Patents

Literature

93results about How to "Achieving flexible contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

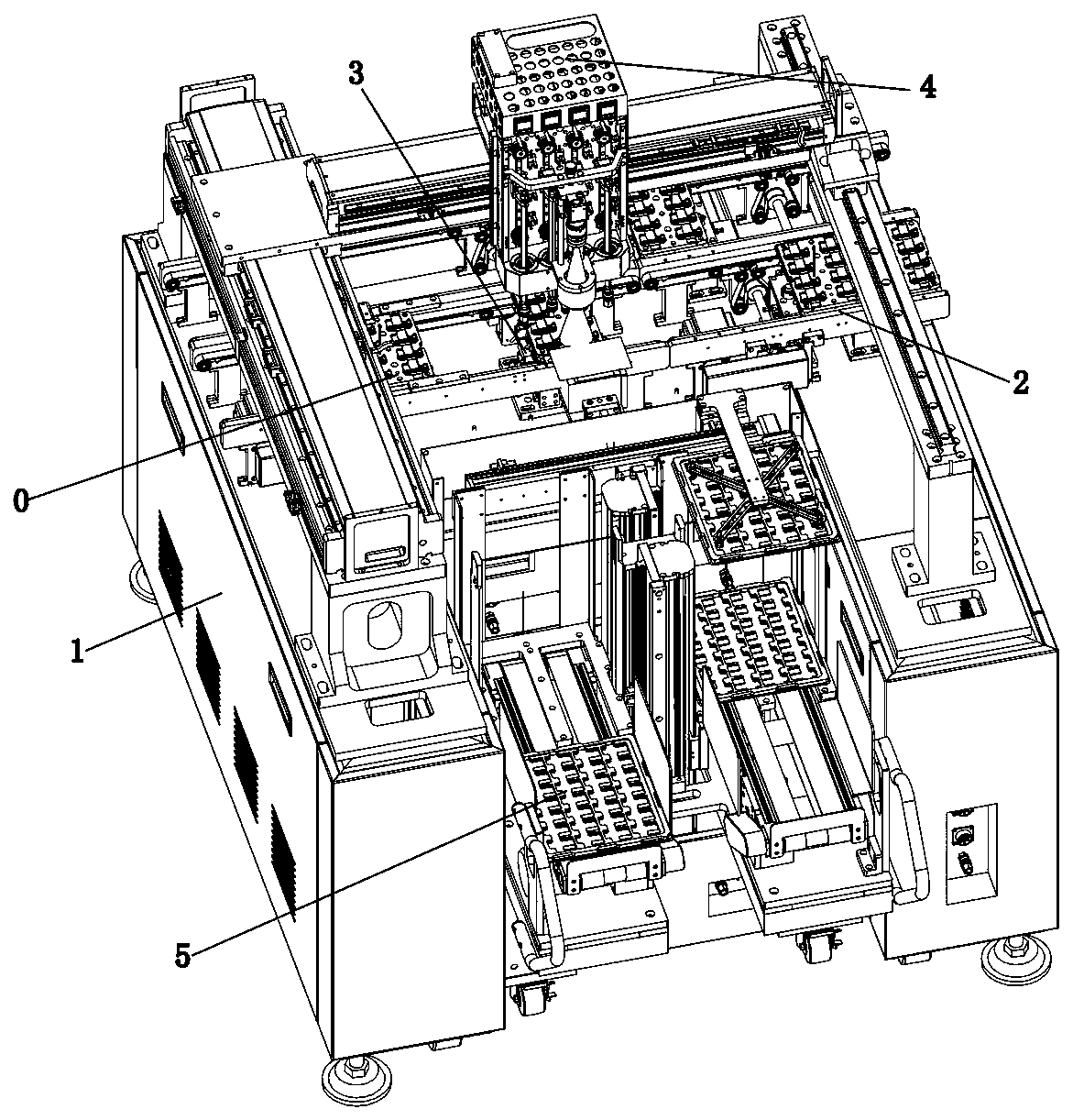

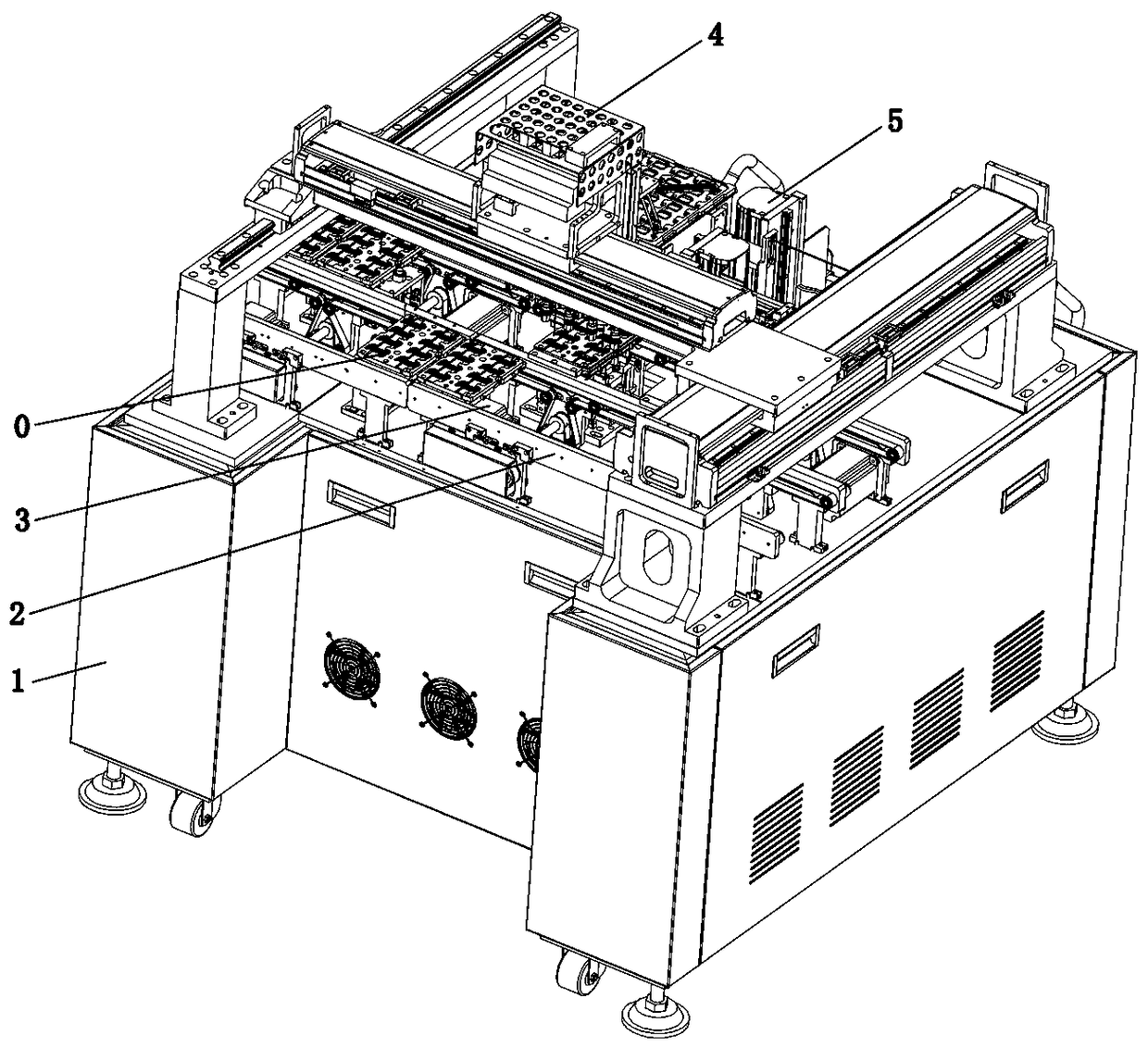

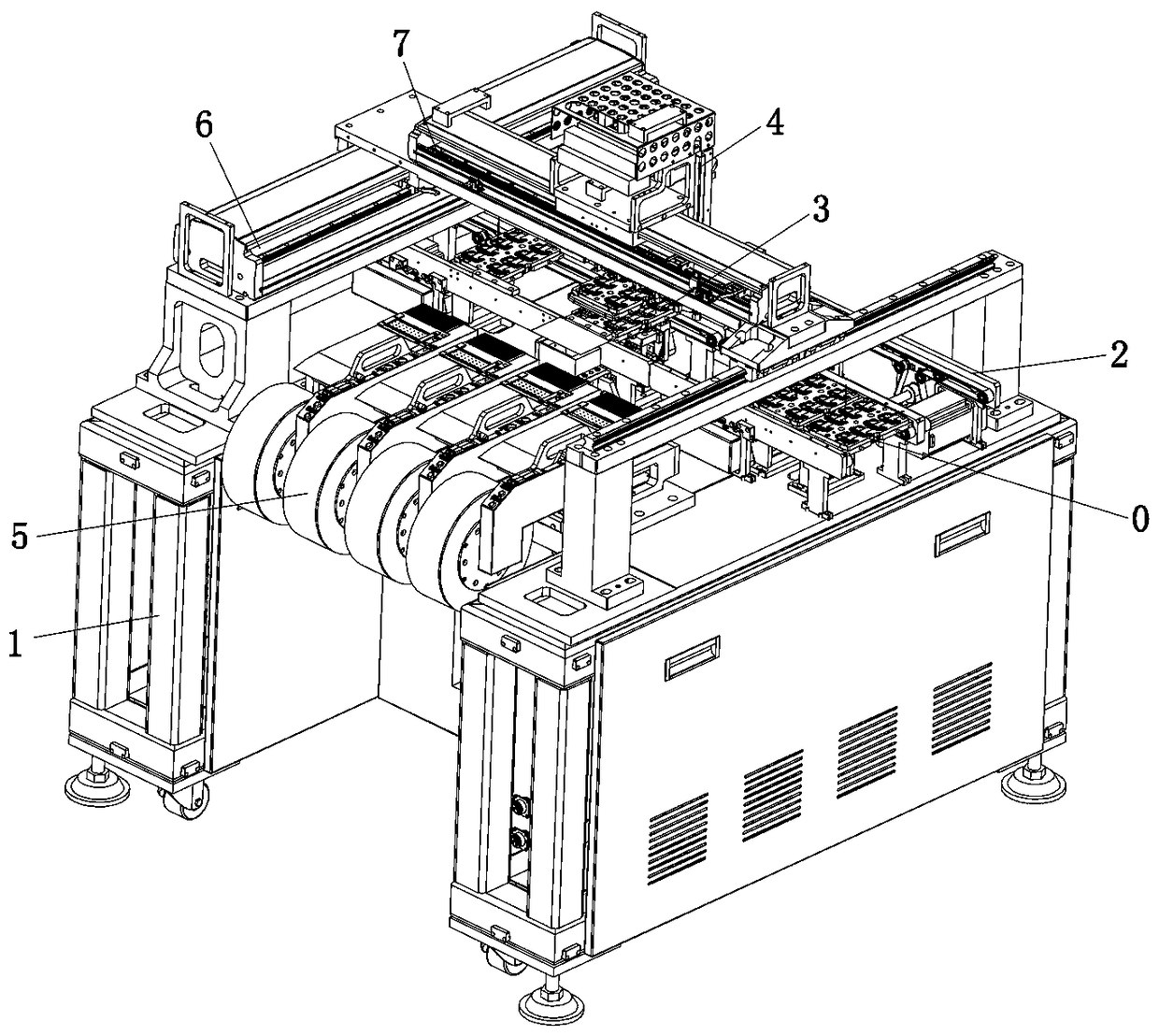

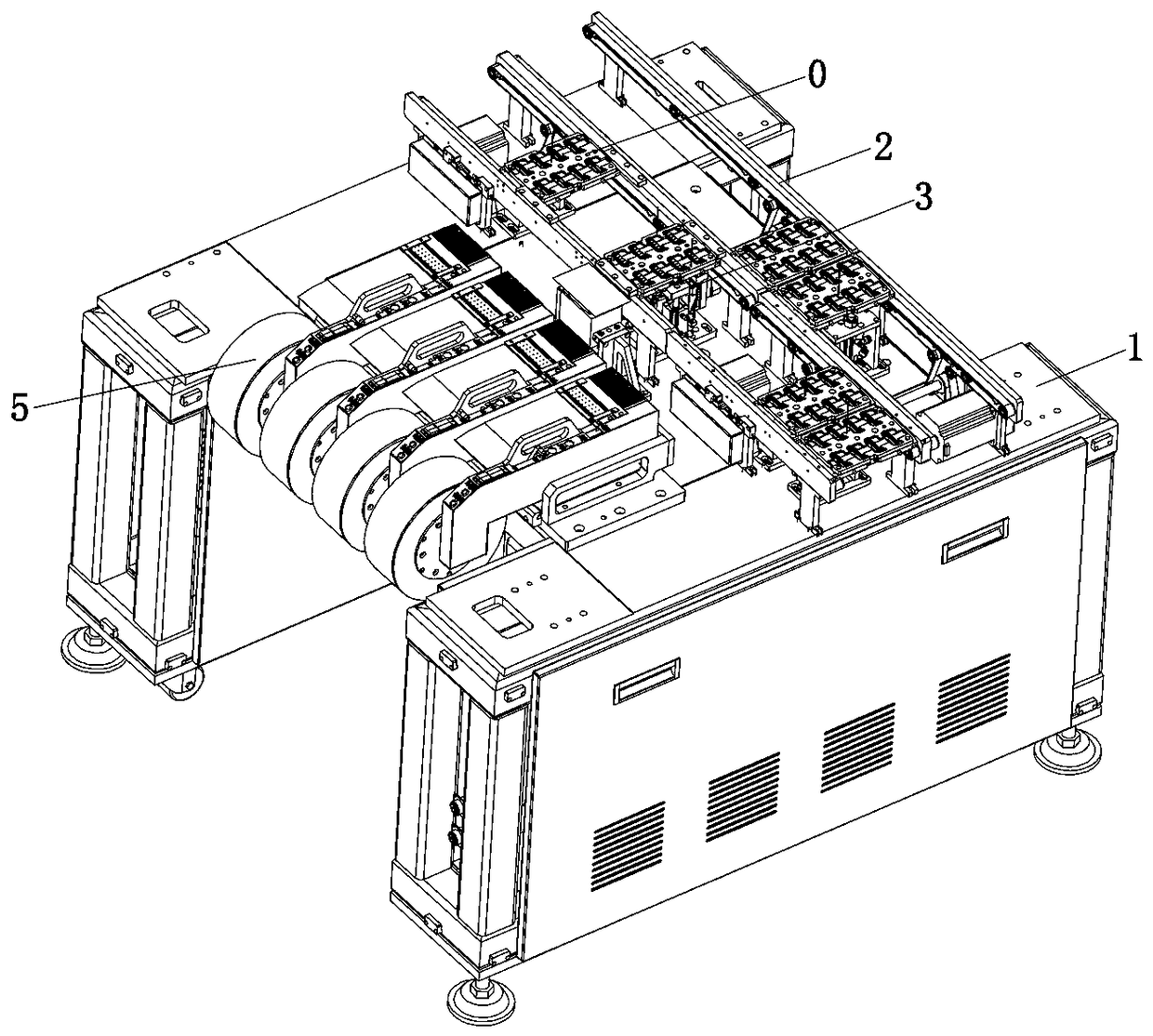

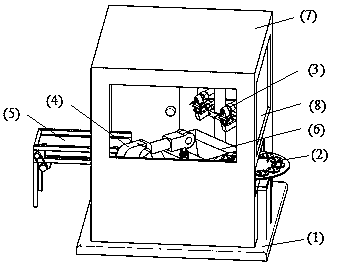

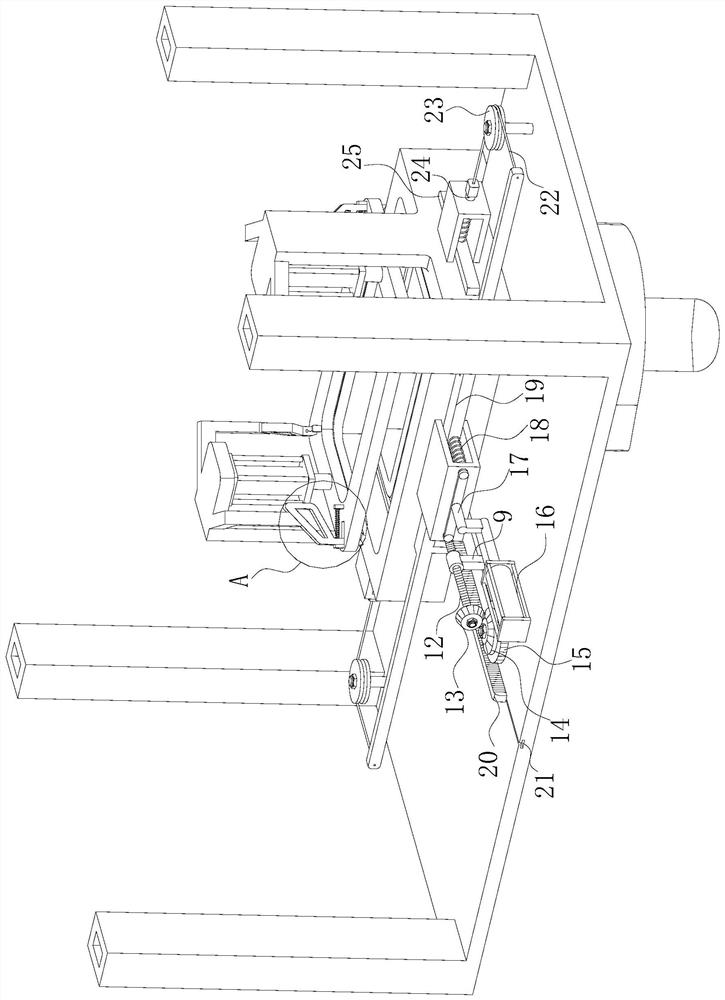

Automatic film tearing machine for accessory assembly

ActiveCN109334215AAvoid position shiftGuaranteed assembly accuracyLamination ancillary operationsLaminationTectorial membraneGlass sheet

The invention discloses an automatic film tearing machine for accessory assembly. The automatic film tearing machine comprises a transmission mechanism, a positioning and supporting mechanism, a filmtearing mechanism and a feed box, wherein the transmission mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at a film-tearing station; the film tearing mechanism is arranged above the film-tearing station; the film tearing mechanism comprises a rotating component, a film clamping component and a pressing component; the film clamping component and the pressing component are respectively connected to the output end of the rotating component; the film clamping component and the pressing component comprise at least two groups, and every two groupsare arranged at an interval; the output ends of the film clamping component and the pressing component are downwards obliquely arranged opposite to each other; the feed box is arranged below the filmtearing mechanism and has an upward opening; after the protective film on gum is torn out by the film tearing mechanism, the torn protective film is put in the feed box. The automatic film tearing machine for accessory assembly disclosed by the invention is applicable to automatic whole line assembly of accessories, multiple films are torn each time, the film tearing efficiency is effectively improved, position offset of the gum or the glass sheet in the film tearing process is effectively avoided, and the assembling precision and quality are ensured.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

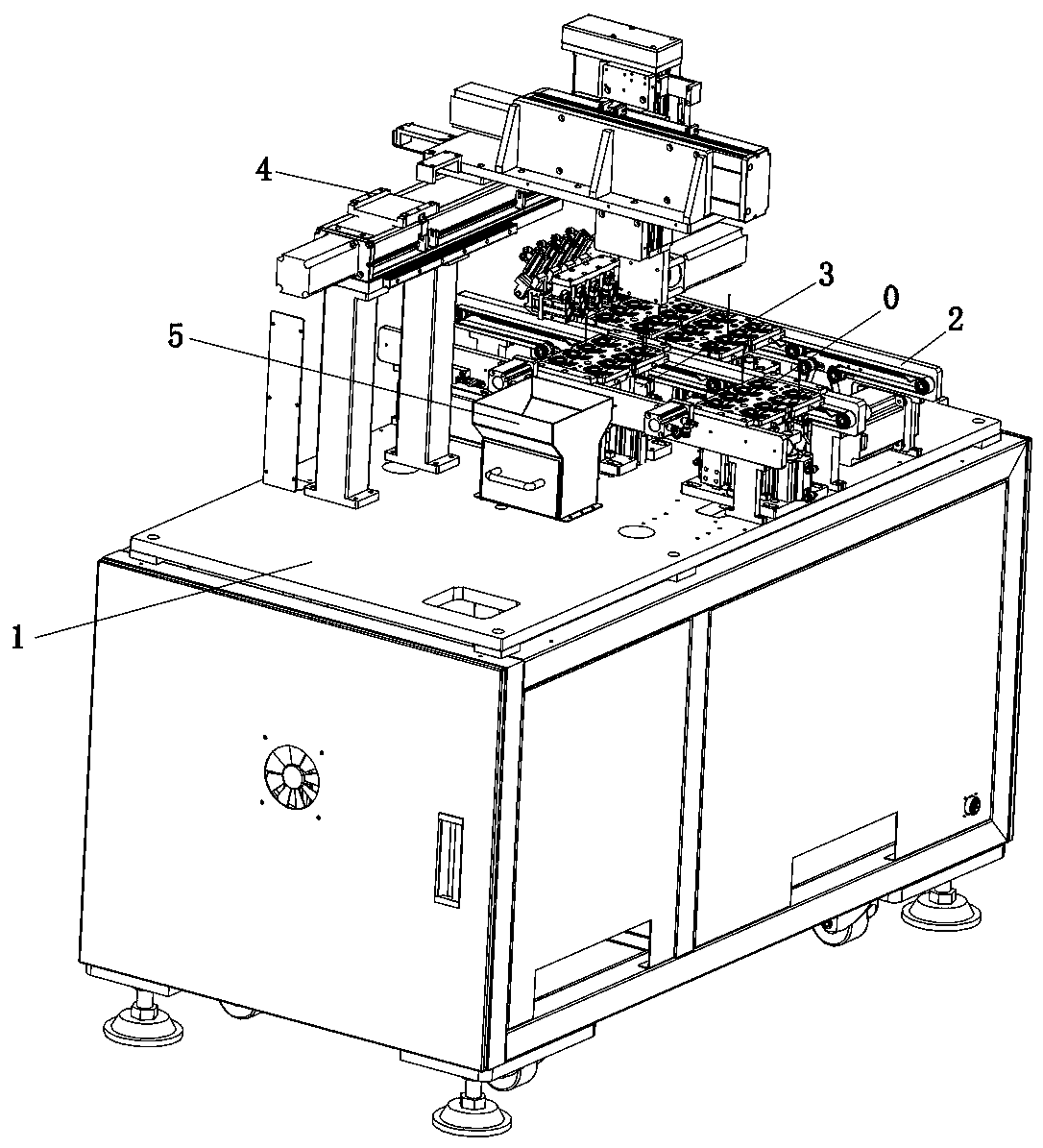

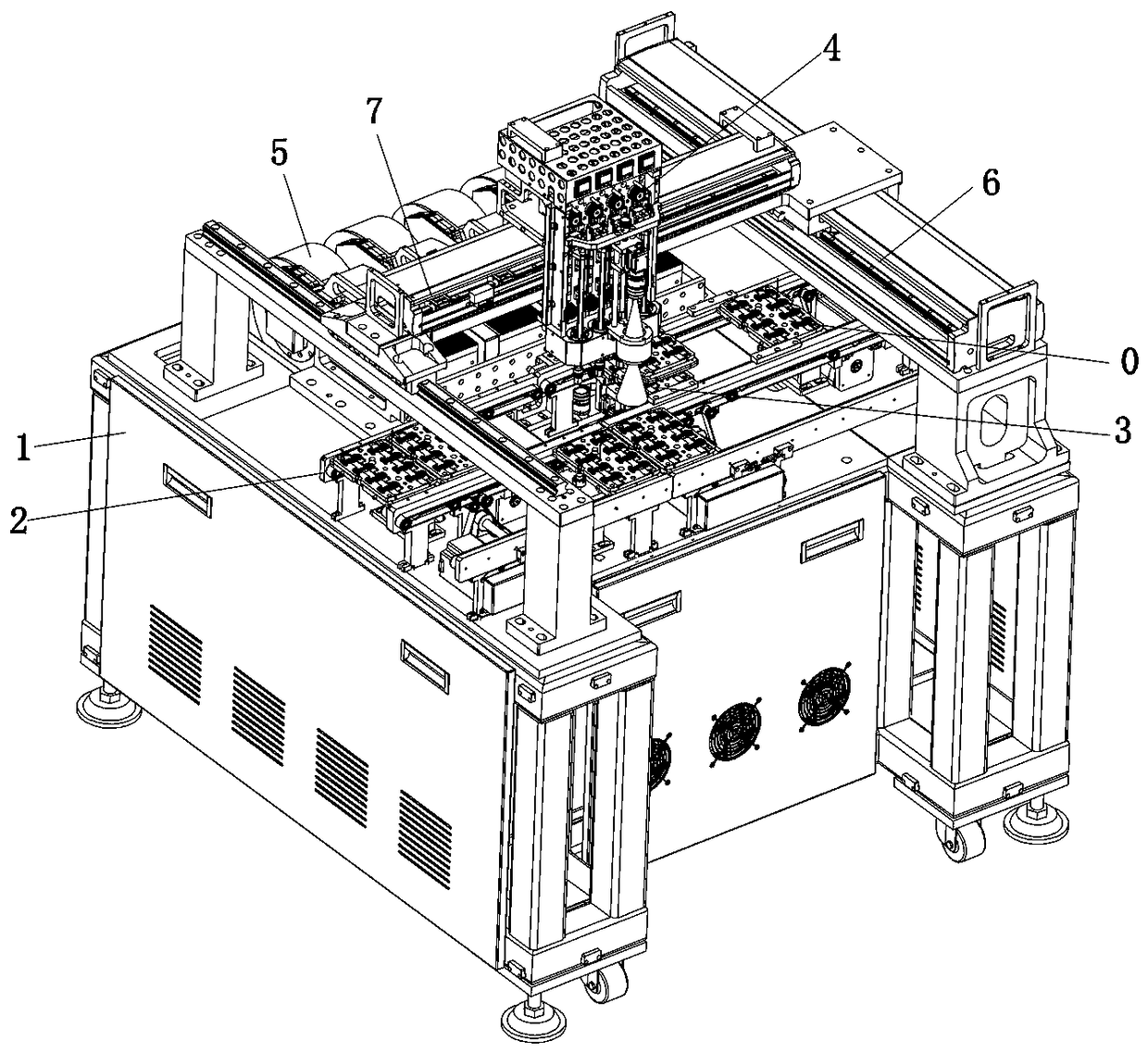

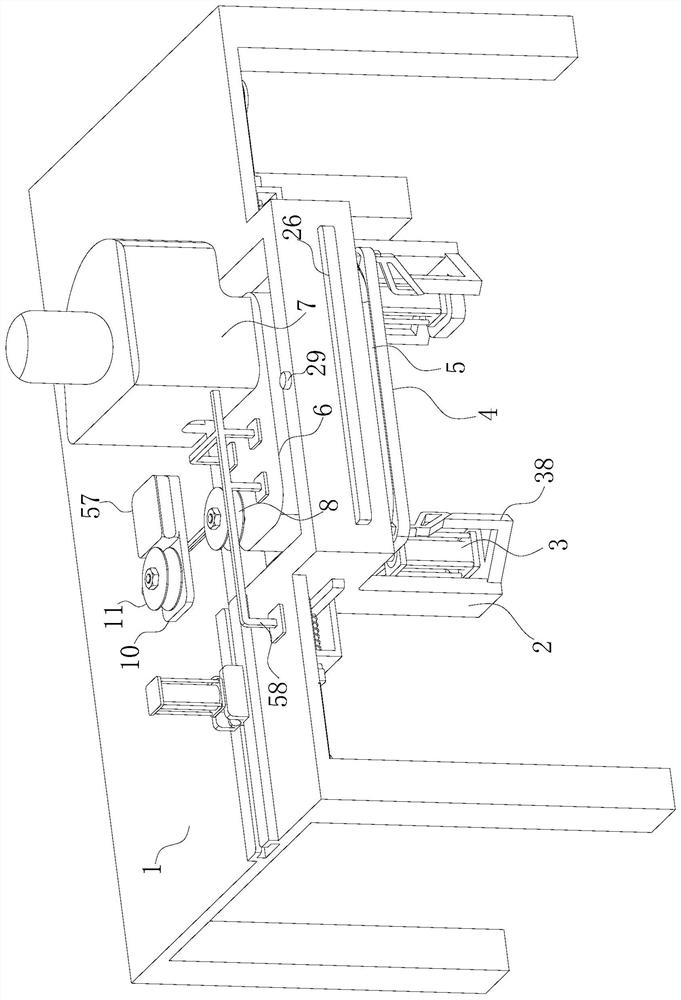

Automatic precise assembly machine

InactiveCN109317967AReduce the frequency of replacement and retransmissionAvoid position shiftAssembly machinesEngineeringGlass sheet

The invention discloses an automatic precise assembly machine. The automatic precise assembly machine comprises a conveying mechanism, a positioning and support mechanism, an assembly mechanism and aloading mechanism; the conveying mechanism is horizontally arranged on the frame; a synchronous belt is arranged on the inner side of the conveying mechanism; a tool for loading materials is placed onthe synchronous belt; at least two through grooves are formed in the tool; materials to be assembled are placed in the through grooves; and the assembly modules once absorb multiple materials from the loading mechanism, and assemble the materials to fittings in the through grooves of the tool. Through downward absorption fixation and flexible support of glass sheets, the displacement of the glasssheets in the assembly process is prevented, so that the assembly precision is guaranteed, the pressure crushing condition of the glass sheets is prevented, the loading and unloading time is shortened, the centralized unloading and loading of multiple products once are realized, the tray replacing and reloading time is shortened, and the overall production capacity is effectively improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

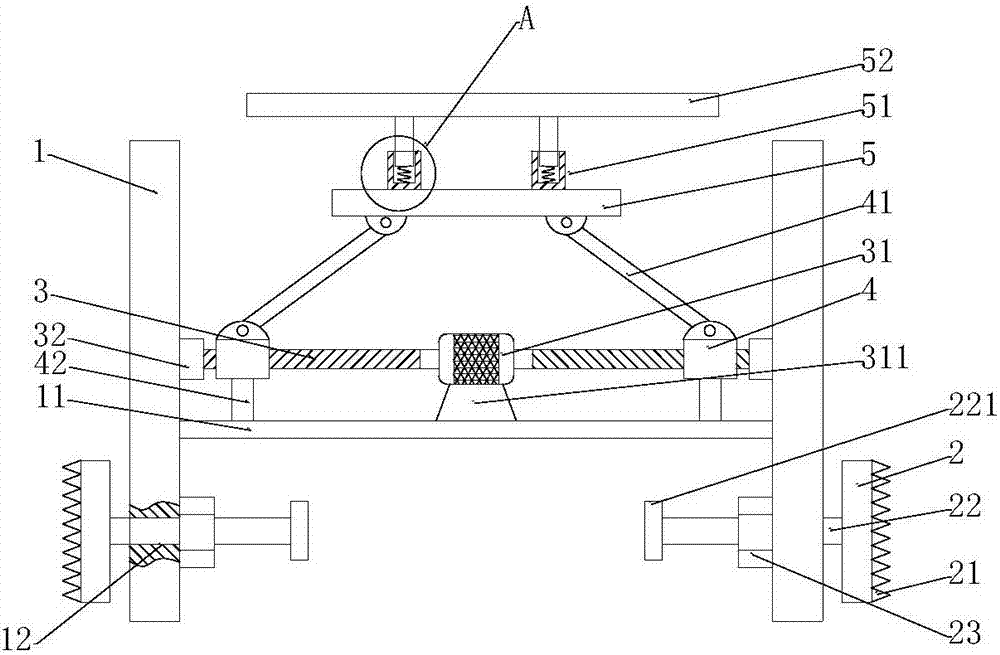

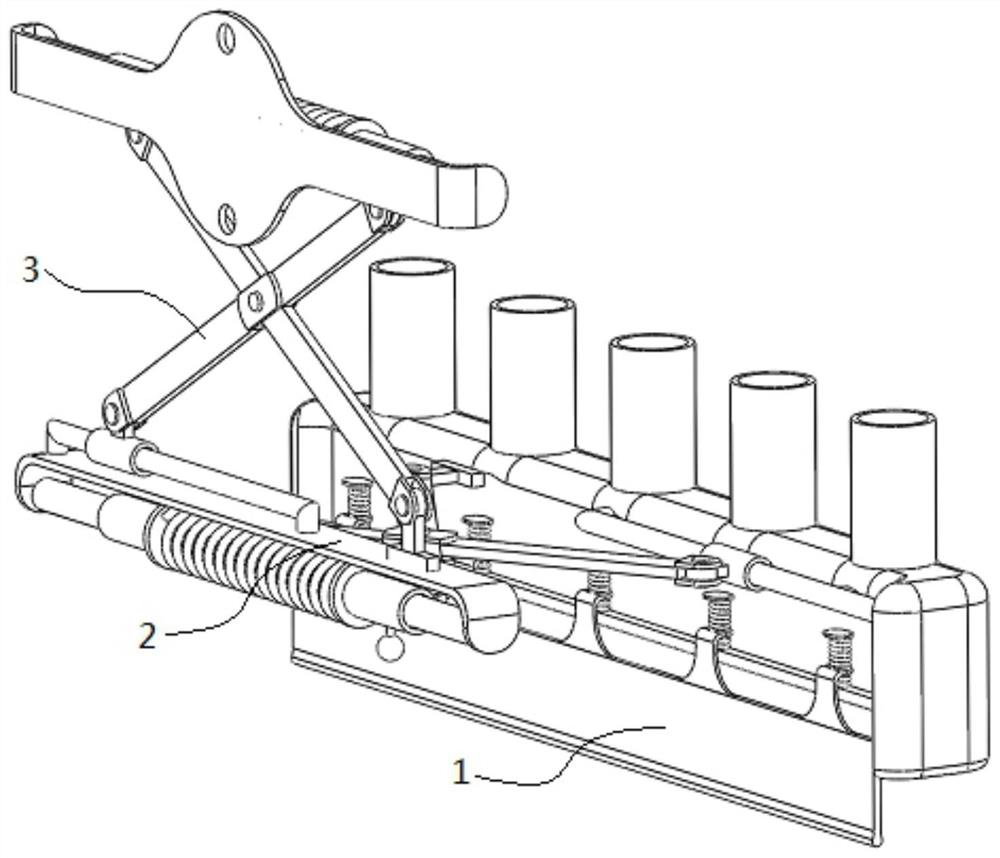

Externally-arranged type printer scraper device

The invention discloses an externally-arranged type printer scraper device. The externally-arranged type printer scraper device comprises a supporting frame, fixing plates and lead screws; the fixing plates are symmetrically arranged on the two sides of the bottom of the supporting frame, adjusting screw rods are connected to the end faces, close to the supporting frame, of the fixing plates, and penetrate through holes in the supporting frame to extend, adjusting nuts matched with the adjusting screws are arranged on the adjusting screws in a sleeving manner, the adjusting nuts are rotatably fixed to the inner side of the supporting frame, the two lead screws are symmetrically and rotatably arranged on the upper portion of the supporting frame, a dual-shaft motor driving the lead screws to rotate is arranged on the center of the supporting frame, lead screw sleeves matched with the lead screws are arranged on the lead screws in a sleeving manner, connecting rods are hinged to the upper ends of the lead screw sleeves, the other ends of the connecting rods are hinged to the bottom of a connecting plate, and a scraper is connected to the top of the connecting plate through an elastic telescopic part. External arrangement of the scraper is achieved, the manufacturing cost of a printing production line is reduced, and meanwhile the device has the beneficial effects of being easy to adjust and good in ink scraping effect.

Owner:GUANGDONG SHUNCHANG PRINTING

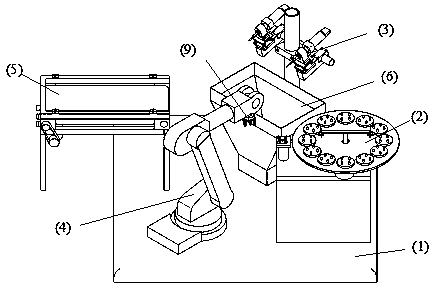

Visual guidance intelligent force control grinding and polishing device

ActiveCN108284388AAvoid interferenceAvoid writingMeasurement devicesGrinding feed controlSelf adaptivityClosed loop

The invention belongs to the field of intelligent processing and manufacturing and discloses a visual guidance intelligent force control grinding and polishing device which comprises grinding and polishing visual sensors, a movement unit, a force sensor, a grinding head and a control unit, wherein the movement unit is connected with the force sensor, has two degrees of freedom and is used for driving a tail end grinding head to move; the force sensor is used for detecting the contact force between the tail end grinding head and a to-be-processed workpiece; the grinding and polishing visual sensors are symmetrically arranged on two sides of the movement unit and are used for monitoring the three-dimensional structure and spatial position of the to-be-processed workpiece, the position of thegrinding head and the surface processing quality of the to-be-processed workpiece; and the control unit is connected with the movement unit, the force sensor and the grinding and polishing visual sensors. The visual guidance intelligent force control grinding and polishing device is high in grinding and polishing intelligent degree and processing efficiency and excellent in self-adaptivity, realizes integration of part unstructured modeling, pose path guidance, self-learning grinding and polishing processing and quality test, effectively realizes obstacle avoidance and migration of processingand detecting experience and conforms to online full closed-loop processing detection of the part.

Owner:HUST WUXI RES INST

Air suspension flexibility space buttjunction platform

Owner:CHONGQING UNIV

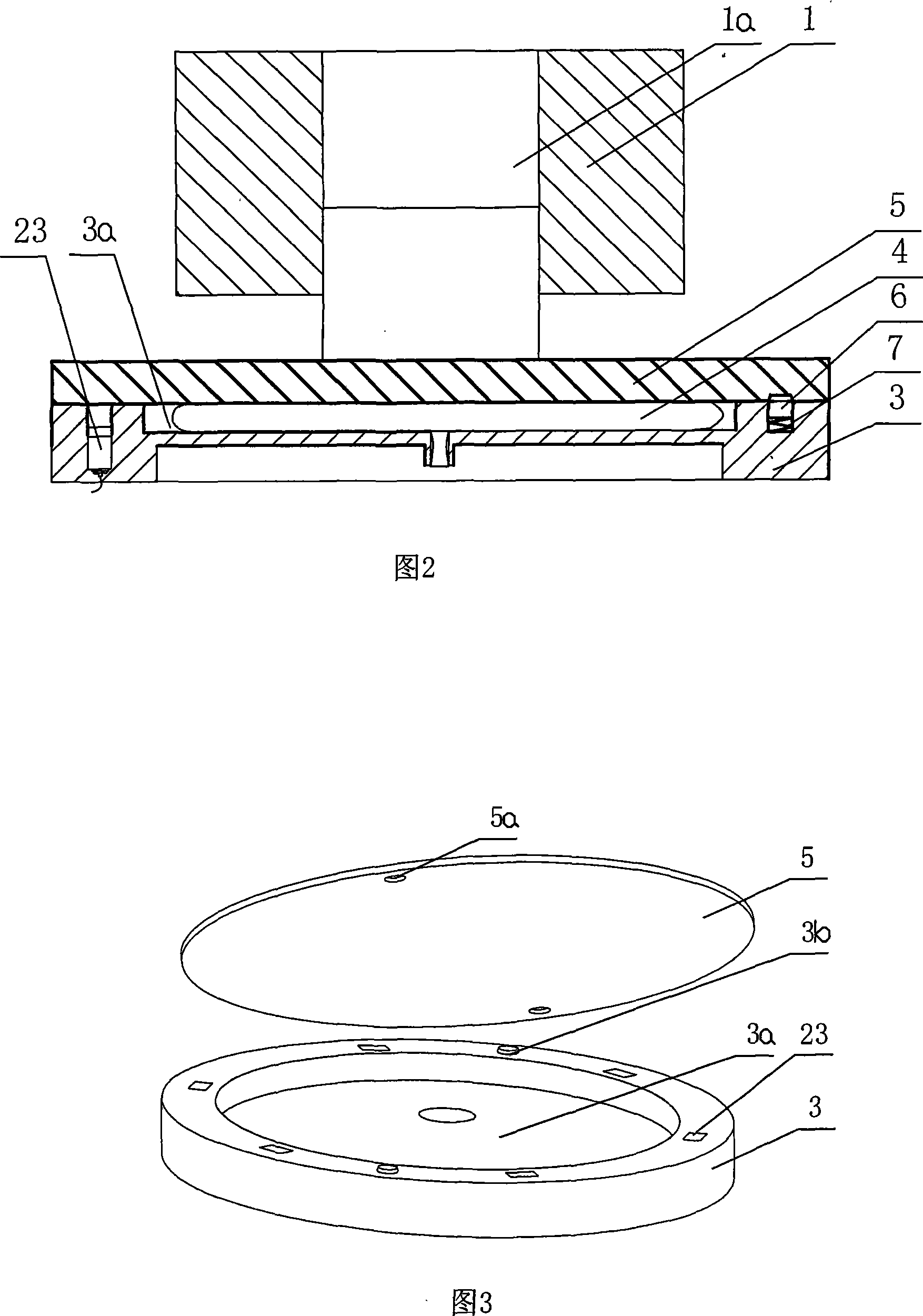

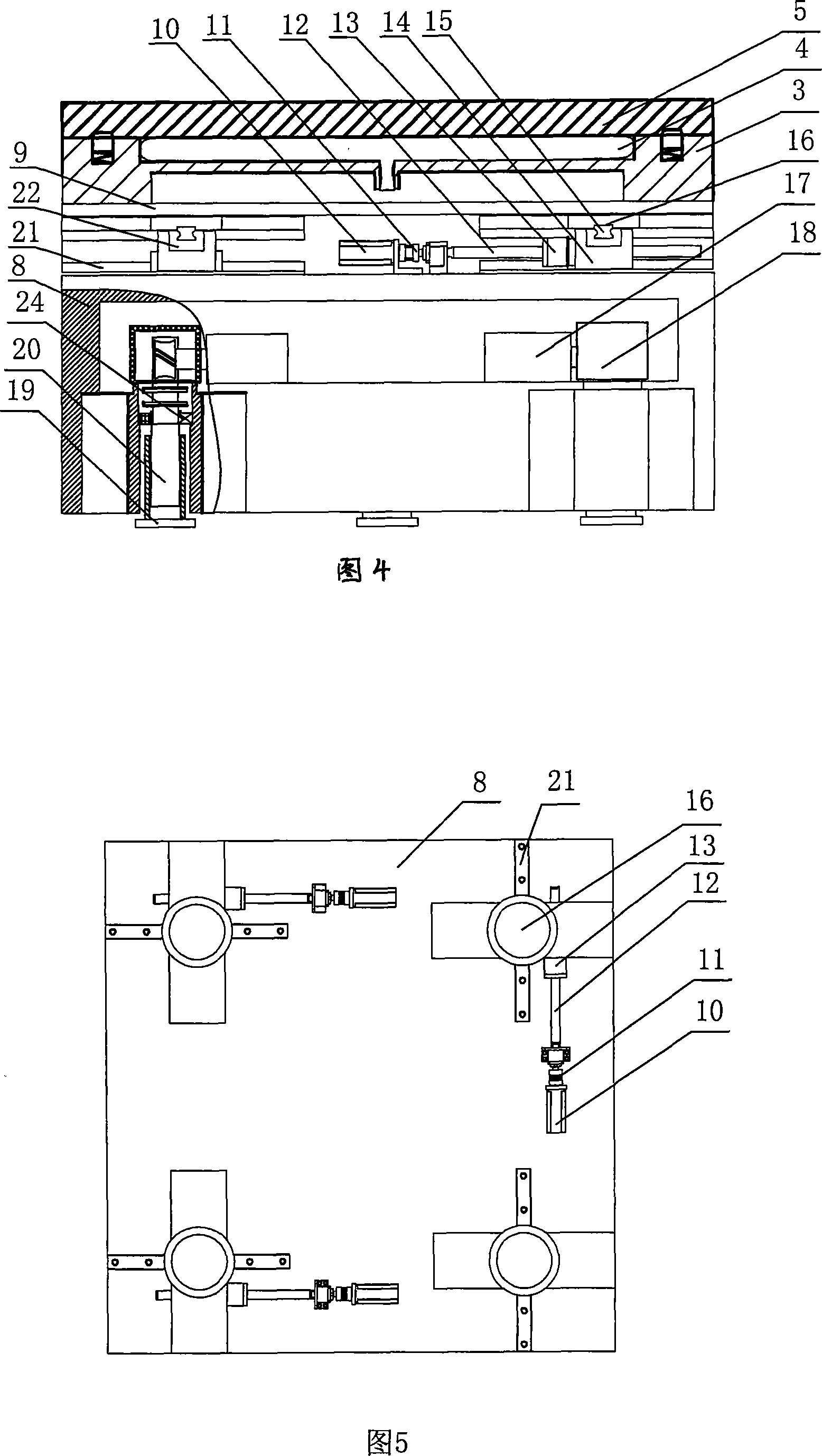

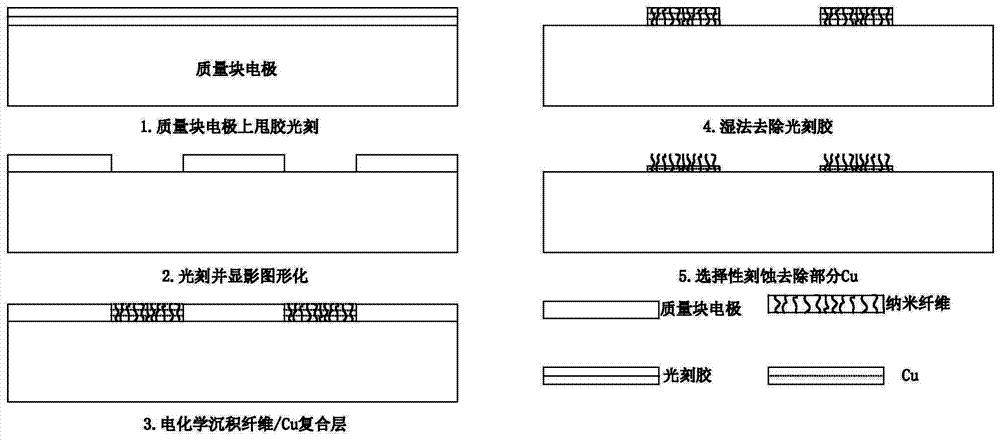

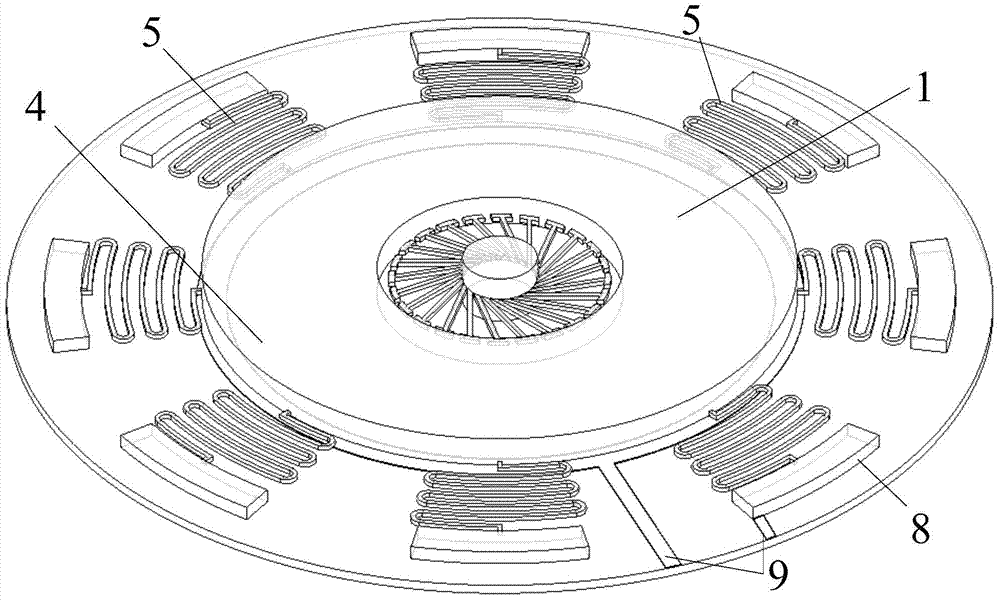

Multi-direction vibration threshold value sensor for achieving contact time delay through nano-micro flexible arrays

InactiveCN103575931AIncrease contact timeImprove contact effectAcceleration measurement using interia forcesContact timeEngineering

The invention provides a multi-direction vibration threshold value sensor for achieving contact time delay through nano-micro flexible arrays. A mass block electrode is respectively connected with one end of each of eight sets of serpentine springs, and the other ends of the springs are connected with spring supporting bases and enable the mass block to be suspended between a perpendicular lower fixed electrode and a cantilever beam upper fixed electrode. The carbon nanofiber cluster array structures are distributed on the upper surface of a mass block and the lower surface of the cantilever upper fixed electrode respectively, the spring supporting bases are arranged on an insulating substrate and evenly distributed around the mass block, and one end of a radial radial-direction elastic horizontal fixed electrode is connected to a supporting column. The supporting column is arranged in the center of the mass block and suspends the radial radial-direction elastic horizontal fixed electrode between the upper surface and the lower surface of the mass block. The lower fixed electrode is fixed to the insulating substrate. Flexible contact between a movable electrode and the fixed electrode of the multi-direction vibration threshold value sensor is achieved, and the multi-direction vibration threshold value sensor sensitively responds accelerated speed impact in the + / -Z directions and the horizontal 360-degree direction.

Owner:SHANGHAI JIAO TONG UNIV

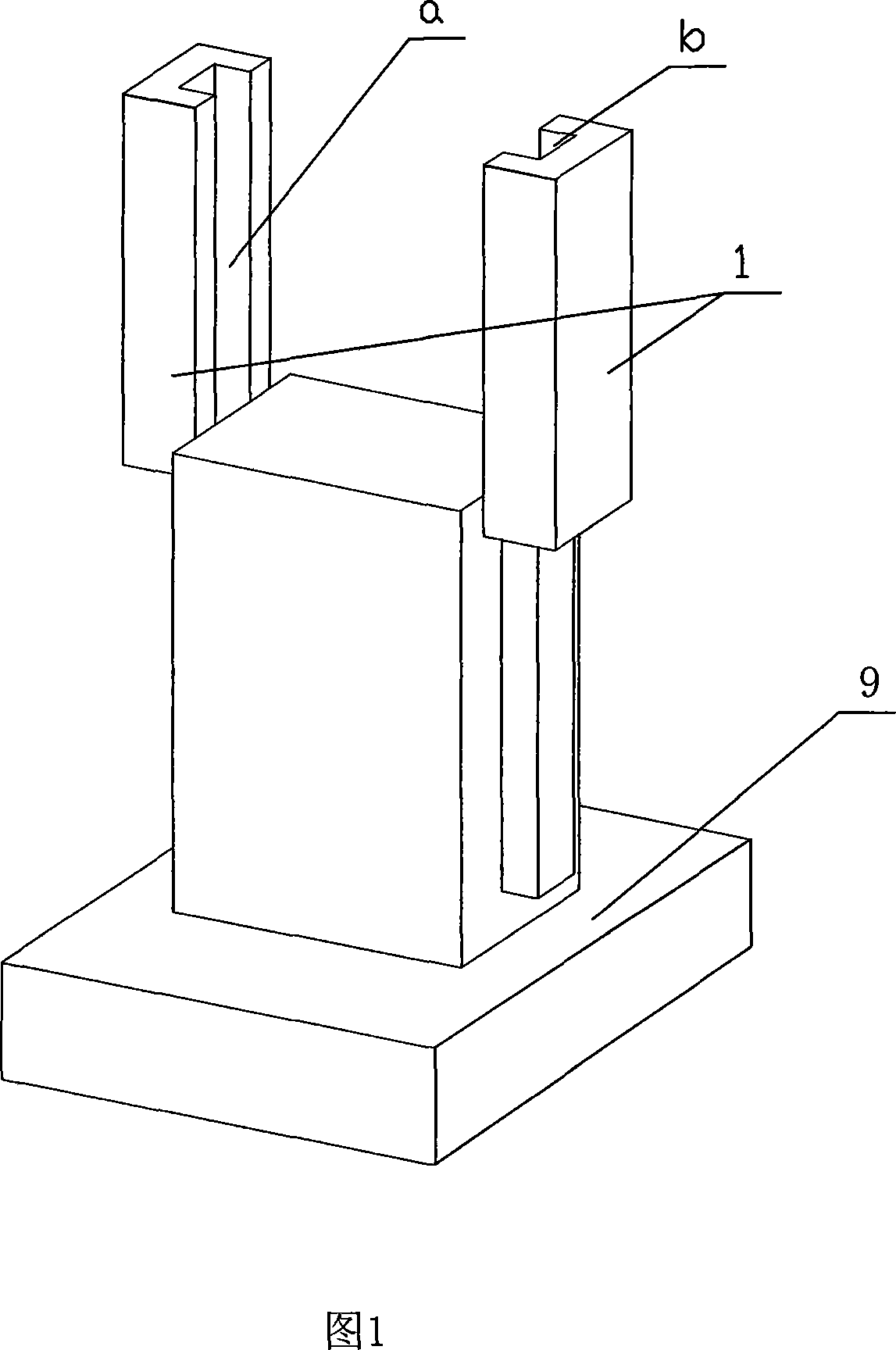

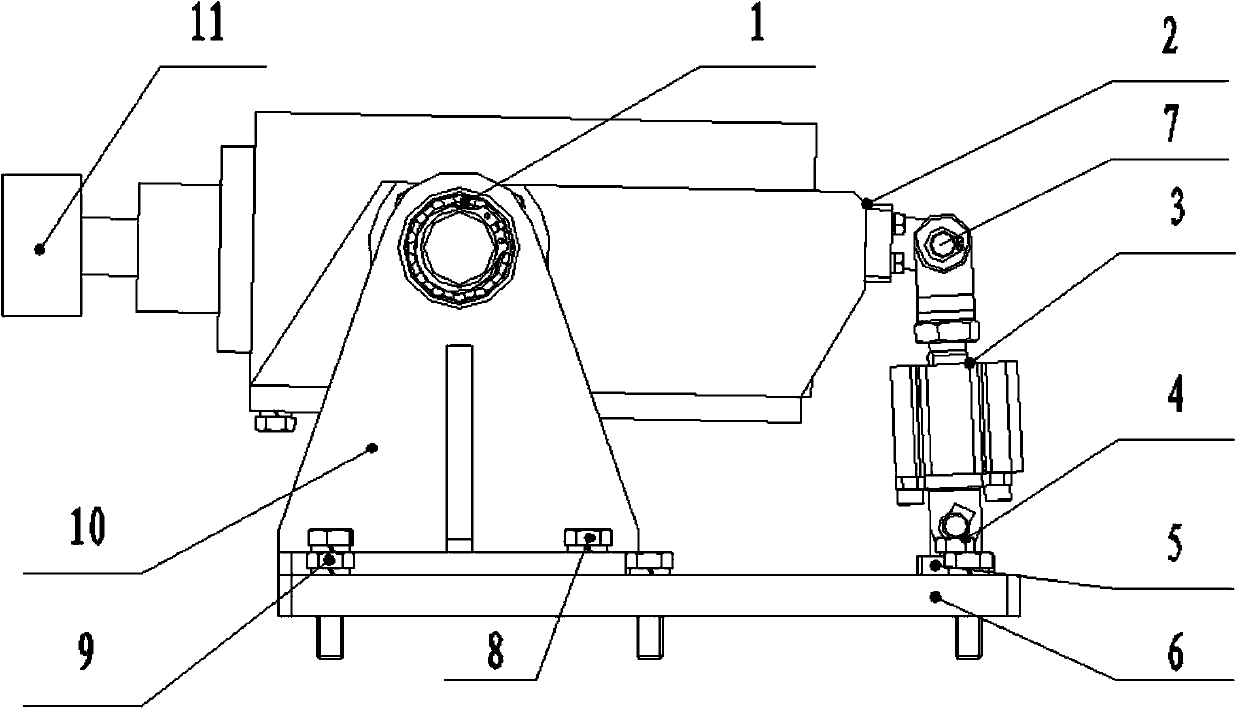

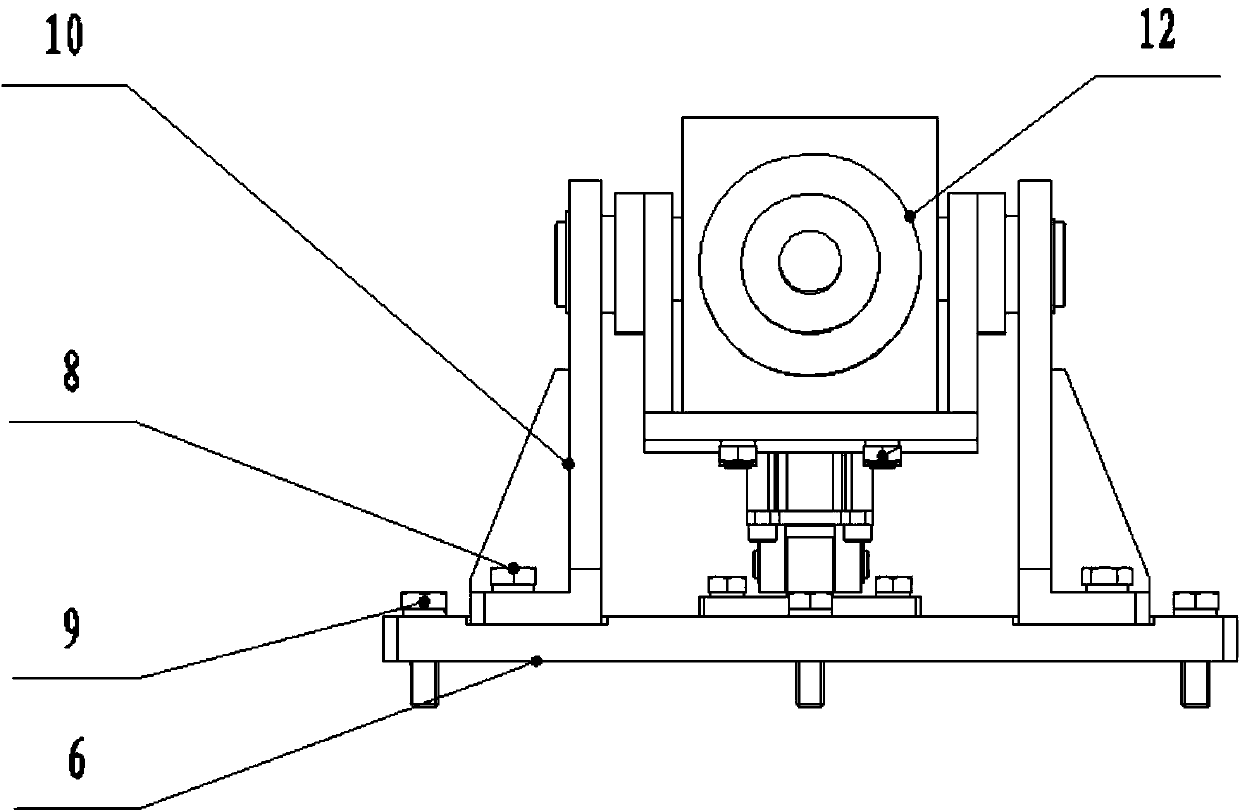

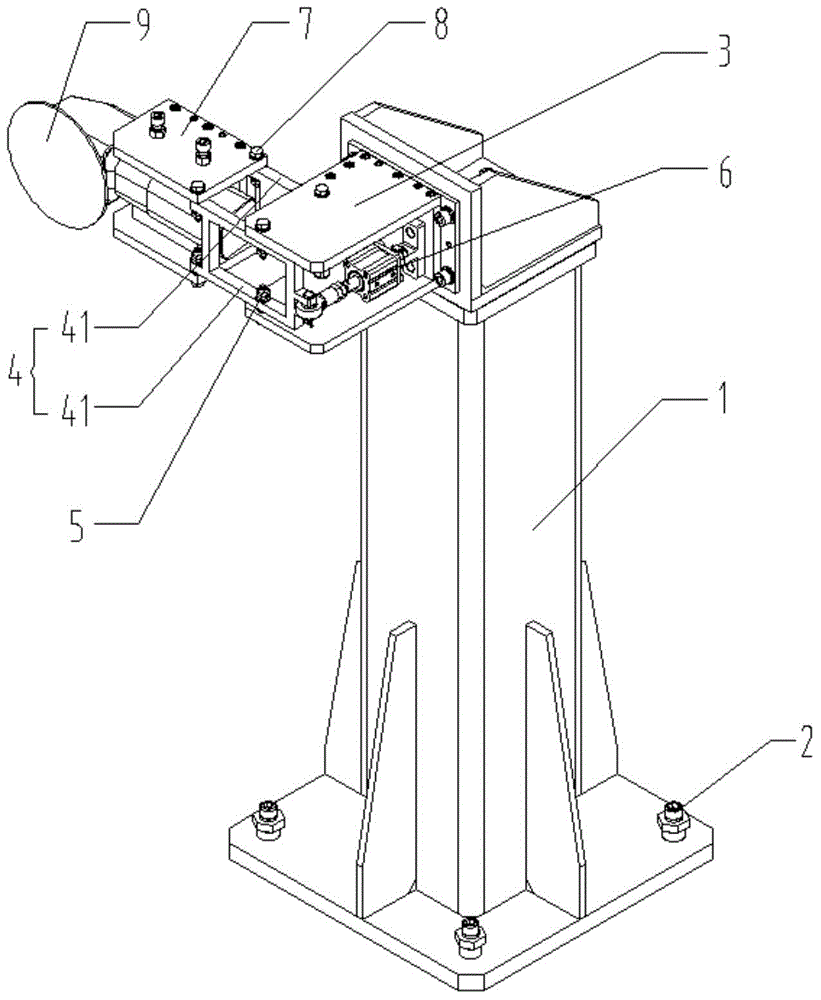

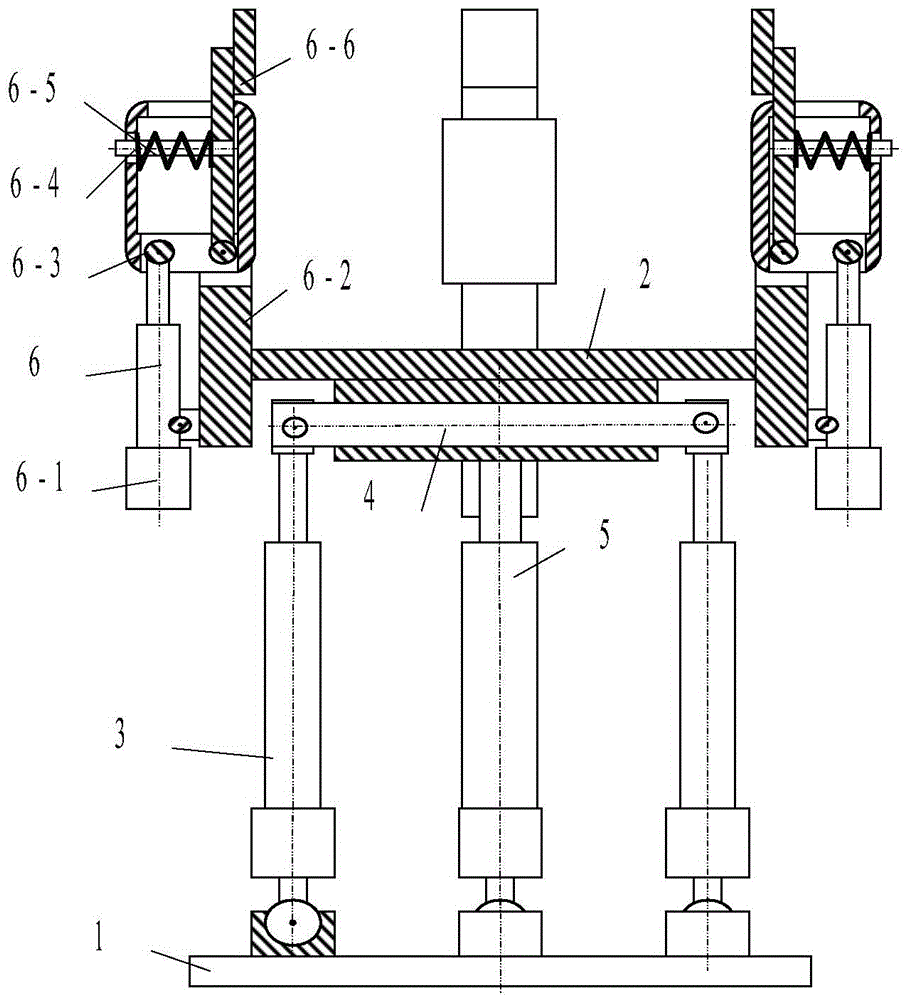

Floating type rotating grinding main shaft mechanism and grinding method

ActiveCN103737484AAvoid damageAchieving flexible contactGrinding machine componentsRevolution surface grinding machinesEngineeringMechanical engineering

The invention discloses a floating type rotating grinding main shaft mechanism and grinding method. The mechanism comprises a base, a hinge support, a grinding tool, a main shaft motor, a main shaft support and a floating air cylinder assembly, wherein the floating air cylinder assembly comprises an air cylinder base, a floating air cylinder and a Y-type joint, and the grinding tool is rotatably connected with the main shaft motor. When the mechanism works, air is sealed in the floating air cylinder through an electromagnetic valve, a piston of the air cylinder can be adjusted at will through a pneumatic element, when a workpiece makes contact with the grinding tool from top to bottom or from bottom to top, the workpiece is supported by the hinge support, air on one side of the piston of the floating air cylinder is compressed to generate elastic resistance, flexible contact between the workpiece and the grinding tool can be achieved, and the grinding tool is prevented from being damaged. Meanwhile, the floating air cylinder is adopted to conduct flexible adjustment, movement damping can be increased, vibration is reduced, and the mechanism is suitable for being applied to the field of grinding and finishing an automatic casting with a robot, and can precisely control loads and impact resistance of the robot in the working process.

Owner:CHANGSHA CTR ROBOTICS

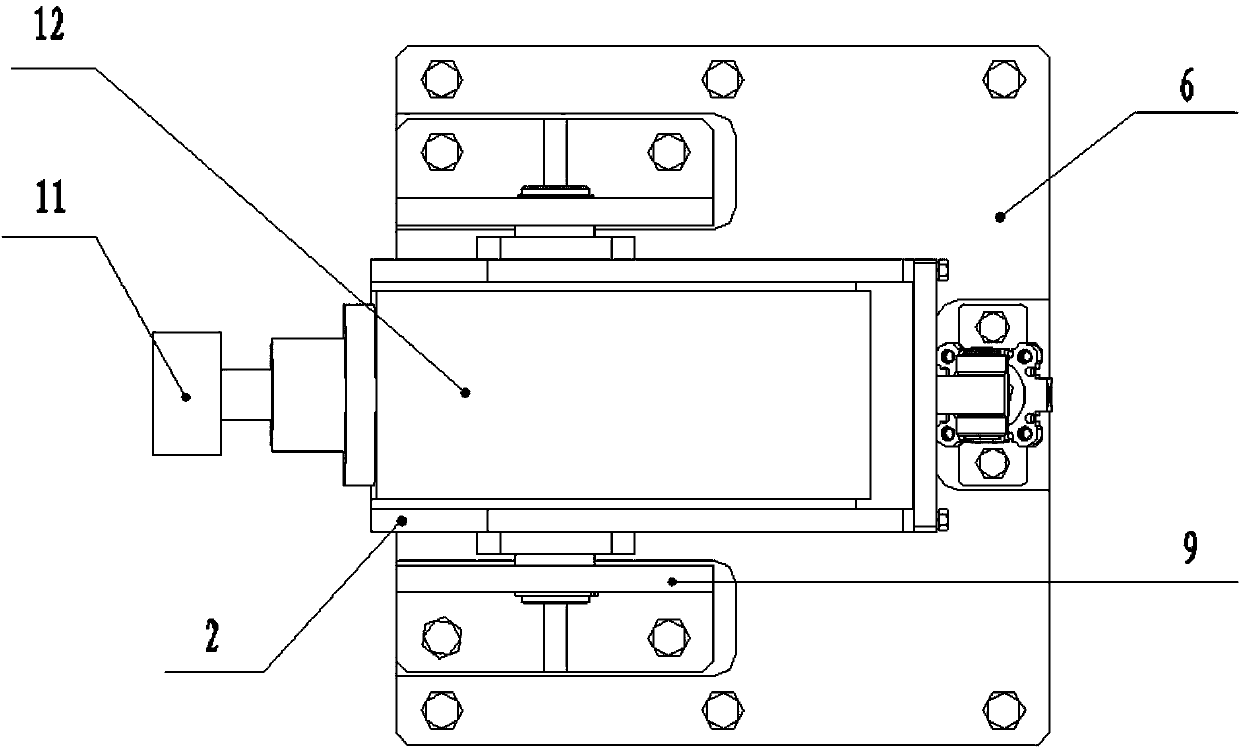

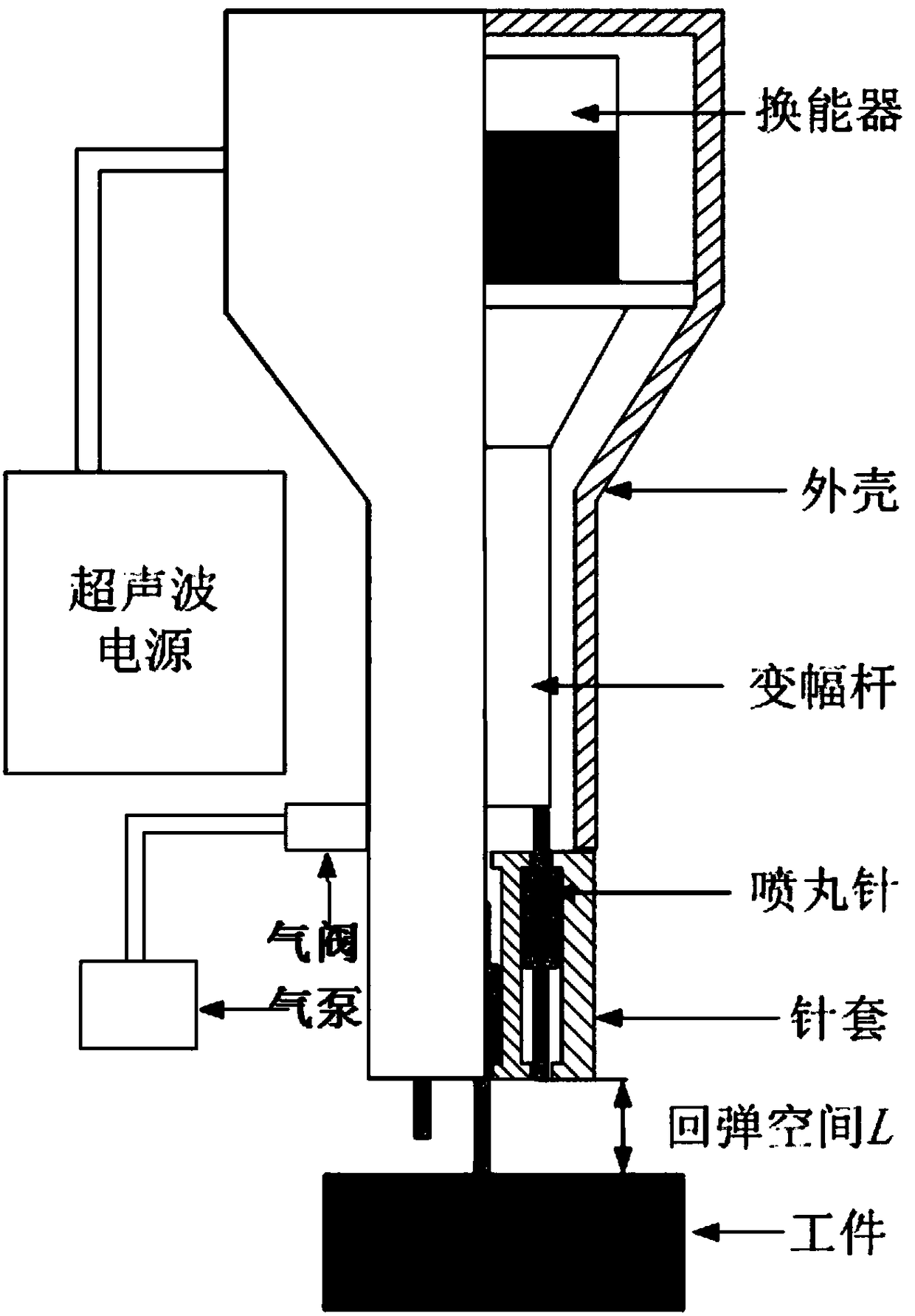

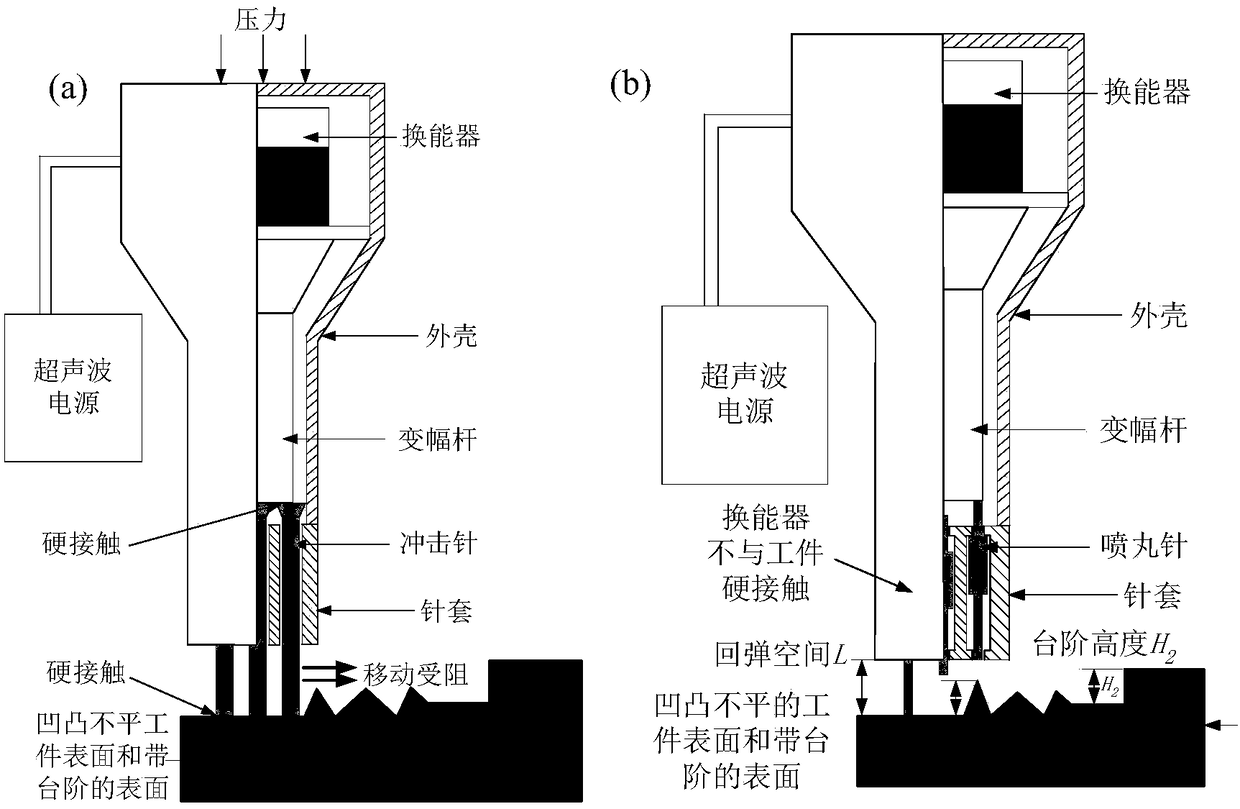

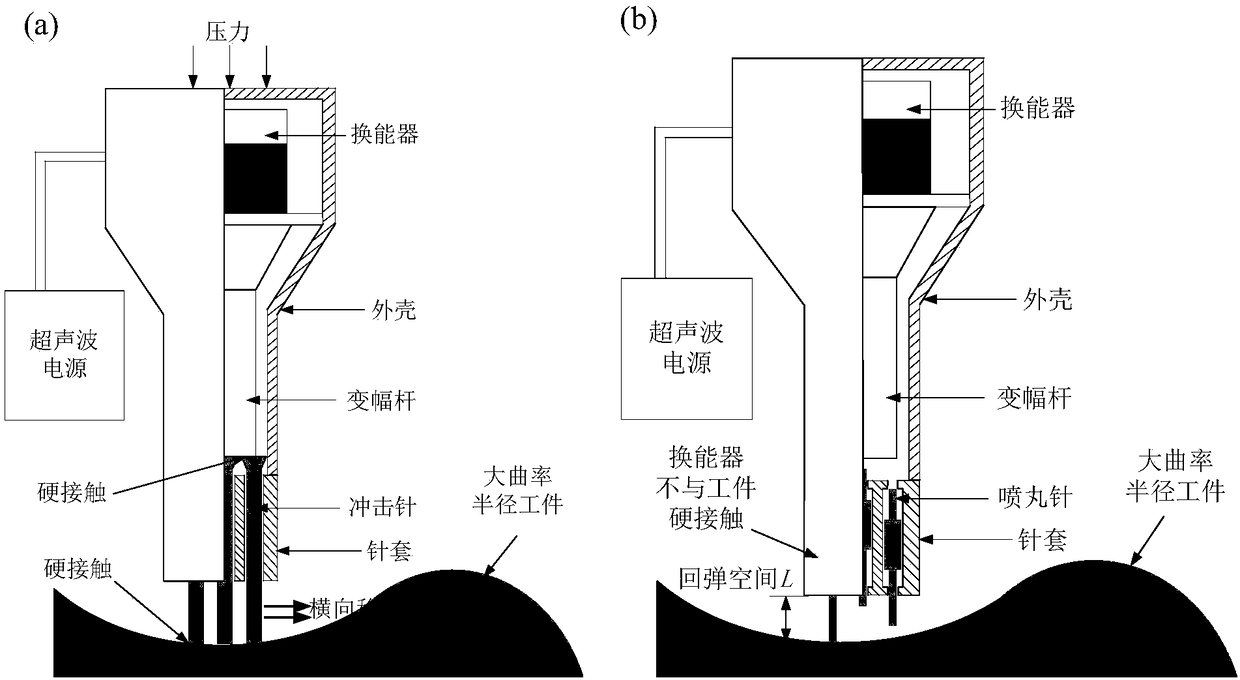

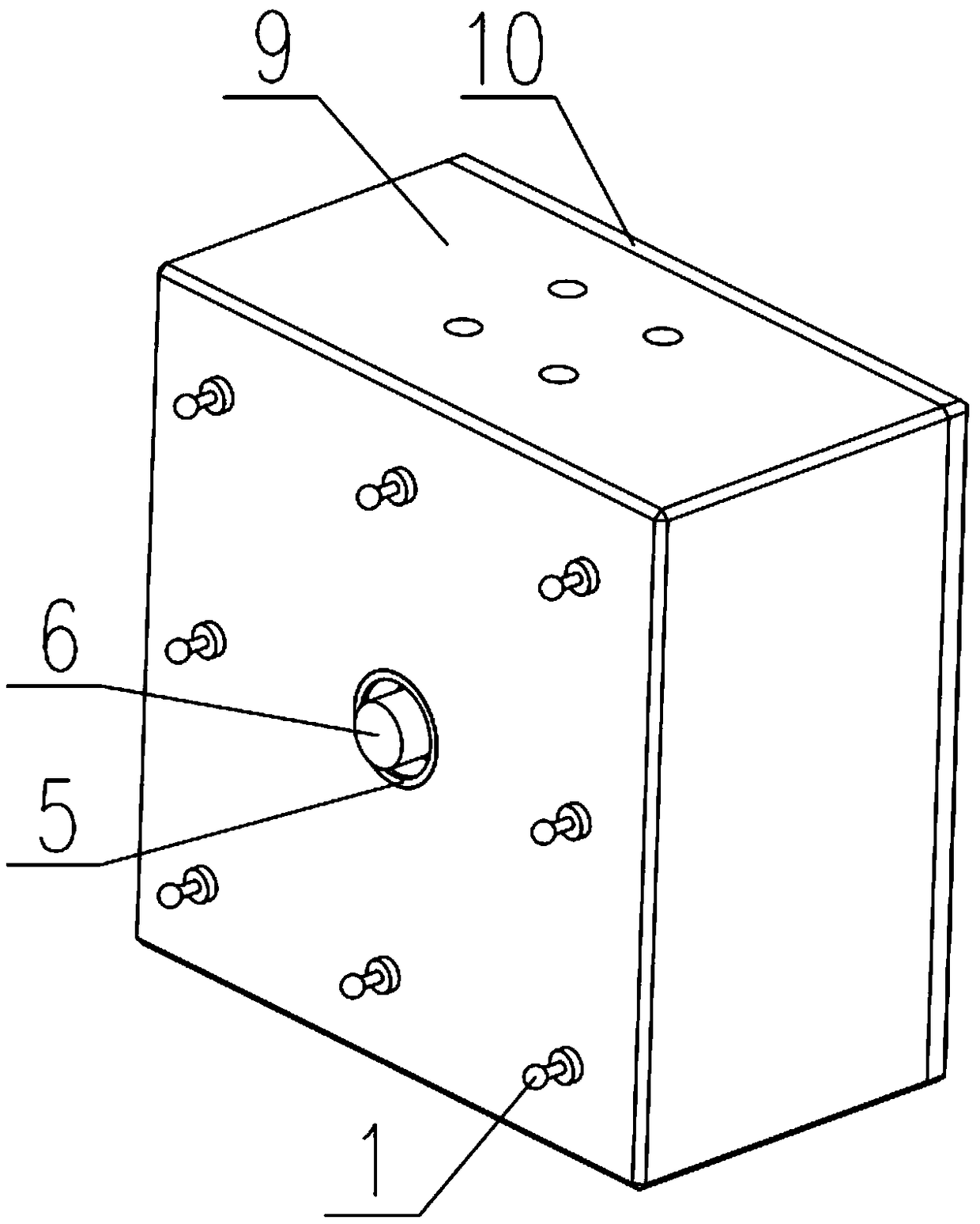

Full-angle flexible needle type ultrasonic shot blasting device

InactiveCN109420988AAchieving flexible contactVibratory devicesGrinding/polishing apparatusSuction forceTransducer

The invention discloses a full-angle flexible needle type ultrasonic shot blasting device. The full-angle flexible needle type ultrasonic shot blasting device is composed of an ultrasonic transducer,a shot blasting needle sleeve, a shot blasting needle and a suction device. The tail end of the shot blasting needle is adsorbed to the end face of the tail end of an amplitude-change pole of the transducer through suction force, and the shot blasting needle is popped out through ultrasonic vibration of the tail end of the amplitude-change pole. The shot blasting needle cannot be completely poppedout of the needle sleeve due to stop of the needle sleeve, and therefore the shot blasting needle can achieve constant reciprocating impacting between the amplitude-change pole of the ultrasonic transducer and a to-be-treated metal workpiece within a wide distance range, flexible contact between the shot blasting needle and the surface of the workpiece is achieved, the end of the shot blasting needle impacts on and is in contact with the surface of the to-be-treated metal workpiece only at the ultrasonic shot blasting moment, and the whole ultrasonic shot blasting device does not need to be in hard contact with the surface of the metal workpiece before shot blasting.

Owner:TIANJIN UNIV

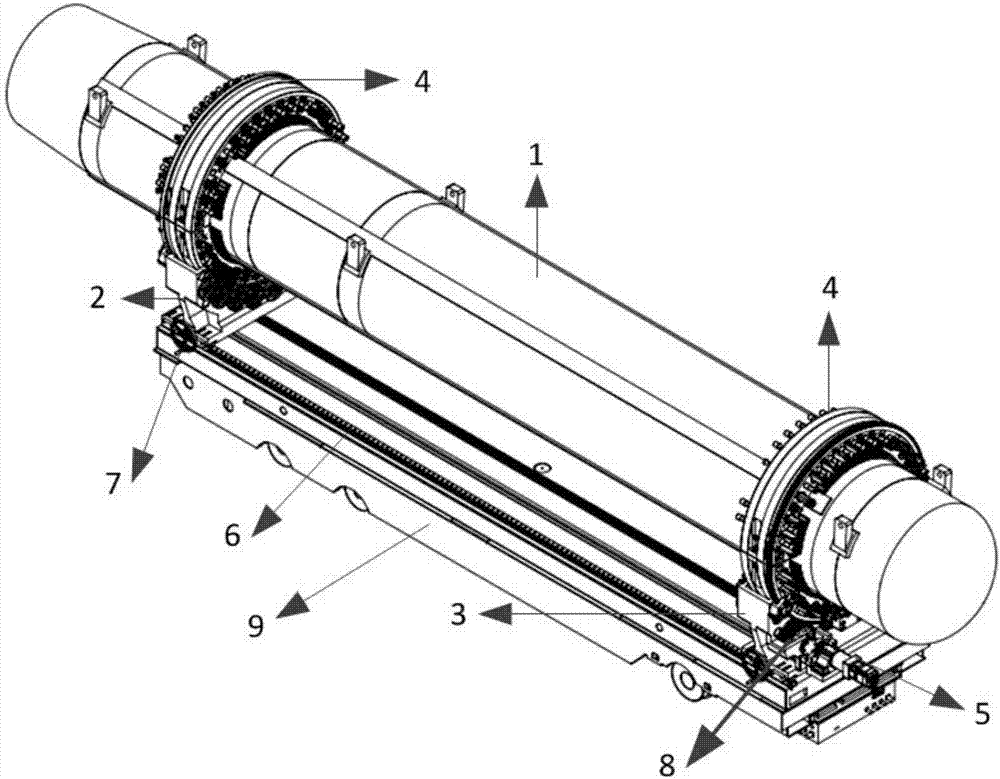

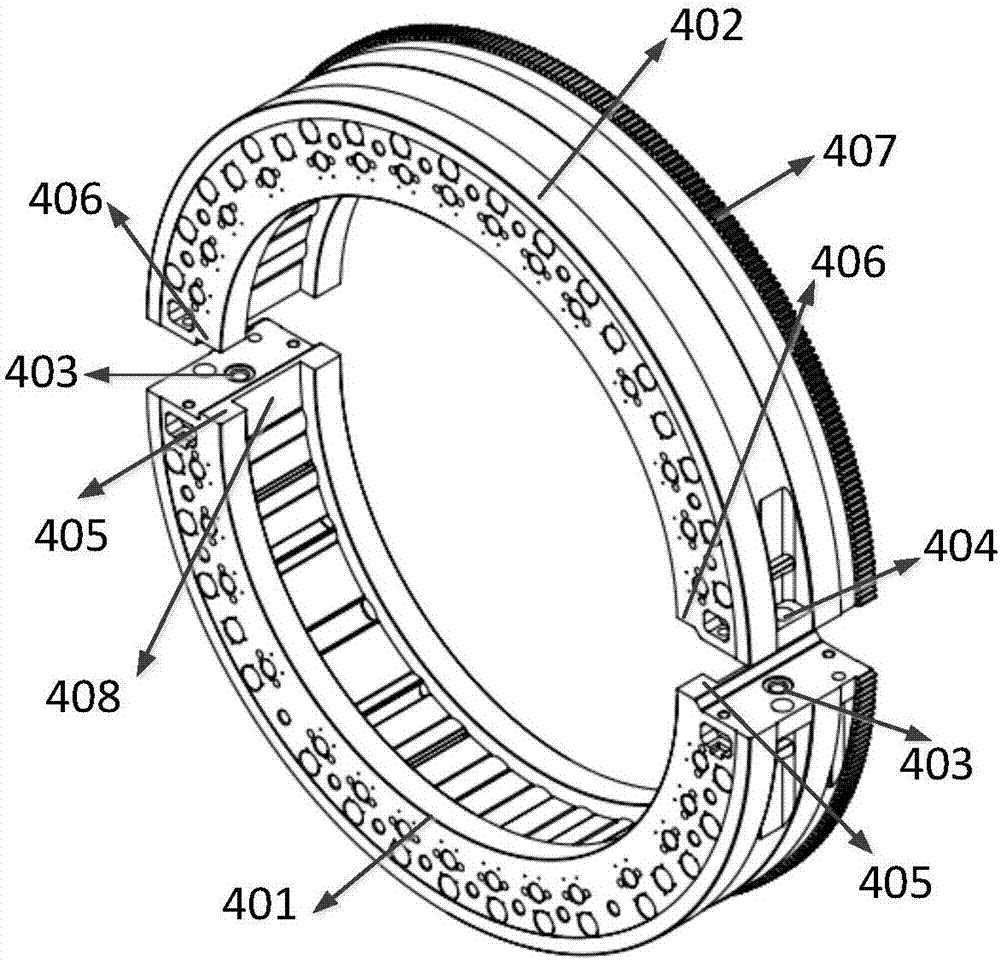

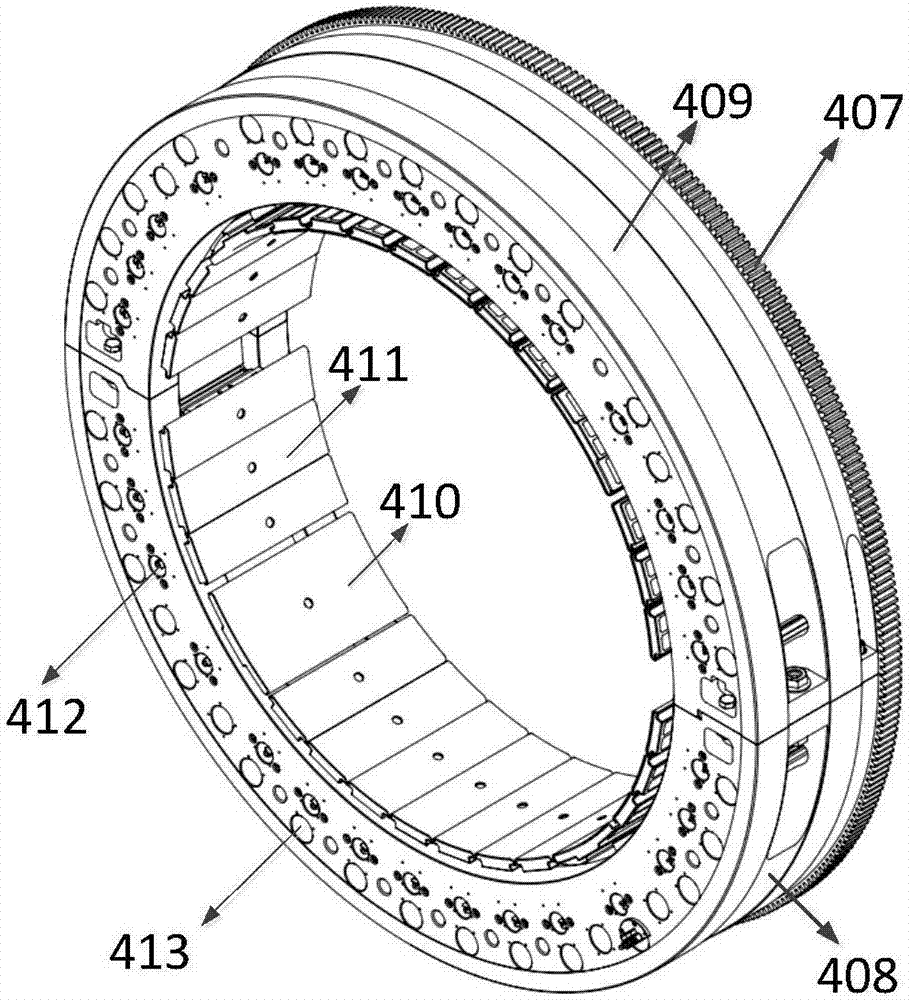

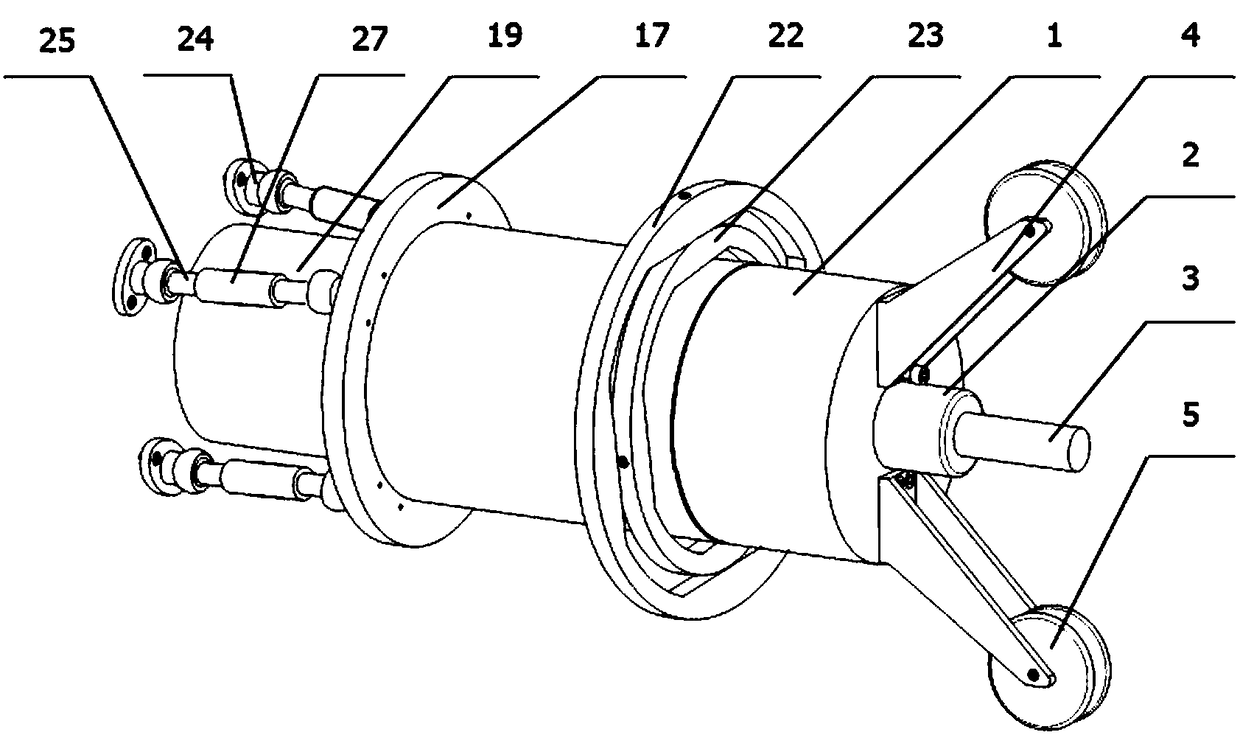

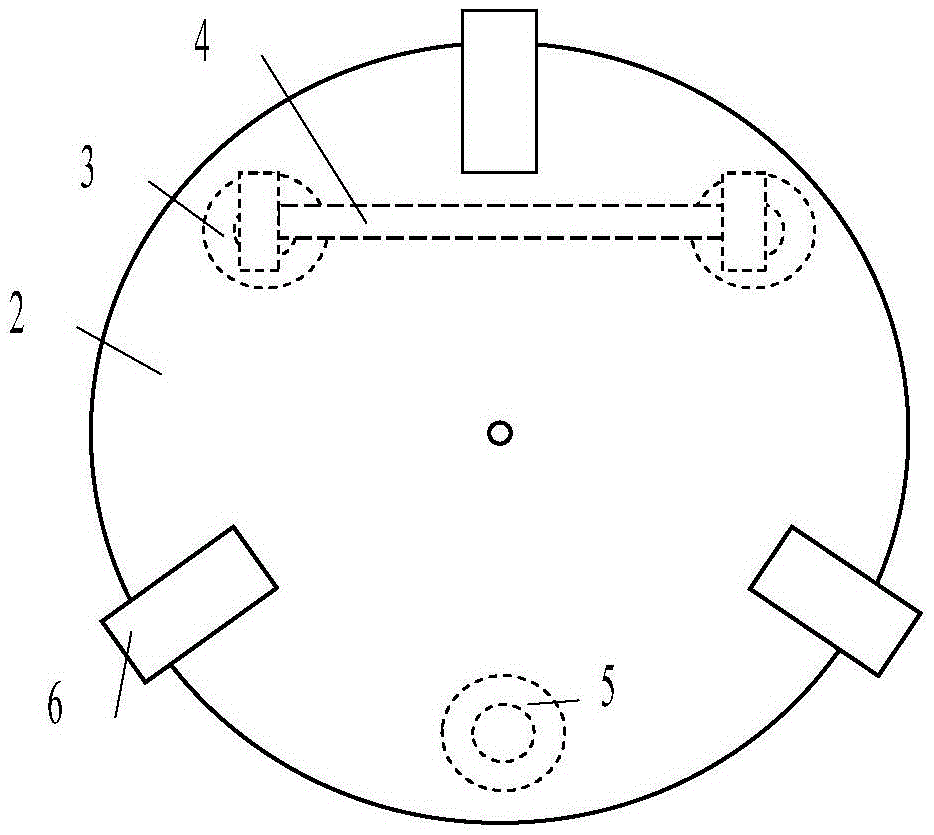

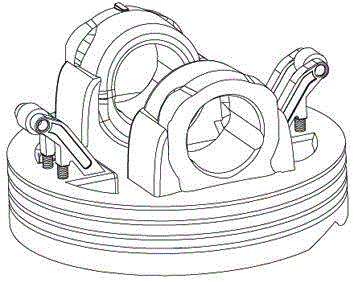

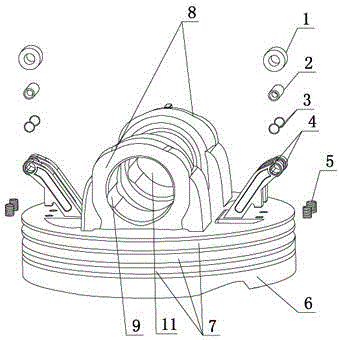

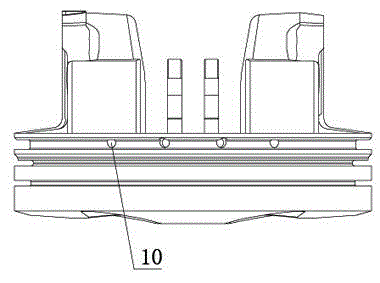

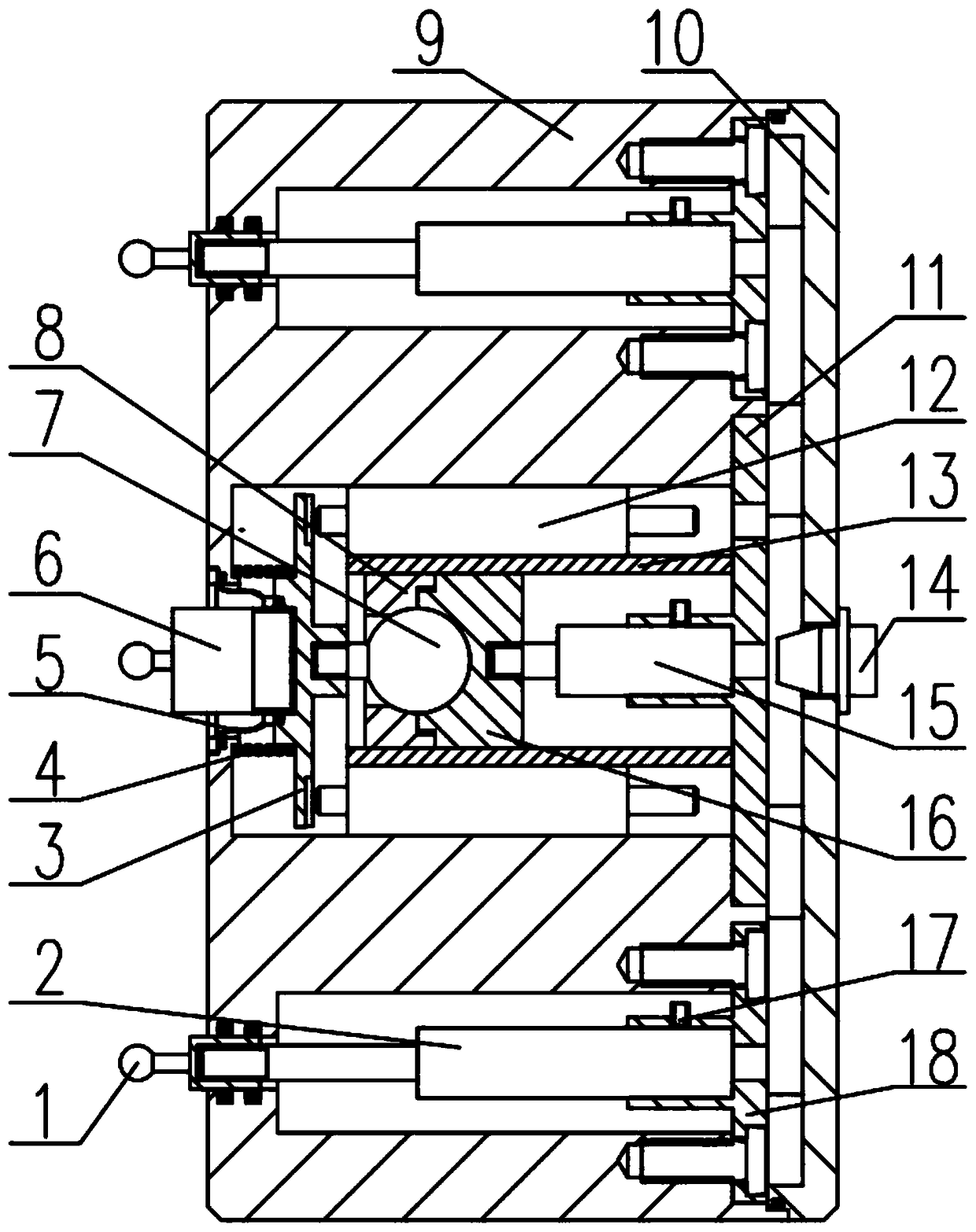

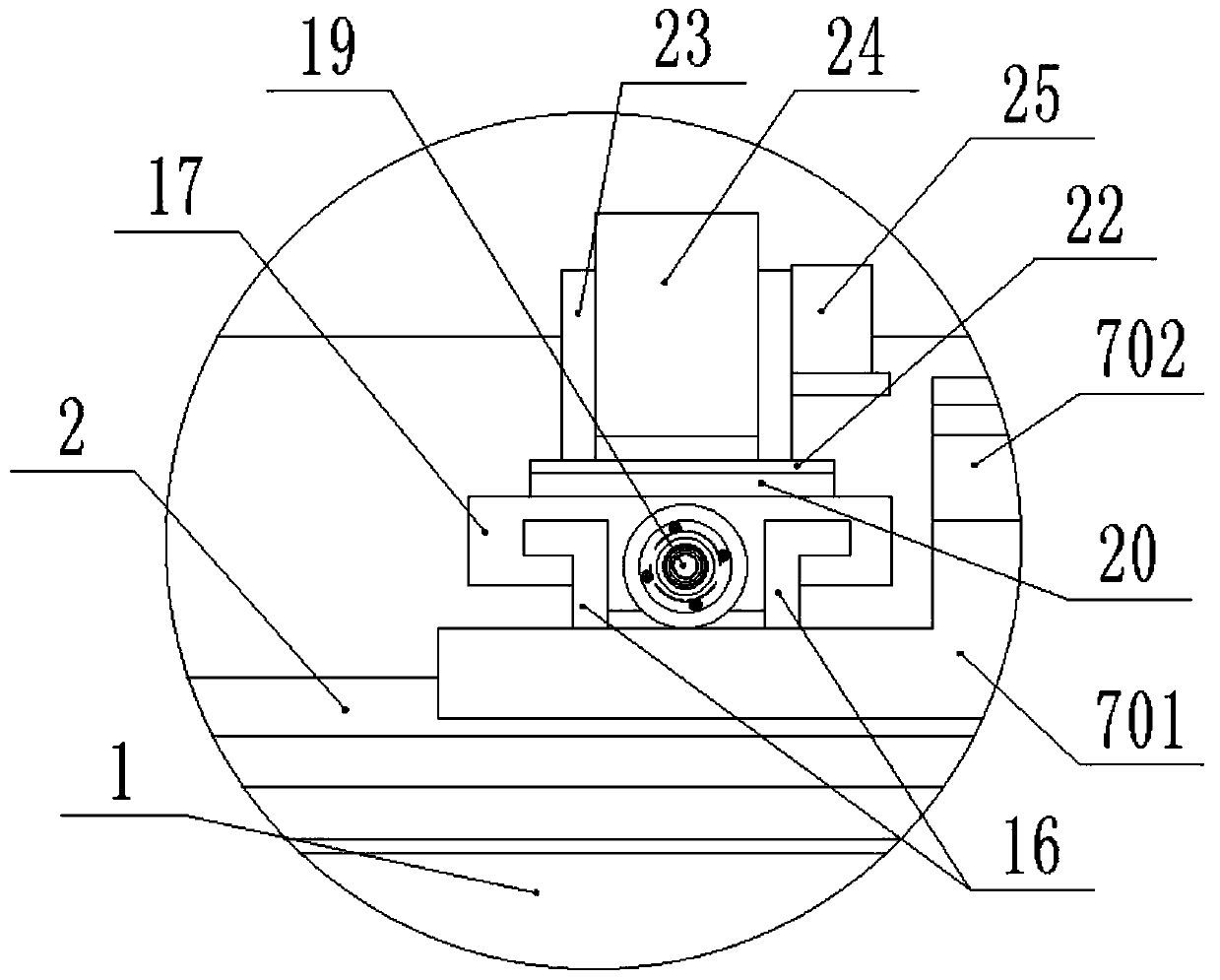

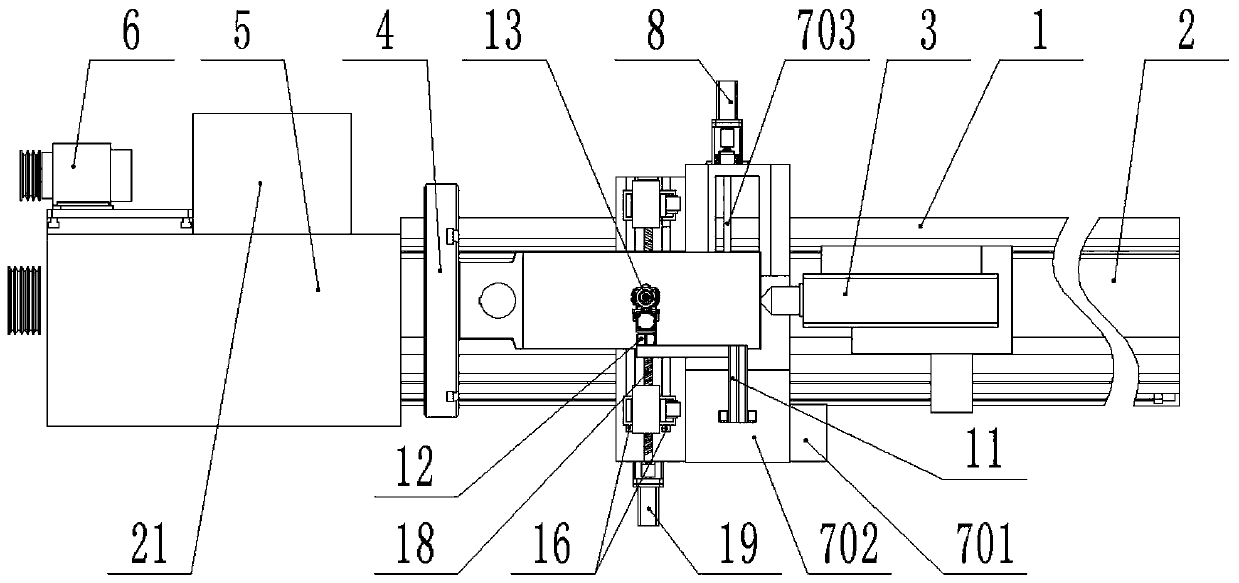

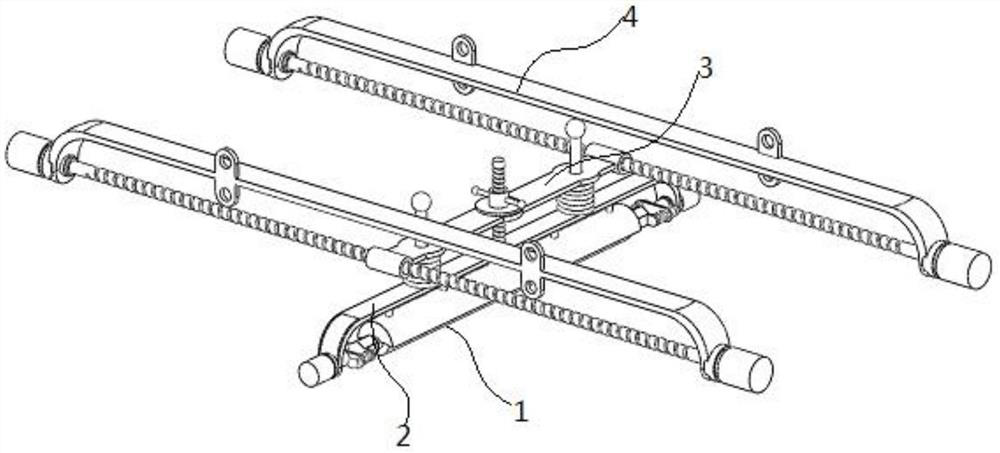

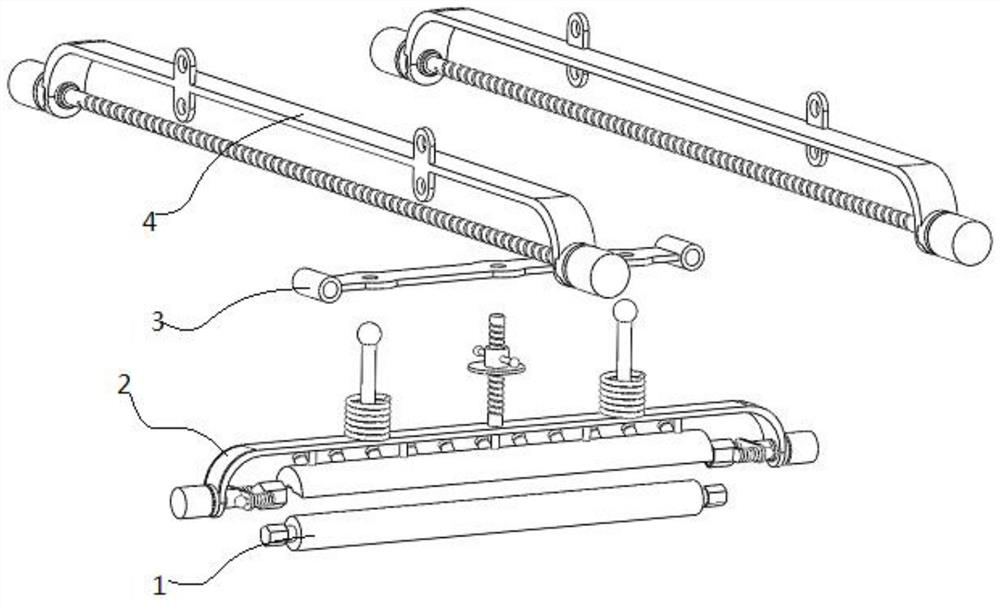

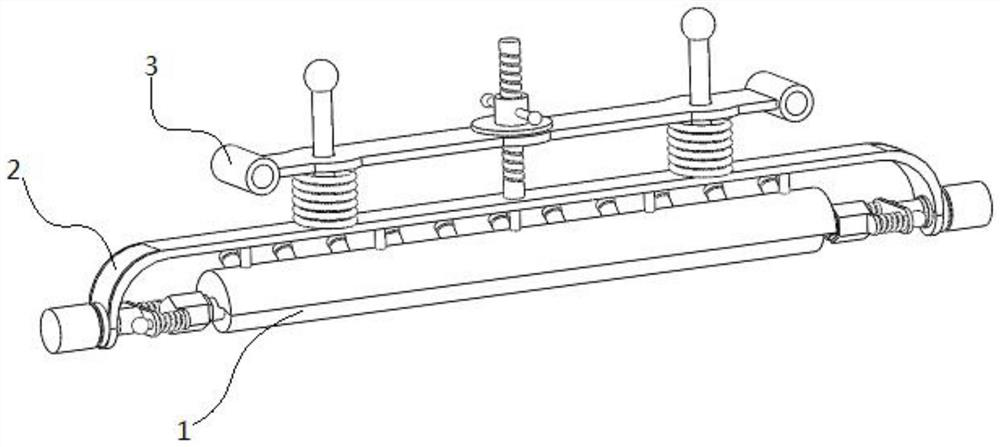

Clamping system and clamping method for large similar cylindrical workpieces

PendingCN107283191AAvoid collision and friction damageEasy and accurate clampingWork holdersPositioning apparatusPhysicsEngineering

The invention provides a clamping system for large similar cylindrical workpieces. The clamping system comprises at least two workpiece clamping devices; the workpiece clamping devices comprise first fixture bodies with semicircular structures and second fixture bodies; the first fixture bodies and the second fixture bodies are relatively connected to form a complete ring structure; and along the outer edge of the ring structure, transmission teeth engaged with external gears are arranged on the edges of the same side surfaces of the first fixture bodies and the second fixture bodies. The clamping system further comprises a bearing platform, and support bases arranged on the bearing platform in parallel; and a rotary driving device is arranged on one support base, and comprises a rotary driving mechanism and a driving gear connected with an output shaft end of the rotary driving mechanism. The invention further provides a clamping method for the large similar cylindrical workpieces. The clamping system has the advantages of safety, reliability, convenience in operation and high adaptability.

Owner:重庆真测科技股份有限公司 +1

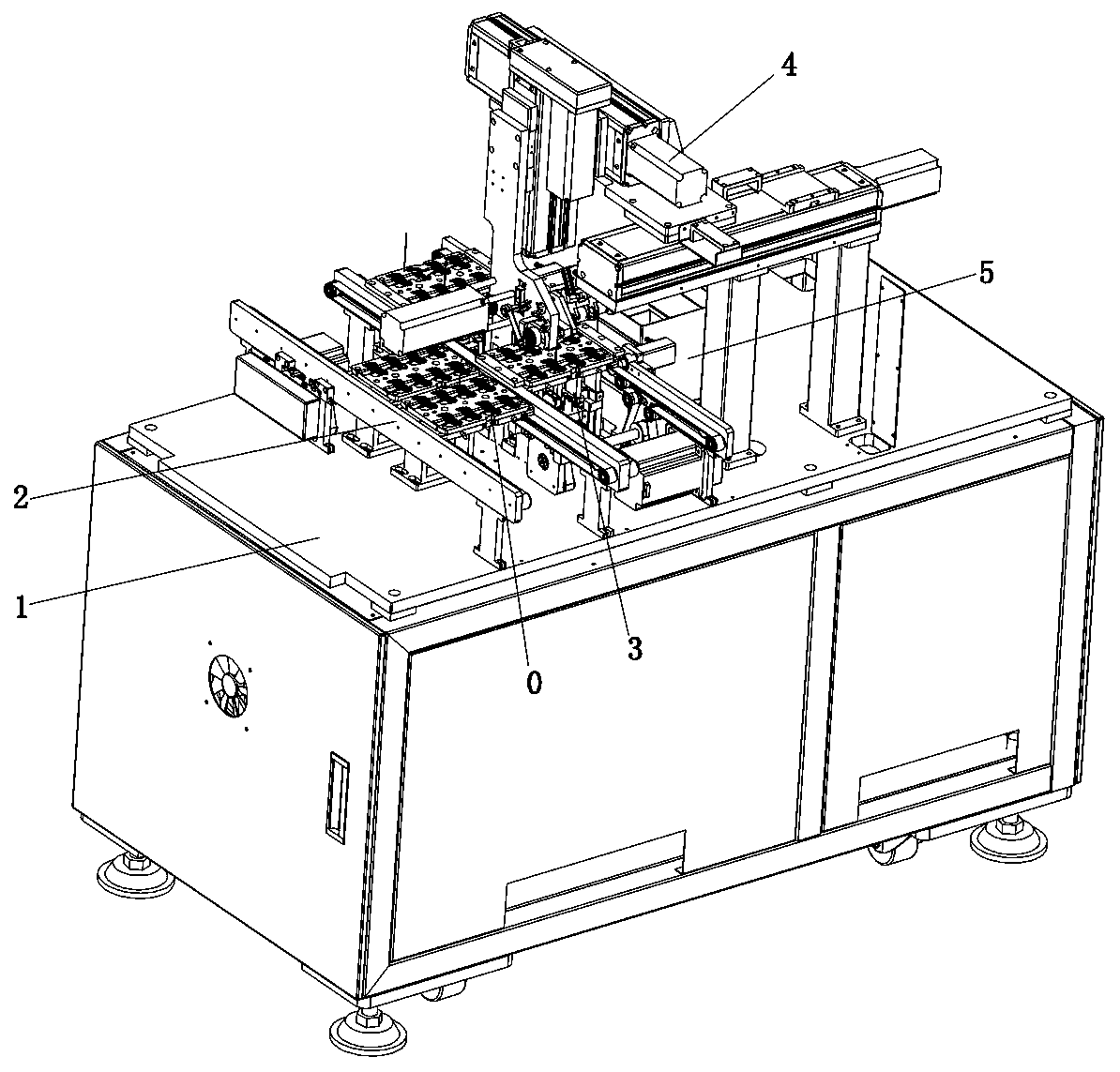

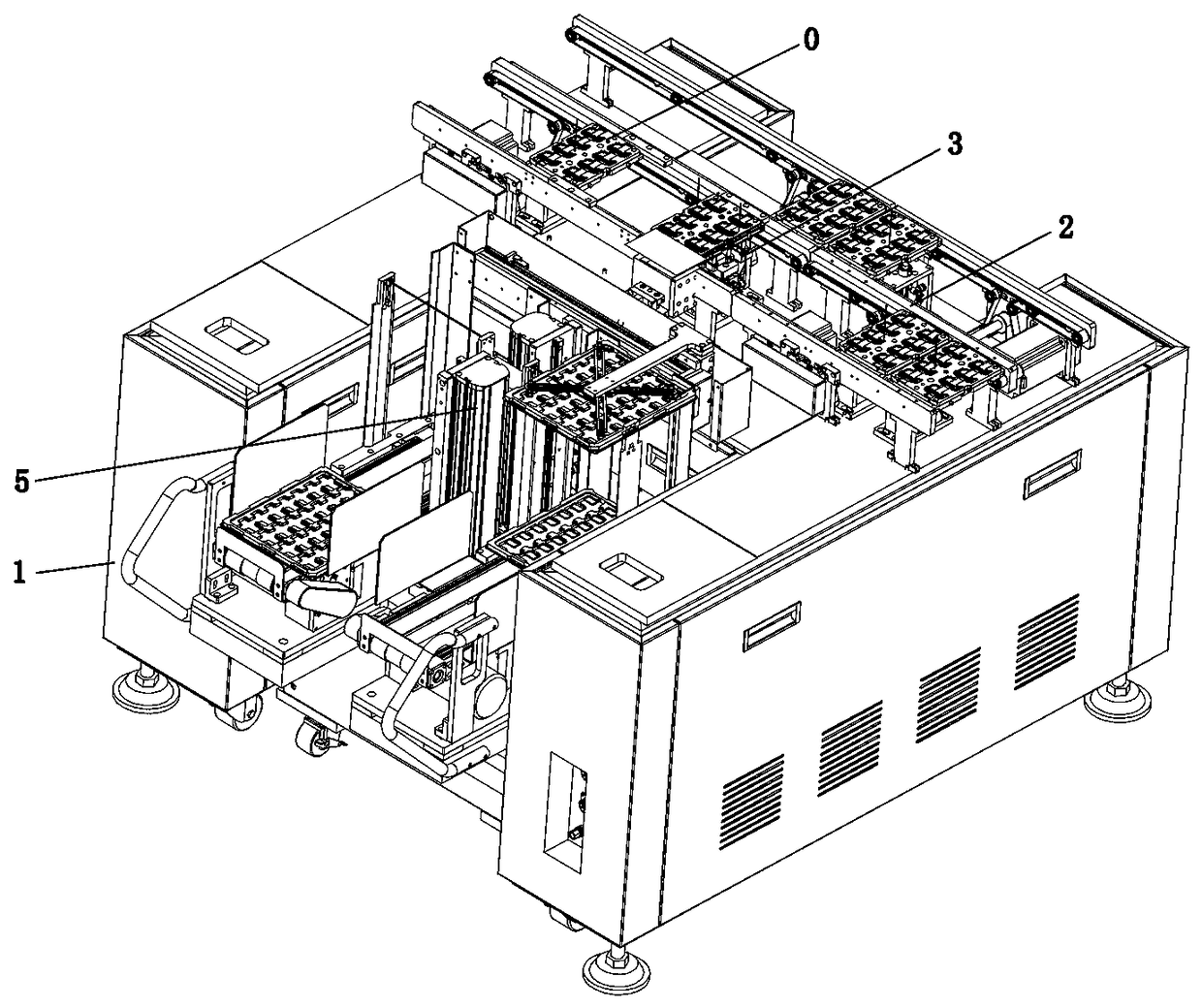

Automatic attaching machine for electronic product auxiliary materials

PendingCN109340233AReduce stuck and broken situationsHigh replaceabilityPlastic deformation fasteningMaterial gluingMulti materialEngineering

The invention discloses an automatic attaching machine for electronic product auxiliary materials. The automatic attaching machine comprises a conveying mechanism, a positioning and supporting mechanism, an attaching mechanism and a material supplying mechanism; the conveying mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at an attaching stationin the conveying mechanism, when a fixture moves to the attaching station, the fixture is positioned by the positioning and supporting mechanism, and a product in the fixture penetrates through the fixture upwards to be jacked and supported and adsorbed and fixed downwards through the positioning and supporting mechanism; the material supplying mechanism is arranged on one side of the conveying mechanism and used for guiding out at least two auxiliary materials; and the attaching mechanism is arranged between the attaching station and the material supplying mechanism in a crossing mode and used for attaching the auxiliary materials to the product after the auxiliary materials guided out of the material supplying mechanism are adsorbed, fixed and moved to the attaching station. According tothe automatic attaching machine for the electronic product auxiliary materials, the functions of multi-product bearing, fixture positioning, product jacking and supporting and adsorbing and heating are achieved, the material supplying assembly achieves quick disassembling and replacing, the condition that a material belt is jammed and pulled to be broken is reduced, a multi-material automatic material taking and attaching function is achieved, the universality is high, and the part replaceability is high.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

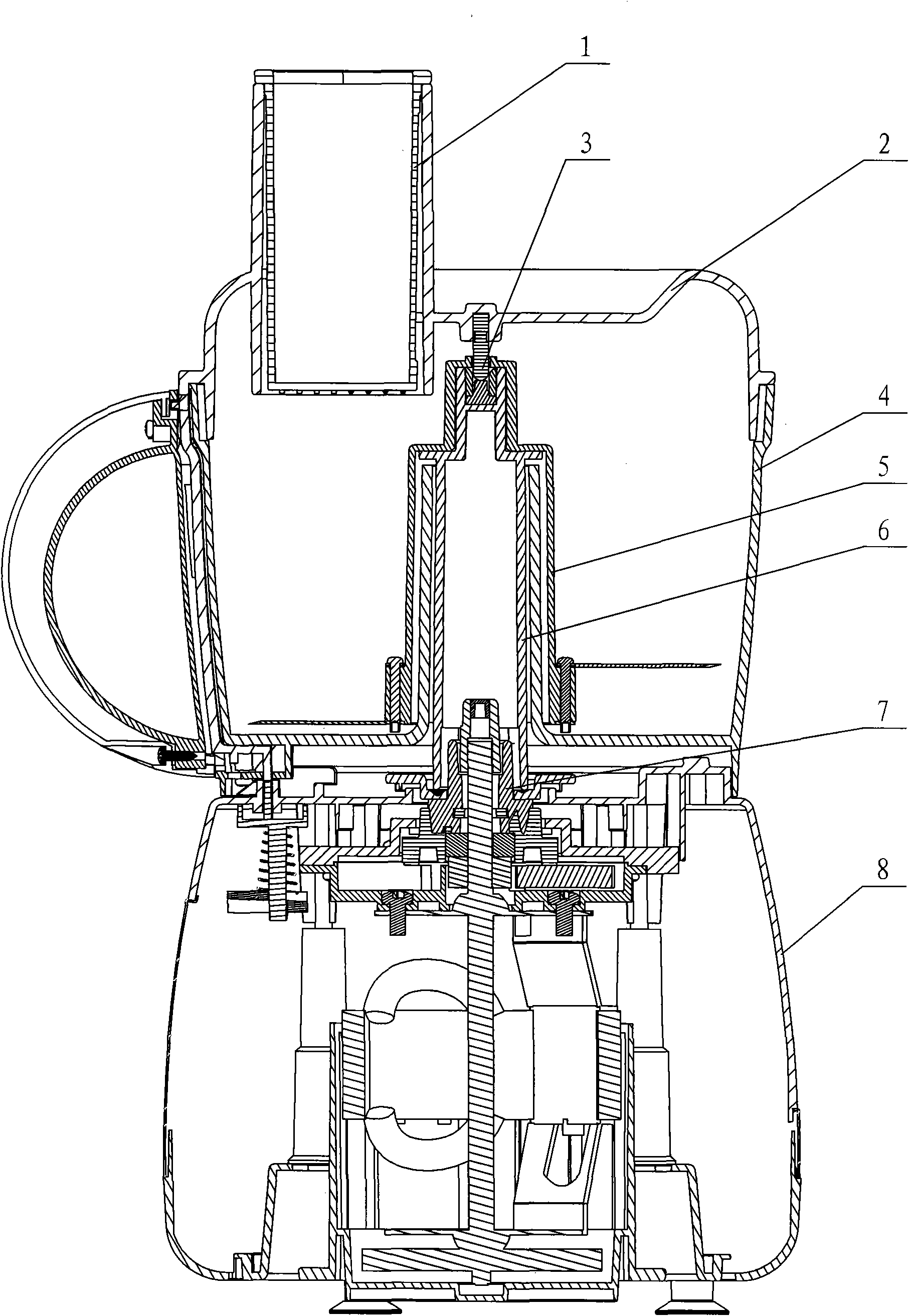

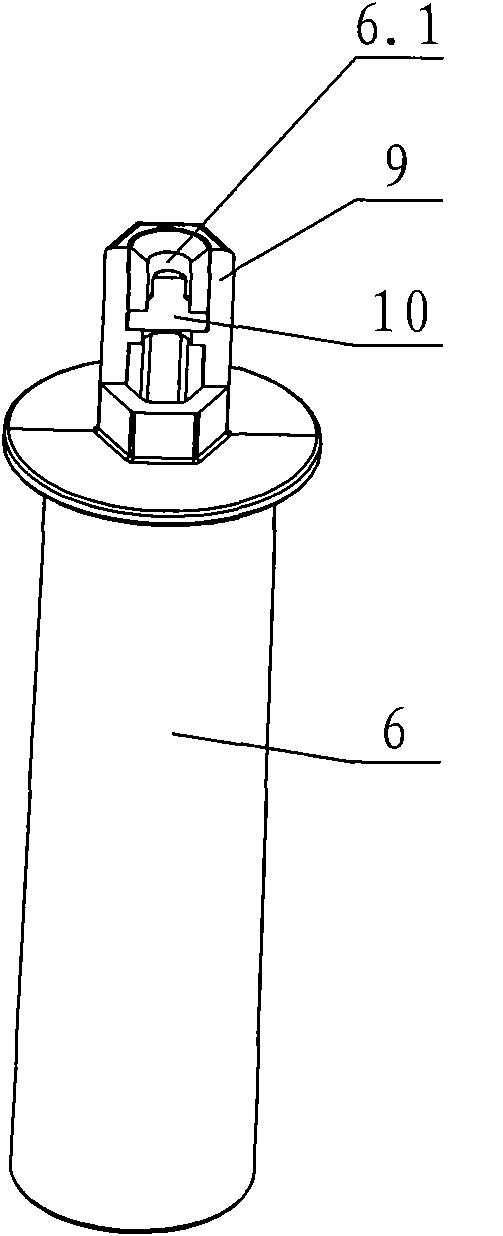

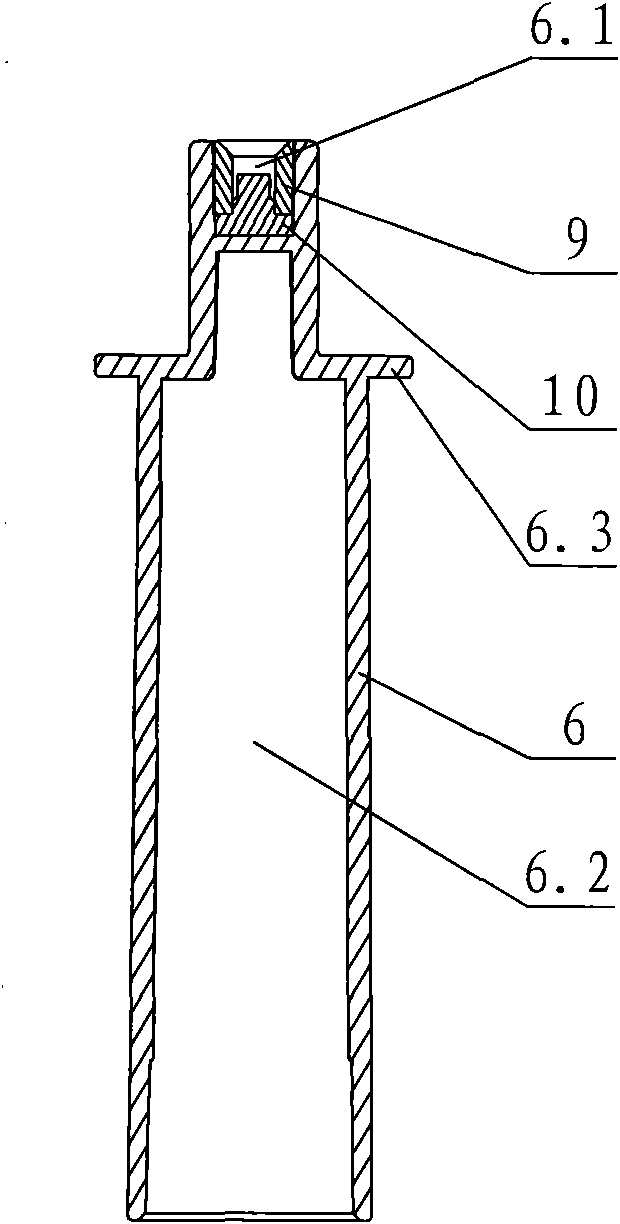

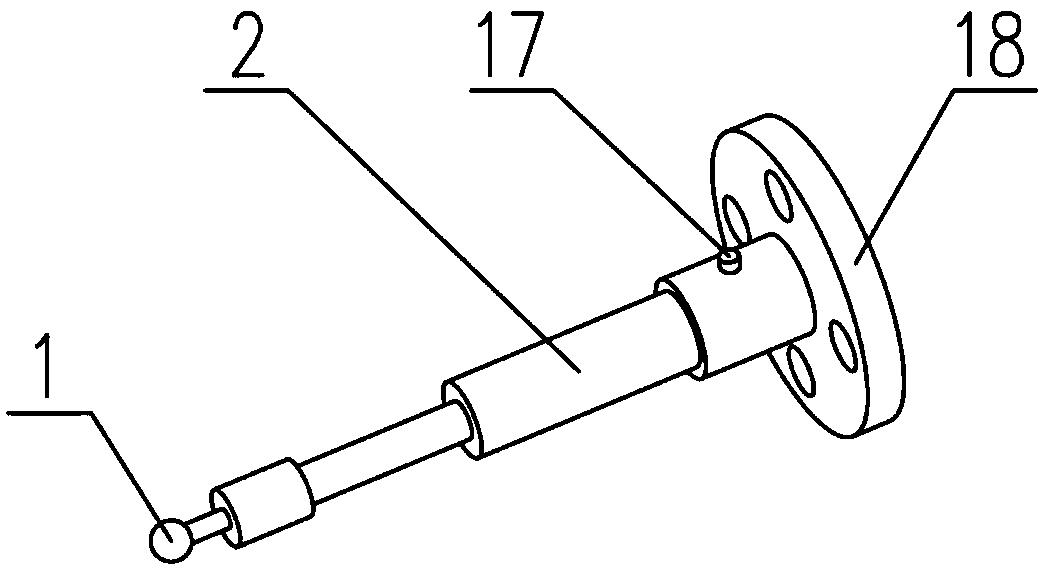

Transmission structure of food processor

ActiveCN101773370AAchieving flexible contactGuaranteed uptimeKitchen equipmentInterference fitMeasuring cup

A transmission structure of a food processor comprises a stirring cup and a measuring cup which are arranged on the upper part of the main machine, wherein a stirring cutter assembly is arranged in the stirring cup; the top of the stirring cup is provided with an opening, and a cup cover is arranged on the opening; the stirring cutter assembly is connected with a connecting head of the main machine through a detachable main shaft assembly; the main shaft assembly comprises a rotating shaft and a shaft sleeve which are in interference fit; one end of the main shaft assembly is provided with an elastic member; the elastic member is a soft rubber plug, a compression spring, a top bead or a rubber sleeve, and the elastic member is integrated with the rotating shaft through the shaft sleeve; and a positioning shaft is arranged in the cup cover, the positioning shaft is inserted in a mounting cavity on the rotating shaft, and the end part of the positioning shaft is contacted with the elastic member. Flexible contact between the stirring cup and the cup cover is realized by using the elasticity of the soft rubber plug or the rubber sleeve or a spring, and the probability that the rotating shaft jumps upwards is reduced, so the stirring cutter assembly runs stably, the purposes of reducing vibration and friction and lowering noise are achieved, and meanwhile, the service life of the food processor is prolonged.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

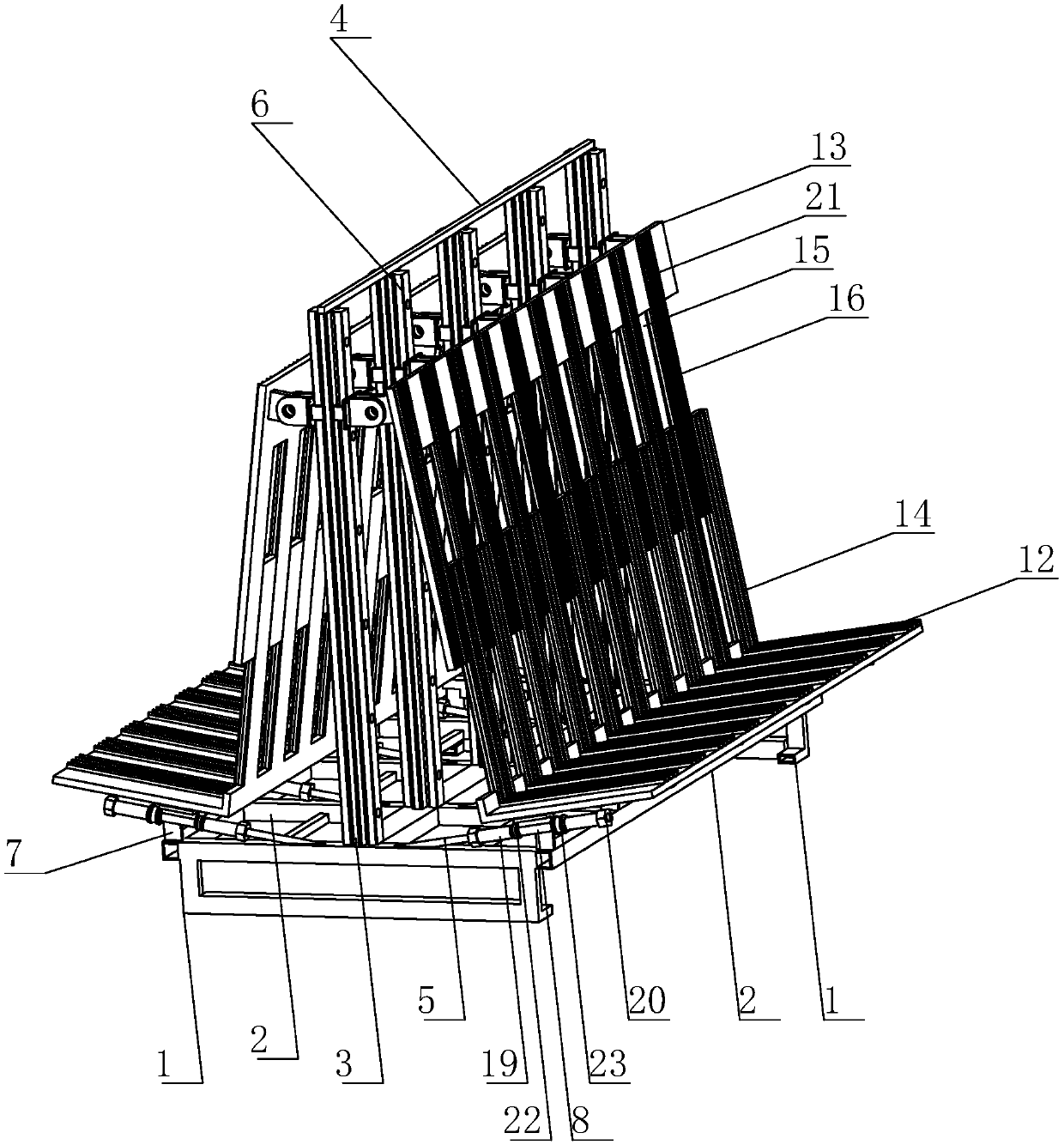

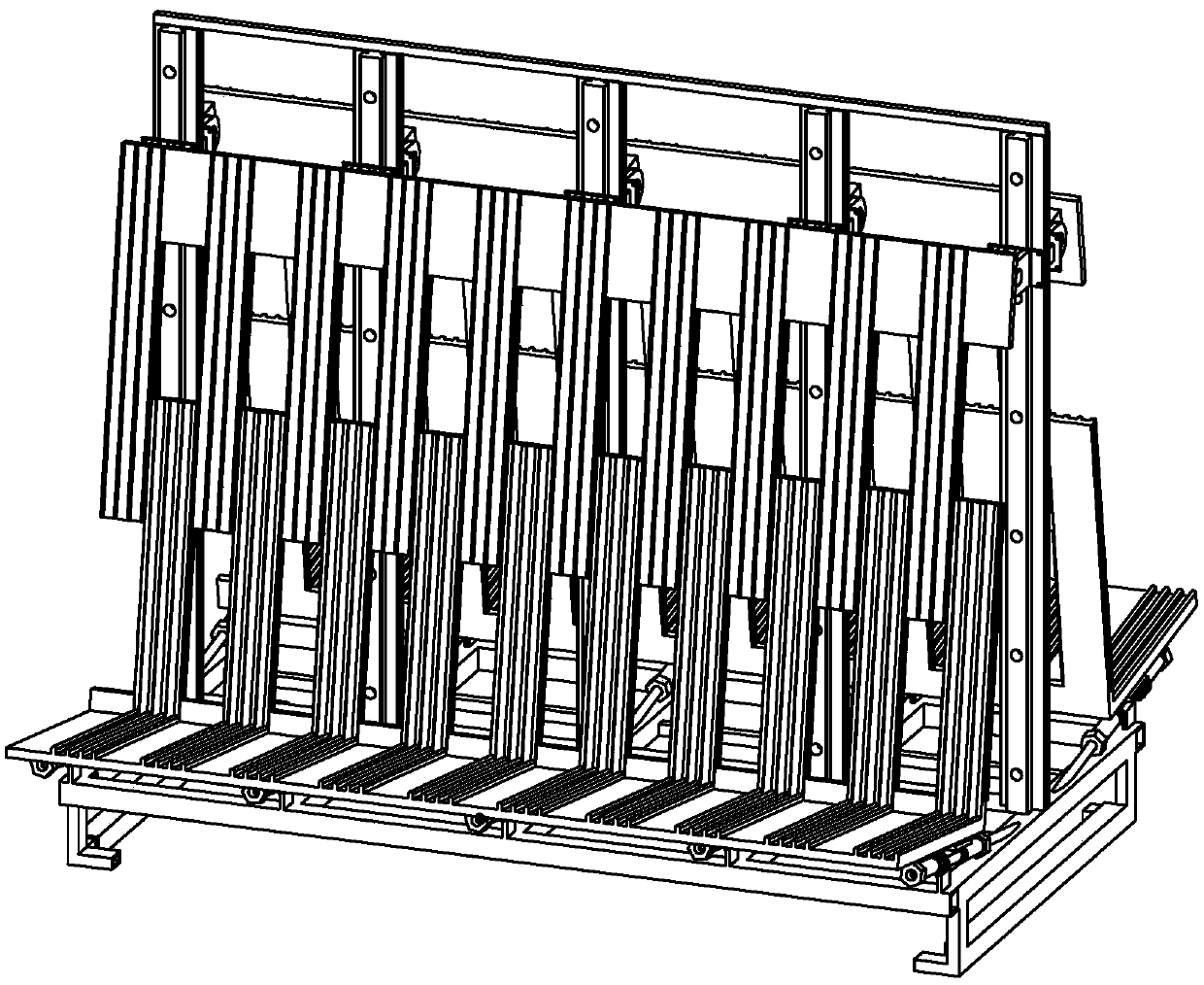

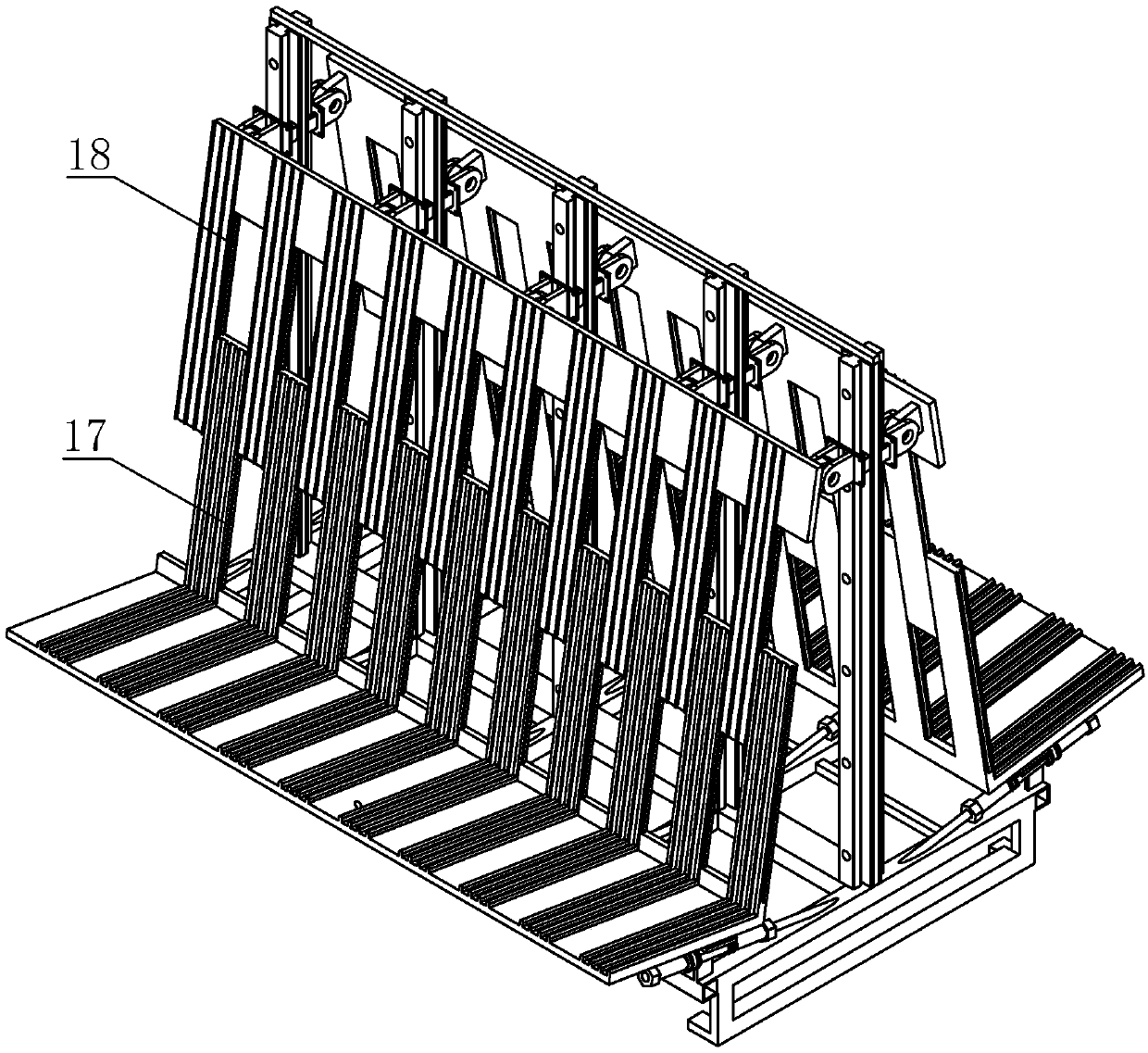

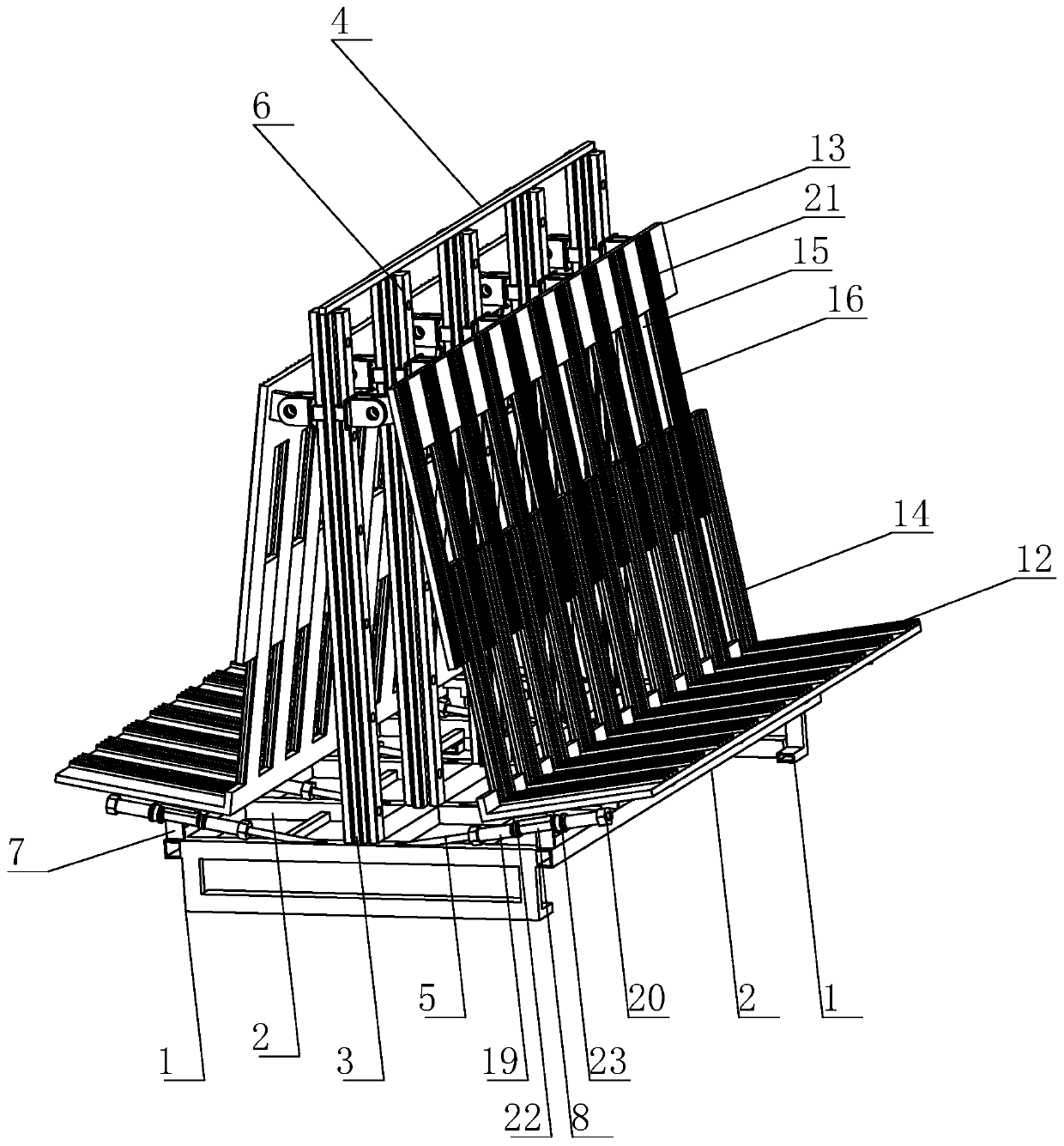

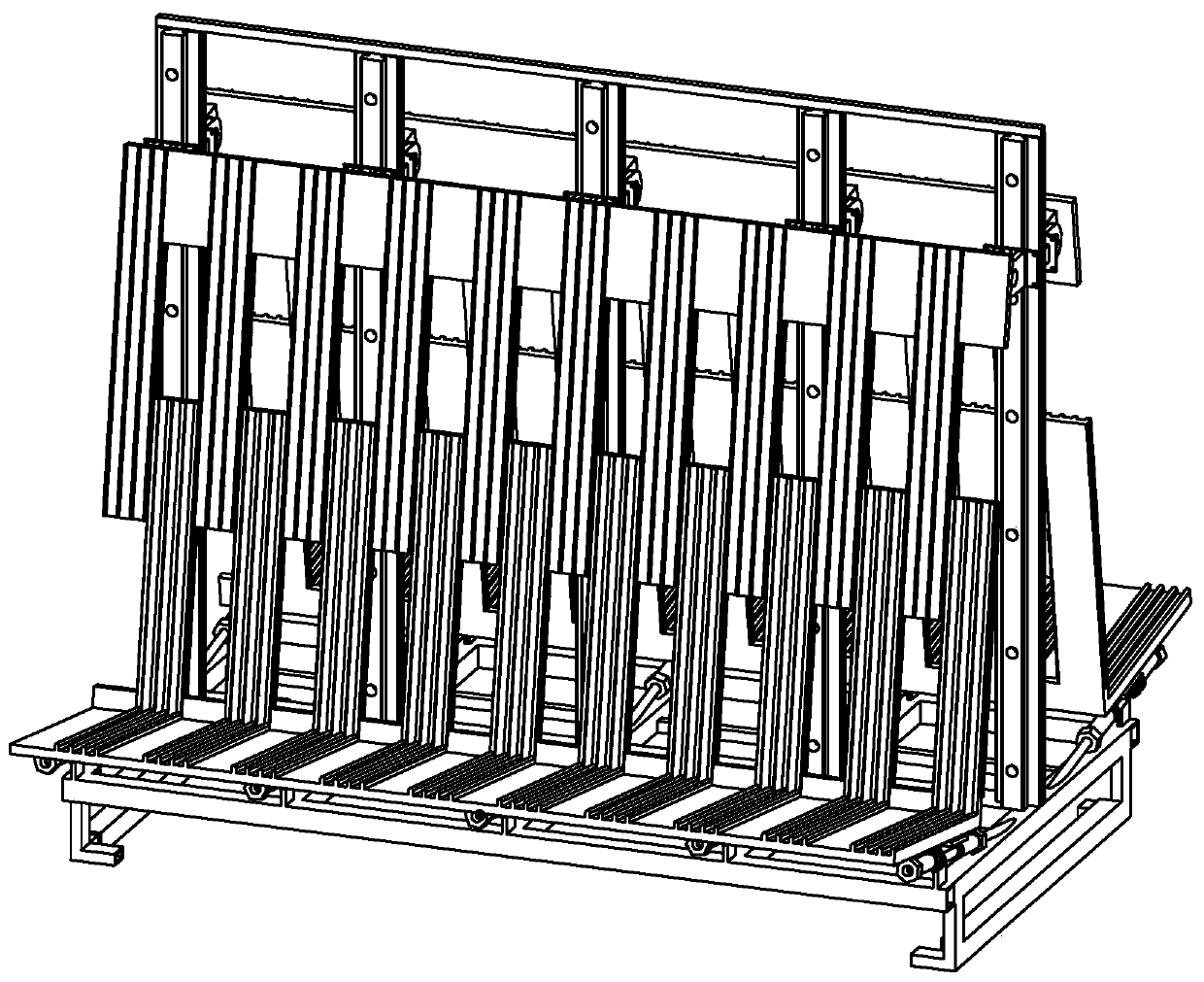

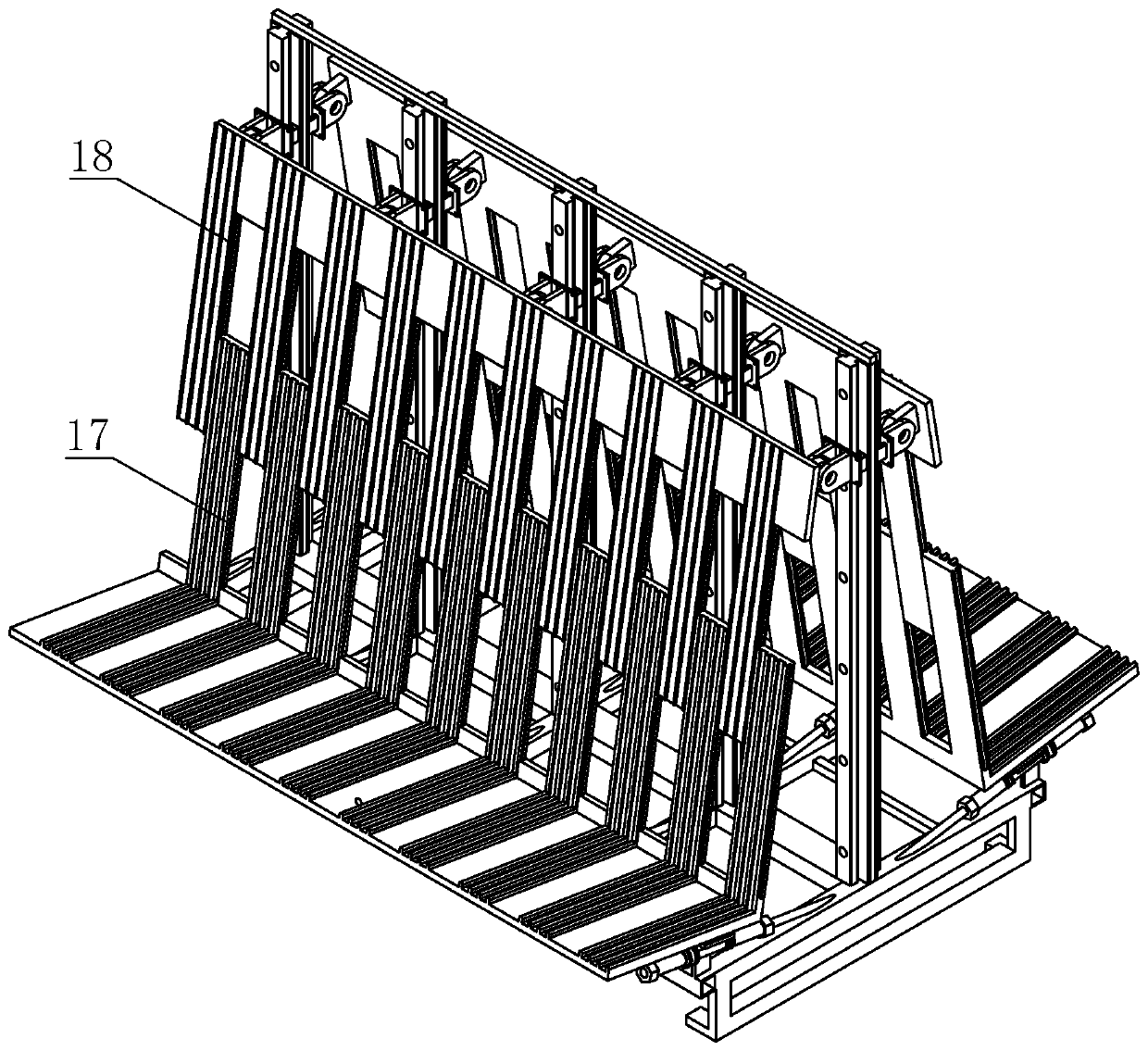

Fixing bracket for glass transportation

ActiveCN108674990AEliminate transportation lossDistribute the load evenlyCharge manipulationConveyor partsEngineeringResource utilization

The invention discloses a fixing bracket for glass transportation, mainly relates to the field of construction equipment transportation. The fixing bracket for glass transportation comprises a main bracket body, a guide rail mechanism, a glass supporting mechanism, a limiting assembly and a buffering piece. The glass supporting mechanism achieves L-shaped extension adjustment by the bidirectionalguide rail mechanism, and achieves fixing and limiting by the limiting assembly; and the buffering piece achieves rigid shock absorption of glass. The fixing bracket has the beneficial effects of being capable of adapting to different conditions on site according to the glass with different sizes and characteristics to fix and transport the glass, significantly lowering transportation losses and improving resource utilization rate.

Owner:王盼

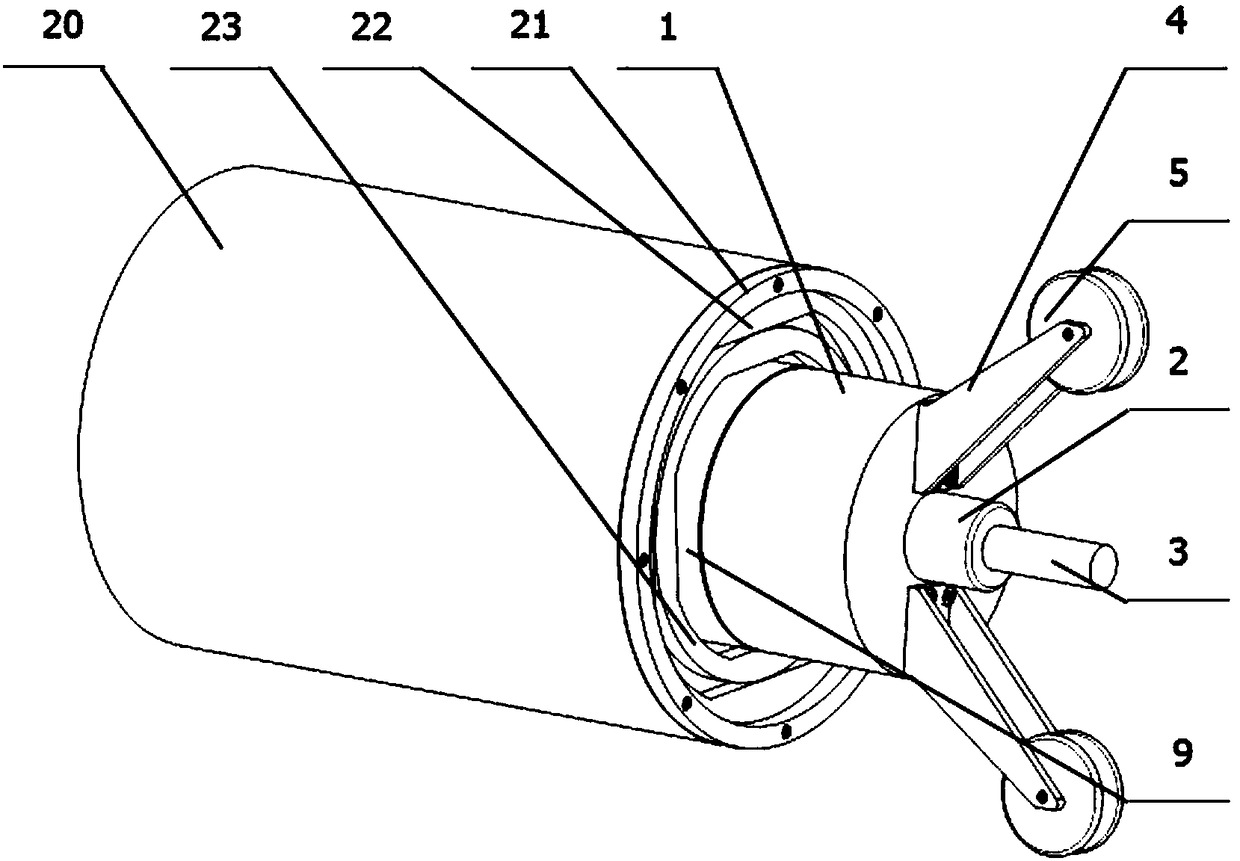

Passive adaptive multifunctional detection device for nuclear fuel assembly

ActiveCN108534657ASolve the problem of smooth alignmentImprove detection accuracyNuclear energy generationNuclear monitoringEddy currentEngineering

The invention provides a passive adaptive multifunctional detection device for a nuclear fuel assembly. The detection device includes an oxide film thickness detection mechanism, a probe flexible feeding mechanism and a deformation detection mechanism. The deformation detection mechanism is in contact with the to-be-detected nuclear fuel assembly. The probe flexible feeding mechanism is in rigid connection with the oxide film thickness detection mechanism and the deformation detection mechanism separately. The oxide film thickness detection mechanism includes a probe spline groove, a spline slide block, an eddy current probe, a guide wheel support and a guide wheel. The deformation detection mechanism includes a mounting housing, an end cover, an outer rotary rack, an inner rotary rack, apedestal, a connection rod, an LVDT sensor and a sleeve. The device is simple and compact in structure, convenient in mounting, good in sealing performance, can adapt to different transformation and attitudes of fuel rods, can have flexible contact with the fuel rods and performs flexible measurement on the fuel rods and has multiple detection functions.

Owner:HEBEI UNIV OF TECH

Floating polisher and polishing method

ActiveCN103600275AAchieving flexible contactExtended service lifeEdge grinding machinesGrinding/polishing safety devicesPull forceEngineering

The invention discloses a floating polisher and a polishing method. The floating polisher comprises a base, a supporting seat, an angle grinder, a fixed support and a connecting rod mechanism. The connecting rod mechanism comprises two parallel connecting rods, and a thin cylinder assembly is arranged between the two connecting rods. During work, a robot grabs a workpiece to enable the workpiece to approach the angle grinder. When the workpiece is in contact with the angle grinder, the angle grinder is subjected to external force exerted by the workpiece, the external force is transferred to a piston rod of a cylinder through the connecting rod mechanism, the piston rod is pulled out, and the angle grinder starts polishing the workpiece with certain floating quantity. After polishing is finished, the robot moves the workpiece away, the external force is eliminated, pressure difference is generated at the two ends of a cylinder piston, the piston rod generates pulling force, and the polisher is pulled to an initial position through the connecting rod mechanism. The floating polisher can achieve parallel floating by means of the connecting rod mechanism, floating and resetting can be achieved through the cylinder, flexible contact between the polisher and the workpiece is achieved, the service life of the polisher is prolonged, and automation of work of casting cleaning and the like is achieved.

Owner:CHANGSHA CTR ROBOTICS

Substrate glass cutting and grinding device

ActiveCN112428452AImprove stabilityAvoid damageLapping machinesWorking accessoriesStructural engineeringMechanical engineering

The invention discloses a substrate glass cutting and grinding device. The device comprises a plurality of substrate cutting knife assemblies, and the plurality of substrate cutting knife assemblies are installed on pressurizing limiting plate assemblies in an elastic abutting sliding mode. The device has the beneficial effects that a top cutting air cylinder drives the substrate cutting knife assemblies to move downwards in the cutting process, at the moment, cutting knife discs on the substrate cutting knife assemblies make contact with the surface of the substrate glass, the cutting pressurizing force applied to the substrate glass during cutting of the substrate cutting knife assemblies is changed through fine adjustment of an automatic pressurizing air cylinder, and through elastic abutting of an ejecting guide sliding rod and an ejecting pressurizing spring, the knife bodies of the cutting knife discs elastically jack and move relative to plate bodies of the pressurizing limitingplate assemblies; and the knife bodies of the cutting knife discs on the multiple substrate cutting knife assemblies elastically jack and move relative to the plate bodies of the pressurizing limiting plate assemblies, during cutting, the knife bodies of the cutting knife discs on the multiple substrate cutting knife assemblies are in elastic jacking and pressing contact with a substrate glass plate, and in this way, flexible contact is achieved when the multiple substrate cutting knife assemblies make contact with the substrate glass plate.

Owner:彩虹(合肥)液晶玻璃有限公司

Accurate-positioning floating-type deburring and polishing device

InactiveCN108620976AContinuous automationIncrease productivityEdge grinding machinesGrinding carriagesDie castingEngineering

The invention provides an accurate-positioning floating-type deburring and polishing device. The accurate-positioning floating-type deburring and polishing device is characterized by comprising a carrying device, a deburring and polishing device, a robot mechanism, a discharging conveying device and a dust collection device. The robot mechanism grabs a to-be-deburred and to-be-polished die castingplaced on the carrying device, then the to-be-deburred and to-be-polished die casting is moved onto the deburring and polishing device so as to be polished, and afterwards, the polished die casting is conveyed to the discharging conveying device so as to be discharged. A flattening device is arranged at the tail end of a mechanical claw of the robot mechanism and is matched with a secondary positioning fixture arranged on the carrying device to make sure that the robot mechanism grabs castings at a fixed position; and meanwhile, the deburring and polishing device is provided with a floating assembly for achieving flexible contact between the castings and a polishing motor, so that burrs are prevented from being left while blade breakage and even casting damage caused by the non-retreatingproperty of the polishing motor are avoided, and accordingly, accurate-positioning floating-type deburring and polishing effects are achieved. By adoption of the accurate-positioning floating-type deburring and polishing device, full-automatic continuous deburring and polishing work can be achieved, the degree of automation is high, and one worker can operate multiple devices.

Owner:刘少军 +1

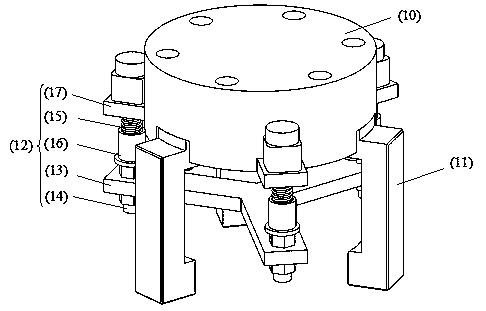

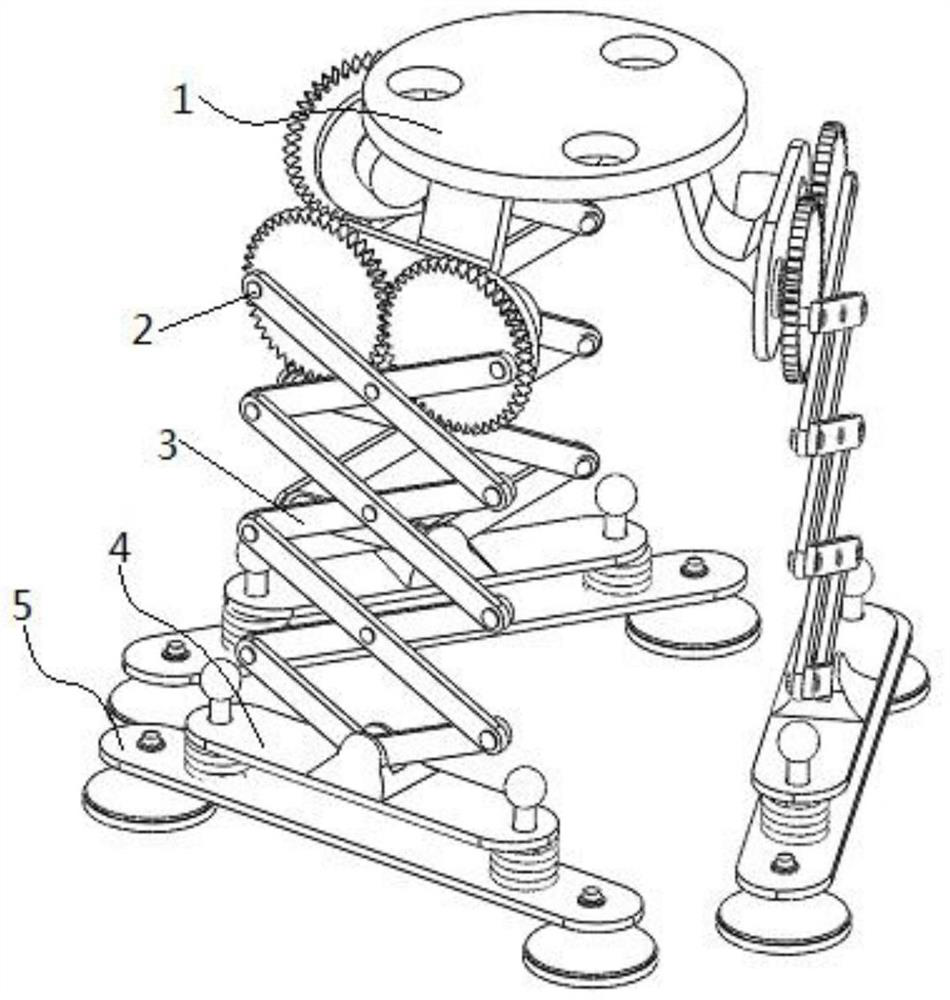

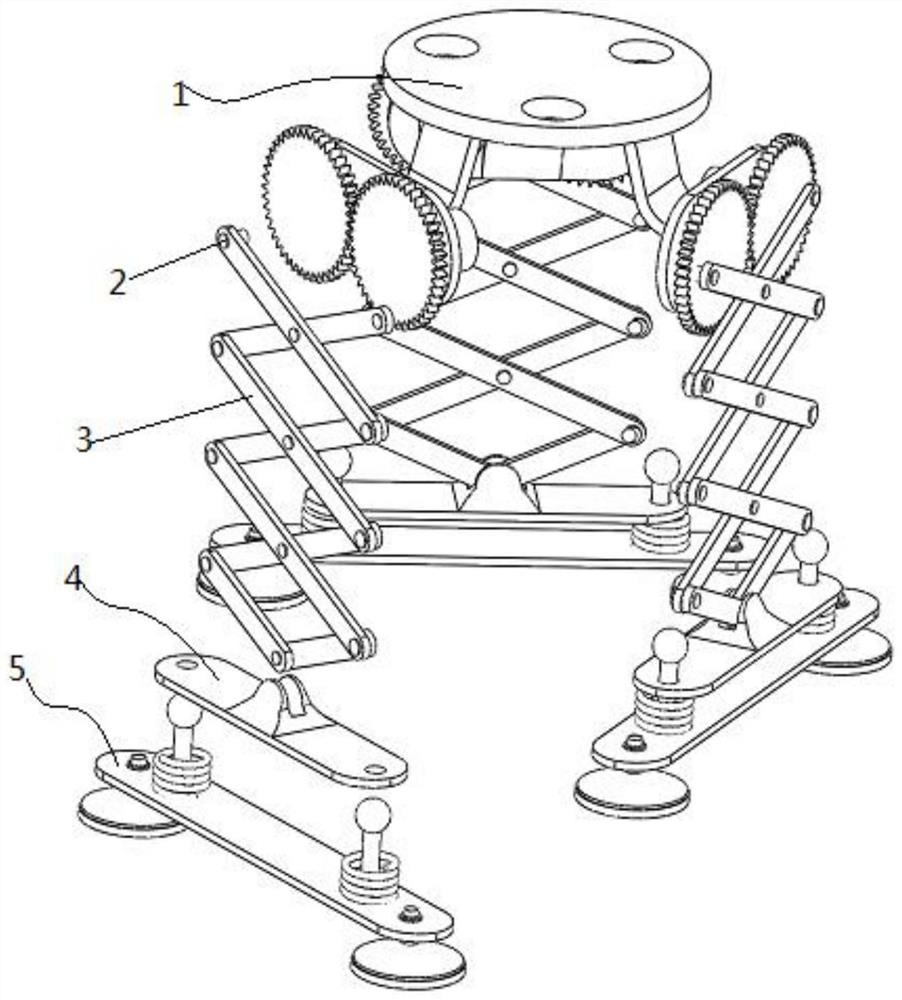

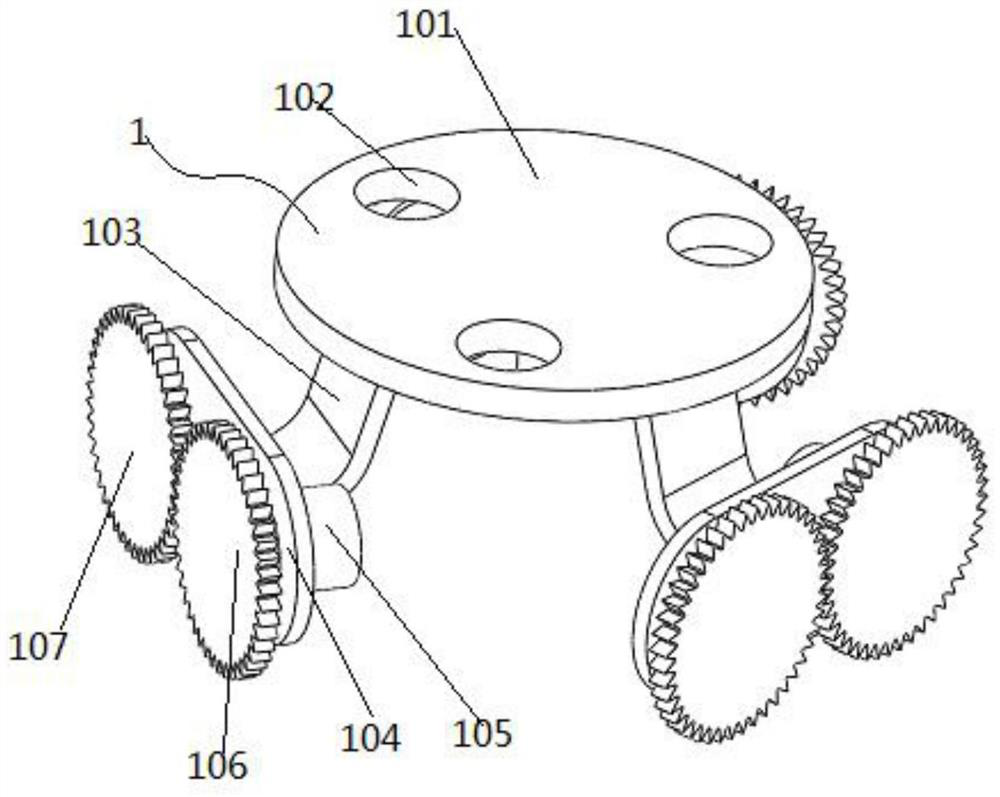

Robot hand with three under-actuated fingers connected in parallel

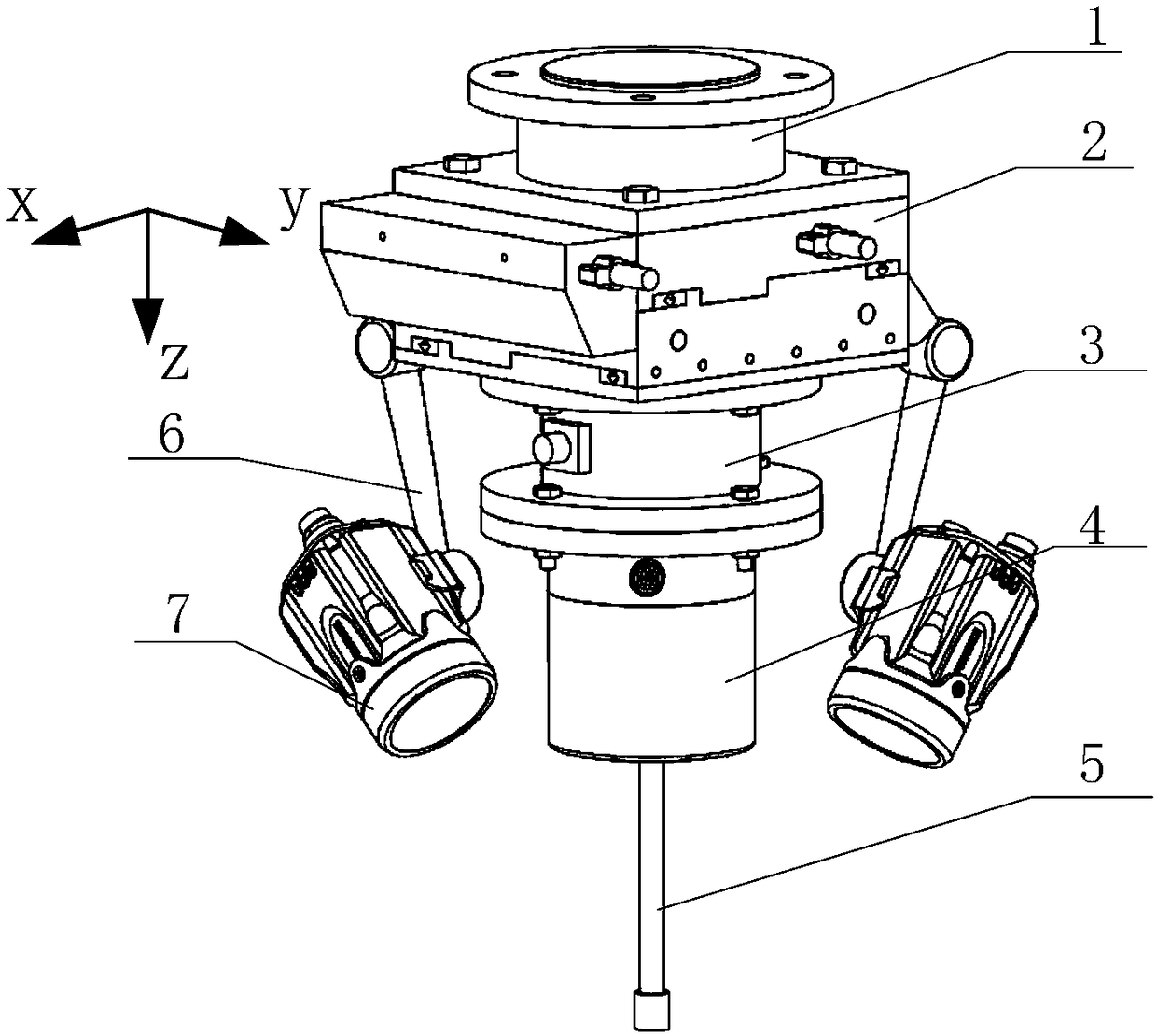

ActiveCN105479441ASimple structureLess freedomProgramme-controlled manipulatorGripping headsRobot handEngineering

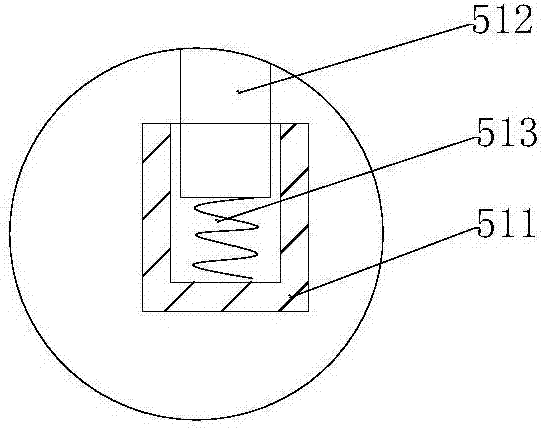

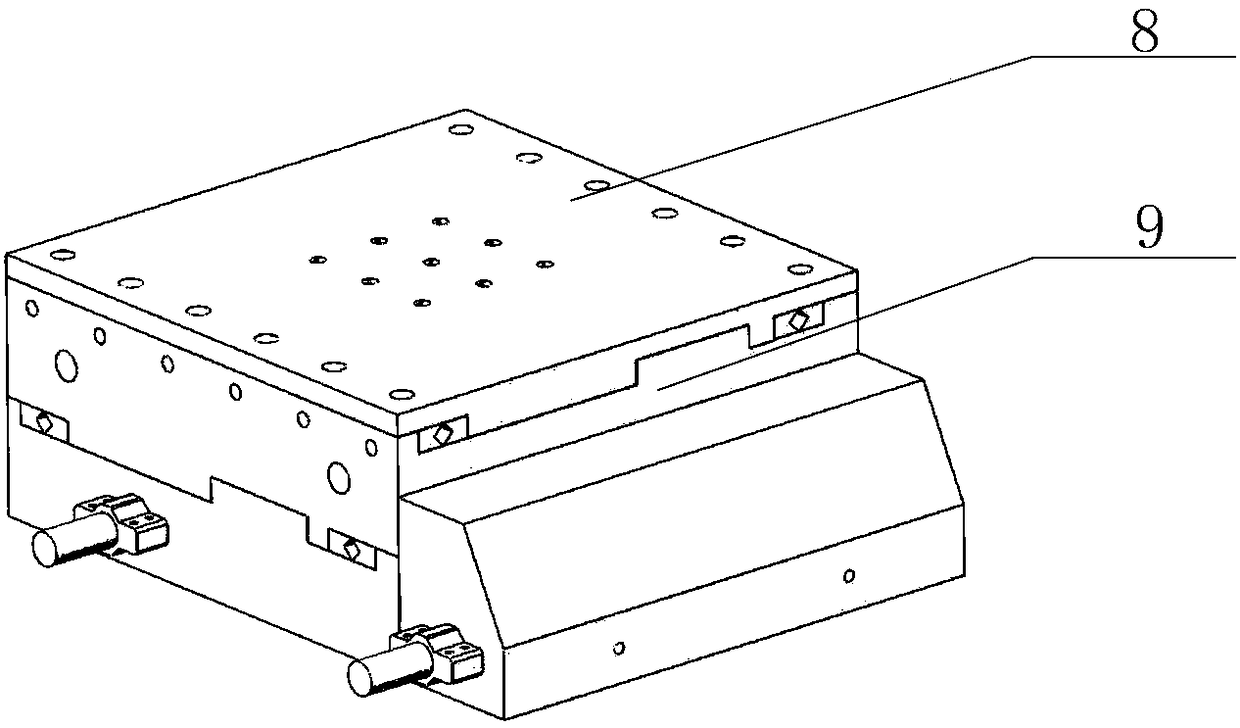

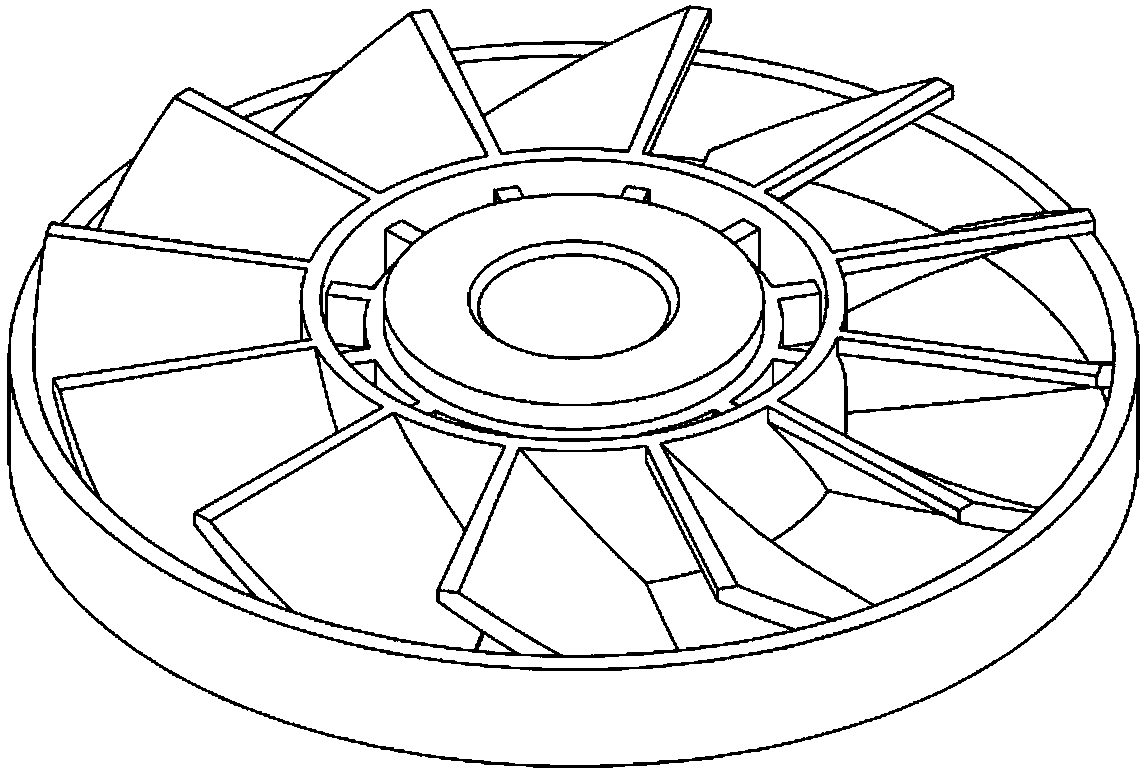

The invention provides a robot hand with three under-actuated fingers connected in parallel. The robot hand comprises a machine base, a movable platform, a connecting rod, an SP type drive branch, two SPR type drive branches and three under-actuated finger mechanisms. The three drive branches and the three under-actuated finger mechanisms are evenly distributed between the movable platform and the machine base in a staggered manner in the circumferential direction. The upper end of the SP type drive branch is fixedly connected with the movable platform. The lower end of the SP type drive branch is in linkage with machine base ball pairs. The two ends of the connecting rod are in linkage with the upper ends of the two SPR type drive branches. The middle portion of the connecting rod is in linkage with the movable platform. The lower ends of the SPR type drive branches are in linkage with the machine base ball pairs. Each under-actuated finger mechanism comprises a supporting frame, the finger, a spring, an electric cylinder and a support. The supports are vertically and fixedly connected with the movable platform. The fingers are connected with the supporting frames. The electric cylinders drive the supporting frames to rotate. The flexible object grabbing motion of the tail ends of the fingers is achieved through the springs between the supporting frames and the fingers. The robot hand is simple in structure, large in finger pose working space and good in flexibility, can achieve flexible grabbing operation and can be used for the outer space, the deep-sea detection, forging operation, rescue, medical treatment operation and the like.

Owner:YANSHAN UNIV

Engine piston mechanism and machining method thereof as well as corresponding engine and automobile

InactiveCN103147873AReduce wearReduce contact areaMachines/enginesPistonsReciprocating motionControl theory

The invention discloses an engine piston mechanism which comprises a piston head, a piston pin seat fixedly connected to the end surface of the piston head, and a piston skirt part arranged at the periphery of the piston pin seat, wherein the piston skirt part comprises two support parts and a roller column; the two support parts are fixedly connected to the end surface of the piston head and are symmetrically arranged at the two sides of the piston pin seat along the axial direction of the piston pin seat; and the roller column is fixedly connected to the support parts and is contacted with the wall of a cylinder in a rolling way when a piston makes reciprocating motion. The invention also discloses a machining method of the engine piston mechanism, and an engine and an automobile which are respectively provided with the engine piston mechanism. According to the engine piston mechanism, the piston skirt part and the wall of the piston are in rolling friction, so that the frictional loss of the piston skirt part and the wall of the cylinder can be reduced, and the fuel economy is improved. The engine piston mechanism is suitable for various automobile engines, and is further applied to various automobiles.

Owner:GREAT WALL MOTOR CO LTD

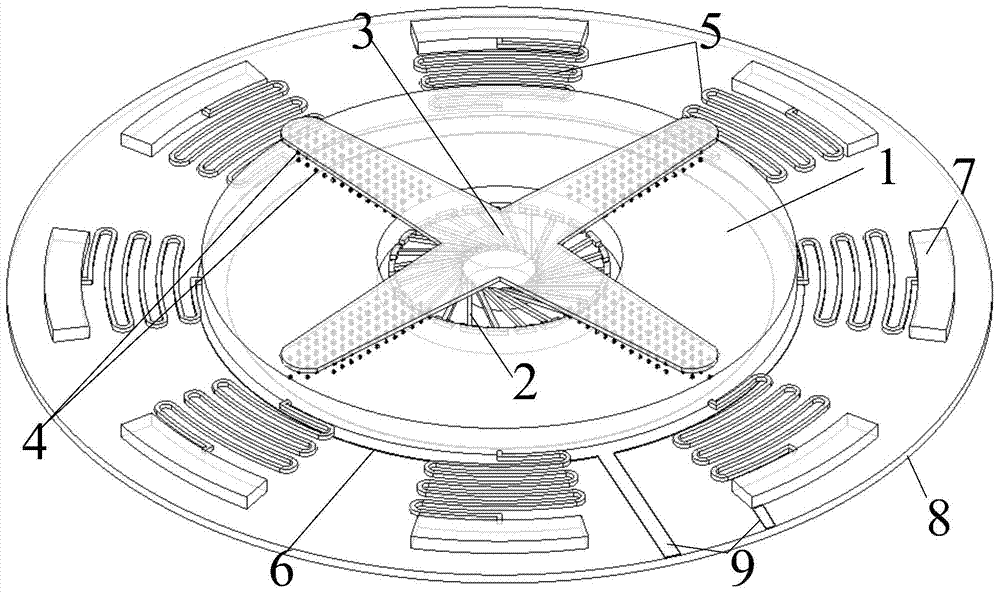

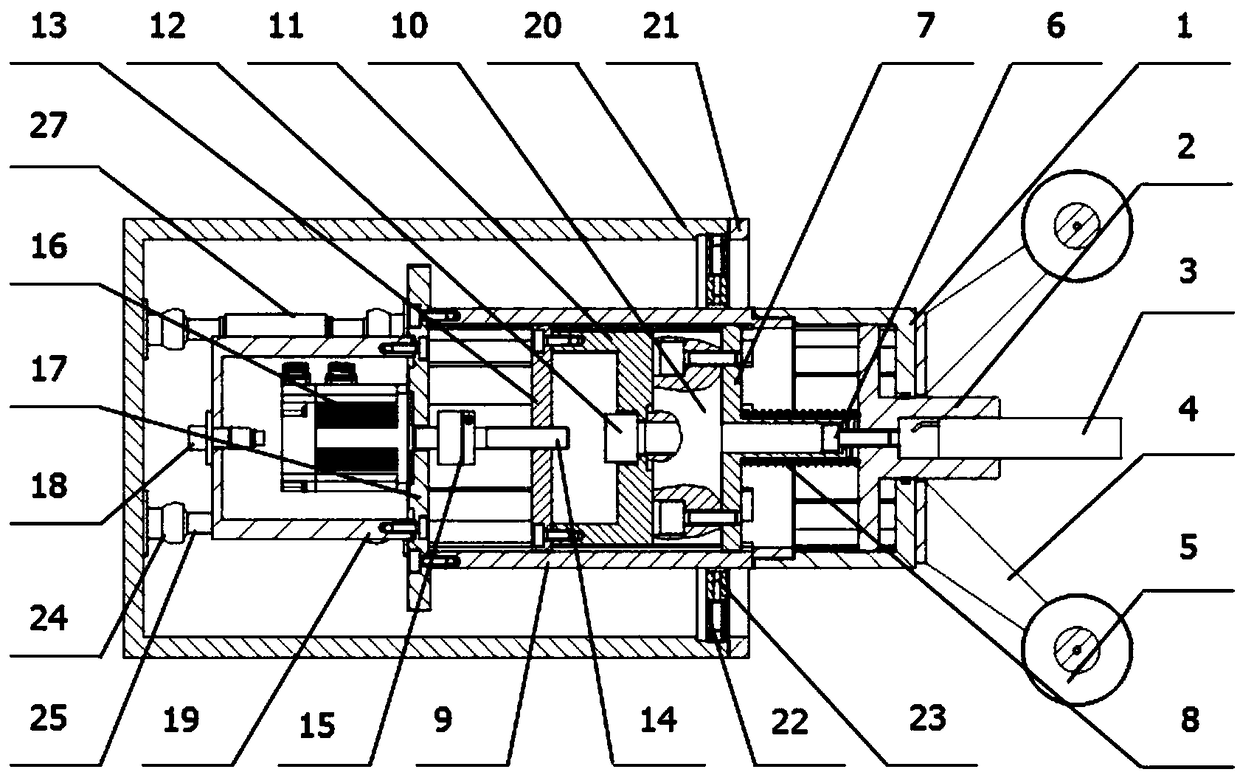

Nuclear fuel assembly multifunctional detecting device based on array type flexible detection

ActiveCN109373885AAchieving flexible contactGuaranteed flexible contactNuclear energy generationNuclear monitoringEngineeringNuclear fuel

The invention discloses a nuclear fuel assembly multifunctional detecting device based on array type flexible detection. The nuclear fuel assembly multifunctional detecting device comprises a fuel roddeformation detecting unit, an oxidation film thickness detecting unit and a loading platform, wherein the fuel rod deformation detecting unit and the oxidation film thickness detecting unit are fixedly mounted on the loading platform, and the loading platform is rigidly connected with an external transfer platform. The nuclear fuel assembly multifunctional detecting device can adapt to various deformations of a fuel rod, can realize flexible contact and flexible measurement of the fuel rod, and improves detection precision while ensuring safety of the device. The nuclear fuel assembly multifunctional detecting device has various detection functions, and can realize high-precision detection of fuel rod deformation and oxidation film thickness on the surface of the fuel rod; the nuclear fuel assembly multifunctional detecting device innovatively adopts a fuel rod deformation detecting method for array detection, ensures the detection precision while greatly improving the detection efficiency, is simple and compact in structure, has good sealing performance, and is convenient in installation and high in universality.

Owner:HEBEI UNIV OF TECH

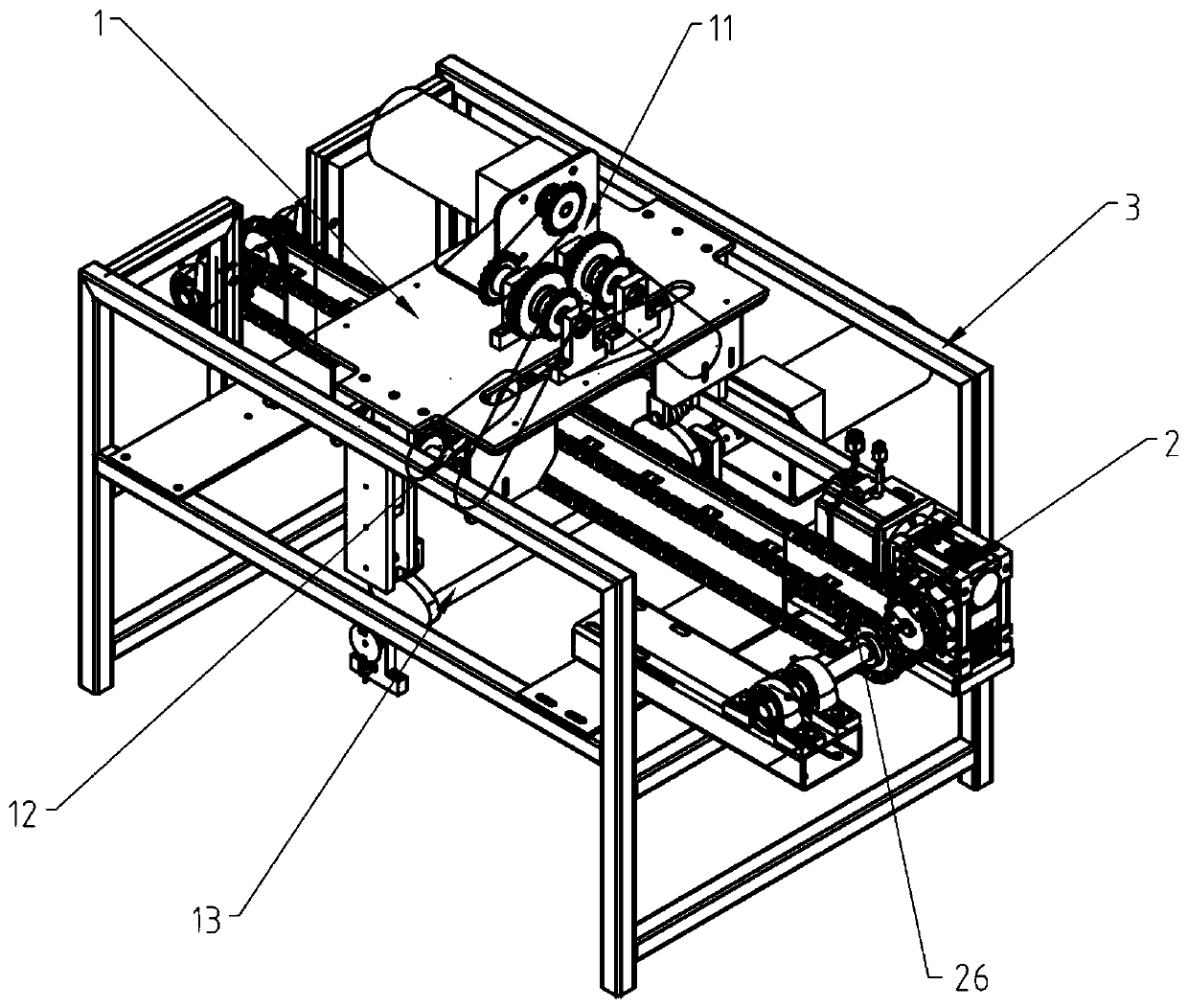

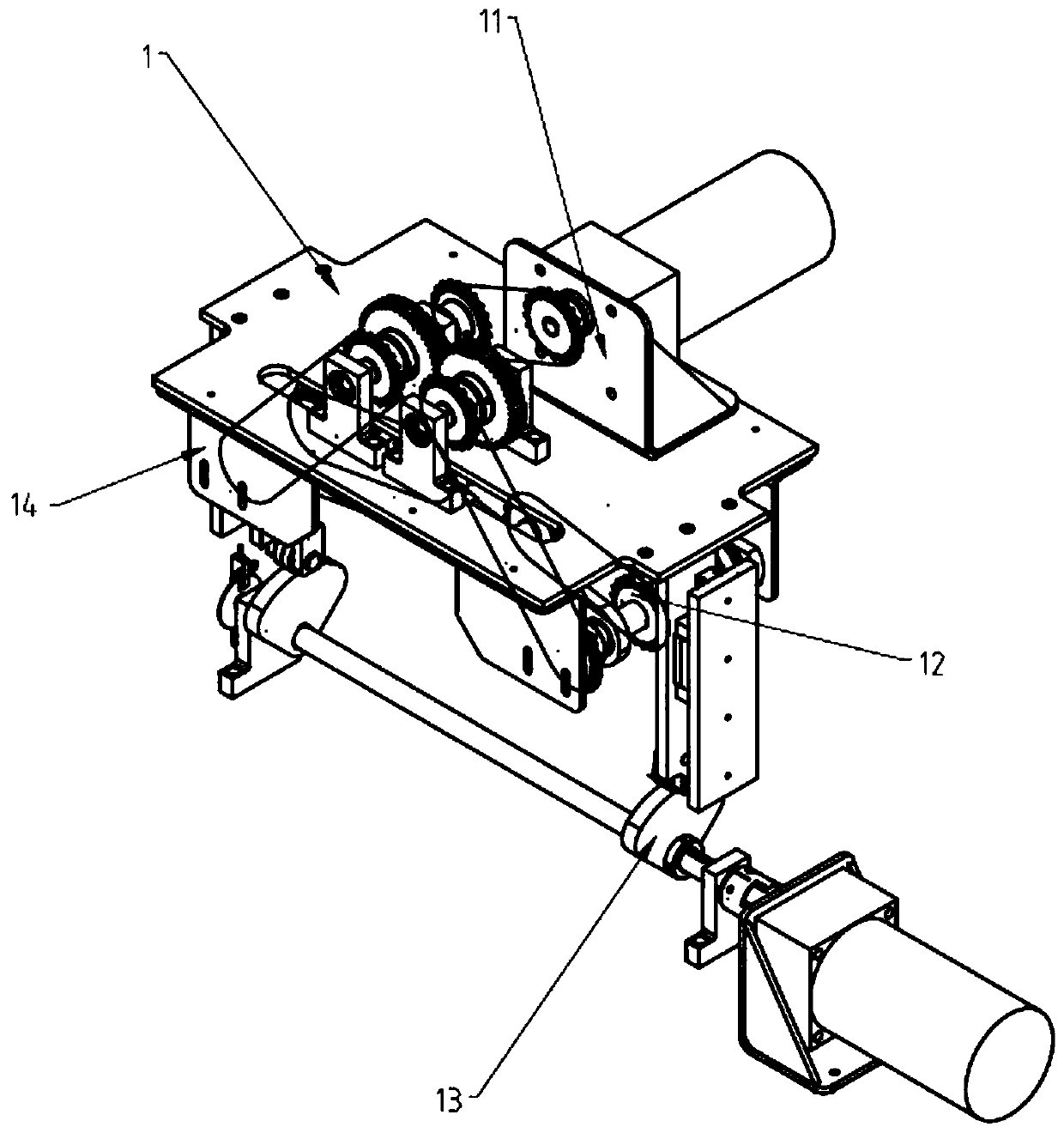

Poultry gizzard surface cleaning device

ActiveCN110269083AEasy to cleanImprove protectionPoultry cleaning/disinfectionPoultry transferring/conveying devicesGizzardSurface cleaning

The invention discloses a poultry gizzard surface cleaning device. The poultry gizzard surface cleaning device comprises a scraping assembly, a transfer assembly and a rack, wherein the scraping assembly is assembled on the upper half part of the rack, the transfer assembly penetrates through the scraping assembly, and the two ends of the transfer assembly are installed on the rack. The scraping assembly comprises a power delivery mechanism, an executing mechanism and a lifting mechanism, wherein the power delivery mechanism is connected with the executing mechanism, and supplies power to the executing mechanism, the executing mechanism is higher than the transfer assembly, and a cleaning tool is arranged on the executing mechanism; the power delivery mechanism and the executing mechanism are connected with the lifting mechanism, and the cleaning tool on the executing mechanism can periodically get close to the transfer assembly under the action of the lifting mechanism. According to the poultry gizzard surface cleaning device, grease on the surfaces of poultry gizzards can be cleaned away one by one, and the cleaning effect is improved; moreover, the device adopts assembly line operation, the labor cost is greatly reduced, and the harm to the human body is reduced.

Owner:南京深农智能装备有限公司

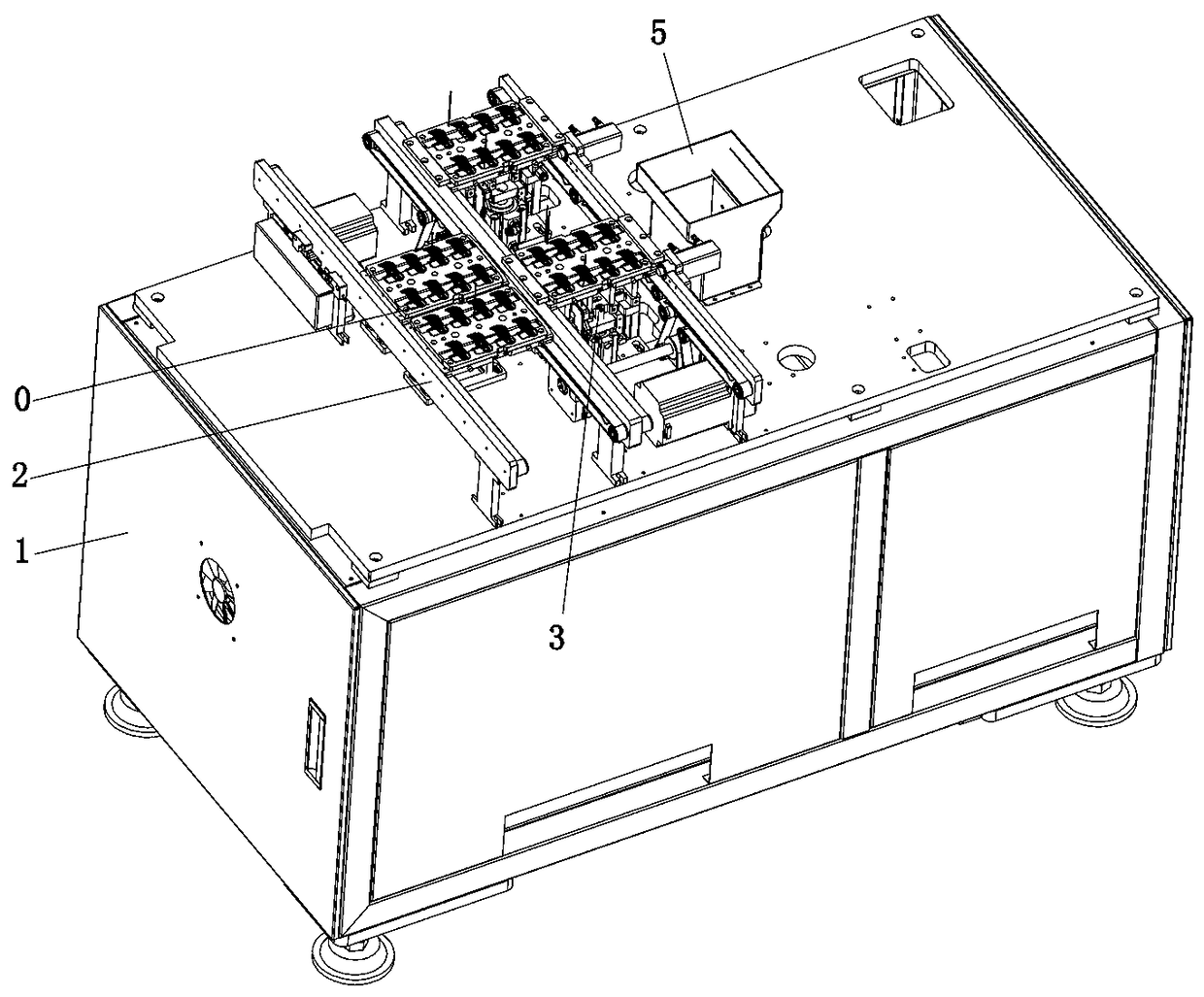

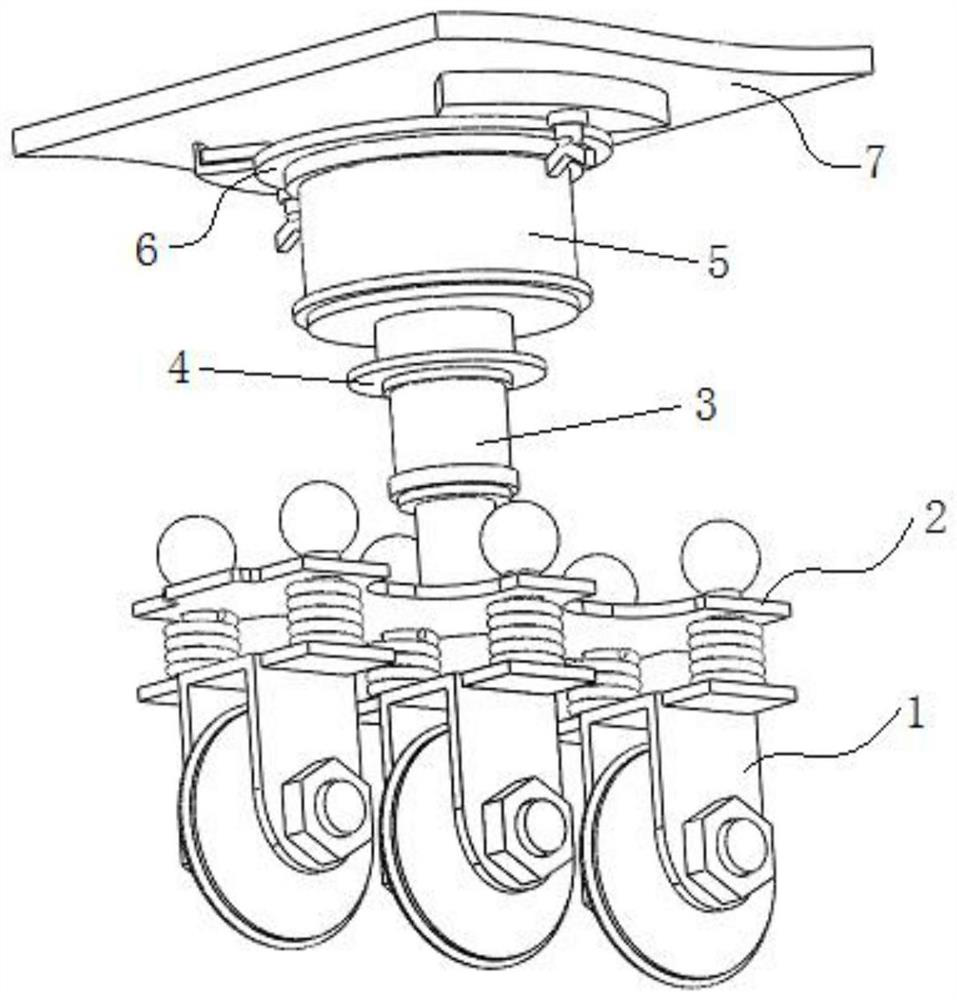

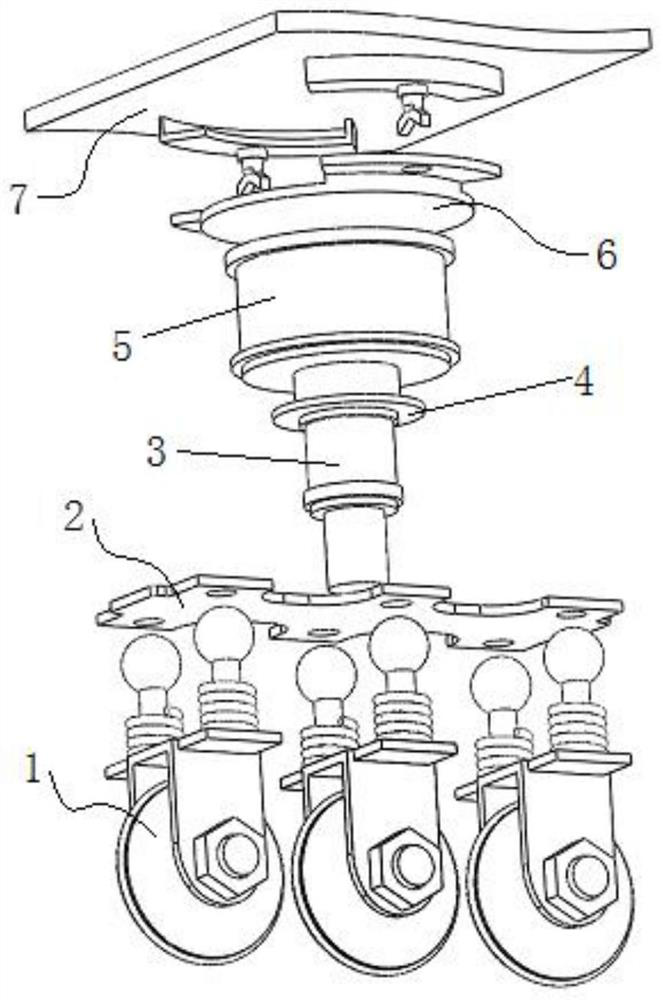

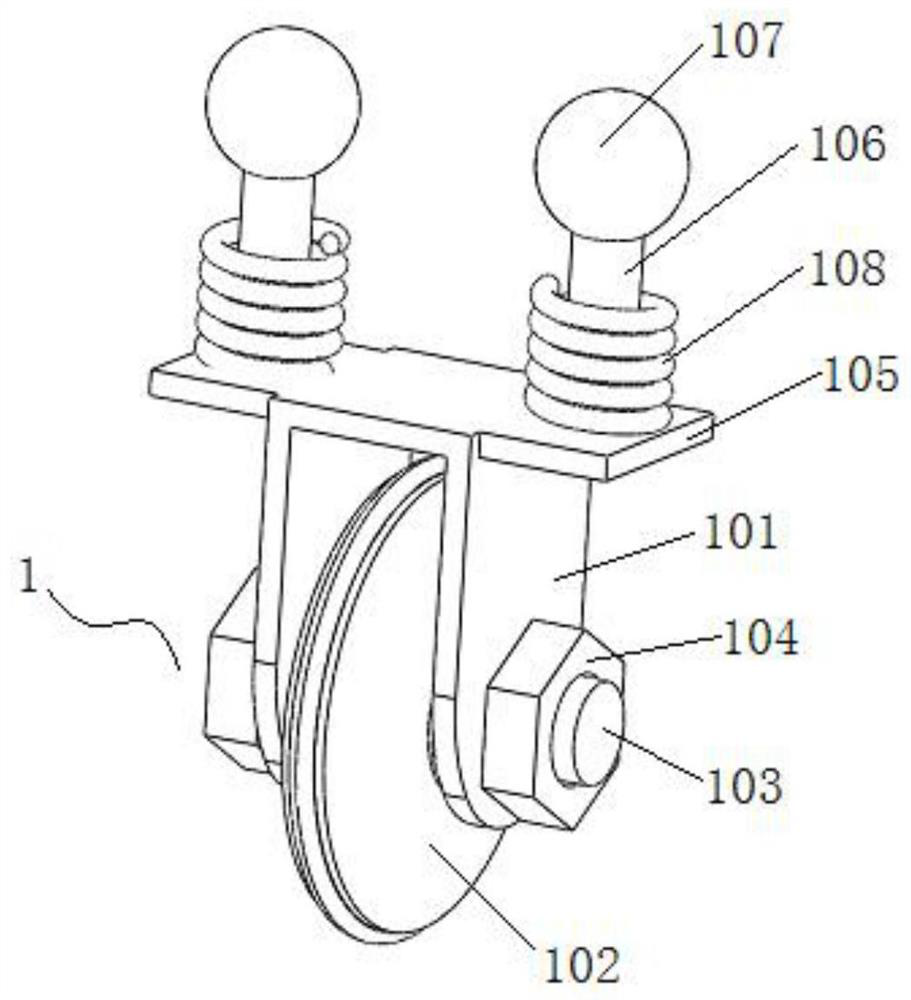

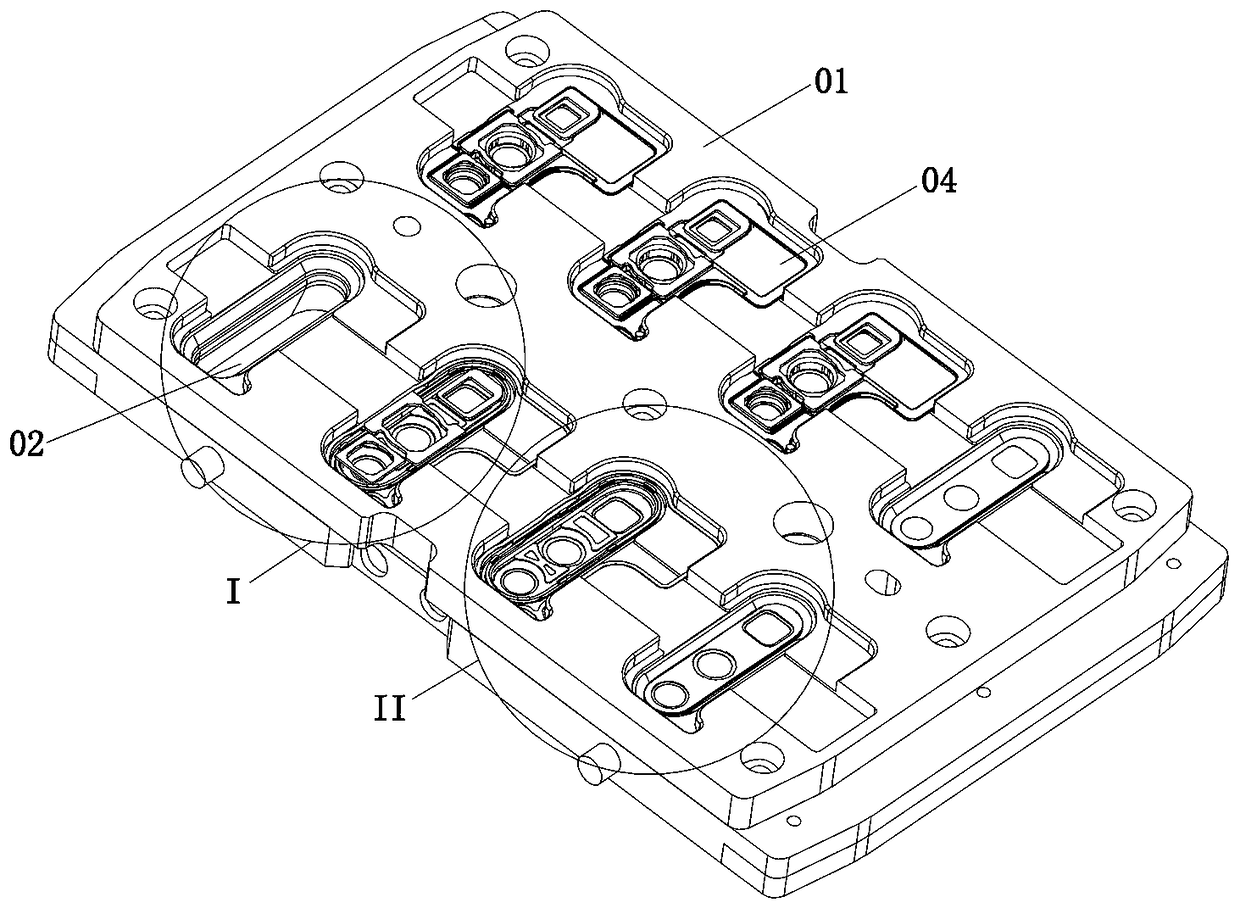

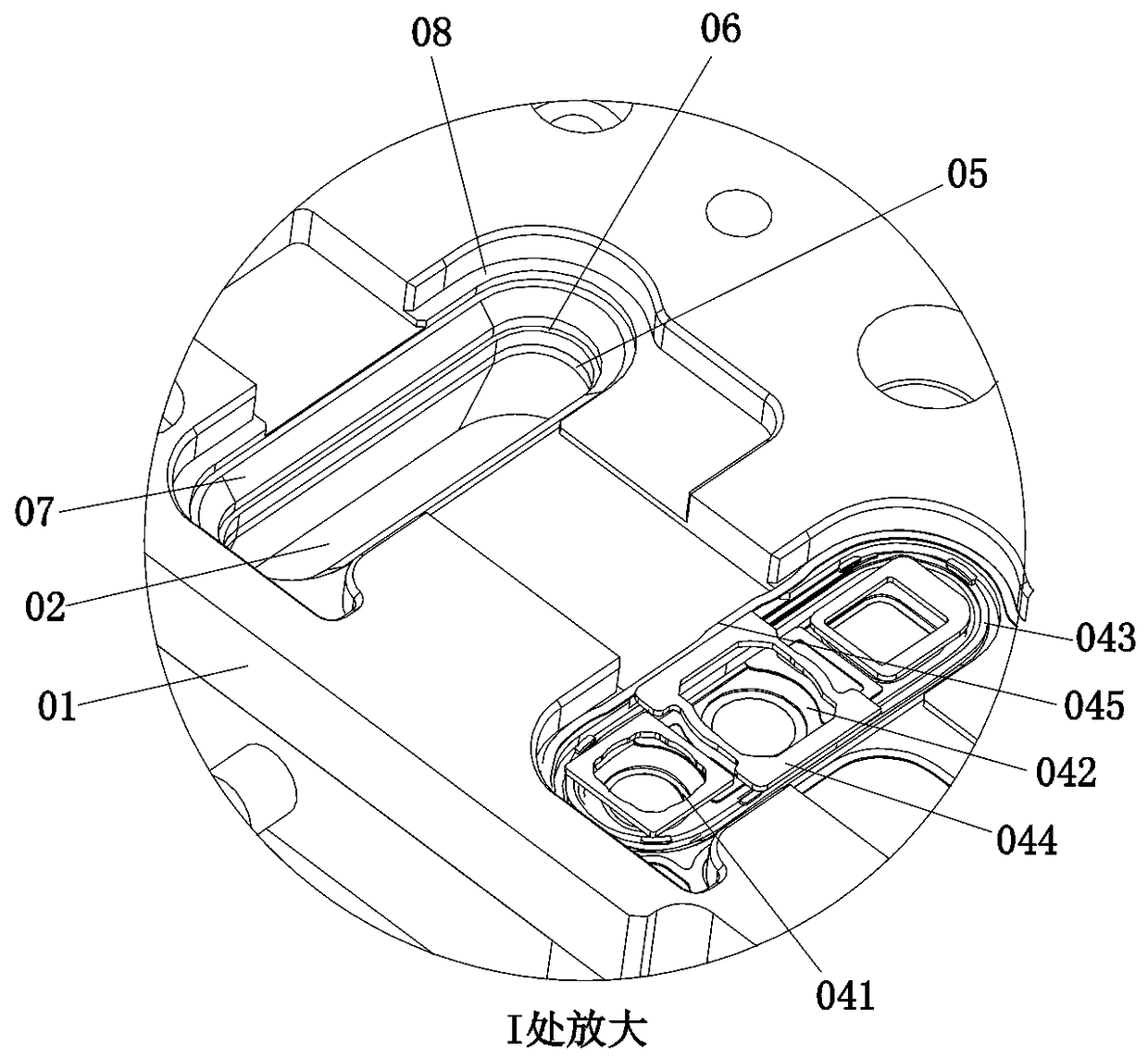

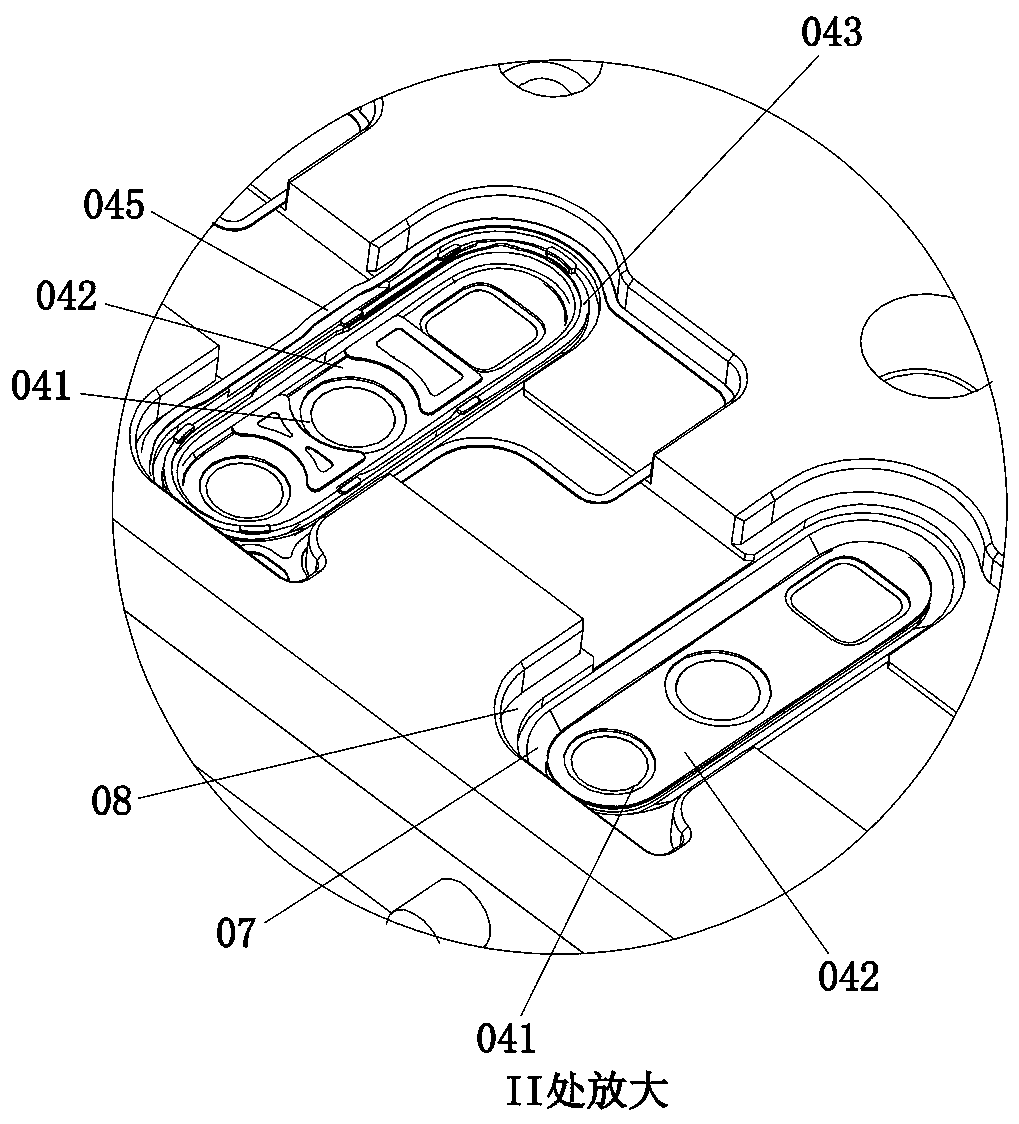

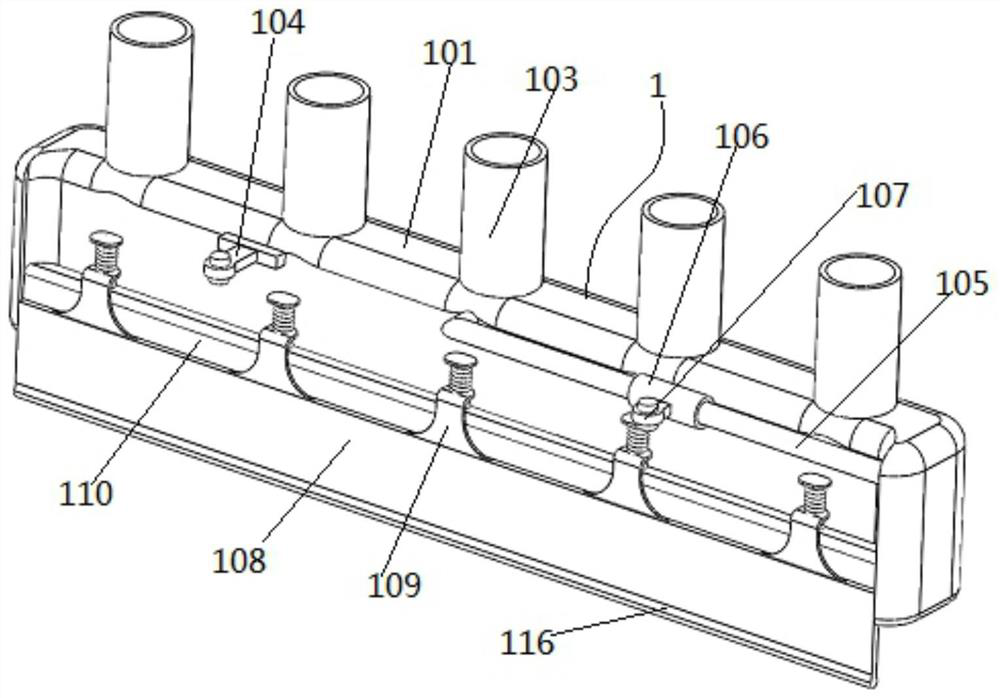

Mobile phone accessory automatic assembly positioning and adsorption supporting device and jig thereof

PendingCN109290988AImprove versatilityImprove assembly capacityMaterial gluingWork holdersEngineeringMobile phone

The invention discloses a mobile phone accessory automatic assembly positioning and adsorption supporting device and a jig for the mobile phone accessory automatic assembly positioning and adsorptionsupporting device. The positioning and adsorption supporting device comprises a support plate, a positioning component, adsorption supporting components and a guiding component, wherein the support plate is horizontally arranged below a material belt of an auxiliary material assembling machine, the positioning component is arranged on the support plate, the adsorption supporting components comprise two sets, the two adsorption supporting components are located on two sides of the positioning component correspondingly, the guiding component comprises a first guiding assembly and a second guiding assembly, the first guiding assembly is connected with the positioning component, and the second guiding assembly is connected with the adsorption supporting components. The jig comprises a jig seat, straight slots and positioning holes, and each straight slot is internally provided with at least two layers of step supporting faces to support all accessories of products. By means of the mobile phone accessory automatic assembly positioning and adsorption supporting device and the jig for the mobile phone accessory automatic assembly positioning and adsorption supporting device, automation assembly of the products at all assembly stations is realized in an assisted manner, the component universality is effectively improved, and the accessory assembly production capacity and quality are greatly improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

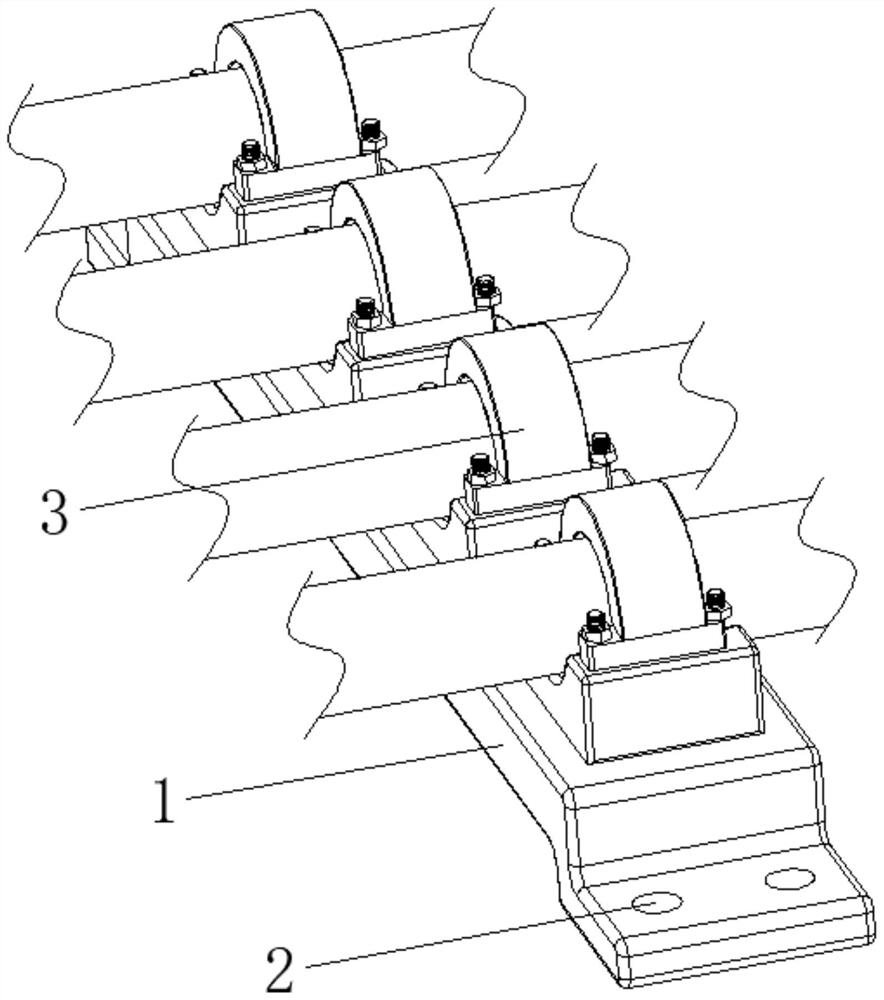

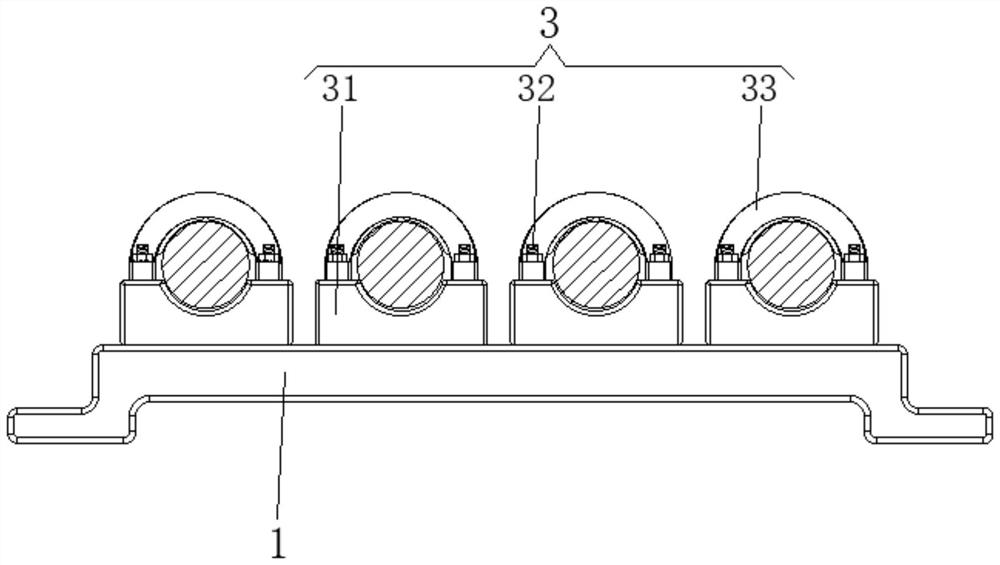

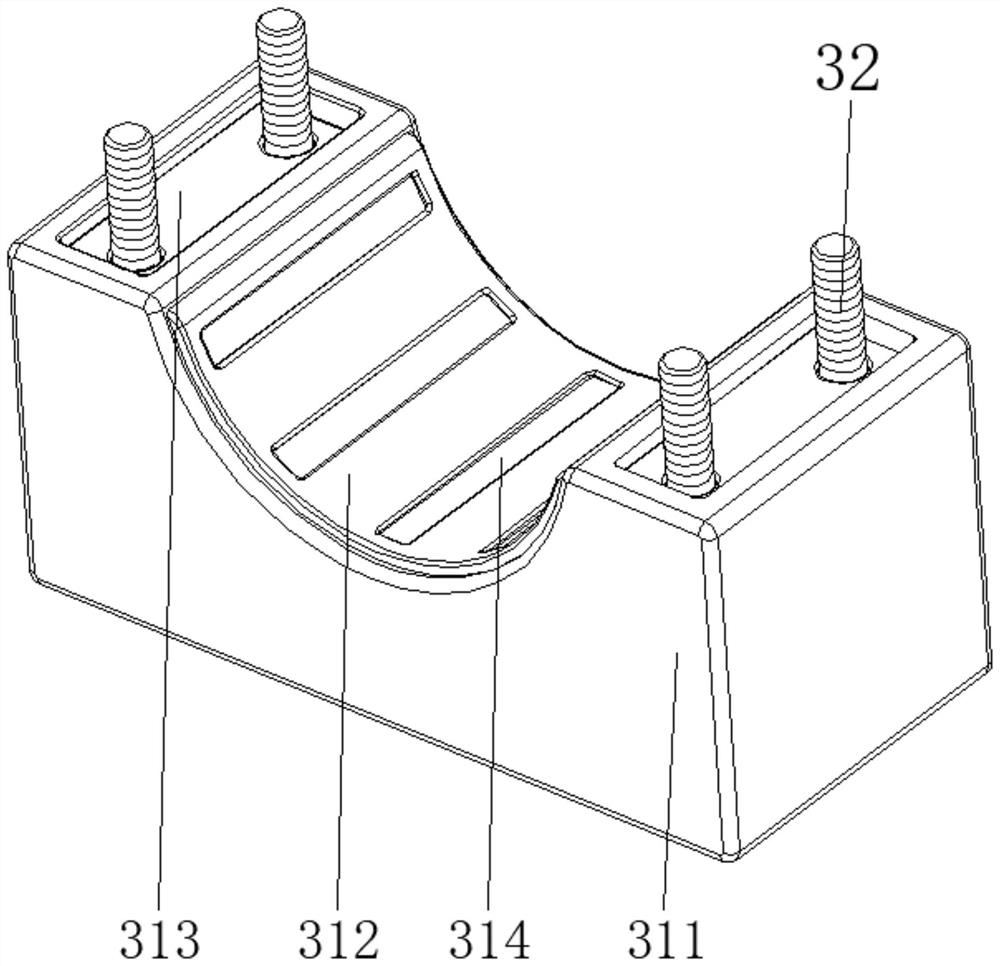

Fixing device for cable laying

InactiveCN113629584AReduce wearReduce vibrationCable fittingsApparatus for laying cablesMagnetic effectVibration amplitude

A fixing device for cable laying disclosed by the present invention comprises a mounting base, fixing holes and wire clamping devices, the fixing holes are formed in the two corresponding sides of the bottom edge of the surface of the mounting base, and the wire clamping devices are arranged at the top of the mounting base and are uniformly distributed at the top of the mounting base. The bottom of a limiting device is fixedly connected with the top of the mounting base, the bottom end of a connecting stud is fixedly connected with the position, close to the end, in the limiting device, a pressing device is connected to the top of the limiting device in a matched manner, and the pressing device and the connecting stud are connected in a matched manner and are fixed through a nut. The invention relates to the technical field of power construction devices. According to the fixing device for cable laying, the anti-vibration effect is achieved, the cable can be flexibly fixed and is not prone to being affected by a current magnetic effect, the vibration amplitude is effectively reduced, abrasion to a cable is reduced, the service life is prolonged, and the use performance is improved.

Owner:謝金吉

Dust collection device used during edge breaking of substrate glass

ActiveCN113149419AExtended length maintainedAchieving flexible contactSuction cleanersGlass severing apparatusStructural engineeringMechanical engineering

The invention discloses a dust collection device during edge breaking of substrate glass. The device comprises a substrate glass edge breaking dust collection assembly, a transverse movement adjusting assembly is arranged on one side of the substrate glass edge breaking dust collection assembly, and a longitudinal movement adjusting assembly is arranged above one end, far away from the substrate glass edge breaking dust collection assembly, of the transverse movement adjusting assembly. The extension length of a scissor arm between a first cross arm and a second cross arm is changed through sliding of a movable sleeve on a guiding main sliding rod, and the extension length of the scissor arm between the first cross arm and the second cross arm is kept through automatic jacking meshing between a positioning toothed plate and a positioning rack plate. Through elastic cooperation of a second boss sliding rod jacking spring and a first boss sliding rod jacking spring and vertical sliding of an L-shaped fixing plate on a boss guiding sliding rod, elastic up-down movement of a dust collection isolation plate relative to a rectangular dust collection cover is achieved, and therefore flexible contact between a substrate glass contact rubber cushion and the surface of substrate glass is achieved.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

Bending device for aluminum alloy production

InactiveCN111774462AImprove work efficiencyReduce collision damageVibration suppression adjustmentsAluminium alloyMaterials science

The invention discloses a bending device for aluminum alloy production, and relates to the technical filed of aluminum alloy bending. The bending device comprises a rack, wherein the left side of theupper surface of the rack is slidably connected with a clamping and conveying unit of an aluminum alloy pipe, a rectangular notch is formed in the middle of the top of the rack, L-shaped supporting frames are fixedly connected to the two sides of the bottom of the rectangular notch correspondingly, the two L-shaped supporting frames are fixedly connected with first electric cylinders, the ends ofejector rods of the two first electric cylinders are fixedly connected with a rectangular extrusion plate, a lower correcting groove is formed in the top of the rectangular extrusion plate, and a bending unit is fixedly connected to the right side of the top of the rack. By arranging a first fixing plate, a second fixing plate, a third fixing plate, the rectangular extrusion plate, the first electric cylinders, second electric cylinders, an upper correcting groove and the lower correcting groove, the problem of head and tail dislocation after aluminum alloy is bent and formed is solved, manualtransferring to the next procedure for dislocation correction treatment is not needed, and the working efficiency is improved.

Owner:吉安县森博木业有限公司

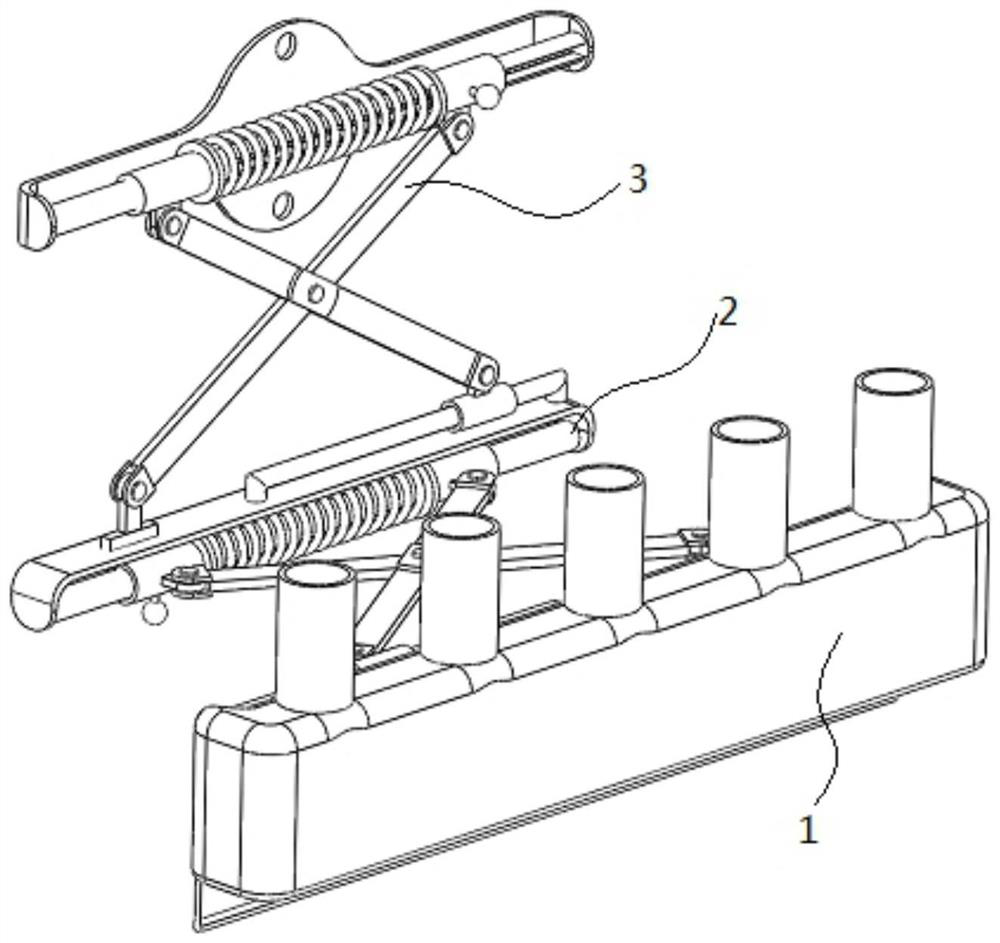

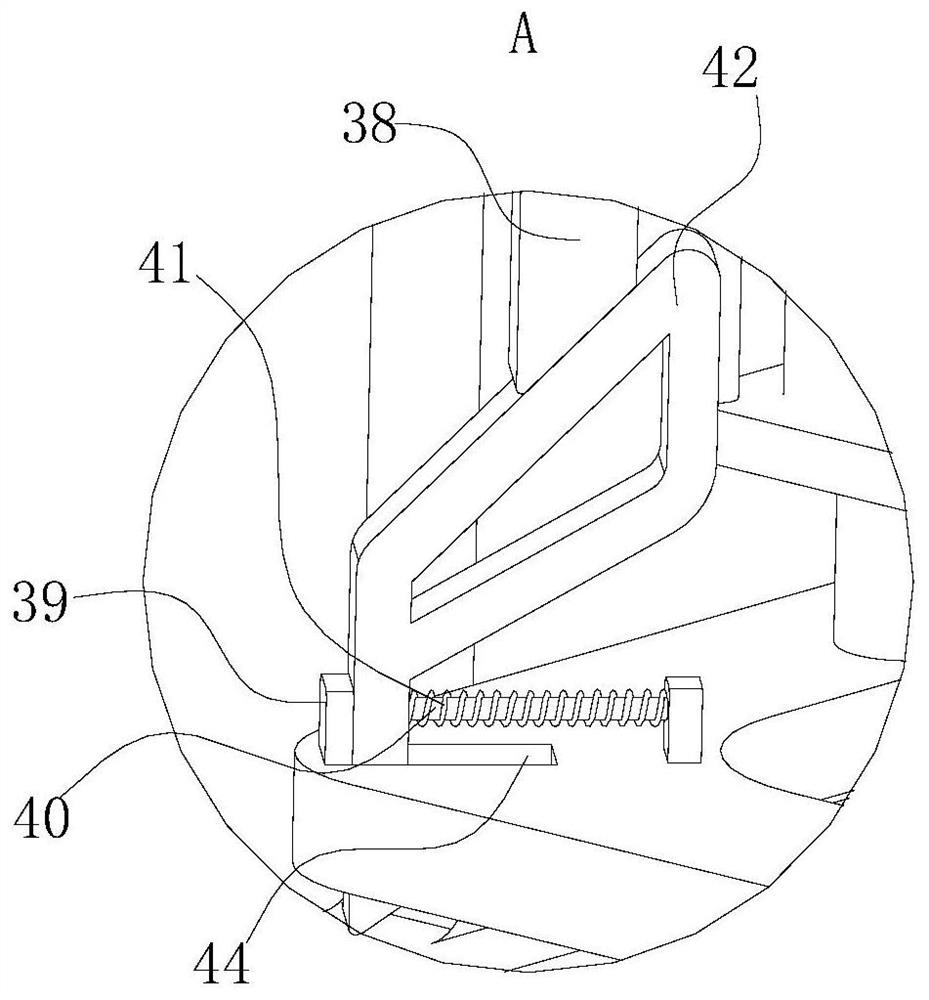

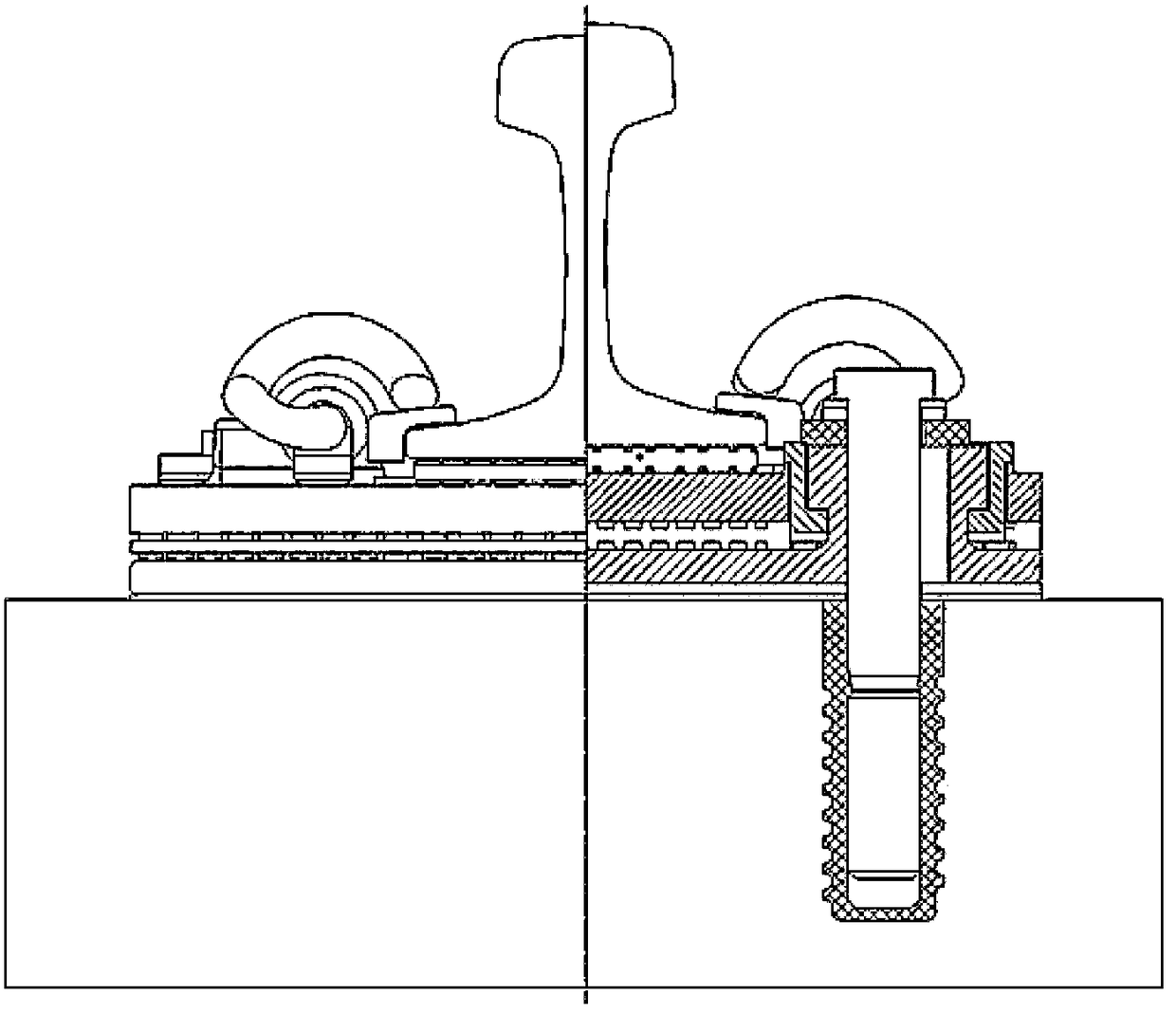

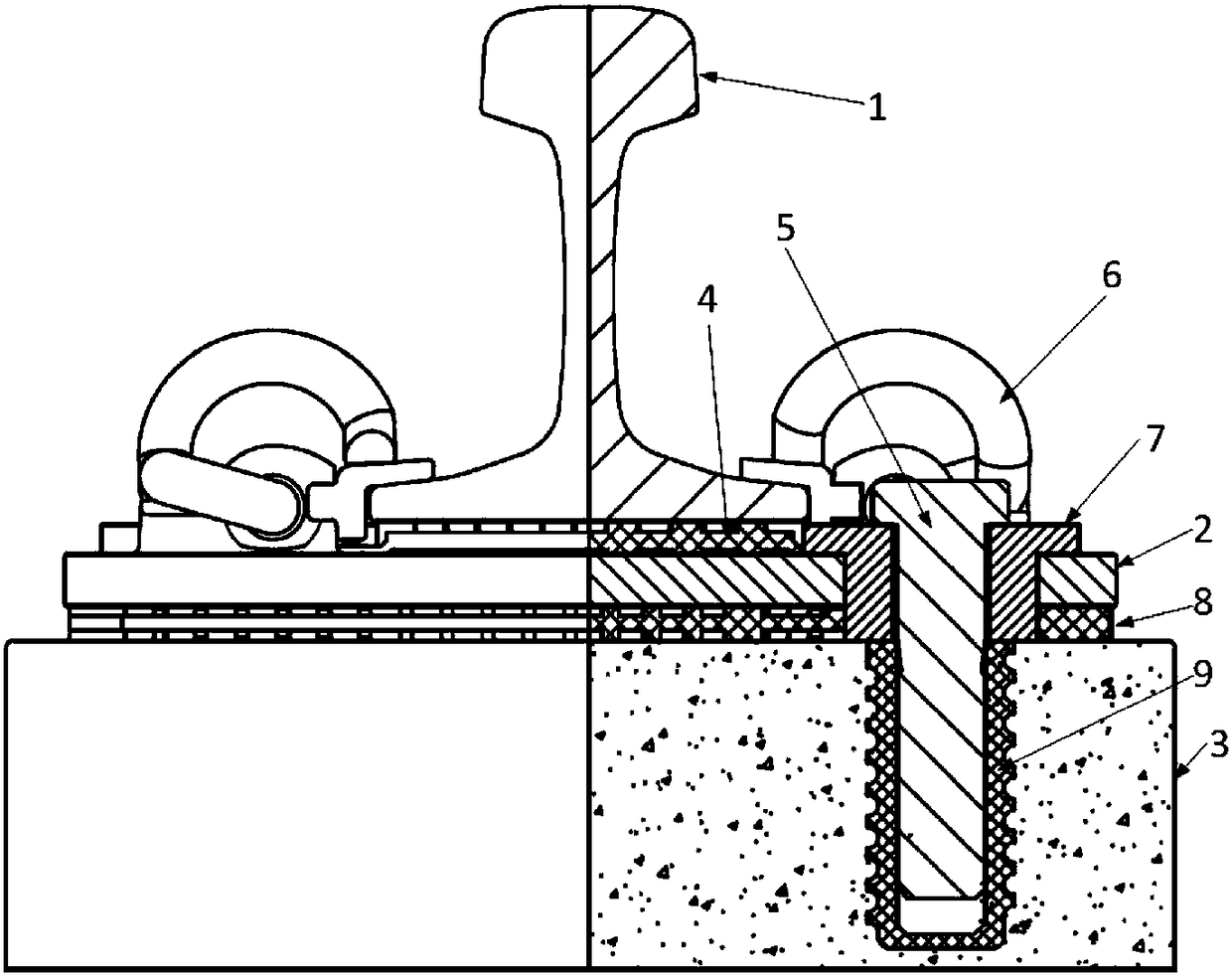

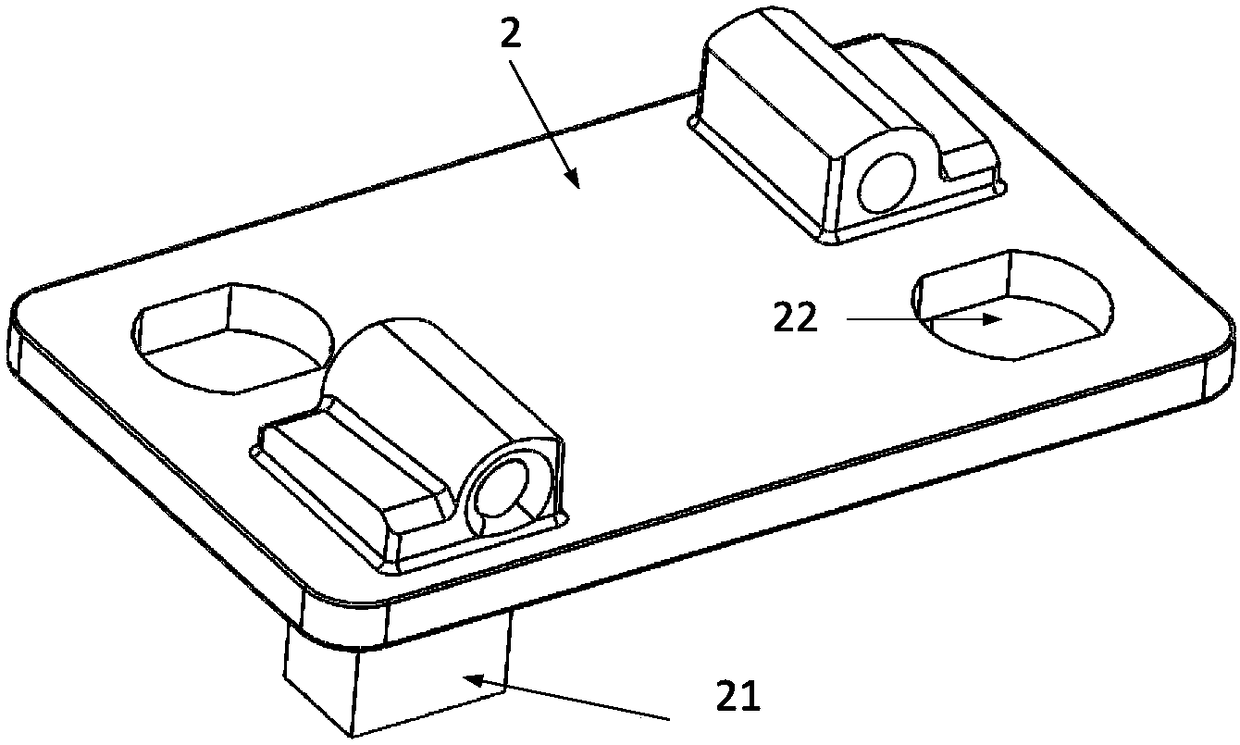

A shoulder damping fasten

PendingCN108978364ARealize lateral limit operationRealize vertical limit operationRail fastenersElastomerEngineering

A shoulder damping fastener is disclosed, which comprises a cushion plate and an anchor bolt. A through hole is formed in the cushion plate, the anchor bolt passes through the through hole to fix thecushion plate on the rail foundation; At least two elastic strip seat are arranged on that upper surface of the backing plate; The backing plate is provided with a limiting shoulder for limiting the lateral displacement between the backing plate and the track foundation, and the limiting shoulder is cooperatively connected with a groove arranged on the track foundation. The invention can be applied to the field of rail transit, and the application of the invention can effectively overcome the defects in the prior art, can effectively reduce the overall cost of the fastener and can effectivelyshorten the length of the anchor bolt. Furthermore, the vibration damping technology effect of the double-layer elastomer can be realized.

Owner:洛阳科博思新材料科技有限公司

Glass Transport Fixtures

ActiveCN108674990BDistribute the load evenlyImprove adaptabilityCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:王盼

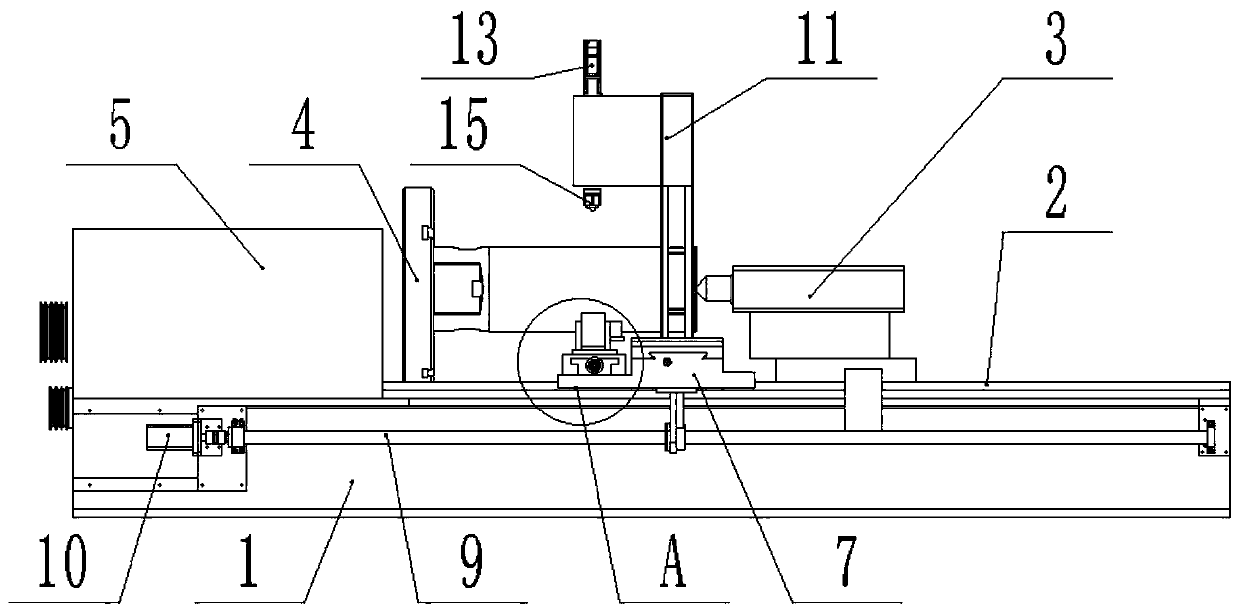

High-speed laser cladding processing machine tool and processing method

InactiveCN111451845AStable supportRelieve stress concentrationGrinding carriagesGrinding drivesEngineeringMachine tool

The invention discloses a high-speed laser cladding processing machine tool, and belongs to the technical field of machine tool processing. The high-speed laser cladding processing machine tool comprises a base, wherein a slide rail is arranged on the base; a rotary ejector pin is arranged on the slide rail in a sliding mode; one end of the slide rail is equipped with a chuck; the chuck is connected to a reduction box; the reduction box is connected to a first servo motor; a first slide table is mounted on the slide rail; one end of the first slide table is connected to a second servo motor, and the other end of the first slide table is connected to a first lead screw; the first lead screw is connected to a third servo motor; a bracket is fixedly mounted on the first slide table; a secondslide table is mounted on the bracket; one end of the second slide table is equipped with a fourth servo motor; a laser cladding head bracket for mounting a laser cladding head is fixedly arranged onthe second slide table; a small slide rail is arranged on the first slide table at one side of the laser cladding head bracket; two movable bases are mounted on the small slide rail in the sliding mode; the movable bases are connected to a two-way lead screw; the two-way lead screw is connected to a fifth servo motor; a grinding mechanism is mounted on the movable bases; and a damping mechanism ismounted between the movable bases and the grinding mechanism.

Owner:山东高锻机械有限公司

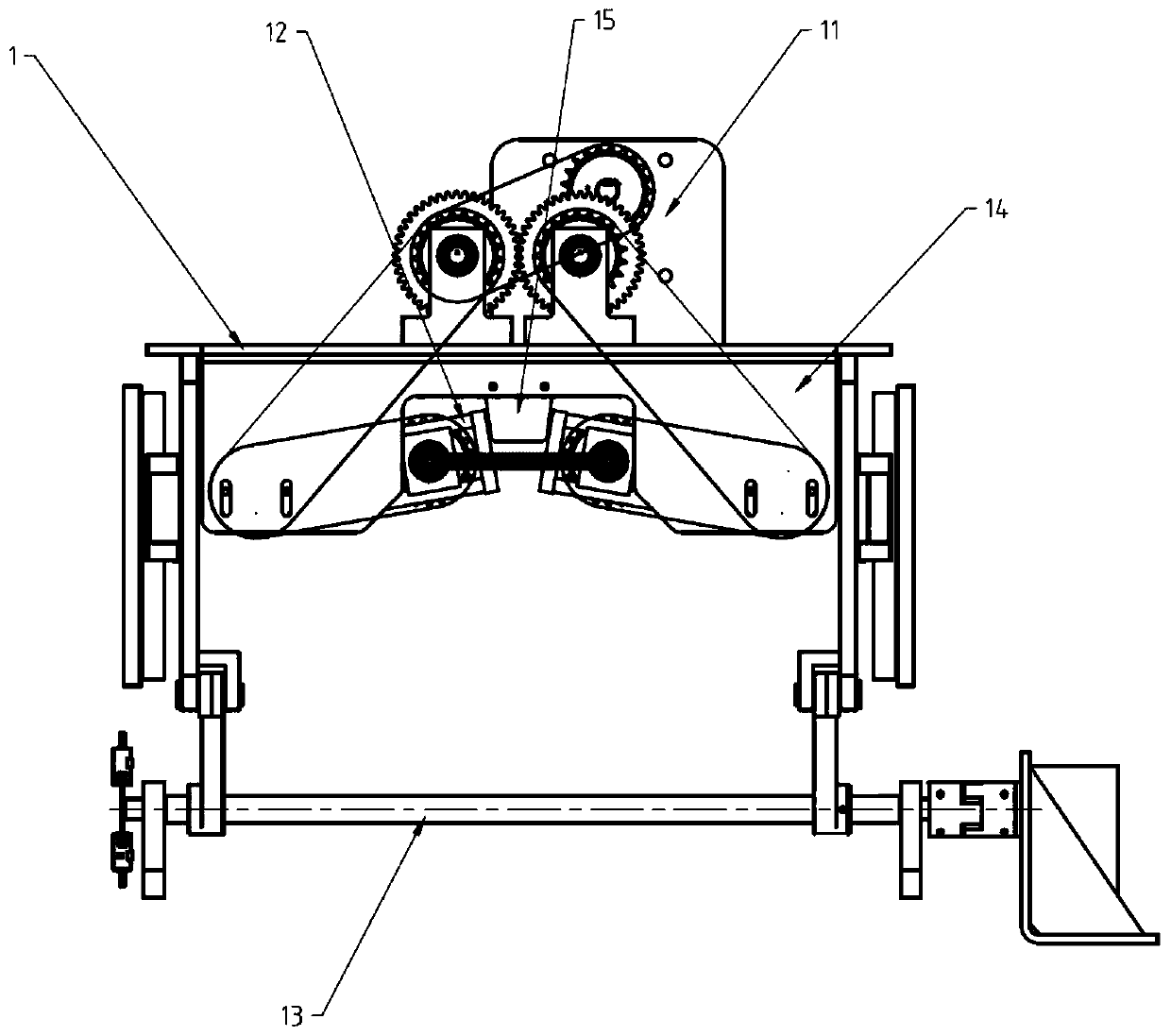

Base plate glass lifting and extracting rack arm device

PendingCN113681459AAchieve stabilityAchieve reliabilityGrinding feedersElectric machineryStructural engineering

The invention discloses a base plate glass lifting and extracting rack arm device. When base plate glass is in contact, lifted and extracted for use, a rack arm mounting footstock cone at the top of a rack arm mounting footstock stand assembly is fixedly connected with an end seat of an external mechanical arm through a mounting hole and a fastening bolt, and a base plate glass contact vacuum suction cup communicates with external vacuum generation equipment through a hose; a lifting driving motor drives a main driving fluted disc to rotate, and the main driving fluted disc drives an auxiliary driving fluted disc to rotate; and through driven rotation of the main driving fluted disc and the auxiliary driving fluted disc, opening and closing stretching and closing contraction movement of a base plate glass lifting and extracting telescopic arm are achieved. In this way, lifting and descending placement during contact, lifting and extracting of the base plate glass is achieved, and secondary stretching, lifting and extracting and secondary contraction movement during contact between the external mechanical arm and the base plate glass are achieved through cooperation of the base plate glass lifting and extracting rack arm device and the external mechanical arm.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

Grinding cleaning rolling brush device

ActiveCN113770088AEasy to assemble and disassembleAchieving flexible contactCleaning using toolsCleaning using gasesElectric machineryEngineering

The invention discloses a grinding cleaning rolling brush device. When the grinding cleaning rolling brush device is used, a guide rail driving motor drives a guide rail threaded rod to rotate bidirectionally, so that a grinding cleaning rolling brush assembly below a buffering jacking top frame assembly is driven to carry out reciprocating movement on a glass substrate which is well adsorbed and fixed; and in the process, a rolling brush driving motor drives the grinding cleaning rolling brush assembly to rotate, so that rolling brush cleaning of the grinding cleaning rolling brush assembly on the glass substrate is realized, and through pushing of an installation pushing spring, front-back pushing movement of hexagonal rolling brush installation groove seats during installation and using is realized; and hexagonal installation shaft rods at the two ends of the grinding cleaning rolling brush assembly are clamped and inserted into the two hexagonal rolling brush installation groove seats at the two ends of the rolling brush installation top seat assembly in a pushing mode, through a rolling brush jacking buffering spring, elastic displacement of the rolling brush installation top seat assembly relative to a buffering jacking top frame assembly is realized, and therefore flexible contact between the grinding cleaning rolling brush assembly and the glass substrate during the rolling brush cleaning is realized.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

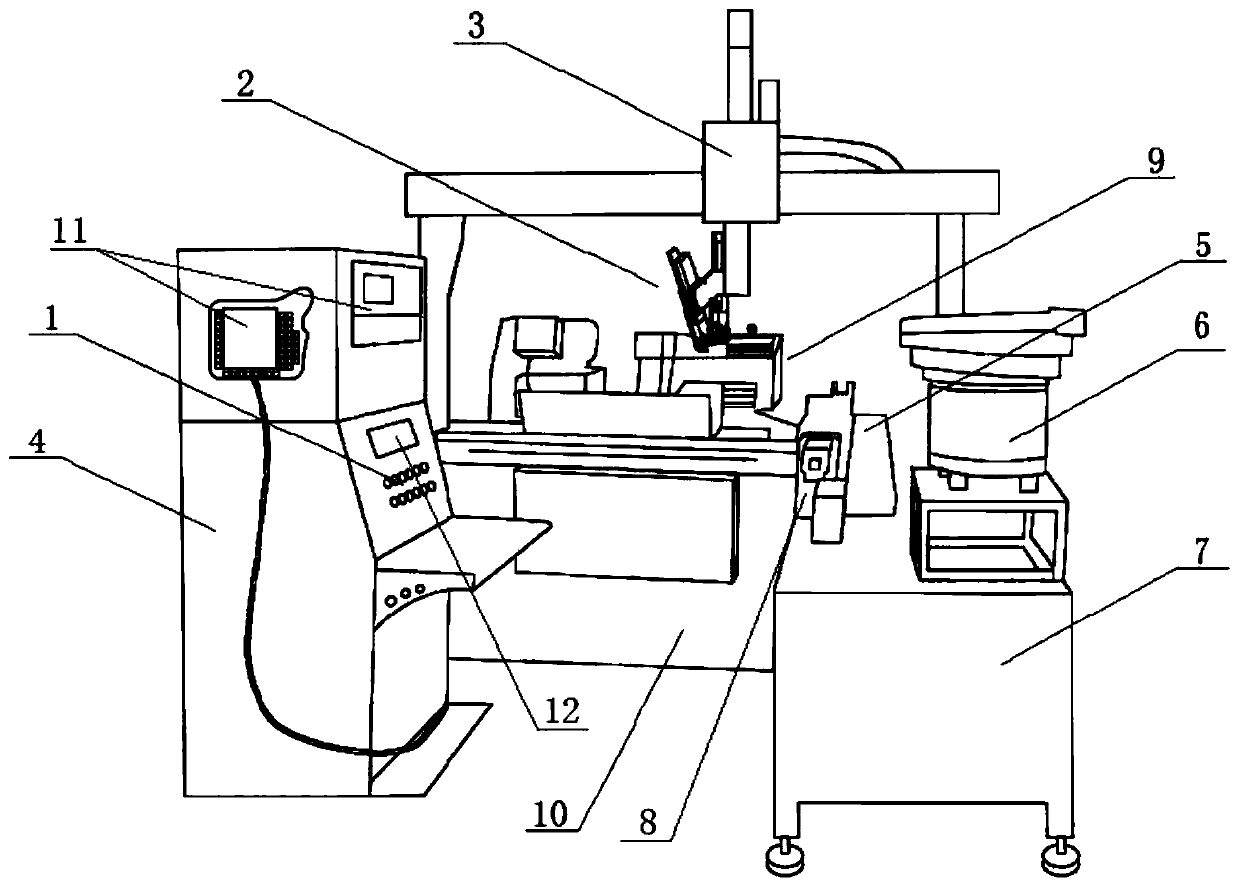

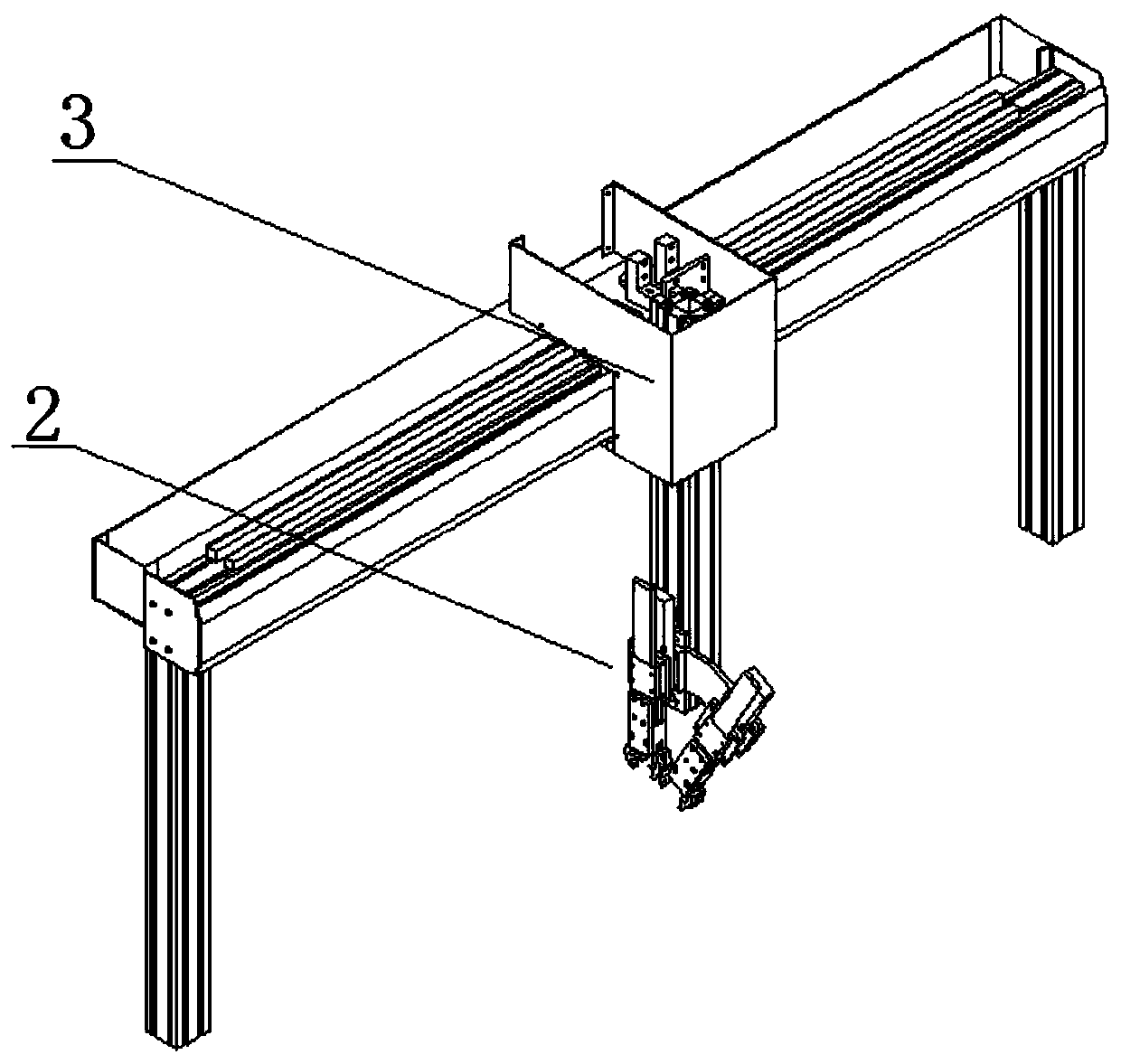

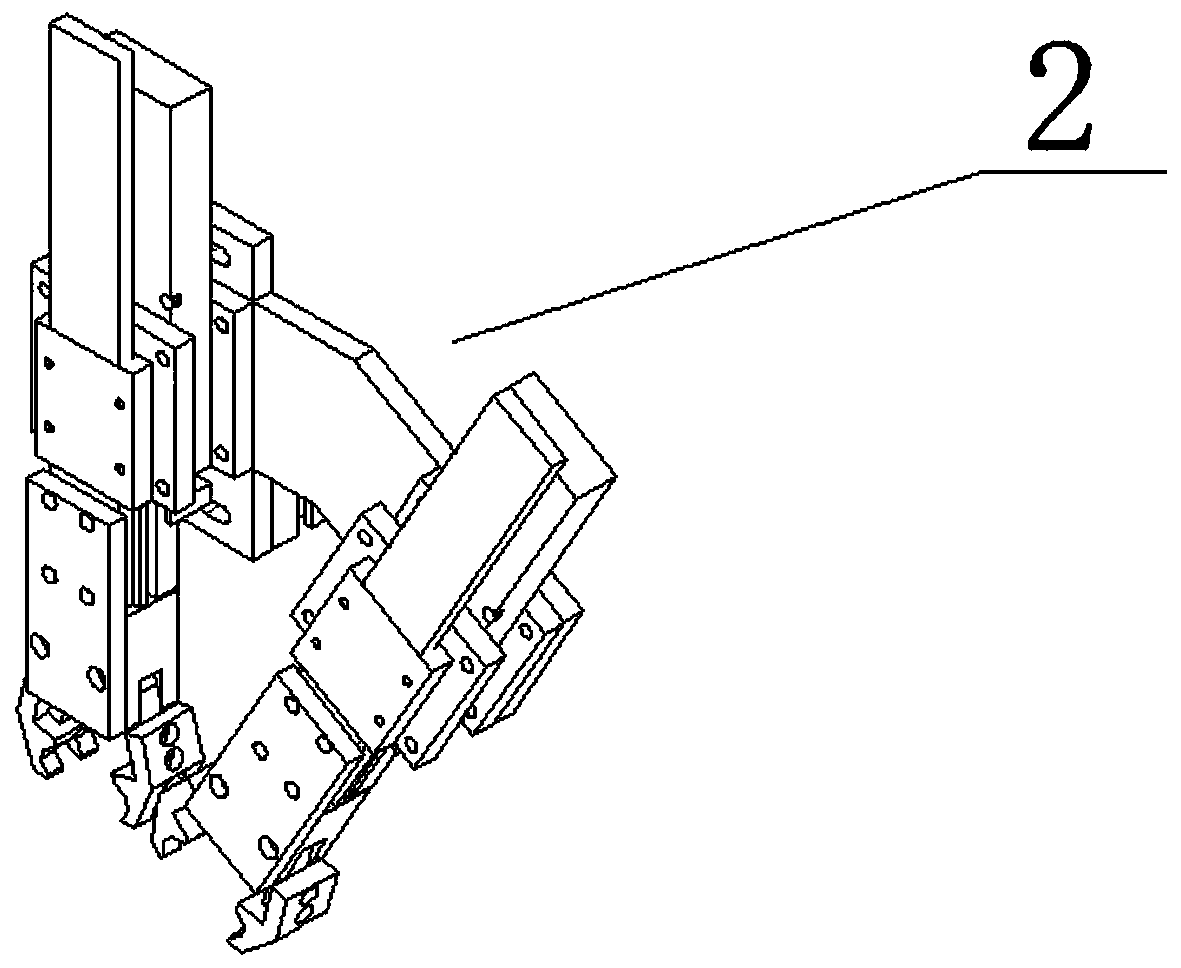

Machining tool truss manipulator

InactiveCN111215912ASave human resourcesNot easy to rustLarge fixed membersMetal working apparatusManipulatorNumerical control system

The invention discloses a machining tool truss manipulator. The machining tool truss manipulator comprises a rack, wherein a machine tool machining mechanism is arranged at the top of the rack; a workpiece and tool clamp loading and unloading mechanism is arranged at the top of the rack and is positioned right above the machine tool machining mechanism; the workpiece and tool clamp loading and unloading mechanism comprises a clamping jaw mechanism and a truss manipulator; the truss manipulator comprises an aluminum alloy section horizontal beam and an aluminum alloy section vertical arm; the clamping jaw mechanism is arranged on the vertical arm; a base is arranged on one side of the rack; a movable workbench and a loading, unloading, conveying and receiving mechanism are arranged at the top of the base; an electric control box is arranged on one side of the rack; and a switch button knob, two numerical control system controllers and a motion controller are arranged on the surface of the electric control box. According to the machining tool truss manipulator, steel beams and columns are replaced with aluminum alloy sections, secondary machining of mounting holes is not needed, thelength is random, large equipment for machining the mounting holes is omitted, tedious machining procedures and tool clamps are omitted, and manpower resources required by secondary machining are saved.

Owner:宁波广博瑞数控设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com