Patents

Literature

404results about How to "Avoid Rigid Collisions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

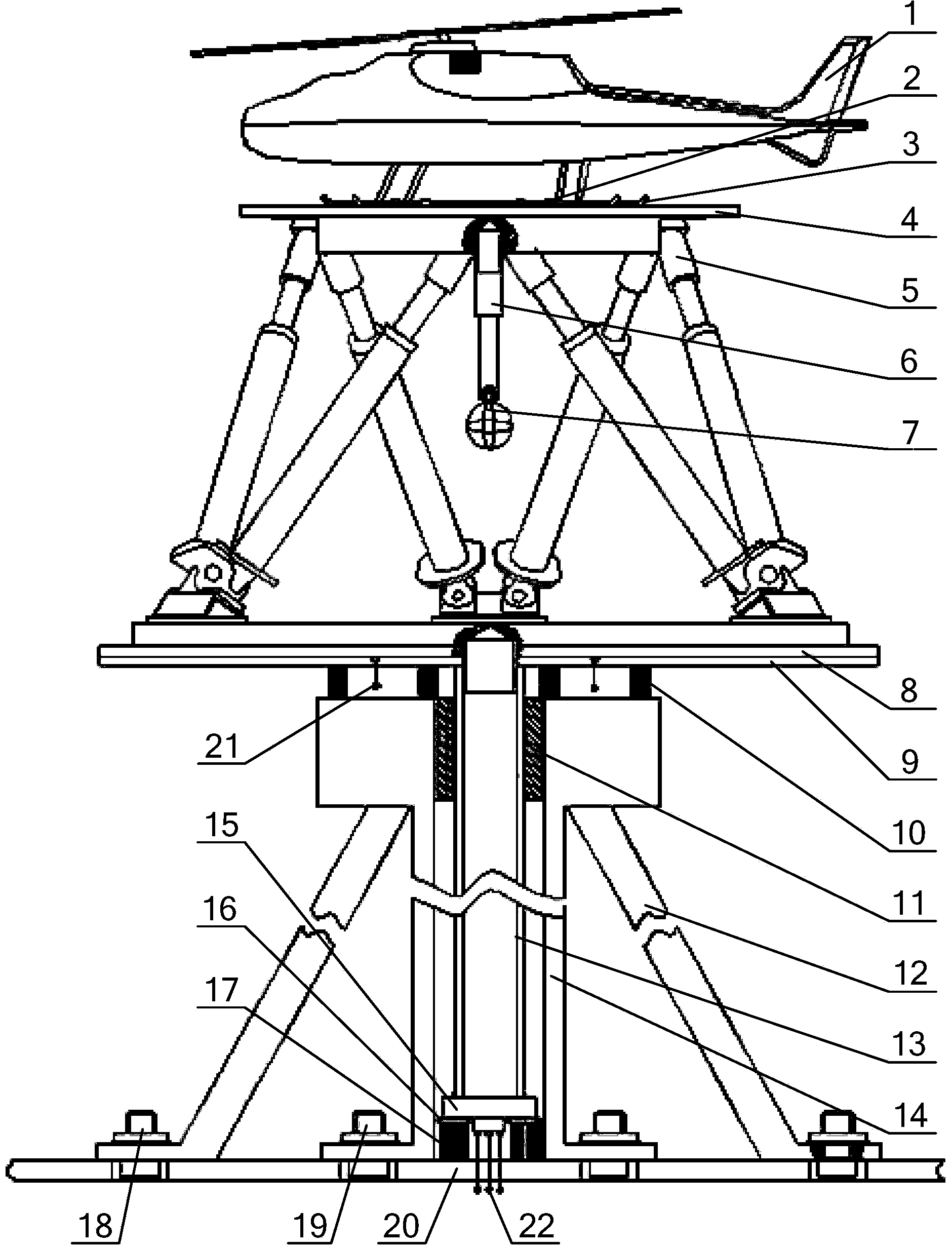

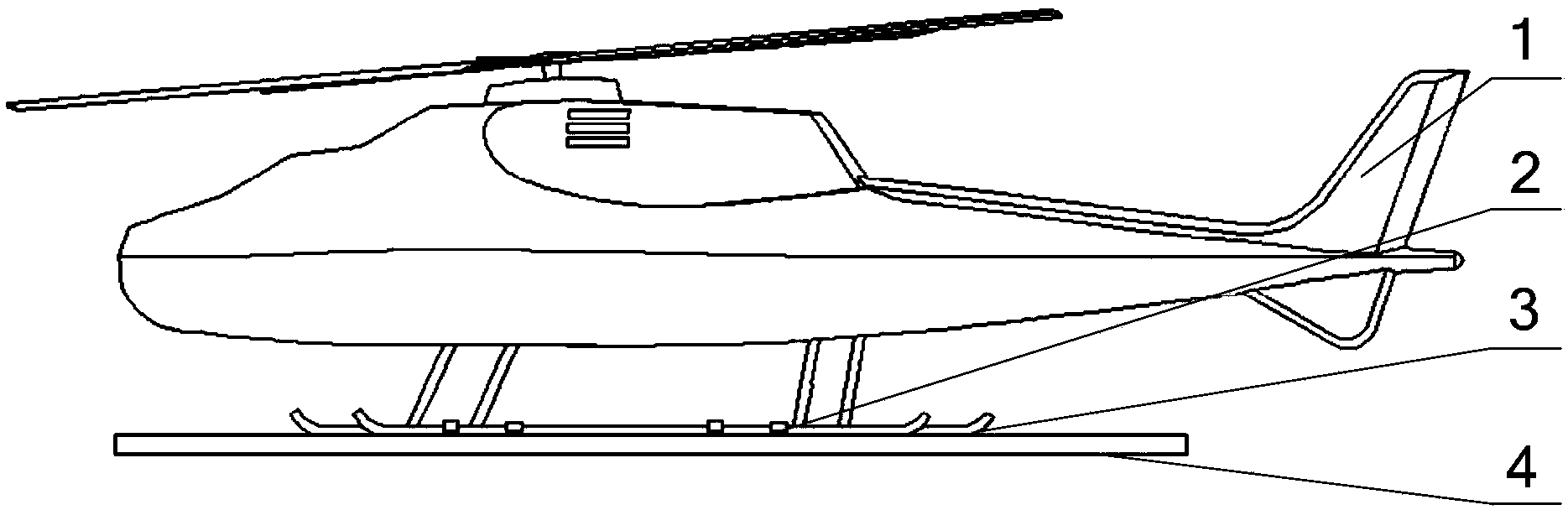

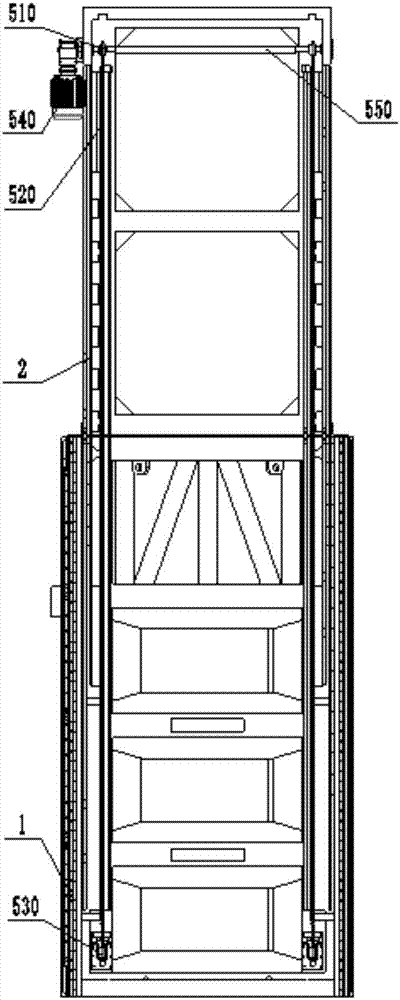

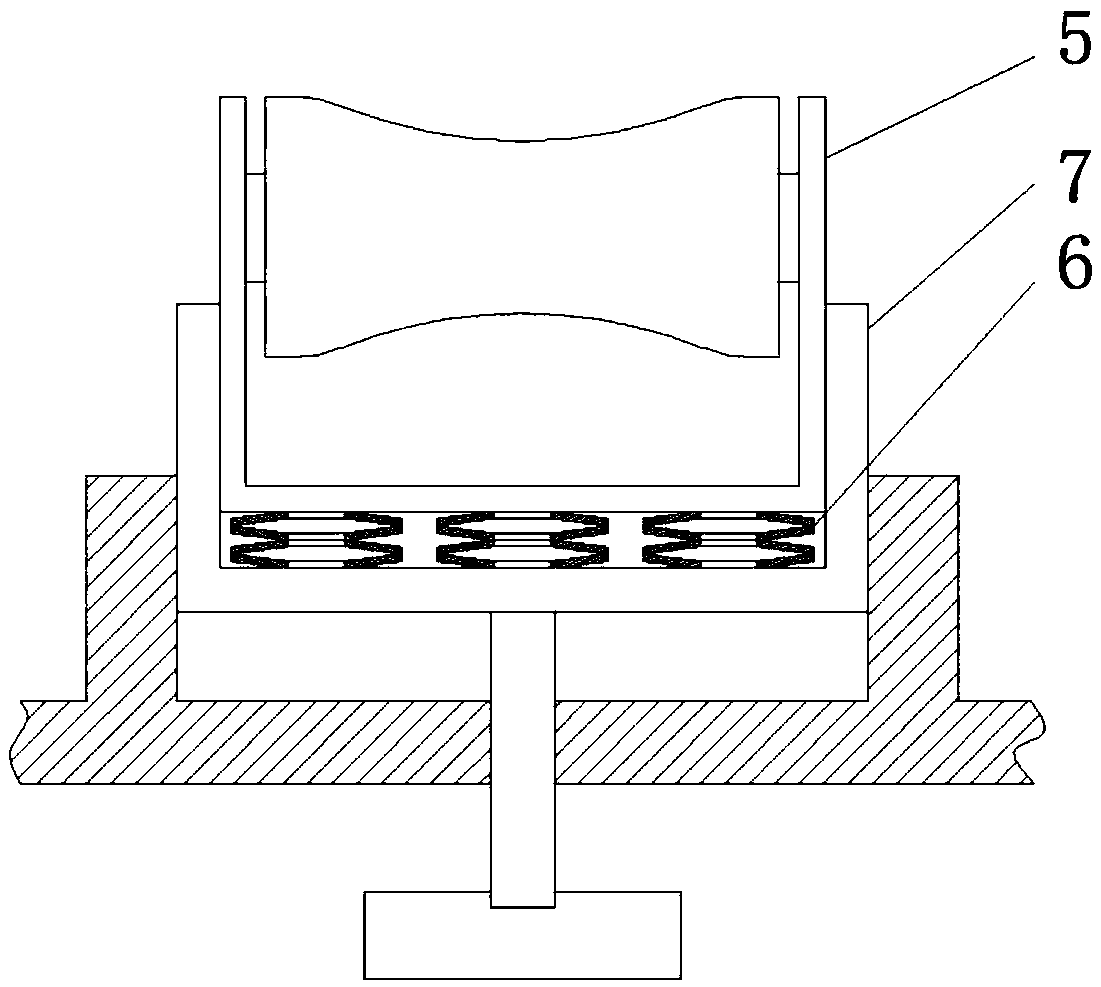

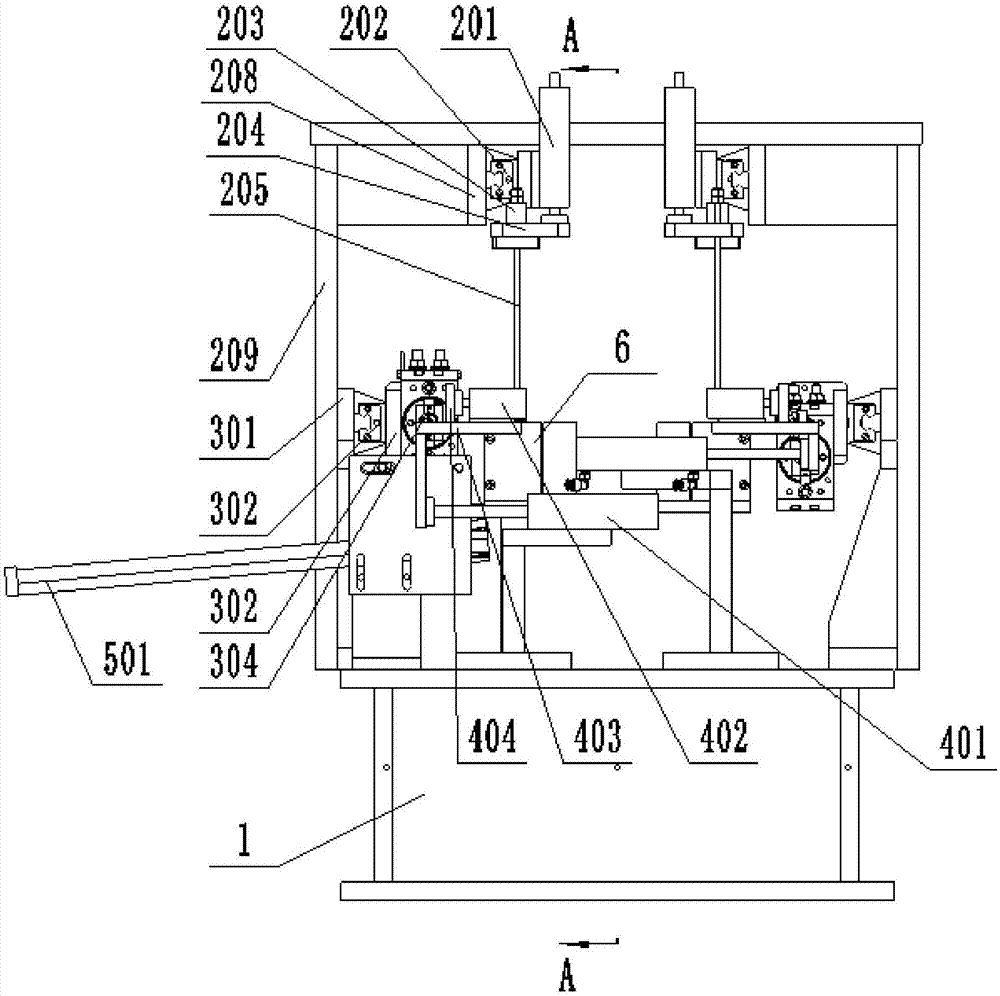

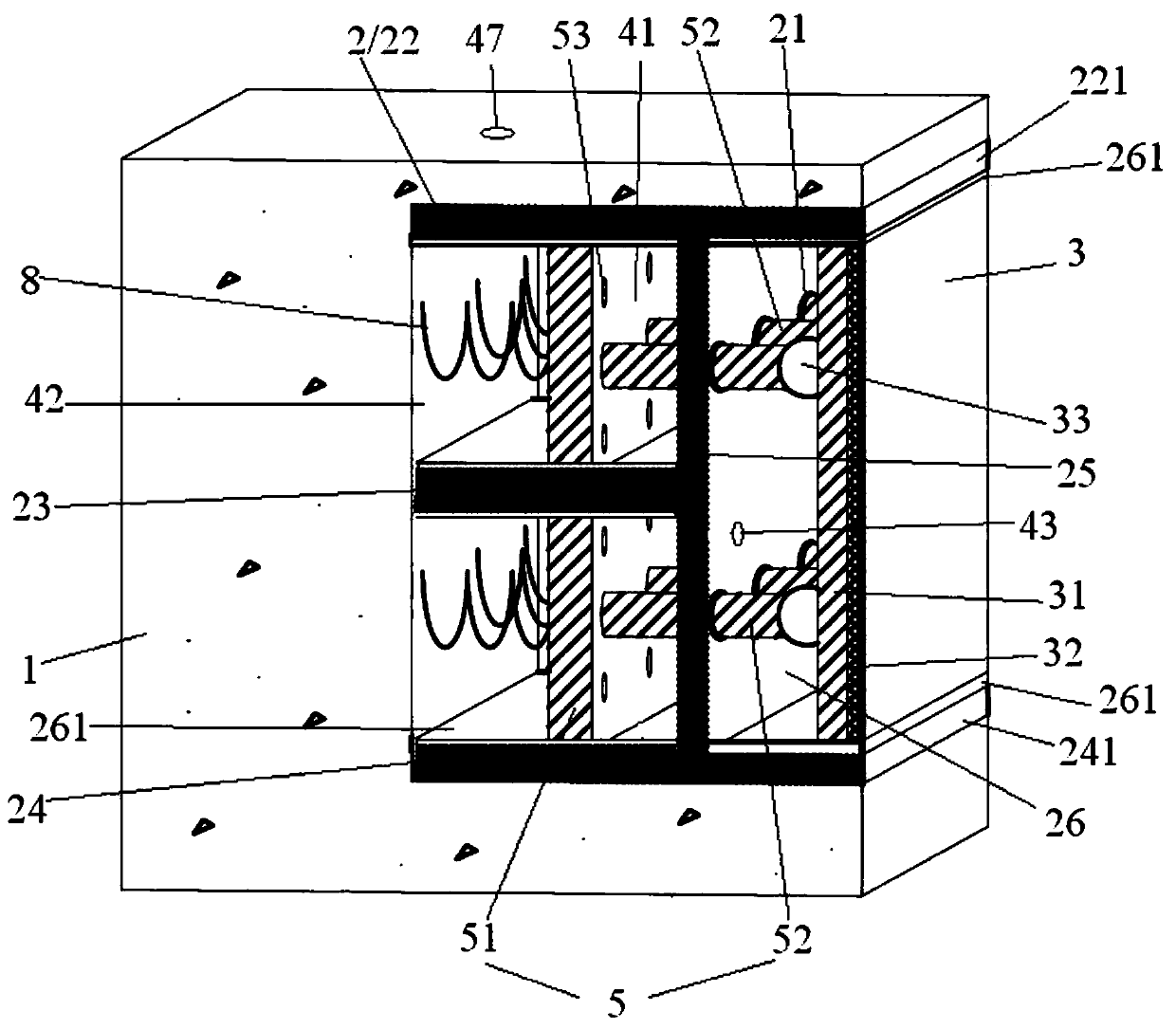

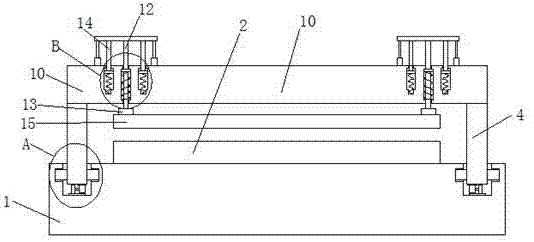

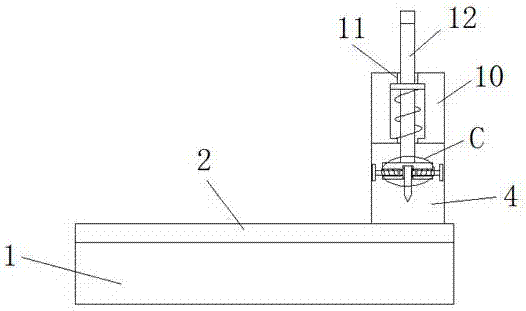

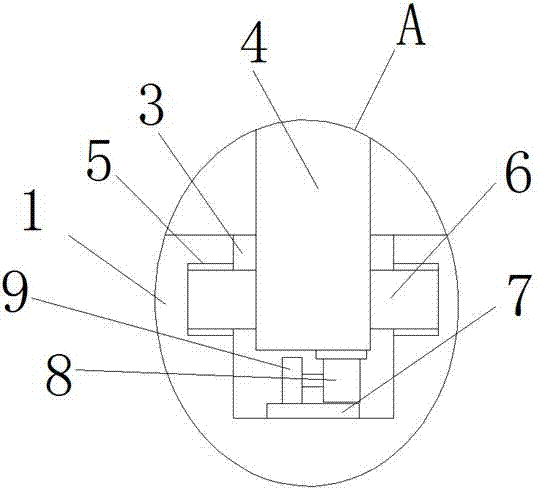

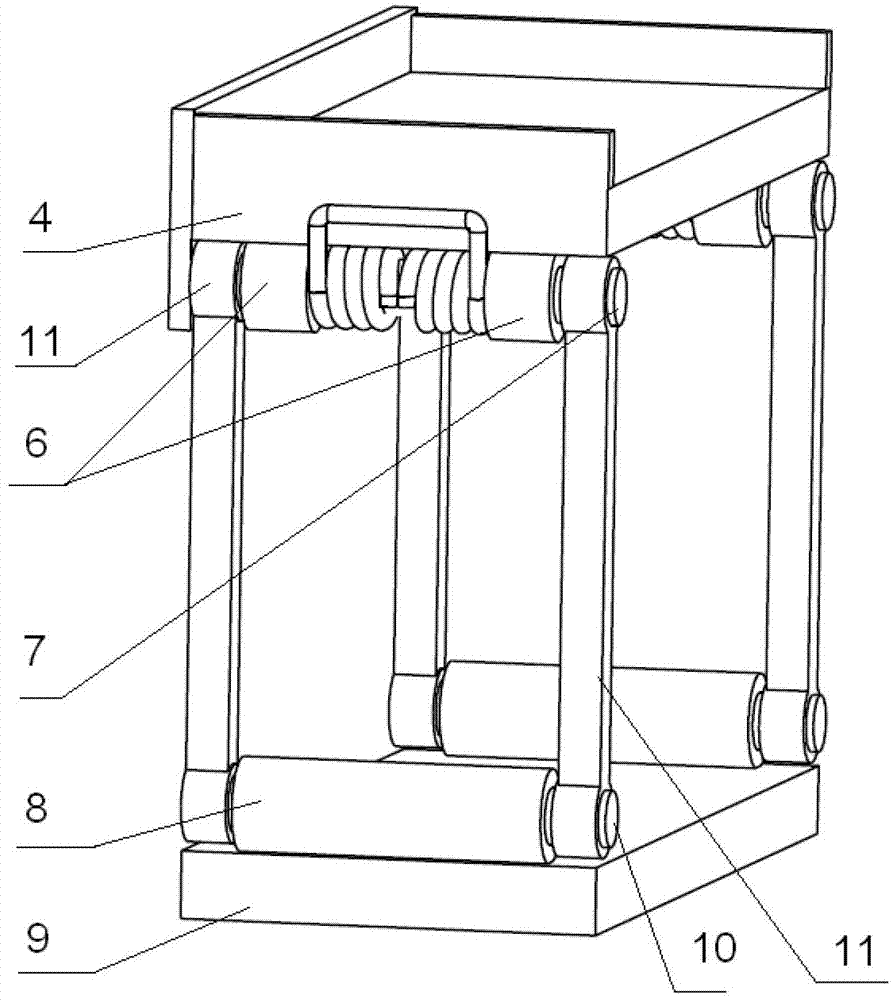

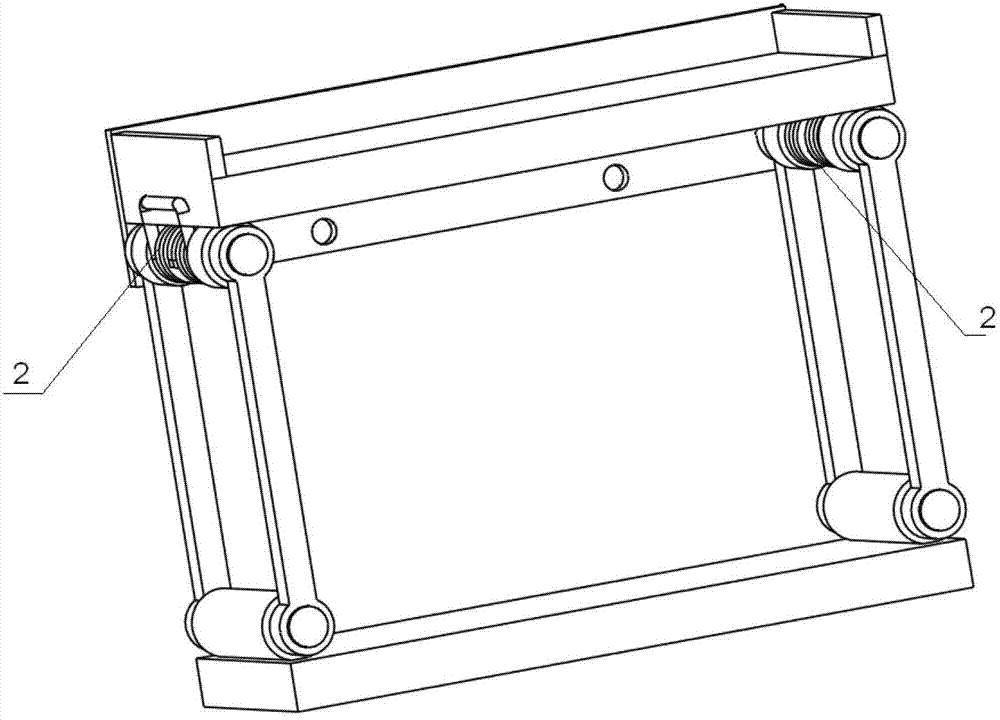

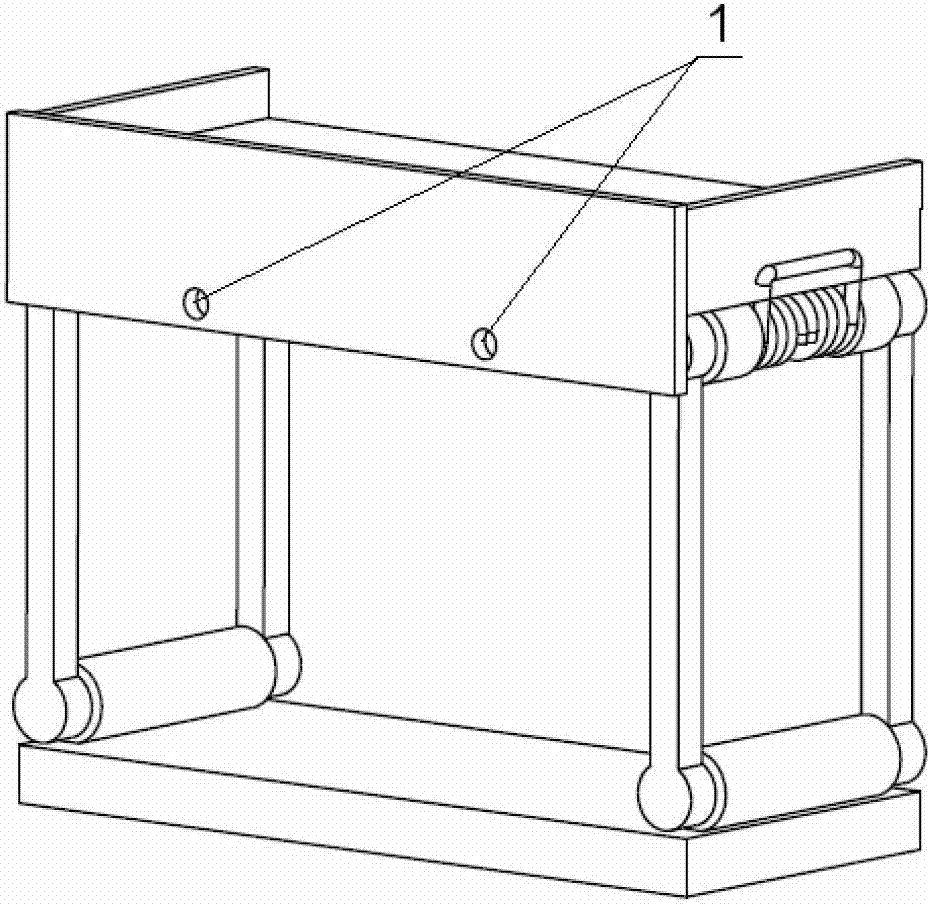

Unmanned helicopter performance testing platform

InactiveCN103863576AAvoid flying awayEnsure balanceAircraft components testingAviationMarine engineering

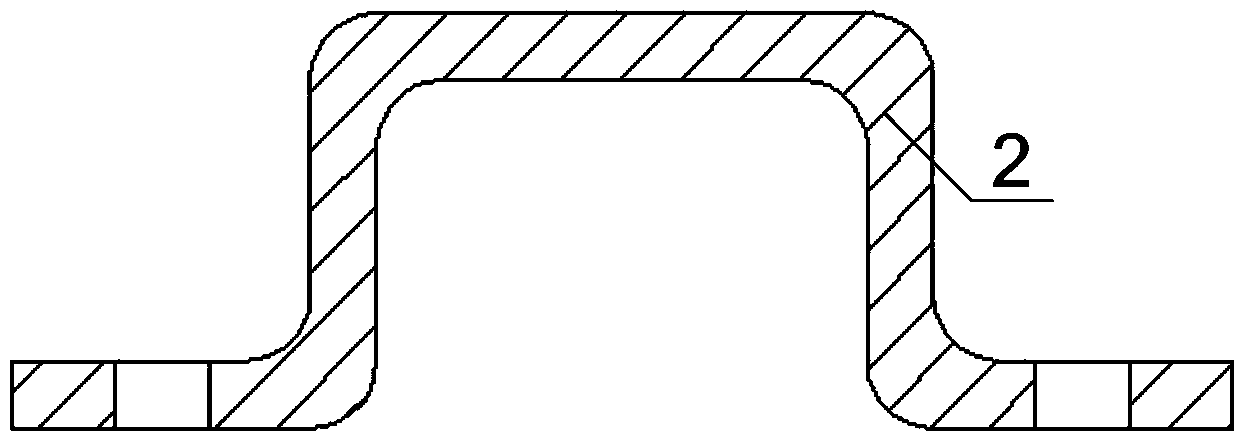

The invention relates to an unmanned helicopter performance testing platform, belongs to the field of aerospace technologies and aims at solving the problems that the fixing structure is unstable, the balance performance in the movement process is poor and a testing table is damaged in the prior art. The unmanned helicopter performance testing platform comprises a platform body assembly and a flight simulator, wherein an unmanned helicopter is fixedly arranged on an upper platform of a six-degree-of-freedom moving platform, and lifting force data generated during the flight of the unmanned helicopter is transmitted to a computer through a lifting force sensor A which is fixedly arranged on the lower surface of a lower platform of the six-degree-of-freedom moving platform and a lifting force sensor B which is fixedly arranged on the lower surface of an iron plate module, so as to realize performance testing. The unmanned helicopter performance testing platform has the beneficial effects that the action of the unmanned helicopter is provided by virtue of the six-degree-of-freedom moving platform and a positioning sleeve can prevent the helicopter from flying away from the testing table when the flight control of the helicopter fails or an experiment fails; since the lower surface of the lower platform of the six-degree-of-freedom moving platform is seated on the upper surface of a shock absorbing plate, the balance of the unmanned helicopter is kept; the shock absorbing plate, a large compression spring and a small compression spring also play a certain role in buffering.

Owner:JILIN UNIV

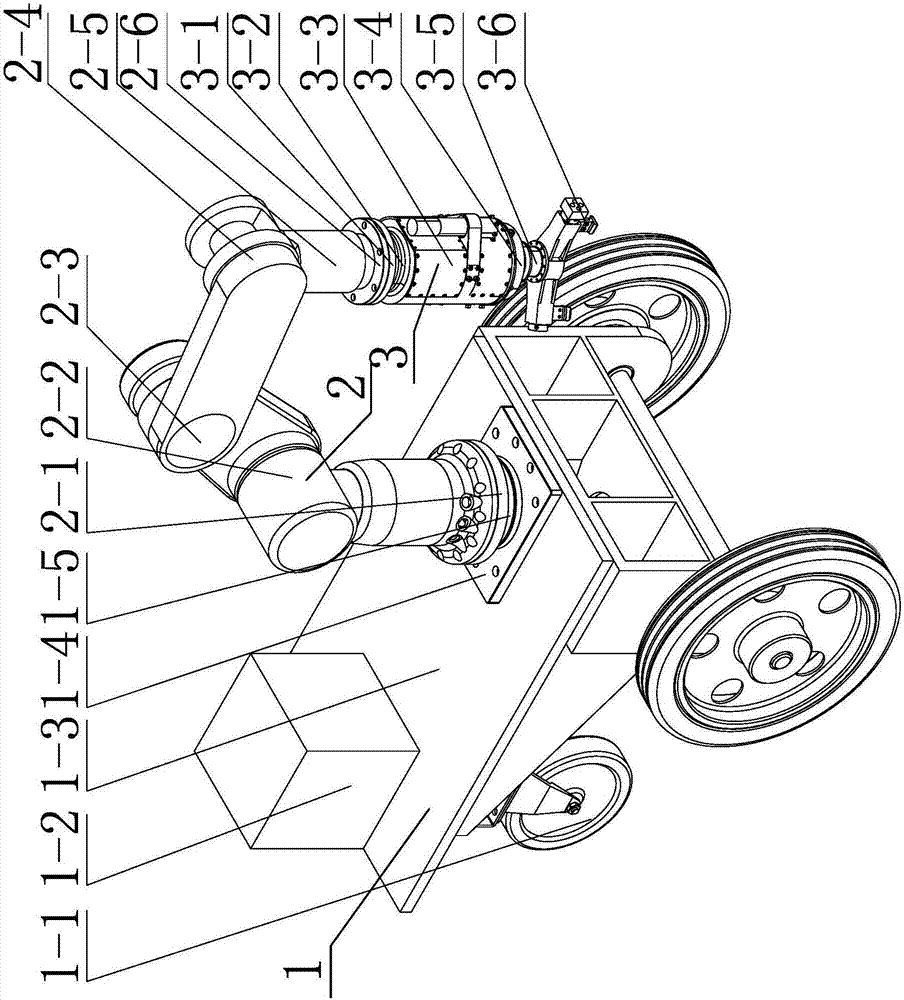

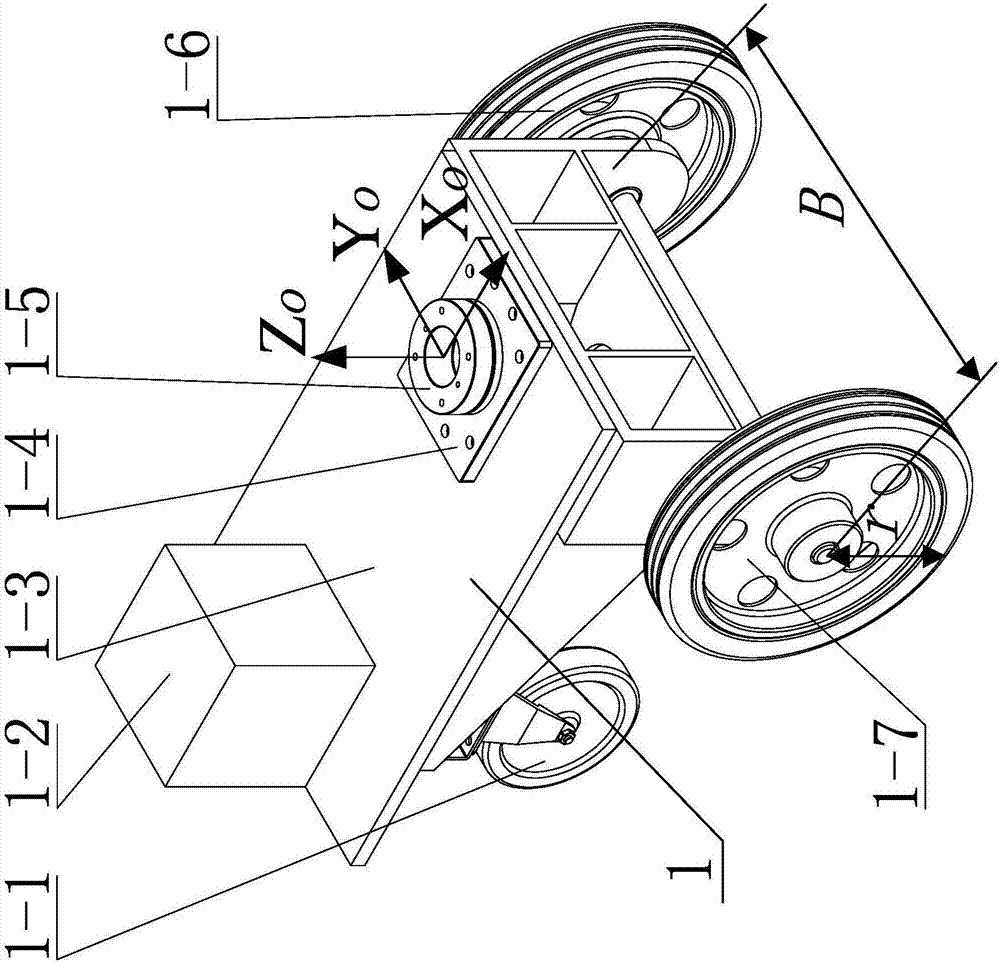

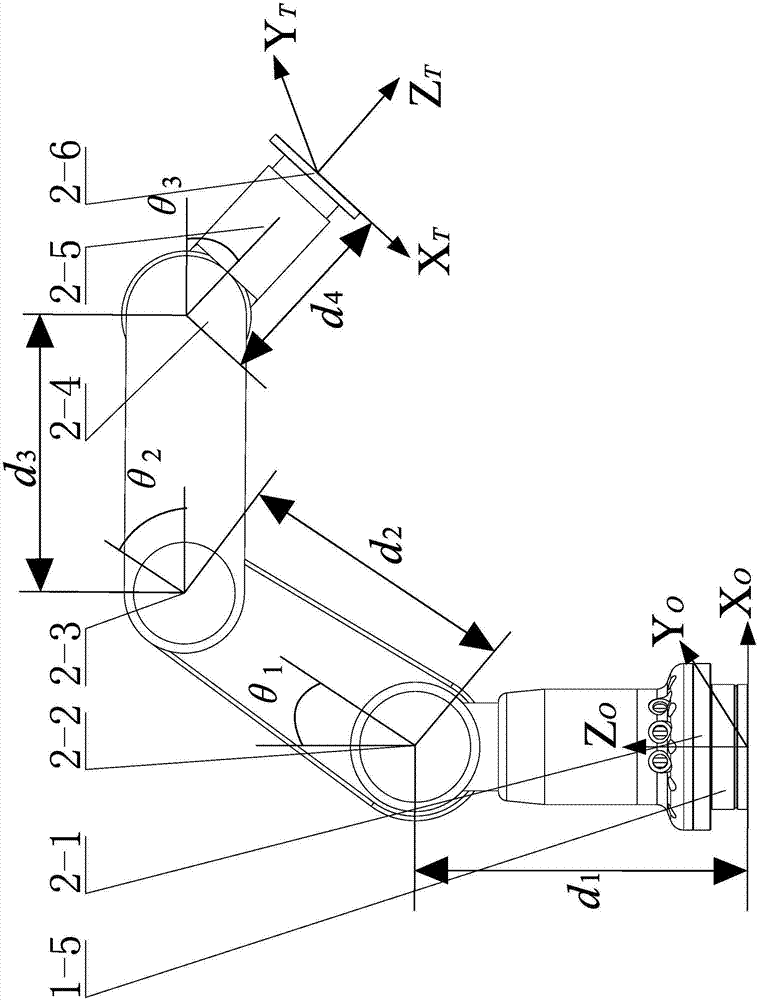

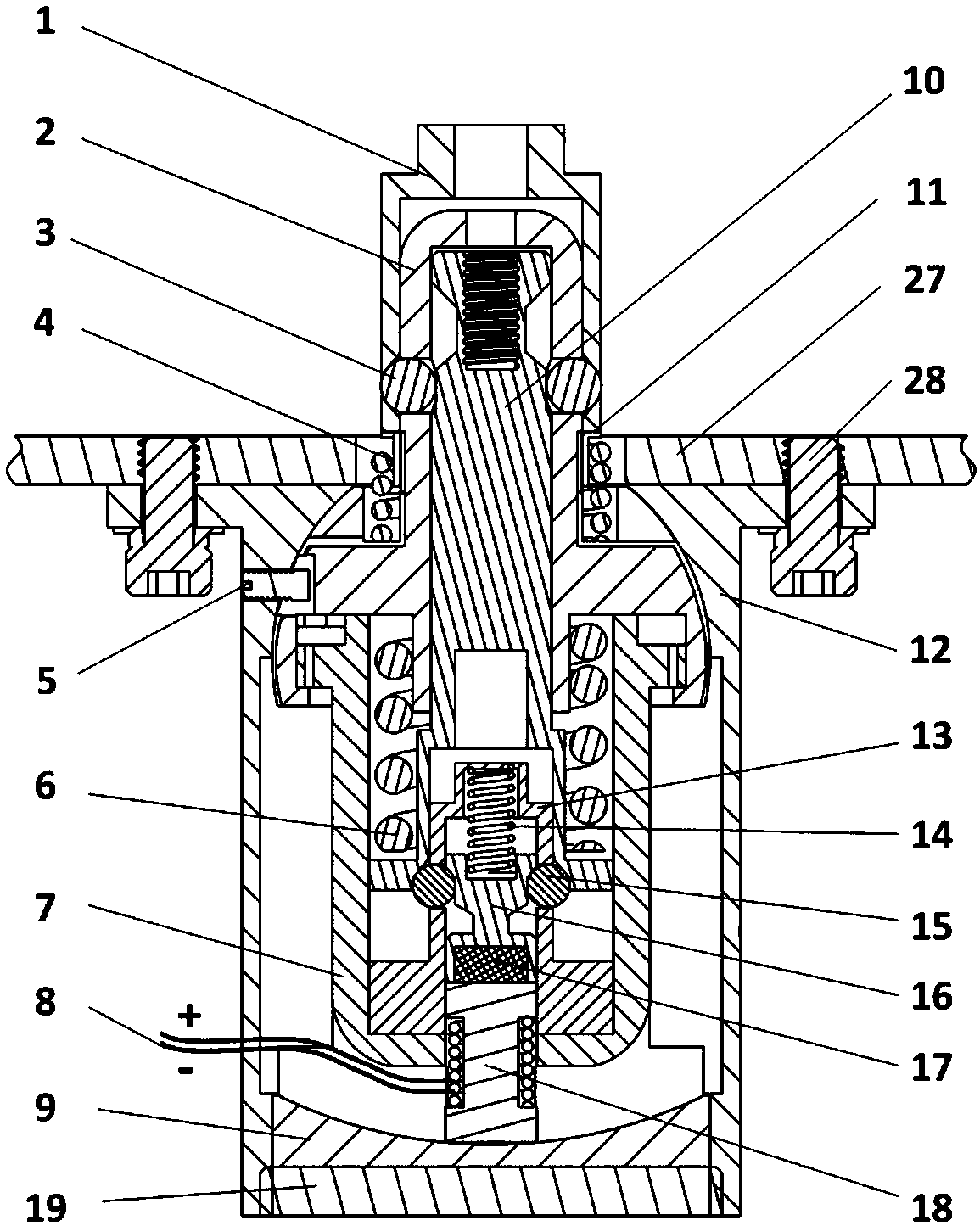

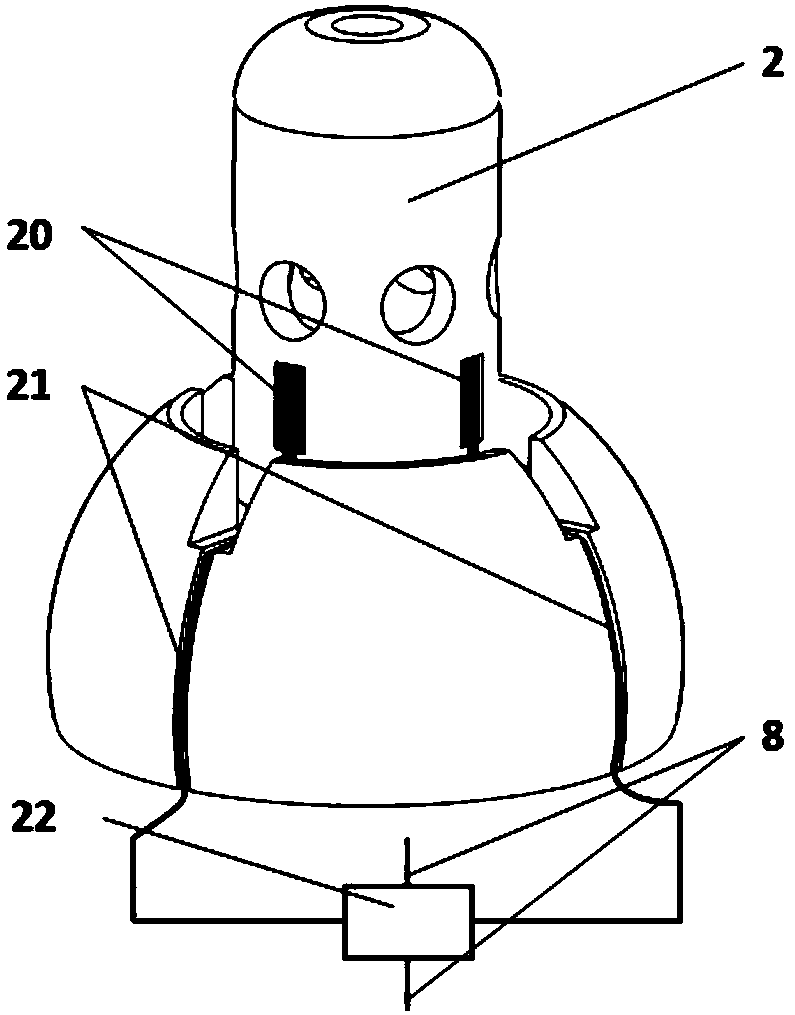

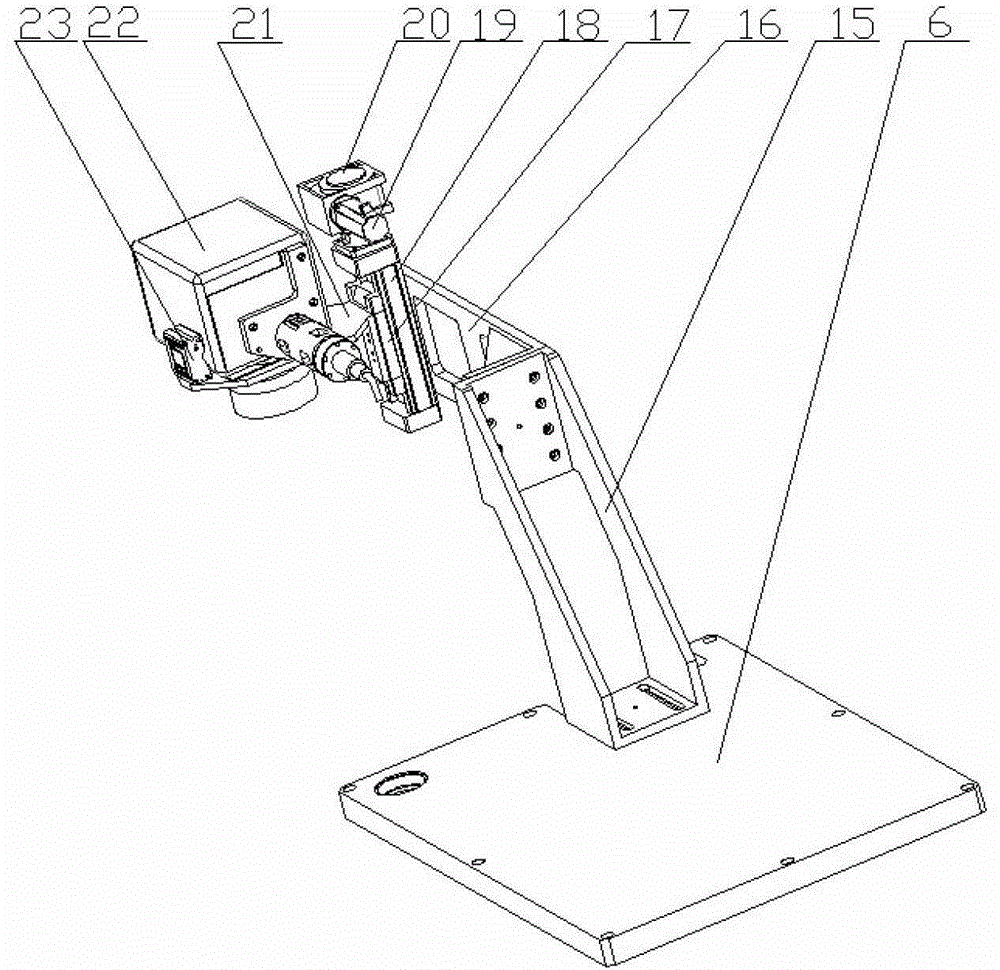

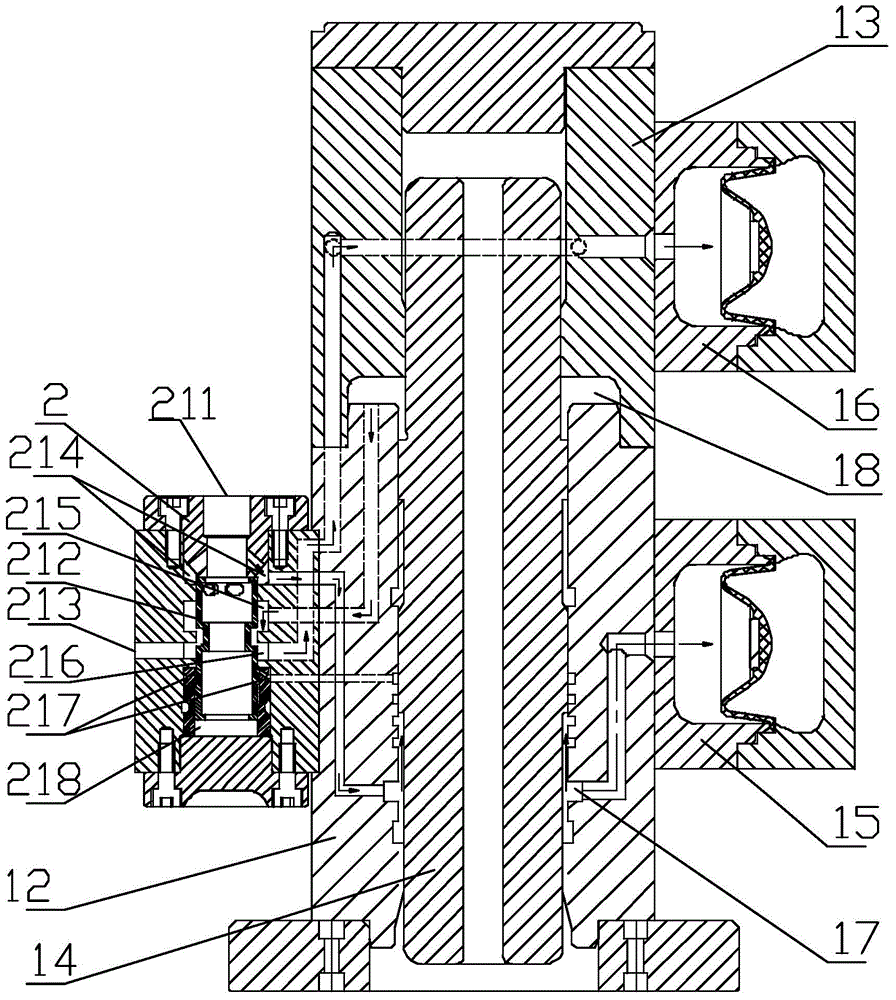

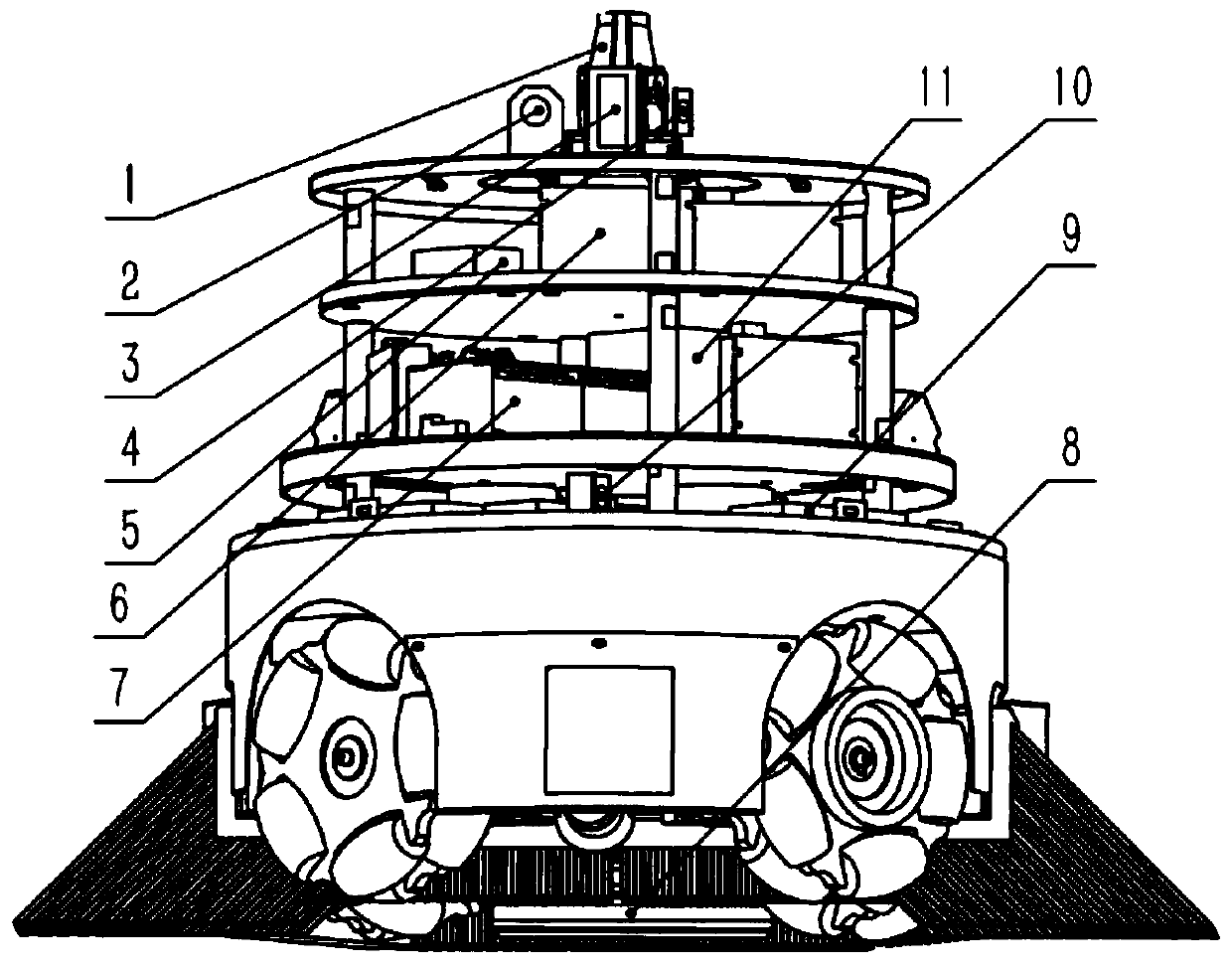

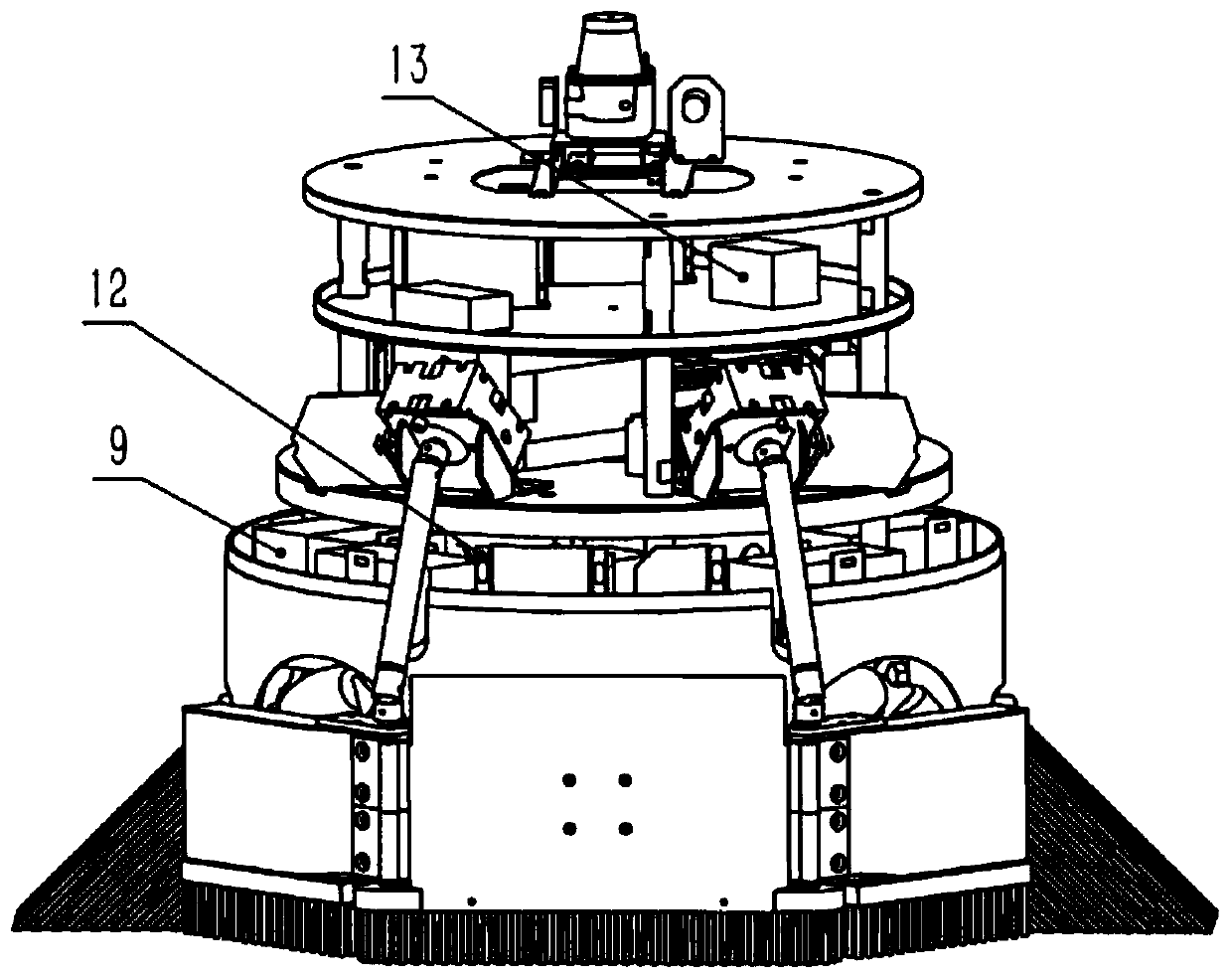

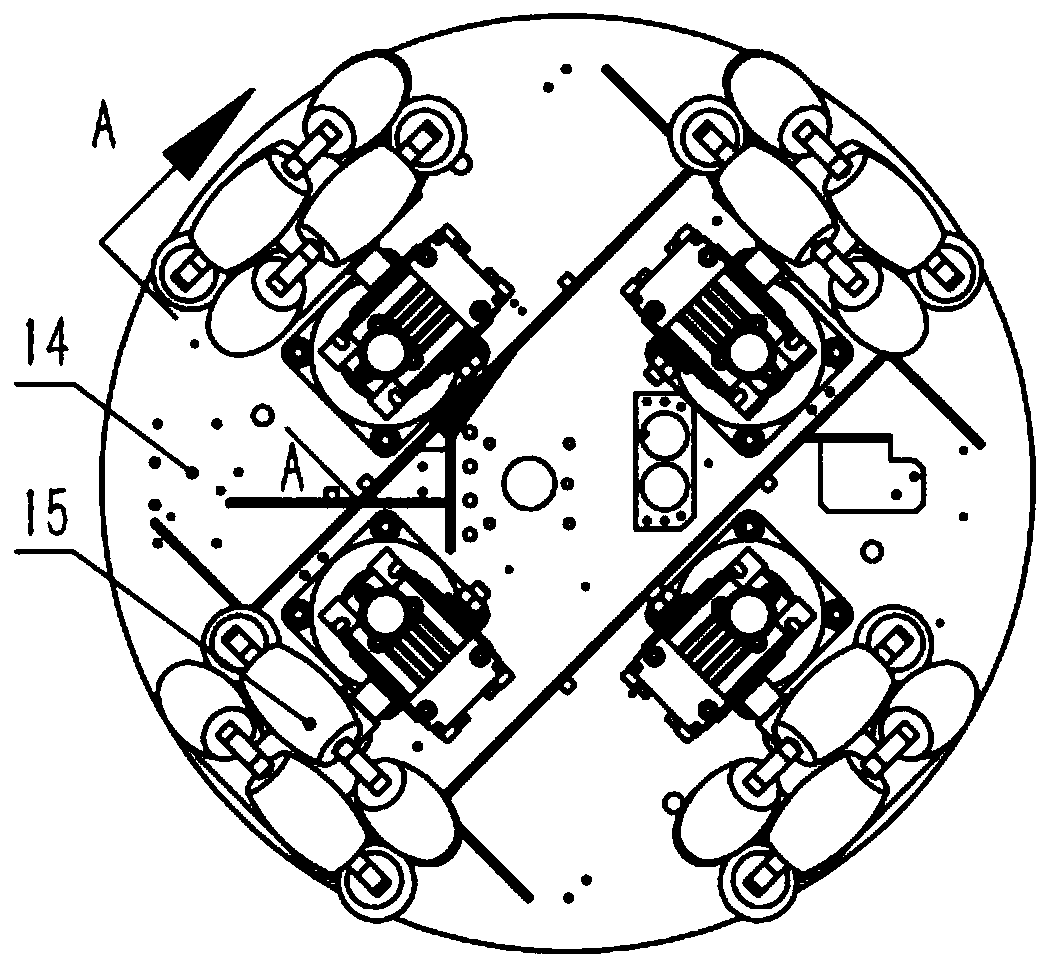

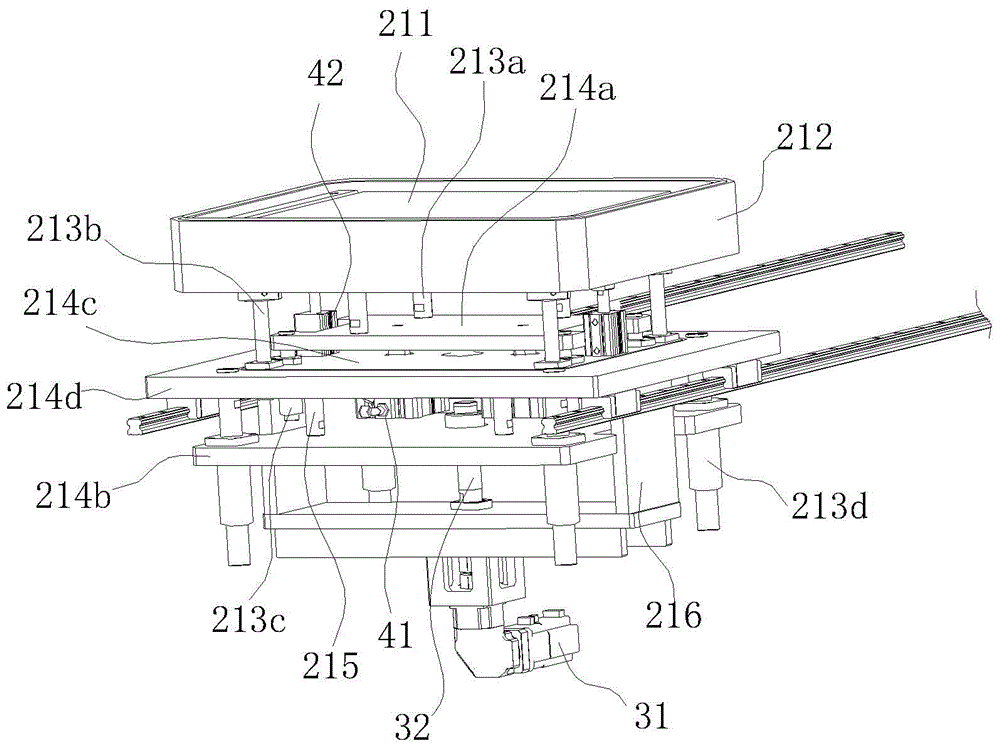

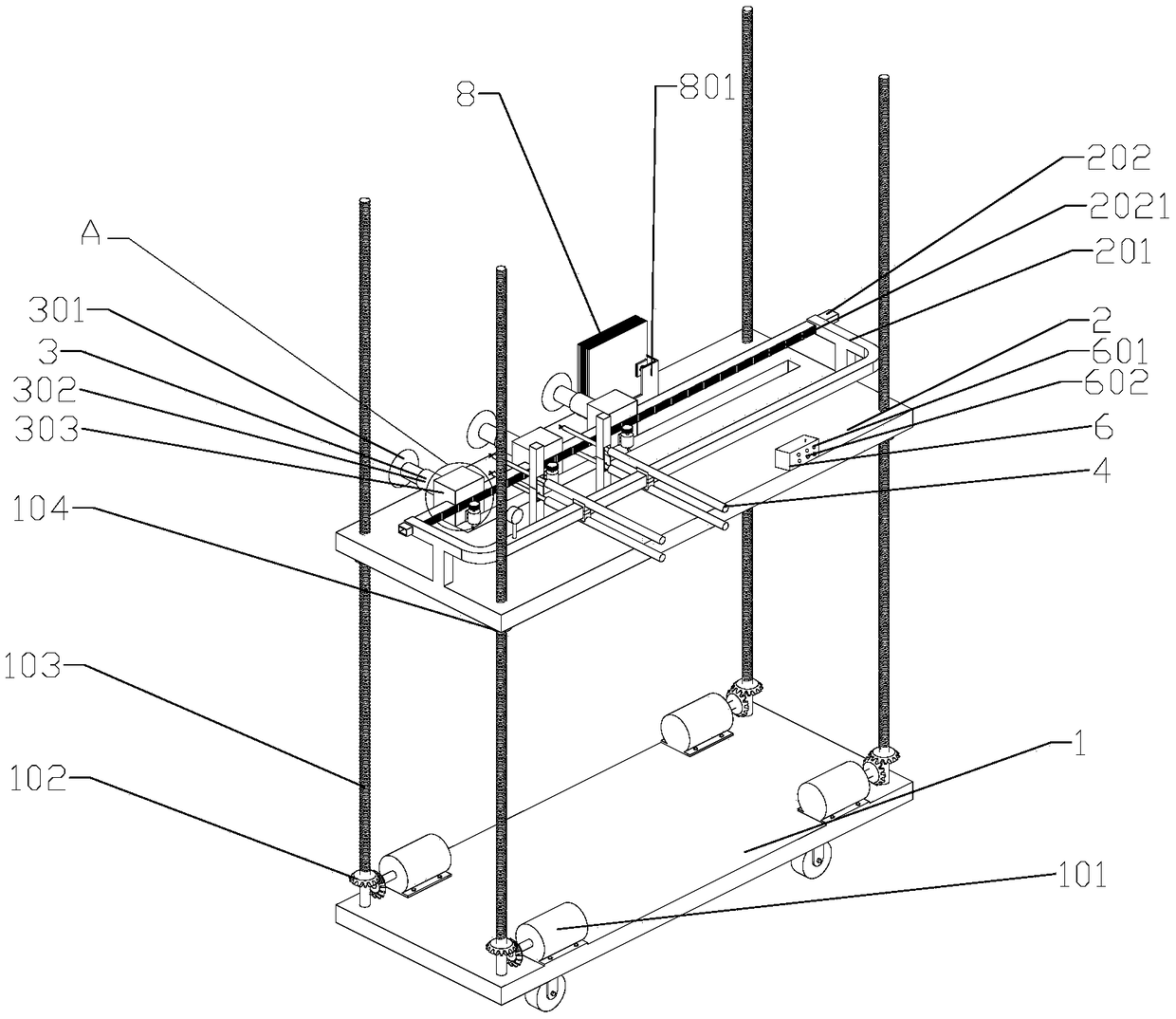

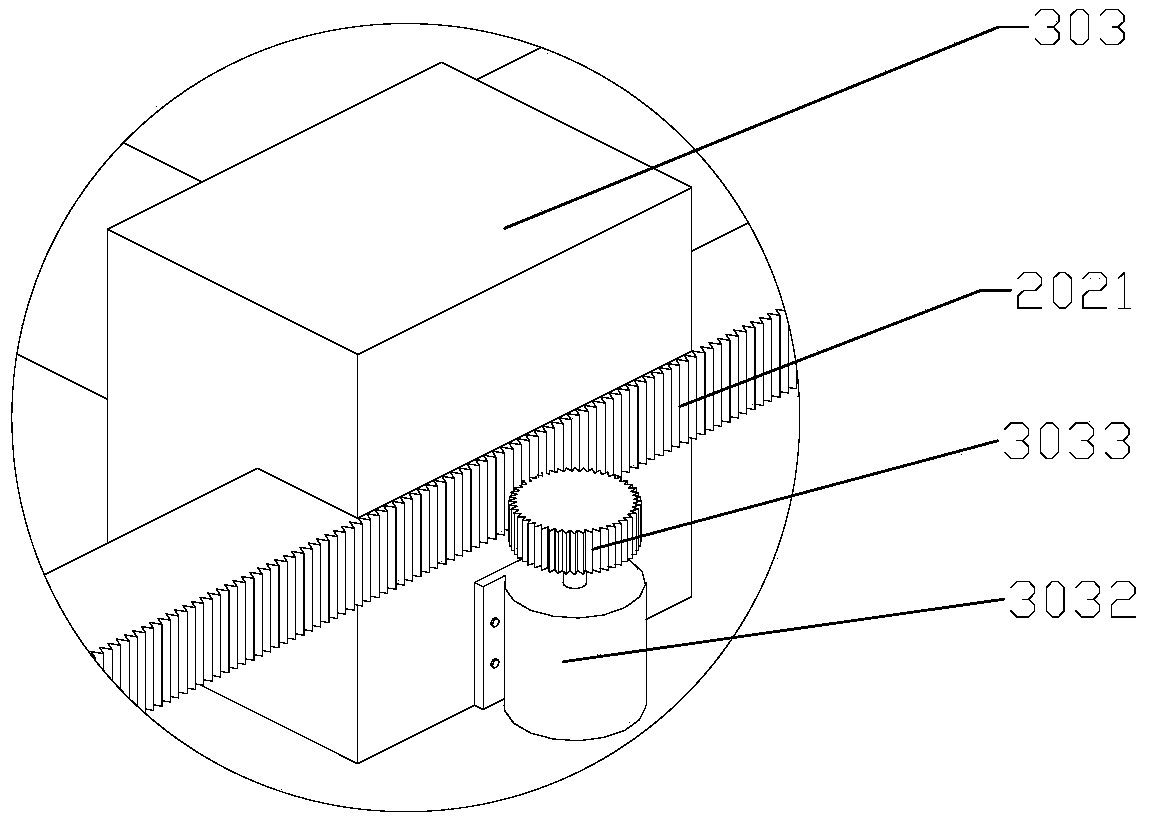

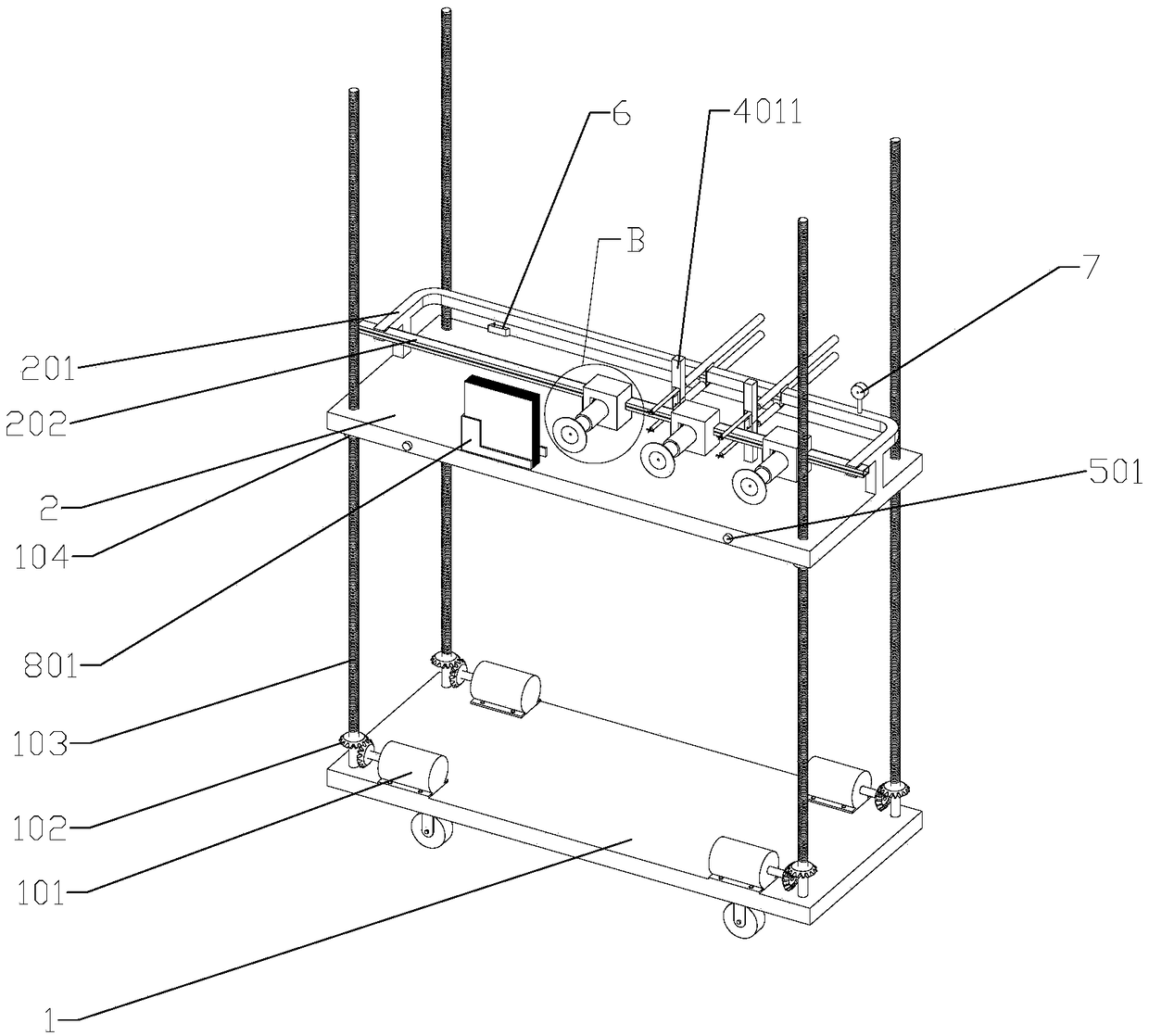

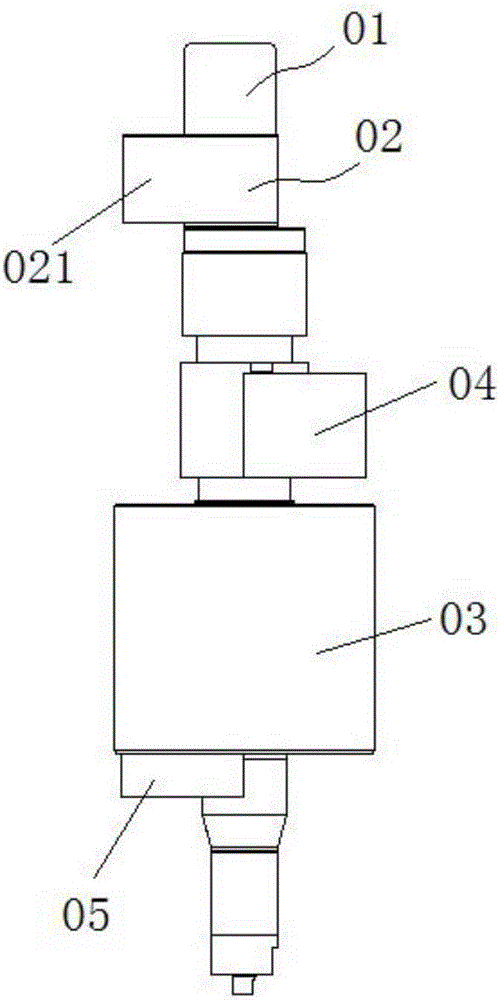

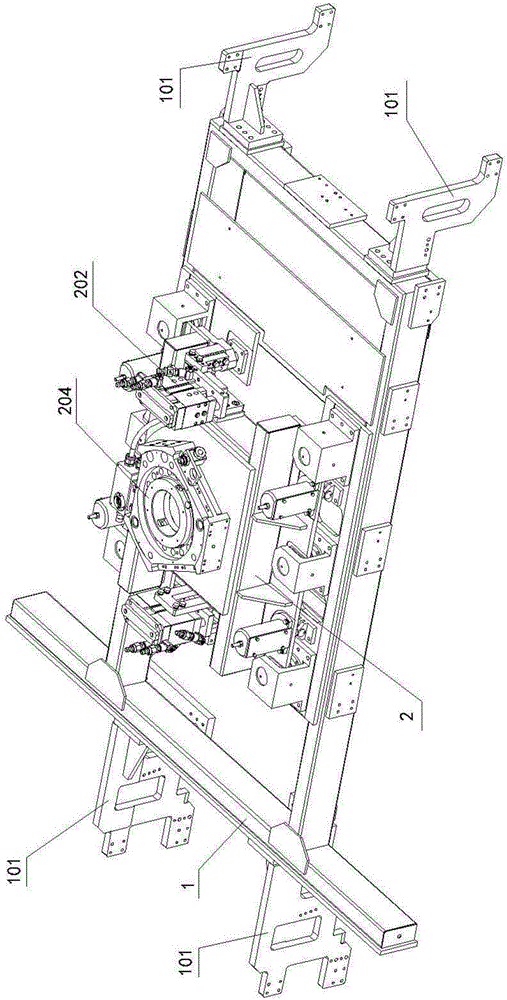

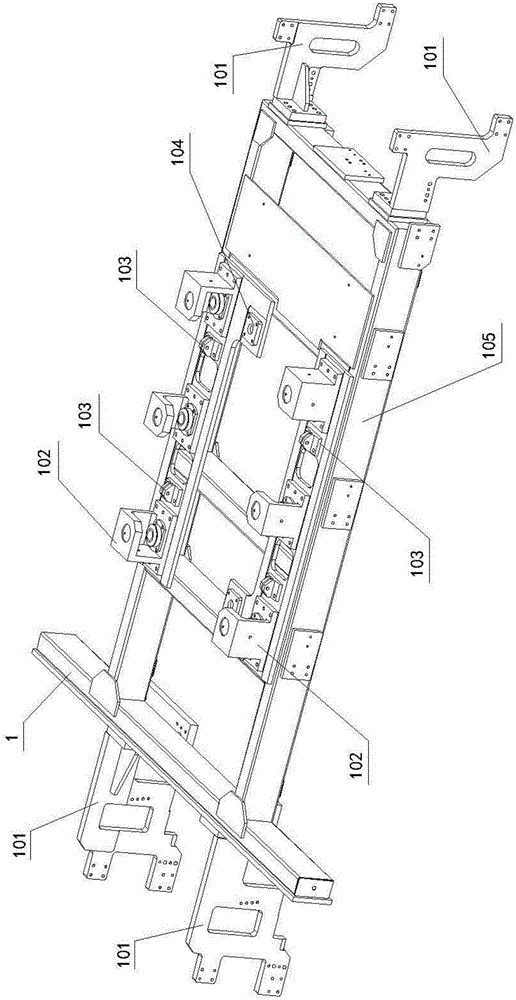

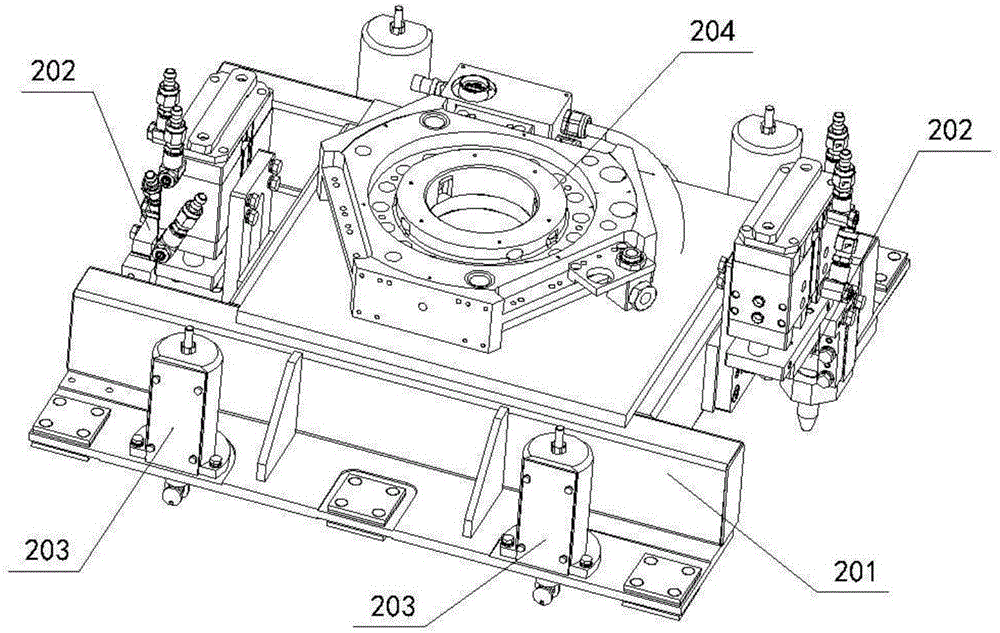

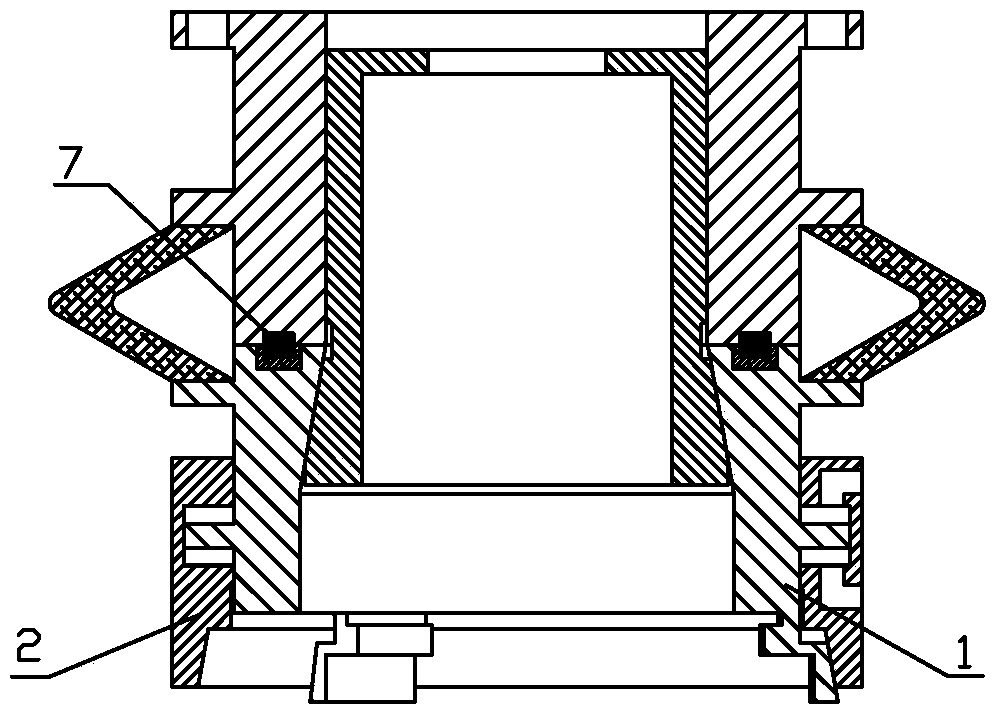

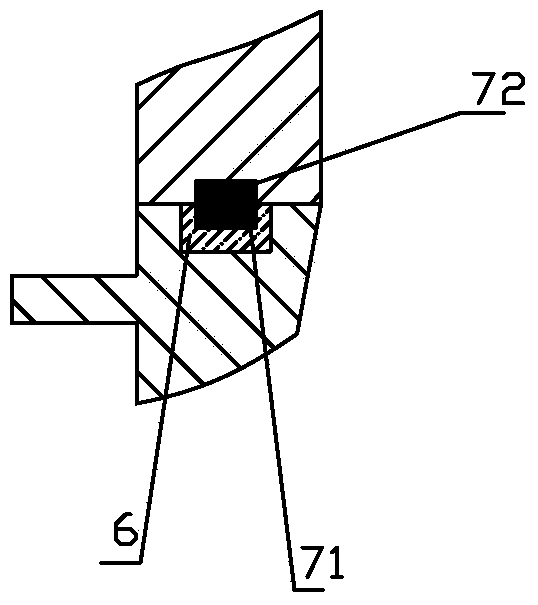

Full-pose-and-position active-passive compliant robot and valve screwing-twisting method utilizing robot

ActiveCN108000477AImprove adaptabilityAvoid Rigid CollisionsGripping headsAxial displacementEngineering

The invention provides a full-pose-and-position active-passive compliant robot and a valve screwing-twisting method utilizing the robot, and relates to a robot and a valve screwing-twisting method utilizing the robot. The full-pose-and-position active-passive compliant robot and the valve screwing-twisting method utilizing the robot aim to solve the problems that an industrial robot cannot conductlarge overall motion, and the operating range is narrow; rigid collision and radial contact force are generated between an end actuator and a valve handwheel; damage of operating devices is possiblycaused due to the fact that screwing-twisting resistance torques of different valves are different; and the valve handwheel can produce axial displacement while rotating, and axial contact force of the tail end is brought. The full-pose-and-position active-passive compliant robot comprises a wheel type moving platform, a four-degree-of-freedom manipulator and a compliant end actuator, the four-degree-of-freedom manipulator is mounted on the wheel type moving platform, and a six-axis force sensor is mounted between the four-degree-of-freedom manipulator and the wheel type moving platform; the compliant end actuator is mounted at the tail end of the four-degree-of-freedom manipulator, and a six-axis force sensor is mounted between the compliant end actuator and the four-degree-of-freedom manipulator; and through information of the two sensors, impedance control can be conducted on the wheel type moving platform and the four-degree-of-freedom manipulator. The full-pose-and-position active-passive compliant robot and the valve screwing-twisting method utilizing the robot are suitable for robot remote operation, robot compliant control and valve screwing-twisting operation.

Owner:HARBIN INST OF TECH

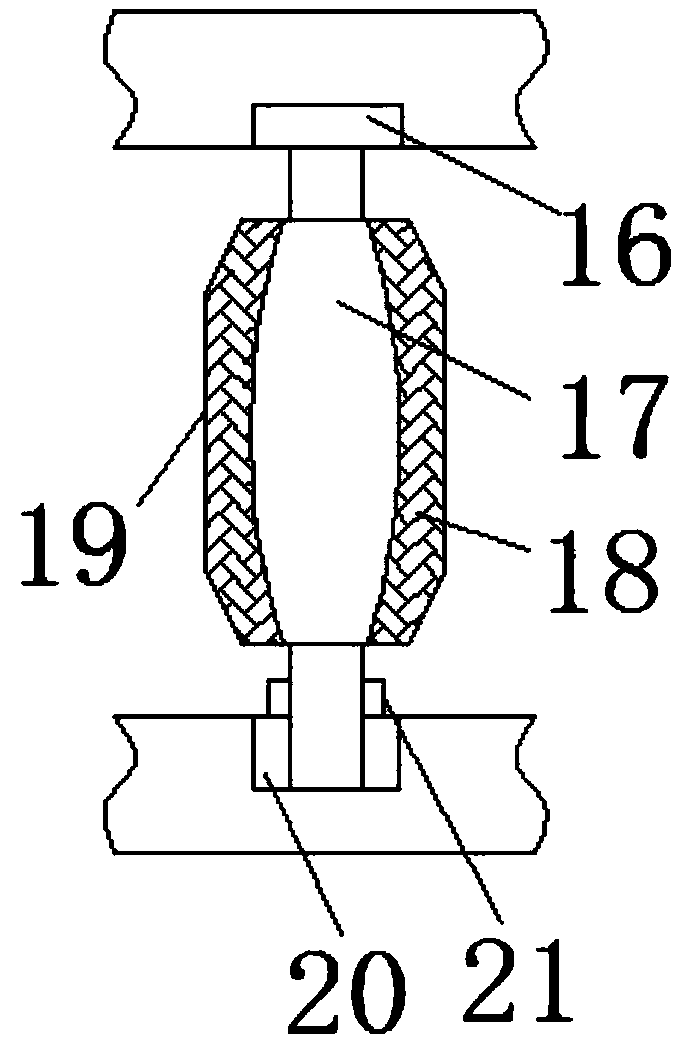

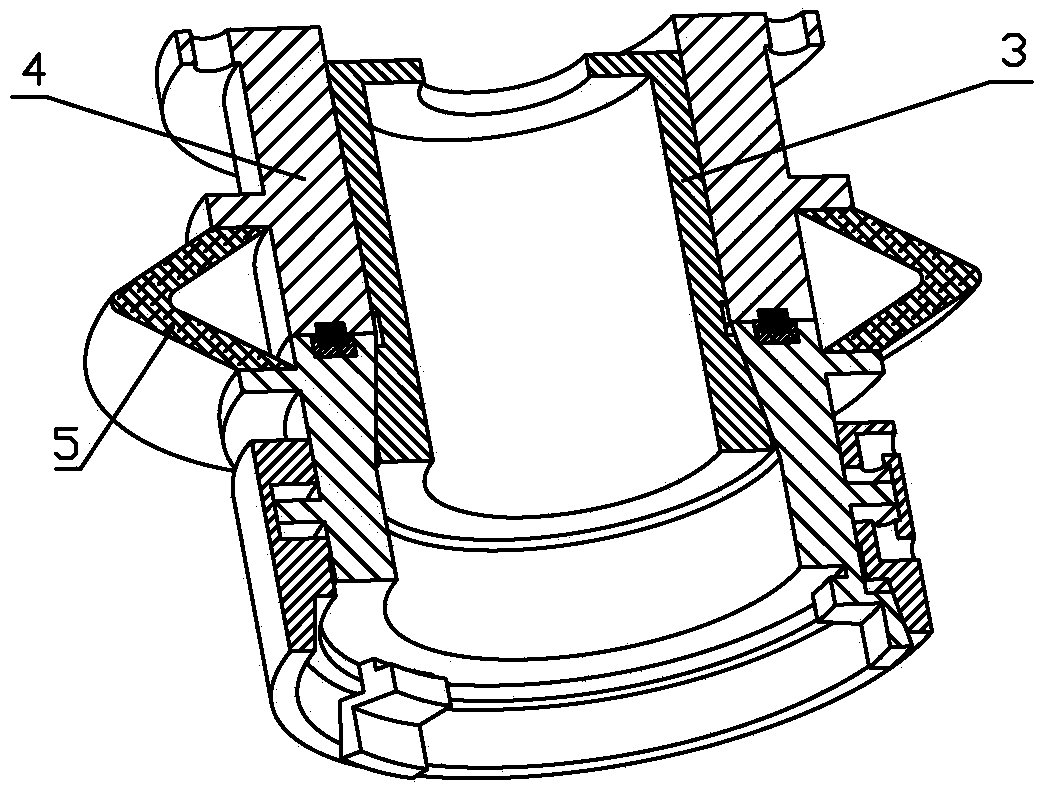

Non-fire-worker-driven two-stage compressing releasing mechanism

ActiveCN108298112AHeavy loadImprove vibration resistanceCosmonautic vehiclesCosmonautic component separationEngineeringDriven element

The invention provides a non-fire-worker-driven two-stage compressing releasing mechanism. Pretightening force applied to the mechanism can be accurately measured by means of strain gages; in the compressing state, a separating cap is limited by upper balls; a releasing pin is clamped by lower balls; the positions of the upper balls are determined by the separating cap, an upper retainer and the releasing pin; the positions of the lower balls are determined by the releasing pin, a sliding block and a lower retainer; and the sliding block is compressed by an anti-impact spring. During releasing, a non-fire-worker-driven element is powered on to start working to drive the sliding block to upwards move, after the sliding block upwards moves by a certain distance, the lower balls enter a groove of the sliding block, the releasing pin is unclamped and moves downwards under the effect of a driving spring, then the upper balls are unrestrained and fall into a groove of the releasing pin, theseparating cap is separated, and thus releasing is completed. In this mechanism, a plurality of spherical pairs are adopted, the influence of moment transferring on the part cooperation relationship and the releasing reliability is avoided, and meanwhile the mounting accuracy requirement is reduced; and control is convenient, vibration resistance is high, the borne load is large, and reliability is high.

Owner:北京深空动力科技有限公司

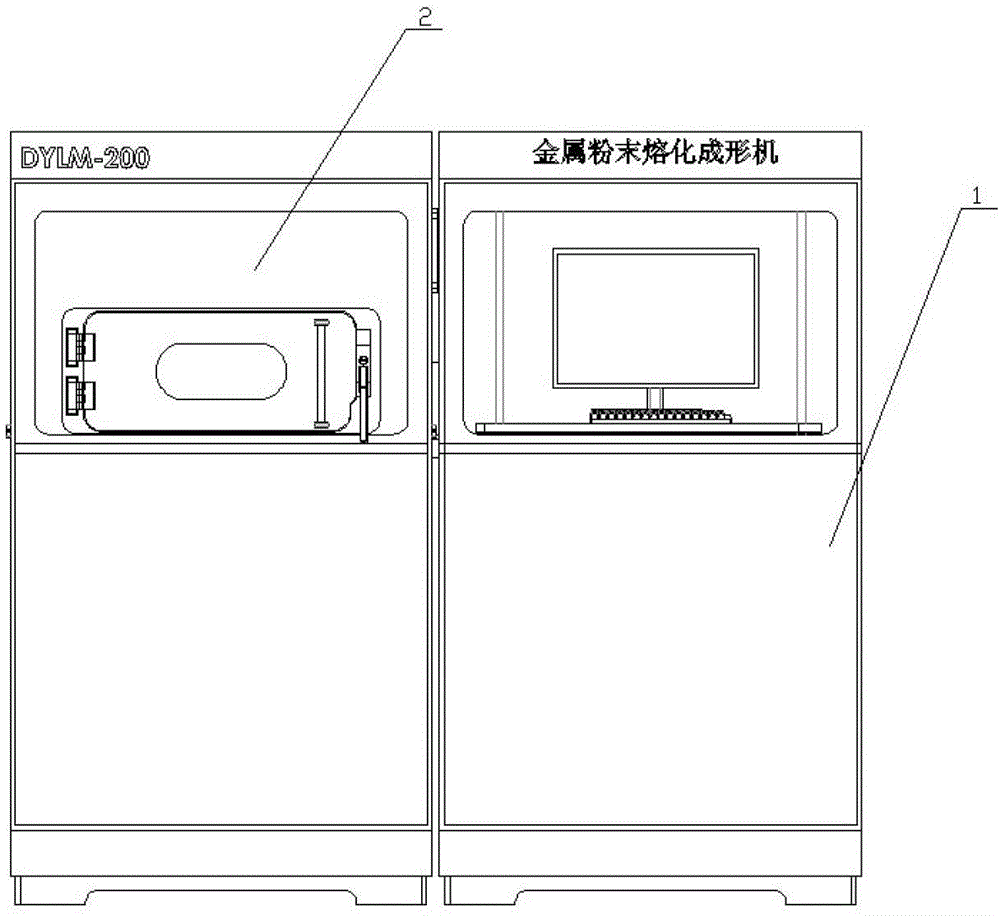

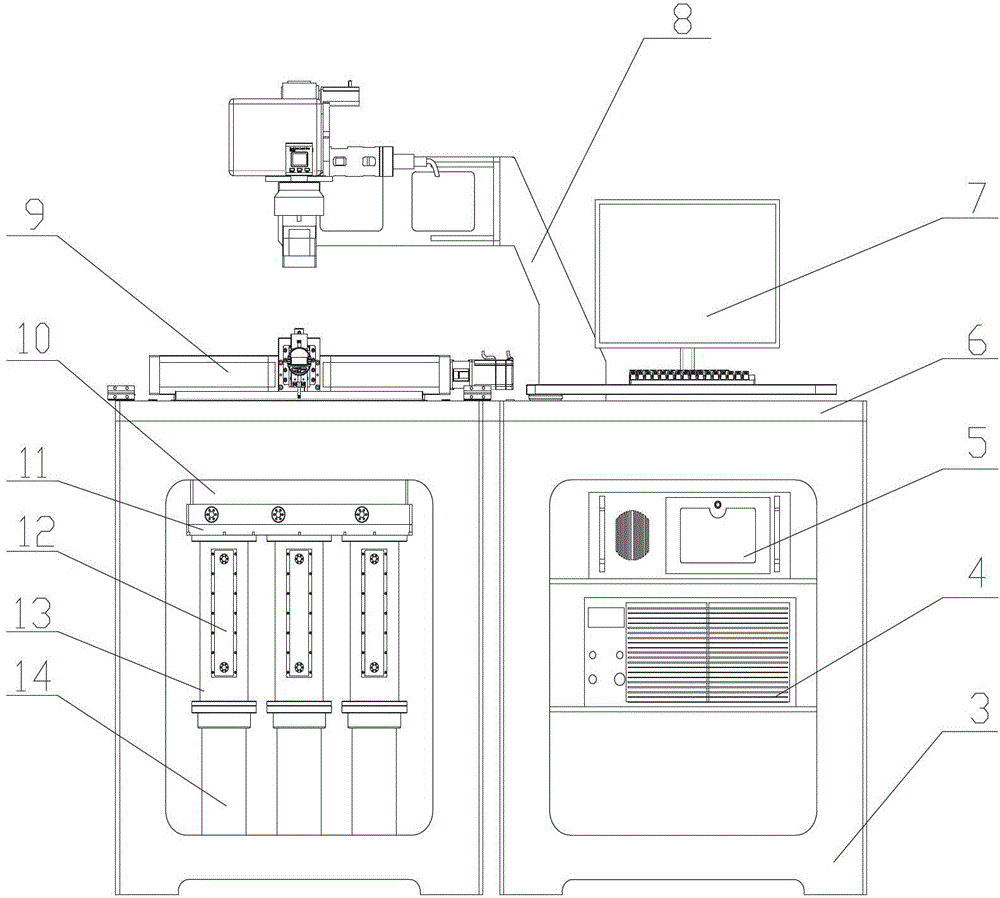

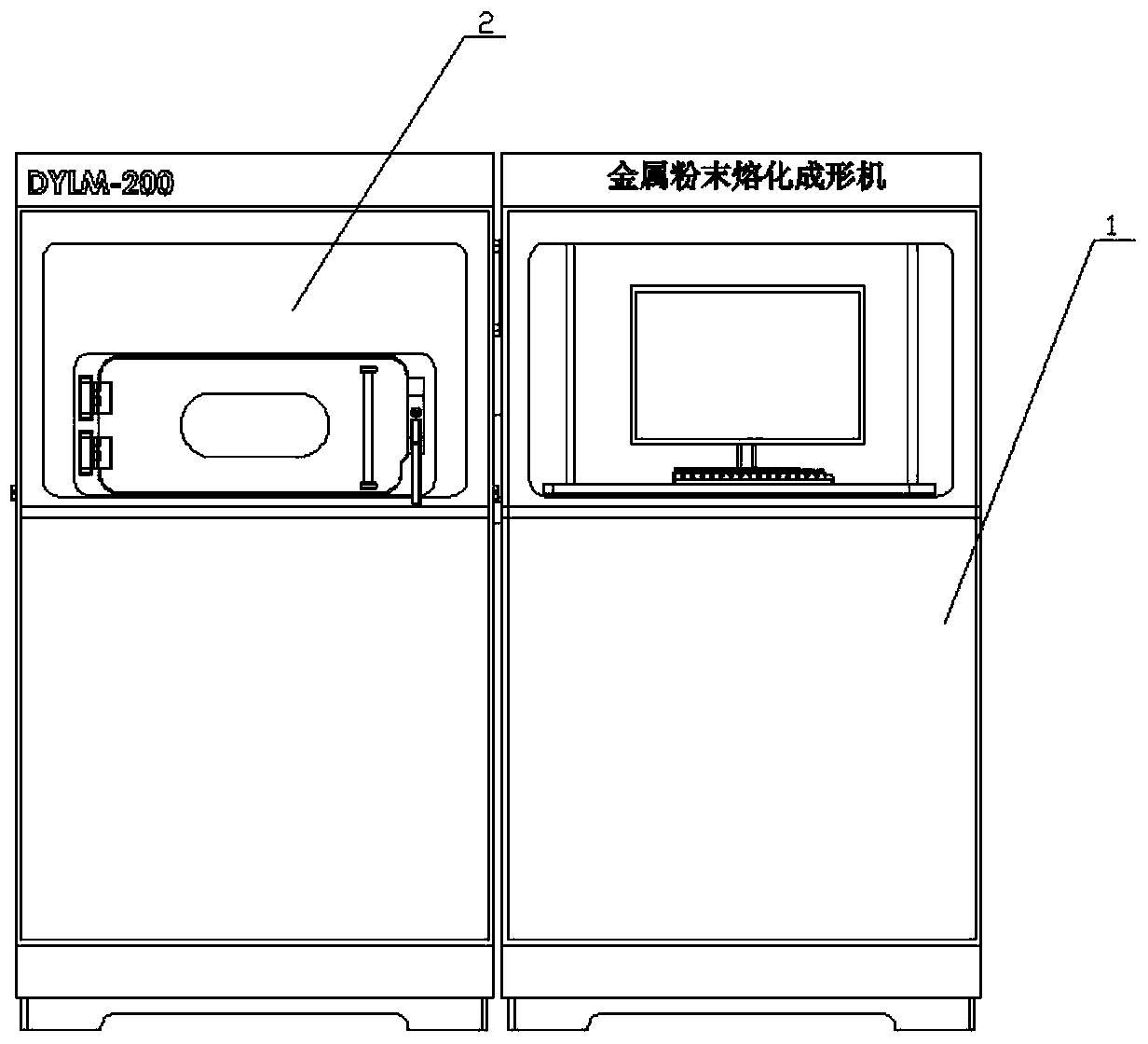

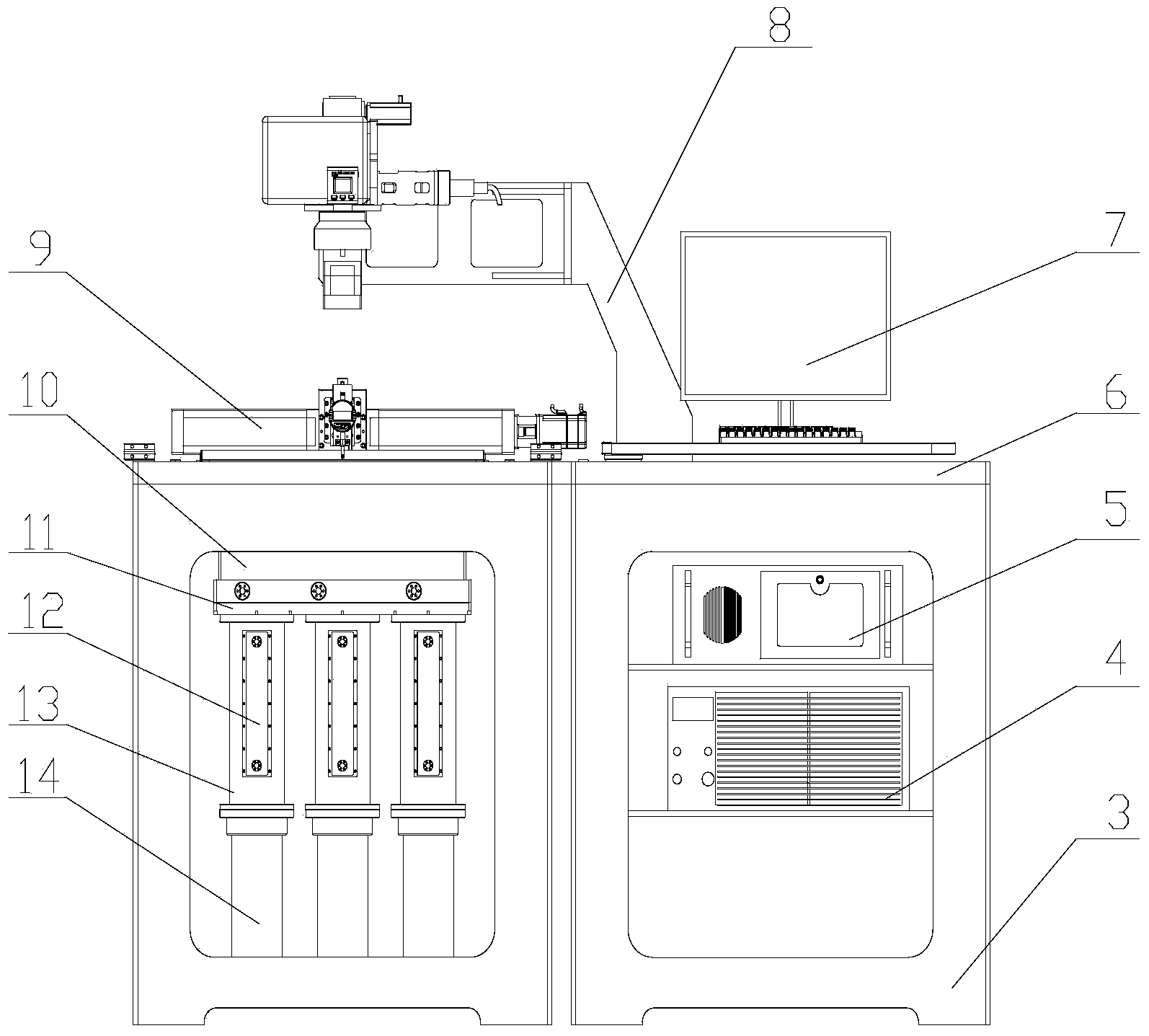

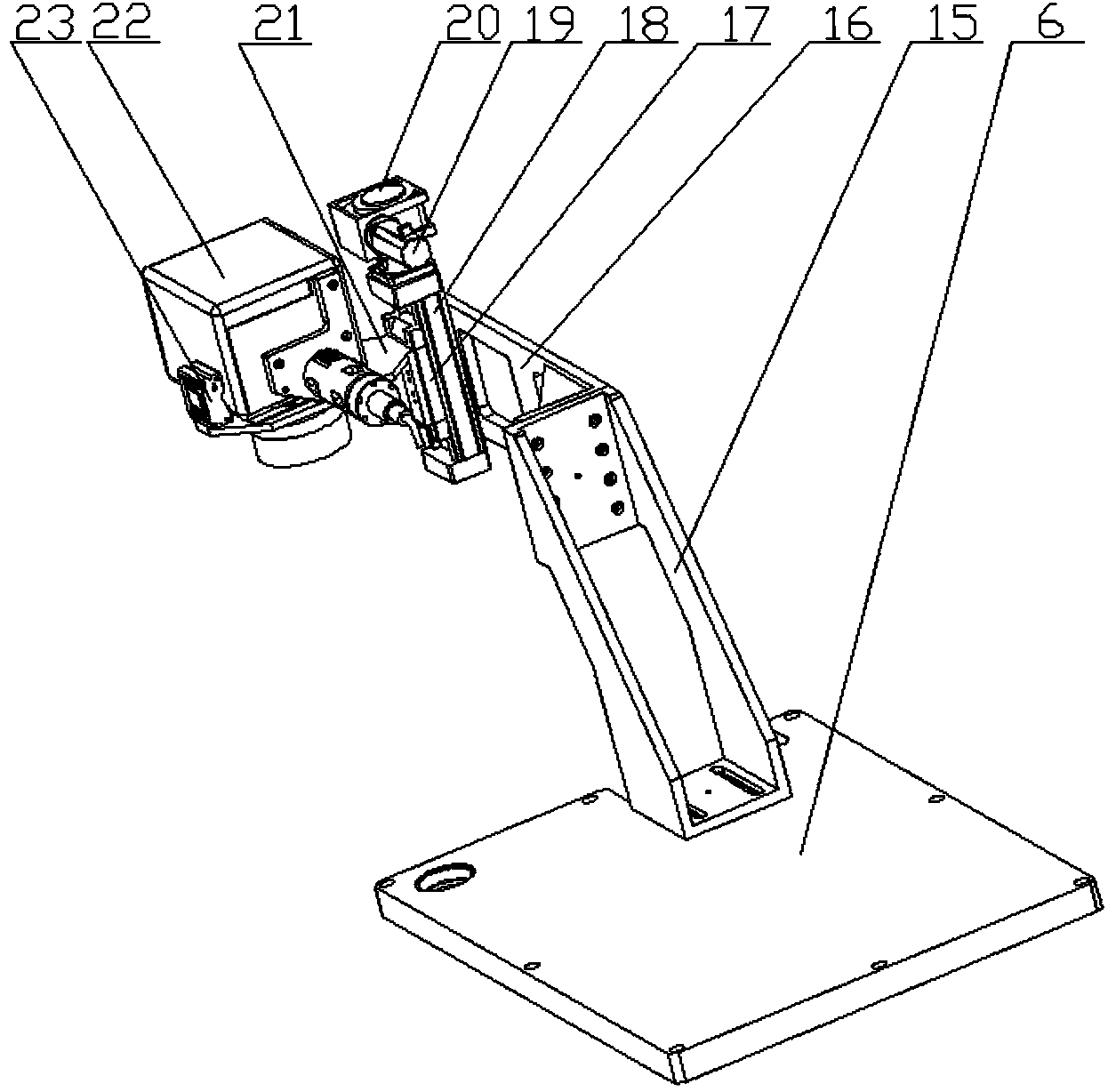

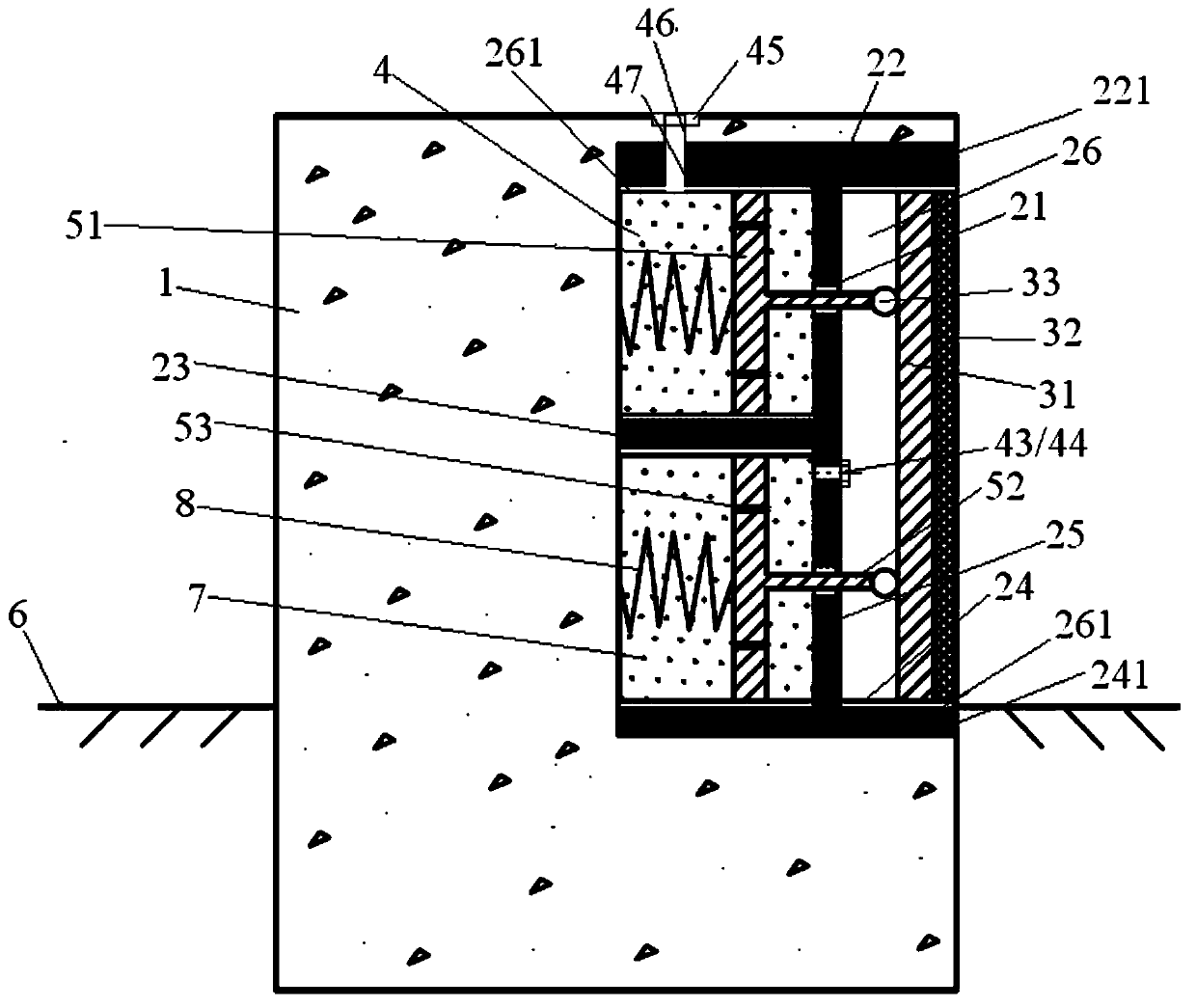

Novel metal powder melting and quick forming machine

InactiveCN103143707ASave processing time and costsShorten the development cycleGalvanometerAerospace

The invention relates to a novel metal powder melting and quick forming machine which comprises a frame, a control system, a laser galvanometer scanning device, a powder laying device, a three-cylinder body and a laser, wherein the control system, the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all arranged on the frame, the laser galvanometer scanning device is in optical connection with the laser, and the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all connected to the control system. The novel metal powder melting and quick forming machine has the advantages that a nonequilibrium supersaturated solid solution and uniform and fine metallographic structures can be obtained, the density of a formed part is close to 100%, the mechanical performance is equivalent to that of a forging part, the processing time and cost can be obviously reduced, and the development cycle of a new product is shortened. The novel metal powder melting and quick forming machine greatly adapts to the requirements of quick, individuated and flexible development of the modem manufacturing industry and has a broad application prospect in the manufacturing fields of aviation, aerospace, medicine, molds, weaponry and the like.

Owner:钱波

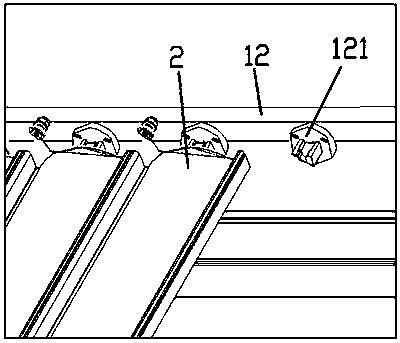

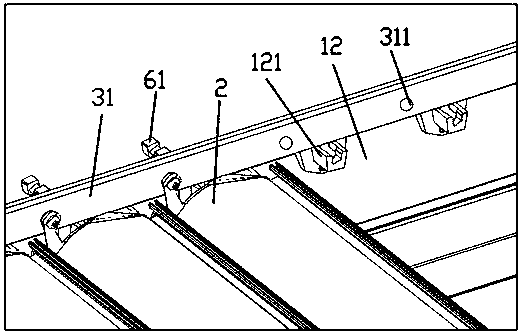

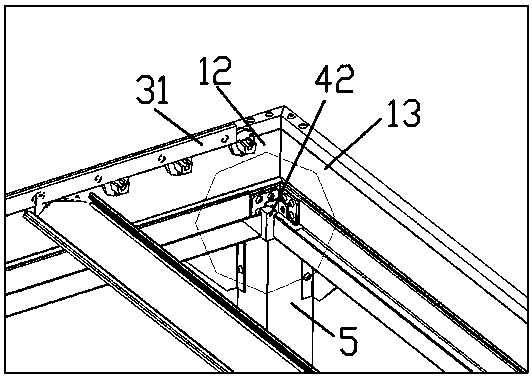

Louver turning-plate awning

PendingCN110043110AFit clearance is smallImprove the problem of water leakage in the gapTents/canopiesSunshadesWater leakageEngineering

The invention discloses a louver turning-plate awning. The louver turning-plate awning comprises a cross beam frame body with a square shape, a plurality of louver turning-plates, a drainage mechanism, a plurality of stand columns, a transmission assembly and a driving device. The louver turning-plates are sequentially arranged in the cross beam frame body, and the louver turning-plates are transmitted through the transmission assembly, and the louver turning-plates can rotate synchronously through the driving device, so that the louver turning-plate awning has the advantages of neat opening and closing, simple structure and convenient control. The louver turning-plates are closely matched, so that the problem of water leakage in gaps between the louver turning-plates is solved; and in addition, due to the arrangement of the drainage mechanism, rainwater falling into the louver turning-plates can be discharged to the outside in rainy weather, and adverse situations of water seepage andside leakage cannot occur in the drainage process, so that a good rain-proof drainage effect is achieved.

Owner:广东格绿朗节能科技有限公司

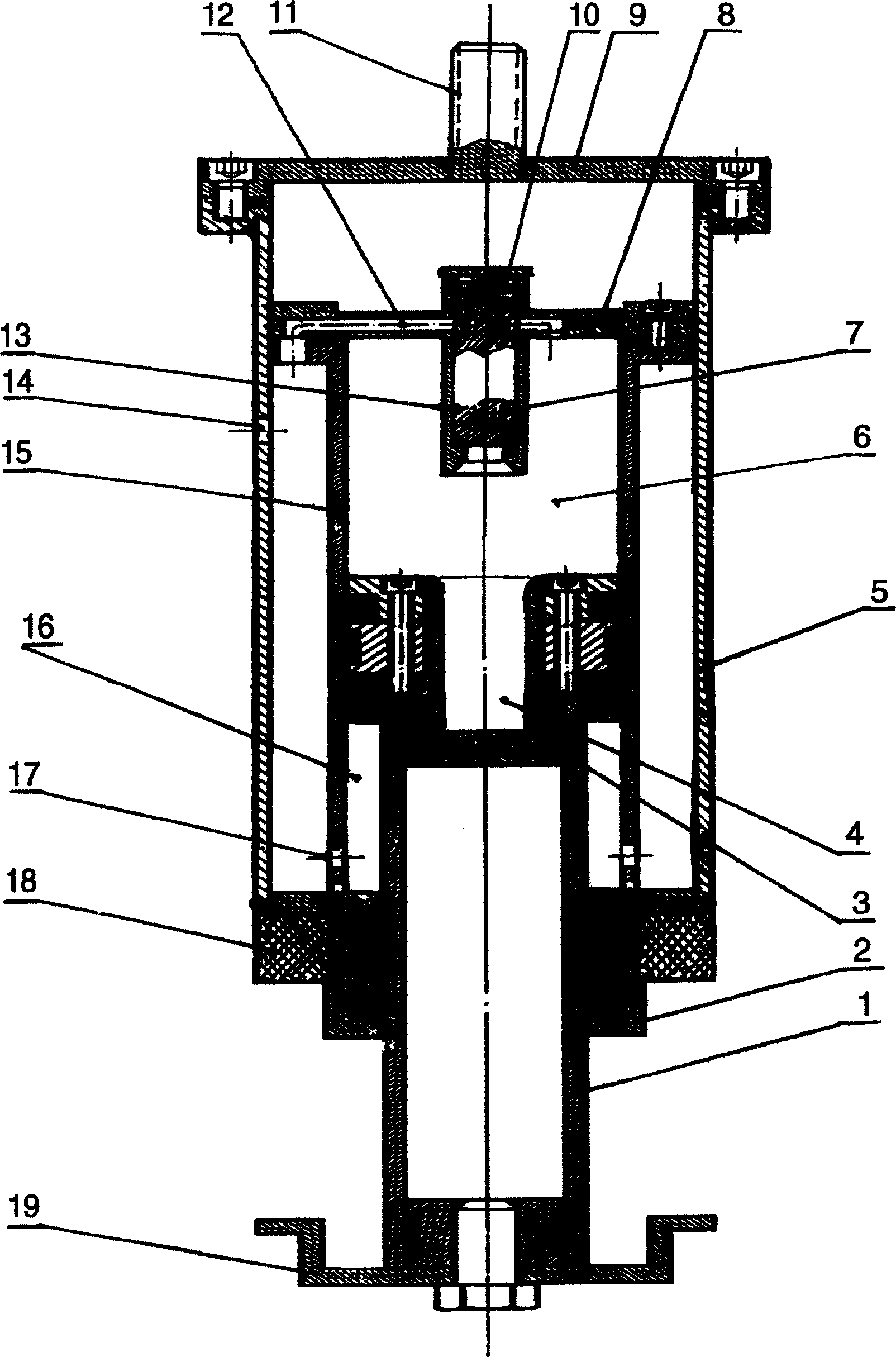

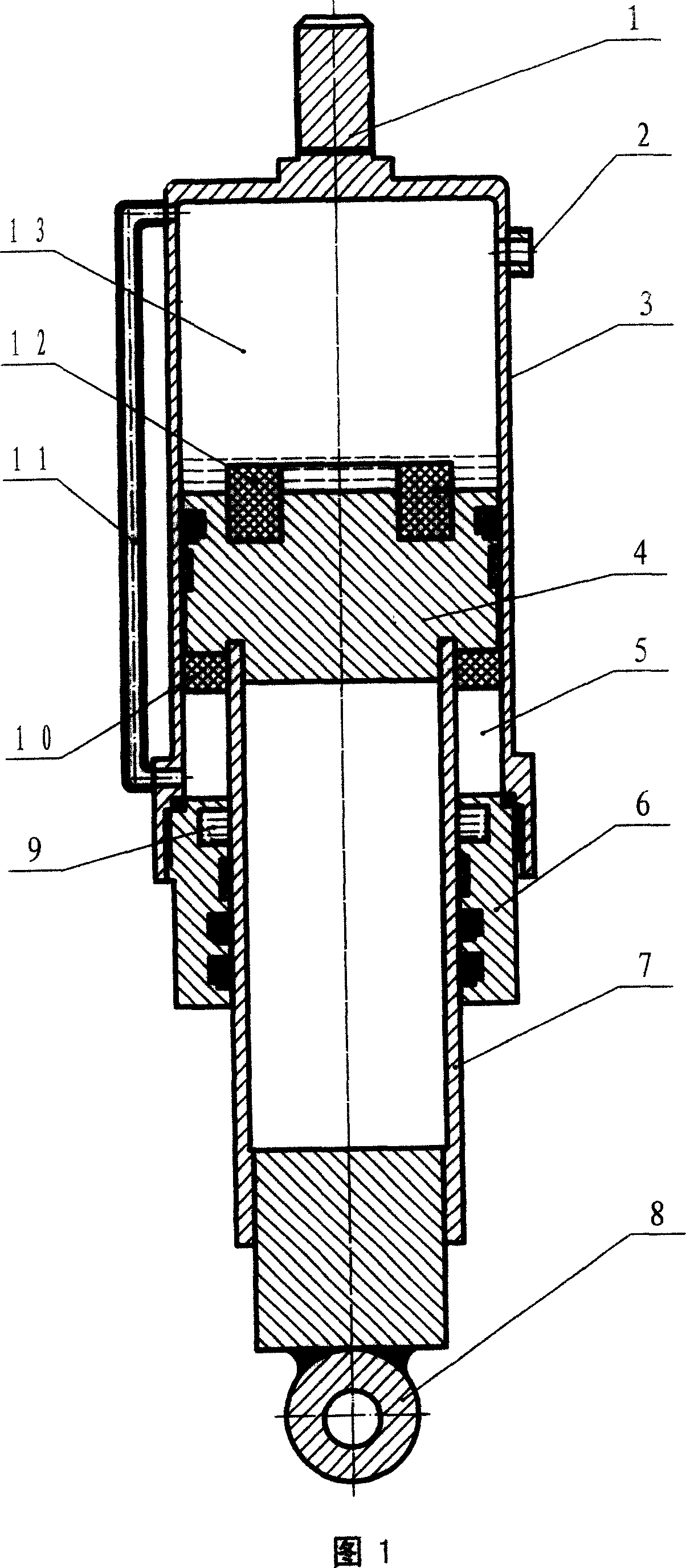

Intelligent gas spring

InactiveCN1858459AHigh sensitivityImproved ride comfort and smooth handlingSpringsGas based dampersCylinder blockAuto regulation

The intelligent gas spring includes a casing, an inner cylinder with cylinder cap and piston to separate the space inside the casing into main gas chamber and subsidiary gas chamber communicated through an on-off gas channel, and a stroke valve installed on the inner cylinder cap to suit with the damping cylinder on the piston. The gas channel may be opened or closed accurately and timely based on the varying road condition so as to regulate the rigidity of the gas spring intelligently to suit for different road condition. The present invention has excellent shock absorbing performance to make the automobile possess high riding comfort and excellent operation stability, and may be installed widely in various kinds of automobile.

Owner:SICHUAN LIDI VEHICLE CHASSIS TECH CO LTD

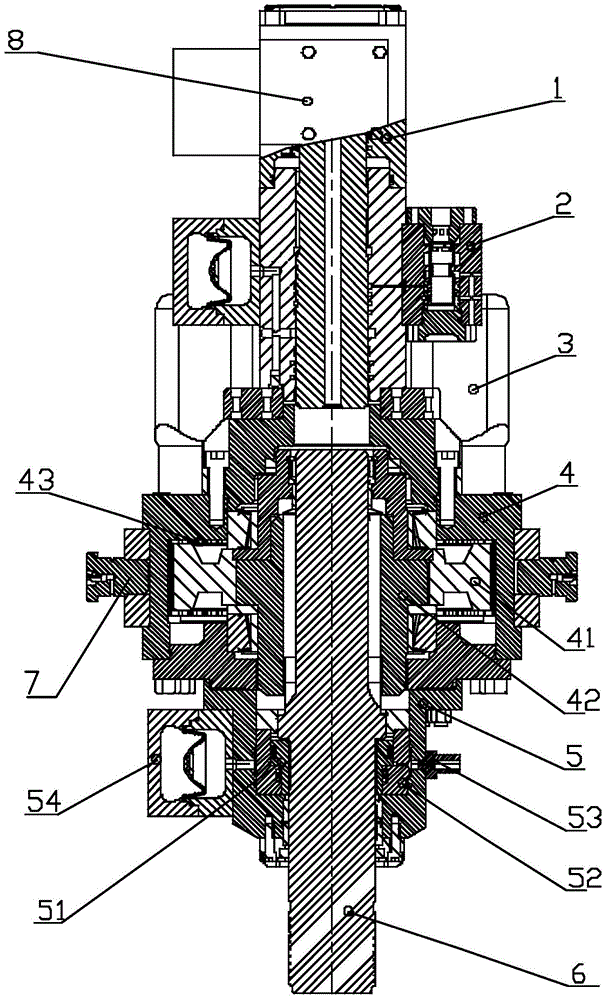

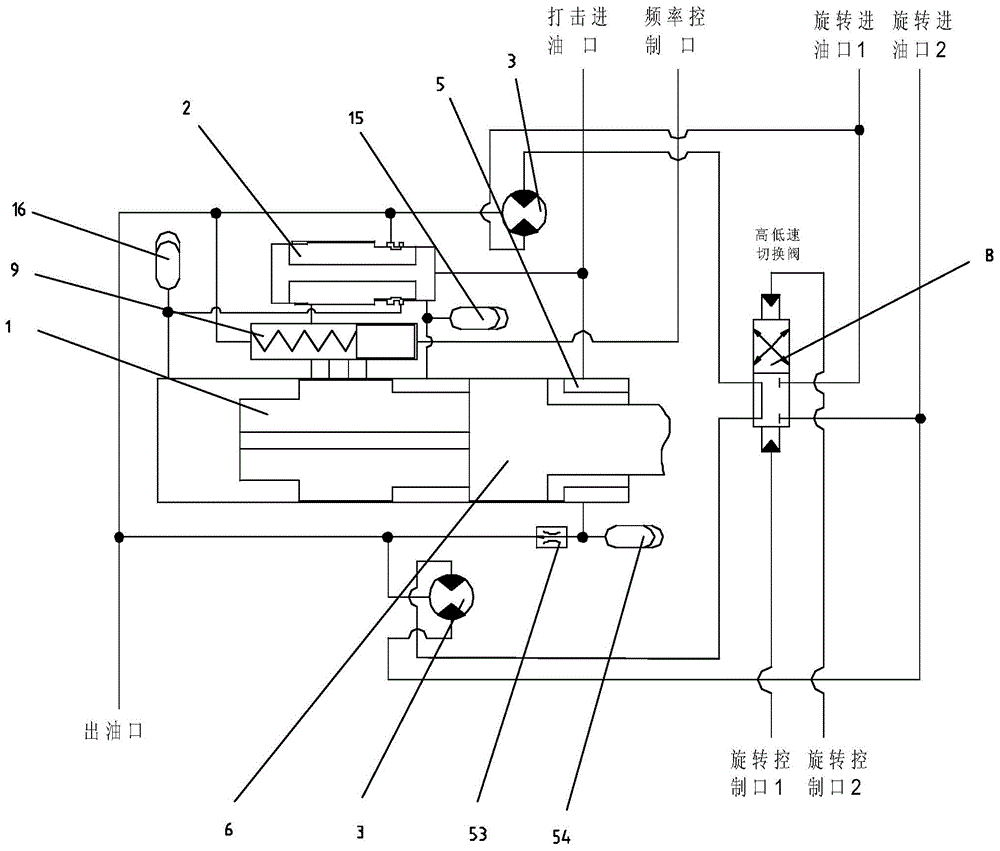

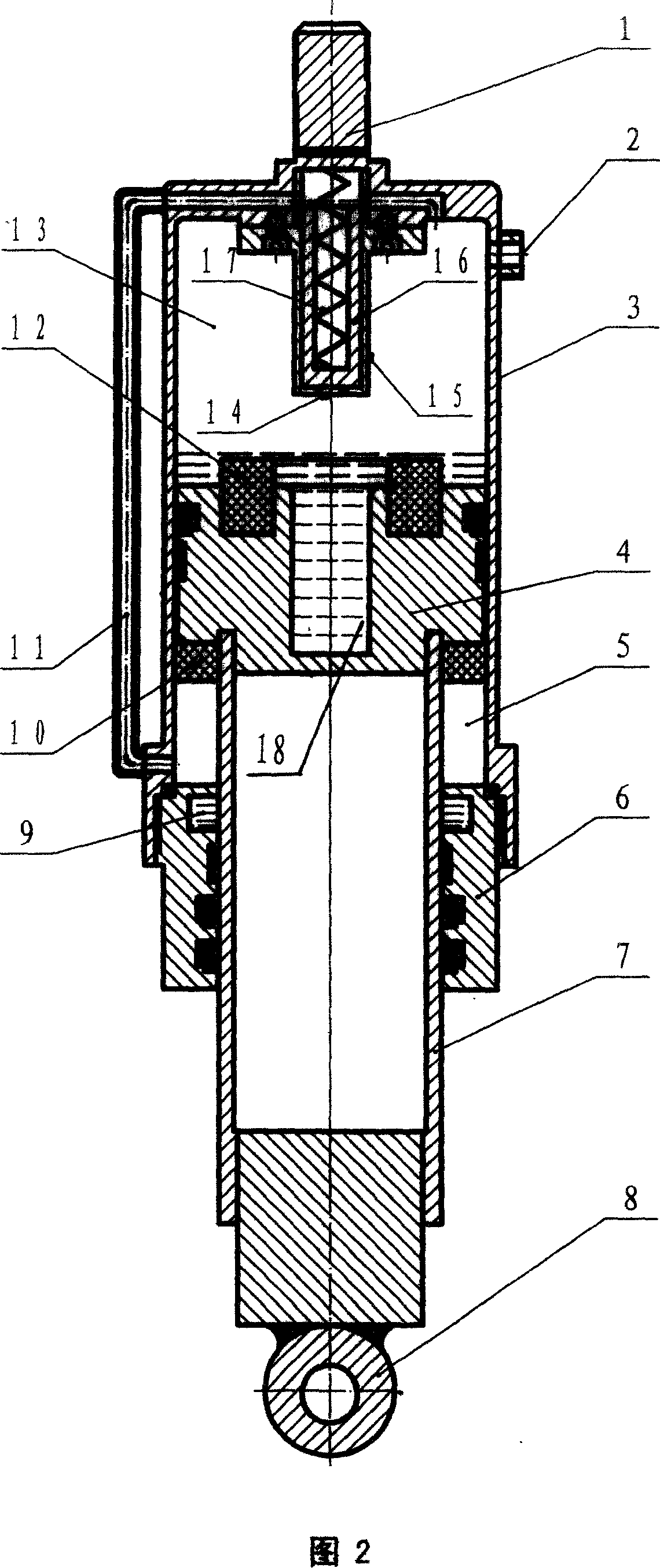

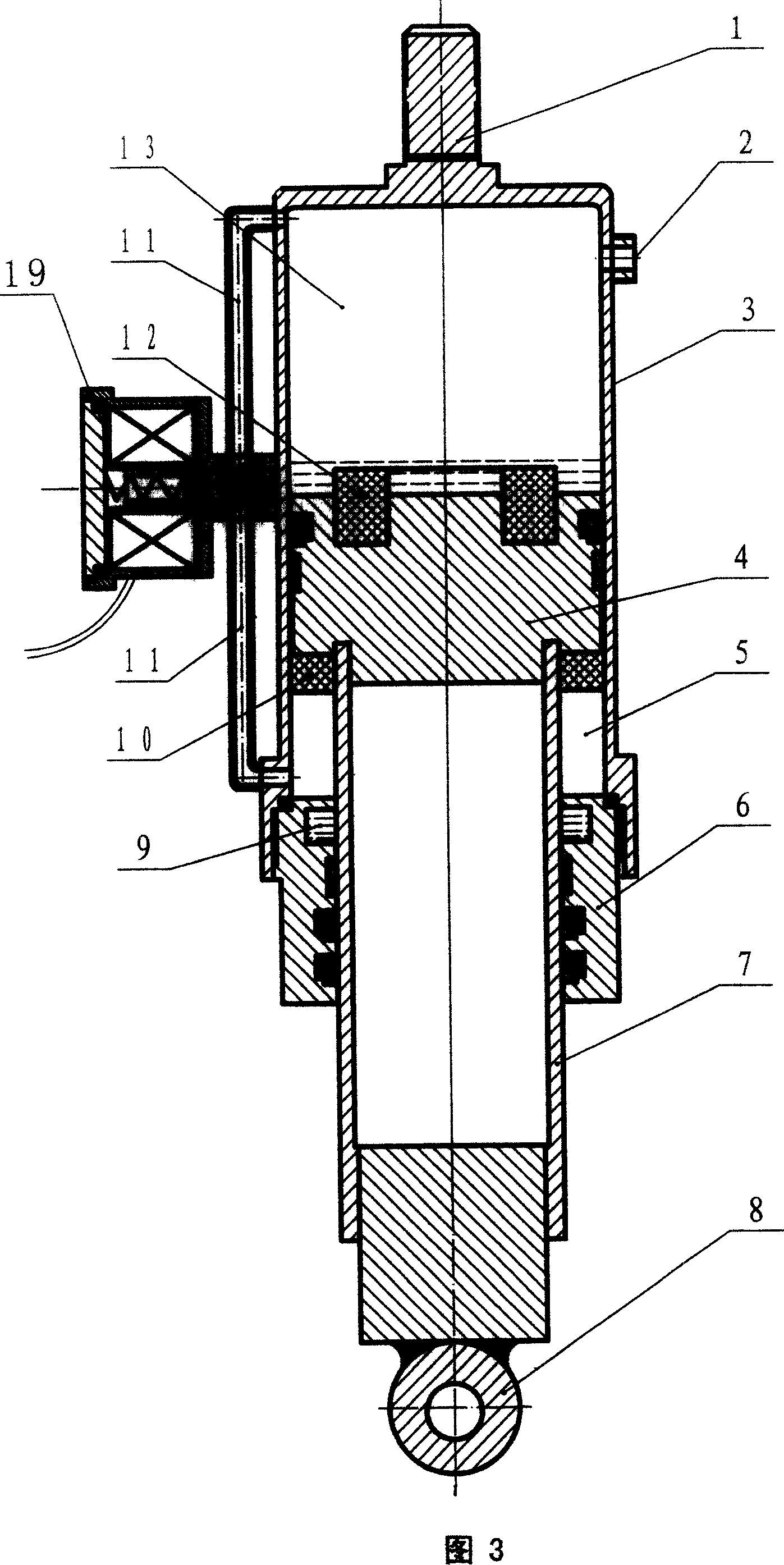

Top hammer type impact rotary power head of hydraulic drilling machine

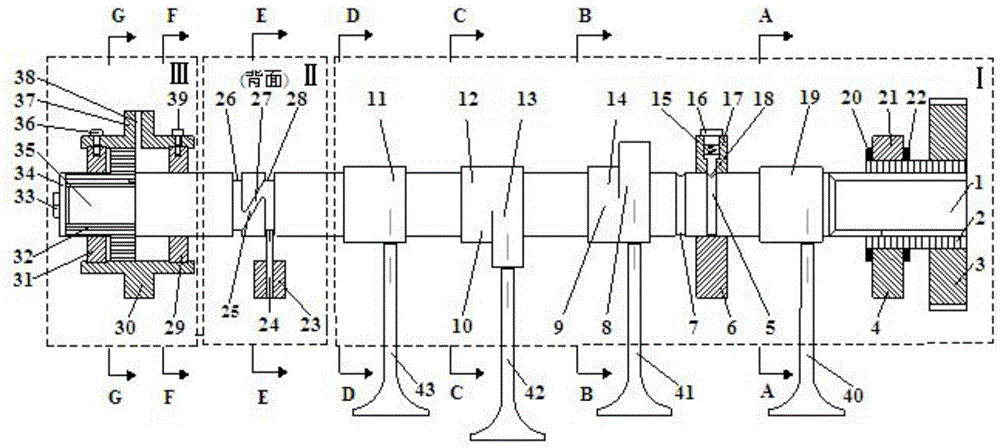

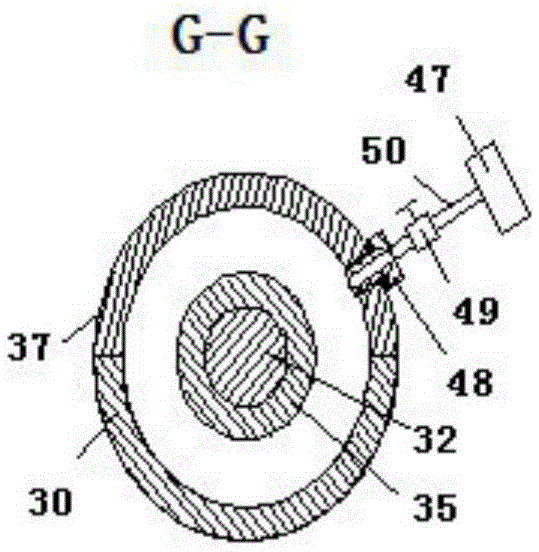

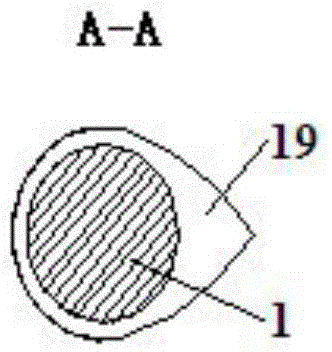

The invention provides a top hammer type impact rotary power head of a hydraulic drilling machine. The top hammer type impact rotary power head comprises an impact mechanism and a rotary mechanism. The impact mechanism comprises a striking set, a frequency set and a limiting set. The rotary mechanism comprises a rotary set, a reverse striking set, a spline shaft and a reverse striking buffer. The limiting set is connected with the striking set and the frequency set through oil ways. The limiting set controls a piston of the striking set to move, and the frequency set is connected with the striking set and controls the striking frequency of the piston of the striking set. The top hammer type impact rotary power head has the advantages of being simple in structure, high in impacting frequency, large in impact power, wide in application range, long in service life and the like. The top hammer type impact rotary power head can be applied to the hydraulic anchor rod drilling machine, and the impact rotary drilling method is one of the best choices for rock anchoring engineering in which a great number of broken rocks and layers of sand and gravel exist.

Owner:长沙天和钻具机械有限公司

Gas spring

InactiveCN1975194AAvoid Rigid CollisionsTimely opening and closingSpringsGas based dampersMobile vehicleAuto regulation

There is disclosed a gas springs, in which a closed air compression system made up of a damping air passage is disposed between main and secondary elastic air cavities formed by separating the cylinder body via the piston. By using the damping force action of the damping air passage on the medium, there is unequal gas pressure in the main and secondary air cavities. When the piston up and down moves under the action of the external force, i.e., the gas spring is expressed externally as compression or extension, it can automatically regulate its rigid change to balance the action adapted to external force.

Owner:杨德君

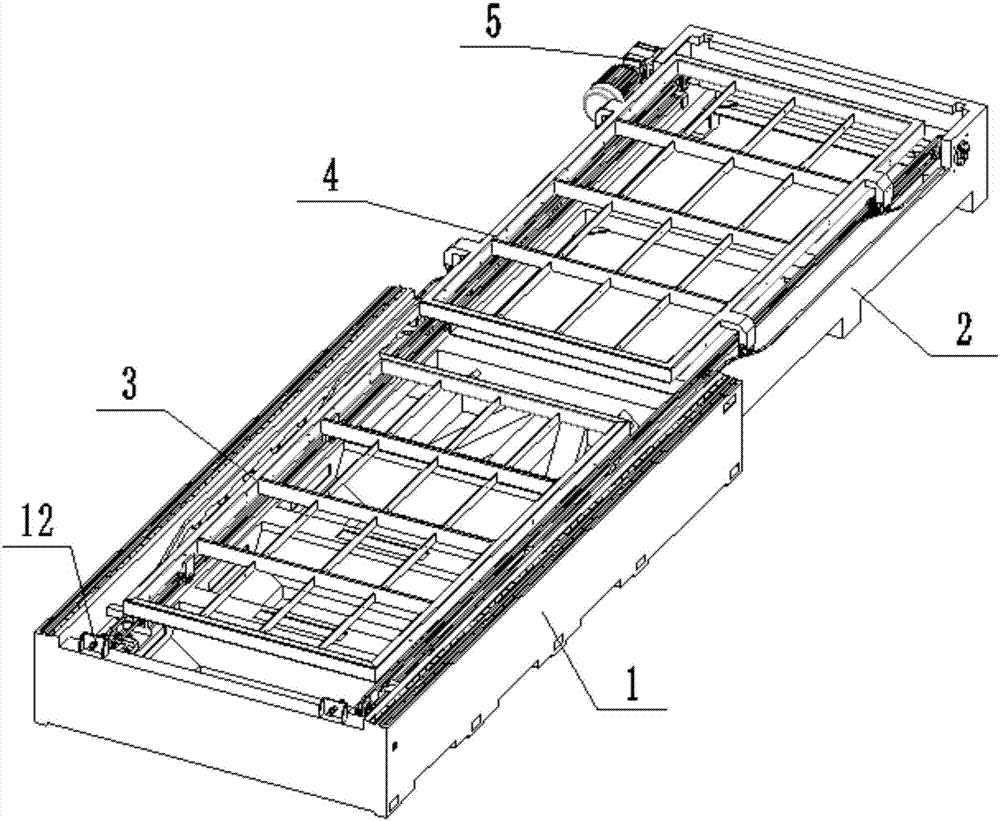

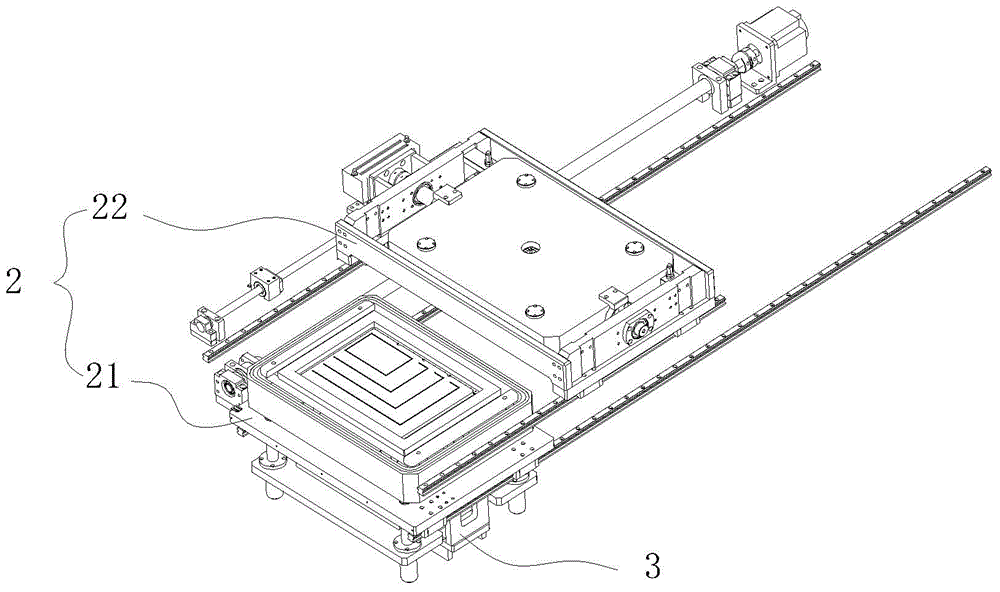

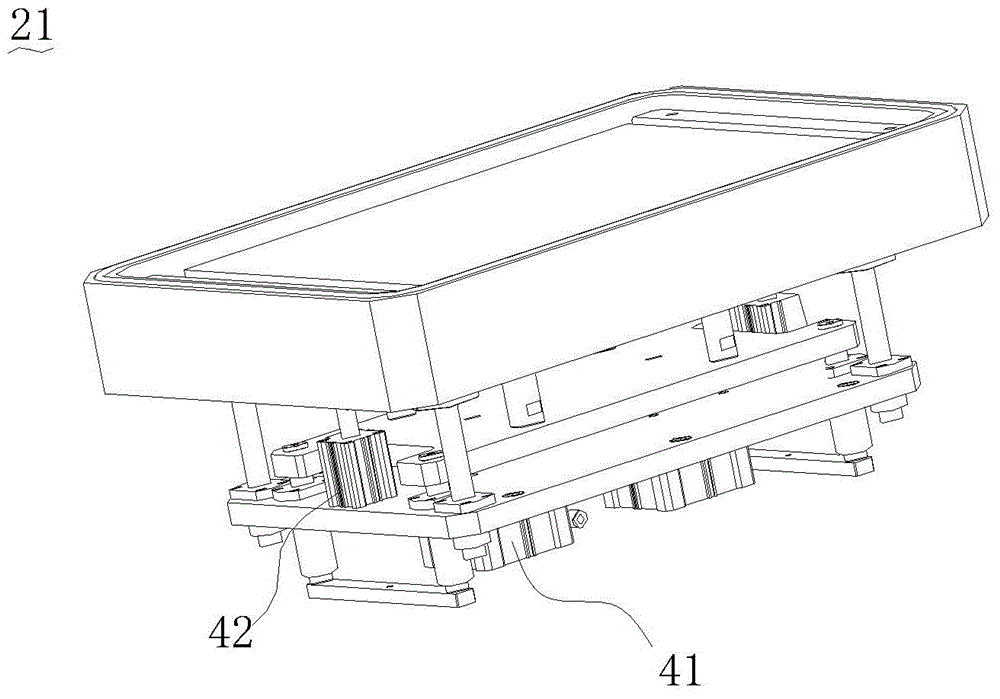

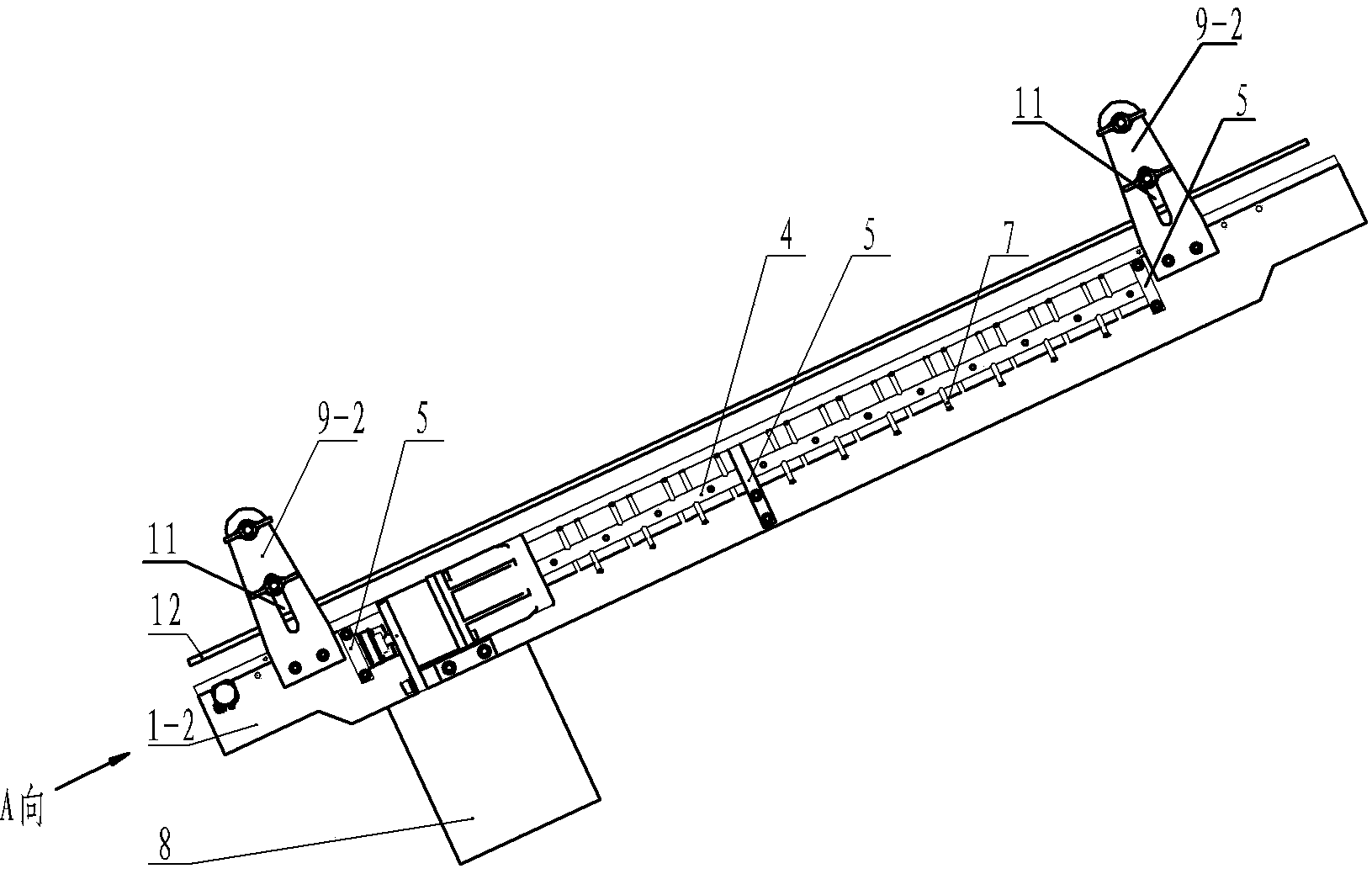

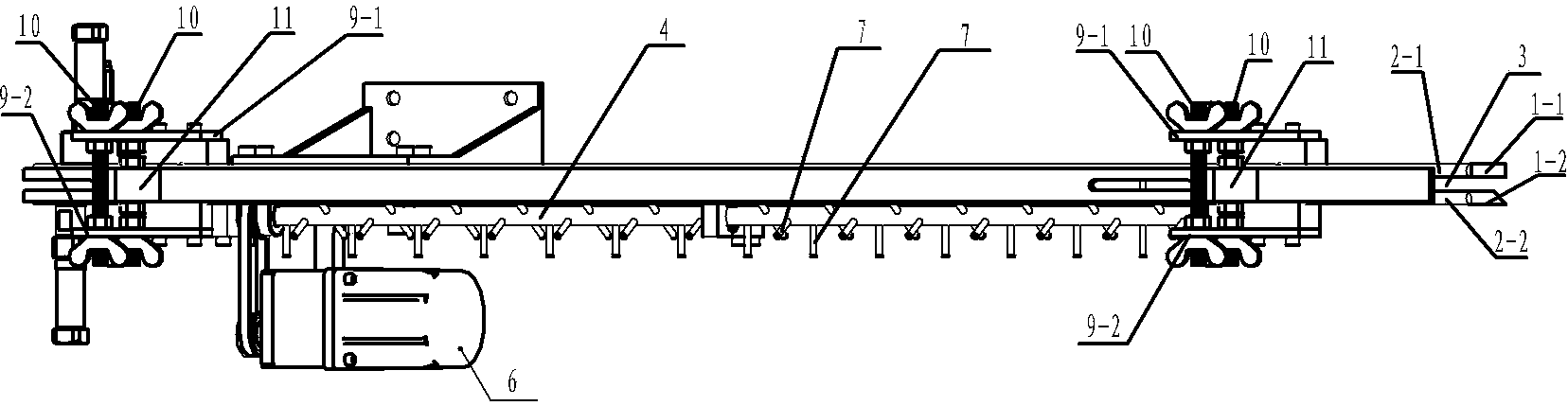

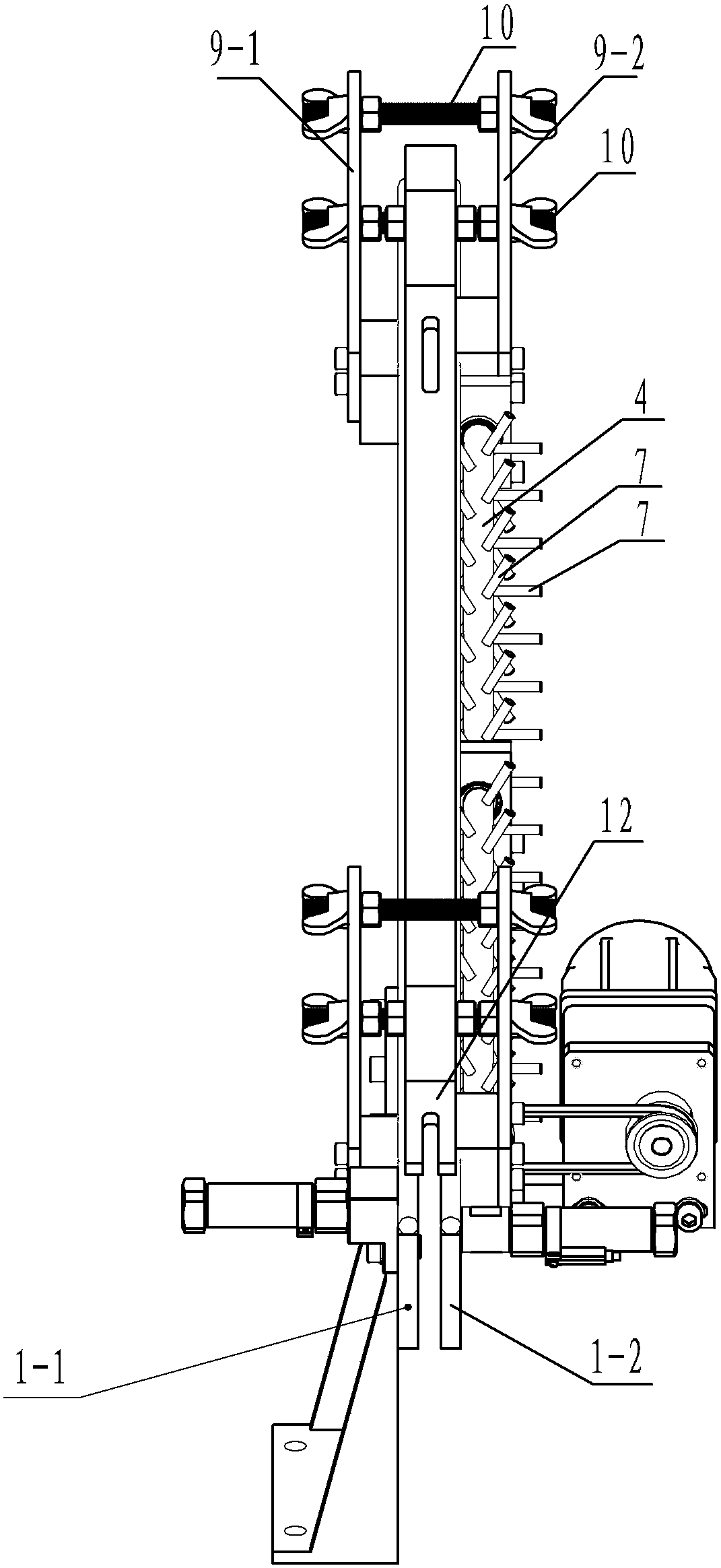

Double-worktable-exchange device of laser cutting machine

ActiveCN106862781AAvoid interferenceImplement the swap operationLaser beam welding apparatusManufacturing cost reductionEngineering

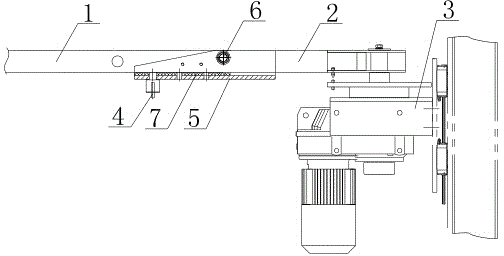

The invention discloses a double-worktable-exchange device of a laser cutting machine, and belongs to the technical field of laser cutting machines. The double-worktable-exchange device comprises a first worktable and a second worktable, wherein the first worktable and the second worktable are arranged on a worktable rail of a lathe bed, and position exchange of the two worktables is achieved through driving of a chain transmission mechanism. The worktable guide rail is divided into a lifting worktable outer guide rail with the middle high and the two ends low, a lifting worktable inner guide rail with the middle high and the two ends low, and a linear horizontal movement worktable guide rail, wherein transition of each middle high section and the corresponding low sections at the two ends is achieved through inclined sections. Two front side wheels at one end of the second worktable are arranged on the lifting worktable outer guide rail, and two rear side wheels at the other end of the second worktable are arranged on the lifting worktable inner guide rail. The first worktable is arranged on the horizontal movement worktable guide rail. The device does not need to be provided with a lifting mechanism, exchange between the two worktables can be completed by only reasonably designing the guide rails where the worktables operate, the structure is greatly simplified, the manufacture cost is reduced, and the double-worktable-exchange device has the beneficial effects of being convenient to operate and easy to maintain.

Owner:佛山汇百盛激光科技有限公司

Road protective fence for municipal engineering

InactiveCN108797460ADisperse impactAvoid Rigid CollisionsRoadway safety arrangementsArchitectural engineering

The invention discloses a road protective fence for municipal engineering. The road protective fence comprises a lower crossbeam. One end of the lower crossbeam is connected with first vertical columns. The other end of the lower crossbeam is fixed to second vertical columns. The inner sides of the top ends of the second vertical columns and the first vertical columns are connected through an upper crossbeam. Connecting pieces are arranged at the two ends of the upper crossbeam. Sliding sleeves are arranged at one ends of the connecting pieces and arranged at the peripheries of bosses in a sleeving mode. The bosses are integrally formed at the tops of the first vertical columns and the second vertical columns. The top ends of the bosses are wrapped with rubber sleeves. The peripheries of the middles of the first vertical columns and the second vertical columns are movably connected with first rotating barrels. An anti-collision net is fixed between the upper crossbeam and the lower crossbeam. According to the road protective fence, the first rotating barrels and second rotating barrels are arranged, thus when a vehicle accidentally hits against the protective fence, a vehicle bodymoves after making contact with the first rotating barrels and the second rotating barrels, part of impact force is dispersed, rigid collision with hard objects is avoided, the damage extent is small,and safety is high.

Owner:芜湖等莱智能科技有限公司

Robot for clearing dung in pig house

PendingCN109997704ARealize fully automatic cleaning methodImprove environmental conditionsAnimal housingPig farmsEnvironmental hygiene

The invention provides a robot for clearing dung in a pig house, belongs to the field of mechatronic intelligent equipment for animal husbandry, and particularly relates to the robot for clearing dungin the pig house. The robot comprises a robot body, a moving mechanism, an execution mechanism, a navigation mechanism and a control mechanism. The robot is mainly used for clearing dung in the pig house, and problems of difficulty in pig house cleaning, poor environmental sanitation, high water source wastage and high labor cost in large-scale pig farms are solved.

Owner:哈尔滨天河自动化设备有限公司

Laminating equipment

ActiveCN104691077AAvoid Rigid CollisionsAvoid structural damageLaminationLamination apparatusEngineeringElectrical and Electronics engineering

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

Steel bar straightening machine

PendingCN109365684AEliminate internal stressImprove straightening effectMetal working apparatusSteel barMultiple point

The invention discloses a steel bar straightening machine. The steel bar straightening machine straightening cylinder and a plurality of inclined rolling wheels which are arranged in the straighteningcylinder and are used for eliminating internal stress of a steel bar, the multiple inclined rolling wheels are arranged on the two radial sides of the steel bar in a staggered mode, the axis of the inclined rolling wheels is arranged at an angle with the axis of the straightening cylinder, the outer peripheral surfaces of the inclined rolling wheels are provided with hemispherical touch protrusions which protrude outwards in the radial direction of the inclined rolling wheels, the axial middle of the inclined rolling wheels is gradually increased towards the radius of the contact protrusionsat the two ends of the inclined rolling wheels, the contact protrusions distributed on the outer peripheral surfaces of the inclined rolling wheels are externally cut into inwards-concave annular cutting surfaces, and the annular sections are arranged coaxial with the inclined rolling wheels. According to the steel bar straightening machine, the internal stress of the steel bar is eliminated through interaction of multiple points with different friction force and torque; and by correction of the multiple inclined rolling wheels located on the two sides of the steel bar, the stress in the steelbar reaches a stress balance state, and the straightening effect of the steel bar is improved.

Owner:重庆宏扬电力器材有限责任公司

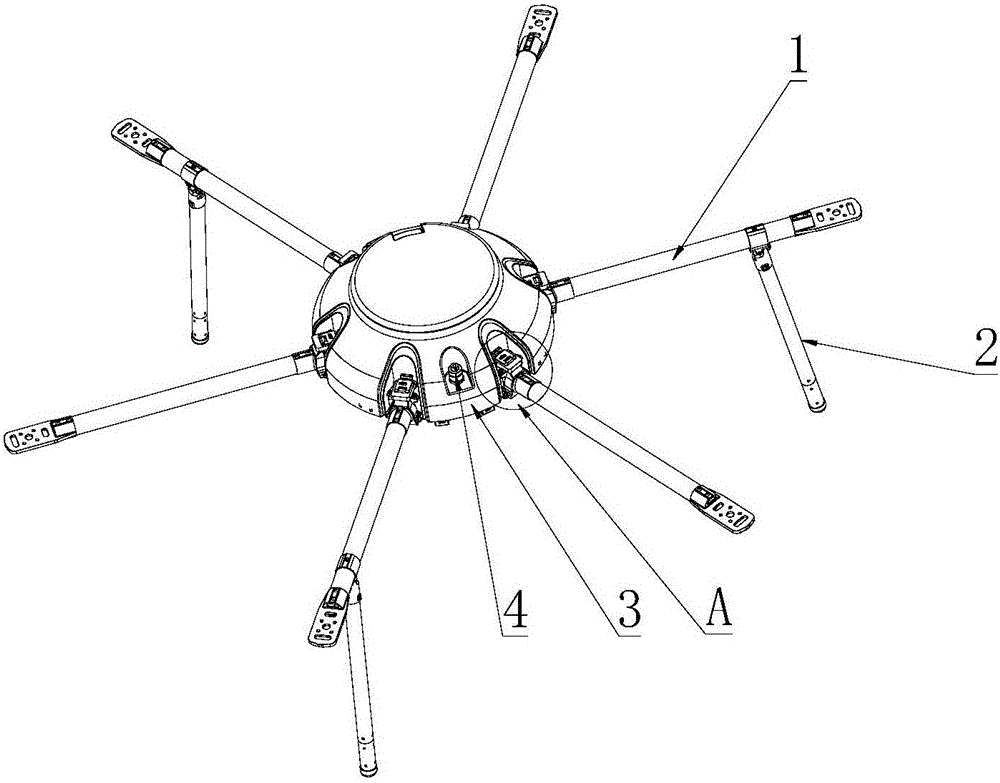

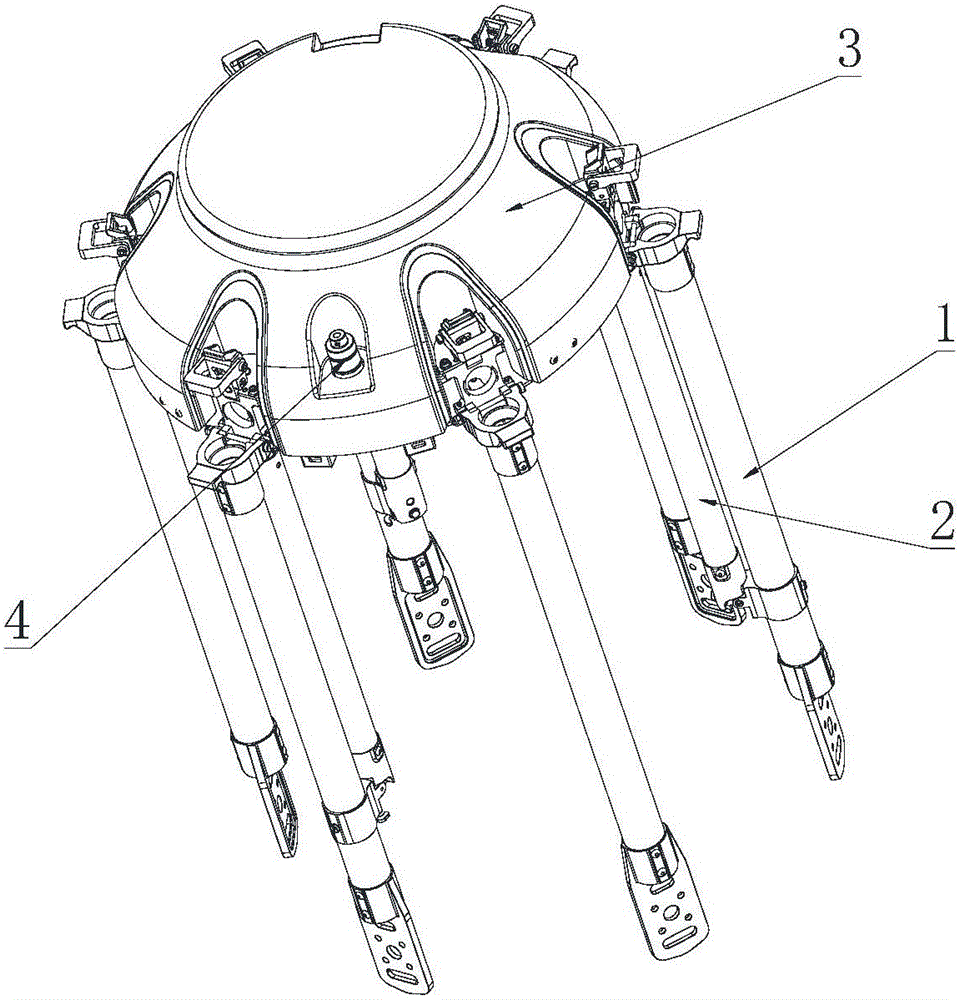

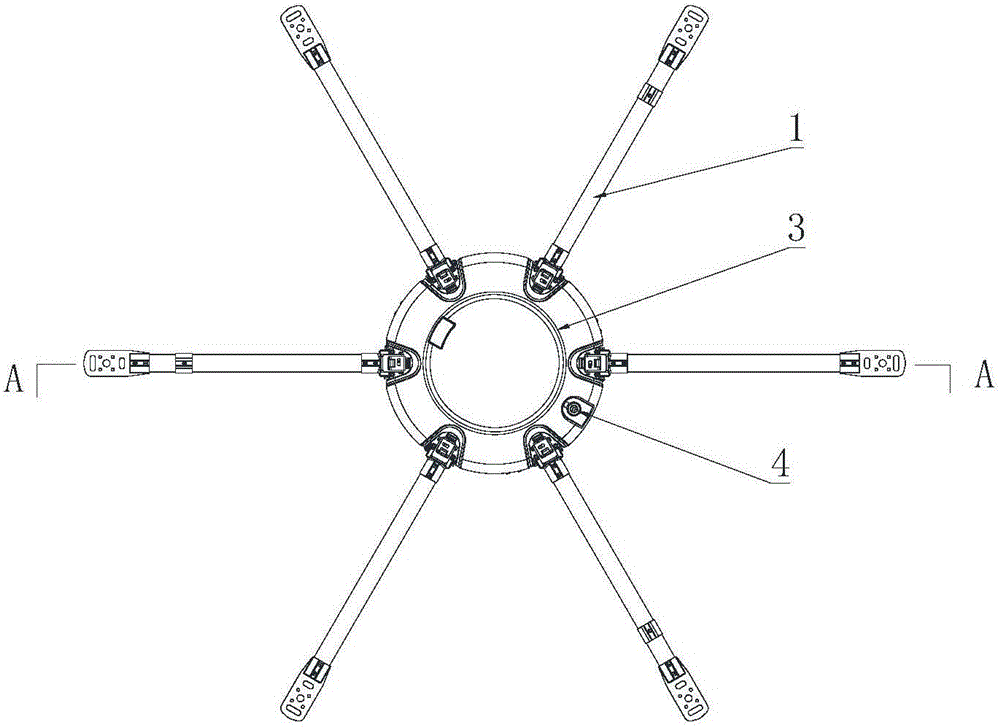

Stable multi-shaft unmanned aerial vehicle

ActiveCN106081057AFirmly connectedConnecting seat, set the arm on the arm for easy foldingFuselagesAir-flow influencersDrive motorFuselage

The invention discloses a stable multi-shaft unmanned aerial vehicle which comprises a vehicle body. A plurality of vehicle arms are arranged on the vehicle body. Drive motors are arranged at the ends, away from the vehicle body, of the vehicle arms correspondingly. Oar blades are arranged on rotary shafts of the drive motors correspondingly. The vehicle arms are connected with the vehicle body through connecting mechanisms. Each connecting mechanism comprises a vehicle arm connecting base and a vehicle arm foldable base, wherein one end of the vehicle arm foldable base is hinged to the vehicle arm connecting base, and a folding mechanism is arranged on the vehicle arm connecting base and movably connected with the other end of the vehicle arm foldable base. Each folding mechanism further comprises an outer handle and an inner handle, wherein one end of the inner handle is hinged to the corresponding vehicle arm connecting base, an outer handle rotary shaft is movably arranged at the other end of the inner handle, one end of the outer handle is hinged to the outer handle rotary shaft, a movable part movably connected with the corresponding vehicle arm foldable base is arranged at the other end of the outer handle, and the inner handle is further provided with a locking mechanism used for locking the inner handle.

Owner:GUANGZHOU REDBIRD HELICOPTER REMOTE SENSING TECH

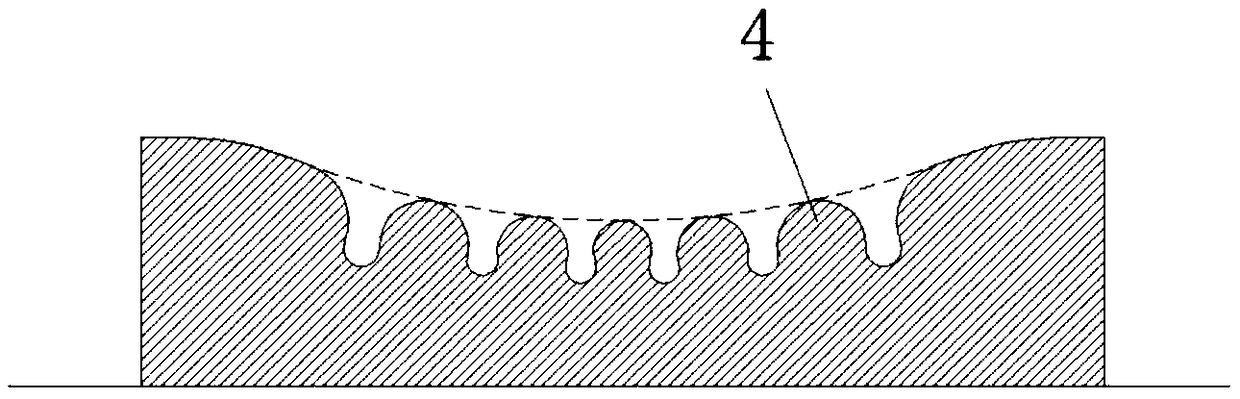

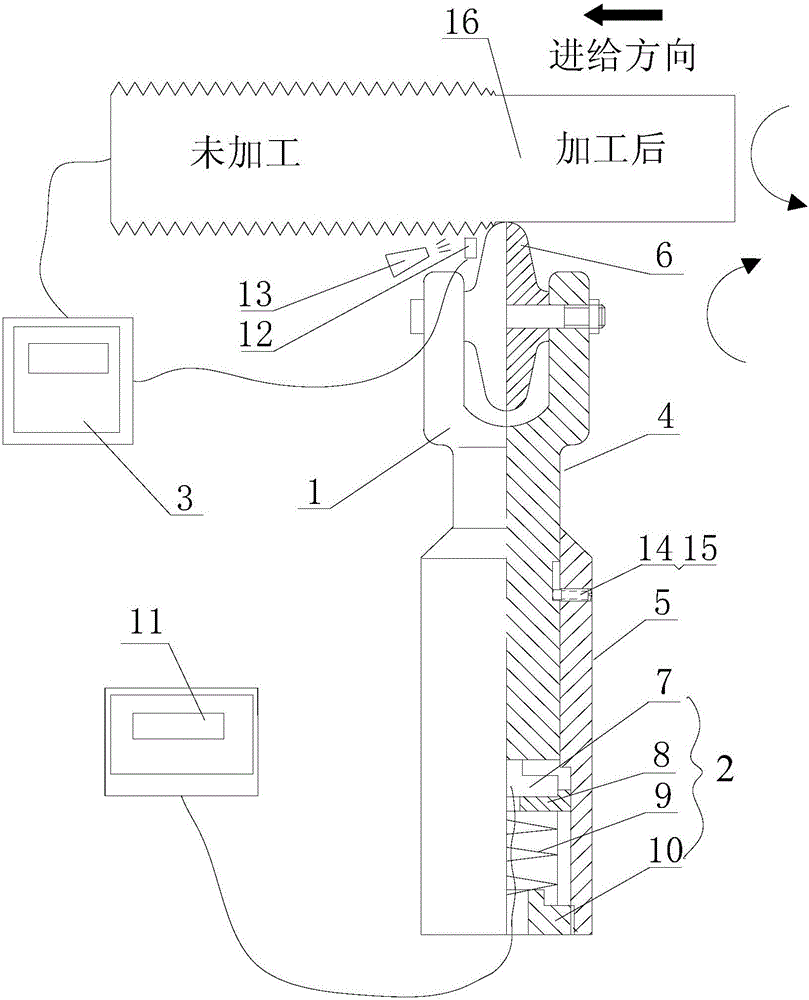

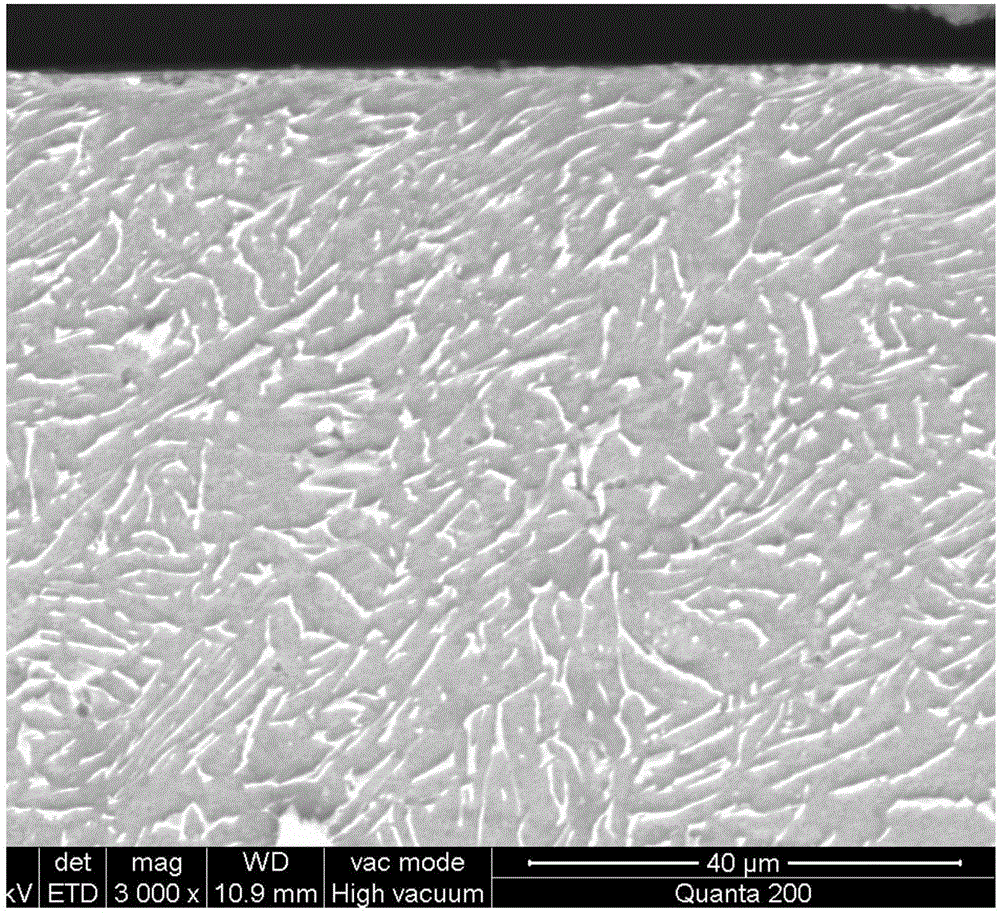

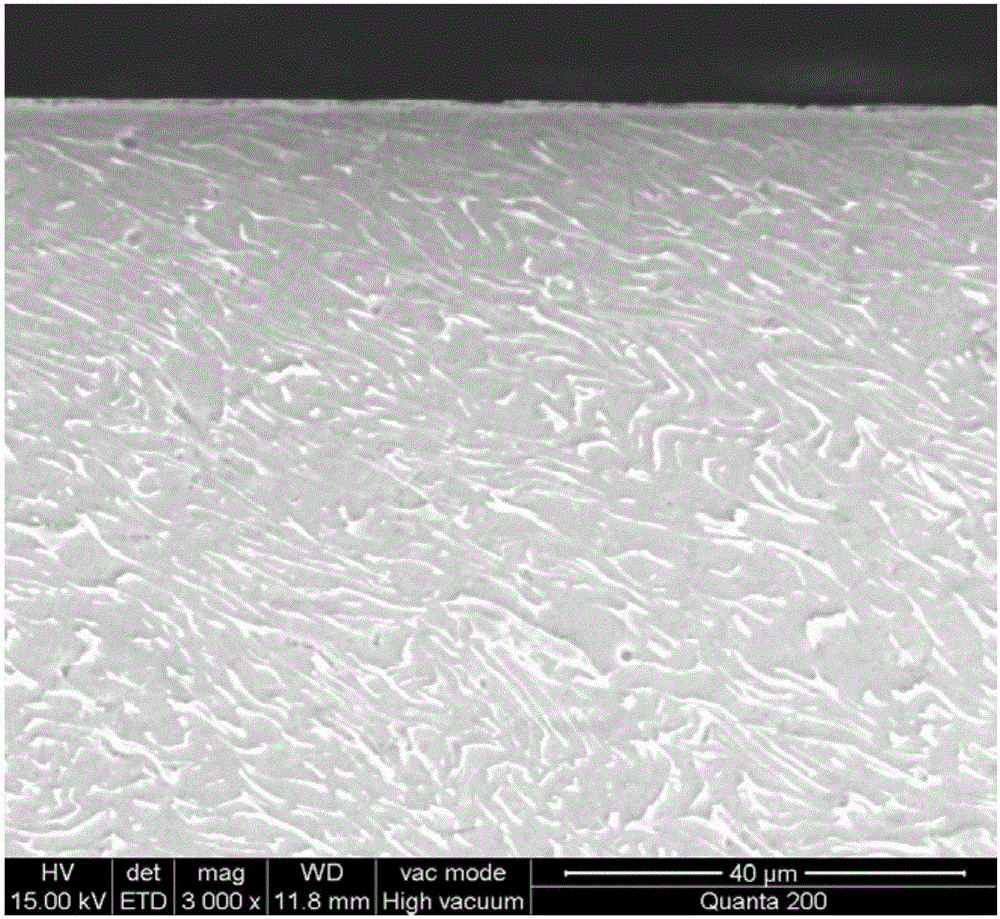

High-frequency pulse discharge assisted surface rolling strengthening processing device and method

The invention discloses a high-frequency pulse discharge assisted surface rolling strengthening processing device. The high-frequency pulse discharge assisted surface rolling strengthening processing device is composed of a rolling mechanism, a force measuring mechanism and a pulse discharge mechanism; the rolling mechanism comprises a sleeve with a rolling rod, and a rolling wheel is arranged at the end of the rolling rod; a pressure sensor, a supporting plate and a spring of the force measuring mechanism are sequentially arranged at the rear end of the rolling rod in the sleeve and are fixed through an end cover; a pressure display instrument of the force measuring mechanism is connected with the pressure sensor through a data line; the pulse discharge mechanism is a high-frequency pulse power source connected with a work electrode; and a cooling nozzle is formed in one side of the rolling wheel. The invention further discloses a high-frequency pulse discharge assisted surface rolling strengthening processing method. On the basis of surface rolling processing, the high-frequency pulse discharge is introduced into the surface rolling processing process, and through combination of surface rolling and high-frequency pulse discharge, a strengthening layer which is good in performance and uniform in structure is obtained from the surface of a workpiece, and wear-resisting performance and anti-fatigue performance of a part are improved.

Owner:SOUTH CHINA UNIV OF TECH

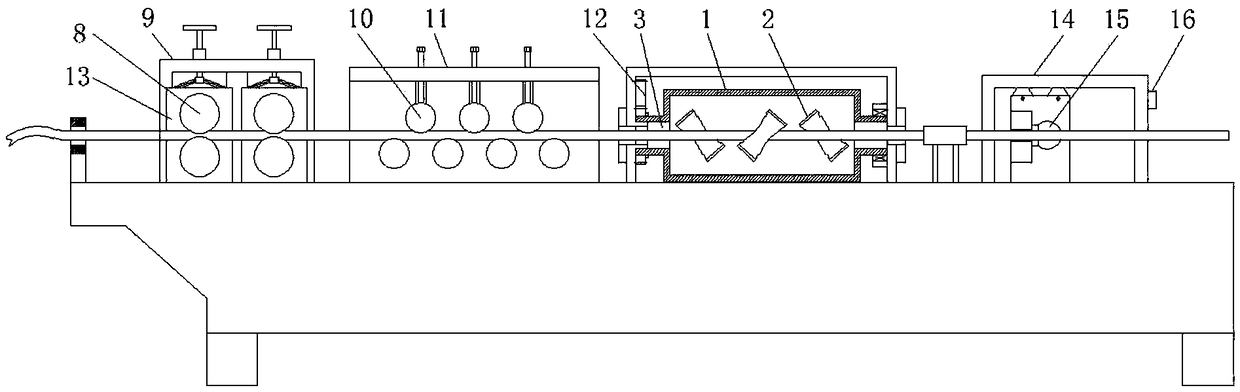

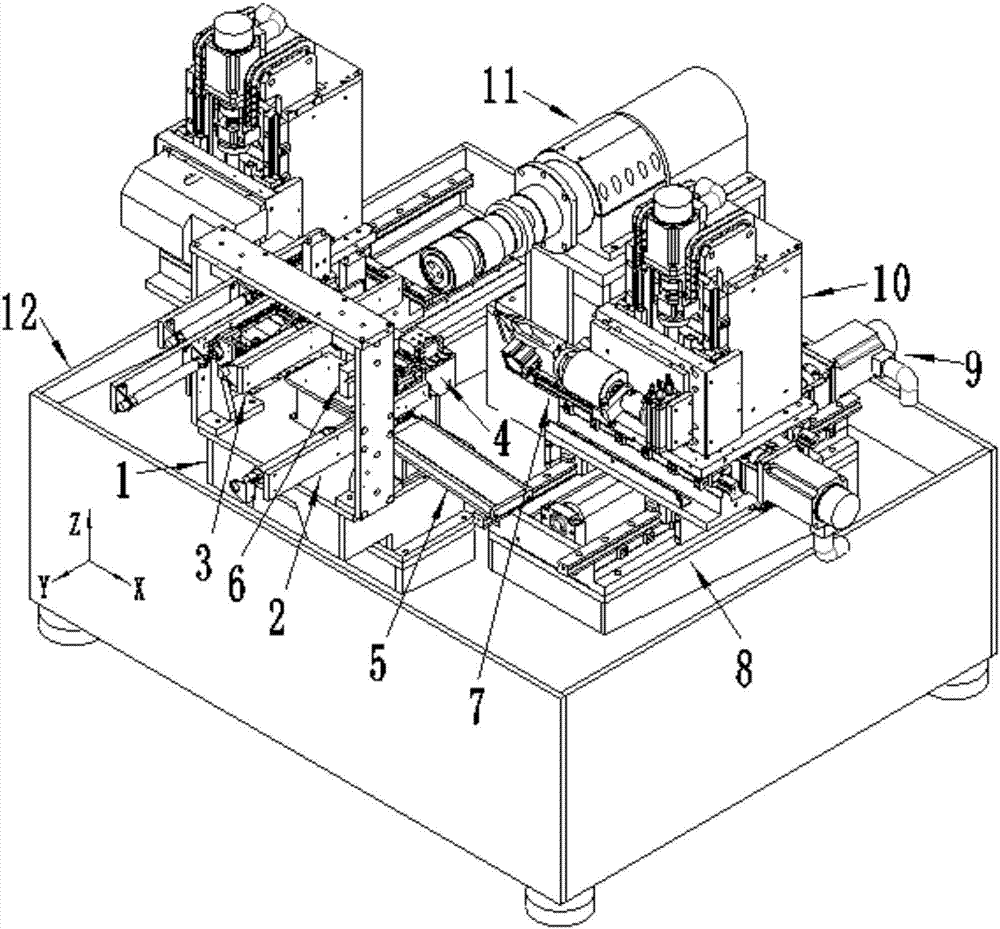

Grinding machine

ActiveCN107199485AAutomate operationImprove quality and efficiencyGrinding drivesOther manufacturing equipments/toolsMachineMaterial distribution

The invention discloses a grinding machine, belonging to the field of machine tool equipment. The grinding machine comprises a grinding wheel spindle component used for grinding a blade, an automatic material fetching and placing device and a manipulator part; the automatic material fetching and placing device comprises a material charging mechanism, a material discharging mechanism, a material distribution mechanism and a material collection component; the material charging mechanism is used for grabbing the blade, and placing the blade on the material distribution mechanism; the material distribution mechanism is used for receiving the blade on the material charging mechanism, adjusting the position of the blade and receiving the finished product of the blade; the material discharging mechanism is used for taking the finished product of the blade from the material distribution mechanism; the material collection component is used for receiving the finished product of the blade which is taken from the material discharging mechanism and finishing collection; and the manipulator part is used for conveying the to-be-machined blade on the material distribution mechanism to the grinding wheel spindle component for grinding and conveying the finished product of the blade back to the material distribution mechanism. The grinding machine has the advantages that automatic grabbing and grinding of the blade are integrated; the whole process is completely finished automatically; and grinding quality and efficiency of the blade and an edge are improved.

Owner:马鞍山俊强精密机械设备有限公司

Fast tile attaching machine for building construction

InactiveCN109083381AFast layingAccurate and standard layingBuilding constructionsLaser sensorMechanical engineering

The invention discloses a fast tile attaching machine for building construction. The fast tile attaching machine comprises a vehicle body, an operation platform, a sucker device, multiple seam clamping device conveying mechanisms, a distance setting device and a controller; the seam clamping device conveying mechanisms are arranged at the rear portion of a guide rail, each seam clamping device conveying mechanism comprises a storage clamp and two air cylinders II vertically arranged on a crossbar of a U-shaped support frame, and the front ends of piston rods of the air cylinders II are provided with clamping parts; each storage clamp comprises two identical clamp bodies, each clamp body is internally provided with a cavity, positioning slots are symmetrically formed in both sides of each cavity, positioning plates are disposed above the positioning slots, and gaps are reserved between the positioning plates and the positioning slots and used for seam clamping devices to slide out; thedistance setting device includes two laser sensors arranged in the front of the operation platform and a laser source arranged outside the vehicle body; an infrared emitter, an audible and visual alarm and a tile placement frame are arranged on the operation platform. The fast tile attaching machine can suck multiple tiles at the same time, the laying precision is high, the tiles can be attached automatically, and the seam clamping devices are placed at the same time.

Owner:湖北屹峡峰建设工程有限公司

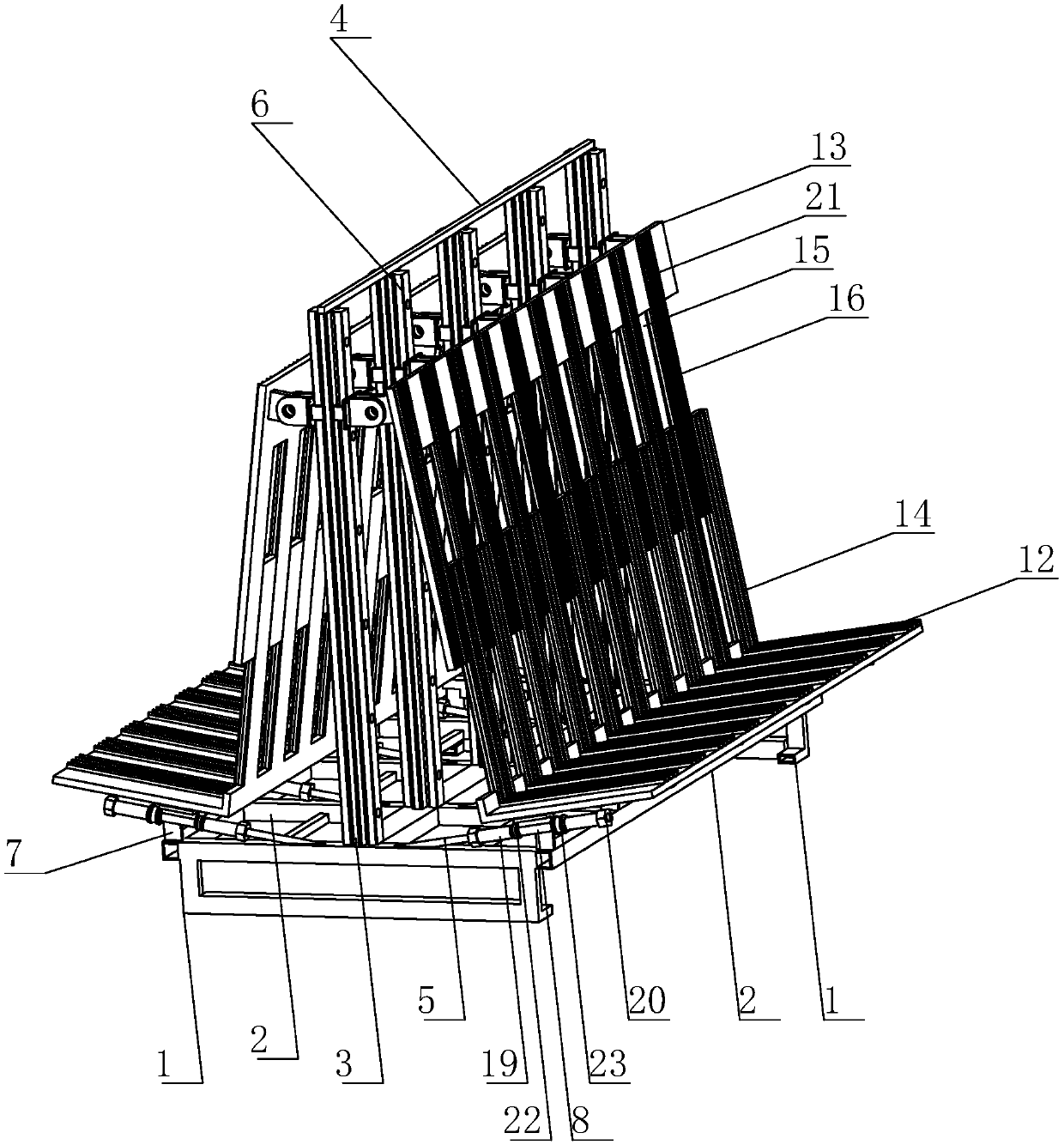

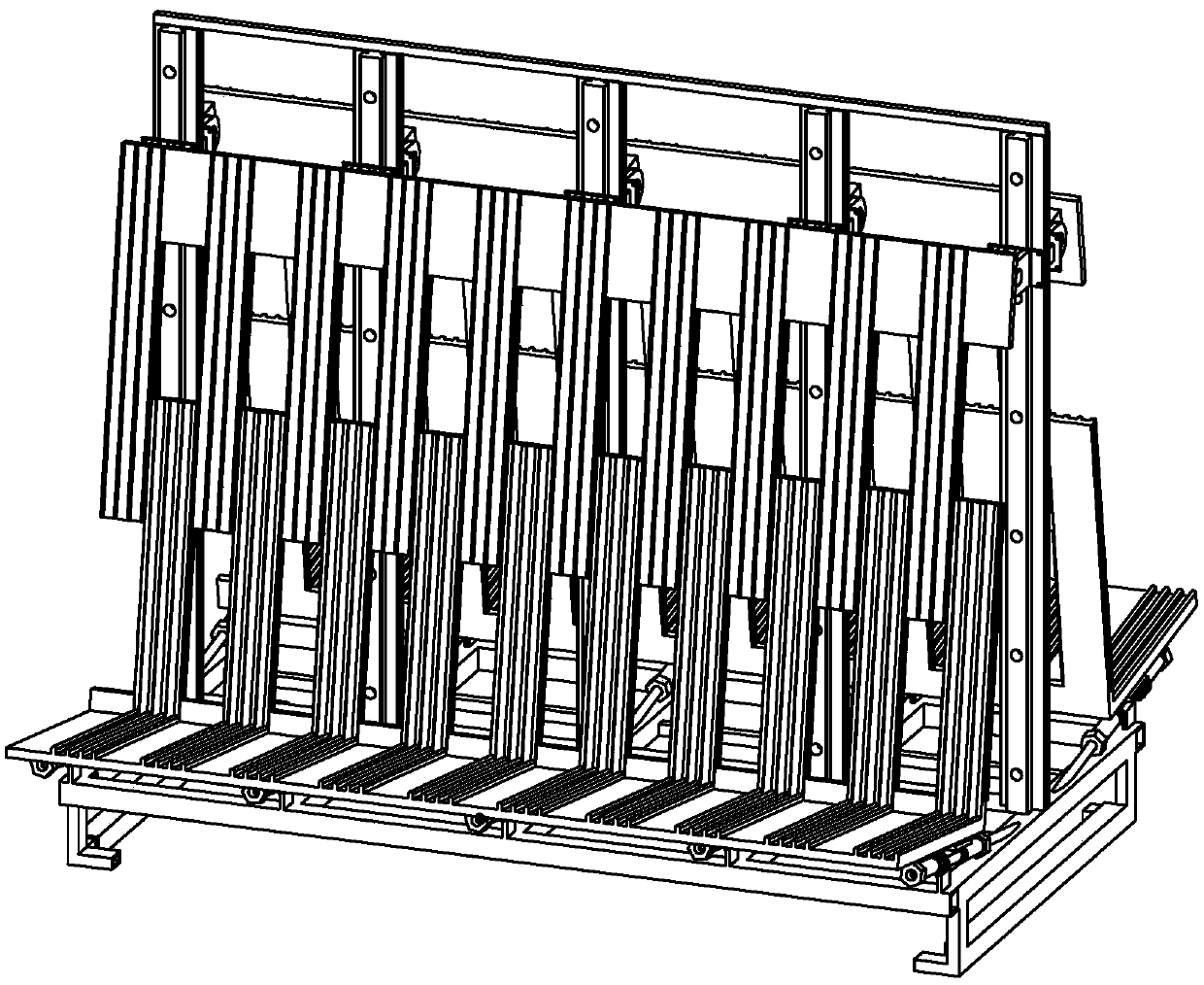

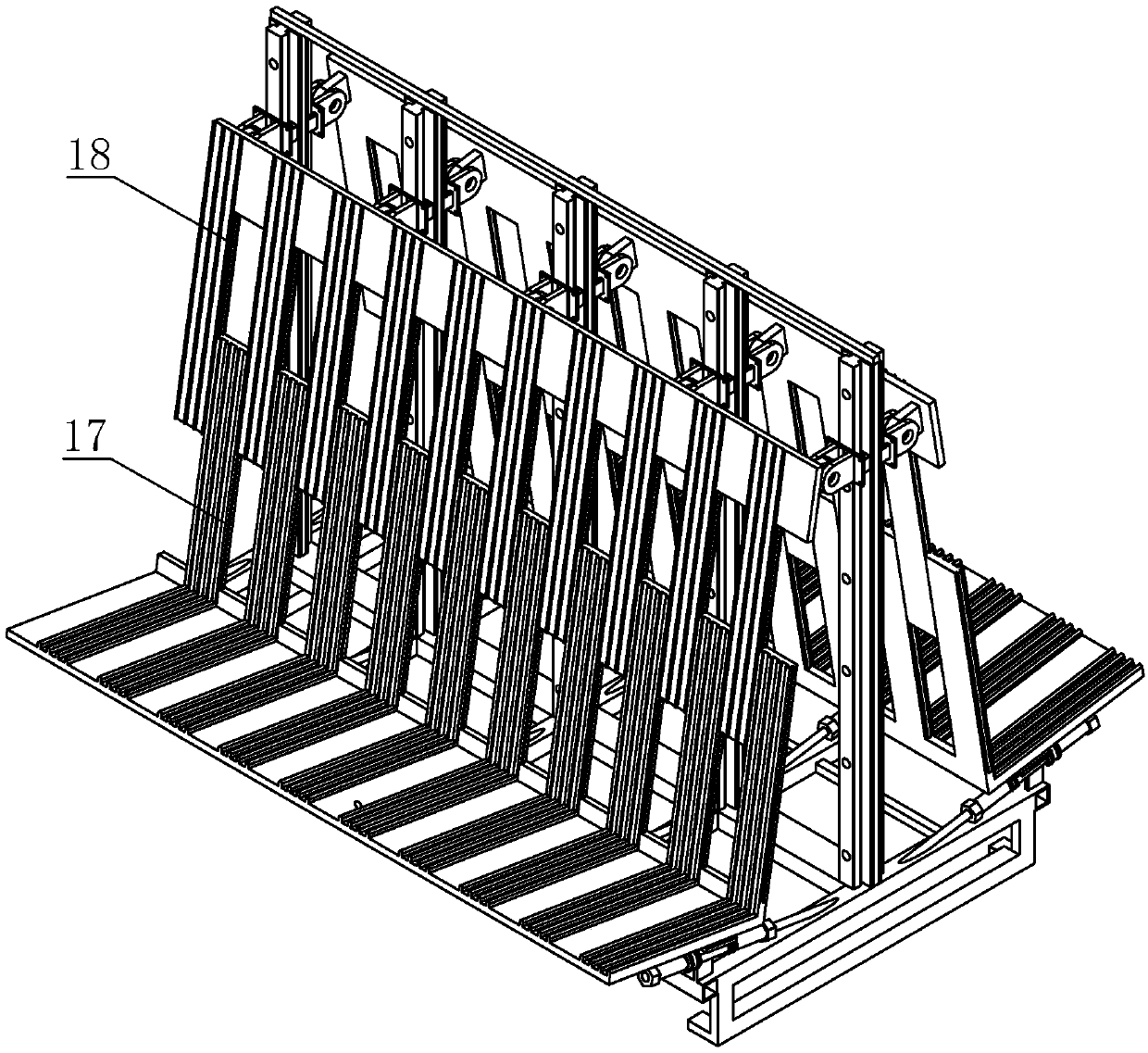

Fixing bracket for glass transportation

ActiveCN108674990AEliminate transportation lossDistribute the load evenlyCharge manipulationConveyor partsEngineeringResource utilization

The invention discloses a fixing bracket for glass transportation, mainly relates to the field of construction equipment transportation. The fixing bracket for glass transportation comprises a main bracket body, a guide rail mechanism, a glass supporting mechanism, a limiting assembly and a buffering piece. The glass supporting mechanism achieves L-shaped extension adjustment by the bidirectionalguide rail mechanism, and achieves fixing and limiting by the limiting assembly; and the buffering piece achieves rigid shock absorption of glass. The fixing bracket has the beneficial effects of being capable of adapting to different conditions on site according to the glass with different sizes and characteristics to fix and transport the glass, significantly lowering transportation losses and improving resource utilization rate.

Owner:王盼

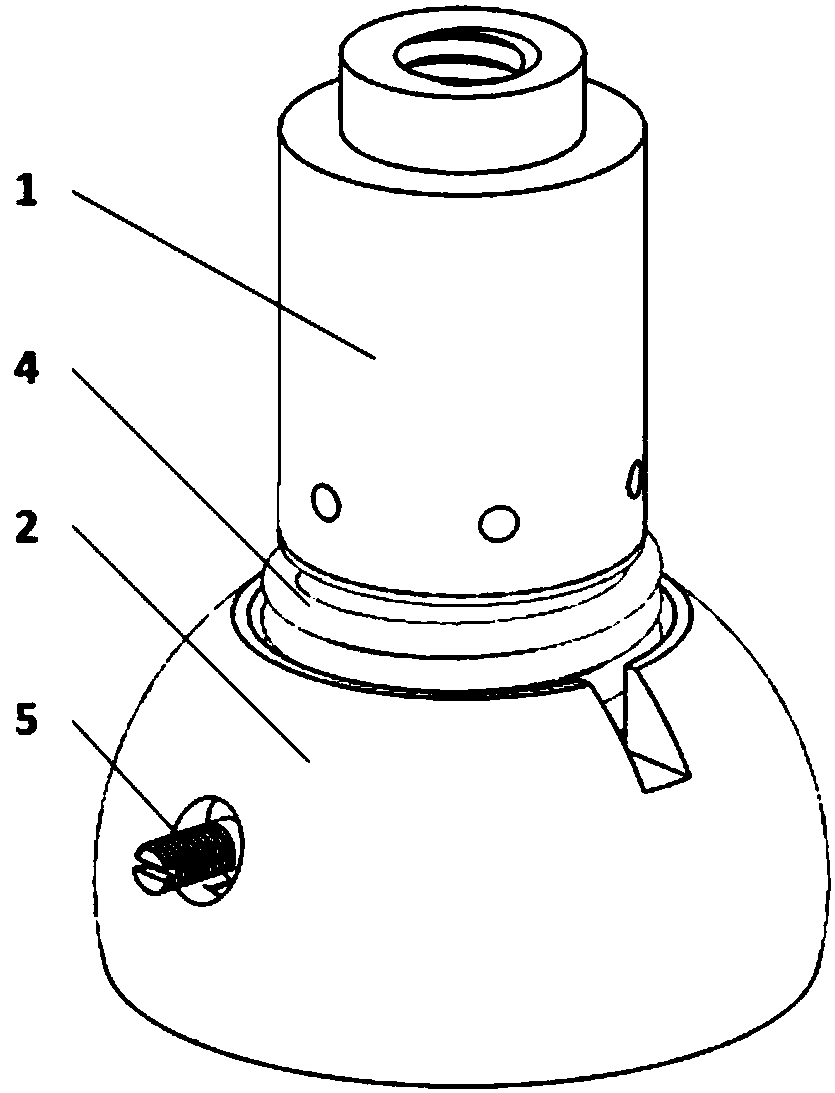

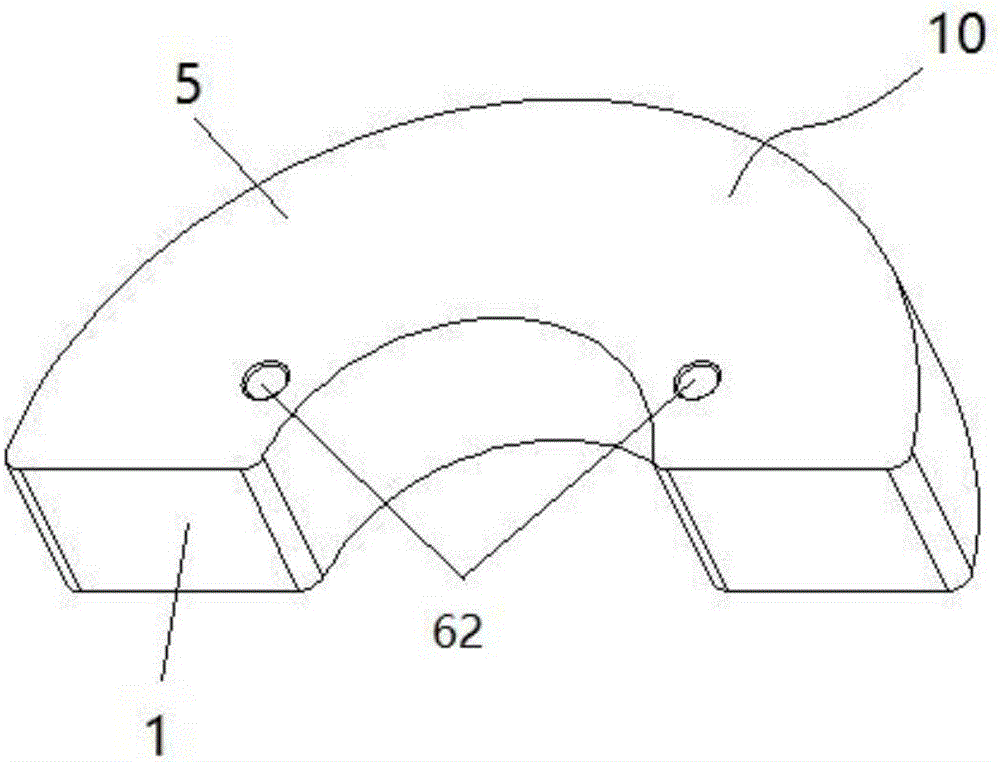

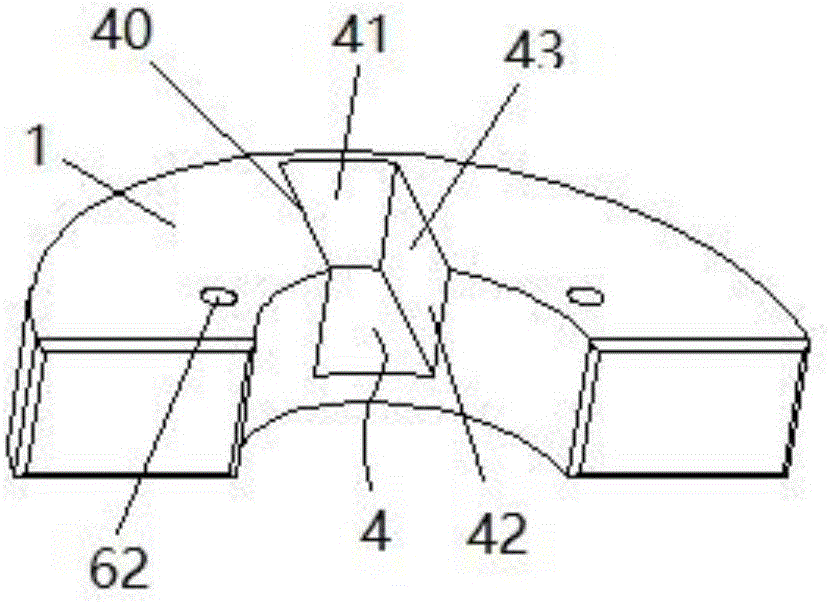

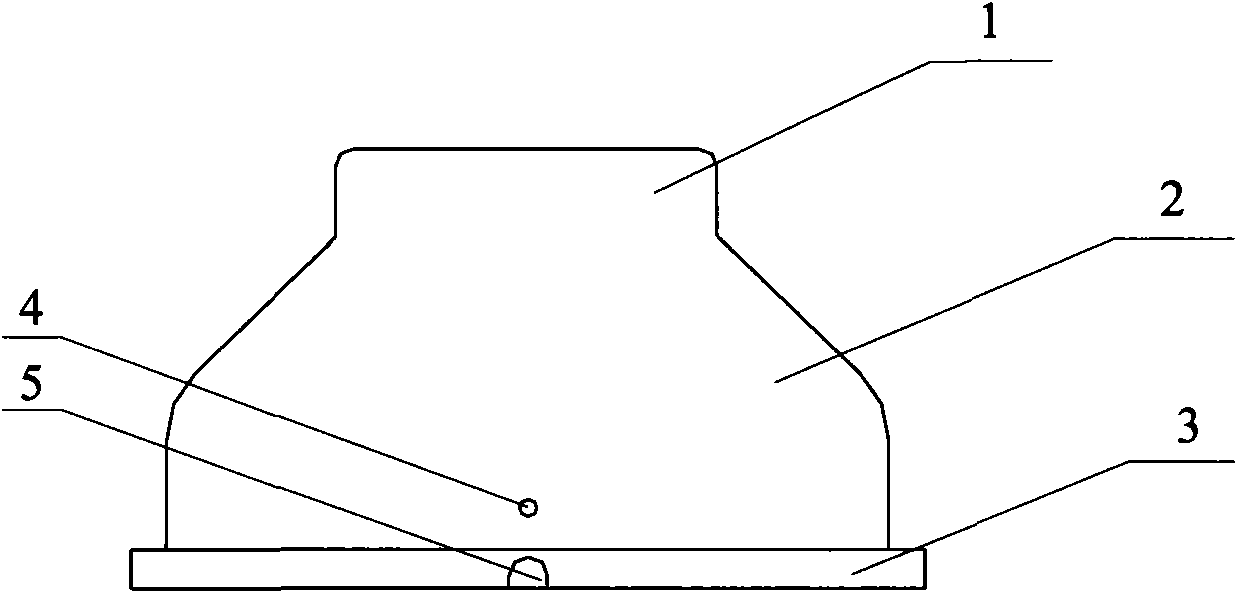

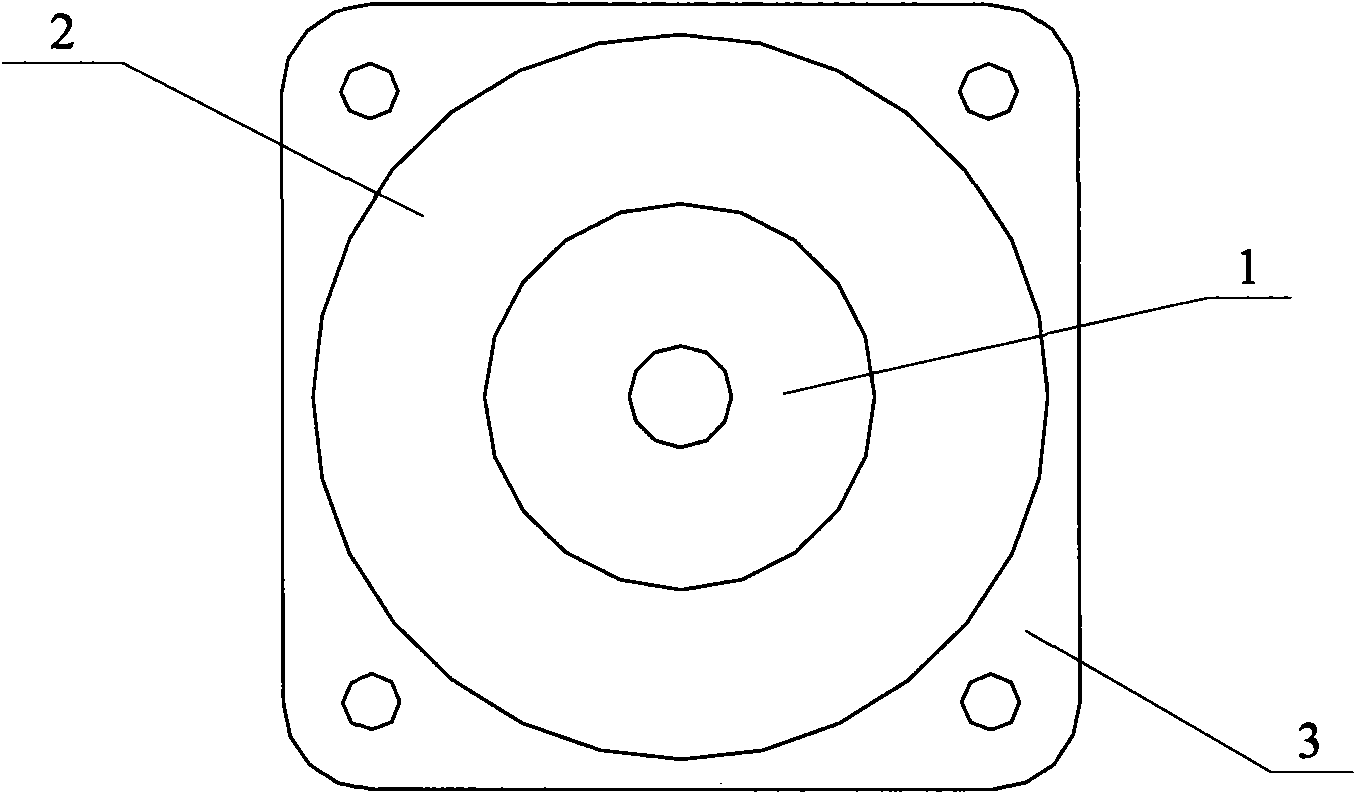

Balance block and rotor assembly, shaft assembly and compressor with balance block

InactiveCN106337812AIncrease centripetal forceOffset eccentricityRotary/oscillating piston pump componentsLiquid fuel engine componentsCentripetal forceEngineering

The invention provides a balance block and a rotor assembly, a shaft assembly and a compressor with the balance block. The balance block comprises a main body (1) and a movable block body (2), wherein the main body (1) is suitable for being installed on a rotatable piece; and the movable block body (2) is connected with the main body (1) through an elastic piece (3). When the rotatable piece rotates, the movable block body (2) can move in the direction that the elastic piece (3) is squeezed or stretched, so that the relative positions of the movable block body (2) and the main body (1) are changed, and then the distance between the center of mass of the balance block (10) and a rotation shaft of the rotatable piece is changed. According to the balance block, under the condition that the mass of the balance block is small, the centripetal force is improved by increasing the distance between the center of mass of the balance block and the rotation shaft of the rotatable piece, and the beneficial technical effects that the eccentric magnitude generated when a crankshaft rotates can be counteracted, and the situation that vibration of the compressor is caused during low-speed rotation due to the large mass of the balance block, and consequently abrasion of the compressor is accelerated is avoided are achieved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

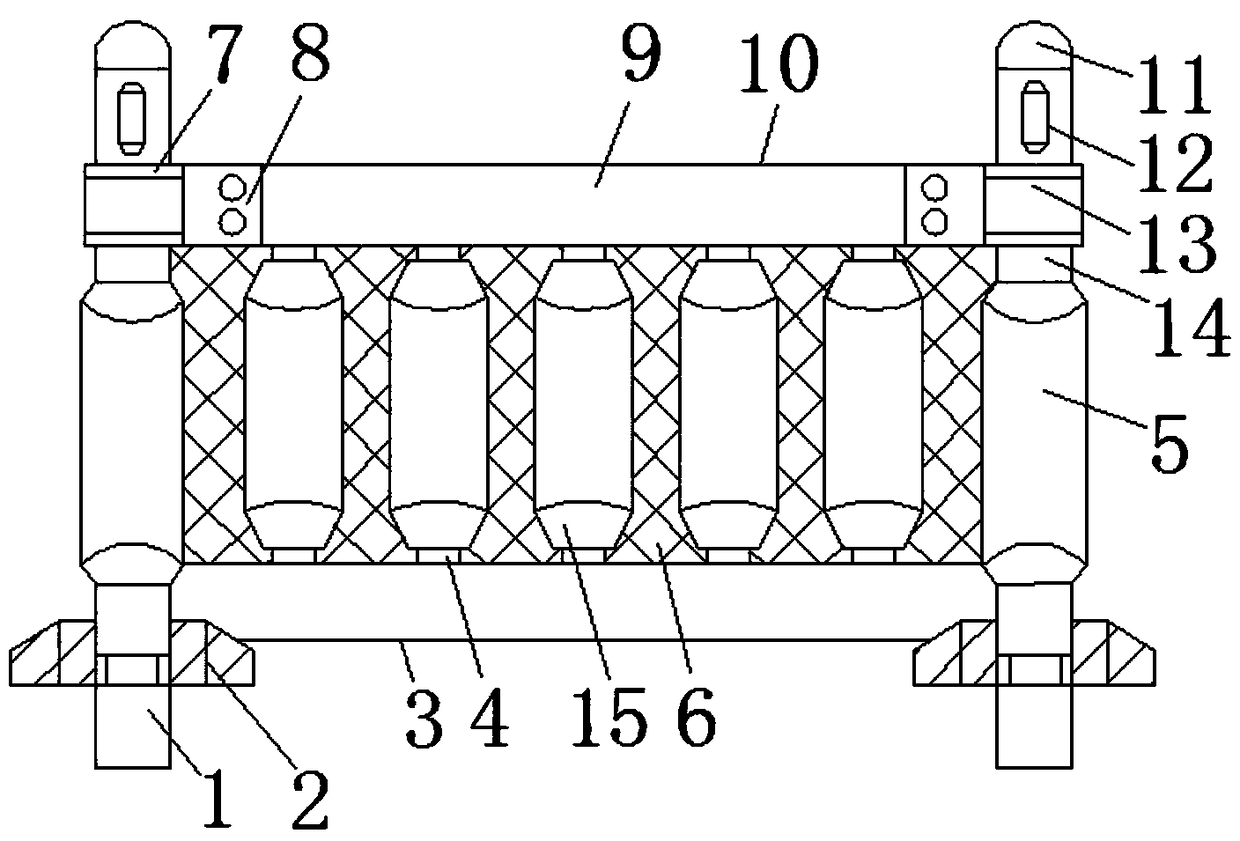

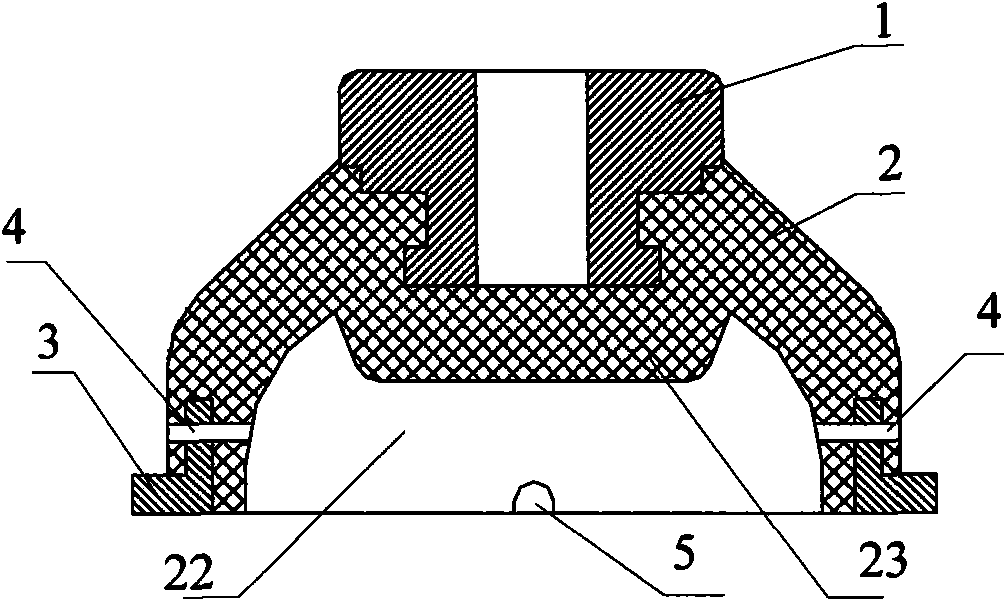

Rubber buffering and vibration isolating elastomer structure

The invention relates to a rubber buffering and vibration isolating elastomer structure which comprises an upper metal part, a rubber part and a lower metal part. An internal cavity structure is adopted by the rubber body of the invention to increase the buffering stroke of the rubber body, and the buffering deformation of the rubber body can reach 100%; and if the space along the axial direction of the elastomer structure is large enough, the buffering deformation can reach about 150%. The design of the cavity structure greatly increases the buffering deformation stroke of the rubber part by 2-4 times of the traditional rubber isolator, thereby greatly improving the buffering effect. The structure of the invention adopts the design of a gas channel; on the one hand, by the design of the gas channel, when the elastomer bears the impact load, because the action time of the load is short, the gas in the cavity is quickly discharged outwards through the gas channel, and the friction action of the gas and the channel increases the damping of the elastomer structure, thereby increasing the buffering effect of the elastomer structure; and on the other hand, by the design of the gas channel, the gas in the cavity can be smoothly discharged under the action of the load to avoid the uneven deformation of the rubber part caused by sealing of the cavity, thereby ensuring the rigidity stability of the elastomer structure in the deformation process.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Self-adaptive flexible floating gripper applied to door covers on welding and assembling line

ActiveCN106272489AAvoid Rigid CollisionsGood effectGripping headsMarine engineeringLocking mechanism

The invention discloses a self-adaptive flexible floating gripper applied to door covers on a welding and assembling line. The self-adaptive flexible floating gripper is characterized in that a fixing frame is arranged; a robot connection disc used for connecting a robot is fixedly arranged on the top surface of a rectangular gripper positioning frame; flexible floating frame locking mechanisms are arranged on the left side and the right side respectively at the periphery of the gripper positioning frame; floating balancing mechanisms are arranged on the front side and the rear side of the gripper positioning frame respectively; a floating frame is arranged and is characterized in that plate positioning and clamping mechanisms are fixedly arranged at the periphery of a rectangular floating frame body; floating frame constraining mechanisms, floating balancing mechanism mounting seats and a locking-limiting mechanism positioning seat are arranged in an inner frame of the floating frame body respectively. Through synergistic actions of the floating frame constraining mechanisms, spring floating balancing mechanisms and the flexible floating frame locking mechanisms, the flexibility of the processes of loading and unloading plates and the self-adaptability of plate lamination can be achieved; the rigid collision is avoided; the damage to the plates, the clamp and the gripper can be avoided.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Novel metal powder melting and quick-molding machine

The invention relates to a novel metal powder melting and quick forming machine which comprises a frame, a control system, a laser galvanometer scanning device, a powder laying device, a three-cylinder body and a laser, wherein the control system, the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all arranged on the frame, the laser galvanometer scanning device is in optical connection with the laser, and the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all connected to the control system. The novel metal powder melting and quick forming machine has the advantages that a nonequilibrium supersaturated solid solution and uniform and fine metallographic structures can be obtained, the density of a formed part is close to 100%, the mechanical performance is equivalent to that of a forging part, the processing time and cost can be obviously reduced, and the development cycle of a new product is shortened. The novel metal powder melting and quick forming machine greatly adapts to the requirements of quick, individuated and flexible development of the modem manufacturing industry and has a broad application prospect in the manufacturing fields of aviation, aerospace, medicine, molds, weaponry and the like.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

Self-adaptive deformation reset anti-collision method capable of resisting uneven impact force

ActiveCN110295557AAvoid Rigid CollisionsImprove securityRoadway safety arrangementsViscous dampingViscous liquid

The invention provides a self-adaptive deformation reset anti-collision method capable of resisting uneven impact force. A self-adaptive viscous damping anti-collision pier is arranged on the foundation, the anti-collision pier comprises a main structure and a rigid framework embedded in the main structure, a viscous damping chamber is arranged in the rigid framework, a piston with a damping holeand a spring abutting against the piston are arranged in the viscous damping chamber, and the tail end of a piston rod extends out of the rigid framework and is connected with a collision plate in a hinged mode. During collision, the collision plate enables a viscous liquid to flow through the damping hole to consume collision energy. The collision plate can be subjected to tipping movement in various directions when bearing eccentric collision impact, and the anti-collision pier can automatically adapt to the situation of eccentric collision. After the collision occurs, the collision plate can be automatically reset under the action of the spring. During manufacturing of the anti-collision pier, the rigid framework is firstly manufactured, a liquid injection hole is drilled in the rigid framework, and then the rigid framework is integrally cast with the main body structure, the anti-collision pier is simple and convenient, the practicability is strong, and the economical efficiency isgood. The method is particularly suitable for bridge abutments, bridge bodies, mountain roads and the like.

Owner:CENT SOUTH UNIV

Buffer feeding device of air valve

ActiveCN104108599AAvoid Rigid CollisionsGuarantee the quality of production and testingConveyor partsEngineeringMaterial storage

The invention provides a buffer feeding device of an air vale. Automatic feeding in the air valve production and detection process is achieved, production efficiency is improved, rigid collision between air valves in the feeding process is effectively avoided, and air valve production and detection quality is guaranteed. The buffer feeding device of the air vale comprises material receiving plates on the two sides, the upper end of each material receiving plate is provided with a material storage rod, and then a material channel is formed. The buffer feeding device of the air vale is characterized in that rotary shafts are arranged corresponding to the lower ends of the material receiving plates, a plurality of material blocking bars are arranged on the rotary shafts, and the adjacent material blocking bars are arranged in an intersection mode.

Owner:WUXI SHUANGYI PRECISION MACHINERY

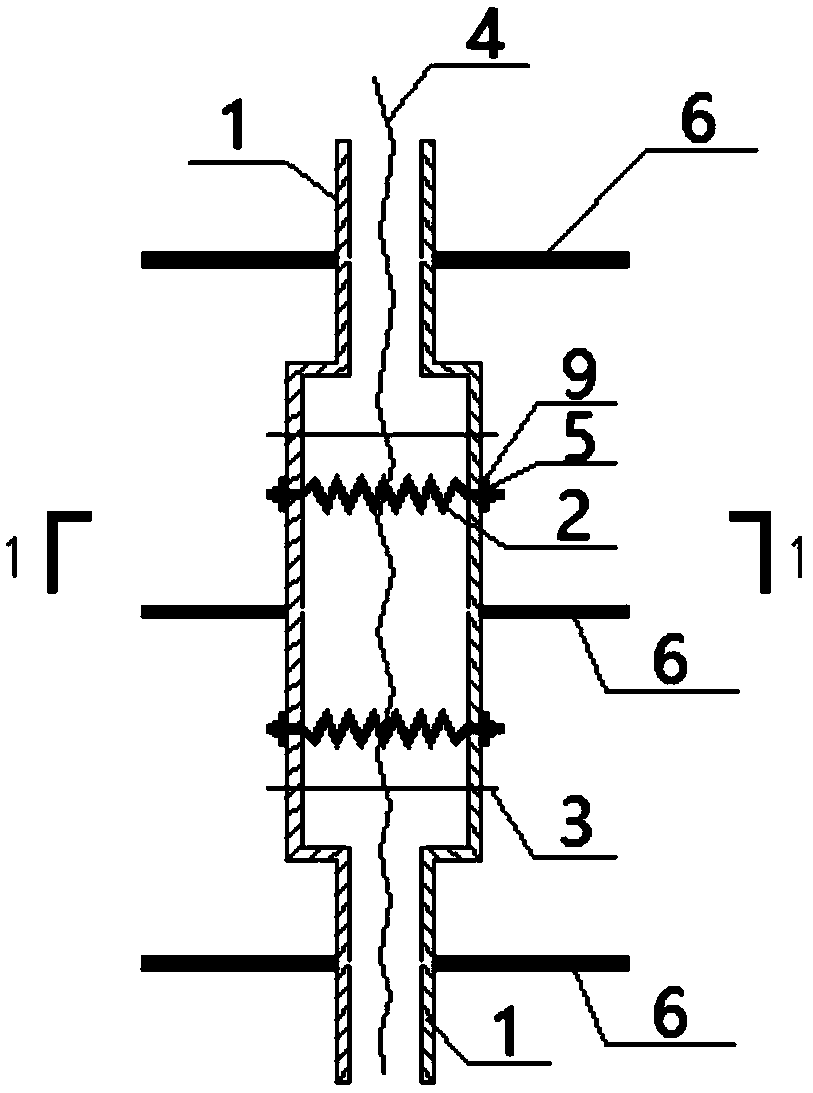

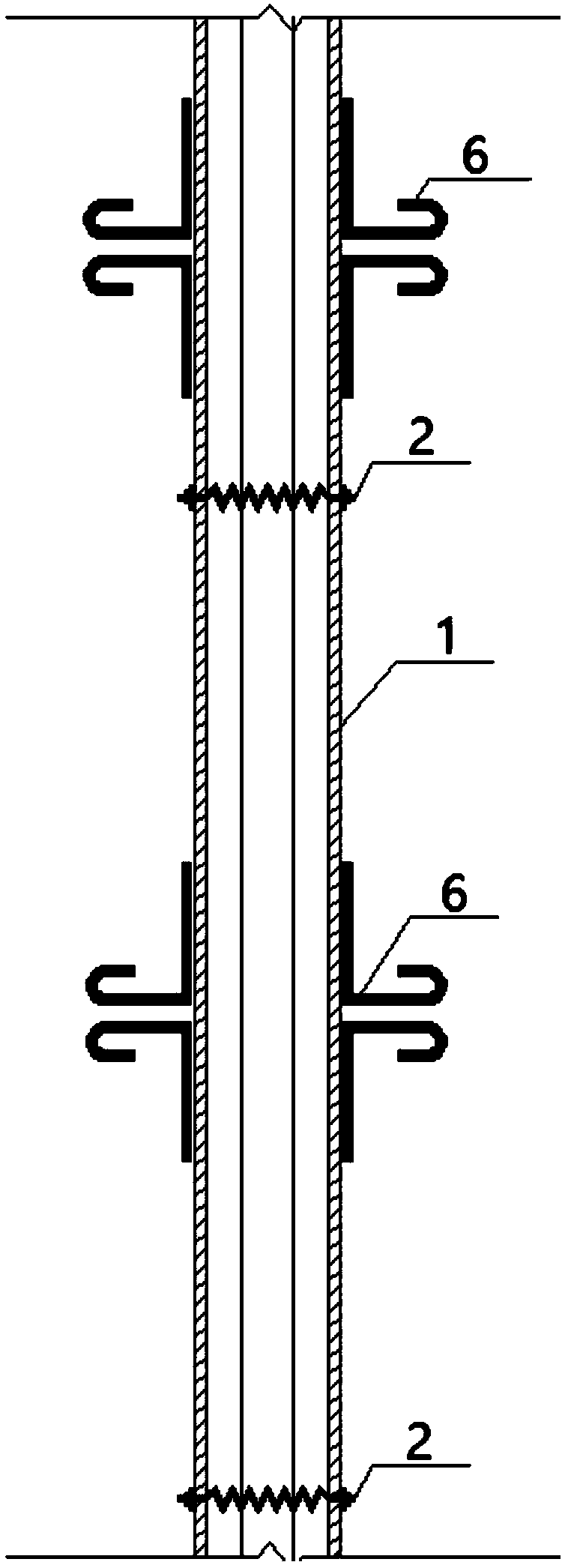

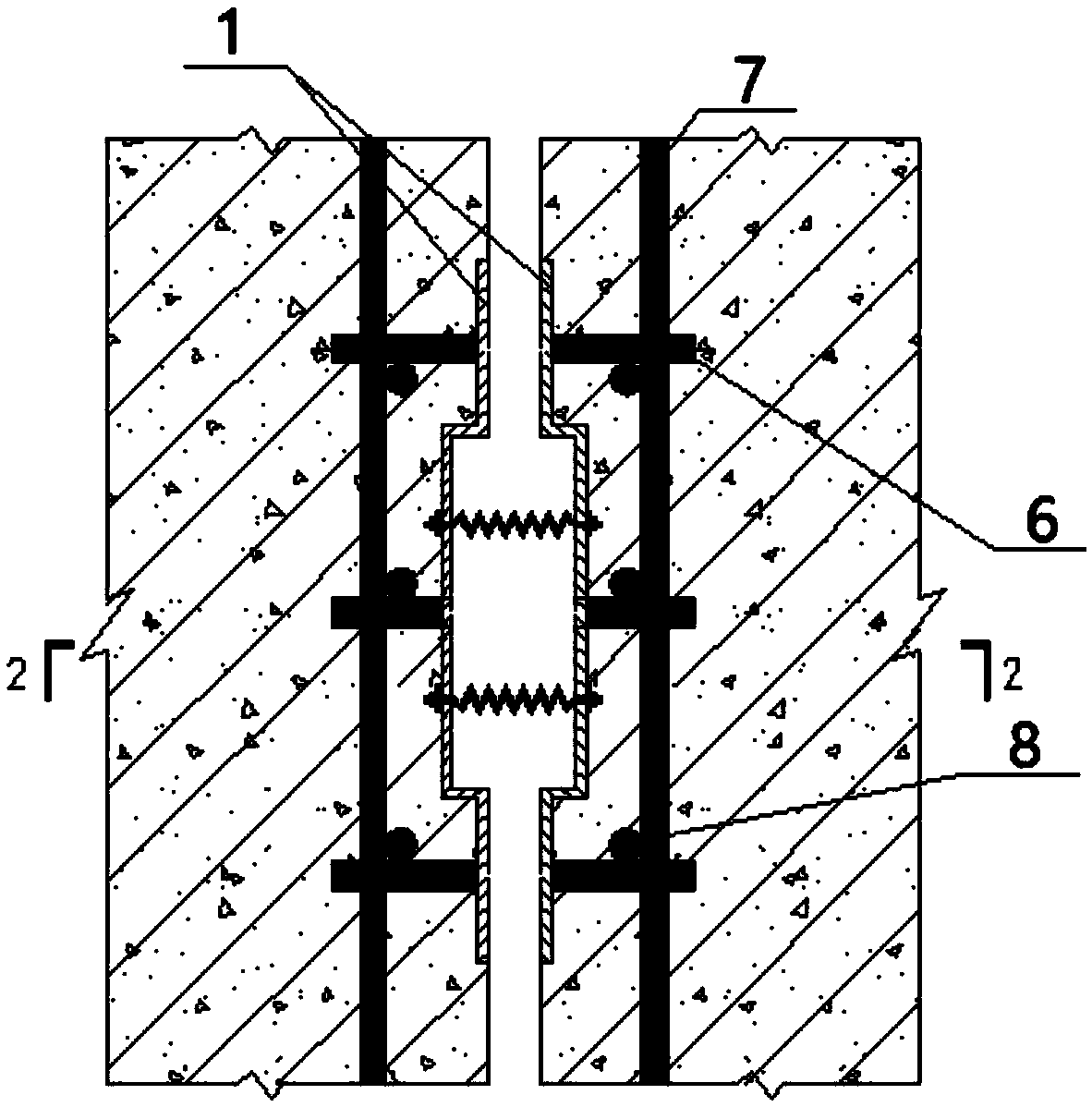

Inter-building joint buffering force transmitting box and installing method thereof

PendingCN108867929AAvoid Rigid CollisionsPrevent sideways slipProtective buildings/sheltersShock proofingStructural engineeringSteel plates

The invention discloses an inter-building joint buffering force transmitting box and an installing method thereof. The inter-building joint buffering force transmitting box comprises a pair of vertically installed damping steel plates and a plurality of longitudinally installed damping springs. The two damping steel plates are parallel and installed symmetrically. Two ends of the damping springs are respectively connected with the two damping steel plates. All of the damping springs are vertically distributed between the two damping steel plates along a horizontal direction and a vertical direction. Performance and precompression of all of the damping springs are the same. The inter-building joint buffering force transmitting box is installed in a joint between buildings. Lateral slippingof the building at the edge side can be prevented and an uneven coefficient can be adjusted, and rigid collision between the buildings can be avoided. The inter-building joint buffering force transmitting box is particularly suitable for two buildings with large volume difference and high seismic intensity.

Owner:陈亚军

Cloth cutter applied to spinning mill

InactiveCN107988780AEasy to disassembleAvoid Rigid CollisionsSevering textilesTextile millMechanical engineering

The invention discloses a cloth cutter applied to a spinning mill. The cloth cutter comprises a base. An operation platform is fixedly installed on the top of the base. Sliding grooves formed in the top of the base are symmetrically formed in the two sides of the operation platform. Supporting rods are installed inside the sliding grooves in a sliding mode. Sliding modules are arranged inside thesliding grooves. A beam is welded to the tops of the two supporting rods. Two first through holes are symmetrically formed in the top of the beam, first sliding rods are installed inside the first through holes in a sliding mode, the two ends of the first sliding rods extend out of the first through holes, buffer modules are symmetrically arranged on the two sides of the first sliding rods, installing blocks are welded to the bottoms of the sliding rods, installing grooves are formed in the bottoms of the installing blocks, and blades are installed inside the installing grooves. The cloth cutter is simple in structure and convenient to operate, rigid collision between the blades and the operation platform is effectively avoided, the blades can be quite convenient to disassemble, the time is shortened, and the disassembling efficiency is improved.

Owner:刘丽影

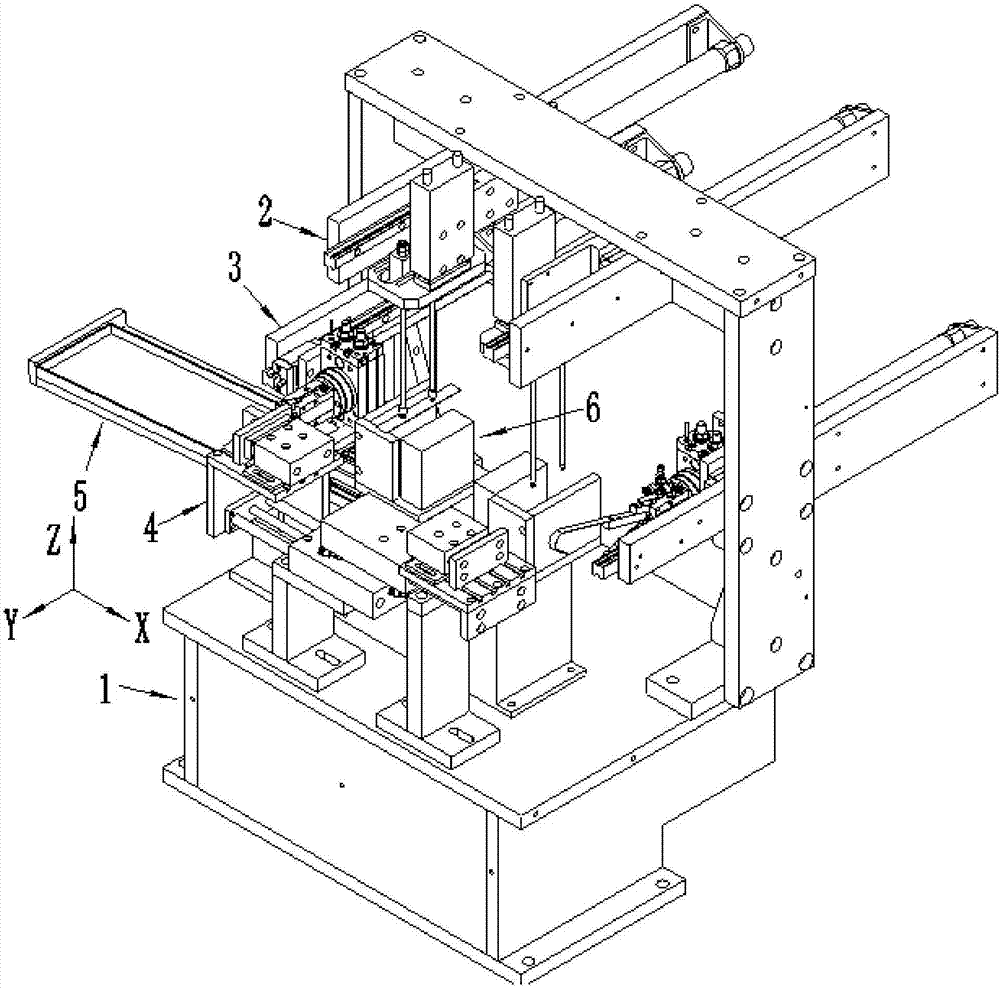

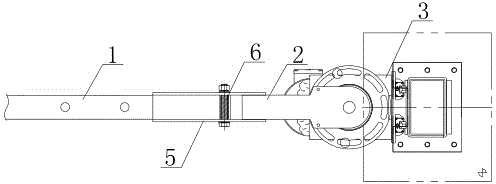

Fuzzy positioning based elastic shaft hole automated assembly device and assembly method thereof

The invention discloses a fuzzy positioning based elastic shaft hole automated assembly device and an assembly method thereof. The fuzzy positioning based elastic shaft hole automated assembly device comprises a mandrel, a connecting seat, a sleeve and a shaft sleeve, wherein the inner walls of the connecting seat and the shaft sleeve are respectively and slidably connected with the outer wall of the mandrel through a first motion pair and a cone matching connecting pair, and the outer wall of the connecting seat is elastically connected with the outer wall of the shaft sleeve; a conductive ring a is embedded in the end surface, adjacent to the connecting seat, of the shaft sleeve, and more than three clamping jaws are circumferentially arranged on the end surface, back to the connecting seat, of the shaft sleeve; a conductive ring b corresponding to the conductive ring a is embedded in the end surface, adjacent to the shaft sleeve, of the connecting seat, and the inner wall of the sleeve is slidably connected with the shaft sleeve through a motion pair, and is connected with the clamping jaws through a cone matching movable connecting pair; a driving cylinder is formed between the inner wall of the sleeve and the outer wall of the shaft sleeve. Therefore, the positioning precision can be far less than the assembly clearance of a shaft hole as long as the position is roughly correct, and the positioning precision reaches 0.1mm order of magnitudes.

Owner:KUNSHAN TUNGRAY IND AUTOMATION

Hanging ladder

The invention relates to a hanging ladder which is provided by aiming at the defect that a hanging ladder on the traditional mobile mechanical equipment is easily collided by the ground or materials and damaged. The hanging ladder comprises at least two pedals which are arranged up and down, wherein each pedal below the upper most pedal is hung and connected with a next stage of pedal through connecting parts at both ends of the pedal, and the pedals comprise at least one swinging pedal; the connecting parts for hanging the pedals are swinging connecting parts, and a parallelogram structure is formed by the swinging pedal, an adjacent pedal above the swinging pedal and left and right swinging connecting parts connected with the swinging pedal and the adjacent pedal above the swinging pedal; and both ends of the swinging connecting parts are respectively hinged with an upper pedal and a lower pedal, and hinge pivot shafts are horizontally arranged and vertical to the pedal length direction. According to the hanging ladder, when the lower end of the hanging ladder is collided by the ground or materials in an advancing process of equipment, the hanging ladder can be swung towards a direction opposite to the advancing direction of the mechanical equipment so as to avoid damaging the hanging ladder, and after the collision is relieved, the hanging ladder can be automatically reset to a normal state.

Owner:GUANGXI LIUGONG MASCH CO LTD

Cylinder deactivation engine valve stop camshaft device

InactiveCN105604708ATaking into account emissionsGuaranteed Excess Air CoefficientValve arrangementsEngine controllersControl systemCam

The invention relates to a cylinder deactivation engine valve stop camshaft device, belonging to the technical field of engines. A hydraulic control system, a chute slide system and a camshaft main body system are respectively arranged on the left, middle and right parts of a camshaft, wherein the upper end of a valve guide rod a and a cam a form a slide connection, and the upper end of a valve guide rod b and a cam b form a slide connection. When a locating pin slides on a sliding chute a, the upper end of a valve guide rod c and a normal-contour cam a form a slide connection, and the upper end of a valve guide rod d and a normal-contour cam b form a slide connection. When the locating pin slides on a sliding chute b, the upper end of the valve guide rod c and a base-circle-contour cam a form a slide connection, and the upper end of the valve guide rod d and a base-circle-contour cam b form a slide connection. By using the camshaft device, the engine adopting the cylinder deactivation technique can implement no ventilation of the non-working cylinder, thereby ensuring the excess air coefficient of the exhaust, and giving consideration to the emission property of the cylinder deactivation engine. The cylinder deactivation engine valve stop camshaft device has the advantages of high control accuracy, smooth transition, simple structure and low cost, and is easy to manufacture and convenient for popularization.

Owner:JILIN UNIV

Safety protection mechanism on cantilever in laminated base plate centralized transferring machine

InactiveCN104860027AAvoid Rigid CollisionsAvoid damageControl devices for conveyorsProtection mechanismCantilever

The invention discloses a safety protection mechanism on a cantilever in a laminated base plate centralized transferring machine for preventing a laminated base plate from causing rigid collision with an obstacle when the laminated base plate is downwards placed. The safety protection mechanism includes a horizontal cantilever formed through a first cantilever and a second cantilever; the rear end of the second cantilever is supported on a mounting base; the rear end of the first cantilever is connected with the front end of the second cantilever; a connection structure between the first cantilever and the second cantilever enables the first cantilever to be horizontally supported on the second cantilever, enables the front end of the first cantilever to be upwards cocked for avoiding when the first cantilever encounters an obstacle during the downward movement of the cantilever, and enables the first cantilever to downwards rotate to an original horizontal position under the action of gravity after the obstacle is removed; a detection switch at the connecting part of the first cantilever and the second cantilever can be used for detecting the upward cocking action of the first cantilever, and sending a signal obtained through detection to a control device to drive a control device to issue an alarm and a halt instruction.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com