Variable-displacement engine

An engine and variable displacement technology, applied in combustion engines, engine control, engine components, etc., can solve the problems of engine service life decline, engine heat loss, temperature drop, etc., to avoid alternation of cold and heat, improve fuel consumption, improve The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

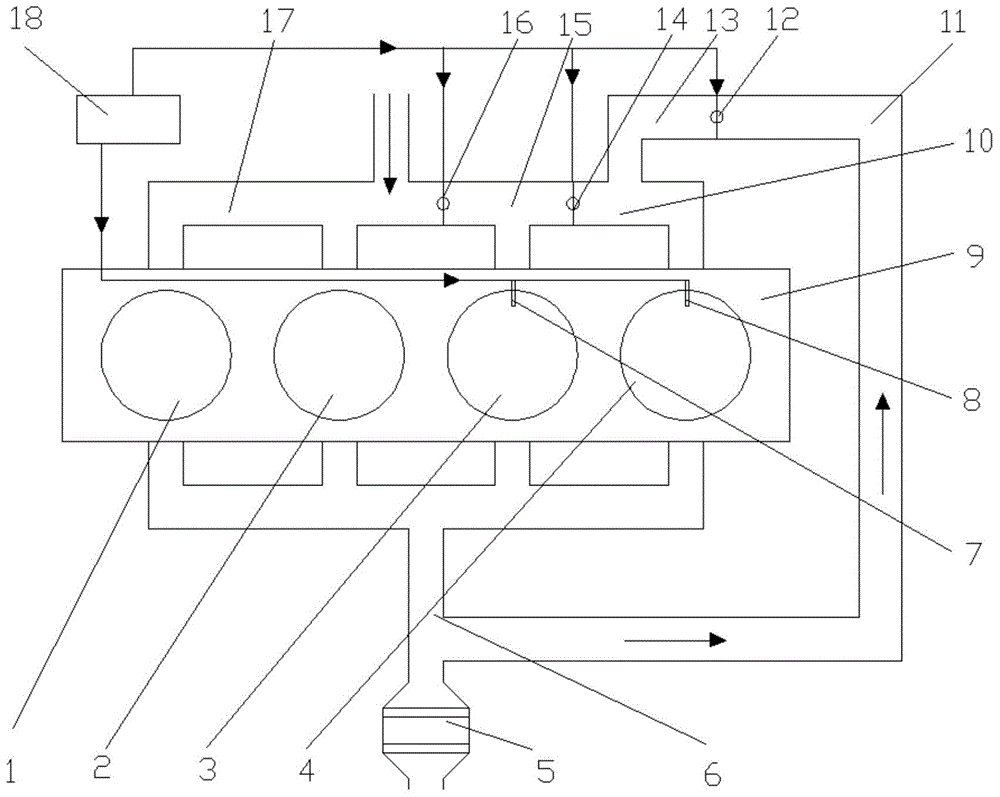

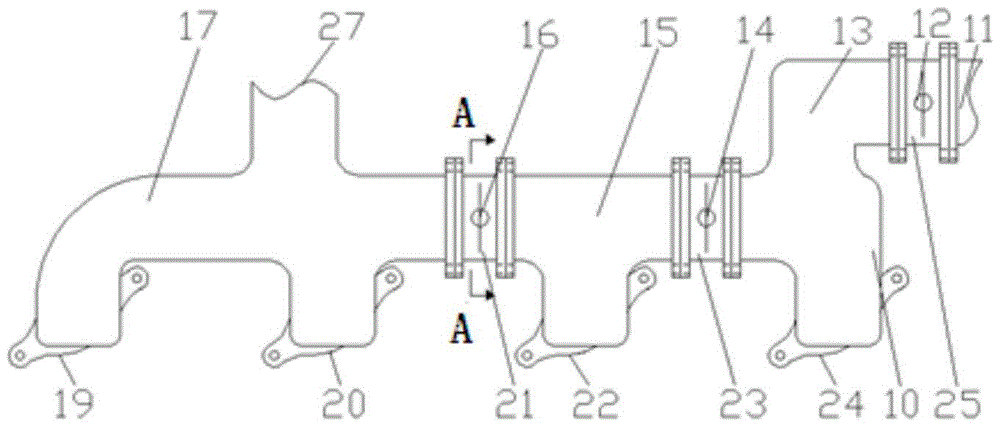

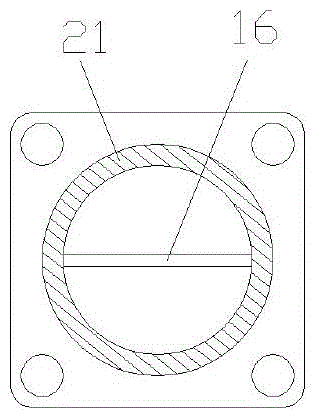

[0020] refer to figure 1 , the circular parts in the figure are engine one cylinder 1, engine two cylinder 2, engine three cylinder 3, and engine four cylinder 4 from left to right. Each cylinder head is equipped with an electronically controlled fuel injector, and only listed below The three-cylinder fuel injector 7 and the four-cylinder fuel injector 8 that the present invention needs to use, one and two cylinder intake pipes 17 are connected with the three-cylinder intake pipe 15 through the throttle connector I21, and the three-cylinder intake pipe 15 is connected through the throttle valve connector II 23 is connected with the intake pipe 10 of the four cylinders. Exhaust gas return pipe I11 connects the exhaust manifold 6 with the four-cylinder intake pipe 10 to realize the function of exhaust gas return. The first and second cylinder intake pipes 17 are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com