Patents

Literature

101results about How to "Improve unpacking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

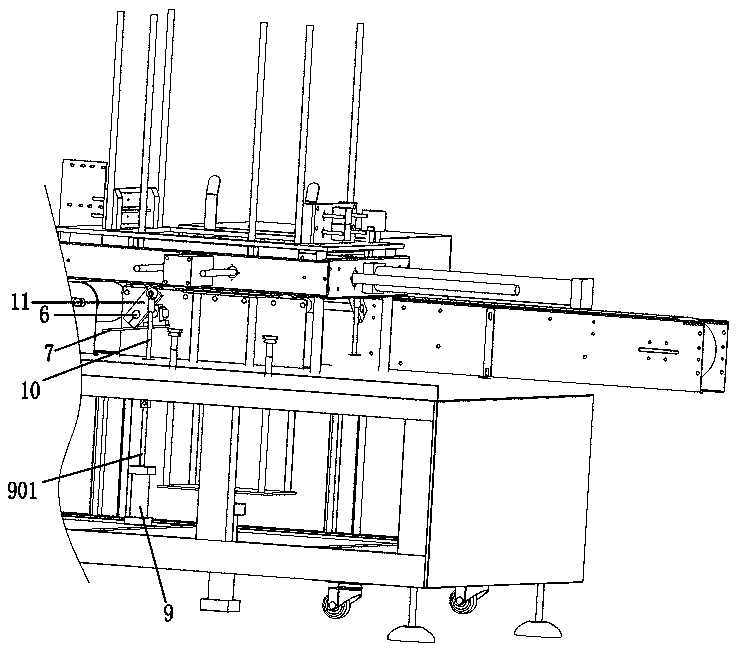

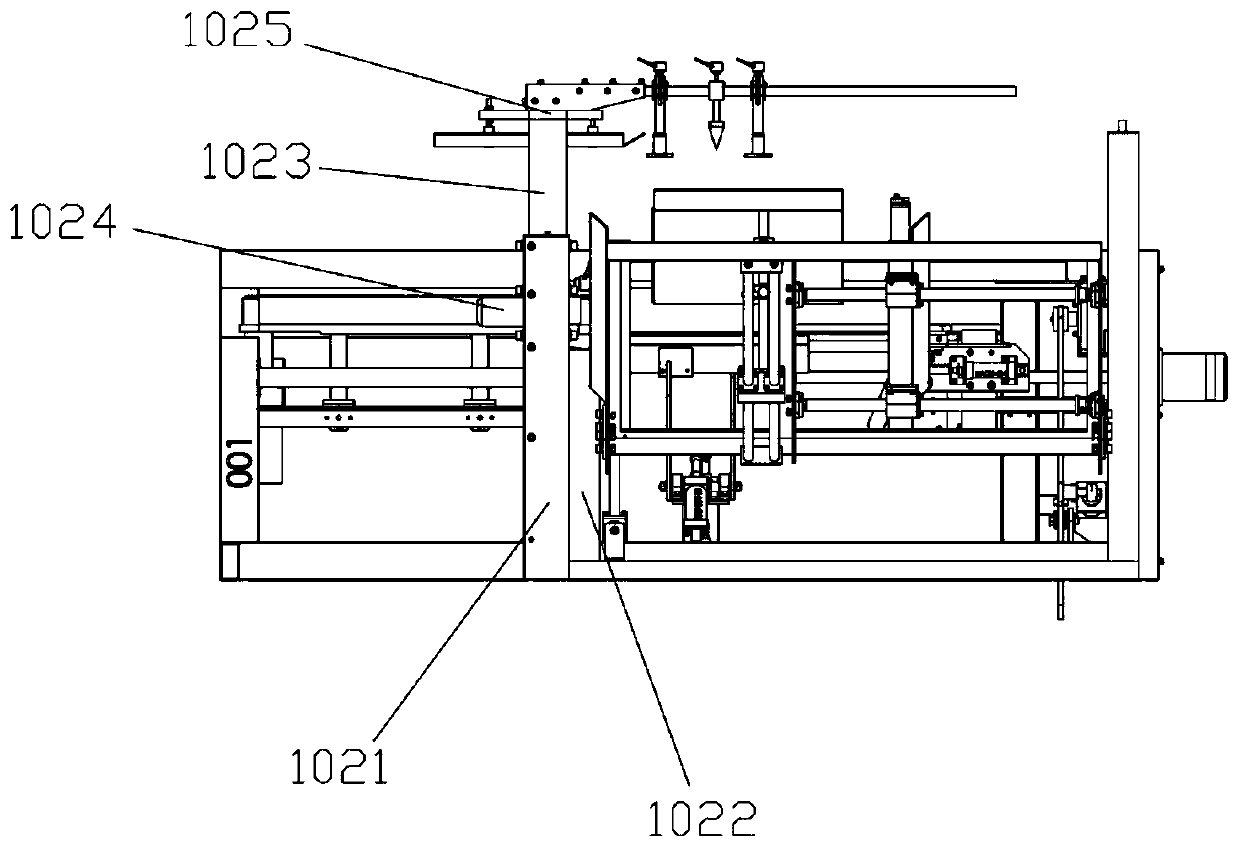

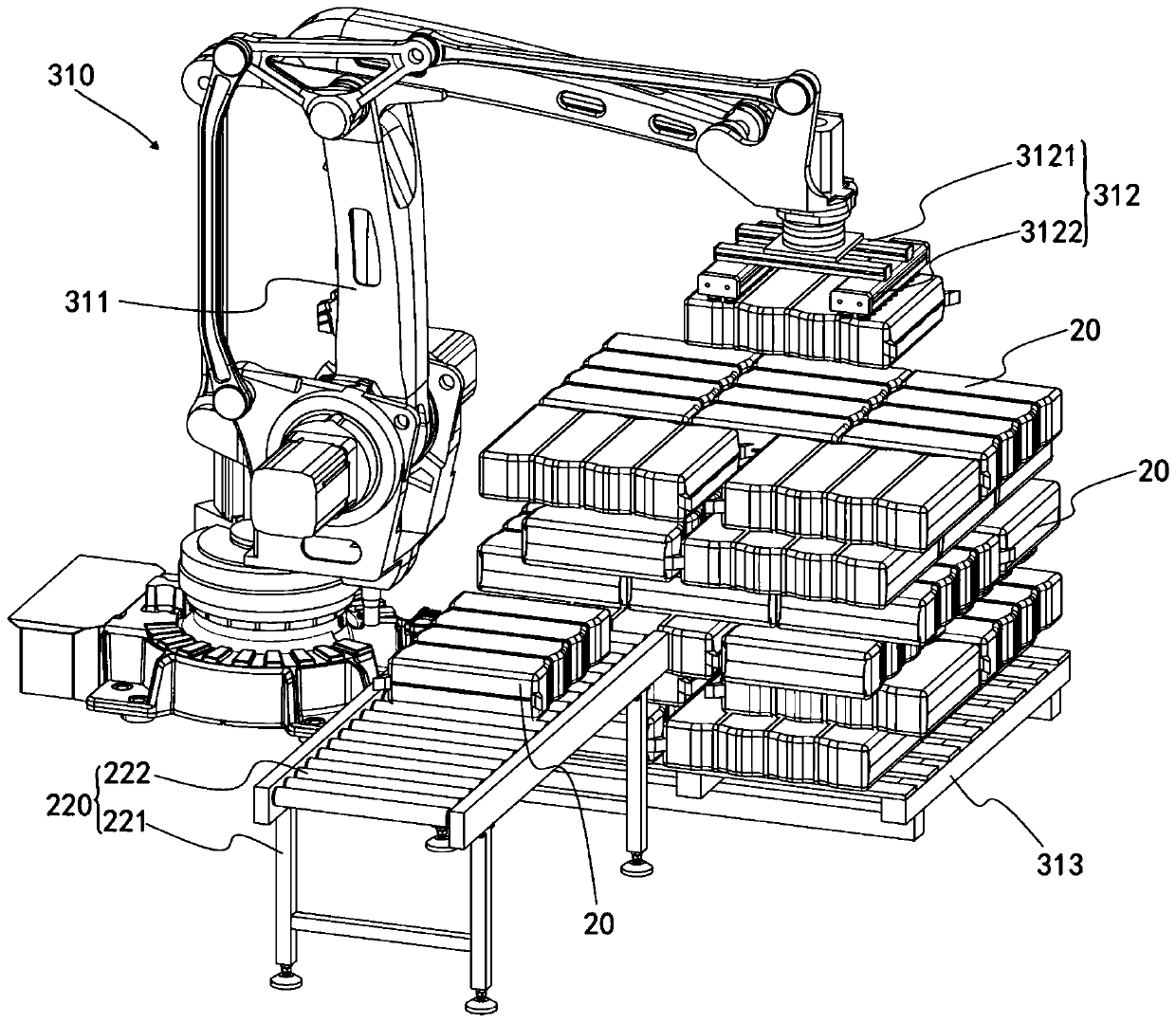

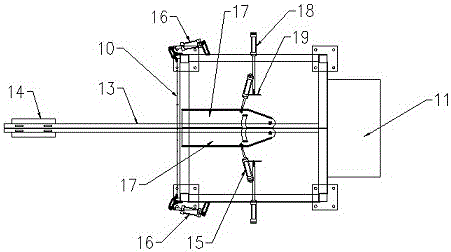

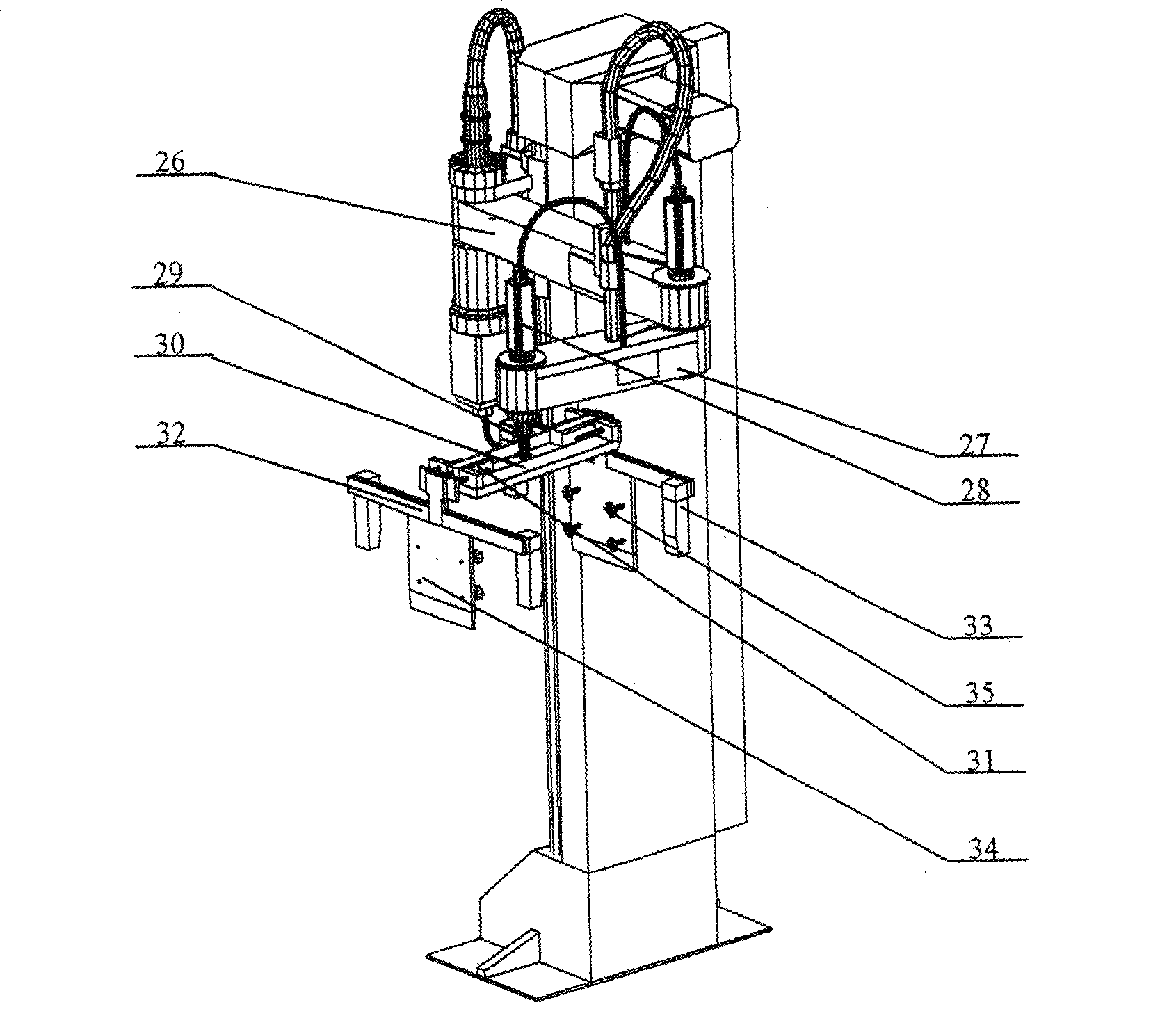

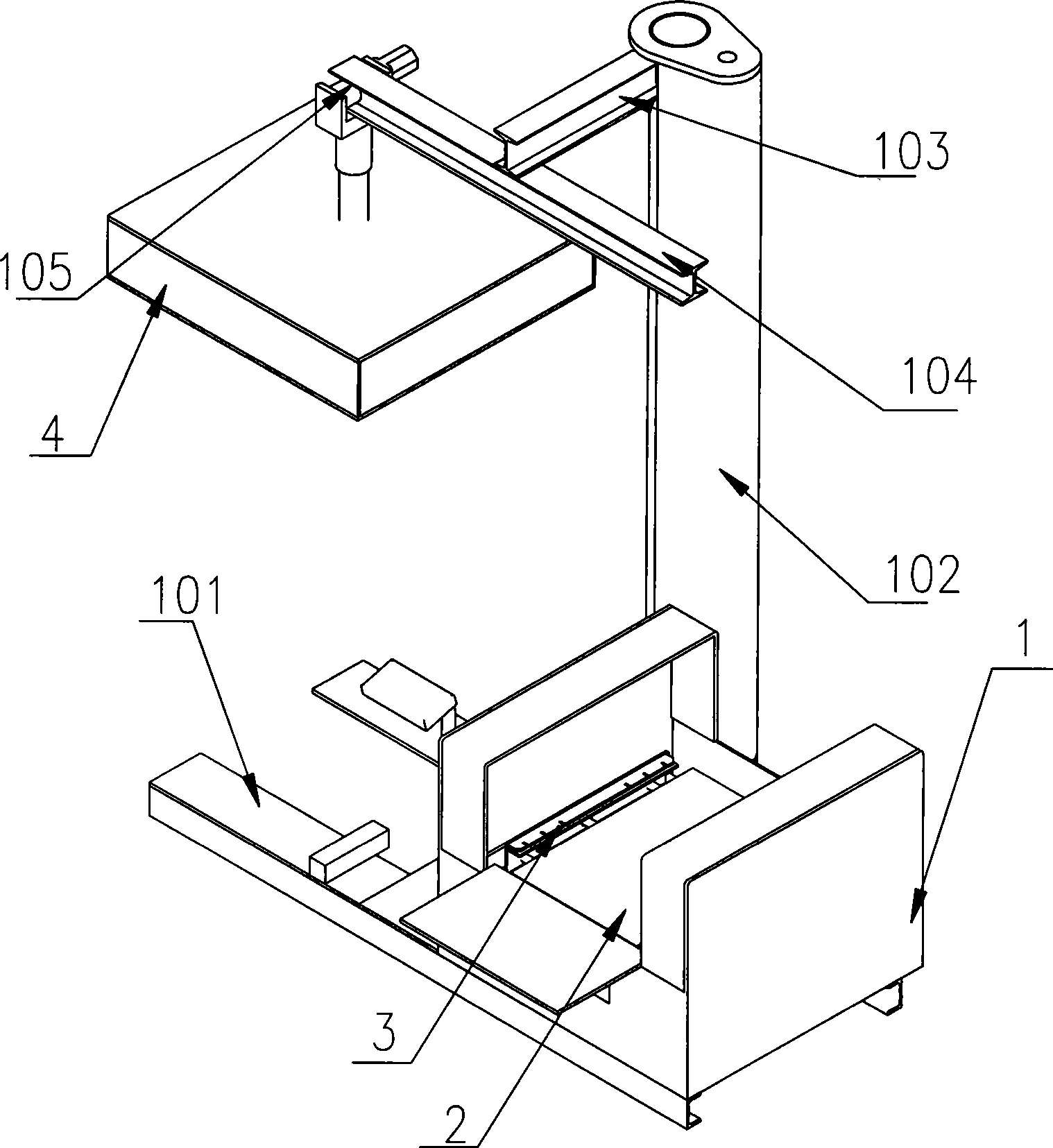

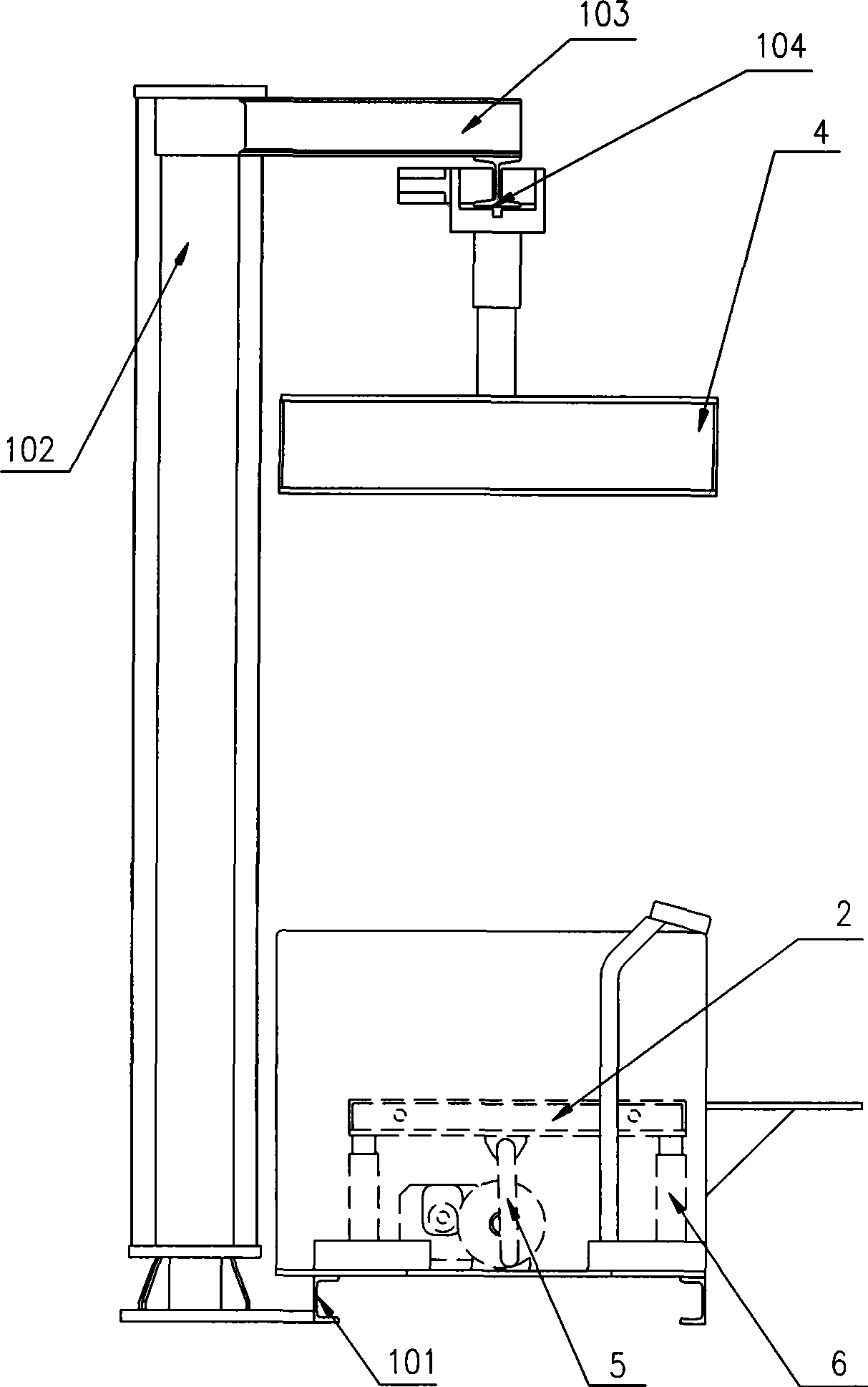

Unpacking equipment of robot and unpacking method

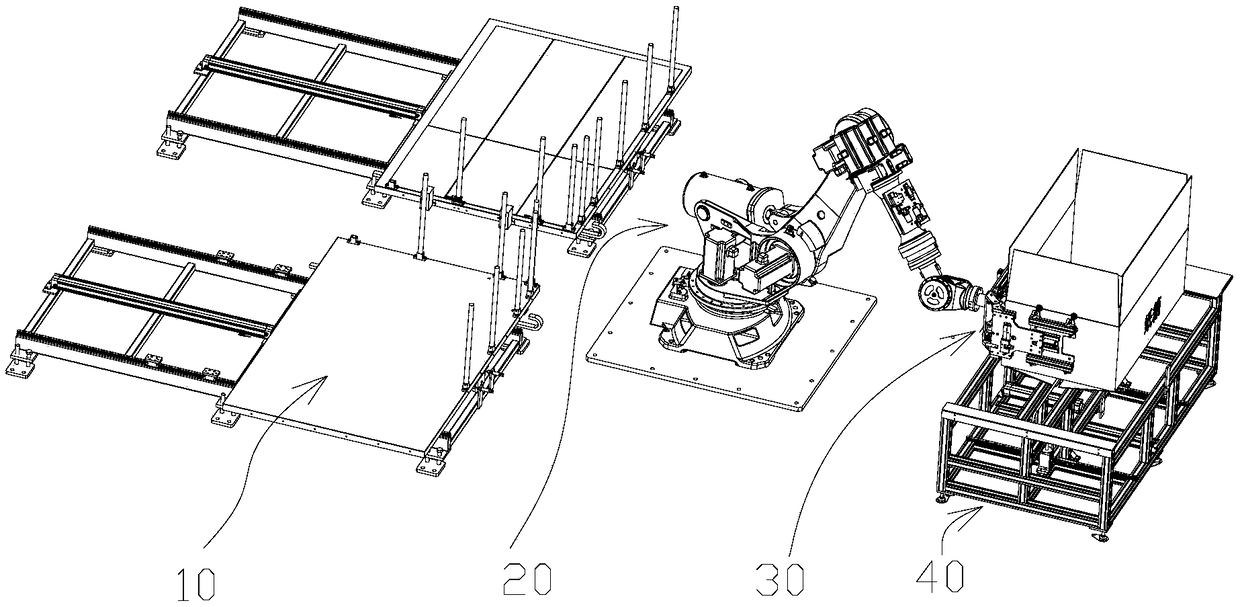

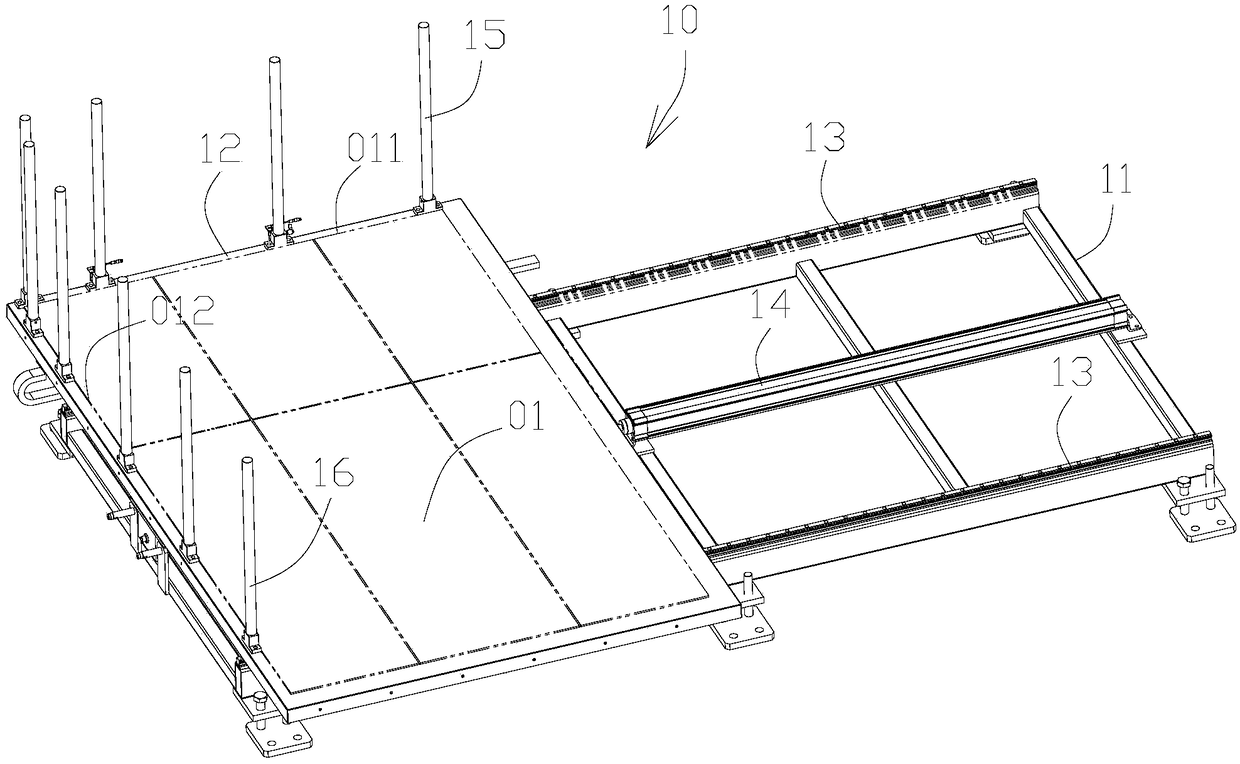

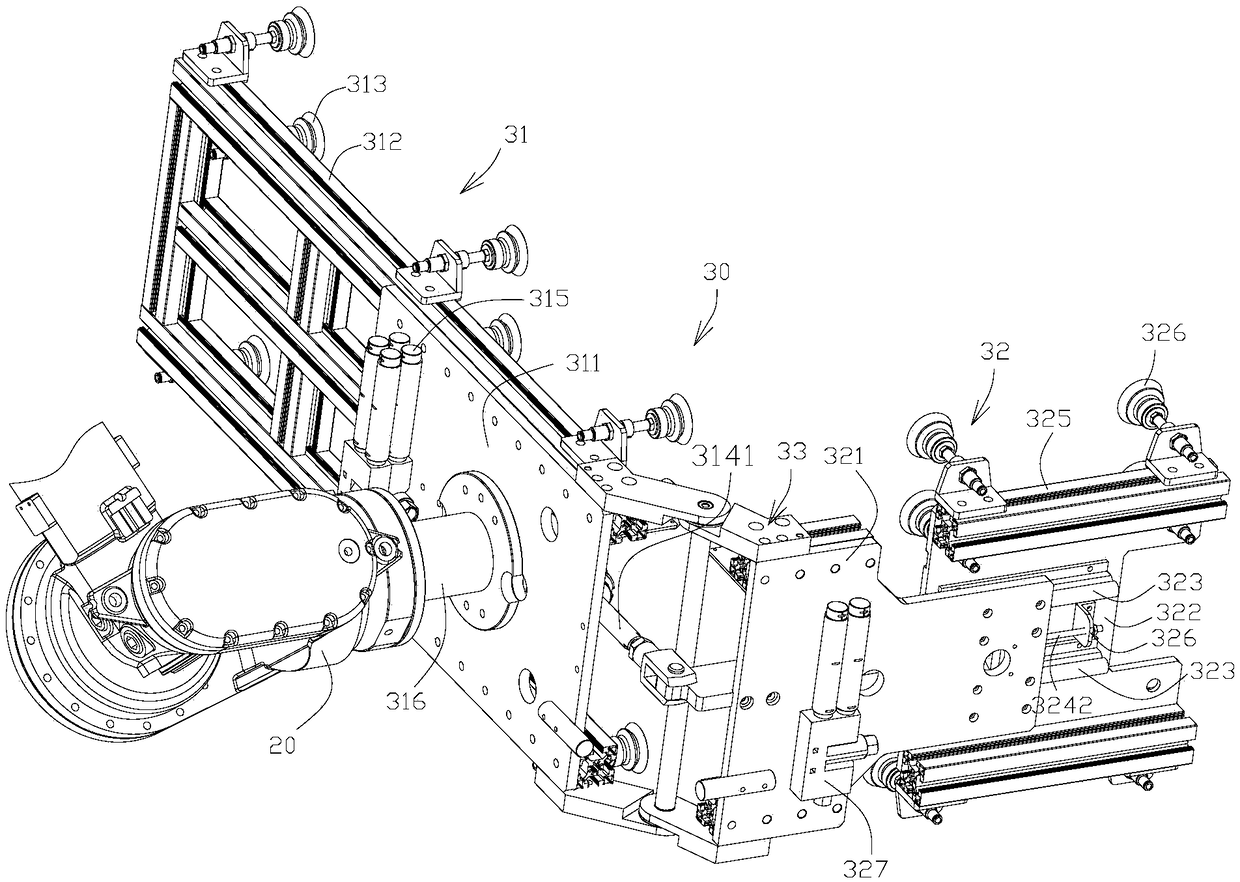

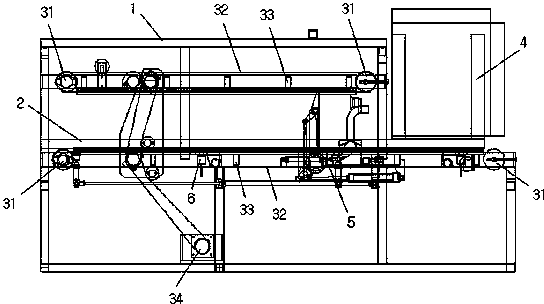

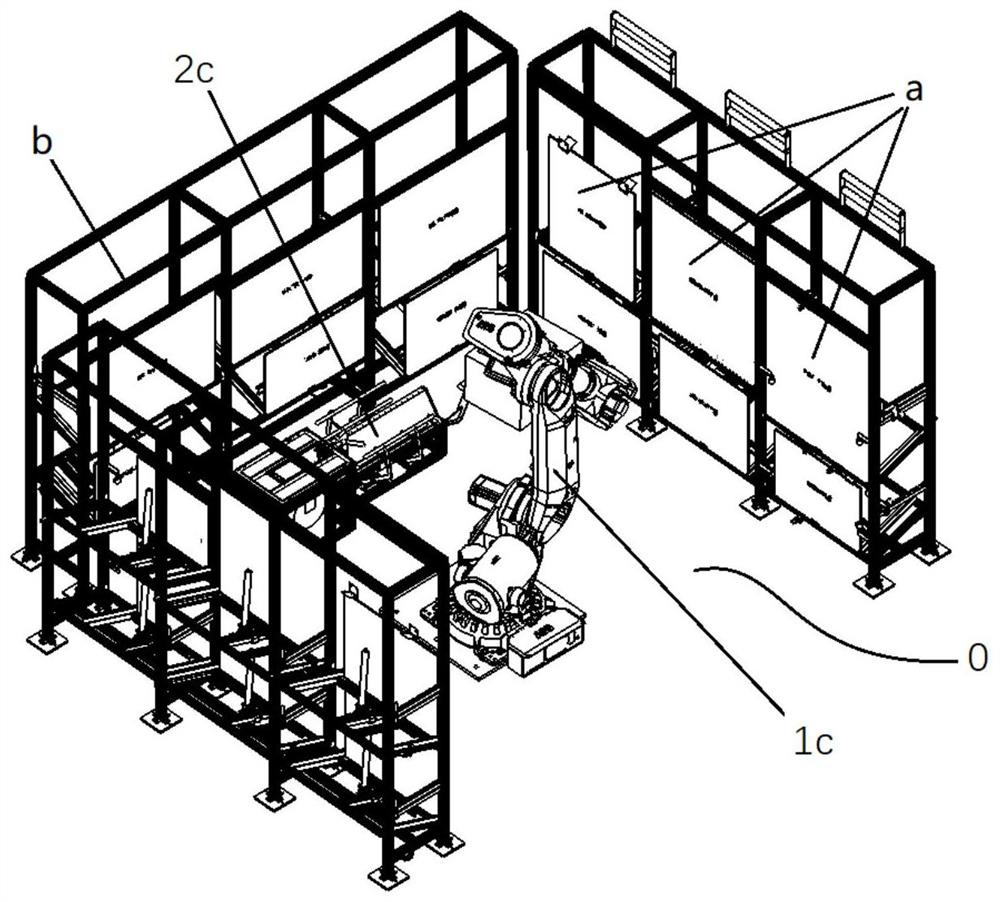

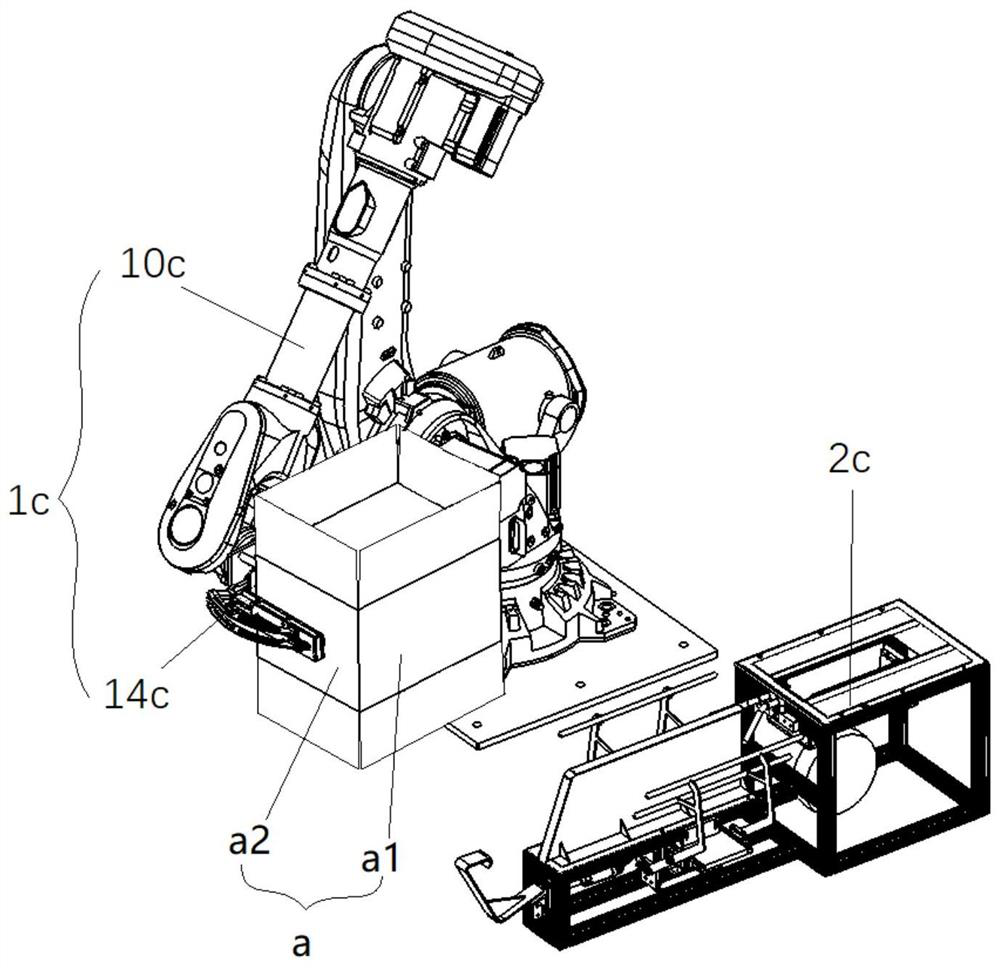

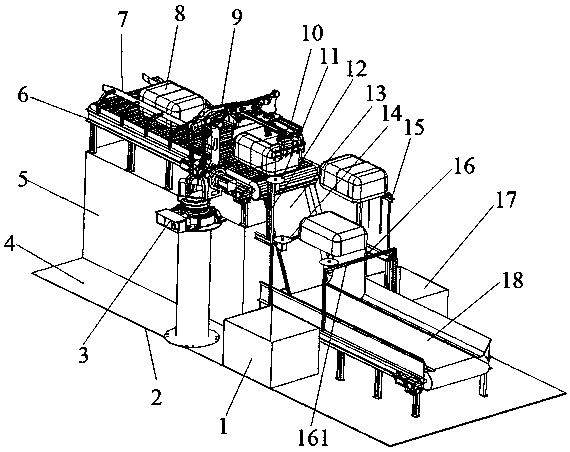

The invention discloses unpacking equipment of a robot. The unpacking equipment comprises a feed platform, the robot, an unpacking manipulator and a folding machine, wherein the feed platform is usedfor feeding and supplying materials; the robot is connected with the unpacking manipulator so as to drive the unpacking manipulator to take the materials and open cartons above the folding machine under the overturning action of a vacuum chuck; and the folding machine is matched with the robot so as to press and fold large and small hinges of the cartons. The invention further discloses an unpacking method. The unpacking method comprises the steps that the unpacking manipulator is driven to grab the cartons by the robot, the manipulator is driven to put the cartons above the folding machine and open the cartons by the robot, and the robot is matched with the folding machine so as to press and fold the large and small hinges at the bottoms of the cartons. Compared with the prior art, the feed process is simple and convenient, continuous material taking and supplying can be realized, and the unpacking efficiency is greatly improved. The unpacking equipment of the robot has the characteristic of flexibility in production and is suitable for unpacking various cartons of different specifications.

Owner:南京埃斯顿智能系统工程有限公司

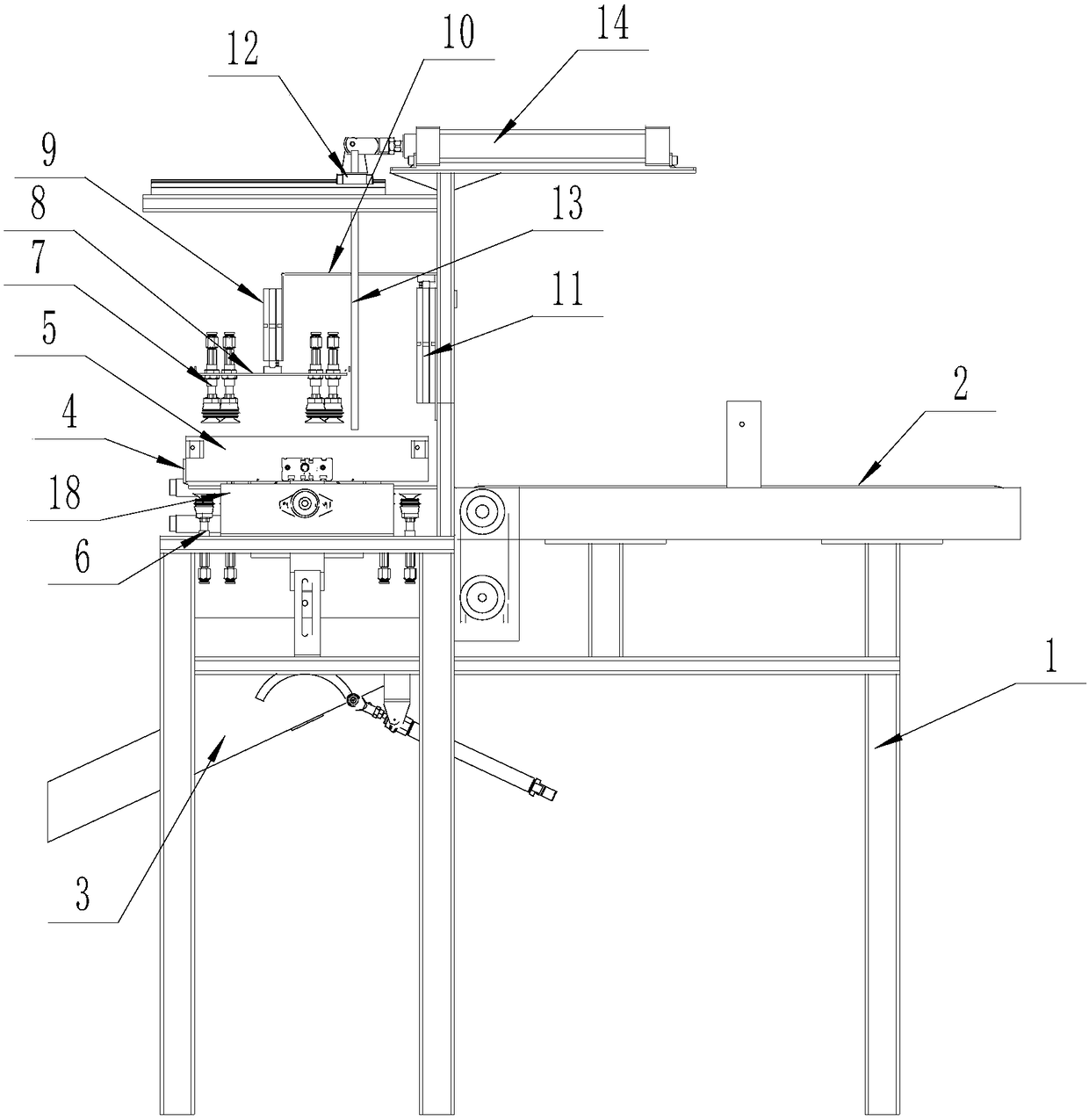

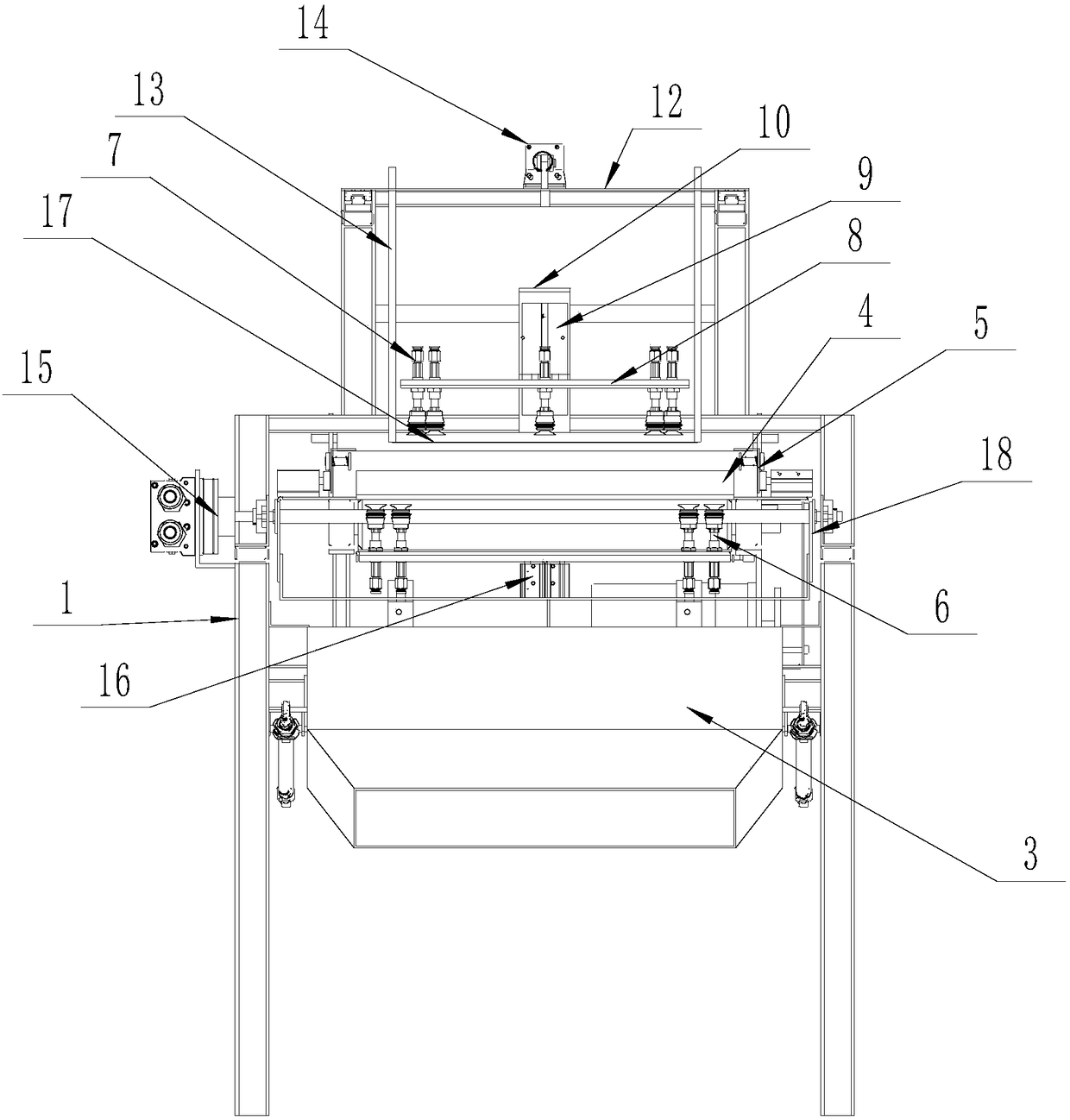

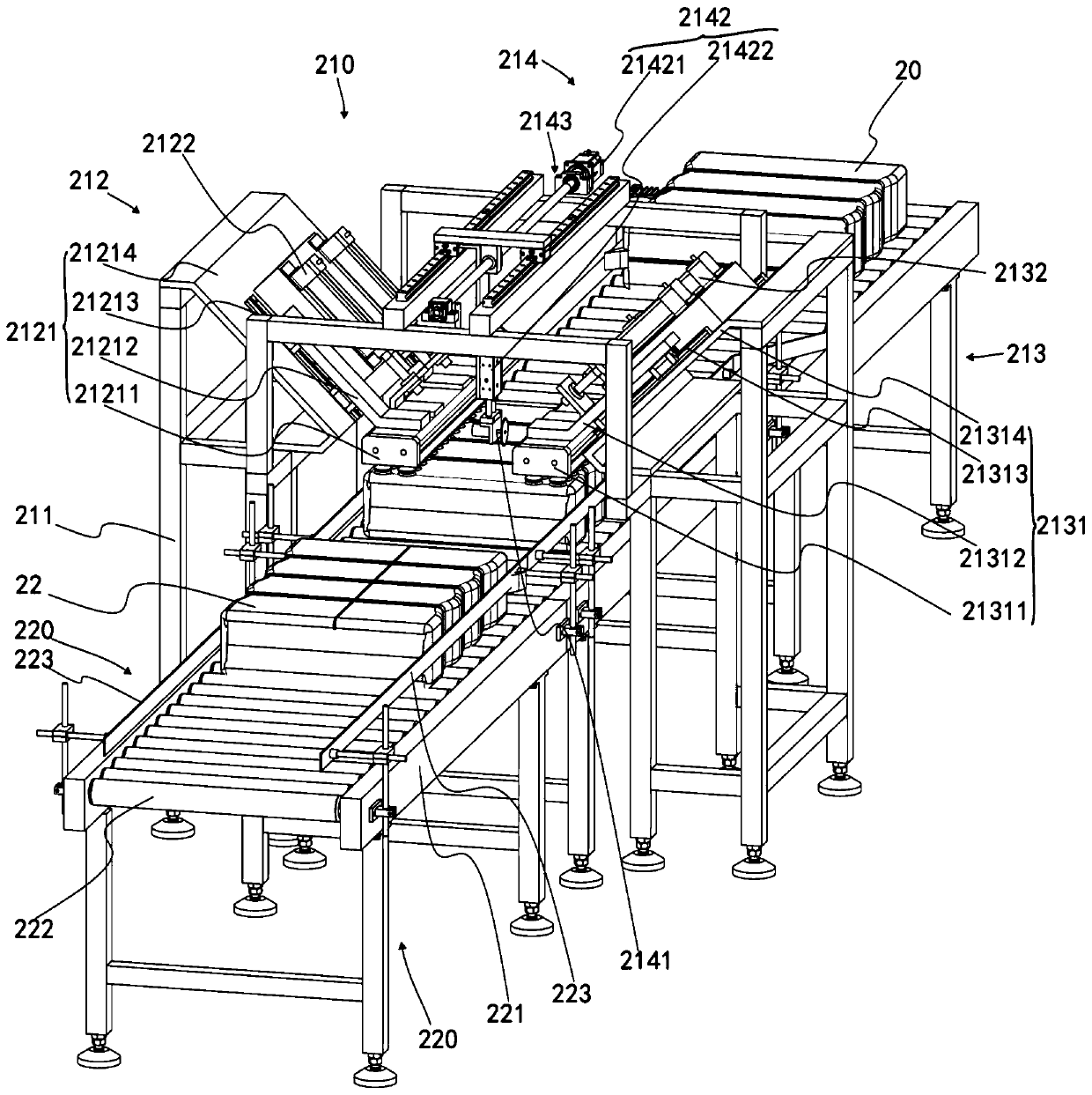

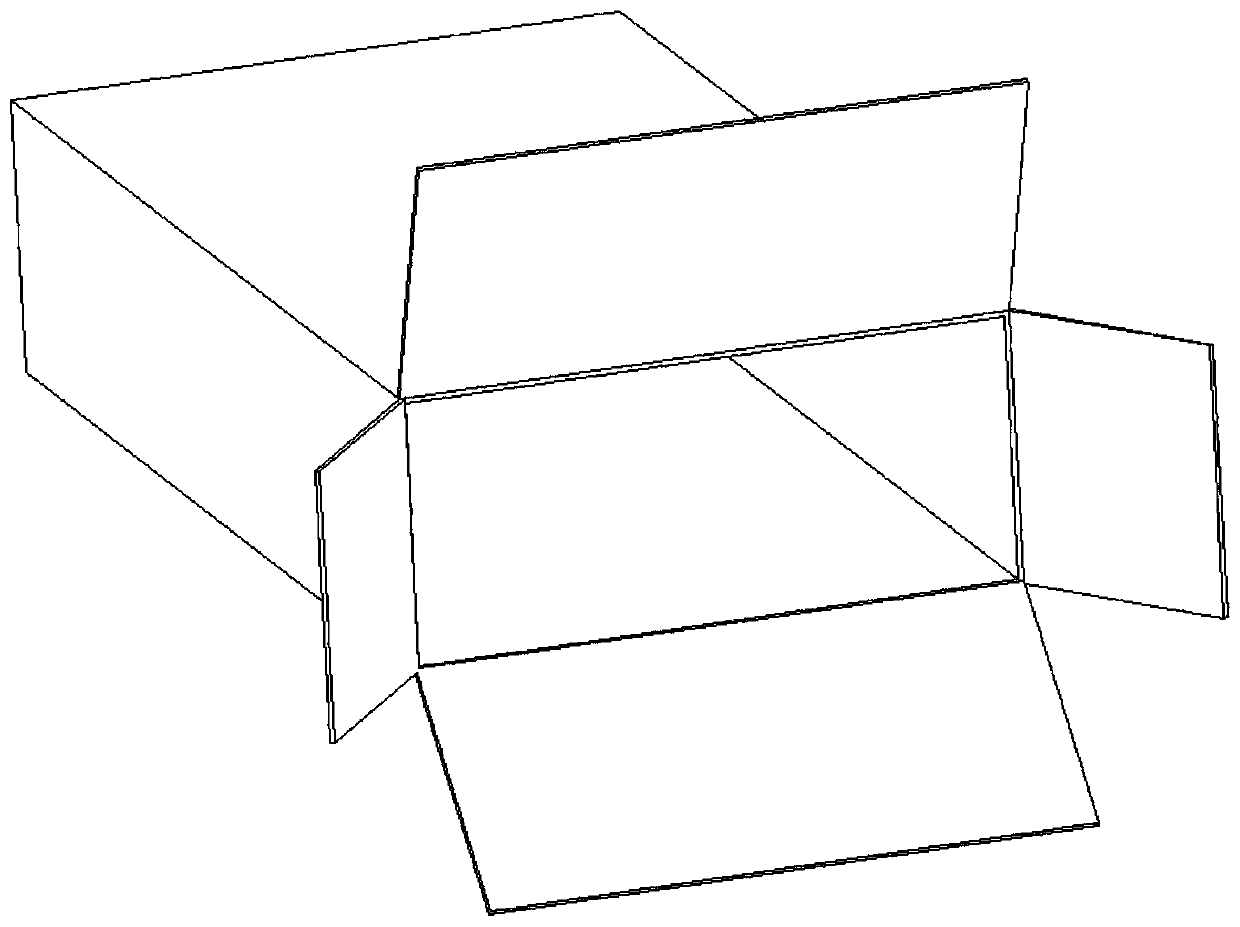

Carton forming machine

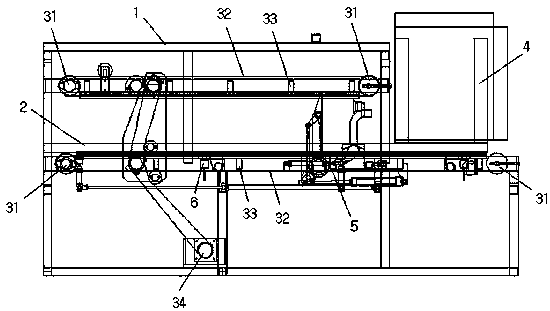

The invention relates to the technical field of packaging equipment, in particular to a carton forming machine which aims to improve carton unfolding efficiency and relieve labor intensity. The carton forming machine comprises a rack, four stations are sequentially arranged on the rack from right to left, an upper horizontal motion driving mechanism and a lower horizontal motion driving mechanism which are used for pushing cartons to move from right to left are arranged on the rack, and a linear carton body guide rail transversely penetrating through the four stations is fixed to the rack. A feeding frame is fixed to the first station of the rack, a carton unfolding mechanism used for unfolding carton pieces to form rectangular cartons and an inner fold folding cylinder used for folding inner folds of the front ends of the cartons are arranged on the second station, an outer fold folding cylinder used for folding outer folds of the front ends of the cartons is arranged on the third station, and an adhesive tape pasting device is arranged on the fourth station and arranged on the front edge of the carton body guide rail. The carton forming machine is high in carton unfolding efficiency and low in labor intensity.

Owner:迈巴赫机器人(昆山)有限公司

Full-automatic packing machine

The invention relates to a full-automatic packing machine. The full-automatic packing machine comprises an emptying frame mounted on a machine body; an opening box forming cavity is formed below the emptying frame; a foldable carton is horizontally placed on the emptying frame; a positioning foldable edge and an opening box foldable edge are arranged on two sides of the foldable carton; a bearing plate is fixed on the opening box forming cavity; a sucker is vertically mounted below the bearing plate through a drive, is driven to lift through the drive, and transfers the foldable carton from the emptying frame to the bearing plate of the opening box forming cavity for positioning; a positioning side plate leveled with the positioning foldable edge is arranged on one side of the opening box forming cavity; an opening box rotating shaft is rotationally connected below the bearing plate near the opening box foldable edge; and an opening box arm is mounted on the opening box rotating shaft, is driven to swing through rotation of the opening box rotating shaft, and is pressed against the foldable carton near the opening box foldable edge to open the foldable carton. The full-automatic packing machine is simple and reasonable in structure, and achieves simple and fast box opening effects through simple structure combination.

Owner:广州市利悦食品包装技术有限公司

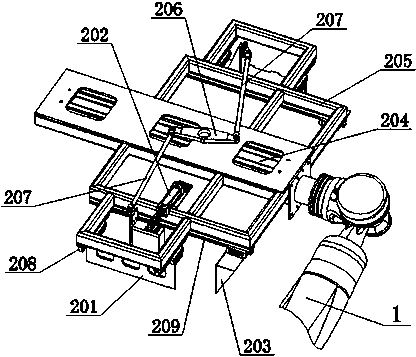

Penicillin bottle automatic bale breaker

ActiveCN108190159AAutomate unpackingImprove unpacking efficiencyUnpacking by heatingPenicillinEngineering

The invention discloses a penicillin bottle automatic bale breaker. The penicillin bottle automatic bale breaker comprises a rack, a conveying belt, a material overturning frame, a material overturning holding plate, an upper suction cup assembly, a lower suction cup assembly, a film breaking component and a hopper. The conveying belt conveys a penicillin bottle set onto the material overturning holding plate, then the lower suction cup assembly sucks a lower film of a packaging film, and the upper suction cup assembly sucks an upper film and slightly lifts the upper film up. Then through thefilm breaking component, the bulged upper film is destroyed to enable a pouring opening to be formed in the upper film, and then the material overturning frame is overturned to enable the penicillin bottles to be poured into the conveying hopper. According to the automatic bale breaker, the structure is reasonable, automatic bale breaking and pouring of the packaging film of the penicillin bottleset can be achieved, and the bale breaking efficiency is improved.

Owner:HIT SMART FACTORY CO LTD

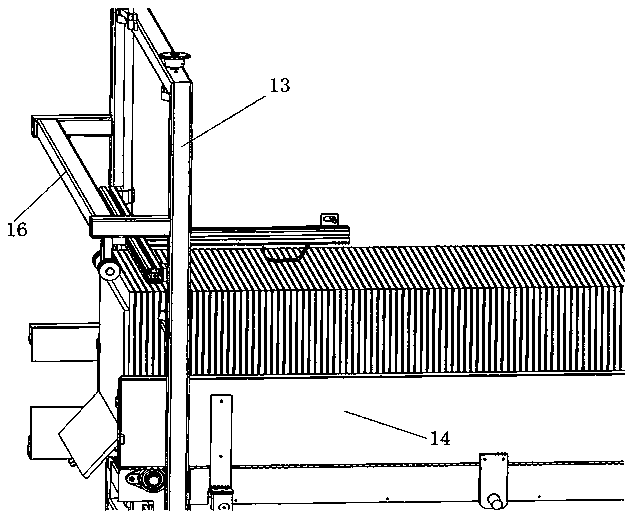

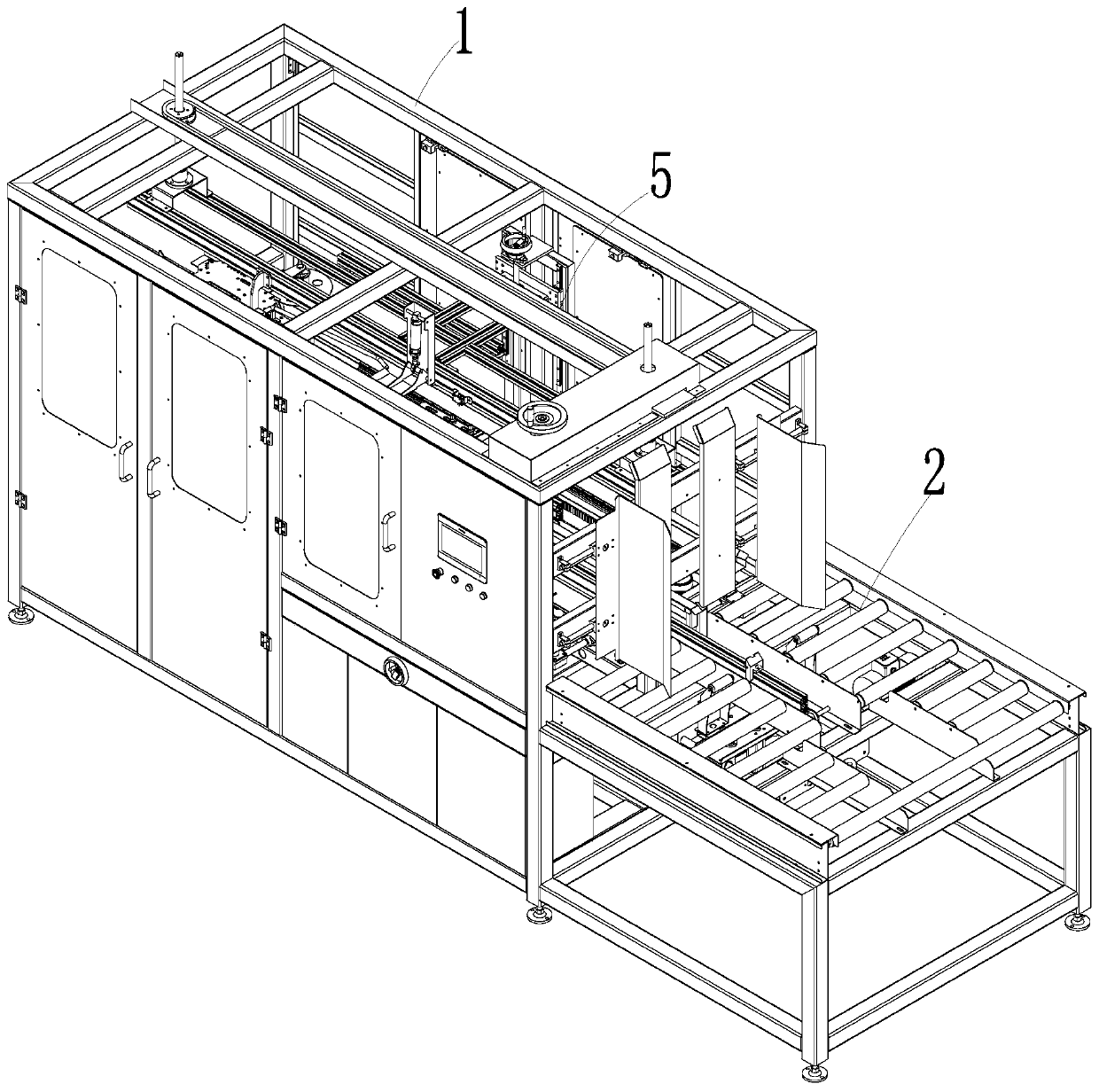

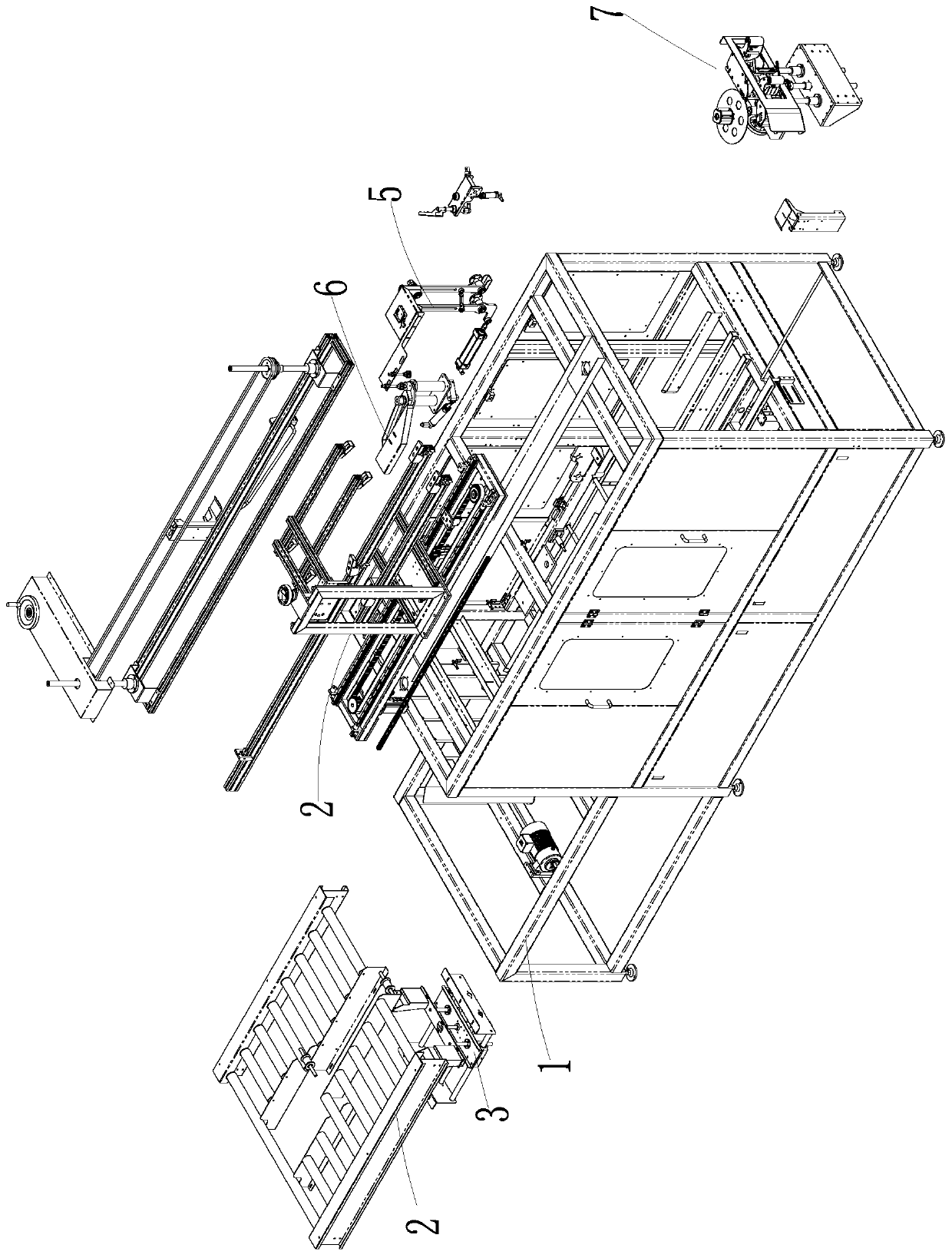

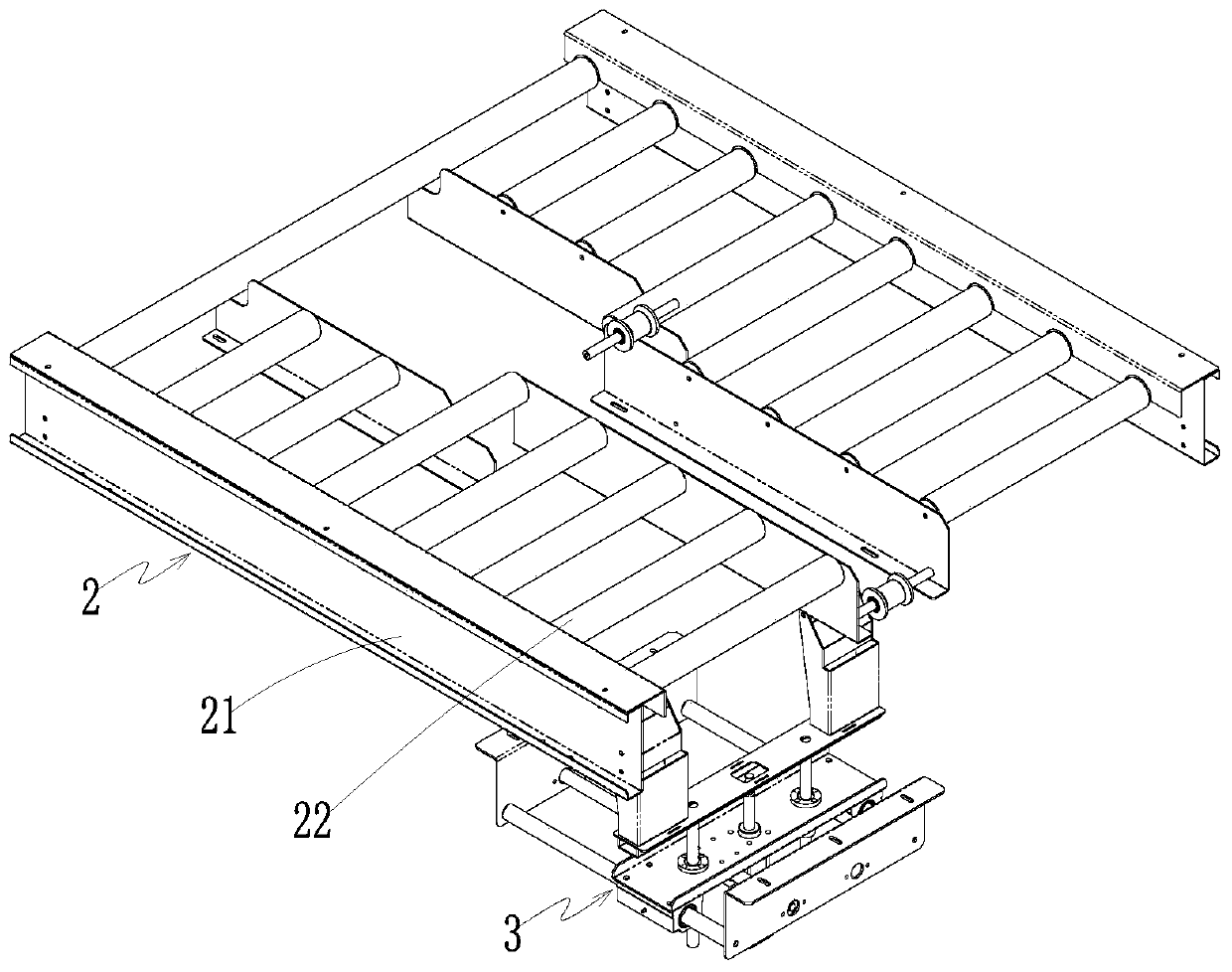

Horizontal case unpacking machine

PendingCN112407434ARealize unpacking and back-sealing operationsImprove unpacking efficiencyWrapper twisting/gatheringAdhesive beltCarton

The invention discloses a horizontal carton unpacking machine which comprises a grabbing and conveying mechanism used for sucking cartons, clamping the four side faces of the cartons into rectangles and bending upper side covers at the bottom sides of the cartons downwards, a side cover pressing mechanism used for oppositely bending two side covers at the bottom sides of the cartons, a turnover mechanism used for upwards bending lower side covers at the bottom sides of the cartons and turning over the bottom sides of the cartons to the bottoms, and a bottom sealing mechanism used for adheringadhesive tape to the bottom sides of the cartons to realize bottom sealing. According to the horizontal carton unpacking machine, the grabbing and conveying mechanism, the side cover pressing mechanism, the turnover mechanism and the bottom sealing mechanism are arranged in a matched mode, so that assembly-line carton unpacking and bottom sealing operation of the cartons can be achieved, manual connection is not needed, and the carton unpacking efficiency is high; and meanwhile, the distance between two side face clamping plates in a grabbing assembly can be adjusted through an adjusting air cylinder, so that cartons of different specifications and sizes can be grabbed and clamped, the application range of the carton unpacking machine is widened, manual adjustment is not needed in the conversion process, and the conversion efficiency is high.

Owner:CMT HICORP MACHINERY QINGDAO

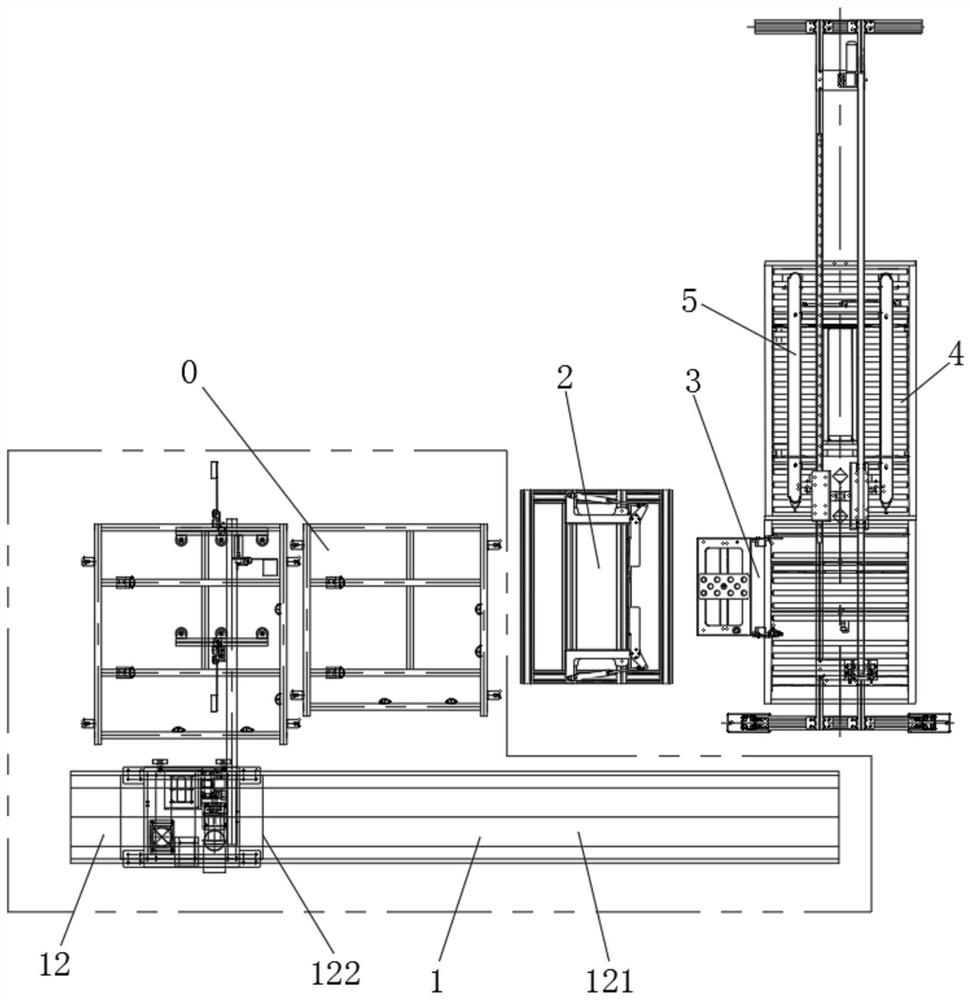

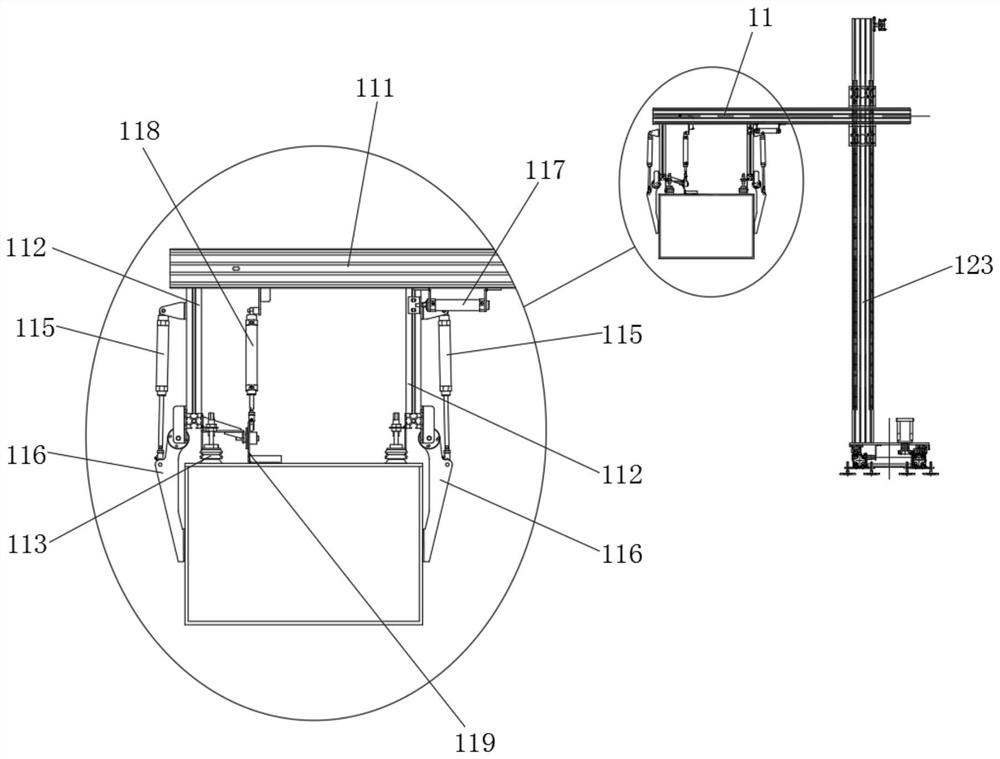

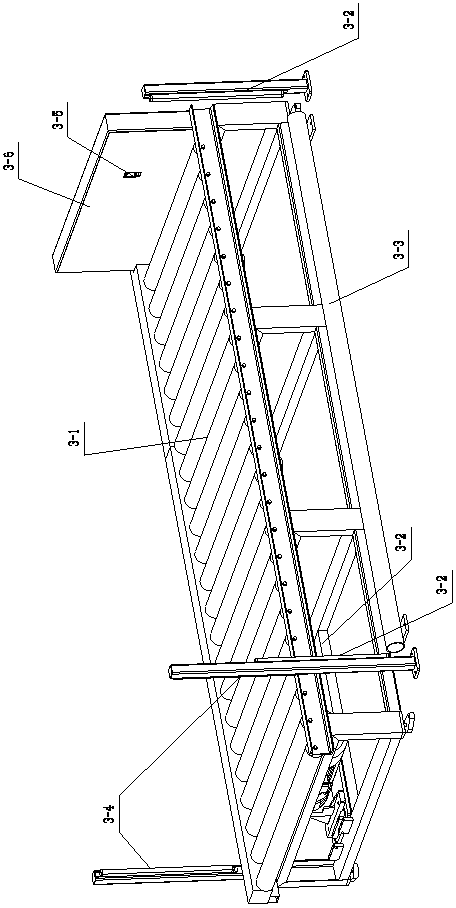

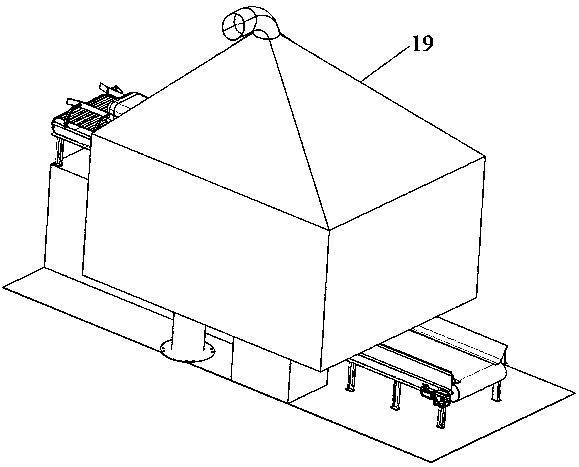

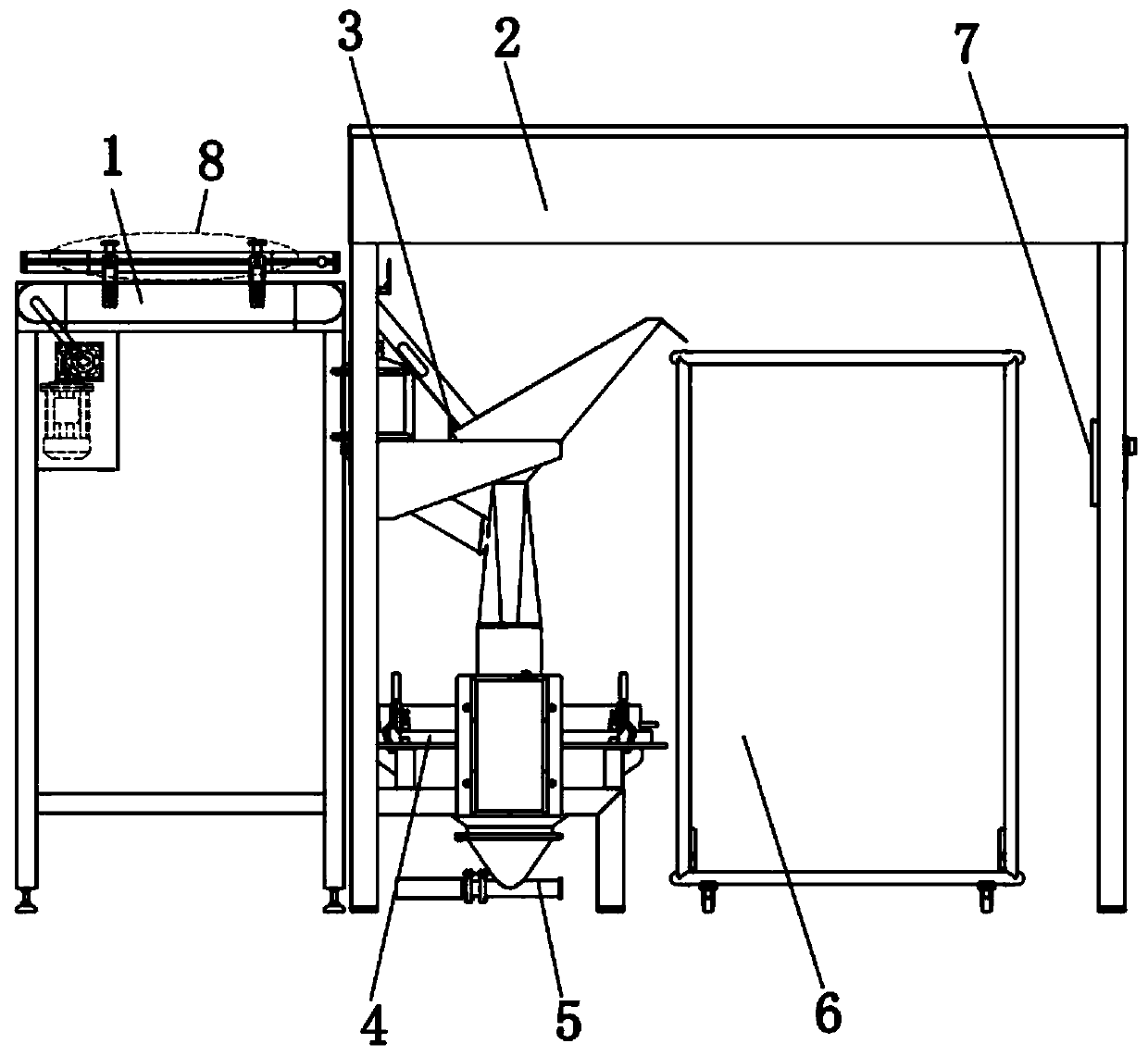

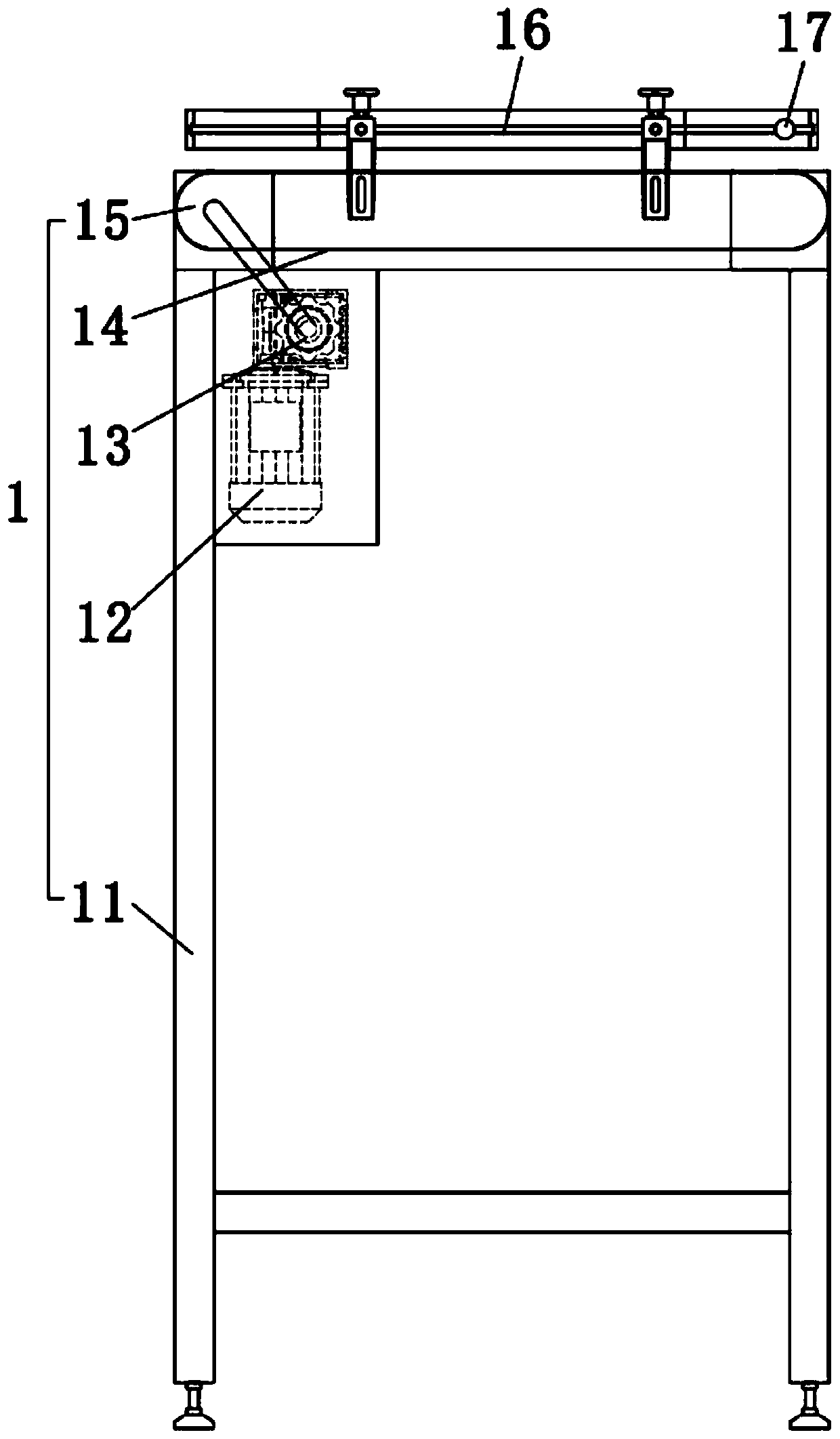

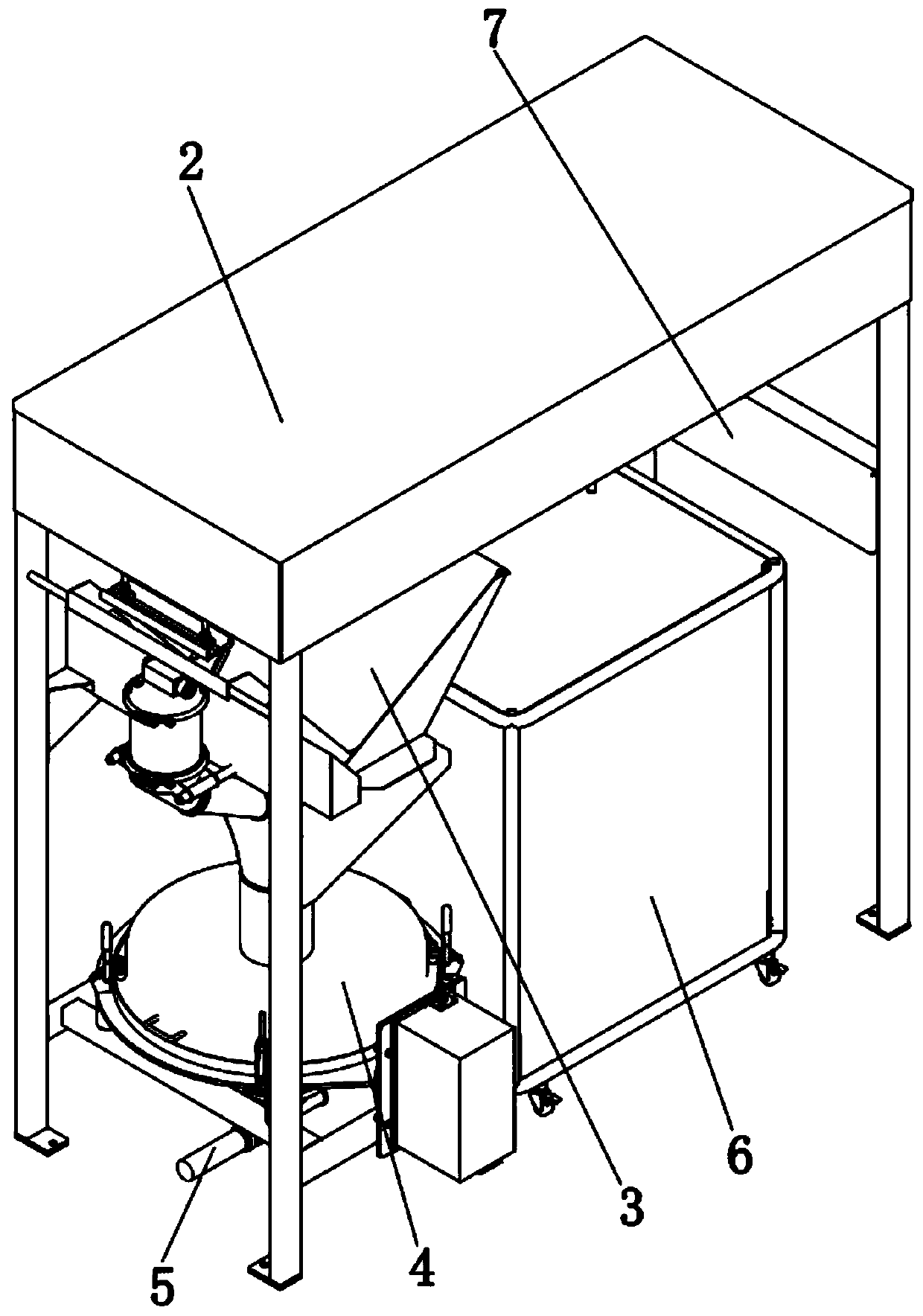

Full-automatic unpacking and feeding machine for bagging raw materials into stacking bags

PendingCN110654857AVersatileImprove unpacking efficiencyConveyor partsUnpacking by cuttingDust controlEngineering

The invention discloses a full-automatic unpacking and feeding machine for bagging raw materials into stacking bags. The full-automatic unpacking and feeding machine includes a control cabinet, a conveyor belt, an elevator, an automatic unpacking and feeding machine, an empty tray collector, a package-breaking waste bag automatic packaging machine and a dust removal system. Stacked bag-shaped rawmaterials are placed on the conveyor belt, the conveyor belt is connected to the elevator, the conveyor belt transfers the stacked bag-shaped raw materials to the elevator, the elevator is connected to the automatic unpacking and feeding machine, the elevator feeds the stacked bag-shaped raw materials into the automatic unpacking and feeding machine layer by layer, packages of the stacked bag-shaped raw materials are broken in the automatic unpacking and feeding machine, raw materials are fed to a putting opening, the broken bags enter the package-breaking waste bag automatic packaging machineafter two times of residual material screening, the empty tray collector is connected with the elevator, and the automatic unpacking and feeding machine is provided with a dust cover and is connectedwith the dust removal system. The full-automatic unpacking and feeding machine has complete functions, the unpacking efficiency is improved, the removal rate of residual materials is improved, and the applicability is high. The full-automatic unpacking and feeding machine can be in butt joint with an intelligent warehouse, unmanned operation is realized, and work without dust is achieved.

Owner:江苏恒创机械设备有限公司

Full-automatic carton automatic opening device and carton opening method thereof

The invention discloses a full-automatic carton automatic opening device and a carton opening method thereof. The full-automatic carton automatic opening device comprises a rectangular frame, a cartonmodeling device and a conveying device. A carton is ascended and descended through a first servo motor and is fixed and positioned through a pressing plate adjusting mechanism. Meanwhile, a telescopic cylinder drives second linear guide rails and suction cups on a cross beam to move synchronously. The full-automatic carton automatic opening device conducts modeling on the carton through the two sets of suction cups, meanwhile, drives a lead screw to rotate through a second servo motor after completion of modeling, then drives a push rod device to push the modeled carton onto the conveying device and conducts bottom sealing through a bottom sealing assembly. The full-automatic carton automatic opening device automatically controls to implement left-right, up-down and front-back adjustmentin an electrical control mode, is fast and convenient to use, controllable in size adjustment and convenient to operate and improves the carbon opening efficiency.

Owner:JINKEN COLLEGE OF TECH

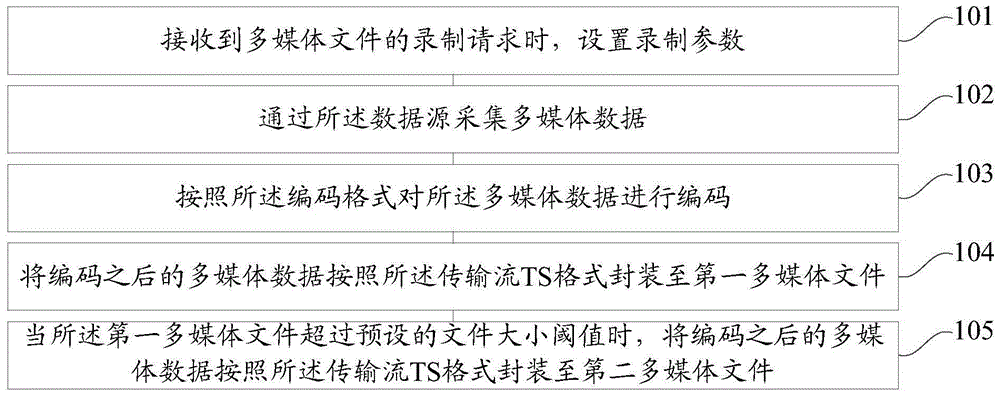

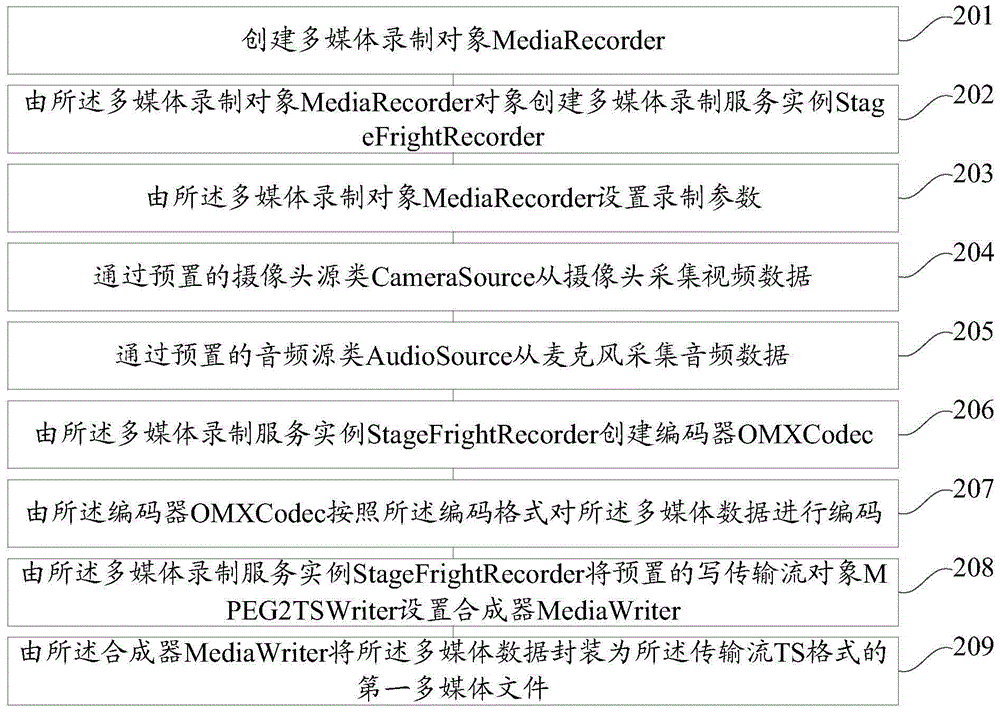

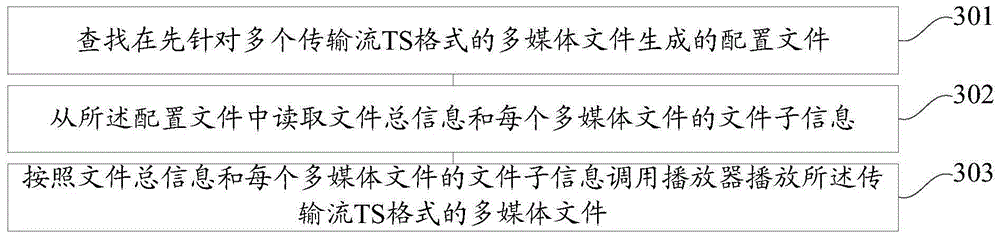

Play method and play device of multi-media files

ActiveCN105049904AImprove unpacking efficiencyAvoid CatonSelective content distributionOperating system

The embodiment of the invention provides a play method and a play device of multi-media files. The play method comprises the following steps: searching a configuration file generated in advance aiming at a plurality of multi-media files in a transport stream (TS) format; reading file total information and file sub-information of each multi-media file from the configuration file; and calling a player to play the multi-media files in the TS format according to the file total information and the file sub-information of each multi-media file. According to the embodiment of the invention, the de-encapsulation efficiency while playing is greatly increased; and the blocking and pausing phenomena in the playing process are avoided.

Owner:青岛海信移动通信技术有限公司

Carton forming machine

ActiveCN110303719AImprove unpacking efficiencyEasy to packBox making operationsPaper-makingMolding machineCarton

The invention discloses a carton forming machine. The carton forming machine comprises a rack, an adsorption device, a lifting device and a forming device. According to the technical scheme, by meansof the adsorption device, the lifting device and the forming device, automatic equipment used for automatically unfolding a carton and forming the carton is formed, and the adsorption device is used for adsorbing the carton. Due to the fact that cartons are in a flat shape when not used, the cartons which are stacked in batches can be put below the adsorption device, under driving of air pressure,the flat cartons are adsorbed to the adsorption device, the lifting device drives the adsorption device to downwards move till to the flat cartons, and the flat cartons are adsorbed to the adsorptiondevice; by means of the forming device, in the process that the flat cartons are upwards moved, under the action of the carton forming device and the gravity of the cartons, the cartons are formed into square from scraps of paper, workers conveniently pack products into the cartons later, the unpacking efficiency is improved for the workers, and the labor intensity is reduced.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

Novel high-speed box taking and box opening mechanism

The invention relates to a novel high-speed box taking and box opening mechanism. The novel high-speed box taking and box opening mechanism is characterized by comprising a box feeding device, a box taking device, a box opening device and a box moving device, wherein the box feeding device cooperates with one-way bearing drive on a conveying frame through a segmented chain and an air cylinder to achieve paper box stepping conveying. When a cam guide rail mechanism rotates to the box taking position, automatic turnover is achieved to adsorb the paper boxes. The box opening device is a connecting rod mechanism driven by the air cylinder to achieve paper box turnover, and when turned over to the position where the paper boxes are about to be adsorbed, the paper boxes are adsorbed. In the boxmoving device, a connecting rod is driven through a motor, and the air cylinder drives a lever to vertically drive the paper boxes to advanced and be transported. In the novel high-speed box taking and box opening mechanism, the box taking and box opening mechanism is adopted for avoiding a vertical stacking manner, the paper boxes do not need to be frequently stacked manually, staff do not need to stand on high platforms to stack the paper boxes, and the working environment is safer; and transmission is stable, and the box taking and box opening efficiency is high.

Owner:NANTONG UNIVERSAL MACHINERY

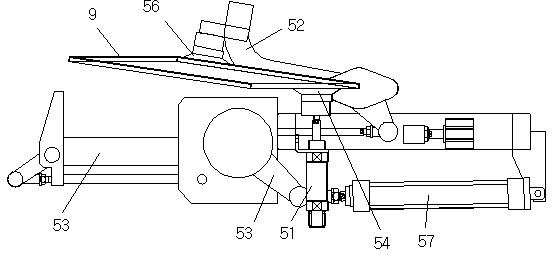

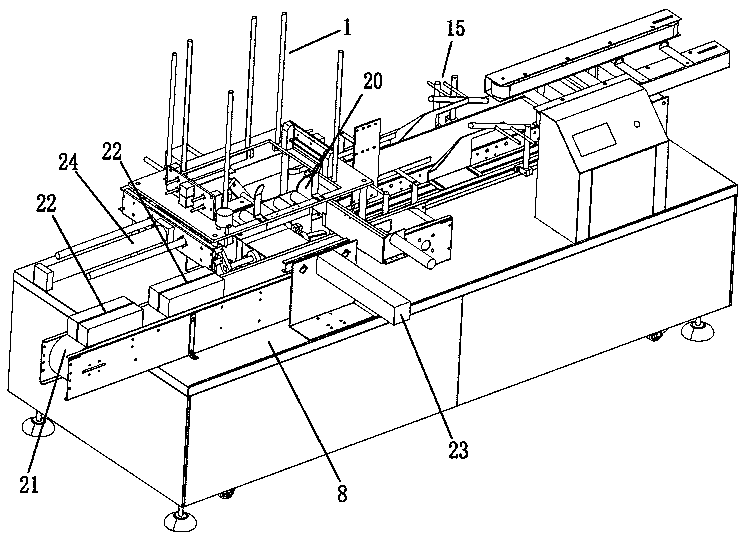

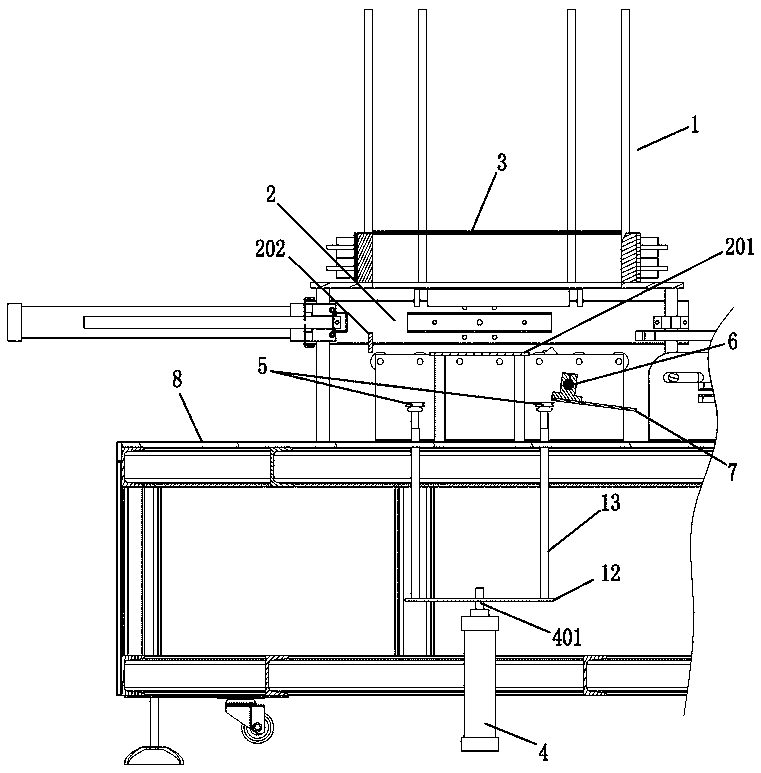

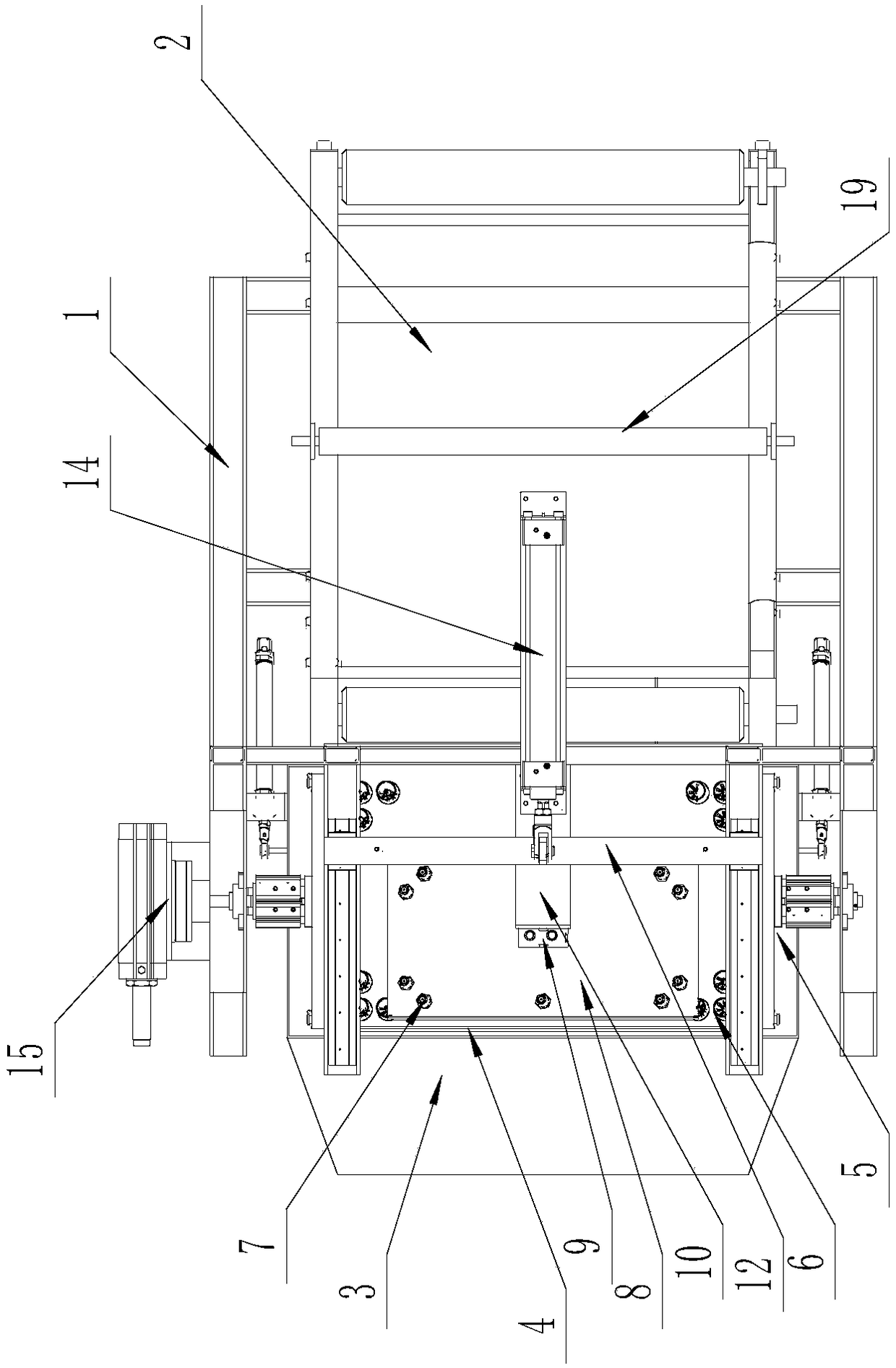

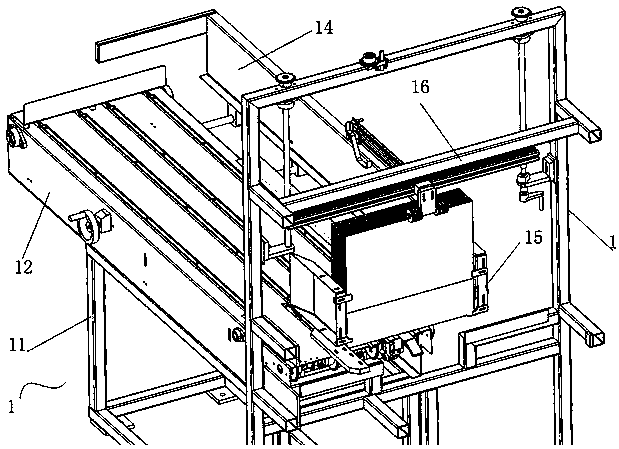

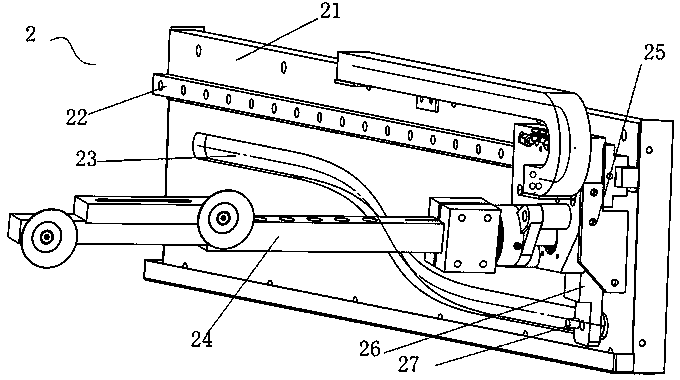

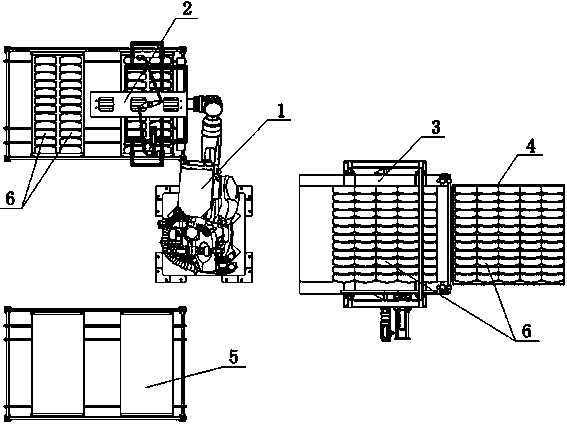

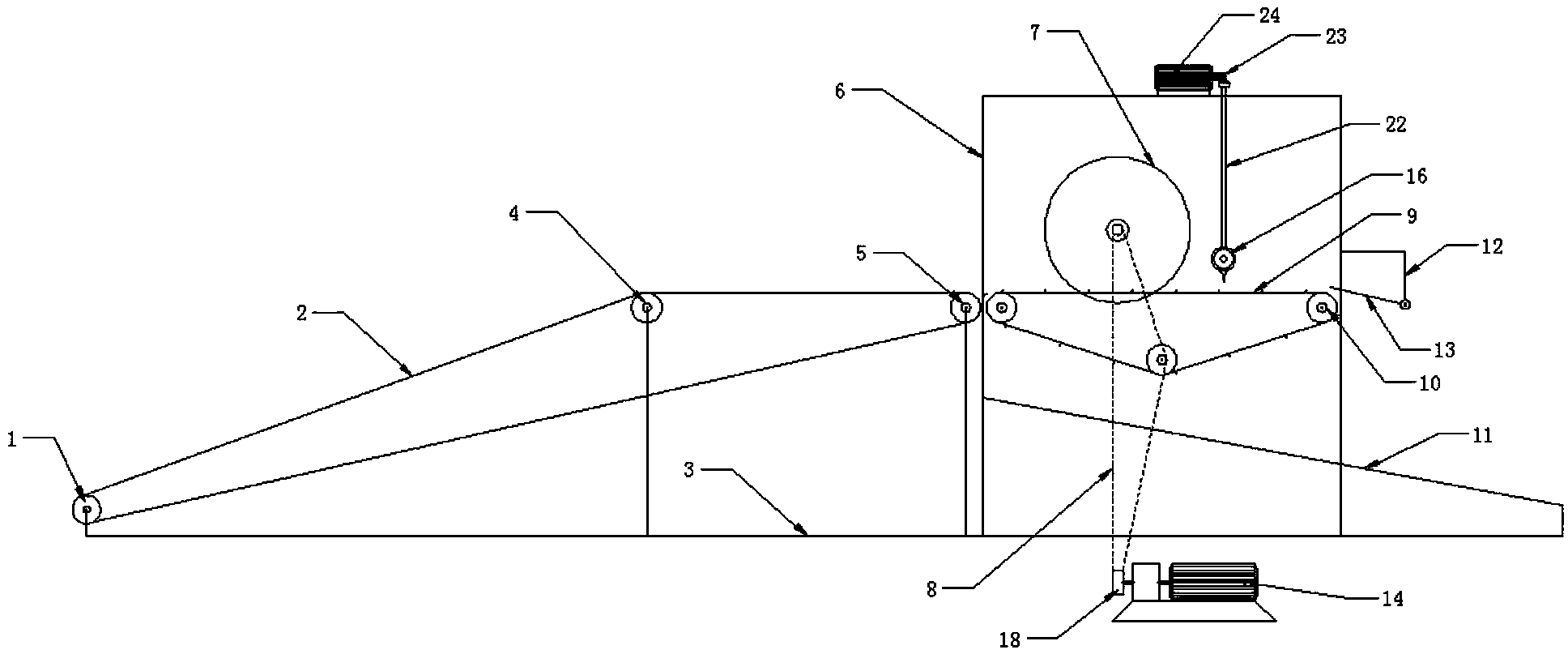

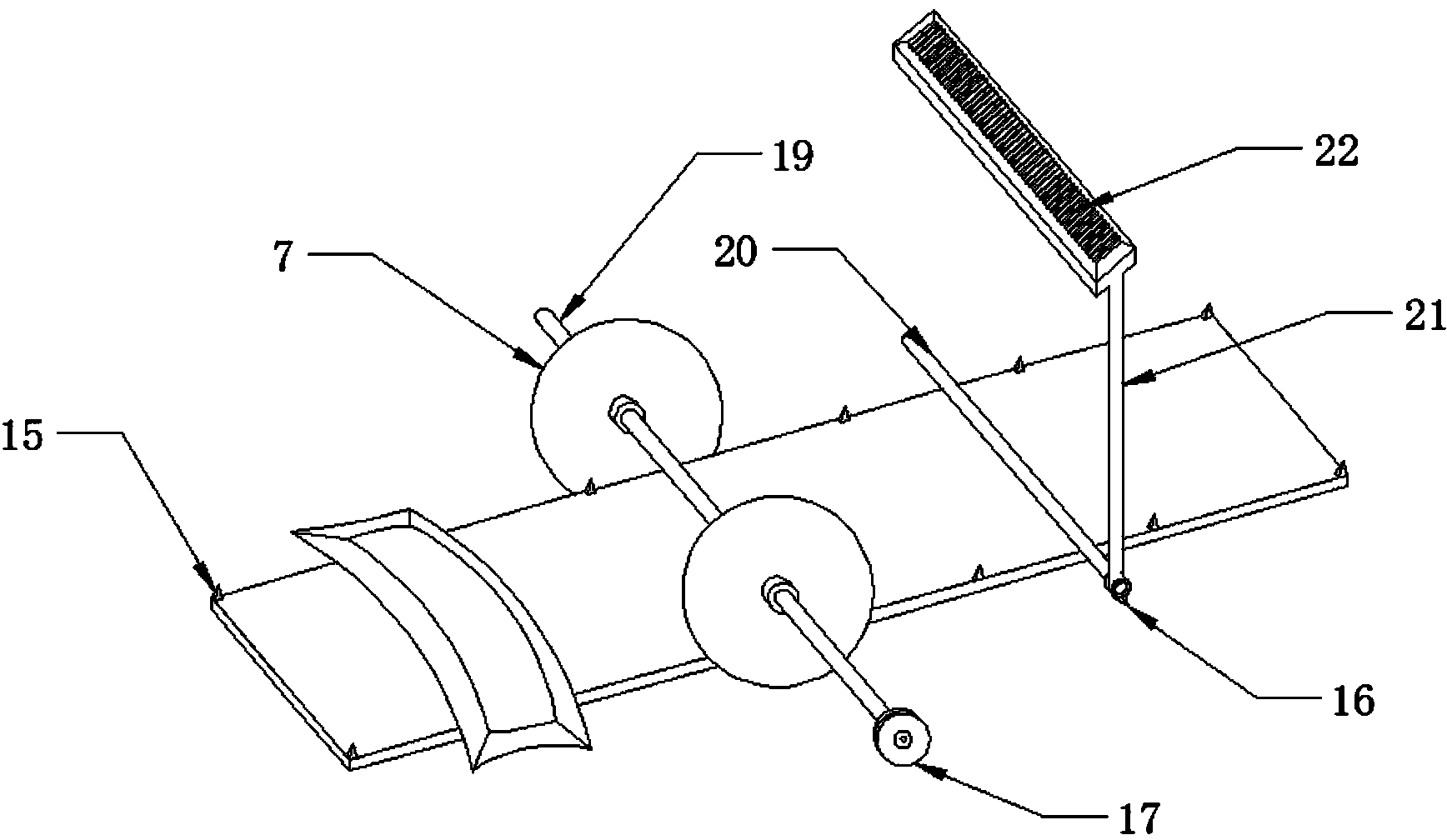

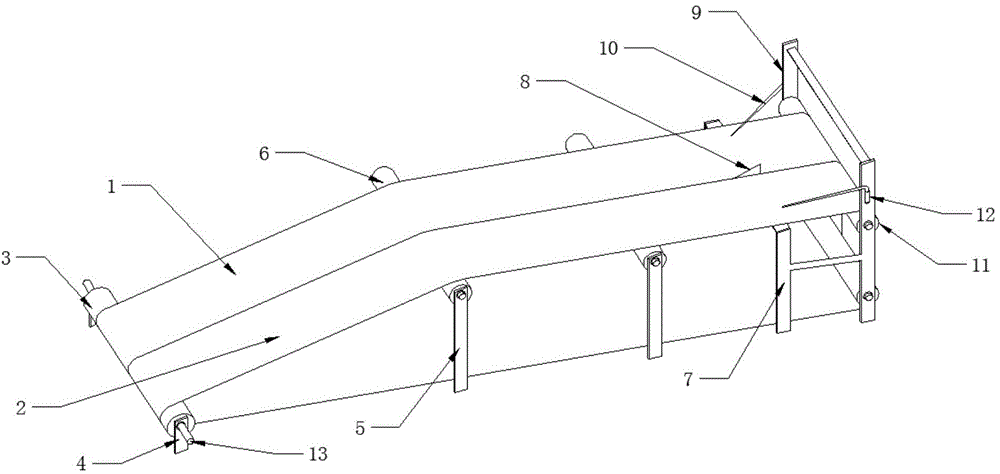

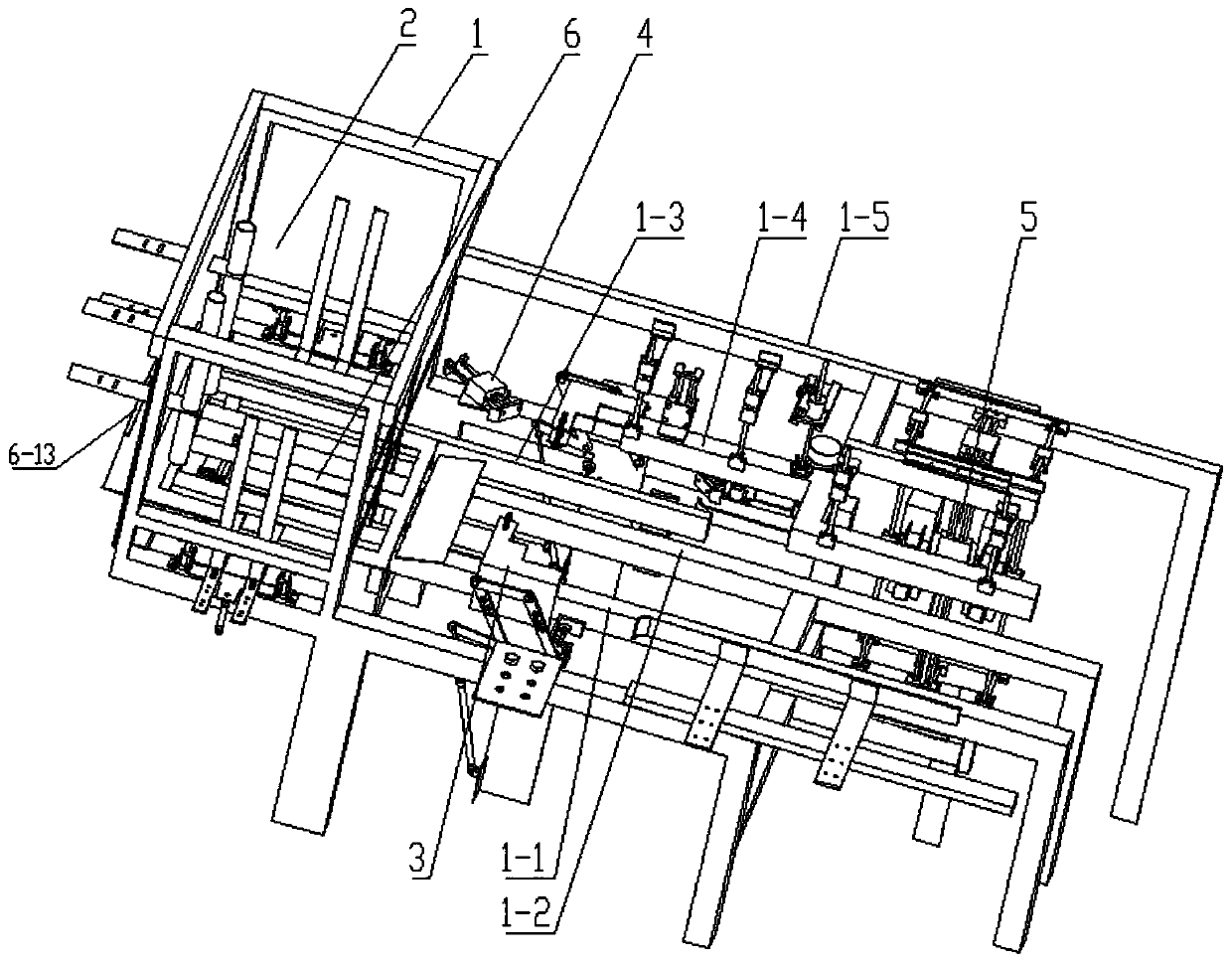

Carton opening system

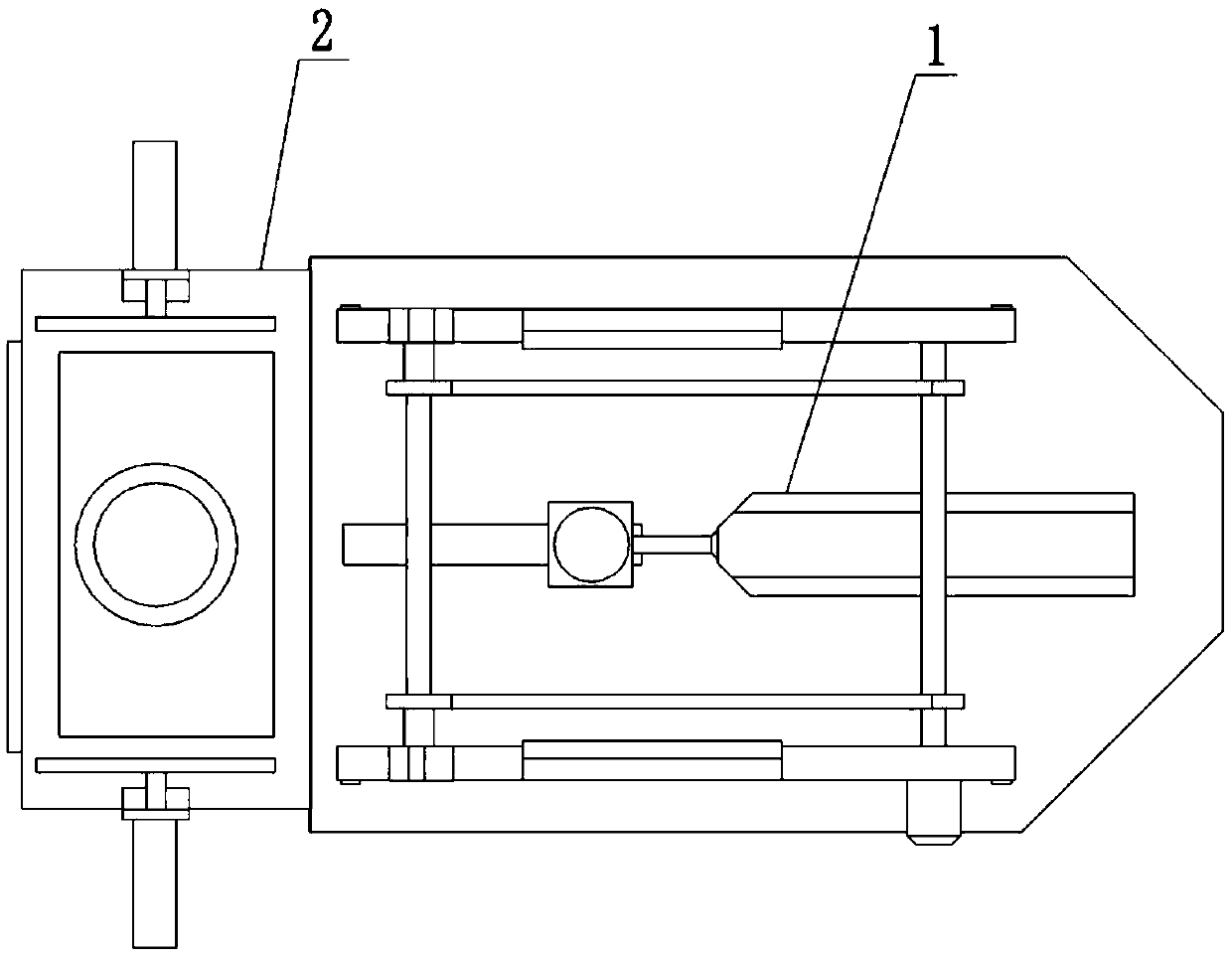

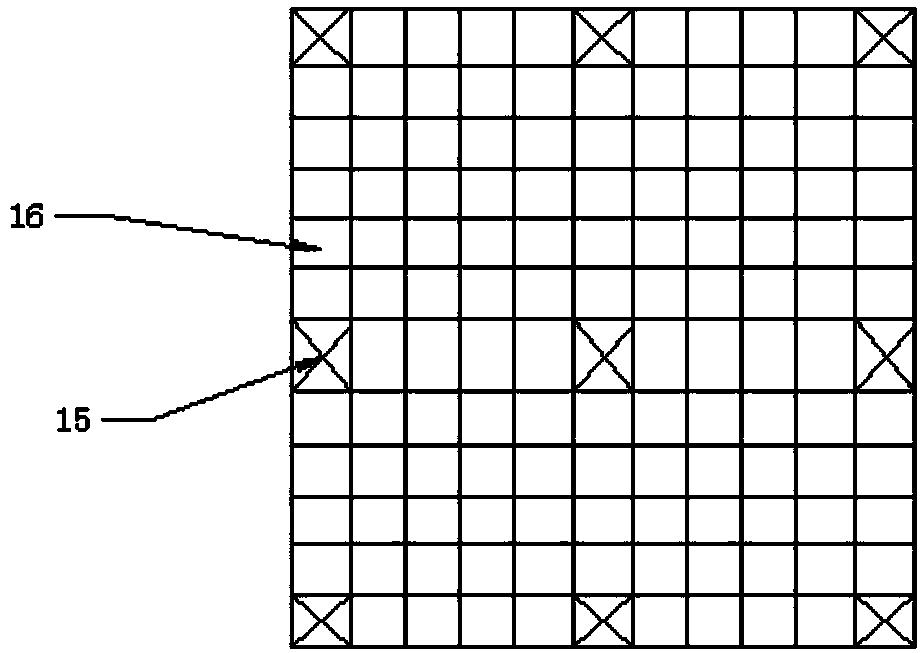

ActiveCN108673940AGuaranteed coincidenceHigh forming precisionBox making operationsPaper-makingCouplingCarton

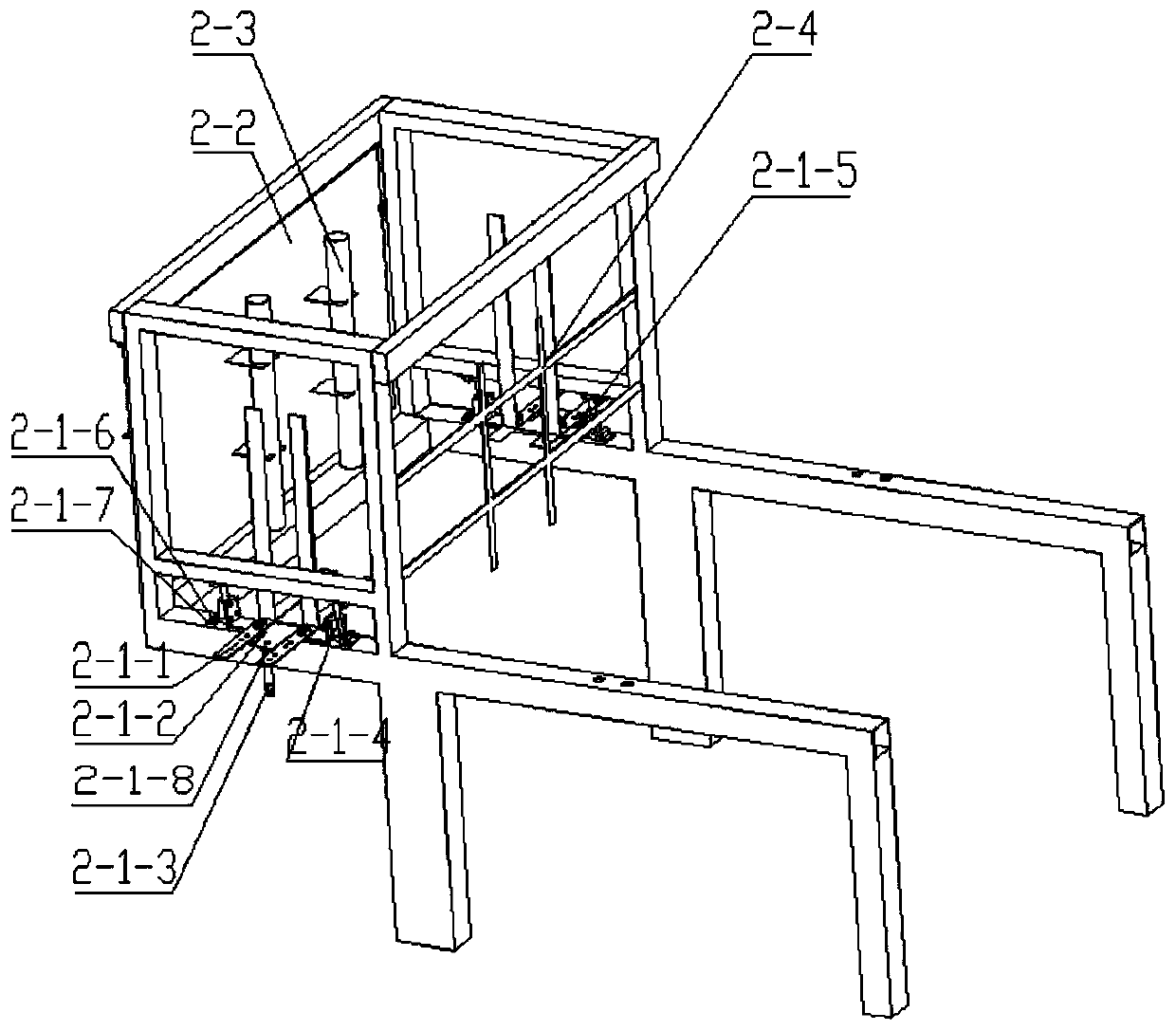

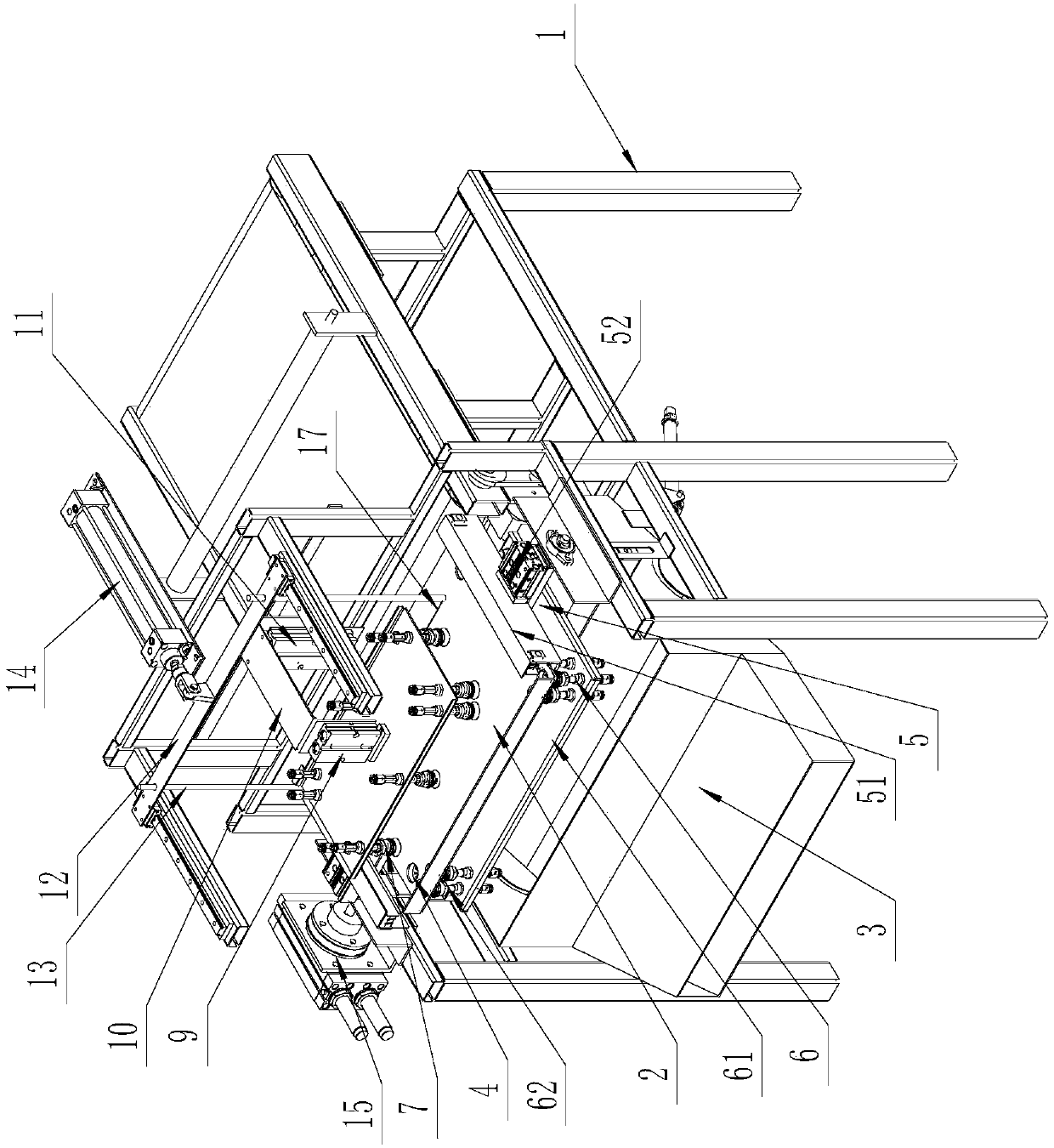

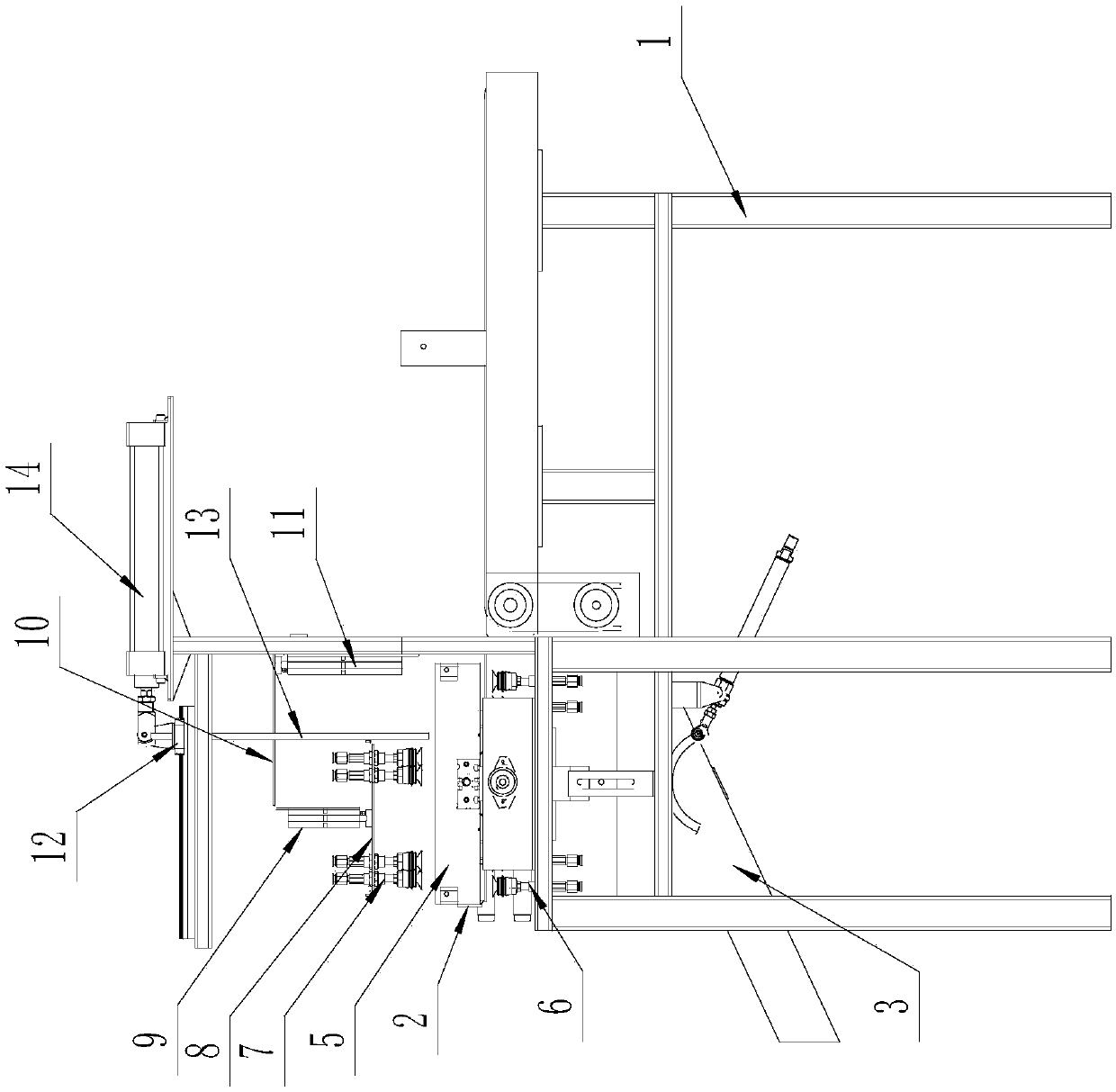

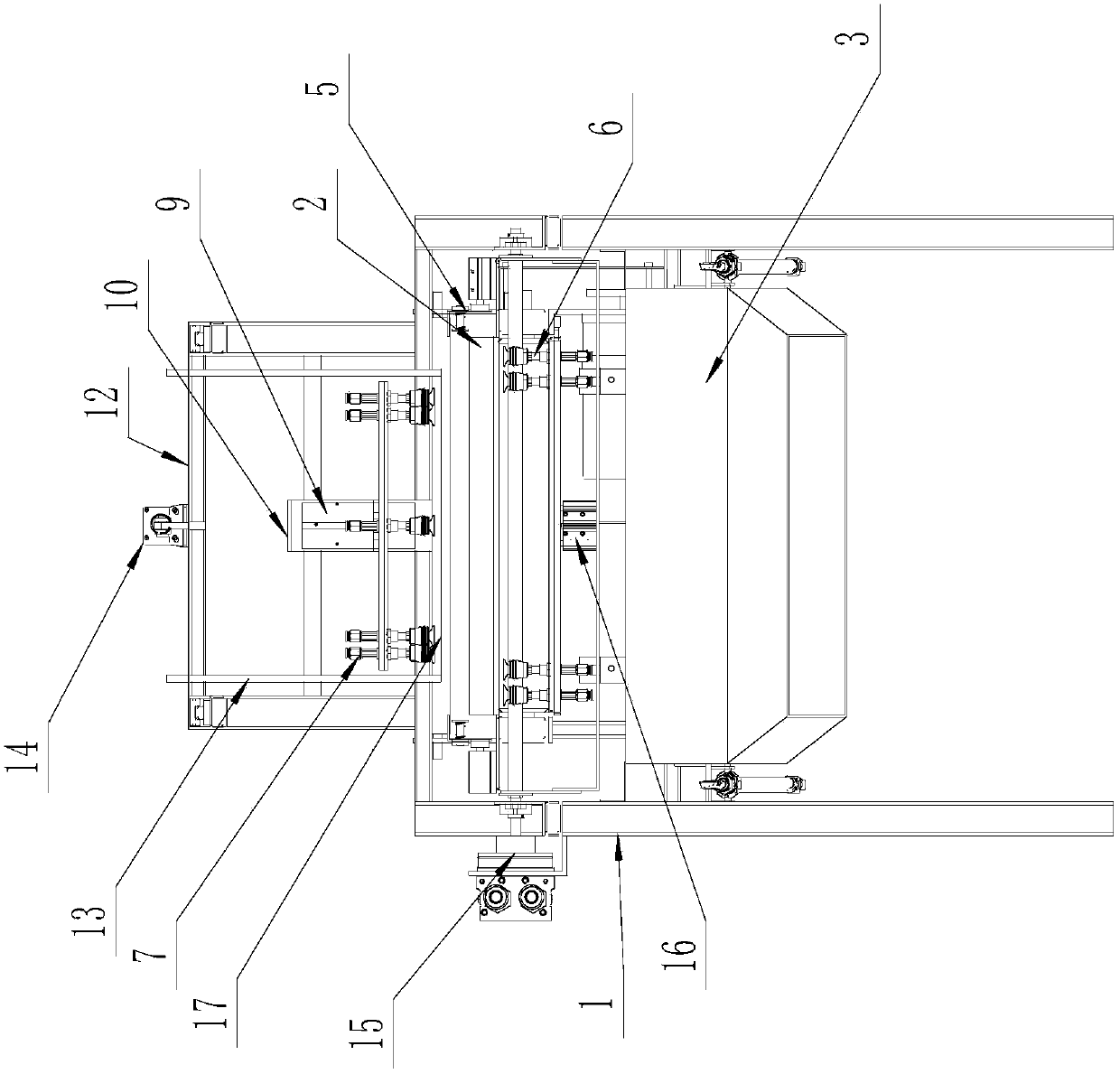

The invention discloses a carton opening system. The carton opening system comprises an unfolded carton conveying mechanism (1), and box forming mechanism (2) for changing unfolded cartons as boxes; the unfolded carton conveying mechanism (1) comprises a frame (3), a base (4) and a linear driving mechanism; a driven rotating shaft (5) and a driving rotating shaft (6) are rotationally mounted at the left and right ends of the frame (3) in the frame (3); a servo motor (7) is fixedly mounted on the side surface of the frame (3); an output shaft of the servo motor (7) is connected with one end ofthe driving rotating shaft (6) by a coupling; two driving belt wheels (8) are mounted on the driving rotating shaft (6); and two driven belt wheels (9), corresponding to the driving belt wheels (8), are mounted on the driven rotating shaft (5). The carton opening system has the characteristics of no need of workers to take and unfold the cartons, high carton opening efficiency, relief of the laborintensity of workers, high box strength after opening, beautiful boxes after opening and reduction of the box opening cost.

Owner:SHANGHAI ZIQI IND

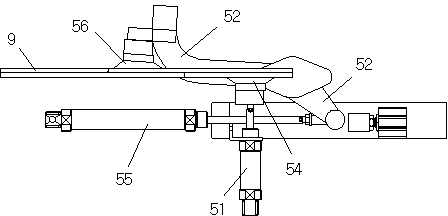

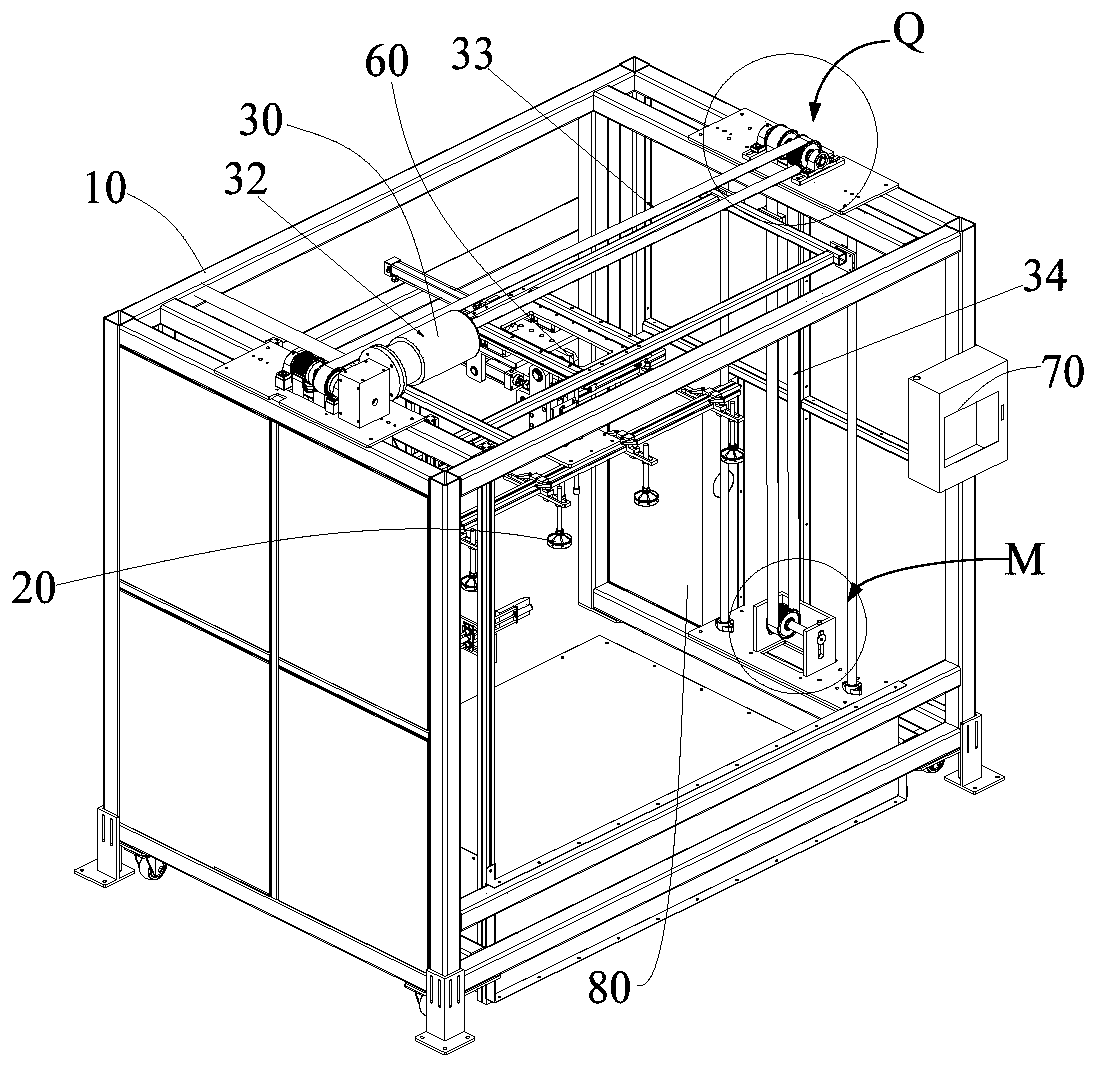

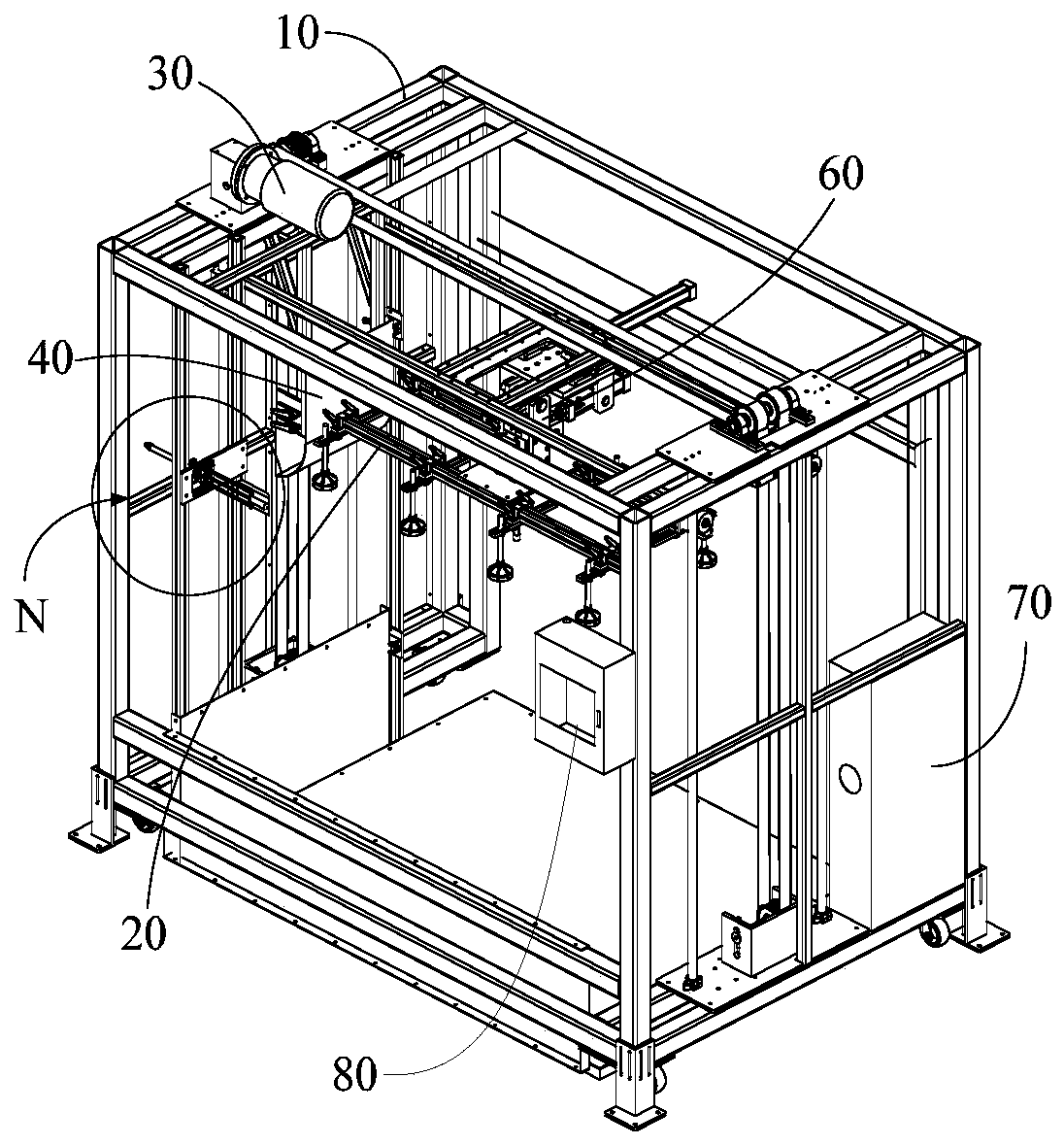

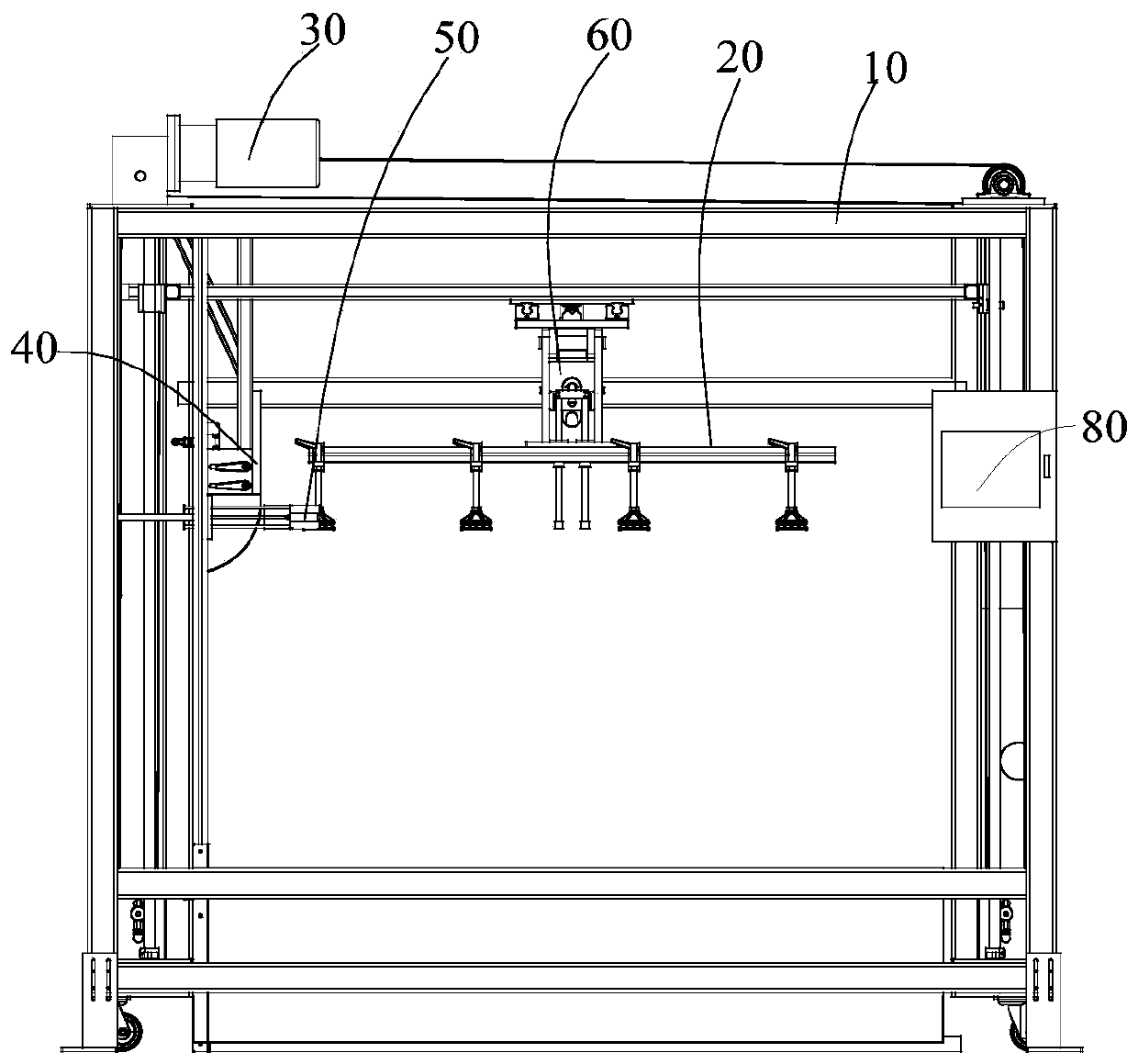

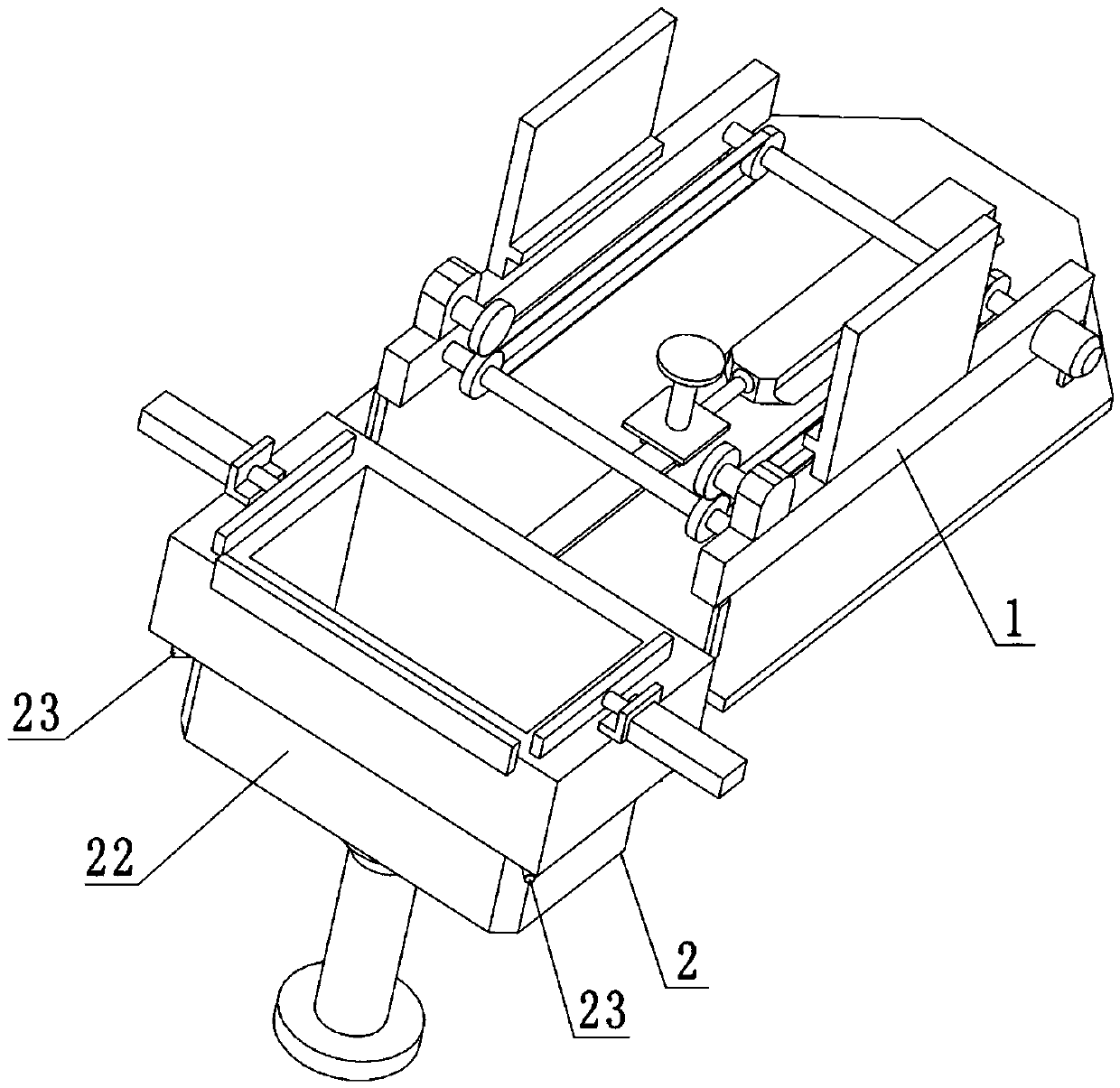

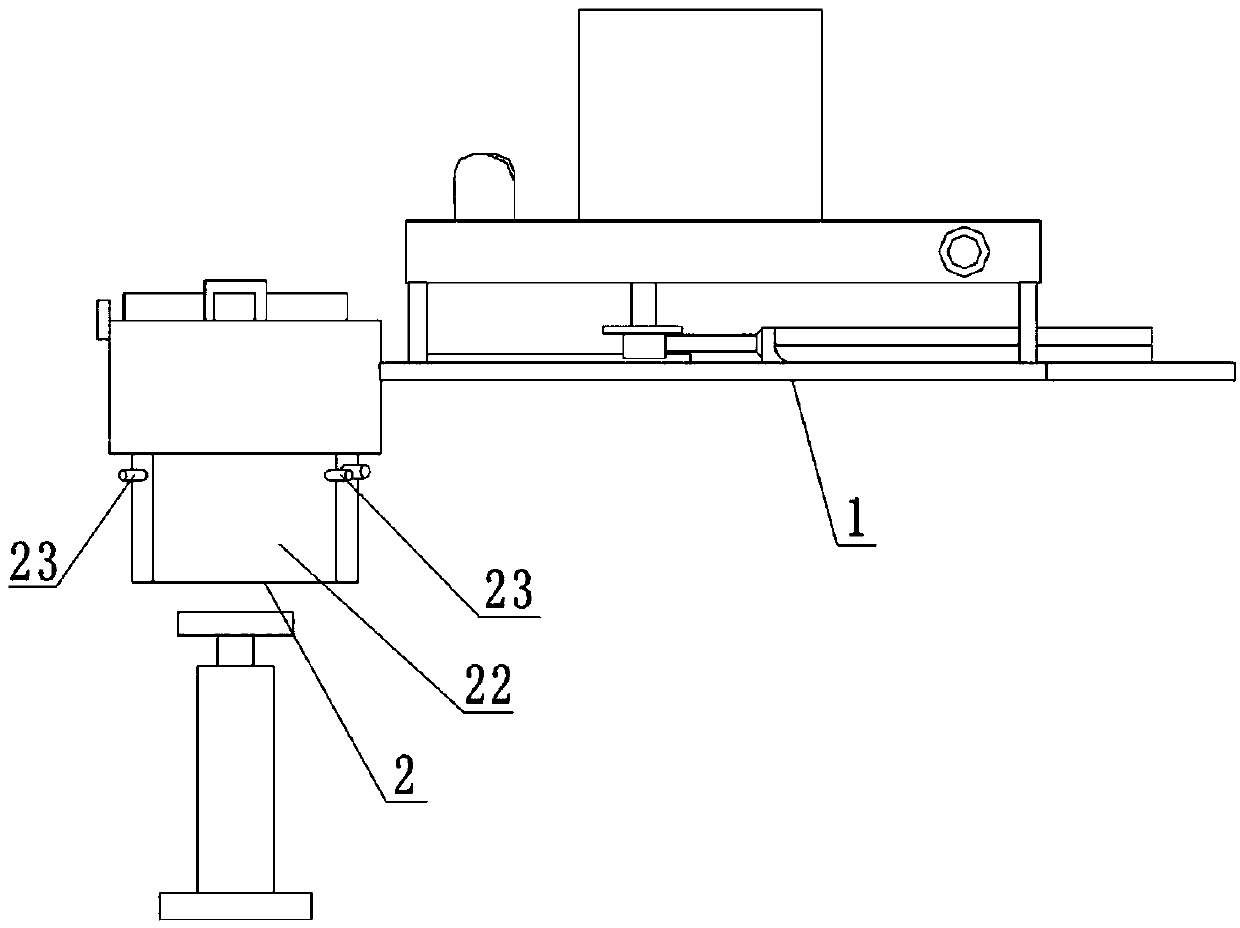

Bottom sealing system of carton opening machine

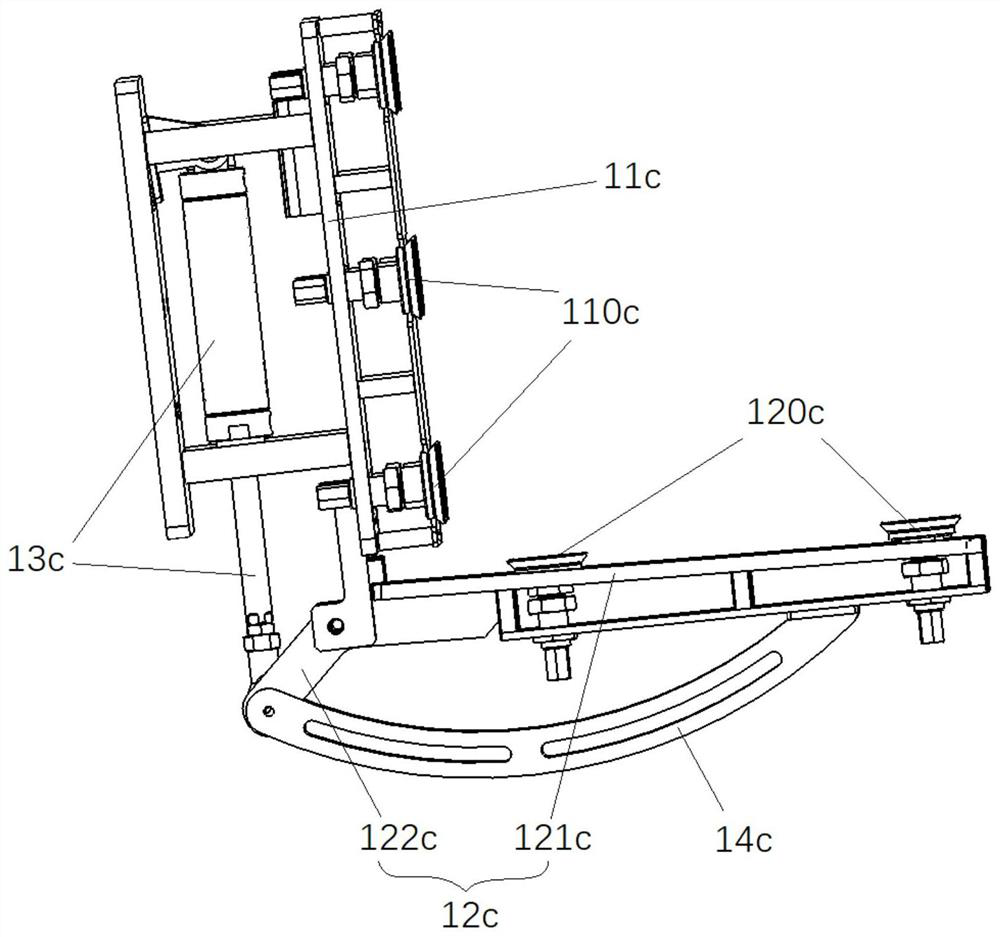

ActiveCN112644790AAchieve random discretizationImprove unpacking efficiencyPackaging machinesRobot handStructural engineering

The embodiment of the invention provides a bottom sealing system of a carton opening machine. The bottom sealing system comprises a rack and a bottom sealing device, wherein the rack is used for placing cartons; the bottom sealing device is used for sealing the bottoms of the cartons; the cartons placed on the rack are in a folded state; each carton comprises long edges and short edges; the bottom sealing system of the carton opening machine further comprises a carton opening mechanical arm; the carton opening mechanical arm is used for grabbing the cartons on the rack and opening the cartons as well as moving the grabbed cartons to the bottom sealing device; and the bottom sealing device is used for bending and sealing the bottoms of the cartons. The bottom sealing system provided by the embodiment of the invention uses the carton opening mechanical arm to replace manual operation, can achieve automatic opening and bottom sealing of folded cartons, achieves random discrete formation and bottom sealing of the cartons of various different specifications, and improves the carton opening efficiency.

Owner:HUAWEI TECH CO LTD

Box opening and conveying device

ActiveCN105501538APrecise and stable movement strokeRealize automatic controlPackagingRange of motionReciprocating motion

The invention discloses a box opening and conveying device, belongs to the field of packaging machinery, and solves the problems that the conventional manual box opening efficiency is low and the cost is high. According to the technical scheme, the box opening and conveying device mainly comprises a box opening assembly, a lifting assembly and a conveying assembly; the box opening assembly comprises a box opening driver and box opening operating parts; the box opening driver drives the box opening operating parts to do linear reciprocating movement, and under the driving of the box opening driver, the moving direction of at least one box opening operating part is opposite to that of another box opening operating part under the driving of the box opening driver; each box opening operating part is provided with a guiding surface and an inserting end; the guiding surfaces are inclined relative to the moving direction of the opening operating parts under the driving of the box opening driver; the inserting ends are positioned at one ends of the guiding surfaces; the conveying assembly is provided with a cyclic conveying route and positioning components distributed on the conveying route; and the moving range of the box opening assembly driven by the lifting assembly is superposed with that of the positioning components. The box opening and conveying device is mainly used for box opening and conveying operations of packaging boxes.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Package separating device and package separating method thereof

The invention discloses a package separating device and a package separating method of the package separating device. The package separating device comprises a bag opening mechanism and an unloading mechanism. The bag opening mechanism comprises a bag separating support, a first clamping component, a second clamping component and a cutting component, the first clamping component is installed on the bag separating support for obtaining the top of a cotton yarn package, the second clamping component is installed on the bag separating support for obtaining the top of the cotton yarn package, andthe cutting component is movably connected to the bag separating support for cutting the top of the cotton yarn package. The unloading mechanism comprises an unloading support, an unloading bearing component, an unloading fixing component and an unloading driving component, the unloading bearing component is rotationally connected to the unloading support, the unloading fixing component is arranged on the unloading bearing component for fixing the opened cotton yarn package, the unloading driving component is arranged on the unloading support and connected to the unloading bearing component, and the unloading driving component is used for driving the unloading bearing component to rotate to pour out cheese in the cotton yarn package. The package separating device is high in bag separatingefficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

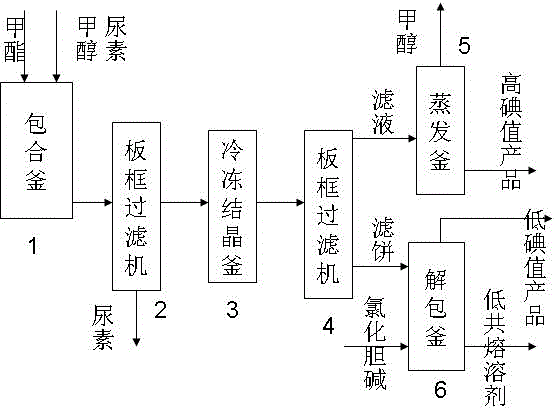

Clean technology for enriching unsaturated fatty acid methyl ester

ActiveCN105779123AImprove recycling efficiencyLow costOrganic compound preparationCarboxylic acid esters preparationUnsaturated fatty acidEngineering

In order to solve the technical problems that in the conventional urea adduction method, the energy consumption for separating saturate fatty acid methyl ester is high, the product purity is low, and a large amount of urea wastewater cannot be processed, the invention provides a eutectic solvent method unpacking technology, which has high urea recovery efficiency. According to the technology, the unpacking is realized by forming a eutectic solvent, the urea recovery rate is high, and almost all urea in inclusion compounds can be separated through once mixing in an unpacking kettle. The cost of choline chloride taken as the unpacking agent is low, and choline chloride is biodegradable and environment-friendly. The technology has the characteristics that the unpacking efficiency is high and urea can be radically removed. At the same time, the formed eutectic solvent has a certain effect on removing water and few metal impurities in fatty acid methyl ester; the energy consumption and production cost are prominently reduced, and fatty acid methyl ester with a high iodine value can be obtained.

Owner:石家庄搏澳增塑材料科技有限公司

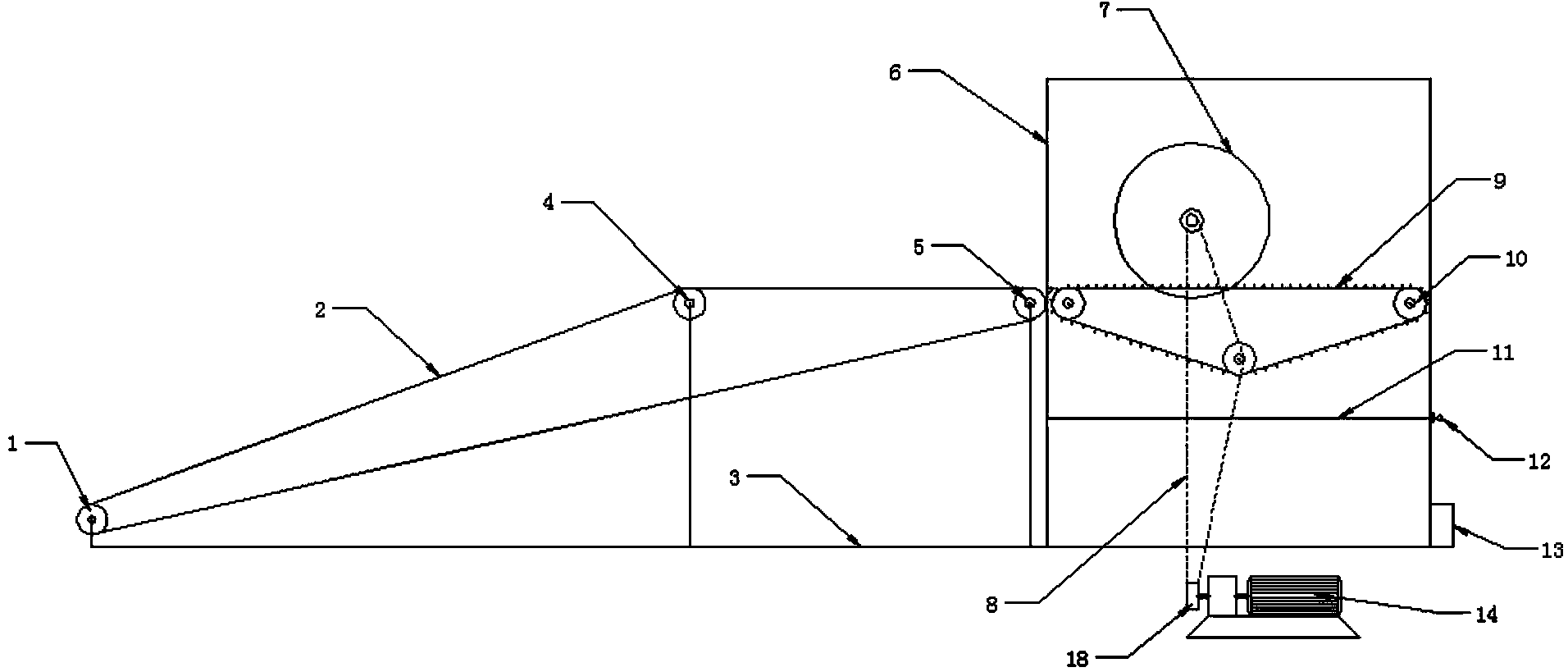

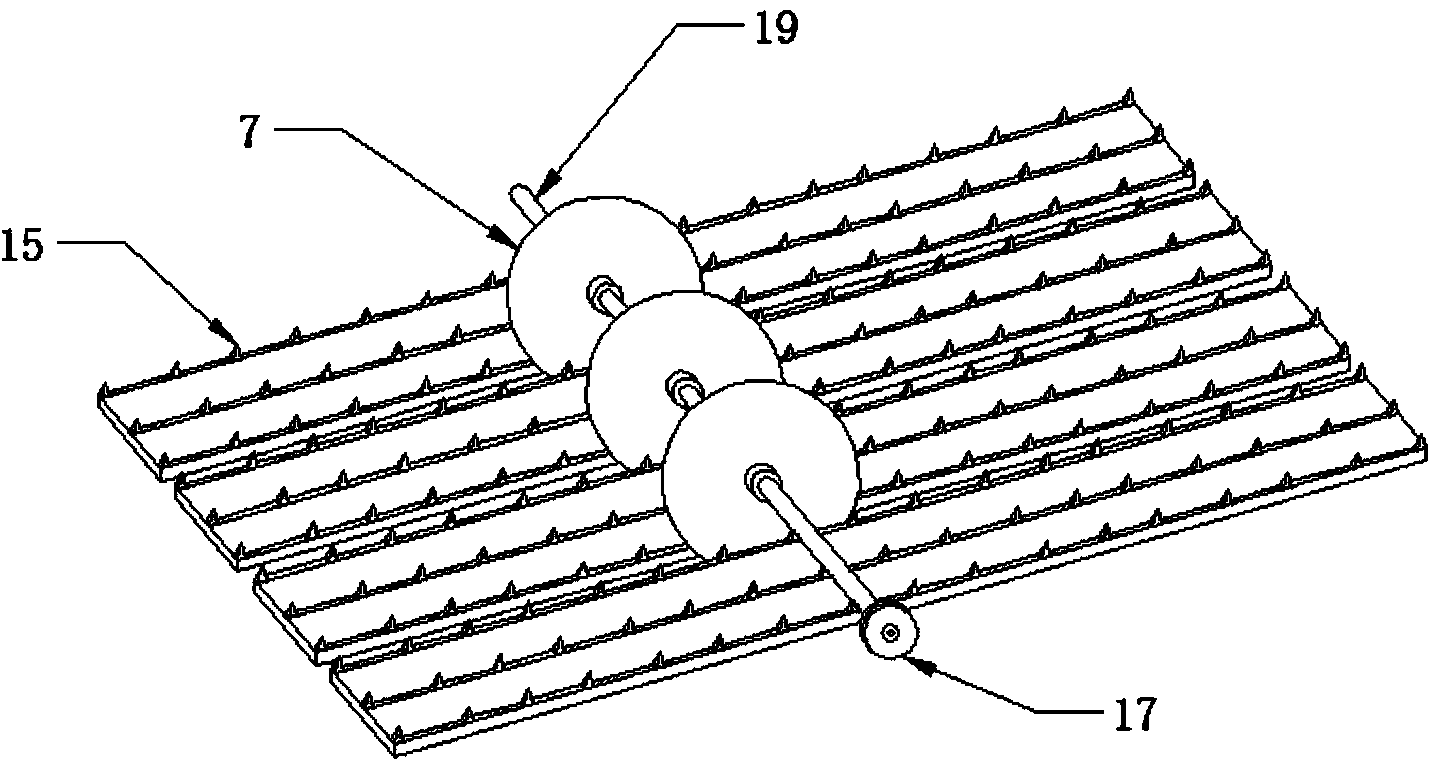

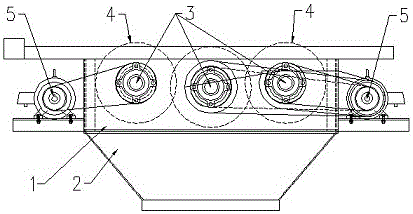

Screening bale opener

The invention discloses a screening bale opener, which comprises a conveying rack, a rack, cutters and a tool shaft, wherein a delivery roller wheel, a steering roller wheel and a returning roller wheel are sequentially arranged on the conveying rack, and a conveyor belt is connected among the delivery roller wheel, the returning roller wheel and the steering roller wheel; the tool shaft with the cutters is arranged on the rack, and bale cutting roller wheels positioned below the cutters are arranged on the rack; cutting retaining belts with material holes are arranged on the bale cutting roller wheels, and a plurality of puncture teeth are uniformly arranged on the cutting retaining belts; a vibration screen is arranged below the cutting retaining belts, and a variable frequency motor with a speed reducer is arranged at the lower end of the rack; a drive pulley arranged at the tail end of the variable frequency motor drives the driven pulley on the tool shaft through a belt. The screening bale opener provided by the invention has the advantages of simple and reasonable structure, practicality and safety, high bale opening efficiency, material cleaning, reduction in total cost of equipment, continuous automatic bale opening regulation and control, reduction in human and material resources, and reduction in total cost of production.

Owner:常州兆伯瑞人工智能科技有限公司

Multifunctional large packing bag opening machine

InactiveCN105819044AHigh unpacking efficiencySimple structureUnpacking by cuttingEngineeringMechanical engineering

The invention discloses a multifunctional large packing bag opening machine which comprises a dust seal case. A tape breaking device used for opening a packing bag automatically is arranged at the bottom of the dust seal case. According to the technical scheme of the multifunctional large packing bag opening machine, the large packing bag opening can be completed, the packing bag opening efficiency is high, the structure is simple, and the large packing bag opening machine is safe and reliable.

Owner:ANQIU BOYANG MACHINERY MFR

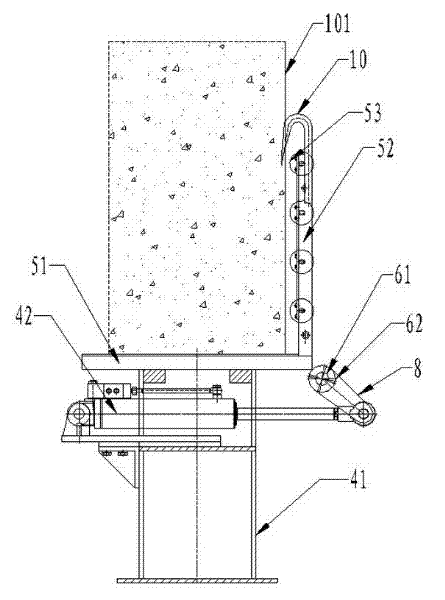

Unpacking and feeding machine

InactiveCN102390582AQuick unpackingImprove unpacking efficiencyArticle unpackingAgricultural engineeringCompression device

The invention discloses an unpacking and feeding machine which comprises a frame, a turnover device and a compression device, wherein the compression device is arranged on the left side and the right side of the frame, the turnover device is arranged at the center of the frame, material is re-extruded through the compression device for easily untying wrapping tapes on the material, and turnover and feeding of the material after untying the wrapping tapes and cutting open wrapping cloth are completed by the turnover device. The unpacking and feeding machine can reduce the labor intensity of operation staff, the unpacking efficiency is high, the high-strength polyester wrapping tapes can be completely recycled, the environmental friendliness is strong and the unpacking and packing cost of the material is further reduced.

Owner:LUZHOU SHUIYUAN HYDRAULIC MACHINE +1

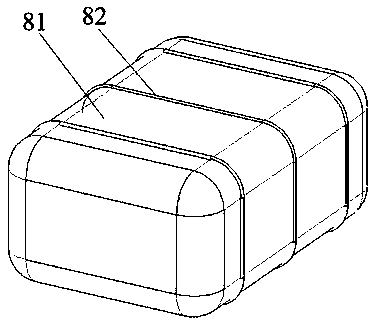

Ton bag unpacking device

ActiveCN111846492ALarge operating rangeReduce the number of shipmentsBags openingUnpacking by cuttingSimulationMechanical engineering

The invention discloses a ton bag unpacking device. The ton bag unpacking device comprises a support structure, a stock bin, a bag breaking mechanism and a linear walking mechanism, wherein a part ofthe support structure is hollow; the stock bin is installed on the support structure and is provided with a material chamber, and the material chamber communicates with the hollow part of the supportstructure, so that materials passes through the material chamber and fall through the hollow part; the bag breaking mechanism is installed on the stock bin and is arranged in the width direction of the stock bin; and the linear walking mechanism is installed on the support structure and is located outside the stock bin and is arranged in the length direction of the stock bin, the linear walking mechanism is connected with the bag breaking mechanism, and the bag breaking mechanism can be driven to walk on a straight line in the length direction of the stock bin. According to the technical scheme of the ton bag unpacking device, several ton bags can be broken and unpacked once, so that the unpacking efficiency is improved.

Owner:江苏琪联华赫智能装备科技有限公司

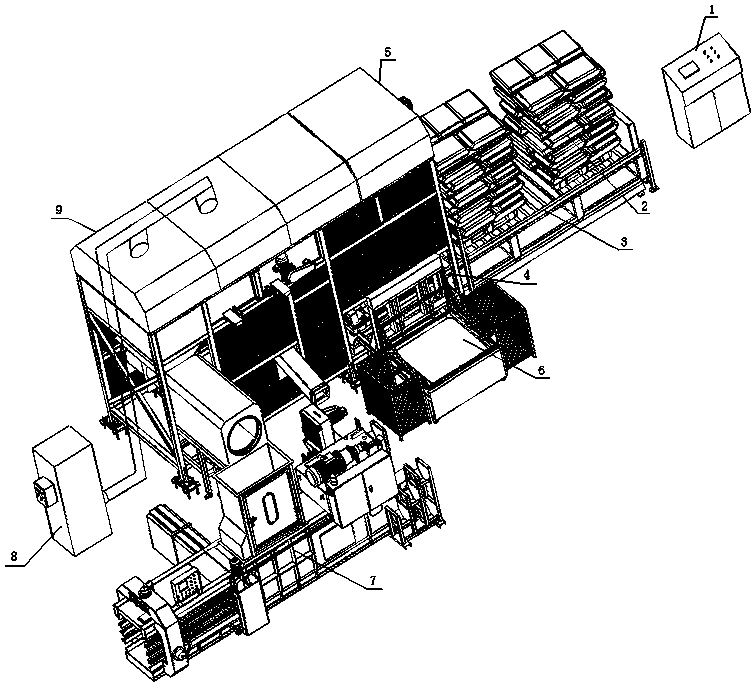

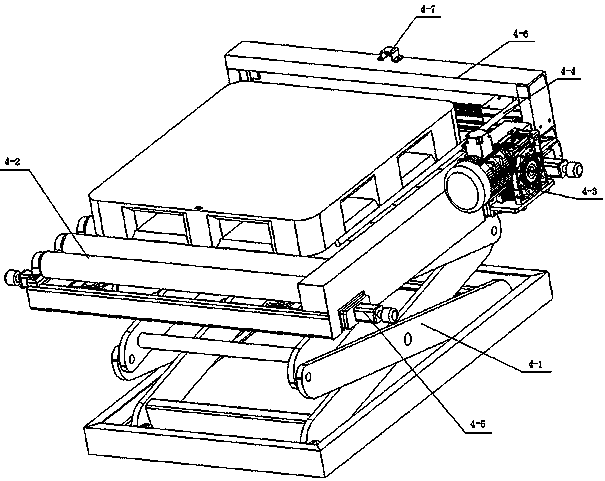

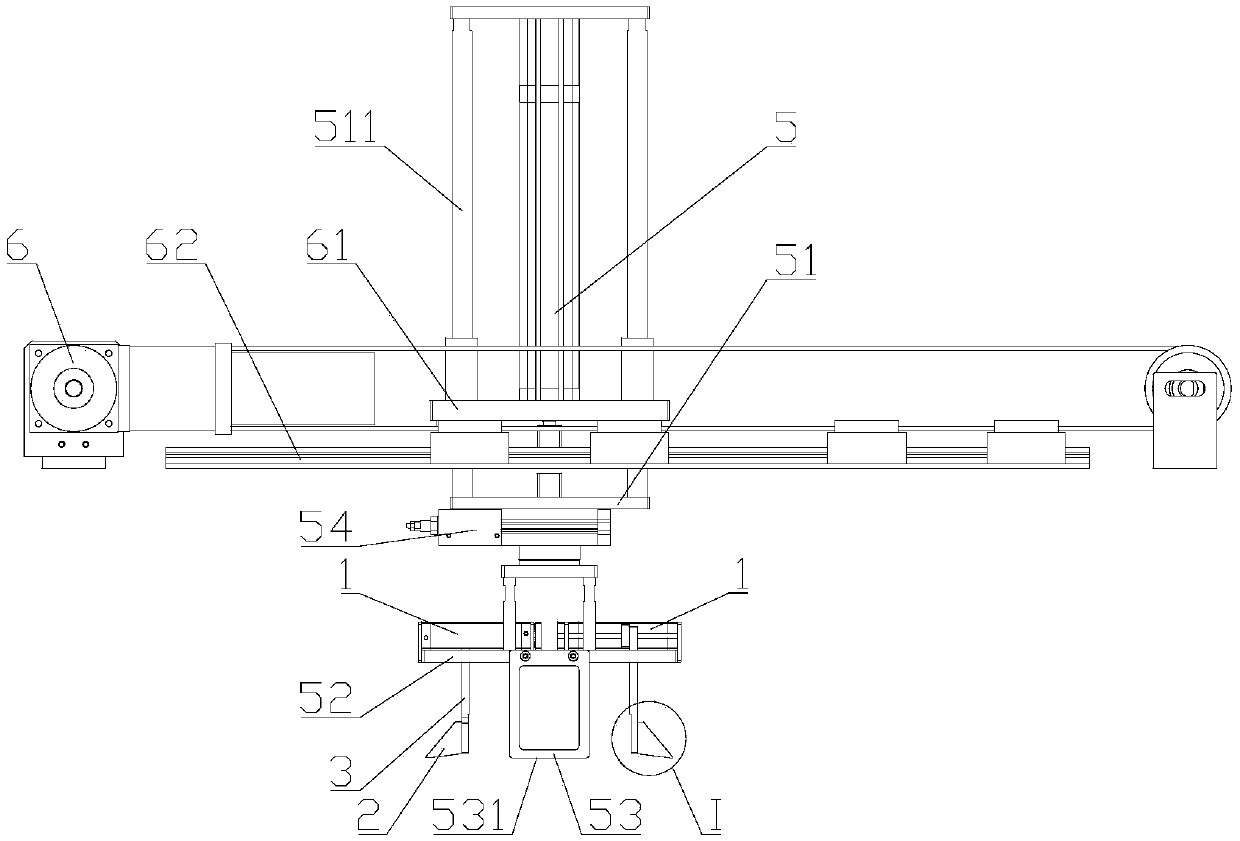

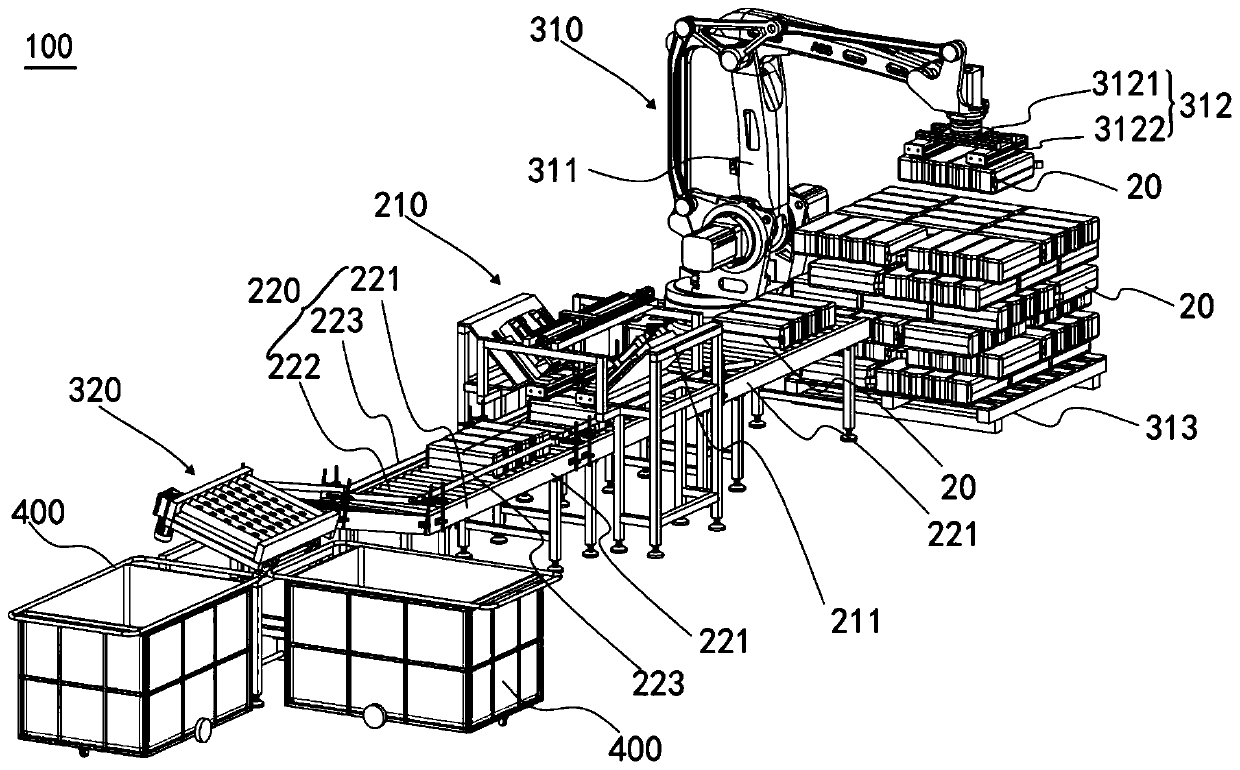

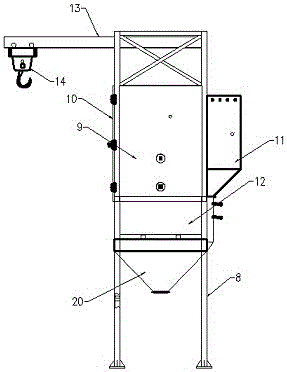

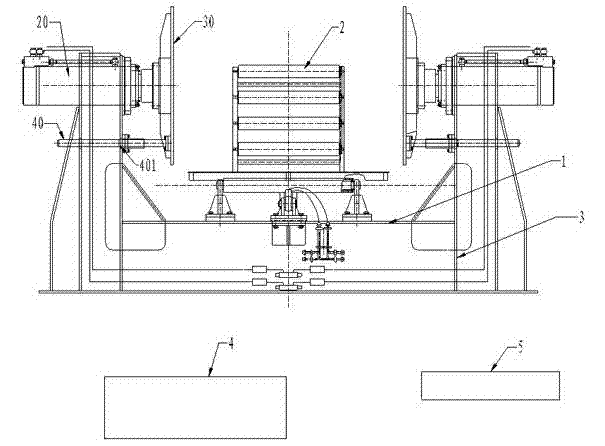

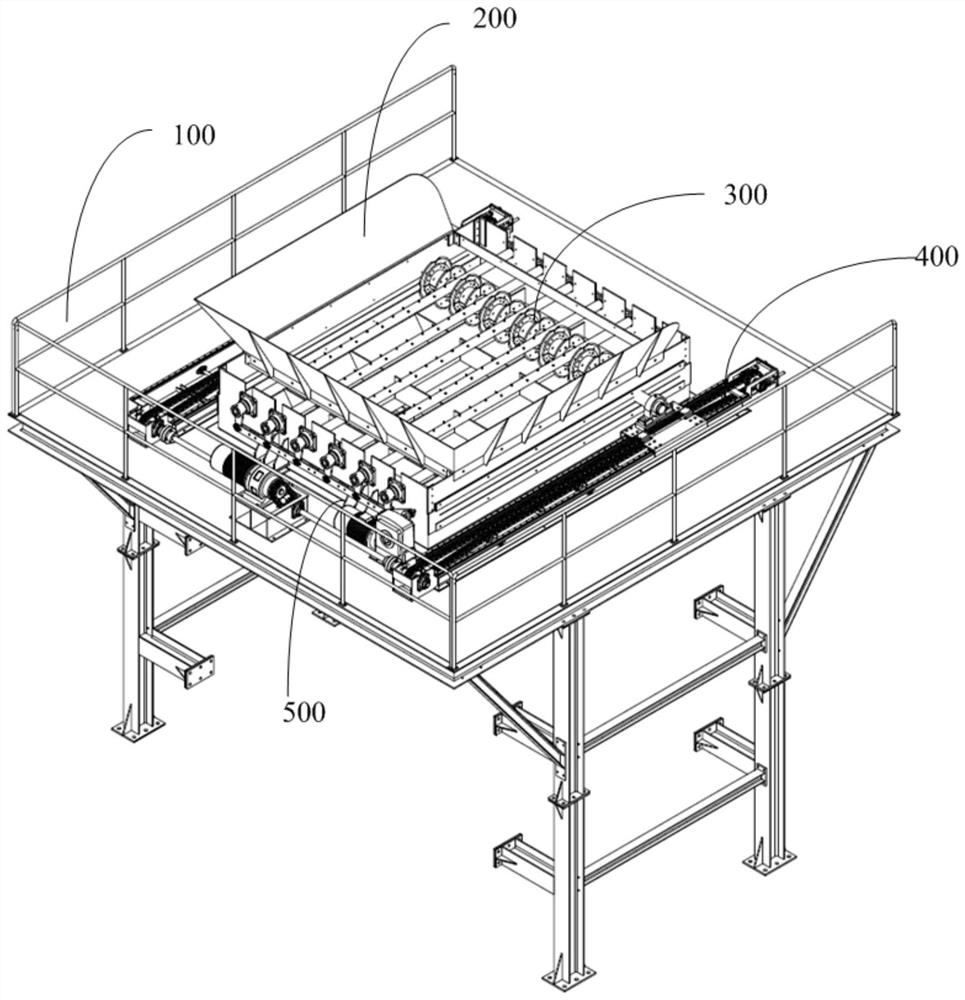

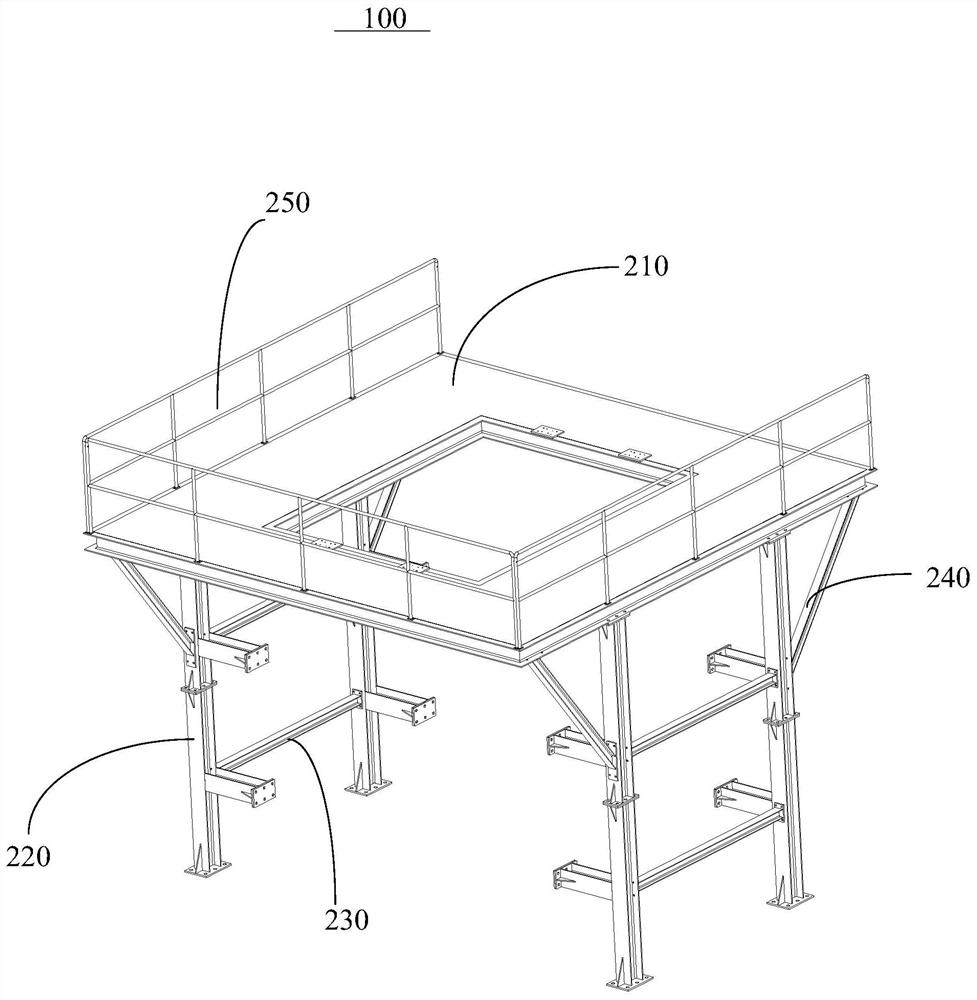

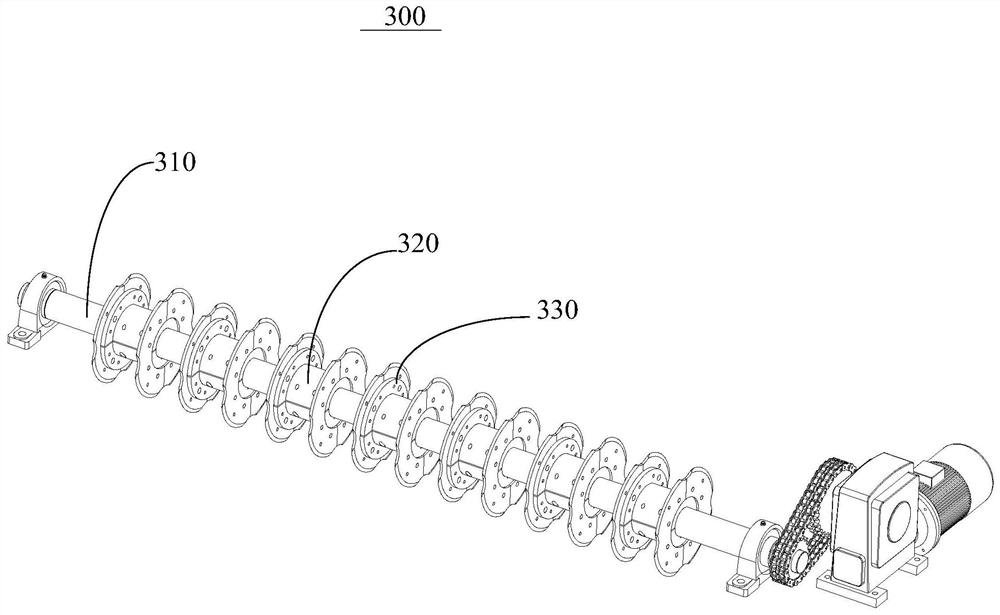

Efficient intelligent wine making yeast cake destacking system

PendingCN108516355AImprove unpacking efficiencyReduce labor intensityStacking articlesDe-stacking articlesYeastAgricultural engineering

The invention discloses an efficient intelligent wine making yeast cake destacking system. The system comprises a robot, a clamp, a lifting machine, a yeast basket and a yeast frame. The clamp is fixedly connected with the wrist of the robot, a hook for clamping the yeast frame and a driving device I for driving the hook to move are arranged on the two sides of the clamp, the clamp is further provided with a push plate for pushing a yeast cake on the yeast frame to move front and back and a driving device II, the lifting machine is arranged on one side of the robot and corresponds to the yeastbasket in position, the lifting machine is provided with a material plate and a drive device III for driving the material plate to move up and down, the lifting machine is further provided with a drive device IV for driving the material plate to move front and back, and the end, close to the yeast basket, of the upper portion, in the front and back moving direction of the material plate, of the lifting machine is provided with a material blocking plate and a drive device V. The robot is provided with the clamp adapting to the yeast frame, in cooperation with the lifting machine capable of moving up and down and front and back, yeast cakes can be automatically taken out from the yeast frame and are stacked in to the yeast basket in a layered manner, and the beneficial effects of being intelligent, high in destacking efficiency and high in adaptation are achieved.

Owner:LUZHOU PINCHUANG TECH CO LTD +2

Automatic unpacking system for packaging bag, and bag unpacking release mechanism of same

ActiveCN110683145ACompact structureCompact layoutPlastic recyclingBags openingRobot handStructural engineering

The invention relates to an automatic unpacking system for a packaging bag, and a bag unpacking release mechanism of the same, wherein a first cutter is installed on a cutter support, and the first cutter is used for being hung on one side of a conveying platform and thus cutting the lower part of a corresponding side face of the packaging bag when a material bag is driven by a mechanical hand tomove backwards horizontally; supporting rods which extend horizontally are disposed on the cutting support and under the first cutter, the quantity of the supporting rods is two, the supporting rods are disposed at an interval from front to rear, second cutters are assembled on the two supporting rods respectively in a guiding manner, blades of the two second cutters are disposed in a face-to-facemanner, and the second cutters are equipped with driving mechanism; and the mechanical hand is provided with a limiting structure and can stop moving when the material bag is moved downwards to a setdistance, so an incision of the first cutter can be aligned with cutting positions of the second cutters, and a U-shaped incision can be formed through cutting of the lower part of the packaging bag.The system and the mechanism provided by the invention have the beneficial effects that an overall automation degree is high; unpacking efficiency can be greatly increased; and labor and unpacking cost can be saved.

Owner:ZHENGZHOU UNIV

carton forming machine

The invention relates to the technical field of packaging equipment, in particular to a carton forming machine which aims to improve carton unfolding efficiency and relieve labor intensity. The carton forming machine comprises a rack, four stations are sequentially arranged on the rack from right to left, an upper horizontal motion driving mechanism and a lower horizontal motion driving mechanism which are used for pushing cartons to move from right to left are arranged on the rack, and a linear carton body guide rail transversely penetrating through the four stations is fixed to the rack. A feeding frame is fixed to the first station of the rack, a carton unfolding mechanism used for unfolding carton pieces to form rectangular cartons and an inner fold folding cylinder used for folding inner folds of the front ends of the cartons are arranged on the second station, an outer fold folding cylinder used for folding outer folds of the front ends of the cartons is arranged on the third station, and an adhesive tape pasting device is arranged on the fourth station and arranged on the front edge of the carton body guide rail. The carton forming machine is high in carton unfolding efficiency and low in labor intensity.

Owner:迈巴赫机器人(昆山)有限公司

Servo horizontal type carton unpacking machine

The invention discloses a servo horizontal type carton unpacking machine which comprises a rack, a feeding device erected at the rear end of the rack, a jacking device for jacking cartons except the lowest carton, a carton taking and pushing mechanism for taking a carton and synchronously pushing the former unpacked carton, a rotary oscillating carton unpacking device, a side page folding mechanism, and a belt pasting device arranged at the front end of the rack, wherein the carton taking and pushing mechanism is arranged on the rack and comprises a base, a carton taking and pushing device, and a driving device capable of driving the carton taking and pushing device to act back and forth; the driving device is arranged on the base; and the carton taking and pushing device comprises a framebody, a carton pushing component arranged on the frame body, and a carton taking and pushing component for synchronously taking and pushing the carton. The servo horizontal type carton unpacking machine synchronously takes and pushes cartons through the carton taking and pushing device, is driven by one motor only, reduces energy consumption, simplifies the machine structure, reduces the machinecost, and improves the carton unpacking efficiency.

Owner:浙江思密达智能科技有限公司

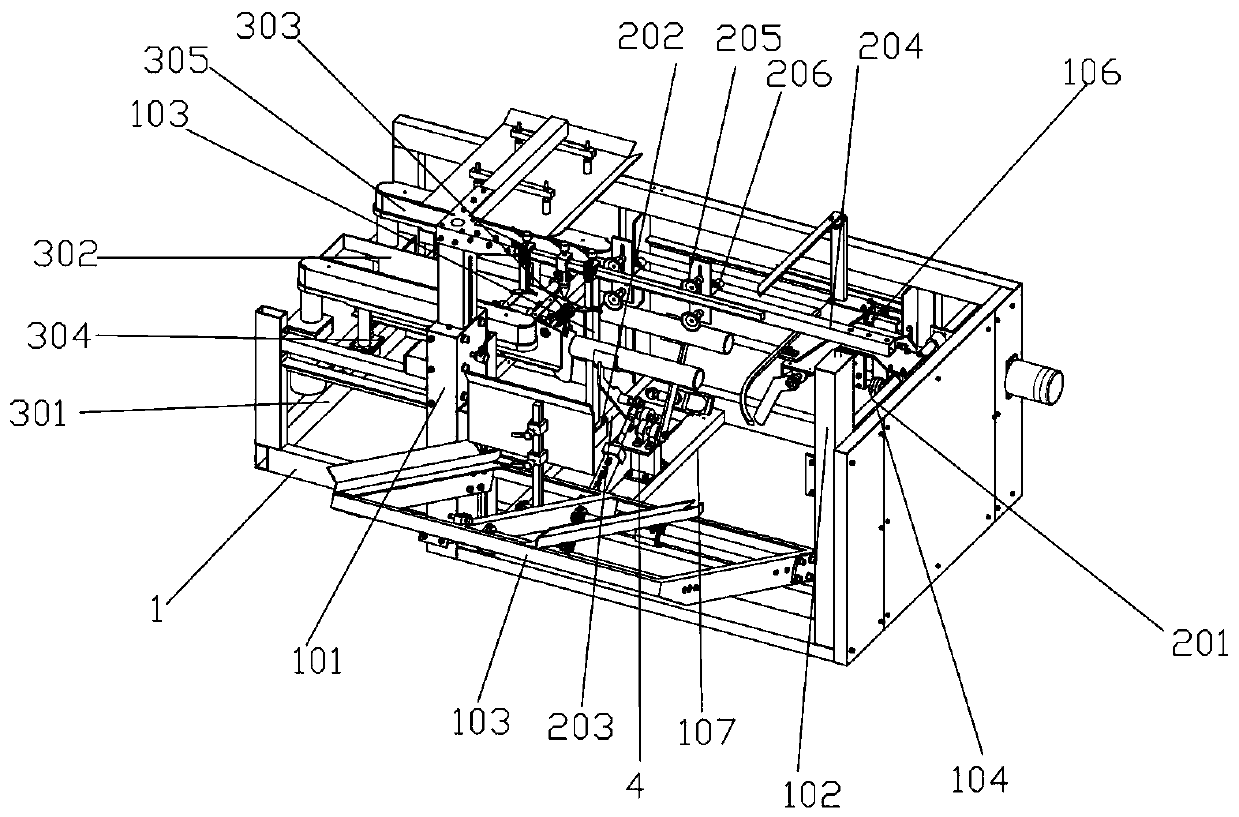

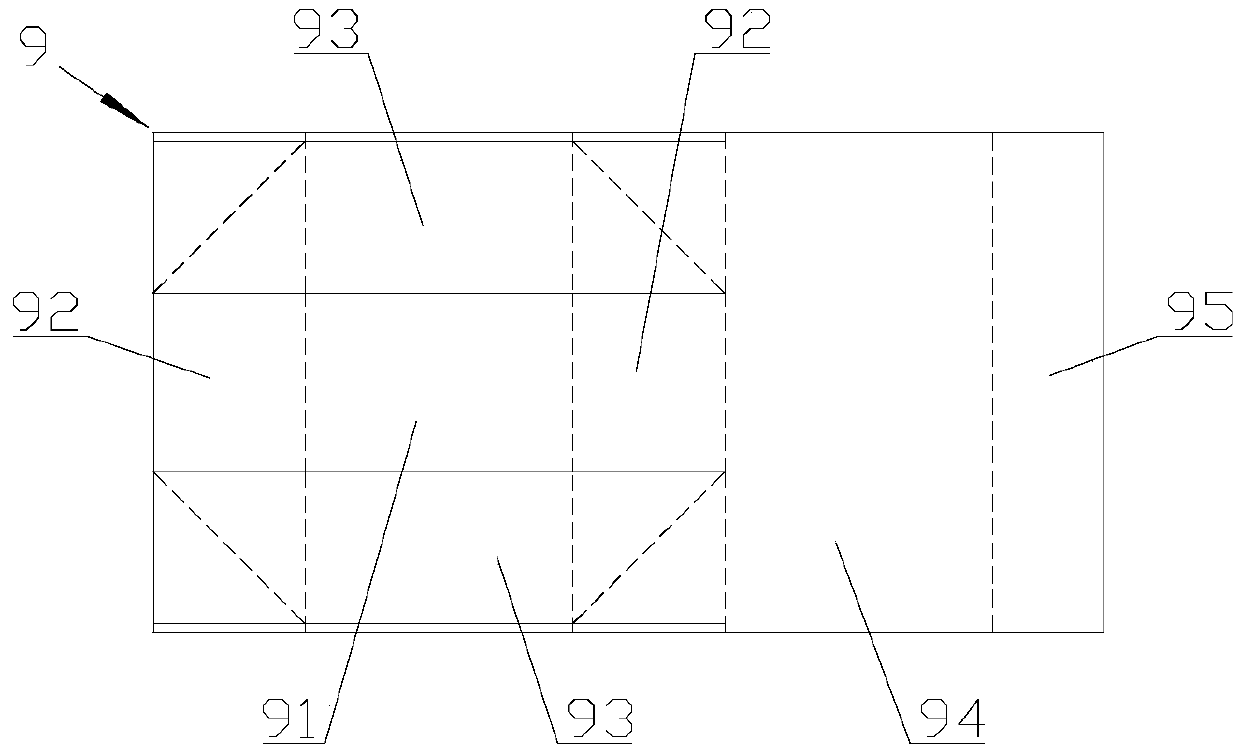

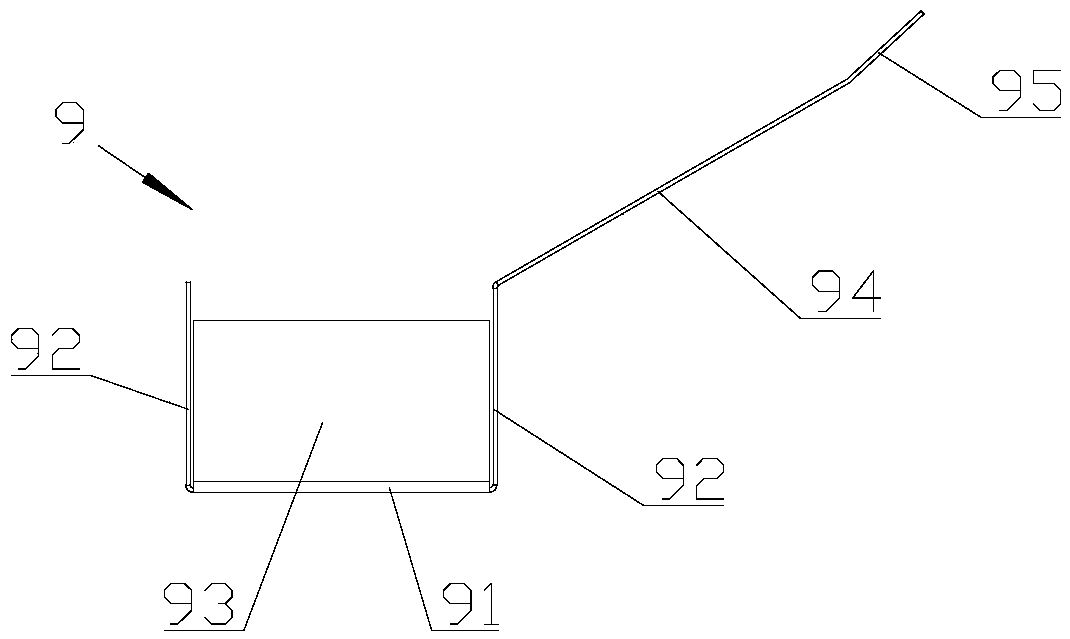

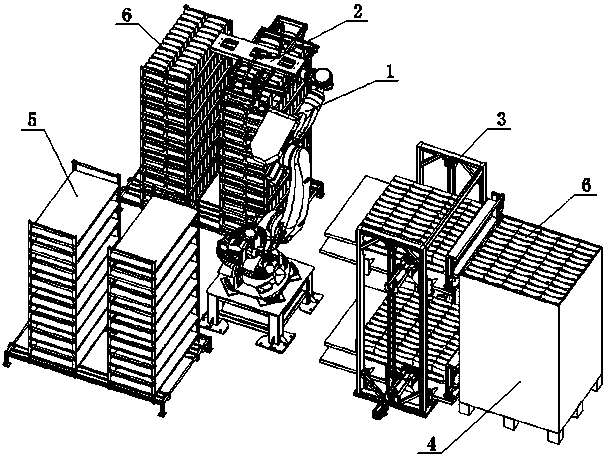

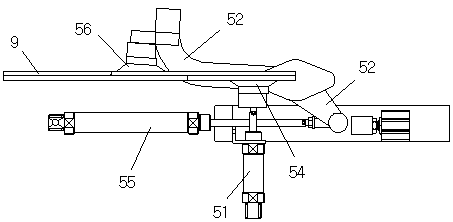

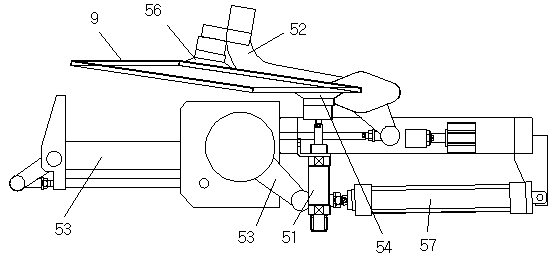

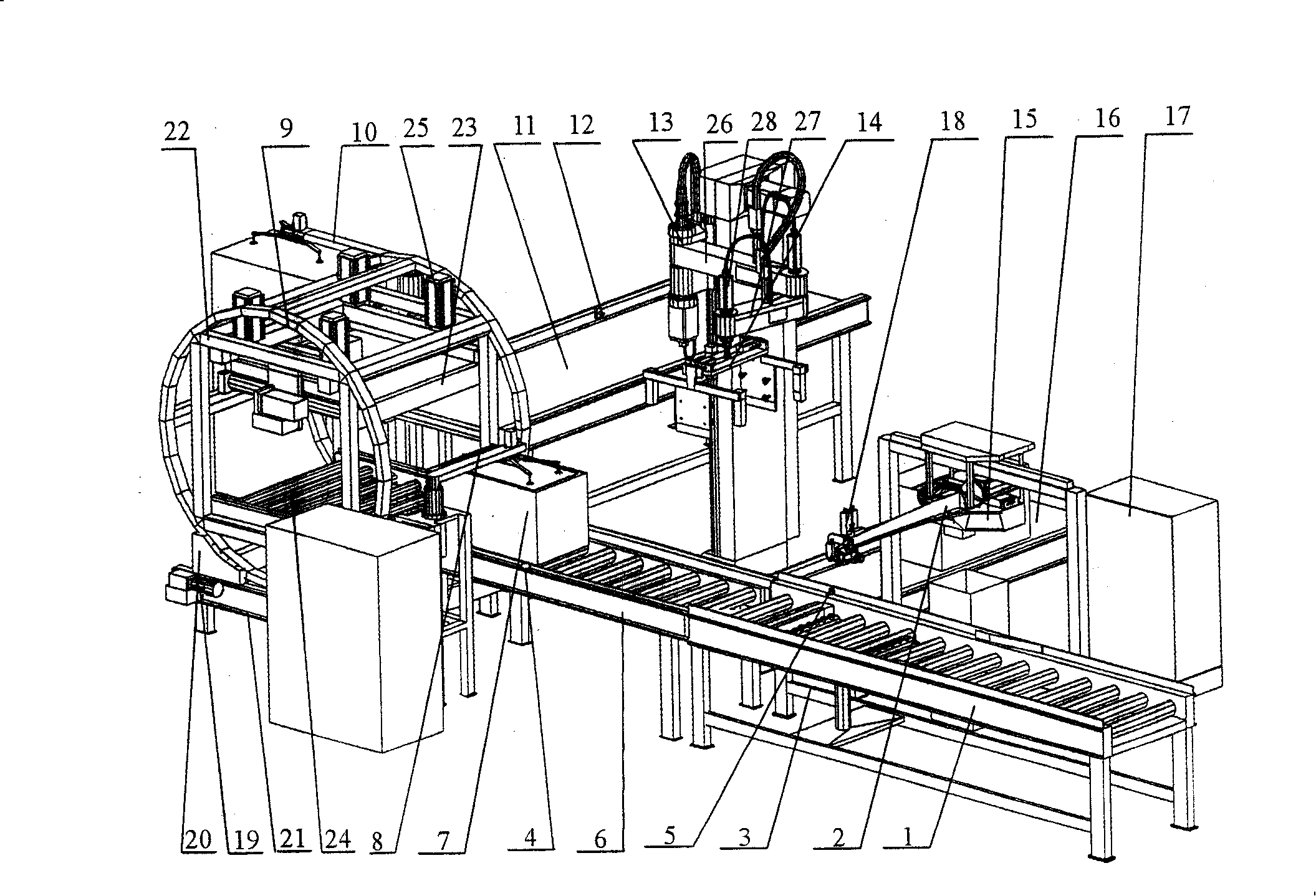

Apparatus for automatically opening cardboard box for cigarette

The invention relates to tobacco package carton automatic open technics and facility. The technics includes steps such as carton transferring and locating, package enlace belts testing, cutting, removing, and collecting, outer carton removing, upper interleaver removing, carton reversing, inner carton removing, lower interleaver removing, tobacco transferring. The facility are carton transferring machine(1) whose back is reversing machine(9), tobacco package transferring machine(11) and interleaver removing machine hand(10) by the side of reversing machine(9), porter robot(13) is between the carton transferring machine(1) and the tobacco package transferring machine(11). The invention has a proper process arrangement and a high efficiency by adopted with pipelining parallel processing method. It is highly automated and adapted to the opening of different sized carton, also to the deformed carton. It does no damage to the carton so to recycle the carton much better.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

Slide cutter type bag opening machine

InactiveCN104139897AEasy to cleanContinuous cleaningChemical industryArticle unpackingMotor driveReducer

The invention discloses a slide cutter type bag opening machine, which comprises a transporting frame, a machine frame, cutters and a cutter tool shaft, wherein a conveying start rolling wheel, a direction change rolling wheel and a return rolling wheel are arranged on the transporting frame in sequence, a transporting belt is connected among the conveying start rolling wheel, the direction change rolling wheel and the return rolling wheel, the cuter tool shaft with the cutters is arranged on the machine frame, bag cutting rolling wheels positioned under the cutters are arranged on the machine frame, a cutting baffle belt with material holes is arranged on the bag cutting rolling wheels, a plurality of puncture teeth are uniformly distributed on the cutting baffle belt, a slide cutter moving to and fro is arranged behind the cutters, the lower end of the machine frame is provided with a variable frequency motor with a speed reducer, and a driving belt wheel arranged at the tail end of the variable frequency motor drives a driven belt wheel arranged on the cutter tool shaft through a belt. The slide cutter type bag opening machine has the advantages that the structure is simple and reasonable, practicability and higher safety are realized, the bag opening efficiency is high, materials are cleanly cleaned, the total cost of equipment is reduced, in addition, the continuous automatic bag opening can be realized, the labor and the materials are reduced, the total production cost is reduced, and material bags after the bag opening can be effectively recycled.

Owner:深圳市日高精机自动化有限公司

Automatic continuous bale opener

The invention discloses an automatic continuous bale opener which comprises a left conveying belt, a right conveying belt, a driving rolling wheel and a rack. The rack comprises a lifting fixing frame, a conveying fixing frame, a tool rest and a fork wheel fixing frame, the driving rolling wheel is fixed to the lifting fixing frame through a central rotary shaft, a conveying rolling wheel is arranged at the upper end of the conveying fixing frame, an upper layer of returning rolling wheel and a lower layer of returning rolling wheel are arranged on the fork wheel fixing frame, symmetric rotary sleeves are arranged on the two sides of the upper end of the fork wheel fixing frame, bale forking rods for adjusting rotation are arranged in the rotary sleeves, the left conveying belt and the right conveying belt are arranged on the driving rolling wheel, the conveying rolling wheel and the returning rolling wheels in parallel, a tool is arranged in the middle of the tool rest, and the tool is located between the left conveying belt and the right conveying belt. The automatic continuous bale opener is simple in structure and low in manufacturing cost, unified regulation is achieved, automatic continuous bale opening can be achieved, the bale opening efficiency of material bales is greatly improved, materials are treated fully and cleanly, manpower cost is lowered, economic benefits are improved, and waste plastic bags generated after bale opening can be recycled.

Owner:STATE GRID CORP OF CHINA +1

Opening equipment of packaging box

The invention discloses a packing container opening device which comprises a drive part that comprises an electric servomotor or an electric moment motor, a drive circuit, an electric current sensor, and the opening device also comprises a device frame, on which a working platform is installed, at least a pair of clamping boards that can move on the working platform under the drive of the electric servomotor are arranged on the working platform, a cam is arranged under the working platform and driven by an alternate current servomotor, edges of the cam are contacted with the bottom of the working platform, and a spring is respectively arranged under the working platform as well as between the working platform and the device frame; a grabbing device that is driven by the electric servomotor or the electric moment motor is arranged on the device frame above the working platform. The packing container opening device can automatically fit for bank packing containers with different size, does not destroy the container body when opening the container, is convenient for recycling the container, is favorable for realizing fully automatic container opening by adopting electric control, raises container opening efficiency, reduces noise and does not produce waste pollution.

Owner:CHENGDU BANKNOTE PRINTING

Multi-specification corrugated carton forming machine

ActiveCN111186166AHigh degree of automationImprove unpacking efficiencyPaper-makingBox making operationsCorrugated fiberboardFront cover

The invention discloses a multi-specification corrugated carton forming machine. The multi-specification corrugated carton forming machine comprises a rack, and further comprises a material initial position placing area, a carton opening area, a carton folding area and a carton sealing area which are sequentially arranged in the length direction of the rack; and a material conveying device is arranged below the material initial position placing area, a carton is of a duck tongue overlapping structure, a front cover and a side cover of the carton are equal to the carton in height, and the carton forming machine is provided with a carton model adjusting mechanism. According to the multi-specification corrugated carton forming machine, cartons of various models can be opened, the opened cartons are large flat cartons, a feeding port is open, the carton opening and sealing are integrated, the automation degree is high, the carton opening efficiency is high, and meanwhile the labor cost ofcorrugated carton forming processing is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

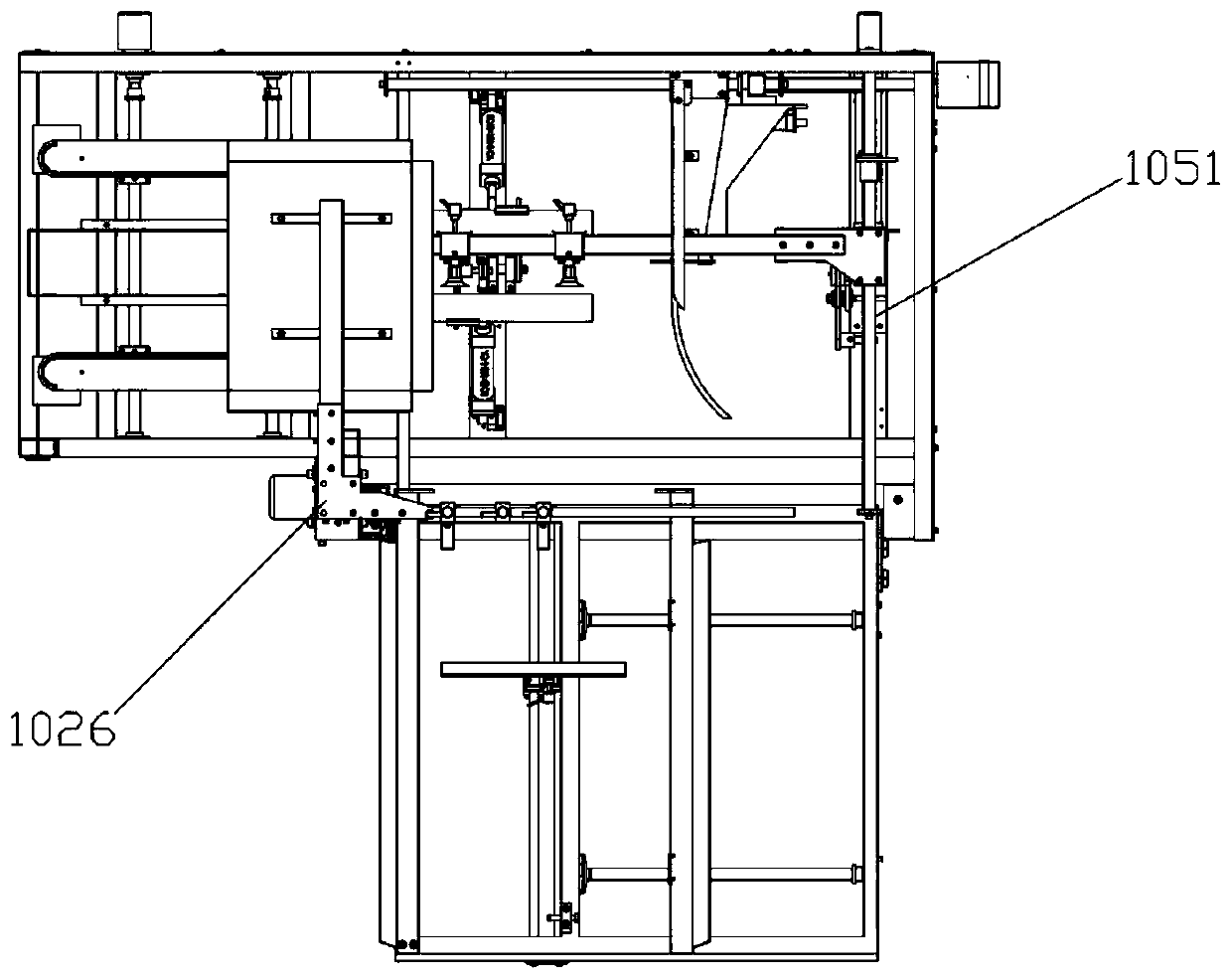

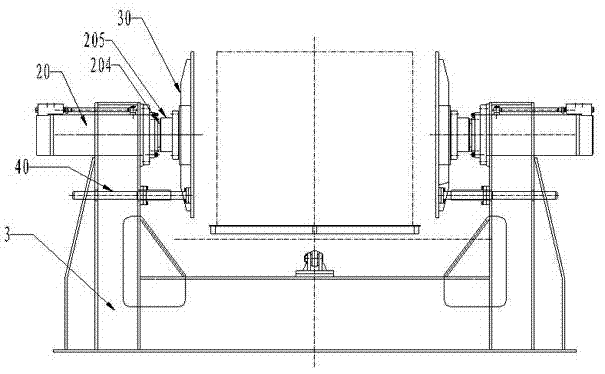

Unpacking device for penicillin bottle sets

ActiveCN108045678AAutomatic unpacking implementationAutomate unpackingUnpacking by cuttingPenicillinEngineering

The invention discloses an unpacking device for penicillin bottle sets. The unpacking device comprises a rack, and an unpacking platform is mounted on the rack. A storing area is arranged on the unpacking platform, a lower suction cup assembly is vertically and slidably mounted on the rack, located below the unpacking platform and driven to rise and fall through a lower lifting power device, and an avoidance through hole is formed in the unpacking platform. An upper lifting frame is vertically and slidably mounted on the position, above the unpacking platform, of the rack and driven to rise and fall through an upper lifting power device, and an upper suction cup assembly is vertically and slidably mounted on the upper lifting frame, located above the storing area and driven to rise and fall through a sucking power device. A horizontal sliding seat is horizontally and slidably mounted on the rack and driven by a film breaking power device mounted on the rack, a film breaking component is mounted on the horizontal sliding seat, and the film breaking power device drives the horizontal sliding seat to horizontally slide between a film breaking initial position and a film breaking terminating position. According to the unpacking device for the penicillin bottle sets, automatic unpacking is achieved, and the unpacking efficiency is improved.

Owner:HIT SMART FACTORY CO LTD

Unpacking device and work method thereof

PendingCN110466853ARealize automatic feeding processNo manual operationUnpacking by cuttingEngineeringSlide plate

The invention relates to an unpacking device and a work method thereof. A clamping mechanism and an unpacking mechanism are included; the clamping mechanism comprises a machine body, clamping jaws, clamping cylinders, a shaking cylinder and a travelling cylinder; the shaking cylinder is fixedly connected to the stretch-out end of the travelling cylinder; the upper half portions of the clamping jaws are fixedly connected with the stretch-out end of the shaking cylinder; the clamping cylinders are fixedly connected to the two sides of the upper half portions of the clamping jaws; the stretch-outends of the clamping cylinders are fixedly connected with the lower half portions of the clamping jaws; a material bag is clamped on the clamping jaws; the unpacking device comprises a bag supportingslide plate, a V-shaped hopper, a bag breaking cylinder, a tool rest and a blade; the bag supporting slide plate is fixedly connected to one side in the V-shaped hopper; the bottom of the V-shaped hopper is provided with an end port; the blade is connected in the end port in a sliding manner; the bag breaking cylinder is fixedly connected to one side of the bag supporting slide plate; one end ofthe tool rest is fixedly connected with the stretch-out end of the bag breaking cylinder; and the other end of the tool rest is fixedly connected with the blade. The unpacking device has the advantages of being simple in structure and low in cost, automatic operation of bag breaking, bag shaking and waste bag recycling can be achieved just through cylinder driving, and manpower is saved.

Owner:BEIJING GOLDENTEAM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com