Fixing bracket for glass transportation

A fixed frame and glass technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of high construction cost, serious loss of construction materials, and instigation of glass deformation, and achieve the effect of eliminating transportation loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

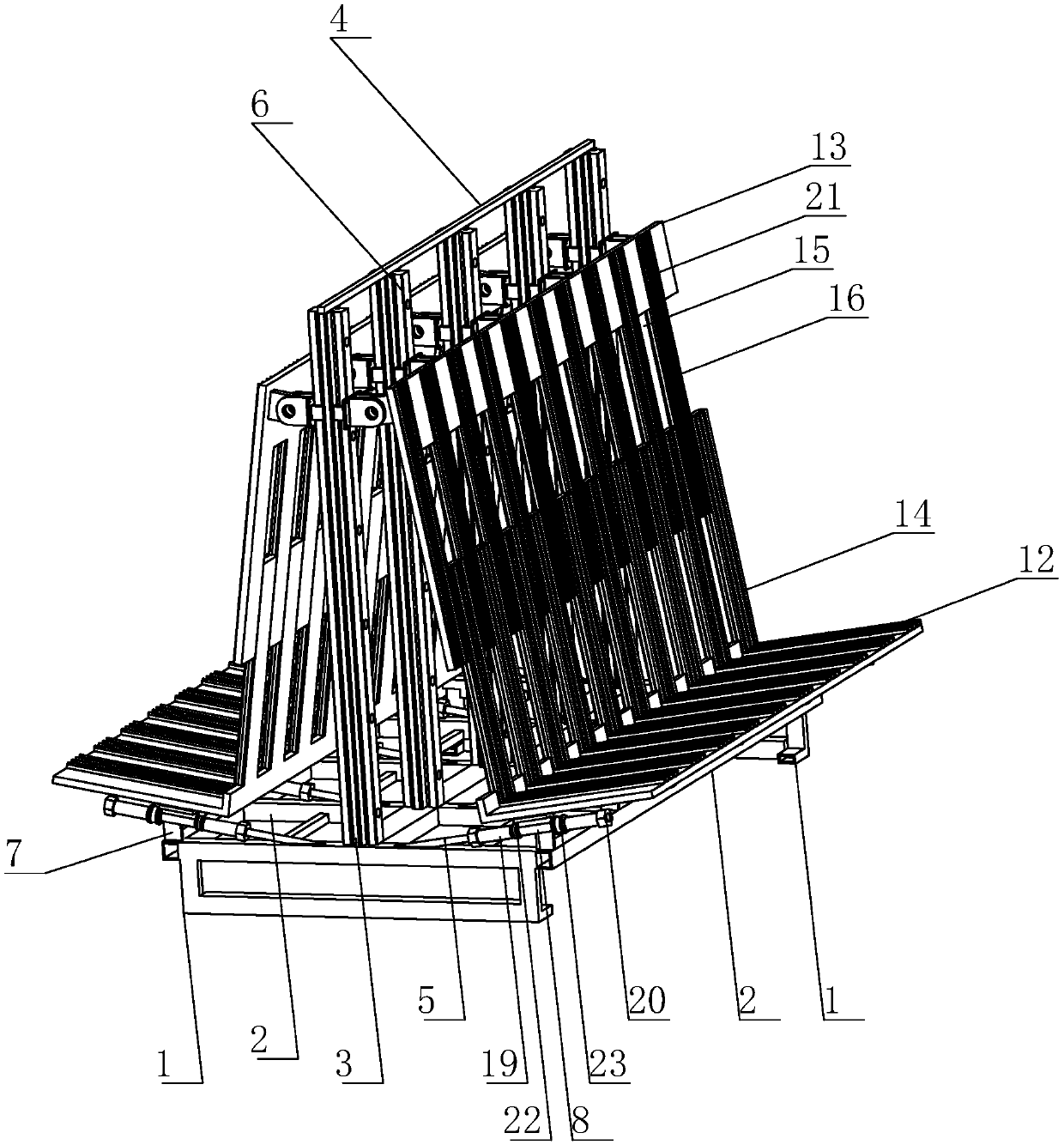

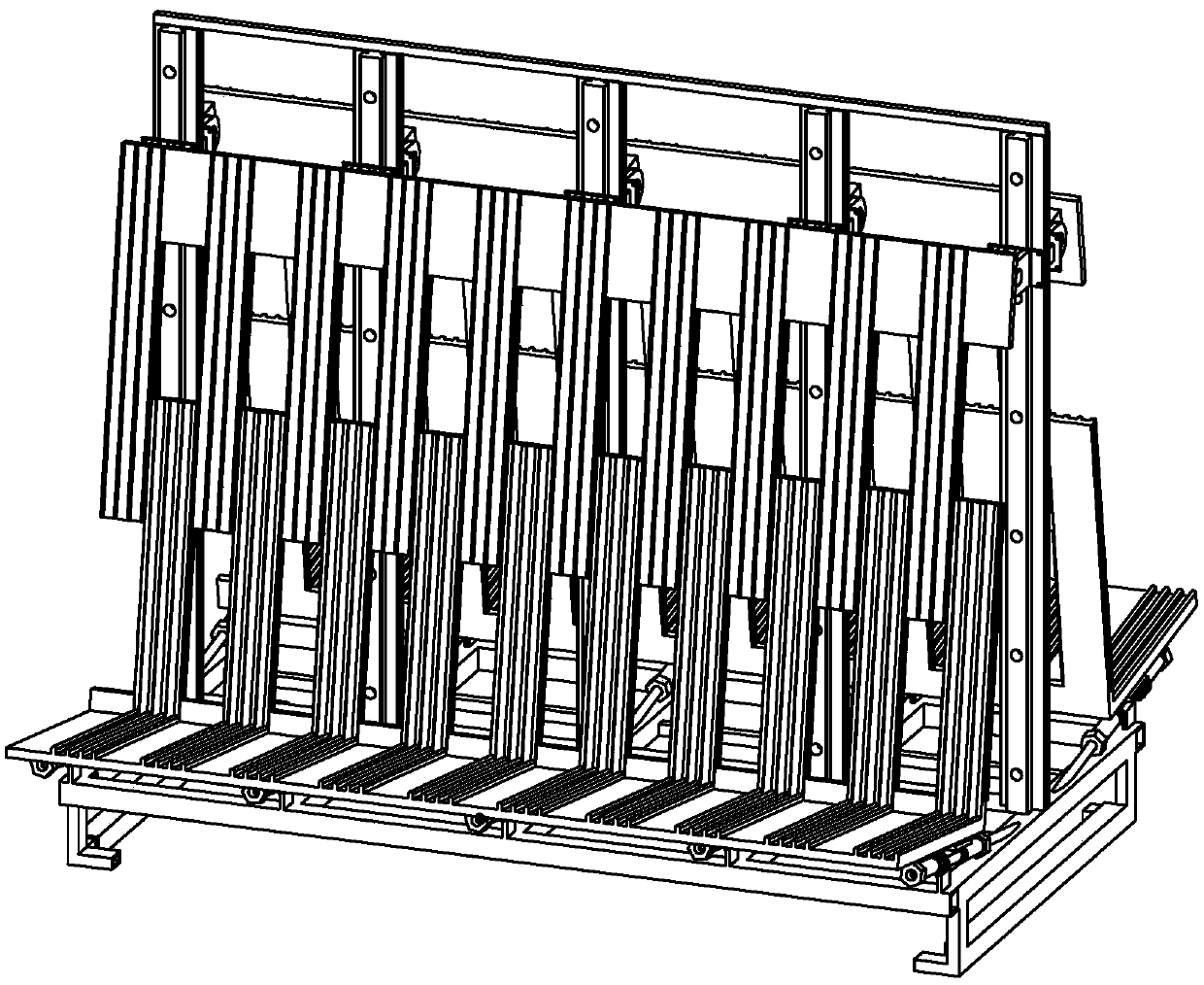

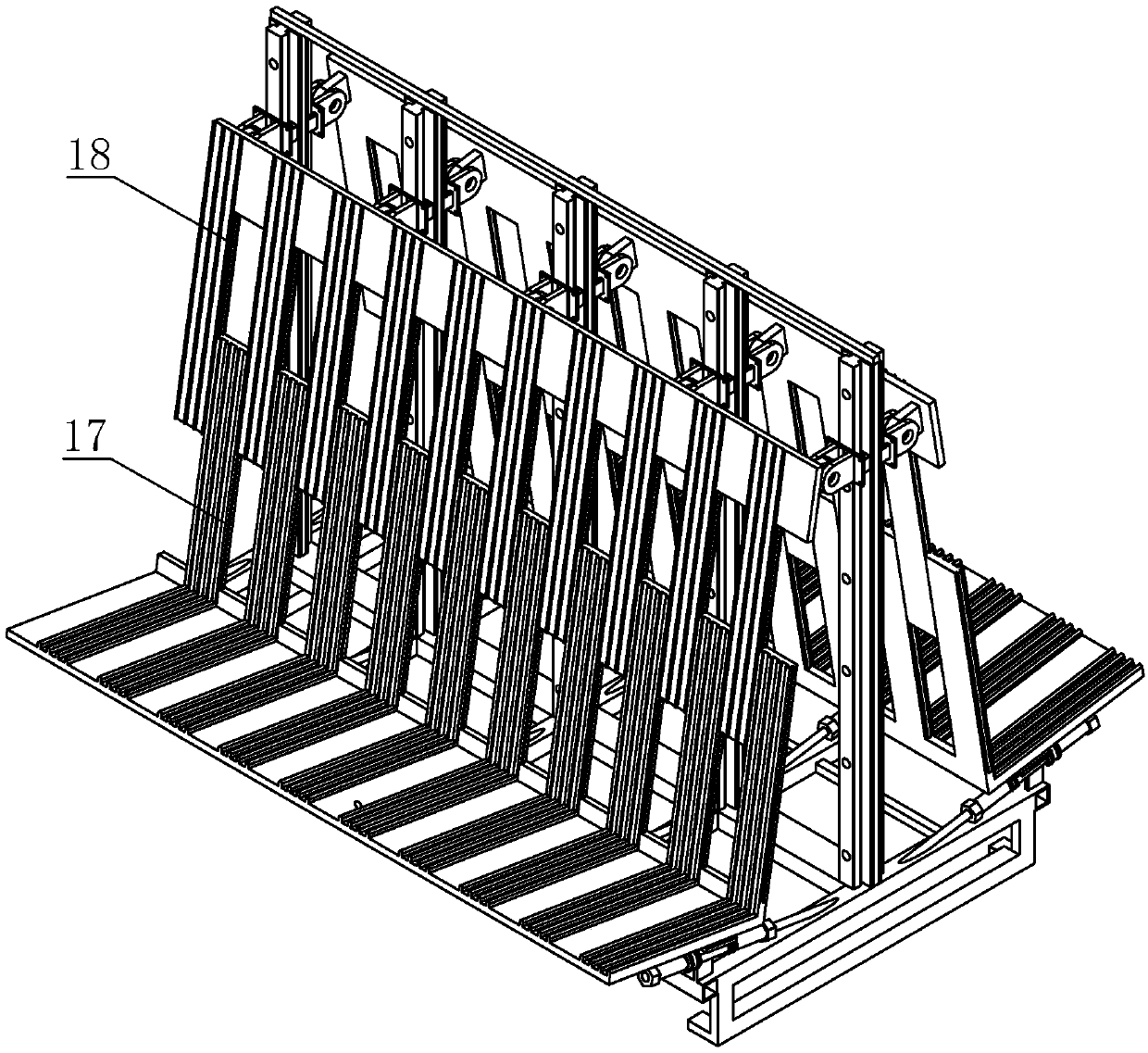

[0041] Example: glass shipping fixture, the subject structure includes:

[0042] The main frame body, the main frame body includes a tray seat, a column 3, and a beam plate 4, and the tray frame is made by welding standard channel steel. The tray seat includes a support part 1 and a load-bearing part 2. The load-bearing part 2 is a rectangular frame and is arranged horizontally. The support part 1 is symmetrically arranged on both sides of the load-bearing part 2, so that the load-bearing part 2 is 20 cm away from the ground, which is convenient Forklift operation. The column 3 is vertically arranged and distributed along the axis of the length direction of the tray seat, and the beam plate 4 is fixed on the top of the column 3; the top side of the beam plate 4 is provided with an iron ring, and the iron ring extends along the beam There are 6 boards 4 distributed along the length direction, and the iron rings are used for binding and fixing auxiliary ropes.

[0043]Track me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com