Patents

Literature

52results about "Unpacking by heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

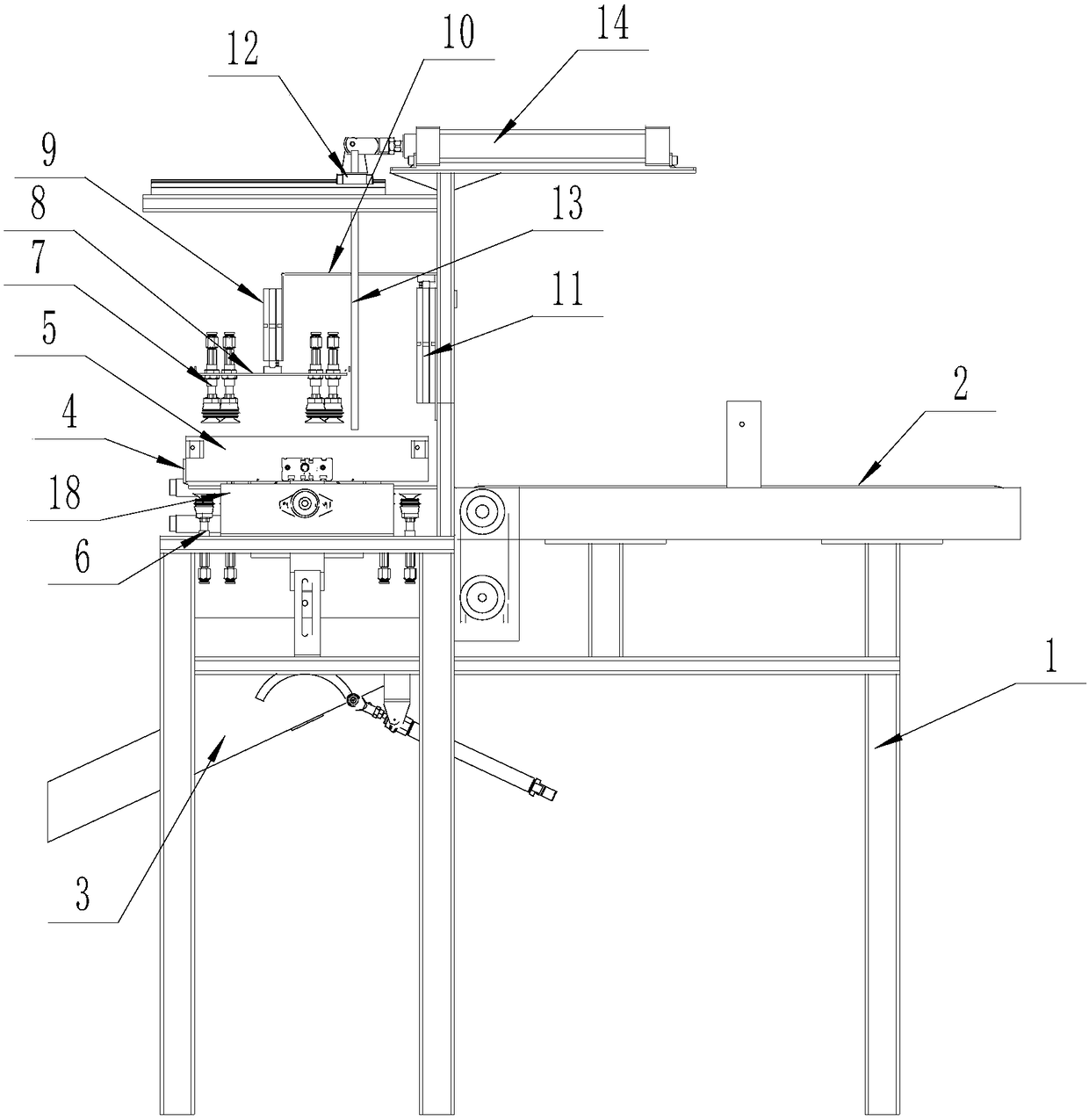

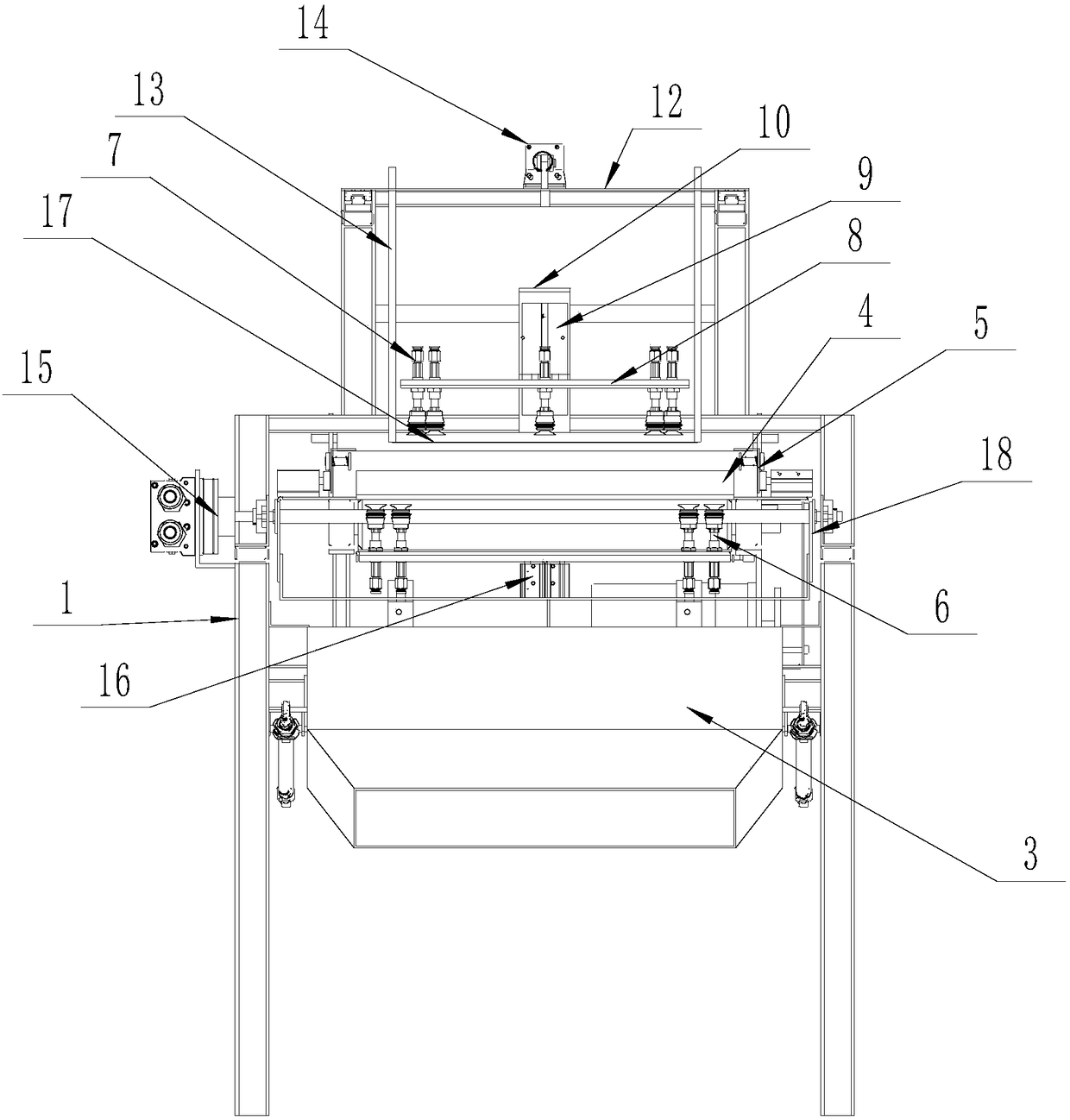

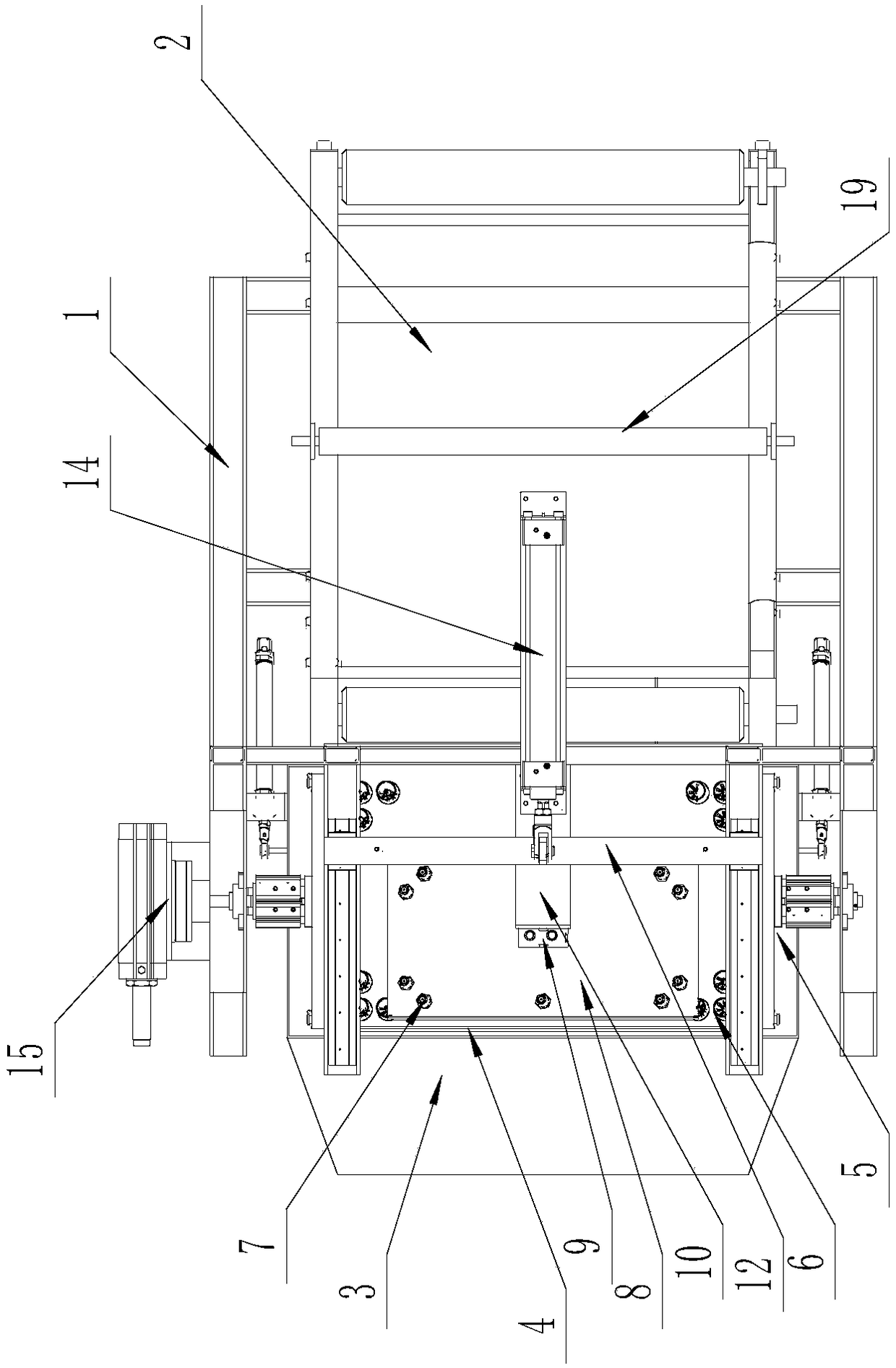

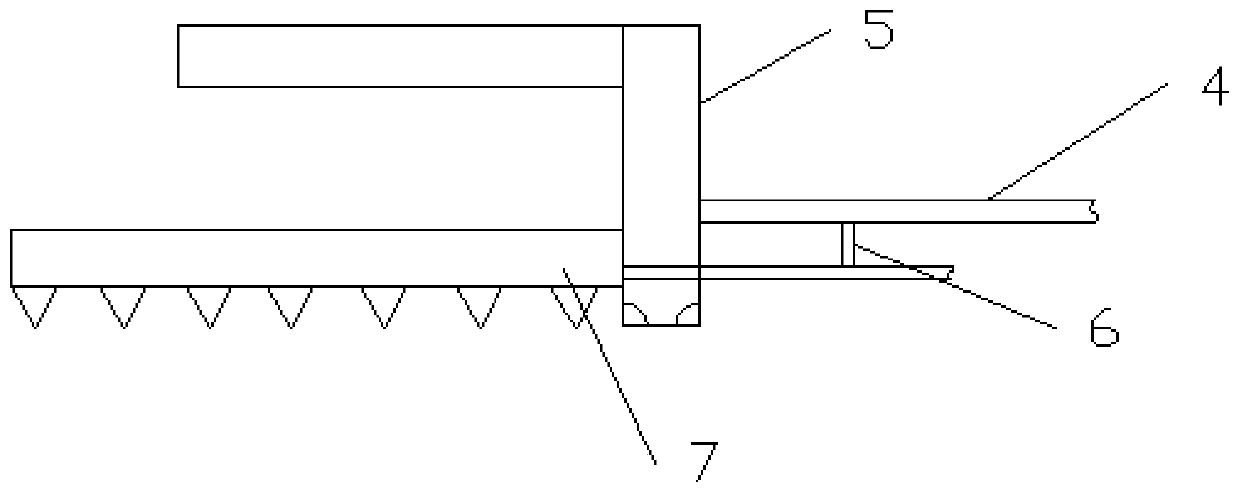

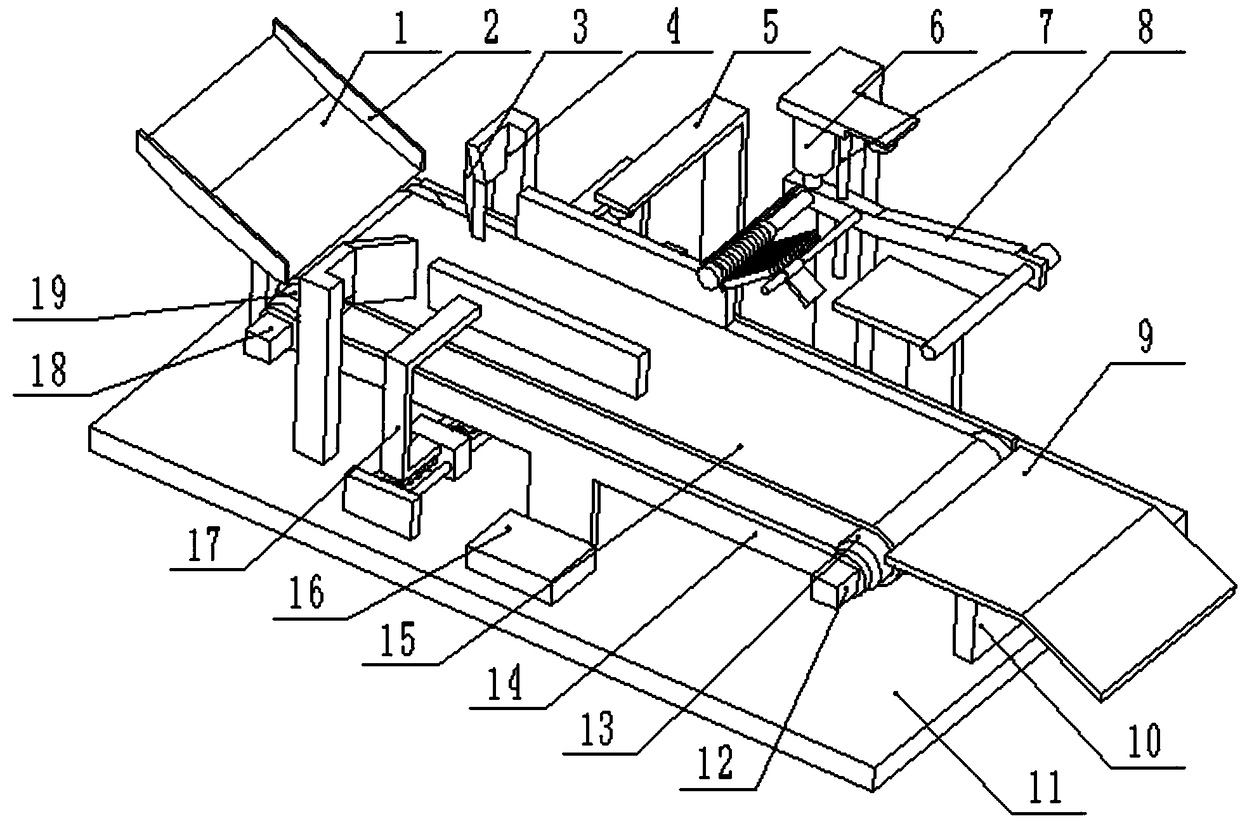

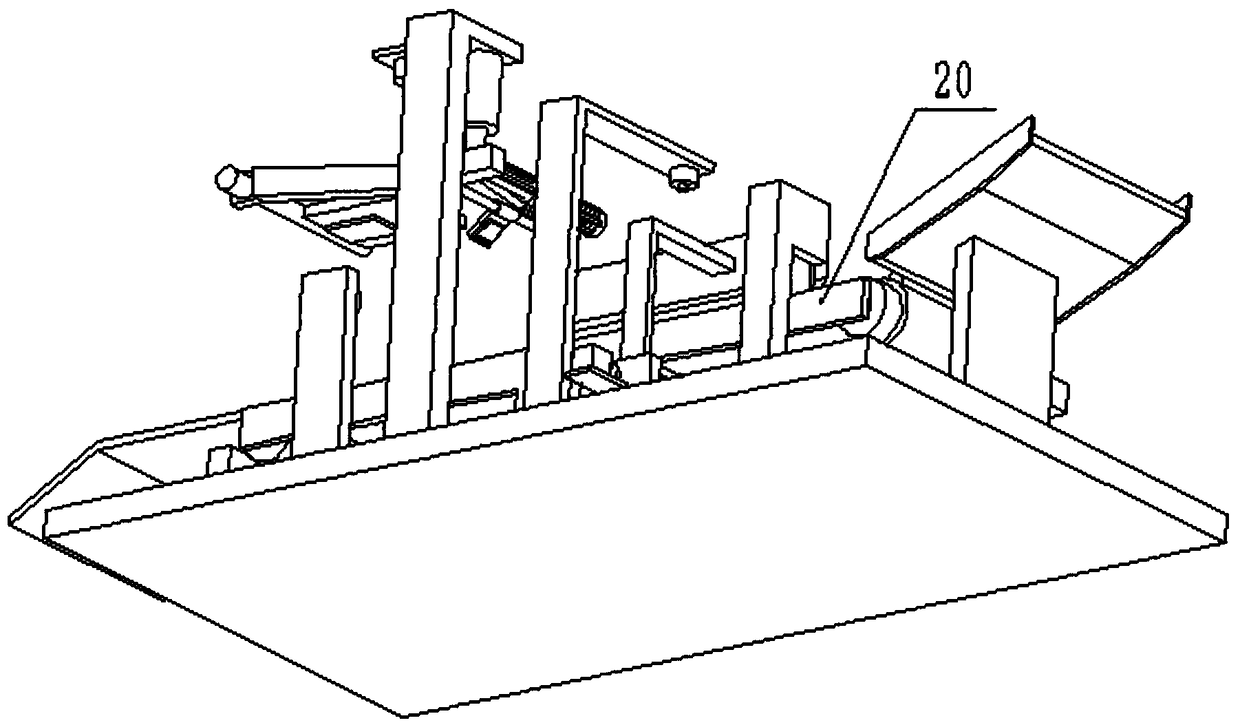

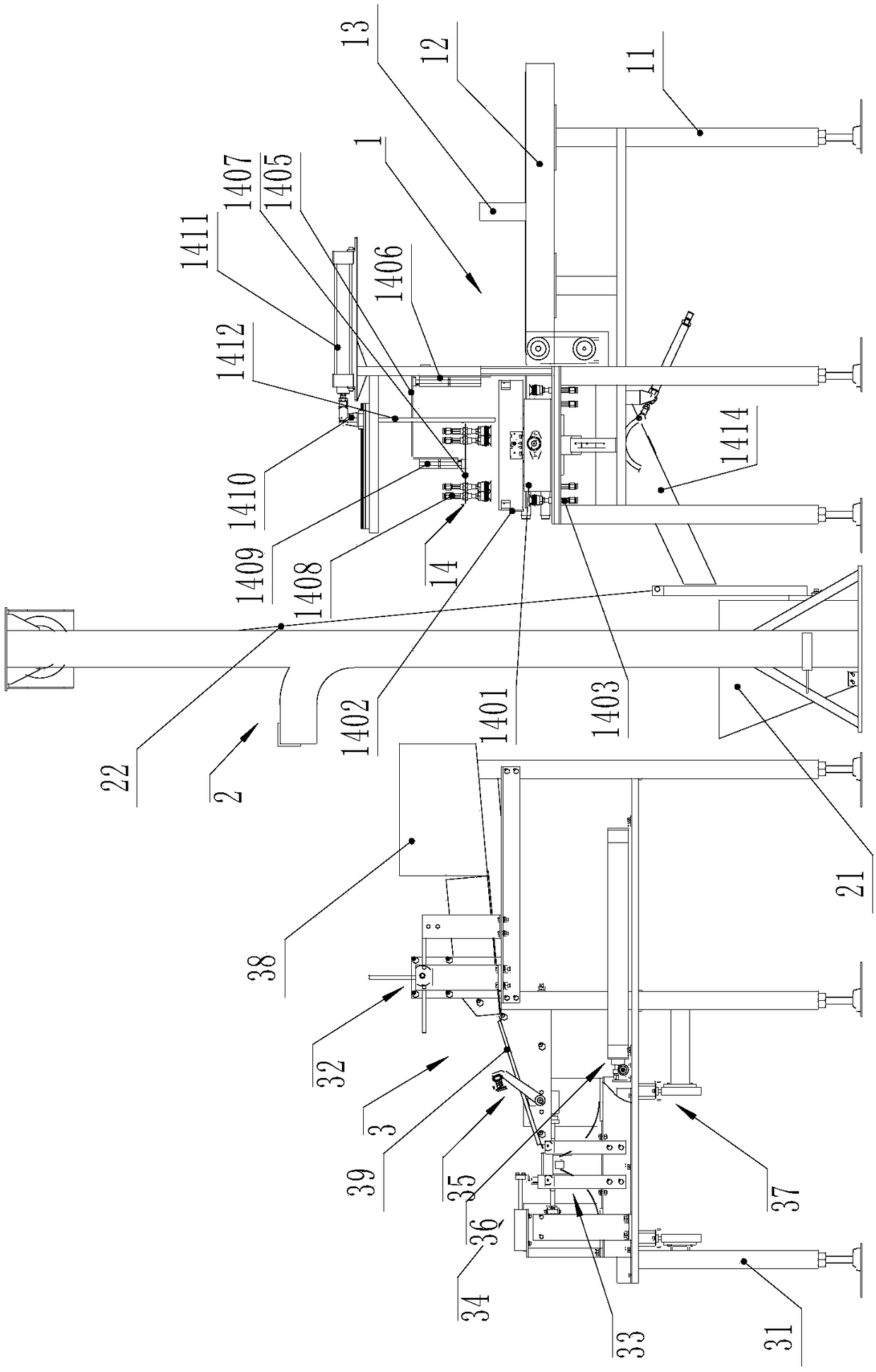

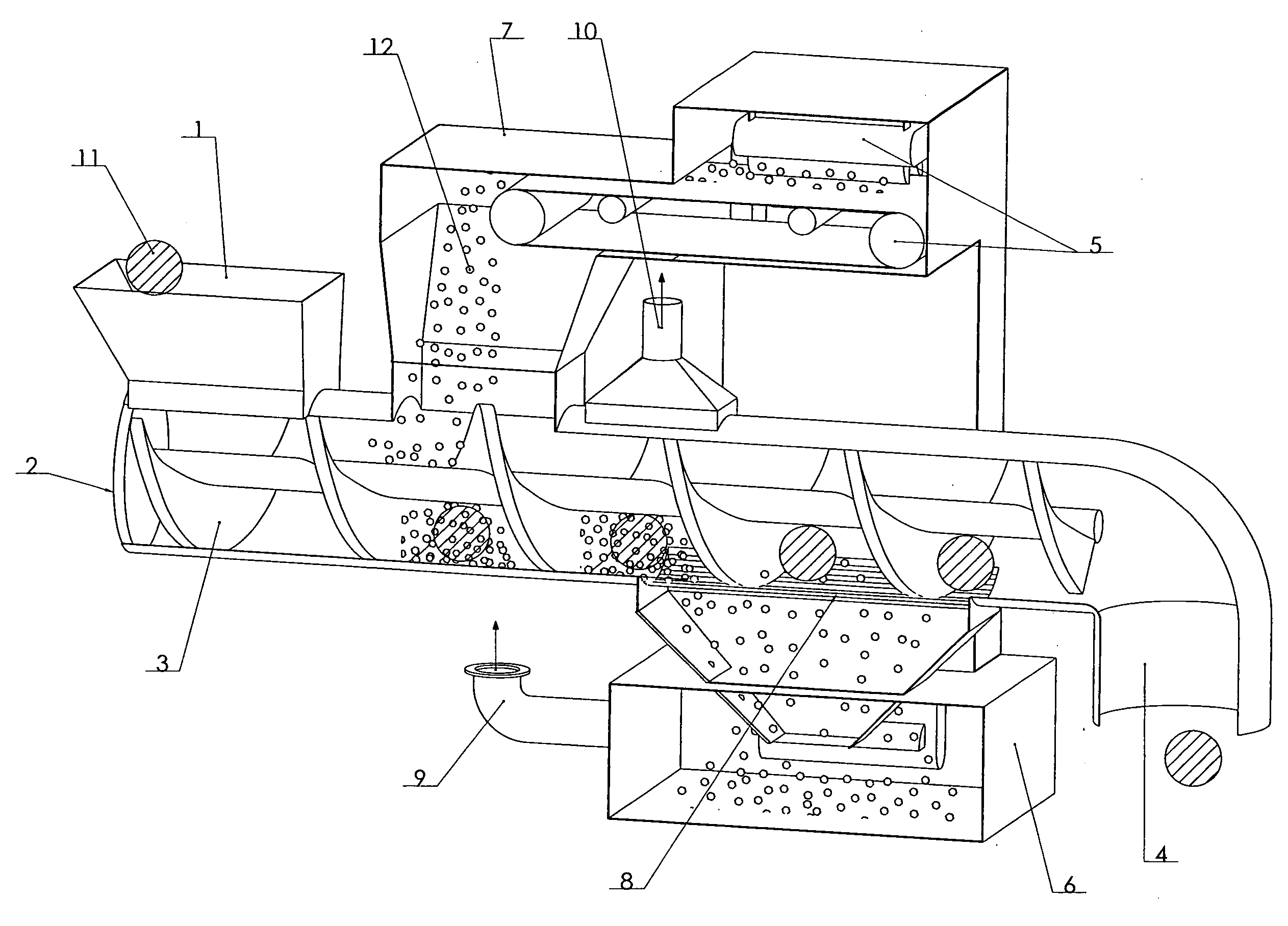

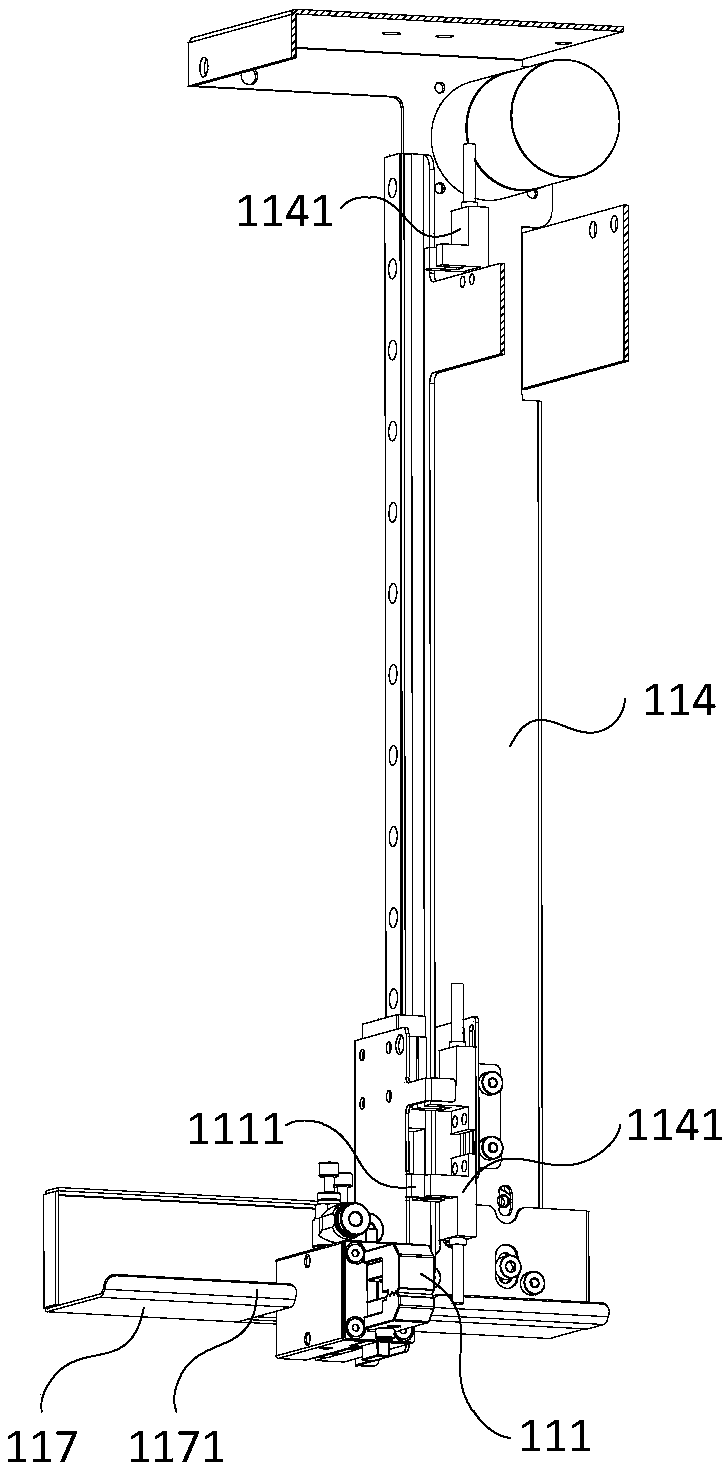

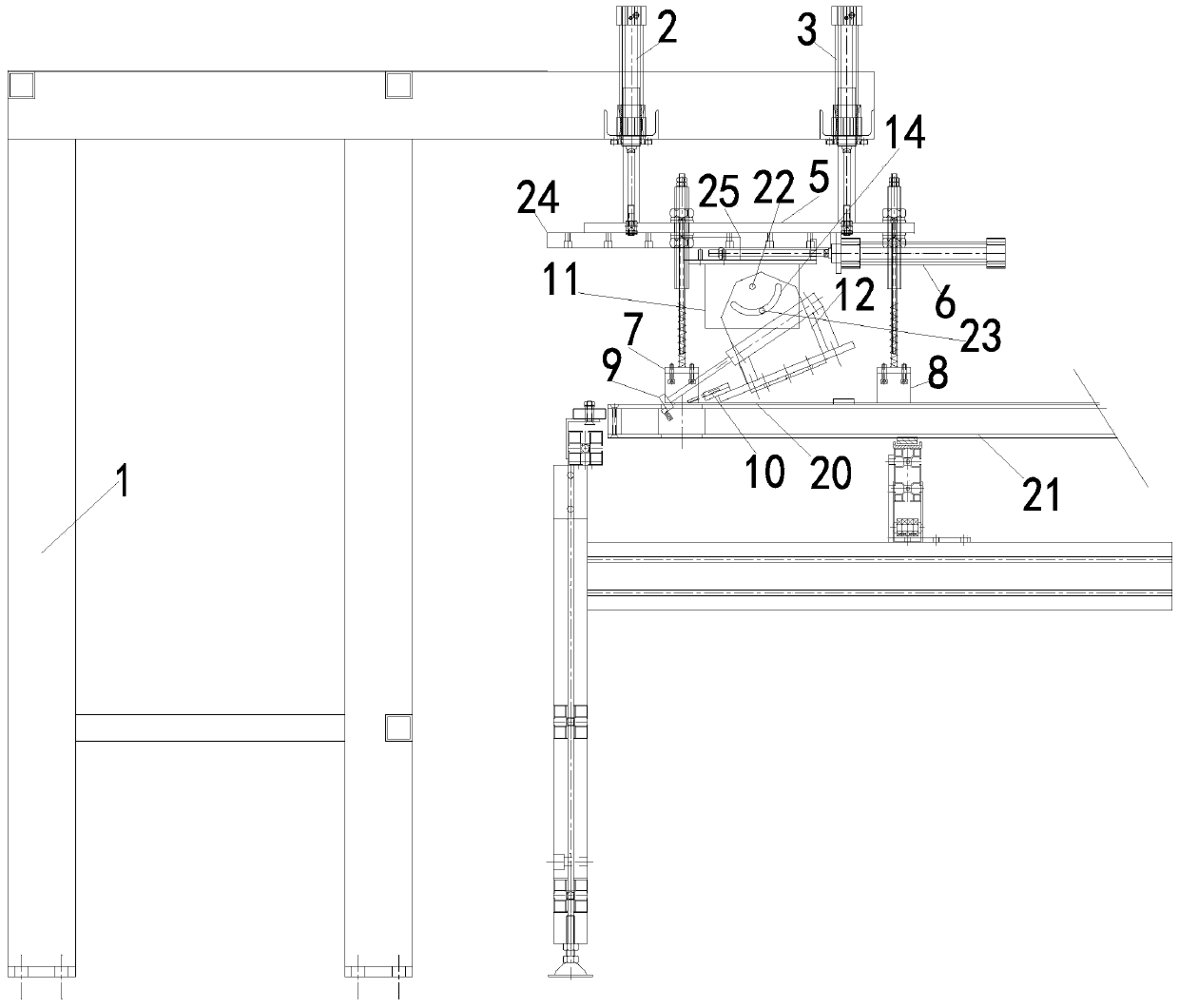

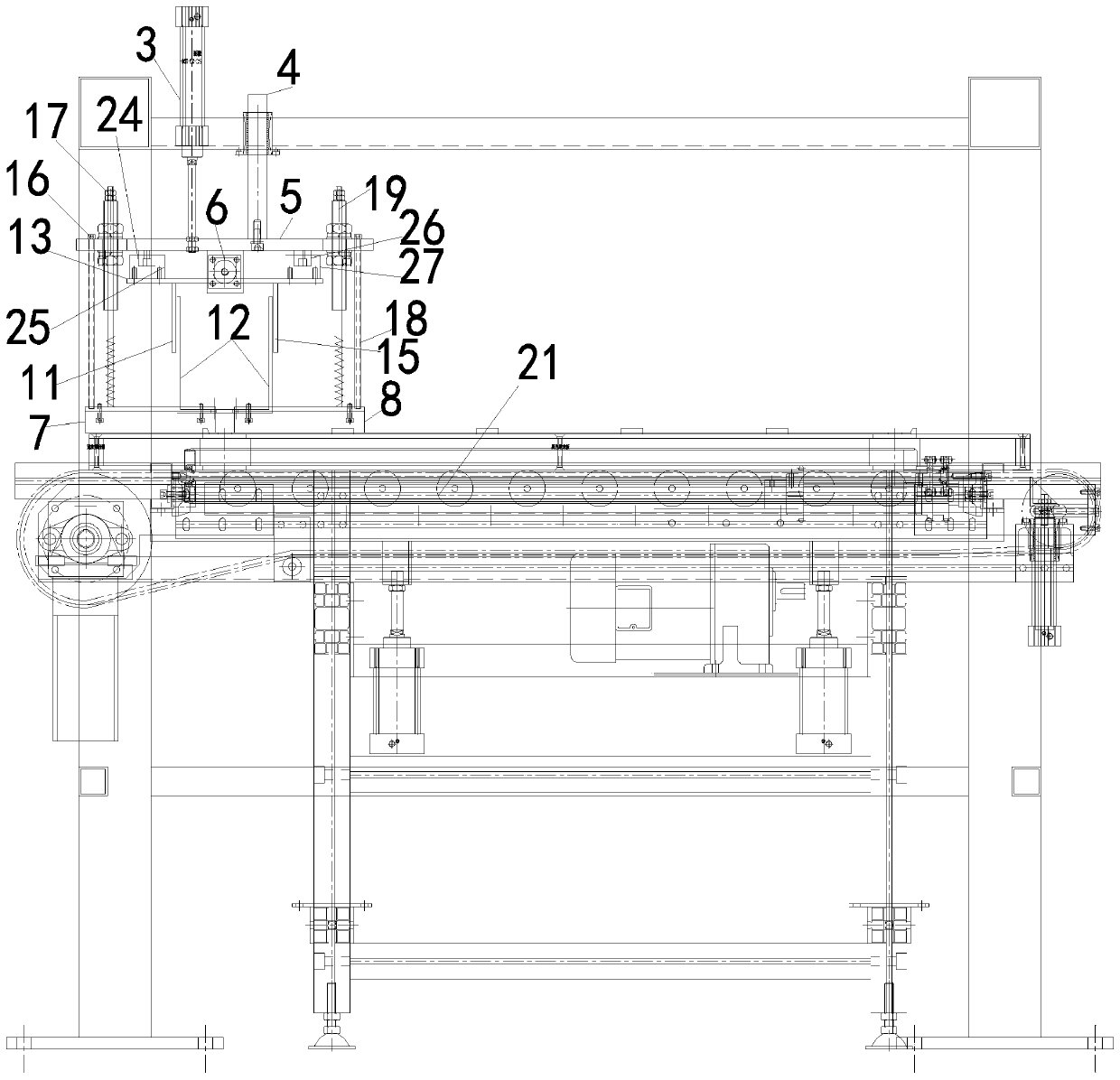

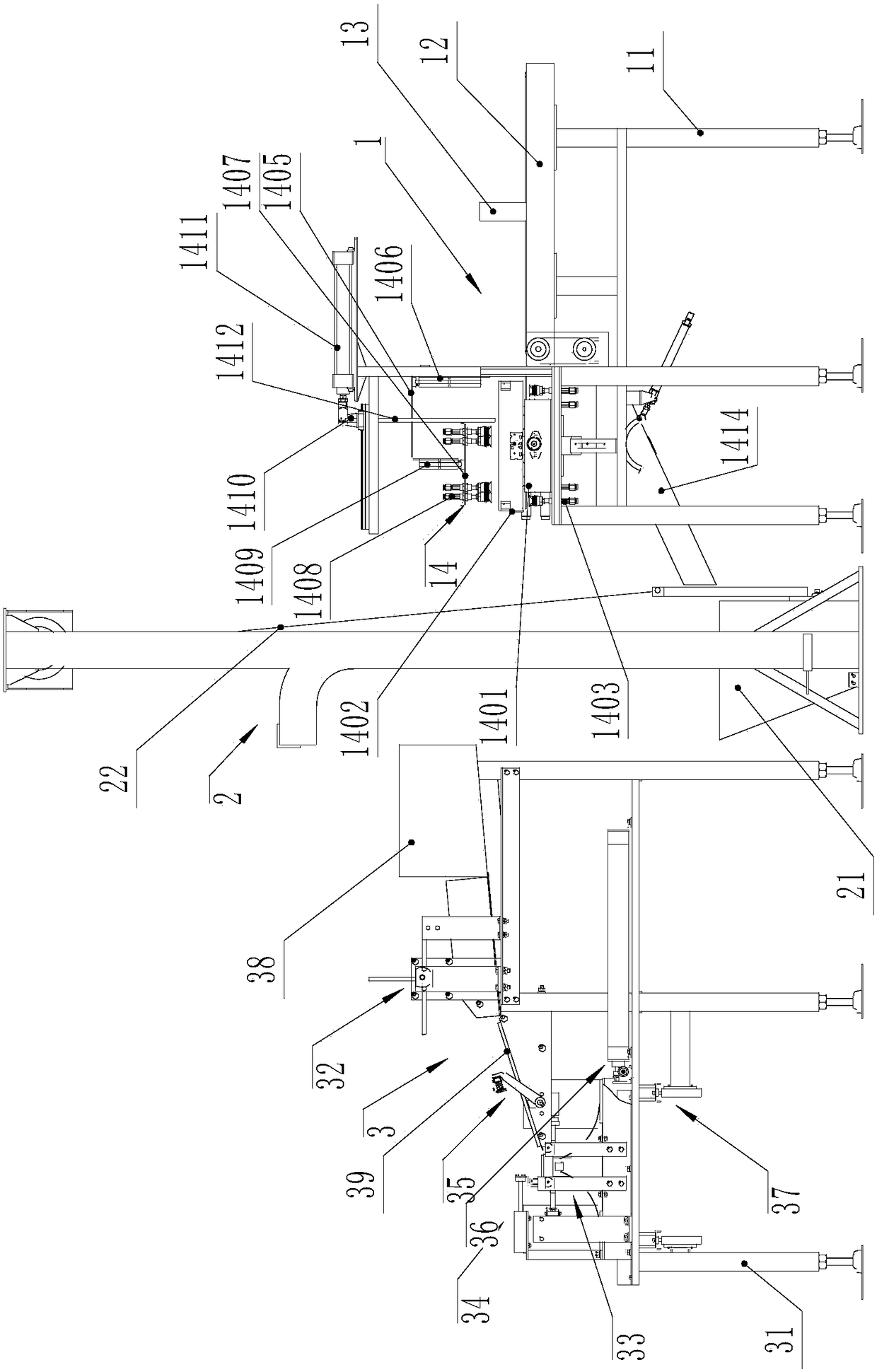

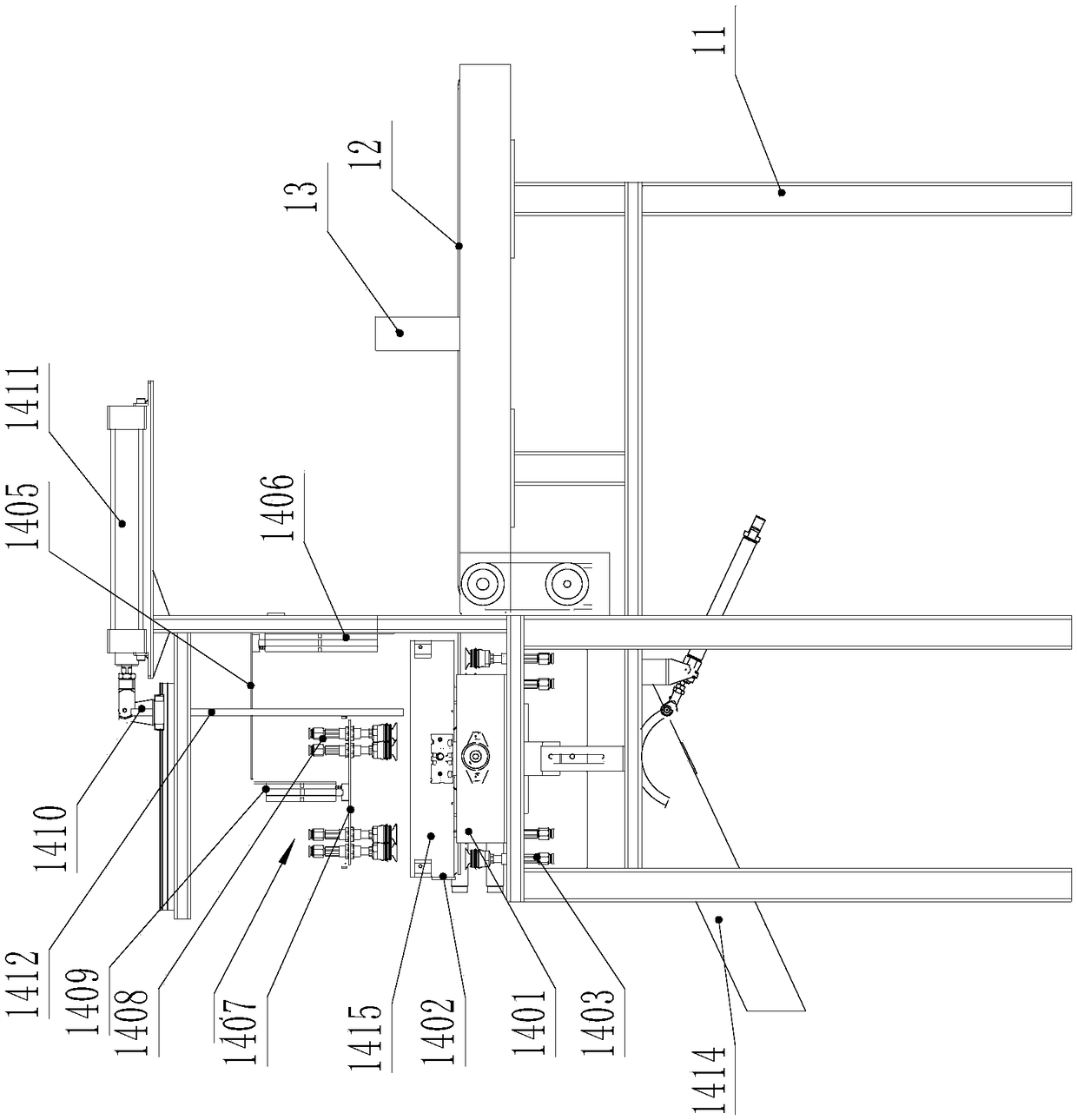

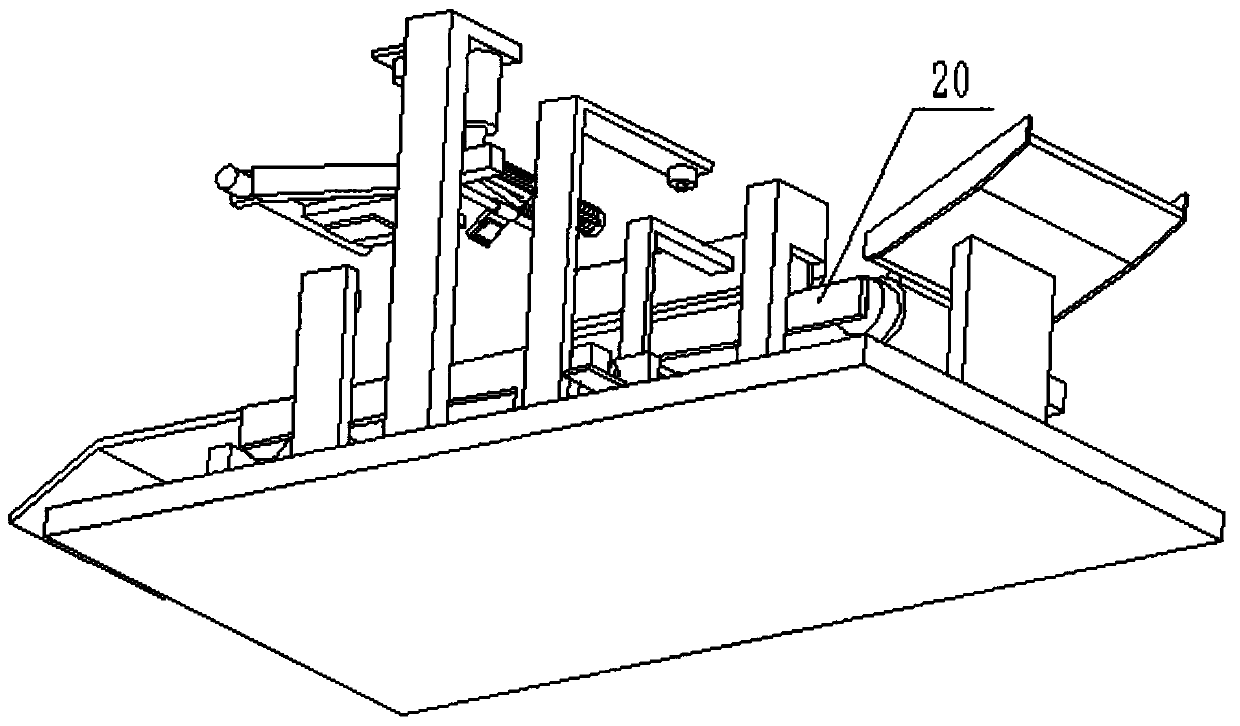

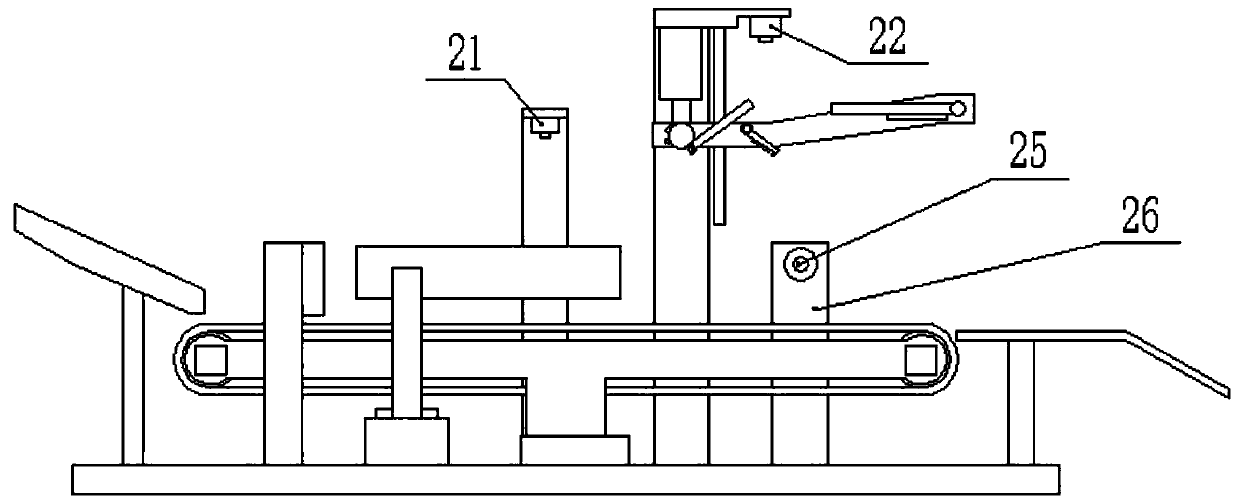

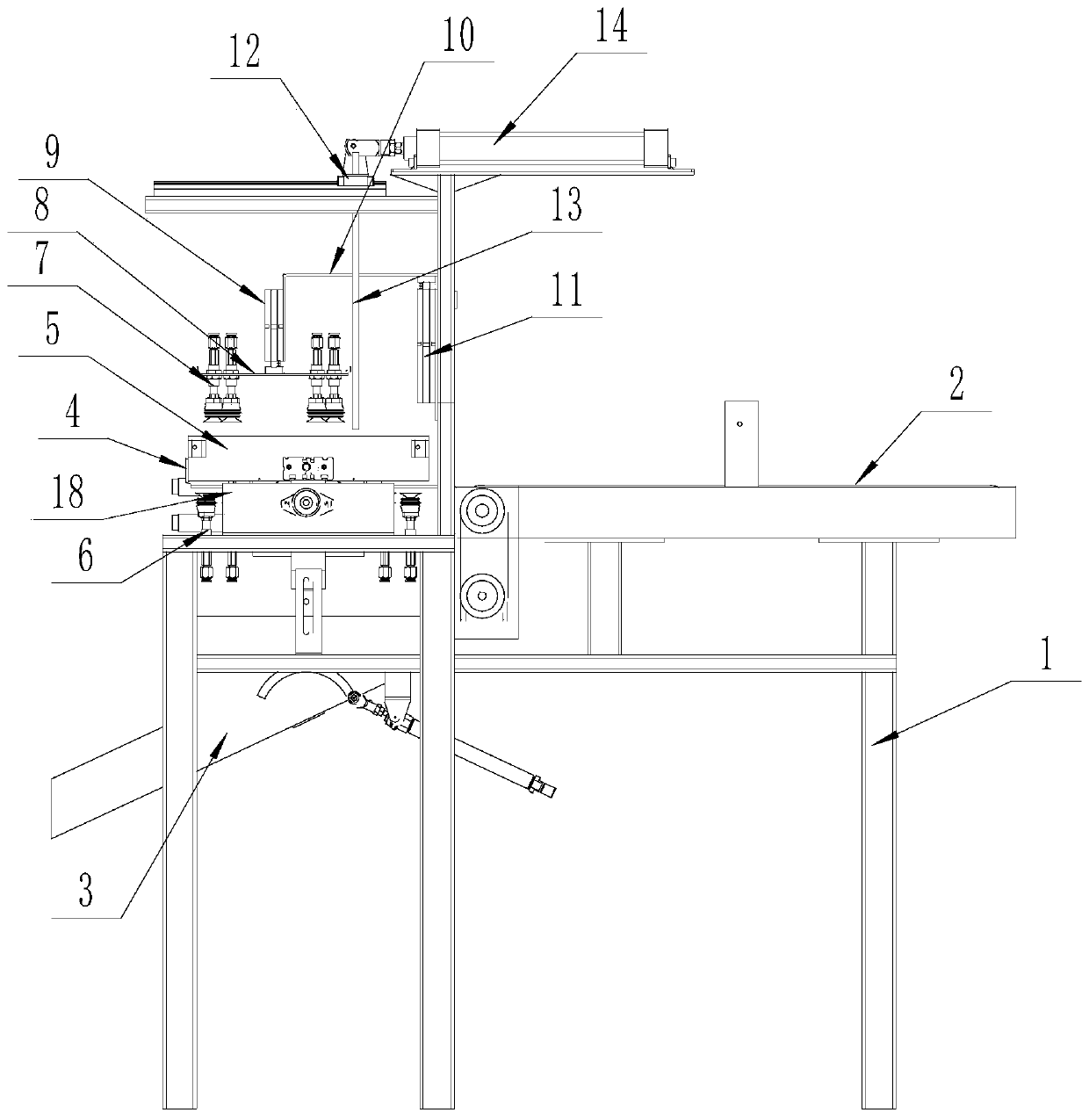

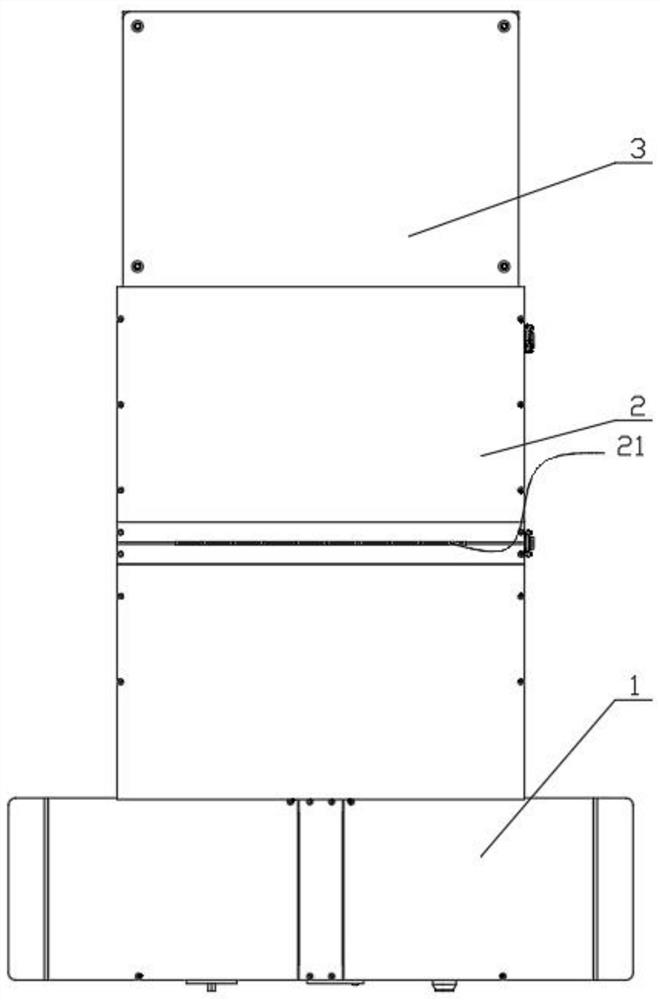

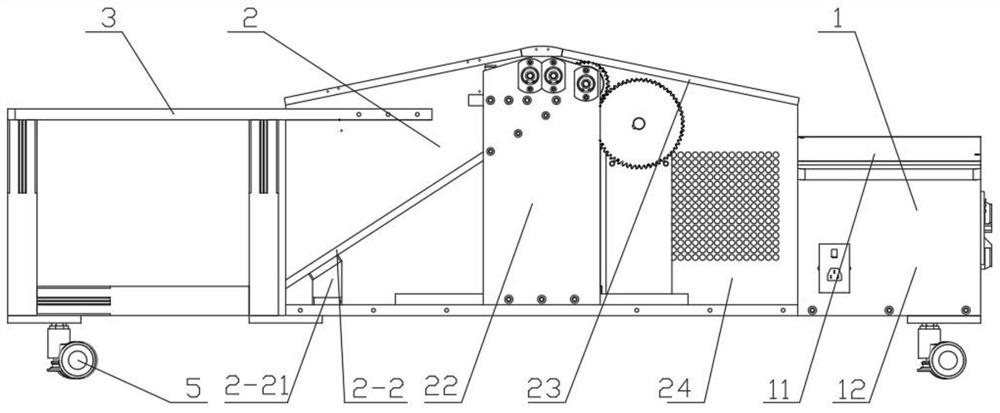

Penicillin bottle automatic bale breaker

ActiveCN108190159AAutomate unpackingImprove unpacking efficiencyUnpacking by heatingPenicillinEngineering

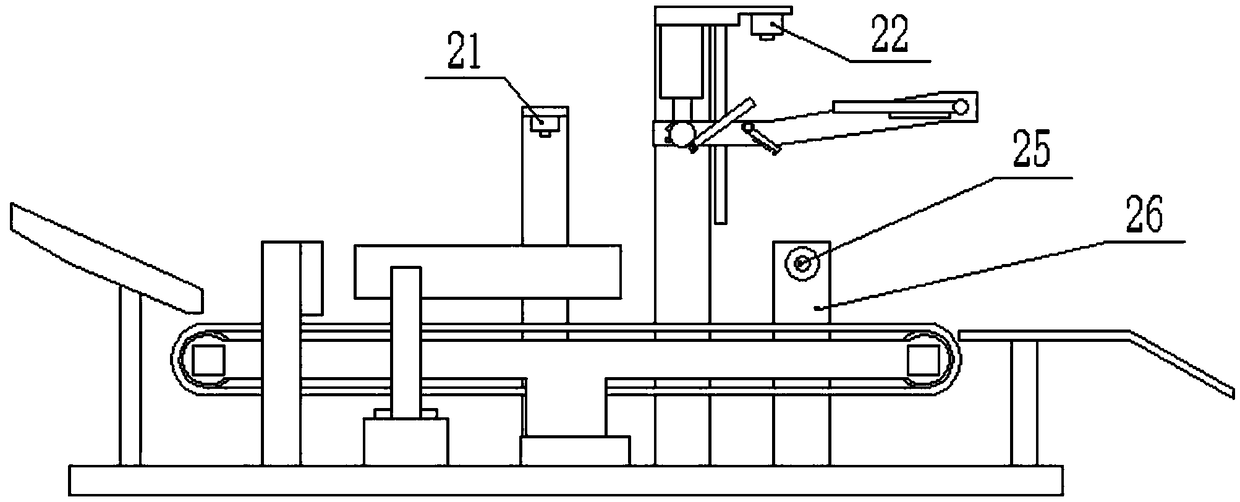

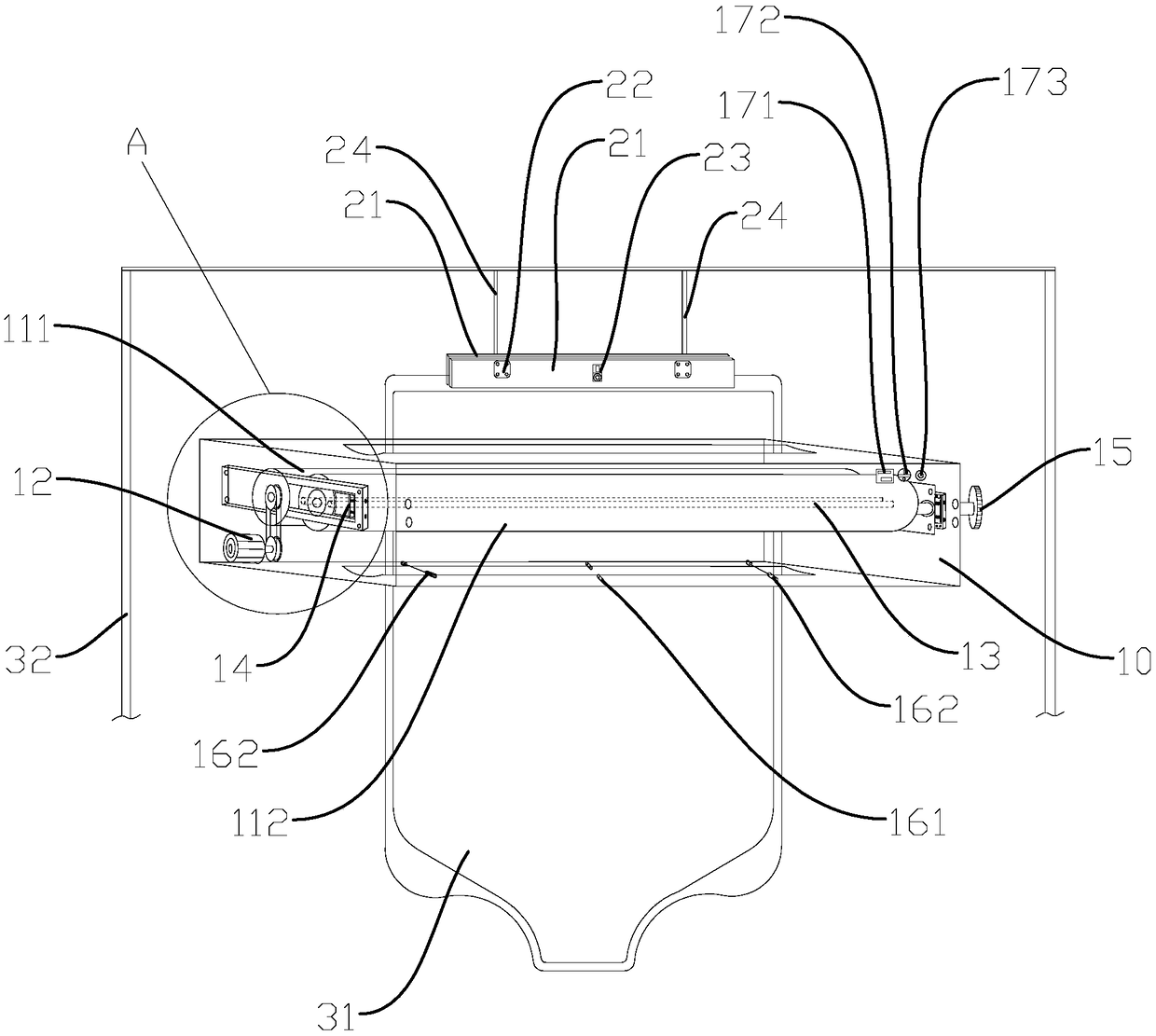

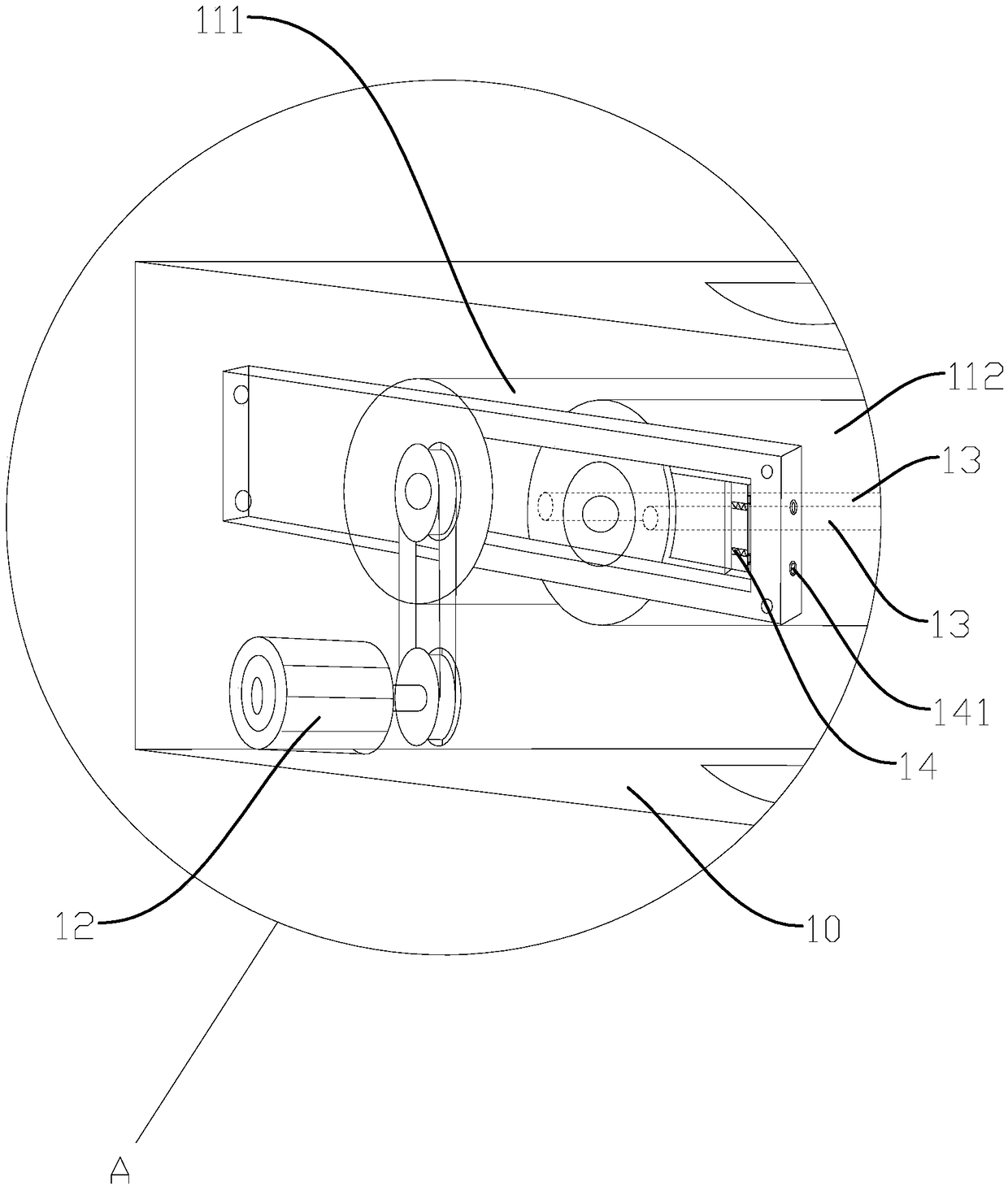

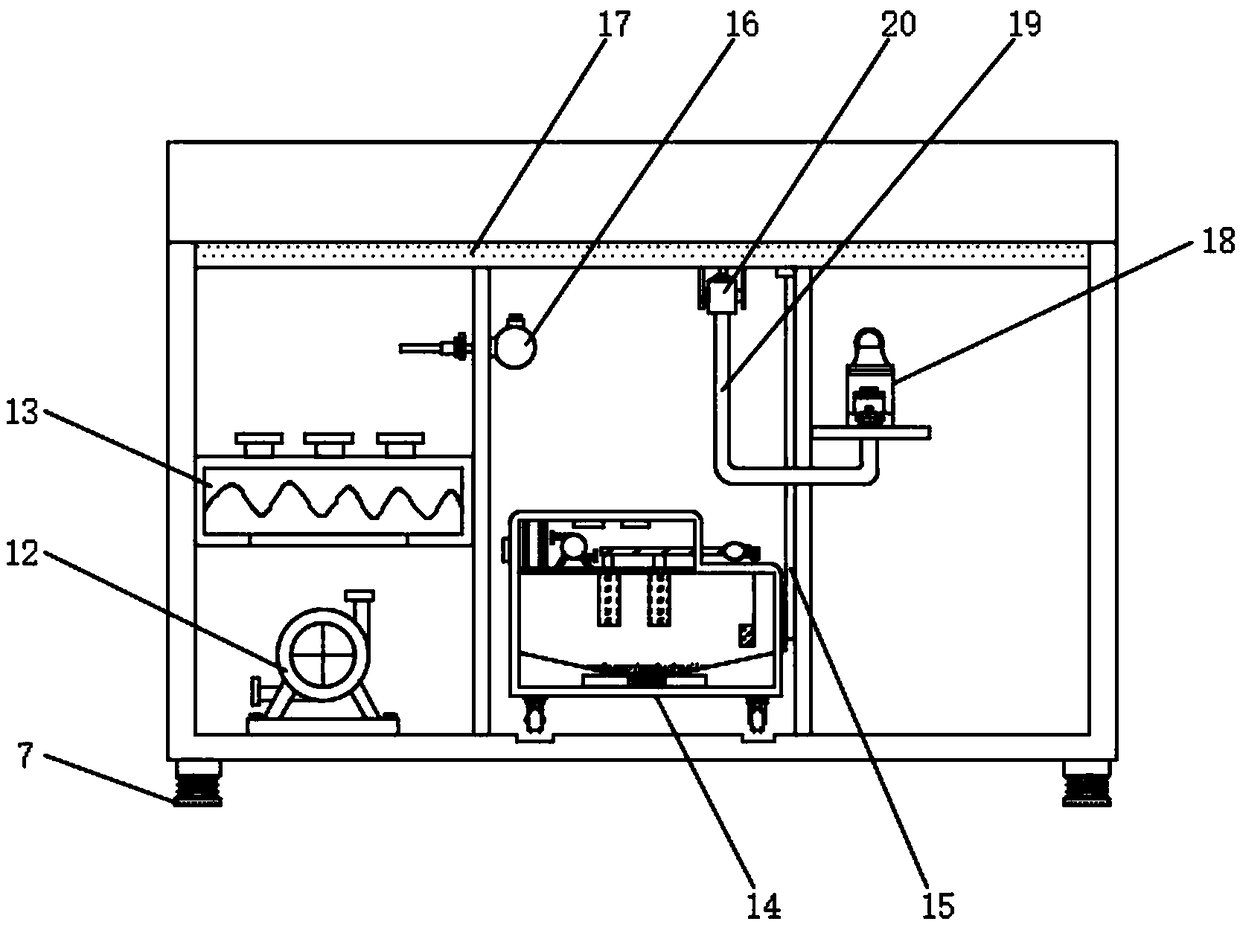

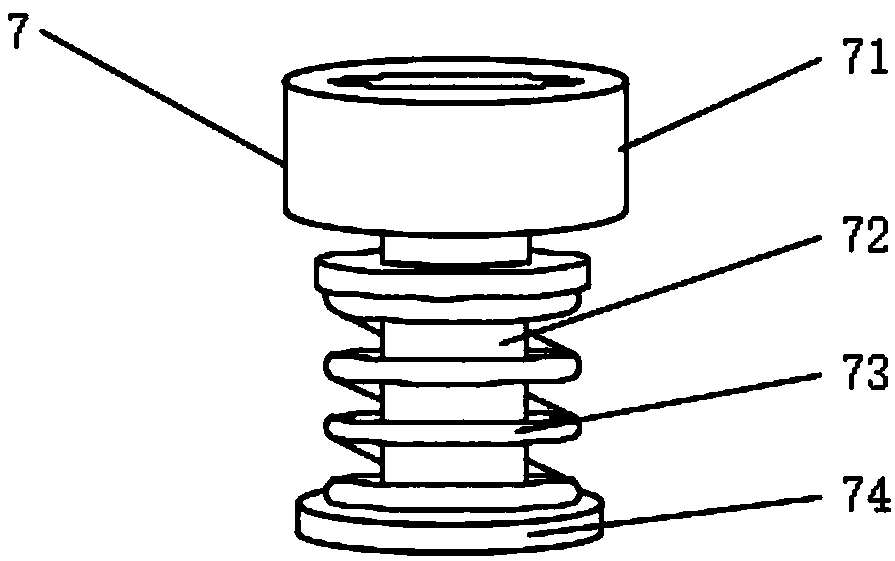

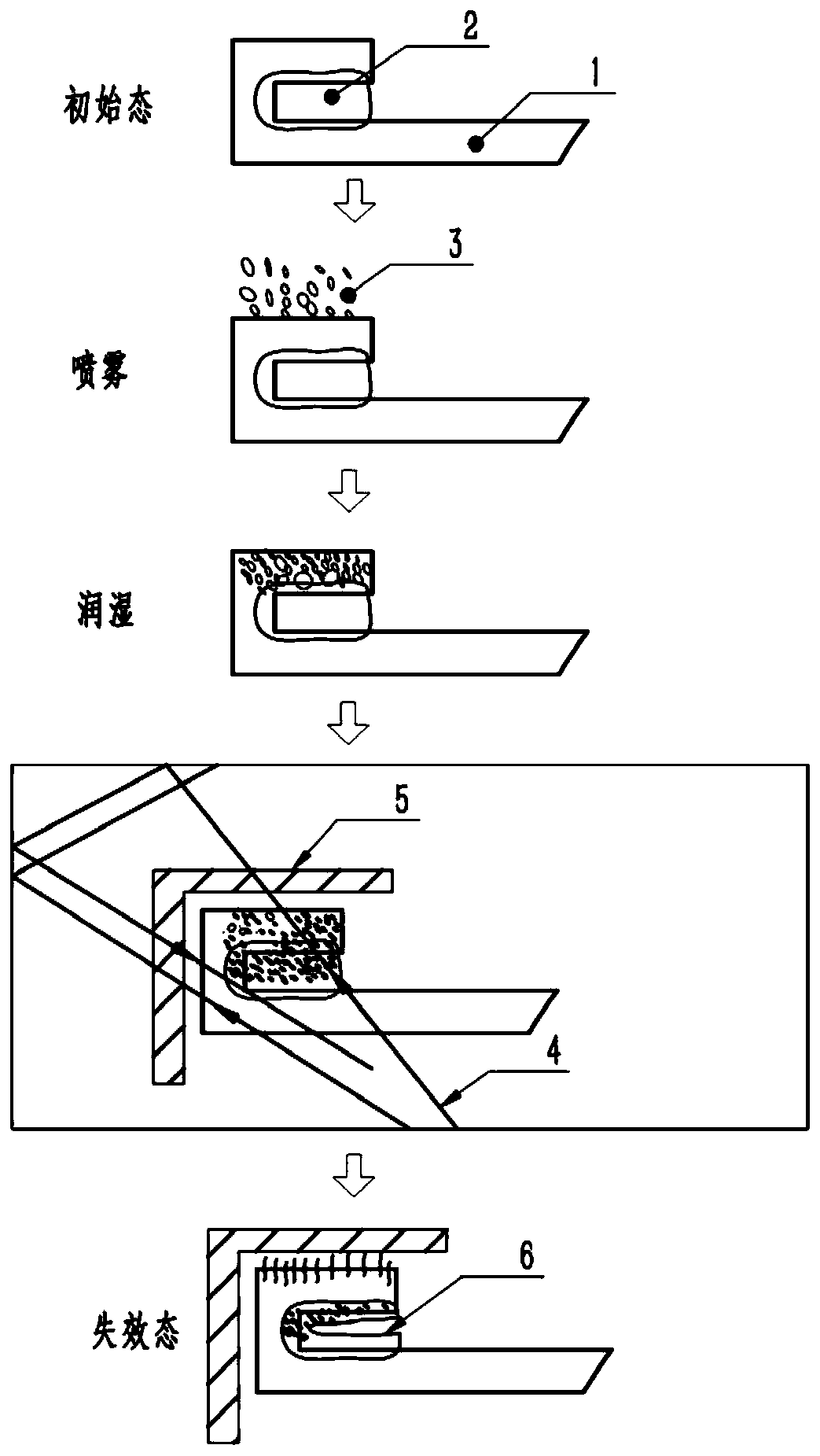

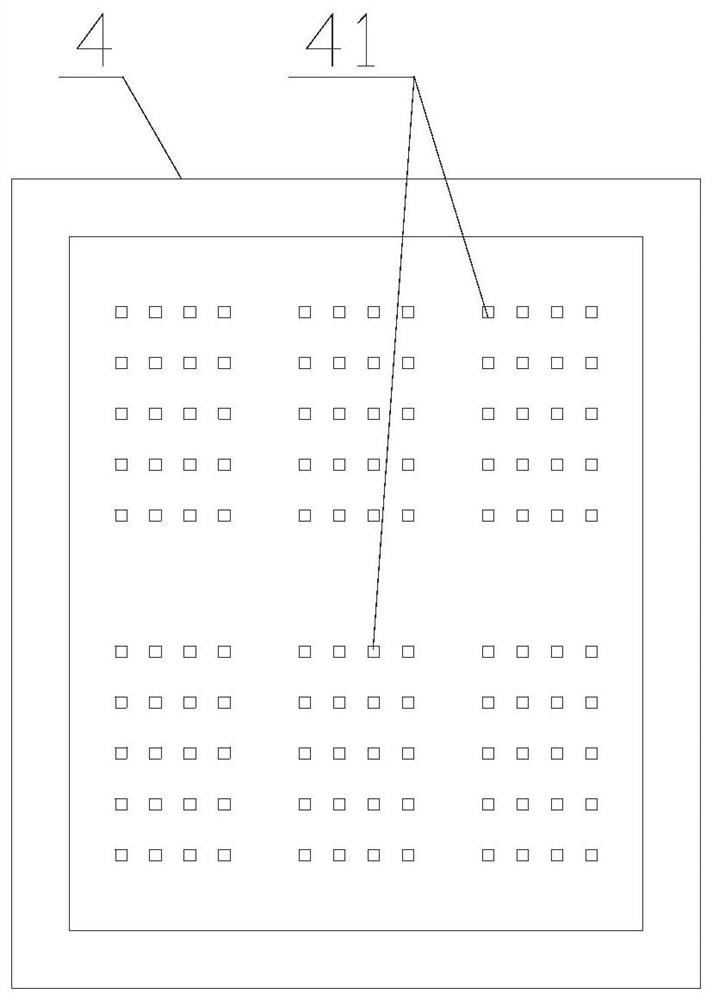

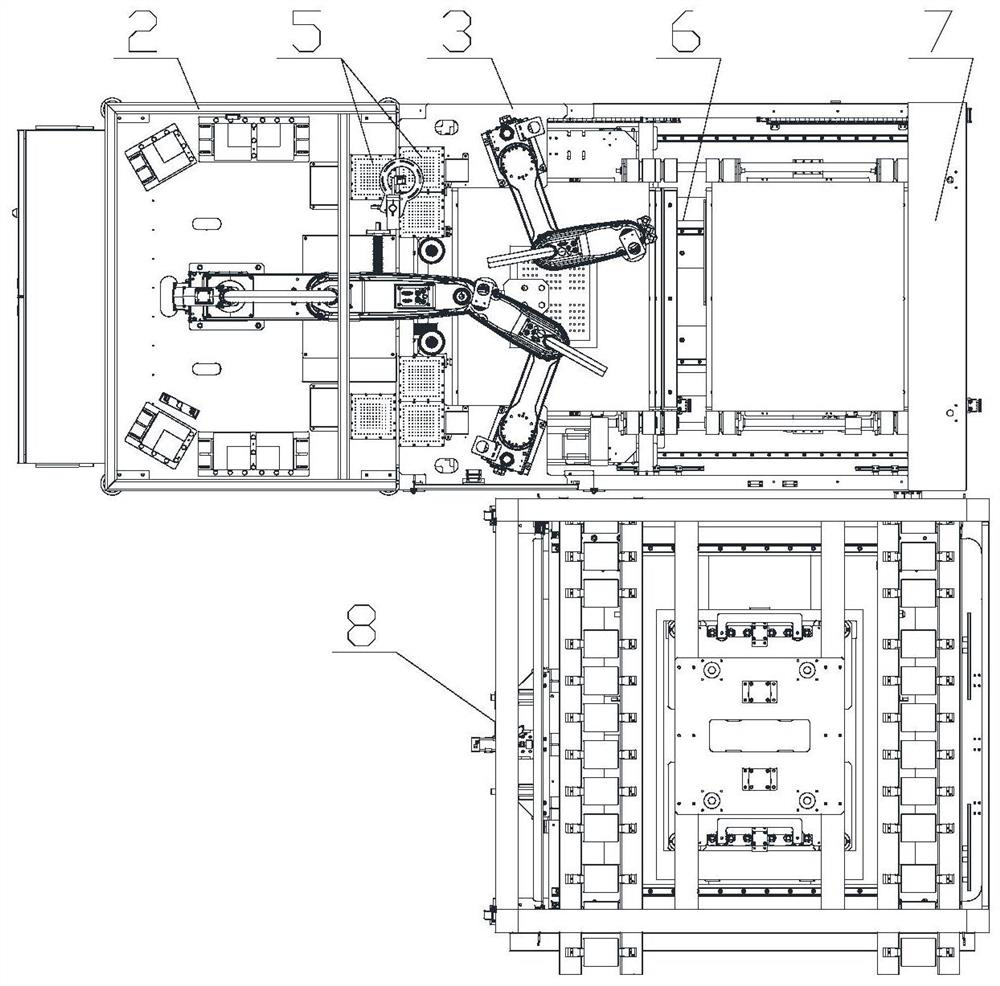

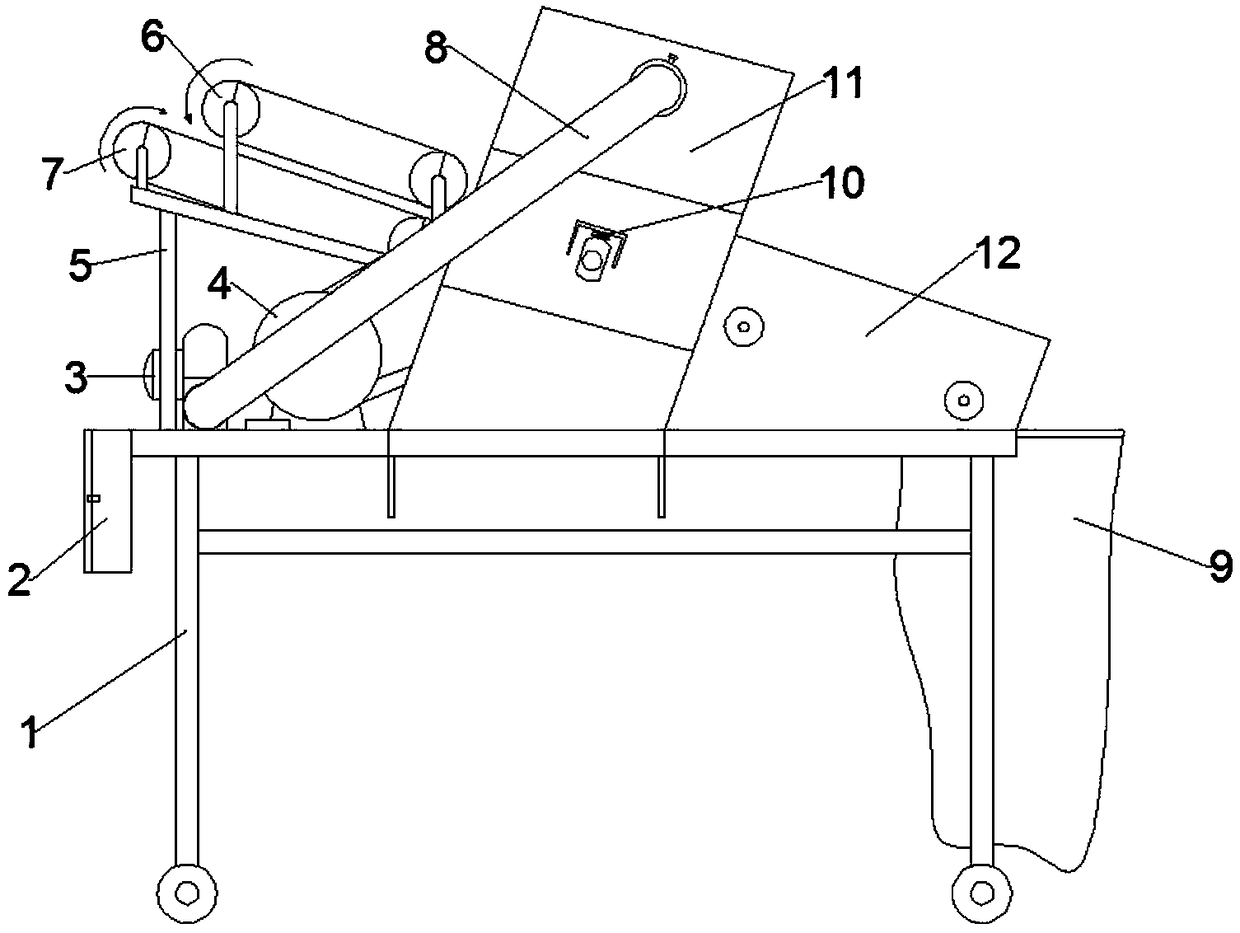

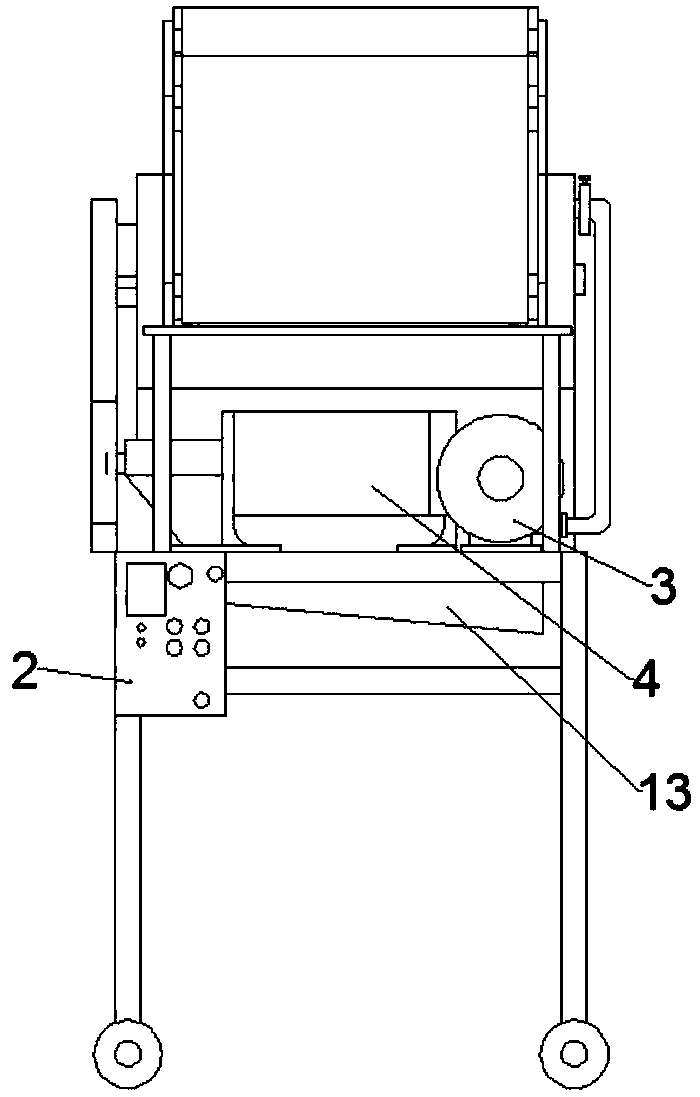

The invention discloses a penicillin bottle automatic bale breaker. The penicillin bottle automatic bale breaker comprises a rack, a conveying belt, a material overturning frame, a material overturning holding plate, an upper suction cup assembly, a lower suction cup assembly, a film breaking component and a hopper. The conveying belt conveys a penicillin bottle set onto the material overturning holding plate, then the lower suction cup assembly sucks a lower film of a packaging film, and the upper suction cup assembly sucks an upper film and slightly lifts the upper film up. Then through thefilm breaking component, the bulged upper film is destroyed to enable a pouring opening to be formed in the upper film, and then the material overturning frame is overturned to enable the penicillin bottles to be poured into the conveying hopper. According to the automatic bale breaker, the structure is reasonable, automatic bale breaking and pouring of the packaging film of the penicillin bottleset can be achieved, and the bale breaking efficiency is improved.

Owner:HIT SMART FACTORY CO LTD

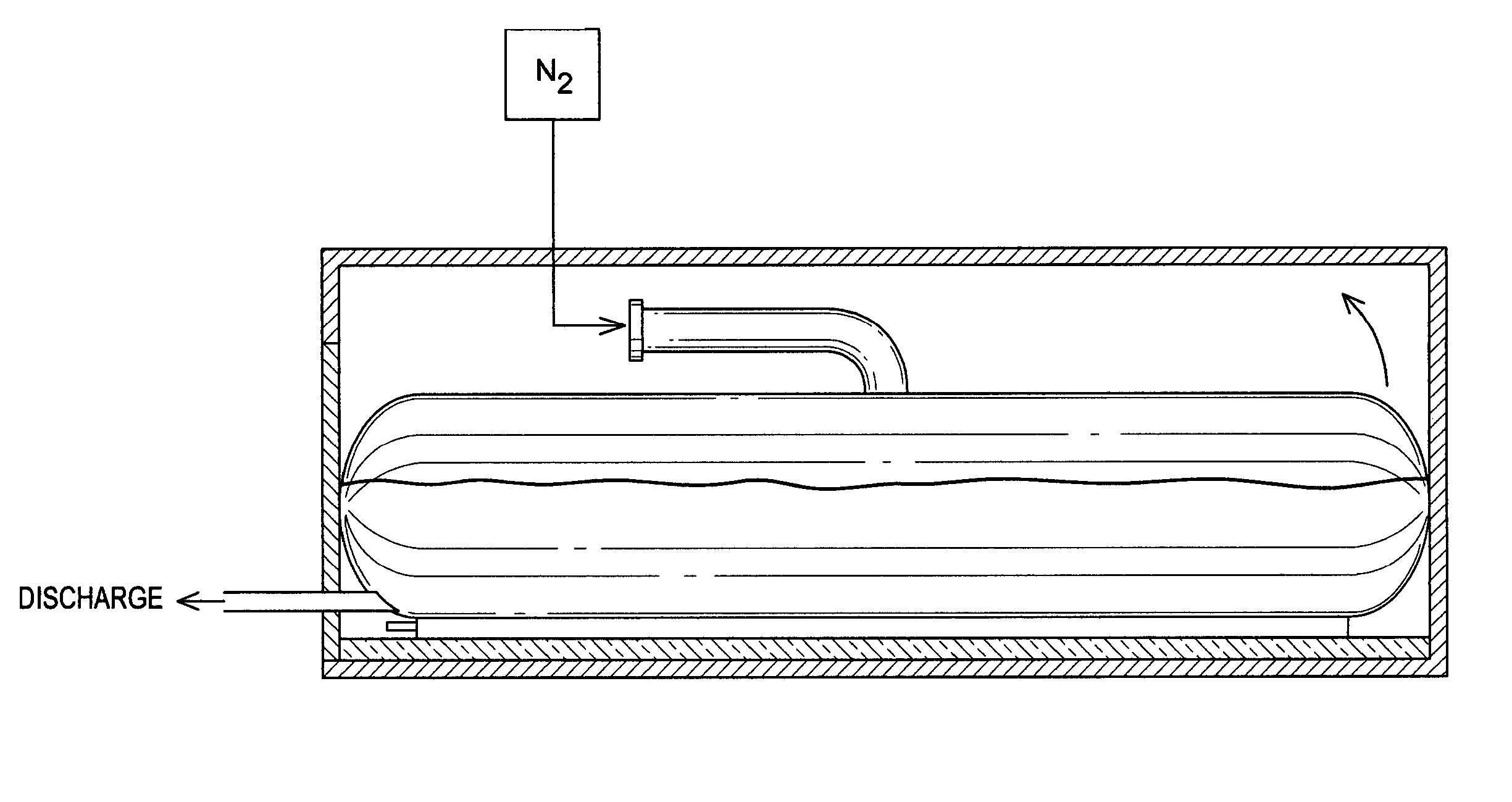

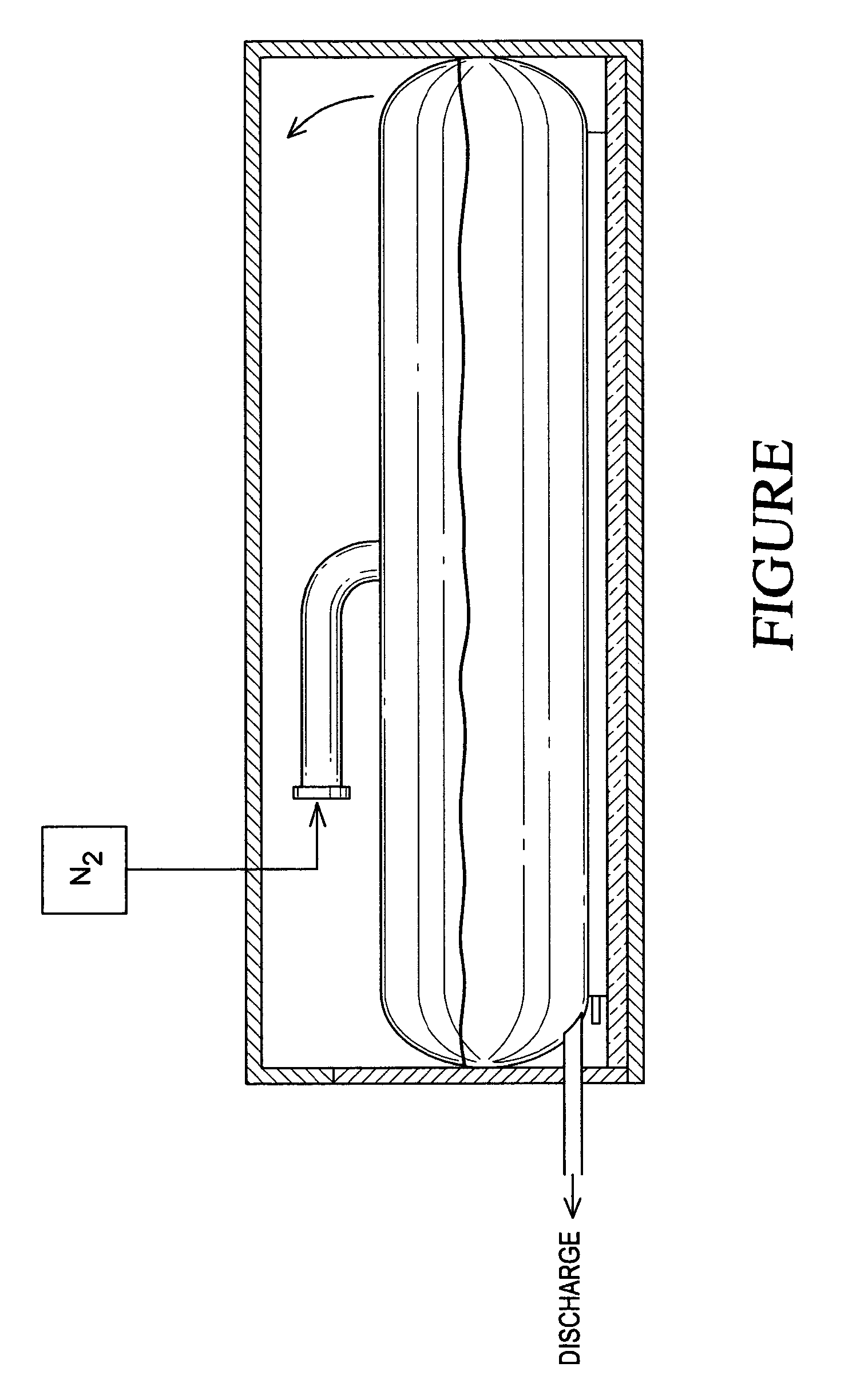

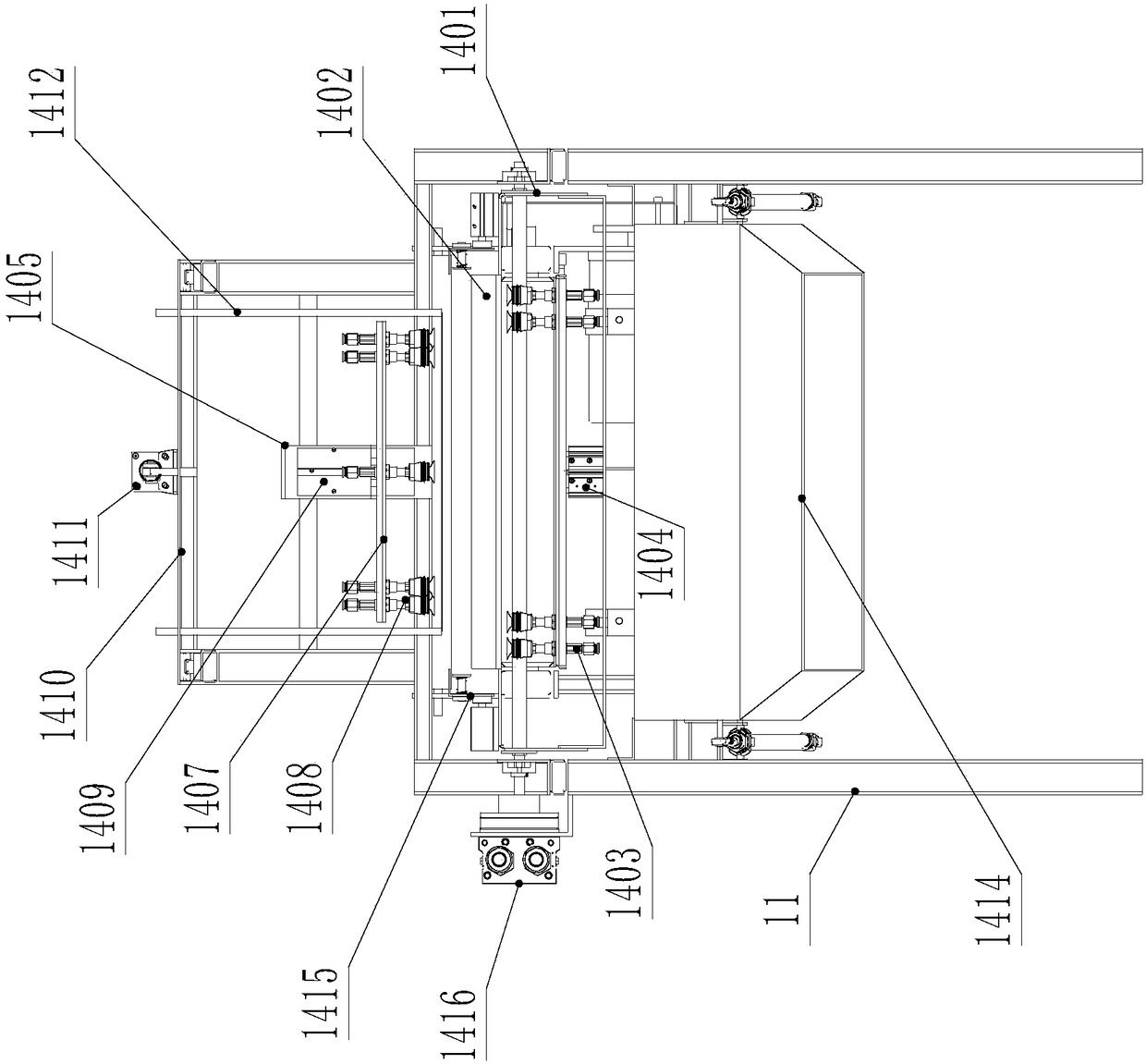

Method for transport of heat-sensitive liquids

InactiveUS20070116811A1Minimizes HMF buildupMinimizing heat absorbedPower operated devicesLarge containersAir entrainmentNitrogen

A specially designed flexible tank is installed in a standard 20 foot overseas shipping container or in a standard trucking dry van trailer. A conductive heat serpentine plastic tubing system is also installed underneath the flexible tank allowing heat to liquefy the honey near the bottom discharge location. Nitrogen is introduced through an upper air purging valve and flow is controlled by a regulator allowing tank to stand and not be conducive to cling of product on the roof or the sidewalls and to assist in discharging product without need of a pumping mechanism. Due to the continued shape of the flexible tank there will be very little product loss allowing virtually all product to be expelled. The discharge valve will remain open when the heat is started and this allows the honey to be removed as quickly as it becomes liquid. The method permits bulk shipped honey to be unloaded without substantial increase in HMF levels or air entrainment caused by pumping which could lead to crystallization, and avoids substantial product loss due to clinging on the inside of the tank. The invention also provides substantial labor savings along with freight savings compared to the prior honey industry method of shipping honey in 55 gallon drums.

Owner:ROSE J MICHAEL +1

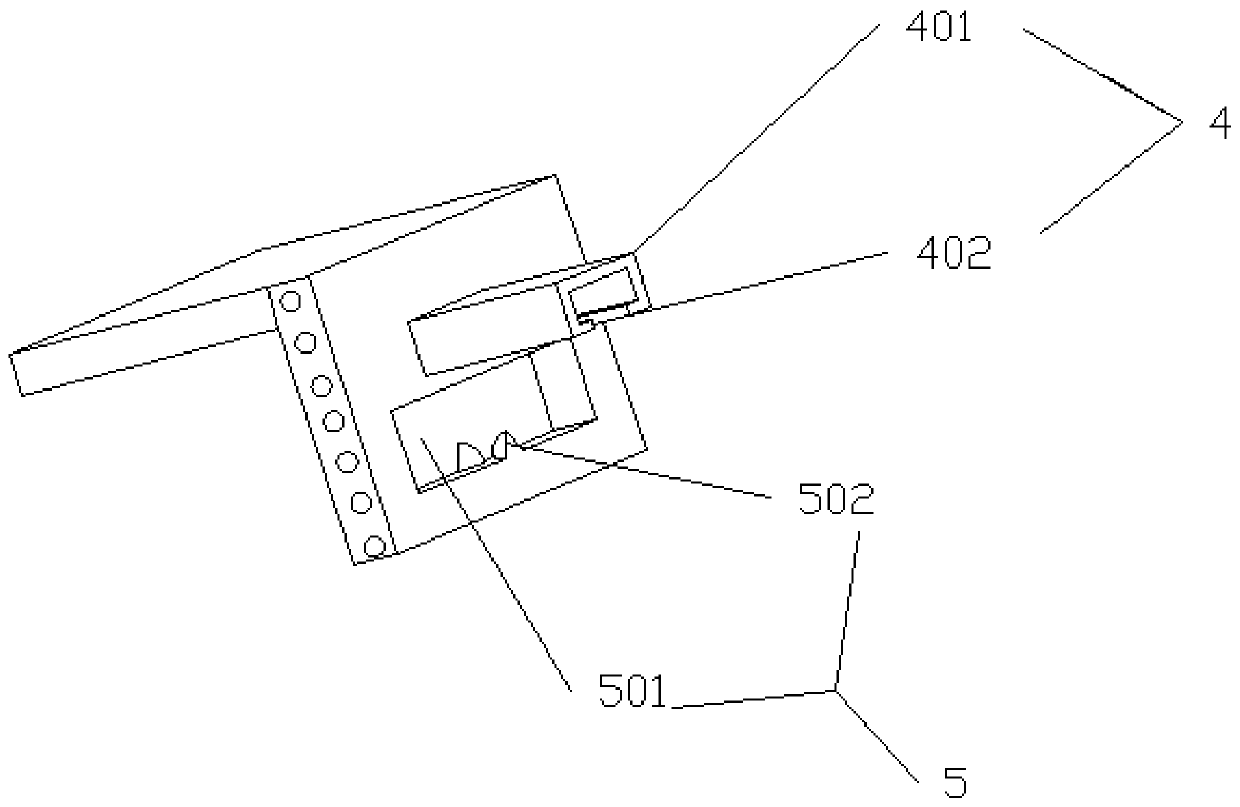

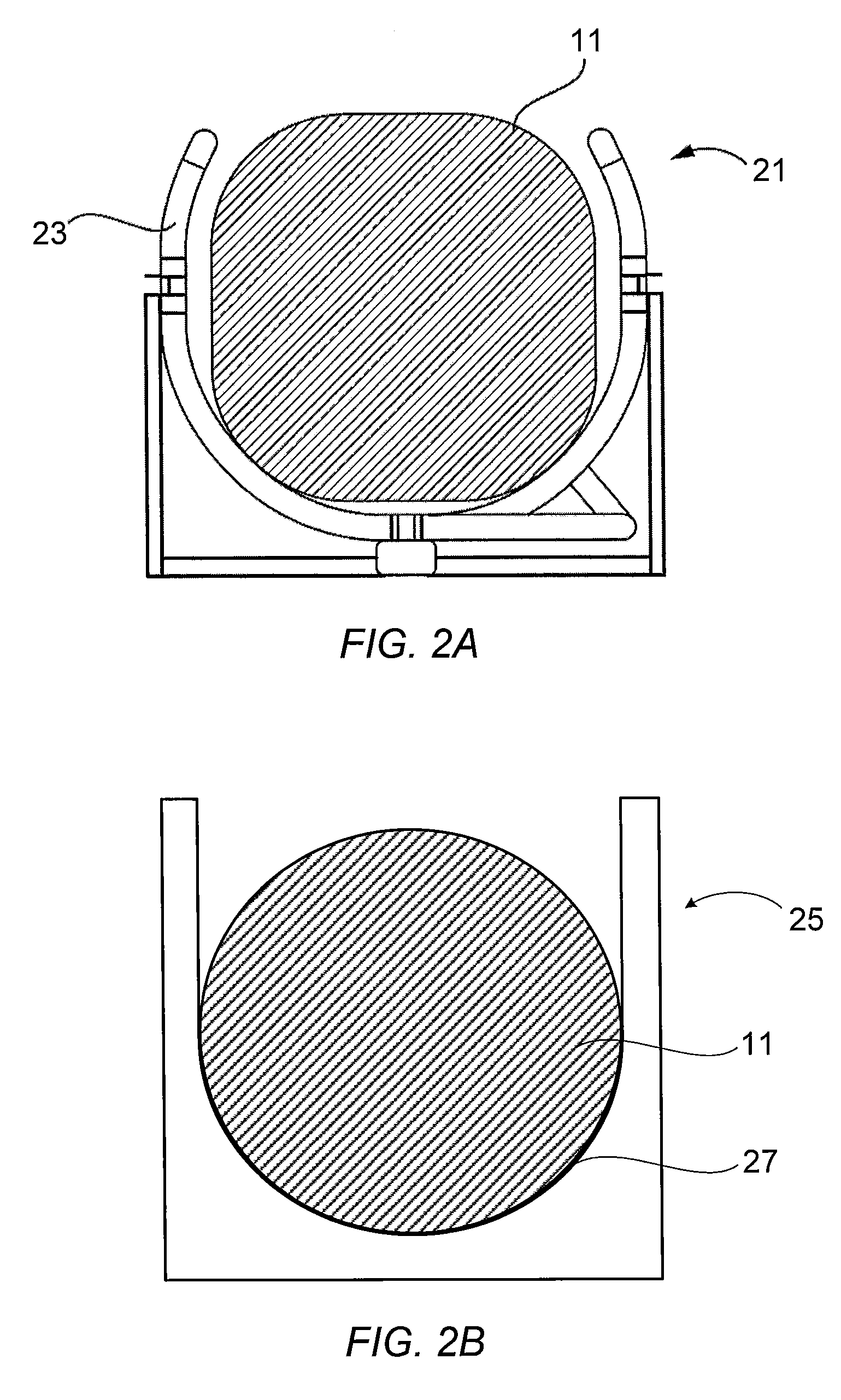

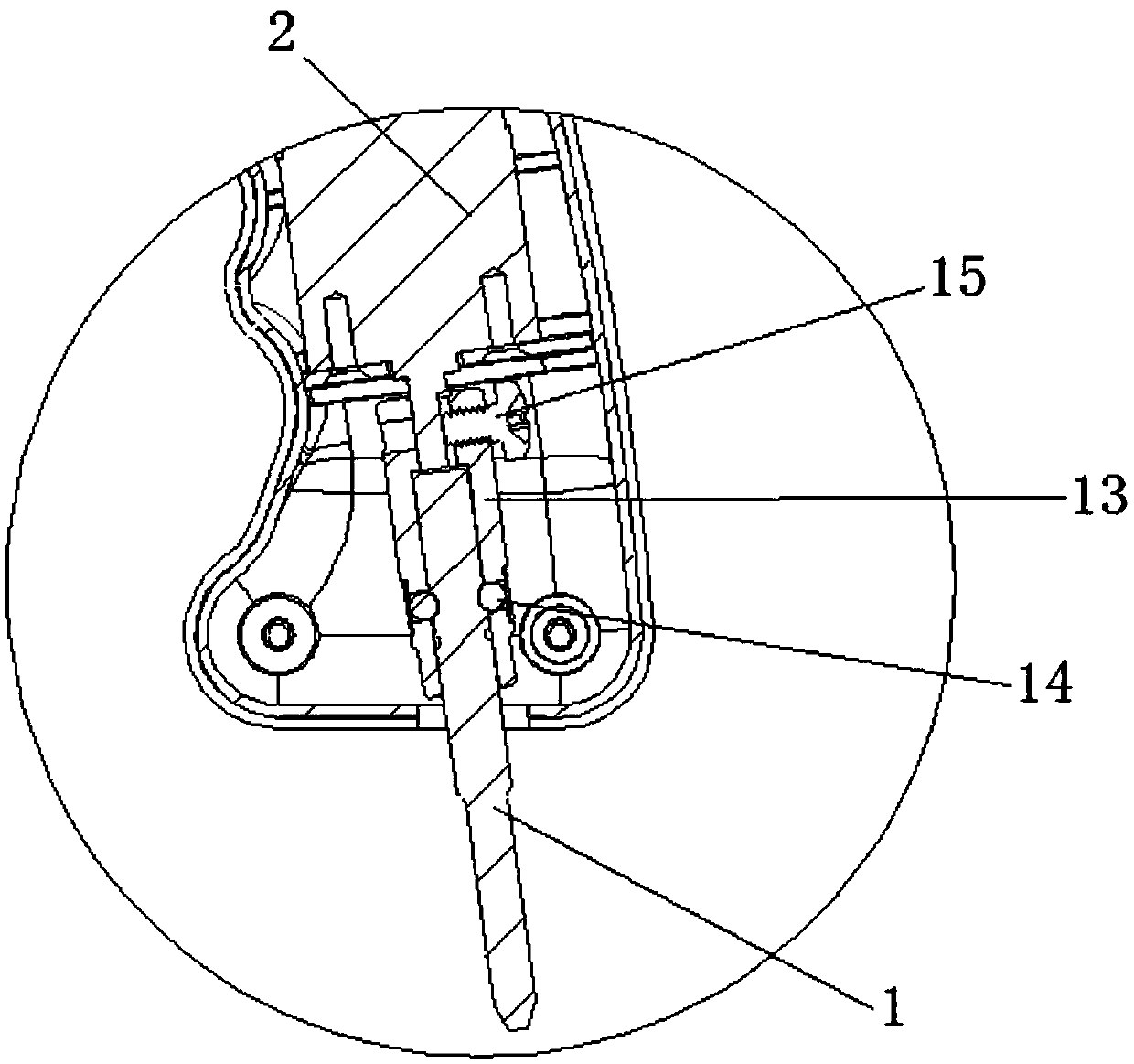

Method for disassembling flexible screen and TP and clamp

ActiveCN110328637AReduced risk of burnsSimple structureWork holdersMetal-working hand toolsTectorial membraneEngineering

The invention relates to a method for disassembling a foldable flexible screen and a TP. The method comprises the following steps that S1, the TP is placed downwards to be adsorbed on a heating platform, a hard protective film is attached on the flexible screen, and it needs to be ensured that the attachment is smooth and free of bubbles; S2, then heating is carried out by using heating equipmentto reach 50-70 DEG C; S3, a diamond wire with the diameter of 0.05-0.07 mm is used for separating the flexible screen and the TP through scraping, a disassembling clamp for the flexible screen and theTP is used for supporting the flexible screen, the flexible screen is taken down and reversely rotated, so that the hard protective film faces downwards to be adsorbed on the heating platform, and then the protective film is attached to the TP for protection; and S4, the hard protective film is heated by utilizing the heating equipment again. The invention further discloses the disassembling clamp for the flexible screen and the TP. When the disassembling clamp for the flexible screen and the TP is used for disassembling, the relative position of a connecting piece and a sliding assembly is adjusted so that the distance between an arm of an operator and the heating platform can be relatively far away during disassembly, and then the risk of scalding is reduced.

Owner:淮北摩兰科技有限公司

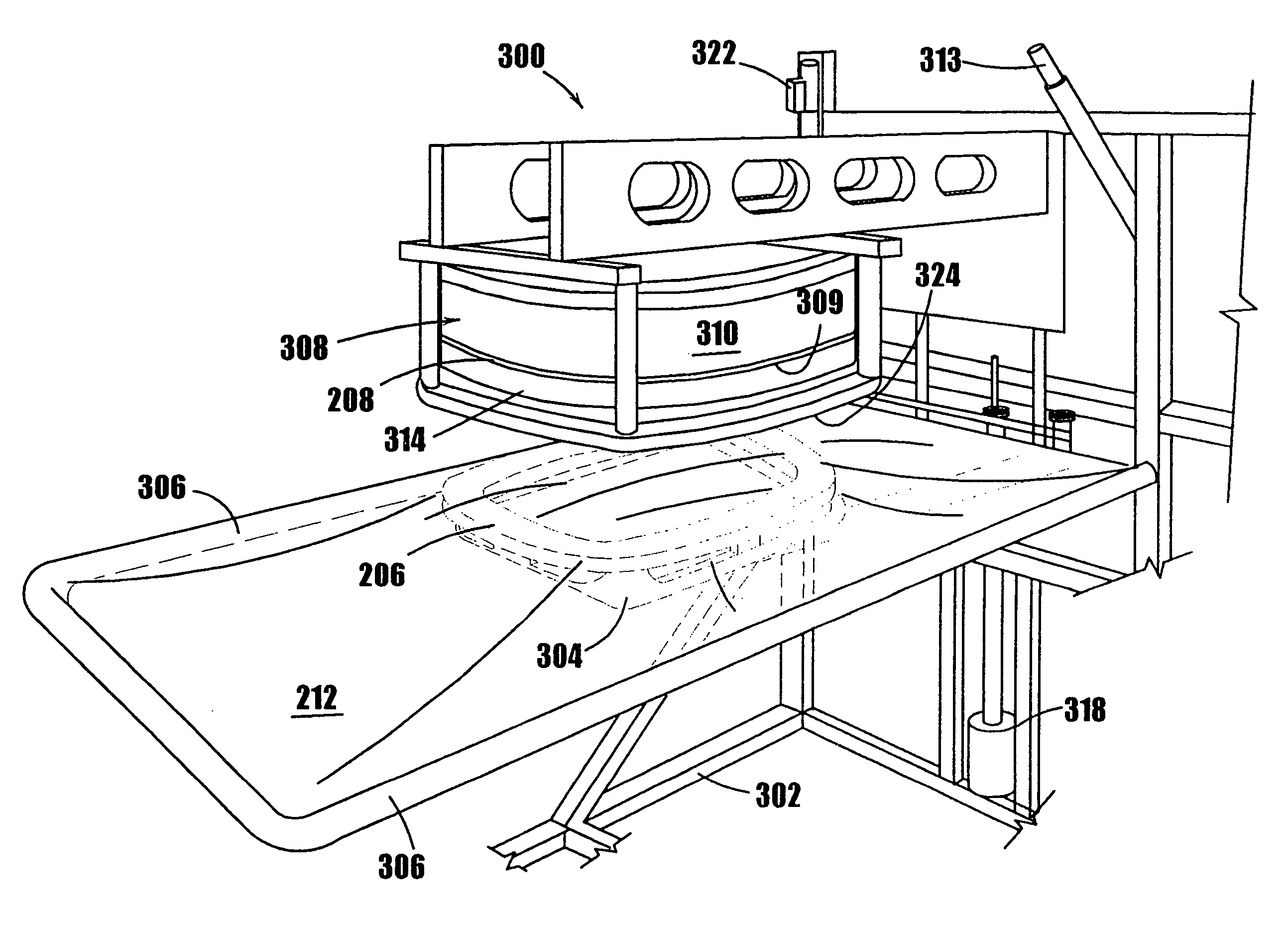

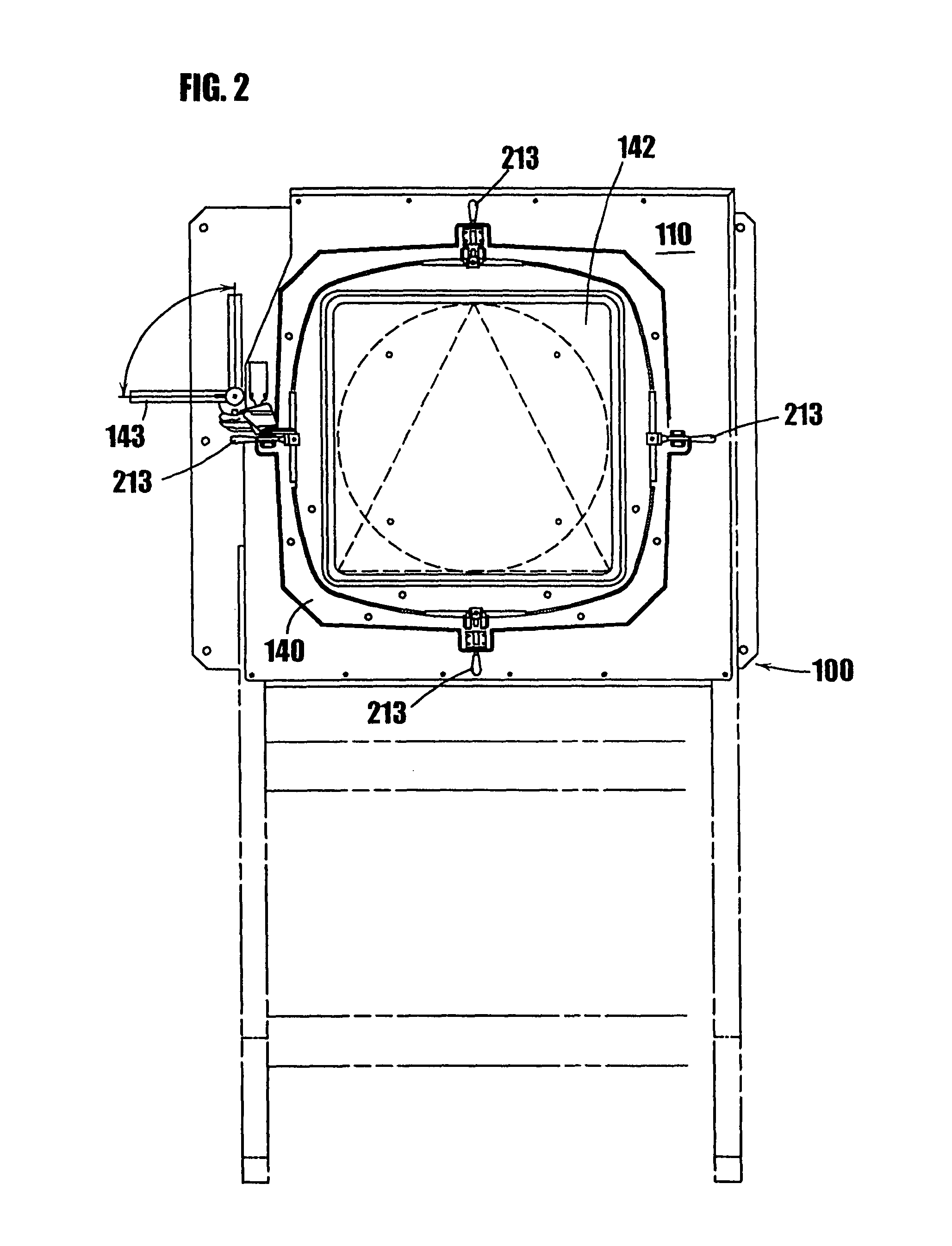

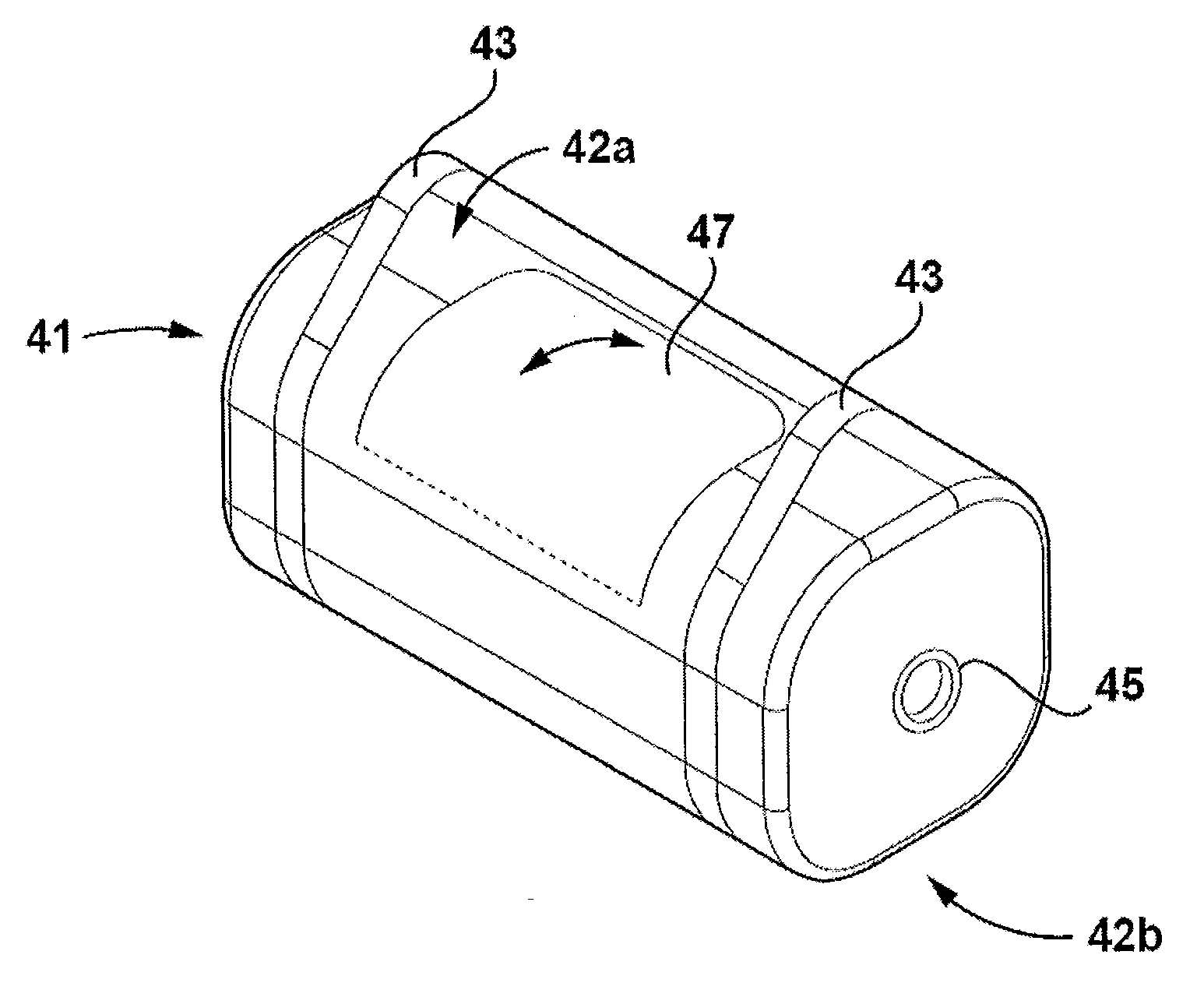

Transfer port and method for transferring sterile items

InactiveUS8163251B2Inhibit migrationWrappers shrinkagePackage sterilisationSterile environmentEngineering

A sterile enclosure contains a transfer module defining a window. A port covers the window to maintain the inside of the enclosure as a sealed and sterile environment. A sliding, heated cutting element mounted on the port serves to sterilize and sever a portion of a sterile transfer bag assembly attached to the port. Preferably, the excised portion of the sterile transfer bag assembly is affixed to the port when the port opens. The sliding cutting element remains extended and heated to prevent contamination when the port is open. Further, a heating element is mounted about the window in order to sterilize around the opening when the port is open.

Owner:MAEJ LLC ODONNELL & TESSITORE

Method for transport of heat-sensitive liquids

InactiveUS7681757B2Minimizing heat absorbedMinimizes buildupPower operated devicesLarge containersAir entrainmentNitrogen

A specially designed flexible tank is installed in a standard 20 foot overseas shipping container or in a standard trucking dry van trailer. A conductive heat serpentine plastic tubing system is also installed underneath the flexible tank allowing heat to liquefy the honey near the bottom discharge location. Nitrogen is introduced through an upper air purging valve and flow is controlled by a regulator allowing tank to stand and not be conducive to cling of product on the roof or the sidewalls and to assist in discharging product without need of a pumping mechanism. Due to the continued shape of the flexible tank there will be very little product loss allowing virtually all product to be expelled. The discharge valve will remain open when the heat is started and this allows the honey to be removed as quickly as it becomes liquid. The method permits bulk shipped honey to be unloaded without substantial increase in HMF levels or air entrainment caused by pumping which could lead to crystallization, and avoids substantial product loss due to clinging on the inside of the tank. The invention also provides substantial labor savings along with freight savings compared to the prior honey industry method of shipping honey in 55 gallon drums.

Owner:ROSE J MICHAEL +1

Receptacle of gel card type equipped with a lid comprising a precut

ActiveUS20140124510A1Avoid downtimeGood curative effectOpening closed containersBottle/container closureEngineering

Owner:BIO RAD EURO GMBH

Carton opening device

ActiveCN109367933AImprove work efficiencyImprove abilitiesUnpacking by heatingUnpacking by cuttingUltrasonic sensorAdhesive

The invention discloses a carton opening device, and belongs to the field of carton processing equipment. A feeding sliding plate is fixed above a base, an air pressure cylinder is vertically positioned right above a conveying belt, the carton opening device is installed at the bottom of an air pressure cylinder main shaft, a discharging sliding plate is fixed at the top of a third support, a first motor is fixed at the right end of a motor base, the conveying belt is wound between a first roller and a second roller, a controller is installed in front of the motor base, a positive displacementdevice is fixed below the conveying belt, a second motor is fixed at the left end of the motor base, and a second ultrasonic sensor is fixed above the carton opening device. According to the carton opening device, the conveying belt drives the carton to advance, the height and position information of the carton are detected through the ultrasonic sensor, the direction of the carton adhesive tapewhich is corrected by a positive position device is consistent with the advancing direction of the conveying belt, the carton opening device is used for cutting off the adhesive tape around the cartonto finish the carton opening operation, so that the manual labor is reduced, and the production efficiency is improved.

Owner:台州舒倍康医疗科技有限公司

Automatic bagged printing ink extruder

PendingCN109335183AExtrude quicklyFully squeeze outBags openingUnpacking by expelling contentsPrinting inkEngineering

The invention discloses an automatic bagged printing ink extruder which comprises a base, a clamping roller assembly and a drive device. The clamping roller assembly comprises a first clamping rollerand a second clamping roller rotatably arranged on the base; the first clamping roller and the second clamping roller can clamp a printing ink bag; and the drive device is arranged on the base and isused for driving the first clamping roller and / or the second clamping roller to rotate so as to enable the clamping roller assembly to move along the printing ink bag, so that printing ink can be extruded out from the printing ink bag. According to the automatic bagged printing ink extruder provided by the invention, the first clamping roller and the second clamping roller can clamp the printing ink bag and can rotate under the drive of the drive device so as to move along the printing ink bag, so that printing ink can be quickly and sufficiently extruded, the production demand of corresponding equipment can be met, the printing ink residues can be effectively reduced, the waste is reduced, the printing ink bag can be conveniently recovered, the environment pollution can be effectively reduced, and the automatic bagged printing ink extruder is simple in structure and convenient to use.

Owner:中山互润天成环保包装有限公司

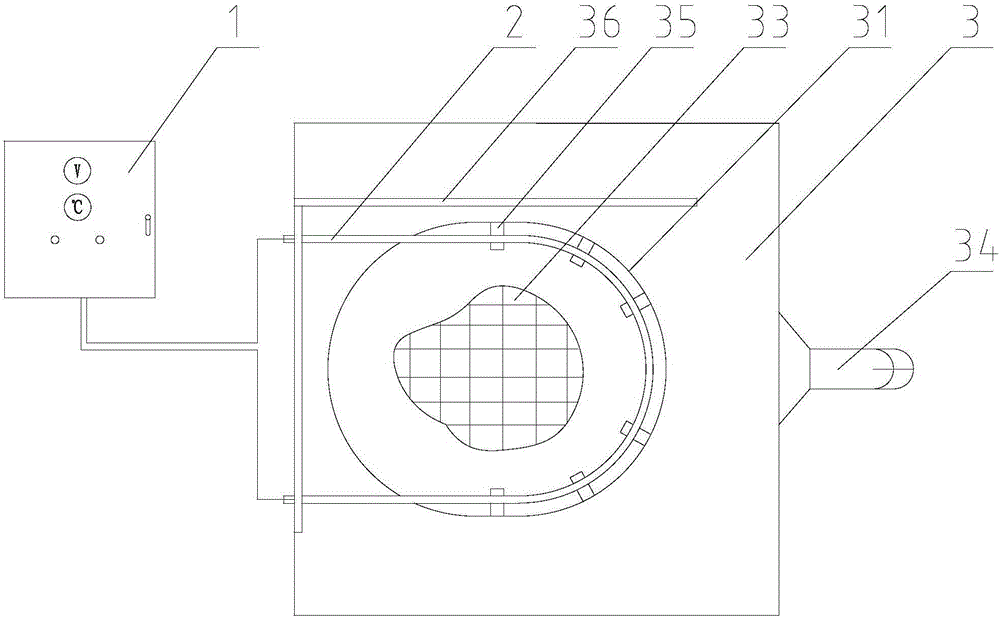

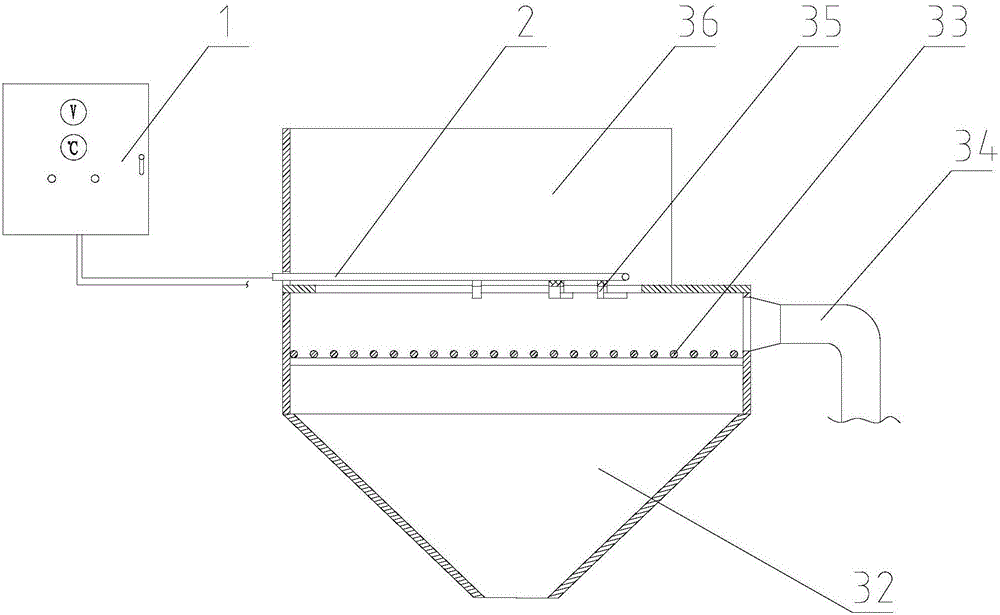

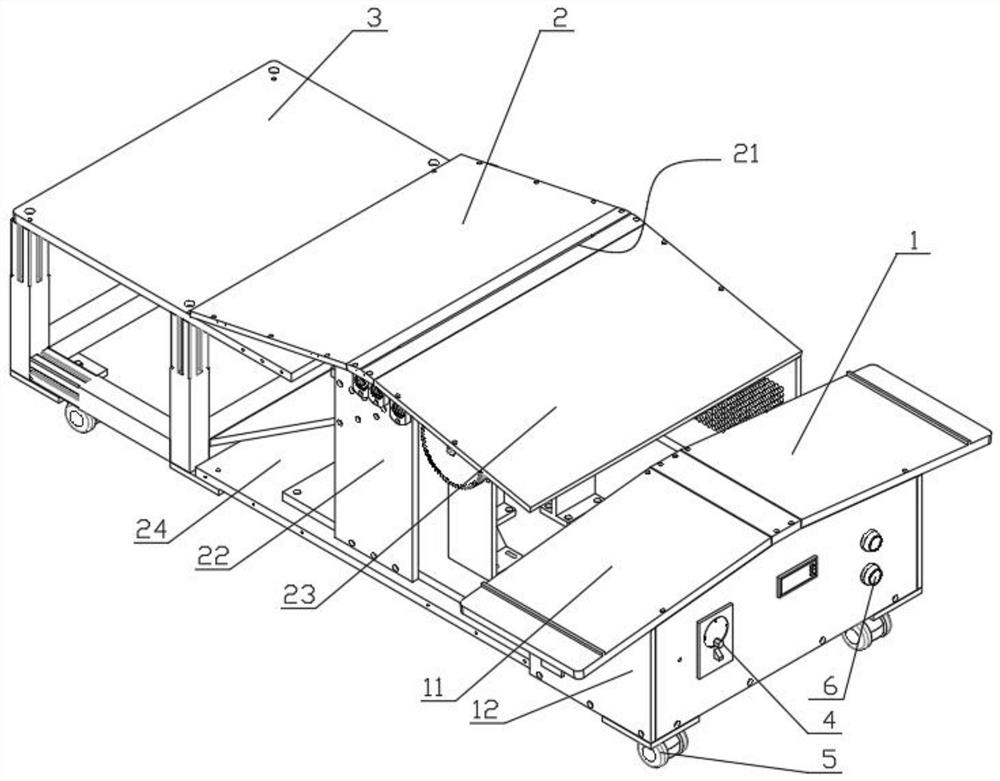

Ton bag unpacking device

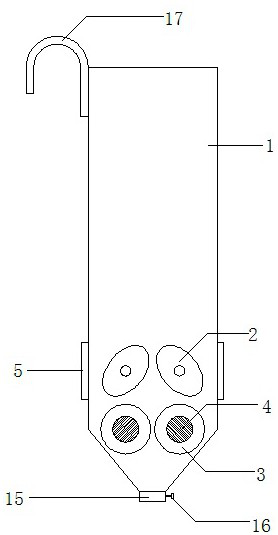

InactiveCN105819046ASmooth feedingMeet melting temperature requirementsUnpacking by heatingElectrical controlElectric heating

The invention discloses a ton bag unpacking device which carries out unpacking through electric heating and melting of a ton bag. The device has the advantages that production efficiency can be increased; hidden safety hazards can be reduced; and dust pollution can be reduced. The device comprises an electric control box, a heater and an unloading platform, wherein the electric control box is electrically connected to the heater, and the heater is heated up under heating of the electric control box and then melts the ton bag; an unloading hole is disposed in the unloading platform and disposed under the heater; and an unloading funnel is connected under the unloading platform. The bottom face of the ton bag is melted by the heater, materials are closely clung to the unloading hole and poured out from the unloading hole, and the whole unloading course is smooth and closed, so that a lot of raised dust is avoided; only a part of the bottom face of the ton bag is melted by the heater, so that a residual body of the ton bag is prevented from entering the unloading hole and causing blocking; a positioning plate is used to position the ton bag, and the ton bag can be accurately lifted to the position above the unloading hole without manual straightening; and the structure is simple, unpacking efficiency is high, material leakage can be avoided, and raised dust pollution will not be generated.

Owner:四川启明星铝业有限责任公司

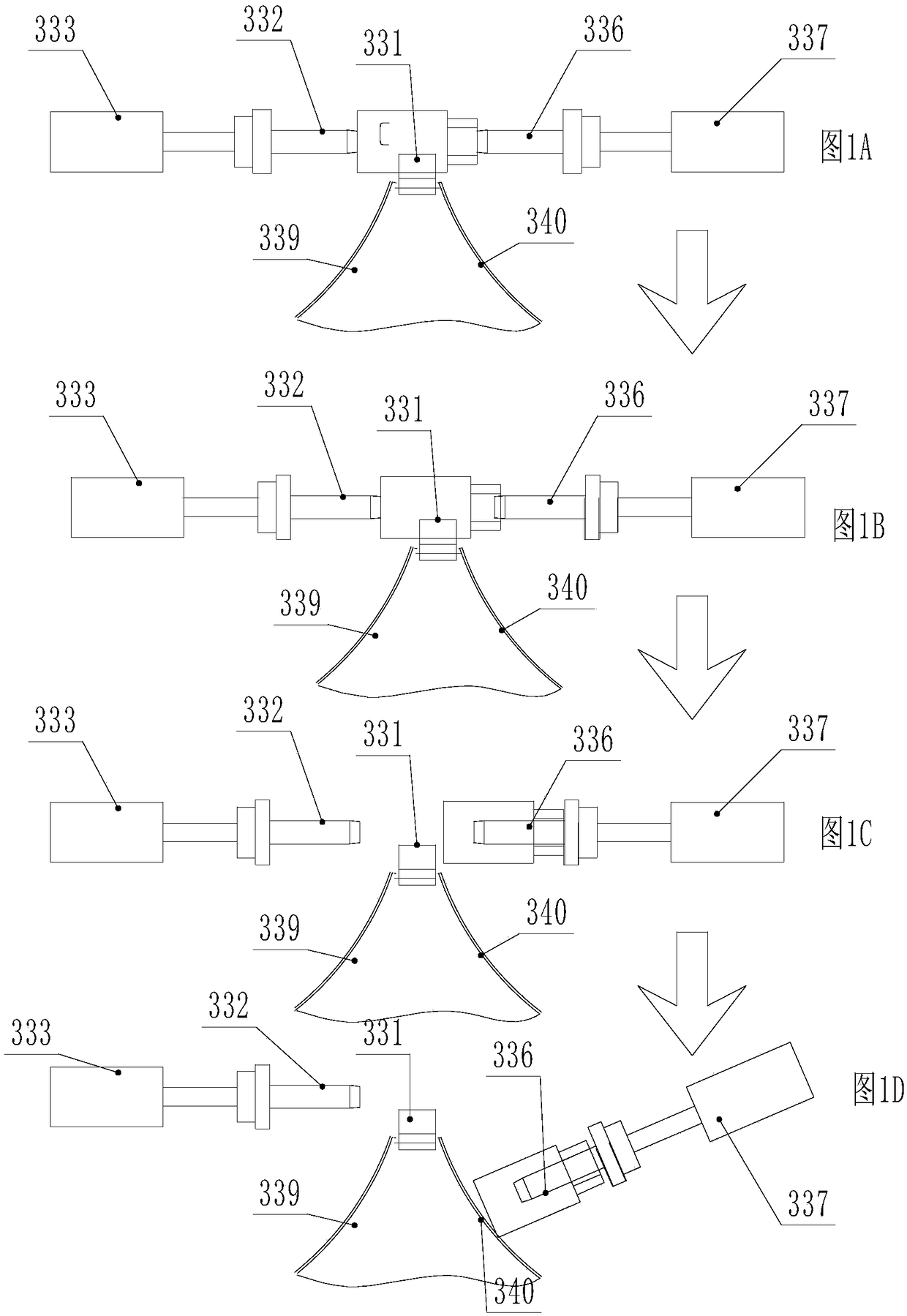

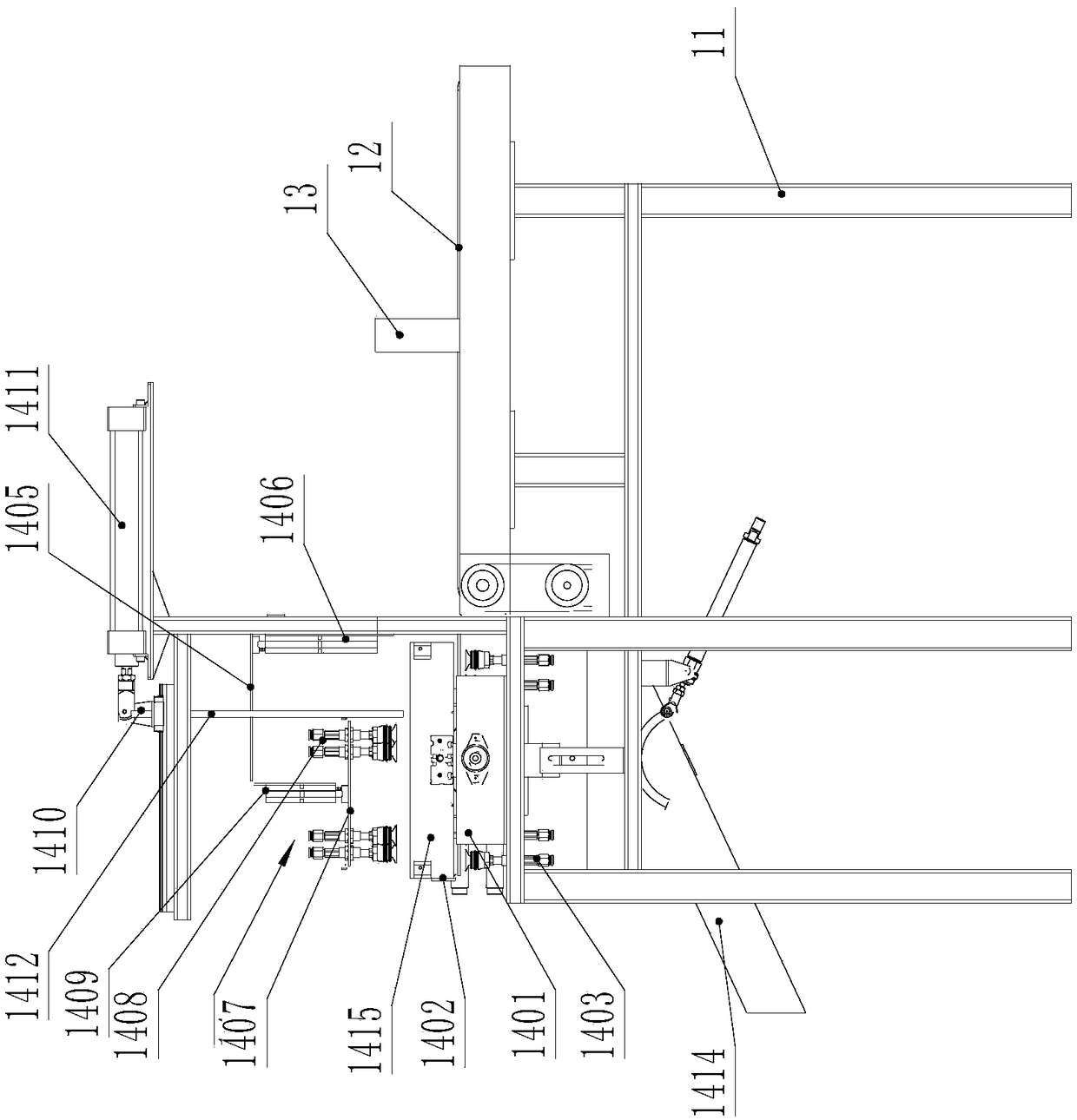

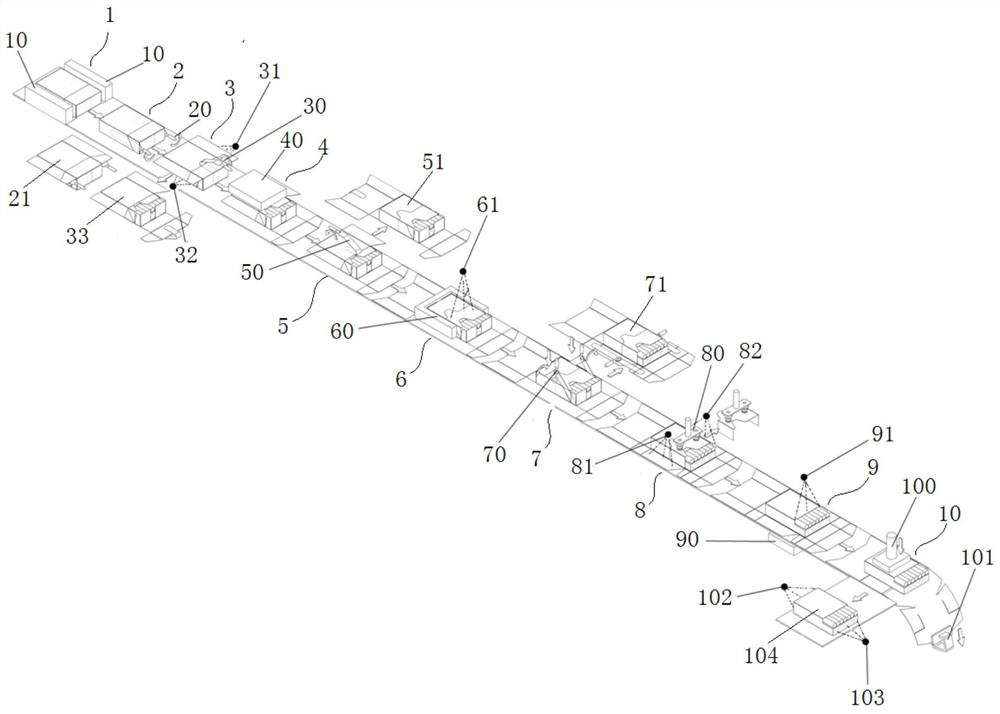

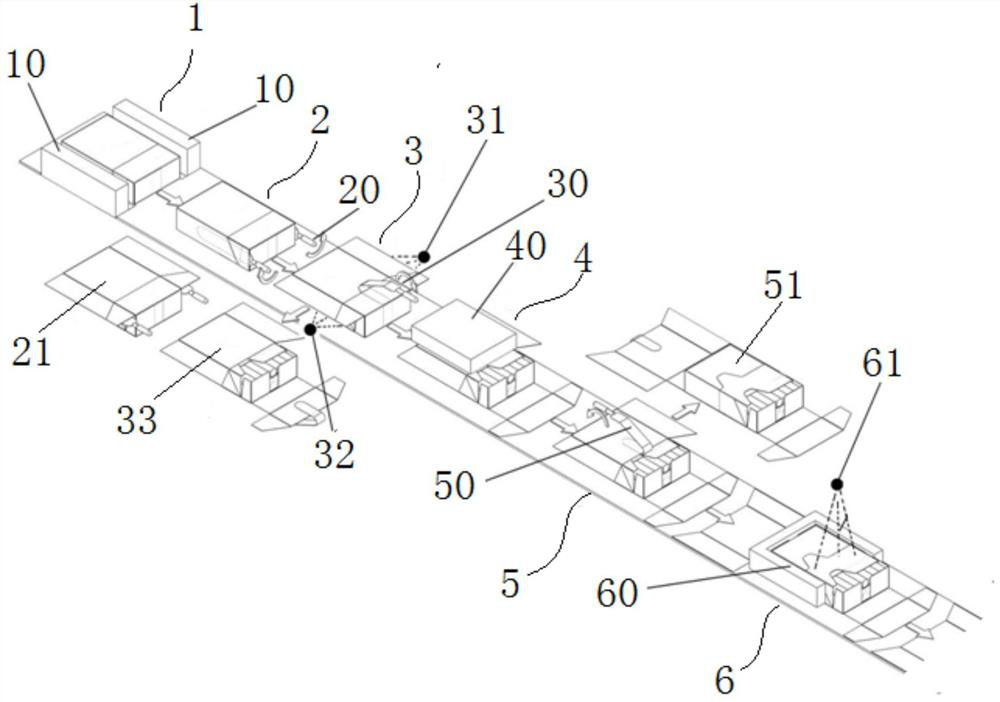

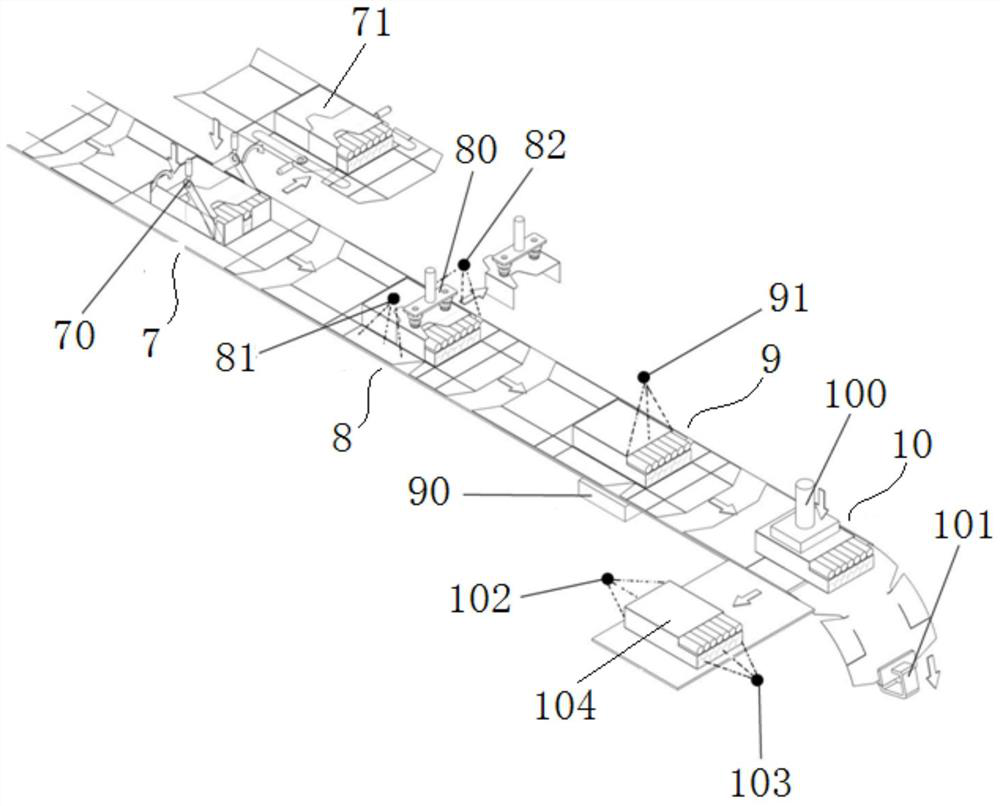

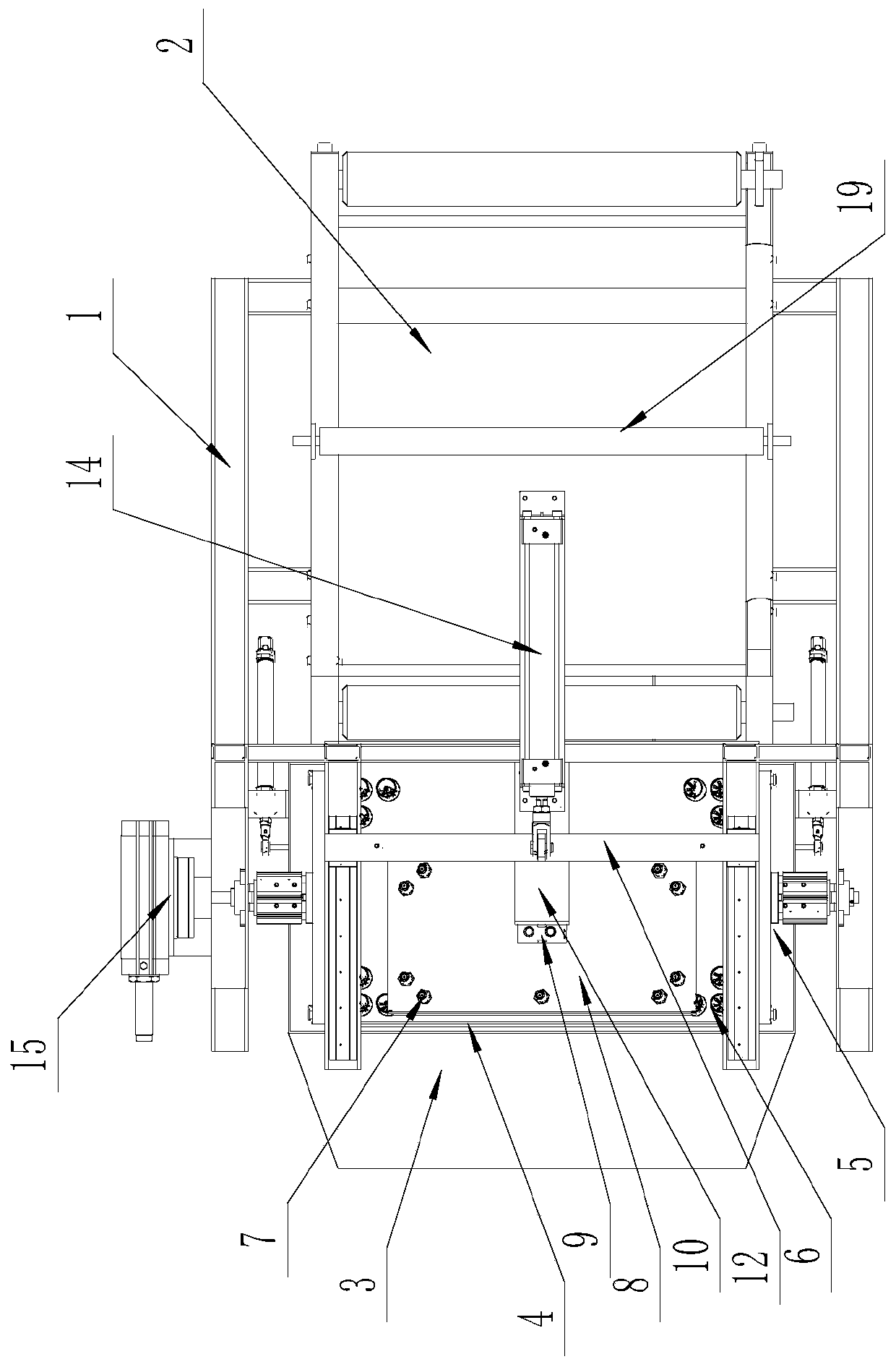

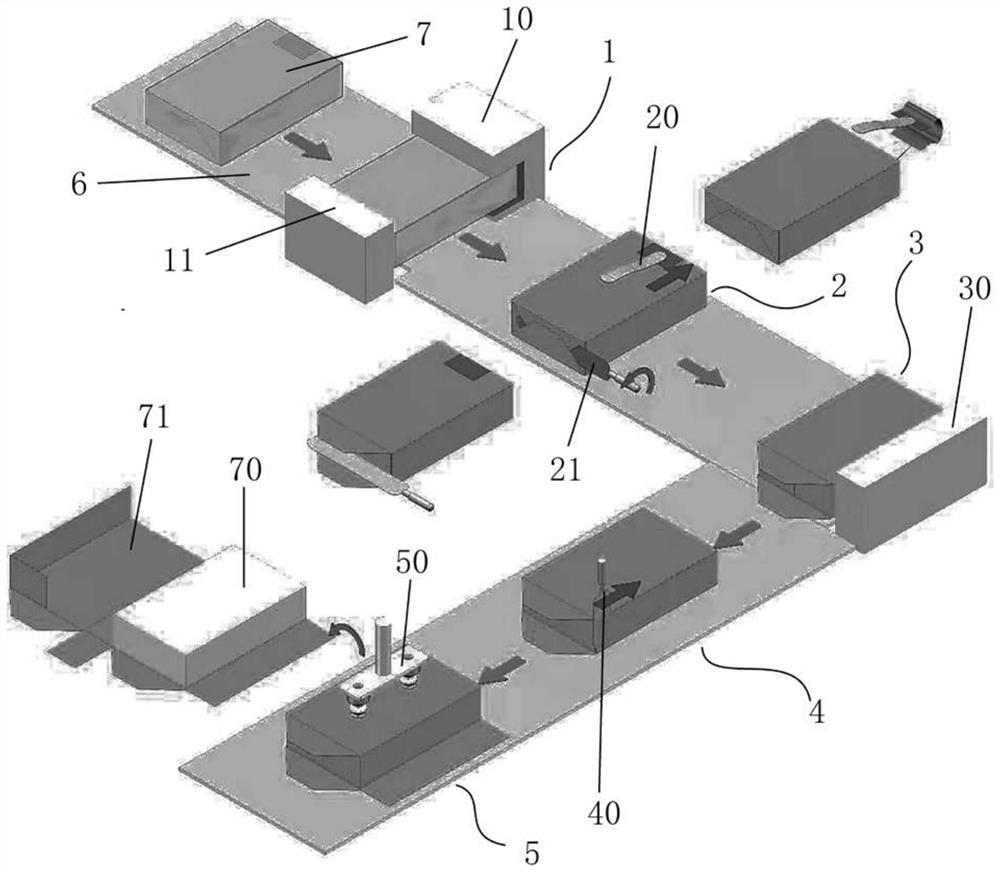

Penicillin bottle turnover standing method and unpacking bottle straightening method

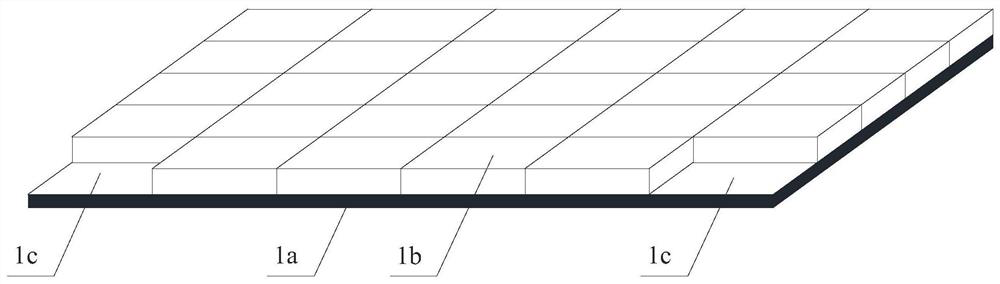

ActiveCN108100391AImprove bottle unscrambling efficiencyPrevent dumpingConveyorsUnpacking by heatingPenicillinEngineering

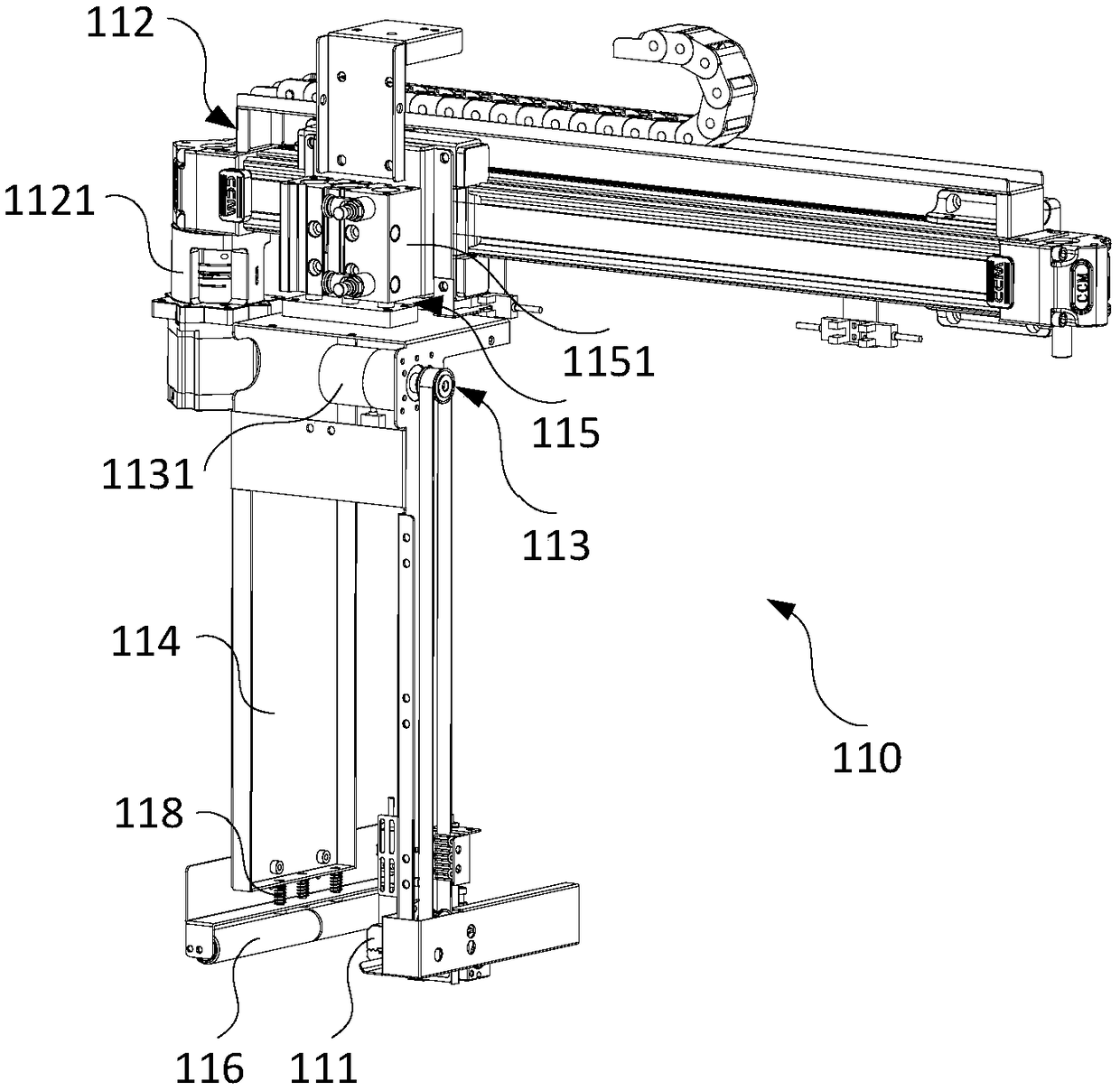

The invention discloses a bottle turnover standing method which can realize turnover standing of penicillin bottles without taking bottle opening directions of the penicillin bottles into consideration, so that the bottle straightening efficiency of the whole penicillin bottles is improved. In addition, the invention further discloses an unpacking bottle straightening method which includes the steps: B1 unpacking a penicillin bottle group and then pouring the penicillin bottles into a material collecting hopper; B2 enabling the penicillin bottles in the material collecting hopper to enter a combing conveying channel for combing and then conveying the penicillin bottles in a flatly lying single-row arranged manner; B3 conveying the combed penicillin bottles to a bottle supporting frame by atransition conveying channel; B4 straightening the penicillin bottles to stand by the bottle turnover standing method; B5 vertically dropping the standing penicillin bottles into an output channel and pushing out the penicillin bottles. By the bottle turnover standing method, the unpacked penicillin bottles are combed and then enter the bottle supporting frame, and then bottle turnover standing is finished by a left contact pin and a right contact pin, so that bottle straightening efficiency is improved.

Owner:HIT SMART FACTORY CO LTD

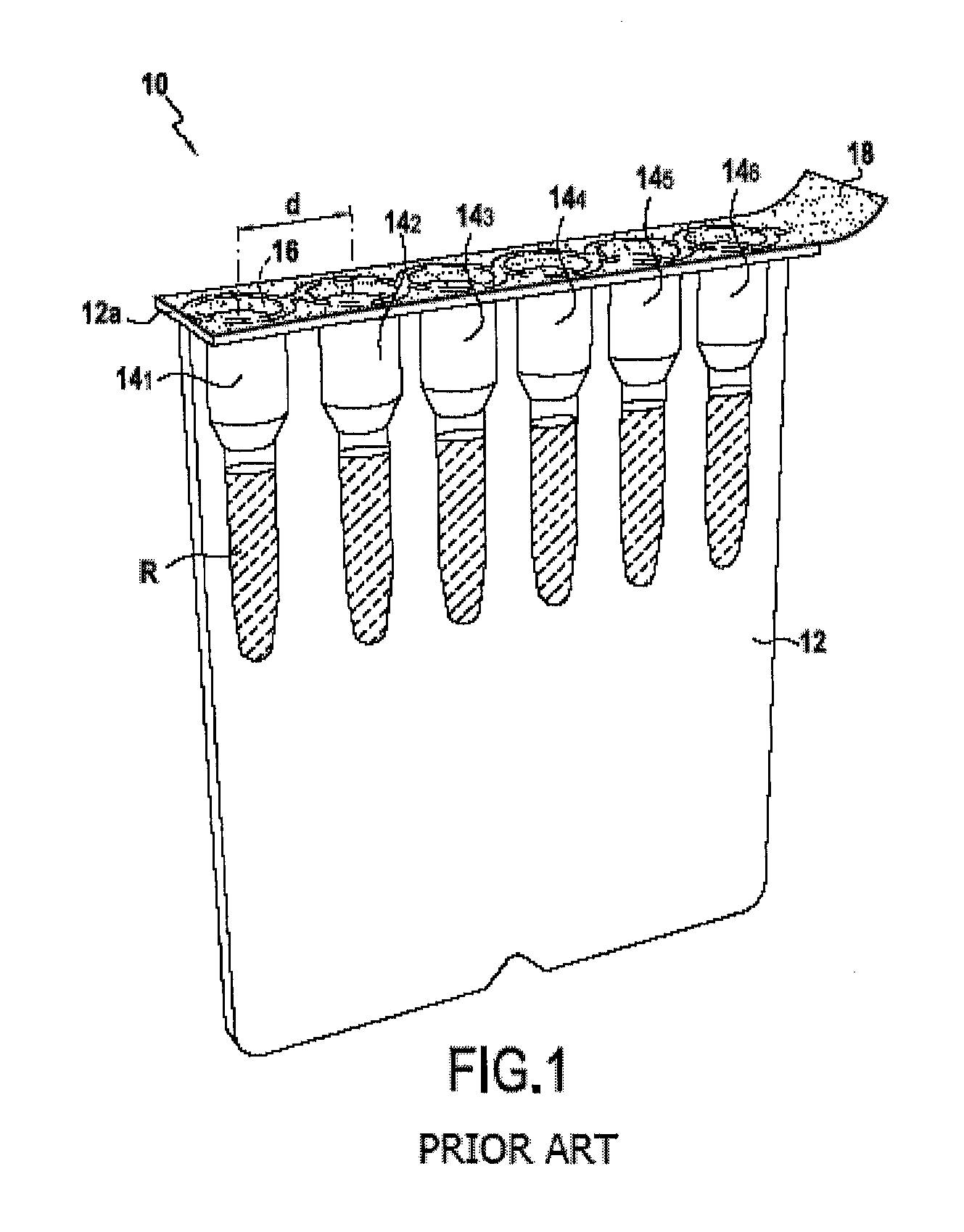

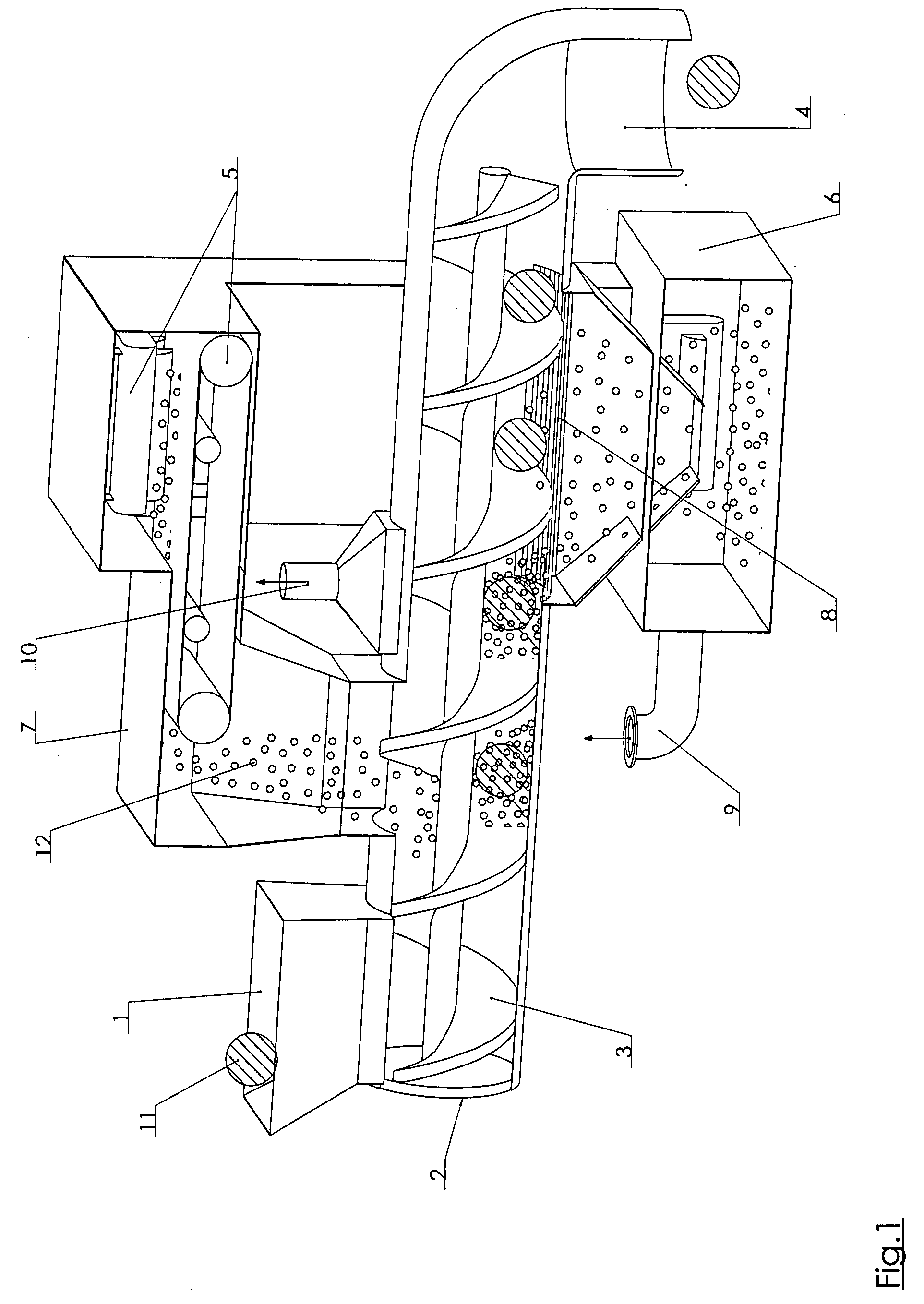

Method and apparatus for removing a plastic film from packages

InactiveUS20070215276A1High purityTemperature controlAdhesivesUnpacking by heatingPolyolefinEngineering

Present invention relates to the method and apparatus for removing a plastic film from packages, where packages covered by the plastic film are introduced to the first transport path characterized in that an sorbent (12) is introduced to the second transport path. Next the sorbent (12) is heated to the flow temperature of the plastic that is removed, in particular plastics from the polyolefin's group. Afterwards within the common part of the first and second transport path (2) of the separating device the sorbent (12) is mixed with transported packages (11) covered with a plastic film. A sieve (8) of the separating device directs sorbent (12) covered by absorbed plastic to the removing path (6,9), while packages (11) free from plastic film are directed towards the exit gate (4) of the separating device.

Owner:INT TOBACCO MACHINERY POLAND

Film tearing machine

PendingCN108313439AGood tearing film working environmentImprove tearing efficiencyUnpacking by heatingMechanical engineeringEngineering

The invention discloses a film tearing machine. The film tearing machine comprises a machine body; a partition plate is arranged above the machine body and near the middle position; a first discharging shaft is arranged above the machine body and near one side of the partition plate; a second discharging shaft is arranged above the machine body and near the other side of the partition plate; a first material guide rod is arranged above the machine body and near one side of the first discharging shaft; and a second material guide rod is arranged above the machine body and near one side of the second discharging shaft. An atomizer and an atomizing spray head are provided, bubbles generate in the film tearing process and the bubbles are reduced through the action of the atomizer and the atomizing spray head, so that beautiful appearance after the film is torn is enhanced and the qualification rate of the film-tearing products is increased; a buffer device is provided, so that the work stability of the machine body in the film-tearing process can be guaranteed and the fact that the film can be torn normally is guaranteed; and a PT100 temperature sensor, a heating device and a fan are provided, so that the success rate of film tearing is increased, the working efficiency of film tearing is improved and the production cost is reduced.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Film tearing mechanism and automatic kitchen system

PendingCN109436490ATear off completelyThe film tearing process is stableCooking-vessel lids/coversWarming devicesEngineeringMechanical engineering

The invention discloses a film tearing mechanism and an automatic kitchen system. The film tearing mechanism comprises a fixed bracket, a horizontal transmission mechanism, a film piece clamp and a front pressing and holding mechanism, wherein the horizontal transmission mechanism is used for driving the fixed bracket in the horizontal direction; the film piece clamp is arranged on the fixed bracket and is used for clamping a sealing film piece attached to the opening position of a container; and the front pressing and holding mechanism is arranged on the fixed bracket, is positioned on the front side of the film piece clamp in the horizontal movement direction of the film piece clamp and is used for pressing and holding the sealing film piece and the container. According to the film tearing mechanism and the automatic kitchen system, by arranging the film tearing mechanism and the front pressing and holding mechanism, the sealing film piece can be torn off from the container, and thefilm tearing direction and force are accurately controlled mechanically; meanwhile, the front pressing and holding mechanism can enable the film tearing process to be more stable, the container is notprone to being damaged, the sealing film piece can be completely torn off, and subsequent processing is facilitated.

Owner:长沙易爱智能科技有限公司

Automatic electric heating scraper device

PendingCN110143334AEasy to scratch offScratch off easilyCleaning using toolsUnpacking by heatingEngineeringElectric heating

The invention discloses an automatic electric heating scraper device which comprises a rack, wherein a first air cylinder, a second air cylinder, a first sliding rod and a second sliding rod are perpendicularly arranged at the top end of the rack; a flat plate is arranged on output shafts of the first air cylinder, the second air cylinder, the first sliding rod and the second sliding rod; a secondscrew rod is arranged at the corner being opposite to a first screw rod arranged at one corner of the flat plate; a first press plate is arranged at the bottom of the first screw rod; a second pressplate is arranged at the bottom of the second screw rod; a first sliding rail is arranged at the bottom of the flat plate; the bottom of the first sliding rail is connected with a first sliding sleeve; a scraper bracket is arranged at the bottom of the first sliding sleeve; a first vertical plate and a second vertical plate are perpendicularly arranged at the bottom of the scraper bracket; a U-shaped frame is arranged between the first vertical plate and the second vertical plate, and capable of rotating between the first vertical plate and the second vertical plate; and a scraper and an electric heating device are arranged on the U-shaped bracket. According to the arrangement sequence, the scraper is arranged on the front side in the running direction and the electric heating device is arranged on the rear side, so that a film on the surface of a workpiece can be easily stripped by the scraper immediately after being conveniently heated by the electric heating device.

Owner:SUZHOU HUQIANG ELECTRIC EQUIP

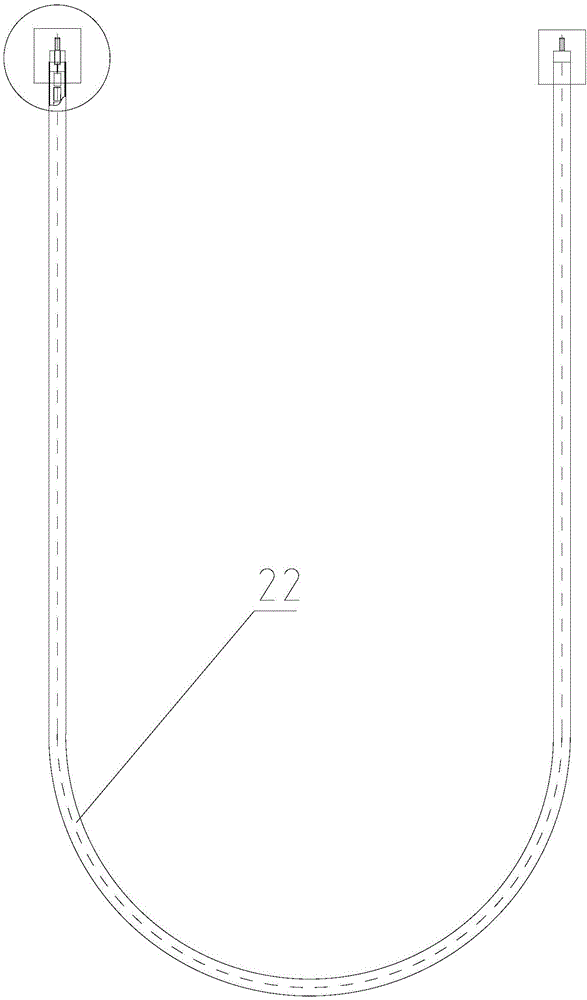

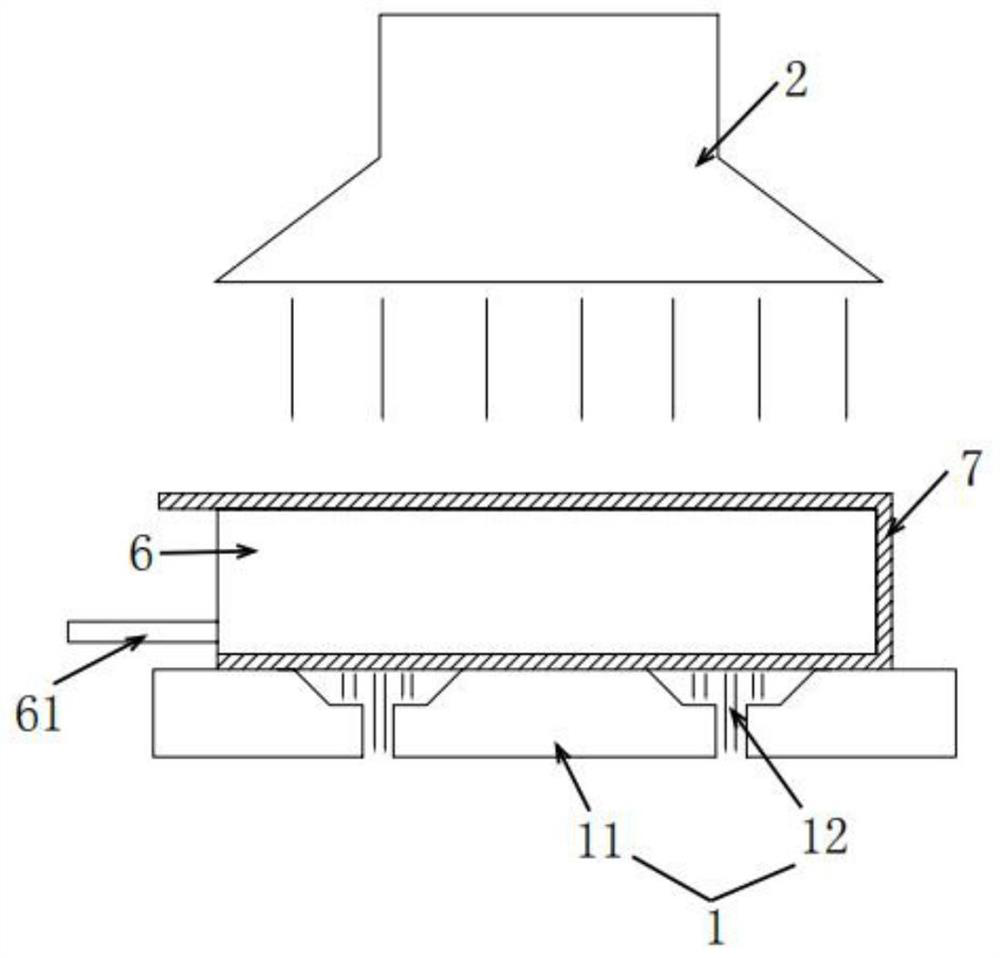

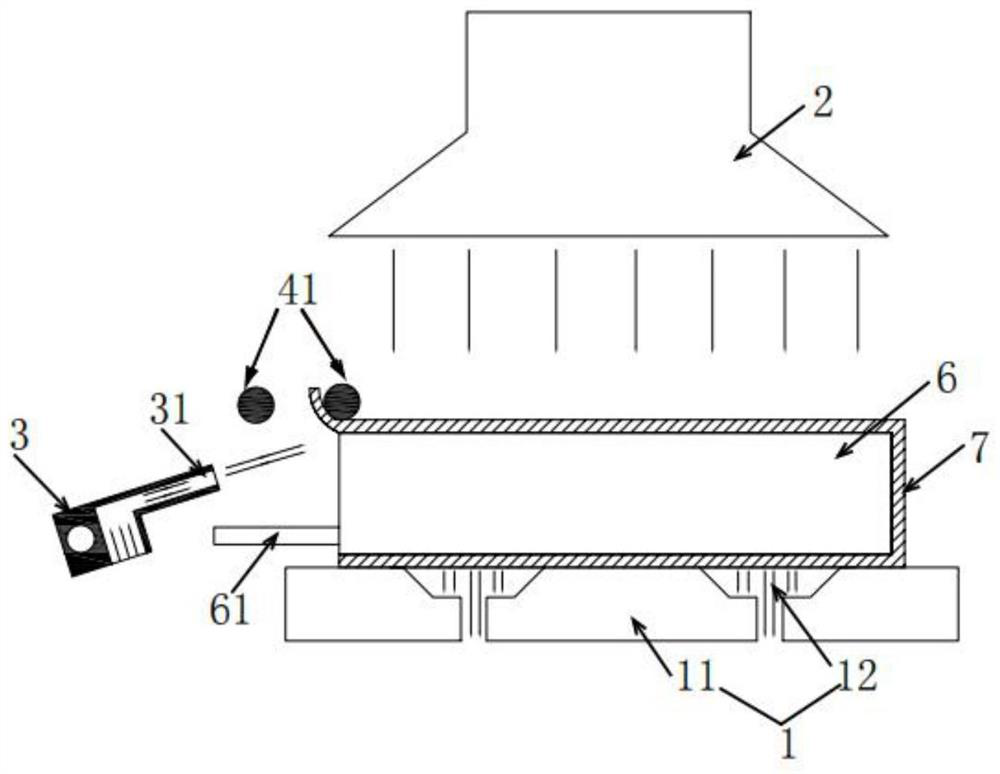

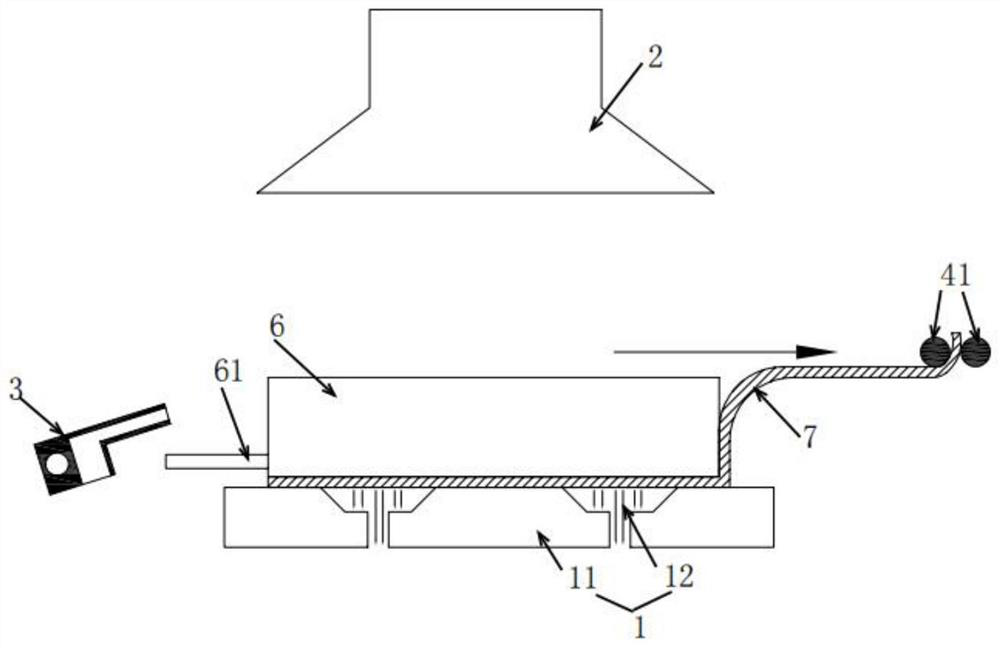

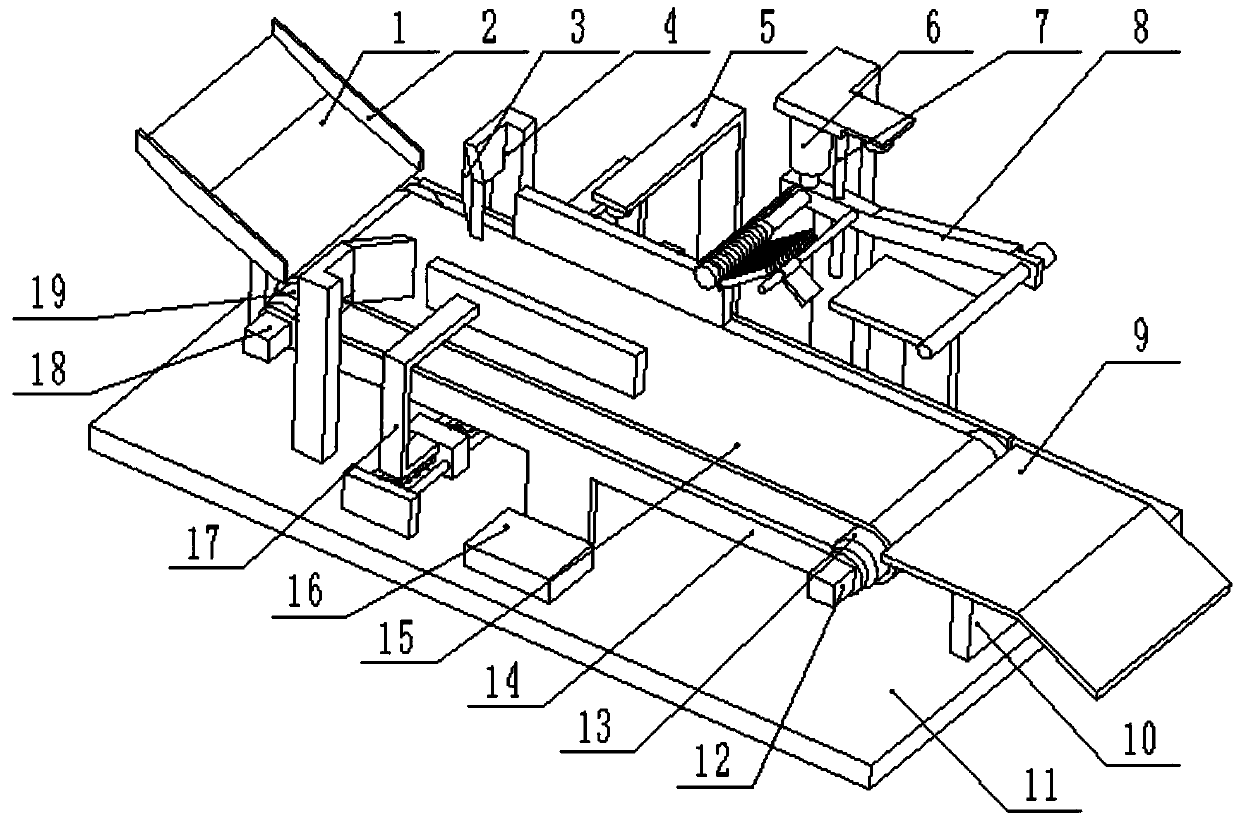

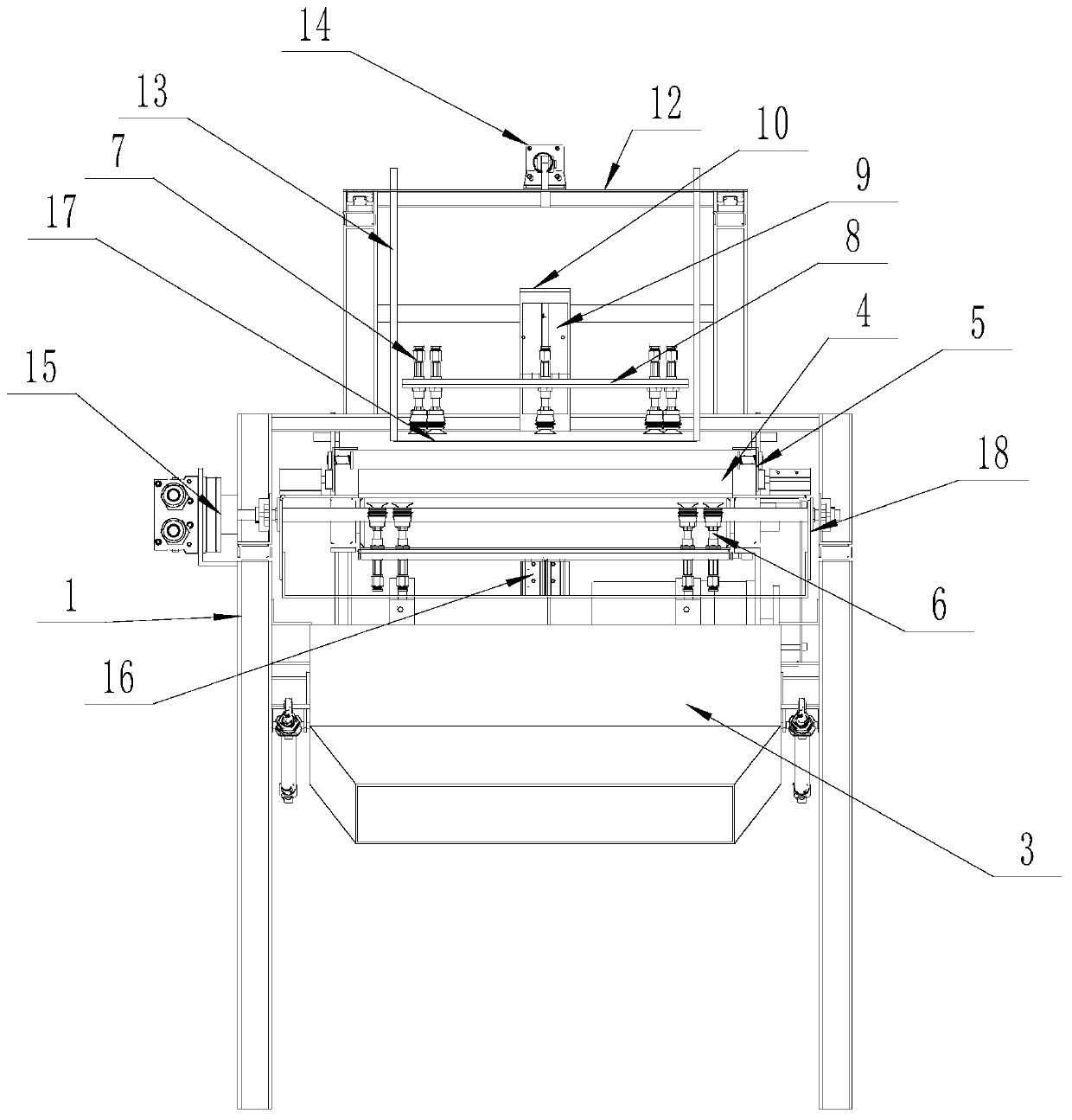

Unpacking and bottle straightening production line for penicillin bottles

ActiveCN108100392AGood unscrambling effectUnscramble bottles quicklyConveyorsUnpacking by heatingProduction linePenicillin

The invention discloses an unpacking and bottle straightening production line for penicillin bottles. The unpacking and bottle straightening production line comprises an unpacking machine, a lifting conveyor and a bottle straightening machine. The unpacking and bottle straightening production line has the advantages that penicillin bottle groups can be unpacked on the unpacking machine and then can be conveyed onto the bottle straightening machine by the aid of the lifting conveyor, the penicillin bottles in a collecting hopper can be sorted by the bottle straightening machine by the aid of asorting device and then can be fed onto a bottle carrying frame, bottle insertion actions can be carried out by left and right insertion needles in movement in opposite directions, and then the penicillin bottles can be driven to rotate by 90-degree angles, can be supported by a right arc-shaped slide plate to stand up, then can fall into an output groove and can be pushed out by a bottle pushingmechanism; the penicillin bottle groups can be unpacked and then conveyed onto the bottle straightening machine by the unpacking and bottle straightening production line, the bottles can be sorted onthe bottle straightening machine, manual unpacking can be omitted, the bottles can be straightened without consideration on the orientation of openings of the penicillin bottles, and accordingly the efficiency of the integral unpacking and bottle straightening production line for the penicillin bottles can be improved.

Owner:HIT SMART FACTORY CO LTD

Heating apparatus, transportation unit, system and method for removing foodstuffs

InactiveUS20120281935A1Improved propertyProne to feverOpening closed containersBottle/container closureEngineeringMechanical engineering

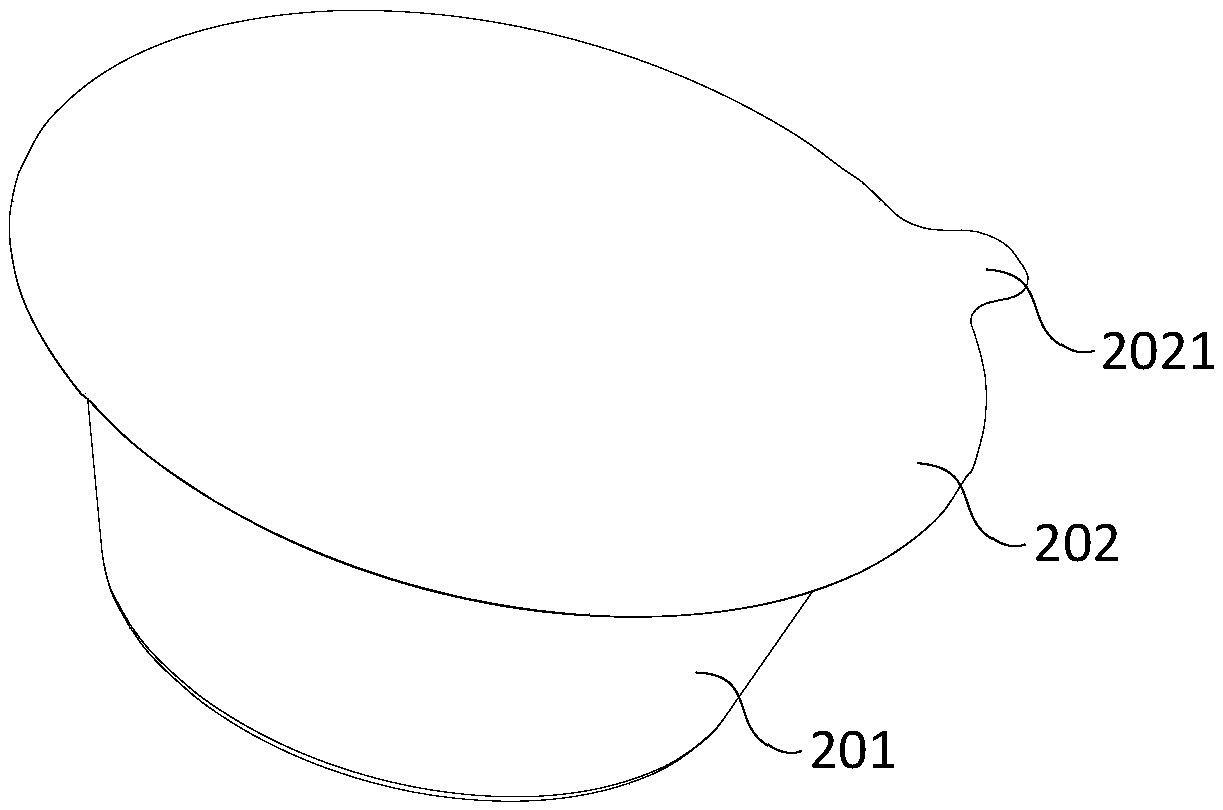

The invention relates to a transportation unit for transport of foodstuffs that are highly viscous or solid at ambient temperatures. The transportation unit comprises a first bag, a second bag arranged to fit into the first bag, and one or more hoist bands wrapped around the bottom side of the first bag and connected thereto. The first bag has an upper side and a bottom side, and is made from a woven fabric, preferably a woven polymer. Additionally, the first bag comprises a transfer opening for removing the foodstuffs from the transportation unit. The second bag comprises an opening for inserting and / or removing the foodstuffs. The second bag is capable of transporting more than 2000 kg of foodstuffs. The one or more hoist bands form loops above the upper side of the first bag.

Owner:AGRIDIENT

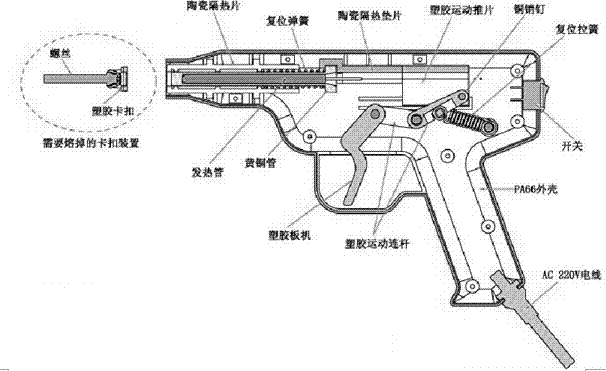

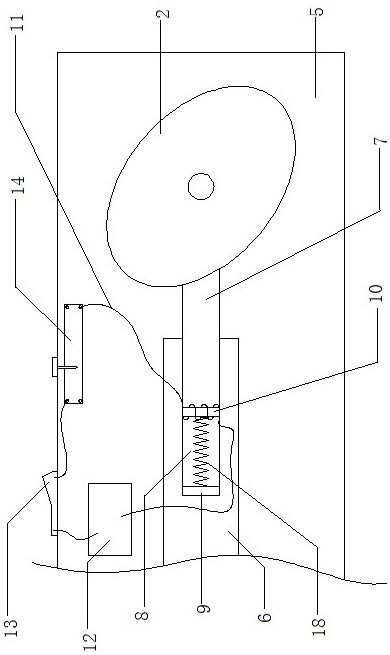

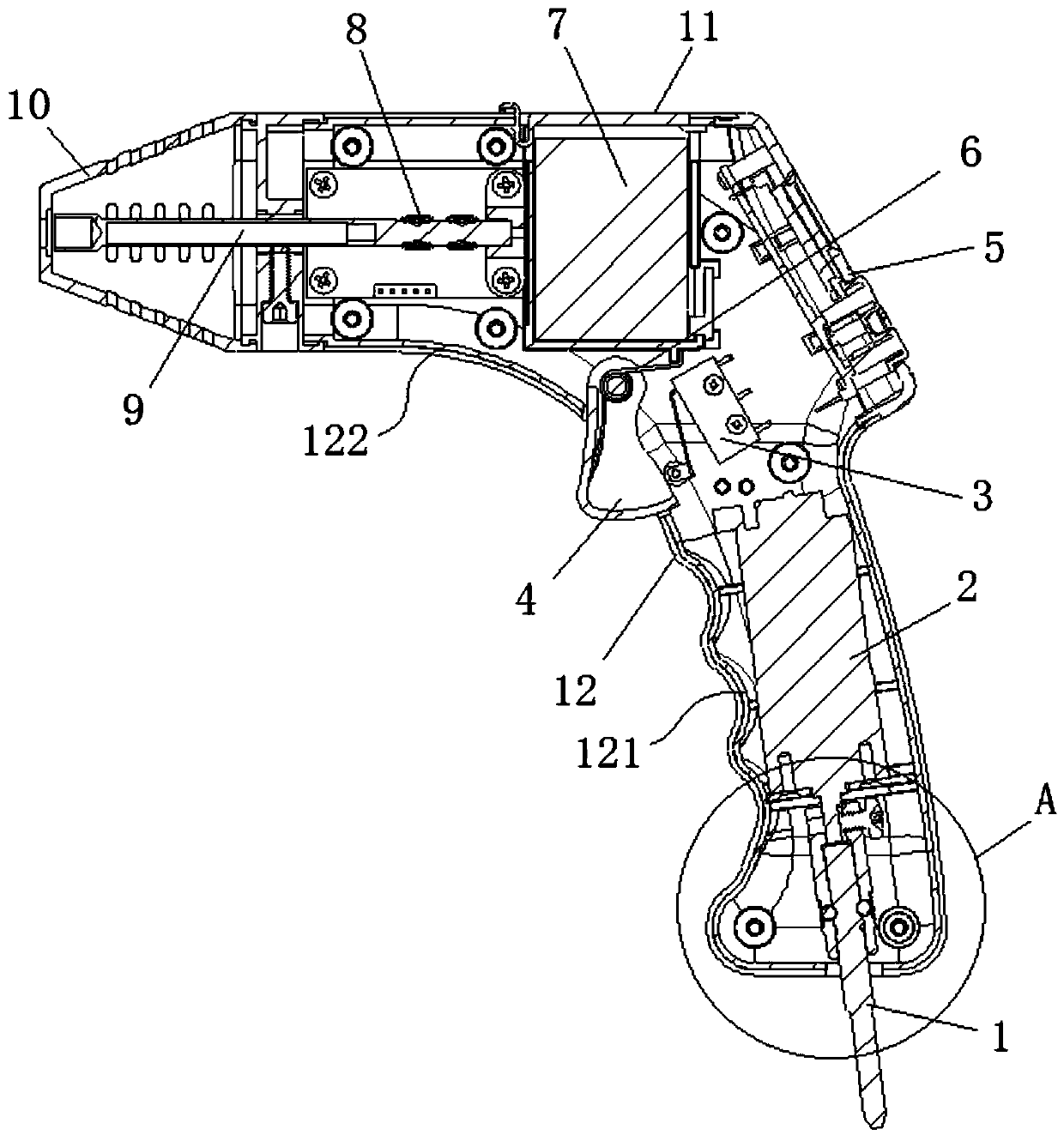

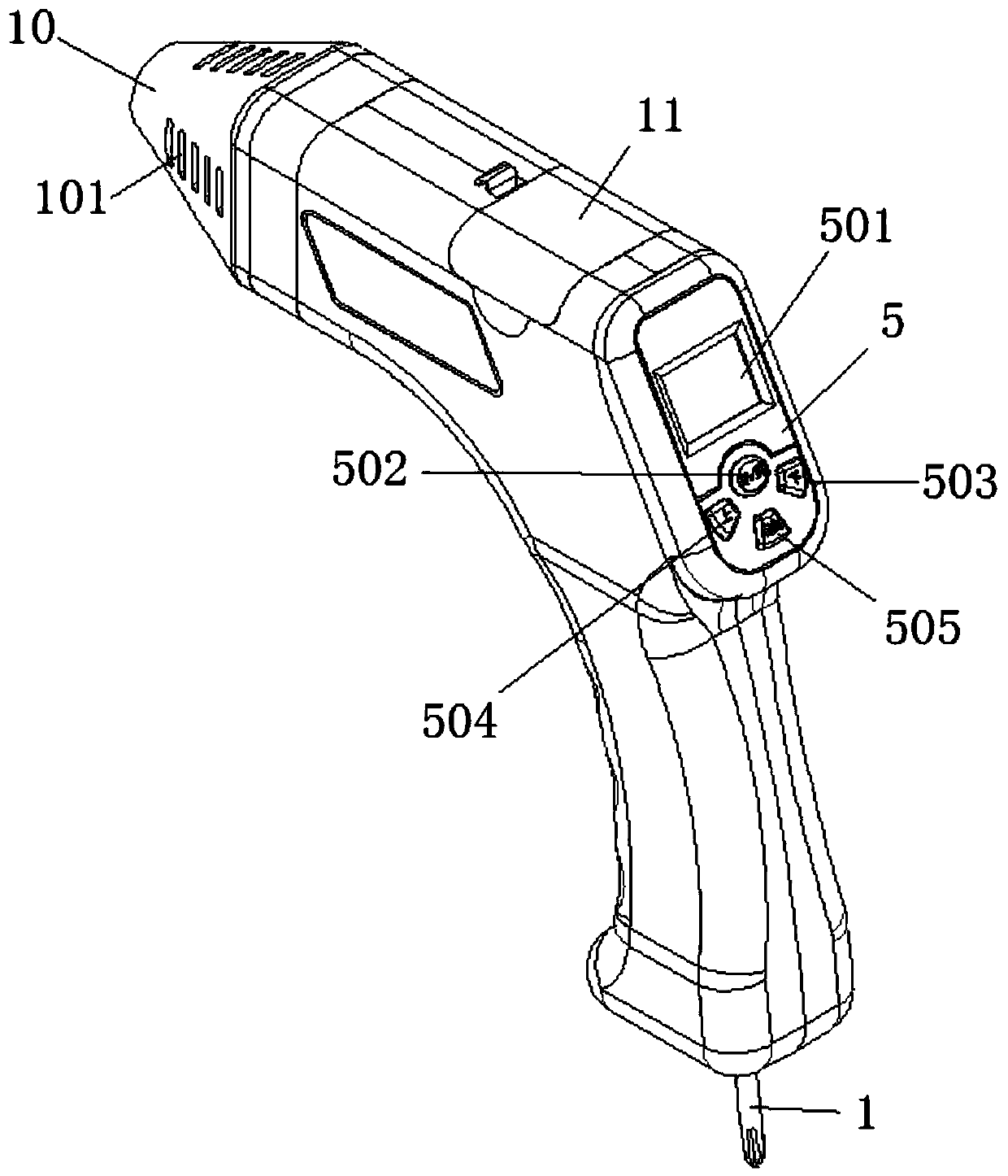

Snap joint type lead sealing electronic unsealing device

The invention relates to a snap joint type lead sealing electronic unsealing device. The snap joint type lead sealing electronic unsealing device comprises a gun body which is divided into a holding cavity, a gun barrel and a bore; a thermal insulation channel composed of ceramic thermal insulation sheets is arranged at the inner wall of the gun barrel, and a trigger is arranged on the communication side of the holding cavity and the bore and movably connected with a first connecting rod; and a second connecting rod is movably connected behind the first connecting rod, the back end of the second connecting rod is movably connected with a fixed shaft which is arranged on a sliding block, and a reset spring is connected to the middle portion of the second connecting rod. The sliding block slides left and right in a sliding way arranged in the bore, a thermal insulation connecting rod connected with a heating pipe is arranged on the front side of the sliding block, and the front end of the thermal insulation connecting rod and the back end of the heating pipe are connected in a clamped manner; and the heating pipe can stretch out and draw back along the thermal insulation channel, and the heating pipe is connected with a switch and an external power circuit. By means of the snap joint type lead sealing electronic unsealing device, a hot melting principle is adopted for melting a seal at a moment so as to achieve the unsealing effect, it can be guaranteed that unsealing operation is completed within three seconds, the snap joint type lead sealing electronic unsealing device is convenient and rapid, the unsealing efficiency is greatly improved, and the self structure of a watch is not damaged.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO URUMQI ELECTRIC POWER SUPPLY CO +1

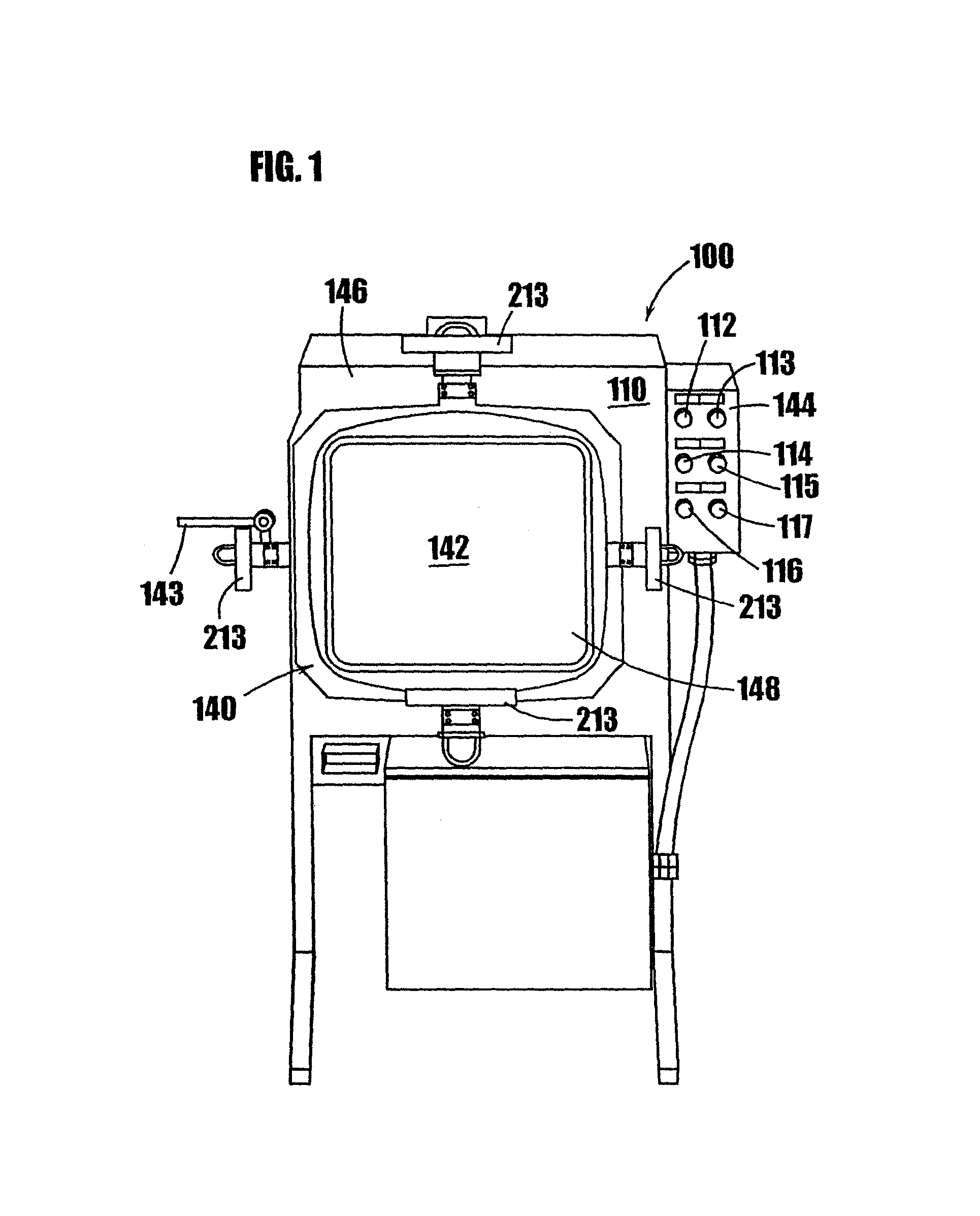

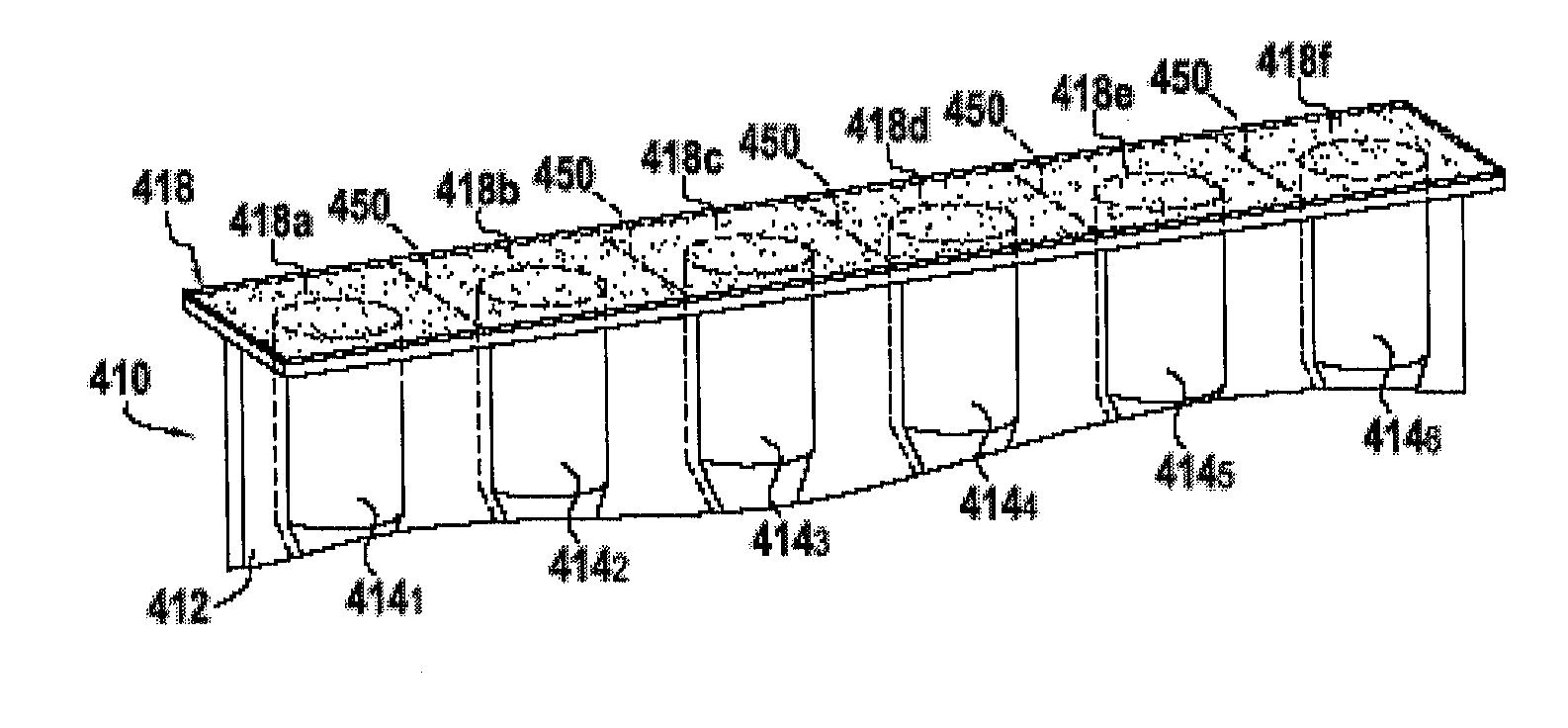

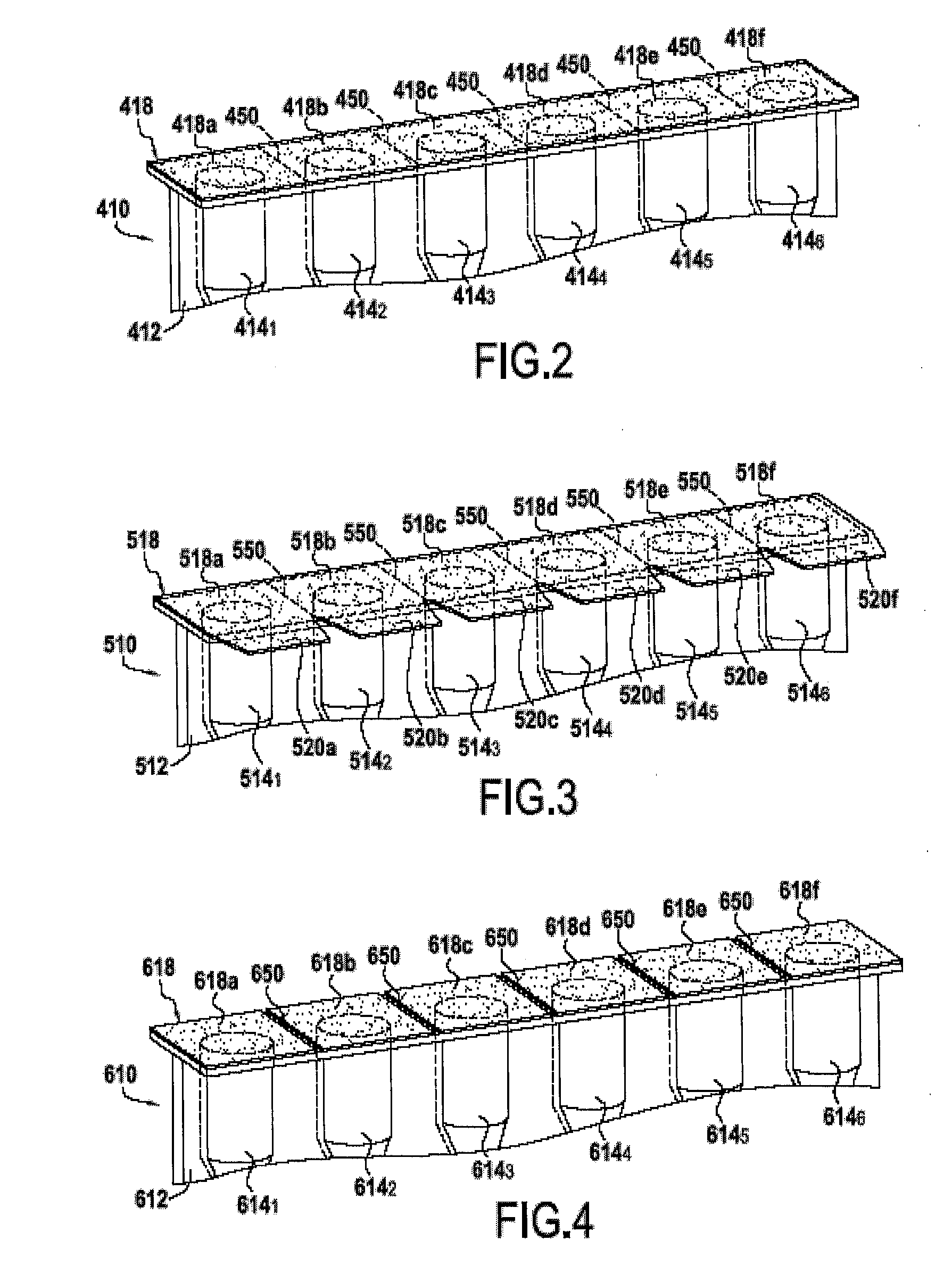

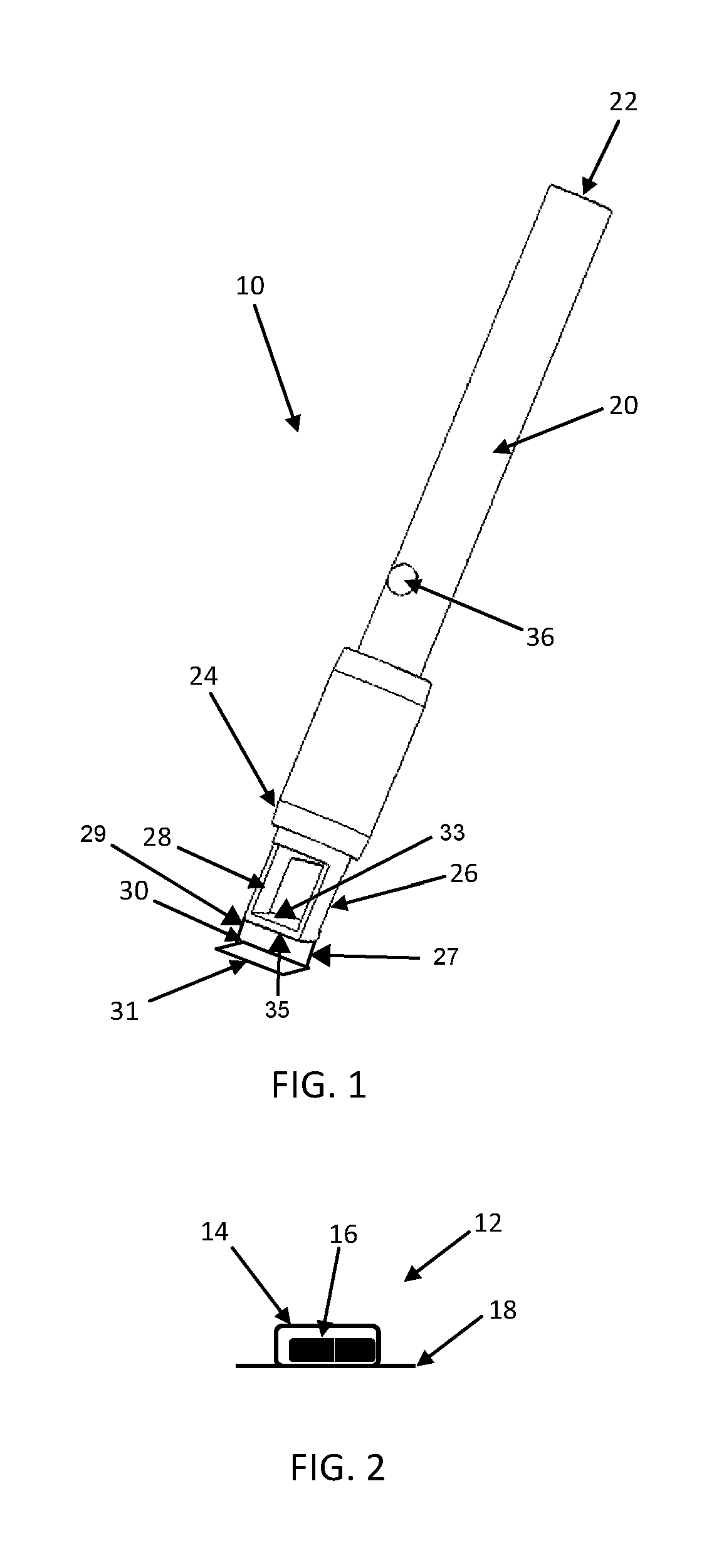

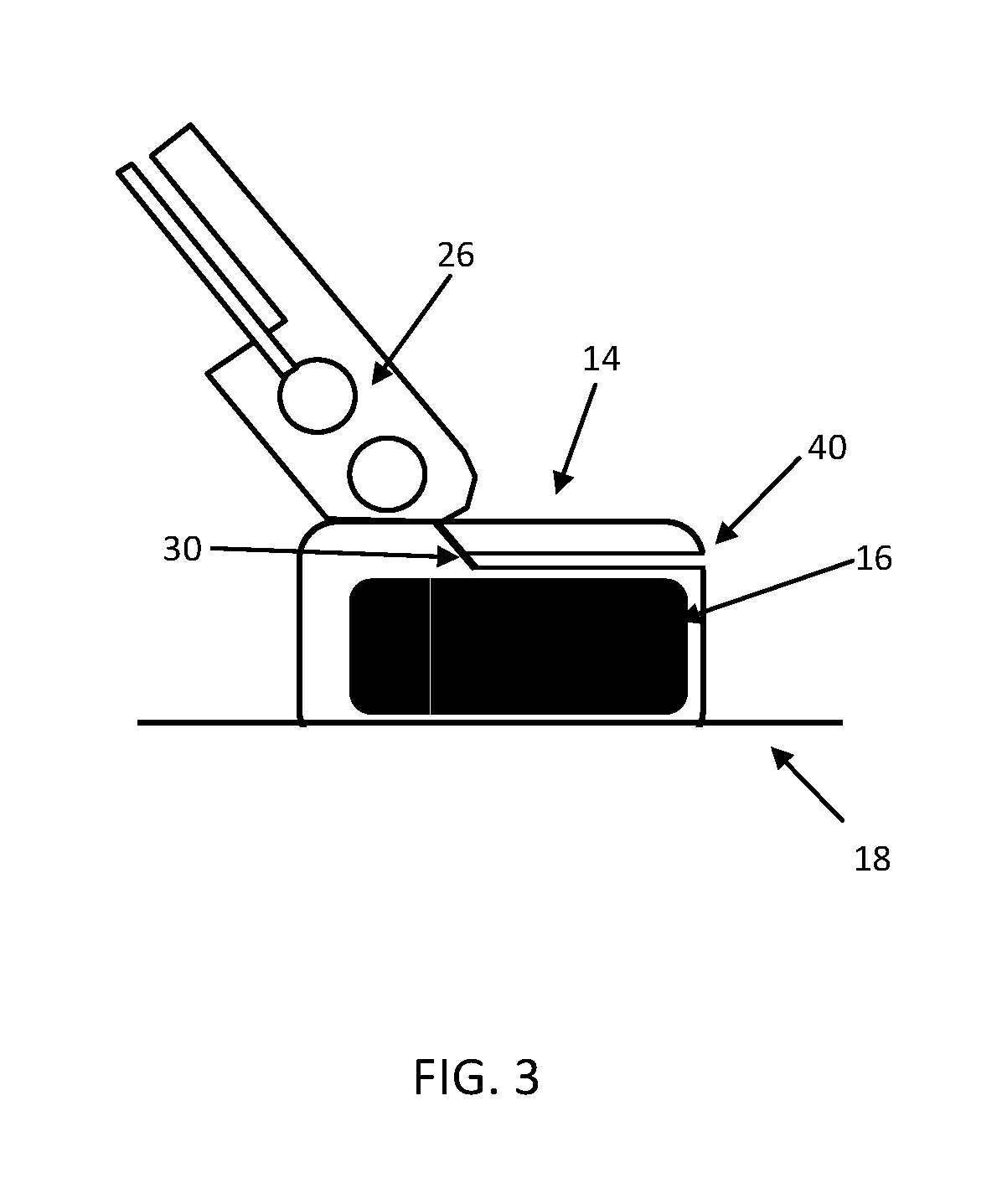

Blister pack opener device and method

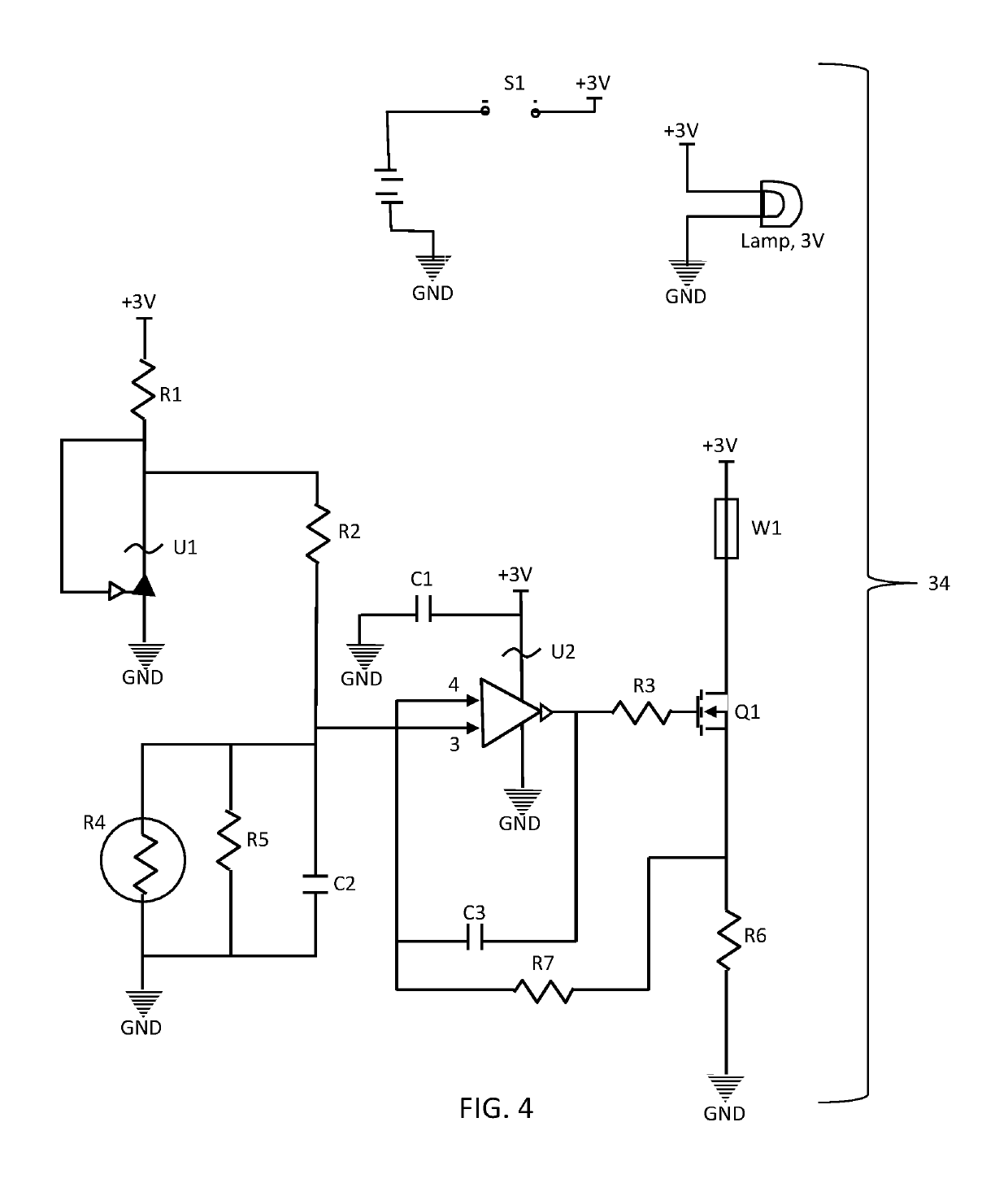

ActiveUS10266295B1Easy and safe and efficientNot harmful wasteMetal working apparatusUnpacking by heatingPower flowBlister pack

A device is provided for removing product items contained in a blister package having raised protrusions containing the product items and a protective membrane holding the items in the protrusions having a holder. The holder has a first and second end. The device has a first and second heating band post, at least one heating band, a power element, a power switch for supplying a power source to the power element, and electronic control circuitry for controlling current to the heating band.

Owner:KELLY EDMUND F

Battery manufacturing process, film tearing method and film tearing device

PendingCN113682586AReduce viscosityEasy to tear offFinal product manufactureElectrolyte accumulators manufactureEngineeringBattery cell

The invention discloses a battery manufacturing process, a film tearing method and a film tearing device. The film tearing method comprises the following steps that heating is carried out on a protective film with an initial adhesive force of 0.2-0.5 N / 25mm; a blowing device blows air to the starting edge of the protective film to blow up the protective film, and a first clamping device clamps the blown-up protective film; the first clamping device moves to separate the protective film from a first surface of a battery cell; a second clamping device clamps the protective film, and the first clamping device loosens the protective film; and the mechanical arm controls the battery cell to move upwards by a certain distance, the second clamping device moves to separate the protective film from a second surface of the battery cell, and then the protective film is conveyed to a waste box. According to the method, the initial adhesive force of the protective film is set in a specific range, so that the protective film does not fall off in the circulation process, the battery cell is protected from being damaged, and meanwhile, heating is carried out on the protective film before the film is torn, so that the viscosity of the protective film is reduced, the protective film is easier to tear off, and the film tearing rate is improved, and therefore the balance of initial viscosity and film tearing degumming is realized.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

Method for making paper adhesive seal lose efficacy in lossless manner

ActiveCN110217451ASimplified failure methodSave operating timeUnpacking by heatingAdhesivePulp and paper industry

The invention discloses a method for making a paper adhesive seal lose efficacy in a lossless manner. Firstly, the side, sealed with adhesive, of a paper adhesive seal end is infiltrated with an appropriate amount of water molecules equivalent to a paper material and thethickness, and except for the side sealed with adhesive, remaining portions are maintained in the original state; secondly, a paper adhesive seal end infiltrated position is shielded with a waterproof material, wherein the escaping amount of the water molecules into air in the microwave radiating process does not exceed 50%; and thirdly, a seal position is placed in the microwave environment, wherein the microwave frequency is 2.45 GHz to 7.5 GHz, the output power is 200 W-900 W, the acting time is 10seconds-60 seconds, andafter the shielding matter is removed, cure adhesive at the seal position is transformed to be ina wet glue state, the infiltrated side of the paper adhesive seal end is dried and free of deformation, and the paper adhesive seal can be opened in a lossless manner under the effect of the external force. Due to the method, an efficiency losing method of paper adhesive is effectively simplified, theoperation time is shortened, and controllability in the process is improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Automatic assembling machine for inlaid ceramic chips

InactiveCN113524111AImprove accuracyQuick degummingMetal-working hand toolsUnpacking by heatingComposite materialAutonomation

The invention provides an automatic assembling machine for inlaid ceramic chips. Theautomatic assembling machine comprises a ceramic chip peptizing and film tearing mechanism, a visual ceramic chip embedding mechanism, a substrate alternate material changing mechanism and a substrate laminating mechanism which are sequentially arranged along a working procedure, wherein the ceramic chip peptizing and film tearing mechanism is used for peptizing and tearing glue films on the back surfaces of ceramic chip slices, and feeding and supplying materials to the visual ceramic chip embedding mechanism; and the visual ceramic chip embedding mechanism is used for embedding the ceramic chip into the through hole of the PCB after the glue film of the ceramic chip is removed by the ceramic chip peptizing and film tearing mechanism, so that embedding of the ceramic chip is realized. Rapid dispergation and tearing of a glue film can be realized, the working efficiency is improved, and the requirements of an automatic production line are met; the sizes of the holes in the plate can be accurately recognized in a visual recognition mode, so that the accuracy of placing the ceramic chips is improved, manual discharging is converted into mechanical arm discharging, and the automation level and the production efficiency are improved.

Owner:苏州达文西自动化科技有限公司

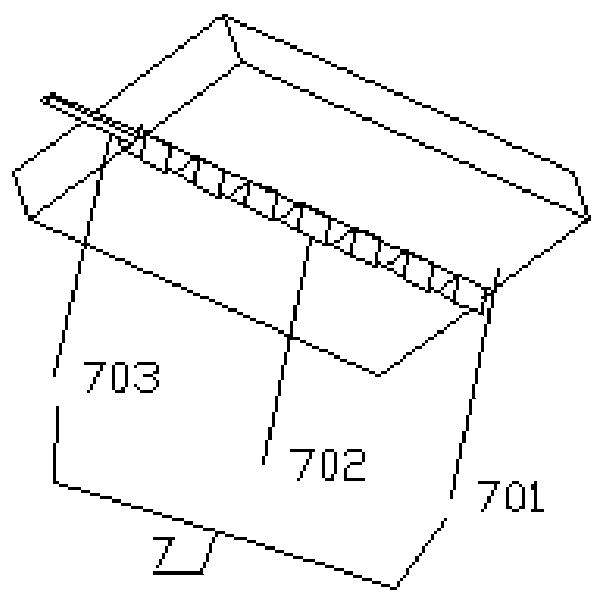

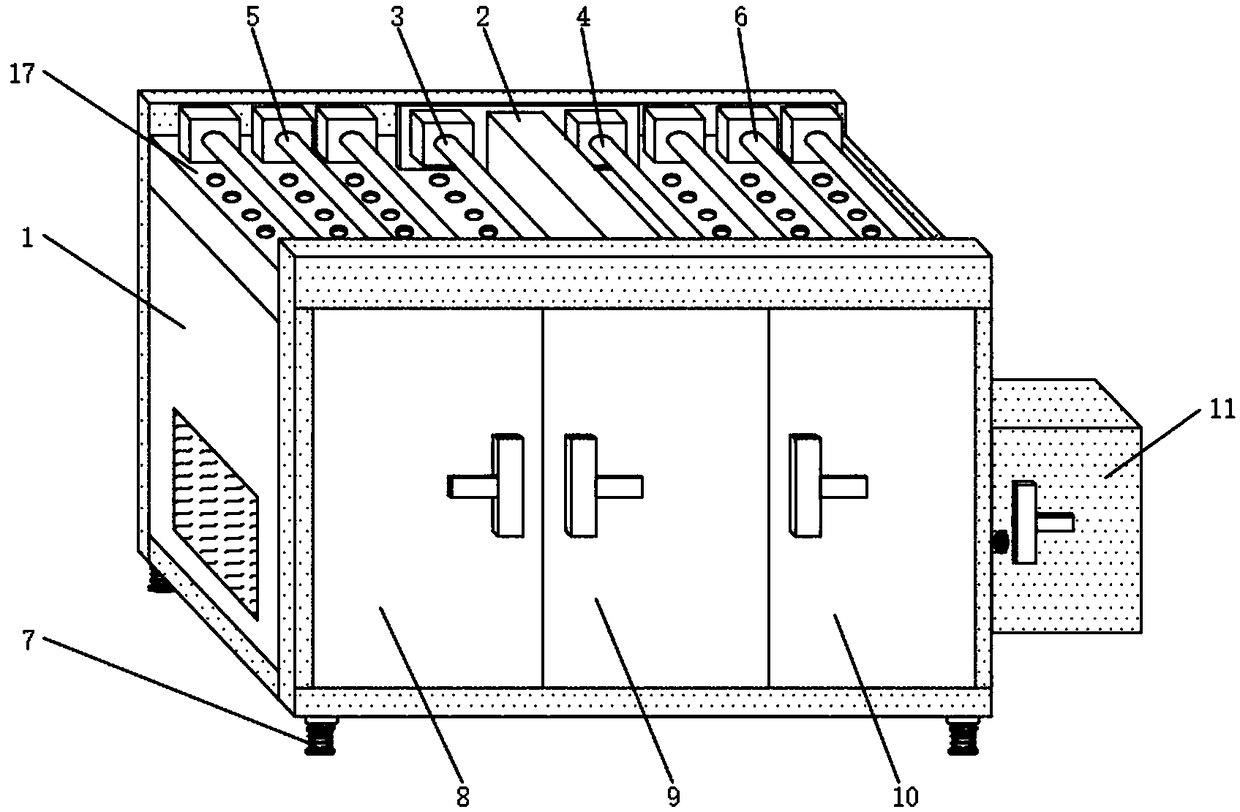

Sauce paste bag unwrapping machine

PendingCN108313437AImprove hygiene levelSteps to Reduce Human DistractionBags openingUnpacking by expelling contentsEngineeringElectric control

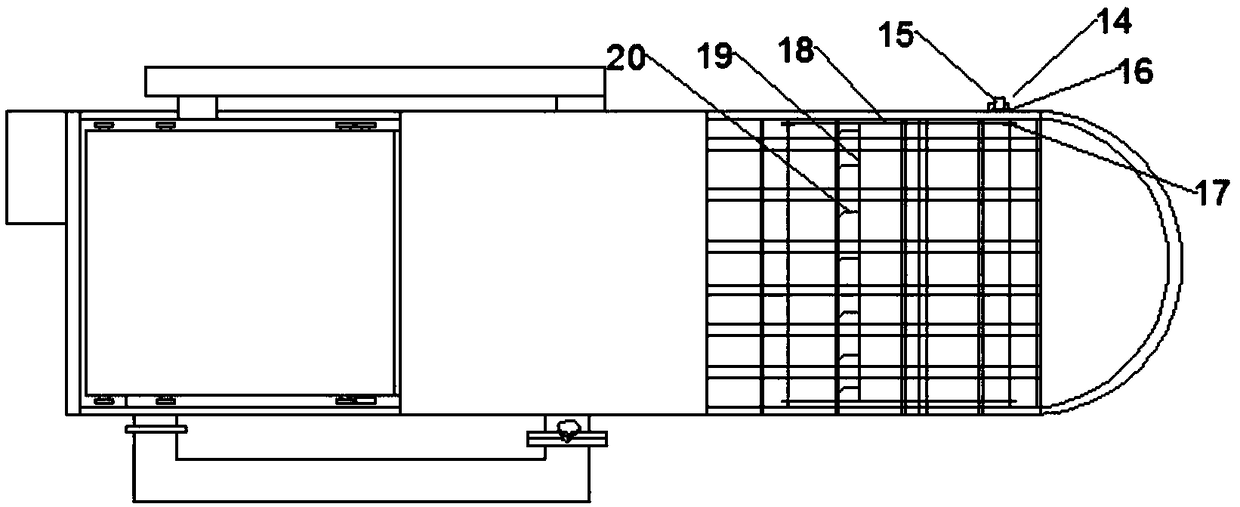

The invention provides a sauce paste bag unwrapping machine. The sauce paste bag unwrapping machine comprises a rack (1), an air blower (3), a power motor (4), conveyor belts, a heating tank (11), a bag discharge tail part (12) and a discharge tail part (13). An electric control cabinet (2) is mounted on the left side face of the rack (1) through bolts. The air blower (3) and the power motor (4) are mounted on the left side of the upper surface of the rack (1). The conveyor belts are mounted on the left side of the rack (1) through a conveyor belt support (5). The conveyor belts include the upper conveyor belt (6) and the lower conveyor belt (7) which are arranged on the conveyor belt support (5). The upper conveyor belt (6) rotates counterclockwise. The lower conveyor belt (7) rotates clockwise. Through cooperation and optimization of the structures, the sauce paste bag unwrapping machine achieves the satisfactory using effect of sauce paste in the process of unwrapping the sauce paste.

Owner:唐永清

Infusion bag cutting device

InactiveCN112718785ASmooth separation operationReduce labor intensitySolid waste disposalUnpacking by heatingEngineeringMechanical engineering

The invention provides an infusion bag cutting device. The infusion bag cutting device comprises a vertically-through shell used for containing an infusion bag, a pressure heating mechanism and a bag breaking mechanism, wherein the pressure heating mechanism and the bag breaking mechanism are installed at the bottom of the shell from top to bottom and used for extruding and softening the infusion bag and breaking the bag separately. When the infusion bag cutting device is used, the infusion bag is placed in the shell, liquid in the bag is pushed upwards through the pressure heating mechanism, meanwhile, the bottom of the bag is softened, at the same time, bag cutting operation is conducted through the bag breaking mechanism, and separation operation of the infusion bag and the liquid in the bag is smoothly completed; the operation of cutting bags by scissors clinically at present is avoided, so that the labor intensity is obviously reduced; parts of assemblies completely support automatic operation, full automation of the whole bag cutting operation is facilitated, and the bag cutting efficiency and quality are greatly improved.

Owner:朱玲

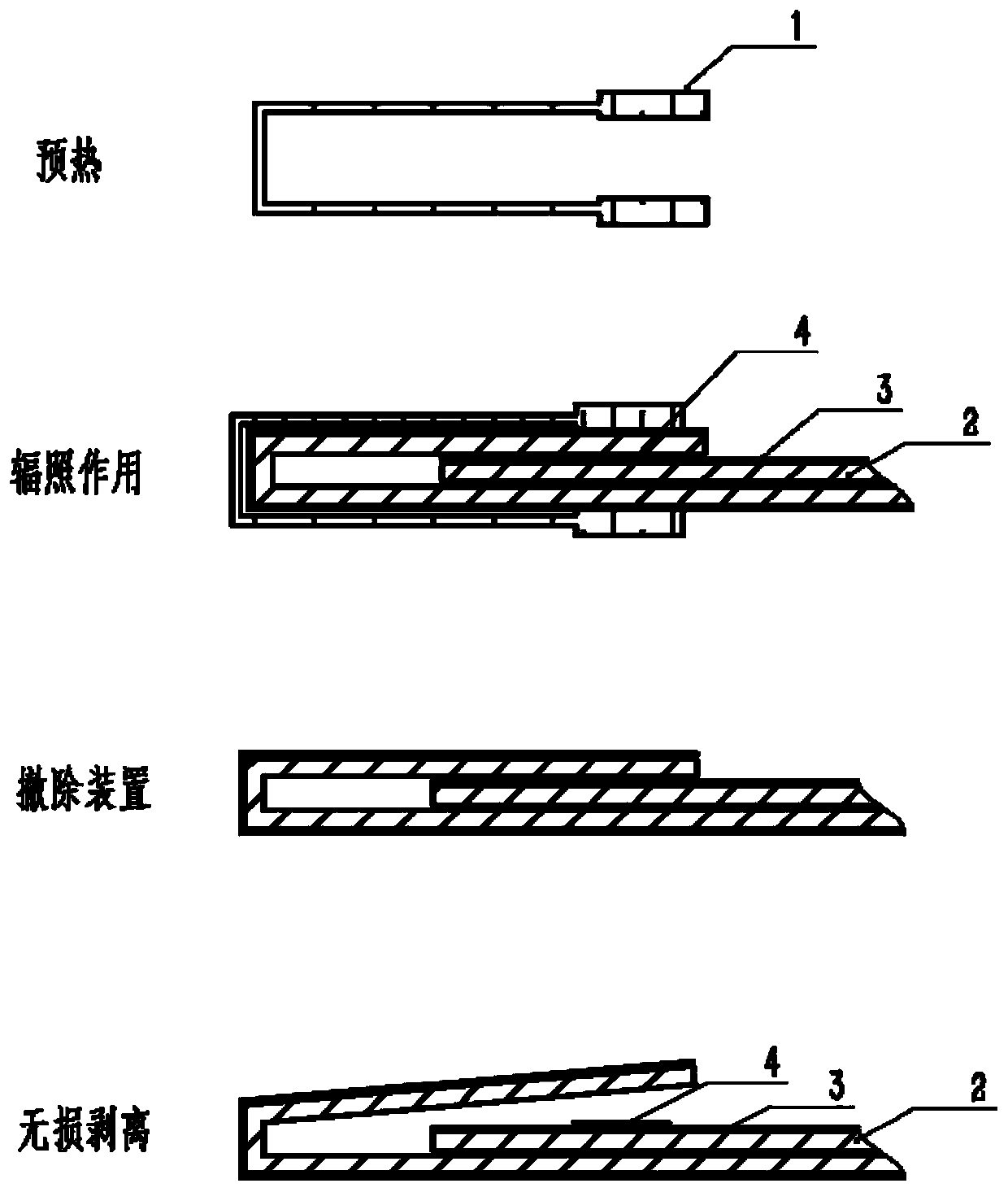

Method for making film-coated hard paper double-faced adhesive tape seal fail without damage

ActiveCN110920302ASimplified failure methodSave operating timeEnvelope openersUnpacking by heatingEngineeringElectromagnetic radiation

The invention discloses a method for making a film-coated hard paper double-faced adhesive tape seal fail without damage. The method comprises the steps: 1, preheating an acting area of an electromagnetic wave radiation device to 100 DEG C or above; 2, placing the seal in an electromagnetic wave radiation environment, wherein the outside of a parting action area is guaranteed not to be affected bya radiation area; 3, performing heat radiation at the position, close to the glue, of the seal, wherein the temperature of the far glue does not exceed 60% of the irradiation temperature; 4, acting for a certain period of time B under the conditions that the electromagnetic radiation wavelength is 4-18 microns, the output power is 200-900W and the clamping temperature of the radiation device is 100-150 DEG C, removing electromagnetic wave radiation, and then uncovering the seal. The method provided by the invention effectively simplifies the method for making the film-coated hard paper doublefaced adhesive tape fail, shortens the operation time, and improves the controllability of the process.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

A carton unpacking device

ActiveCN109367933BImprove work efficiencyImprove abilitiesUnpacking by heatingUnpacking by cuttingAdhesive beltCarton

The invention discloses a carton opening device, and belongs to the field of carton processing equipment. A feeding sliding plate is fixed above a base, an air pressure cylinder is vertically positioned right above a conveying belt, the carton opening device is installed at the bottom of an air pressure cylinder main shaft, a discharging sliding plate is fixed at the top of a third support, a first motor is fixed at the right end of a motor base, the conveying belt is wound between a first roller and a second roller, a controller is installed in front of the motor base, a positive displacementdevice is fixed below the conveying belt, a second motor is fixed at the left end of the motor base, and a second ultrasonic sensor is fixed above the carton opening device. According to the carton opening device, the conveying belt drives the carton to advance, the height and position information of the carton are detected through the ultrasonic sensor, the direction of the carton adhesive tapewhich is corrected by a positive position device is consistent with the advancing direction of the conveying belt, the carton opening device is used for cutting off the adhesive tape around the cartonto finish the carton opening operation, so that the manual labor is reduced, and the production efficiency is improved.

Owner:台州舒倍康医疗科技有限公司

Shell disassembling method and shell disassembling equipment for hard cigarette packet

PendingCN114644159AReduce labor costsRealize intelligent manufacturingUnpacking by heatingEngineeringMechanical engineering

Owner:云南烟草机械有限责任公司 +1

An automatic unpacking machine for vials

ActiveCN108190159BAutomate unpackingImprove unpacking efficiencyUnpacking by heatingPenicillinStructural engineering

Owner:HIT SMART FACTORY CO LTD

Clip type sealing electronic unsealer

InactiveCN111332561AImprove work efficiencyEasy to operateUnpacking by heatingElectrical batteryElectric machine

The invention relates to a maintenance auxiliary tool, in particular to a clip type sealing electronic unsealer. The clip type sealing electronic unsealer comprises a housing, a battery, an electric heating rod, a motor and a screwdriver, wherein both the battery and the motor are arranged in the housing; the electric heating rod is arranged at the front end of the housing and is powered by the battery to heat; a mounting sleeve is arranged on the output shaft of the motor; the lower end of the housing is provided with a through hole; the tail end of the screwdriver extends into the housing from the through hole, and is inserted into the mounting sleeve; a trigger is arranged on the housing; a control circuit board and a travel switch are arranged in the housing; the travel switch is trigged through rotation of the trigger; the motor is controlled to start and stop through the travel switch; and an operation panel is arranged at the rear end of the housing. The clip type sealing electronic unsealer can realize clipping, sealing and melting damages, and automatically mounting and dismounting screws, is simple and convenient to operate, and greatly improves working efficiency.

Owner:陕西正坤锁业有限公司

Shell disassembling method and shell disassembling equipment for soft cigarette packet

PendingCN114644160ANon-destructive disassemblyInternal packaging quality inspectionUnpacking by heatingEngineeringMechanical engineering

The invention relates to a shell disassembling method and shell disassembling equipment for a soft cigarette packet. The shell disassembling method for the soft cigarette packet comprises the following steps that a top edge heating device and a bottom edge heating device are used for heating a top edge floret bonding surface and a bottom edge bonding surface of the soft cigarette packet, so that bonding glue is softened; a bottom edge unfolding mechanism and a top edge unfolding mechanism are used for unfolding the top edge floret bonding surface and the bottom edge bonding surface; a side edge heating device is used for heating the side edge bonding surface of the soft cigarette packet, so that the bonding glue is softened; unfolding the side edge bonding surface by using a side edge unfolding mechanism; and a large-area unfolding mechanism is used for unfolding the packaging shell, and shell disassembly is completed. The device has the beneficial effects that the heating device is used for heating and softening the mucilage glue, so that the cigarette packet can be disassembled without damage.

Owner:云南烟草机械有限责任公司 +1

Automobile instrument curved glass cover plate film tearing equipment

ActiveCN112173324AWith preheating functionThe film tearing process is convenient and quickLamination ancillary operationsLaminationGlass coverStructural engineering

The invention discloses automobile instrument curved glass cover plate film tearing equipment, and belongs to the field of automobiles. The film tearing equipment comprises a preheating device, a filmtearing device and a collecting device, the preheating device and the collecting device are fixedly installed on the two sides of the film tearing device correspondingly, a film inlet is formed in the top of the film tearing device, and a film pulling device is arranged in the film tearing device. The research and development purpose of the film tearing equipment is to solve the problem about removing a protective film on the surface of an instrument glass cover plate of a plane or curved surface automobile, the equipment has a preheating function, the protective film on the surface of the instrument glass cover plate of the automobile can be softened, and the film tearing process is more convenient and faster; and a standard film tearing work flow is set, unnecessary collision and abrasion in the film tearing process are avoided, the installation difficulty is lowered, the installation risk is weakened, the work efficiency is improved, the structure is simple, the design is ingenious, disassembly and assembly are convenient, assembly is firm, and the equipment is suitable for application and popularization.

Owner:HEILONGJIANG TIANYOUWEI ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com