Automatic molding device of carton box

An automatic forming and carton technology, which is applied in packaging and other directions, can solve the problems of production efficiency affecting product production efficiency, unfavorable production efficiency and production quality, and large manual operation errors, so as to avoid scratching or piercing the carton, and the folding effect is good , The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

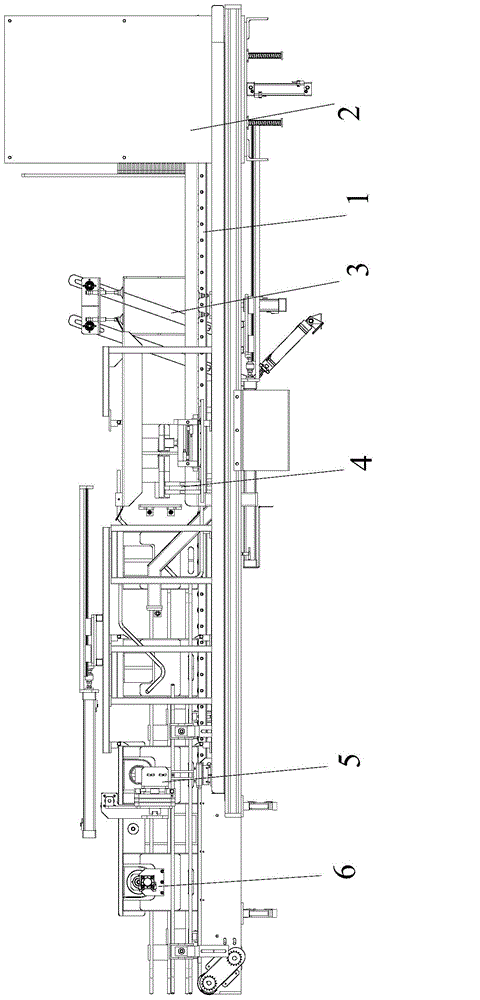

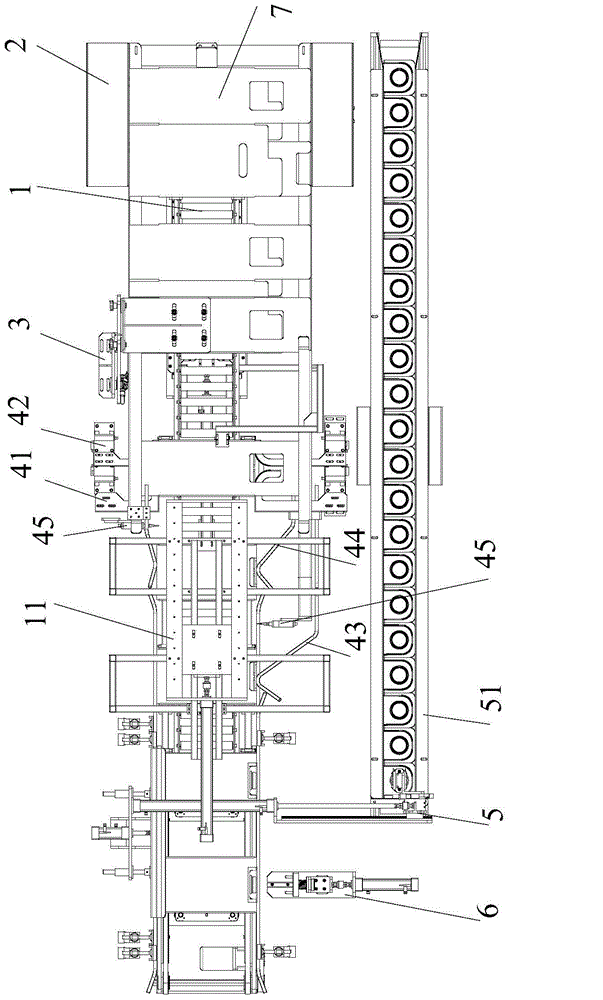

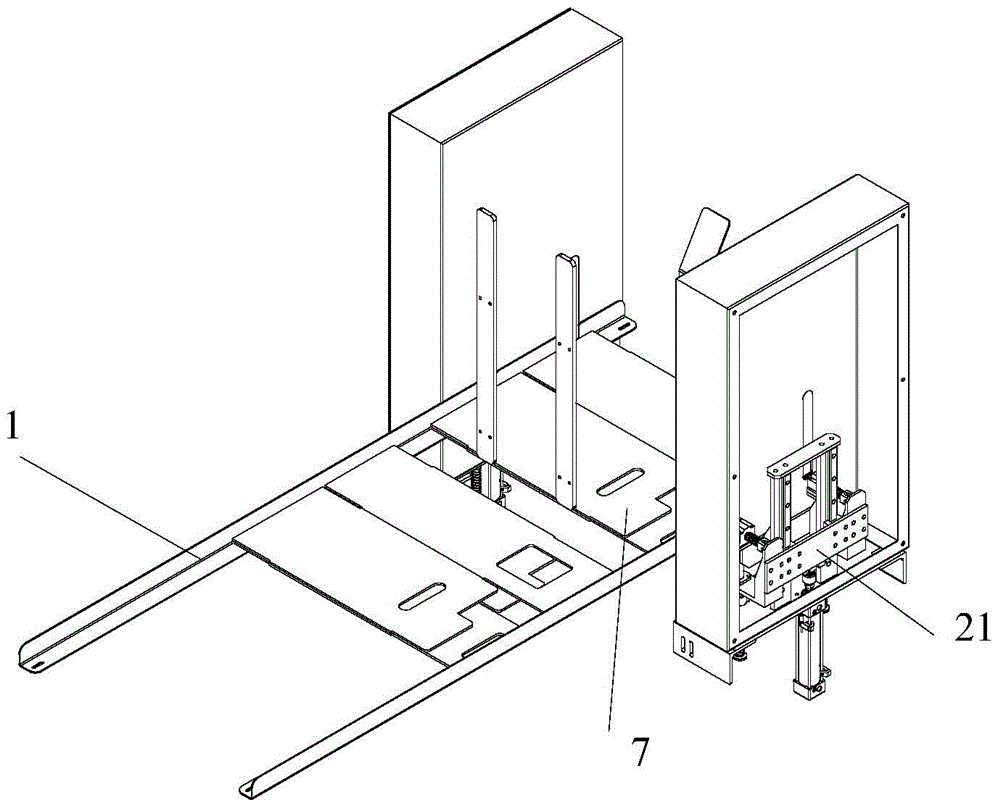

[0057] The equipment of this embodiment is used for automatic carton forming, and its structure is as follows: figure 1 and figure 2 shown; among them, figure 1 is the structural diagram of the side view angle, figure 2 Schematic diagram of the structure viewed from above. The equipment includes a transmission device 1, a feeding device 2, a preliminary forming device 3, a folding glue dispensing device 4, a glue installation device 5, an inflation device 6, a frame 8 and a control device. The feeding device 2, the preliminary forming device 3, the folding and dispensing device 4, the glue installation device 5 and the inflation device 6 are sequentially arranged on the frame 8 along the conveying direction.

[0058] The conveying device 1 is used to move the cartons along the conveying direction; the feeding device 2 is used to feed the folded cartons one by one; the preliminary forming device 3 is used to pull up one side of the folded cartons to make the folded cartons...

Embodiment 2

[0090] The difference between the equipment of this embodiment and that of Embodiment 1 is that the equipment of this embodiment does not include a glue installation device and an inflation device; the equipment includes a transmission device, a feeding device, a preliminary forming device, a folding and dispensing device, a frame and a control device. The feeding device, the preliminary forming device and the folding and dispensing device are sequentially arranged on the frame along the conveying direction. The control device is respectively connected with the feeding device, the preliminary forming device, the folding glue dispensing device and the transmission device in signal connection.

[0091]The folding dispensing device includes a folding mechanism arranged on both sides of the transmission device, and a dispensing mechanism for dispensing and bonding; the folding mechanism includes a rear cover folder, a front cover folder, and an upper and lower cover folder arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com