New energy automobile charging socket assembly

A technology for new energy vehicles and charging sockets, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve problems such as increasing the difficulty of charging and plugging operations, insufficient fixing effect and protection, and damage to charging connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

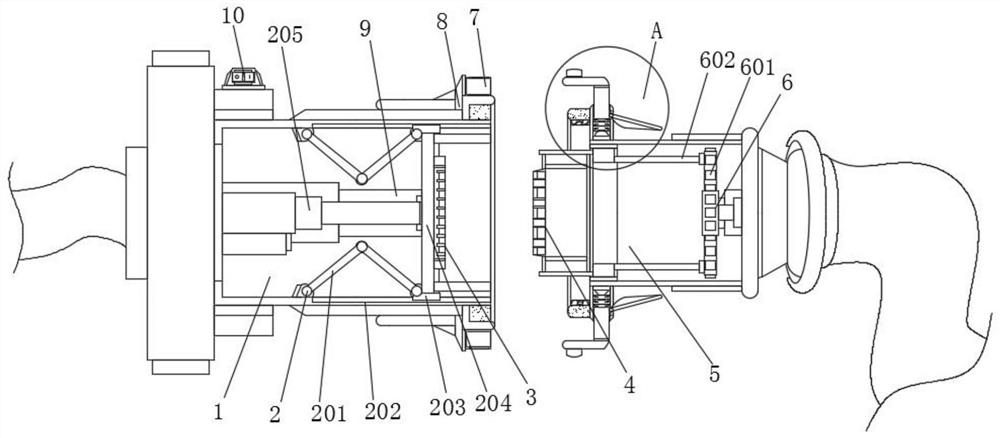

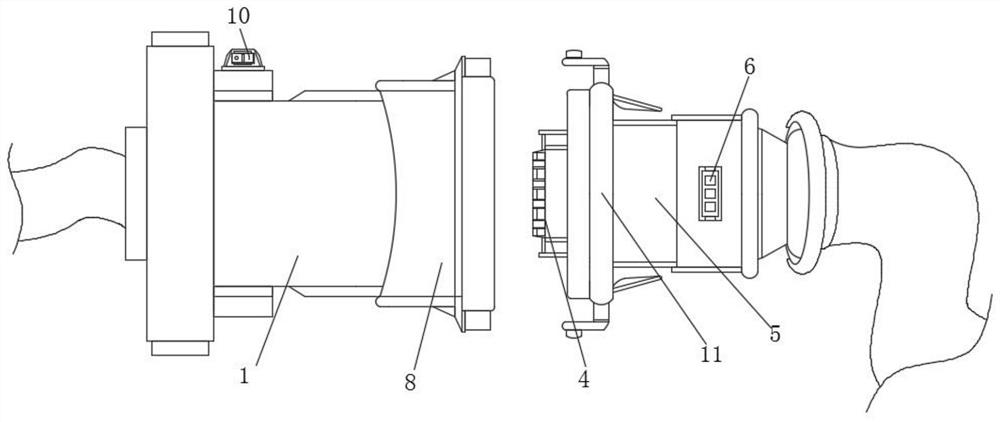

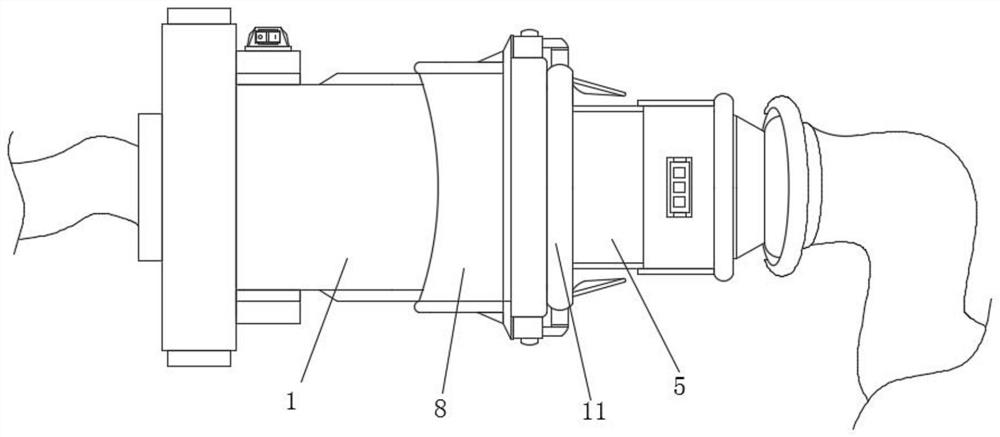

[0043] Example 1, such as Figure 1-8 As shown, when the charging tank 3 is docked with the charging head 4, the two sets of inner sleeves 13 can be manually pressed to drive the plug plate 12 to compress the spring 14, so that the position of the plug plate 12 is lowered. At this time, the control switch 10 can be used to start The miniature electric push rod 205 drives the installation frame 204 and the charging slot 3 back into the installation slot 1. During this period, the charging head 4 and the sleeve 5 are moved to make the installation ring 11 and the annular docking slot 8 approach each other, so that the annular water-absorbing pad and the rubber ring All snap into the annular depression in the annular docking groove 8 to form a protective sealing structure, and with the movement of the sleeve 5, the inserting plate 12 of the pressing device is driven to penetrate into the inserting block 7, and then the inner sleeve 13 is loosened. The elastic restoring force of t...

Embodiment 2

[0044] Example 2, such as figure 1 and Figure 8 As shown, before the charging tank 3 and the charging head 4 are docked and fixed, the toggle dial 6 and the dial 601 are engaged with each other, forcing the dial 601 to drive the connecting column 602 to rotate under the circular guidance of the slider 604 and the annular chute 605 , prompting the slider 604 to drive the mounting plate 603 to rotate with the charging head 4 to adjust the angle, so that the charging tank 3 and the charging head 4 can be docked conveniently and quickly, and after the docking is fixed, the dial wheel 6 and the charging head 4 can be slightly moved again. The dials 601 are engaged with each other, and observe whether the dial 601 drives the mounting plate 603 and the docked charging slot 3 and charging head 4 to shake or shift positions. It is not necessary to touch the charging slot 3 and charging head 4 to ensure that the docking is stable, increasing The functionality of the device and the eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com