Carton opening, carton loading and stacking all-in-one machine with robot

A technology of robots and all-in-one machines, applied in packaging, conveyors, stacking of objects, etc., can solve problems such as high labor intensity, difficult to accommodate space, and damaged products, and achieve a reasonable overall structure layout, high automation, and reduced The effect of damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

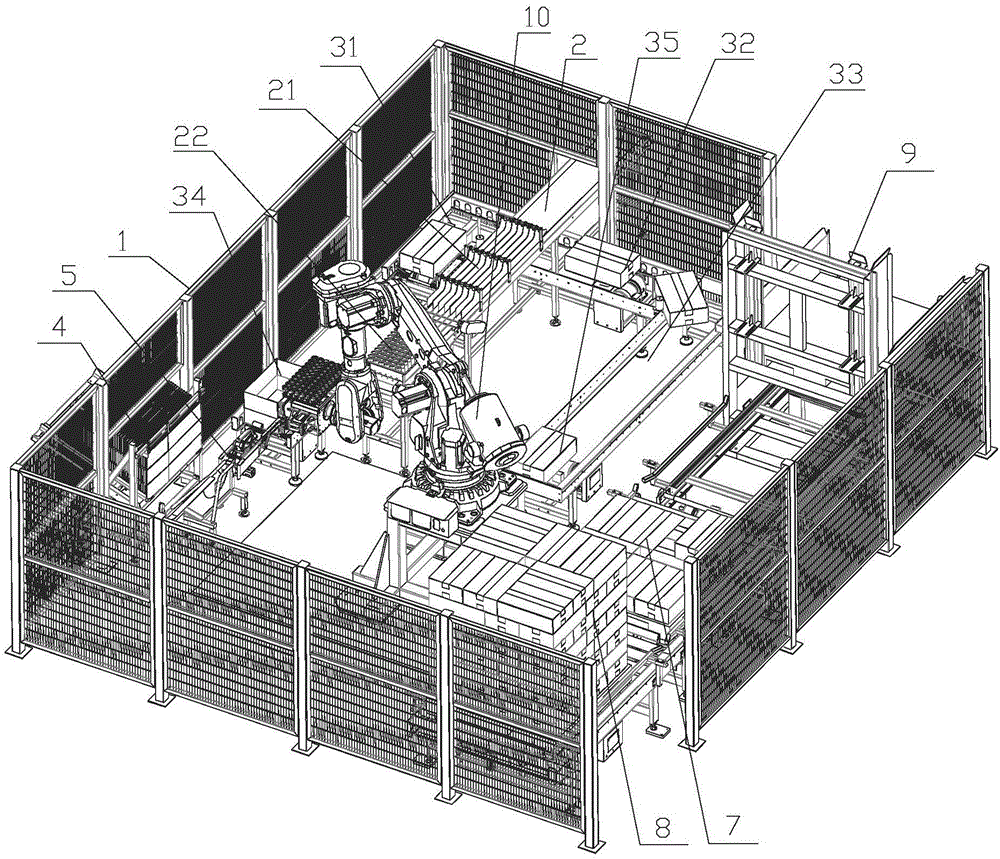

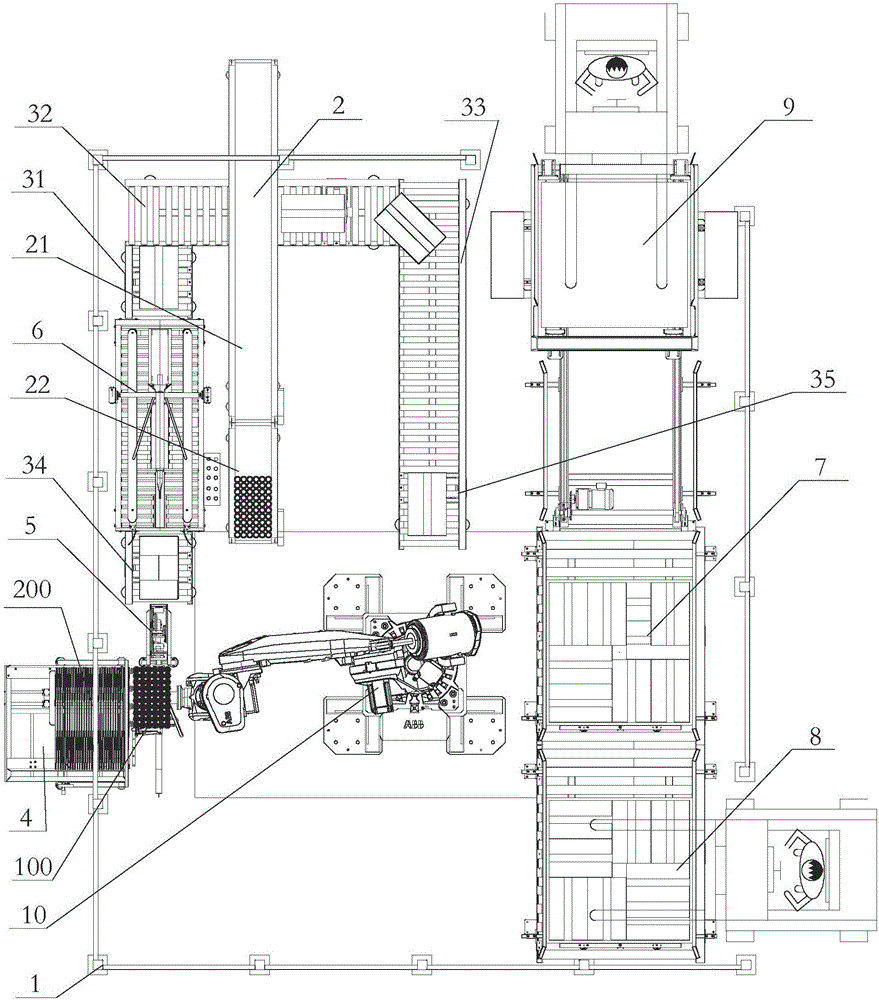

[0033] see Figure 1 to Figure 9 , the robot unpacking, packing and palletizing integrated machine of the present invention is set in the working area surrounded by four-sided guardrails 1 . The integrated machine includes a product conveying line 2, a transition line, a case loading machine 4, a bottom sealing machine 5, a case sealing machine 6, a palletizing station 7, a discharging station 8, a stacker 9 and a robot 10.

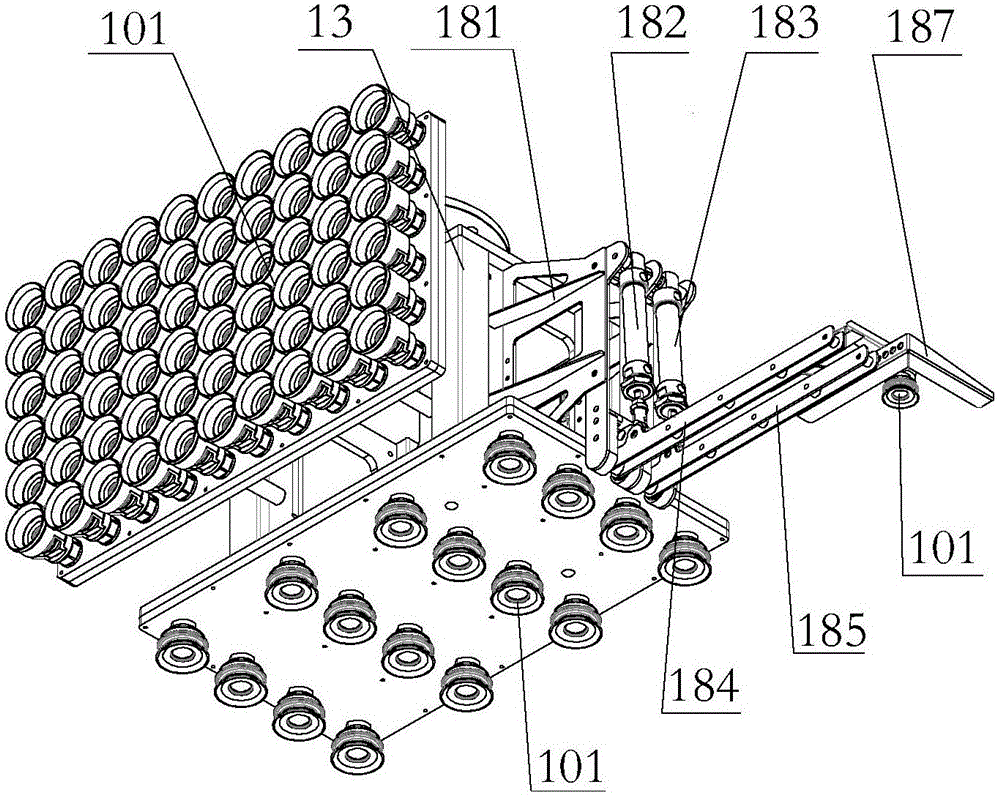

[0034] The product conveying line 2 is a conveying belt, and the product conveying line 2 penetrates into the operation area longitudinally from the rear side wall of the guardrail 1, and includes a product finishing station 21 and a product positioning and grabbing station 22; the product finishing station 21 Multiple partitions are arranged in parallel, so that the products can enter the product positioning and grasping station 22 neatly along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com