Female die for ceramic cup product and using method thereof

A technology for ceramic cups and products, which is applied to ceramic molding machines, ceramic molding cores, ceramic molding mandrels, etc., can solve the problems of blurred patterns, poor fluidity and lack of concave and convex surfaces, and achieve the effect of clear concave and convex patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

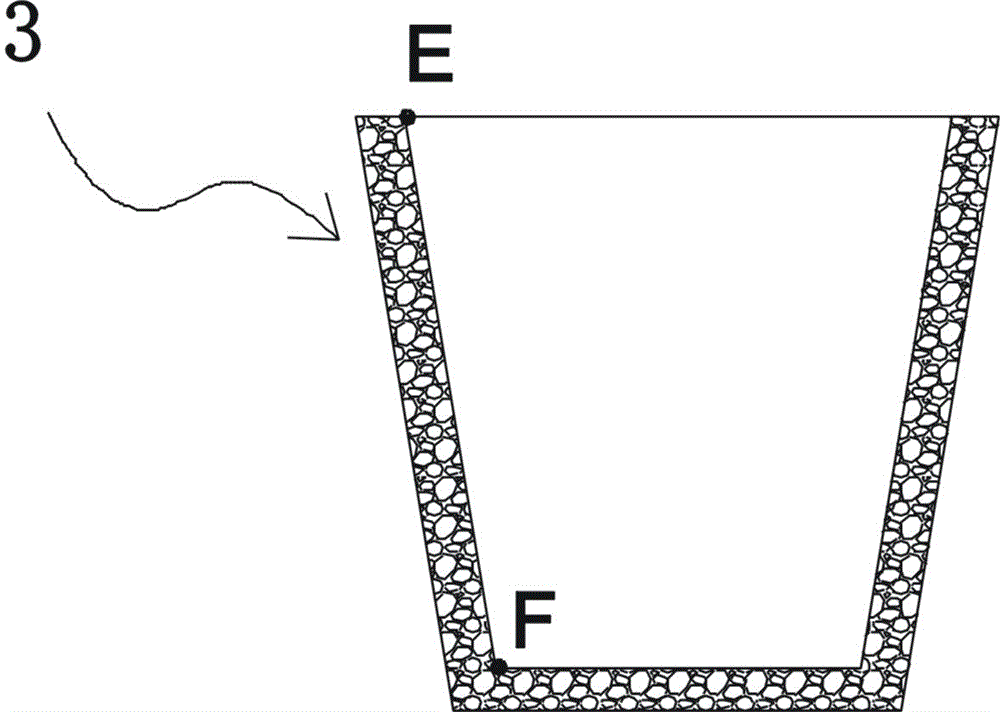

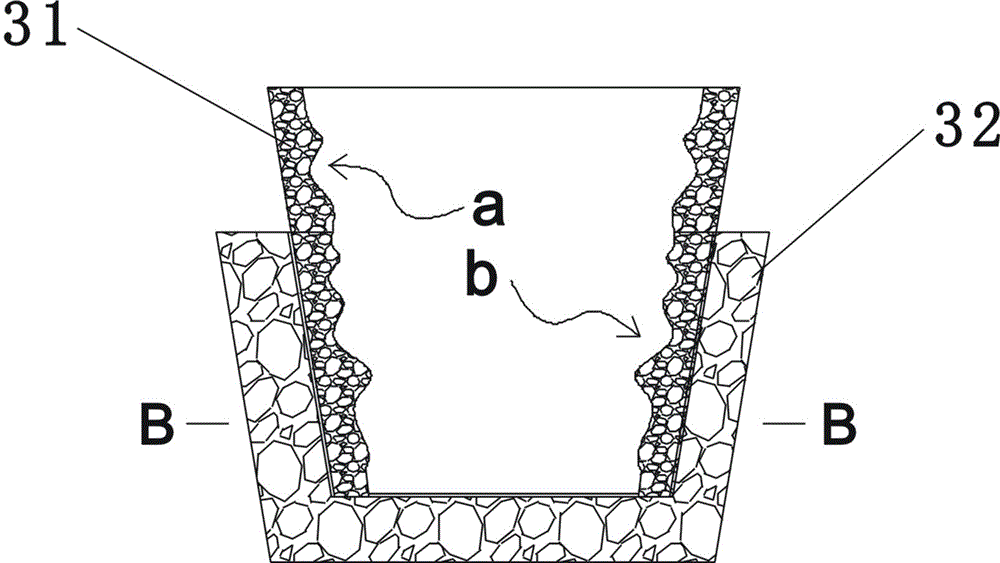

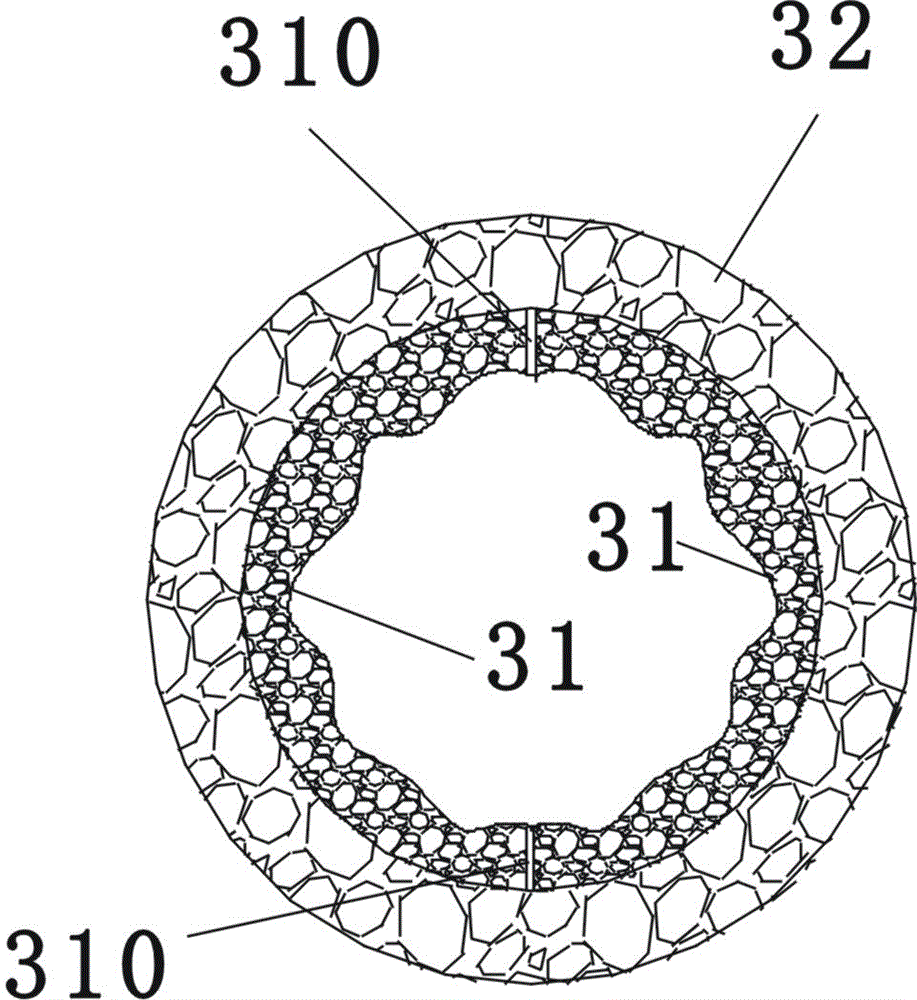

[0040] Figure 5 , Image 6 , Figure 7 The master mold of the shown ceramic cup product includes a first set of master mold assembly 1, and the first set of master mold assembly 1 includes a first mold core 11, a circular first steel mold cover 12, the first mold The core 11 is arranged in the center of the first steel mold cover 12, there is a radial gap between the first mold core 11 and the center of the first steel mold cover 12, the inner peripheral surface of the first steel mold cover 12 is smooth, and the first steel mold cover 12 and the first mold core 11 are formed as a circular first mold cavity 13, the lower bottom surface of the first mold core 11 (such as Figure 5 (shown on the MN surface in the middle) closely contacts the bottom 120 of the first steel formwork 12, leaving no vertical gap between the two; Figure 15 As shown, the first mold core 11 includes a mold core body 110 and a mold core cover 111. The mold core body 110 is made of silica gel. The mo...

Embodiment 2

[0042] A method for using the ceramic cup product master mold described in Embodiment 1, comprising the following steps:

[0043] (1) Under normal pressure, assemble the valve core of the first mold core 1 to the nozzle body of the valve so that the air pressure inside the cavity 113 of the first mold core is normal pressure; The left and right parts of the first mold cavity 13 of a set of master mold components are filled with gypsum respectively;

[0044] (2) After the gypsum pouring is completed, use the inflation device to inflate the cavity of the first mold core through the valve 112, so that the air pressure in the cavity of the first mold core reaches 2.5 standard atmospheric pressure, and the mold core body 110 of the first mold core Expand and squeeze the gypsum in the first mold cavity to make it dense, and then let the gypsum solidify. During the gypsum solidification process, the air pressure in the first mold core cavity remains constant at 2.5 standard atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com