Patents

Literature

221results about How to "Cause wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

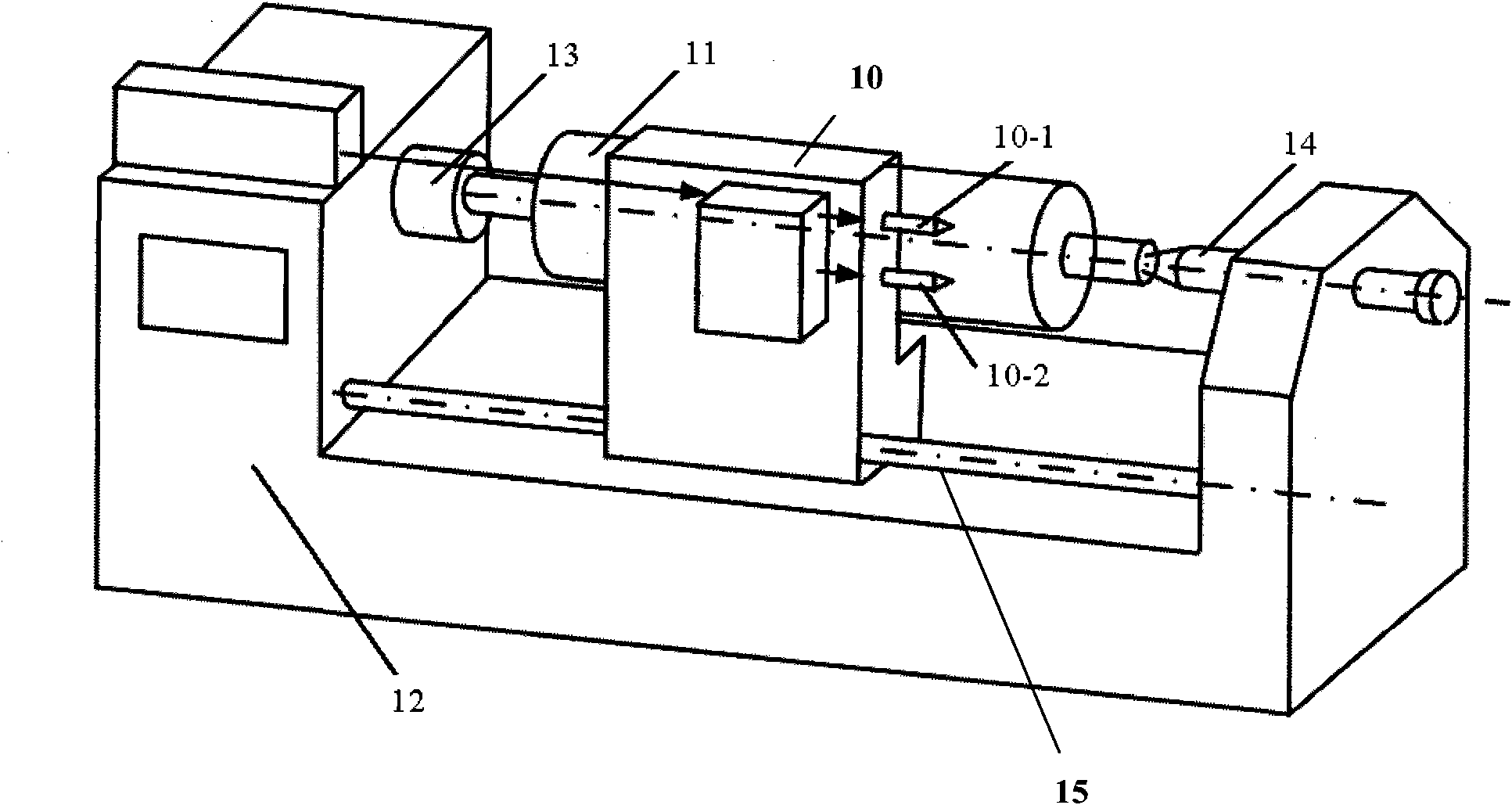

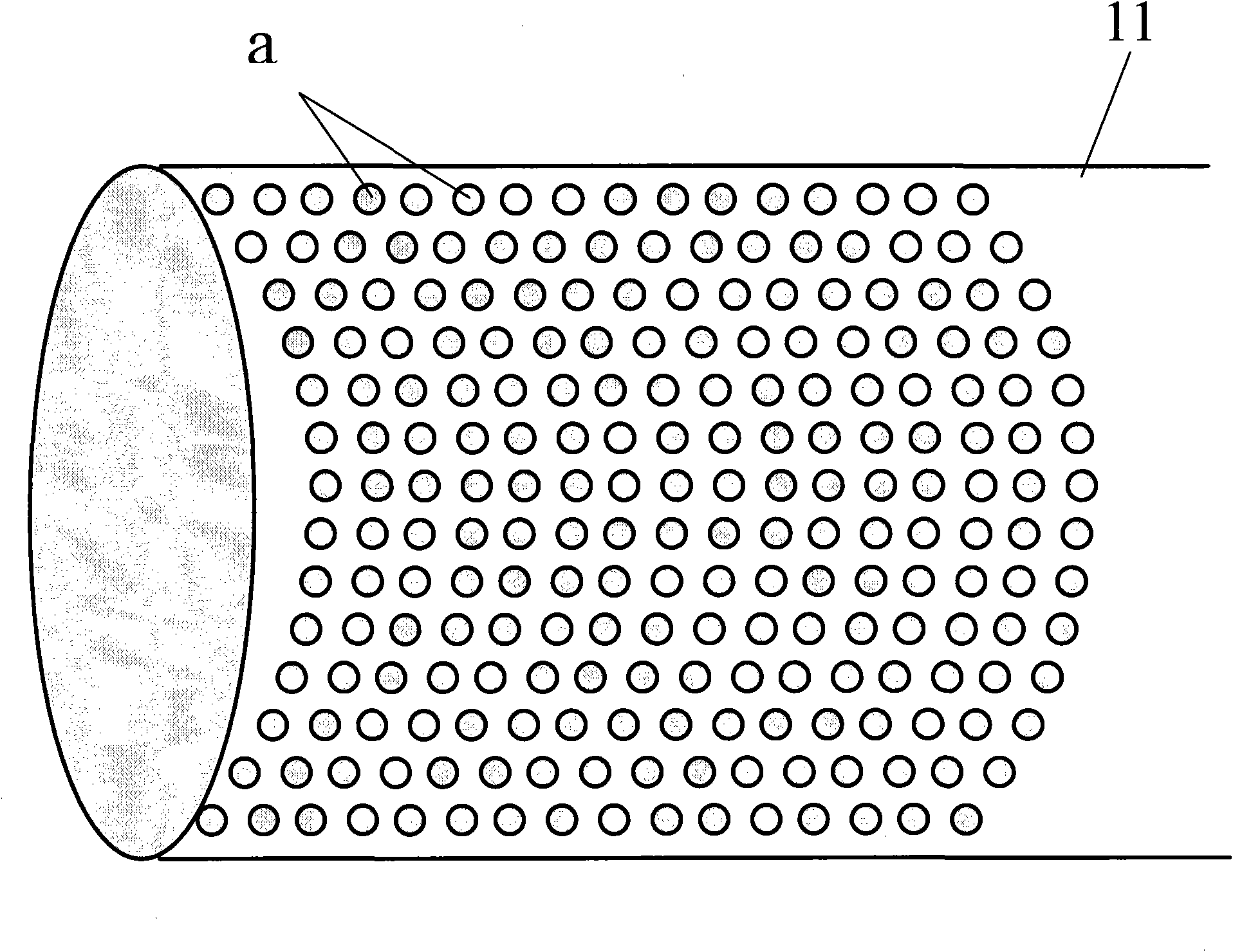

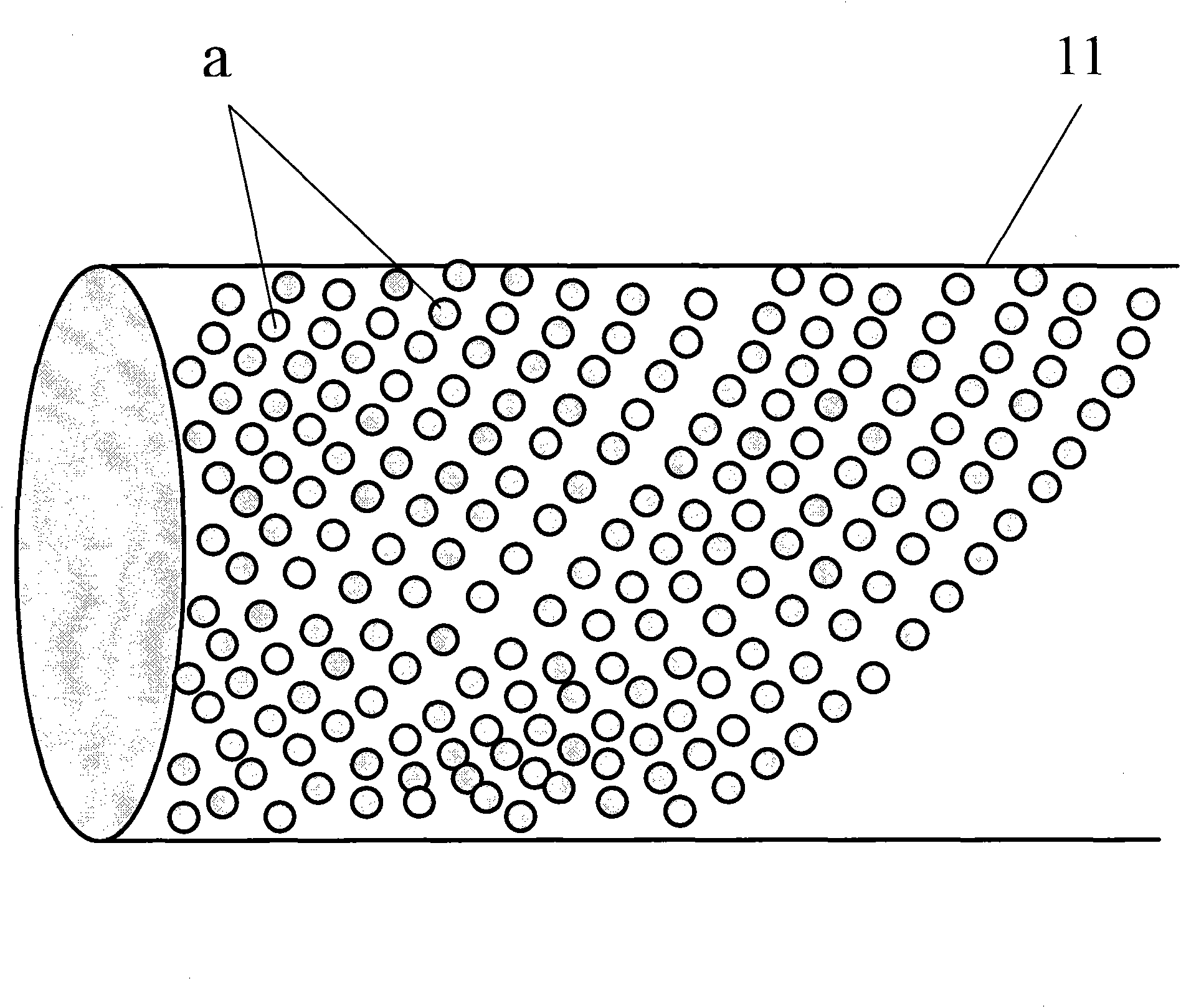

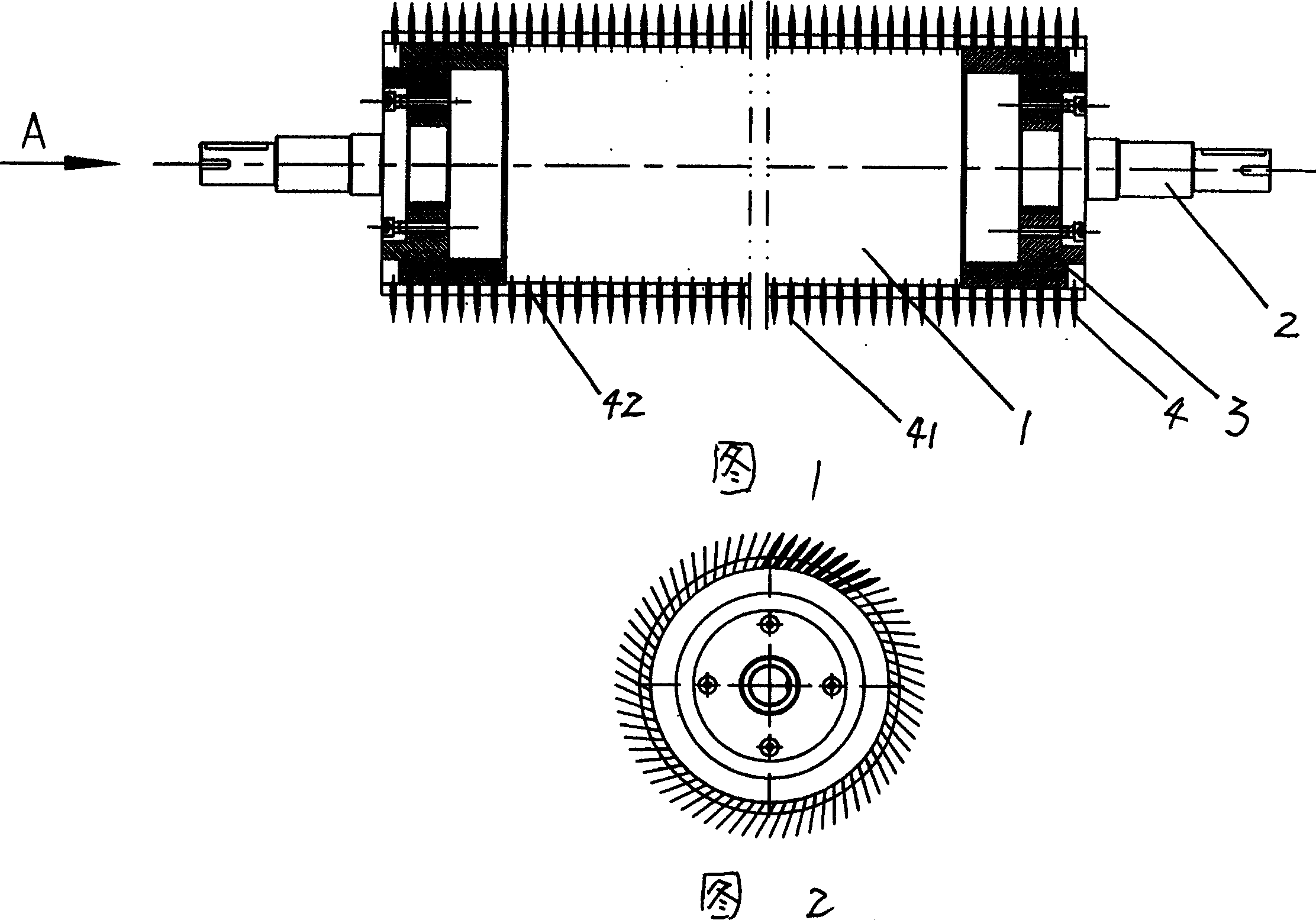

Laser texturing processing method on surface of roller

InactiveCN101642778AImprove rolling qualityImprove wear resistanceRolling equipment maintainenceLaser beam welding apparatusHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

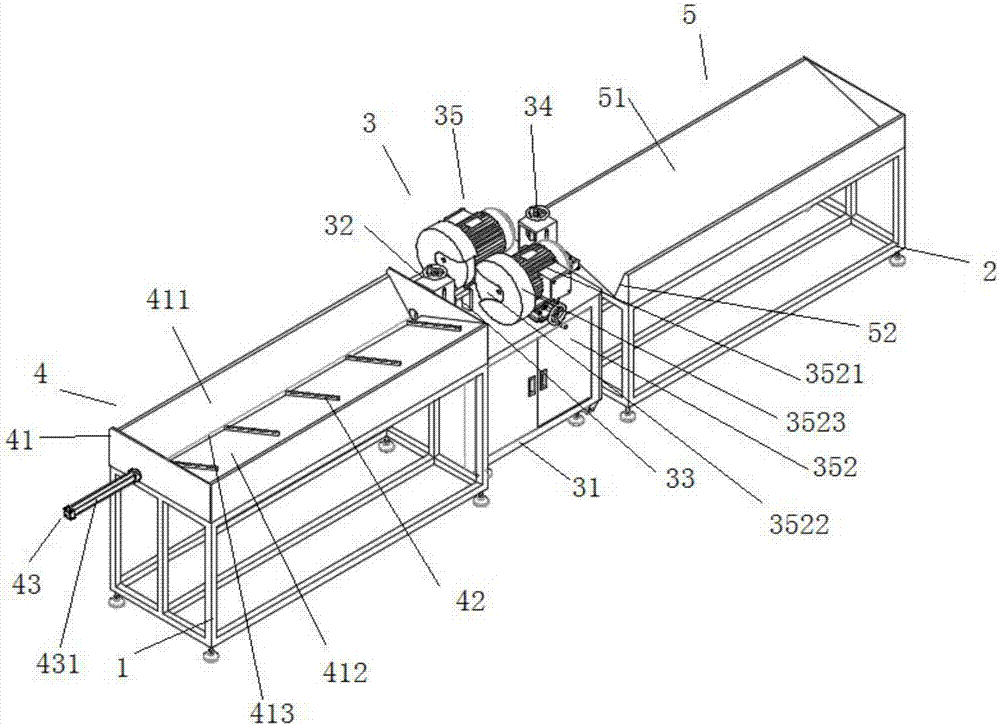

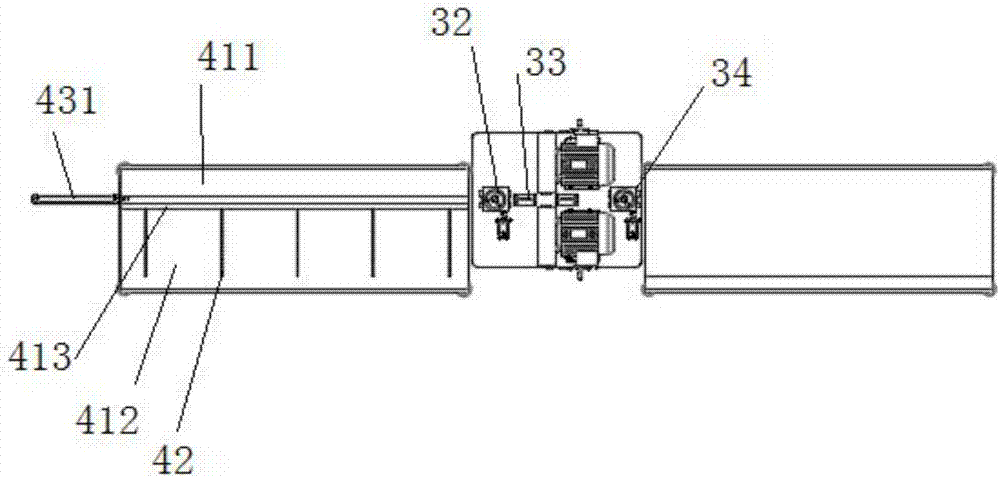

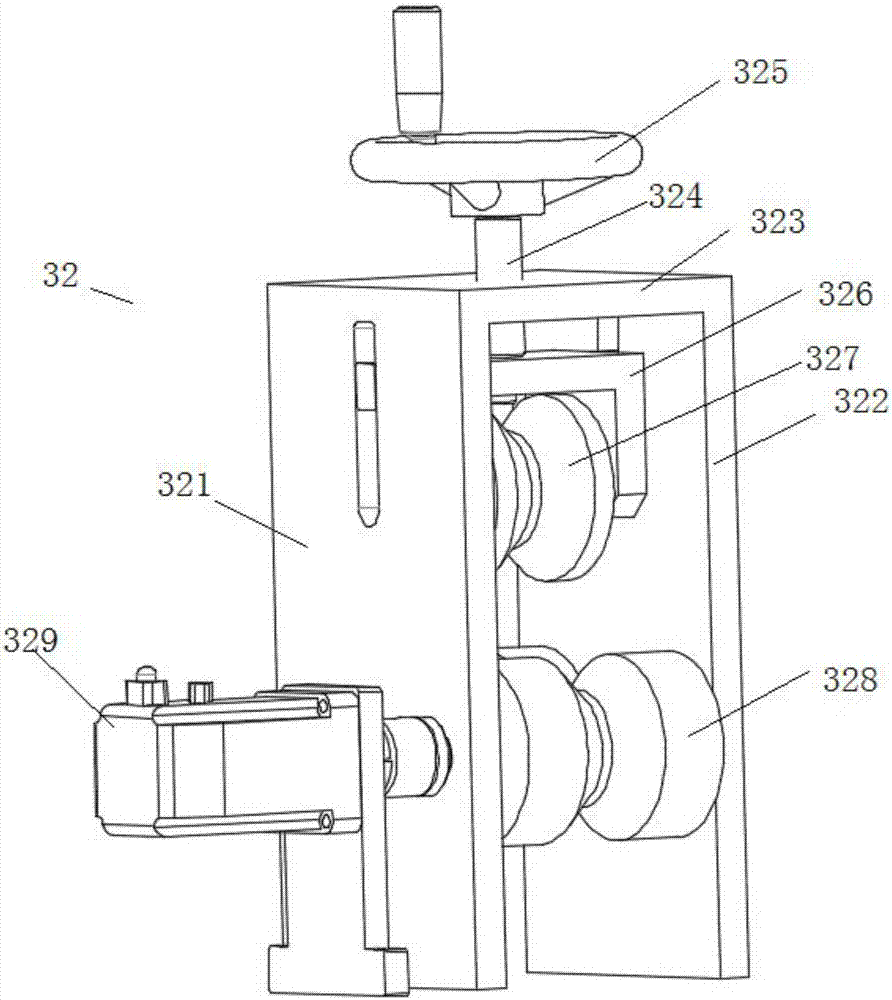

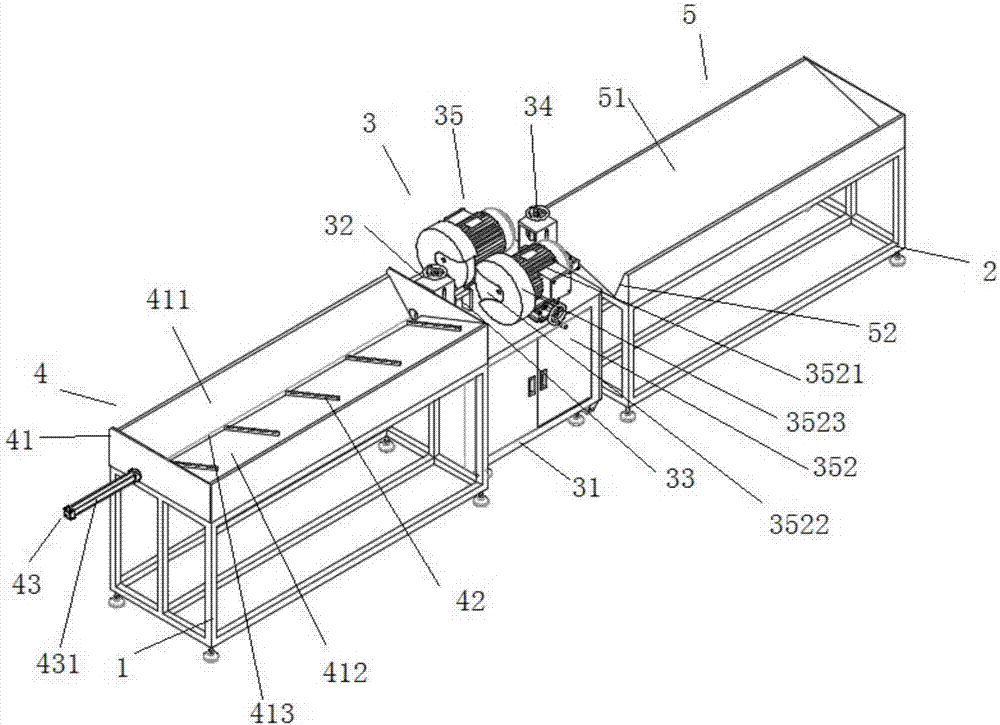

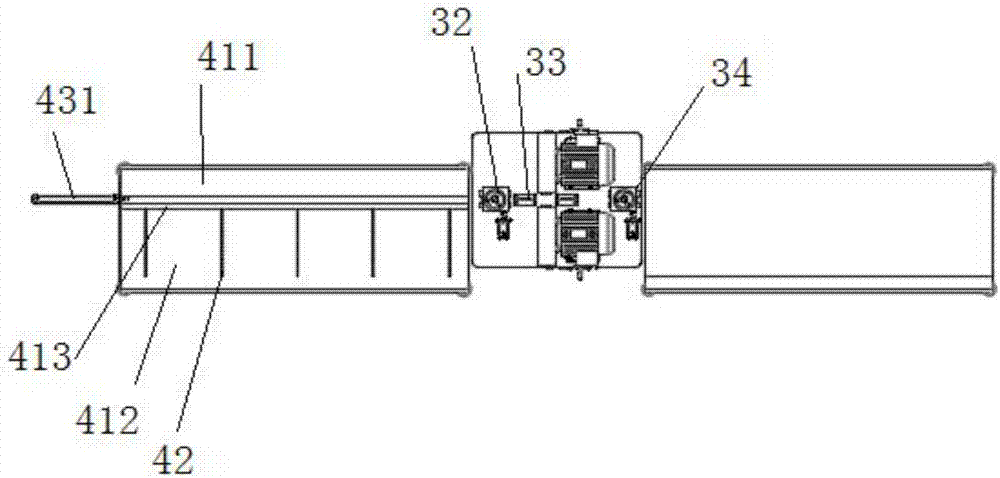

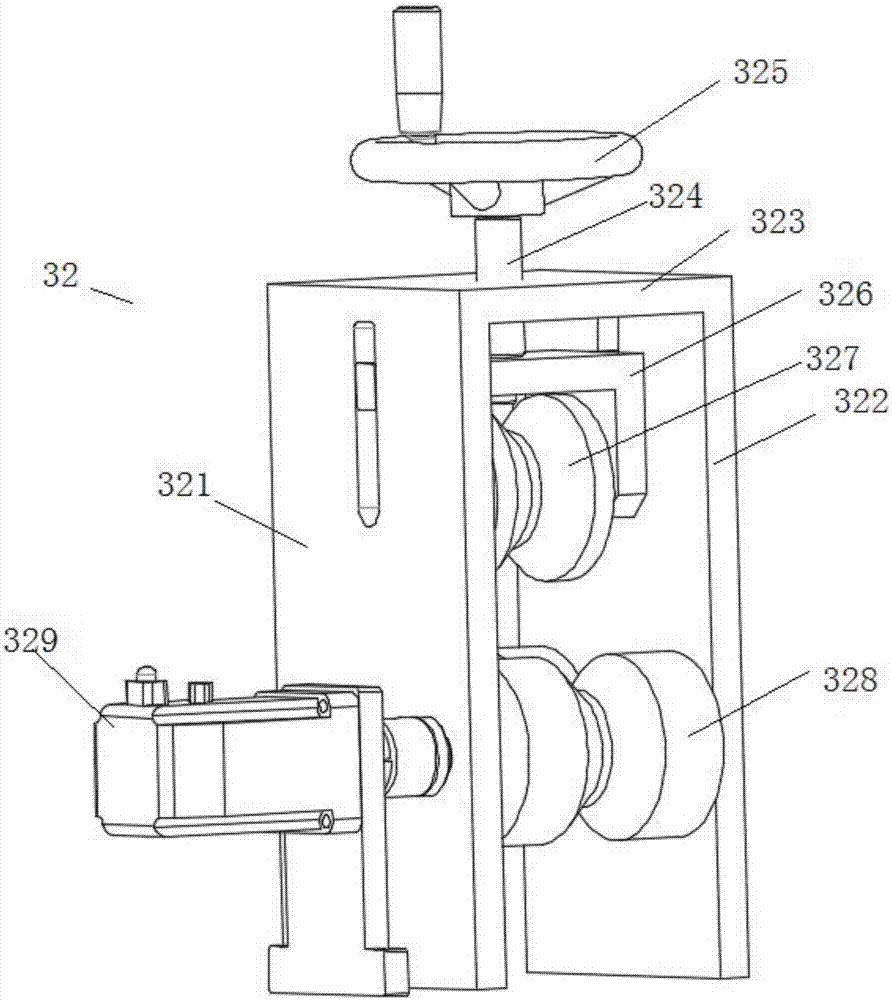

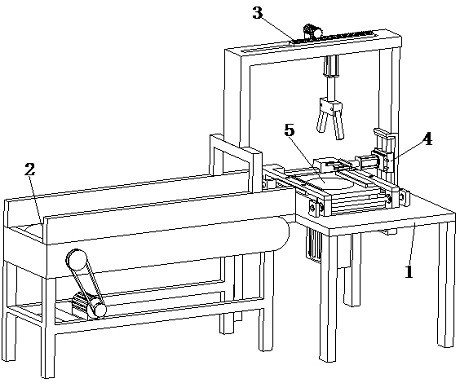

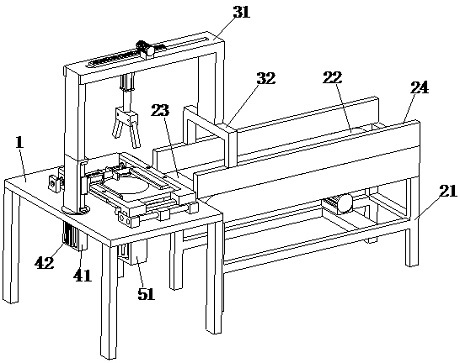

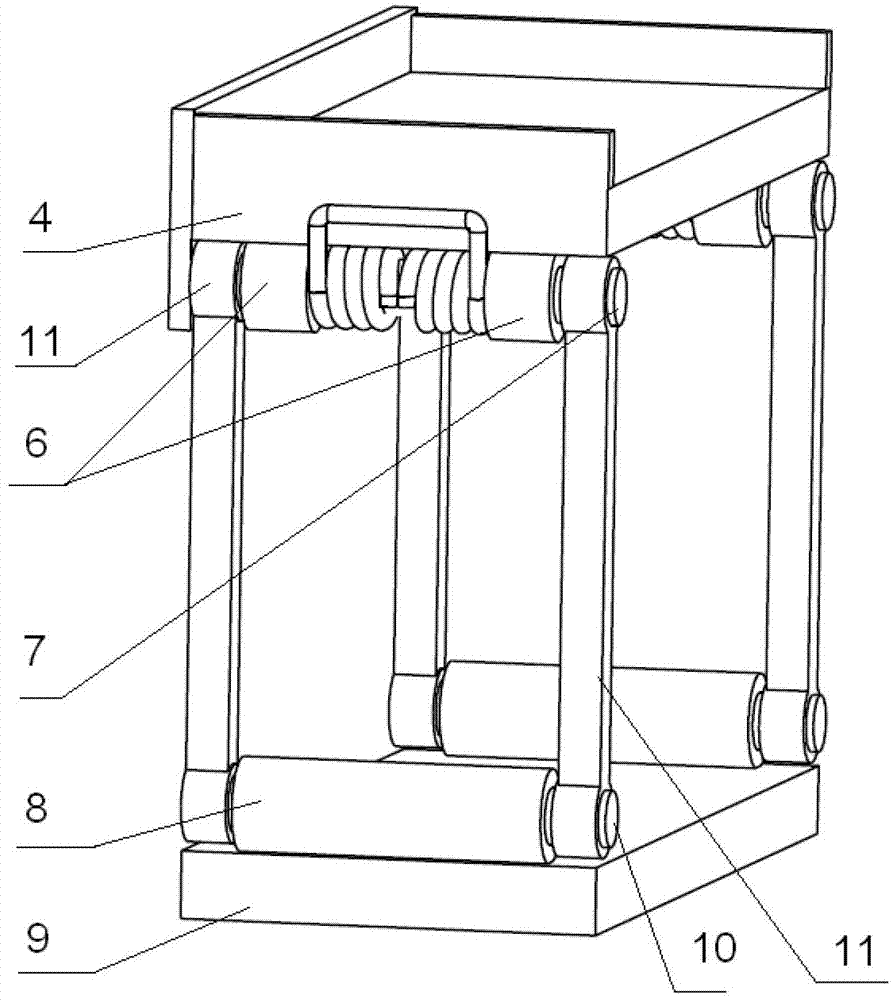

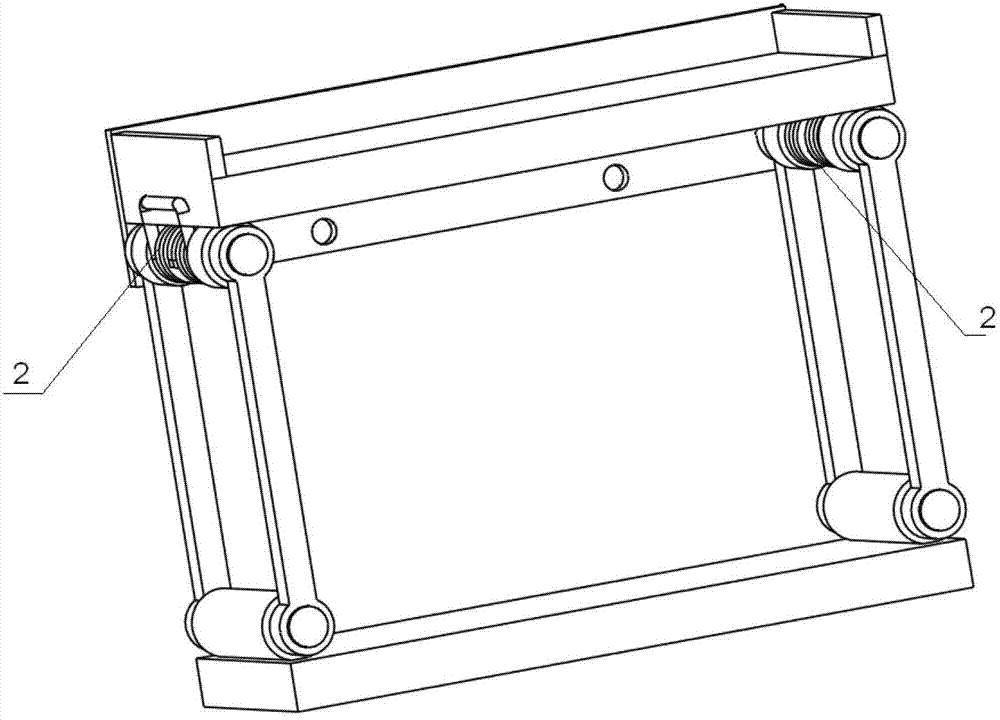

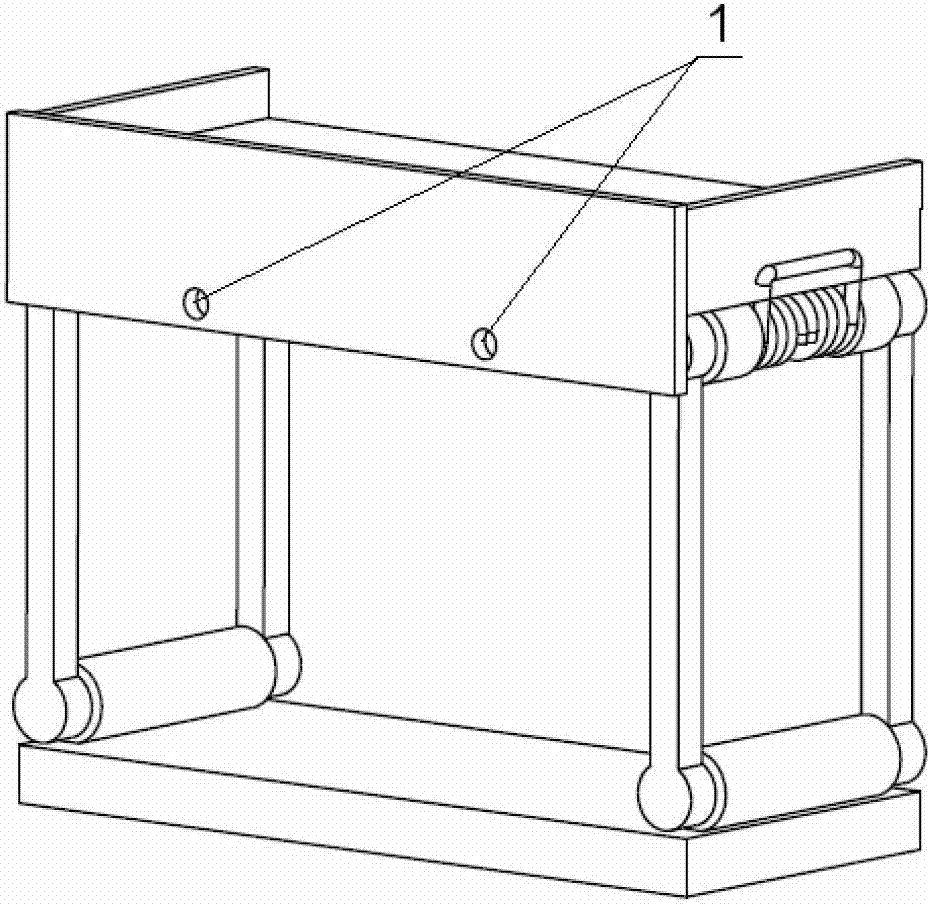

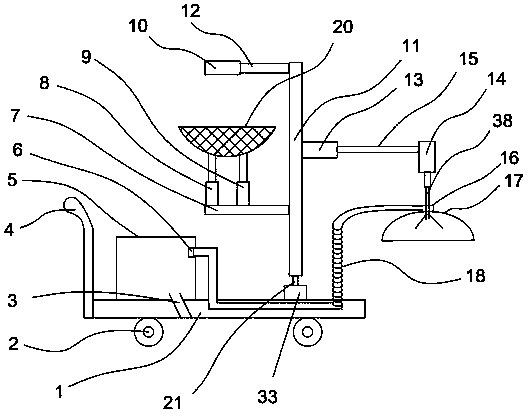

Seamless tube polishing machine

InactiveCN107030588AInnovative designIngenious structureGrinding carriagesPolishing machinesProduction quality

The present invention proposes a seamless pipe polishing machine, which includes a left frame, a right frame, and an automatic polishing machine assembly for pipe polishing, and the automatic polishing machine assembly is located between the left frame and the right frame , the upper end of the left frame is provided with a feeding level, and the upper end of the right frame is provided with a lowering level. The invention has novel design, ingenious structure and low cost, and can be used by most small and medium-sized enterprises; the seamless pipe polishing machine has high working efficiency, good polishing effect, does not cause wear to the pipe itself, and is convenient to operate; The pipe polishing machine can well avoid the backlog of pipes in the feeding process through the set-up branching mechanism; this kind of seamless pipe polishing machine has strong adjustability, and can polish pipes of different specifications, which is conducive to improving production efficiency. Reduce production costs and improve production quality.

Owner:JIASHAN BAOHU CLOTHING

Polisher

InactiveCN107030596AInnovative designIngenious structureGrinding carriagesPolishing machinesMedium enterprisesAgricultural engineering

The invention provides a polisher. The polisher comprises a left rack, a right rack and an automatic polisher component used for polishing tubes, wherein the automatic polisher component is positioned between the left rack and the right rack; a feeding site is arranged at the upper end of the left rack; and a discharging site is arranged at the upper end of the right rack. The polisher is novel in design, skillful in structure and low in cost, can be used by most middle and small-sized enterprises, is high in working efficiency, good in polishing effect and convenient to operate, and can prevent the tubes per se from abrasion; as a tube separation mechanism is arranged, the tubes are well prevented from overstock in the feeding process; and the polisher is strong in adjustability, can be used for polishing the tubes of different specifications, and is conductive to improving the production efficiency and the production quality and lowering the production cost.

Owner:JIASHAN BAOHU CLOTHING

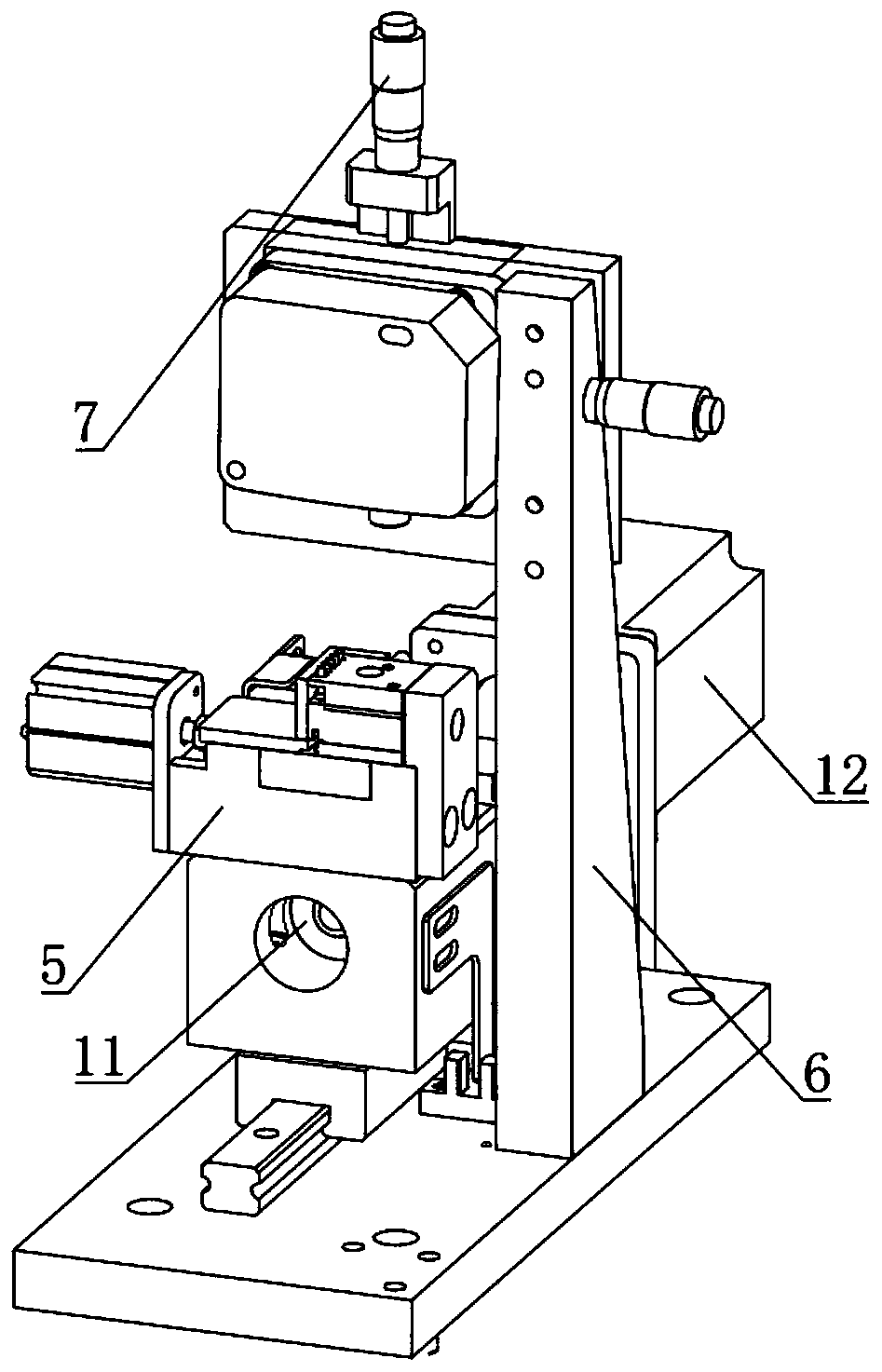

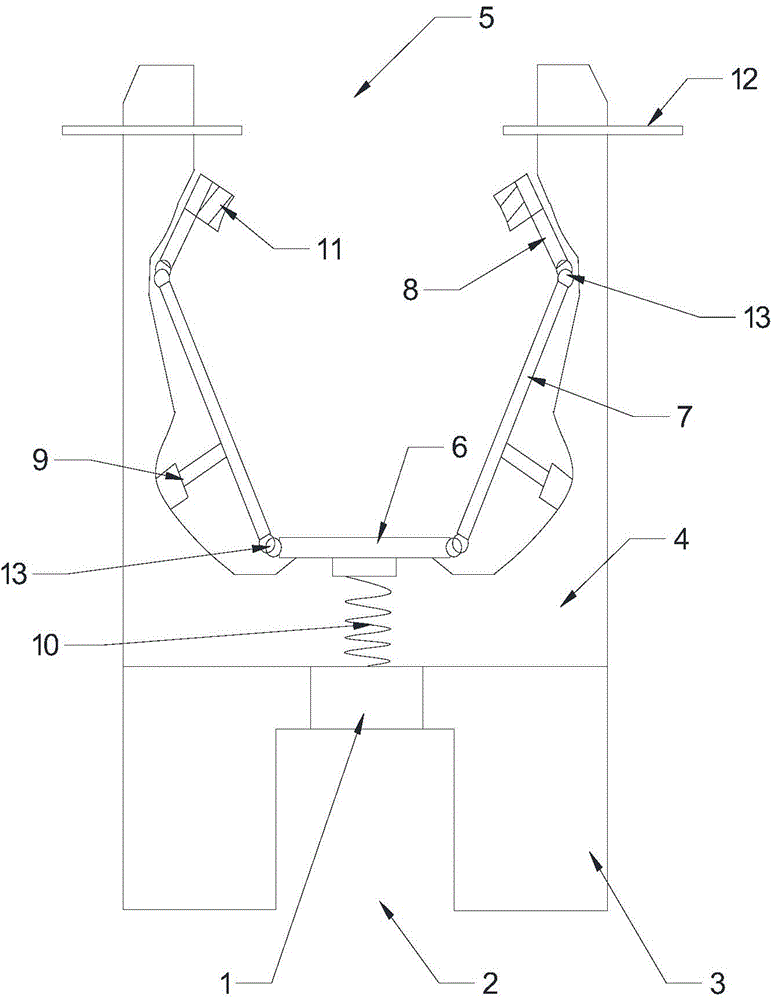

Clamping device for producing transformer

ActiveCN112091359AAutomatic clampingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention relates to the technical field of transformers, in particular to a clamping device for producing a transformer. The clamping device comprises a machining table, a conveying device, a feeding device, a turnover device and a clamping device body, wherein the machining table is arranged on the ground; the top of the machining table is provided with a rectangular groove in sliding fit with the clamping device body; the conveying device is arranged beside the machining table; the feeding device is arranged on the machining table and the conveying device and is located above the clamping device body; the turnover device is arranged above the clamping device body; and the clamping device body is arranged at the top of the machining table. According to the clamping device for producing the transformer, through the mutual operation among the arranged conveying device, the feeding device, the turnover device and the clamping device body, the transformer can be automatically clamped, and pins of the transformer can be welded while the transformer is clamped, so that the welding quality and the production efficiency are improved; and the clamping device can be automatically adjusted, and can clamp transformers with different specifications, so that the use range is enlarged, and wide application and use are facilitated.

Owner:常德创亿电子元件有限公司

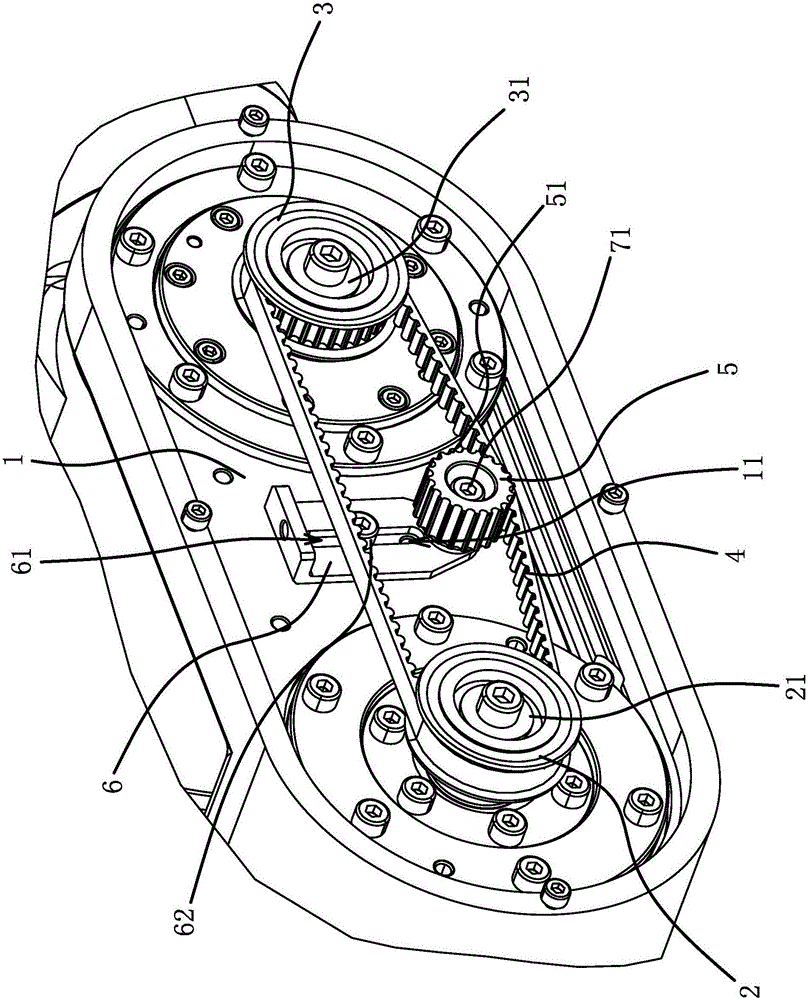

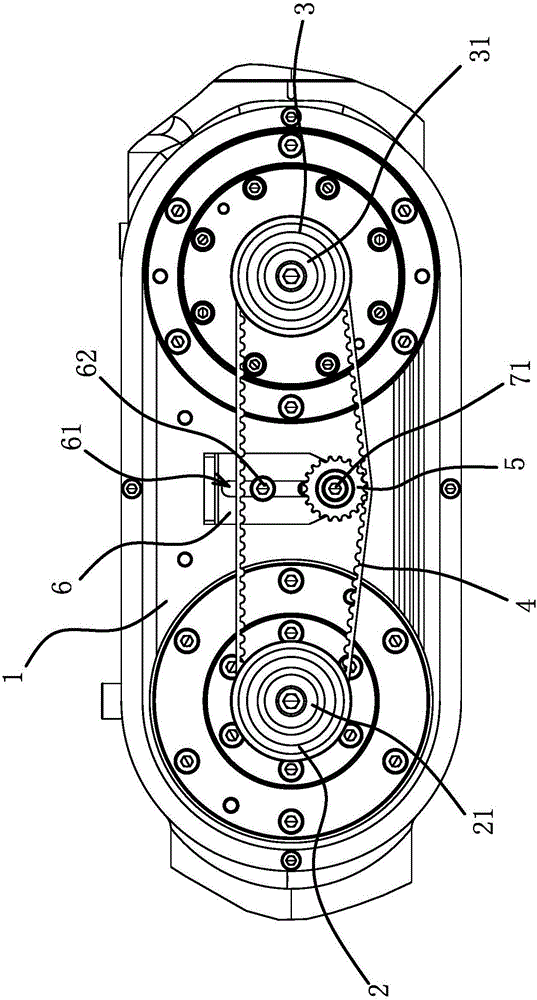

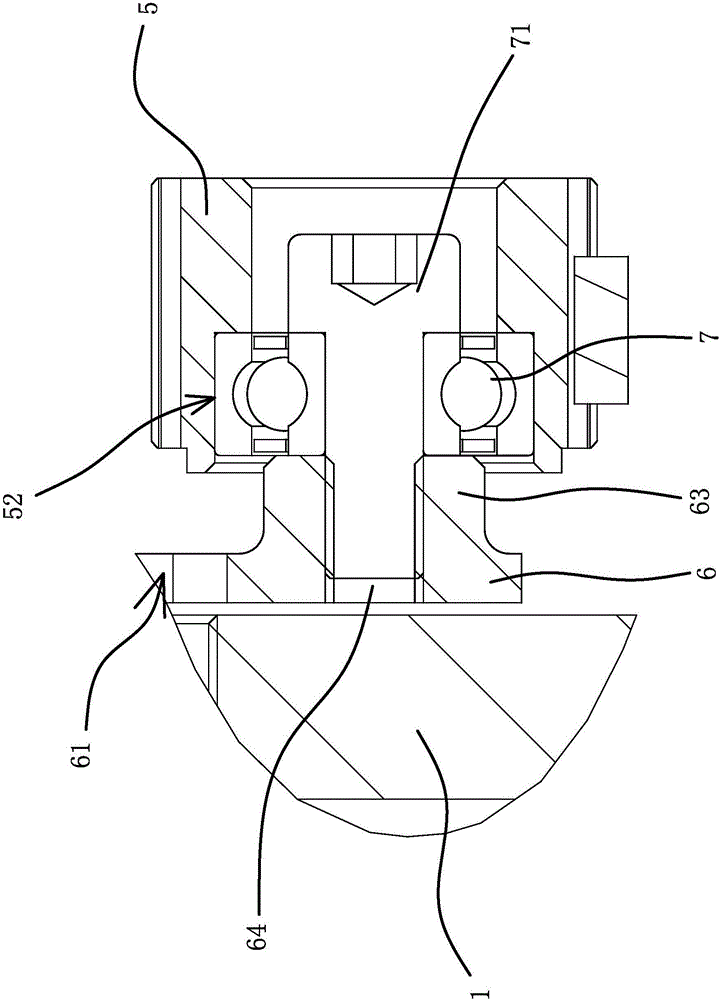

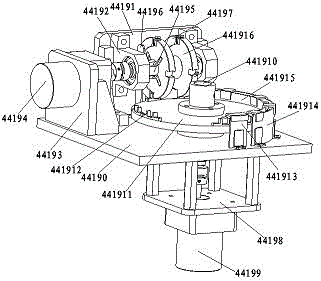

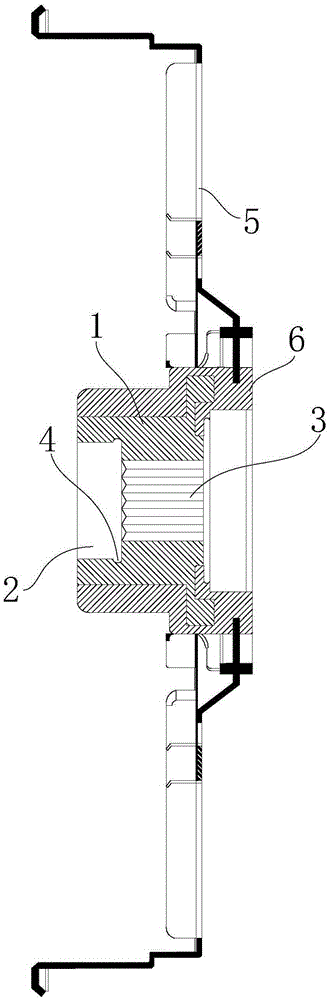

Belt wheel structure for robot

The invention provides a belt wheel structure for a robot, belonging to the technical field of mechanical arms. The technical problems that a current belt wheel structure for the robot is not suitable for the robot and the like are solved. The robot comprises a joint for being connected with a mechanical arm; the belt wheel structure for the robot comprises a driving belt wheel connected with a driving rotation shaft, a driven belt wheel connected with a driven rotation shaft and a tooth-form belt arranged between the driving belt wheel and the driven belt wheel; the driving belt wheel and the driven belt wheel are both arranged in the joint, and the distance between the driving belt wheel and the driven belt wheel is constant; an auxiliary belt wheel with wheel teeth is also arranged between the driving belt wheel and the driven belt wheel in the joint; the auxiliary belt wheel is located on the inner side of the tooth-form belt; and the auxiliary belt wheel can be meshed with one side of the tooth-form belt and enable the tooth-form belt to keep tensioned. The belt wheel structure for the robot disclosed by the invention has the advantages that the tooth-form belt can be enabled to maintain proper tensity, and the stability of transmission is improved.

Owner:ZHEJIANG QIANJIANG MOTORCYCLE +1

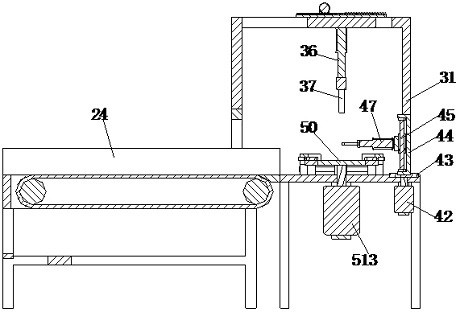

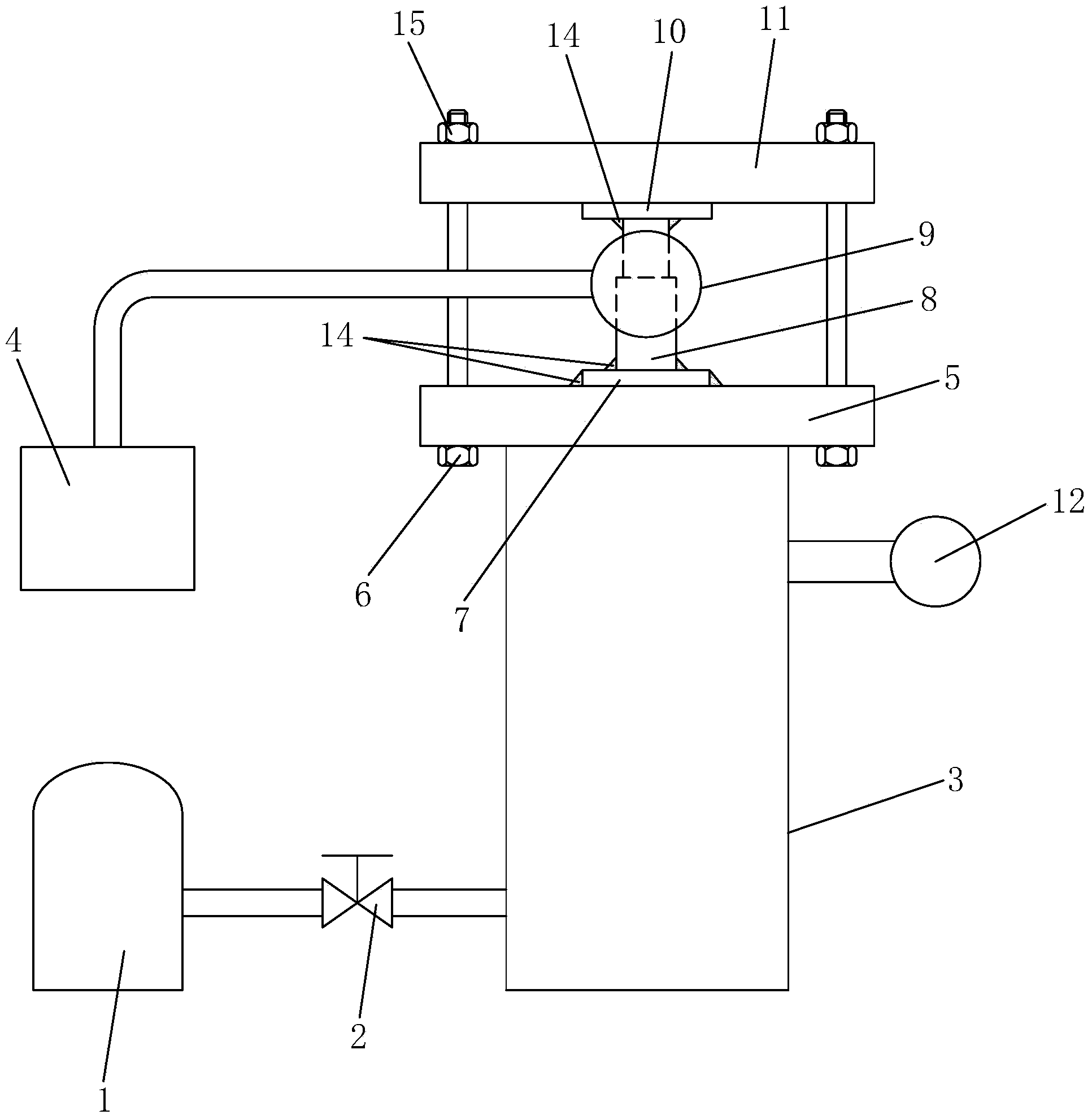

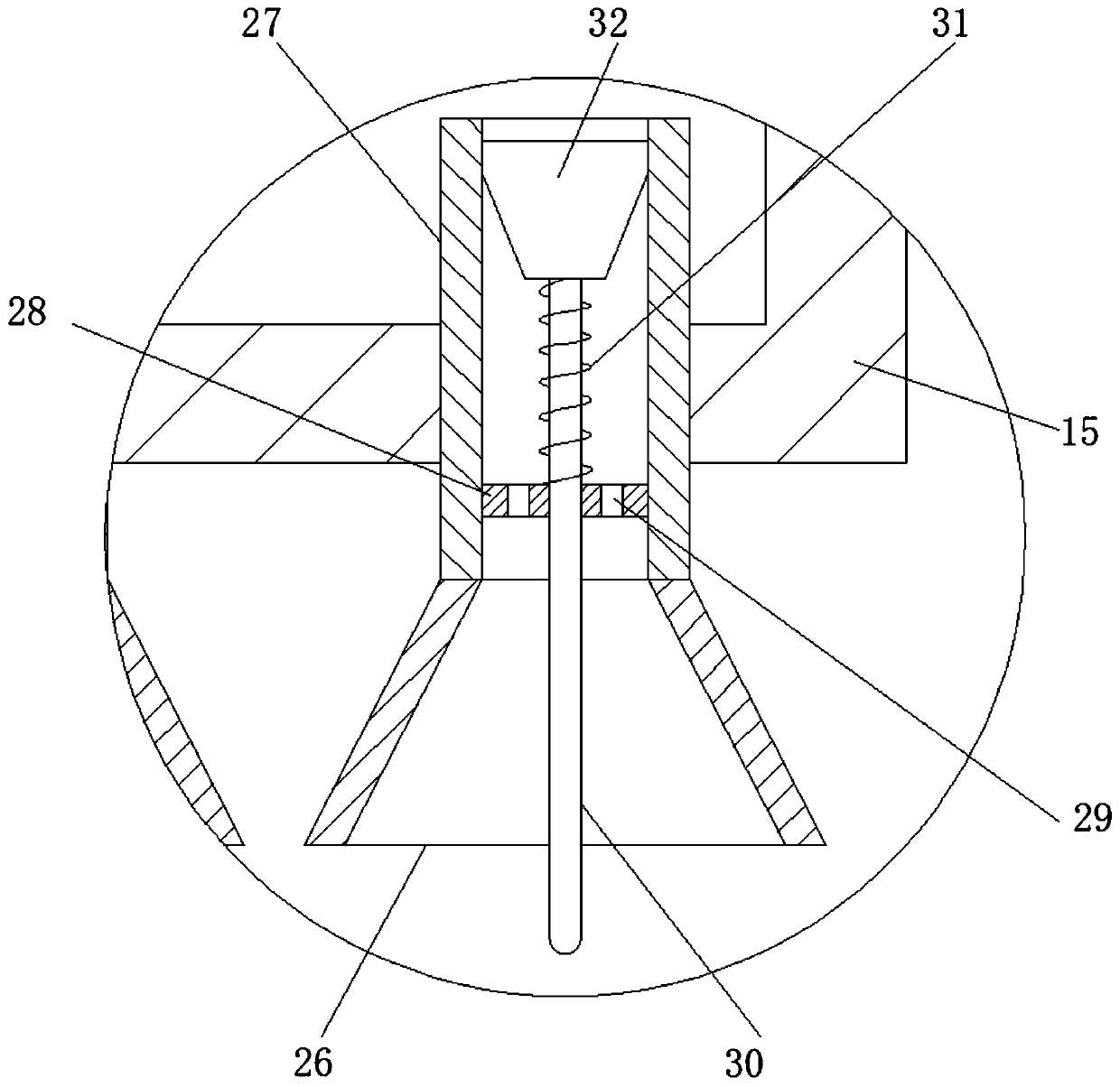

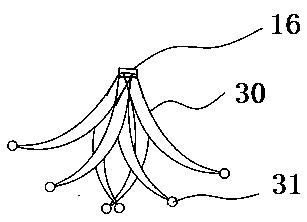

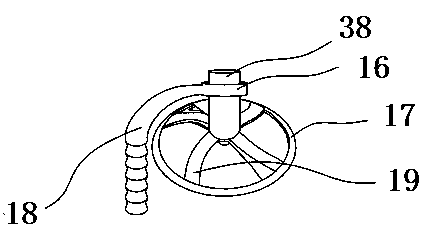

Pipe joint leakage detector

ActiveCN104075855ASimple structureReasonable designDetection of fluid at leakage pointBuffer tankMass spectrometry

The invention discloses a pipe joint leakage detector which comprises a helium tank, a stop valve, a buffer tank, a collecting gas bag and a helium mass spectrometer leak detector, wherein an outlet of the helium tank is connected with one end of the stop valve, and the other end of the stop valve is connected with an inlet of the buffer tank; a pressure meter is connected onto the buffer tank; a pipe joint connecting mechanism is arranged at the top of the buffer tank and comprises a connecting flange, a pressing plate, a first gasket and a second gasket; the connecting flange is fixed at the top of the buffer tank; the pressing plate is arranged above the connecting flange; the second gasket is arranged on the lower end surface of the pressing plate; the first gasket is arranged on the upper end surface of the connecting flange; a pipe joint is arranged between the first gasket and the second gasket; through holes are formed in centers of the connecting flange and the first gasket; the pressing plate is fixedly connected with the connecting flange through fastening pieces; the collecting gas bag is arranged outside the possible leaking part of the pipe joint in a sleeving manner; and a suction gun of the helium mass spectrometer leak detector is communicated with the collecting gas bag. The pipe joint leakage detector can detect leakage of the pipe joint and has high detection sensitivity, accuracy and efficiency.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

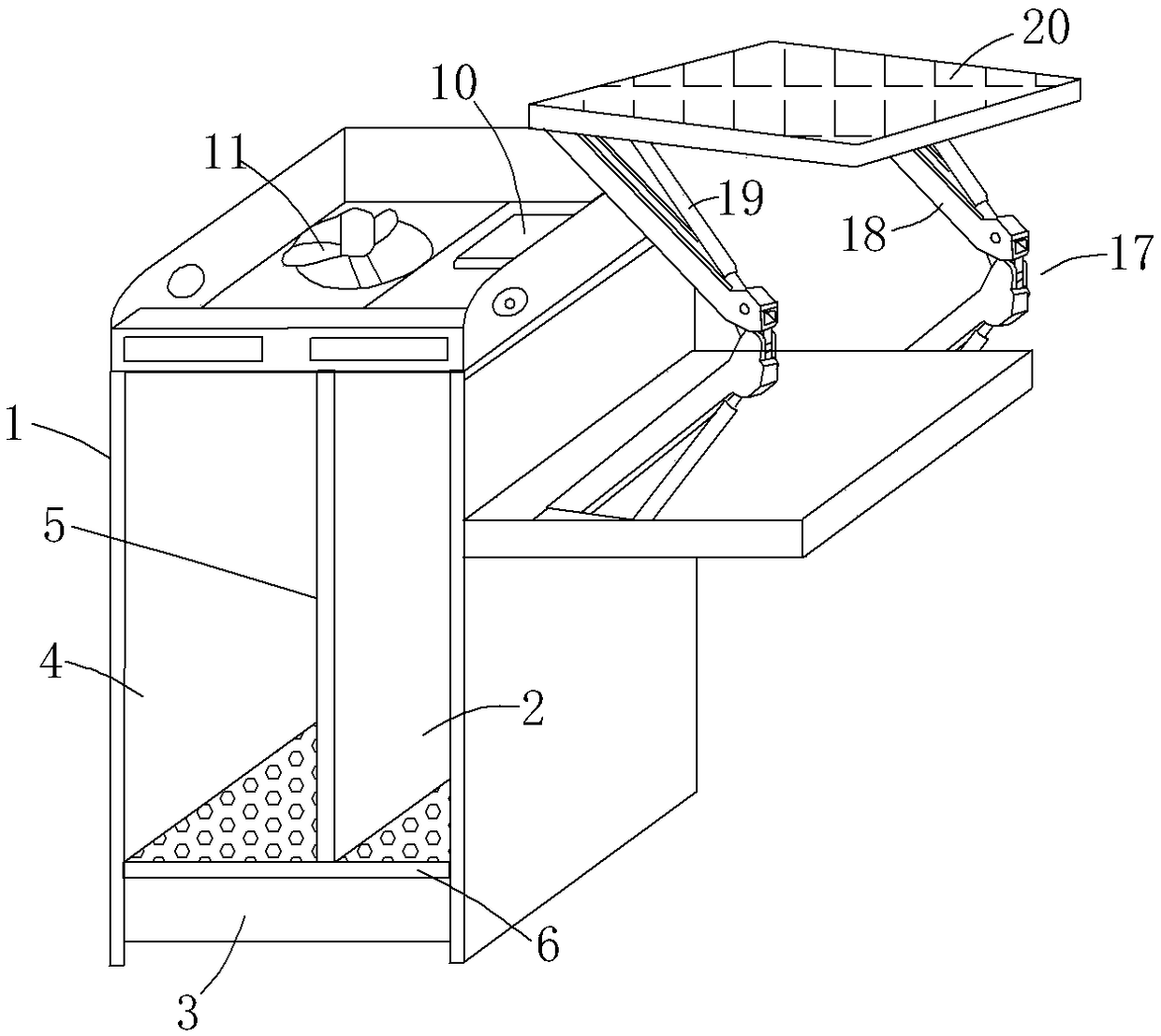

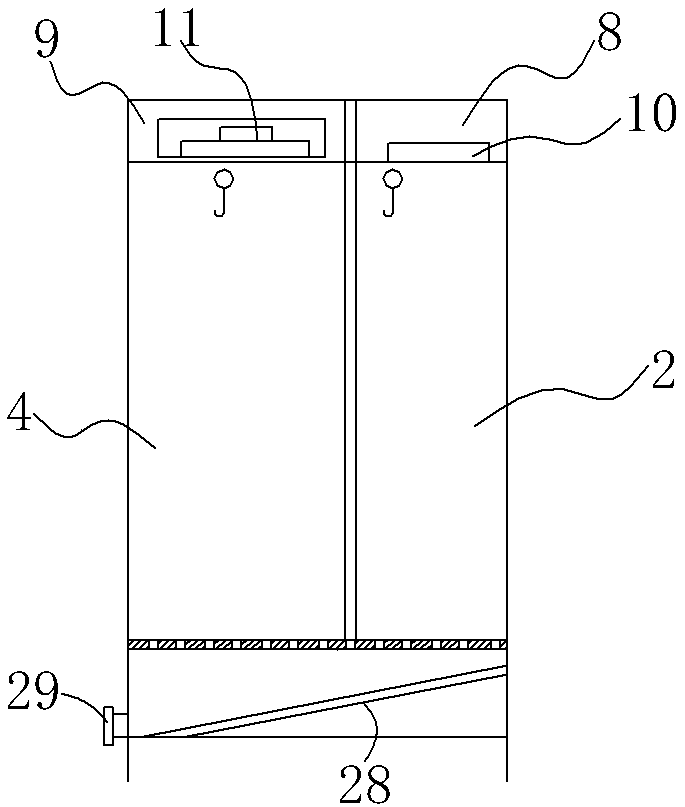

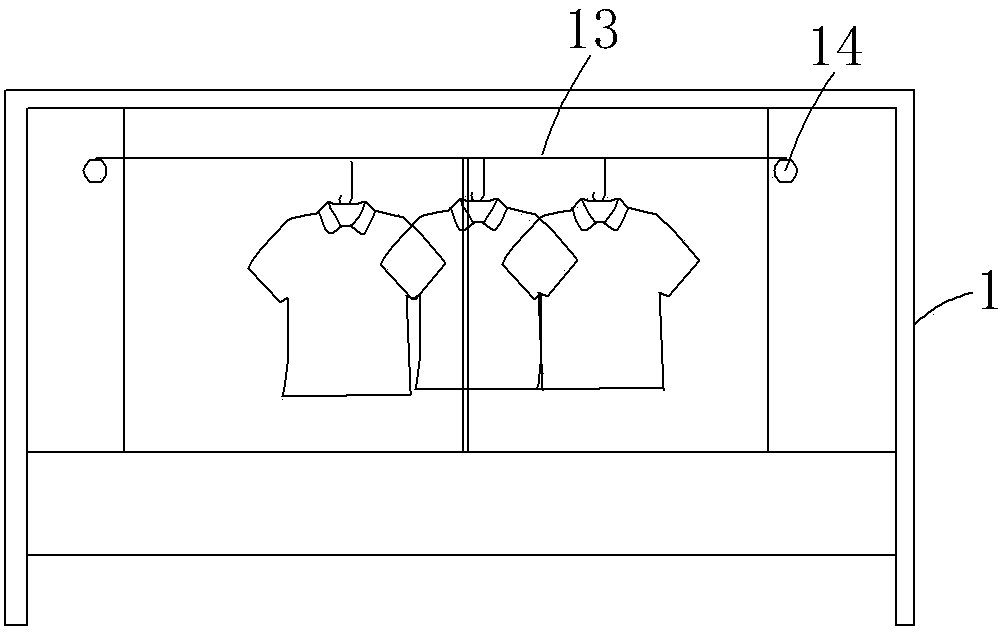

Solar energy clothes drying machine

InactiveCN108265499AReduce Drying CostsEasy to useOther drying apparatusTextiles and paperProcess engineeringElectric energy

The invention relates to a solar energy clothes drying machine, which comprises a clothes drying machine main body, wherein a high-temperature cabin, a flow guide cabin and a low-temperature cabin which are mutually communicated are arranged in the clothes drying machine main body; clothes storage cabins are arranged inside the clothes drying main body and are positioned at the two sides of the high-temperature cabin and the low-temperature cabin; a clothes hanging guide mechanism is respectively arranged among the clothes storage cabins at the two sides and the high-temperature cabin and among the clothes storage cabins at the two sides and the low-temperature cabin; a solar power supply device connected with a power supply is arranged at one side of the clothes drying machine body; the solar panel is used for providing electric energy for a power supply of the clothes drying machine; the electricity can be saved; the clothes drying cost is reduced; the clothes to be dried can be stilly put in the clothes storage cabins at the two sides; the clothes are taken out after the temperature reduction; the solar energy clothes drying machine can also be used as a clothes storage cabinetfor storing clothes and the drying space of the clothes in a next batch cannot be influenced; the clothes completing the drying do not need to be immediately taken out.

Owner:宁波甬辉智能科技有限公司

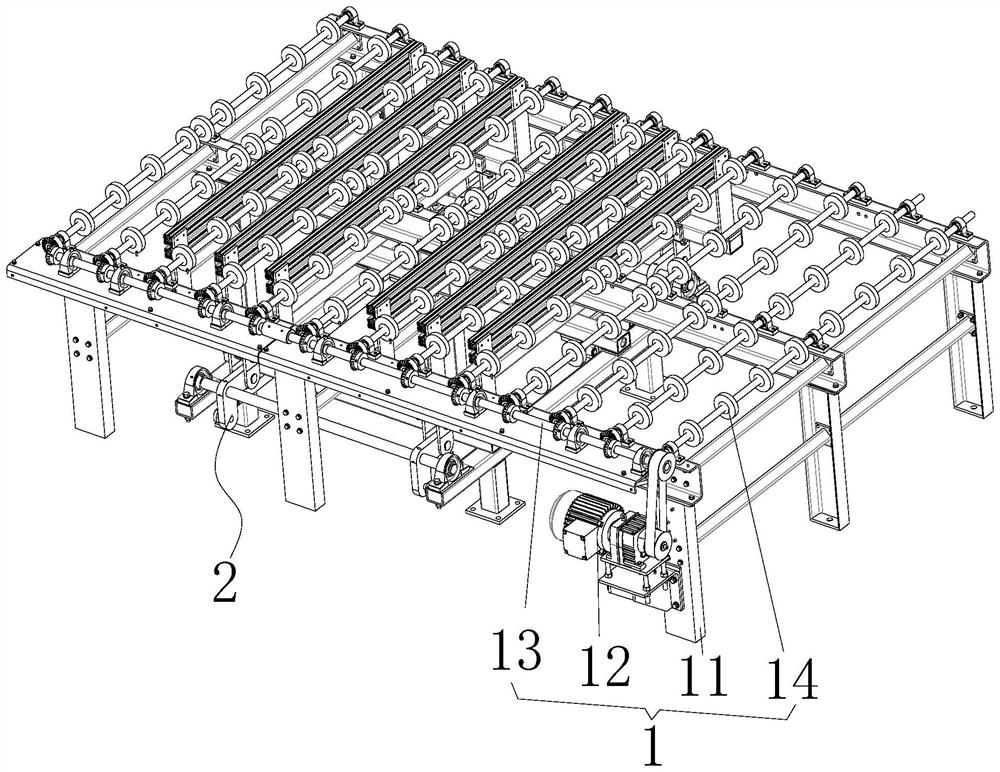

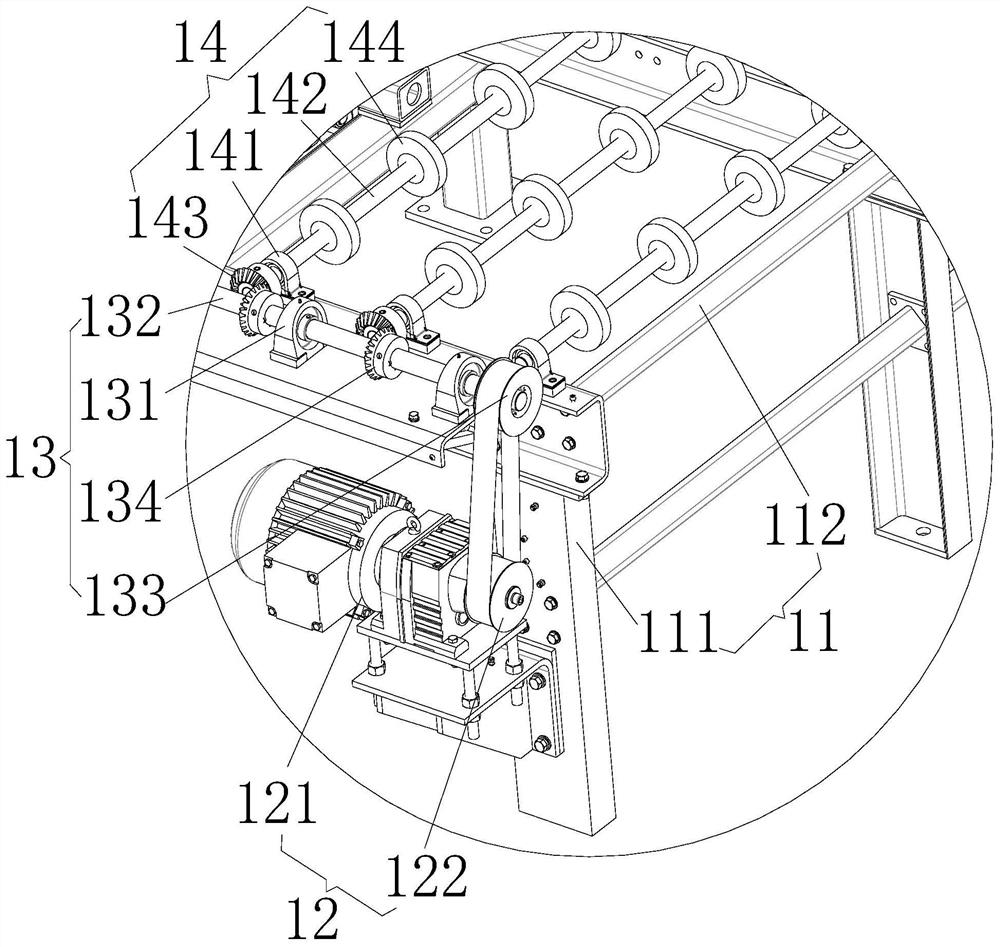

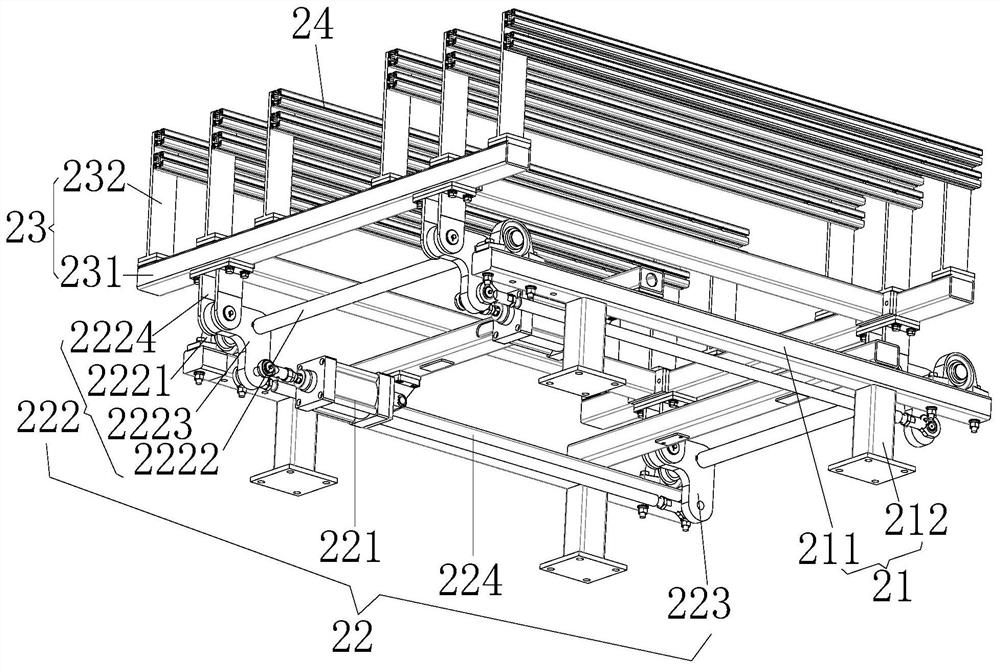

Glass deep processing jacking mechanism

PendingCN111942896AImprove stacking efficiencyIncrease productivityCharge manipulationConveyor partsGlass productionSupport plane

The invention discloses a glass deep processing jacking mechanism. The glass deep processing jacking mechanism comprises a conveying device and a jacking device, wherein the conveying device is provided with the jacking device capable of vertically moving; the conveying device comprises a first rack, a first driving assembly, driving assemblies and driven assemblies, the first driving assembly isdriven, and the driving assemblies rotate to drive the driven assemblies to rotate; and the jacking device comprises a second rack, a second driving assembly, supporting frames and supporting rods, the second driving assembly is driven, and the supporting rods are driven by the supporting frames to vertically move in gaps between the driven assemblies. The glass deep processing jacking mechanism has the advantages that under the condition that the conveying device does not stop running, the jacking mechanism prevents the stacking phenomenon on the conveying device when the manipulators grab and stack glass, and an existing mode of stopping conveying of the conveying device for preventing glass stacking does not need to be adopted, so that the glass stacking efficiency is greatly improved,and then the glass production efficiency is improved.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

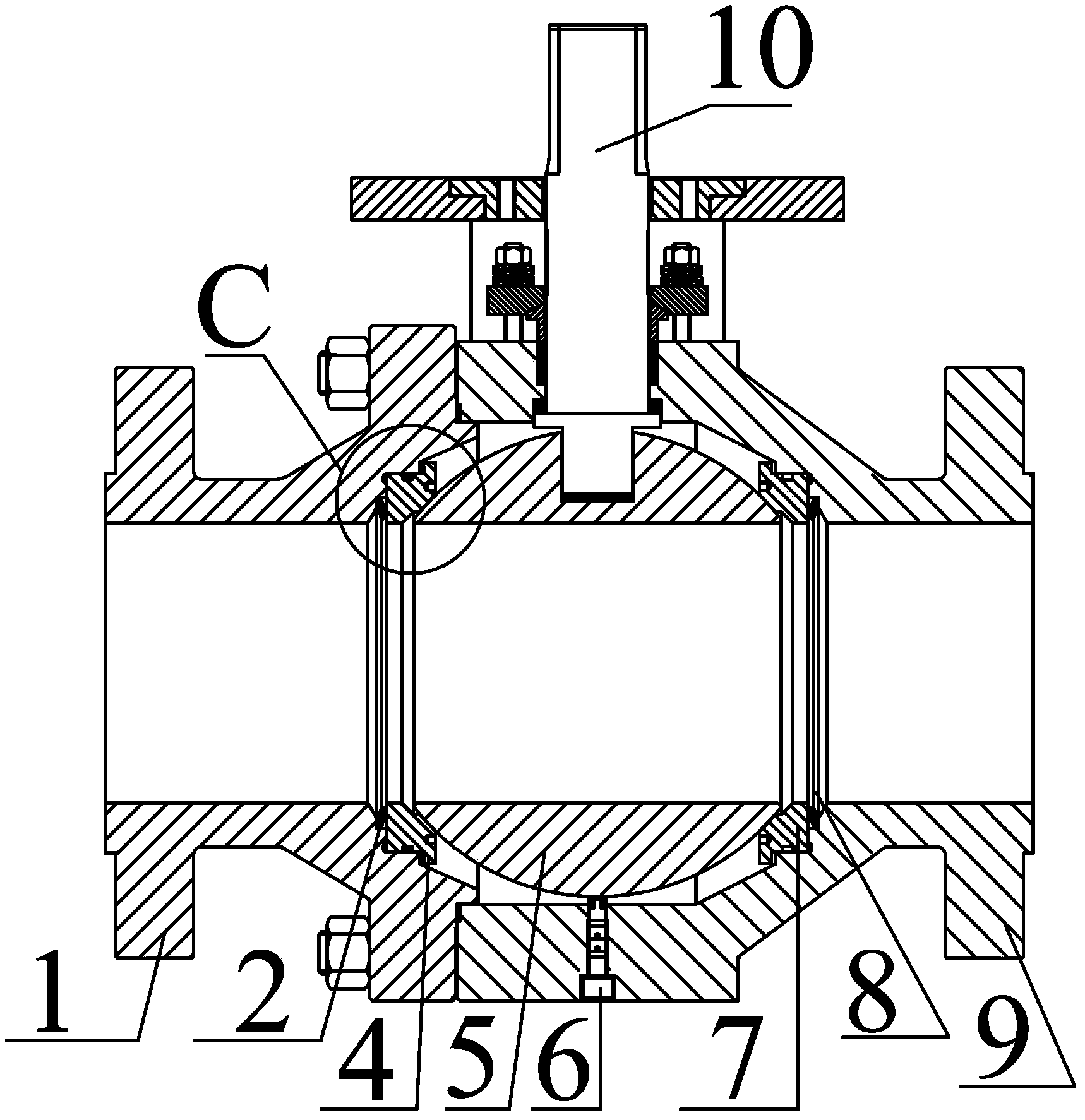

Ball valve

The invention discloses a ball valve which comprises an auxiliary valve body, a first sealing valve seat, a ball core, a second sealing valve seat and a main valve body. The auxiliary valve body and the main valve body are connected with each other, the first sealing valve seat, the ball core and the second sealing valve seat are sequentially mutually abutted and are arranged in a chamber formed by the auxiliary valve body and the main valve body, a first elastic piece is arranged between the auxiliary valve body and the first sealing valve seat, and a second elastic piece is arranged between the second sealing valve seat and the main valve body. The first elastic piece and the second elastic piece cooperatively push the first sealing valve seat and the second sealing valve seat to shift with the ball core, and the first sealing valve seat and the second sealing valve seat are still capable of being abutted and sealed on the surface of the ball core, so that clearance cannot be formed in the valve bodies, inner leakage never occurs, and particles cannot be embedded in the ball core to cause abrasion of the ball core.

Owner:YANKE SHANGHAI VALVE IND CO LTD

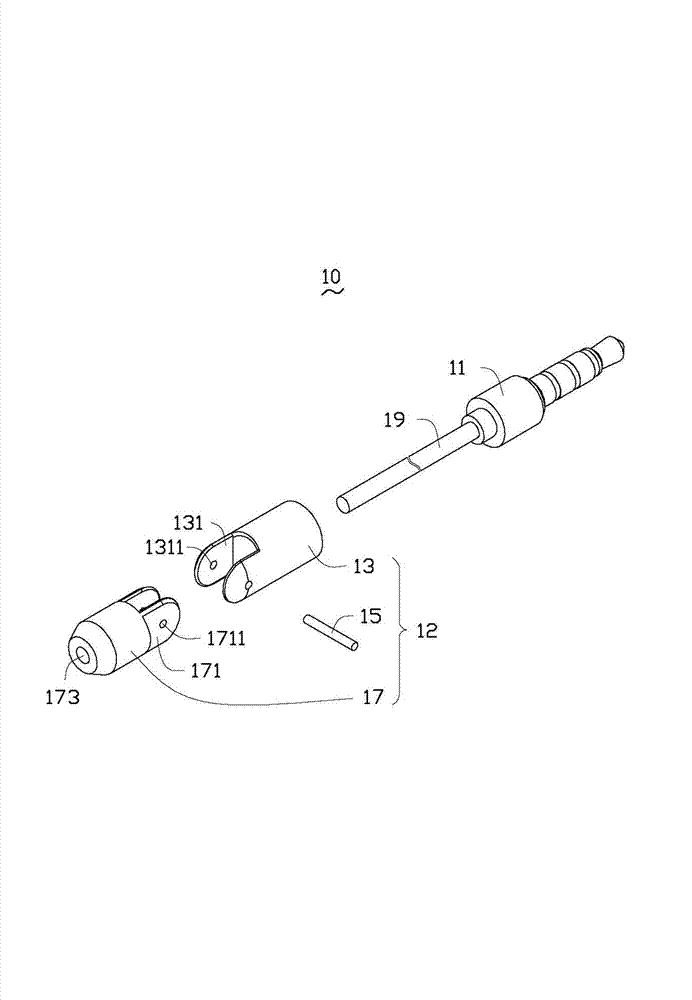

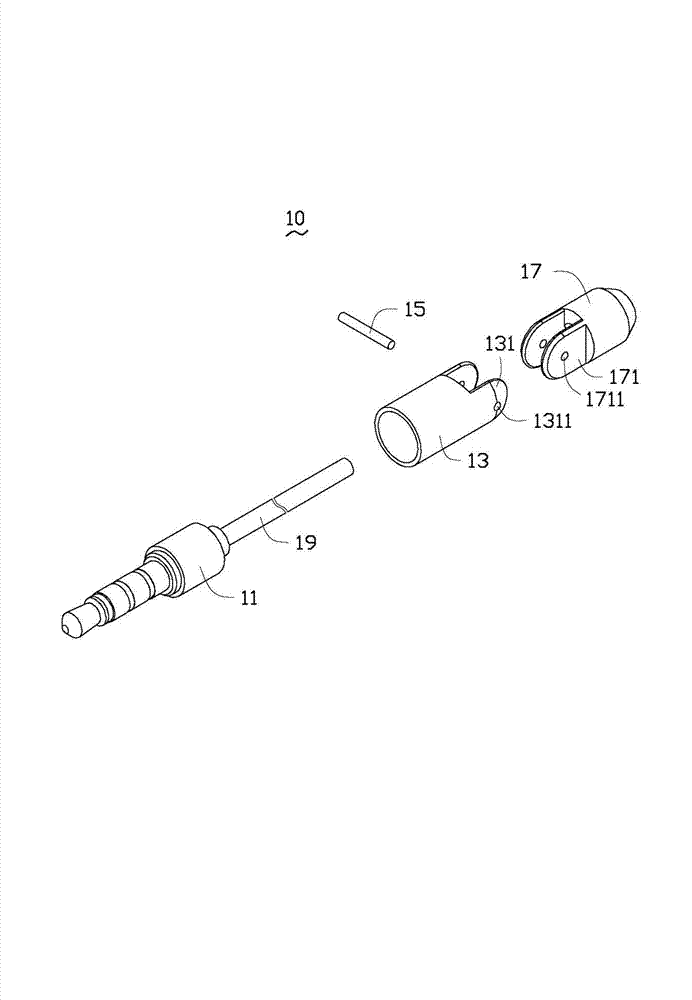

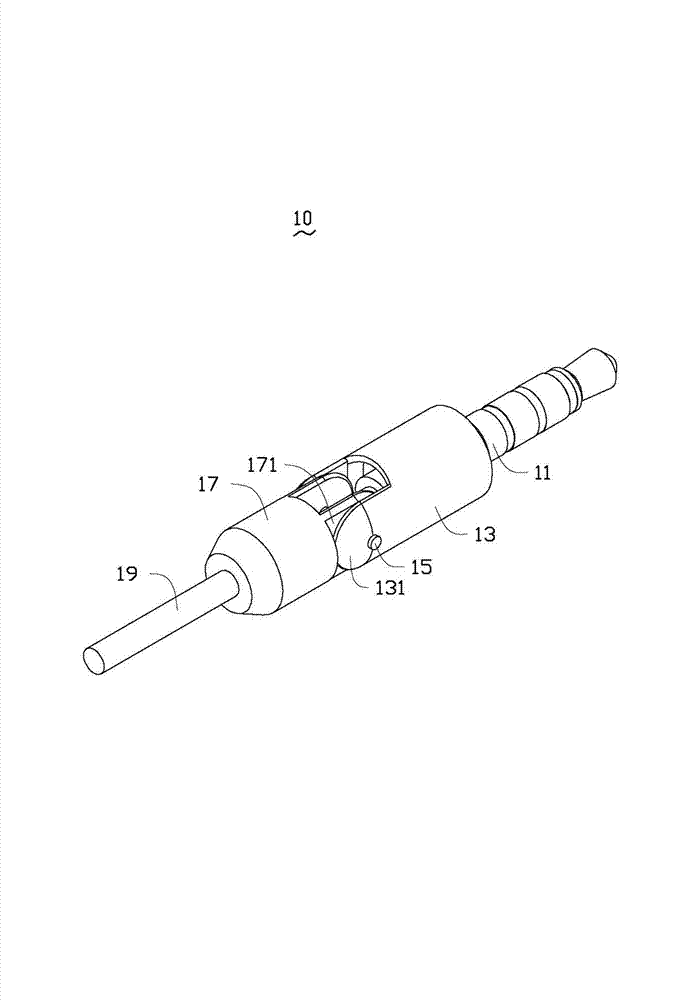

Earphone wire protective casing and earphone with the same

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

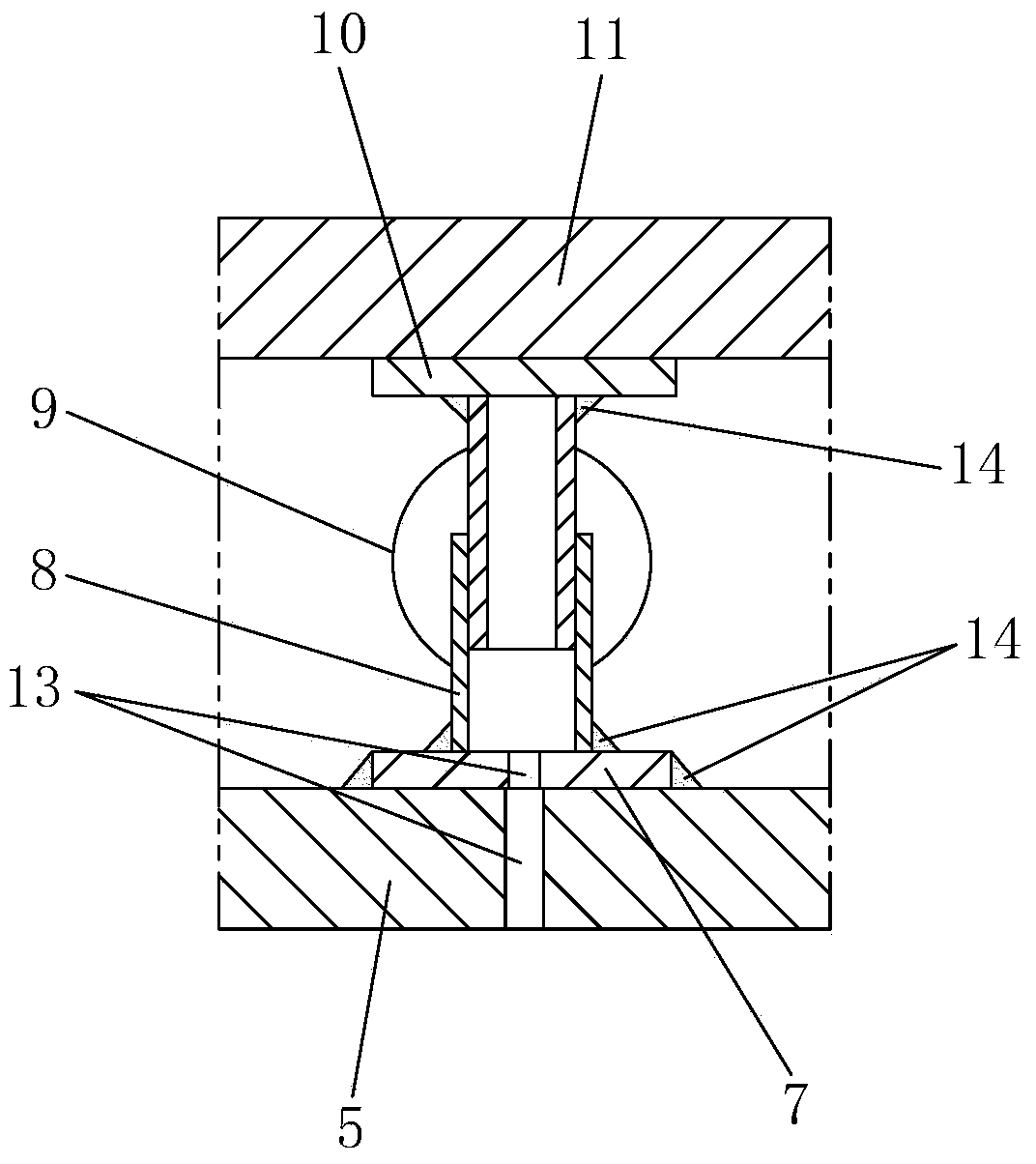

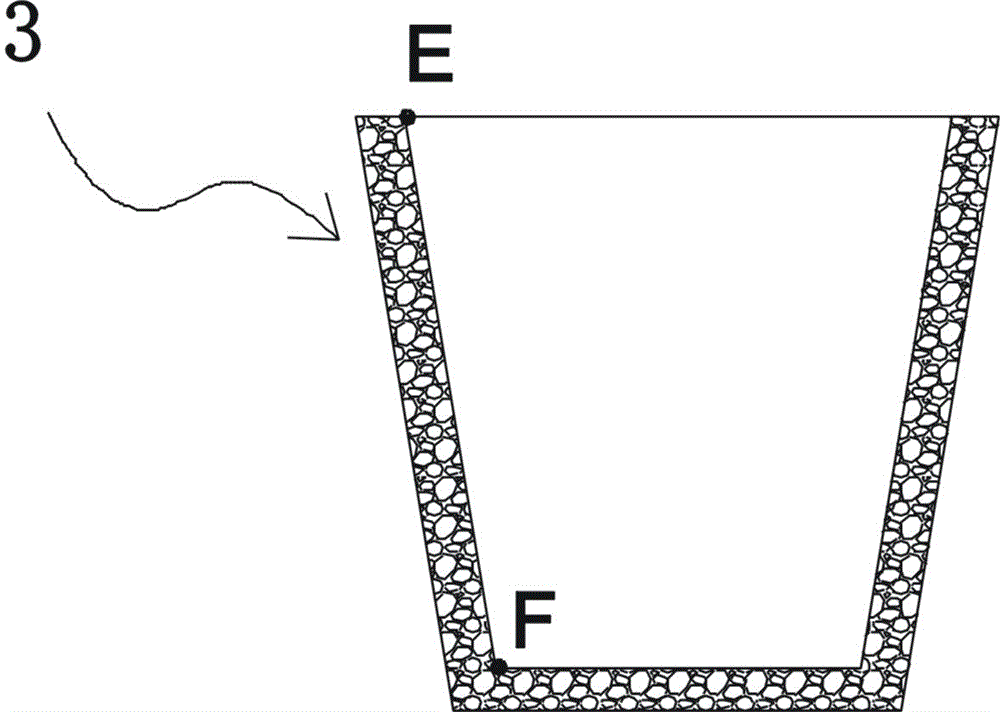

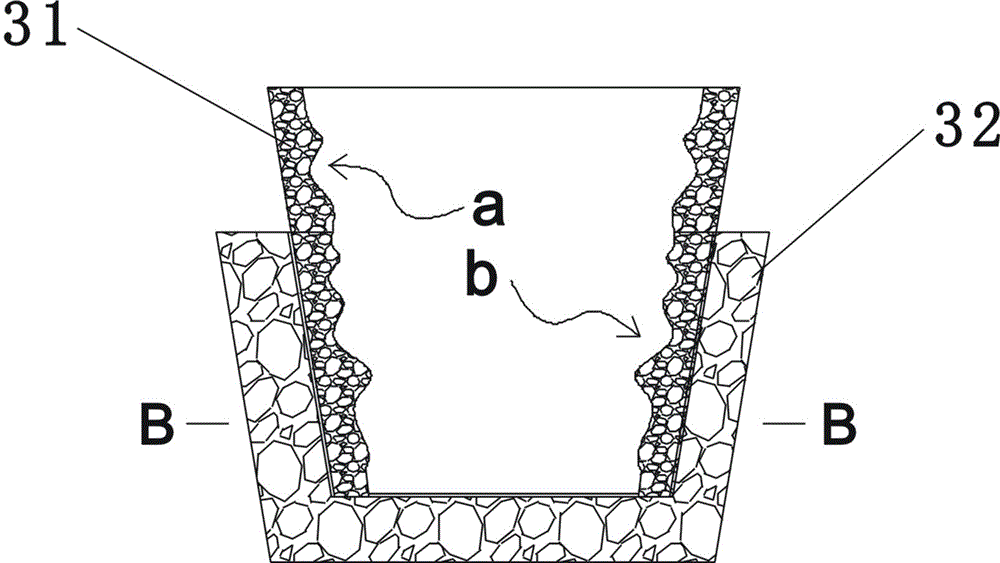

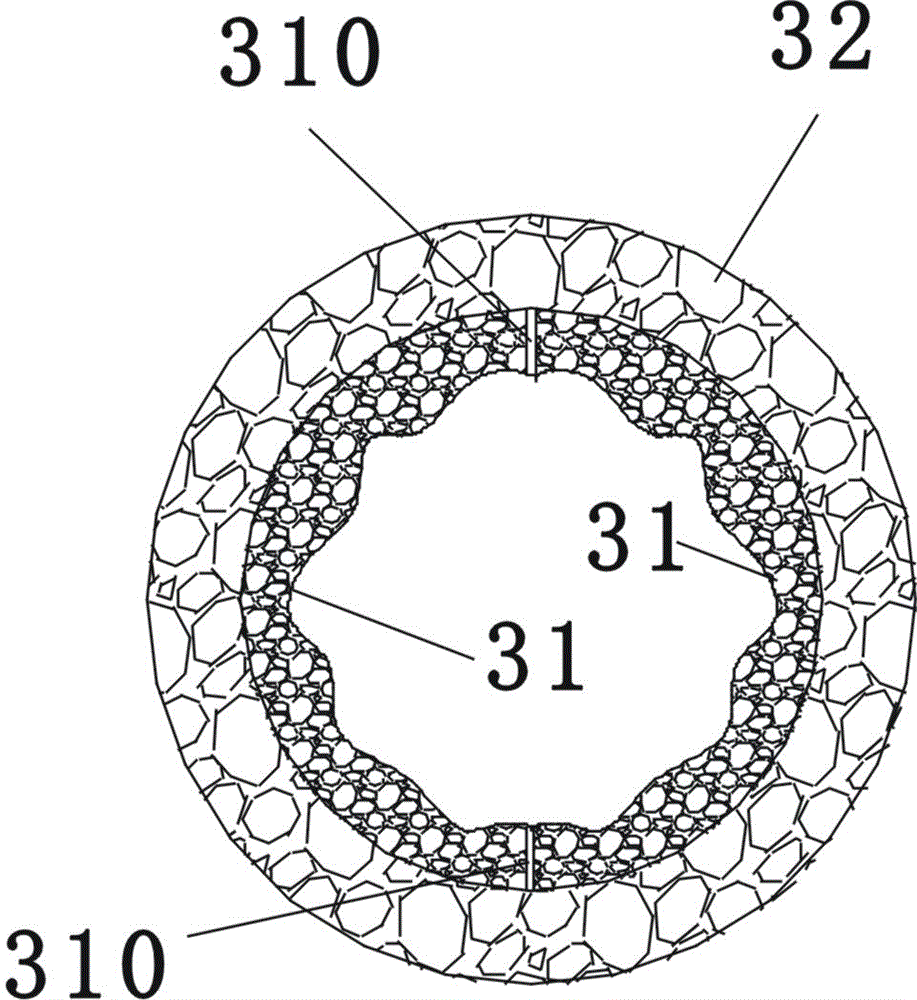

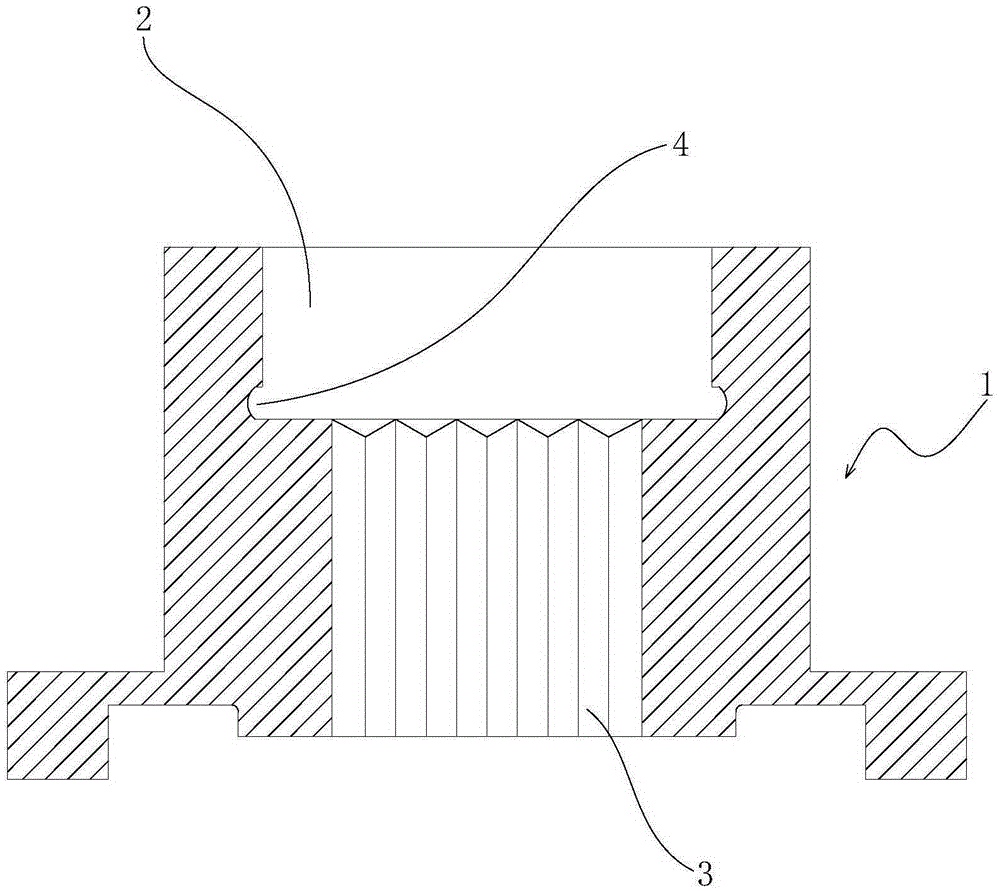

Female die for ceramic cup product and using method thereof

ActiveCN105014777ACause wear and tearEasy to demouldPress rollersCeramic shaping mandrelsSilica gelCeramic

The invention discloses a female die for a ceramic cup product. The female die for the ceramic cup product comprises a first female die assembly. The first female die assembly comprises a first die core and a first annular steel die sleeve. A first annular die cavity is formed between the first steel die sleeve and the first die core. The first die core comprises a die core body and a die core cover. The die core body is made of silica gel. The die core body is hollow, so that a cavity is formed in the die core body. Concave-convex patterns are formed on the outer circumferential surface of the die core body. An inflating valve which can be used for inflation and deflation is further mounted on the die core cover. The female die is further provided with a second female die assembly. The second female die assembly comprises a second die core and a second annular steel die sleeve. A second die cavity is formed by a vertical gap and a radial gap between the second die core and the second steel die sleeve. The invention further provides a using method of the female die for the ceramic cup product. The distinct concave-convex patterns are formed on a ceramic cup finally manufactured; in addition, die releasing can be achieved easily, and abrasion to the concave-convex patterns is avoided in the die releasing process.

Owner:广东皓业青花彩瓷股份有限公司

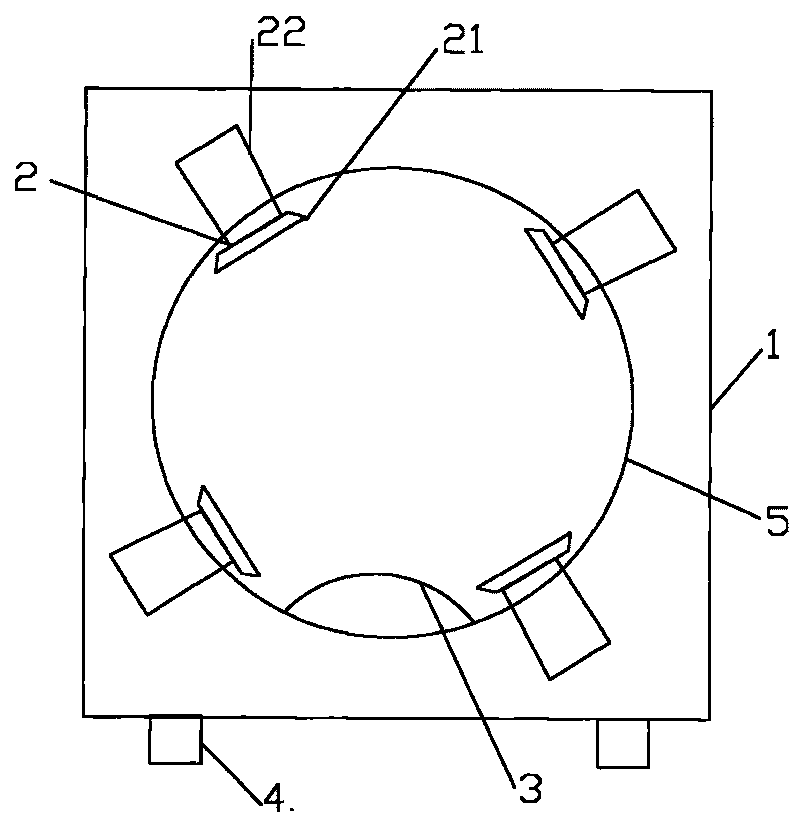

Heavy-caliber plastic pipe cutting machine

The invention discloses a heavy-caliber plastic pipe cutting machine, comprising a machine rack, one group of pipe clamping devices and a saw blade driven by a motor; the machine rack is arranged on bottom studs, pipe mounting holes are arranged in the middle of the machine rack, and the pipe clamping devices are arranged on the machine rack around the pipe mounting holes, and the saw blade is arranged on the machine rack by a connecting rod. The heavy-caliber plastic pipe cutting machine has simple structure and easy operation and can install, clamp and cut the heavy-caliber plastic pipe cutting machine conveniently, thereby being time-saving and labor saving; in addition, in the cutting process, the outer wall of the plastic pipe can not be wore and the processing quality can be improved; meanwhile, the cost is low, thereby being popularized and applied.

Owner:TAICANG MINGXIN ANTICORROSION EQUIP

Hanging ladder

The invention relates to a hanging ladder which is provided by aiming at the defect that a hanging ladder on the traditional mobile mechanical equipment is easily collided by the ground or materials and damaged. The hanging ladder comprises at least two pedals which are arranged up and down, wherein each pedal below the upper most pedal is hung and connected with a next stage of pedal through connecting parts at both ends of the pedal, and the pedals comprise at least one swinging pedal; the connecting parts for hanging the pedals are swinging connecting parts, and a parallelogram structure is formed by the swinging pedal, an adjacent pedal above the swinging pedal and left and right swinging connecting parts connected with the swinging pedal and the adjacent pedal above the swinging pedal; and both ends of the swinging connecting parts are respectively hinged with an upper pedal and a lower pedal, and hinge pivot shafts are horizontally arranged and vertical to the pedal length direction. According to the hanging ladder, when the lower end of the hanging ladder is collided by the ground or materials in an advancing process of equipment, the hanging ladder can be swung towards a direction opposite to the advancing direction of the mechanical equipment so as to avoid damaging the hanging ladder, and after the collision is relieved, the hanging ladder can be automatically reset to a normal state.

Owner:GUANGXI LIUGONG MASCH CO LTD

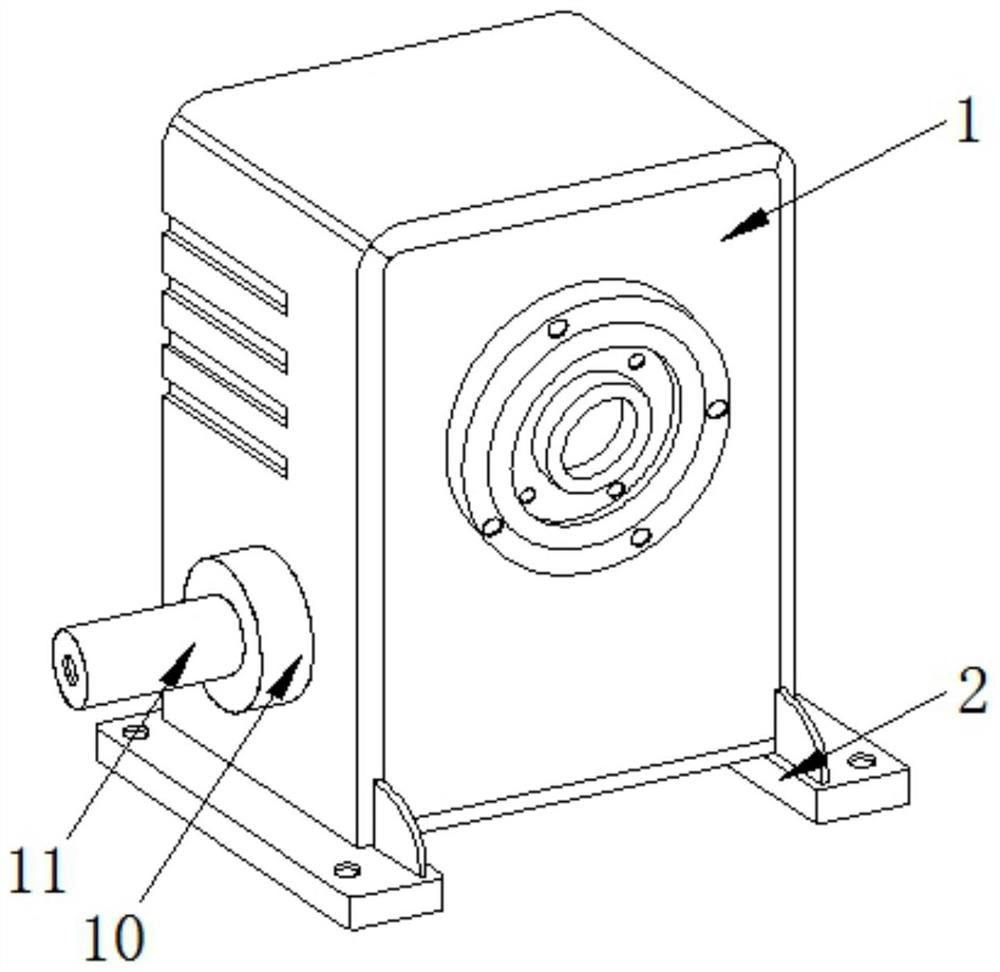

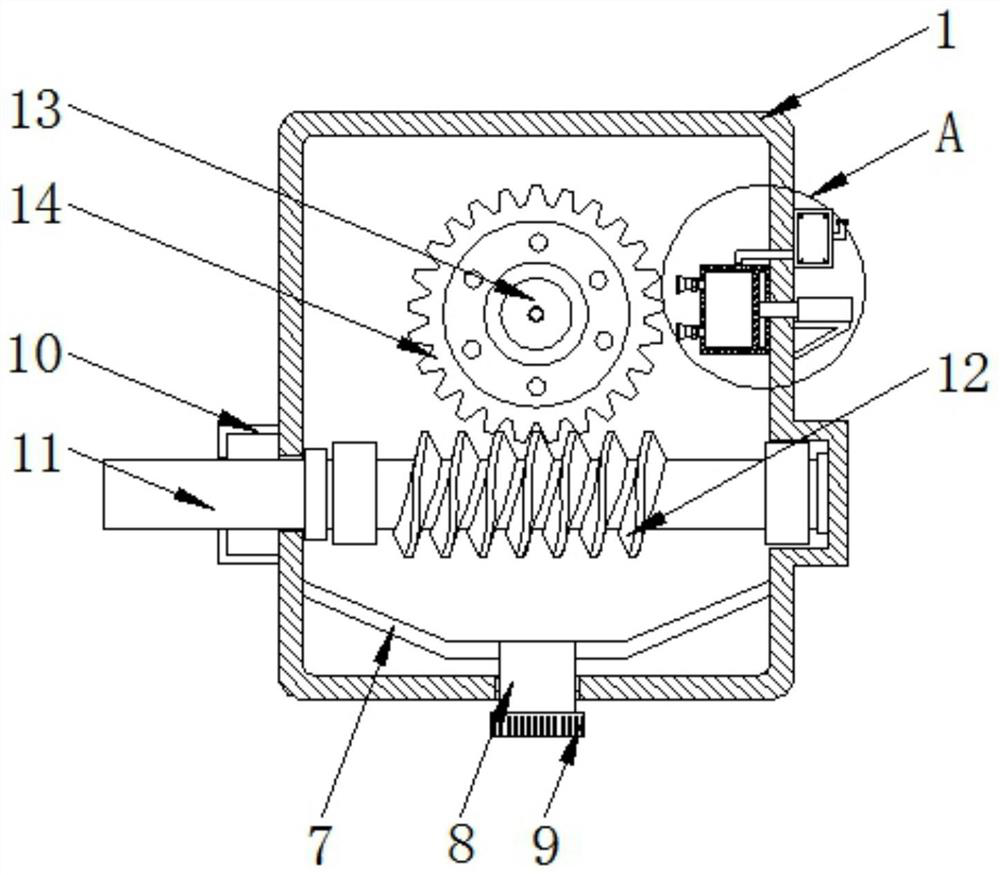

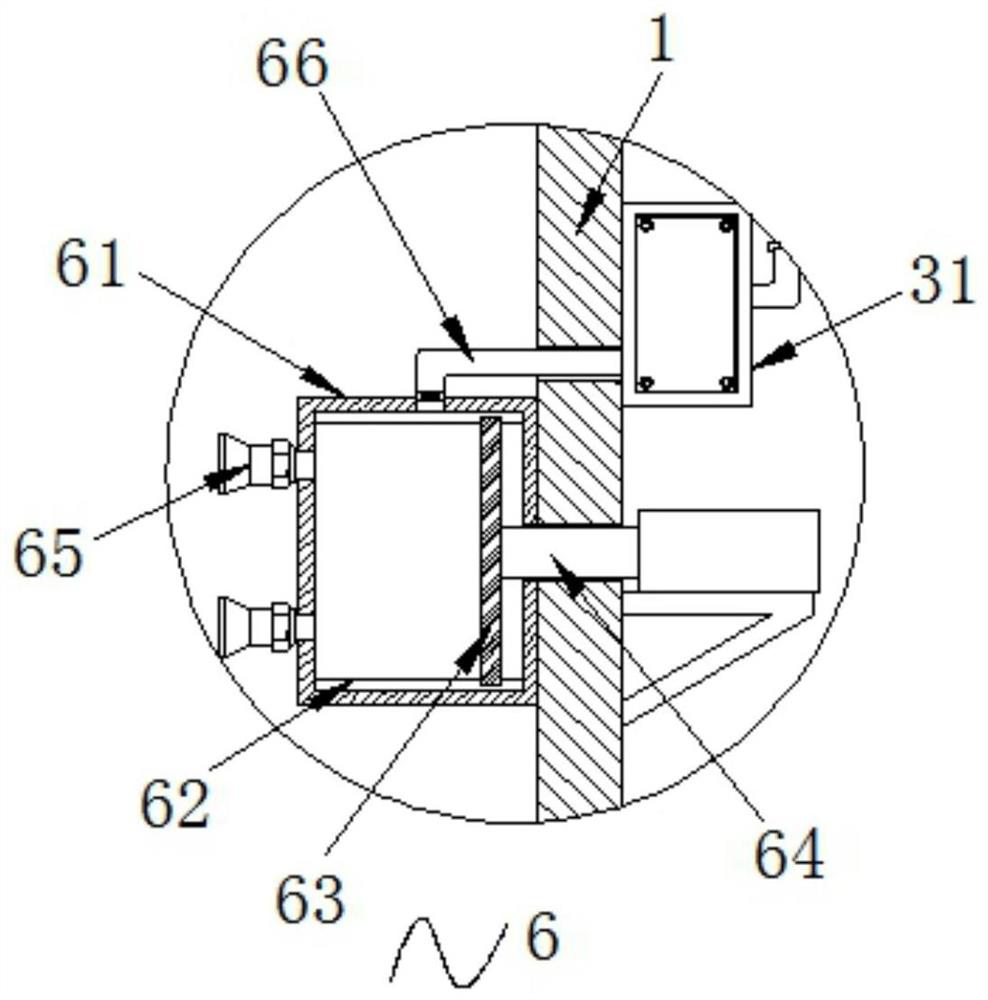

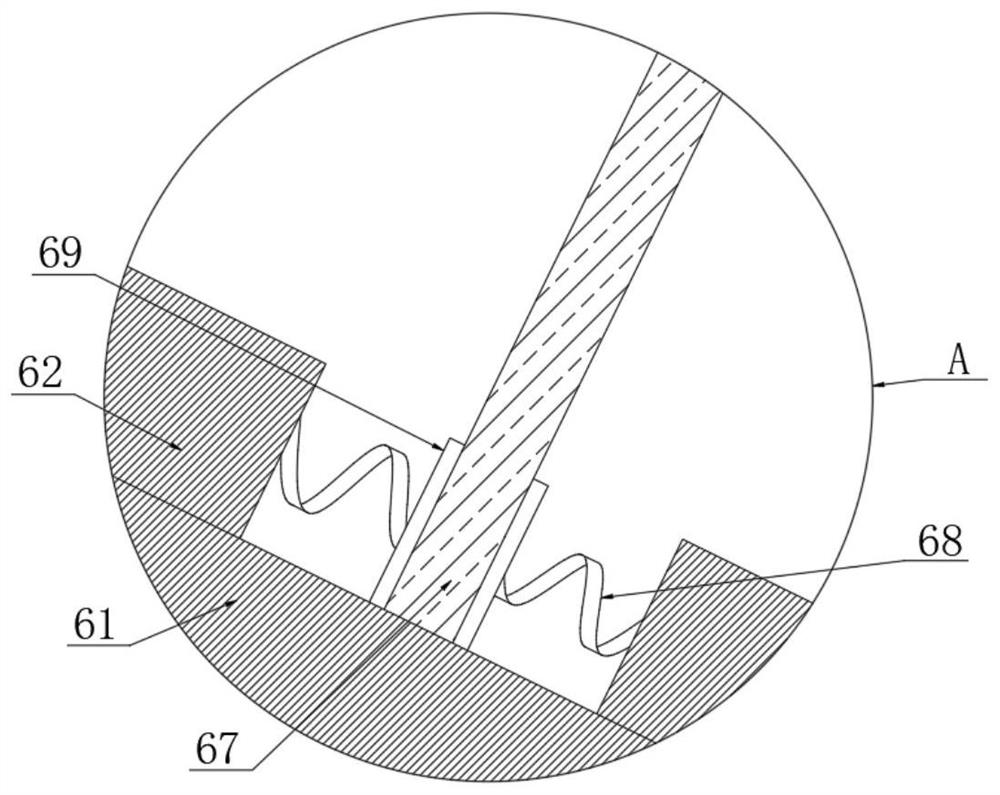

Multifunctional aluminum alloy worm and gear speed reducer and using method thereof

InactiveCN113074238AAvoid wear and tearDoes not affect normal useGearboxesGear lubrication/coolingGear wheelEngineering

The invention discloses a multifunctional aluminum alloy worm and gear speed reducer and a using method thereof, and relates to the technical field of speed reducers. The multifunctional aluminum alloy worm and gear speed reducer comprises a box body and mounting plates fixed to the two sides of the bottom of the box body, a filtering mechanism is arranged at the top of the right side of the box body, a noise reduction mechanism is arranged in the box body, and a heat dissipation mechanism is arranged on the back face of the inner wall of the box body; and a lubricating mechanism is arranged on the right side of the inner wall of the box body and comprises a shell, and the right side of the shell is fixedly connected with the top of the right side of the inner wall of the box body. According to the multifunctional aluminum alloy worm and gear speed reducer and the using method thereof, a piston is pushed by an air cylinder to move in the shell, under the pressure effect of the piston, lubricating oil is sprayed out through an atomization spray head to evenly lubricate a rotating worm gear, the speed reducer can conduct lubricating work without stopping working, and thus the speed reducer is used normally, gear abrasion can be prevented, and the service life of the speed reducer is prolonged.

Owner:杭州誉球机械有限公司

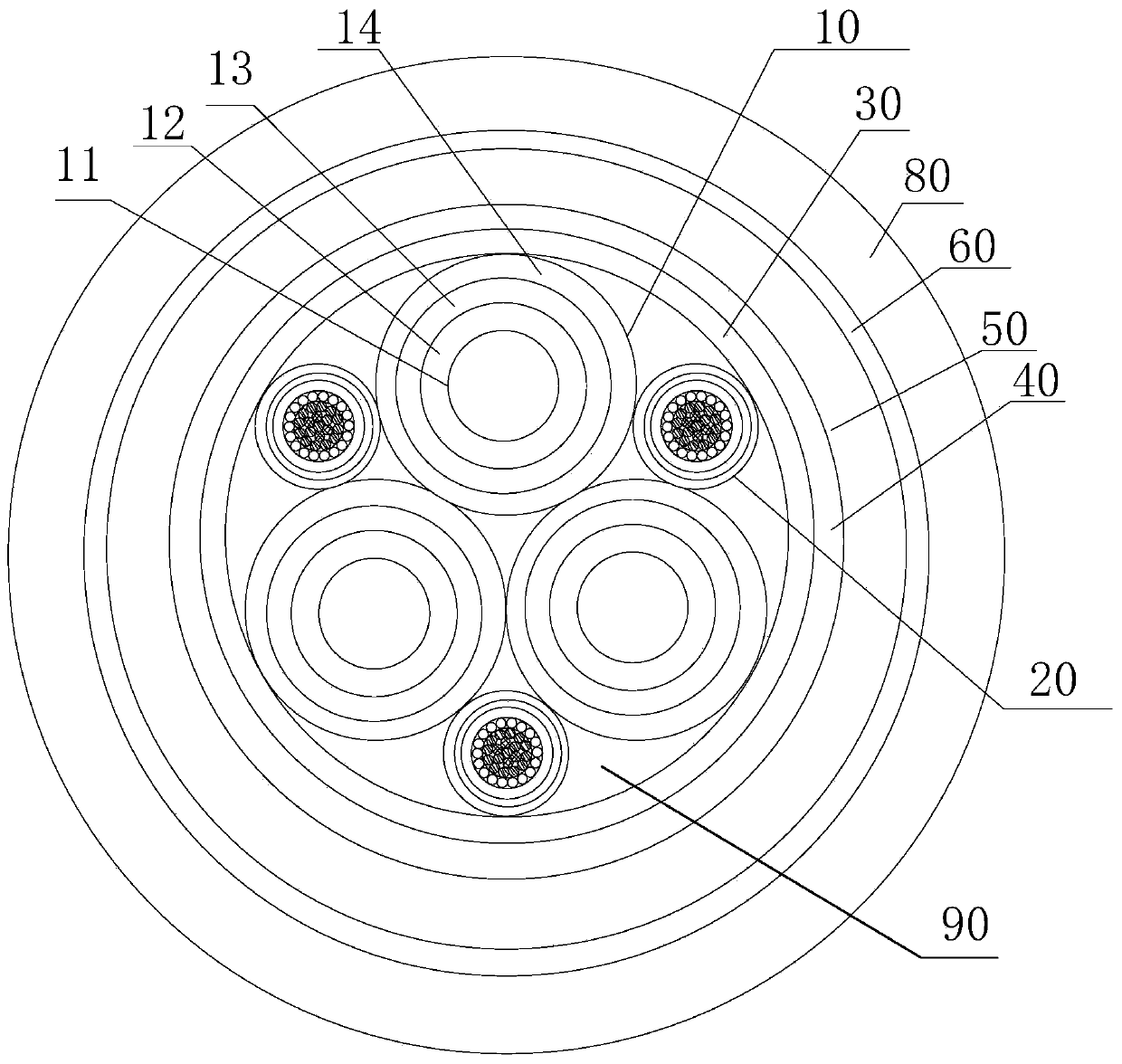

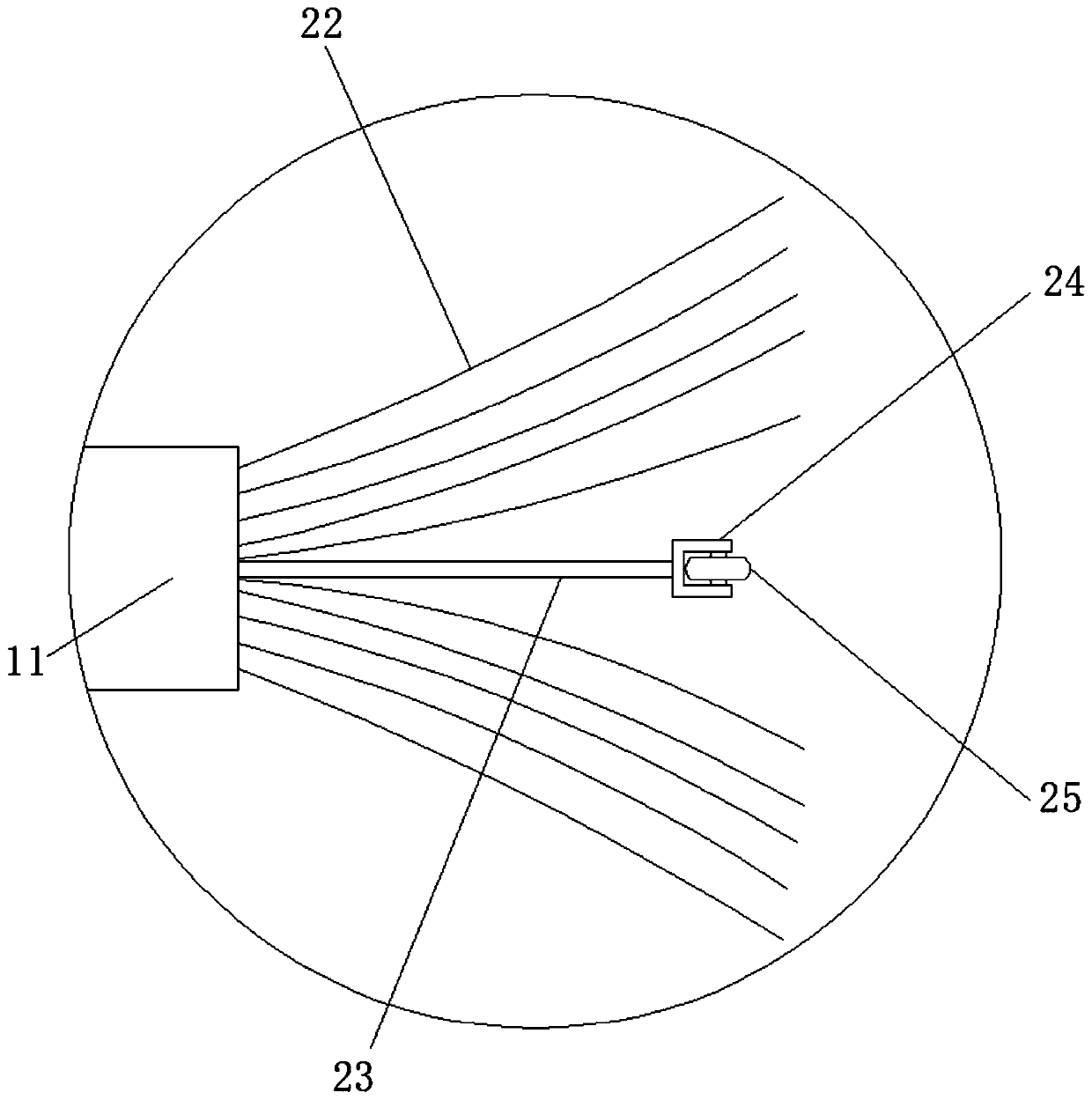

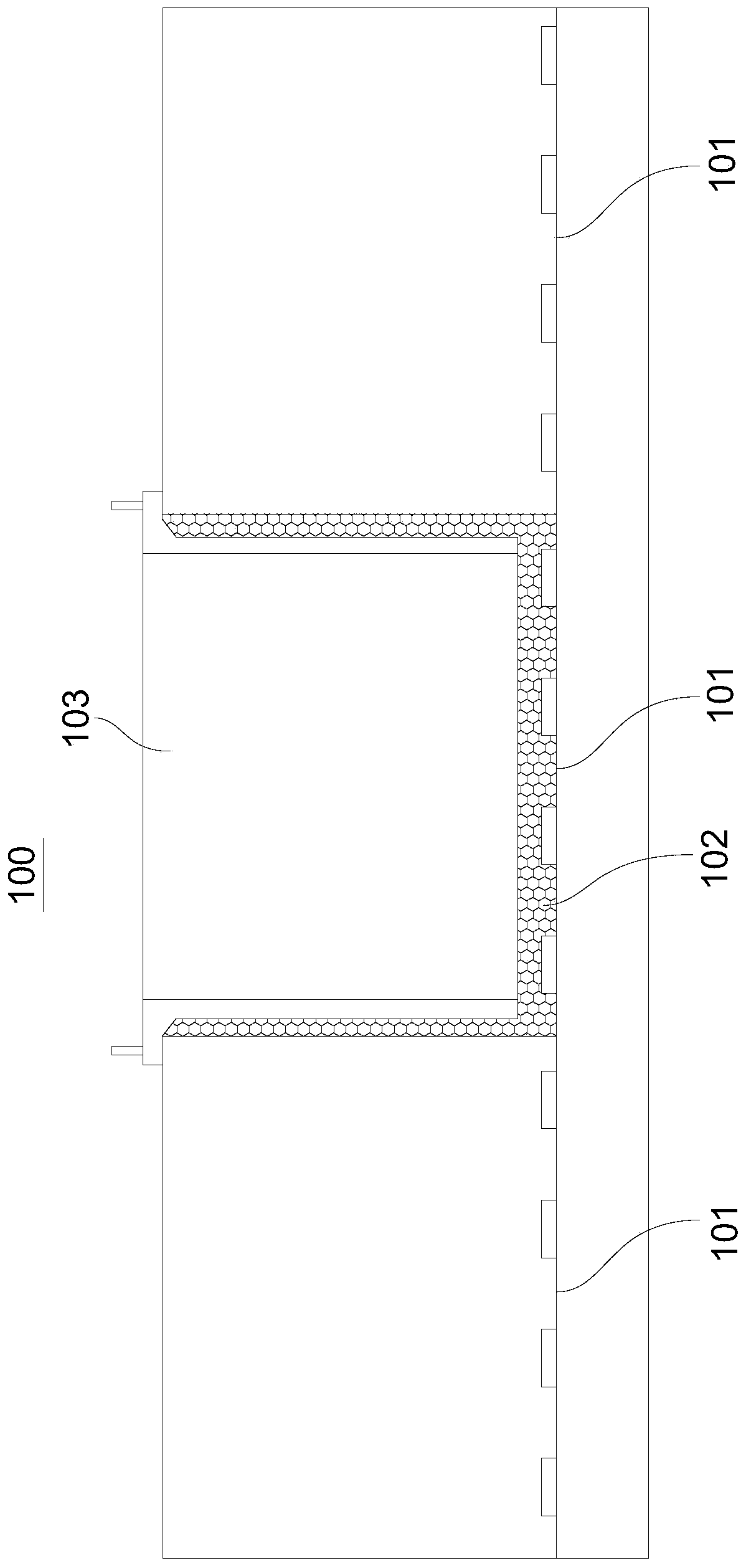

Cable for electric vehicle charging piles, preparation method and light-current flexible linear stranding device

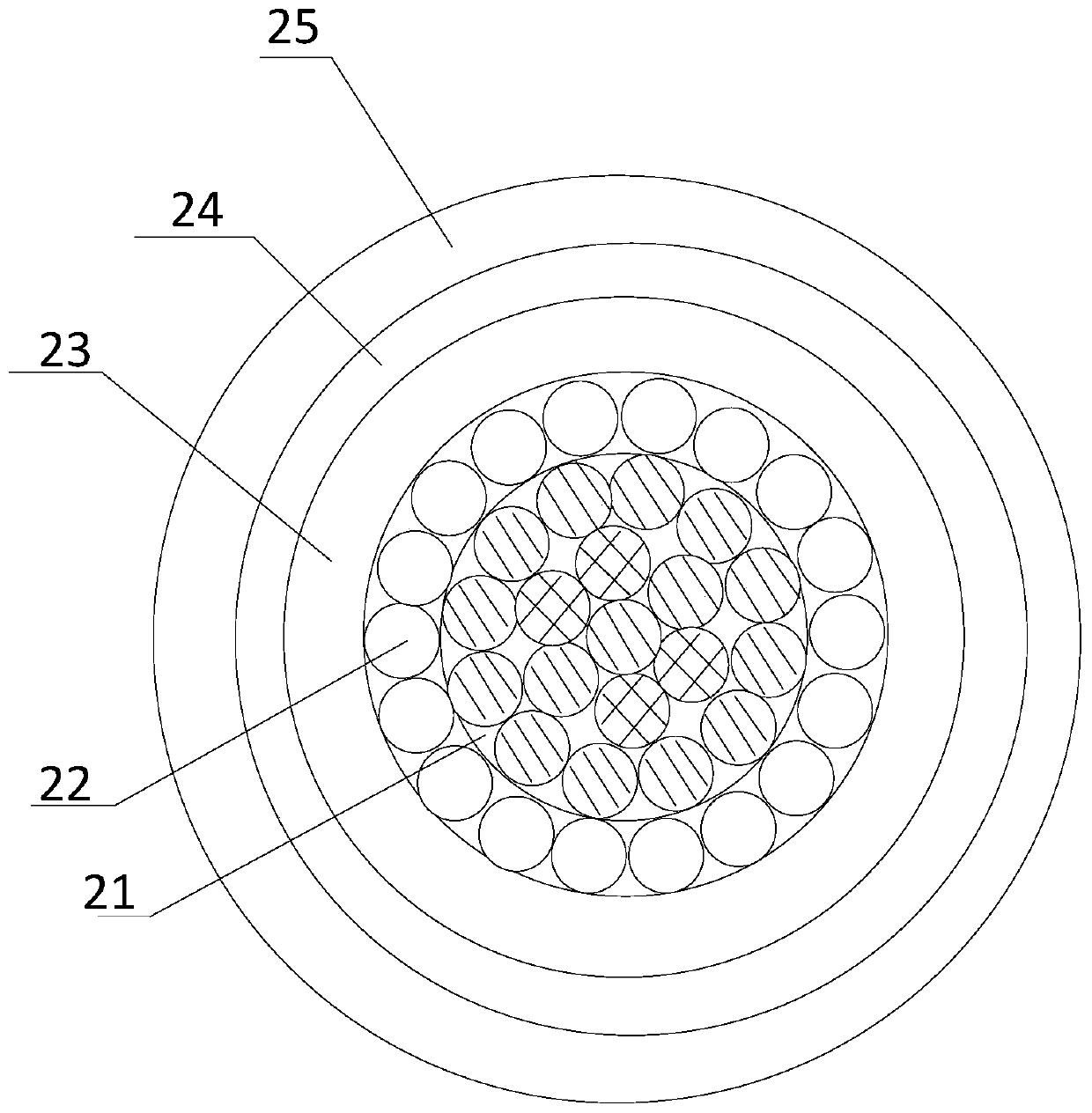

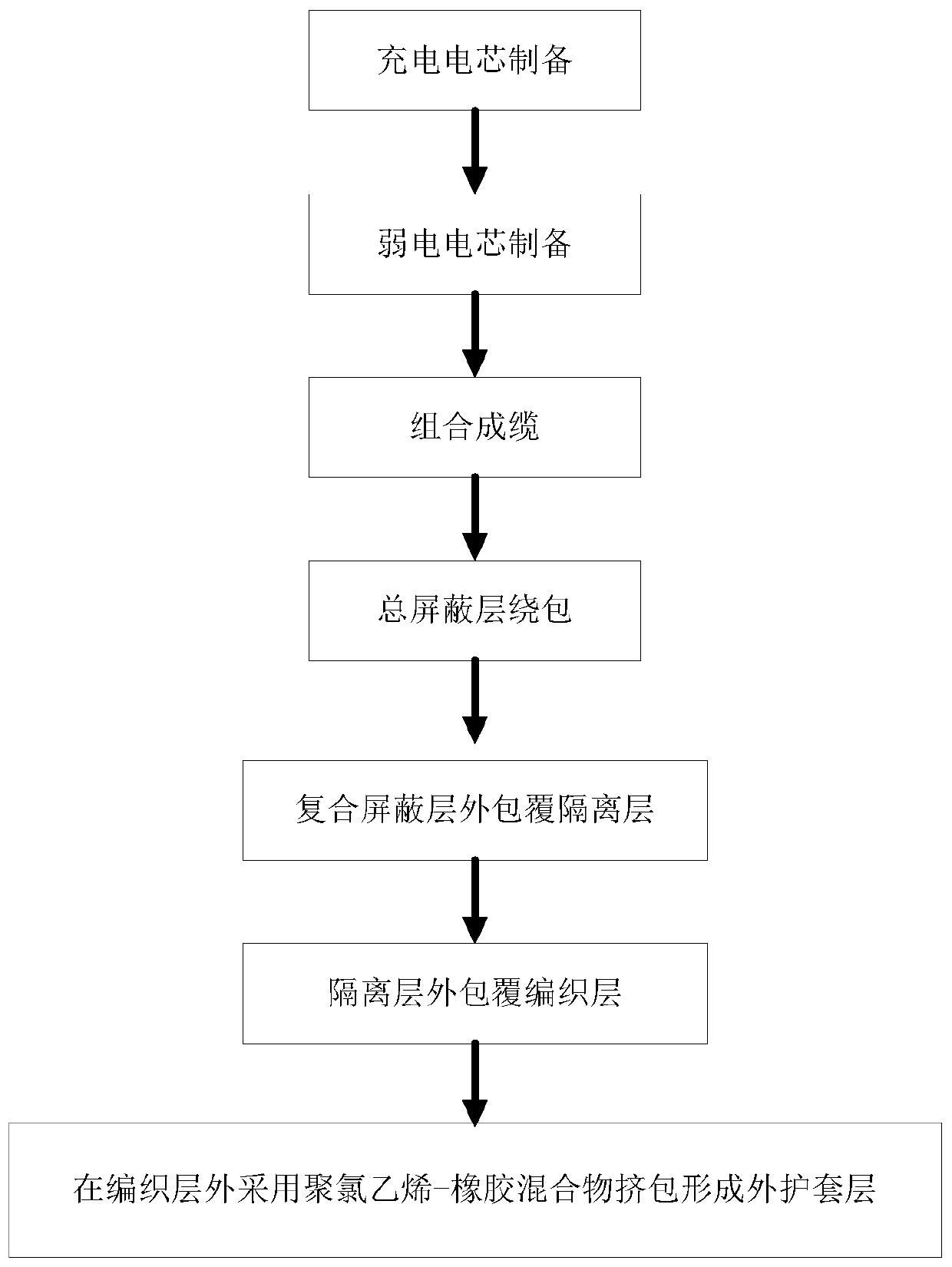

ActiveCN110136876AHigh strengthHigh initial modulusCharging stationsPlastic/resin/waxes insulatorsPolyesterCopper wire

The invention provides a cable for electric vehicle charging piles, a preparation method and a light-current flexible linear stranding device. The cable comprises a core provided with charging cores and light current cores, a polyester belt layer wrapping the core, a main shielding layer wrapping the polyester belt layer, an isolation layer wrapping the composite shielding layer, a braided layer wrapping the isolation layer, an outer sheath layer arranged outside the braided layer, and a filling layer filling the gaps between the charging cores and the light current cores and wrapped in the polyester belt layer. Each light current core includes a flexible wire core and copper wires wound on the flexible wire core. Each flexible wire core is formed by mixing and concentrically stranding aramid and stainless steel wires, wherein aramid accounts for 80-90%, and the pitch multiple is 5-10. The cable of the invention has excellent shielding property and has good bending resistance and heatresistance.

Owner:WUXI HUAMEI CABLE

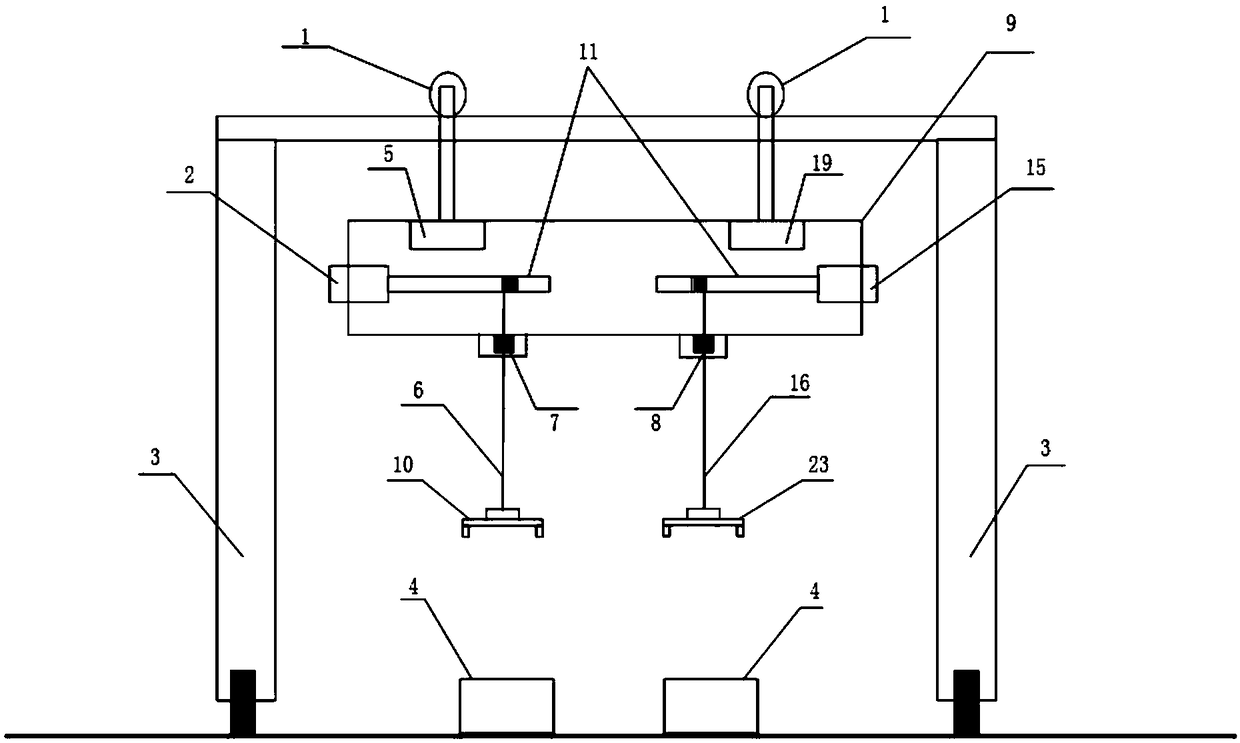

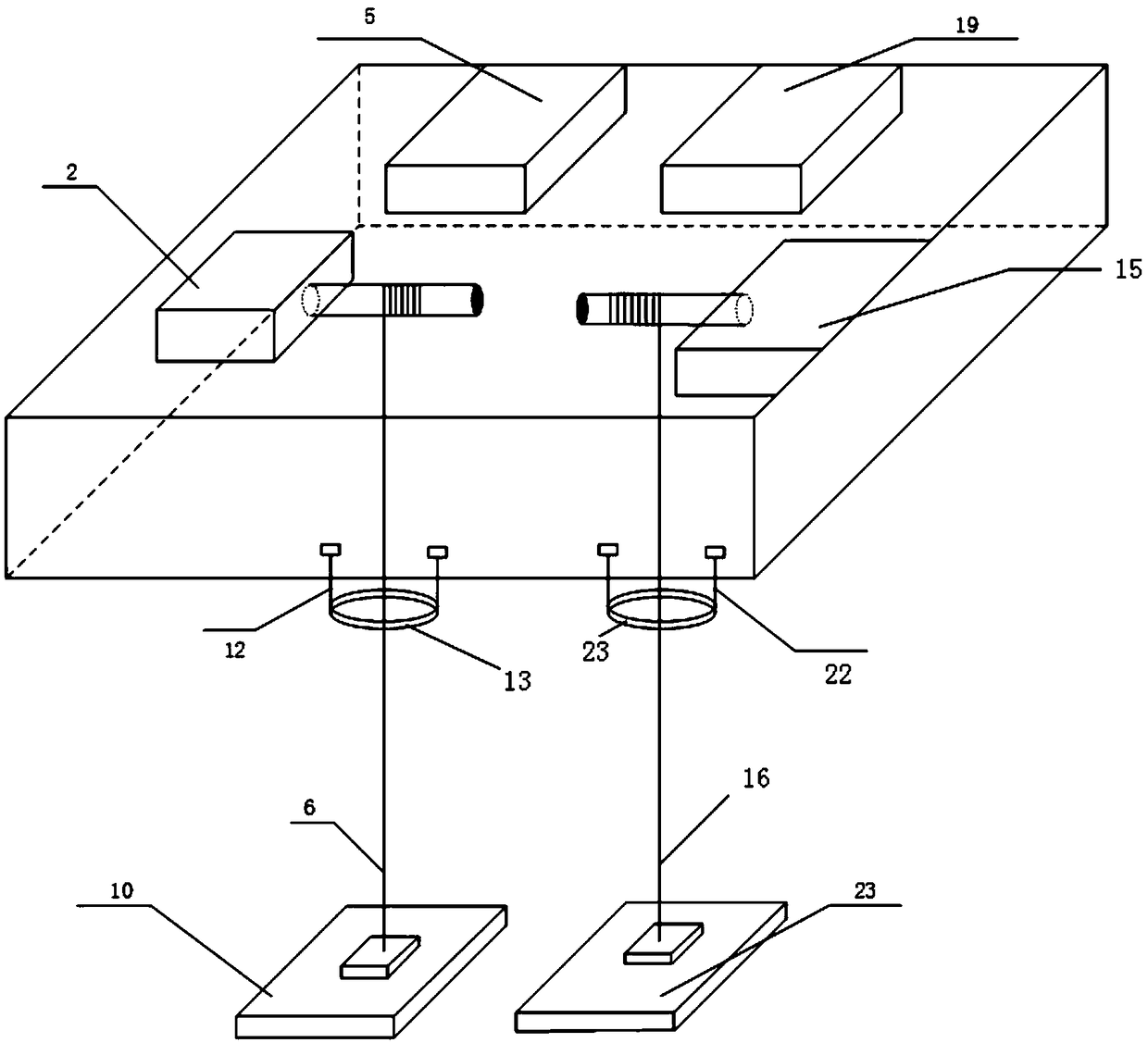

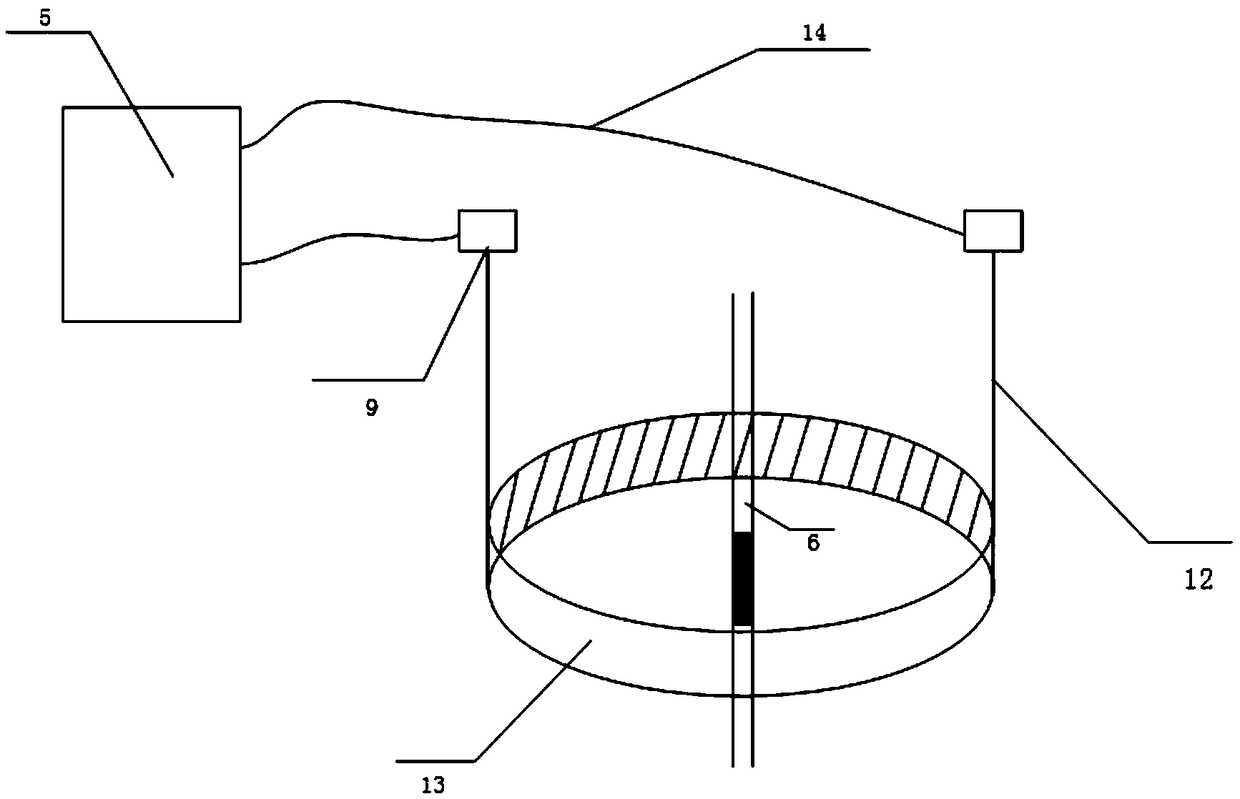

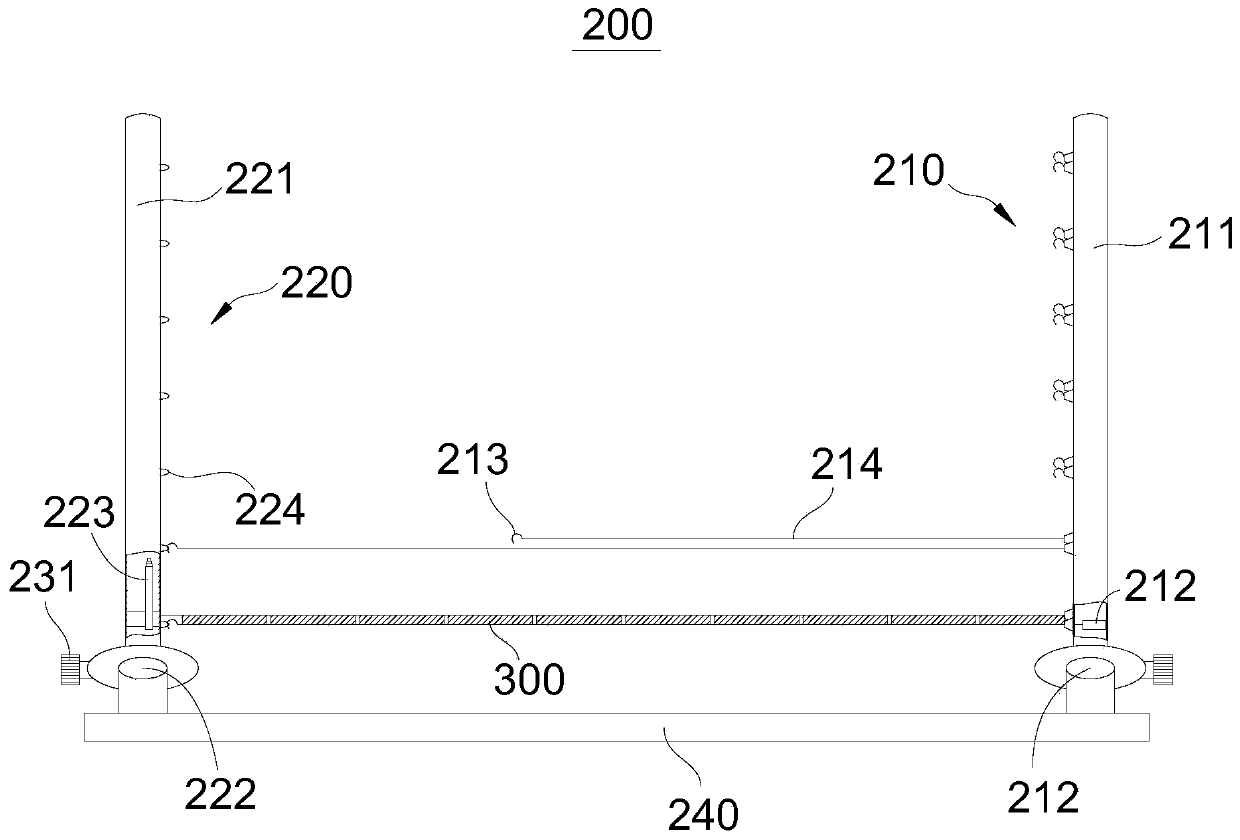

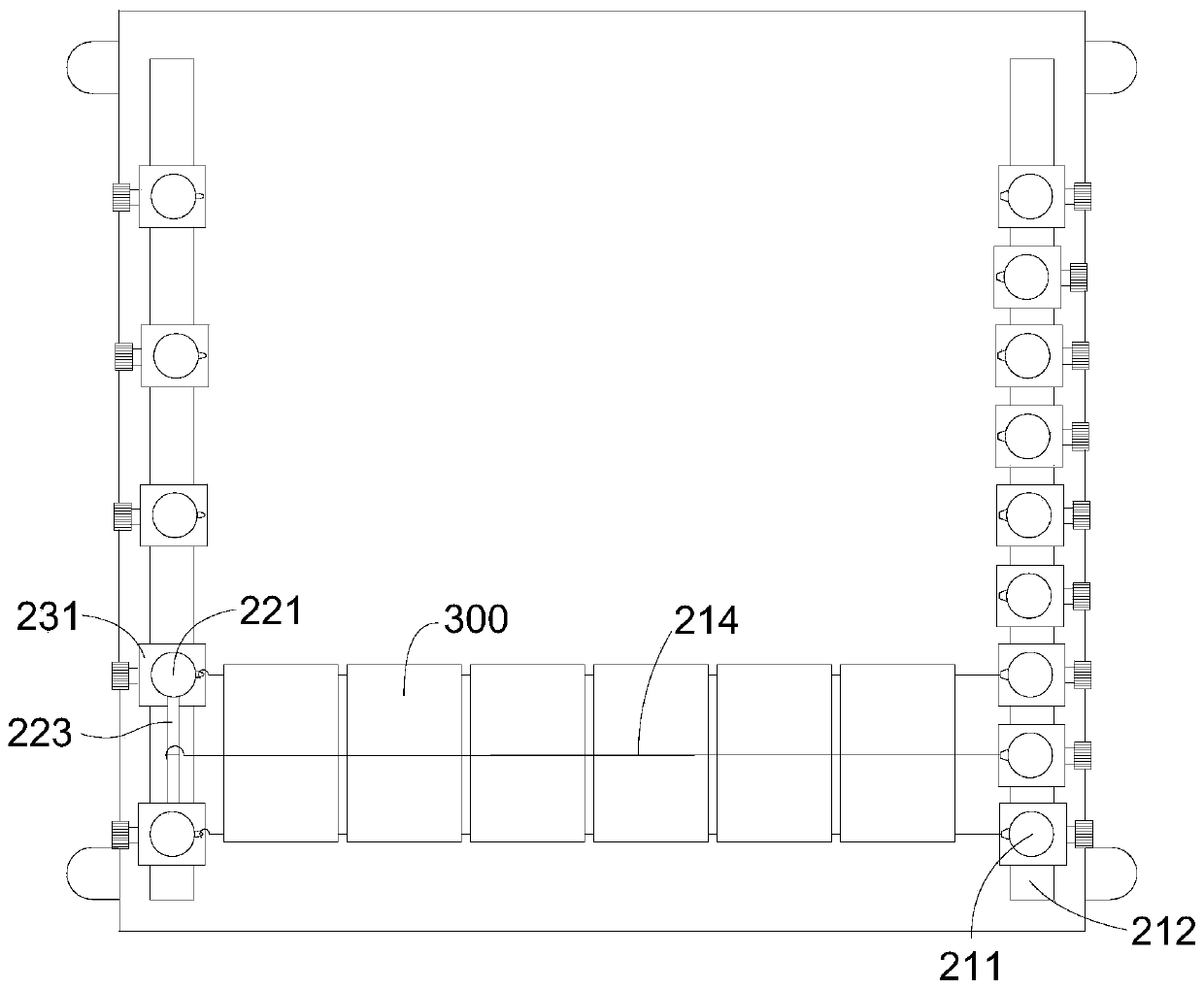

Measuring device for synchronous error of double-lifting-appliance bridge crane based on photoelectric sensing

ActiveCN109052176AInnovativeSimple structureLoad-engaging elementsMeasurement deviceSynchronous motor

The invention discloses a measuring device for the synchronous error of a double-lifting-appliance bridge crane based on photoelectric sensing. The measuring device comprises a first synchronous measuring part, a second synchronous measuring part, a signal measuring integration module and a computer. The first synchronous measuring part is arranged at the bottom of a trolley mechanism and used fordetecting the motion state of a first lifting rope; the second synchronous measuring part is arranged at the bottom of the trolley mechanism and used for detecting the motion state of a second lifting rope; the input end of the signal measuring integration module is connected to the first synchronous measuring part and the second synchronous measuring part, and used for processing the motion state of the first lifting rope and the motion state of the second lifting rope; and the input end of the computer is connected to the signal measuring integration module and used for obtaining the motiontime of the first lifting rope and the motion time of the second lifting rope according to the motion state of the first lifting rope and the motion state of the second lifting rope correspondingly,the corresponding first motion length and the corresponding second motion length of the measuring device for the synchronous error of the double-lifting-appliance bridge crane based on photoelectric sensing are obtained by combining the rotating speed of a first lifting motor and the rotating speed of a second lifting motor, and finally, the synchronous error is obtained.

Owner:SHANGHAI MARITIME UNIVERSITY

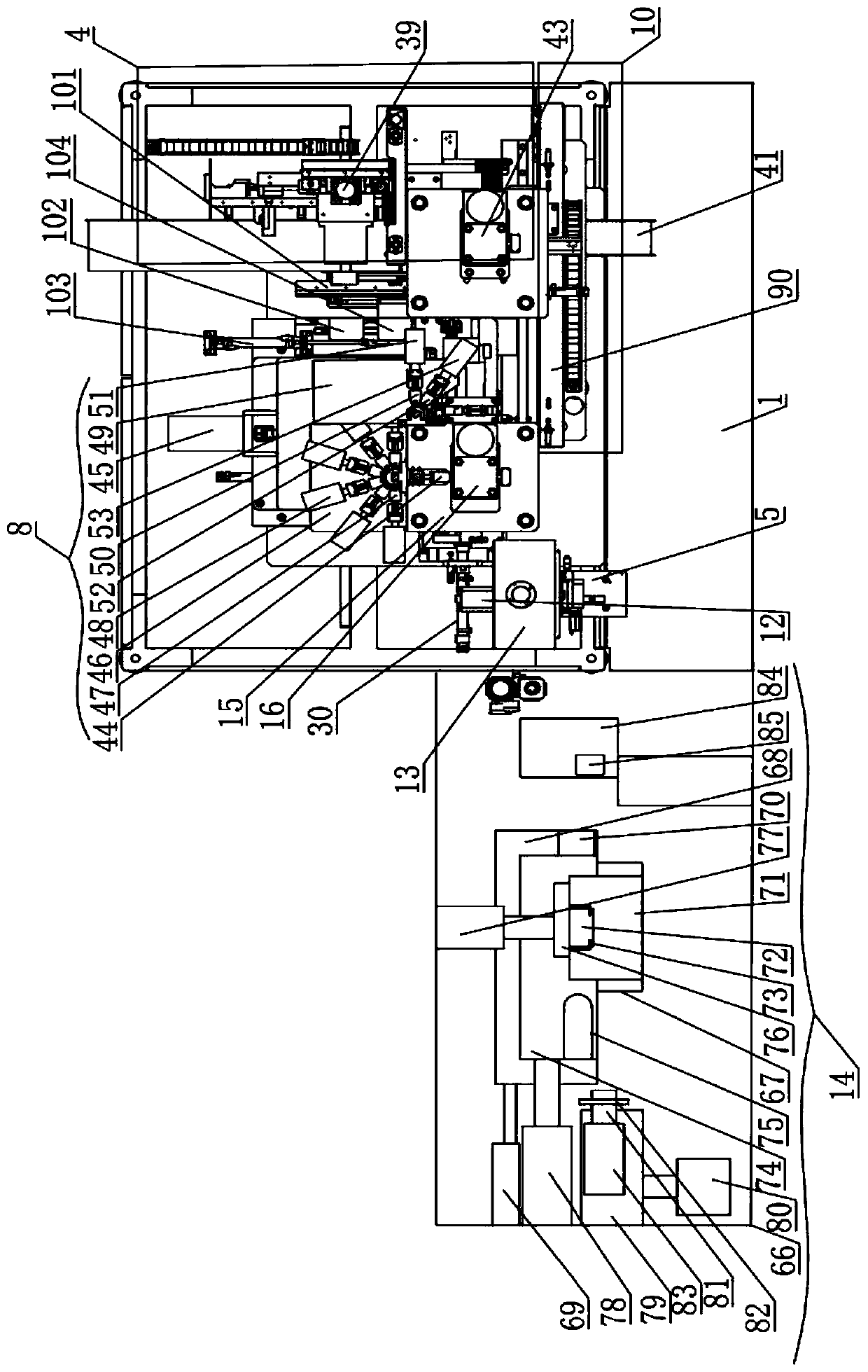

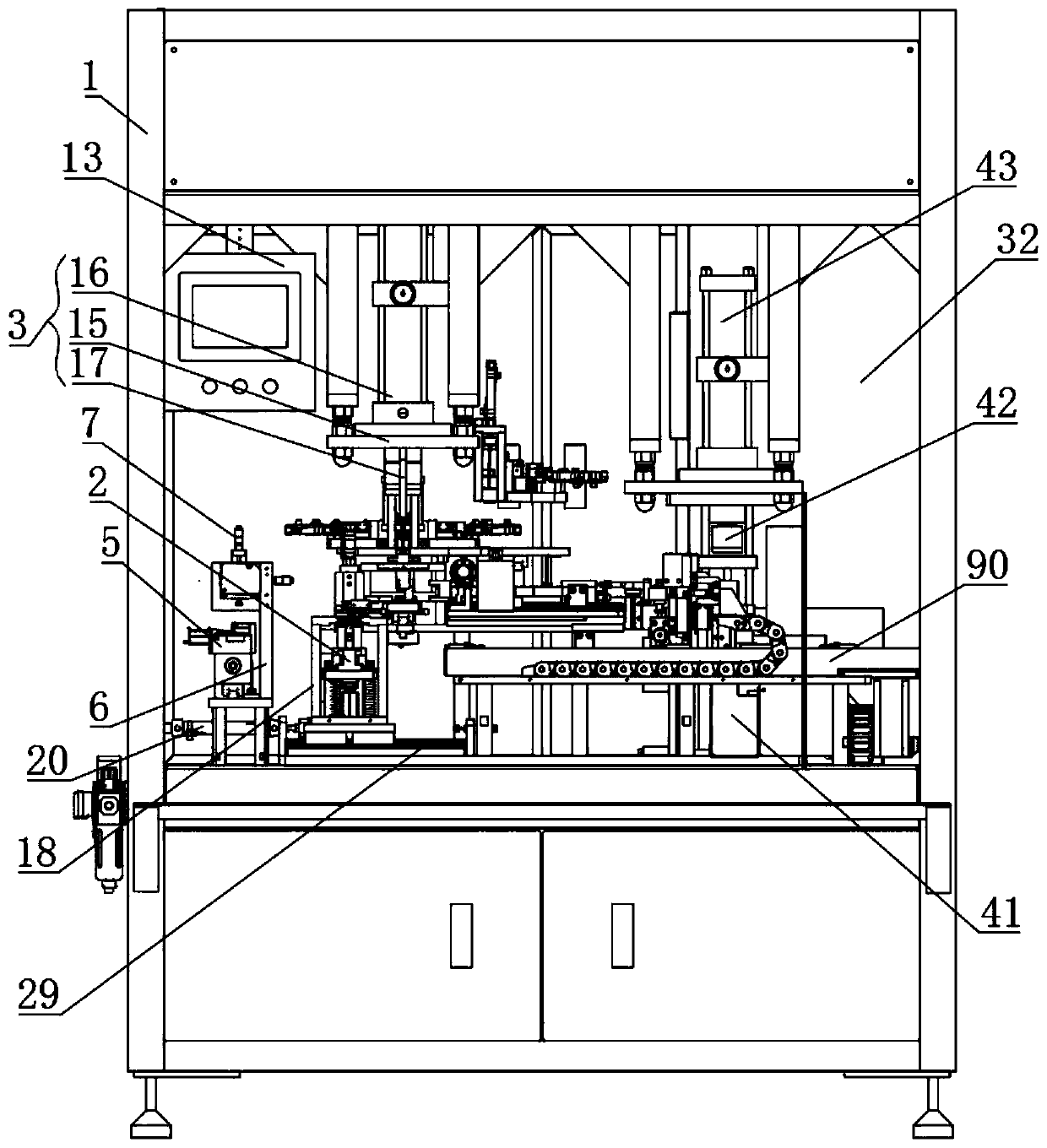

Automatic lock body assembling production line

ActiveCN111152013AReduce scrap rateReduce labor intensityAssembly machinesMetal working apparatusProduction lineBall screw

The invention discloses an automatic lock body assembling production line. The automatic lock body assembling production line comprises an assembling base, and an assembling base is arranged on the assembling base; a press-in device is arranged above the assembling seat; a cutting device, a tooth pattern detection seat and a mounting plate are arranged on the two sides of the assembly seat respectively; a laser detector is arranged at the top end part of the mounting plate; a correction device is arranged between the tooth pattern detection seat and the assembly seat; a feeding device, a storage device and a choke plug press-in device are arranged between the cutting device and the assembling seat; a material moving device is arranged on one side of the feeding device; a ball screw is installed on the bottom face of the tooth pattern detection base, and one end of the ball screw is connected with a servo motor. The automatic feeding device can improve the working efficiency and has theadvantages of being small in occupied area, wide in application range, low in labor intensity, low in rejection rate, good in assembling effect, convenient to use, good in correcting effect, long inservice life and high in feeding stability.

Owner:浦江宝儿制锁有限公司

Overturn discharging unit for iron core component assembly mechanism

InactiveCN106169365ASimple structureEasy to operateInductances/transformers/magnets manufactureManufacturing stator/rotor bodiesCouplingCore component

The invention discloses an overturn discharging unit for an iron core component assembly mechanism. The overturn discharging unit for the iron core component assembly mechanism comprises an overturn mounting plate mounted on a mounting rack, an overturn bearing seat fixing plate perpendicular to one side of an upper plane of the overturn mounting plate is mounted thereon through a reinforcing rib, overturn bearing seats are mounted on both ends of a side face of the overturn bearing seat fixing plate, an overturn guide motor fixing plate perpendicular to the overturn mounting plate is mounted at a position located at one side of the overturn bearing seat fixing plate on the overturn mounting plate, an overturn guide motor is mounted on the overturn guide motor fixing plate, an output shaft of the overturn guide motor is connected with an overturn stepped shaft by a coupling, the overturn stepped shaft penetrates through two overturn bearing seats in sequence, two overturn disks are fixed on the overturn stepped shaft between the two overturn bearing seats, and four opening grooves are formed in the overturn disk with a circle center as a center in an array manner. By means of the above manner, the overturn discharging unit disclosed by the invention is convenient to operate, free of workpiece attrition and high in working efficiency.

Owner:江苏永友食品科技有限公司

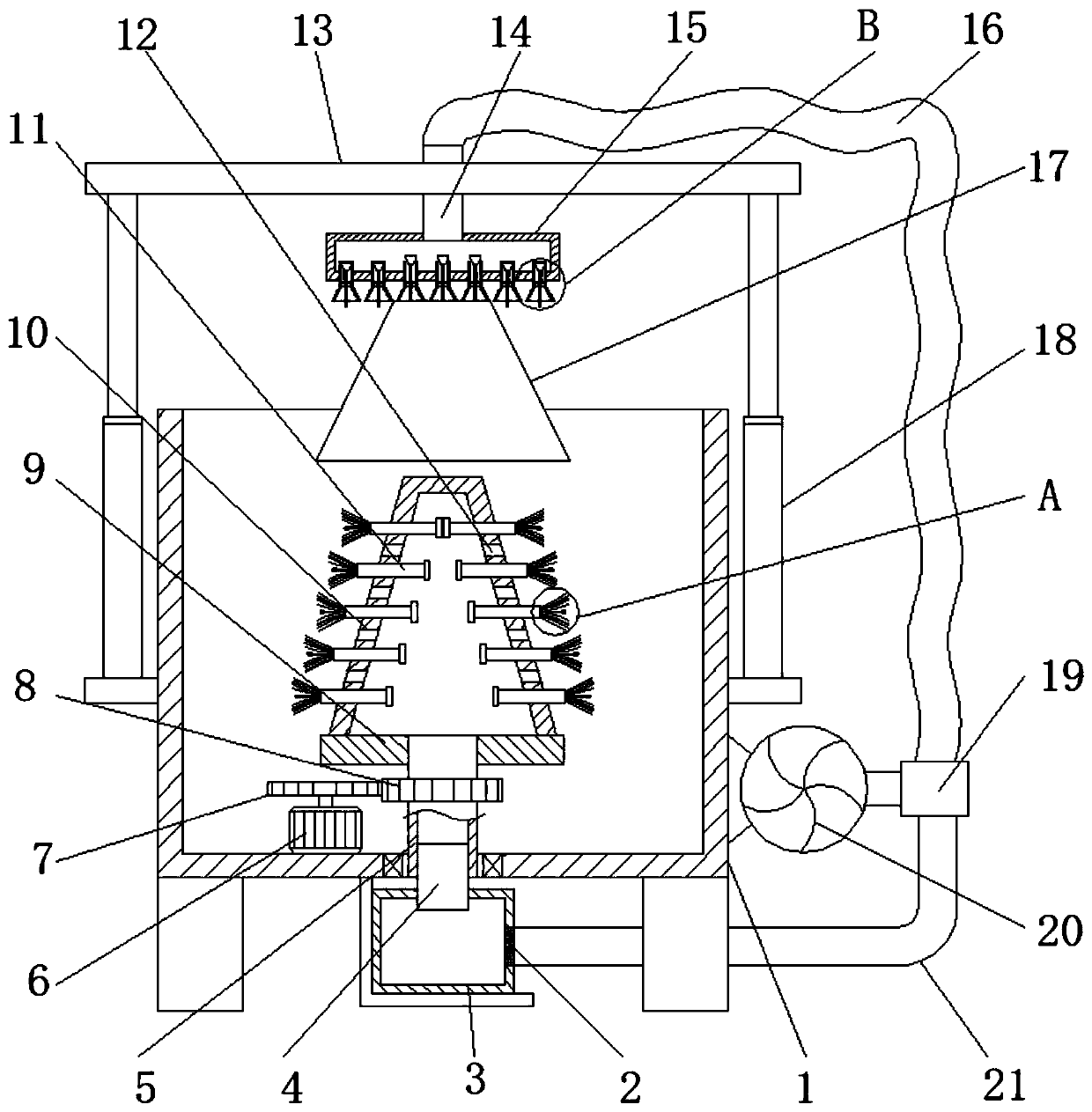

Dust removing equipment for LED lamp

ActiveCN111215371AAvoid uncleannessCause wear and tearDispersed particle filtrationDirt cleaningDust controlStructural engineering

The invention discloses dust removing equipment for an LED lamp. The equipment comprises a dust removing box, a mounting opening is formed in the inner wall of the bottom of the dust removing box, a rotating pipe is rotationally connected to the inner wall of the mounting opening through a bearing, a rotating disc is arranged on the outer wall of the rotating pipe, a fixing cover is welded to theouter wall of the top of the rotating disc, the cross section of the fixing cover is trapezoidal, dust collecting holes annularly distributed at equal intervals are formed in the outer wall of the fixing cover, multiple layers of concave holes annularly distributed at equal intervals are formed in the outer wall of the fixing cover, sliding rods are slidably connected to the inner walls of the concave holes, and stopping blocks are welded to the outer walls of one ends of the sliding rods. According to the equipment, dust on the lamp can be rapidly brushed away; rollers can be in contact withthe inner wall of the lamp, so that the phenomenon that brushes are tightly attached to the lamp due to too large centrifugal force and then the dust cannot be completely brushed away is effectively avoided; the rollers are in rotary contact with the lamp, so that the lamp cannot be abraded; and meanwhile, dust can be effectively collected, so that the situation that dust removing is effected dueto the fact that the dust flies everywhere is avoided.

Owner:深圳市华冠光电科技有限公司

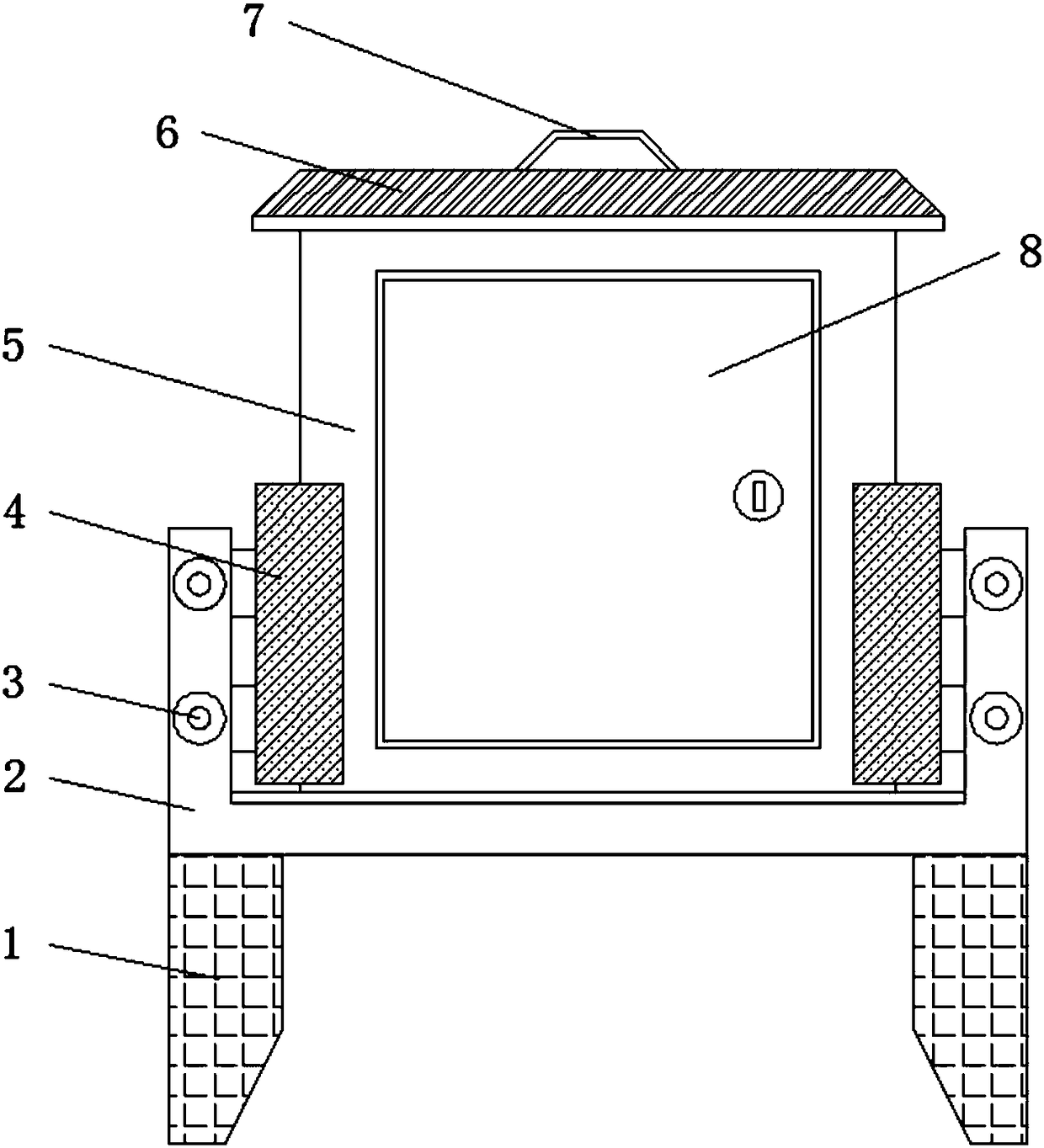

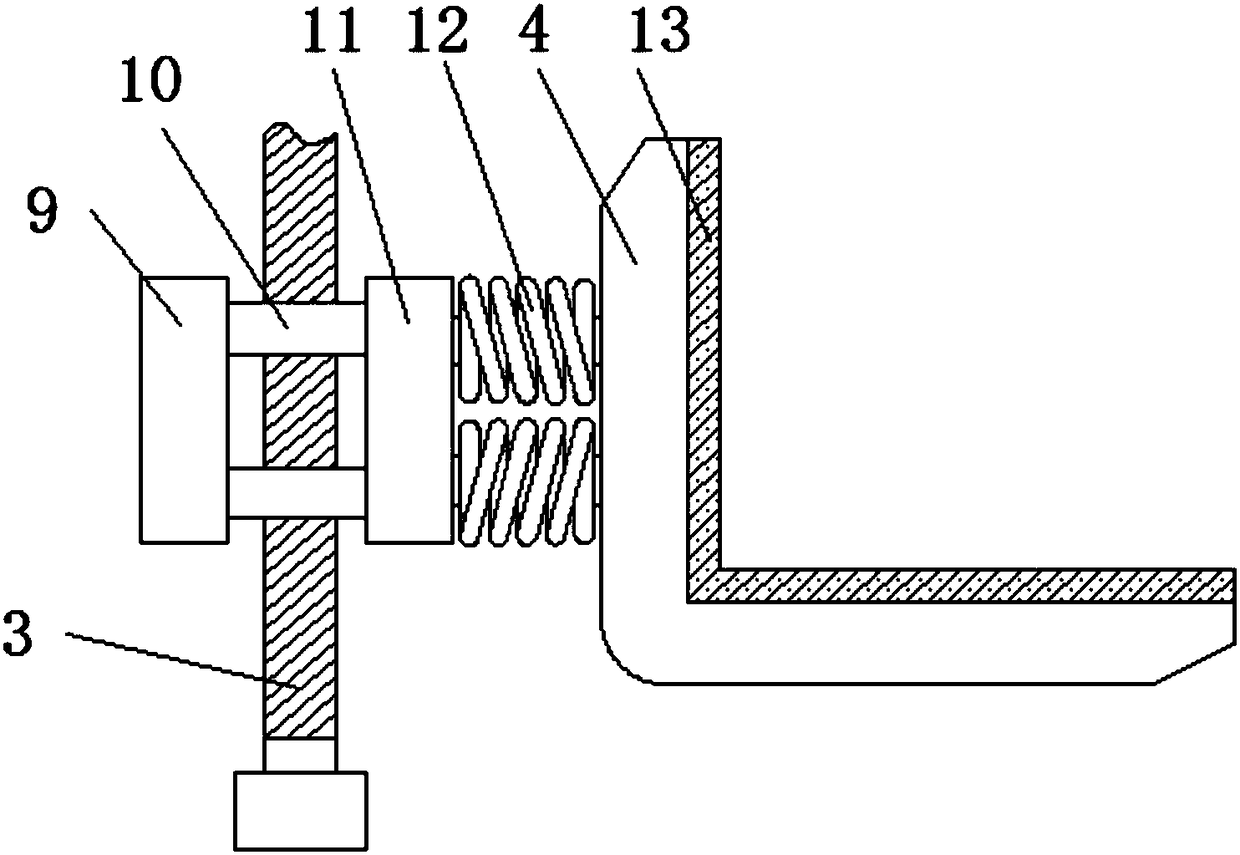

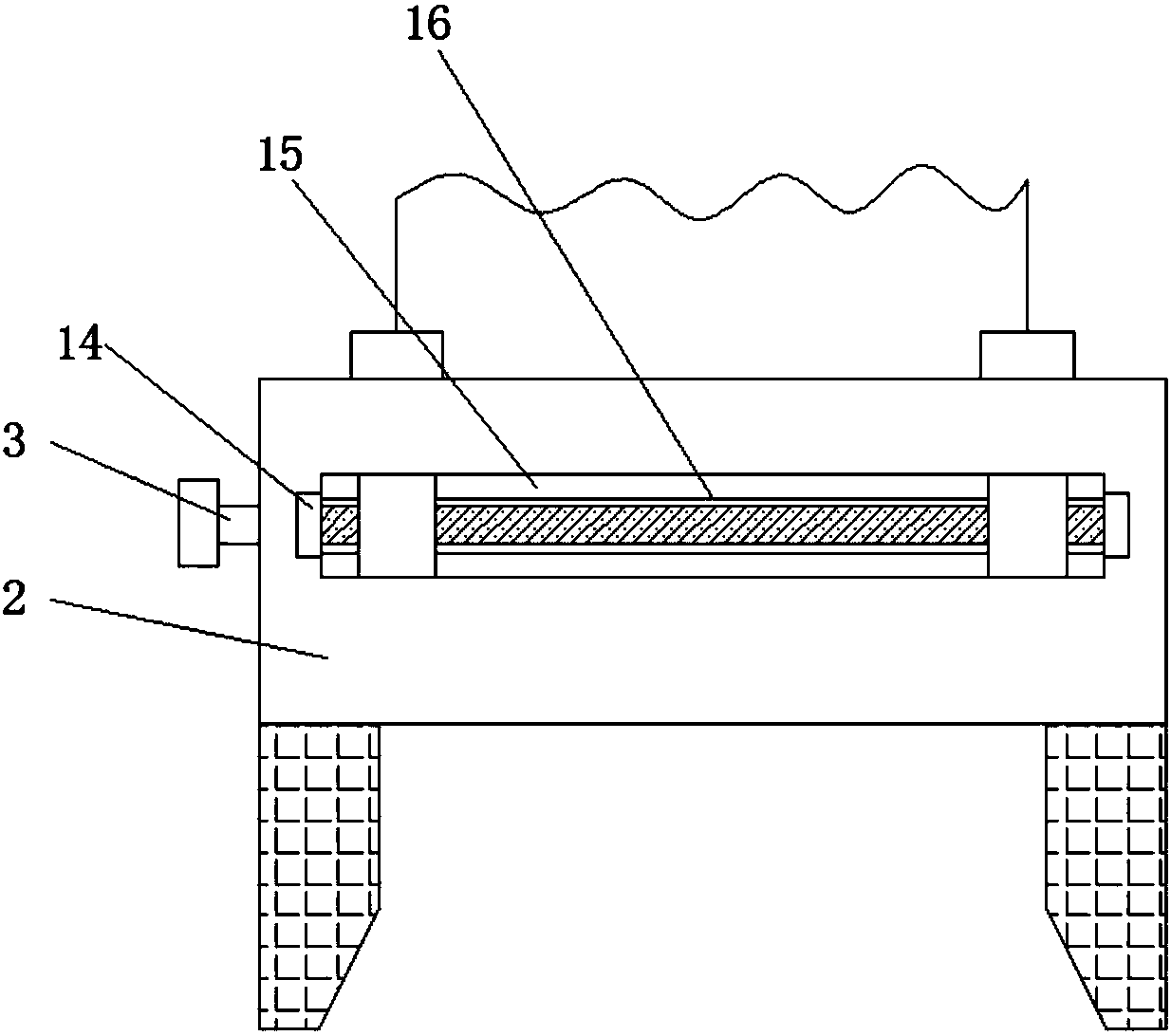

Novel movable power distribution cabinet bracket

InactiveCN108551090ACause wear and tearEasy to installSubstation/switching arrangement casingsSlide plateEngineering

The invention discloses a novel movable power distribution cabinet bracket which comprises a power distribution cabinet bracket and a power distribution cabinet, wherein bases are welded at the four corners of the bottom of the power distribution cabinet bracket; the power distribution cabinet bracket is in a concave structure; clamp grooves are formed on the two sides of the power distribution cabinet bracket; slide grooves are formed on the inner sides of the clamp grooves; slide plates are connected into the slide grooves in a clamping manner; a first clamp plate is welded on one side of each slide plate; a second clamp plate is welded on the other side of each slide plate; the first clamp plates and the second clamp plates are connected into the clamp grooves in a clamping manner; andsplints are connected with the inward sides of the second clamp plates via springs. According to the bracket, the relative positions of the splints can be adjusted by rotating adjustment screw rods, so that the bracket can fix the power distribution cabinets in various sizes; and gaskets are laid on inner walls of the splints, so that an outer wall of the power distribution cabinet cannot be abraded when the power distribution cabinet is clamped by the bracket.

Owner:成都尚智恒达科技有限公司

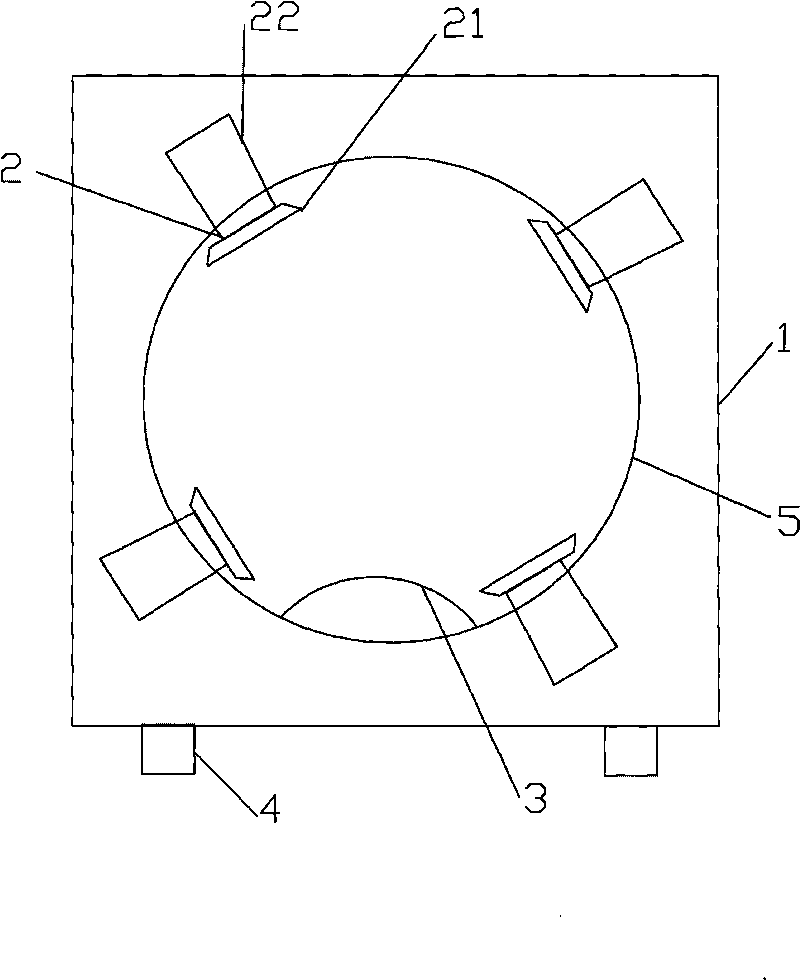

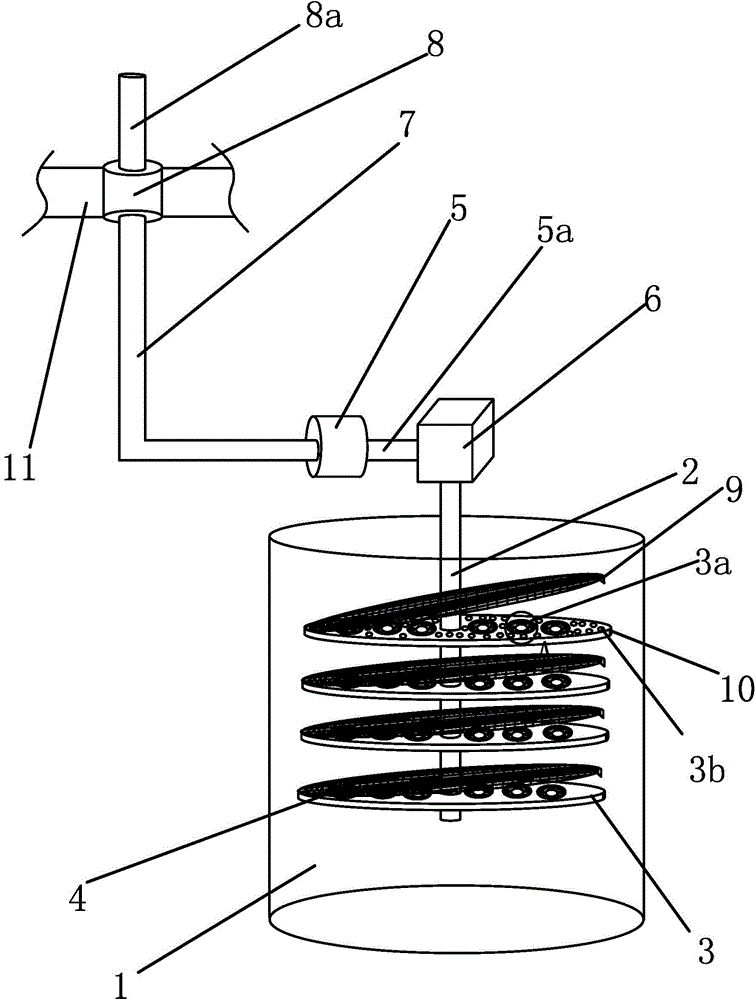

Axis driving type optical lens cleaning equipment

InactiveCN104307828APrevent escapeWon't wear outFlexible article cleaningCleaning using toolsElectric machineryEngineering

The invention provides axis driving type optical lens cleaning equipment, and belongs to the field of optical lens processing equipment. The cleaning equipment comprises a cleaning barrel, wherein a material carrying mechanism is arranged in the cleaning barrel; the material carrying mechanism comprises a material carrying shaft and material carrying plates; a lens trough is formed in the upper side of each material carrying plate; each lens trough is in a reduced orifice shape from top to bottom, and bottom holes penetrating through two sides of the material carrying plate are formed in the bottom center of the lens trough; a first limber hole is formed in each lens trough; a second limber hole is formed in each material carrying plate; each material carrying plate is hinged to a rubber mesh; one end of the rubber mesh is hinged to one end of the corresponding material carrying plate; the upper end of the material carrying shaft is connected with a driving motor; a crank sliding block mechanism is arranged between the driving motor and the material carrying shaft; the sliding block of the crank sliding block mechanism is connected to the material carrying shaft; the crank of the crank sliding block mechanism is connected to the motor rotating shaft of the driving motor; the motor casing of the driving motor is fixedly connected with a lifting rod; one end of the lifting rod is connected with a linear motor. The cleaning equipment is comprehensive in cleaning effect, and excellent in cleaning effect.

Owner:中山市吉尔科研技术服务有限公司

PVC plastic film processing flattening device capable of reducing pressure

The invention discloses a PVC plastic film processing flattening device capable of reducing pressure in the technical field of plastic film processing equipment. The device comprises a mounting frame, a winding roller, a mounting sleeve, a flattening block and a moving rod, wherein an adjusting device is slidably mounted in an inner cavity of the mounting sleeve, the moving rod is slidably connected to the bottom end of the inner cavity of the mounting sleeve in an inserted mode, a pushing spring is fixedly installed between the moving rod and the adjusting device, and the bottom end of the moving rod is fixedly connected with the outer wall of the top of the flattening block. In the device, a moving block slides inwards, the moving block and a mounting block move upwards, the moving block is moved to a position below an upper set of check blocks, a distance between the adjusting device and the moving rod is increased, a degree of compression of the pushing spring is decreased, through automatic adjustment of the adjusting device, the pressure of the flattening block on a thin film wound on the outer wall of the winding roller is not large, the situation that due to the fact that friction force between the flattening block and the thin film is large, the thin film is difficult to wind by the winding roller is avoided, and the flattening block is also prevented from abrading the wound thin film.

Owner:黄攀恒

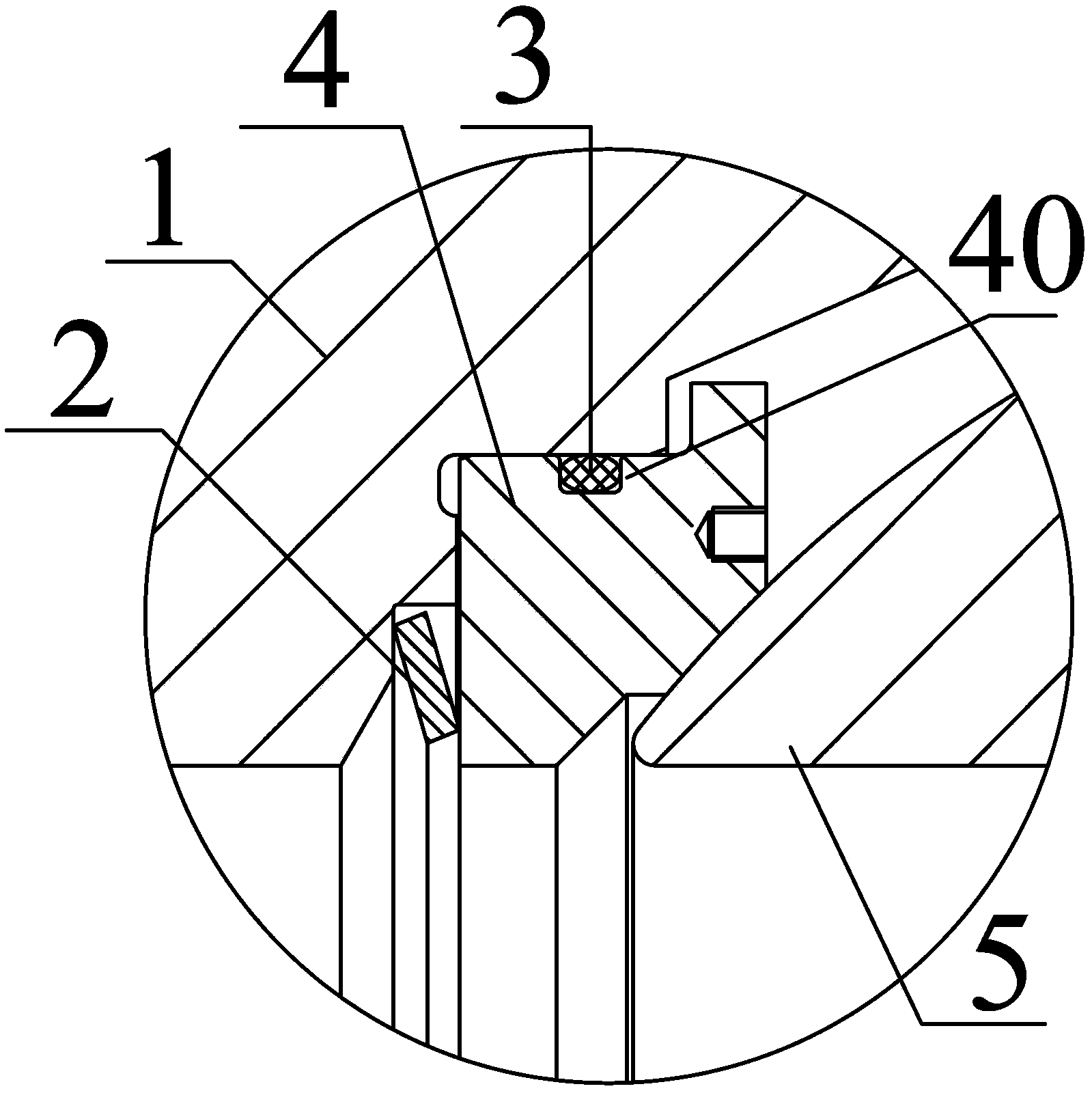

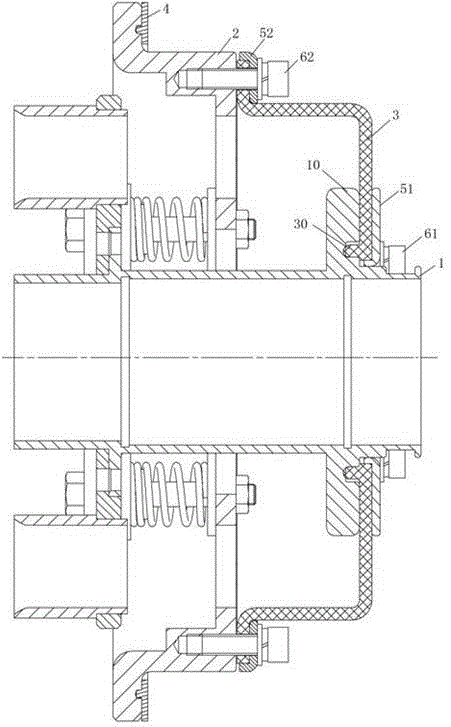

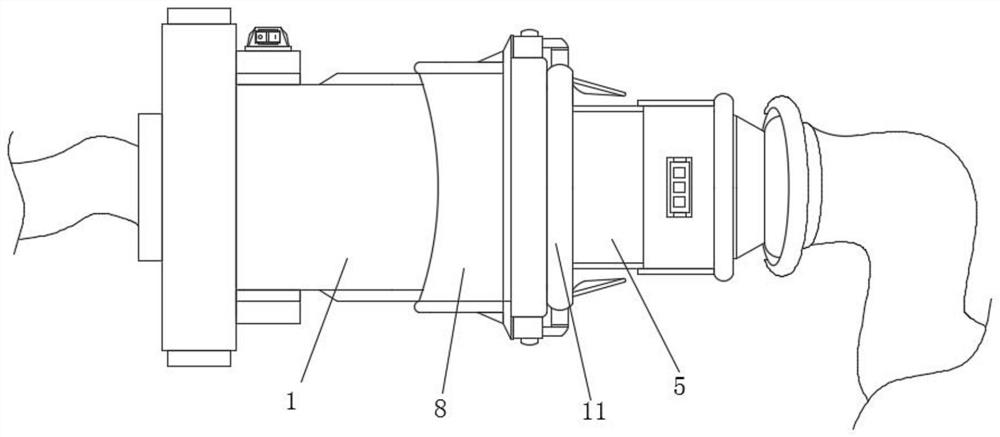

Floating sealing connector

ActiveCN105490072ACause wear and tearPrevent overcompressionCouplings bases/casesEngineeringMechanical engineering

The invention provides a floating sealing connector. The floating sealing connector comprises an outer shell and an inner shell that is connected in the outer shell in a floating connecting manner; the floating sealing connector also comprises a sealing rubber sleeve for sealing and blocking a floating gap between the inner shell and the outer shell; the inner edge of the sealing rubber sleeve is in sealing connection with the inner shell; an outer shell connecting surface used for being connected with the sealing rubber sleeve is arranged on the outer shell; the outer edge of the sealing rubber sleeve is connected with the outer shell connecting surface through an outer edge connecting part and an outer annular pressing plate; and an outer limiting structure used for limiting the compression deformation mount of a sealing rubber mat and extending towards the outer shell connecting surface is arranged on the outer edge or the inner edge of the outer annular pressing plate. According to the floating sealing connector, the sealing rubber sleeve and the inner shell and the outer shell are connected with relatively high connection strength and a relatively better sealing effect.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

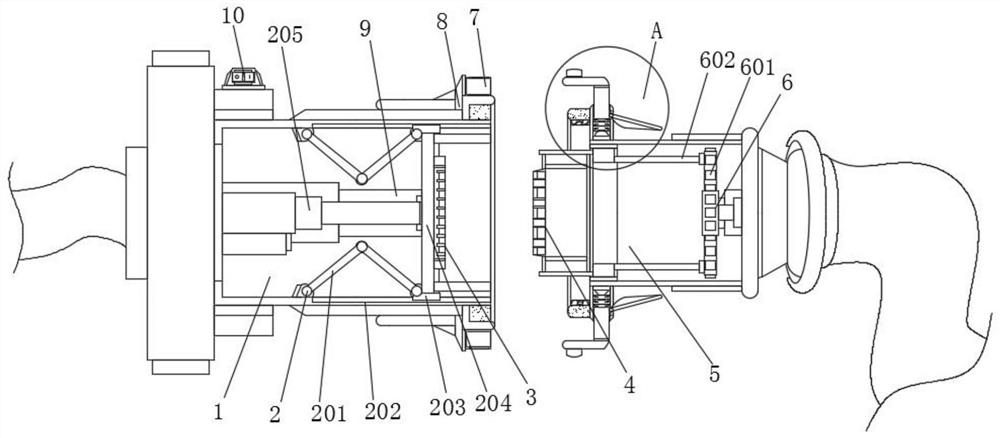

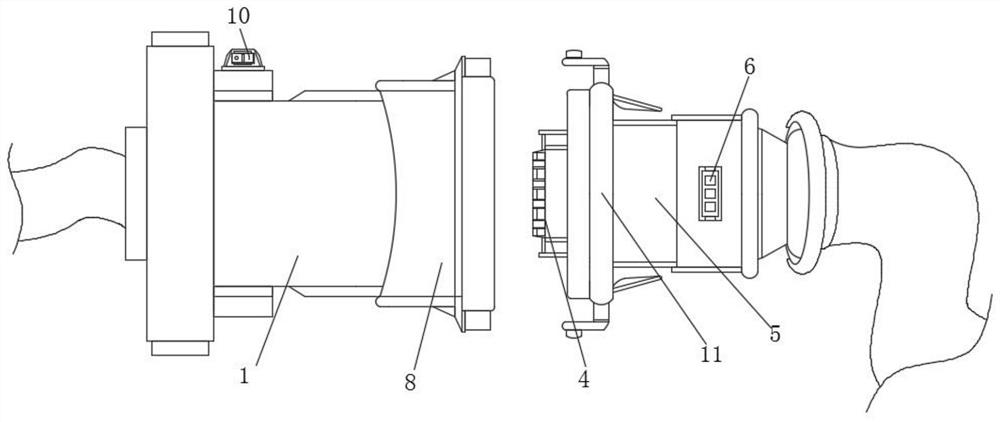

New energy automobile charging socket assembly

InactiveCN112821124APerfect protection functionEasy to observe dockingVehicle connectorsCharging stationsButt jointNew energy

The invention discloses a new energy automobile charging socket assembly. The assembly comprises a mounting groove and a sleeve, one side of the outer side of the mounting groove is provided with annular butt joint grooves which are connected with each other, the middle positions of the top and the bottom of each annular butt joint groove are provided with insertion blocks, and the middle position of the interior of the mounting groove is provided with a wire. Charging grooves which are connected with each other are formed in one side of the wire. Through mutual cooperation of the telescopic moving assemblies, the charging groove can be unfolded and stored before and after butt joint, the charging groove is unfolded into the mounting groove, so that an operator can observe butt joint more conveniently, the operability and convenience of cleaning work are improved, the plugging efficiency between the charging groove and a charging head is effectively ensured, and damage at interface by frequent alignment twist is inhibited. Meanwhile, by means of storage and hiding of the charging groove, the protection function of the charging groove is increased, and the sealing effect after the charging groove and the charging head are in butt joint is enhanced.

Owner:云南夏远新能源发展有限责任公司

Printed circuit board cleaning method, printed circuit board and circuit board clamp

ActiveCN110730571AAvoid direct contactAvoid corrosionCleaning using gasesCleaning using liquidsProcess engineeringPrinted circuit board

The invention discloses a printed circuit board cleaning method, a printed circuit board and a circuit board clamp. The cleaning method comprises the steps of first washing, pre-neutralization treatment, second washing, neutralization treatment and third washing. In a three-stage washing cylinder, a middle-stage washing cylinder is used for pre-neutralization treatment. The cleaning method is characterized in that an isolation air cushion is arranged in the middle-stage washing cylinder and a pre-neutralization container is arranged in the isolation air cushion before pre-neutralization treatment, the isolation air cushion can support the pre-neutralization container and isolate the pre-neutralization container from the middle-stage washing cylinder, and a corrosion-resistant coating is arranged on the inner wall of the pre-neutralization container; and the pre-neutralization container is filled with a pre-neutralization liquid medicine used for removing copper powder / residues on the surface of a printed circuit board, and the pre-neutralization liquid medicine comprises an acid solution and an oxidizing agent / reducing agent. According to the circuit board cleaning method, copper powder, dregs and the like attached to the surface of a printed circuit board can be removed, and the reliability of a manufactured printed circuit board is improved.

Owner:四川普瑞森电子有限公司

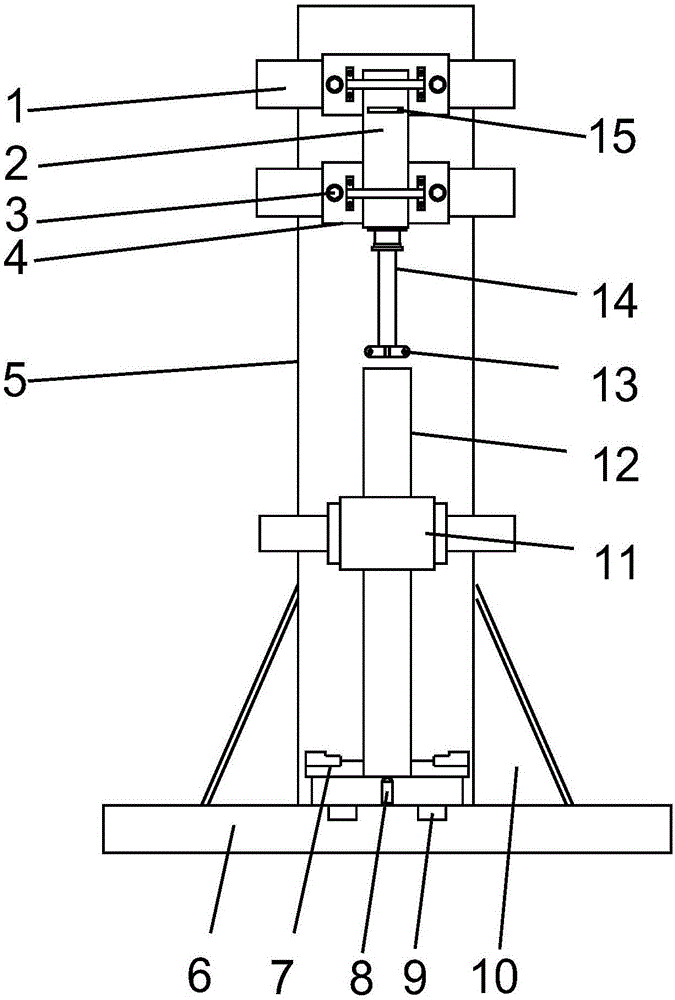

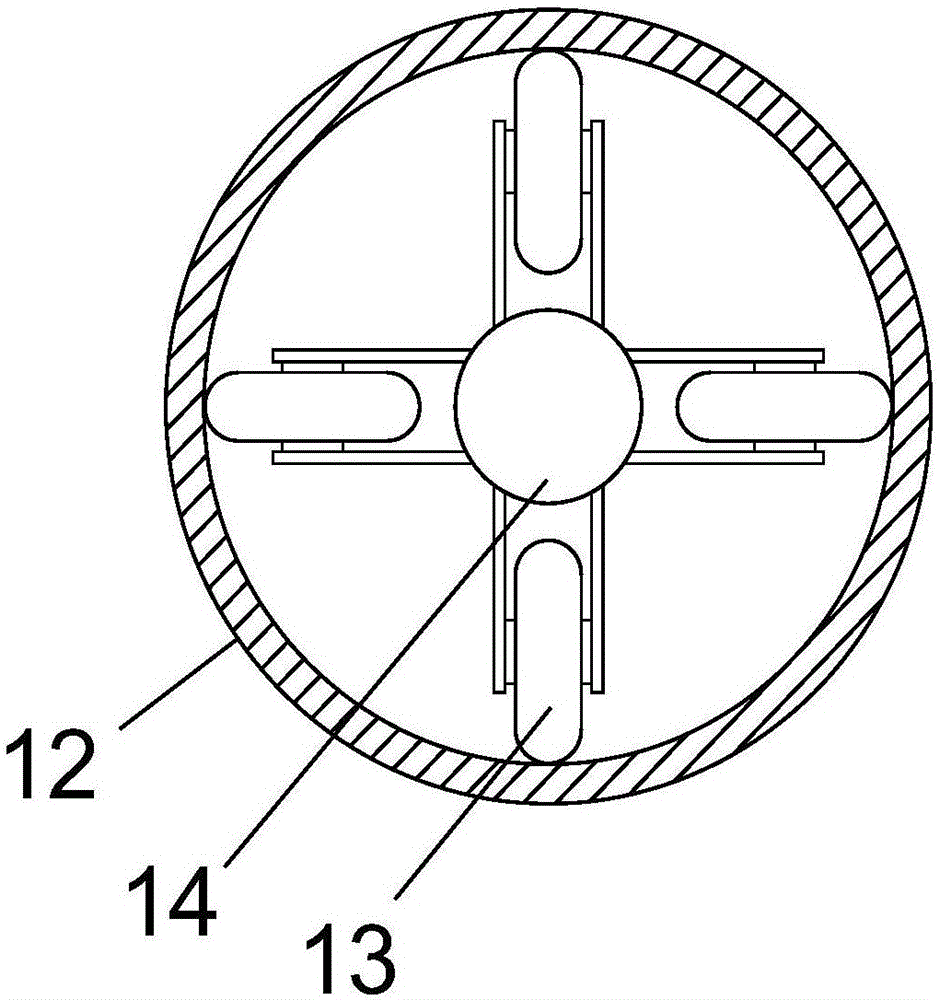

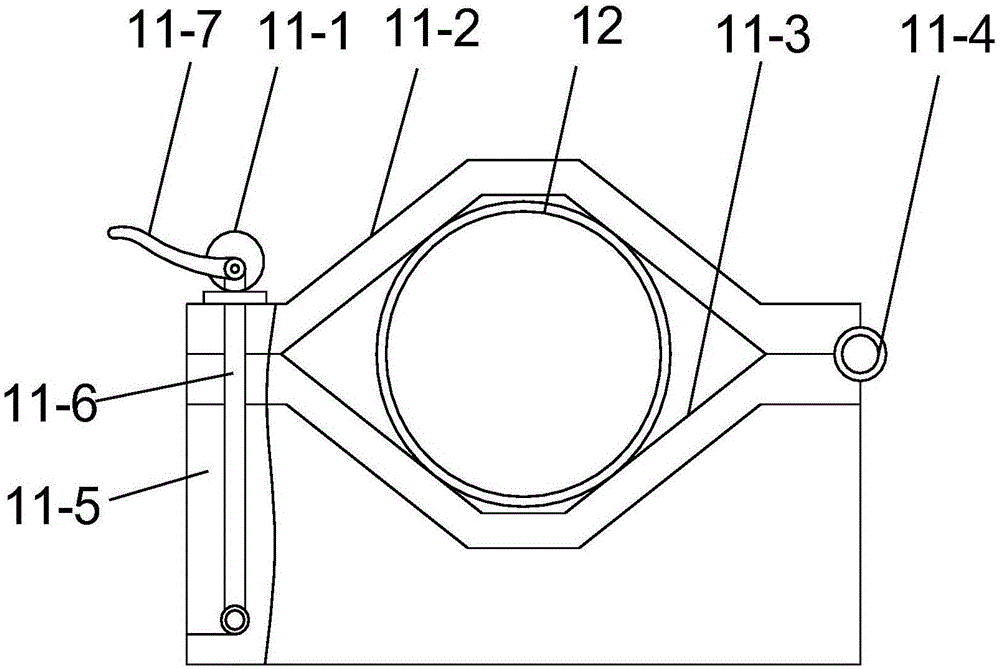

Vertical steel pipe self-centering straightening equipment

InactiveCN106670268AReduce frictionBe at easeMetal-working feeding devicesPositioning devicesSteel tubePiston rod

The invention discloses vertical steel pipe self-centering straightening equipment. The vertical steel pipe self-centering straightening equipment comprises a machine frame, a machine seat, an oil cylinder and straightening rollers; the machine frame is fixed to the machine seat; a three-claw clamping disc is welded and fixed to a welding block which is positioned on the machine seat; the oil cylinder is vertically downward and is fixedly mounted on a sliding seat; the sliding seat is arranged on a transverse guide rail which is positioned on the machine frame in a sliding manner; the straightening rollers are mounted on a connecting shaft; the connecting shaft is welded and fixed to a piston rod of the oil cylinder; at least four straightening rollers are uniformly arranged in the circumferential direction of the connecting shaft; the maximum distance between opposite two straightening rollers is equal to the inside diameter of a steel pipe. According to the vertical steel pipe self-centering straightening equipment, the friction between each straightening roller and the inner wall of the steel pipe is small, and the outer wall of the steel pipe cannot be worn, so that the surface quality of the outer wall of the steel pipe cannot be influenced; during a straightening process, the steel pipe is fixed; the problem of twisting or rotating is avoided; therefore, other negative effects cannot be produced.

Owner:合肥九州龙腾科技成果转化有限公司

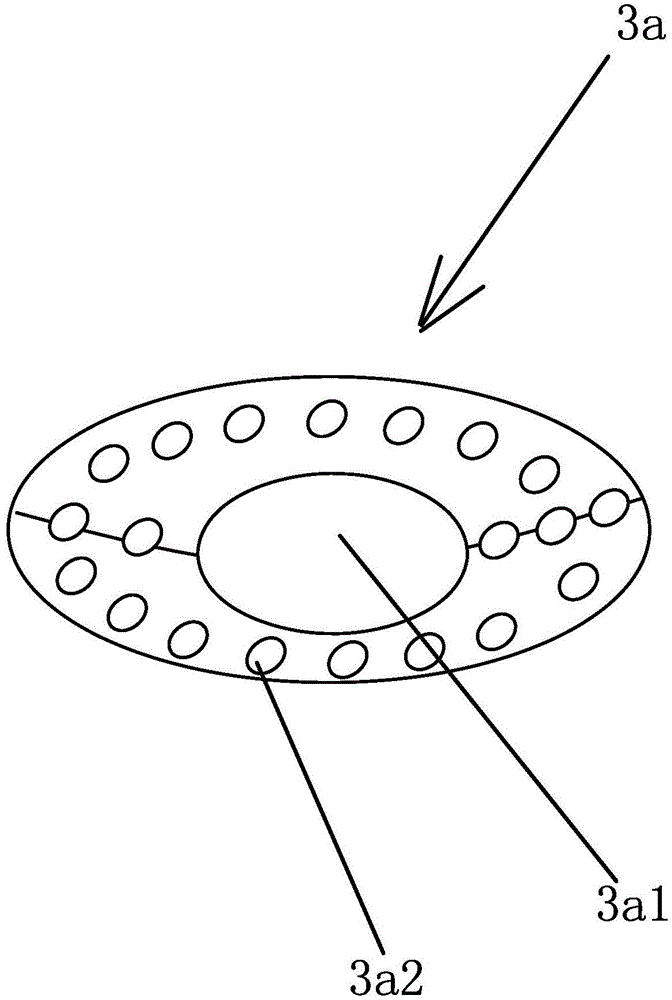

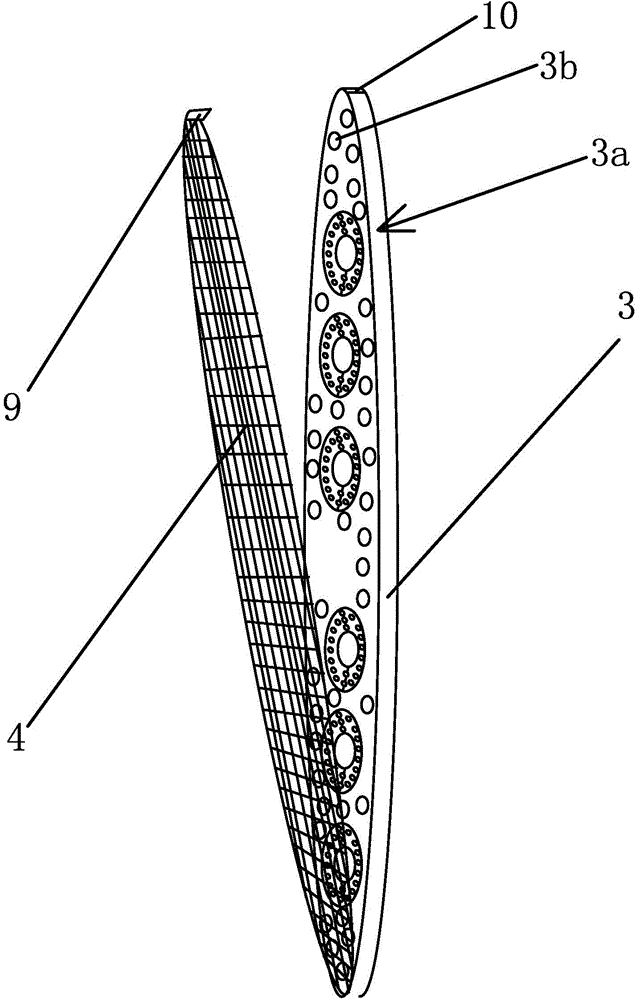

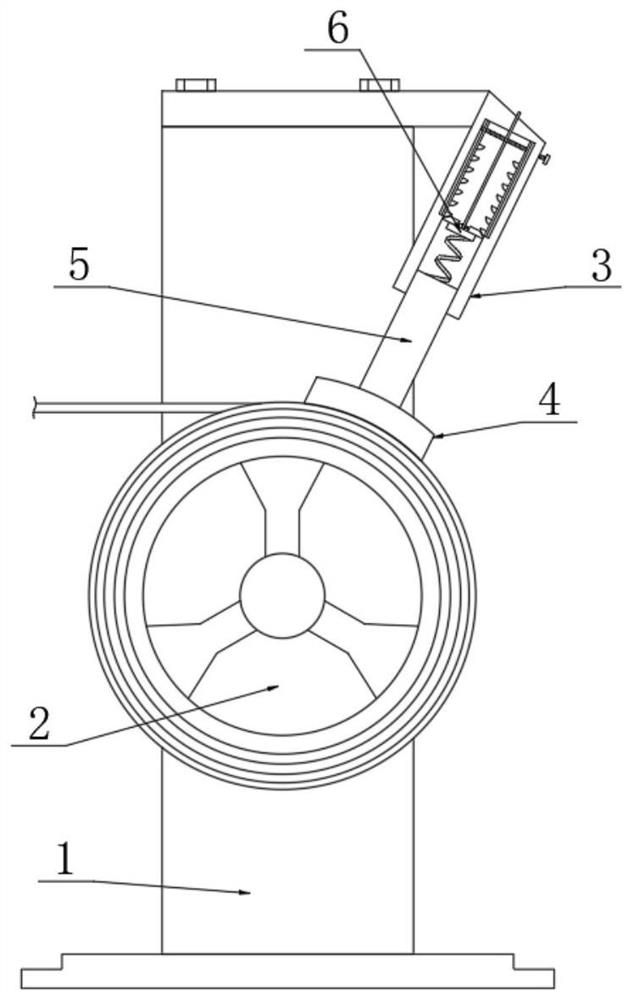

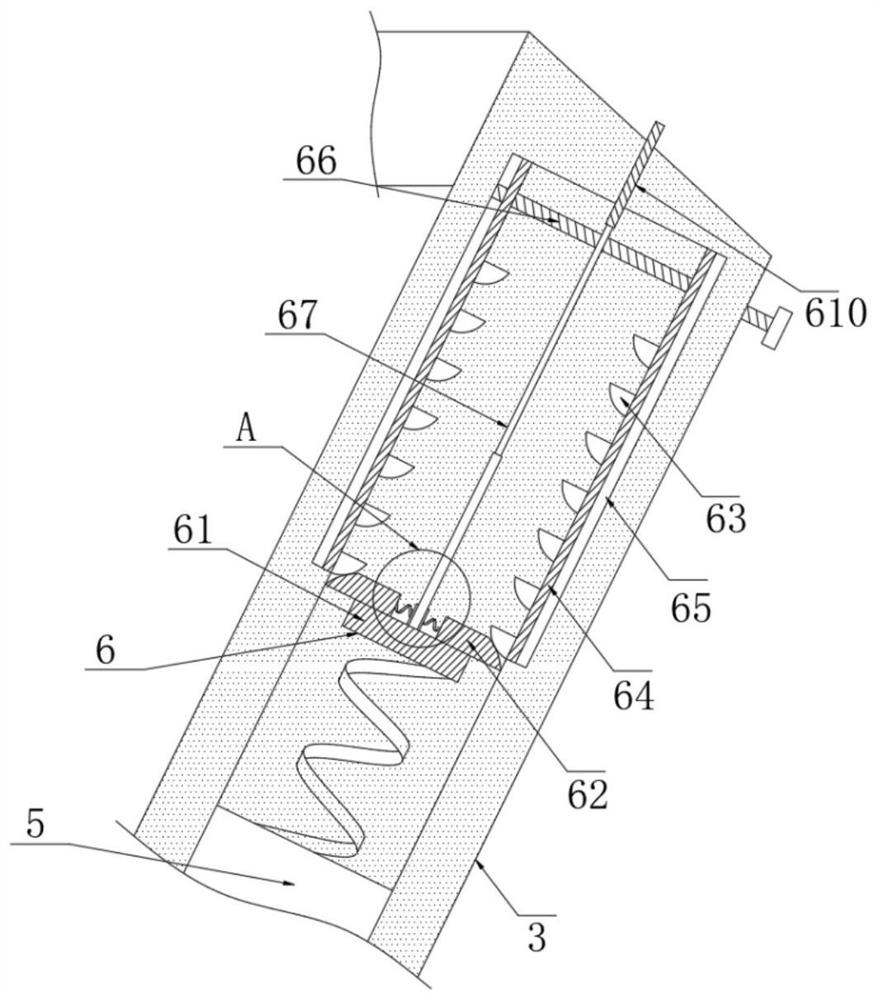

Heat sink for variable frequency motor

A heat sink for a variable frequency motor provided by the invention comprises a radiating impeller. A disc-shaped pedestal is fixed at the center of the radiating impeller, and an intermediate gear is fixed on the disc-shaped pedestal; a through hole is arranged at the center of the intermediate gear and is divided in two sections, one section is a motor shaft containing section, and the other section is an internal spline section; and the diameter of the motor shaft containing section is larger than the diameter of the internal spline section, a step portion is formed at the combination position of the motor shaft containing section and the internal spline section, and grooves are arranged at the connection position of the motor shaft containing section and the internal spline section. Because the grooves are arranged at the connection position of the motor shaft containing section and the internal spline section, the root of the motor shaft and the intermediate gear cannot be worn by friction.

Owner:泰信电机(苏州)有限公司

Safe and practical obstacle avoidance device for plant pruning knife rest

InactiveCN108566838AAvoid wear and tearCause wear and tearCuttersCutting implementsArchitectural engineeringObstacle avoidance

The invention provides a safe and practical obstacle avoidance device for a plant pruning knife rest. The safe and practical obstacle avoidance device comprises a rack, wherein a roller is arranged atthe lower end of the rack, a handle is arranged on one side of the upper end of the rack, a smashing device is arranged above the rack, a lifting table is arranged on one side of the smashing deviceand is located at the upper end of the rack, the upper end of the lifting table is connected with a fixing plate, a guide rail is arranged on the fixing plate, a sliding block is arranged on the guiderail, one end of the sliding block is connected with a telescopic rod, one end of the telescopic rod is connected with a motor, the output end of the motor is connected with a pruning device througha rotary telescopic rod, the guide rail is arranged on the fixing plate, the sliding block is arranged on the guide rail, one end of the sliding block is connected with the telescopic rod, one end ofthe telescopic rod is connected with the motor, the output end of the motor is connected with the pruning device through the rotary telescopic rod. The safe and practical obstacle avoidance device hasthe advantages of being simple in operation, good in pruning effect, capable of effectively preventing the knife rest from being abraded and saving energy and low in cost and being friendly to the environment.

Owner:金华市博益飞科技有限公司

Auto-fastening loading device

The invention relates to the field of machining tool accessories and provides an auto-fastening loading device. The auto-fastening loading device comprises a base, the lower surface of the base is provided with a depression, opposite protrusions on the two sides of the depression are supporting feet, the upper surface of the base is provided with a loading unit, the loading unit comprises an outer frame, the outer frame is folded to form a groove with an opening, an auto-fastening unit is arranged in the groove and comprises a transverse rod parallel to the upper surface of the base, the two ends of the transverse rod are connected with supporting rods, the other end of each supporting rod is provided with a pressing rod, a hydraulic supporting rod is arranged at the center of each supporting rod, the other end of each hydraulic supporting rod is connected with the inner sidewall of the groove, the lower surface of the transverse rod is connected with a pressure spring, and the stretching direction of the pressure spring is perpendicular to the axial direction of the transverse rod. According to the auto-fastening loading device, when a workpiece is placed in the groove, the auto-fastening unit can automatically fasten the workpiece, generated fastening force is appropriate at the same time, and the surface of the workpiece cannot be abraded; the auto-fastening loading device is simple in structure, convenient to operate and practical.

Owner:TERRENCE ENERGY

Needle roller for carding machine and preparation method thereof

A needle roller for carding machine belongs to a piece of equipment for carding machine in the cotton textile industry. The needle roller includes an aluminum pipe and a central axle; both ends of the aluminum pipe are sealed with flanges; the wall of the aluminum alloy pipe is opened with a aluminum hole; a steel needle is planted in the aluminum hole, which consists of a needle tip and a needle bar; the needle bar of the steel needle planted in the aluminum alloy pipe hole is adhered and integrated to the aluminum alloy pipe by super glue. The product quality is reliable; the needle roller and the needle tip have small coaxially and high co-straightness; the needle roller with the aluminum alloy as base structure is convenient in installation, has light weight, less energy consumption, high equipment manufacturing efficiency; in addition, the time for parking for maintenance is short, the carding quality is stable and unchanged, which is applicable to reconstruction of the current carding machines, and improves the performance and quality of the carding machines.

Owner:YIXING FANGZHOU ENVIRONMENT CONSERVATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com