Cylinder deactivation engine valve stop camshaft device

A camshaft and engine technology, applied in engine components, engine control, machine/engine, etc., can solve the problems of reduced nitrogen oxide conversion efficiency, negative impact of engine emissions, and increased air volume, achieving easy promotion, excessive stability, The effect of fast axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

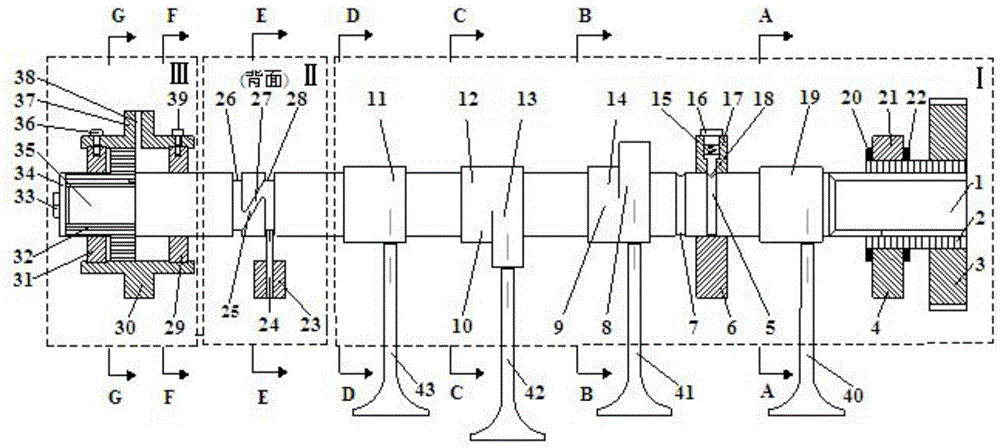

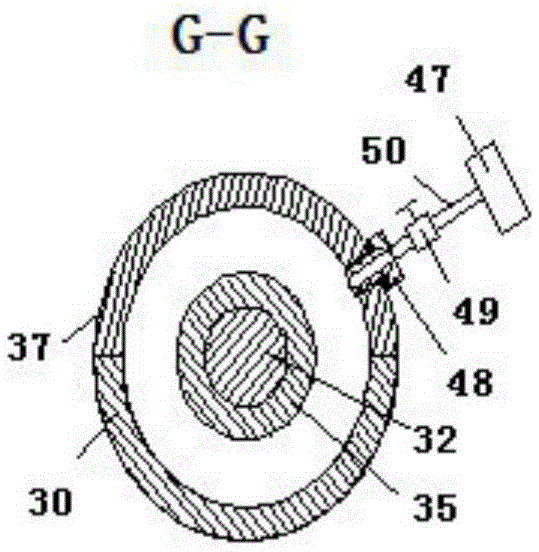

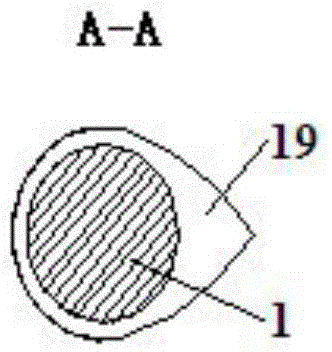

[0041] Combine below Figure 1-Figure 13 The present invention is described in detail.

[0042] like figure 1 As shown, the present invention is composed of camshaft main system I, chute sliding system II and hydraulic control system III, valve guide rod a40, valve guide rod c41, valve guide rod d42 and valve guide rod b43, camshaft main system I, The chute sliding system II and the hydraulic control system III use the same camshaft 1, the camshaft main system I is placed on the right part of the camshaft 1, the chute sliding system II is placed in the middle of the camshaft 1, and the hydraulic control system III is placed on the camshaft 1 Left part, where the upper end of the valve guide rod a40 is slidingly connected with the cam a19 in the main body system of the camshaft, and the upper end of the valve guide rod b43 is slidingly connected with the cam b11 in the main body system of the camshaft.

[0043] When the positioning pin 18 in the camshaft main system I slides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com