Double-injection type fuel gas grading ultra-low nitrogen burner

A gas classification and ejection technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as inability to meet emission requirements, achieve cost savings, maintain stability, and improve adaptability and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with embodiment.

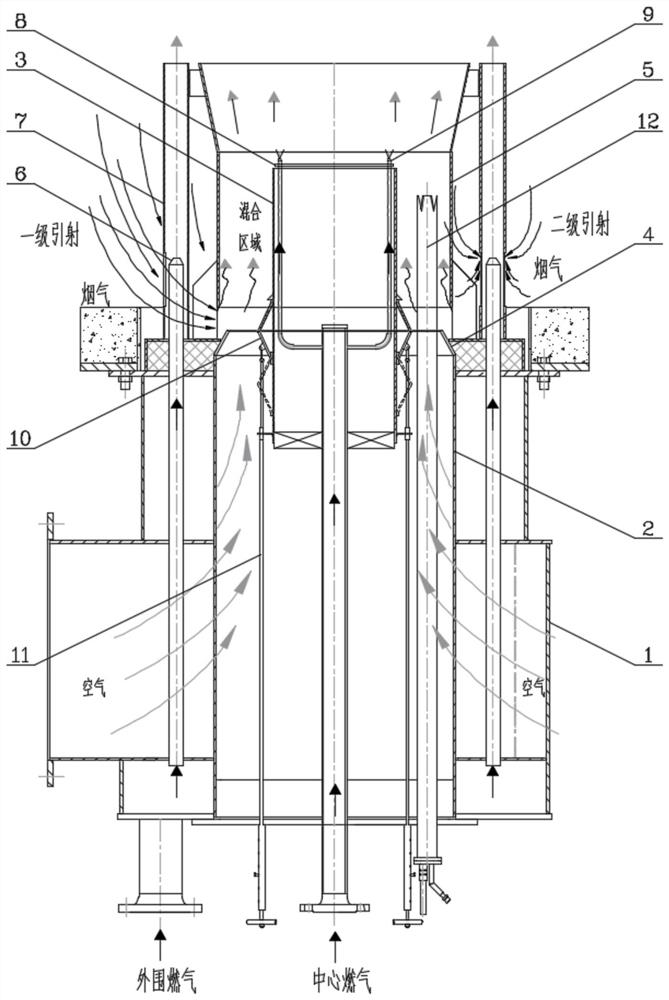

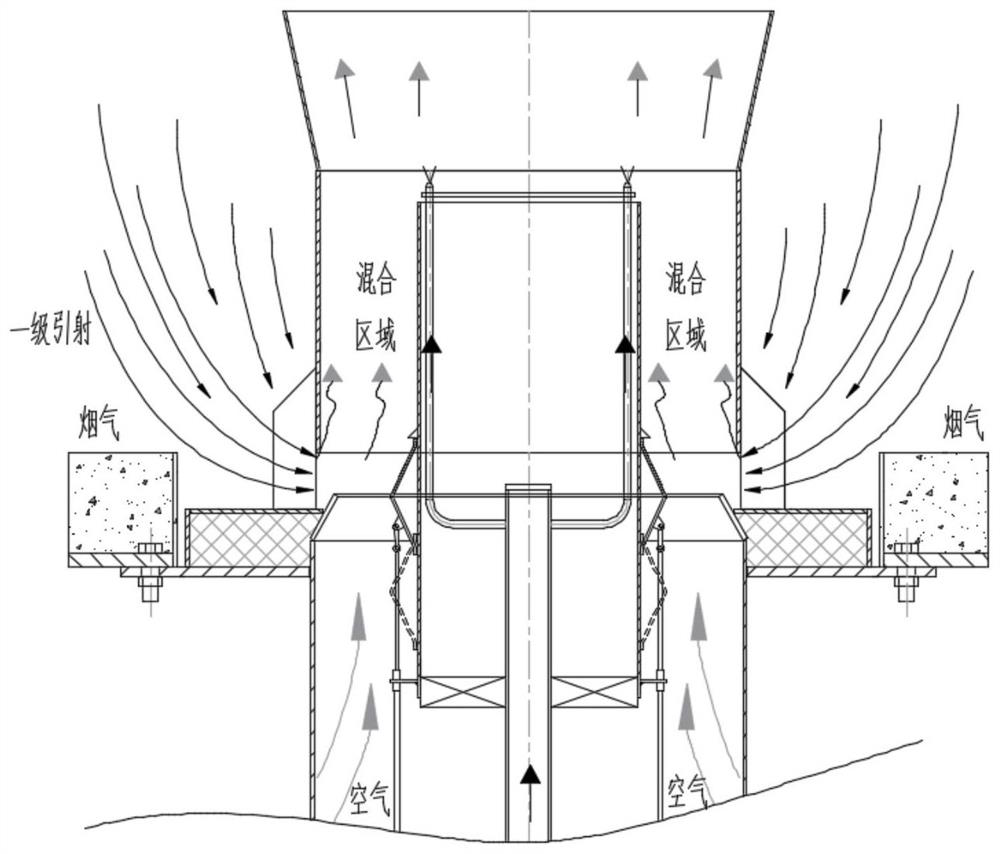

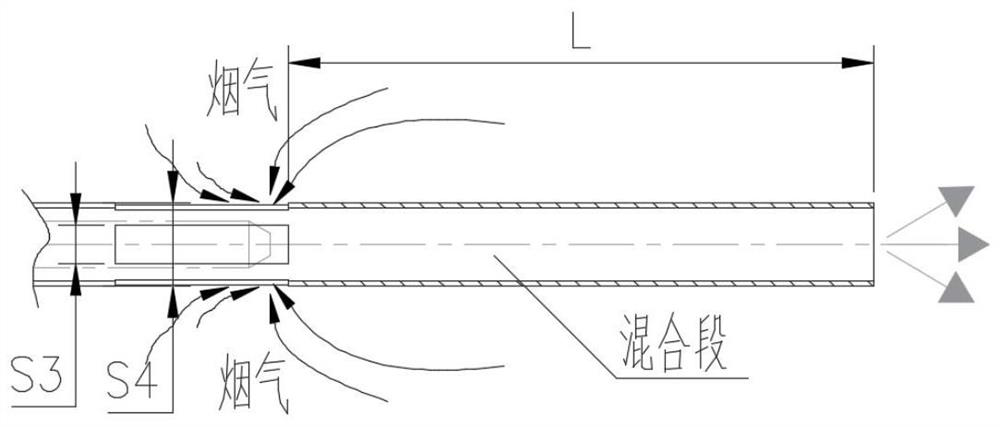

[0027] The present invention designs a double-injection gas graded ultra-low-nitrogen burner. Utilizing the working principle of the injector, high-pressure and high-speed gas (gas and air) is used to inject low-pressure and low-speed flue gas in the furnace, so that fuel, air and flue gas Mixing is performed to achieve low-oxygen combustion of the fuel. The invention can make the current combustion be carried out under the deviation from the stoichiometric ratio, thereby reducing the local high-temperature area in the furnace and reducing NOx emission. The double-injection gas graded ultra-low nitrogen burner of the present invention does not need to increase the induced draft fan and the corresponding process control system and pipeline, which saves the equipment cost, and also reduces the occupied area of the equipment, and has a high promotional use value.

[0028] The inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com