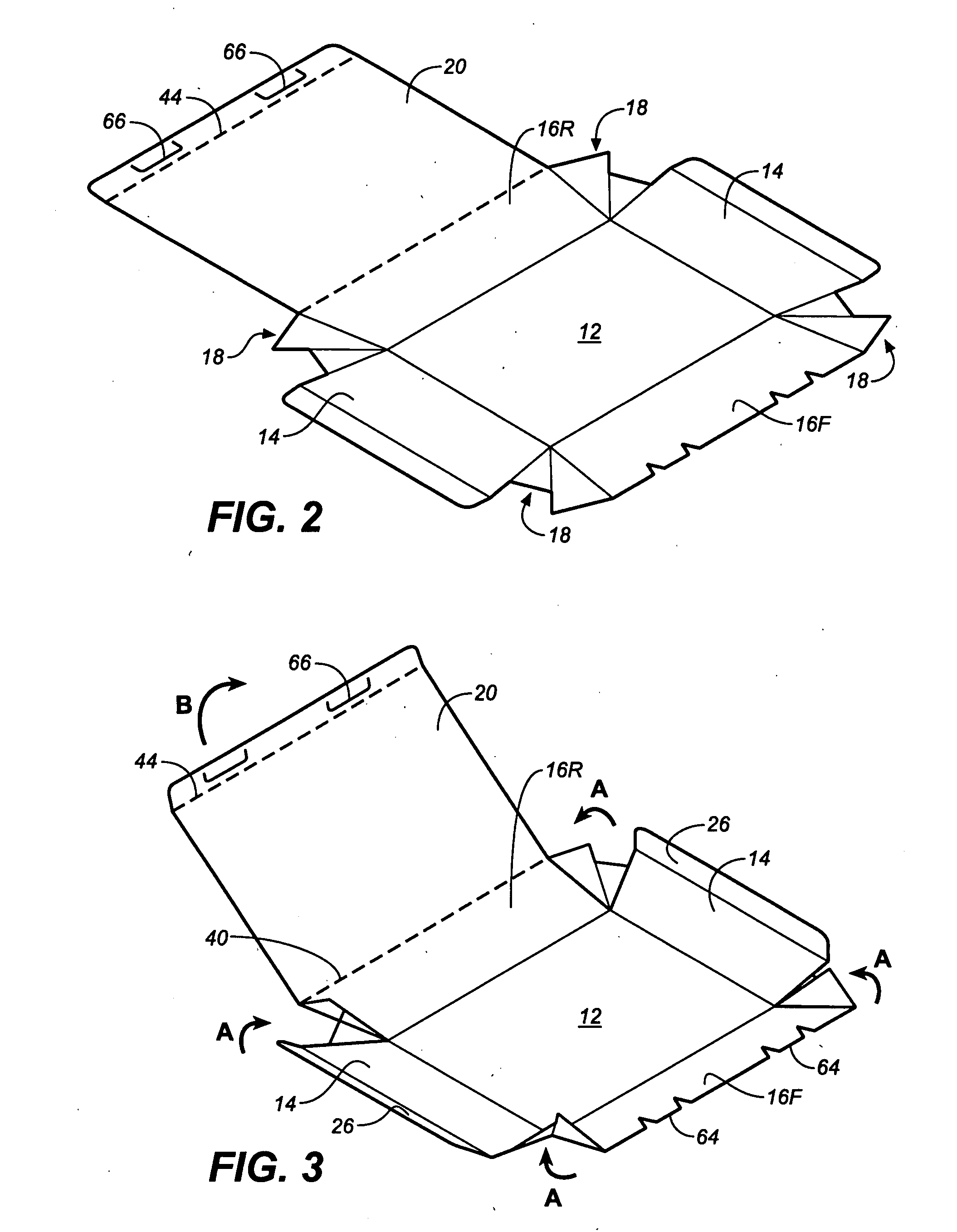

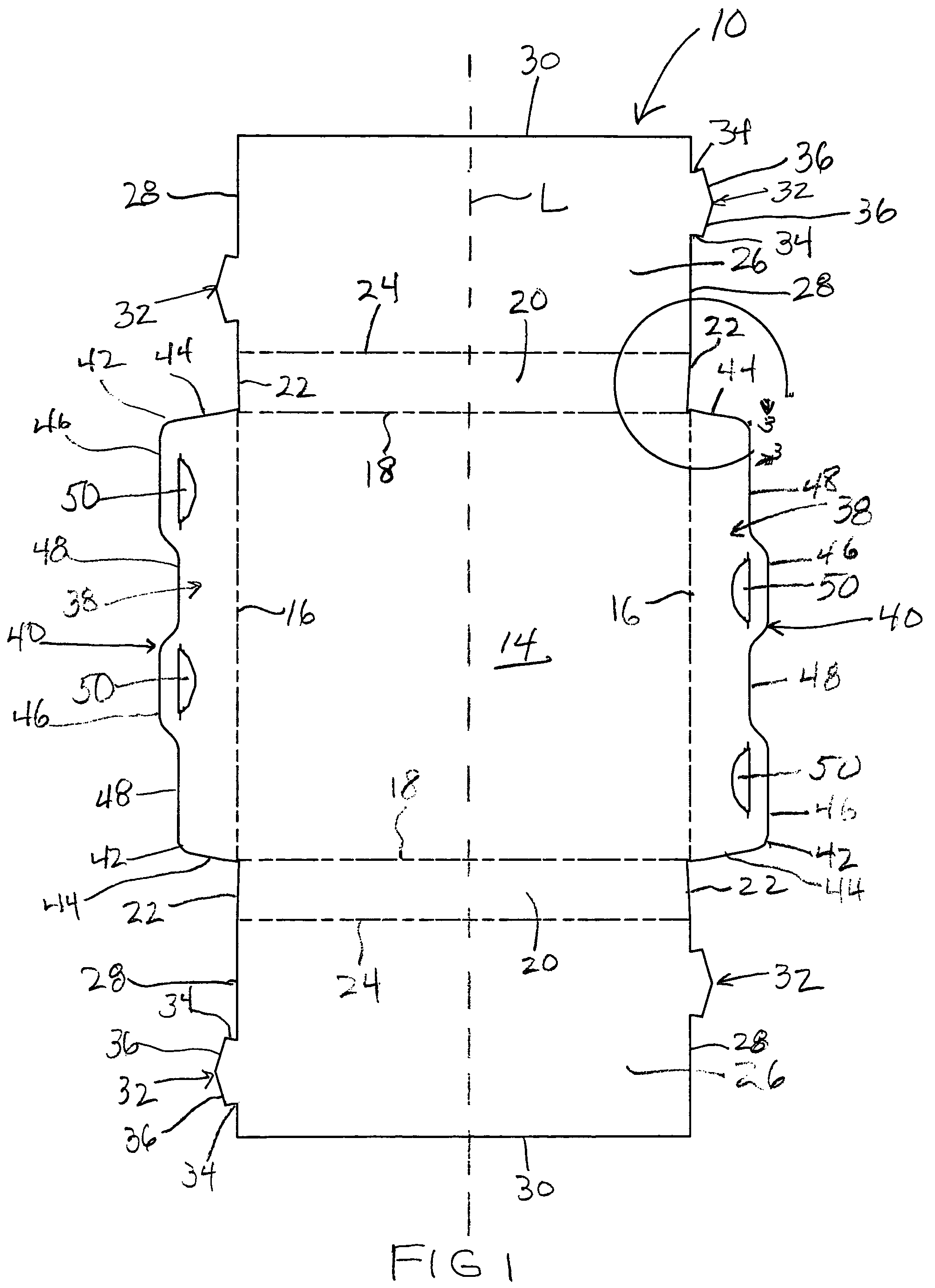

Folded food carton

InactiveUS20090039144A1Good adhesionRigid containersEngineeringElectrical and Electronics engineering

A folded food carton comprises a bottom panel 12, two opposing end panels 14, two opposing side panels 16, four gussets 18, and a top panel 20. Each adjoining pair of end and side panels 14, 16 is hingedly interconnected by one of the gussets 18 each of which includes first and second gusset panels 30, 32. In a fully folded carton configuration, the upper portion 50 of the first gusset panel 30 extends above the upper edge 52 of the second gusset panel 32 and is heat sealed to the inside surface of one of the end panels 14 such that the folded carton presents exterior panel surfaces unbroken by gussets. The top panel 20 folds over the cavity C of the folded carton and is secured in closed position by a tuck flap 42 having slot mechanisms 46 which engage with the upward-extending tabs 64 of flap mechanisms 48.

Owner:HOOI KOON H +2

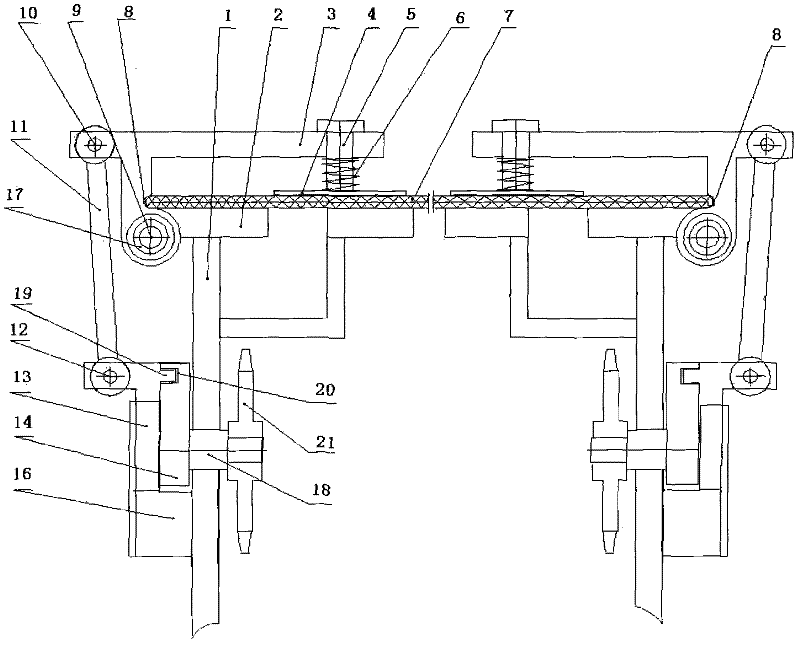

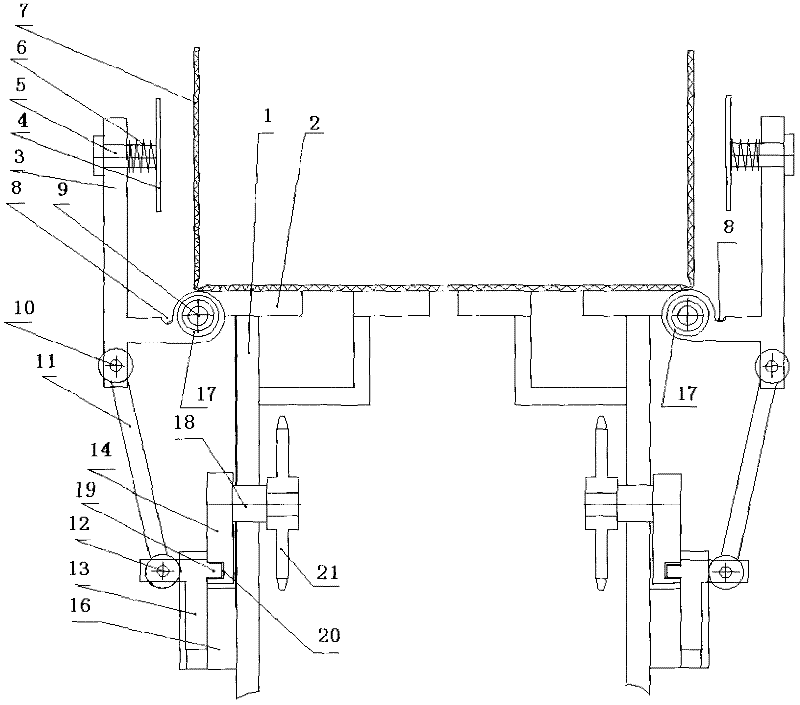

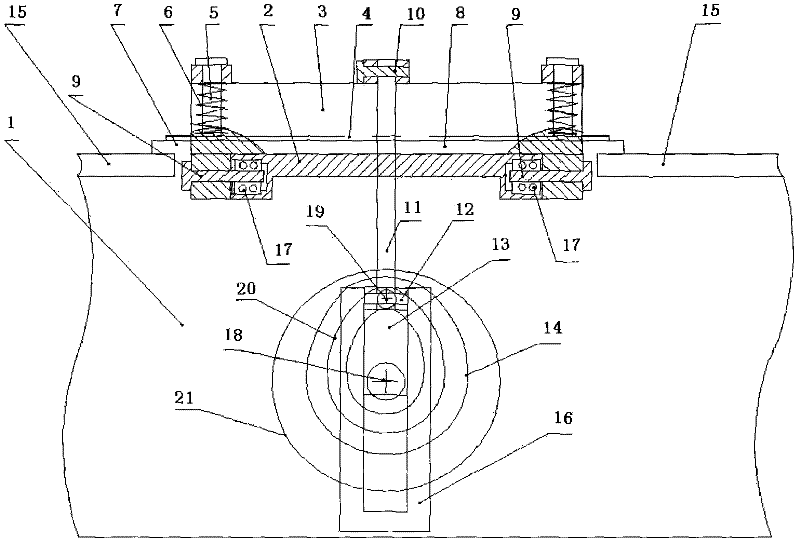

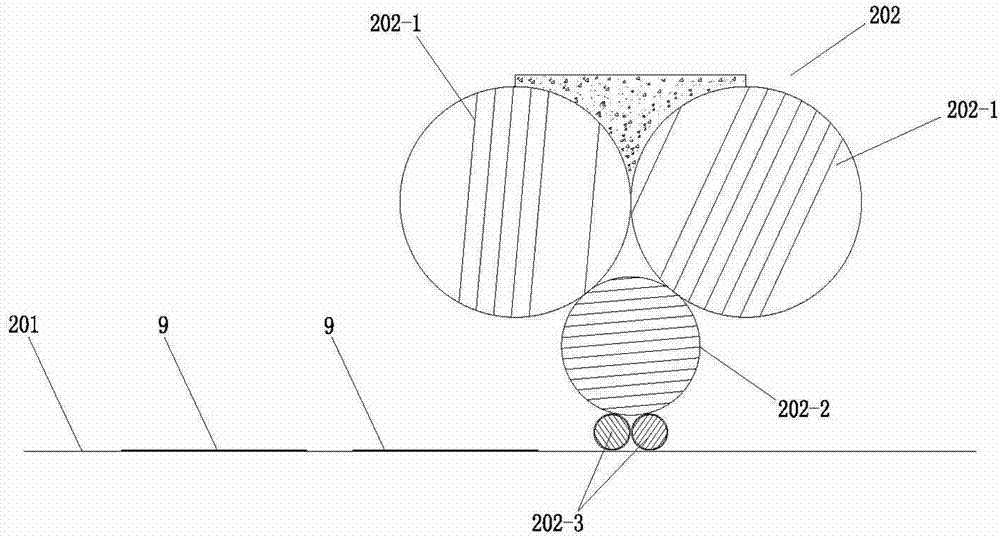

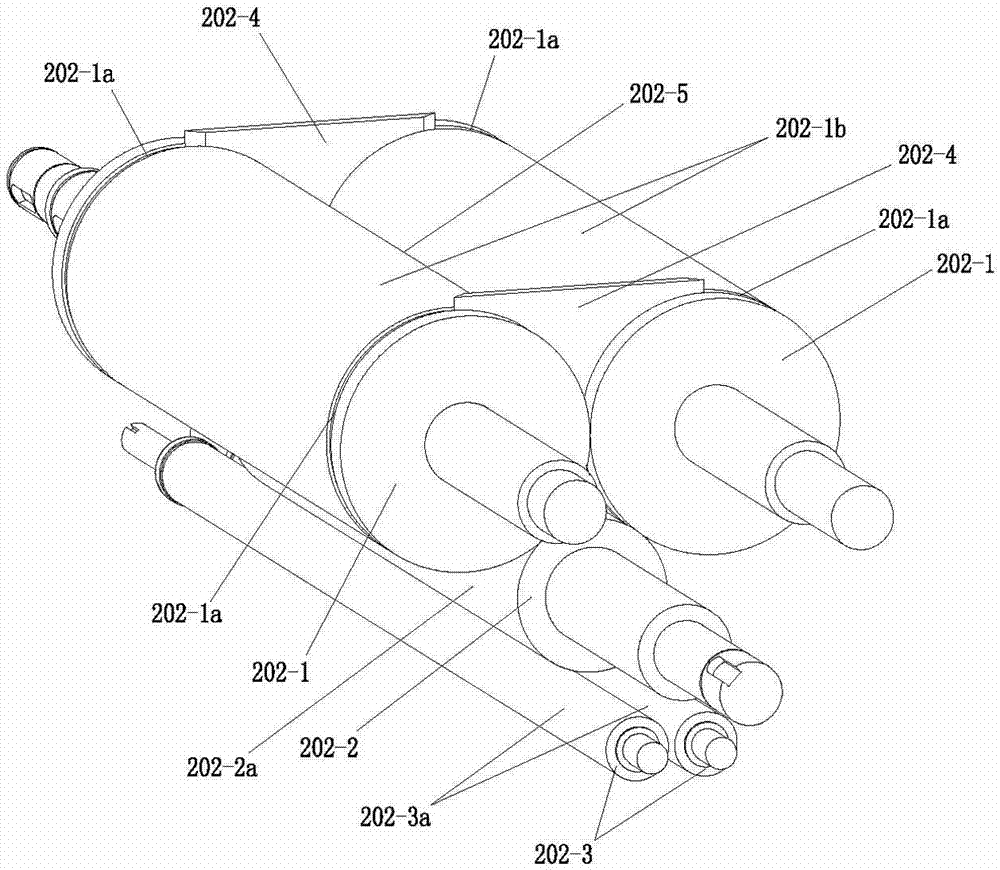

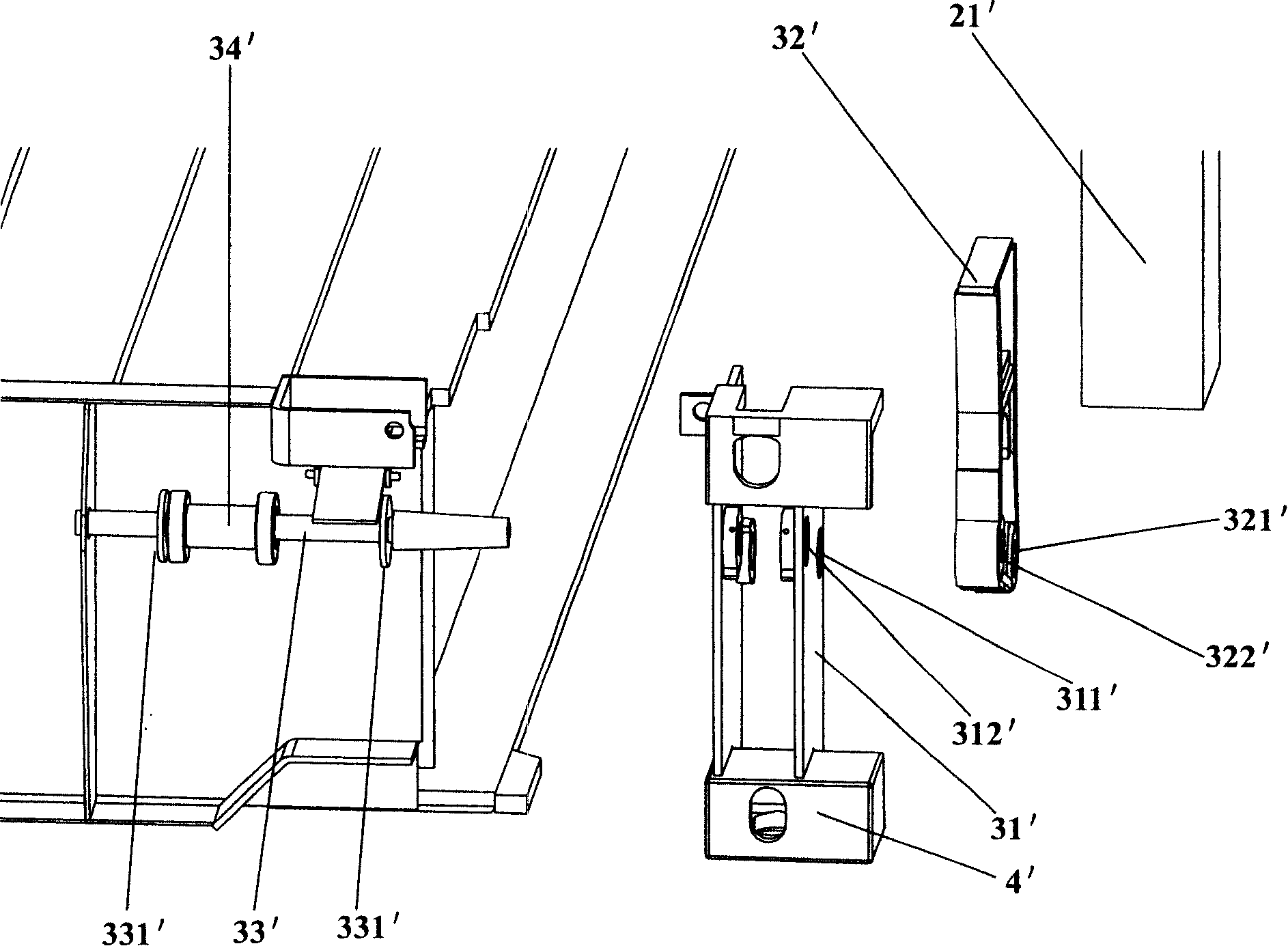

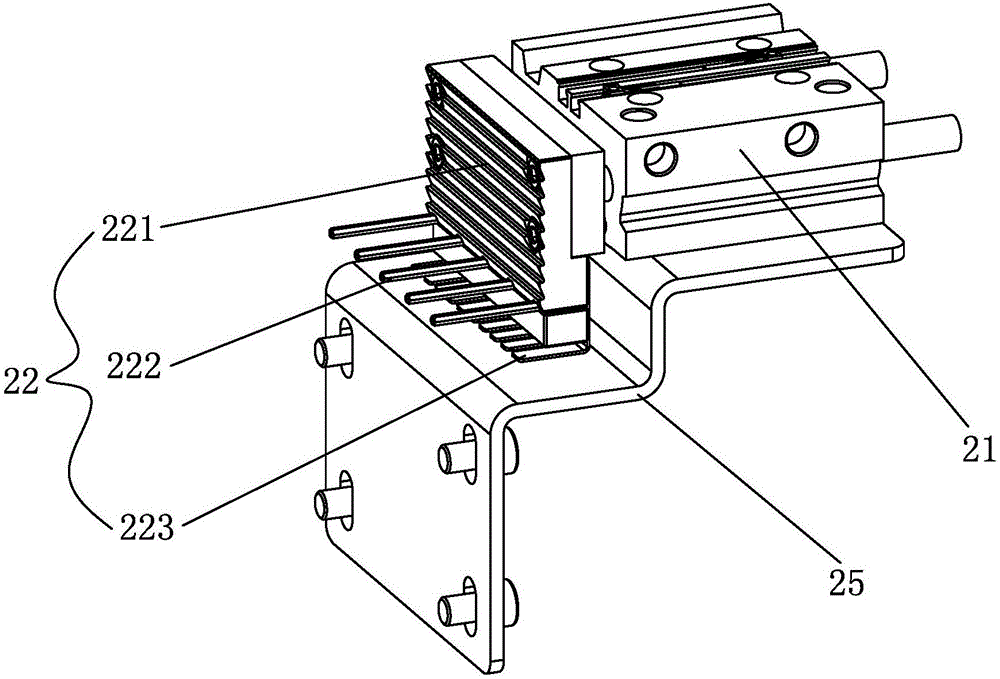

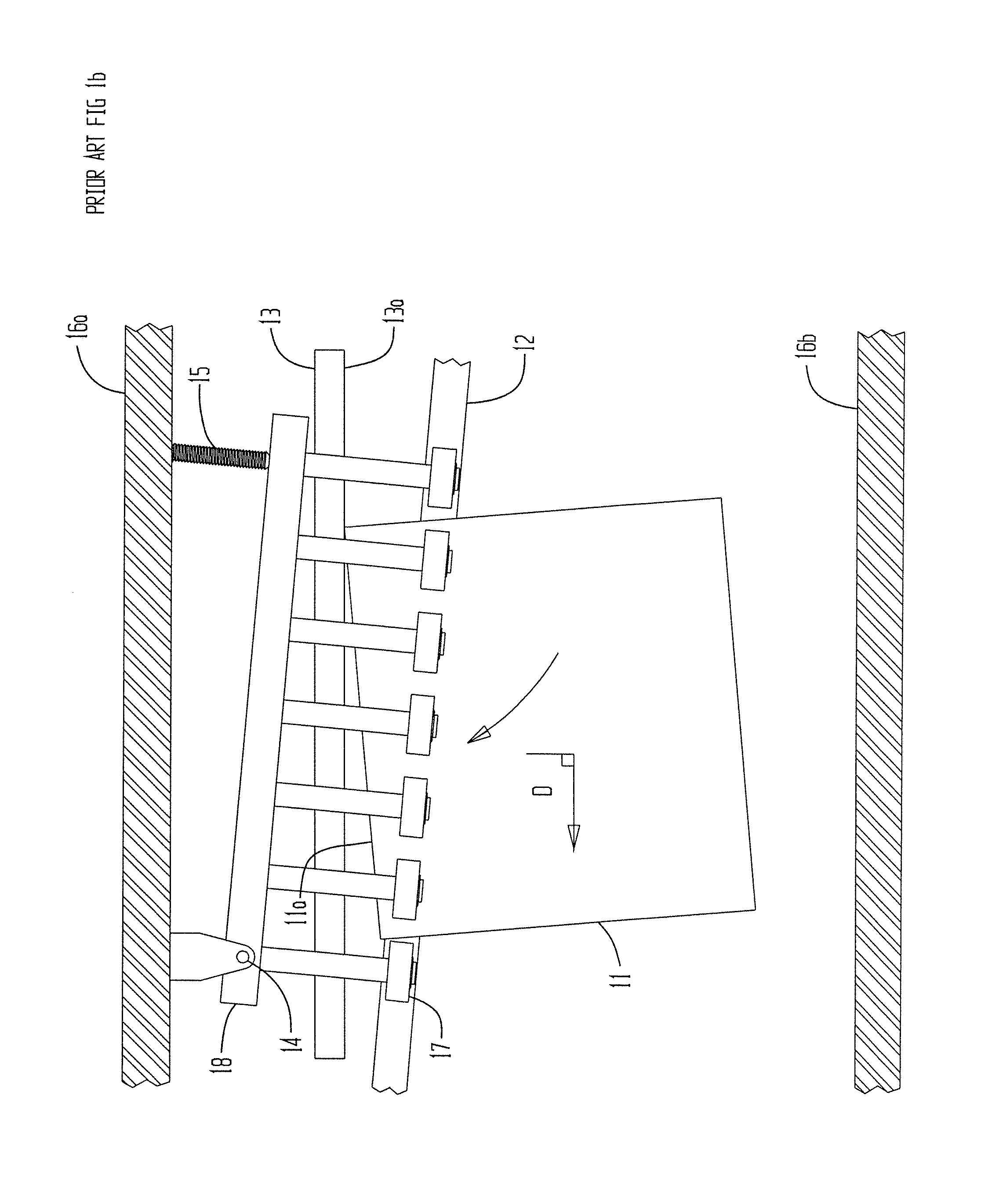

Directional automatic folding device for corrugated carton gluing machines

InactiveCN102343688AGeometrically accuratePrecise positioning of geometric dimensionsContainer making machineryCardboardEngineering

The invention discloses a directional automatic folding device for corrugated carton gluing machines. The device comprises a paper pressing assembly and a moving connection assembly, wherein the paper pressing assembly comprises a folding substrate, a folding support arm, a sliding shaft and a paper pressing plate which are sequentially connected; the moving connection assembly comprises a connecting bar, a slide block and an eccentric cam which are sequentially connected; and the folding substrate is arranged at the upper end of an external side guide seat of a corrugated carton gluing machine, and the eccentric cam is arranged on the outside of the external side guide seat of the corrugated carton gluing machine. The directional automatic folding device disclosed by the invention replaces the traditional belt continuous rolling and folding, the stressed area of a folded carton is large and equalized in exerted force; the folded carton moves along a preset direction, thus being precisely positioned, and no scissors gap and 'fishtail' phenomenon is generated; and a corrugated carton can have a precise geometric size, thereby meeting the need for large-scale and automatic production of the packaging industry.

Owner:施从高

Automatic cover folding carton sealer

Owner:ZHEJIANG SCI-TECH UNIV

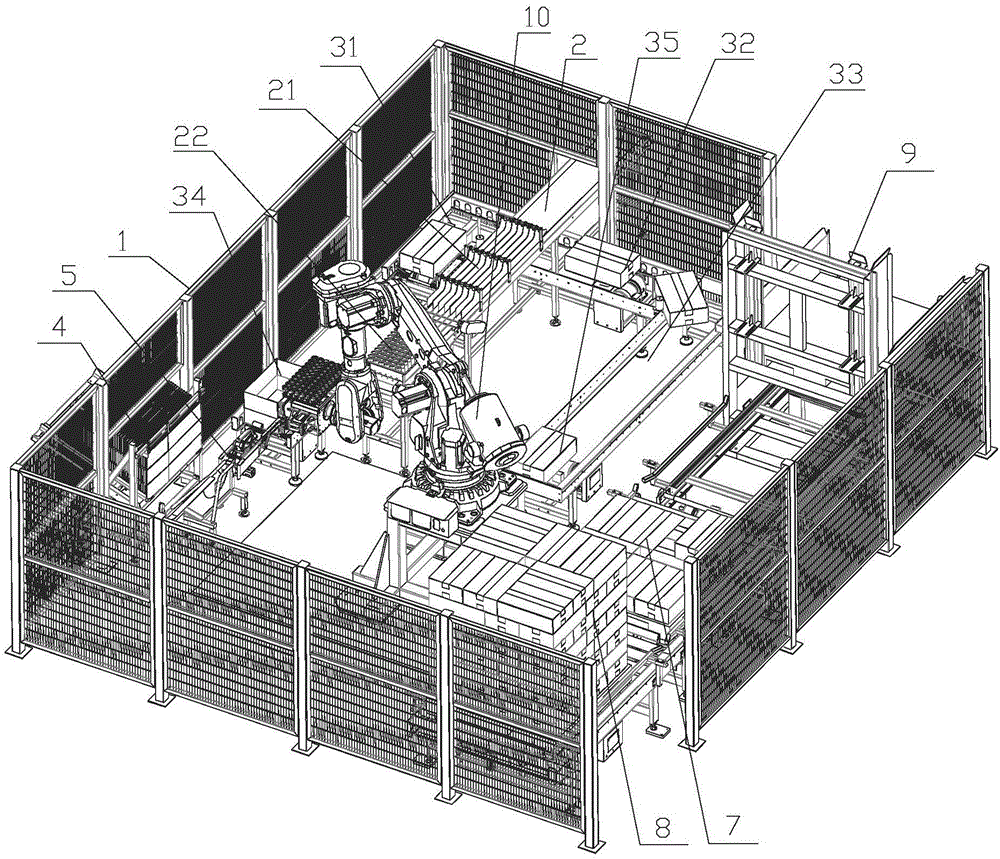

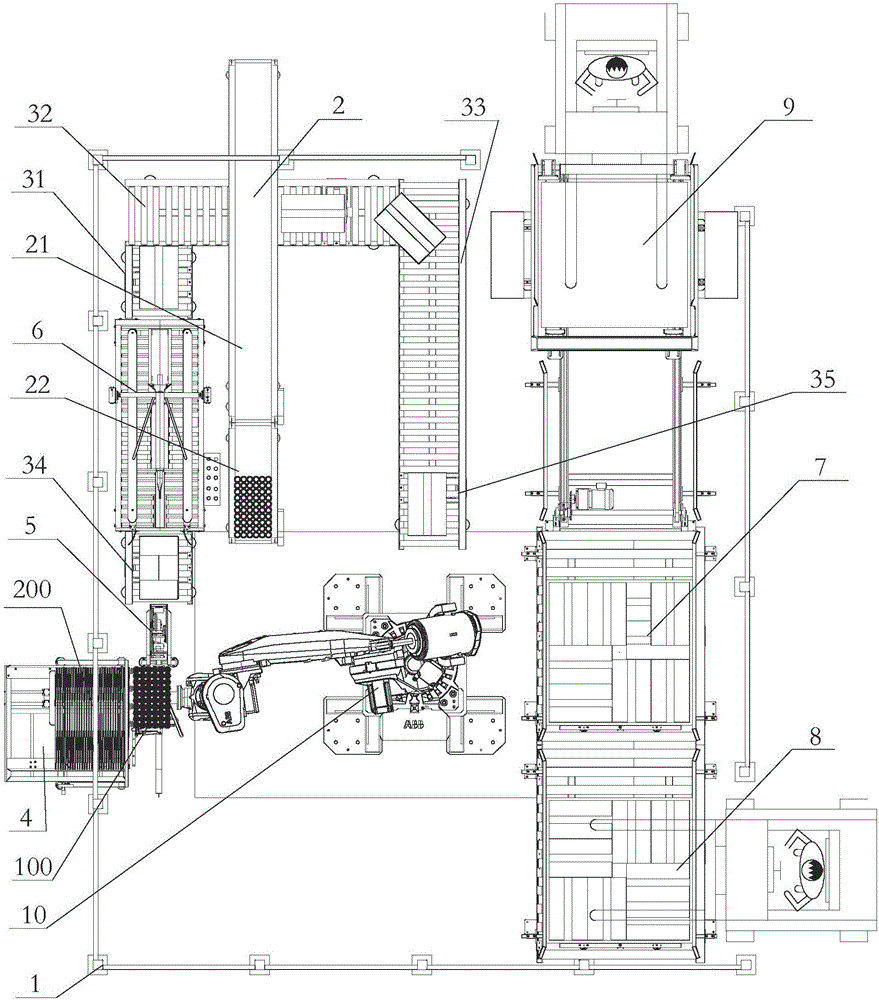

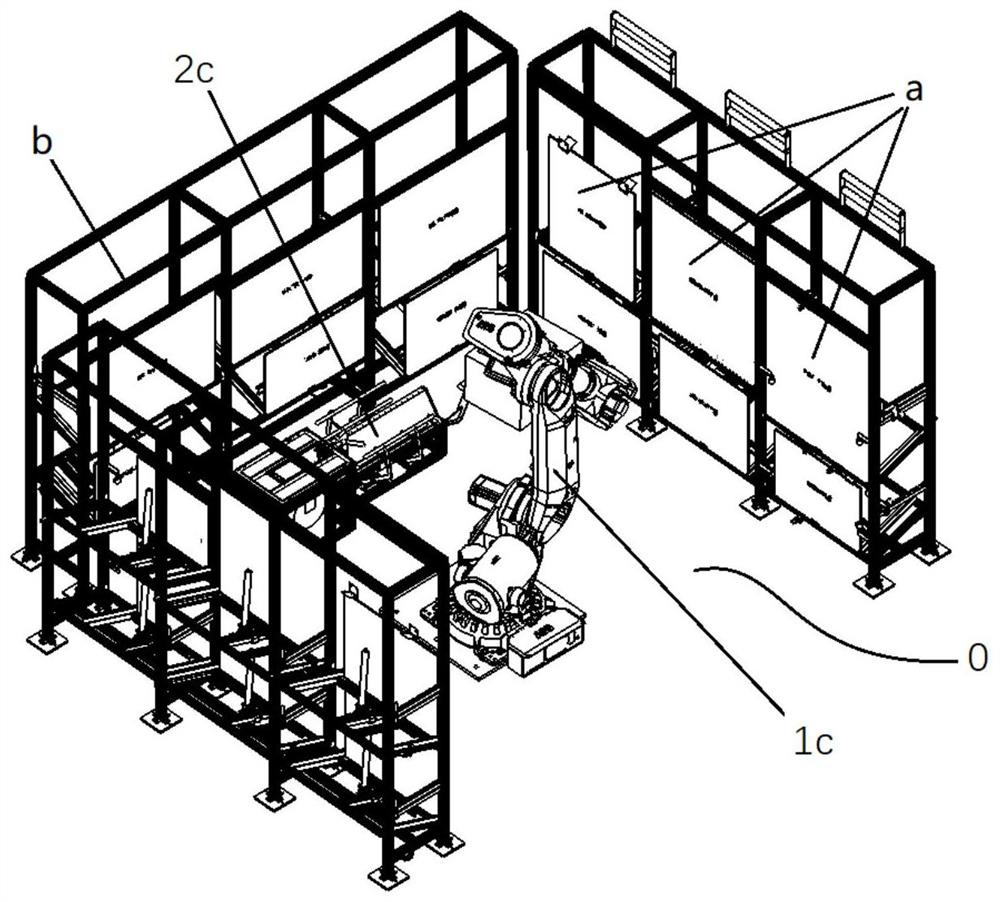

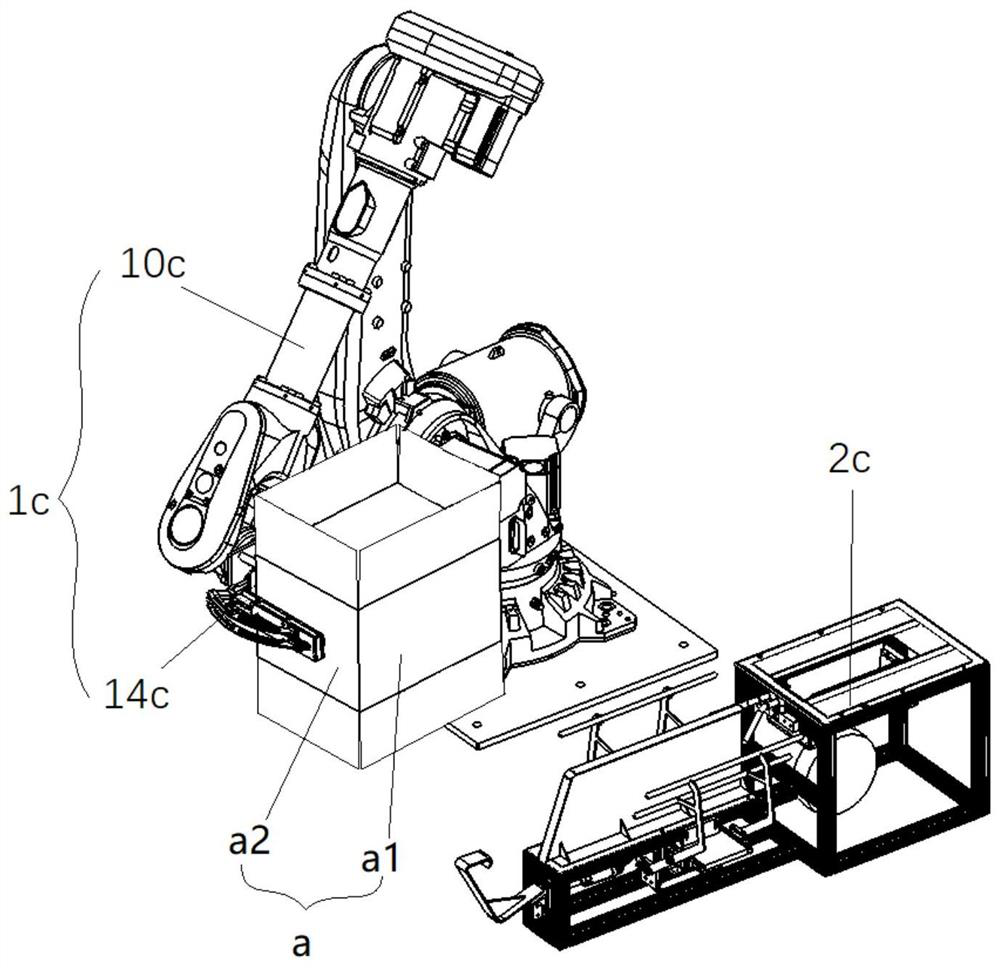

Carton opening, carton loading and stacking all-in-one machine with robot

The invention discloses a carton opening, carton loading and stacking all-in-one machine with a robot. The carton opening, carton loading and stacking all-in-one machine with the robot is arranged in an operation area enclosed by a guardrail and comprises a product conveying line, a transition line, a carton feeder, a carton bottom sealer, a cover-folding carton sealer, a stacking station, a discharge station and the robot, wherein the product conveying line comprises a product arrangement station and a product positioning and gripping station, the transition line comprises a front transition line segment, a transverse transition line and a rear transition line segment, a carton loading station is arranged on the head portion of the front transition line segment, a stacking and gripping station is arranged on the head portion of the rear transition line segment, the carton feeder is arranged in a carton inlet hole in the left sidewall of the guiderail, the carton bottom sealer is mounted at the front end of the front transition line segment, the cover-folding carton sealer is mounted above and behind the carton loading station, the stacking station and the discharge station are arranged in the front right of the operation area, the robot is mounted in the front center of the operation area, and carton opening and stacking suckers, carton loading suckers and a folding fixing sucker are arranged on a gripper of an arm of the robot. The carton opening, carton loading and stacking all-in-one machine with the robot is high in automation degree and needs no human intervention.

Owner:SHANGHAI XINGPACK AUTOMATION CO LTD

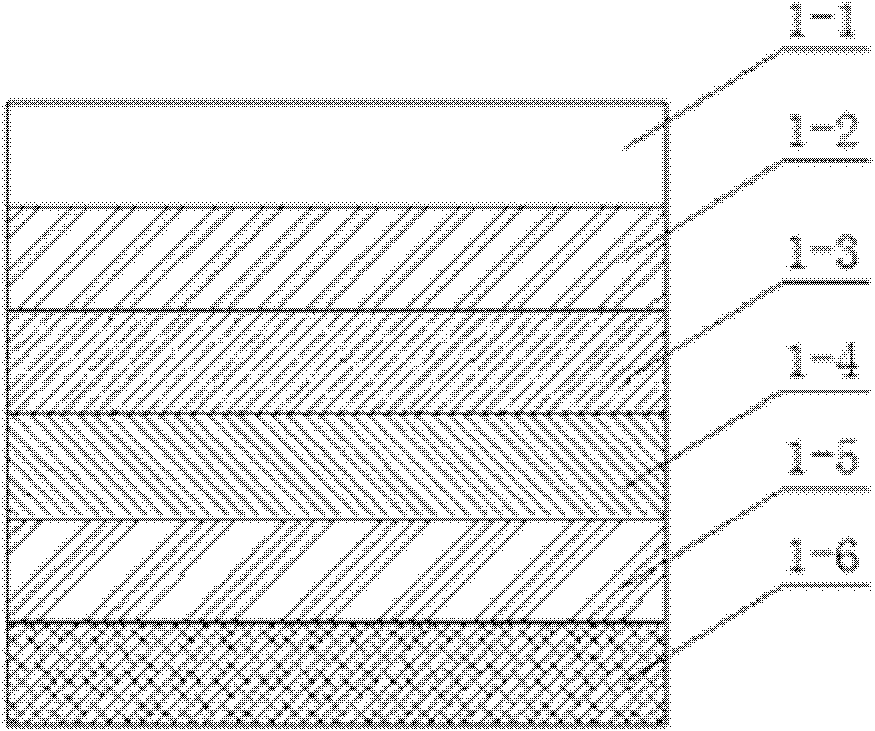

Environment-friendly coated white board

InactiveCN102677549AGood optical performanceGood printabilityCoatings with pigmentsSpecial paperCardboardWhiteboard

The invention discloses an environment-friendly coated white board which sequentially comprises a board body paper bottom layer, a core layer, a surface layer, a bottom coated layer and a surface coated layer from bottom to top. The whiteness of the coated white board ranges from 78% to 88%, and the quantification of the coated white board ranges from 200g / m<2> to 450g / m<2>. The environment-friendly coated white board is characterized in that the board surface layer is made of recycled pulp from waste paper of old corrugated cartons OCC and uncolored wood pulp which are mixed, or is made of one of the recycled pulp from the waste paper of old corrugated cartons OCC and the uncolored wood pulp, the quantification of the board surface layer ranges from 40g / m<2> to 80g / m<2>, the quantification of each of the bottom coated layer and the surface coated layer ranges from 6g / m<2> to 20g / m<2>, and the total coating quantity ranges from 12g / m<2> to 40g / m<2>. The coated white board is mainly made of the unbleached recycle pulp of the waste paper, has the advantages of capabilities of saving wood resources and reducing beaching pollution, low production cost, fine printability, attractive appearance, high strength and the like, and can replace traditional coated kraft card boards and coated white-surface white boards to manufacture packaging cartons and folded cartons such as wine boxes, boxes for articles for daily life, healthcare product boxes, electronic product boxes and high-grade clothing boxes.

Owner:臧永华

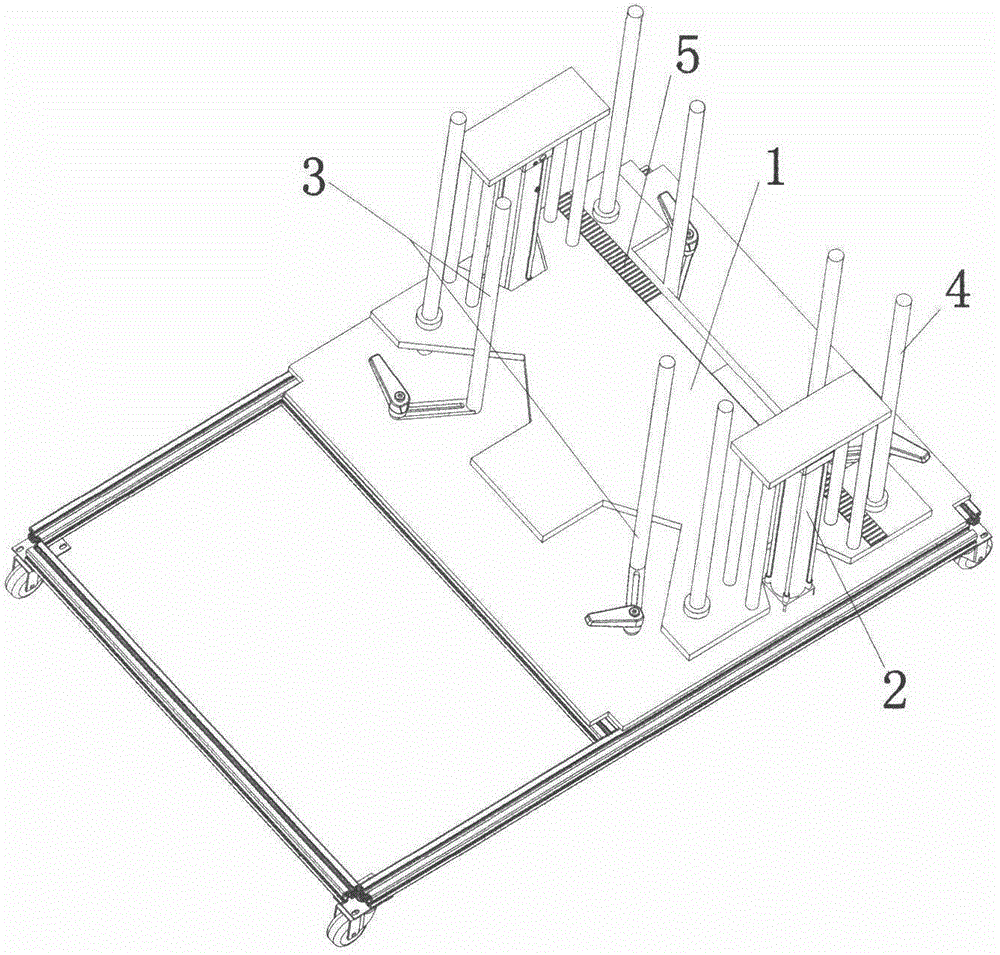

Novel automatic plane-carton folding machine

InactiveCN105459440ARealize the purpose of one machine with multiple purposesImprove efficiencyPaper-makingBox making operationsEngineeringPaper sheet

The invention provides a novel automatic plane-carton folding machine. The novel automatic plane-carton folding machine comprises a stock bin mechanism, a material sucking and feeding mechanism, a carton folding mechanism and an adjusting mechanism. The material sucking and feeding mechanism is arranged above the stock bin mechanism. Carton blanks are sucked and sent to the carton folding mechanism by simultaneous working of the material sucking mechanism and the stock bin mechanism. The carton folding mechanism meets the requirement of the carton blanks with different length and width sizes through the adjusting mechanism. After one carton blank is folded by the carton folding mechanism, the second carton blank is sent out by the stock bin mechanism and the material sucking and feeding mechanism cooperatively, the first finished folded carton product is pushed out, that is, a set of carton folding work is completed. According to the novel automatic plane-carton folding machine, the purpose of one machine with the multiple functions is really realized, and the production cost of an enterprise is reduced; the working efficiency is improved, and the gap of the technology in the prior art is filled.

Owner:昆山金港硕自动化设备有限公司

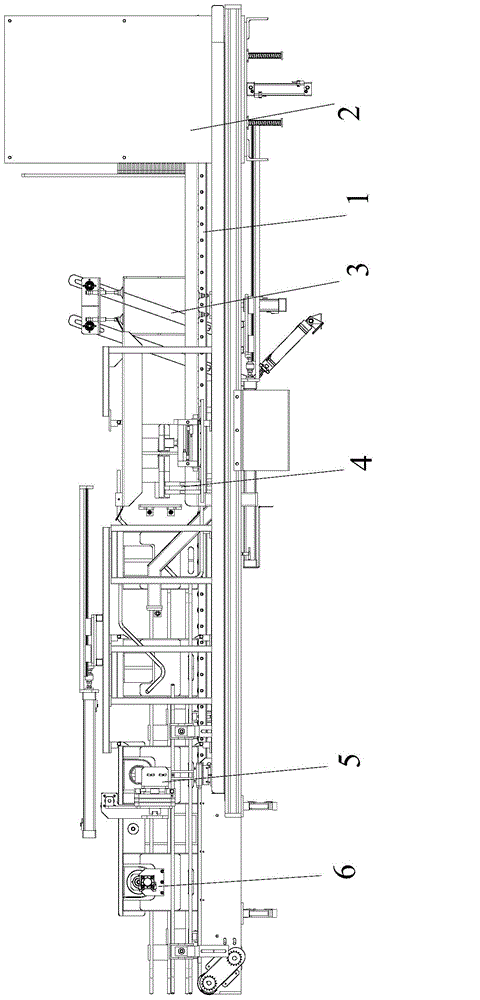

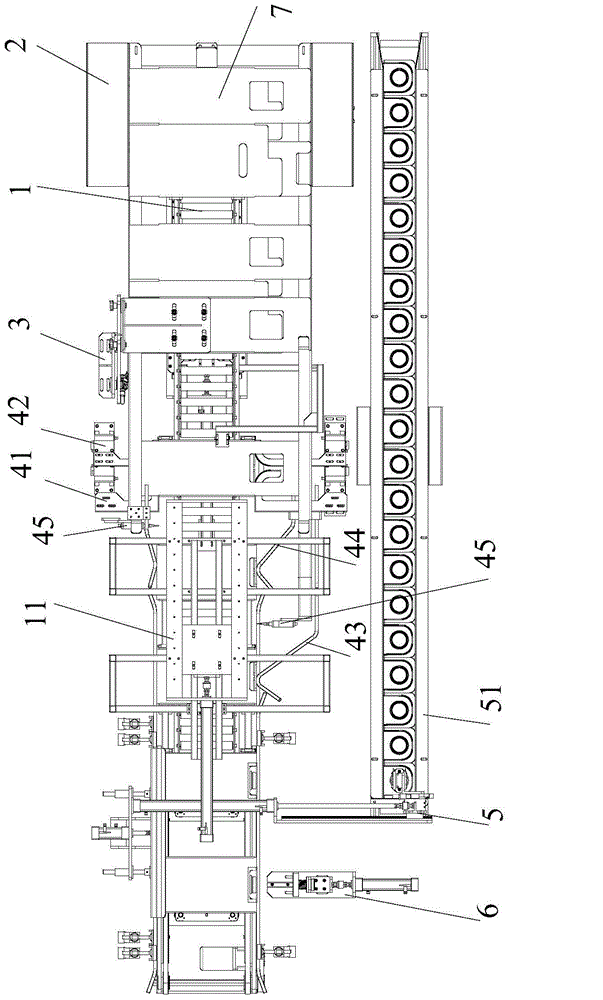

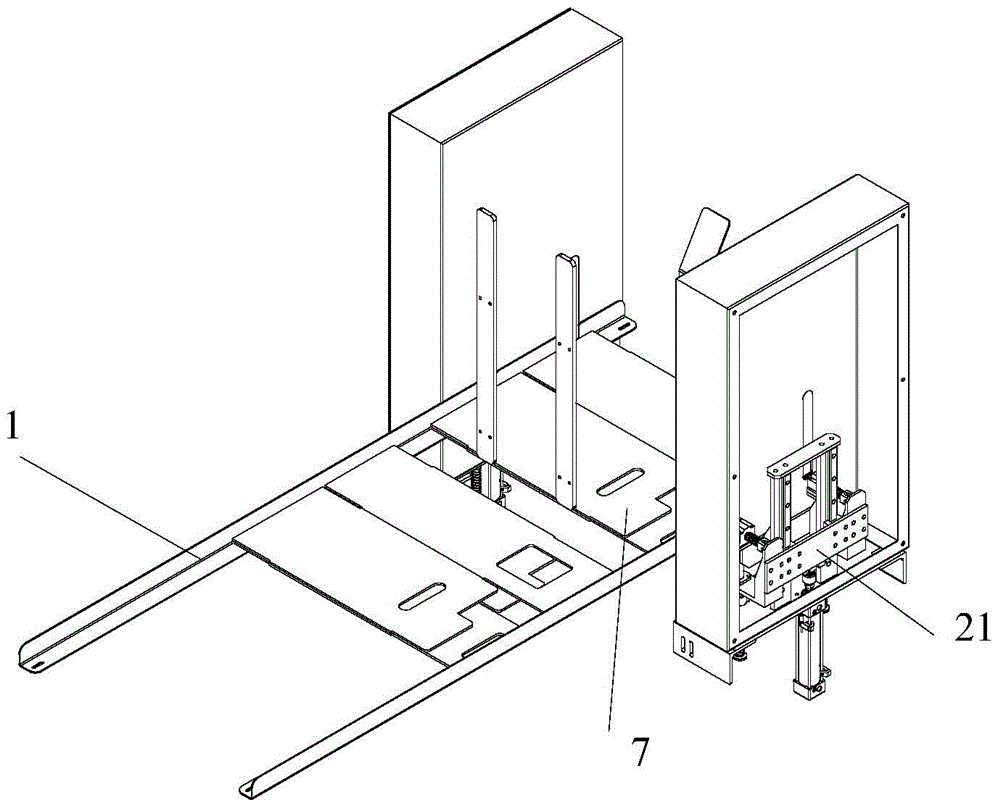

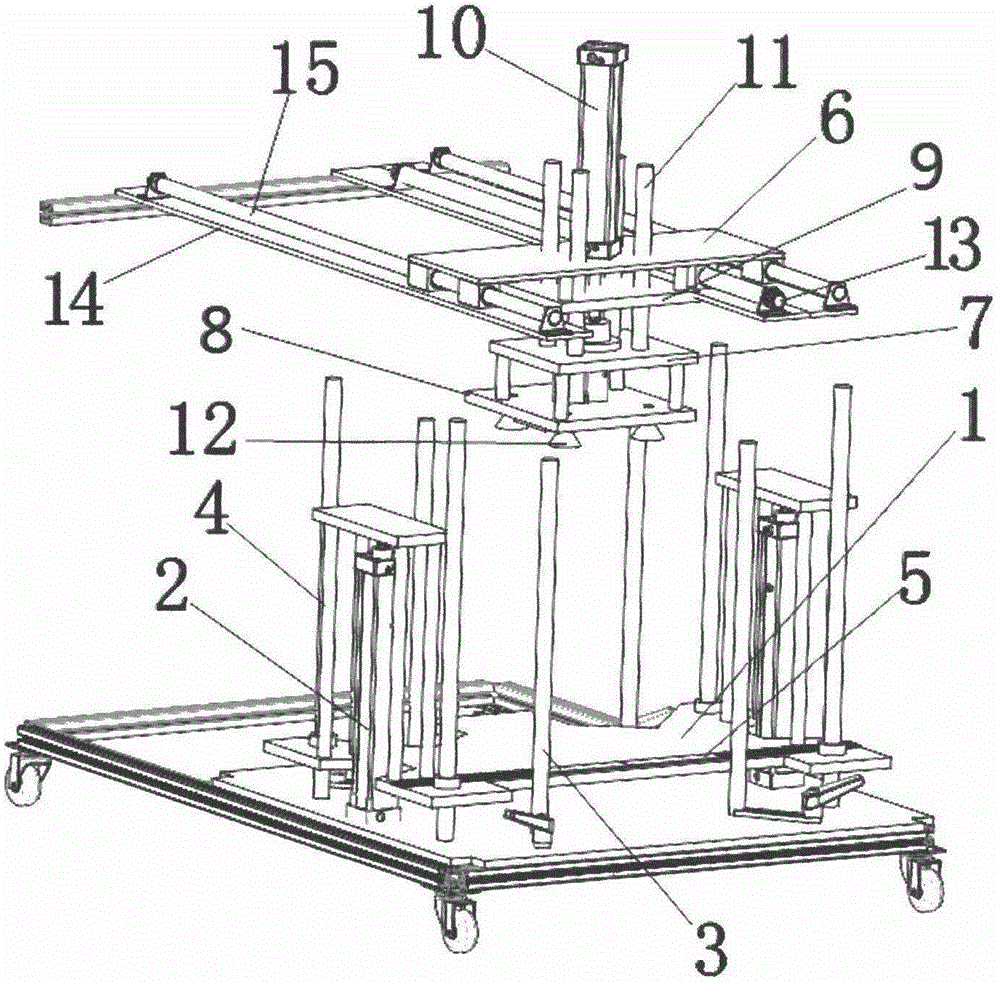

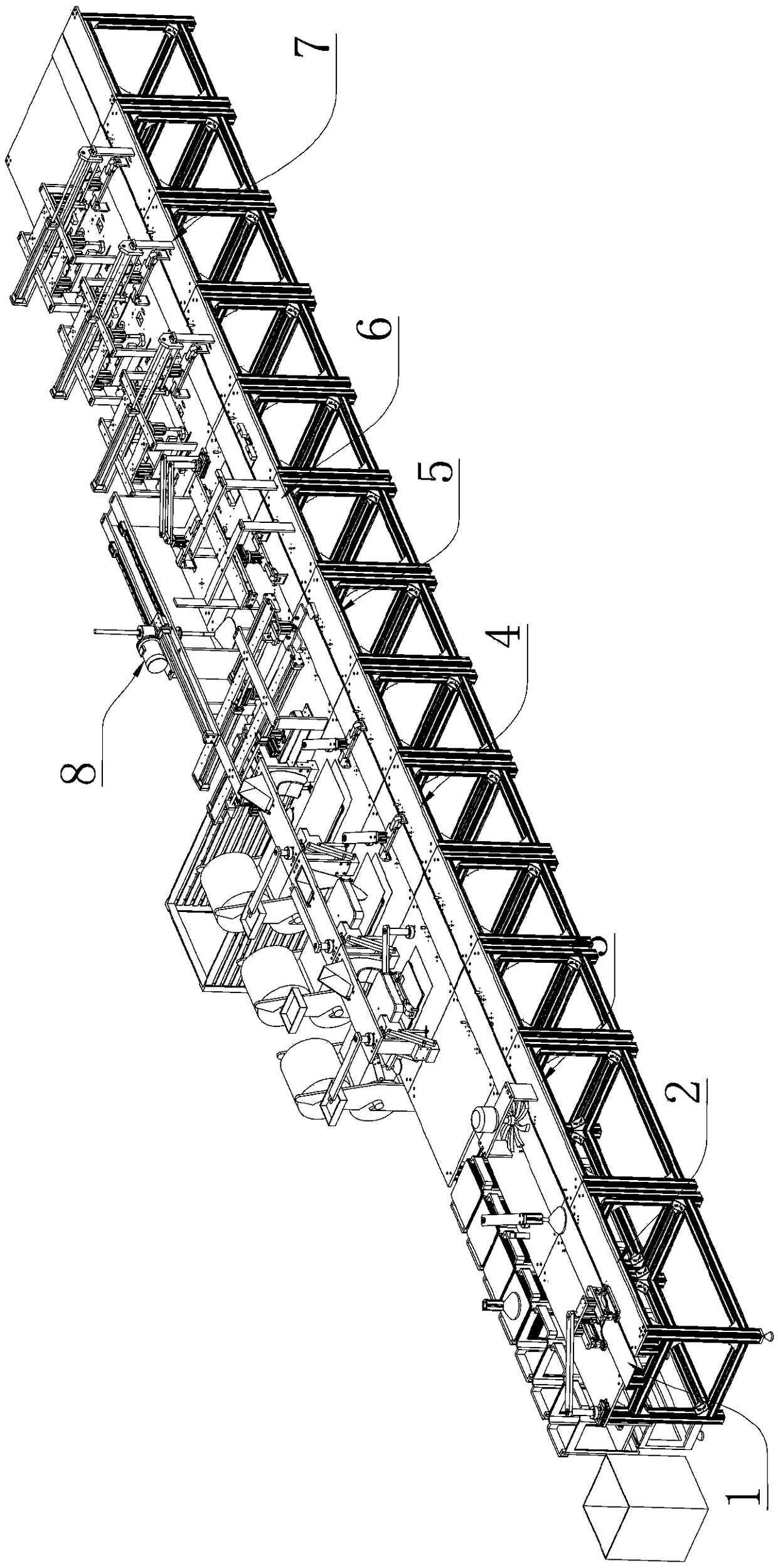

Carton folding production line enabling cartons to be automatically formed

ActiveCN104290362ASimple structureIngenious structureBoxes/cartons making machineryAssembly lineEngineering

The invention relates to a carton folding production line enabling cartons to be automatically formed. The carton folding production line comprises an assembly line and a machine body. An automatic glue coating device, an inner carton locating device, a carton pressing device, a roller device, an outer bottom face plate pressing roller device, a wing plate pressing and attaching device and two outer side face plate pressing roller devices are arranged on the machine body in the advancing direction of the assembly line. The automatic forming folding-carton production line is simple and reasonable in structure, full-automatic production is achieved through the assembly line, production efficiency is high, and processing precision is high.

Owner:广州市利悦食品包装技术有限公司

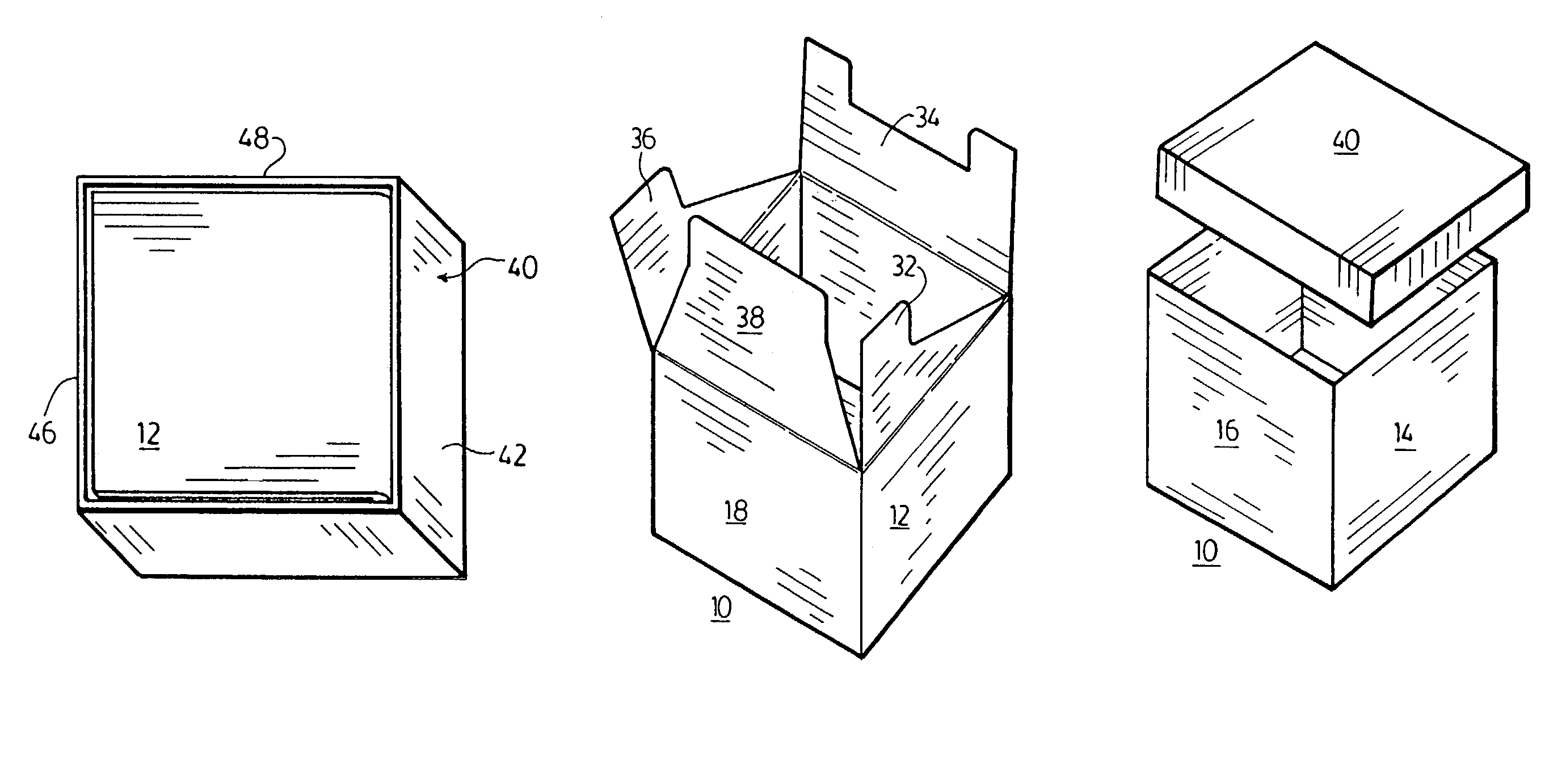

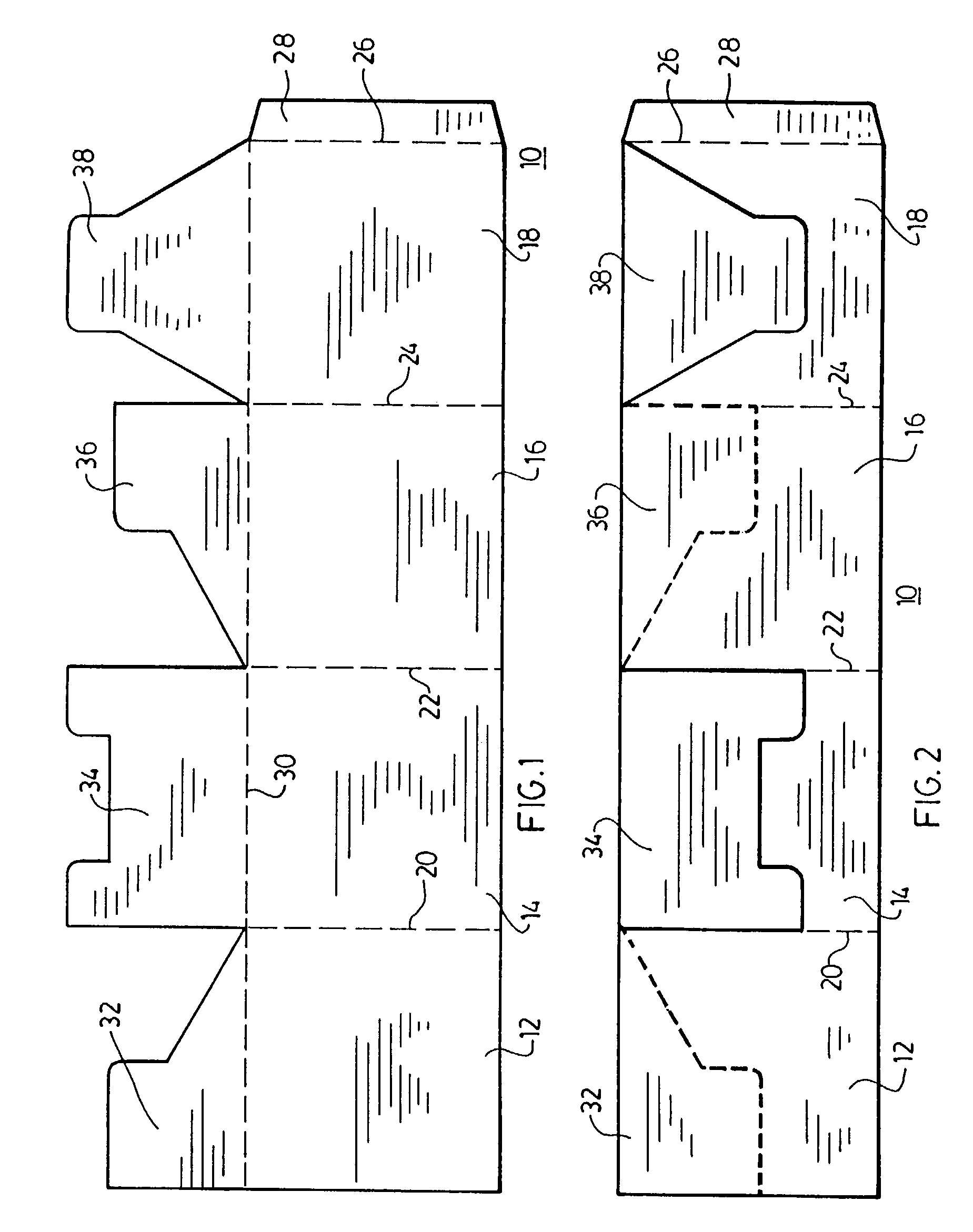

Versatile gift box

A carton which may be ideally used as a gift box comprises a folded carton contained within the lid which ultimately closes the carton. The carton is formed from a blank having four panels which form the sides of the carton. Four end panels connected to the side panels may be folded together to form a bottom for the carton when in its assembled condition. The entire carton blank is folded to fit inside the lid. A transparent wrap, preferably a shrink wrap encloses the carton and any other wrapping paraphernalia within the lid.

Owner:KWONG KWAN WING

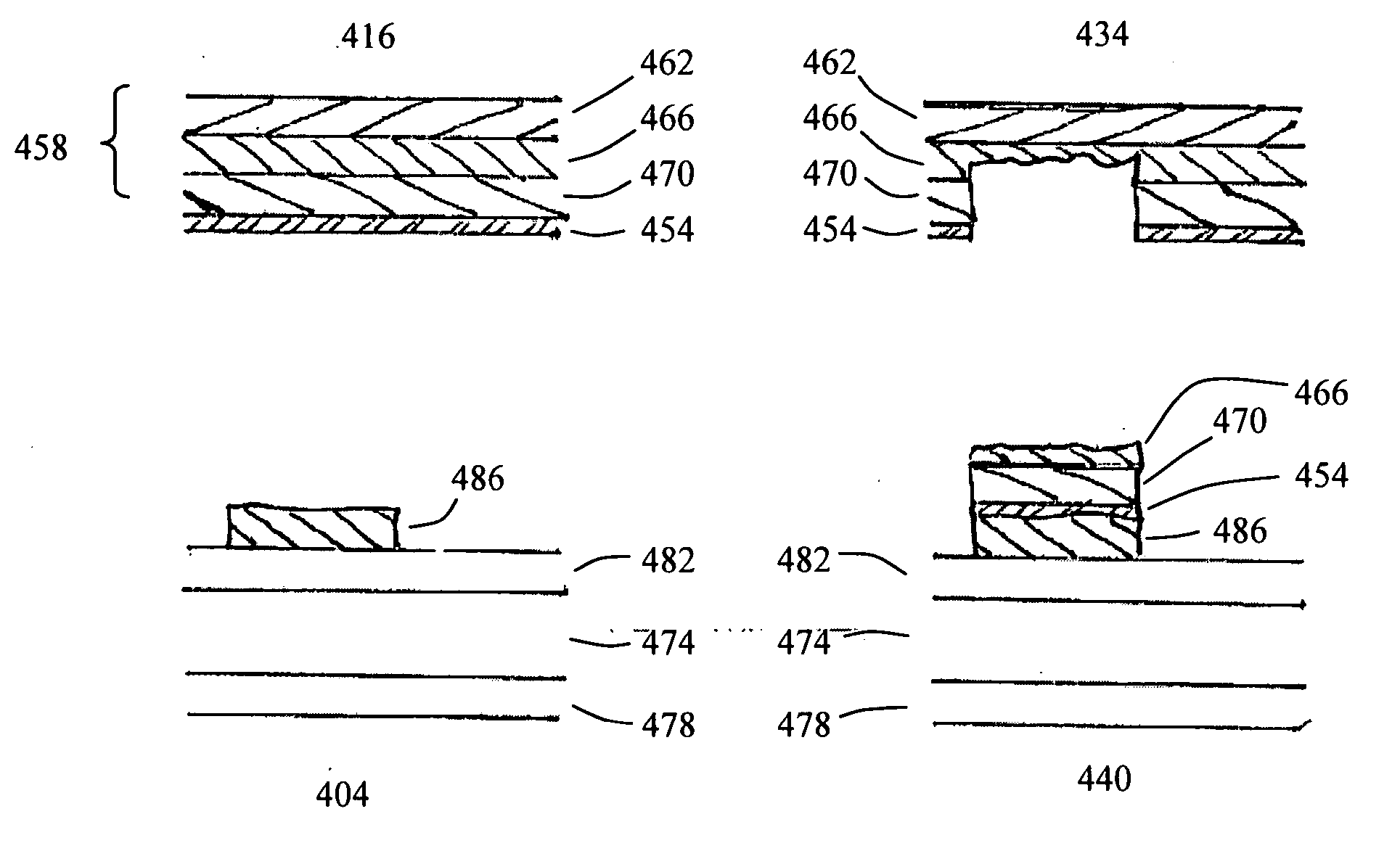

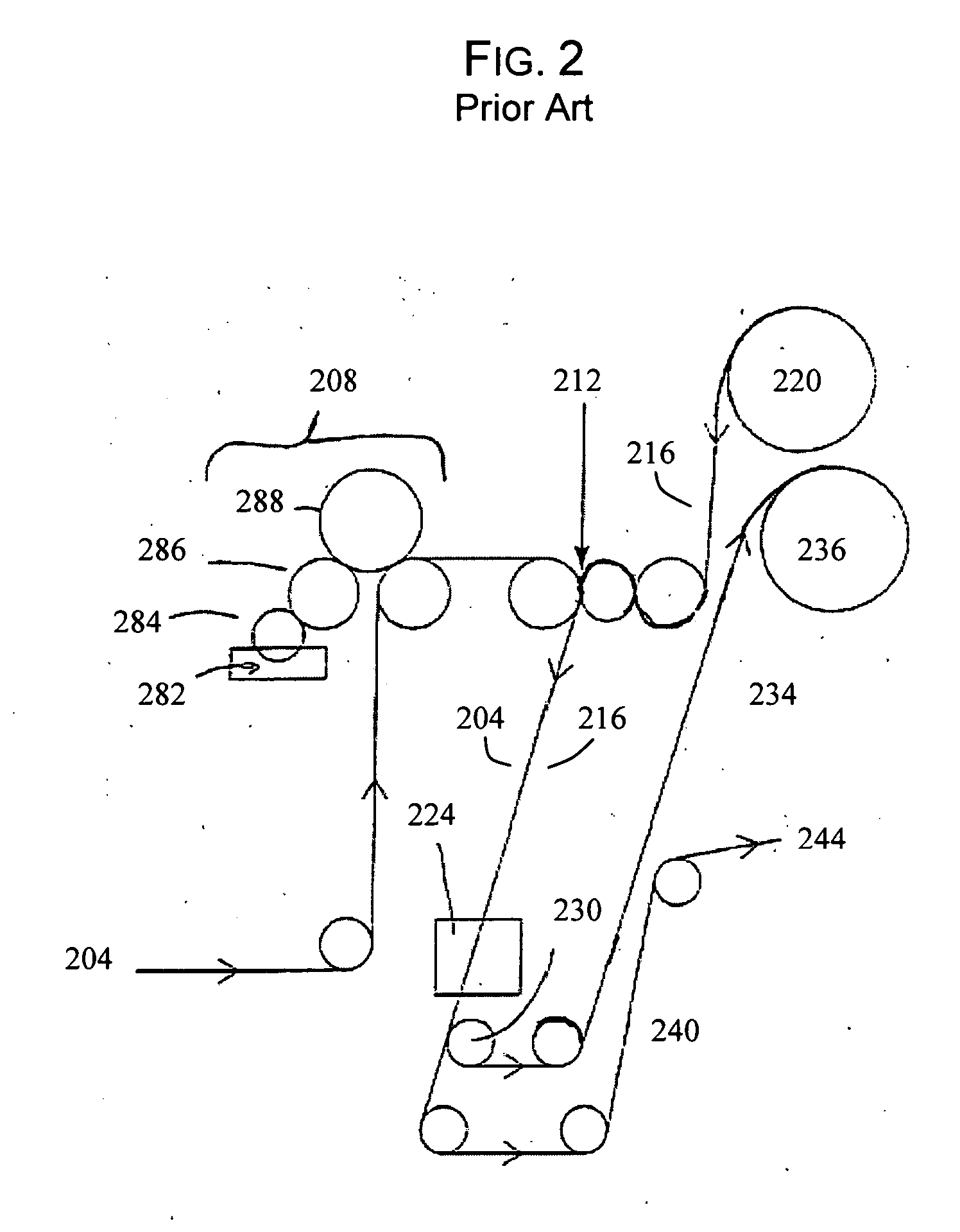

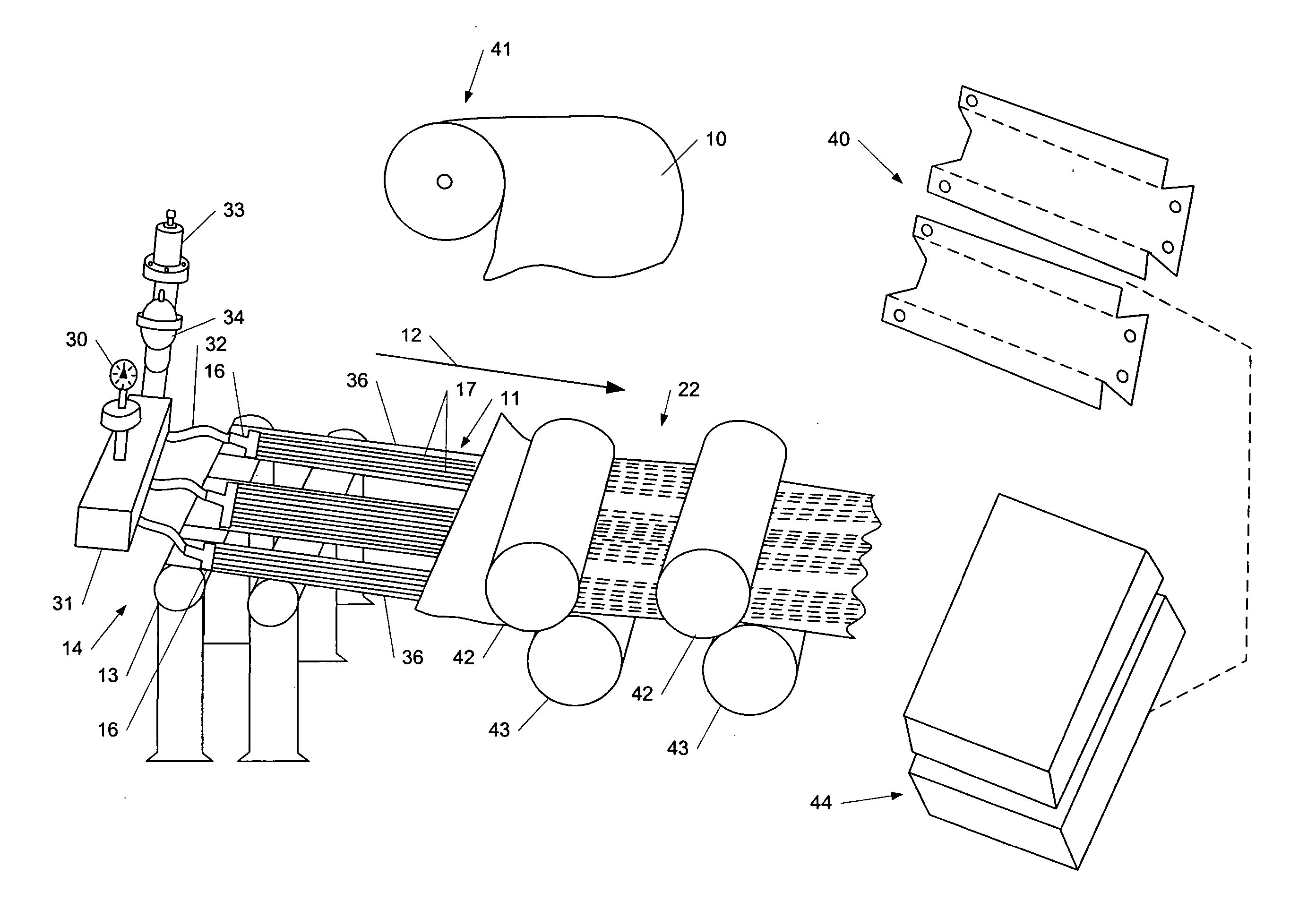

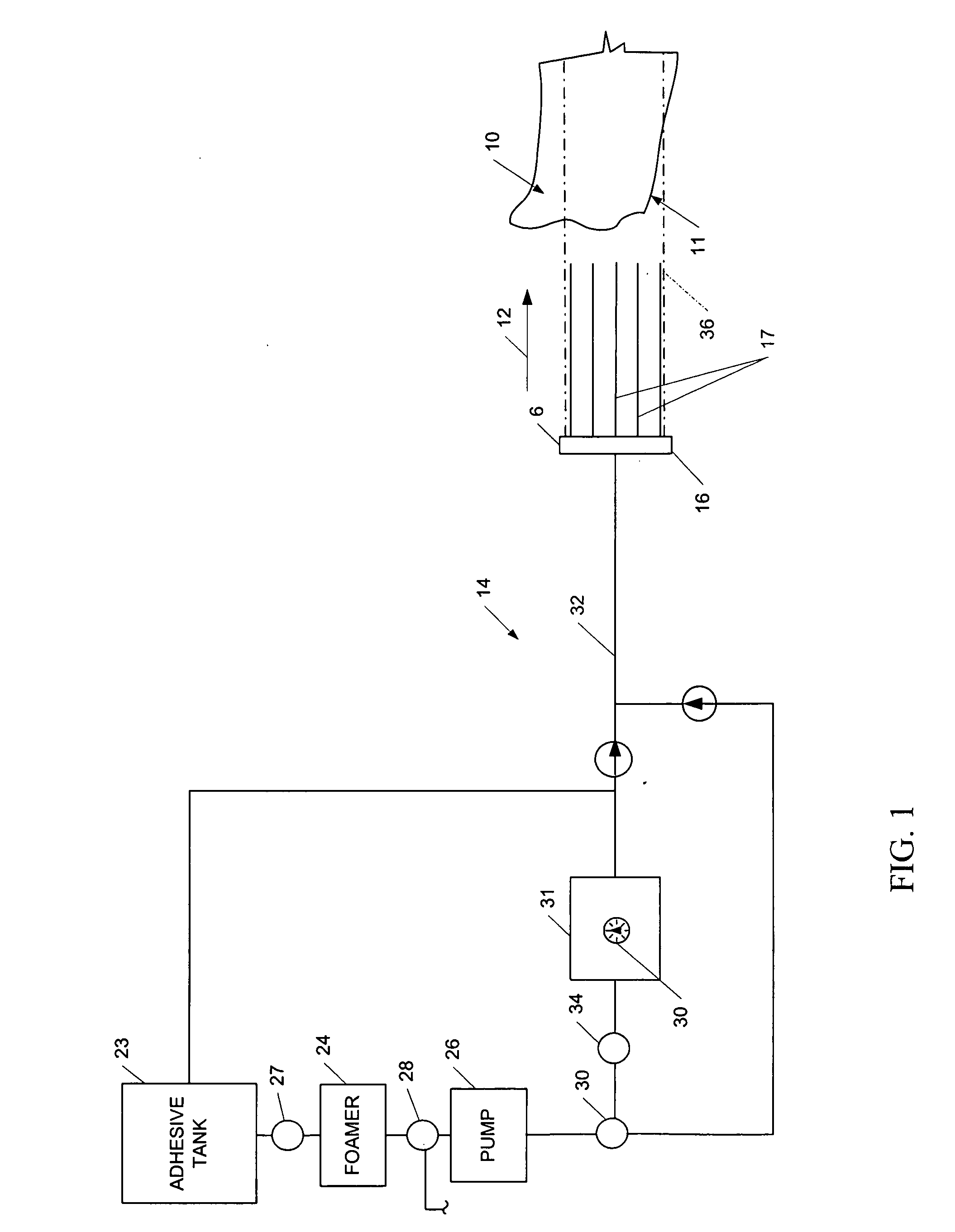

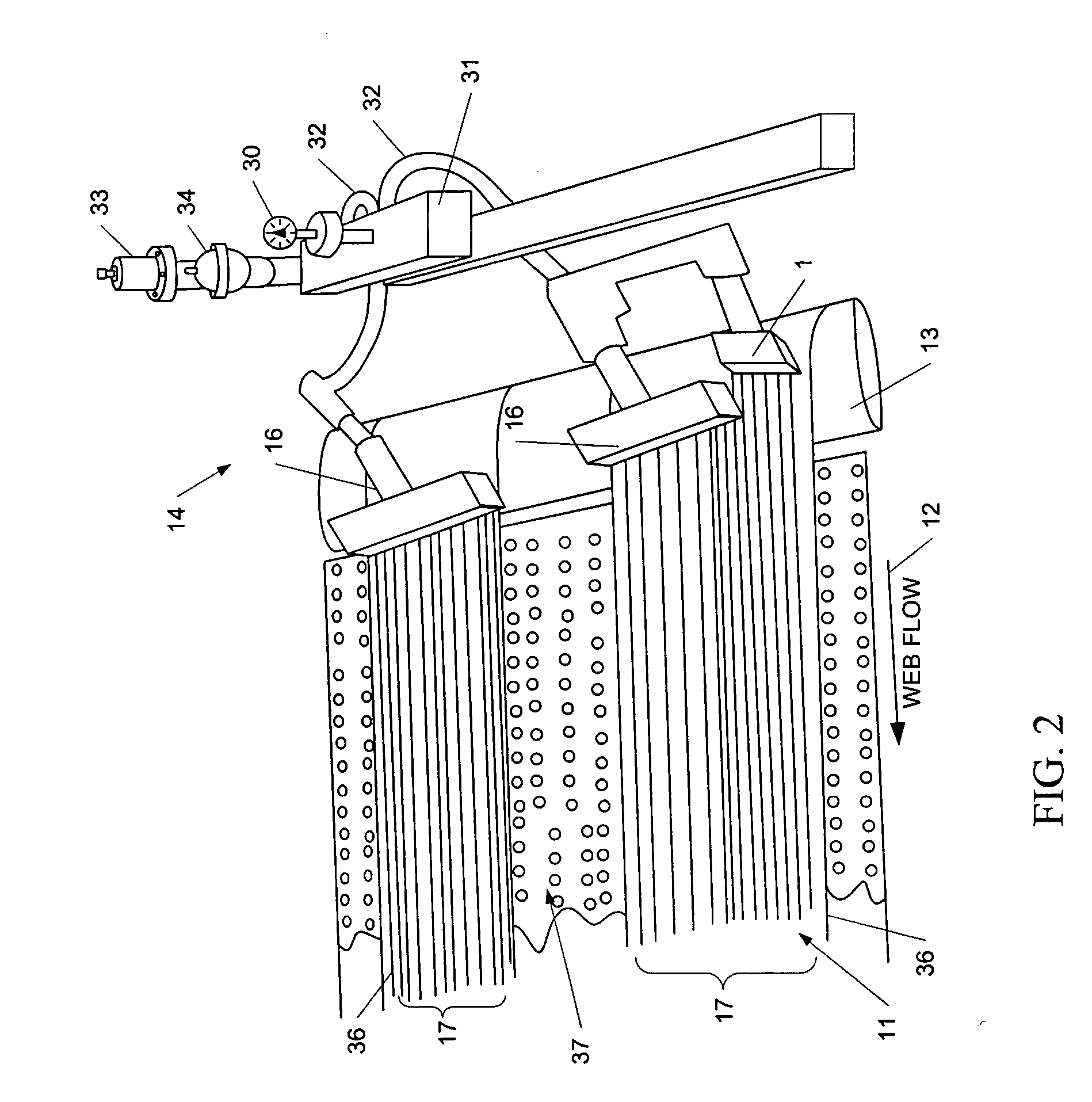

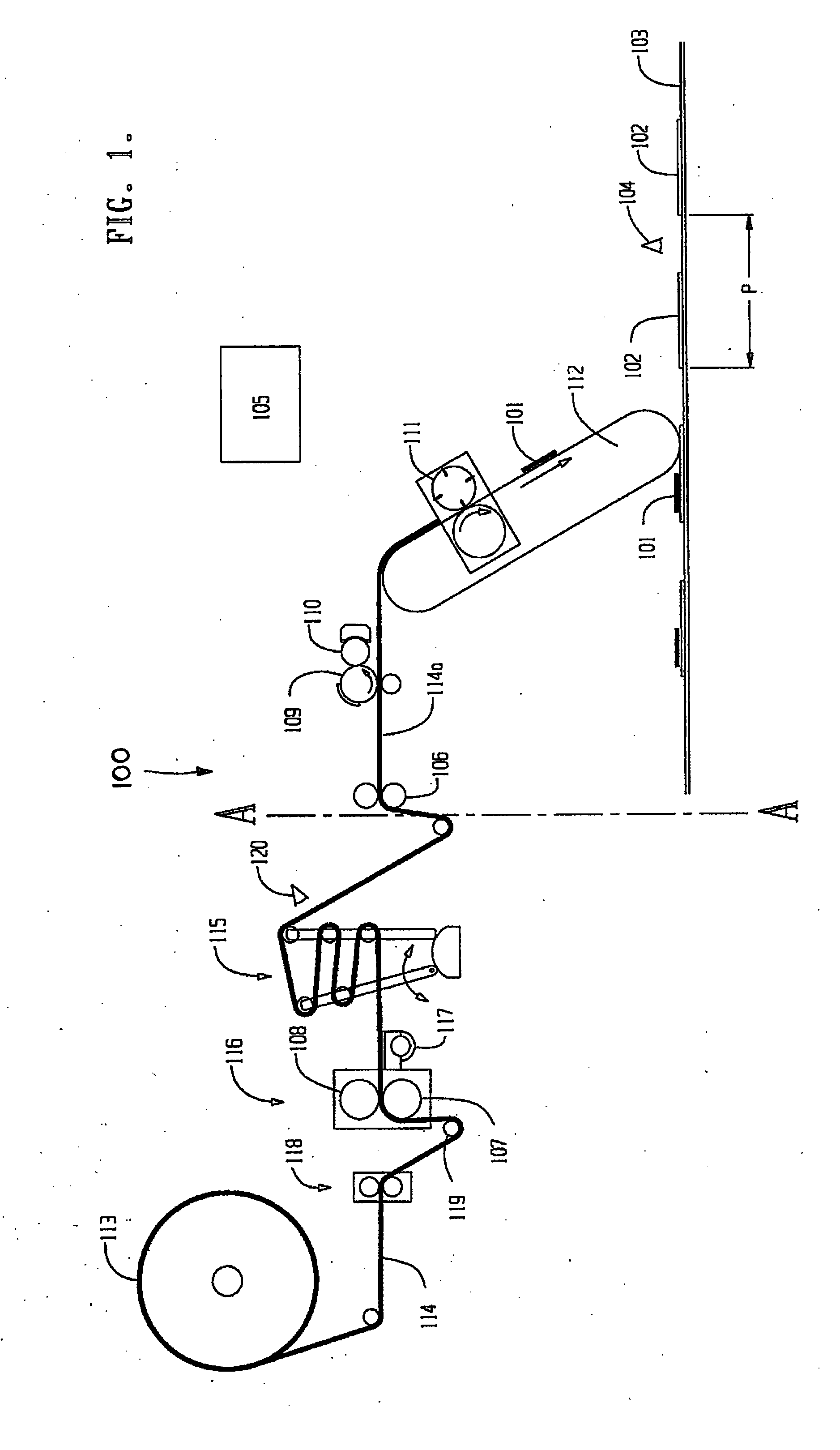

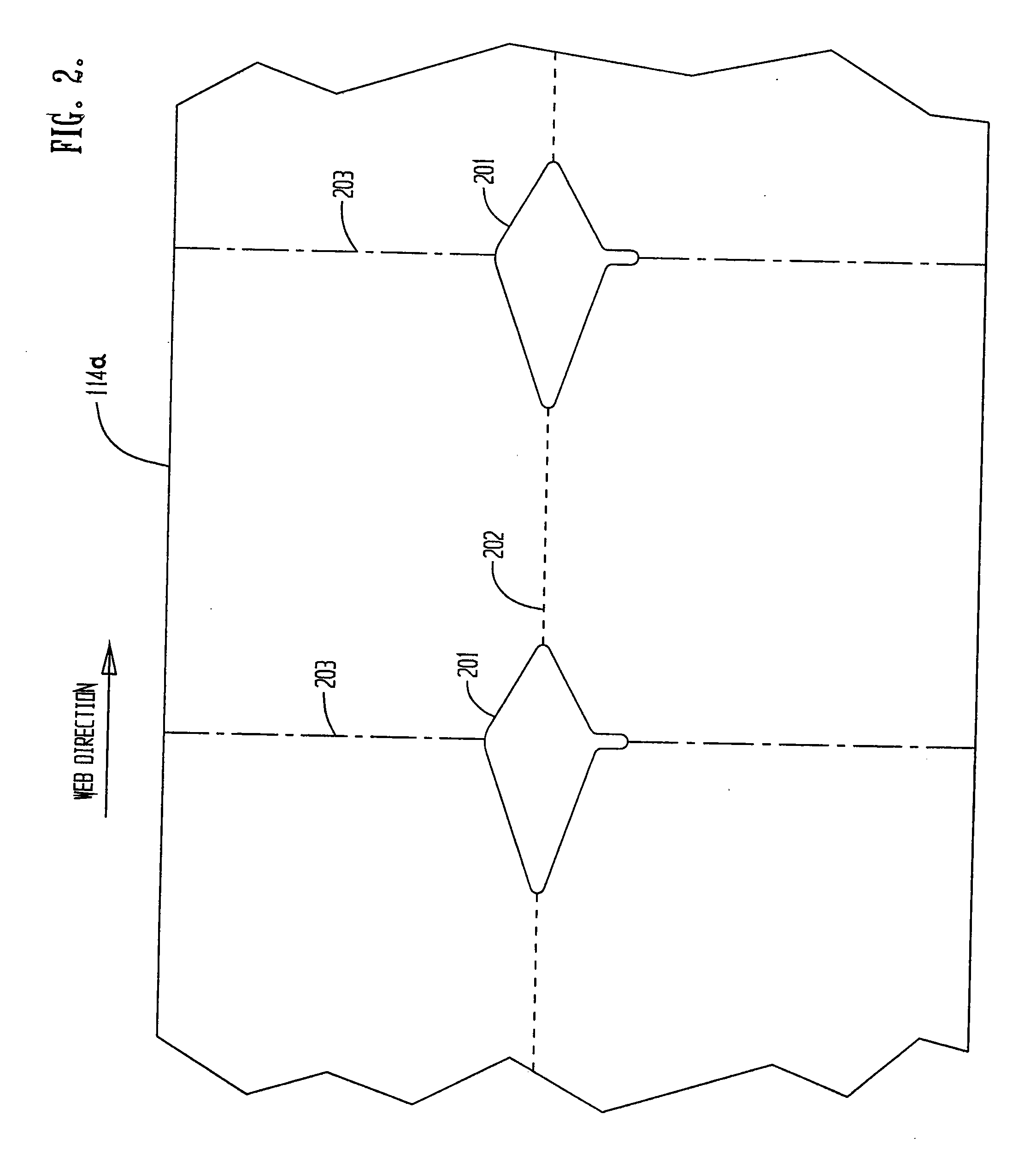

High speed microwave susceptor pattern application

The disclosure for High-Speed Microwave Susceptor Pattern Application discusses various methods for applying microwave susceptor material from a foil web to packaging, particularly food packaging such as folded carton flats. Typically, the microwave susceptor is applied in a pattern rather than uniformly to the packaging. The application can be done at high speeds using a modified form of cold foil printing or hot-stamp foil printing. The application can be done using hot-stamp sheet fed equipment to make use of legacy equipment. This abstract is intended to help those conducting a patent search for relevant disclosures and not intended as a limit on the scope of the claims.

Owner:HALIFAX SCOTT

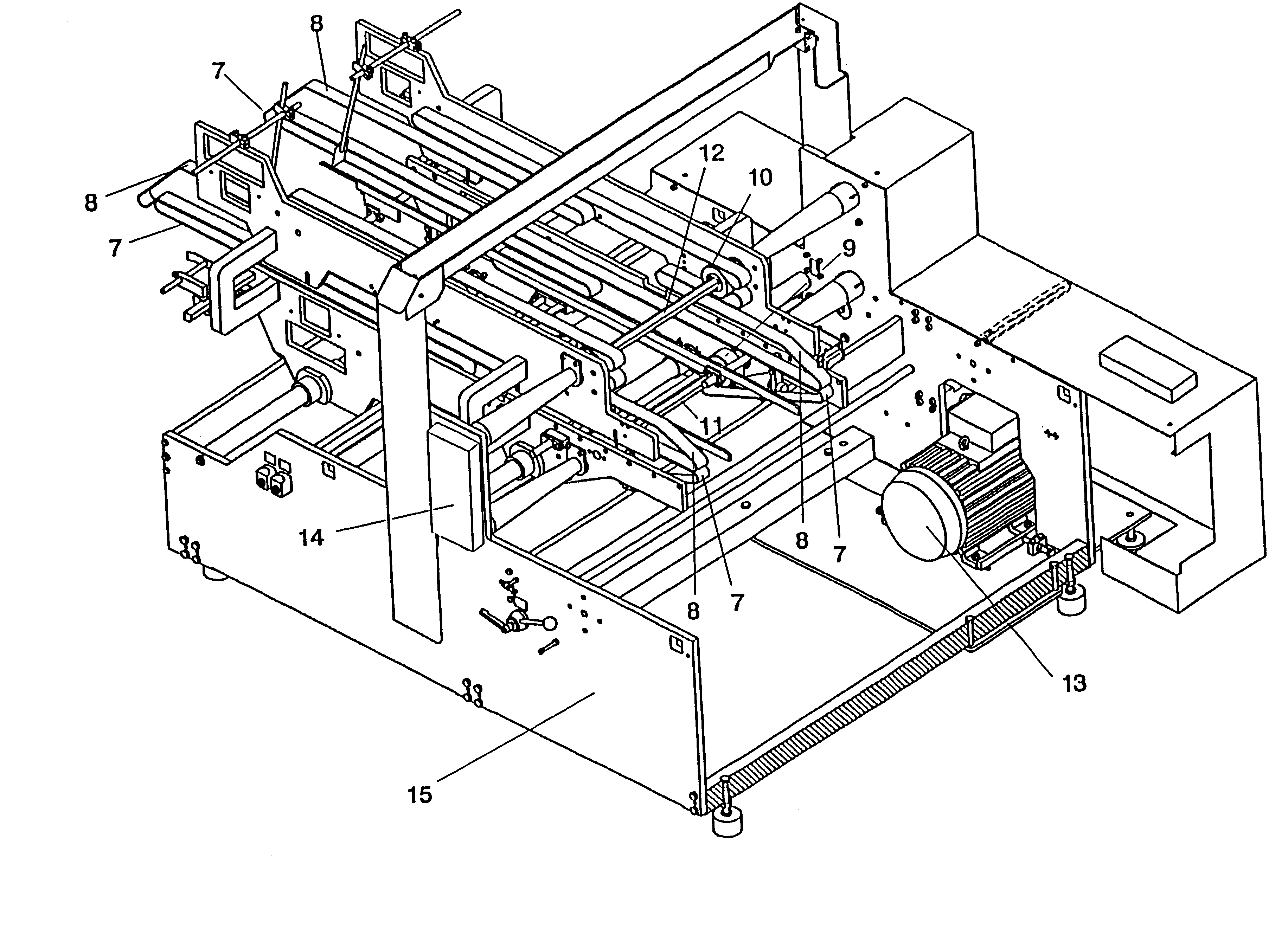

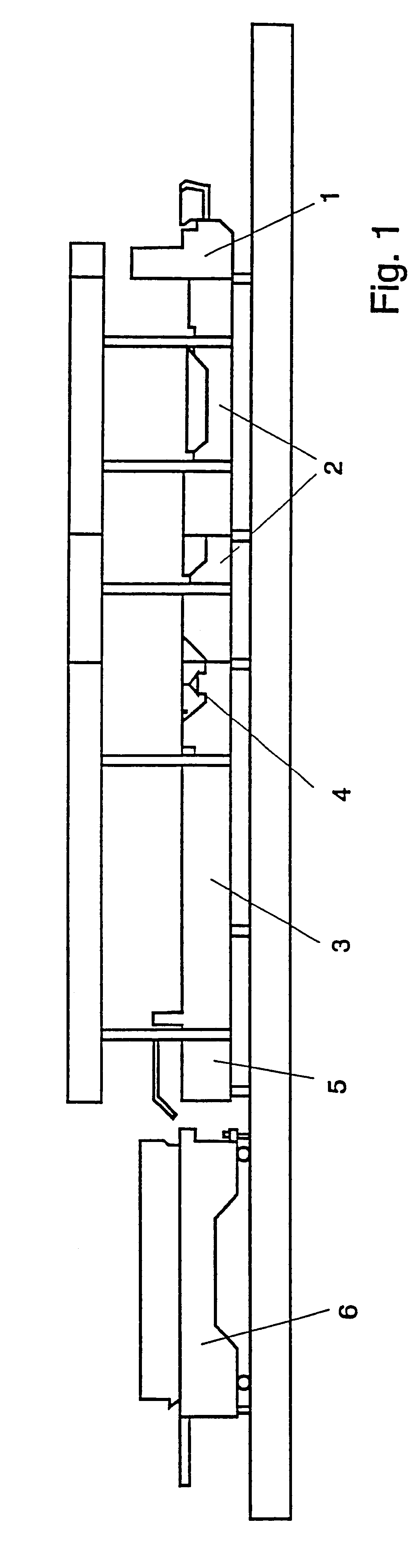

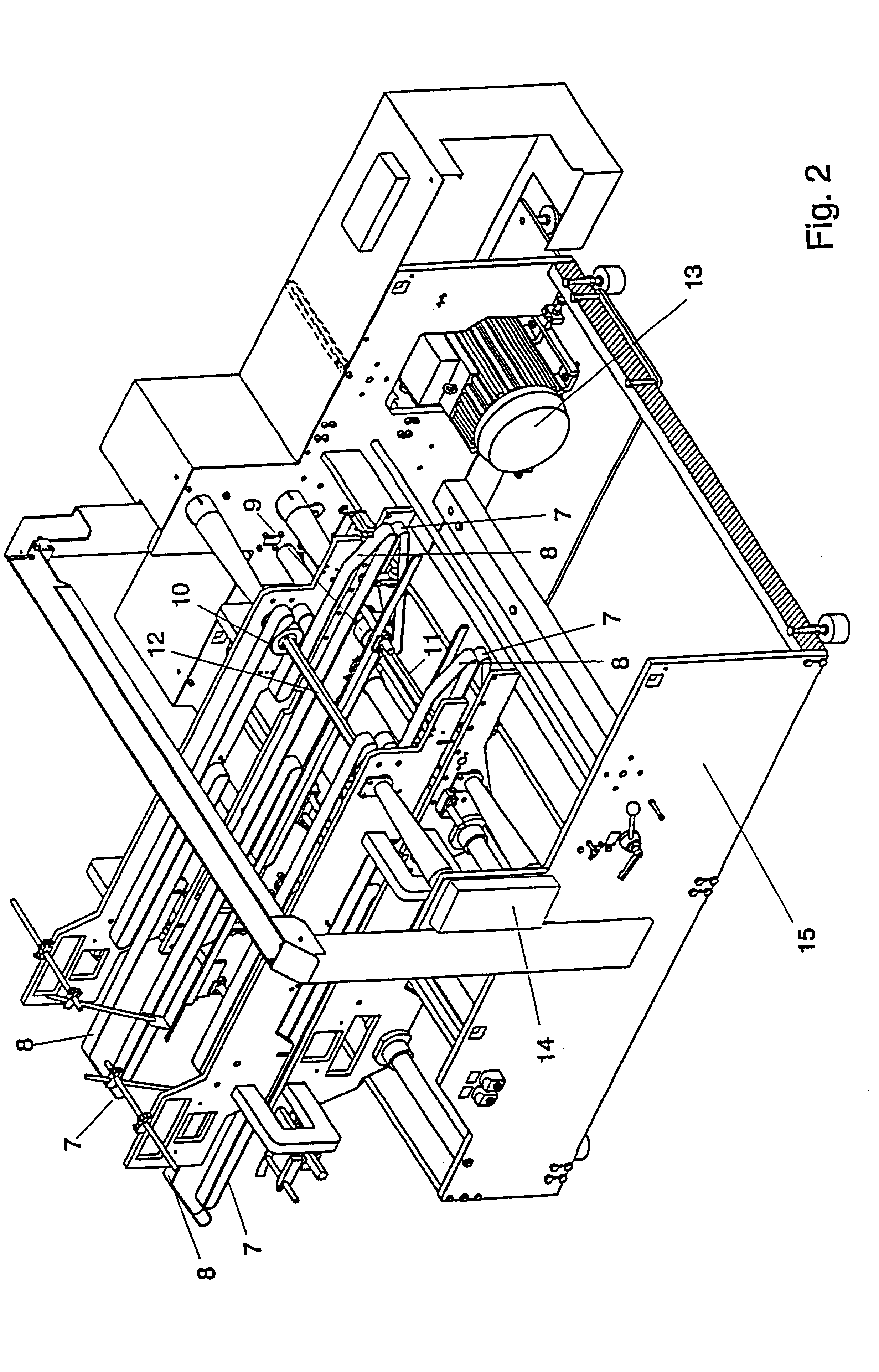

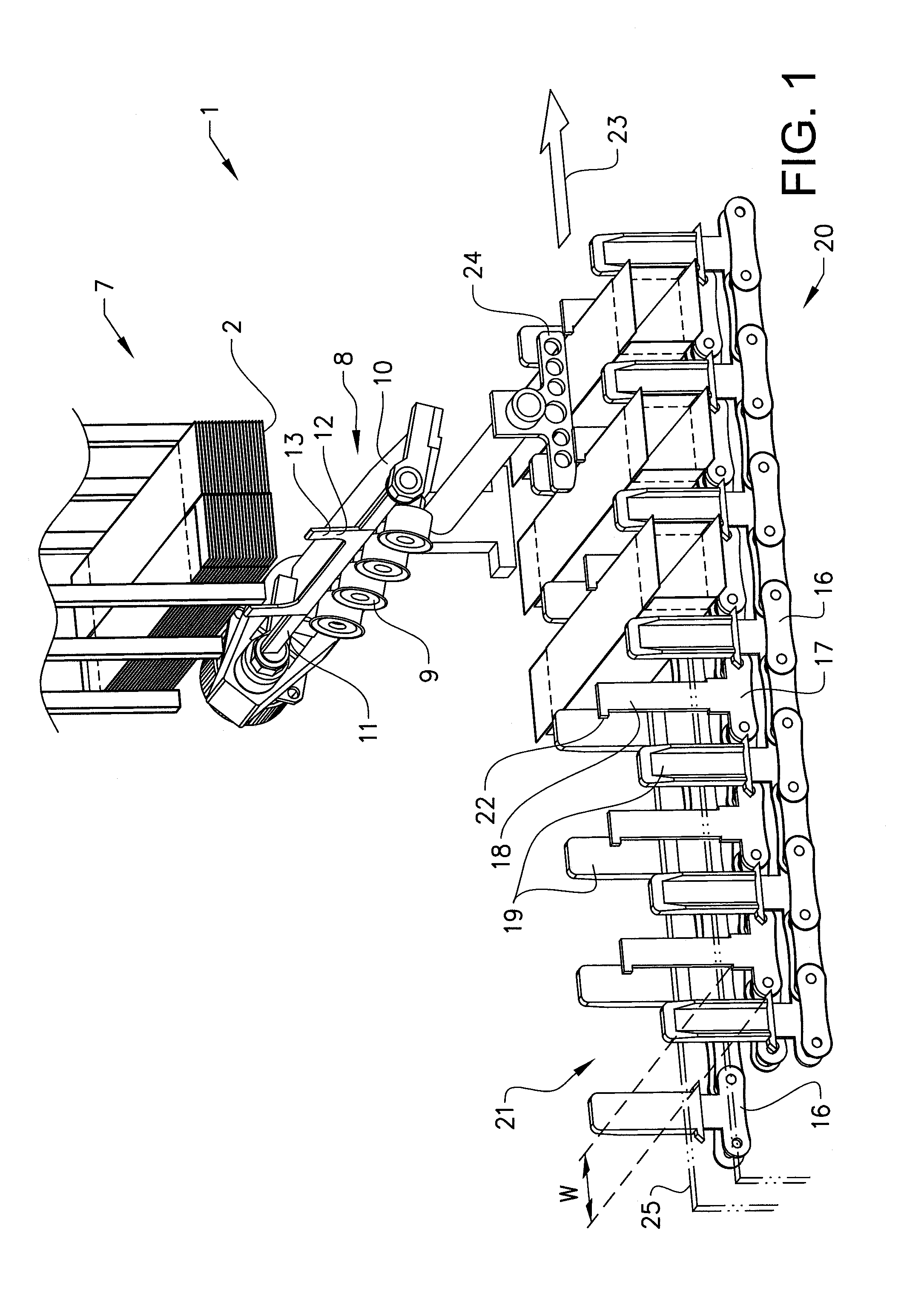

Machine for gluing folding cartons for producing folding cartons from blanks

InactiveUS6503181B1Increase ascent speedThe effect is accurateBoxes/cartons making machineryPaper-makingAdhesiveCompression device

A collapsible-box gluing machine for the production of collapsible boxes from blanks has a folding station for folding blanks, a subsequently arranged transfer station and a collecting and compression device, wherein the flat-lying folded collapsible boxes are pressed for the bonding of the adhesive. The transfer station has at least one pair of conveyor belts as a conveying device, which consists of a lower belt and an upper belt. In order to transfer the blanks with precisely positioned side flaps to the collecting and compression device, the transfer station has a variable ratio transmission to drive the upper conveyor belts at a higher speed than the lower conveyor belts.

Owner:MASTERWORK GROUP CO LTD

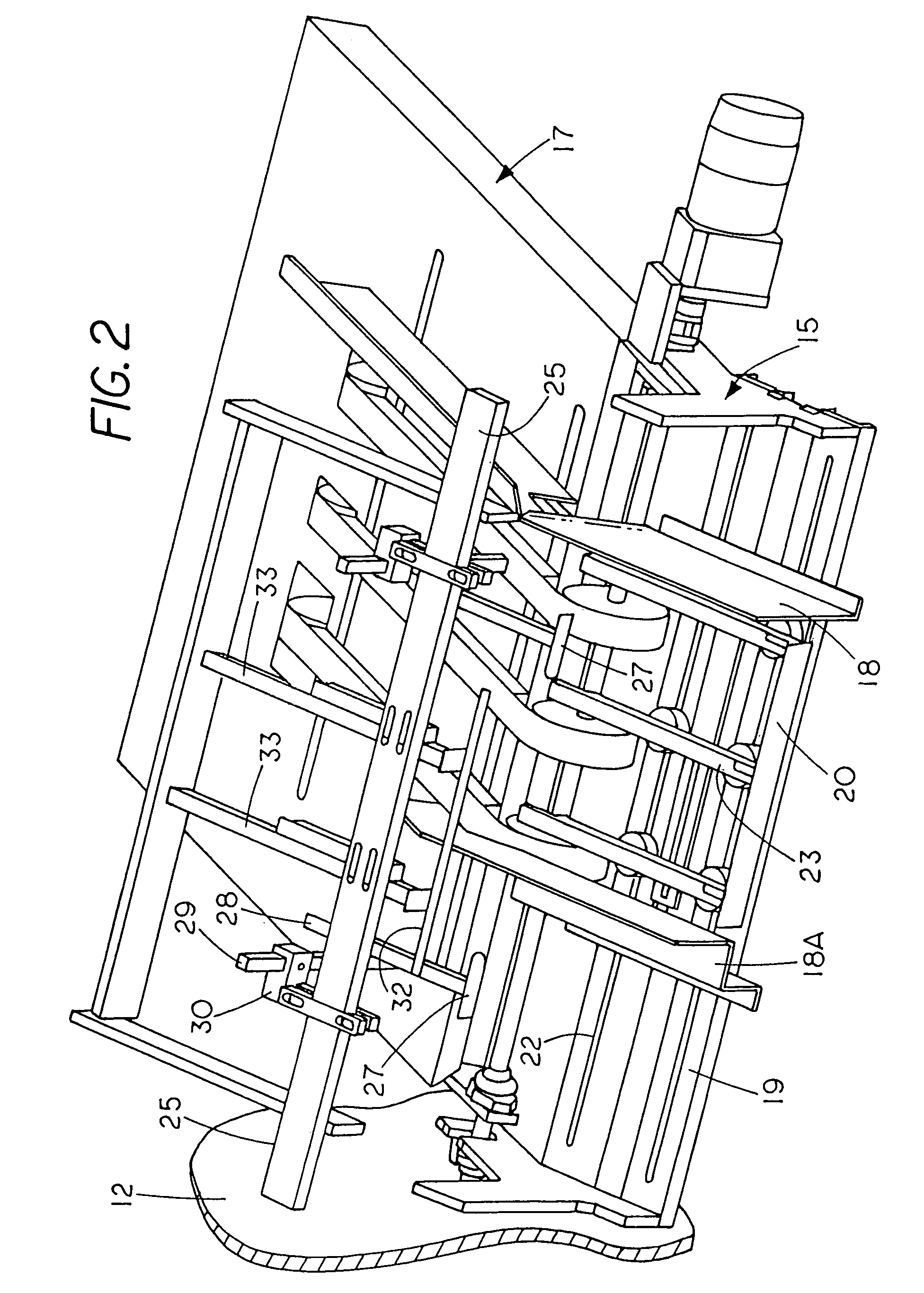

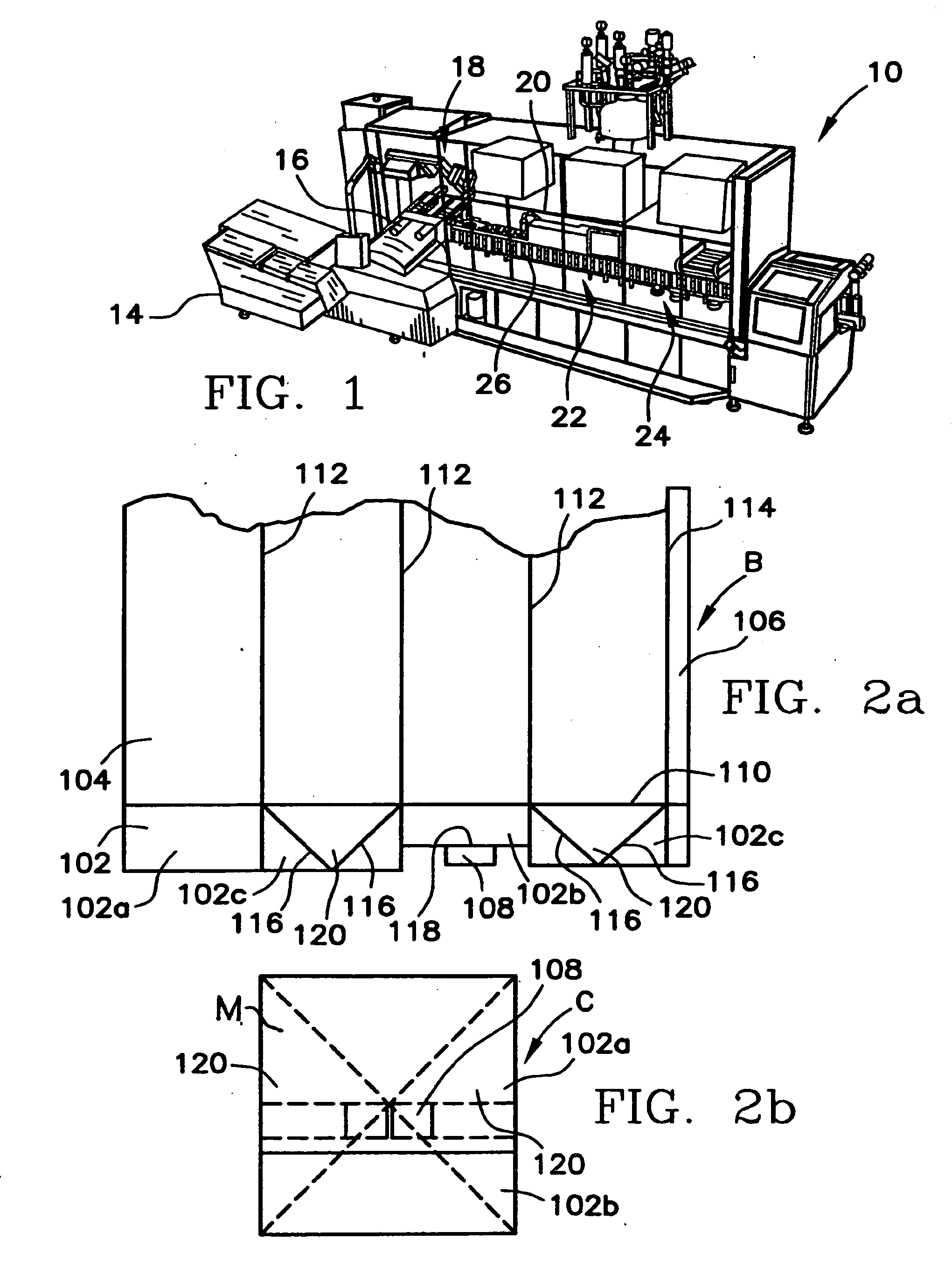

Automatic, T-Fold Carton Erector and Sealer

An apparatus, for automatically erecting a carton for the insertion of a product and then the folding, sealing and mailing address labeling of the carton, includes: an intake mechanism with a distal head that grasps the underside of the carton blank on the bottom of the pile and pulls it down into the apparatus, guides that fold upwards some of the carton's panels when the blank is pulled down into the apparatus so as to create a partially erected carton for the insertion of the product which the carton is to package, a rotatable platform which further folds the carton and its inserted product, a glue applicator, a mailing label applicator, and a control system that controls the coordinated motion of this apparatus' various parts.

Owner:ADAMS ASHLEY JOHN BECK

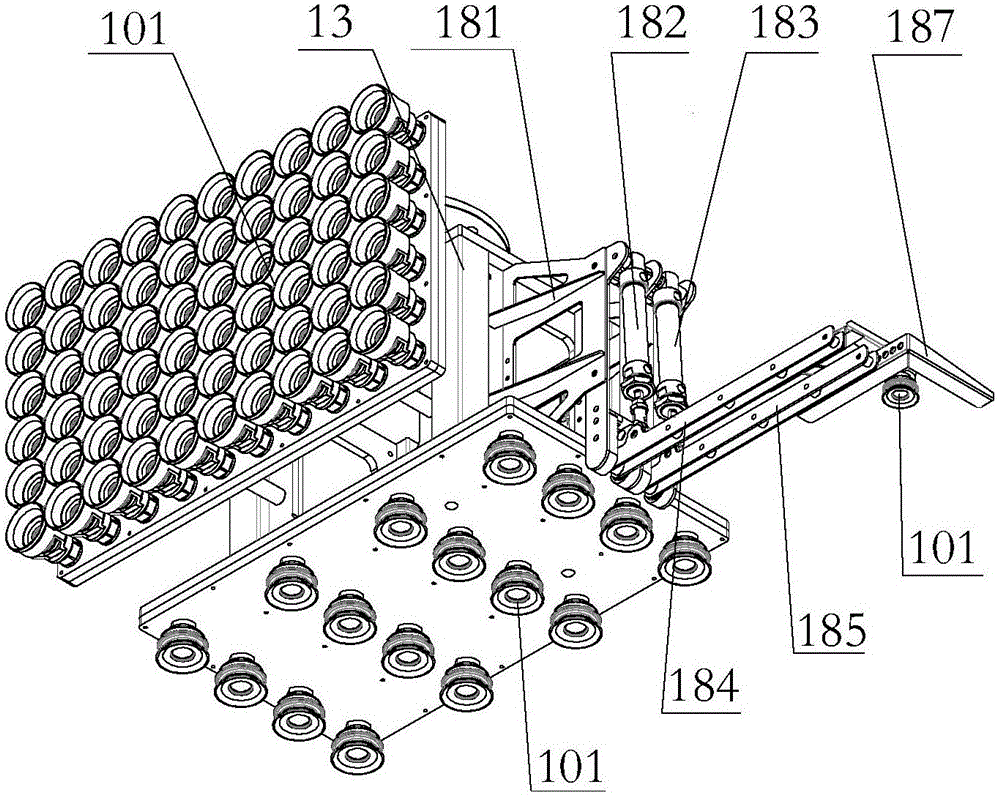

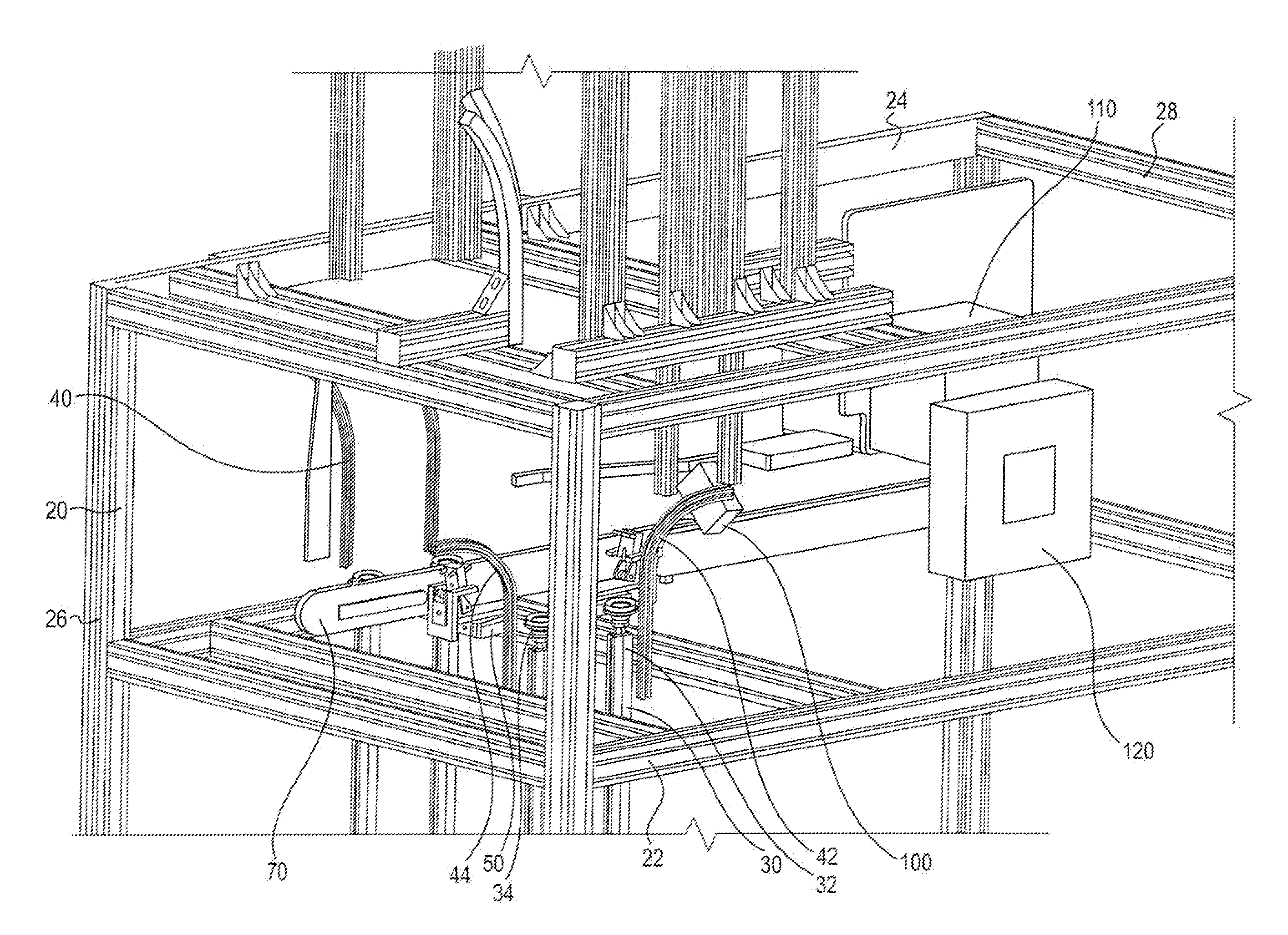

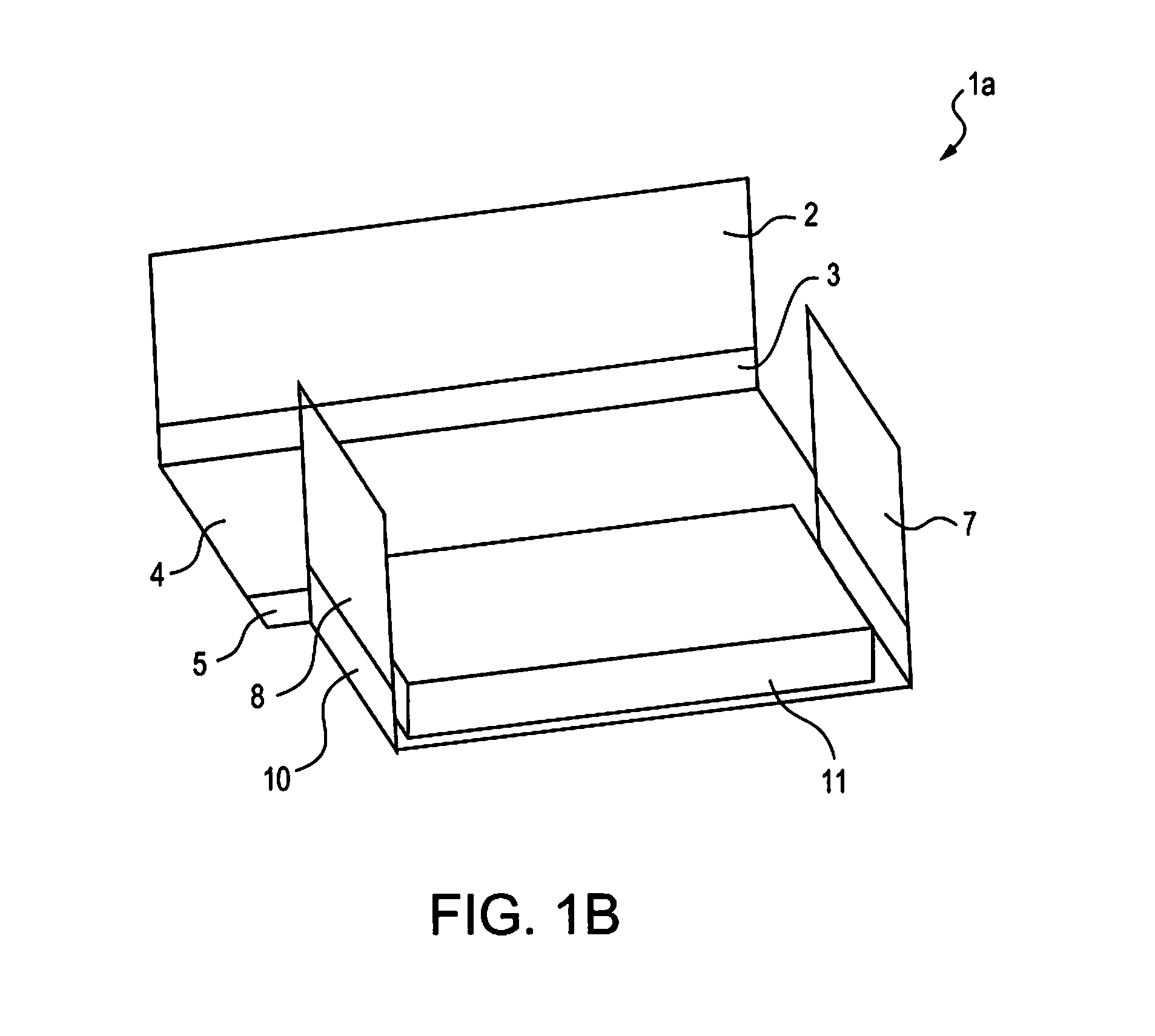

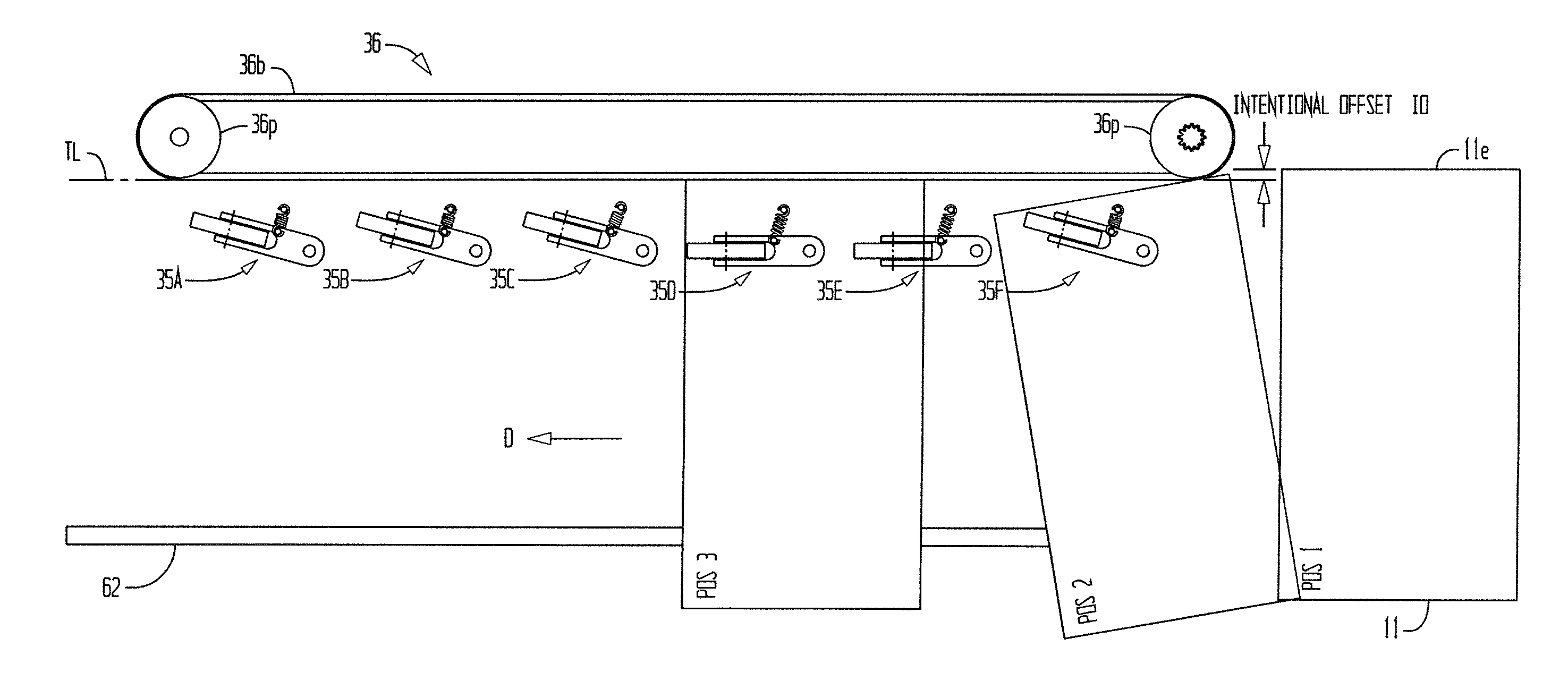

Carton feeder system and method for simultaneously feeding a plurality of cartons to a conveyor track using a plurality of pick-up heads

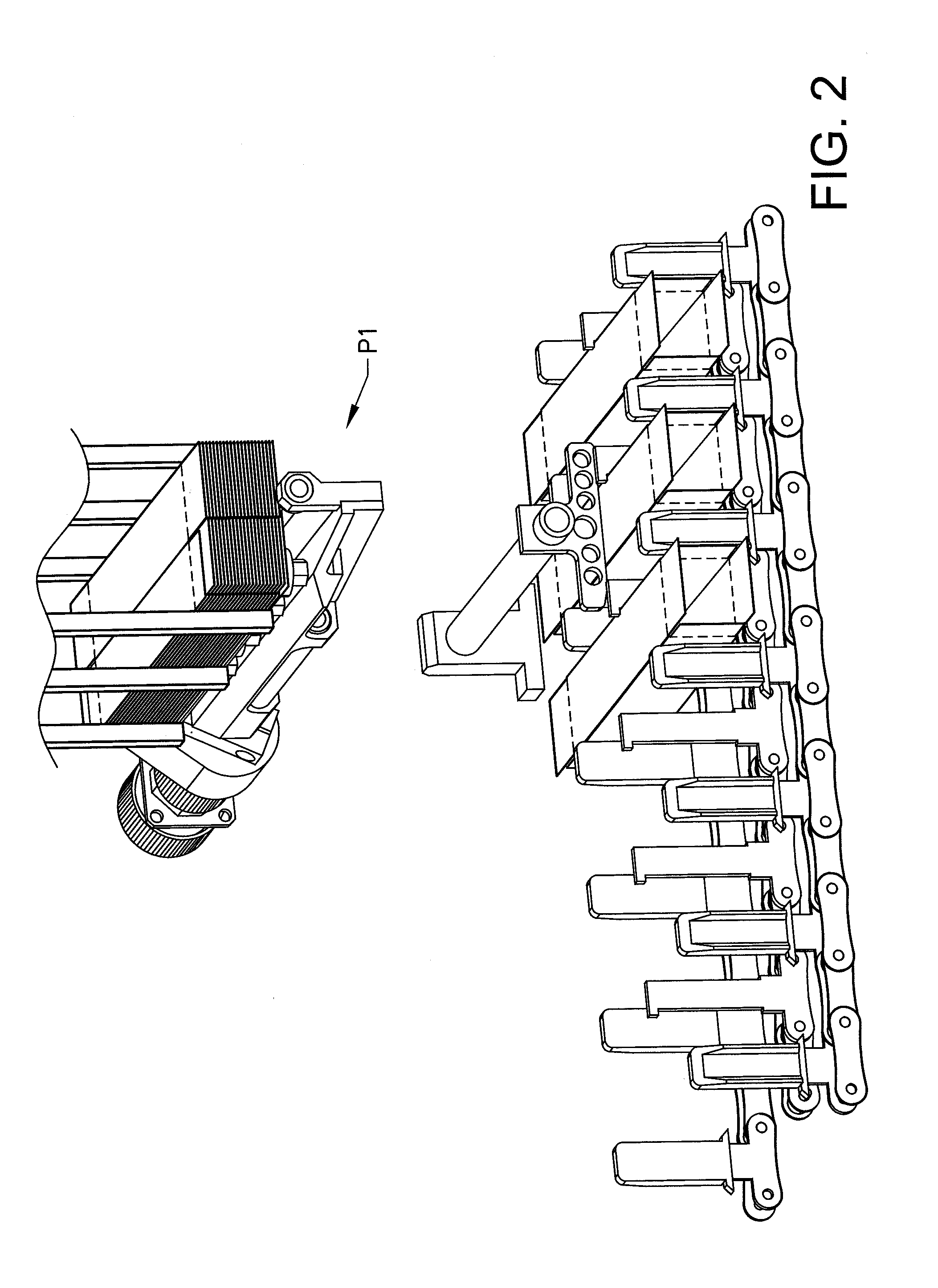

ActiveUS20130039731A1Decreases horizontal extensionHigh insertion ratePaper-makingBox making operationsFolding carton

Embodiments include a carton feeding system for feeding a plurality of cartons to a conveyor track, comprising a plurality of feeding devices, where each feeding device comprises a pick-up head with a plurality of vacuum cups, and an erecting finger pivotally suspended at the pick-up head, where the pick-up head has a pick-up position (P1) in which the holding plane of the pick-up head is positioned parallel to the folded carton blank that is to be picked up, and an insertion position (P2) in which the erecting finger is pivoted with respect to the holding plane of the pick-up head in such a way that the carton is opened, and where at least two cartons are inserted simultaneously into the conveyor track.

Owner:NORDEN MASCH AB

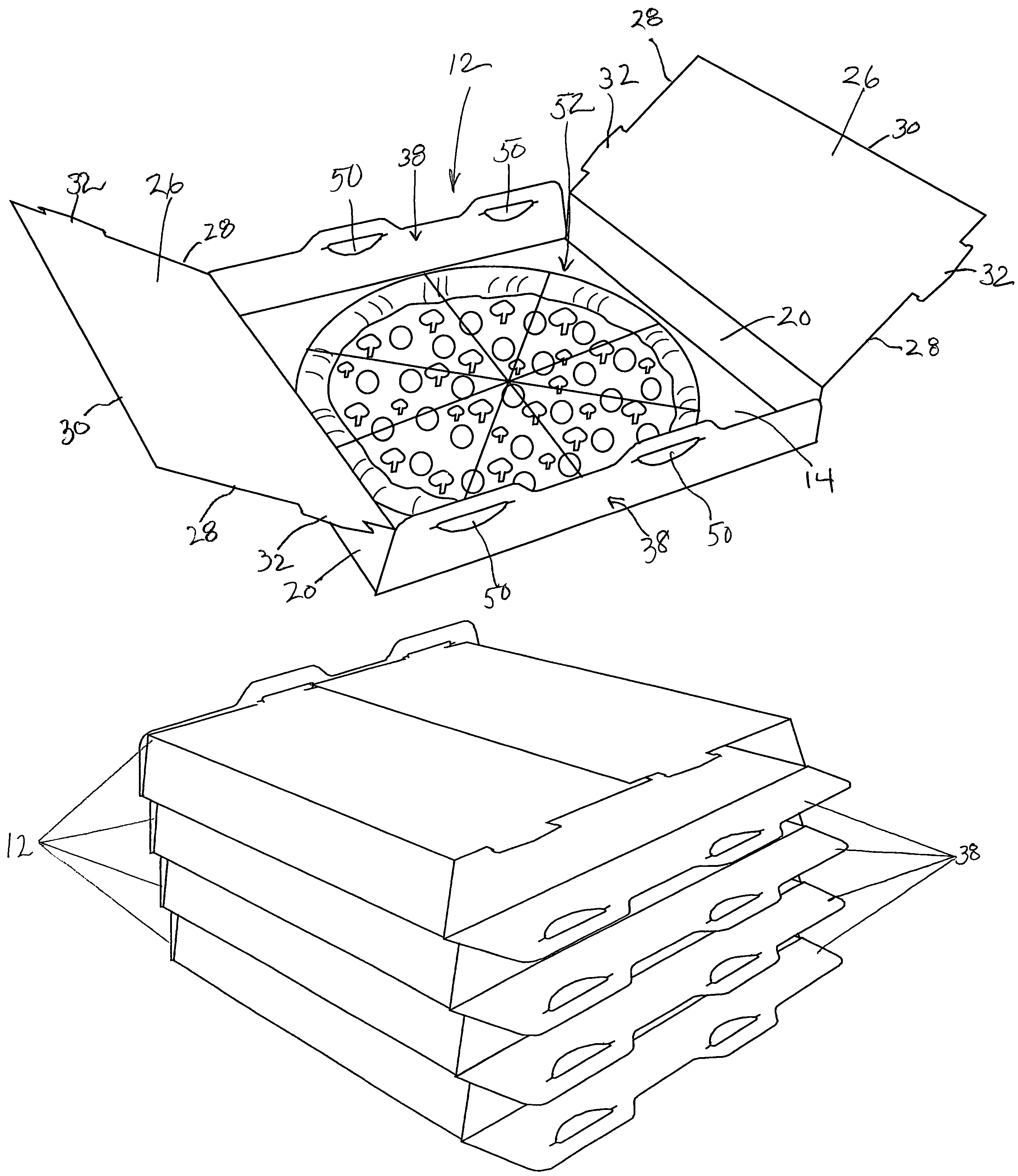

Pizza box

A folded food carton is formed from a matable, lay flat blank for retaining, transporting and serving hot food such as pizza. The blank includes an arrangement of end panels, side panels and cover panels foldable relative to a bottom panel such that, in the erected carton, the cover panels overlap and are interlocked with the side panels by means of offset locking tabs. The end panels slant upwardly and inwardly from the bottom panel to add rigidity and save material for the carton. The side panels flare upwardly and outwardly from the bottom panel and extend above the cover panels to enhance stackability and prevent shifting of stacked cartons one on top of the other. Several methods of packaging pizza in the folded carton are disclosed.

Owner:INT PAPER CO

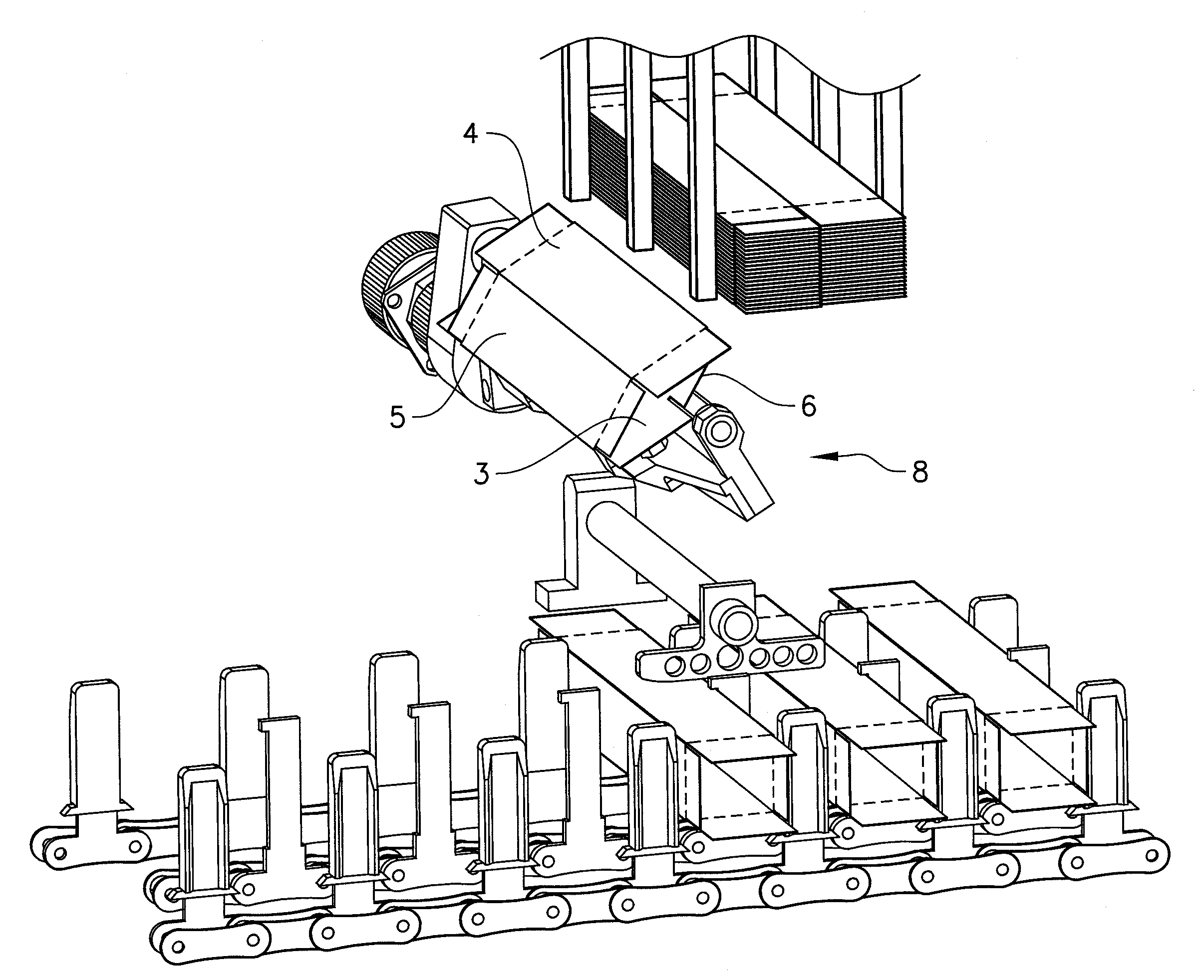

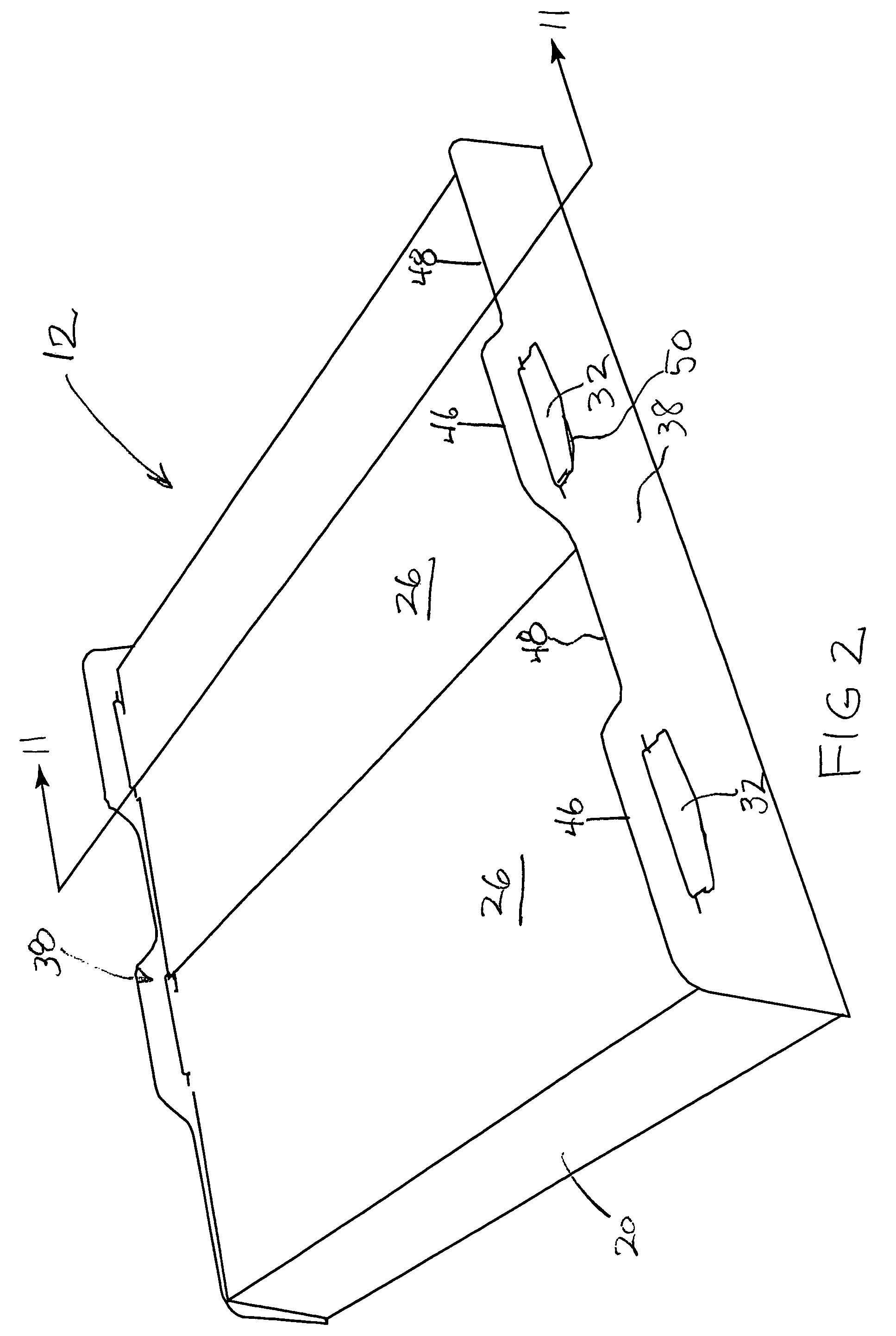

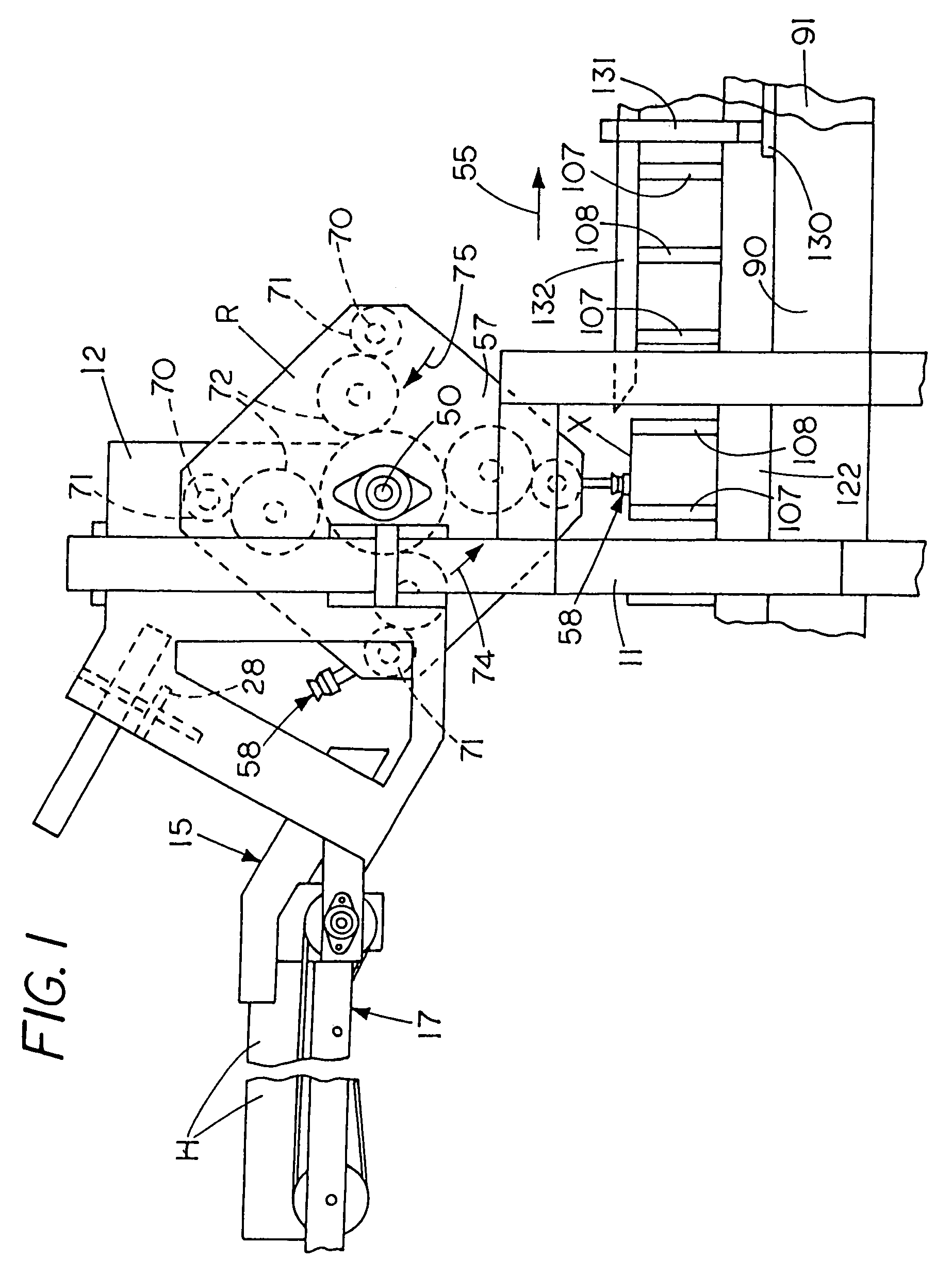

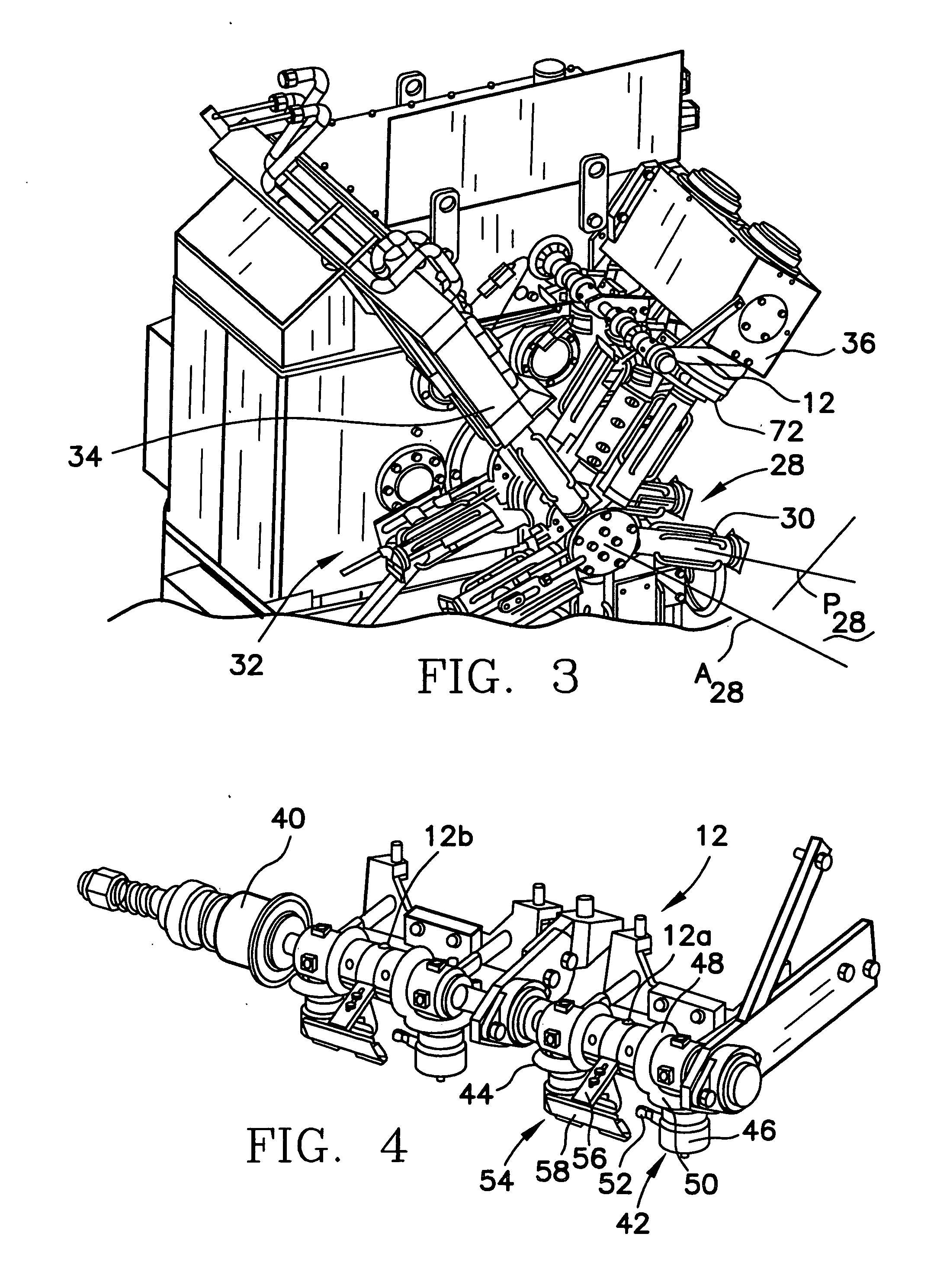

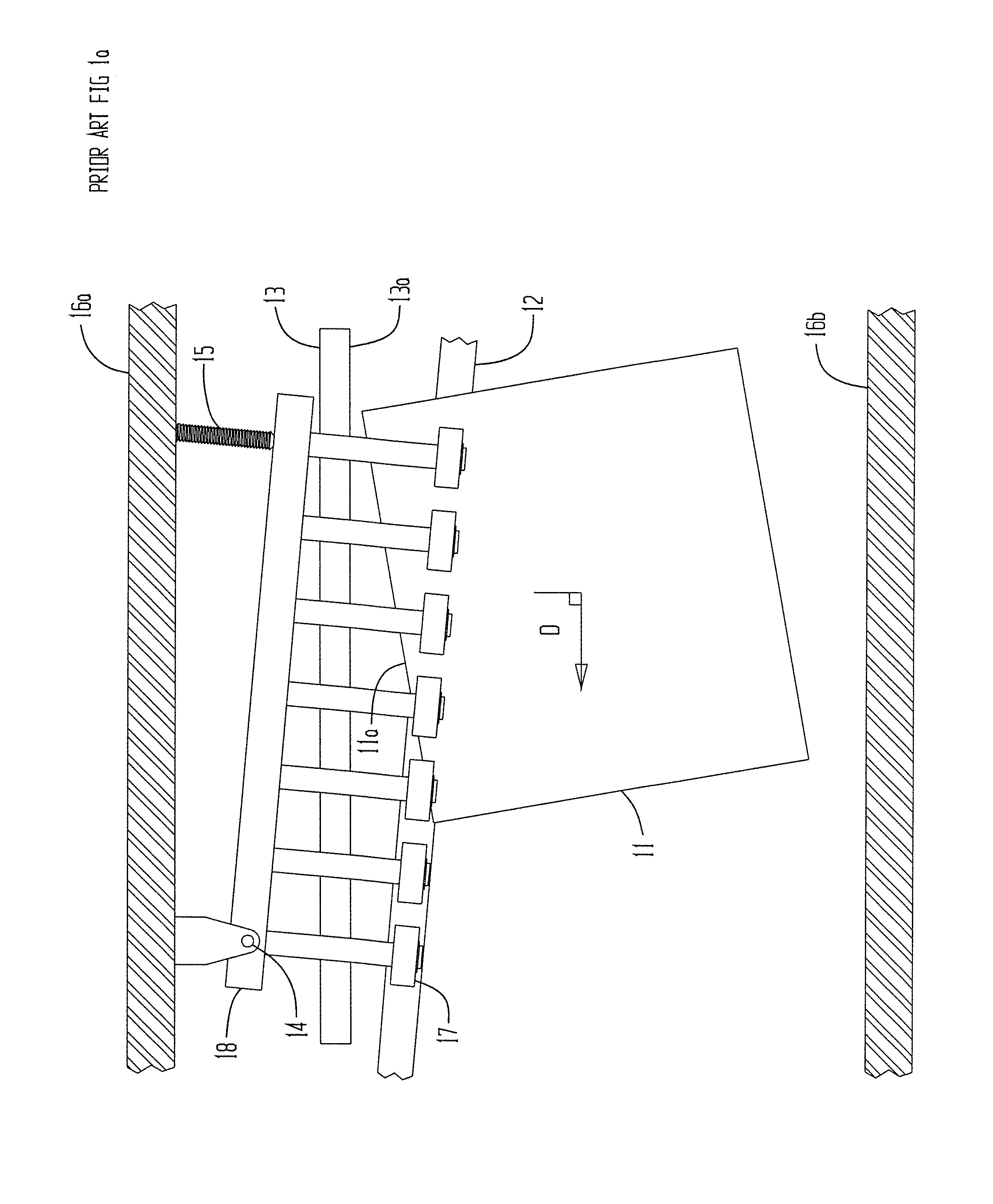

Carton erecting apparatus

InactiveUS7163502B2Avoid hard activationBoxes/cartons making machineryBox making operationsEngineeringTransfer mechanism

Rotary transfer mechanism is mounted on a frame for removing a flat folded carton from a storage hopper to move the carton to a flight conveyor assembly and in cooperation therewith erect the carton to be in an open rectangular condition. The transfer mechanism includes end plates rotated in one angular direction and vacuum cup assemblies rotated therewith and relative thereto in the opposite angular direction. The cup assemblies include transversely opposite cups having adjacent sides less flexible than their remote sides and intermediate cups having buttons therein to form dimples in a carton panel when grippingly engaged. The flight assembly includes guideways to have lugs of flight devices extend into their channels as devices move along the upper run of an endless conveyor. The flight devices include flight bars extending vertically above the lugs as the lugs move in said channels.

Owner:THIELE TECH

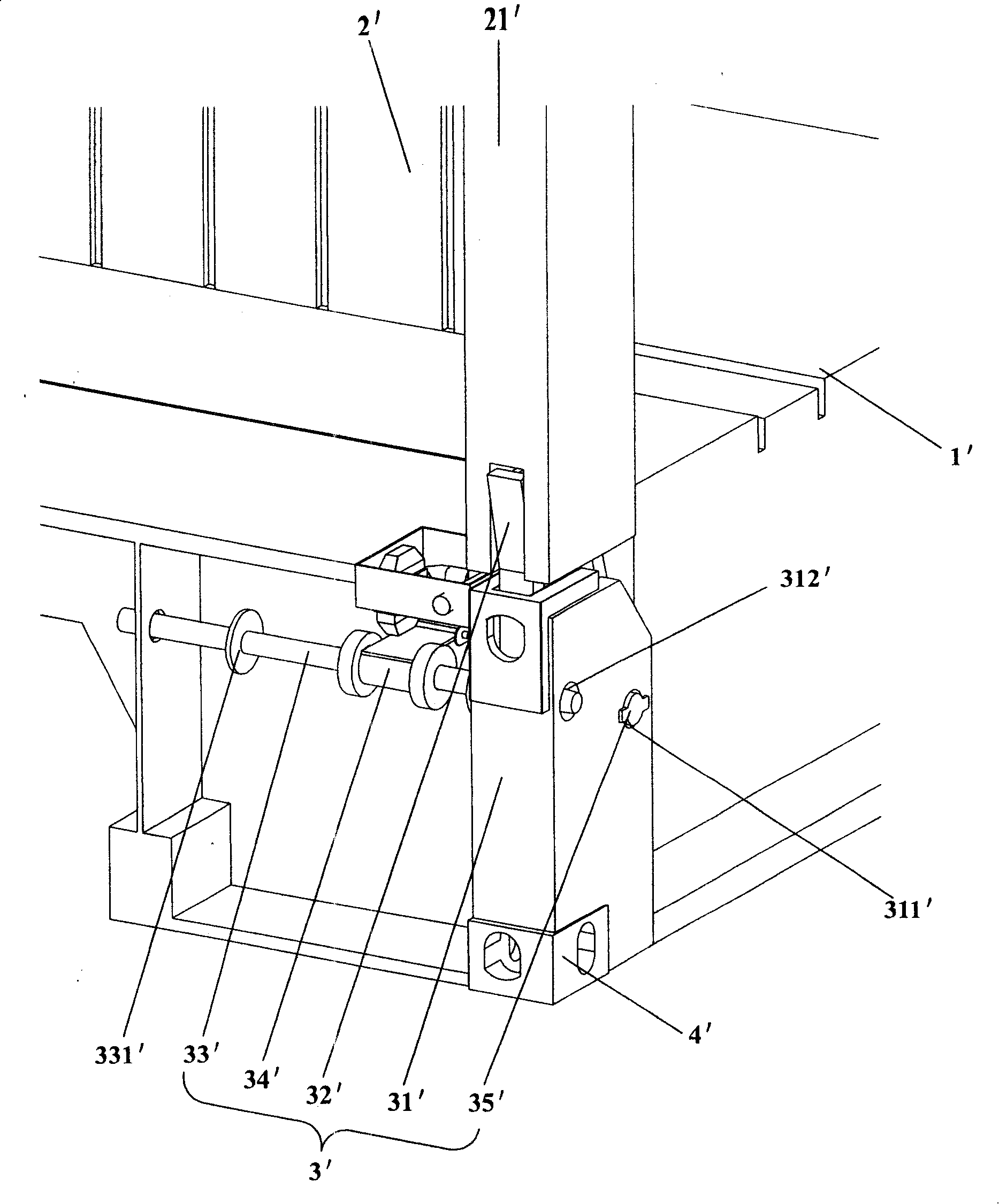

Butt hinge of folding case and folding case

The invention provides a gemel of a folding carton and the folding carton, wherein, the gemel comprises a fixed flap, a movable flap, a rotating pin, a lock pin and an elastic locking device. The fixed flap is provided with a fixed pivotal hole and a fixed locking hole; the movable flap is correspondingly provided with a movable pivotal hole and a movable locking hole; the rotating pin is inserted in the fixed pivotal hole and the movable pivotal hole to connect the fixed flap and the movable flap in a pivotal way; the lock pin can be inserted in and separate from the fixed locking hole and the movable locking hole; the elastic locking device is connected between an underframe of the folding carton and the lock pin; the elasticity of the elastic locking device forces the lock pin to be in parallel move toward the direction along which the lock pin is inserted in the fixed locking hole and the movable locking hole. The invention ensures the safety and reliability of the locking of the gemel with easy and efforts-saving operation, shortened operating time and enhanced working efficiency.

Owner:田东县永高林下养鸡协会

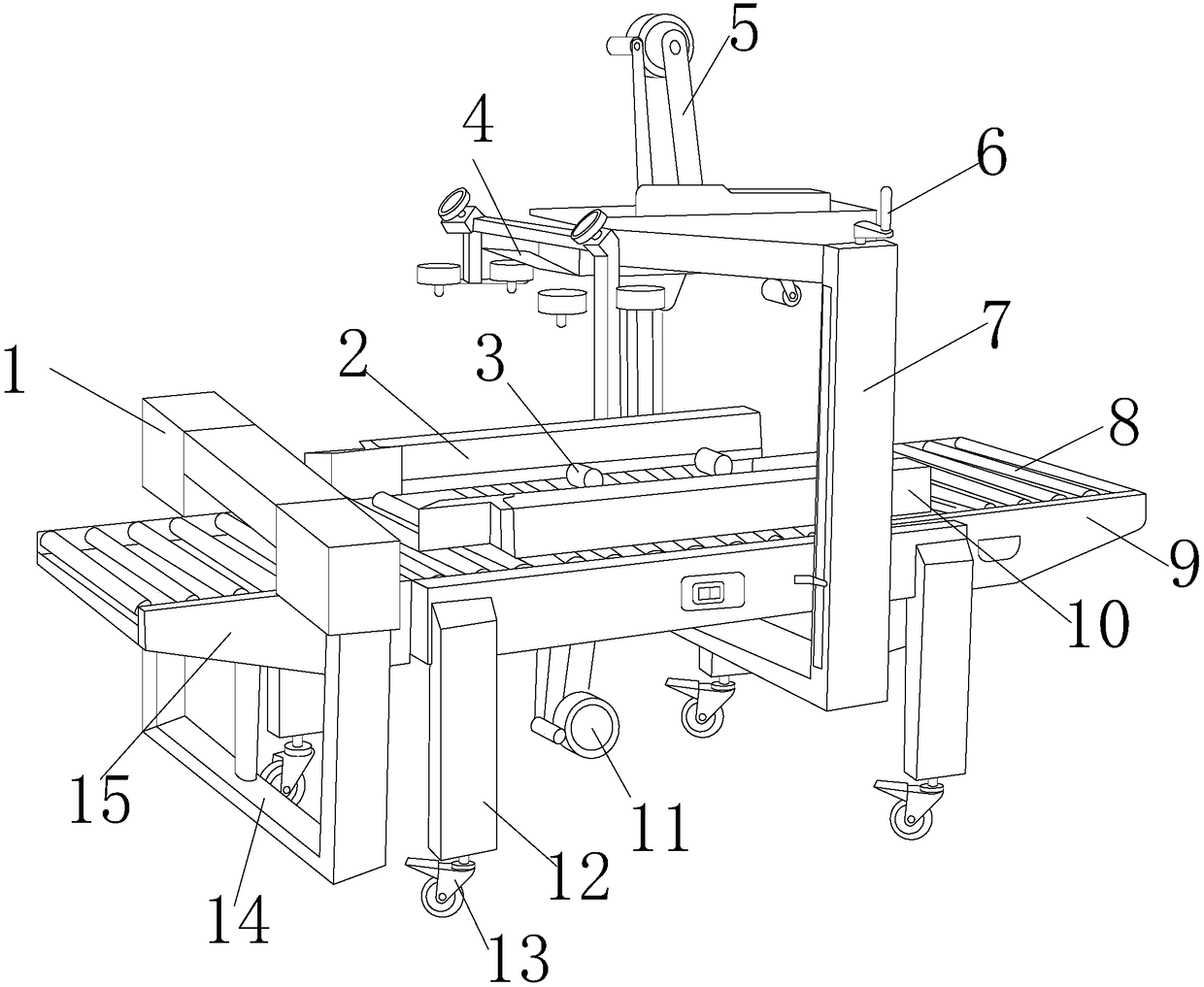

Novel full-automatic hot melt adhesive carton sealing machine

PendingCN108357706ASmooth movementNot subject to wear and tearWrapper twisting/gatheringAdhesive beltAssembly line

The invention discloses a novel full-automatic hot melt adhesive carton sealing machine. The novel full-automatic hot melt adhesive carton sealing machine structurally comprises an automatic cover folding device, a width adjustable left conveying device, a bottom glue pressing mechanism, a carton positioning device, a top adhesive tape barrel mechanism, a height adjusting handle, a lifting frame,a conveying roller, a machine body, a width adjustable right conveying device, an adhesive tape fixing roller, supporting feet, universal wheels, a height adjustable supporting frame and a containingtable. The novel full-automatic hot melt adhesive carton sealing machine has the beneficial effects that the full-automatic carton sealing machine can automatically fold carton folding covers before carton sealing, folding of the left-right folding covers is conducted firstly, then folding of the front-back folding covers is conducted, manual folding is not needed, the labor intensity of workers is relieved, manpower is saved, and the work efficiency is improved; meanwhile, a sealed carton can be uniform and attractive, the quality of the folding covers of the carton can be guaranteed, the modern assembly line operation requirement can be met, and using is safe, stable, convenient and reliable.

Owner:刘福原

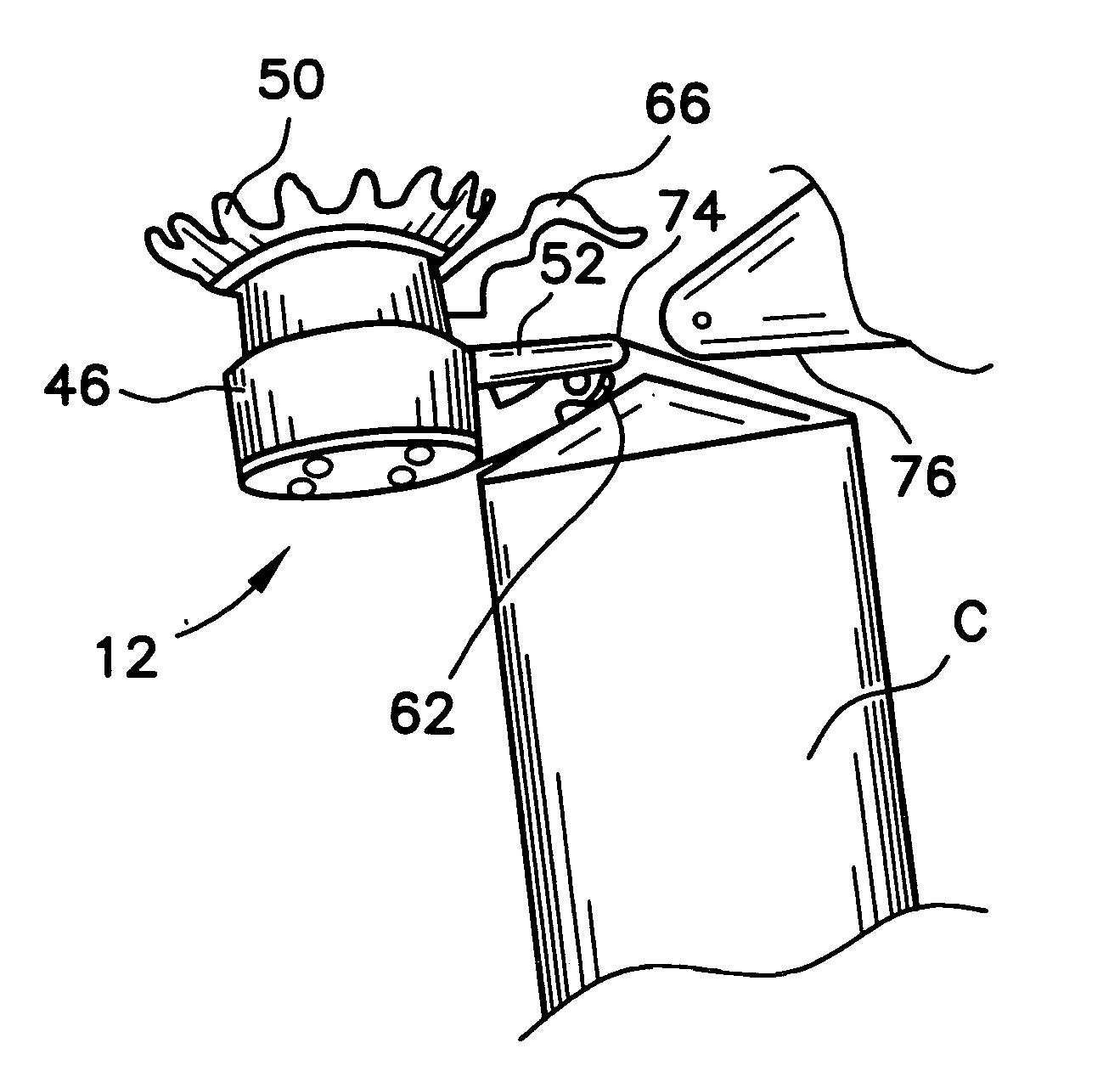

Carton bottom folding assembly

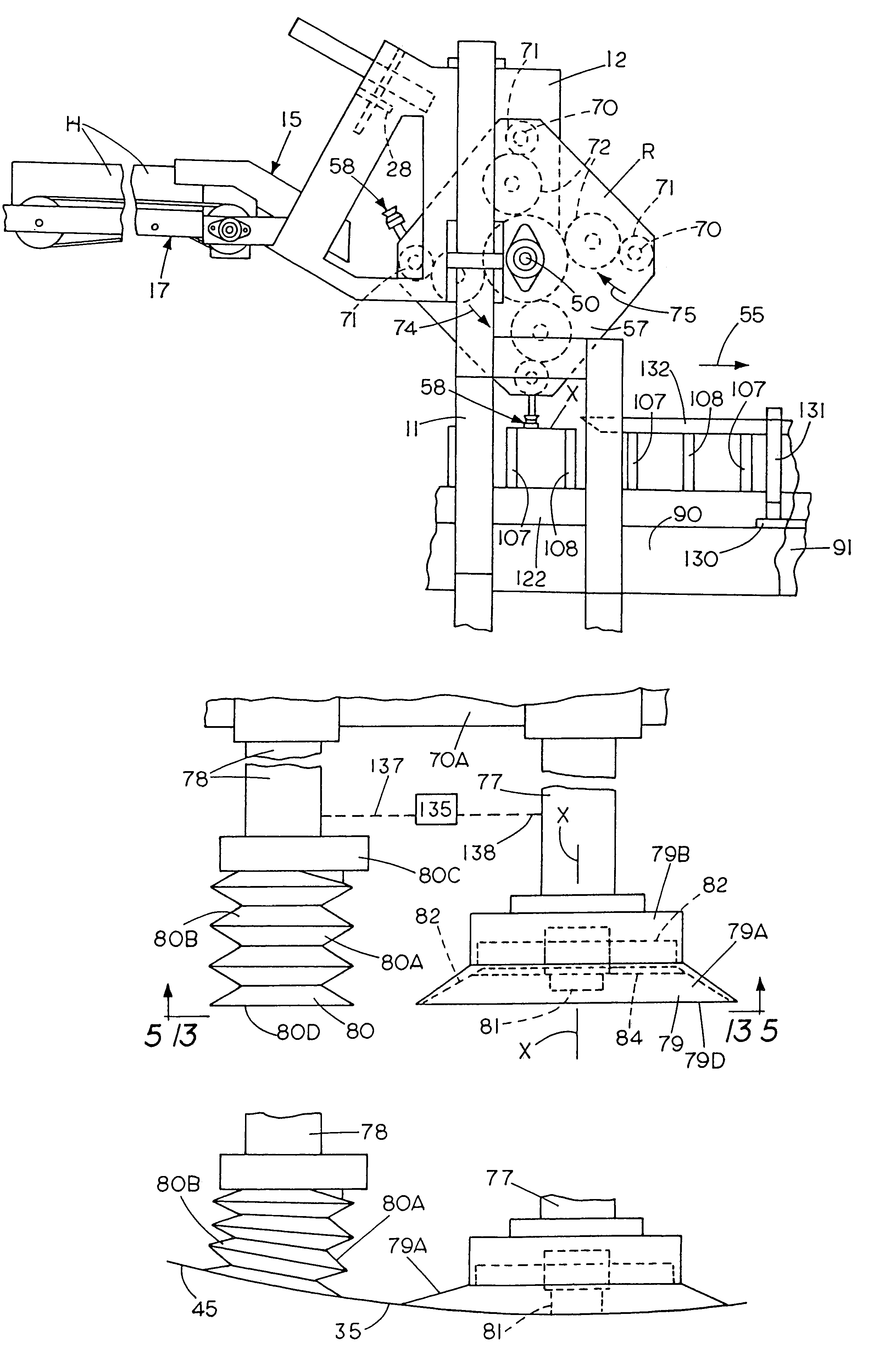

InactiveUS20050060965A1Reduce exposureReduce dust generationBoxes/cartons making machineryWrapper twisting/gatheringDrive shaftTurret

A bottom folding assembly for a packaging machine is configured to infold the bottom side panels, leading panel and trailing panel of a carton for forming a sealed carton bottom in such a manner as to reduce the contact of rotating elements with the carton material to reduce the generation of dust. The bottom folding assembly is positioned about a rotating turret that defines a turret plane. The mandrels are configured to receive a carton in the tubular form and to carry the carton with the carton positioned such that a bottom of the carton is positioned at a free end of the mandrel. The bottom folding apparatus, located between a carton bottom heater and a carton bottom sealer includes a rotating drive shaft mounted transverse to the turret plane and a pair of opposing rotating members are operably mounted to the drive shaft and are disposed on either side of the turret rotational path. The rotating member rotate in a plane transverse to the turret plane. A tucking assembly is disposed between the opposing rotating members and is mounted to the drive shaft for rotating in a plane transverse to the rotating members and parallel to the turret plane. When a carton is positioned on the mandrel and passes the folding assembly, the opposing rotating members contact the bottom side wall flaps, urging the bottom side wall flaps inwardly, and the tucking assembly contacts the bottom trailing flap, urging the bottom trailing flap inwardly, over the bottom side wall flaps. A form, fill and seal machine having the bottom folding assembly is also disclosed.

Owner:TETRA LAVAL HLDG & FINANCE SA

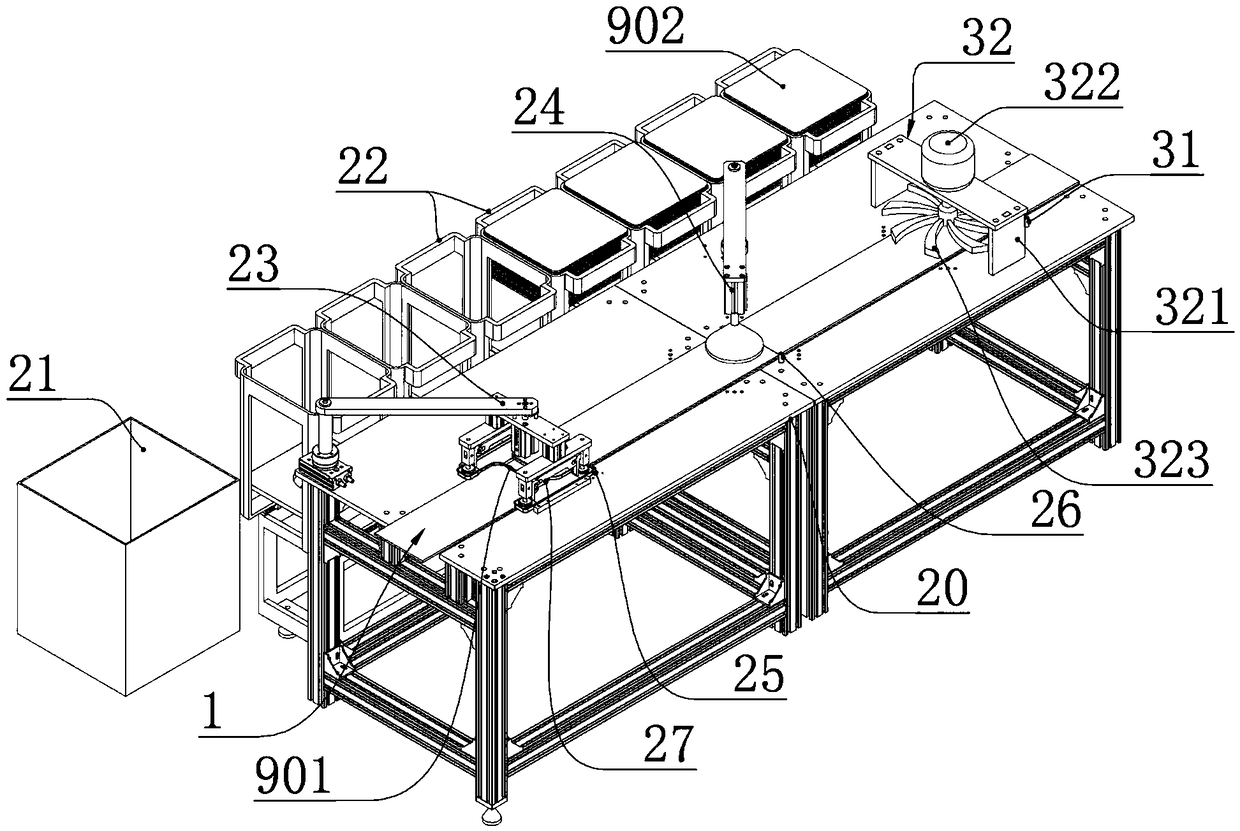

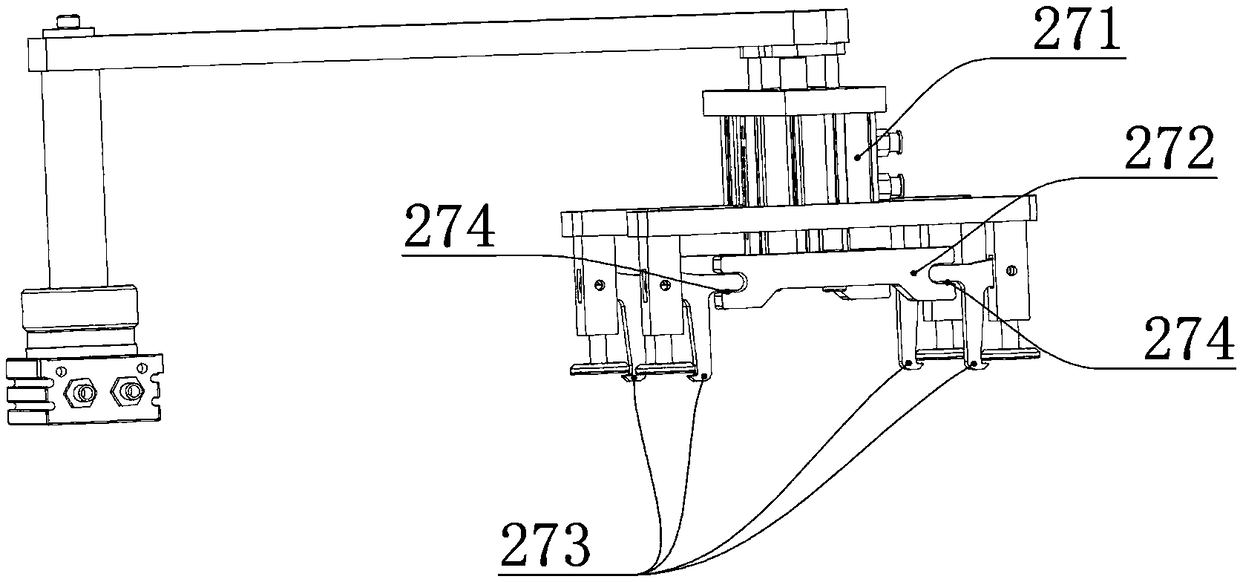

Automatic packaging machine

ActiveCN108860855AHigh degree of automationReduce labor inputWrappers shrinkageWrapper twisting/gatheringEngineeringPlastic film

The invention discloses an automatic packaging machine. The automatic packaging machine includes an automatic conveying line, the automatic conveying line is used for conveying scale frames in a transmission direction and sequentially passes through an assembly work position, a dedusting work position, a plastic wrapping work position, a foam installation work position, an encasement work positionand an encapsulation work position. The assembly work position is used for installing scale discs onto the scale frames to assemble electronic scales; the dedusting work position is used for conducting dedusting on the electronic scales; the plastic wrapping work position is used for packaging the dedusted electronic scales and external accessories into plastic film; the foam installation work position is used for installing anti-collision foam onto the electronic scales after packaging by the plastic film; an unpacking work position is set on the encasement work position, and the unpacking work position is used for making folded cartons open; the electronic scales in which anti-collision foam is installed are loaded into the open cartons at the encasement work position; the cartons withthe electronic scales are encapsulated at the encapsulation work position. Therefore, the automatic packaging machine has the advantages that the automation degree is high, the input amount of labor is small, and the production efficiency is high.

Owner:浙江嘉图创意设计有限公司

Carton folding device

InactiveCN103660371AImprove work efficiencyAvoid damageContainer making machineryCardboardEngineering

The invention discloses a mechanical device for folding paper boards, and particularly relates to a carton folding device. The carton folding device comprises a machine frame, an air cylinder and an assembling arm, wherein the air cylinder and the assembling arm are arranged on the machine frame, a U-shaped concave groove enabling a transmission device to pass is formed in the middle of the upper end of the assembling arm, two assembling holes are symmetrically formed in the two sides of the assembling arm, a pin shaft is arranged in each assembling hole, a first lateral folding arm, a second lateral folding arm, a first upper folding arm and a second upper folding arm are arranged on the pin shafts, the first lateral folding arm and the second lateral folding arm are the same and used for folding lateral faces of a carton, and the first upper folding arm and the second upper folding arm are the same and used for folding the top of the carton. The carton folding device adopting the technical scheme is simple in structure and high in work efficiency.

Owner:重庆信奇建材机械制造有限公司

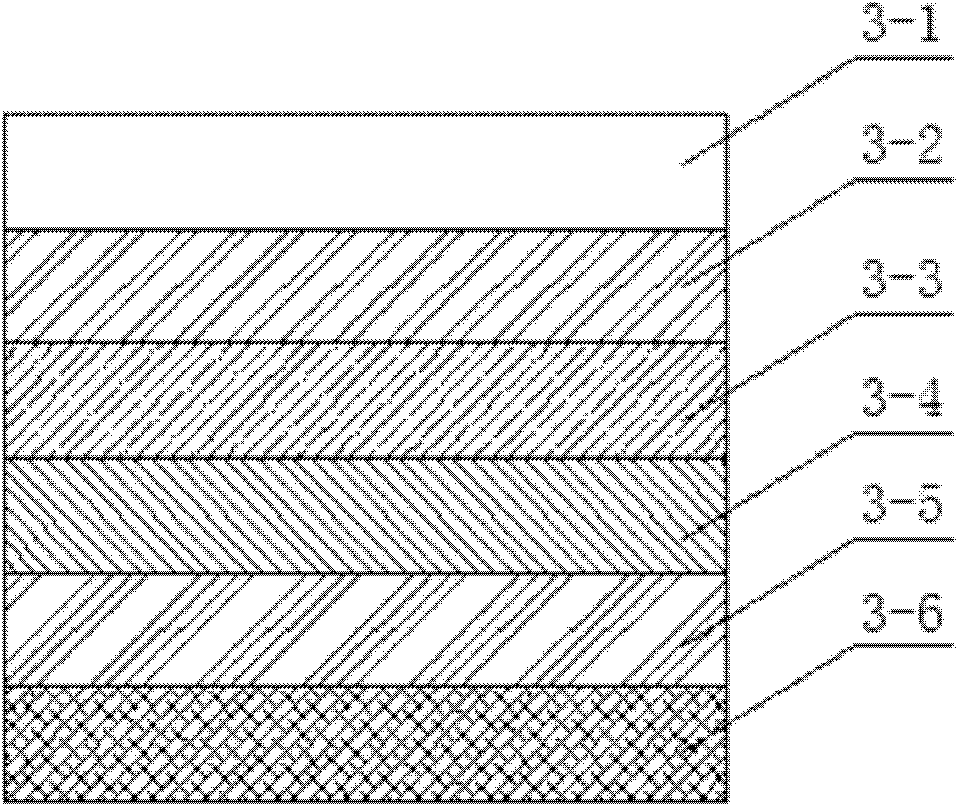

Method of producing cartons

InactiveUS20060000544A1Prevent picking and separationEasy to holdBoxes/cartons making machineryPaper-makingWater basedEmulsion

A process for forming cartons in which one or more reinforcing strips are laminated or adhered to a carton material using an extruded foamed adhesive or folded carton. Typically, the foamed adhesive is a water-based emulsion and applied in strips in either a continuous or non-continuous manner onto strips or substrates.

Owner:RIVERWOOD INT CORP

Automatic ceramic tile packaging equipment

The invention belongs to the technical field of packaging, and provides automatic ceramic tile packaging equipment. The automatic ceramic tile packaging equipment comprises a carton feeding mechanism, a carton opening mechanism and a tile pushing mechanism, wherein the carton feeding mechanism is used for stacking folded cartons and fixedly conveying the cartons, the carton opening mechanism is used for opening the folded cartons, and the tile pushing mechanism is used for holding ceramic tiles and pushing the ceramic tiles to the opened cartons. The carton feeding mechanism is located on one side of the carton opening mechanism, and the tile pushing mechanism is located below the carton opening mechanism. According to the automatic ceramic tile packaging equipment, the folded cartons stacked on the equipment are fixed through the carton feeding mechanism and conveyed to the space below the carton opening mechanism, then the folded cartons are opened through the carton opening mechanism, finally the ceramic tiles placed on the tile pushing mechanism are pushed into the opened cartons, and thus automatic packaging of the ceramic tiles is completed; and the automatic ceramic tile packaging equipment has the advantage of being high in production efficiency.

Owner:SHENZHEN AMI TECH CO LTD

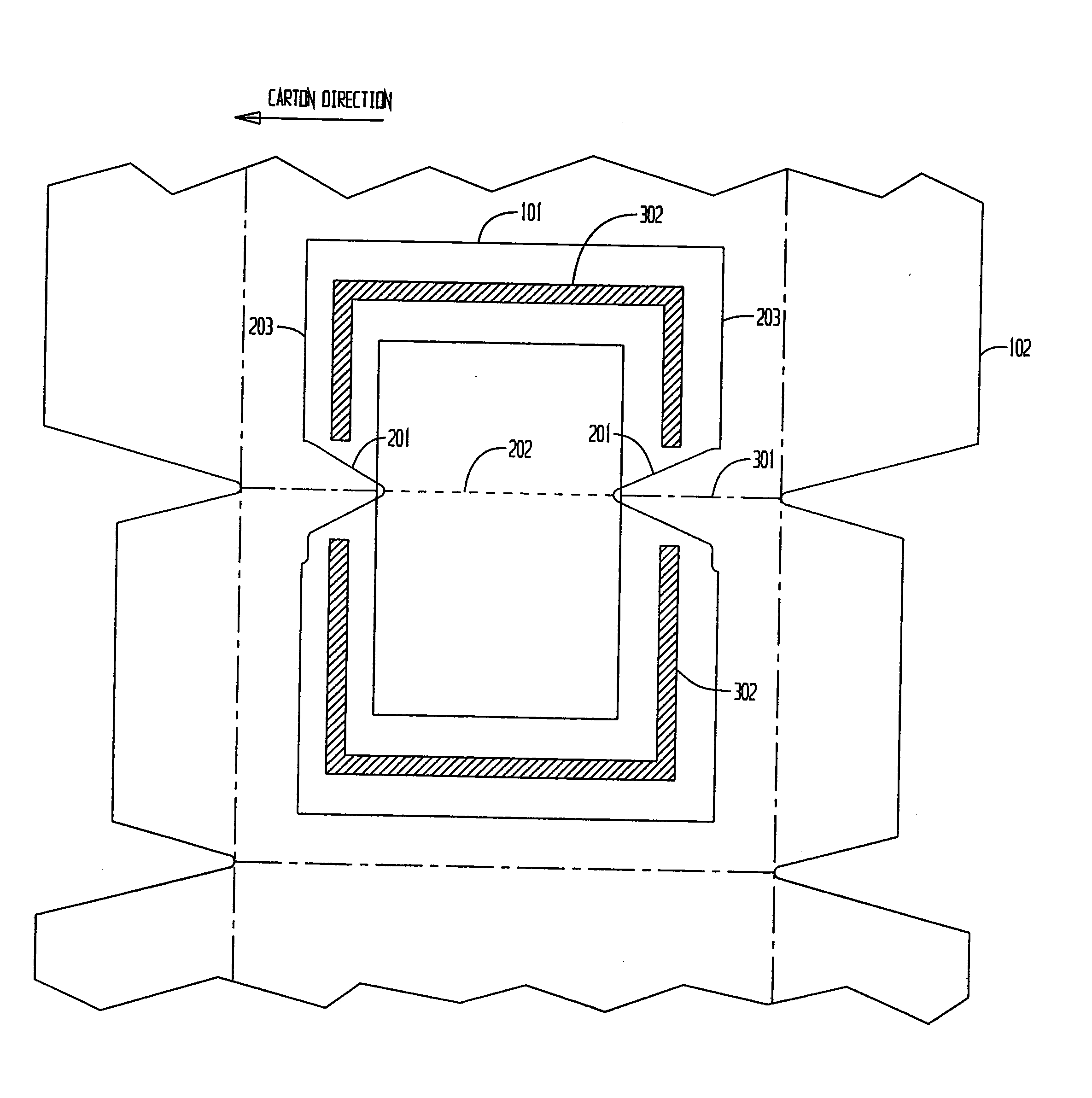

Rigid window applicator and method

InactiveUS20110245056A1Easy to operateImprove efficiencyBoxes/cartons making machineryBox making operationsCardboardAdhesive

Apparatus and method for affixing rigid transparent windows to folding cartons draws rigid window web material from a roll and scores and notches the window material in a continuous manner. Notch waste is removed and collected for disposal by the combination of vacuum and an air jet applied at the point of severance. The transparent window material is then provided to an accumulator and then to a stop-and-go adhesive application and material cutting stage, where adhesive is applied to the material which is cut into individual rigid window patches, with the accumulator serving as a buffer between the high speed continuous scoring and notching stage and the stop-and-go adhesive application and cutting stage. Adhesive-bearing individual window patches are applied to moving folding cartons with registration between the notches and cut lines as well as between the cut window blanks and carton blanks provided by a control system.

Owner:TAMARACK PRODS

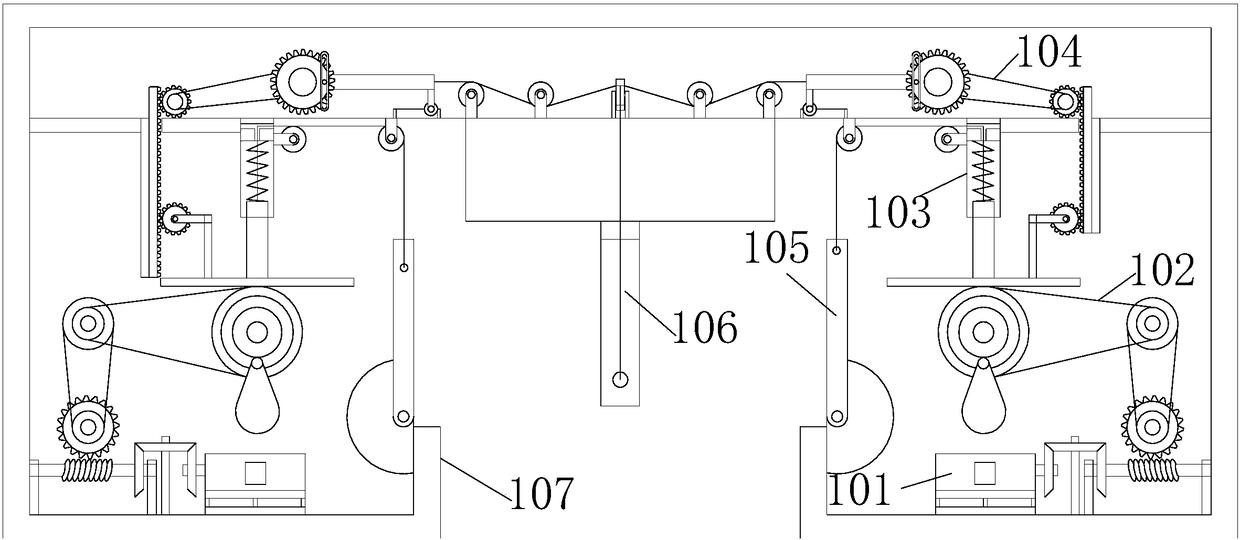

Automatic product packaging, conveying and stacking system

InactiveCN112977957AImprove efficiencyClosely spacedWrapper twisting/gatheringStacking articlesStructural engineeringManufacturing engineering

The invention relates to an automatic product packaging, conveying and stacking system. The automatic product packaging, conveying and stacking system comprises a lifting conveying mechanism, a loading mechanism is arranged at one end of the top of the lifting conveying mechanism, an electric roller conveying line is arranged below the loading mechanism, and two clamping conveying belts are symmetrically arranged on the two sides of the top of the electric roller conveying line in the length direction. A carton unfolding mechanism is arranged at one end of the electric roller conveying line, the end, close to the carton unfolding mechanism, of the electric roller conveying line corresponds to the loading mechanism in position, and a press-fit carton sealing mechanism is arranged below the carton unfolding mechanism. A folded carton conveying mechanism is arranged on the side, away from the electric roller conveying line, of the carton unfolding mechanism, a cover pressing mechanism is arranged on the top of the middle of the electric roller conveying line, and a carton sealing mechanism is arranged on one side of the cover pressing mechanism. The automatic product packaging, conveying and stacking system is more continuous in action and higher in efficiency.

Owner:泸州韶光智造科技有限公司

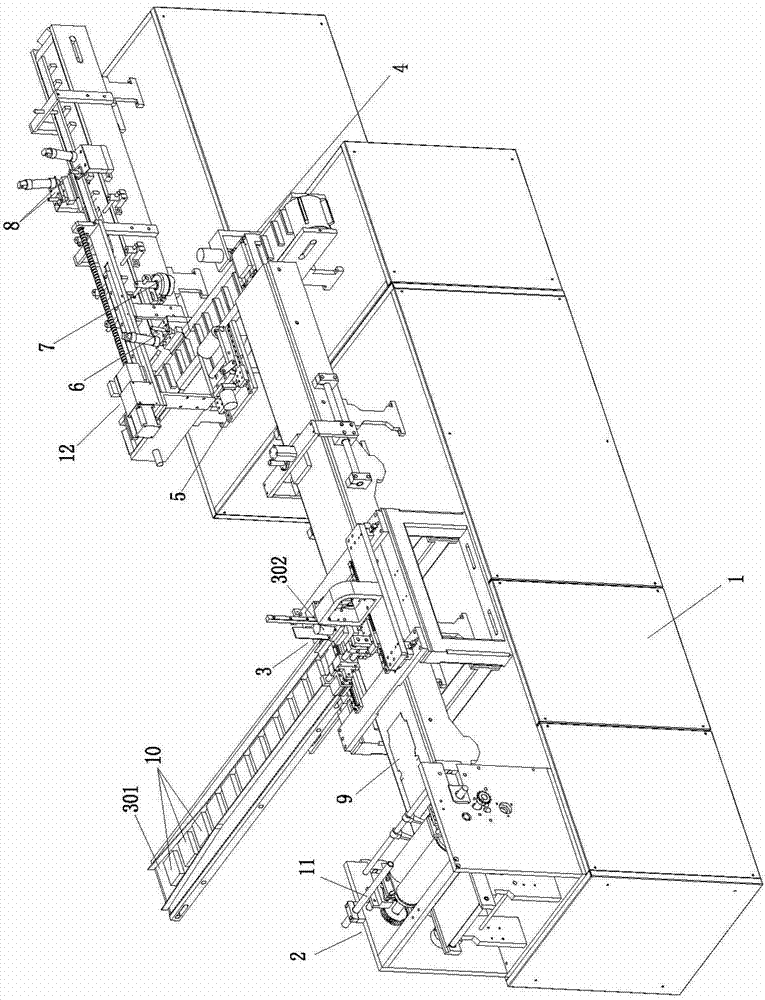

Logistical packaging machine

The invention provides a logistical packaging machine which mainly comprises two parts, that is, a carton forming part on the right and a carton adhesive-sealing part on the left. The carton forming part comprises a paperboard fixing device, a carton forming device, an upper carton closing device, a lower carton closing device, a synchronous belt conveying device and a carton conveying device. The carton adhesive-sealing part comprises an upper adhesive-sealing device, a lower adhesive-sealing device and a clamp-phase mechanism. The clamp-phase mechanism maintains the folded carton state. Adhesive-sealing mechanisms adopt common carton adhesive-sealing mechanisms on the current market. A carton sealing machine core is innovatively designed on the basis of the original adhesive-sealing mechanisms. When cartons are pushed, adhesive tapes are stuck to the upper parts and the lower parts of the cartons synchronously by the adhesive-sealing mechanisms. After one process is finished, all the mechanism are reset. Besides, distance adjusting devices are designed on folding mechanisms and the adhesive-sealing mechanisms of small packaging machines, the distances are adjusted to be proper according to different carton sizes, and the packaging tasks of cartons of different sizes are completed.

Owner:上海矽河矽渼科技发展有限公司

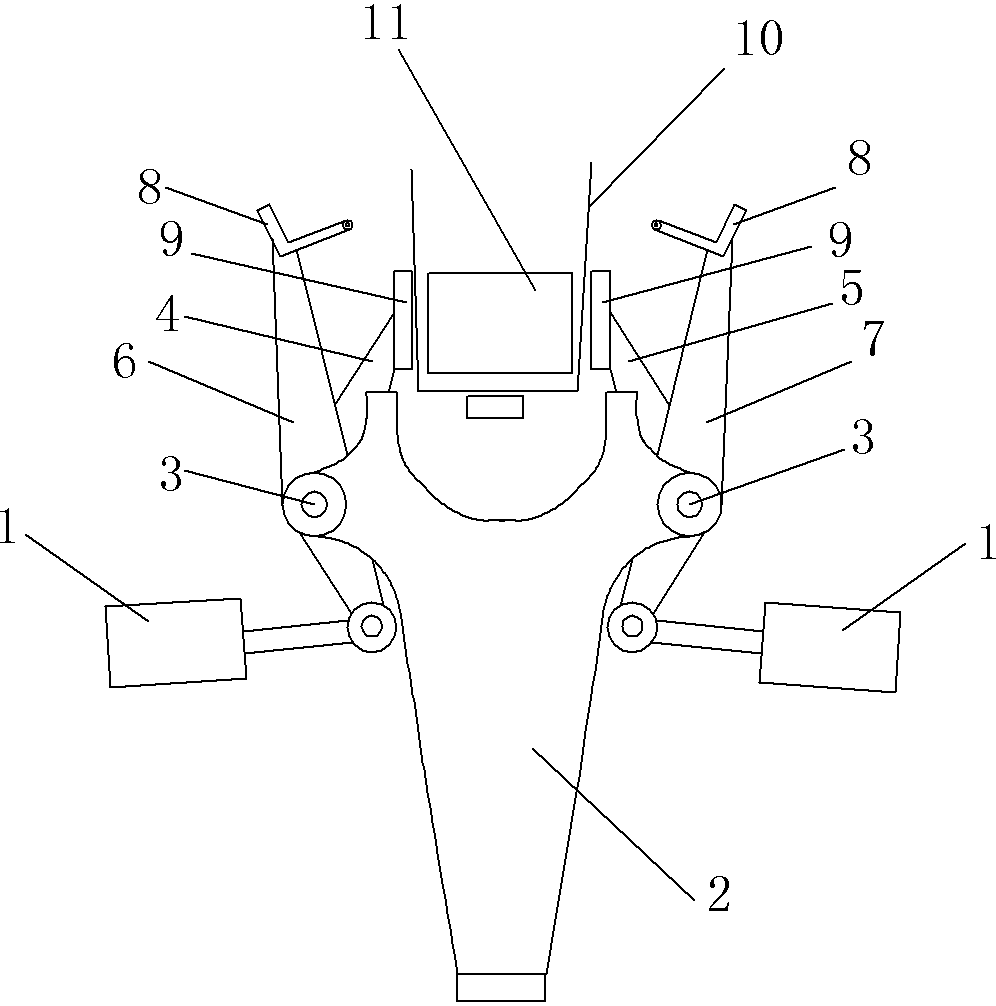

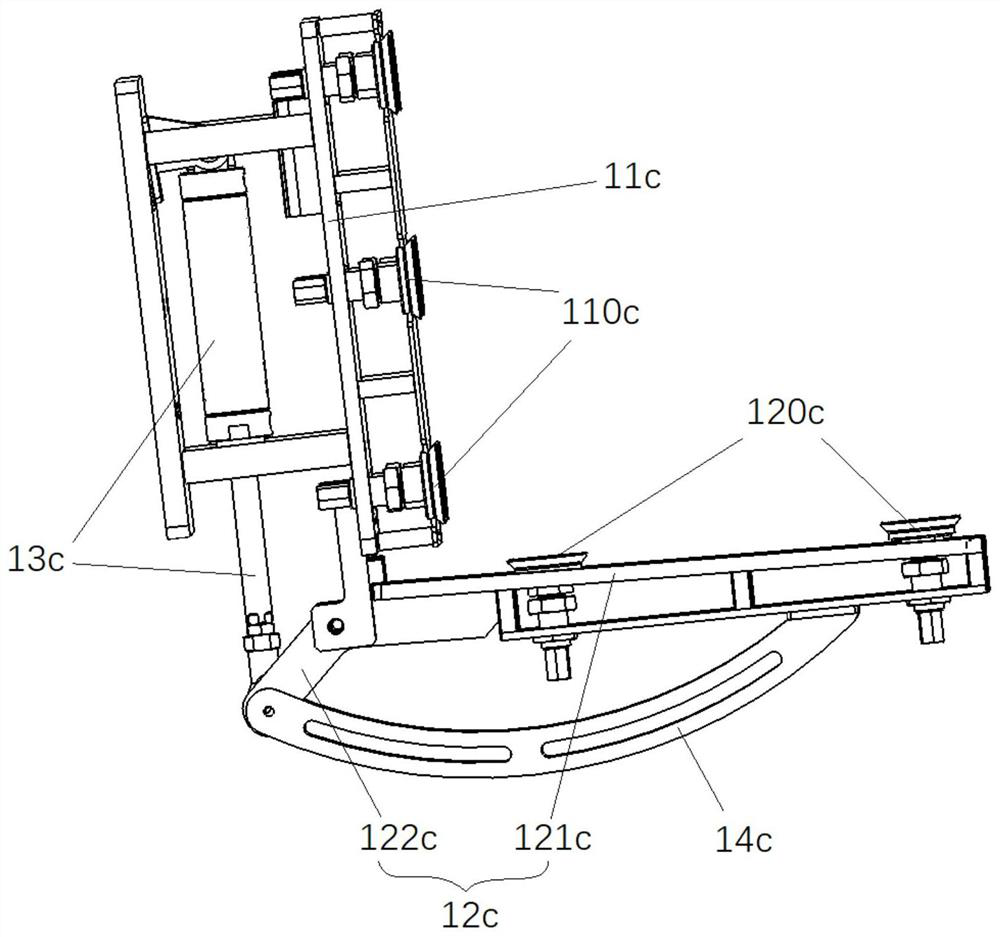

Bottom sealing system of carton opening machine

ActiveCN112644790AAchieve random discretizationImprove unpacking efficiencyPackaging machinesRobot handStructural engineering

The embodiment of the invention provides a bottom sealing system of a carton opening machine. The bottom sealing system comprises a rack and a bottom sealing device, wherein the rack is used for placing cartons; the bottom sealing device is used for sealing the bottoms of the cartons; the cartons placed on the rack are in a folded state; each carton comprises long edges and short edges; the bottom sealing system of the carton opening machine further comprises a carton opening mechanical arm; the carton opening mechanical arm is used for grabbing the cartons on the rack and opening the cartons as well as moving the grabbed cartons to the bottom sealing device; and the bottom sealing device is used for bending and sealing the bottoms of the cartons. The bottom sealing system provided by the embodiment of the invention uses the carton opening mechanical arm to replace manual operation, can achieve automatic opening and bottom sealing of folded cartons, achieves random discrete formation and bottom sealing of the cartons of various different specifications, and improves the carton opening efficiency.

Owner:HUAWEI TECH CO LTD

Method and apparatus for sheet and carton blank aligning using caster effect

ActiveUS20140191465A1Low skill level requiredImprove productivityRegistering devicesFunction indicatorsDelivery systemCaster

An improved apparatus and method for properly orienting and aligning flat sheets or strip material, such as in the form of folding carton blanks, on a conveying system such as used in carton folders / gluers is disclosed. A moving sheet is engaged on at least one surface by plural non-driven movable casters oriented at an angle relative to the sheet's intended direction of travel, or target direction. The casters apply a lateral force to the sheet so that a linear lateral edge of the sheet is brought into contact with an adjacent guide member aligned with the target direction, with the sheet assuming a predetermined orientation relative to the target direction. Each caster is resiliently biased such as by a spring at a predetermined angle relative to the target direction. With the sheet's lateral edge in intimate contact with the guide member, the moving sheet is in the aforementioned predetermined orientation relative to, and is displaced in, the target direction.

Owner:TAMARACK PRODS

Electromechanical folding carton gluer

InactiveCN102909888AEasy to operateCompact structurePaper-makingBox making operationsEngineeringFolding carton

The invention provides an electromechanical folding carton gluer. The gluer comprises a rectangular rack, a shaking conveying mechanism, glue spreading rollers and sensors, wherein the shaking conveying mechanism is arranged on the rectangular rack; a handle of the shaking conveying mechanism is arranged outside the rectangular rack; front and rear rollers of the shaking conveying mechanism drive conveyor belts to implement conveying on a plane parallel to the surface of the rectangular rack; the glue spreading rollers are slightly lower than the plane of the conveyor belts; platens are arranged above the glue spreading rollers and are installed on swing arms; the swing arms are connected with swing shafts; the swing shafts are coupled with a chain of the handle; the sensors are arranged in front of the glue spreading rollers and are photoelectric converters; the photoelectric converters are connected with the platens via signals; and the sensors are linked with the swing shafts.

Owner:昆山市大金机械设备厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com