Self-adaptive flexible floating gripper applied to door covers on welding and assembling line

A welding line, self-adaptive technology, applied in the direction of manufacturing tools, manipulators, chucks, etc., can solve the problems of rigid collision, damaged boards, etc., and achieve the effect of matching, stable function, and difficult function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

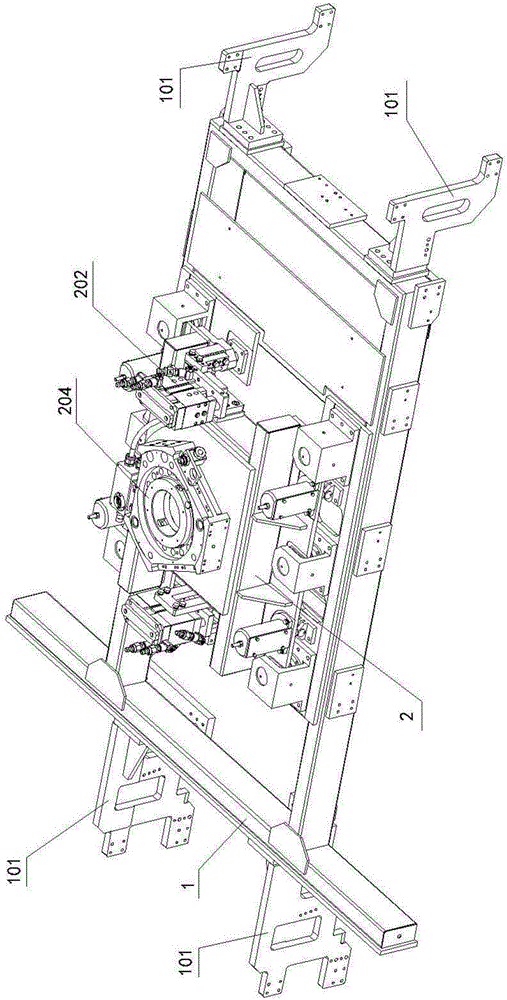

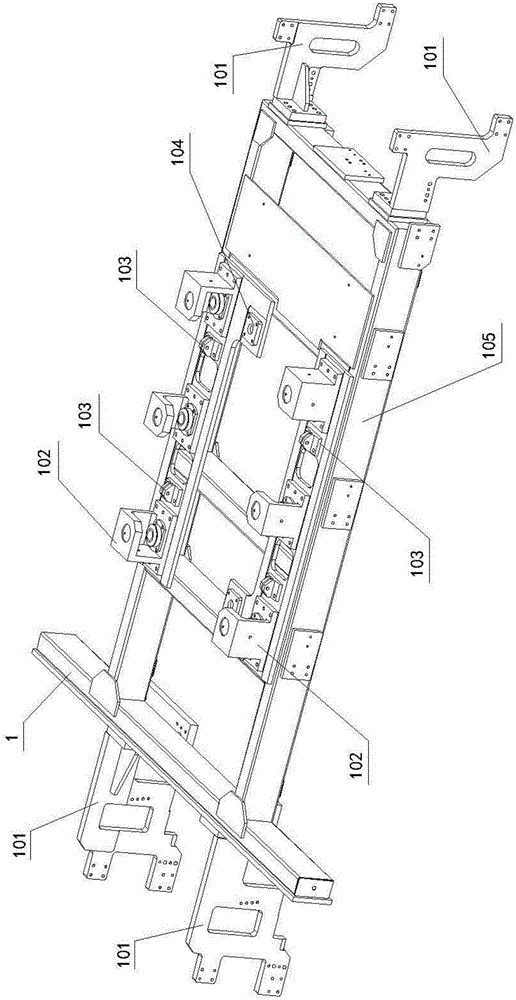

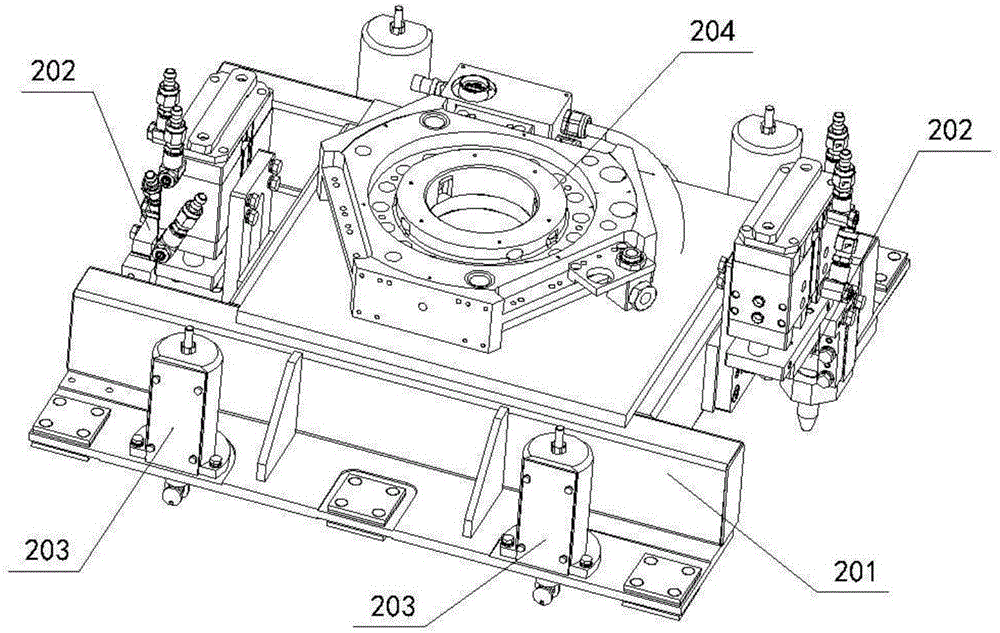

[0025] see figure 1 , figure 2 and image 3 In this embodiment, the adaptive flexible floating gripper for the door cover on the welding line is composed of a floating frame 1 and a fixed frame 2 .

[0026] like figure 1 and image 3 As shown, the fixed frame 2 is fixedly arranged on the top surface of the rectangular gripper positioning frame 201 for connecting the robot robot connection plate 204, and the outer periphery of the gripper positioning frame 201, at the left and right sides of the gripper positioning frame 201. The floating frame locking mechanism 202 is provided with a floating balance mechanism 203 on its front and rear sides respectively.

[0027] like figure 1 and figure 2 As shown, the floating frame 1 is fixedly provided with a panel positioning and clamping mechanism 101 on the periphery of a rectangular floating frame body 105; a floating frame constraint mechanism 102 and a floating balance mechanism mounting seat are respectively arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com