Patents

Literature

105results about How to "Improve tearing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

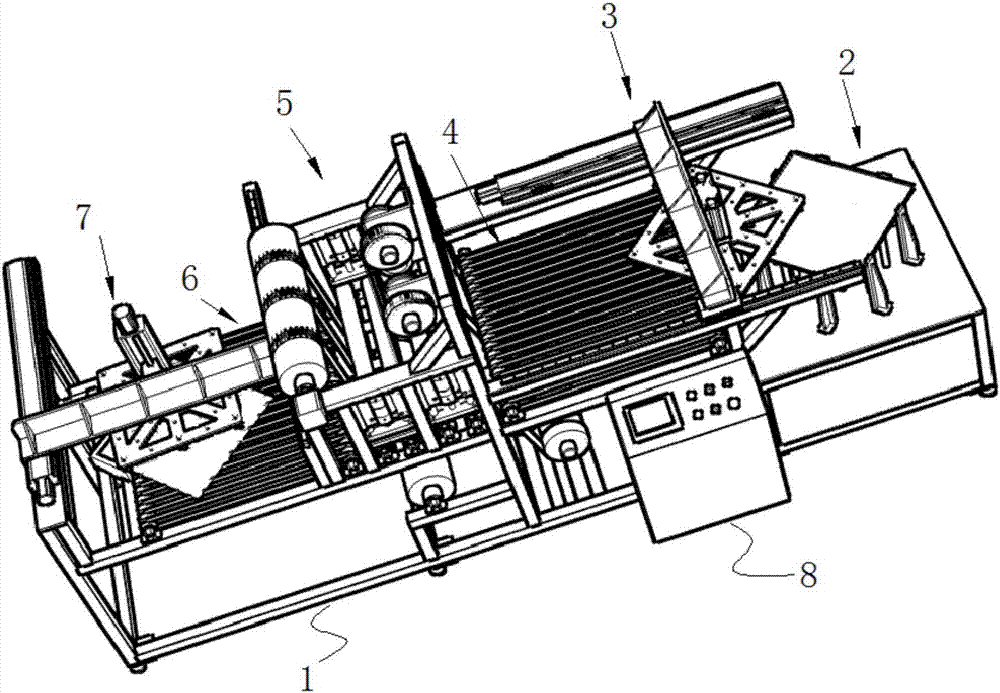

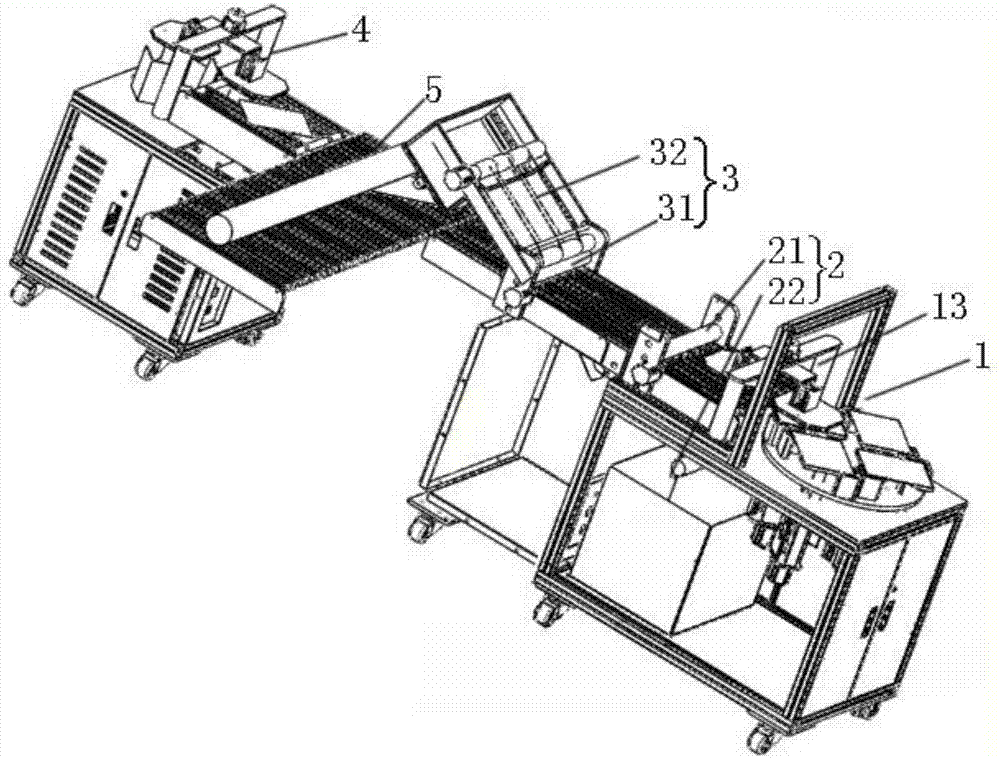

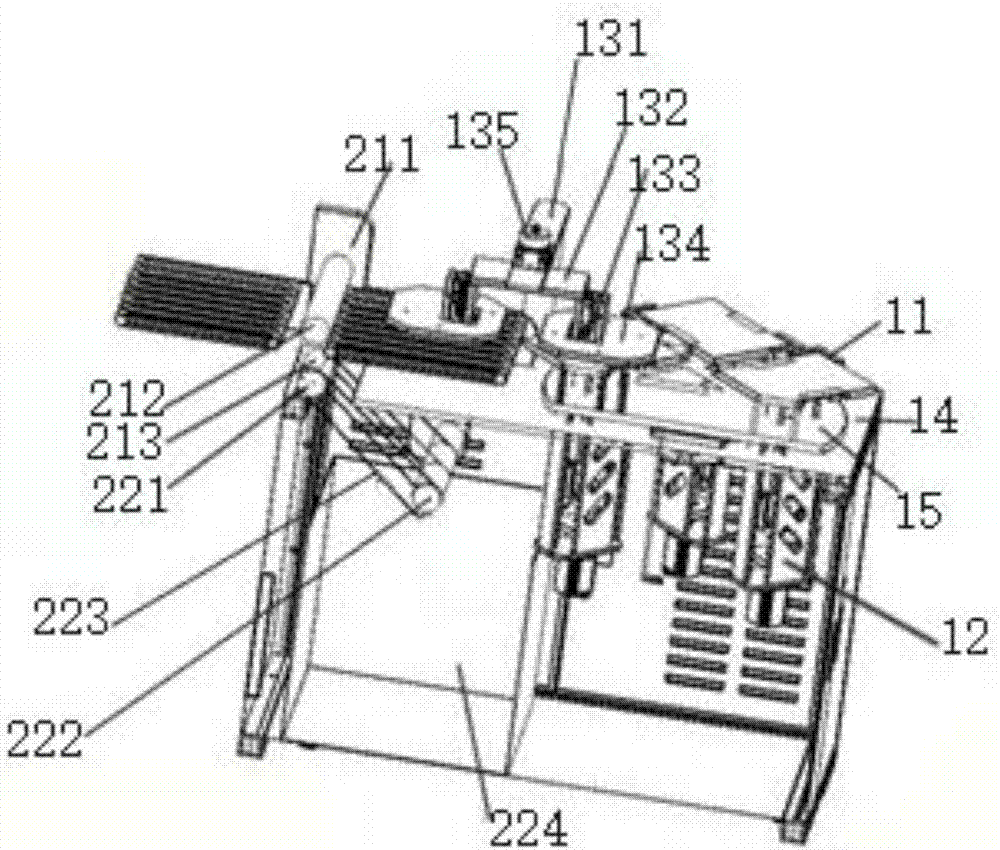

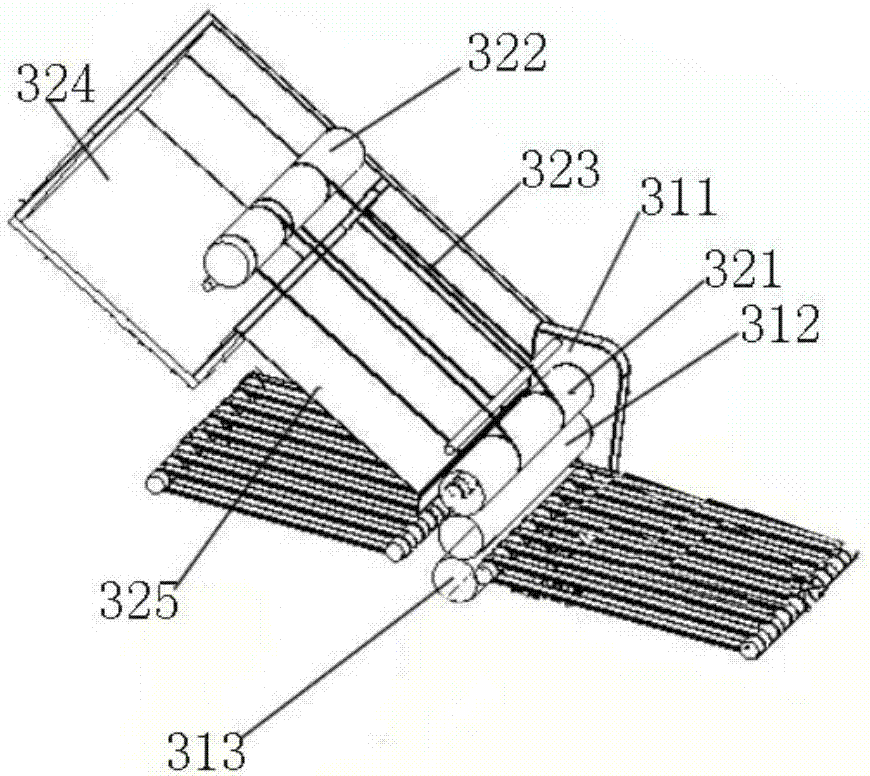

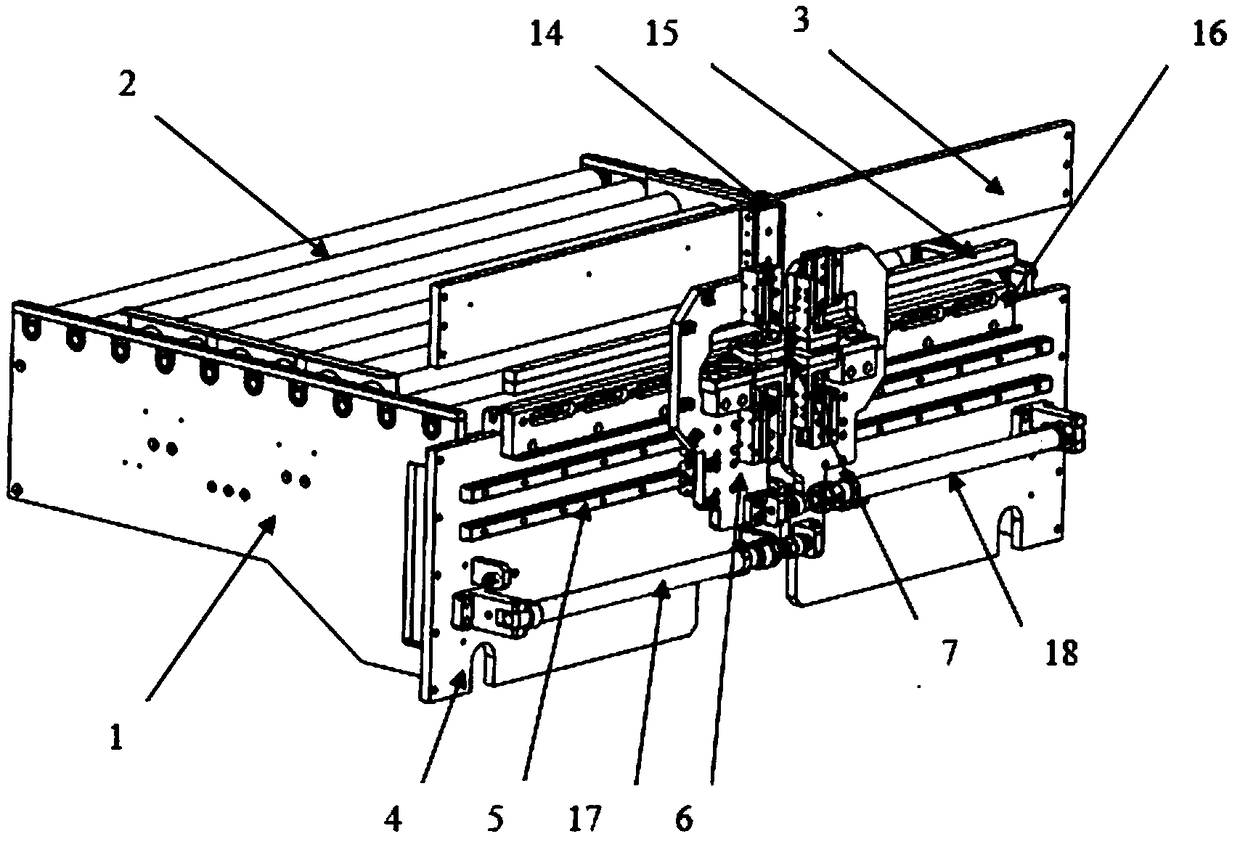

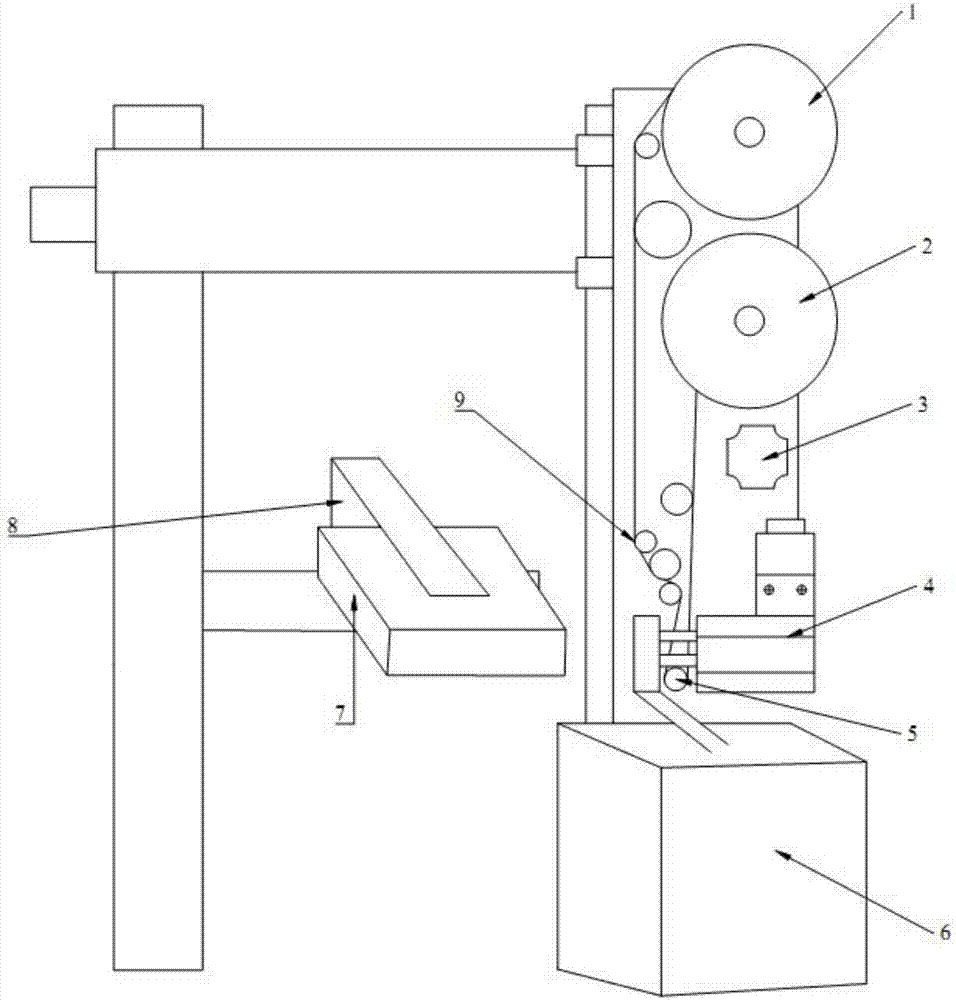

Full-automatic film tearing machine

InactiveCN105129170AAvoid confusionAvoid stickingBinding material removalTectorial membraneConductive rubber

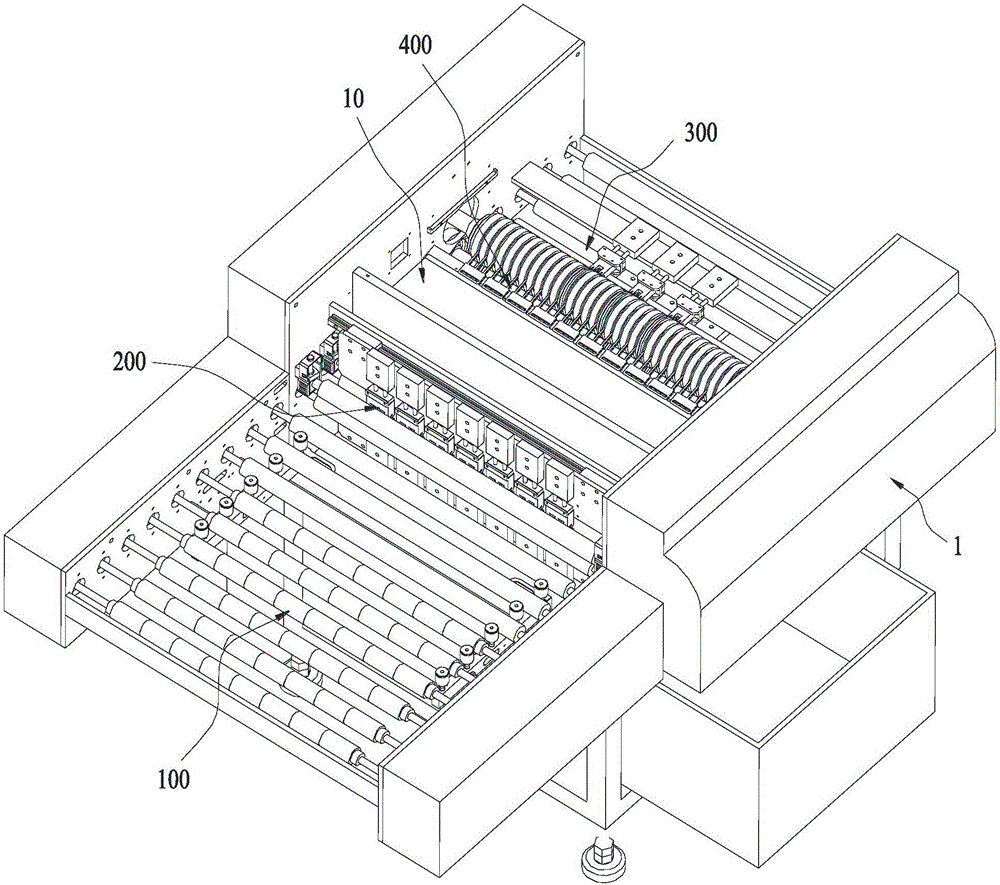

The invention discloses a full-automatic film tearing machine which comprises a support, a conveying mechanism, a film lifting mechanism, a conductive rubber covered roller mechanism, a collection board and a comb-shaped film separation mechanism. The conveying mechanism is used for conveying a PCB with film protective films bonded to the two faces; the film lifting mechanism is installed on the support, used for lifting the edges of the film protective films and provided with a first gap where the PCB penetrates; the conductive rubber covered roller mechanism is pivoted to the support, used for bonding and winding the film protective films, located behind the film lifting mechanism in the conveying direction of the PCB and provided with a second gap where the PCB penetrates; the collection board is used for stacking and collecting the film protective films and fixed to the portion, between the conductive rubber covered roller mechanism and the film lifting mechanism, of the support; and the comb-shaped film separation mechanism is installed on the collection board, used for separating the film protective films wound around the conductive rubber covered roller mechanism and located between the collection board and the conductive rubber covered roller mechanism. By the adoption of the full-automatic film tearing machine, the film protective films on the two faces of the PCB can be automatically torn away, the torn-away film protective films can be stably stacked and collected in order layer by layer, and the film tear-away success rate is increased.

Owner:SHENZHEN YONGNENG MACHINERY

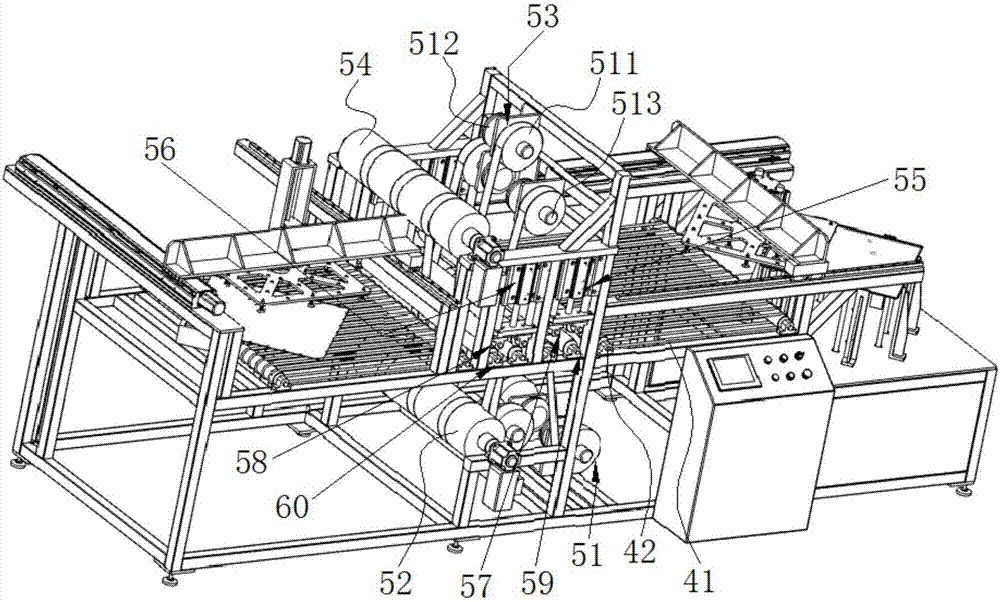

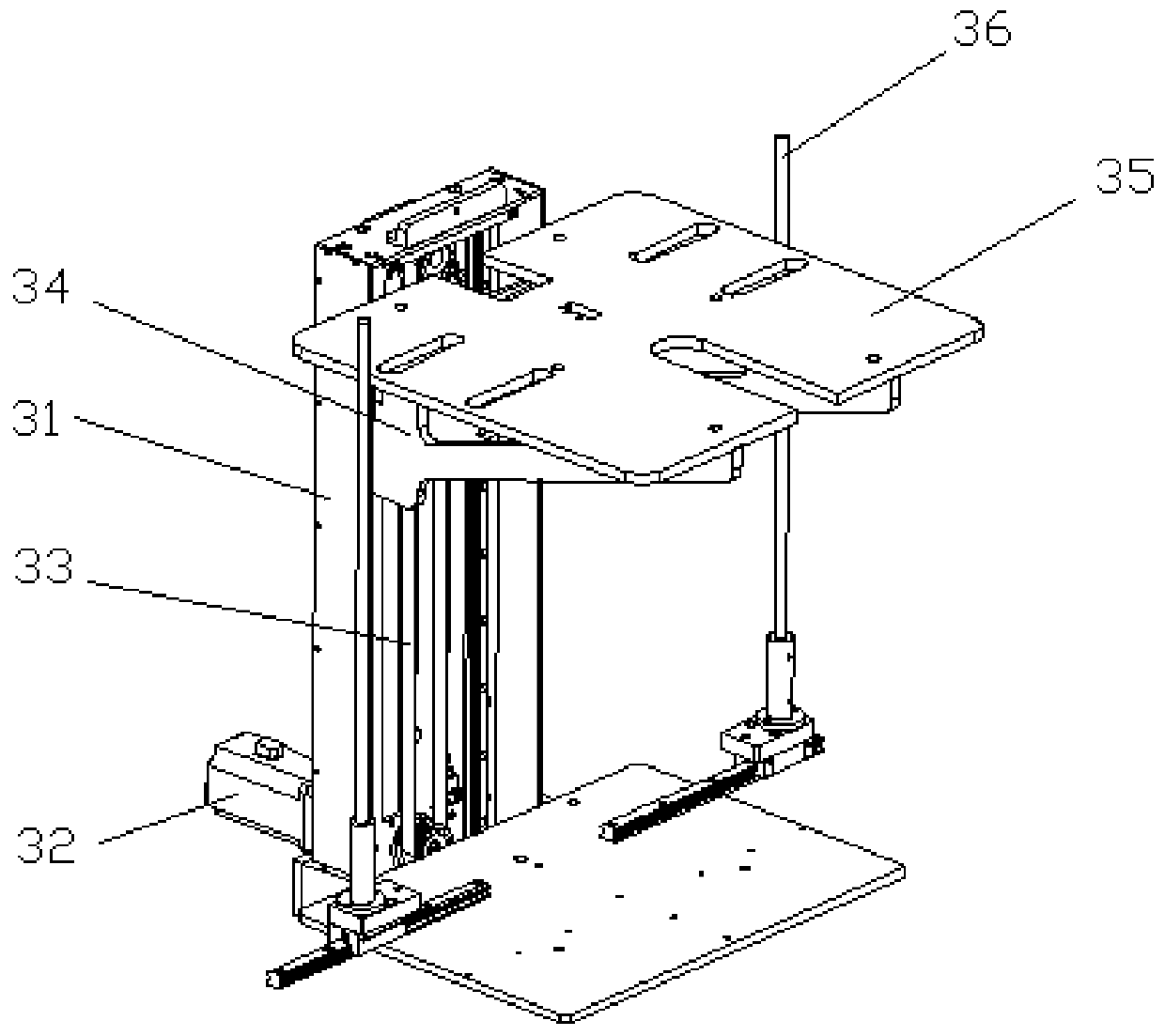

Full-automatic backlight plate assembly device

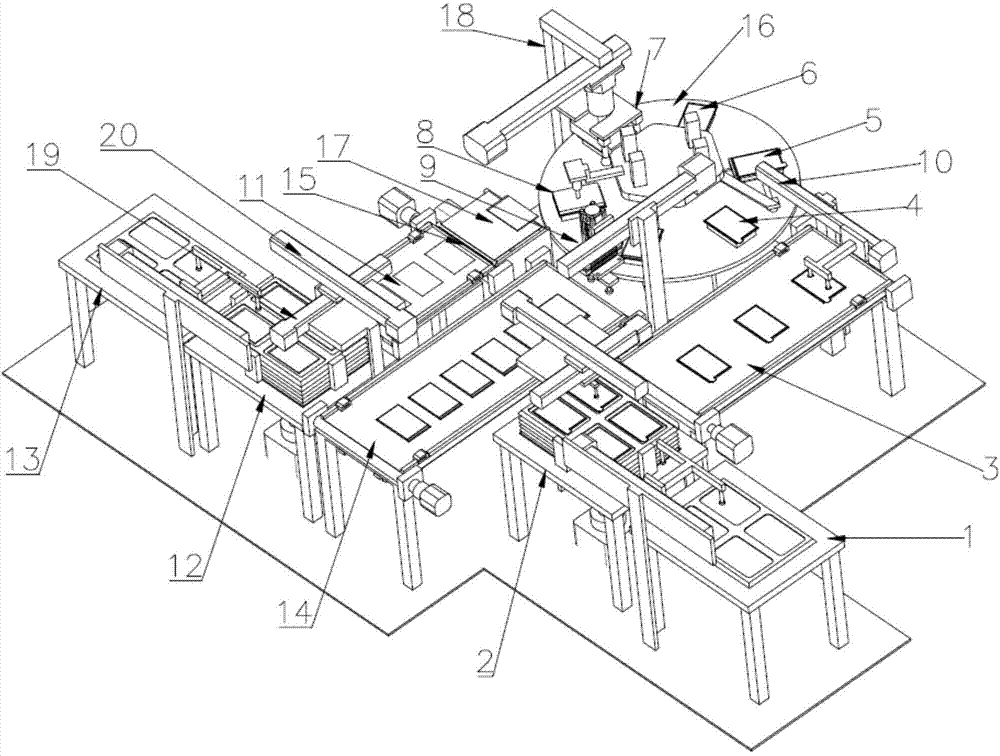

ActiveCN103529585AFully automatedImprove efficiencyNon-linear opticsCircular discLiquid-crystal display

The invention relates to a full-automatic backlight plate assembly device which comprises a backlight plate feeding system, a liquid crystal display panel feeding system, a fitting system, a finished product output system and a carrying device. The carrying device is used for carrying backlight plates supplied by the backlight plate feeding system and liquid crystal display panels supplied by the liquid crystal display panel feeding system to the fitting system and carrying finished products fitted by the fitting system to the finished product output system, the fitting system comprises a disc, and a backlight plate holding area, a backlight plate film tearing area, a backlight plate dust removing area, an alignment fitting area, a pressure compensating area and a finished product output area are sequentially arranged on the disc. By the aid of the backlight plate assembly device, specific operation processes of various procedures and carrying and transfer for connecting the various procedures realize full automation from feeding and fitting to outputting of the finished products, so that efficiency is improved, and cost is reduced.

Owner:SANKYO PRECISION HUIZHOU

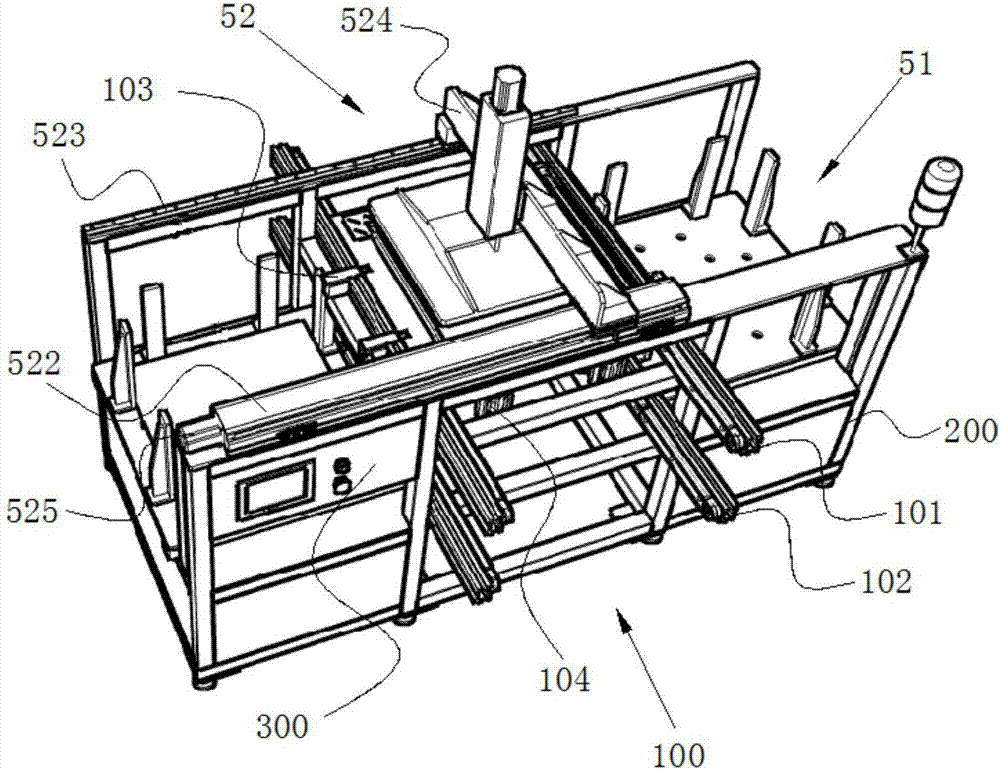

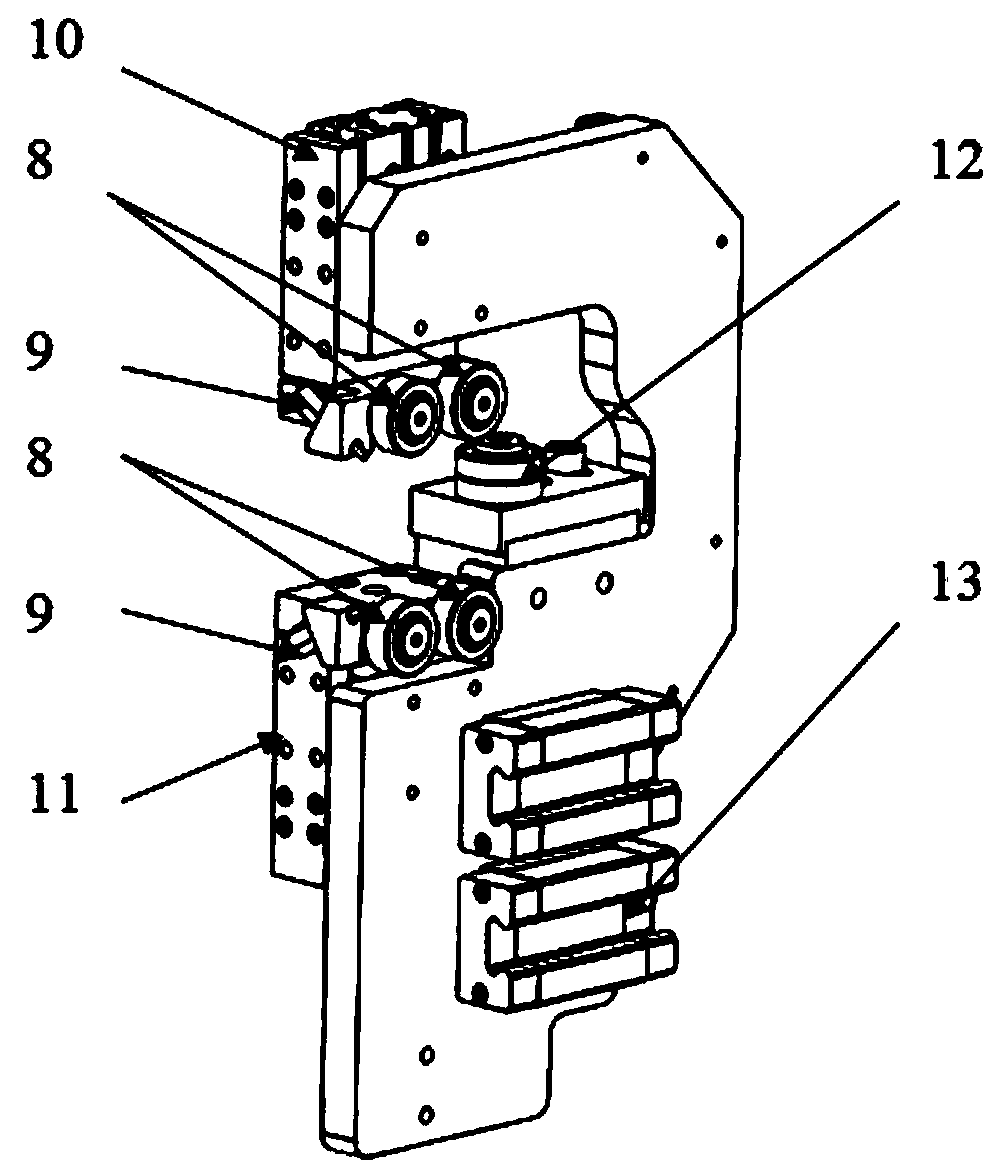

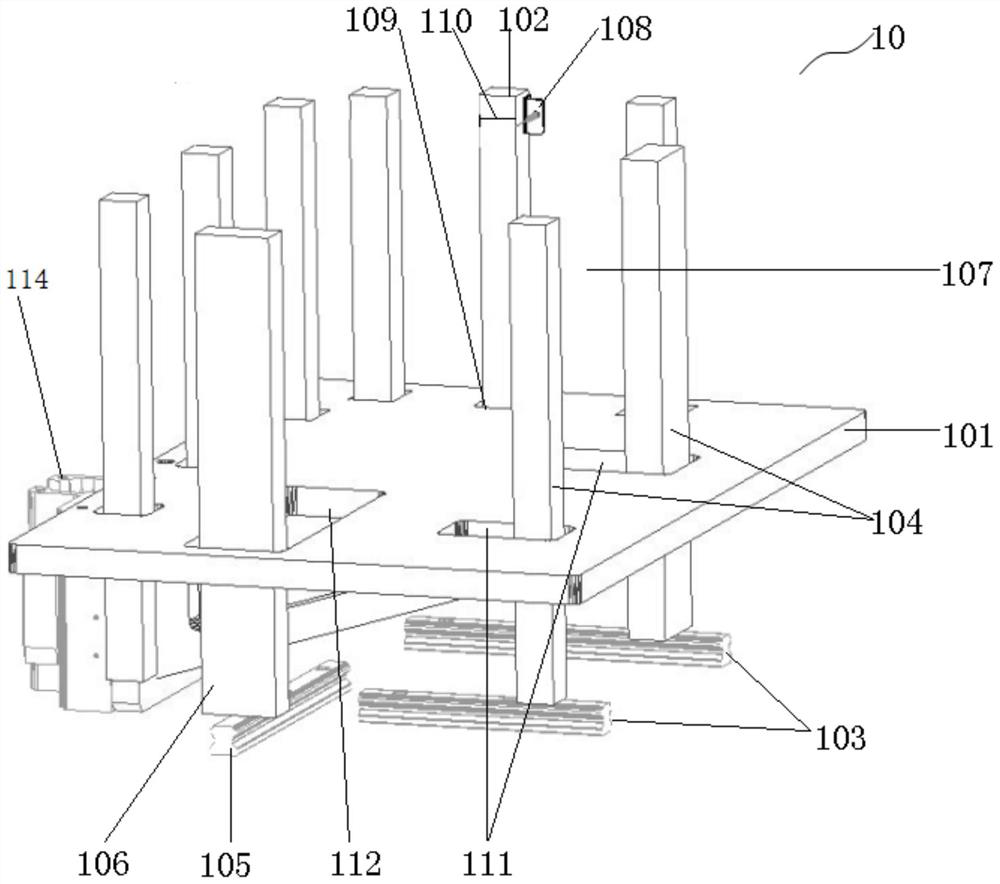

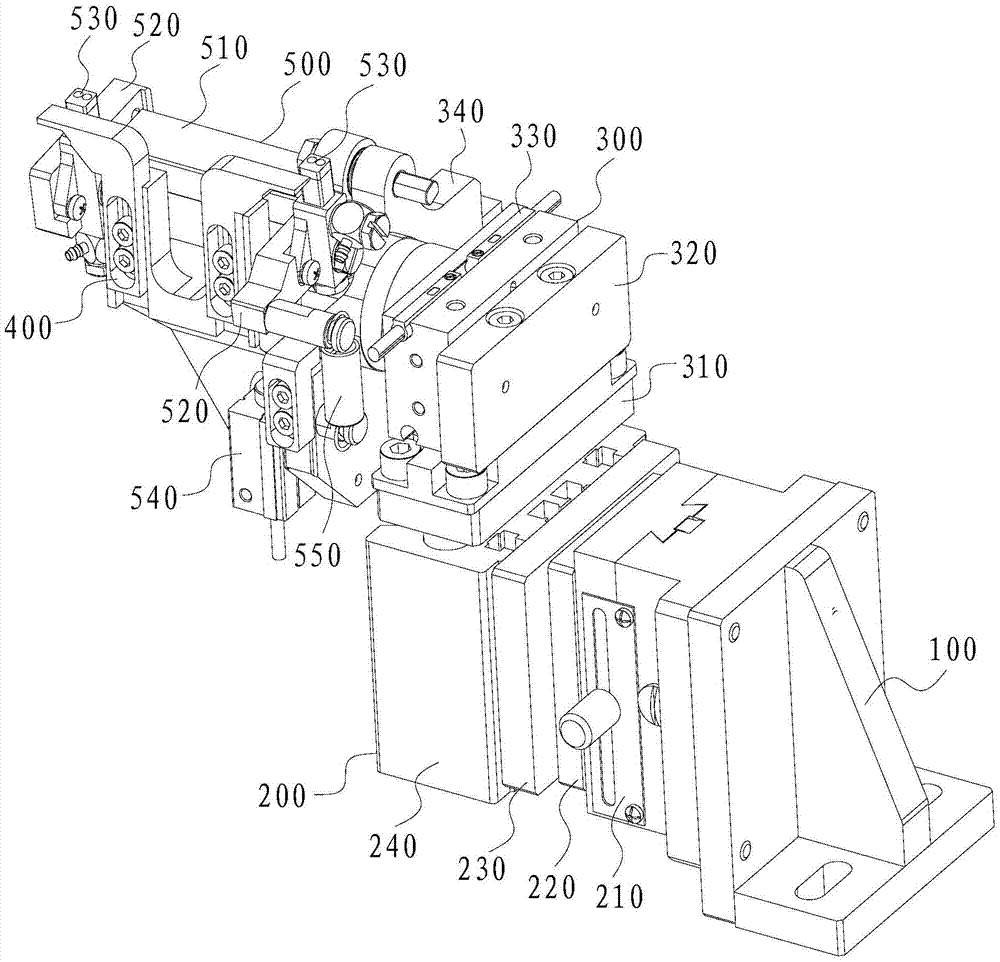

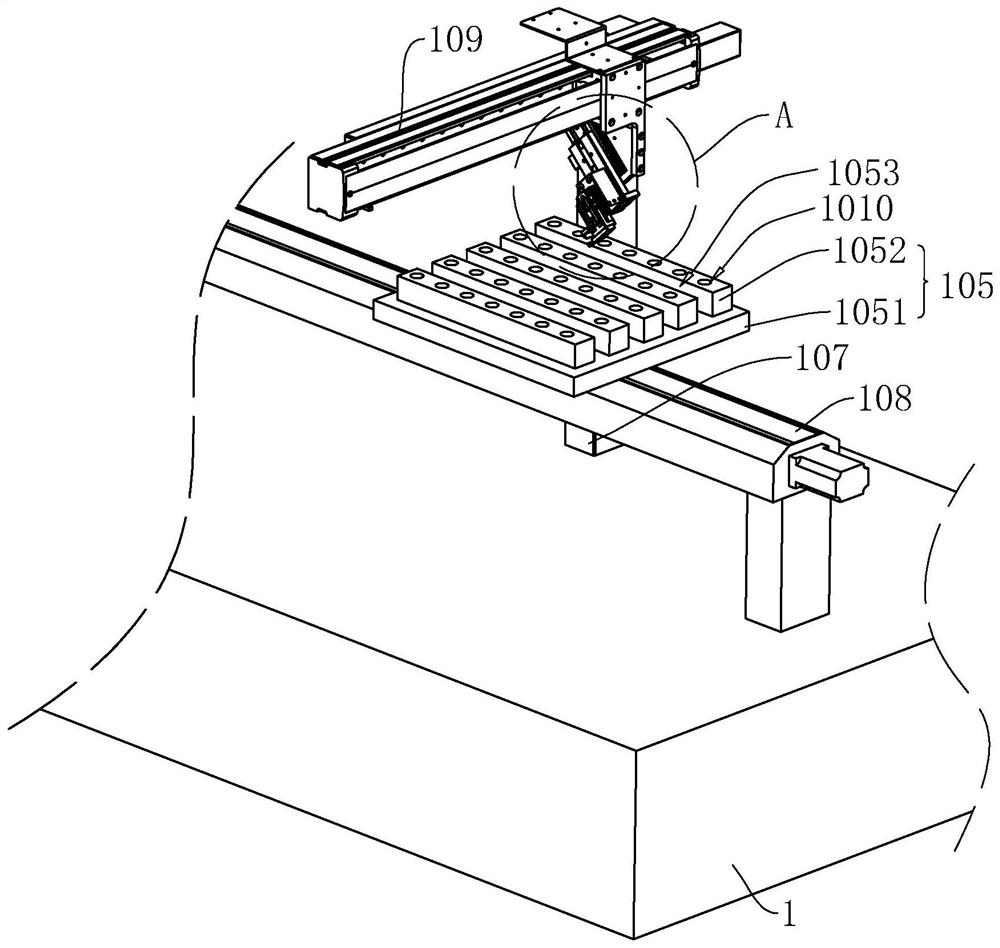

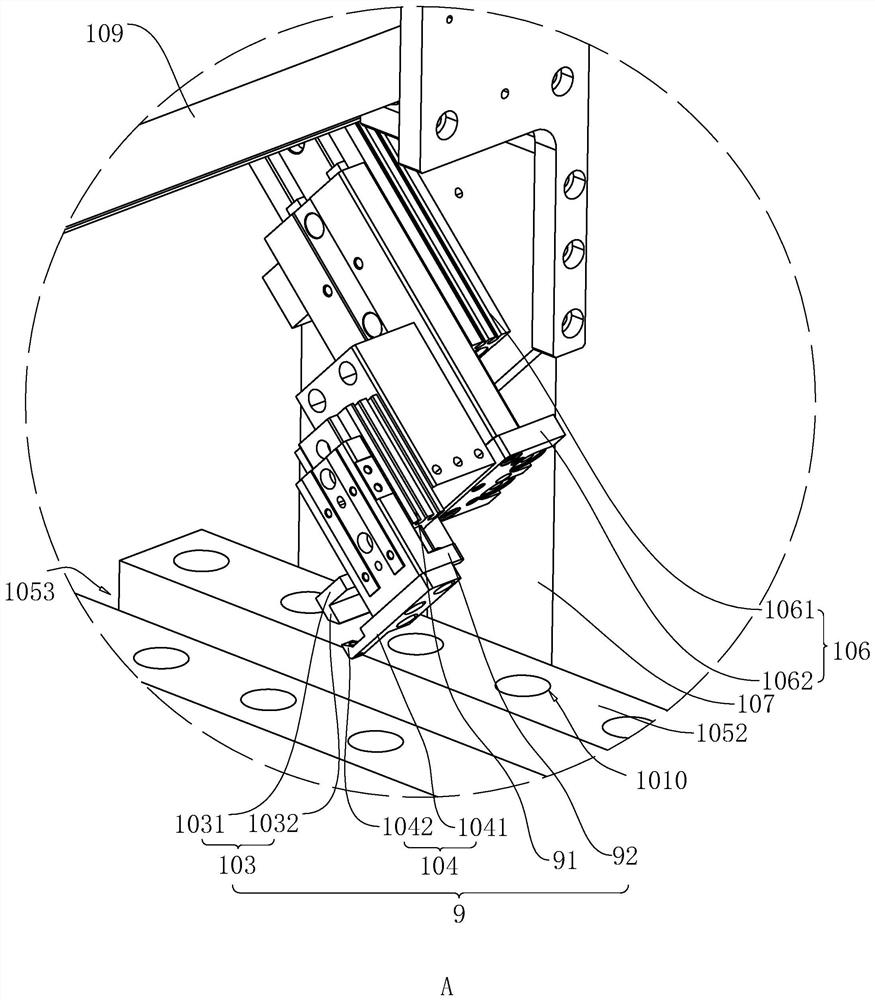

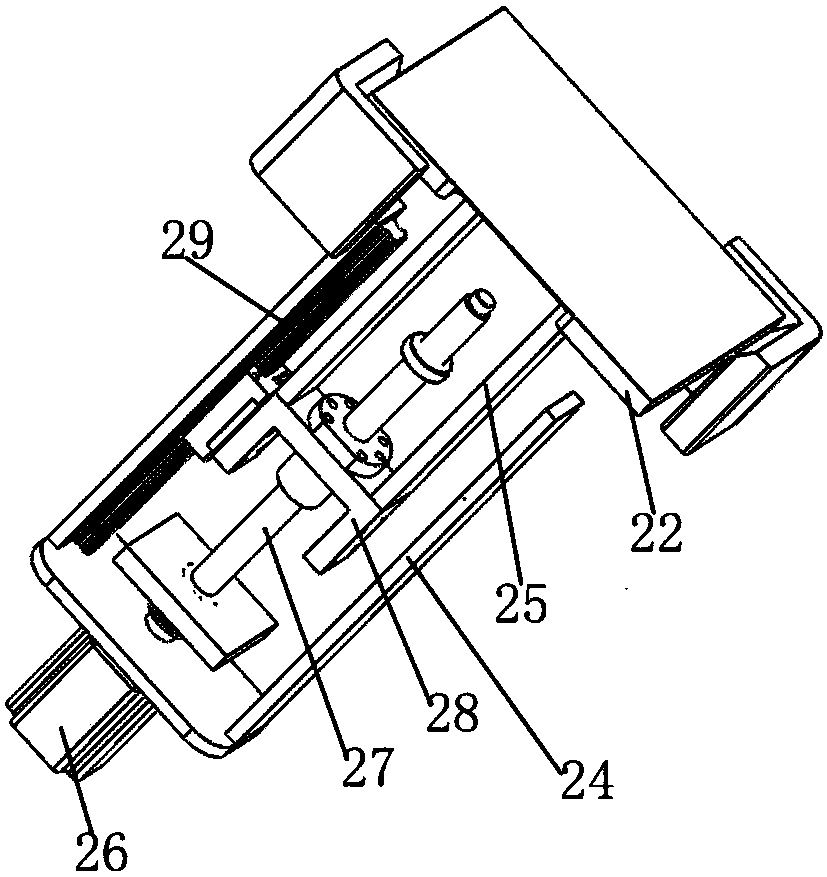

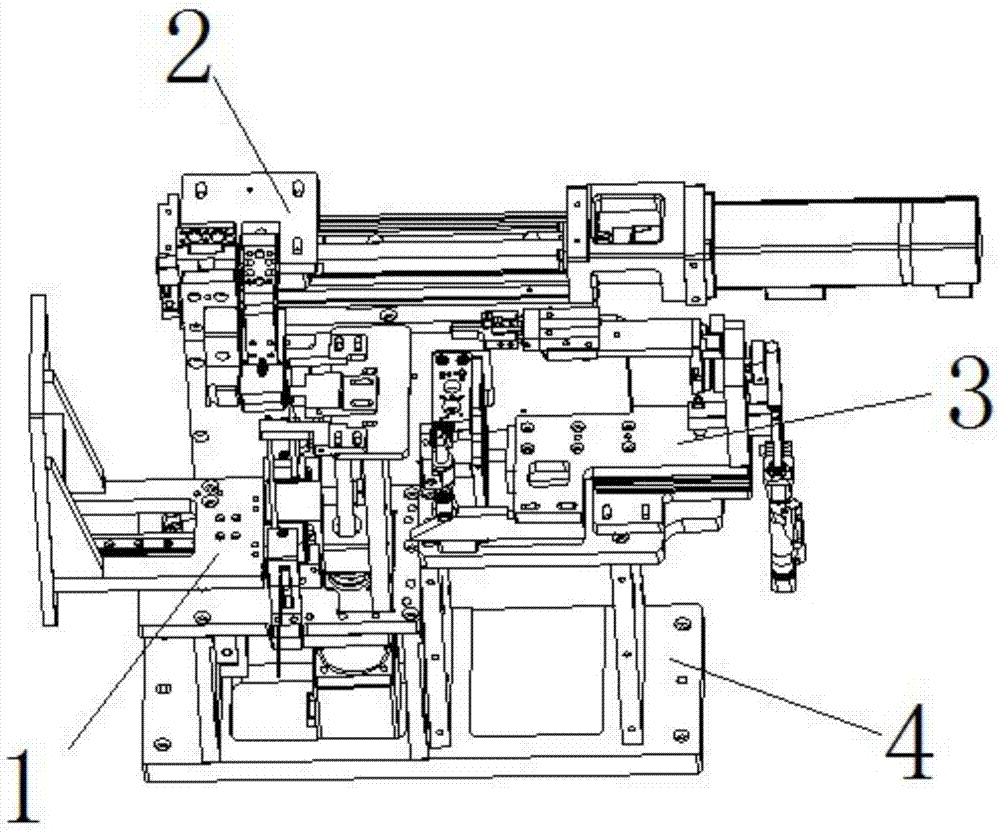

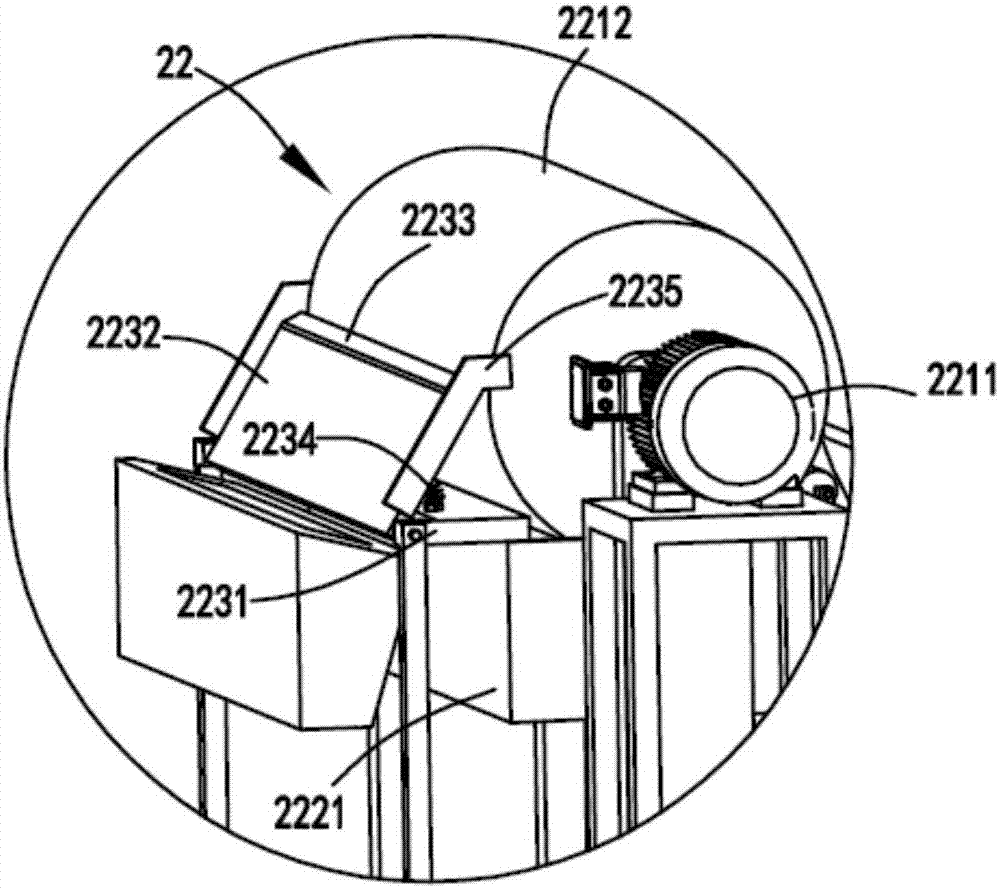

Automatic film tearing machine for accessory assembly

ActiveCN109334215AAvoid position shiftGuaranteed assembly accuracyLamination ancillary operationsLaminationTectorial membraneGlass sheet

The invention discloses an automatic film tearing machine for accessory assembly. The automatic film tearing machine comprises a transmission mechanism, a positioning and supporting mechanism, a filmtearing mechanism and a feed box, wherein the transmission mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at a film-tearing station; the film tearing mechanism is arranged above the film-tearing station; the film tearing mechanism comprises a rotating component, a film clamping component and a pressing component; the film clamping component and the pressing component are respectively connected to the output end of the rotating component; the film clamping component and the pressing component comprise at least two groups, and every two groupsare arranged at an interval; the output ends of the film clamping component and the pressing component are downwards obliquely arranged opposite to each other; the feed box is arranged below the filmtearing mechanism and has an upward opening; after the protective film on gum is torn out by the film tearing mechanism, the torn protective film is put in the feed box. The automatic film tearing machine for accessory assembly disclosed by the invention is applicable to automatic whole line assembly of accessories, multiple films are torn each time, the film tearing efficiency is effectively improved, position offset of the gum or the glass sheet in the film tearing process is effectively avoided, and the assembling precision and quality are ensured.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

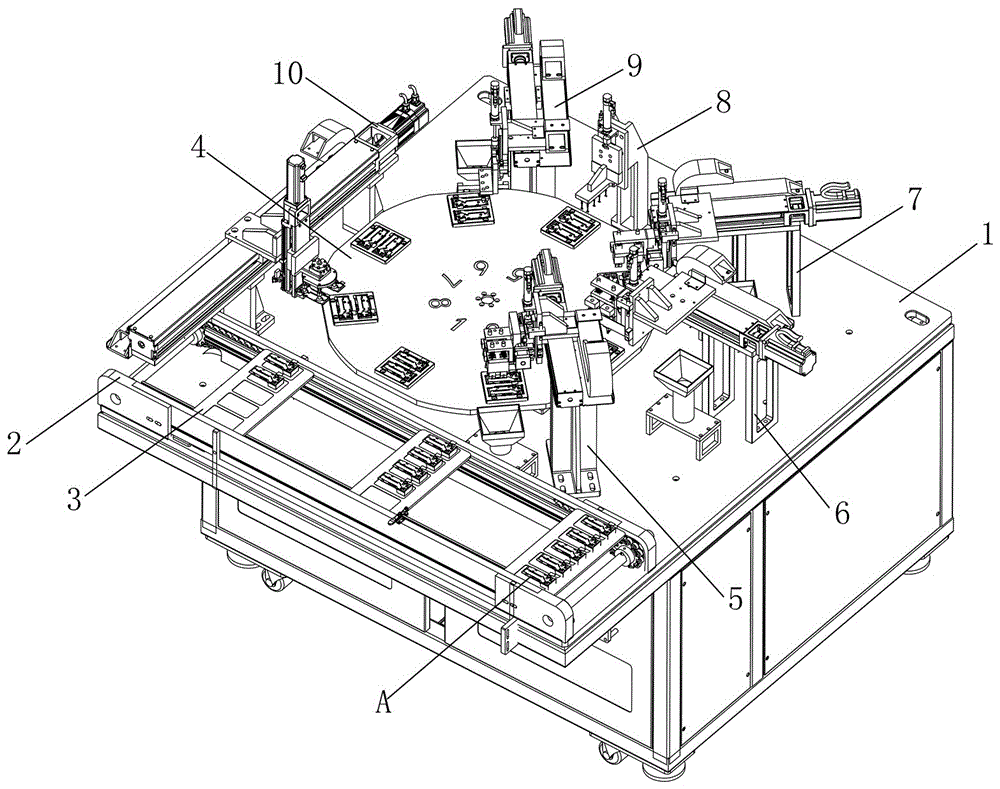

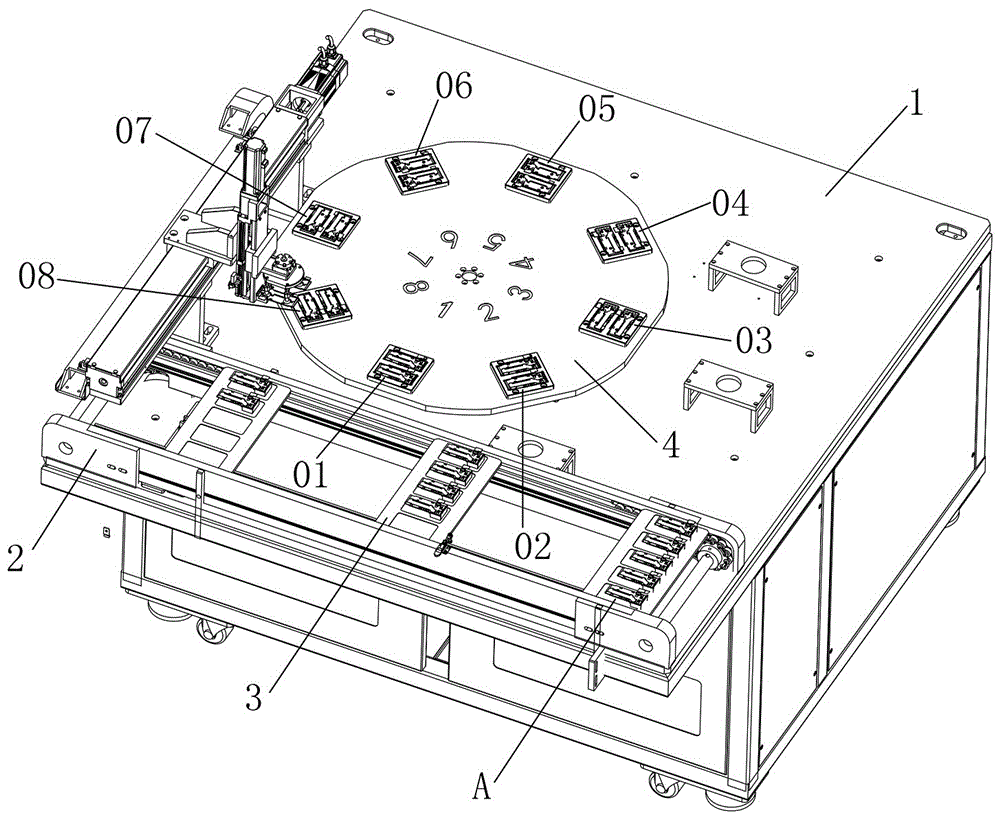

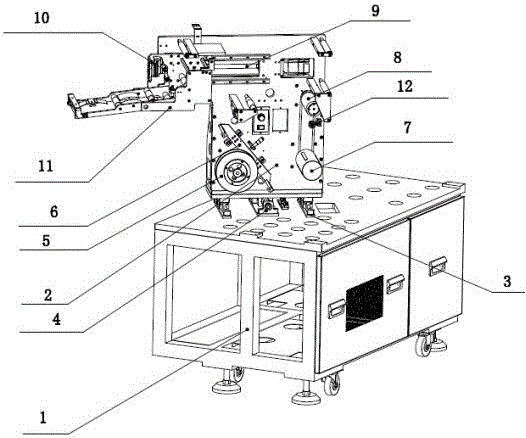

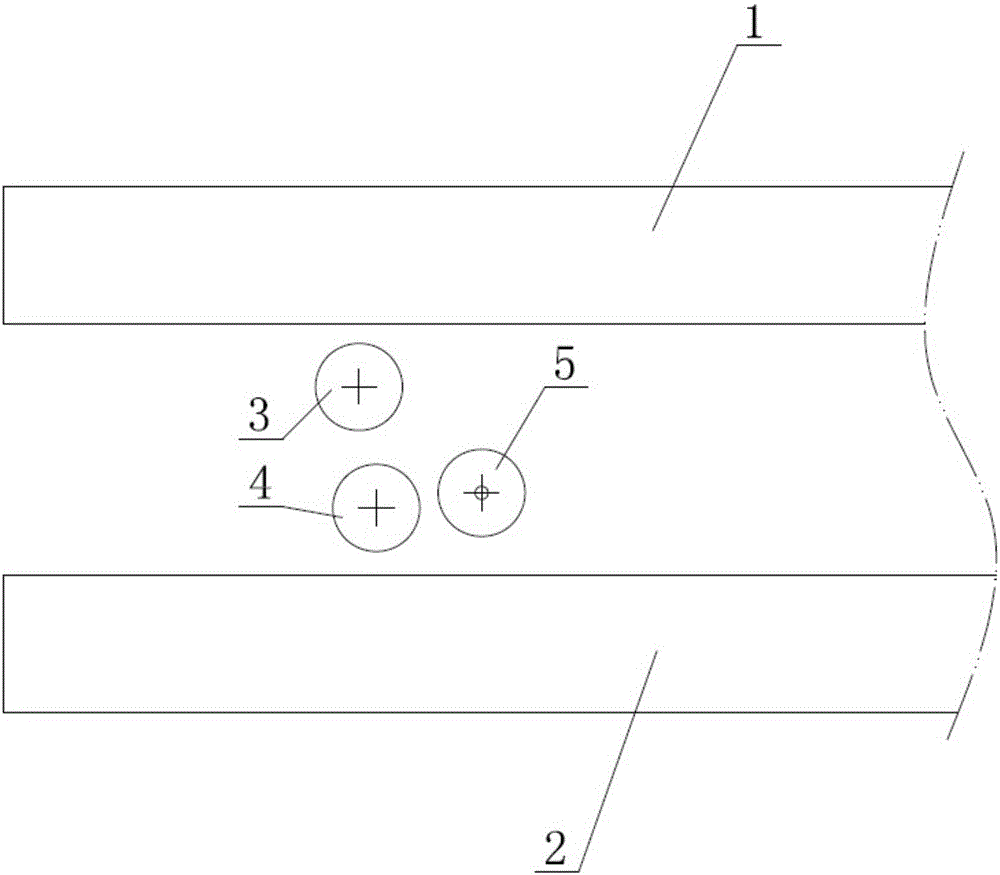

Automatic PCB (Printed Circuit Board) high-temperature adhesive tearing device and adhesive tearing process thereof

ActiveCN106455353AWill not appear to enterFully automaticNon-metallic protective coating applicationElectronic waste recyclingAdhesiveEngineering

The invention discloses an automatic PCB (Printed Circuit Board) high-temperature adhesive tearing device and an adhesive tearing process thereof. The automatic PCB high-temperature adhesive tearing device comprises a double-adhesive tearing mechanism, a first single-adhesive tearing mechanism, a second single-adhesive tearing mechanism, a back surface adhesive tearing mechanism, a wafer adhesive tearing mechanism and a charging and discharging mechanism, which are arranged in sequence along the outer edge of a rotary table, wherein the rotary table moves to carry out working position switching, so that a charging working position, a double-adhesive tearing working position, a first single-adhesive tearing working position, a second single-adhesive tearing working position, a back surface adhesive tearing working position, a wafer adhesive tearing working position and a discharging working position on the rotary table are rotated to the double-adhesive tearing mechanism, the first single-adhesive tearing mechanism, the second single-adhesive tearing mechanism, the back surface adhesive tearing mechanism, the wafer adhesive tearing mechanism and the charging and discharging mechanism in sequence through the charging and discharging mechanism, and furthermore, charging, double-adhesive tearing, first single-adhesive tearing, second single-adhesive tearing, back surface adhesive tearing, wafer adhesive tearing and discharging movements are carried out in sequence. By adopting the automatic PCB high-temperature adhesive tearing device, continuous adhesive tearing is automatically carried out, adhesive tearing automation and efficiency are effectively improved and the production cost is reduced.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

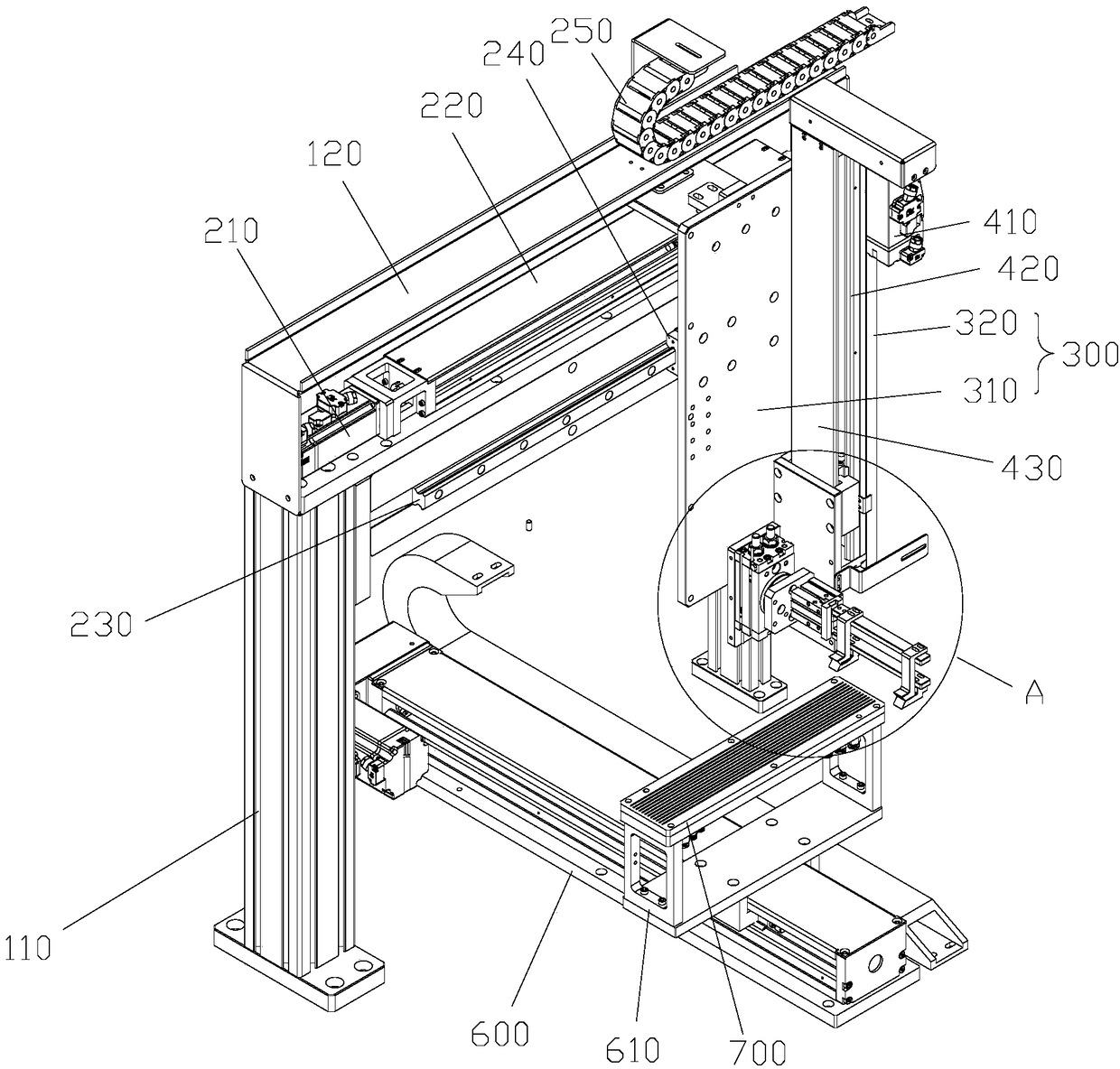

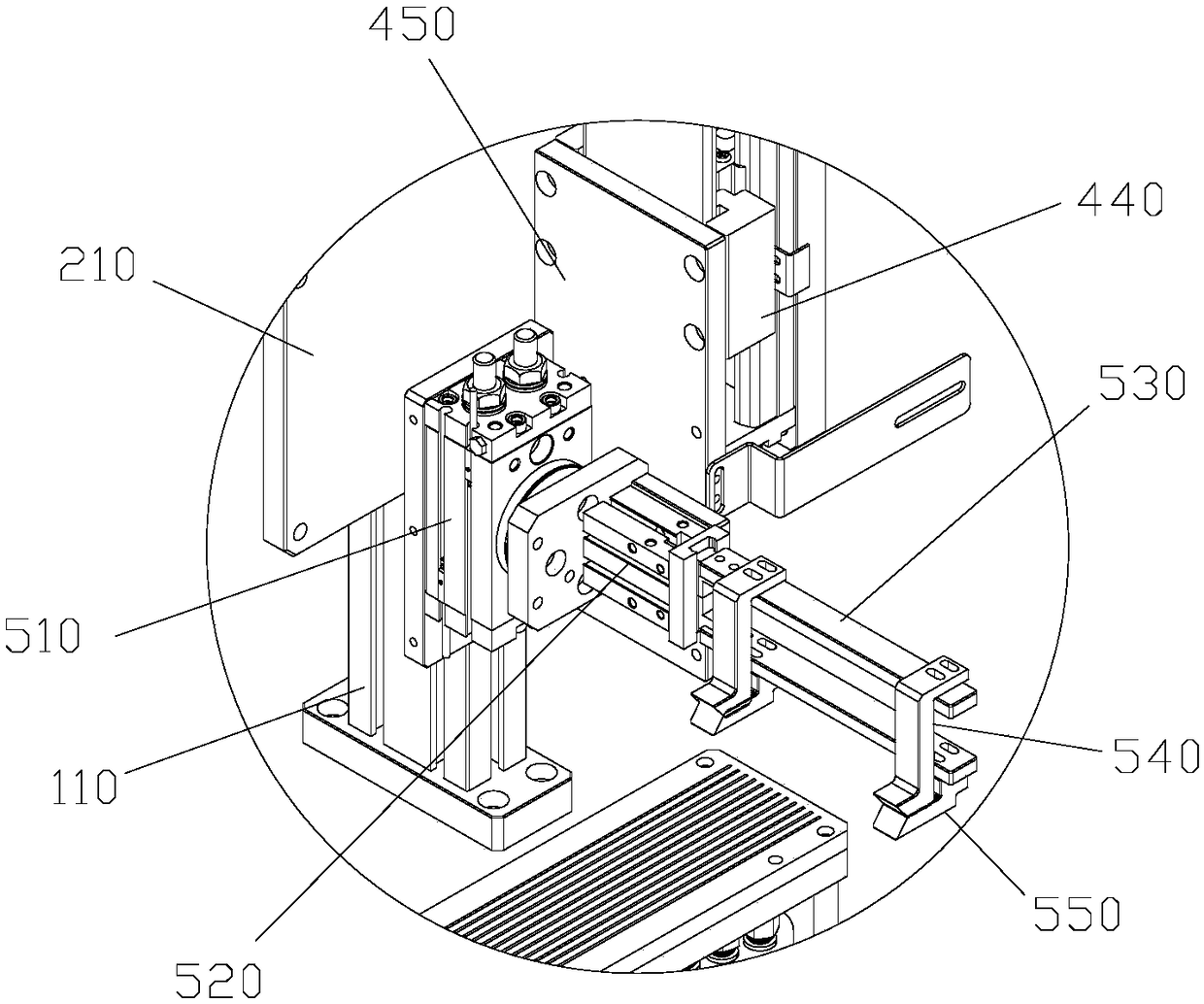

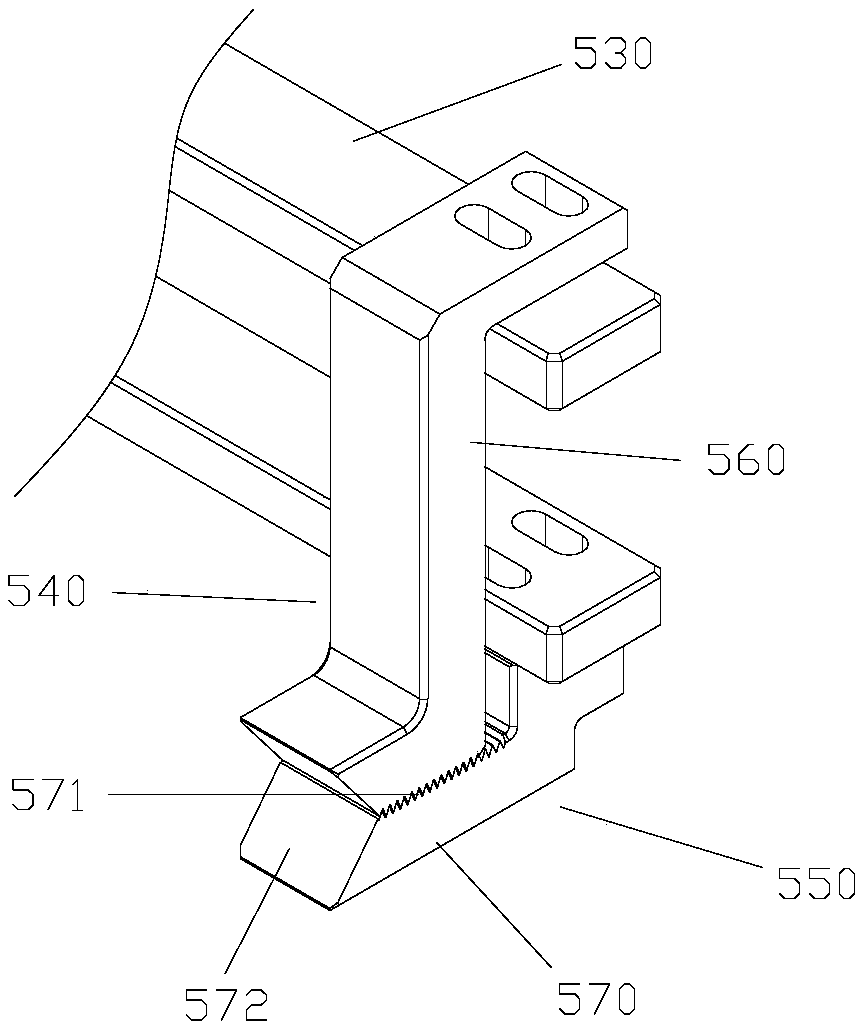

Film tearing device for adhesive tape sticking machine

PendingCN109466966AHigh degree of automationGood tearing effectArticle deliveryReciprocating motionEngineering

The invention discloses a film tearing device for an adhesive tape sticking machine, and the device comprises a pair of cross beam supports, a cross beam connected between the pair of cross beam supports, a moving plate and a clamping mechanism. An X-axis moving system for driving the moving plate to reciprocate in the horizontal direction is arranged on the cross beam, and a Z-axis moving systemfor driving the clamping mechanism to reciprocate in the Z-axis is arranged on the moving plate. The clamping mechanism comprises a clamping jaw cylinder connected to the Z-axis moving system, a pairof clamping jaws of the jaw cylinder are fixedly connected with mounting rods, and a pair of mutually cooperated first clamping plate and a second clamping plate are respectively fixed on the mountingrod. The jaw cylinder is used for driving the first clamping plates and the second clamping plates to approach each other to clamp the film to be torn off. The film tearing device of the adhesive tape sticking machine has the advantages of high automation degree, good film tearing effect and greatly improved film tearing efficiency.

Owner:SUZHOU JQS INFO TECH CO LTD

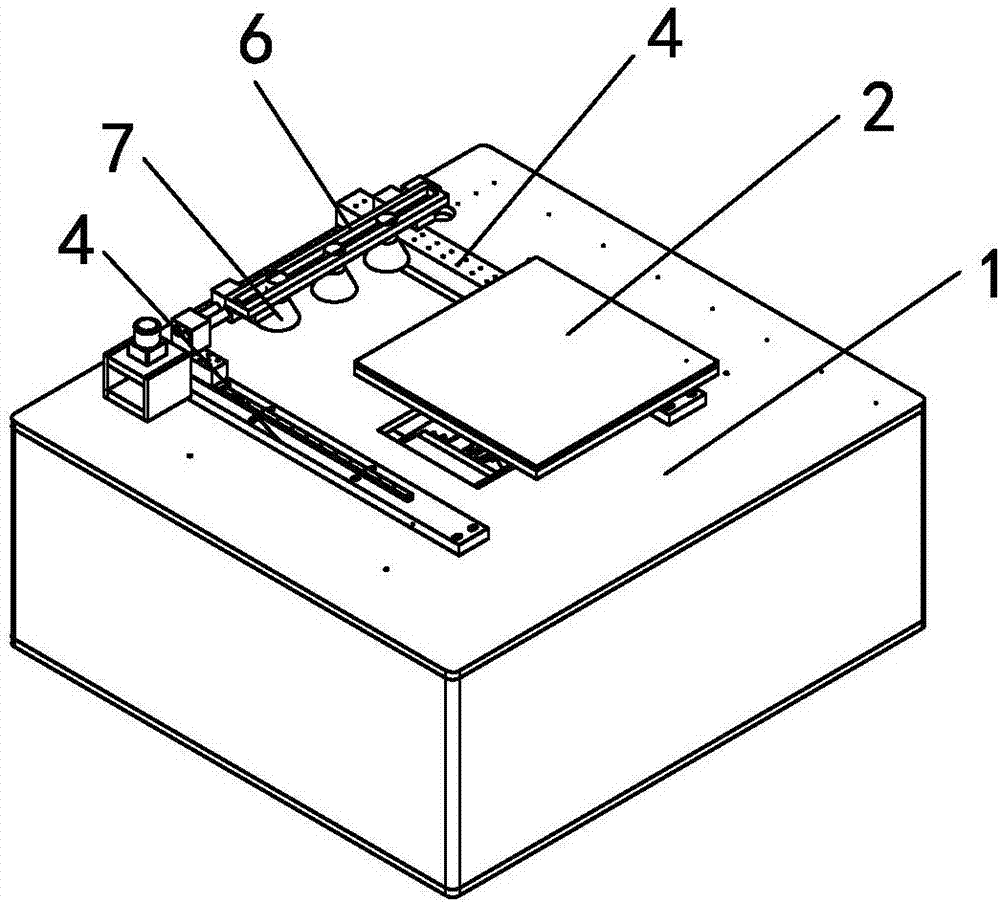

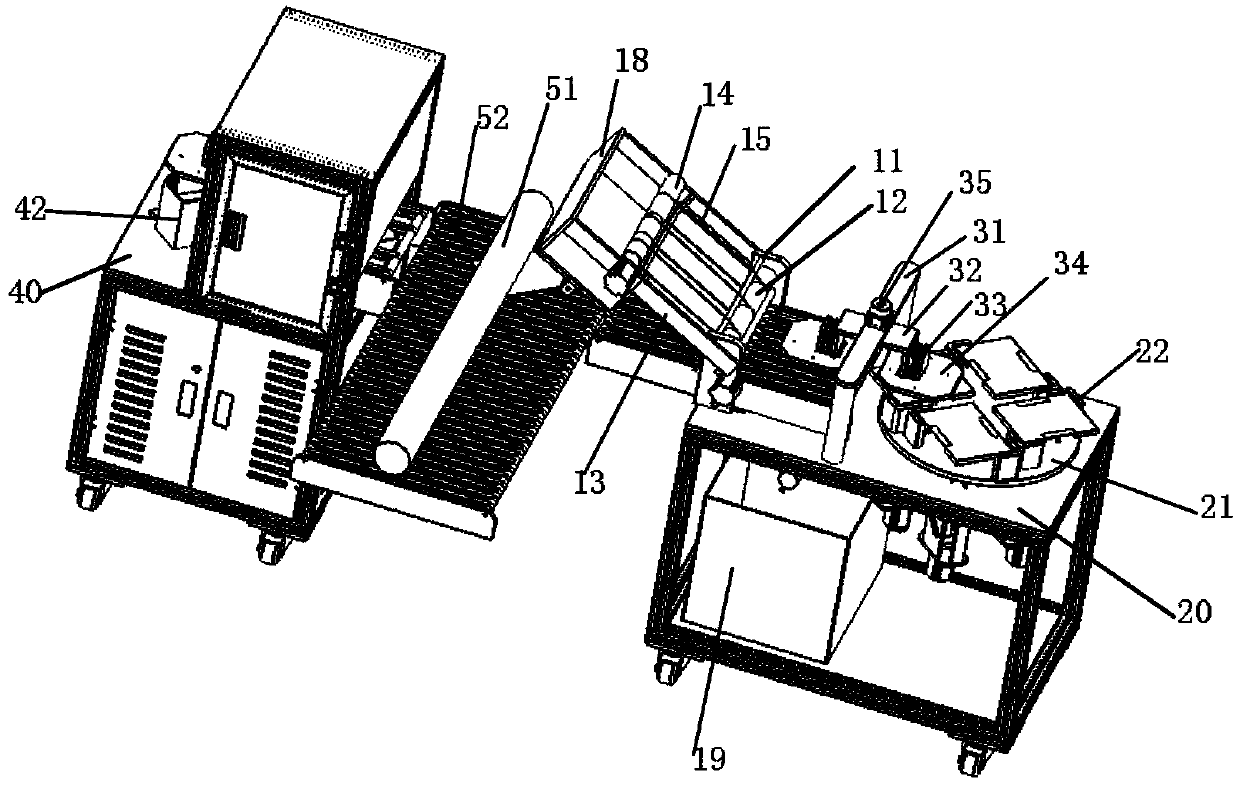

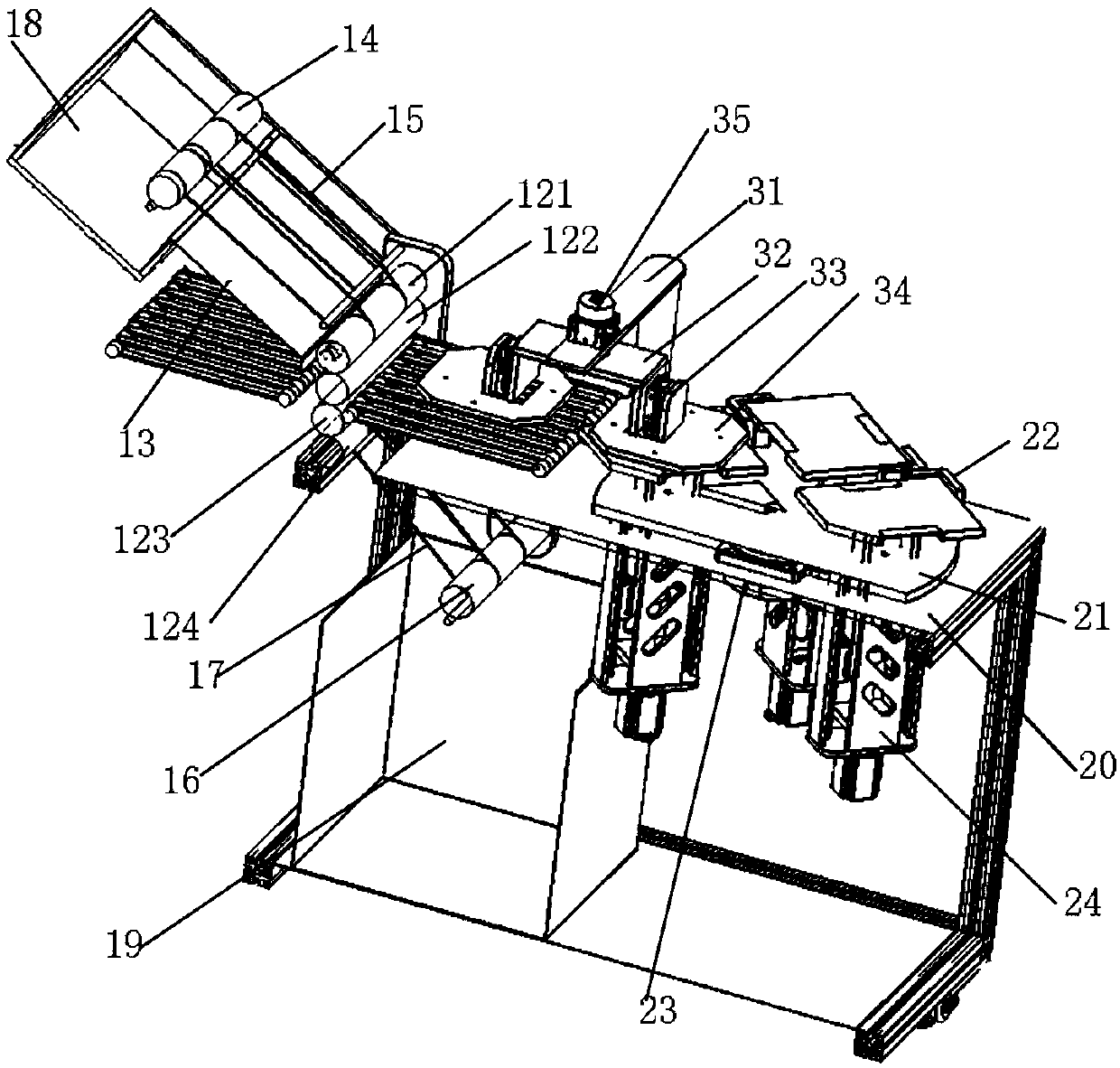

Efficient and automatic film-tearing material-rolling mechanical arm and film tearing method

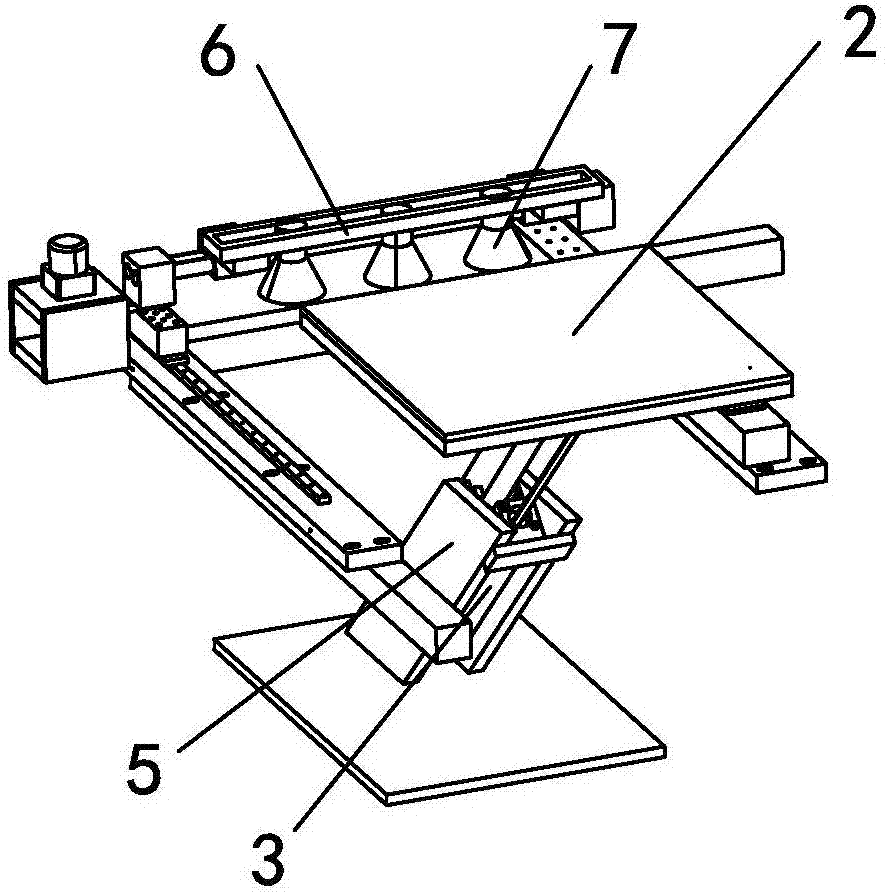

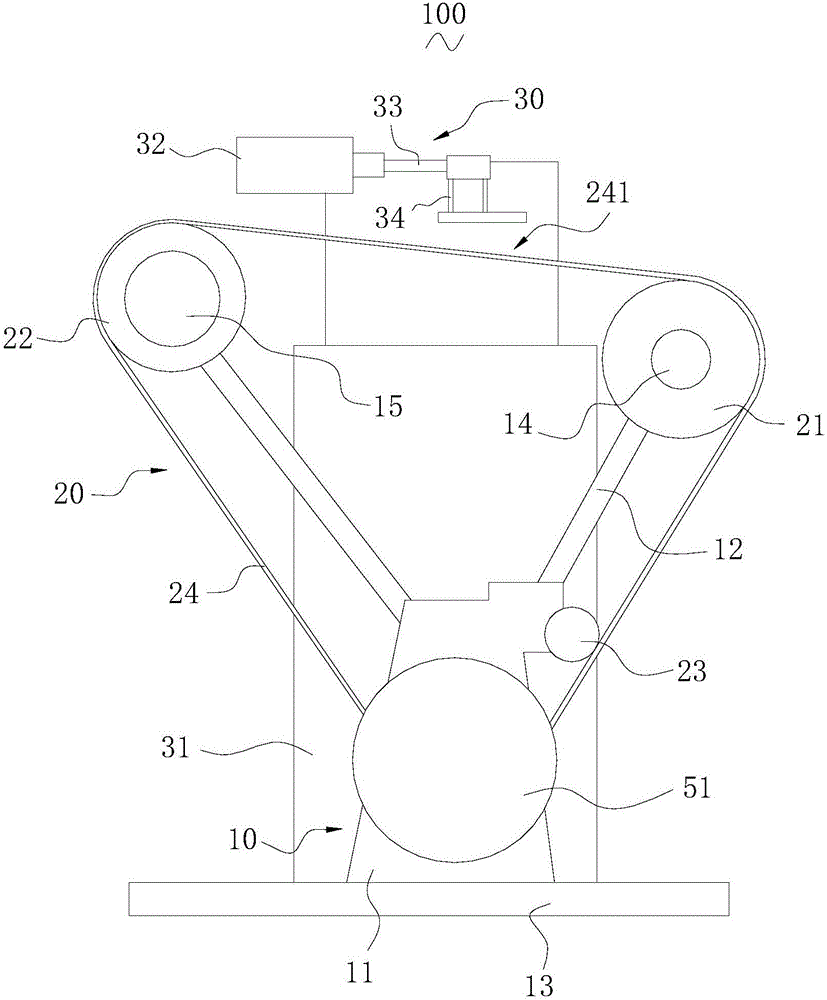

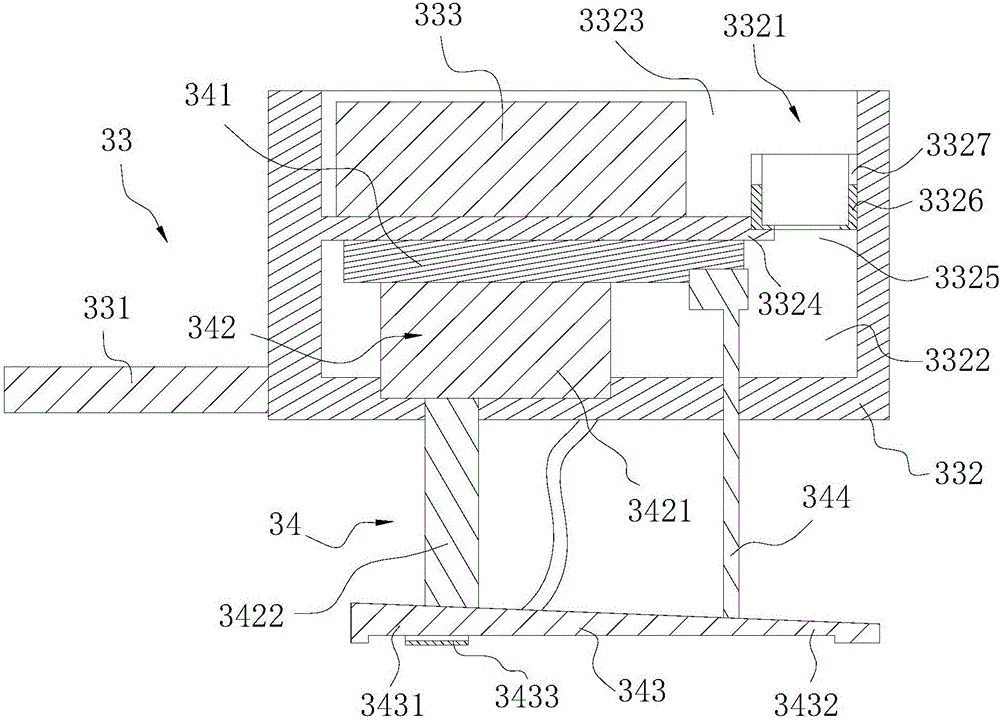

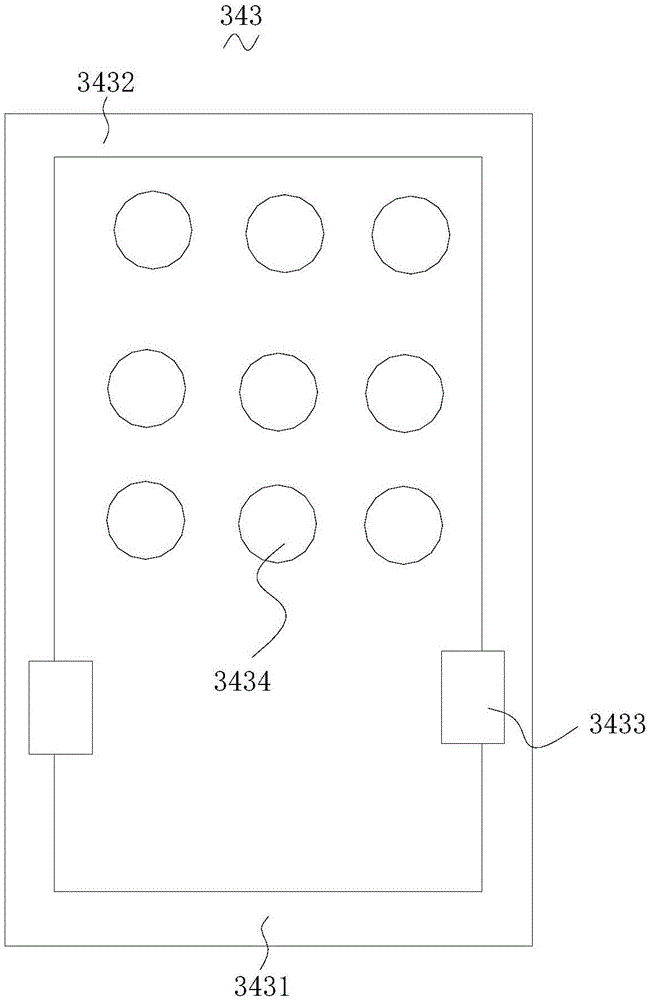

InactiveCN106427183AImprove tearing efficiencyContinuous mechanical actionLamination ancillary operationsLaminationEngineeringSurface plate

The invention discloses an efficient and automatic film-tearing material-rolling mechanical arm and a film tearing method. The mechanical arm comprises a stander main body and a film-tearing main body, wherein the film-tearing main body mounted at the upper end of the stander main body to carry out full-automatic film tearing, a working panel is arranged on the upper end surface of the stander main body, at least one slide rail is arranged on the working panel, and the film-tearing main body can freely slide to be positioned at the upper end of the slide rail, is mounted on the slide rail and is driven to a film-tearing position to be positioned by a film-tearing main body driving component mounted on the slide rail; and a rubber tape detection assembly is mounted at the upper end of a film-tearing emptying assembly, a film-tearing swing arm driving assembly is mounted at the upper end of a film-tearing turning wheel assembly, a film-tearing driving component is mounted on one side of the film-tearing turning wheel assembly, and film-tearing material receiving assemblies are arranged on one side of the film-tearing emptying assembly side by side. According to the mechanical arm, the automatic film tearing is realized, the efficiency of tearing the film by virtue of the film-tearing turning wheel assembly is higher than the efficiency of tearing the film by mechanically clamping an easily-torn adhesive protecting film, the film-tearing success rate reaches 99.8%, and mechanical actions are continuous; and the mechanical arm is simple in structure and low in cost.

Owner:SHENZHEN DEEP HON HAI AUTOMATION EQUIP CO LTD

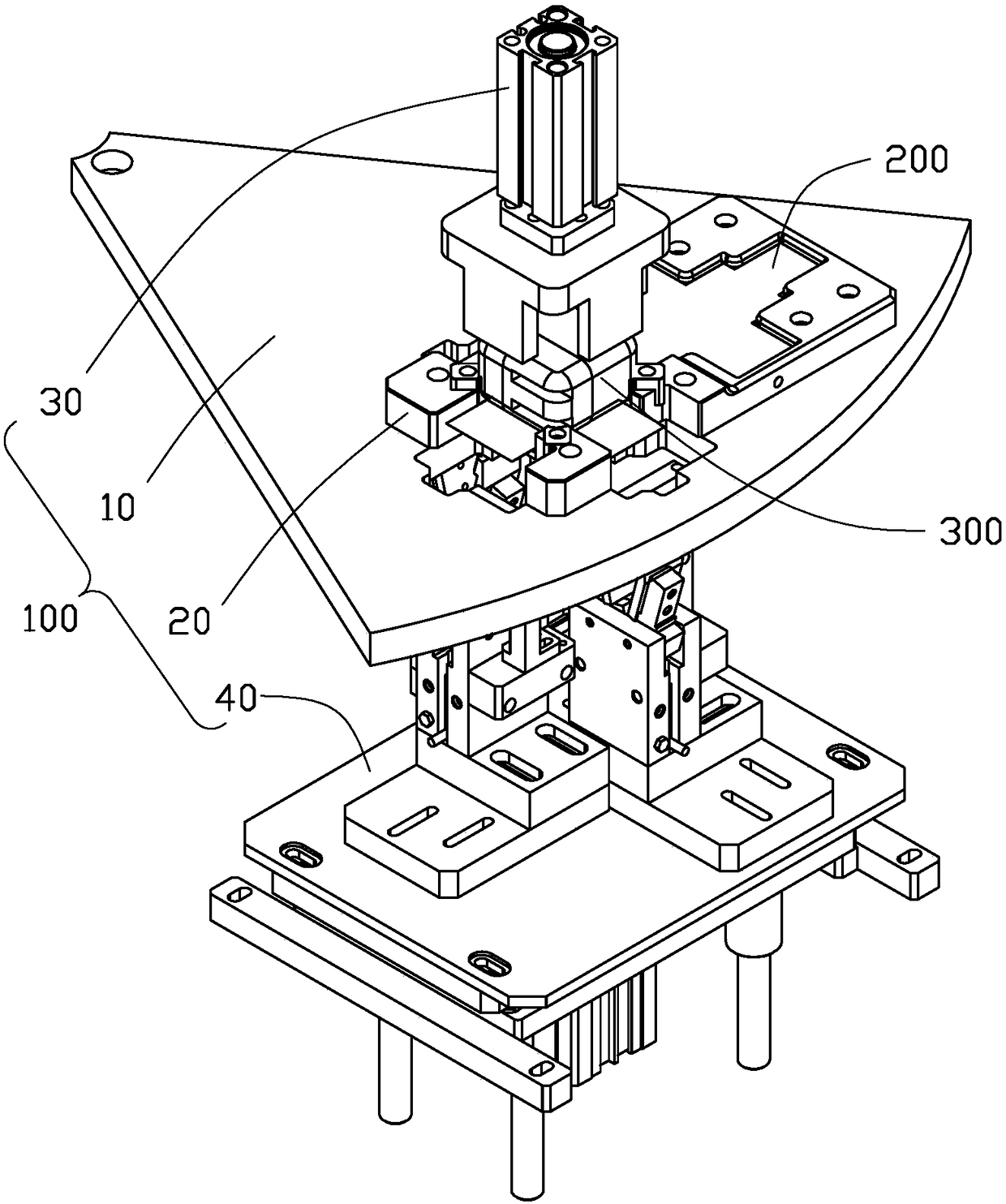

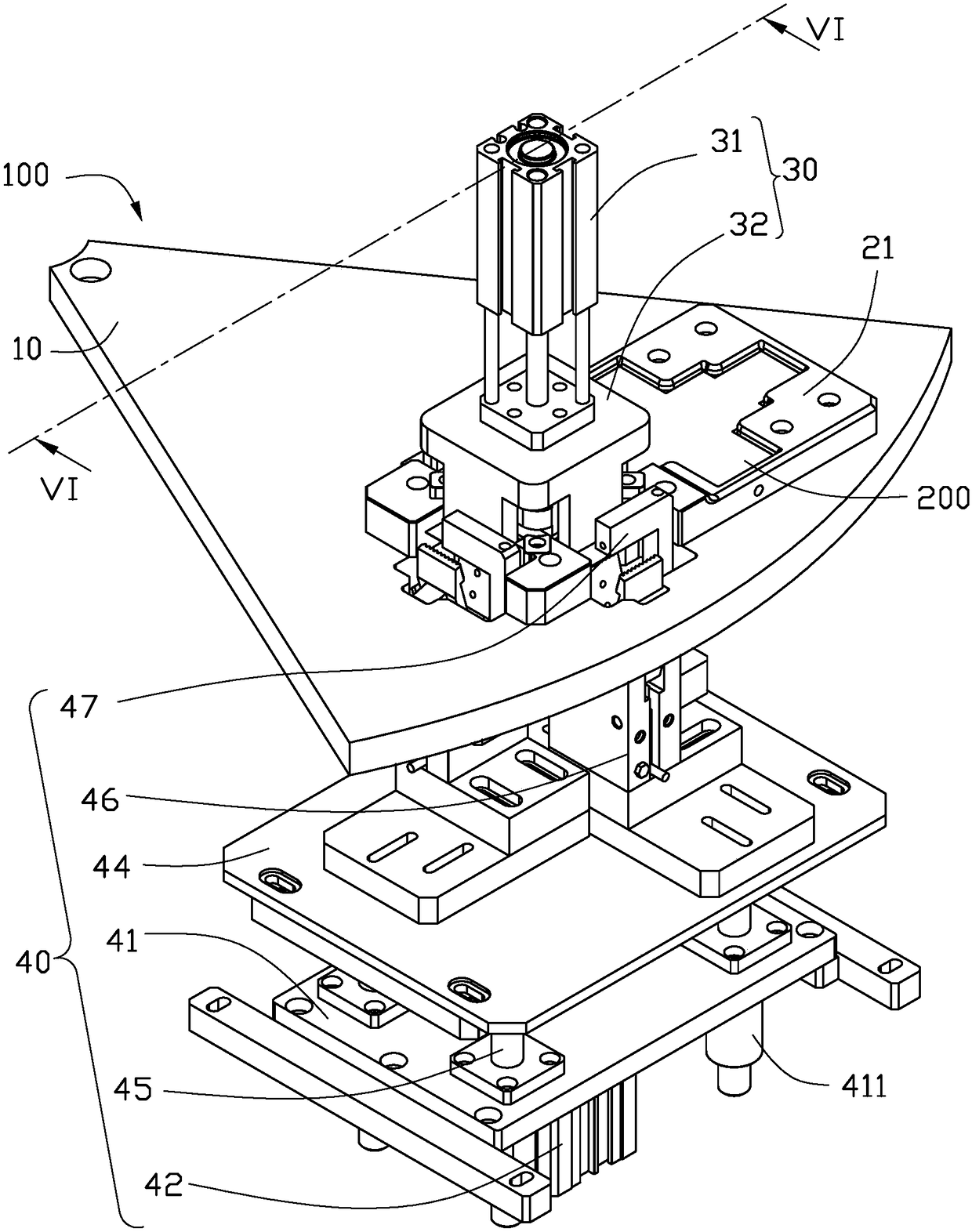

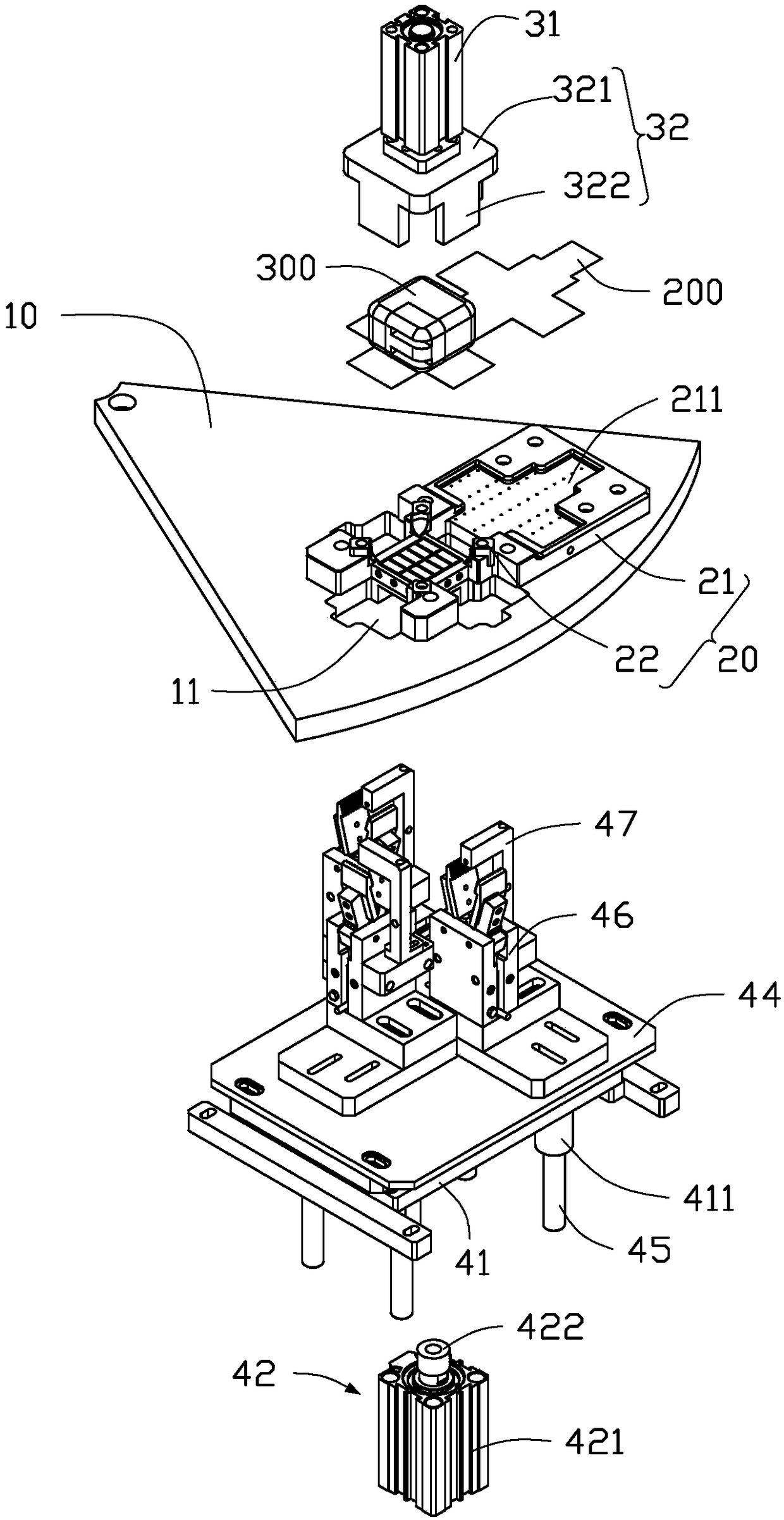

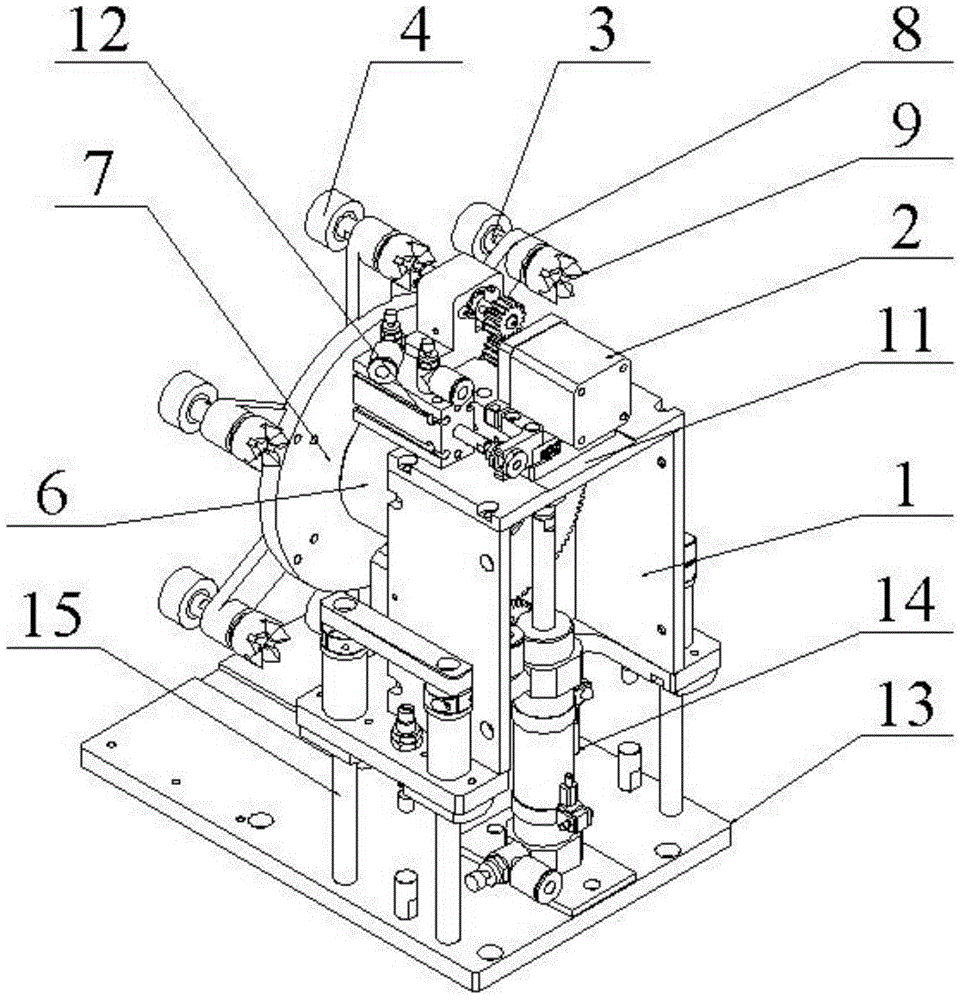

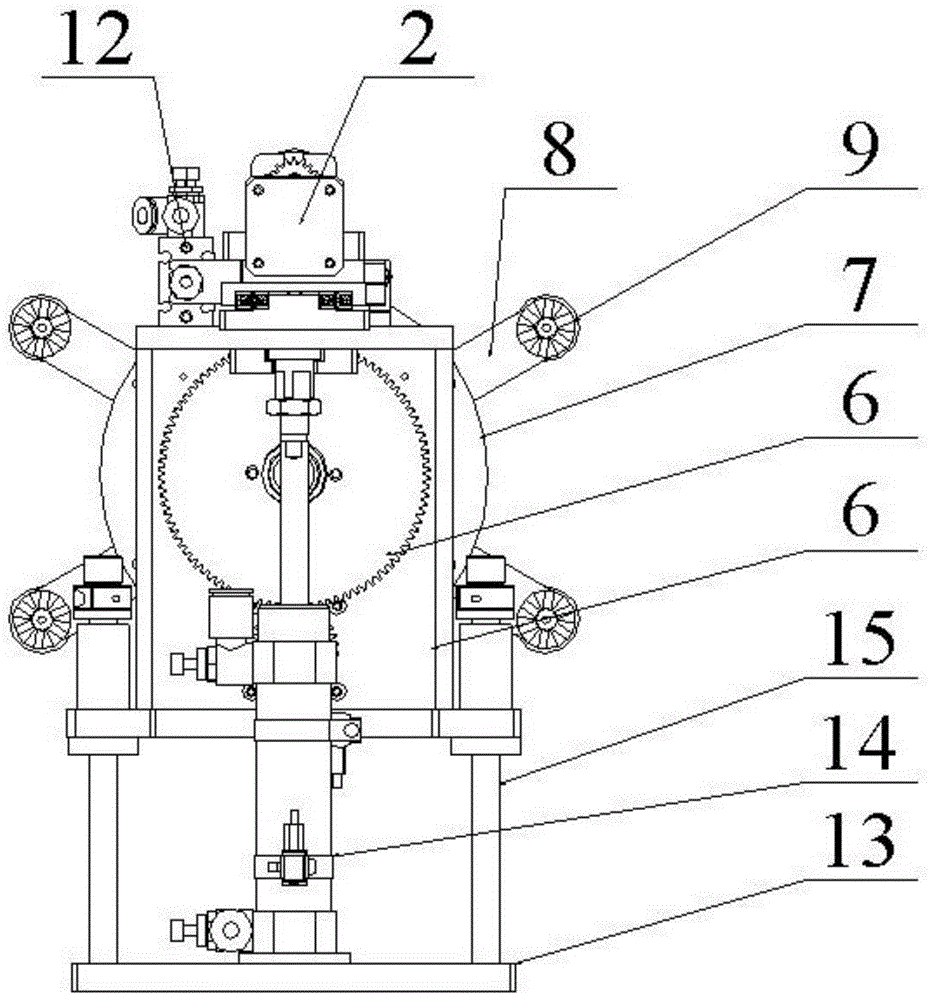

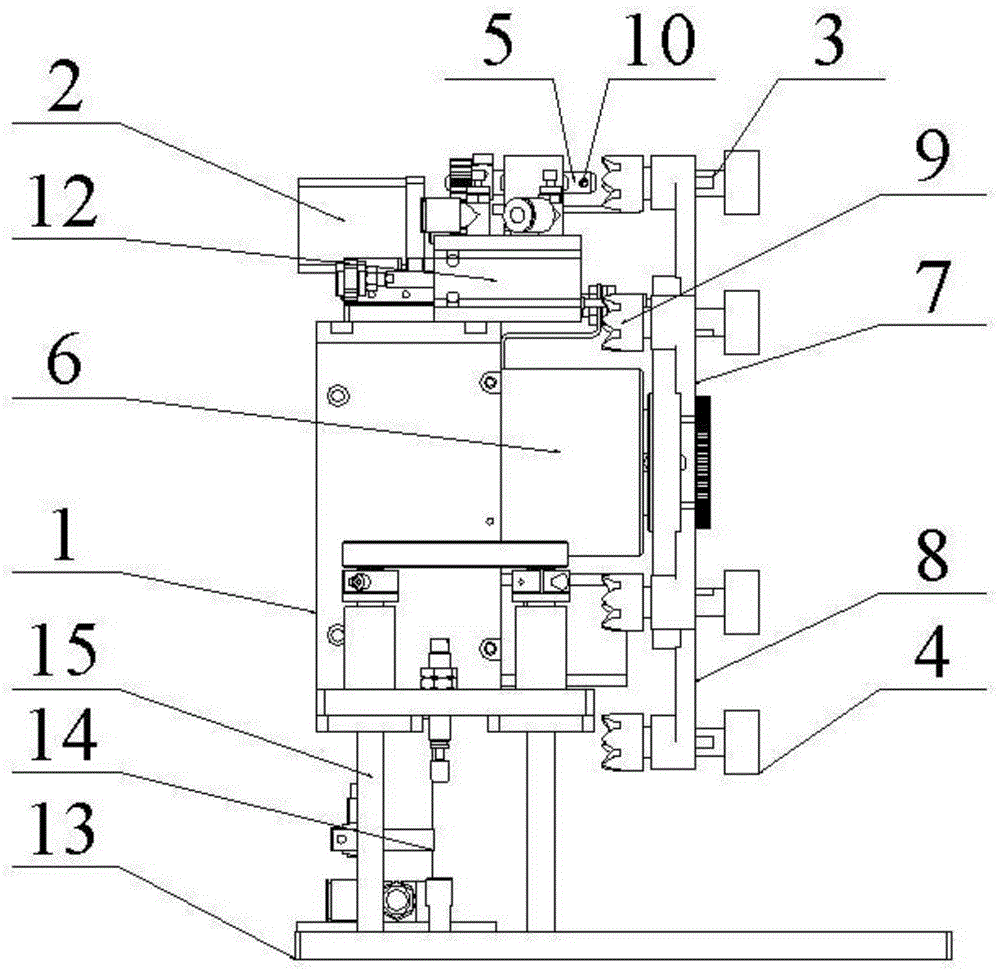

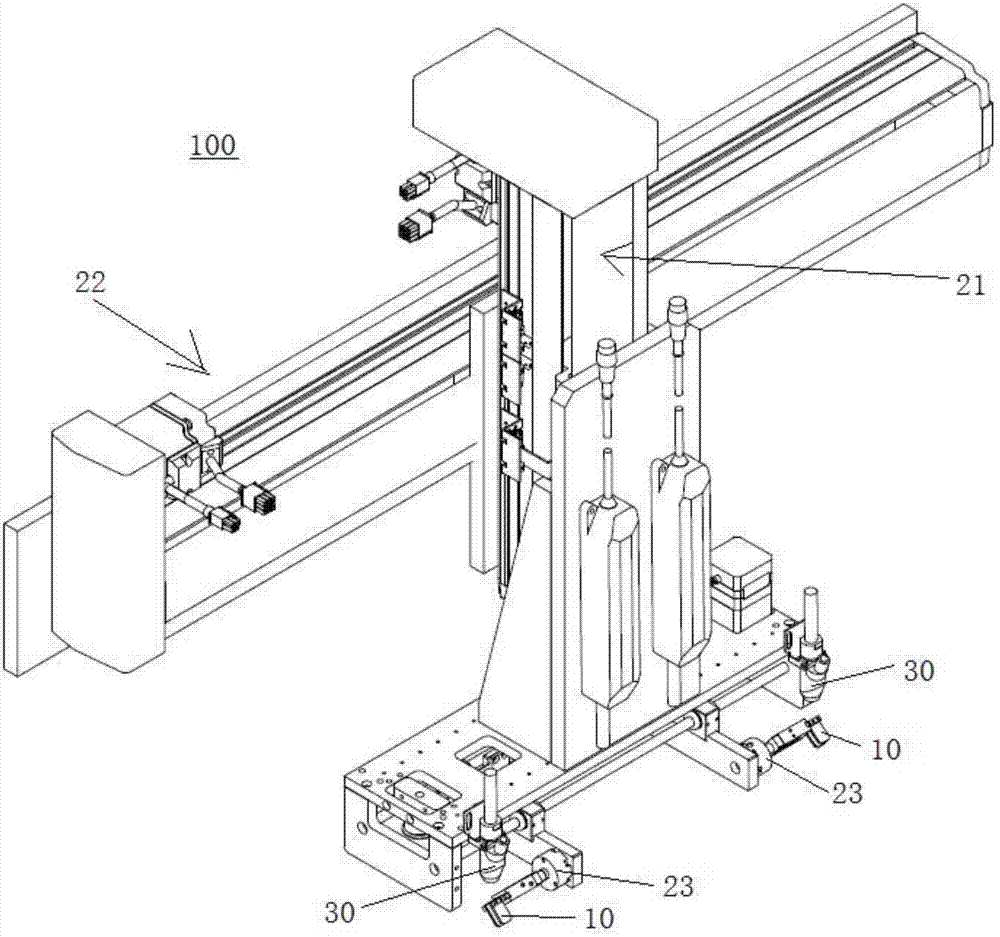

Automatic film tearing device

InactiveCN108313433AReduce labor costsImprove tearing efficiencyArticle unpackingTectorial membraneEngineering

An automatic film tearing device is used for tearing a release film on a protective film and comprises a positioning mechanism, a press-fit mechanism and a film tearing mechanism. The positioning mechanism is used for positioning the protective film, and the press-fit mechanism comprises a press-fit driving piece and a press-fit piece. The press-fit piece is connected to the press-fit driving piece, moves towards the positioning mechanism under the driving effect of the press-fit driving piece, and can abut against the protective film. The film tearing mechanism comprises a base, a film tearing driving piece, a lifting seat, a clamping piece and a material jacking piece. The film tearing driving piece is mounted on the base to be used for driving the lifting seat to make lifting movement.The clamping piece is mounted on the lifting seat, and the material jacking piece is mounted on the clamping piece. The film tearing driving piece drives the lifting seat to move towards the positioning mechanism. The material jacking piece pushes the protective film and the release film to be overturned towards the press-fit piece together so as to enable part of the release film to be separatedfrom the protective film and clamped by the clamping piece. The film tearing driving piece drives the lifting seat to move away from the positioning mechanism, and the clamping piece tears the releasefilm from the protective film.

Owner:FU TAI HUA IND SHENZHEN +1

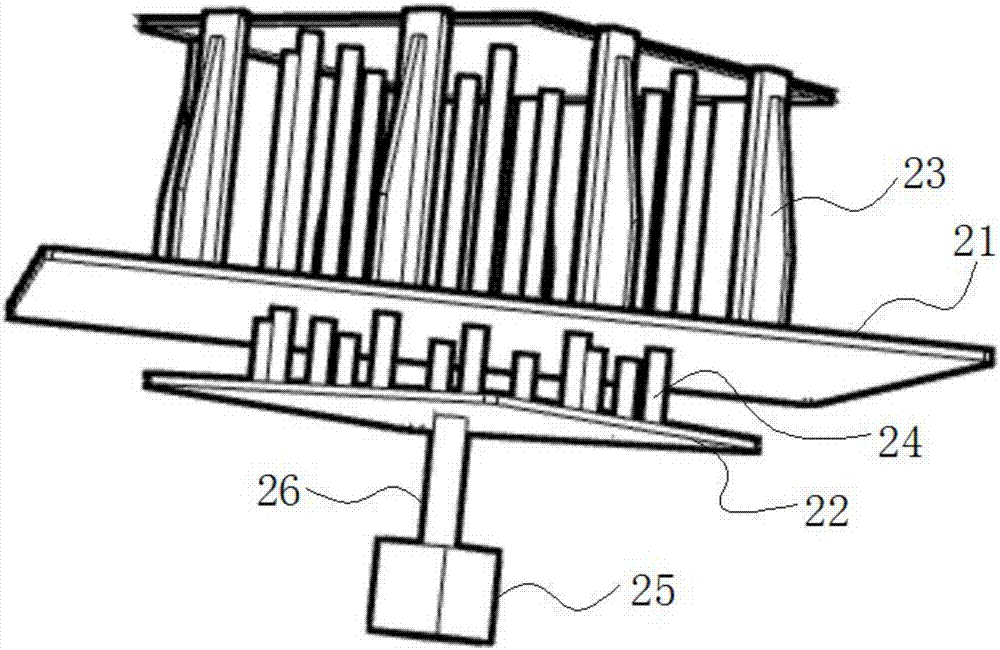

Roller adjusting apparatus, membrane stripping apparatus and membrane stripping method

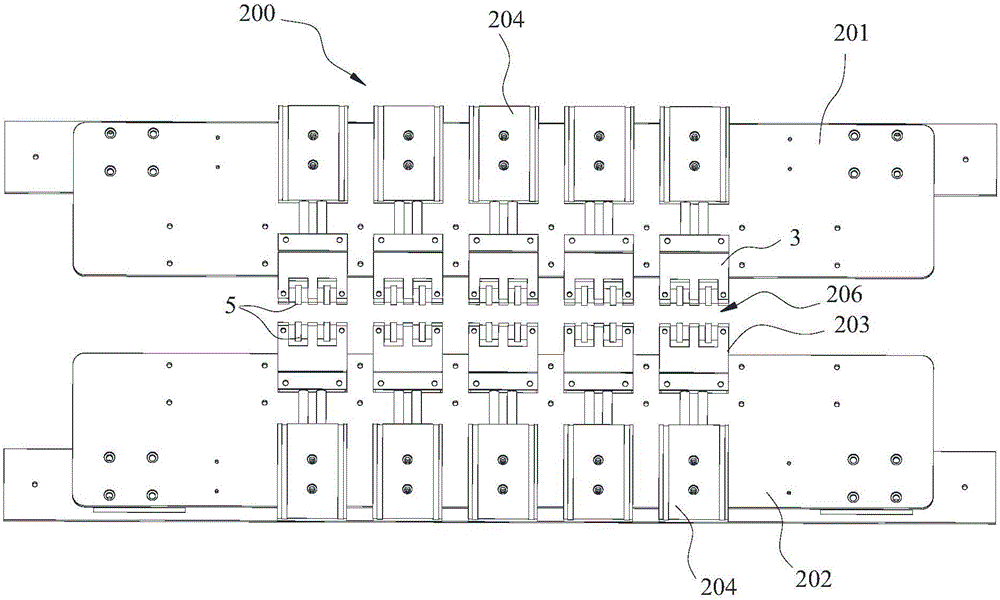

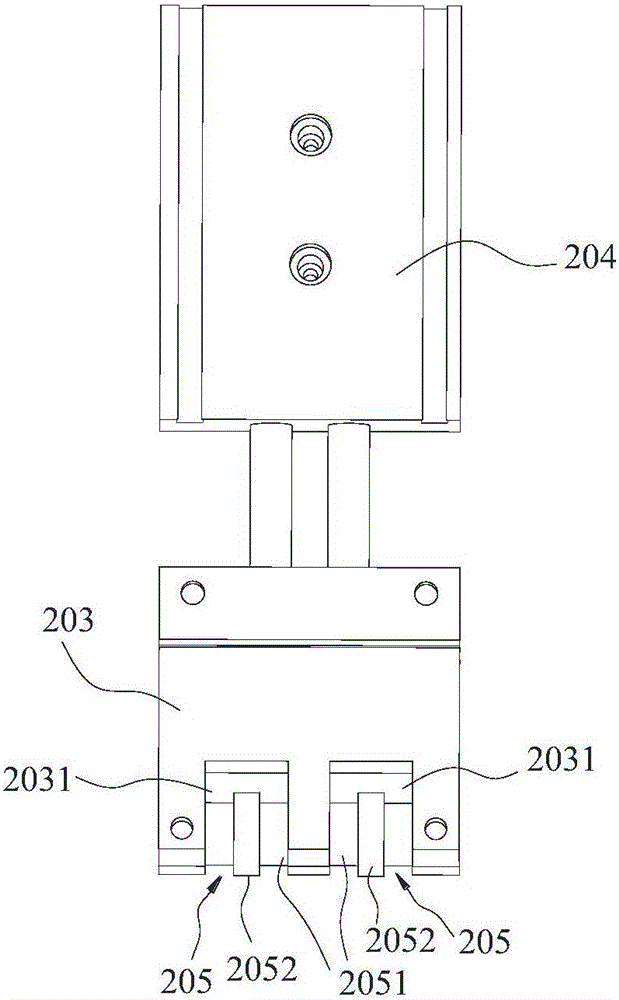

ActiveCN105150667AControl useImprove efficiencyLamination ancillary operationsLaminationEngineeringViscosity

The invention relates to the field of panel production apparatus parts, and concretely relates to a roller adjusting apparatus, a membrane stripping apparatus and a membrane stripping method. The roller adjusting apparatus comprises a first support, the first support is provided with a roller and a first rotation motor; the roller comprises a rotation shaft and a viscous rubber sleeve sleeving the circumferential surface at the left end of the rotation shaft; and the output shaft of the first rotation motor is in transmission connection with the right end of the rotation shaft. The membrane stripping apparatus comprises the roller adjusting apparatus. By installing the rotation motor on the first support for controlling the roller, usage of a viscous material on the roller is effectively controller, switching of the viscosity disappearance part and the viscosity sufficient part on the roller is facilitated, the usage efficiency of the roller viscous material is improved and also roller replacing time is reduced.

Owner:KUSN JINGXUN ELECTRONICS TECH

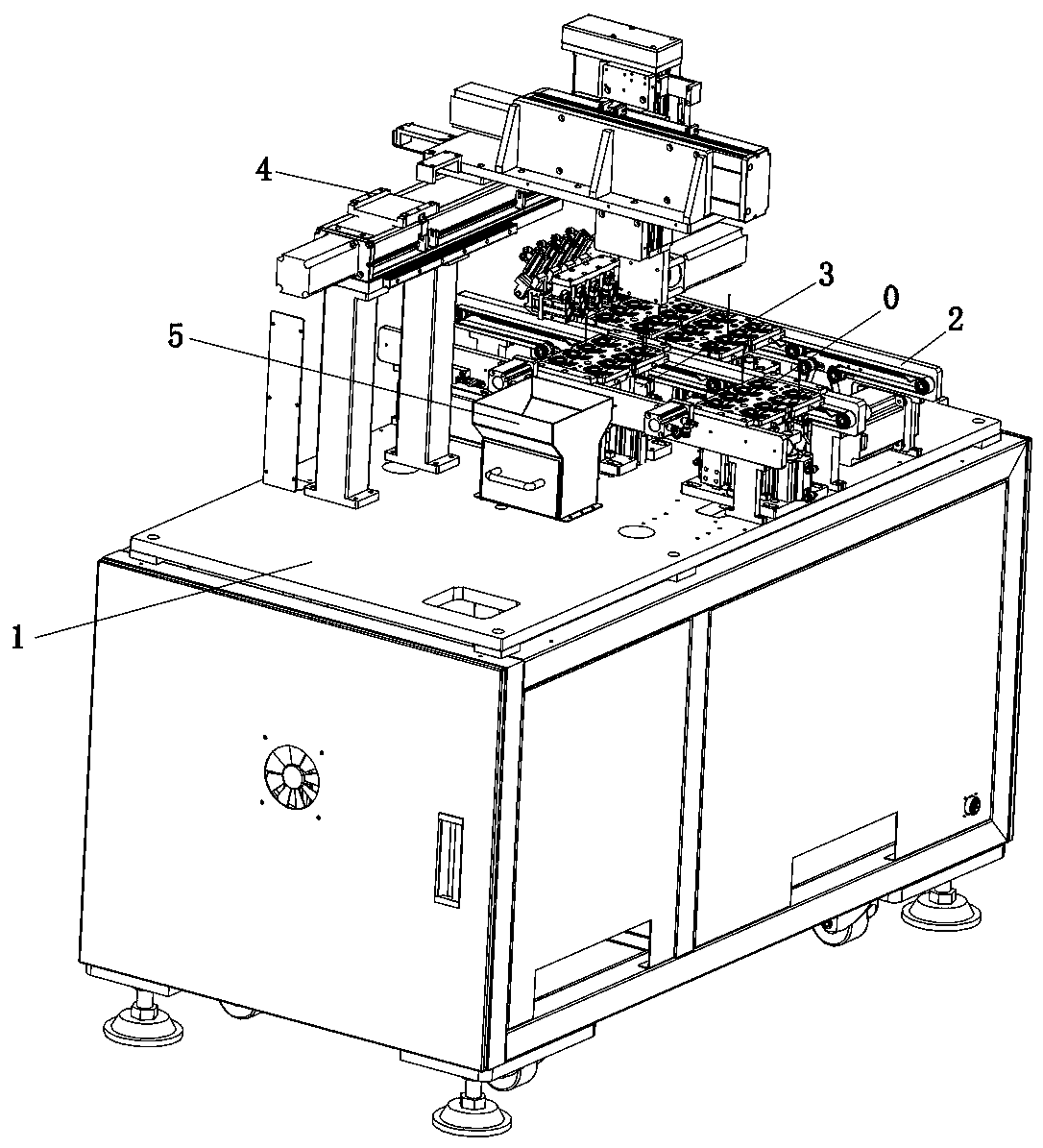

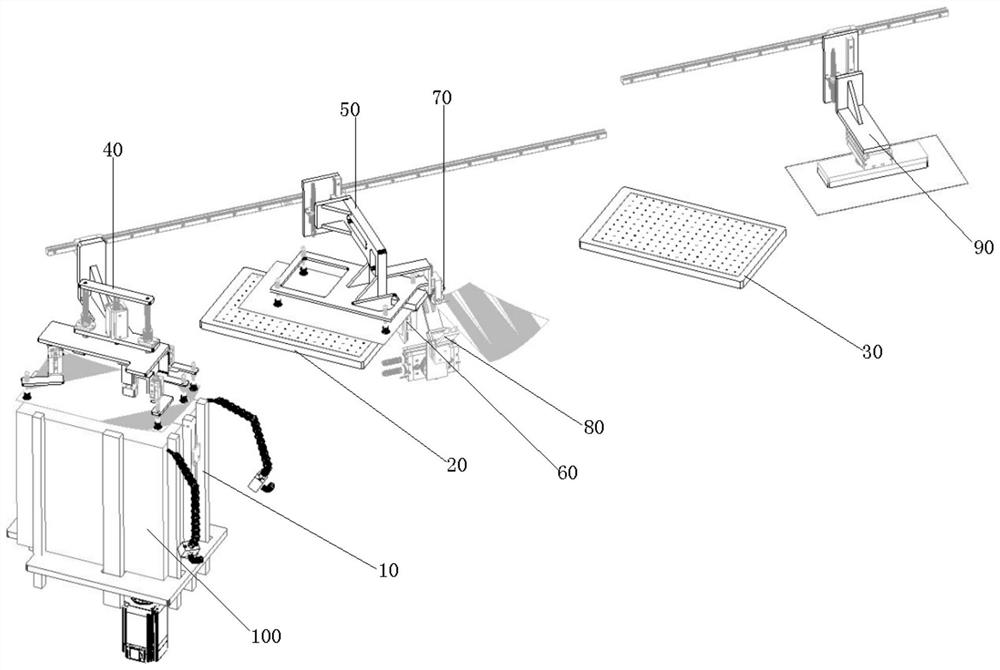

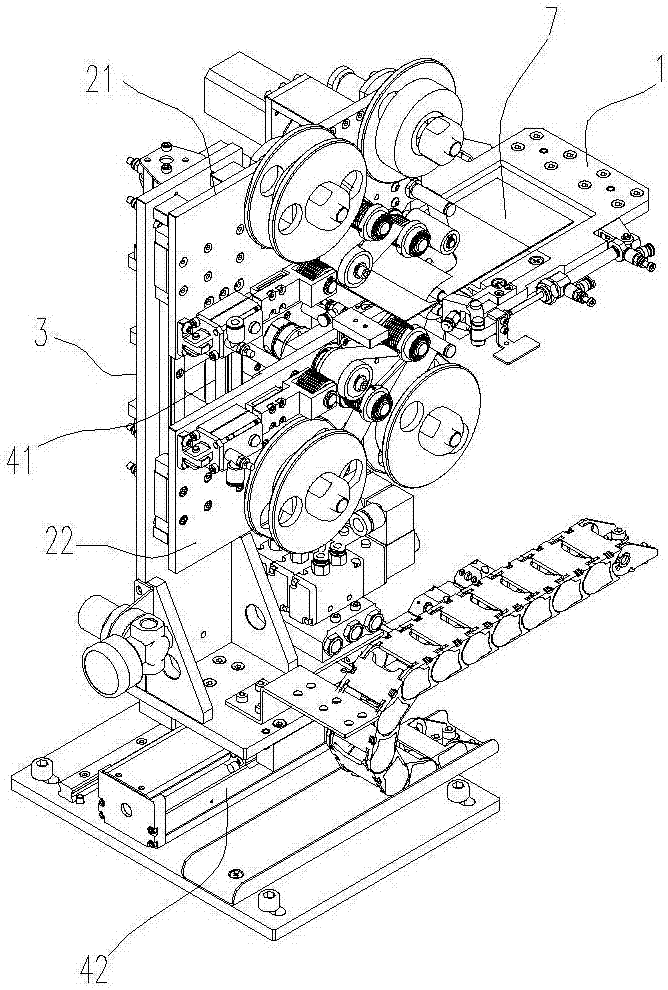

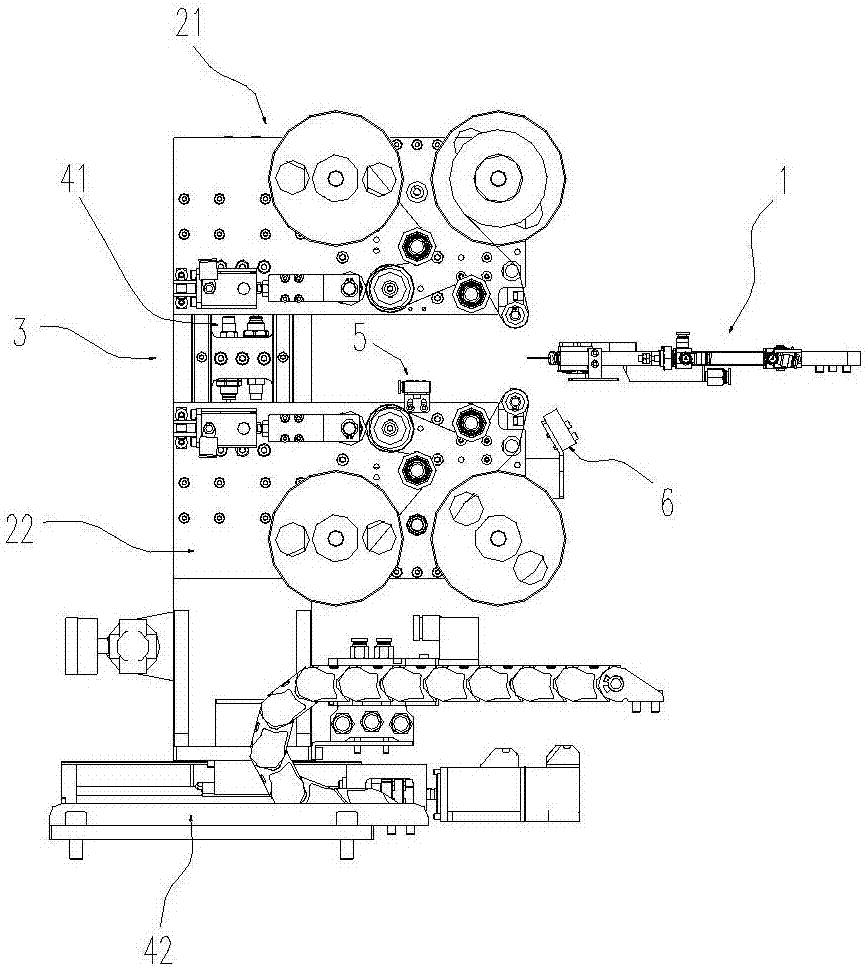

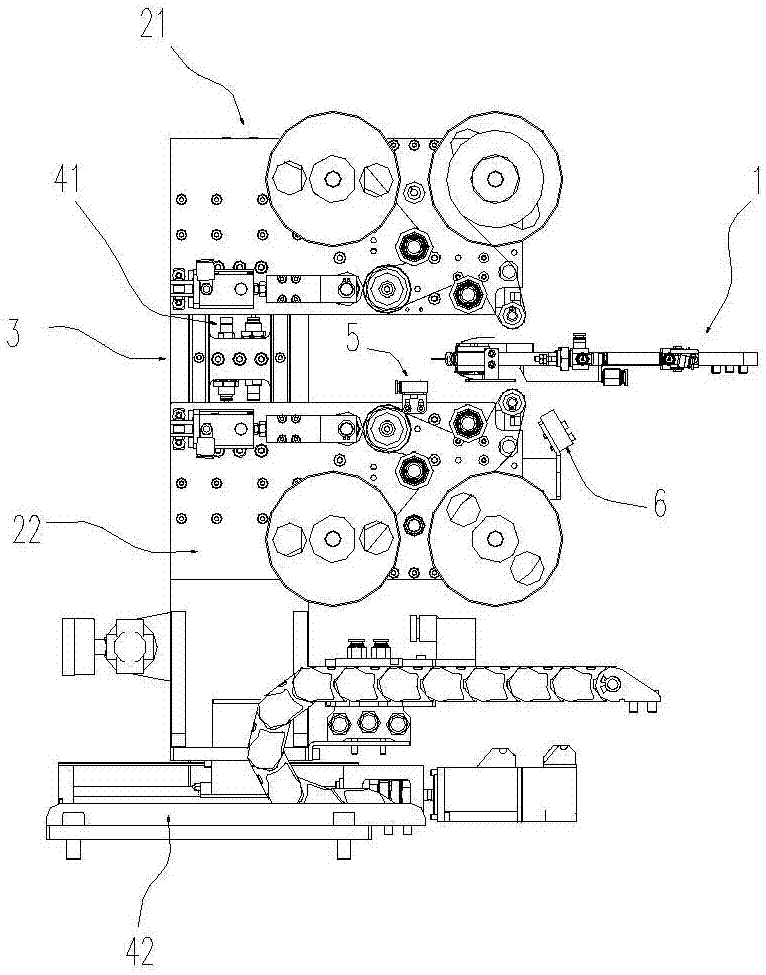

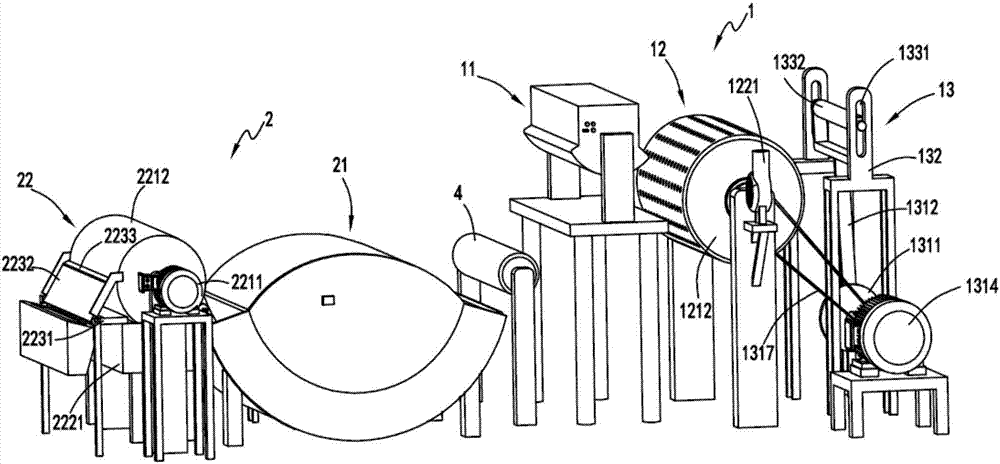

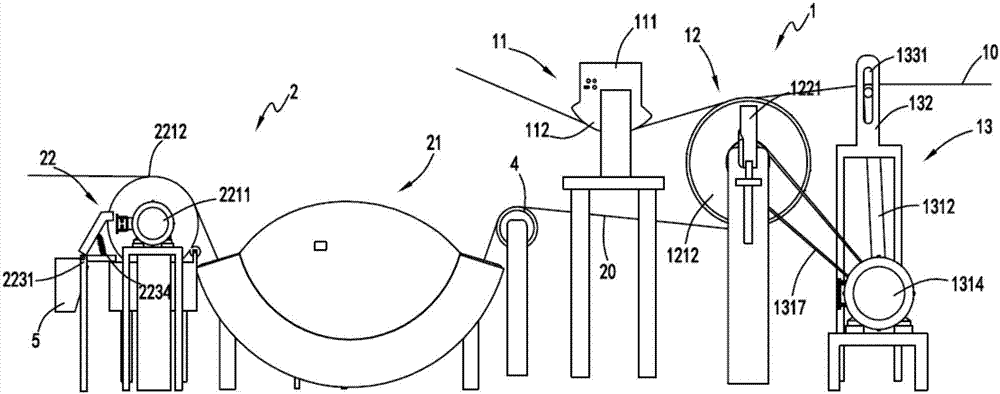

Automatic film stripping equipment

PendingCN107399144ACompact and reasonable structure designReduce scrap rateLamination ancillary operationsLaminationMechanical engineeringPollution

The invention discloses automatic film stripping equipment. The automatic film stripping equipment comprises a feeding mechanism, a first taking mechanism, a first delivery mechanism, a film stripping mechanism, a second delivery mechanism and a second taking mechanism, wherein the film stripping mechanism comprises a first film stripping mechanism and a second film stripping mechanism; the first film stripping mechanism comprises at least one first viscous coil unwinding mechanism and at least one first film collecting wheel; and the second film stripping mechanism comprises at least one second viscous coil unwinding mechanism and at least one second film collecting wheel. The automatic film stripping equipment further comprises a controller, and the feeding mechanism, the first taking mechanism, the first delivery mechanism, the first viscous coil unwinding mechanisms, the first film collecting wheels, the second viscous coil unwinding mechanisms, the second film collecting wheels, the second delivery mechanism and the second taking mechanism are electrically connected with the controller. The automatic film stripping equipment can automatically strip protective films on the upper surface and the lower surface of a product and orderly collect the stripped protective films to reduce environmental pollution; and the whole film stripping process is mechanically controlled fully automatically, the product rejection rate is low, and the automatic film stripping equipment is suitable for wide popularization.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

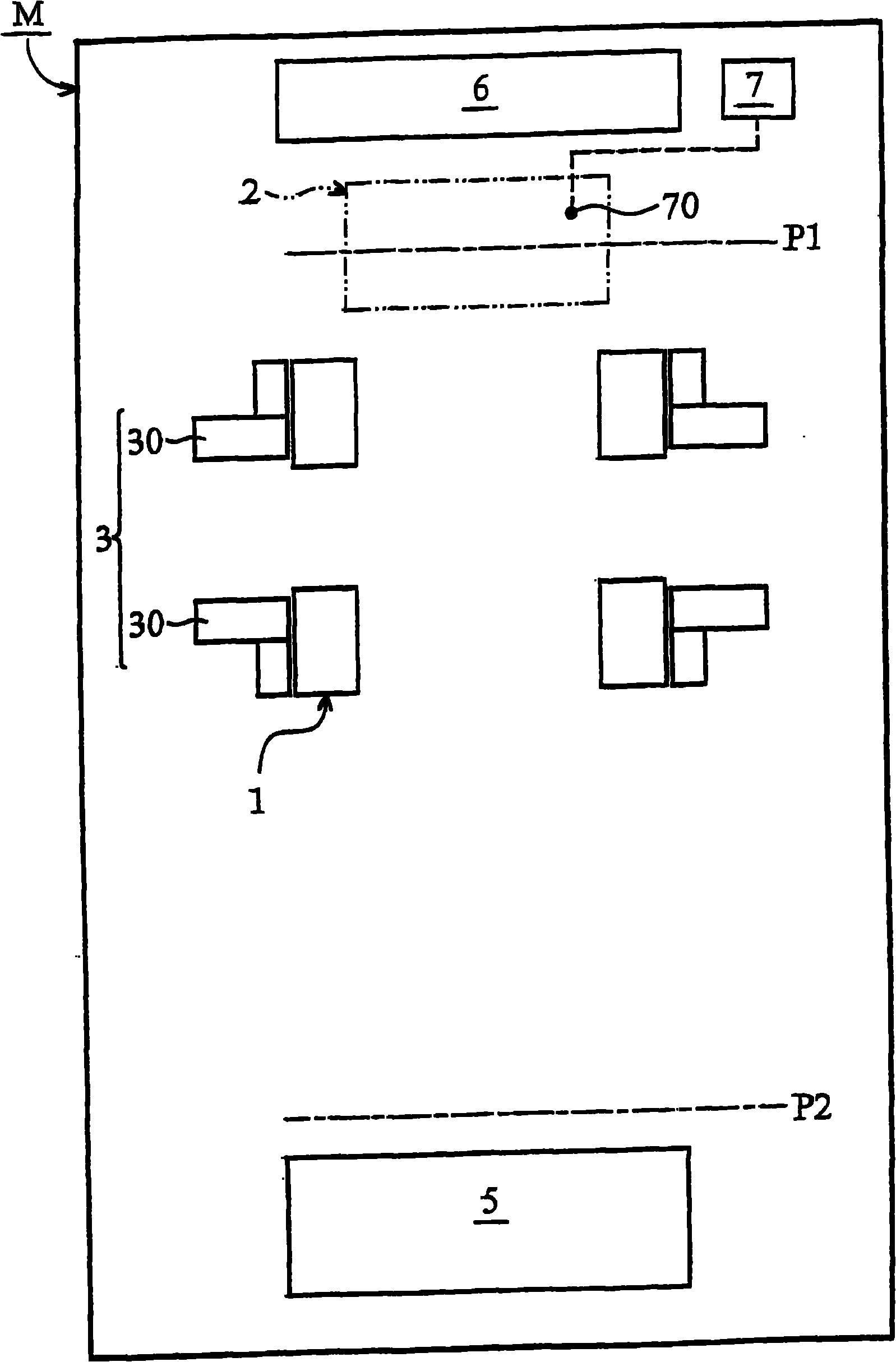

Separation device and separation method thereof

InactiveCN102059842AImprove tearing efficiencyAvoid scratchesLamination ancillary operationsLaminationPrinted circuit boardComputer science

The invention discloses a separation device and a separation method thereof, which can realize complete separation of a first base material and a second base material connected with each other. The separation device comprises a pedestal and a first chuck unit. The pedestal is used for supporting the first base material and the second base material connected with each other. The first chuck unit can move between a first position and a second position relative to the pedestal. When the first chuck unit is positioned at a set position between the first position and the second position, the firstchuck unit causes local separation between the first base material and the second base material and clamps the separated second base material; and when the first chuck unit moves to the second position from the set position, the second base material clamped by the first chuck unit is completely separated from the base material by the drive of the first chuck unit. The separation device and the separation method can effectively promote the film tearing efficiency of a printed circuit board and reduce the manpower cost.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

Fully-automatic PET cover film peel-off machine

PendingCN107985703AReduce labor costsImprove tearing efficiencyArticle unpackingProduct gasEngineering

In order to solve the technical problem that a peel-off machine in the prior art cannot peel off a relatively thick release film, the invention provides a fully-automatic PET cover film peel-off machine. The fully-automatic PET cover film peel-off machine comprises a table board, wherein a platform deck used for placing a product is arranged above the table board; a film peel-off mechanism capableof moving back and forth is arranged above the platform deck; the peel-off mechanism comprises a row of horn covers with downward openings, wherein a gas tube is placed in each horn cover; and the tube opening of each gas tube faces the inner wall of the corresponding horn cover. Gas blown out from the gas tubes is changed into spiral gas flow in the horn covers; and when the horn covers move above the platform deck, the cover film covering a product is peeled off by spiral gas flow. The fully-automatic PET cover film peel-off machine can replace manual work to peel off the relatively thick release film, reduces labor cost and improves film peel-off efficiency.

Owner:苏州福莱科斯电子科技有限公司

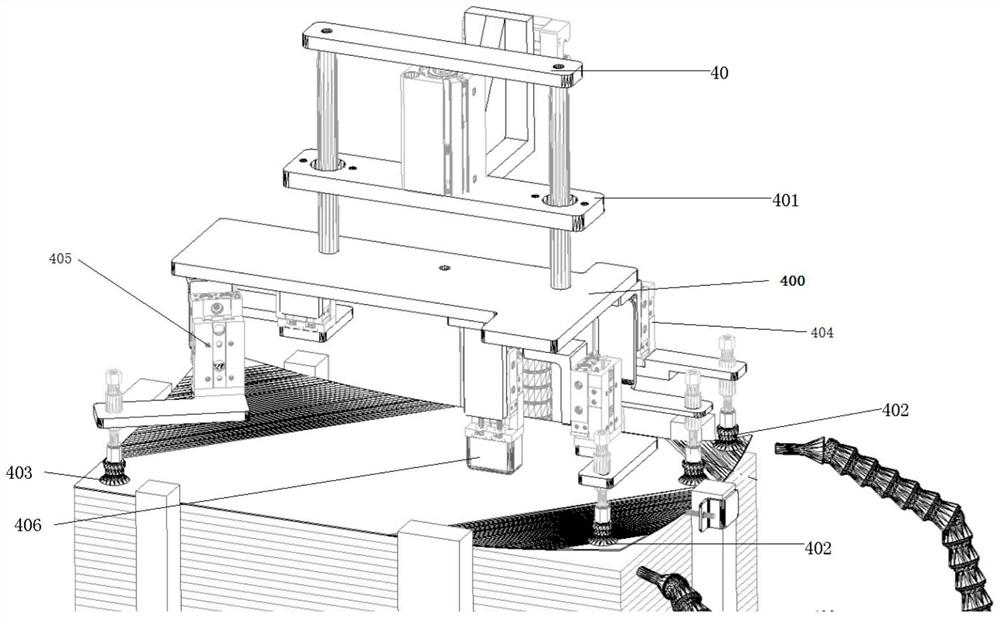

Film tearing equipment for sequentially tearing bottom films and top films of OLED materials

InactiveCN107972940AHigh degree of automationGuaranteed uptimeLamination ancillary operationsLaminationSurface layerEngineering

The invention relates to film tearing equipment for sequentially tearing bottom films and top films of OLED materials. The film tearing equipment comprises a feeding device, a front film tearing device, a rear film tearing device, a receiving device and a horizontal conveying device. The front film tearing device comprises a top film tearing assembly and a top film collecting assembly, and the rear film tearing device comprises a bottom film tearing assembly and a bottom film collecting assembly. The top film tearing assembly comprises a second rubber roller and a third rubber roller which aremutually parallel, are sequentially arranged from top to bottom, are opposite in rolling direction and apply the pressure to the OLED materials. The bottom film tearing assembly comprises a fourth rubber roller and a fifth rubber roller which are mutually parallel, are sequentially arranged from top to bottom, are opposite in rolling direction and apply the pressure to the OLED materials. The second rubber roller and the fifth rubber roller are each provided with a viscous surface layer. According to the film tearing equipment, the top films and the bottom films of the OLED materials can be sequentially torn off, and the film tearing efficiency is greatly improved.

Owner:SUZHOU YILI DINGFENG INTELLIGENT TECH CO LTD

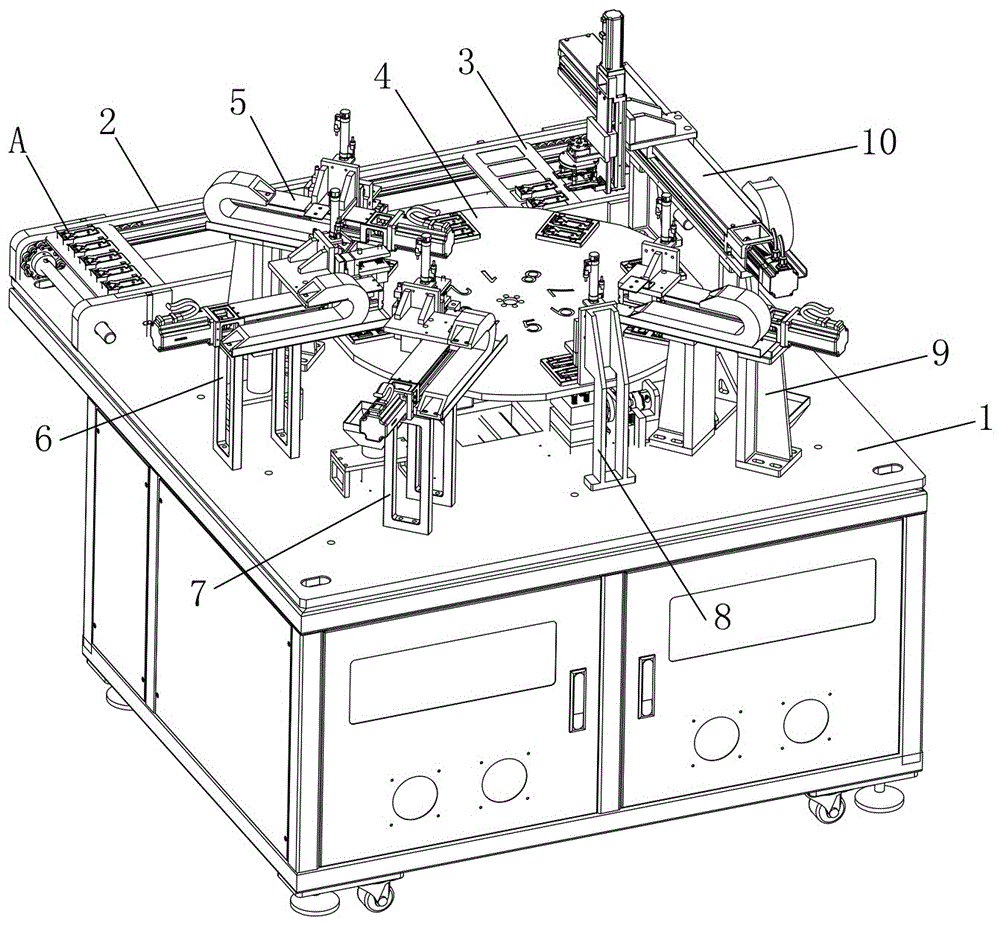

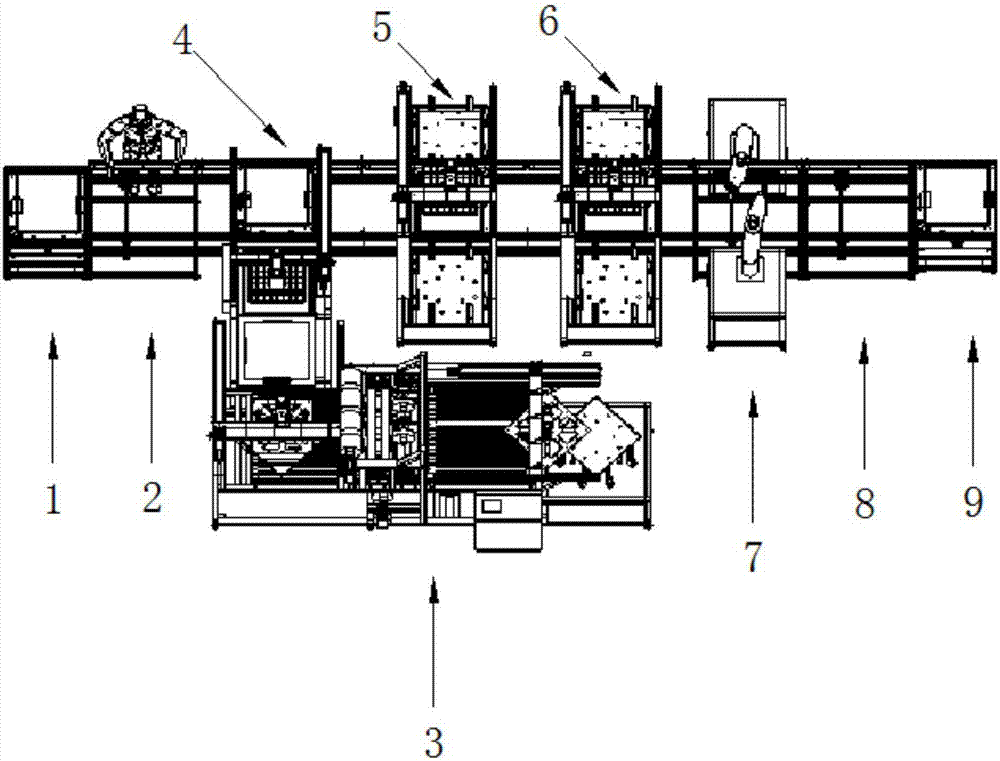

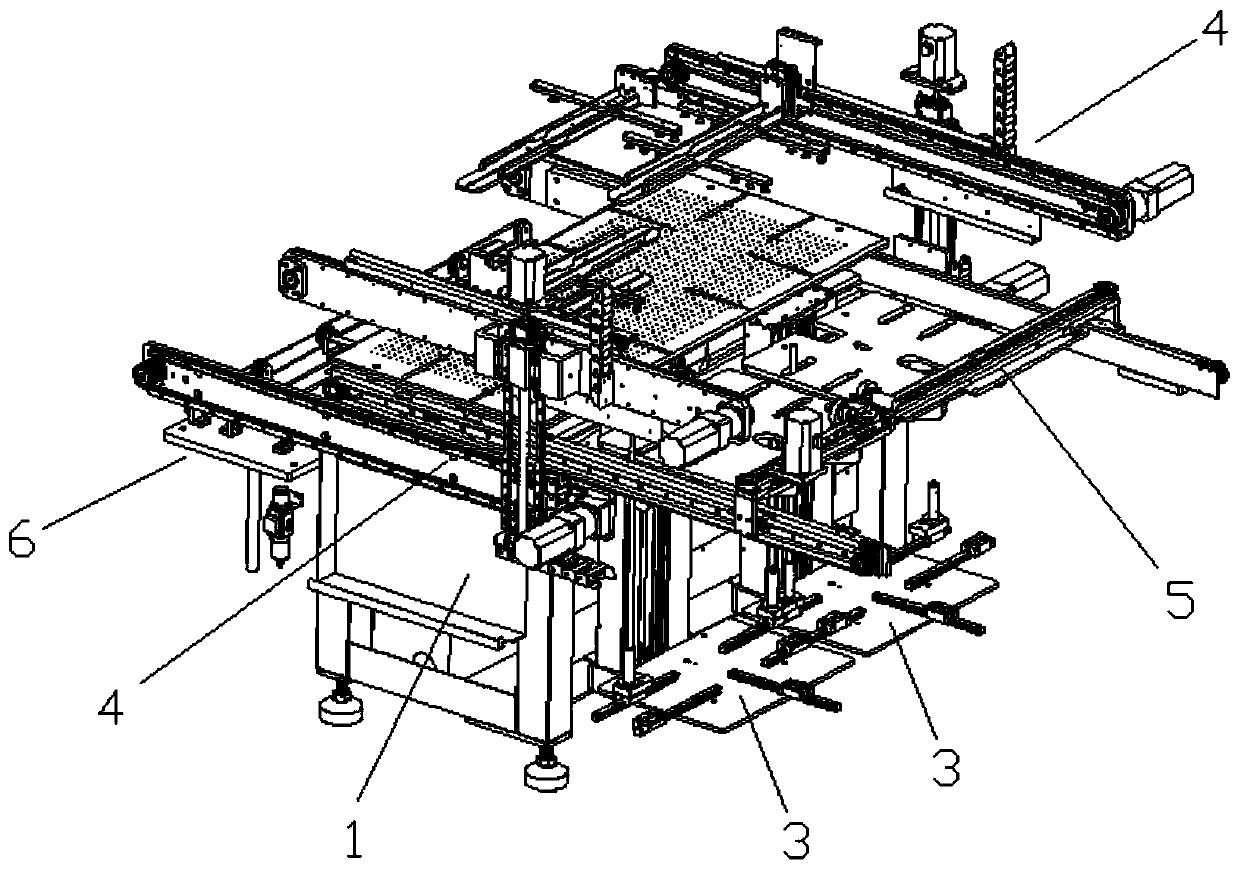

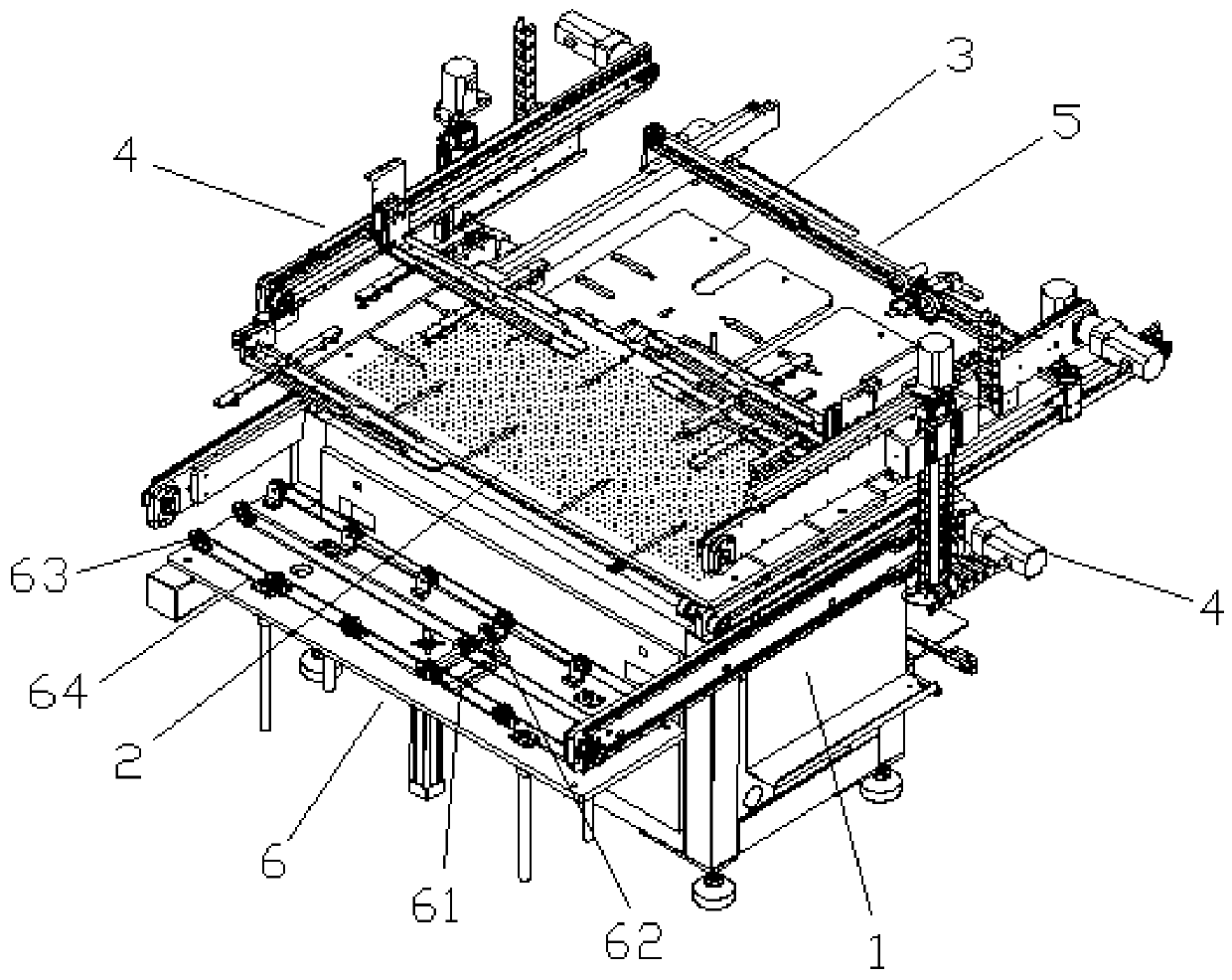

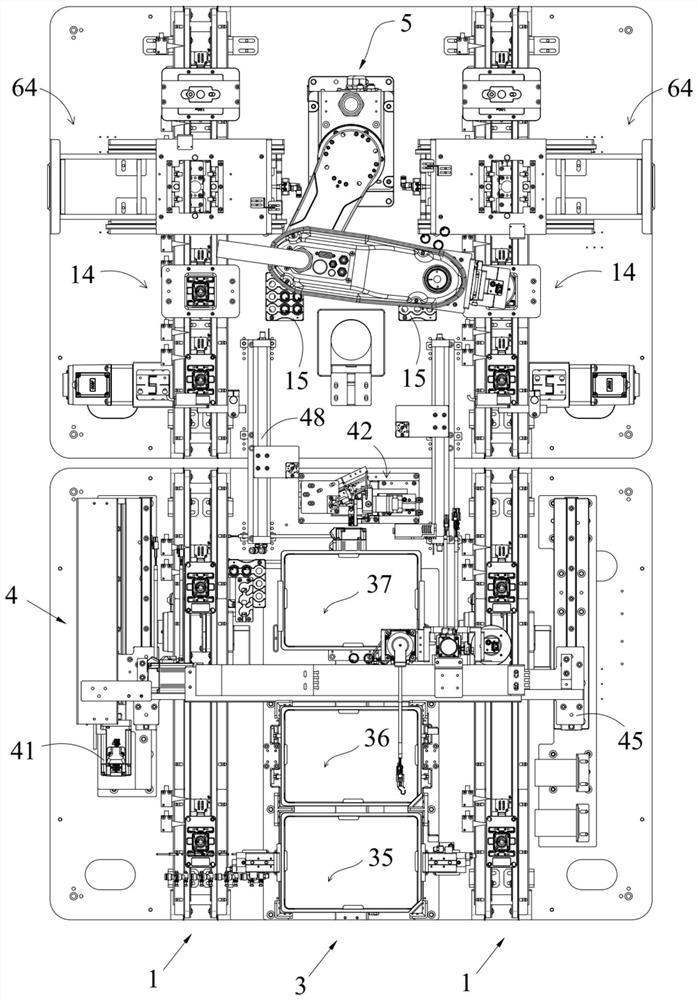

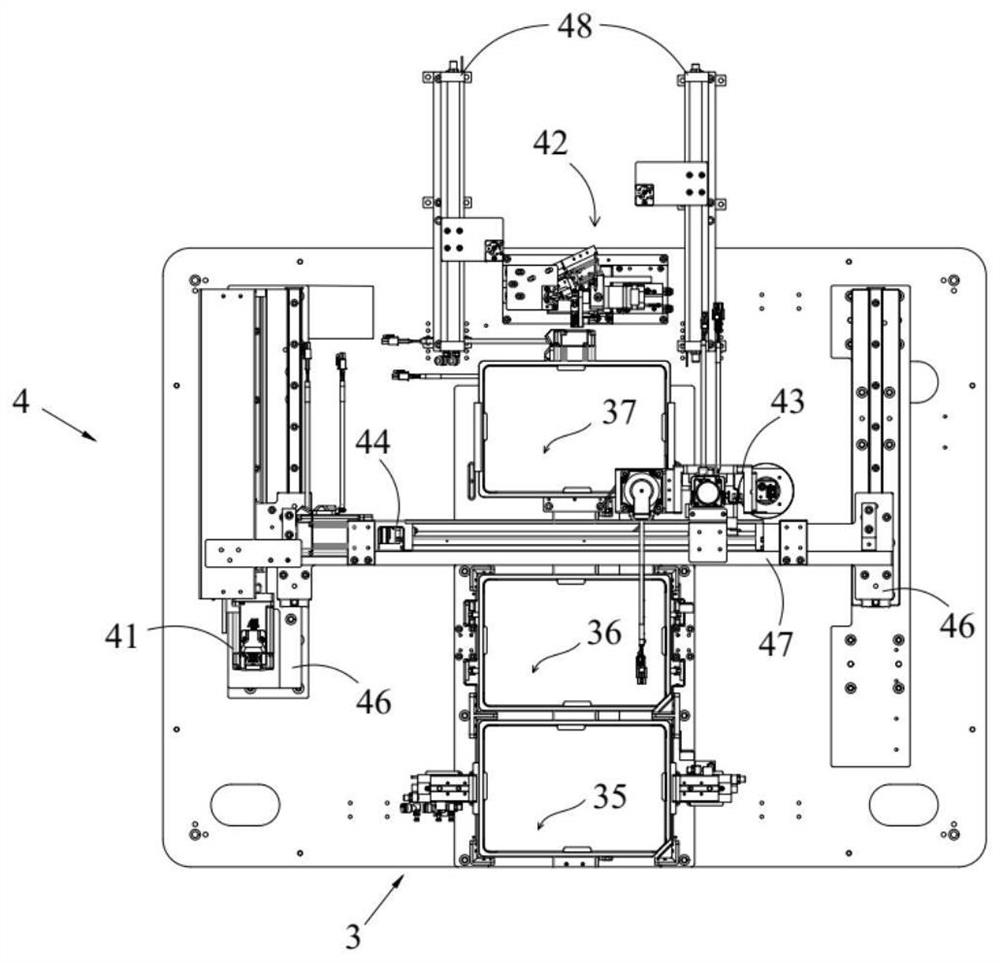

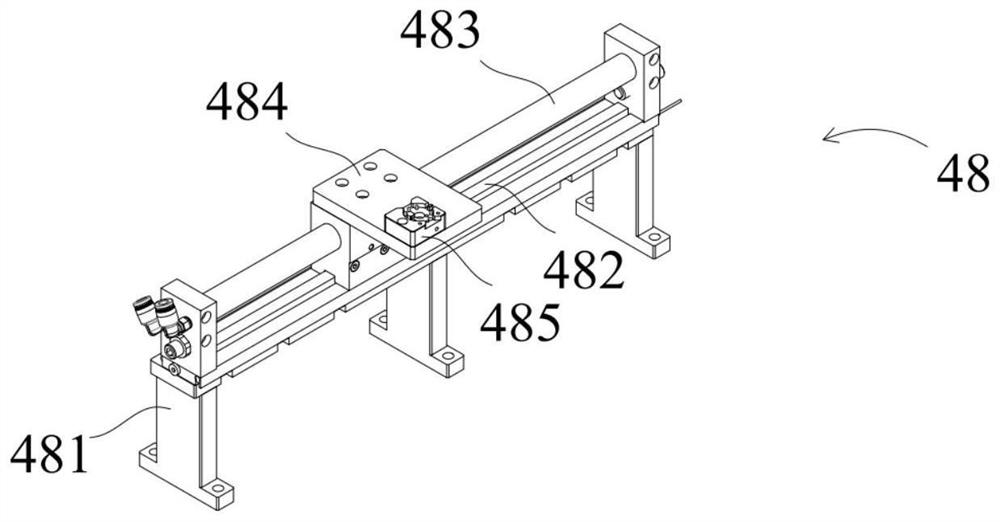

Automatic assembly production line for panel lights

PendingCN107378482AHigh degree of automationImprove assembly accuracyAssembly machinesProduction lineSheet film

The invention discloses an automatic assembly production line for panel lights. The assembly line comprises a carrier jacking station, a light frame feeding station, an optical sheet film-tearing station, a optical sheet assembly station, a reflective plate assembly station, a back plate assembly station, a screw locking station, a finished product collecting station and a carrier return station; the light frame feeding station is located on the downstream portion of the carrier jacking station, the optical sheet assembly station is located on the downstream portion of the light frame feeding station, and the optical sheet film-tearing station is located on the upstream portion of the optical sheet assembly station; the reflective plate assembly station is located on the downstream portion of the optical sheet assembly station, the back plate assembly station is located on the downstream portion of the reflective plate assembly station, the screw locking station is located on the downstream portion of the back plate assembly station, the finished product collecting station is located on the downstream portion of the screw locking station, and the carrier return station is located on the downstream portion of the finished product collecting station. The automatic assembly line for the panel lights has the advantages of being high in automation degree and assembly precision, achieving quick, high-efficiency and high-quality production, reducing labor intensity, and decreasing the scrap rate of the products.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

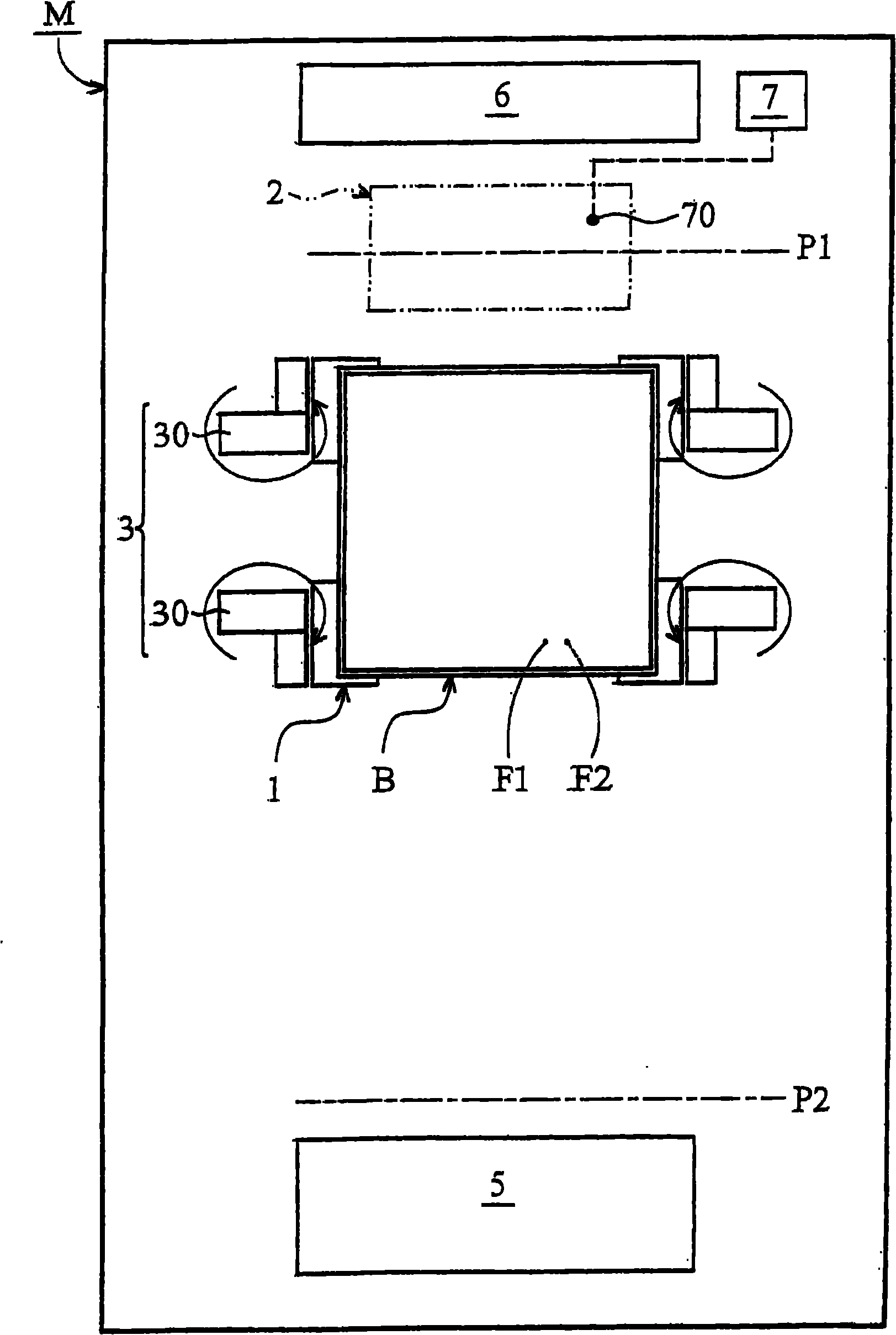

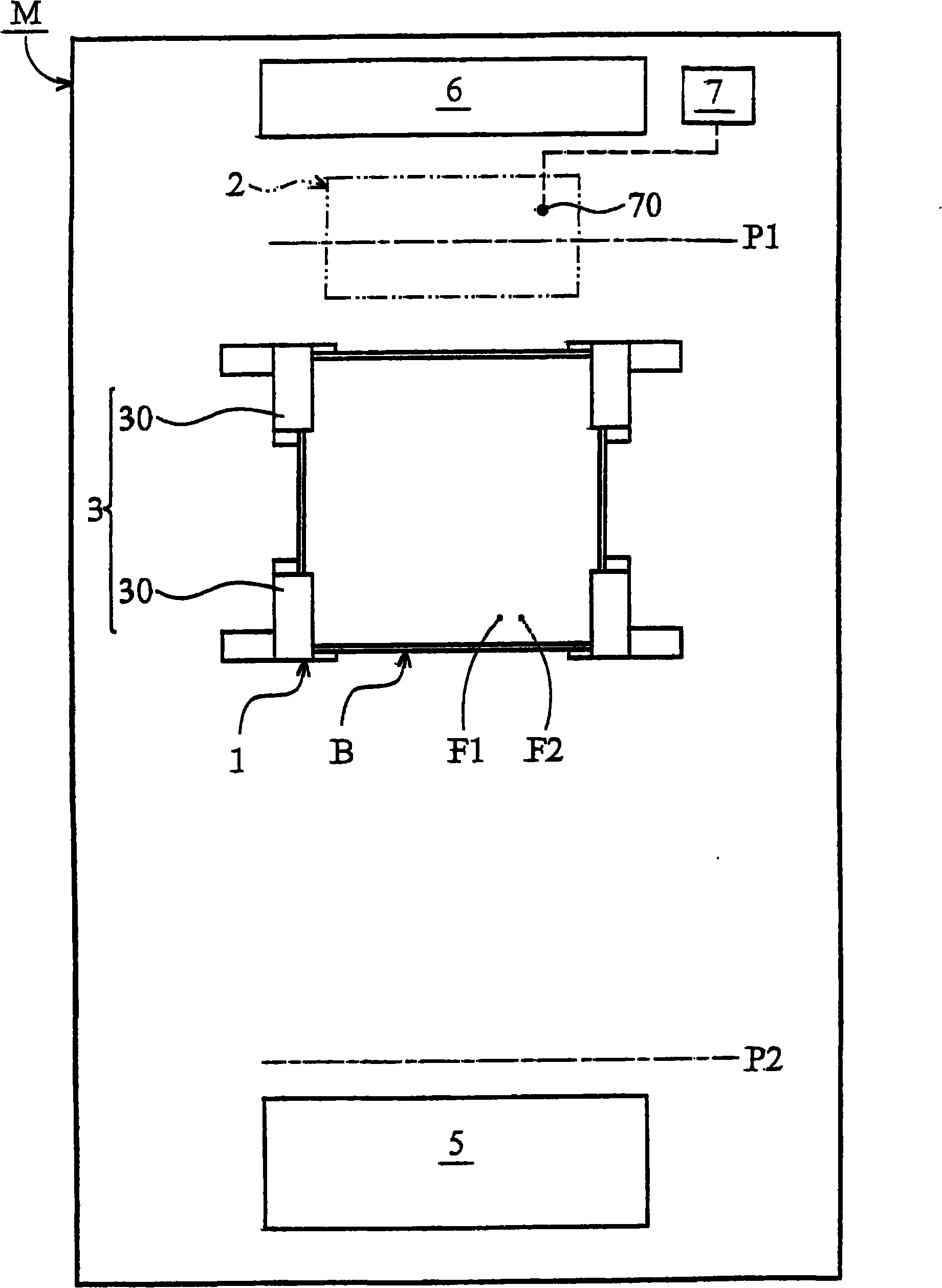

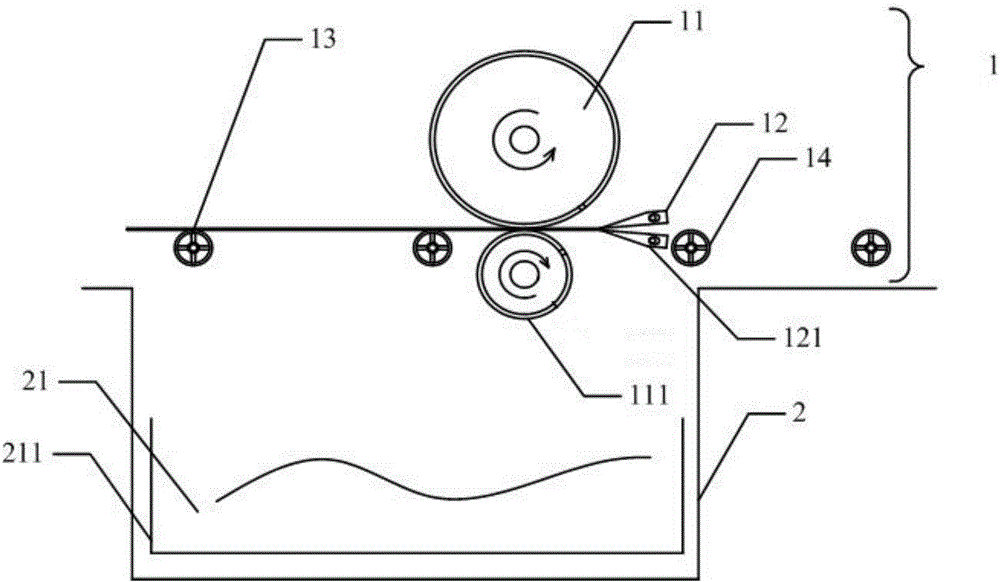

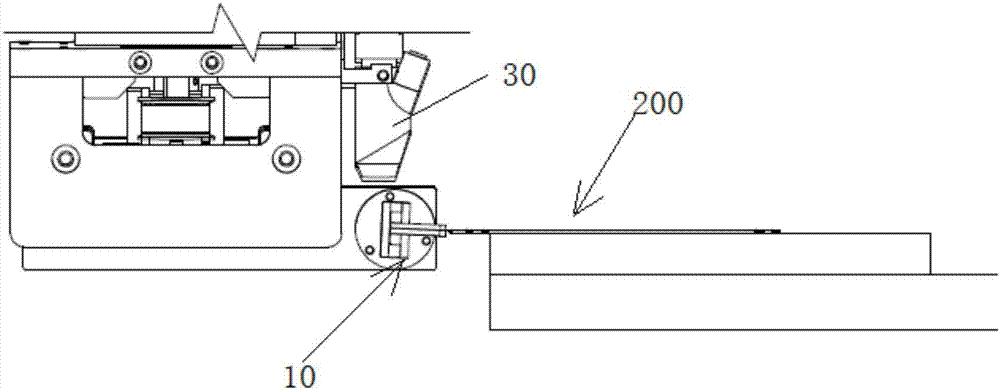

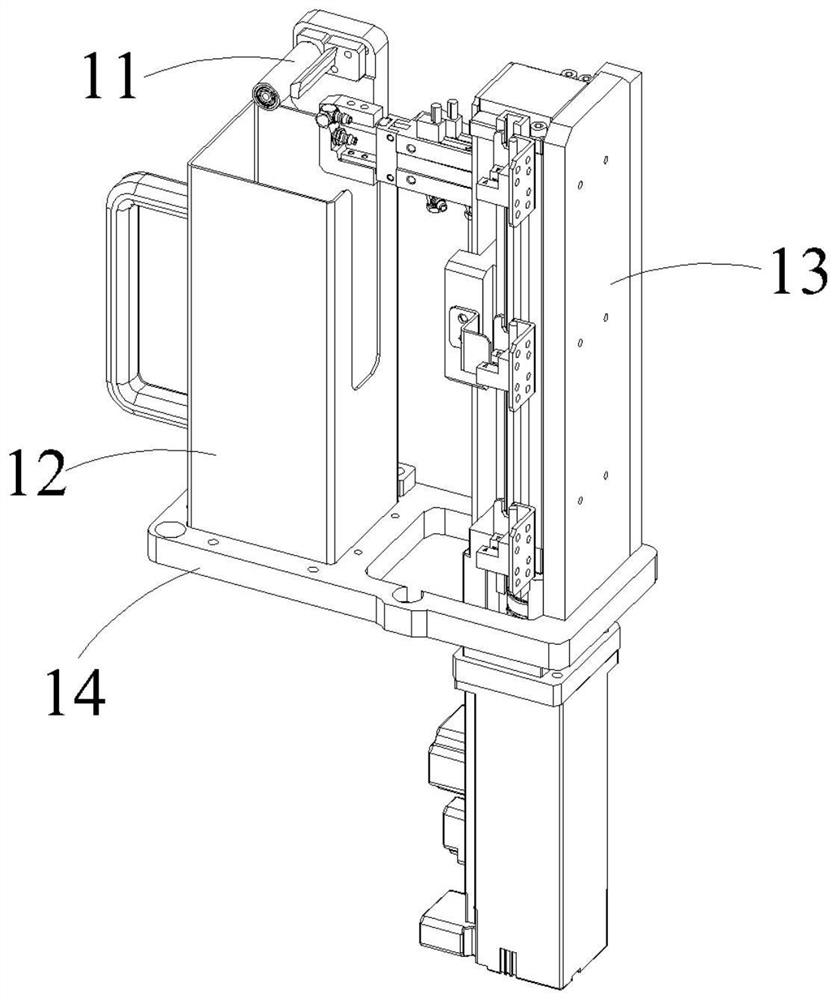

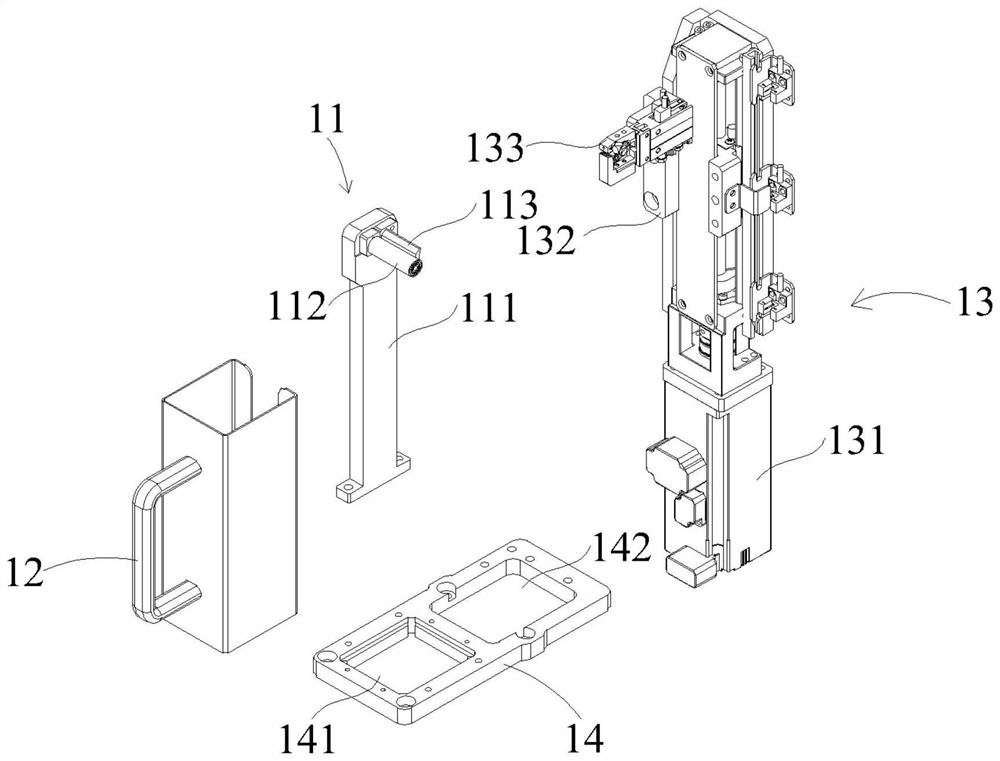

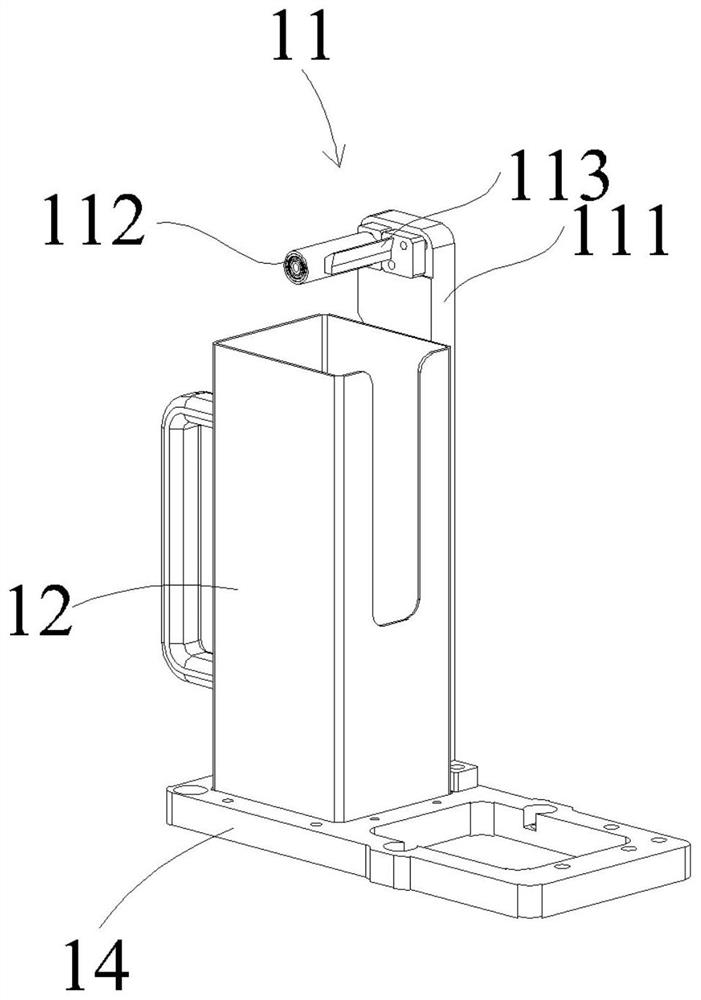

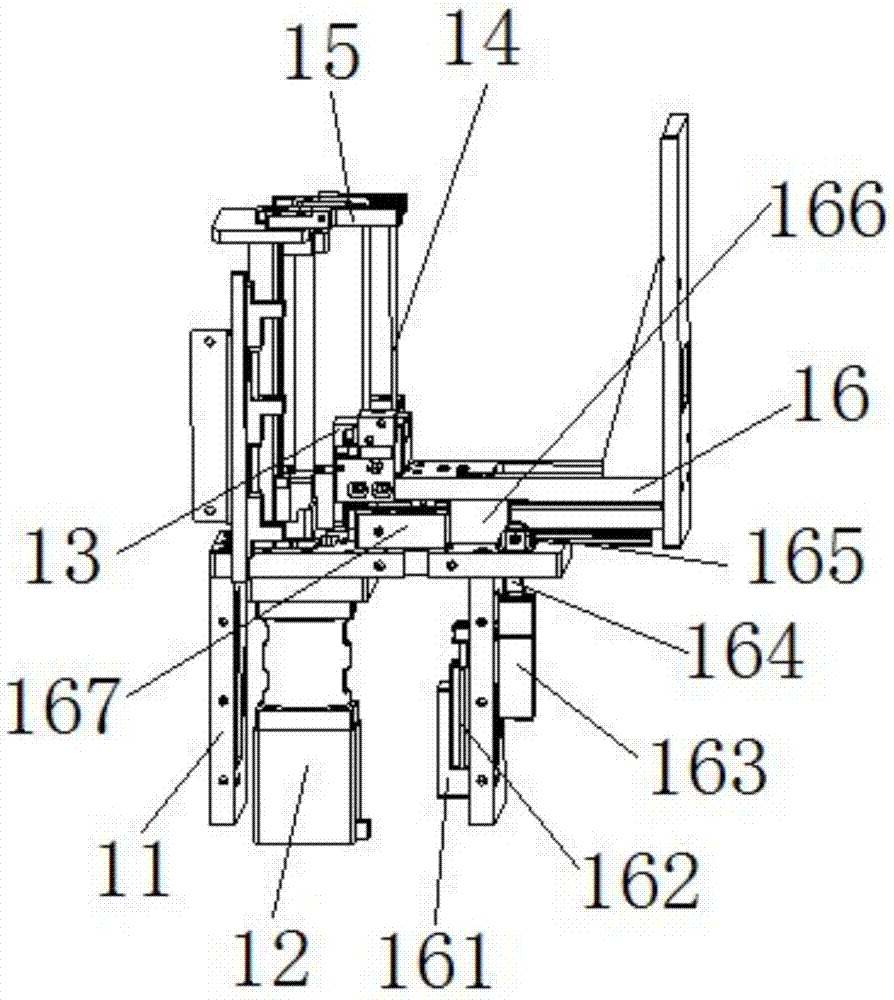

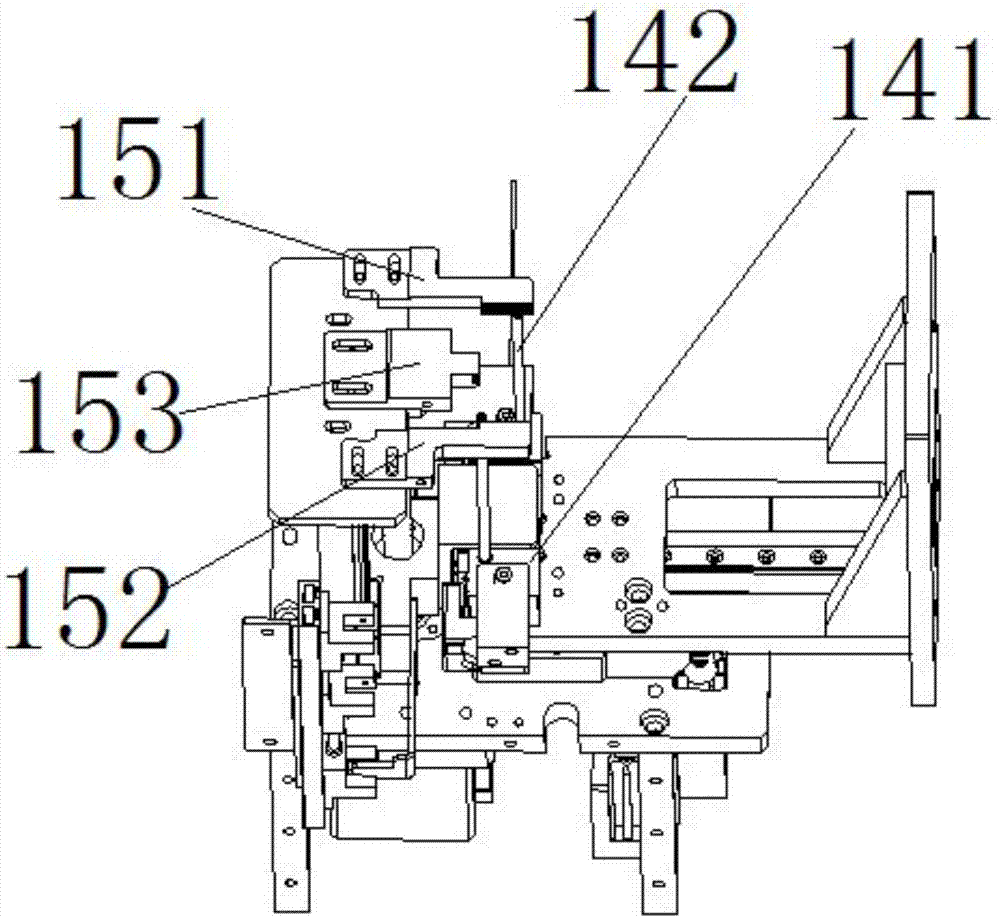

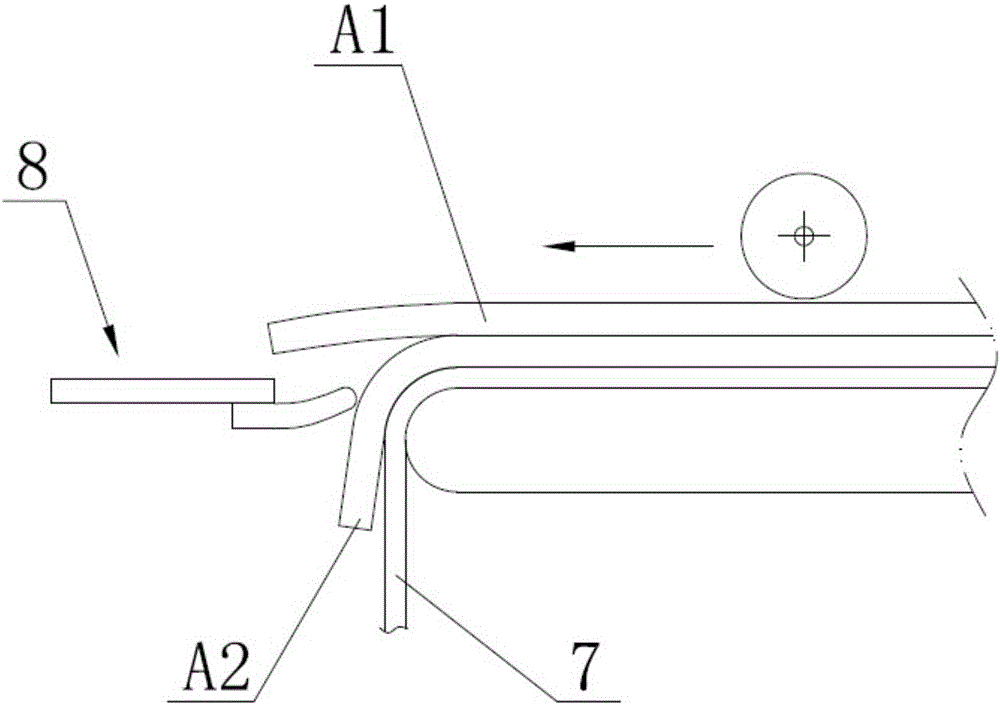

Film-tearing apparatus

InactiveCN106211589AThe film tearing process is complete and easyOperation mechanizationConductive material chemical/electrolytical removalFault rate

The invention discloses a film-tearing apparatus. The film-tearing apparatus can ensure a complete, simple and convenient film tearing process, a mechanical operation and low fault rate, and can lower loss and improve the film-tearing efficiency. The film-tearing apparatus provided by the invention comprises a film-tearing part (1) and a film-collecting part (2), wherein the film-tearing part (1) comprises a film-collecting roller (11) and an edge remover (12); the edge remover (12) can be used for removing a protection film from a circuit board; the film-collecting roller (11) is used for tearing the protection film which is removed by the edge remover (12); and the film-collecting roller (11) and the edge remover (12) are positioned on the same side of the circuit board.

Owner:广州炬森自动化设备有限公司

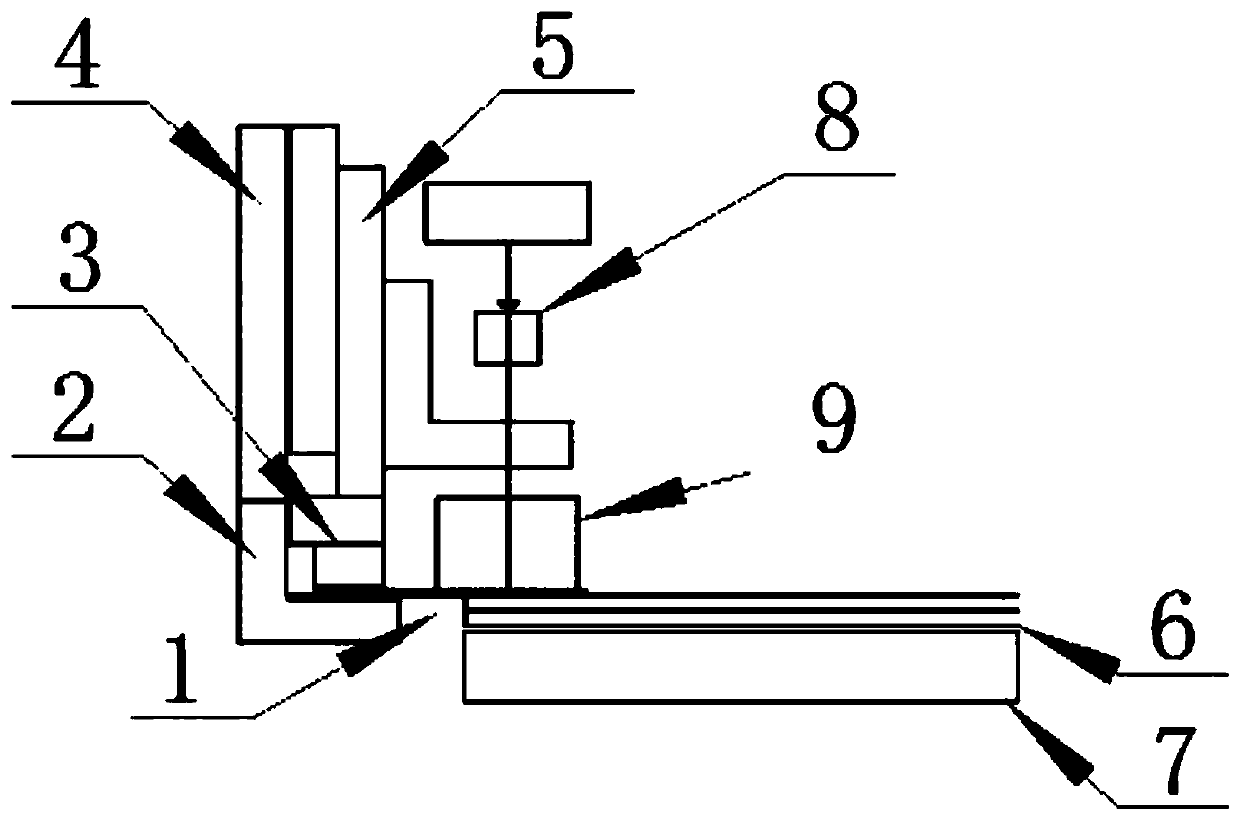

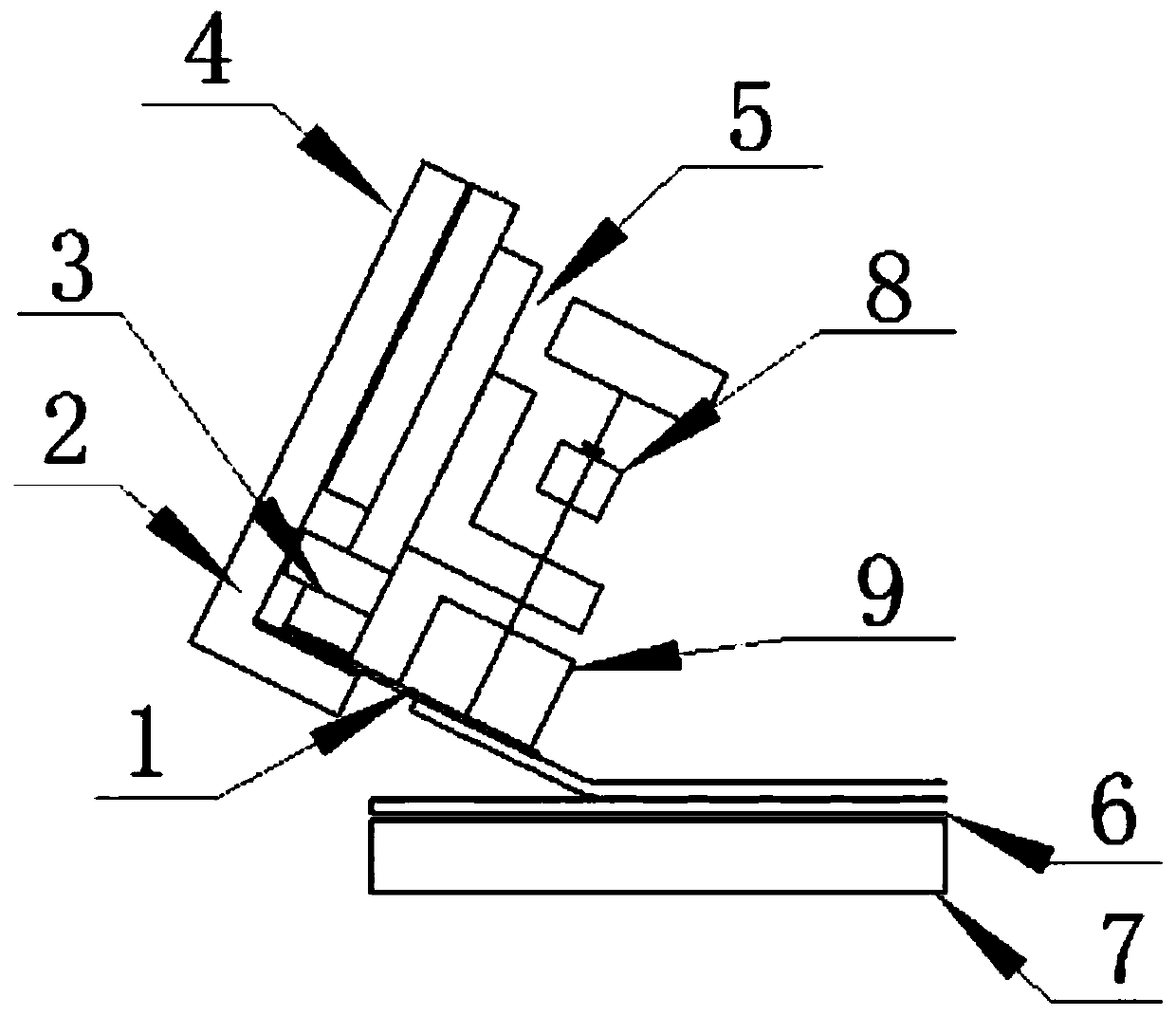

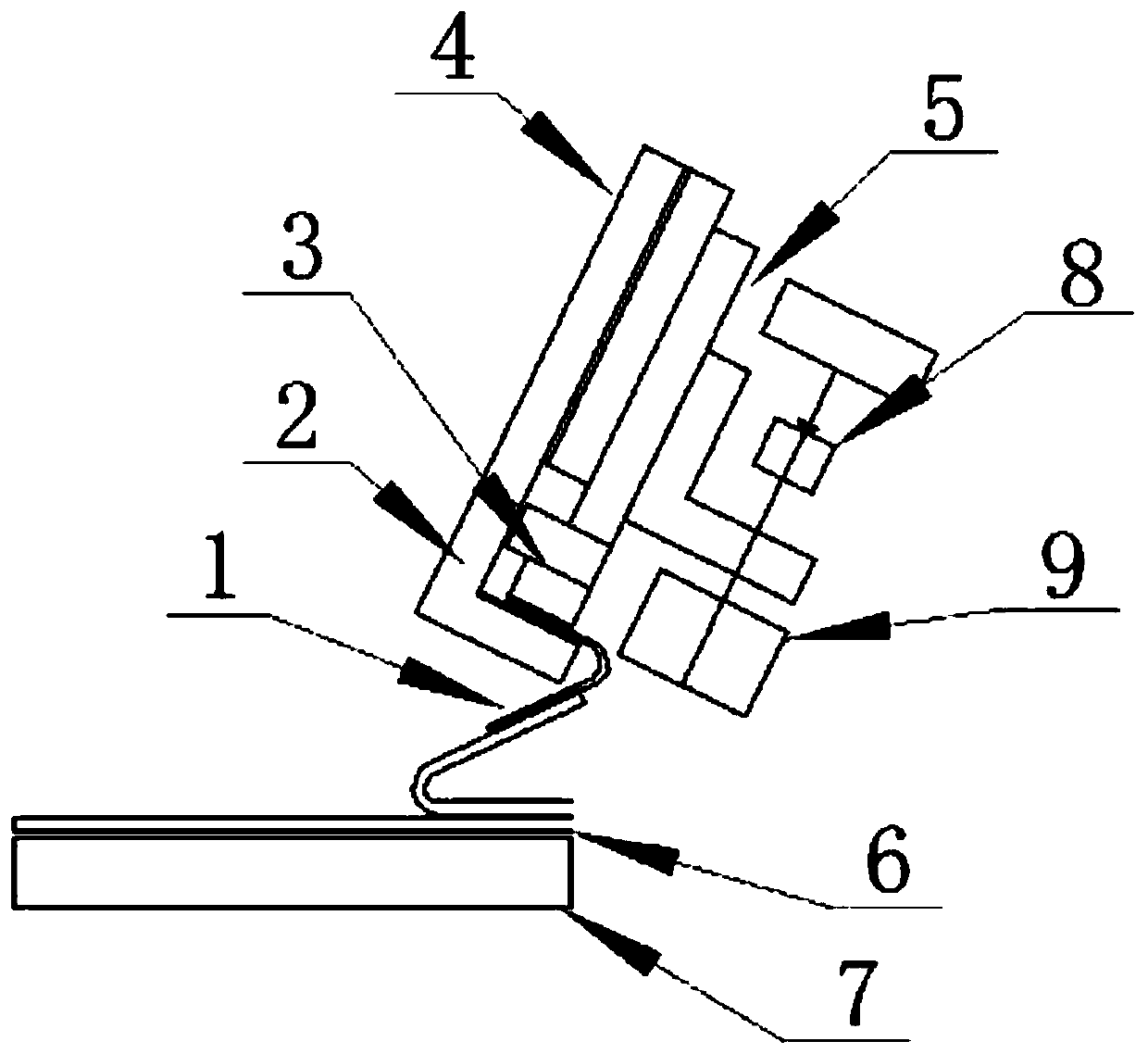

Protection film tearing system

PendingCN110682660AAvoid disadvantagesImprove tearing efficiencyLamination ancillary operationsLaminationForeign matterEngineering

The invention discloses a protection film tearing system, which comprises an easy-to-tear sticker, a first clamping part, a second clamping part, a mounting plate and a clamp driving device, wherein the first clamping part is mounted on the mounting plate, the clamp driving device is mounted on the mounting plate, the second clamping part is arranged at the telescopic end of the clamp driving device so as to make the first clamping part and the second clamping part form a clamp for mounting the easy-to-tear sticker, and the sticking part of the easy-to-tear sticker can be connected to the protection film of a to-be-treated product in a sticking manner. According to the invention, with the protection film tearing system, the first clamping part and the second clamping part clamp the non-sticky part of the easy-to-tear sticker, the protection film is adhered through the sticking part of the easy-to-tear sticker, and the clamping part is displaced through the horizontal moving structure commonly used in the automatic equipment industry to achieve the separation operation of the protection film and the to-be-treated product, so that the defect that the product is brought up in a rollerfilm tearing mode is overcome while the foreign matter brought by a friction force separation mode is eliminated so as to improve the film tearing efficiency and the film tearing effect.

Owner:SHENZHEN JT AUTOMATION EQUIP CO LTD

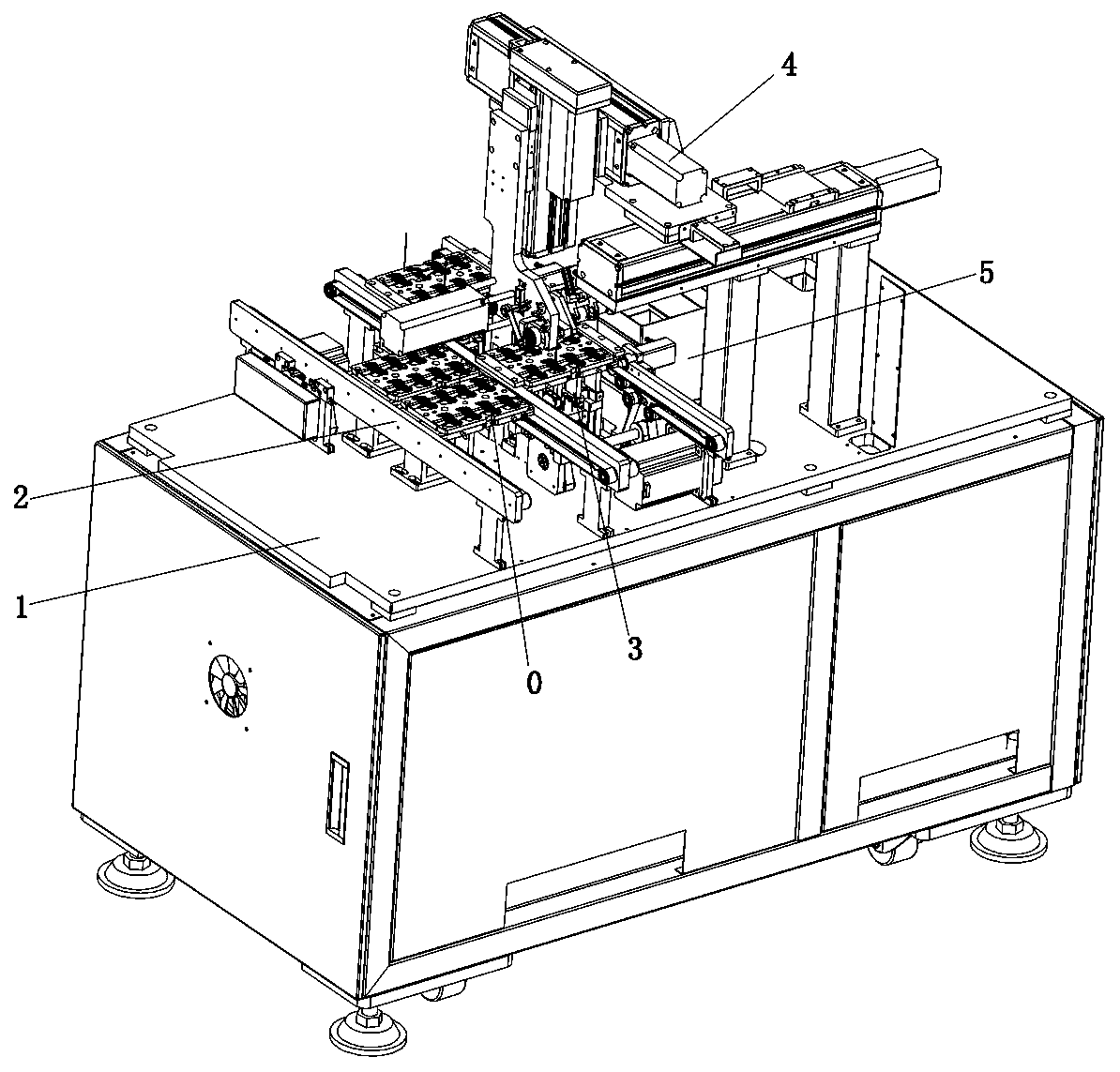

Automatic double-row film tearing machine

PendingCN110370785ALess materialImprove tearing efficiencyLamination ancillary operationsLaminationAgricultural engineeringDouble row

The invention discloses an automatic double-row film tearing machine. A rack is provided with a workbench, a feeding mechanism and a discharging mechanism are respectively arranged on the two oppositesides of the rack, double-layer gripper shifting mechanisms are symmetrically arranged on the other two opposite sides of the rack, the rack is provided with a film tearing mechanism, a film tearinghead includes a first mounting plate, a first fixing block and a second fixing block are arranged on the first mounting plate, a first cylinder is arranged on the first fixing block, the first cylinder is provided with a pressure rod, the second fixing block is provided with a second cylinder, the second cylinder is provided with a film sticking head, a belt retracting shaft and a belt releasing shaft are respectively arranged on the two sides of the second fixing block, continuous tape passing the lower part of the film sticking head is arranged between a loop belt barrel on the outer side ofthe belt retracting shaft and the belt releasing shaft, one side wall of the second fixing block is provided with a third fixing block, and a film clamping cylinder is arranged at the lower end of the third fixing block. According to the automatic double-row film tearing machine, the three cylinders on the film tearing head work together to complete film tearing at the edges and corners, only thetape at the film sticking head can be needed to complete film tearing action, a material is saved, and at the same time, the film tearing efficiency is improved through double-station.

Owner:昆山兑印机械有限公司

Film tearing device based on knurl wheels and film tearing method of film tearing device

The invention provides a film tearing device based on knurl wheels and a film tearing method of the film tearing device. A conveying device is used for conveying a workpiece which is about to be subjected to film tearing to the position of a notch, then, under driving of a third drive device and a fourth drive device, sliding plates slide in the horizontal direction, the knurl wheels and a film blowing air needle are driven to move towards the two sides from the center, knurling is conducted on a protection film on the workpiece through rolling of the knurling wheels, the film blowing air needle conducts air blowing at the same time, and the knurled protection film is separated from the workpiece. Then, the workpiece leaves a sliding film tearing assembly, the sliding plates are driven toreset by the third drive device and the fourth drive device, and arrival of a next workpiece is waited. The knurling wheels and the film blowing air needle are mutually matched, traditional manual film tearing is changed into mechanical automatic film tearing, and the film tearing efficiency is greatly improved.

Owner:SHENZHEN MICRO ZHUO TECH CO LTD

Film tearing device

The invention relates to a film tearing device which comprises a bracket, a film tearing component and a following component, wherein the film tearing component comprises a driving wheel, a guide wheel, an idle wheel and a film tearing adhesive tape, and the peripheries of the driving wheel, the guide wheel and the inert wheel are wrapped with the film tearing adhesive tape, and a film tearing region is formed on the film tearing adhesive tape; the following component comprises a base, a driving part, a load bearing part and a positioning fixture; the positioning fixture comprises a pedestal, a cylinder, a flexible suction plate and a pressing actuation part, wherein the pedestal is arranged on the load bearing part, the cylinder is arranged on the pedestal, and the flexible suction plate is arranged on the cylinder. The film tearing device is relatively high in film tearing efficiency and low in workpiece contamination rate.

Owner:惠州市里斯科技有限公司

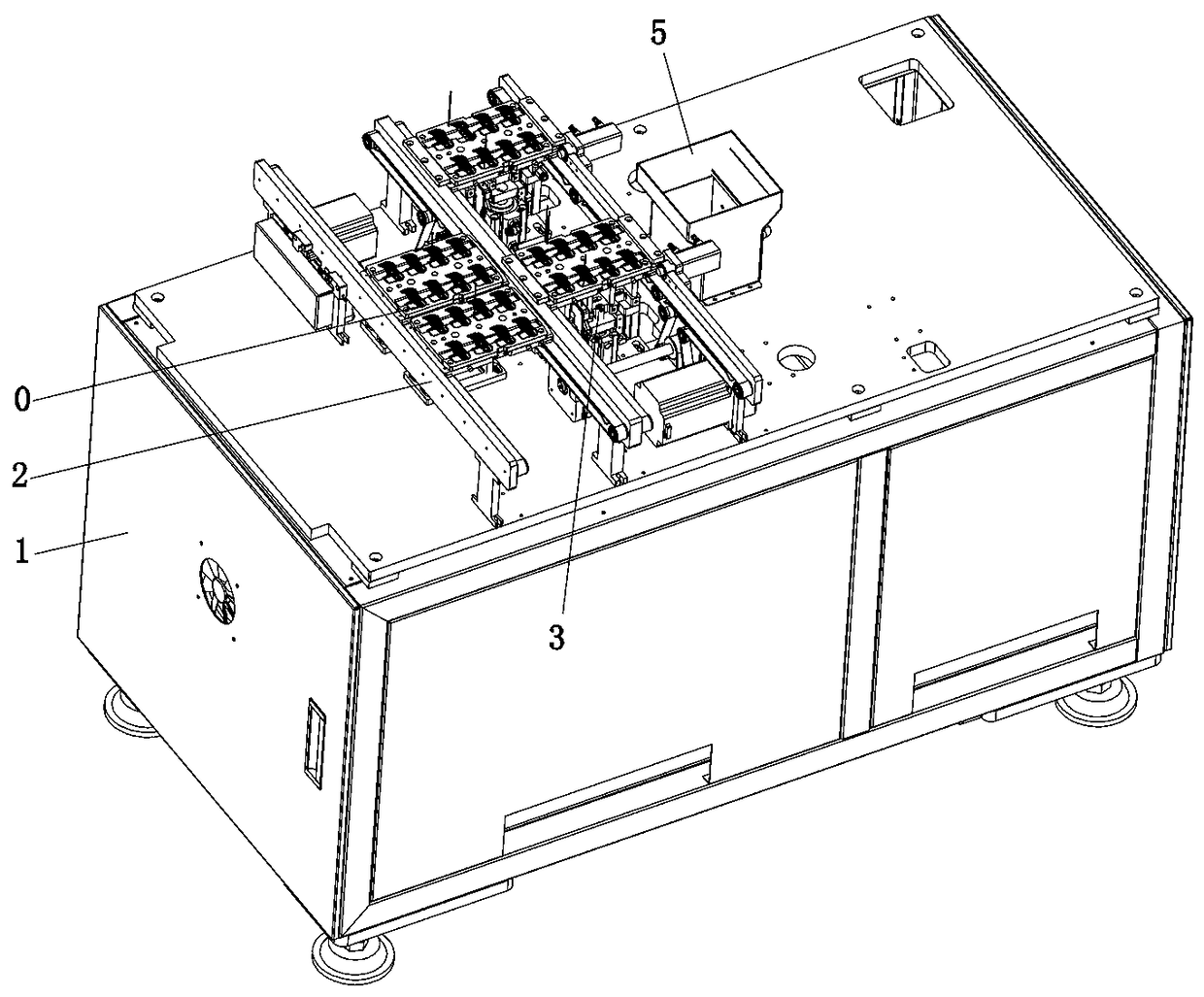

Double-sided film tearing equipment

PendingCN111806816AImprove tearing efficiencyReduce labor costsArticle unpackingThin membraneStructural engineering

The invention discloses double-sided film tearing equipment. The double-sided film tearing equipment is used for automatically removing thin films on the surface of a plate and automatically treatingthe thin films torn from the surface of the plate, the plate is in a sheet shape and at least comprises a corner, the plate comprises a lower surface and an upper surface, the lower surface and the upper surface are respectively provided with the films in an attached mode correspondingly, the double-sided film tearing equipment comprises a material storage frame, a material taking device, a firstfilm tearing station, a first film tearing mechanism, a film tearing conveying device, a second film tearing station, a second film tearing mechanism and the like. Compared with the prior art, the double-sided film tearing equipment provided by the invention is used for automatically tearing off the films attached to the upper surface and the lower surface of the flaky plate, so that the film tearing efficiency is improved, and the labor cost is reduced.

Owner:NICROTEK +1

Film tearing device

InactiveCN107160821AImprove tearing efficiencyLamination ancillary operationsLaminationTectorial membraneDrive shaft

Owner:KUSN JINGXUN ELECTRONICS TECH

Material pulling type film tearing mechanism

PendingCN112537115AImprove tearing efficiencySimple structureLayered productsLaminationReciprocating motionThin membrane

The invention discloses a material pulling type film tearing mechanism which comprises a workpiece bearing module used for bearing a film to be torn, a recycling material box arranged beside the workpiece bearing module, and a material pulling and film tearing assembly arranged beside the recycling material box, wherein the material pulling and film tearing assembly comprises a lifting driving module arranged in a vertical direction, a fixed plate in transmission connection with a movable part of the lifting driving module, and a clamping module fixedly connected to the surface of the fixing plate; and the clamping module clamps a thin film on the surface of a workpiece, and the lifting driving module drives the clamping module to do reciprocating motion in the vertical direction so as tocontrol the clamping module to tear the film on the workpiece and put the film into the recycling material bin. According to the film tearing mechanism, the structure is simple, the layout is reasonable, the automation degree is high, the film tearing efficiency of workpieces is greatly improved, and finally the production efficiency is improved.

Owner:SUZHOU RS TECH

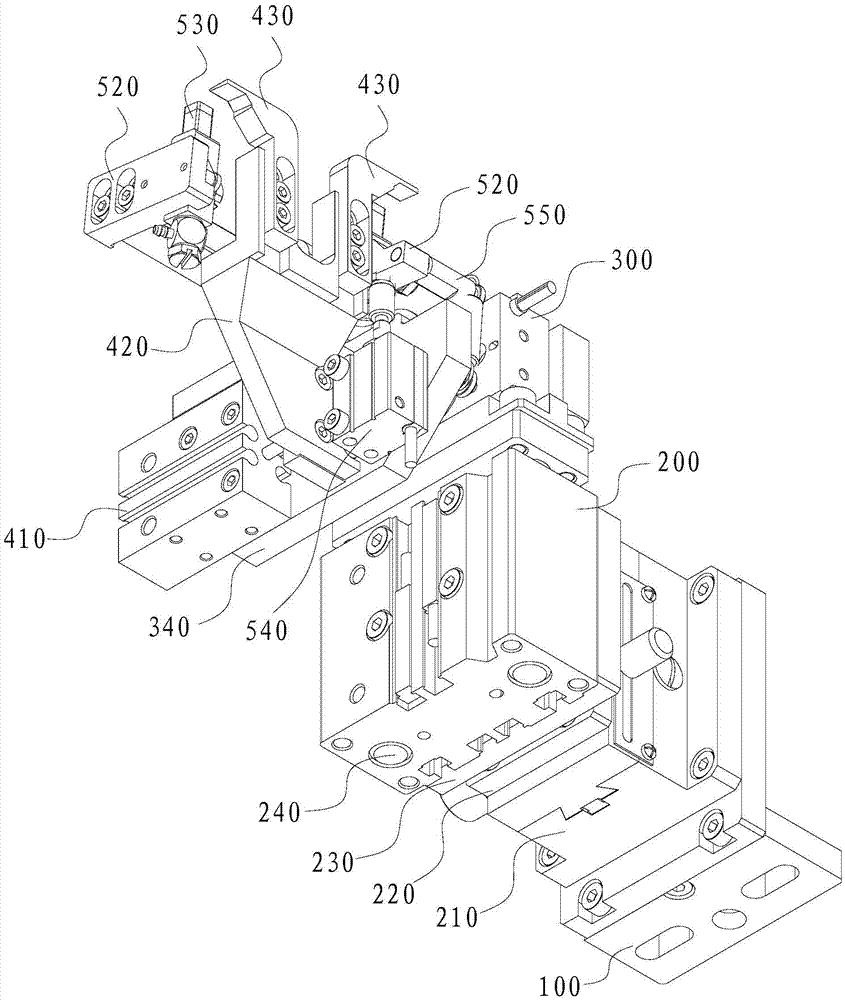

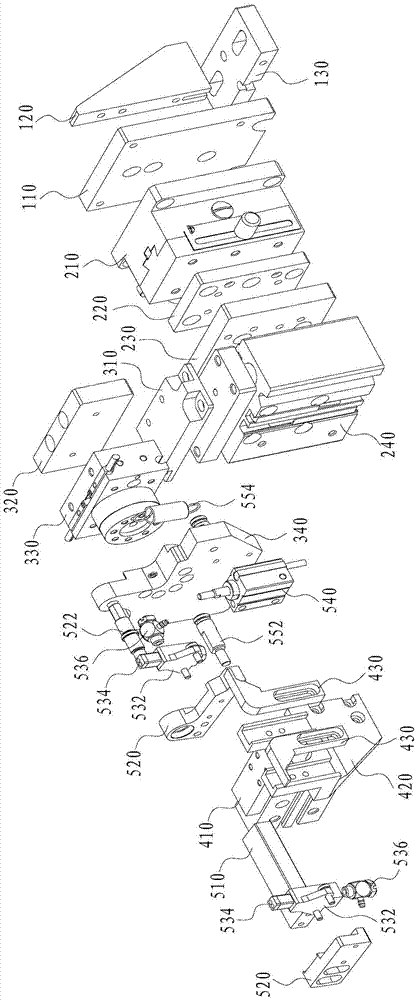

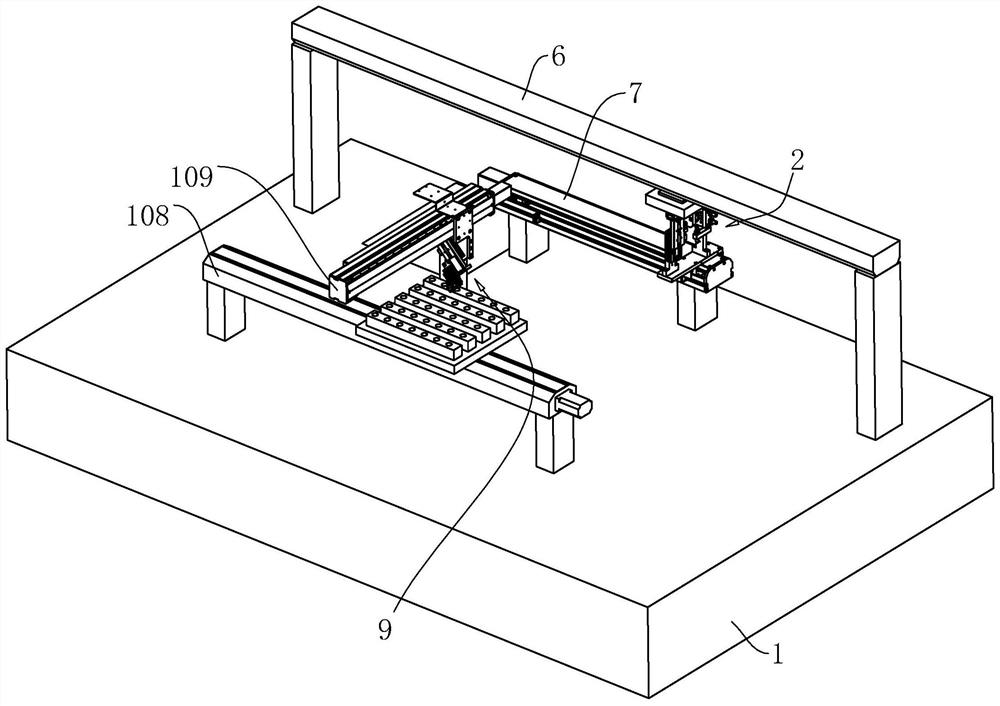

Device for automatically tearing gum film

ActiveCN105437724AGuaranteed reliabilitySmall footprintLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention provides a device for automatically tearing a gum film. The device comprises a mounting seat, a lifting driving mechanism arranged on the mounting seat, and a film adsorbing mechanism and a film pressing mechanism which are connected with the lifting driving mechanism, wherein the film adsorbing mechanism is mutually matched with the film pressing mechanism; the lifting driving mechanism comprises a lifting cylinder connected with the mounting seat and a fixing plate connected with the lifting cylinder; the film adsorbing mechanism comprises an adsorbing connection structure hinged with the fixing plate, one or more adsorbing head structures arranged on the adsorbing connection structure, and a rotation driving structure connected with the adsorbing connection structure; the film pressing mechanism comprises a sliding table cylinder arranged on the fixing plate and a pressing head structure connected with the sliding table cylinder; the pressing head structure is correspondingly matched with the adsorbing head structure. Through adoption of the device provided by the invention, the film tearing quality is guaranteed, the cost is reduced, the productivity is improved, and the automatic assembly requirements on electronic products are met.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Display screen processing technology

InactiveCN113104332AChange work statusImprove tearing efficiencyNon-linear opticsBinding material removalEngineeringMaterials science

The invention relates to a display screen processing technology. The display screen processing technology comprises the following steps: S1a, transporting a backlight source to a first film tearing device so as to tear off a protective film on the surface of the backlight source; S1b, positioning the position of a liquid crystal module; S2, conveying the positioned liquid crystal module to a second film tearing device, so that a protective film on the surface of the liquid crystal module is torn off; S3, conveying the liquid crystal module and the backlight source to a CCD detection system to be positioned; S4, then attaching the liquid crystal module to the surface of the backlight source; S5, pressing the liquid crystal module on the surface of the backlight source; and S6, carrying out automatic optical detection on the assembled product. The film tearing operation on the surfaces of the backlight source and the liquid crystal module is carried out simultaneously, so that the production efficiency of products can be effectively improved; and on the other hand, the protective films on the backlight source and the liquid crystal module are torn off through a mechanical structure, manual operation is reduced, and the automation degree of equipment is effectively improved.

Owner:深圳市精运达自动化设备有限公司

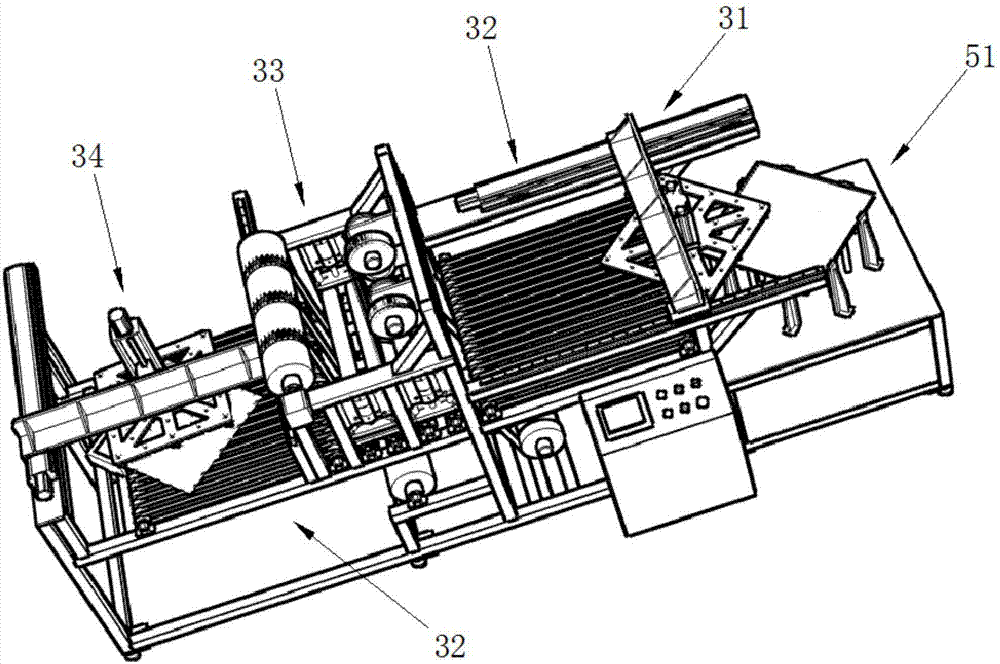

Double-side film tearing device for organic light-emitting diode (OLED) material

ActiveCN107826370AHigh degree of automationGuaranteed uptimeLamination ancillary operationsLaminationTectorial membraneSurface layer

The invention relates to a double-side film tearing device for an organic light-emitting diode (OLED) material. The double-side film tearing device comprises a feeding device, a film tearing device body, a receiving device and a horizontal conveying device; the film tearing device body comprises a first rubber roller, a second rubber roller, a third rubber roller, a fourth rubber roller, an upperconveying roller, an upper protecting film conveying rubber belt running between the first rubber roller and the upper conveying roller in a circulating manner, a lower conveying roller as well as a lower protecting film conveying rubber belt running between the fourth rubber roller and the lower conveying roller in a circulating manner; the first rubber roller, the second rubber roller, the thirdrubber roller and the fourth rubber roller are parallel with one another, are arranged vertically and sequentially and are opposite in rolling direction; and the second rubber roller, the third rubber roller, the upper protecting film conveying rubber belt and the lower protecting film conveying rubber belt have viscous surface layers. By the aid of the double-side film tearing device for the OLED material, protecting films on two sides of the OLED material can be torn off completely, the torn protecting films can be collected automatically, and the film tearing device is high in automation degree and runs smoothly, so that the film tearing efficiency is greatly improved.

Owner:SUZHOU YILI DINGFENG INTELLIGENT TECH CO LTD

Automatic charging and dyestripping mechanism

ActiveCN107264902ASmooth connectionImprove tearing efficiencyArticle unpackingEngineeringElectrical and Electronics engineering

Owner:BOZHON PRECISION IND TECH CO LTD

Automatic film tearing machine

InactiveCN107225839AReduce dosageWide range of useLamination ancillary operationsLaminationTectorial membraneAdhesive

The invention discloses an automatic film tearing machine, which belongs to the field of mechanical equipment and mainly solves the problems of easy adhesion of dust on the surface of the laminated product, waste of tape, increase of cost, and limited use. The receiving device is a disc type hinged through a rotating shaft , the shaft at the lower end of the receiving device is equipped with a feeding device, the bottom of the feeding device is installed with a coil length control device, and the bottom of the coil length control device is equipped with a film throwing device, and one side of the film throwing device is provided with a pressing wheel. There is a protective film collection box at the bottom of the wheel, and a throwing device is installed on the other side of the frame. The throwing product recovery box is installed on the throwing device. The invention has a wide range of applications, and can be replaced with adhesive tapes of corresponding viscosity for different protective films. The amount of adhesive tape is very small, which saves costs. Regardless of the size of the product, the length of the adhesive tape used is fixed, about 10mm-30mm, and the tape is used for a long time. Long, no need to change the tape frequently, thus improving production efficiency.

Owner:广州斯宾莎信息科技有限公司

Film stripping device

ActiveCN107054799AReduce labor intensityImprove tearing efficiencyArticle unpackingElectrical and Electronics engineeringCoating

The invention discloses a film stripping device which comprises a clamp, a first film stripping device, a second film stripping device, an installation plate, a first moving mechanism and a second moving mechanism. The first film stripping mechanism is used for adsorbing or adhering to a coating on one side of glass to be subjected to film stripping when making contact with the glass to be subjected to film stripping. The second film stripping mechanism is used for adsorbing or adhering to a coating on the other side of the glass to be subjected to film stripping when making contact with the glass to be subjected to film stripping. The first film stripping mechanism and the second film stripping mechanism are both installed on the installation plate and can get close to or get away from each other in the first direction under the action of the first moving mechanism, and accordingly the first film stripping mechanism and the second film stripping mechanism can make contact with or get away from the glass to be subjected to film stripping. The second moving mechanism is used for driving the installation plate to move in the second direction so that the glass to be subjected to film stripping can be located between the first moving mechanism and the second moving mechanism. The first direction is perpendicular to the second direction. According to the film stripping device provided by the invention, the film stripping efficiency is improved, and meanwhile, the labor intensity of staff is relieved.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

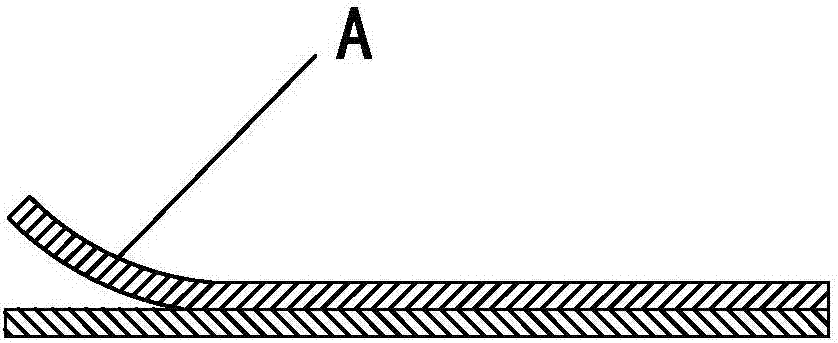

Layer separation method for flexible film

ActiveCN105856799AReduce labor costsImprove tearing efficiencyLamination ancillary operationsLaminationFilm materialEngineering

The invention relates to the technical field of separation of multilayer film materials and particularly relates to a layer separation method for a flexible film. According to the layer separation method for the flexible film, an available film and a waste film in the flexible film are separately stuck to an air suction surface of a first vacuum plate and an air suction surface of a second vacuum plate in a pressing manner by using a film tearing component, and the film tearing component moves along a film tearing direction at a constant speed relative to the vacuum plates; and the available film and the waste film in the flexible film are required to be separated firstly before using the flexible film, and the completely-stuck flexible film can be easily separated by a small section by using the principle that the deformation quantity between the available film and the waste film is different by adopting the layer separation method for the flexible film, disclosed by the invention, so that primary-stage preparation for film tearing by subsequent automated film tearing equipment is completed, artificial participation is not required, the labor cost of a film tearing procedure is greatly reduced, the automated film tearing efficiency is greatly increased, the progress is obvious, and the practicability is high.

Owner:张斌

Efficient processing device for one-way cloth isolation film for production of weft-free cloth

ActiveCN107186919AAvoid problems that cannot be exploited againIncrease profitLamination ancillary operationsPlastic recyclingEngineeringMechanical engineering

The invention relates to an efficient processing device for a one-way cloth isolation film for production of weft-free cloth. The efficient processing device comprises a cloth film separating part and a glue removing part; the cloth film separating part is used for performing cloth and film separation on cloth with a film, the cloth film separating part comprises a heating mechanism for heating the cloth with a film to soften glue, a film separating mechanism for adsorbing the film and driving the film to rotate therewith to change a conveying direction and a cloth separating mechanism for pulling the cloth along a direction opposite to the conveying direction of the film; the glue removing part is arranged on the rear end of the cloth film separating part and used for removing residual glue on the film, and the glue removing part comprises a glue softening mechanism for heating the film to soften the glue on the surface and a glue removing mechanism for removing the softened glue from the film. The efficient processing device overcomes the problem that the film cannot be reused caused by a fact that the film is torn off by manual film tearing and the glue residual on the film after the film tearing cannot be cleaned.

Owner:湖州蓝澳无纬布有限公司

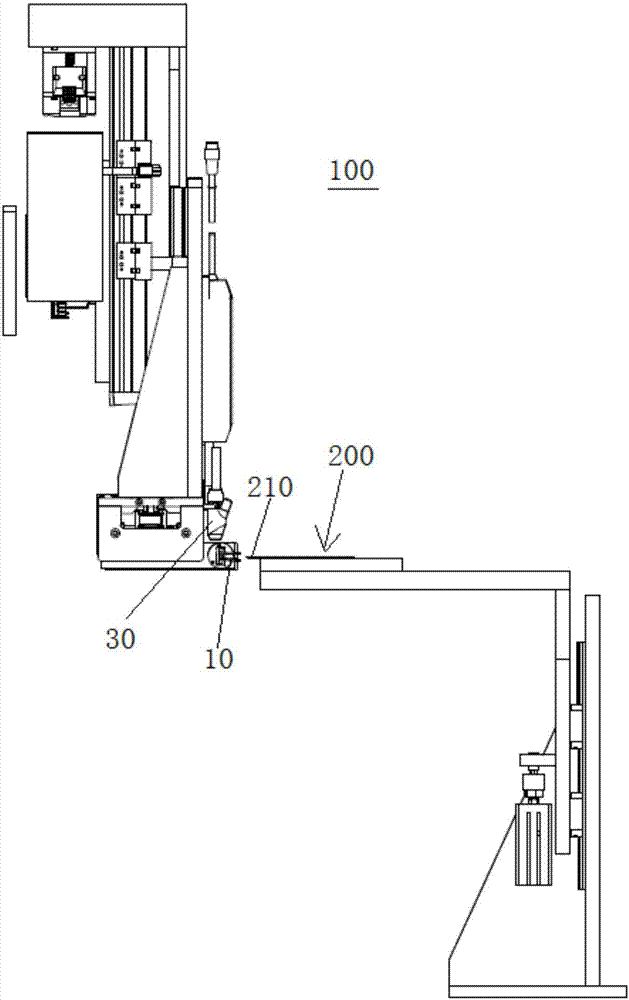

Film-tearing and assembly integrated assembly line

ActiveCN112222820AImprove tearing efficiencyImprove assembly efficiencyAssembly machinesArticle unpackingRobotic handStructural engineering

The invention discloses a film-tearing and assembly integrated assembly line. The film-tearing and assembly integrated assembly line comprises a film-tearing assembly line, a flow assembly and a relaytransfer mechanism, wherein the film-tearing assembly line comprises a product loading device, a product transporting mechanism and a product film-tearing mechanism; a plurality of trays for containing products are stacked in the product loading device; the product transporting mechanism is arranged on the product loading device; the product film-tearing mechanism is arranged at the downstream ofthe loading direction of the product loading device; the flow assembly line comprises an assembly mechanical hand, a carrier loading device and a product buffering jig, wherein an assembling suckingassembly is mounted on the assembly mechanical hand; the carrier loading device is arranged beside the relay transfer mechanism; the product buffering jig is arranged between the relay transfer mechanism and the assembly mechanical hand; and a plurality of product buffering holes are formed in the product buffering jig. The film-tearing and assembly integrated assembly line can save product turnover and positioning times to improve film-tearing and assembly efficiency.

Owner:SUZHOU RS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com