Needle roller for carding machine and preparation method thereof

A carding machine and needle roller technology, which is applied in the field of preparation of needle rollers for carding machines, can solve the problems of easy wear of the rack pin teeth, long parking maintenance time, and decline in carding quality, so as to achieve reliable product quality, parking The effect of short maintenance time and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

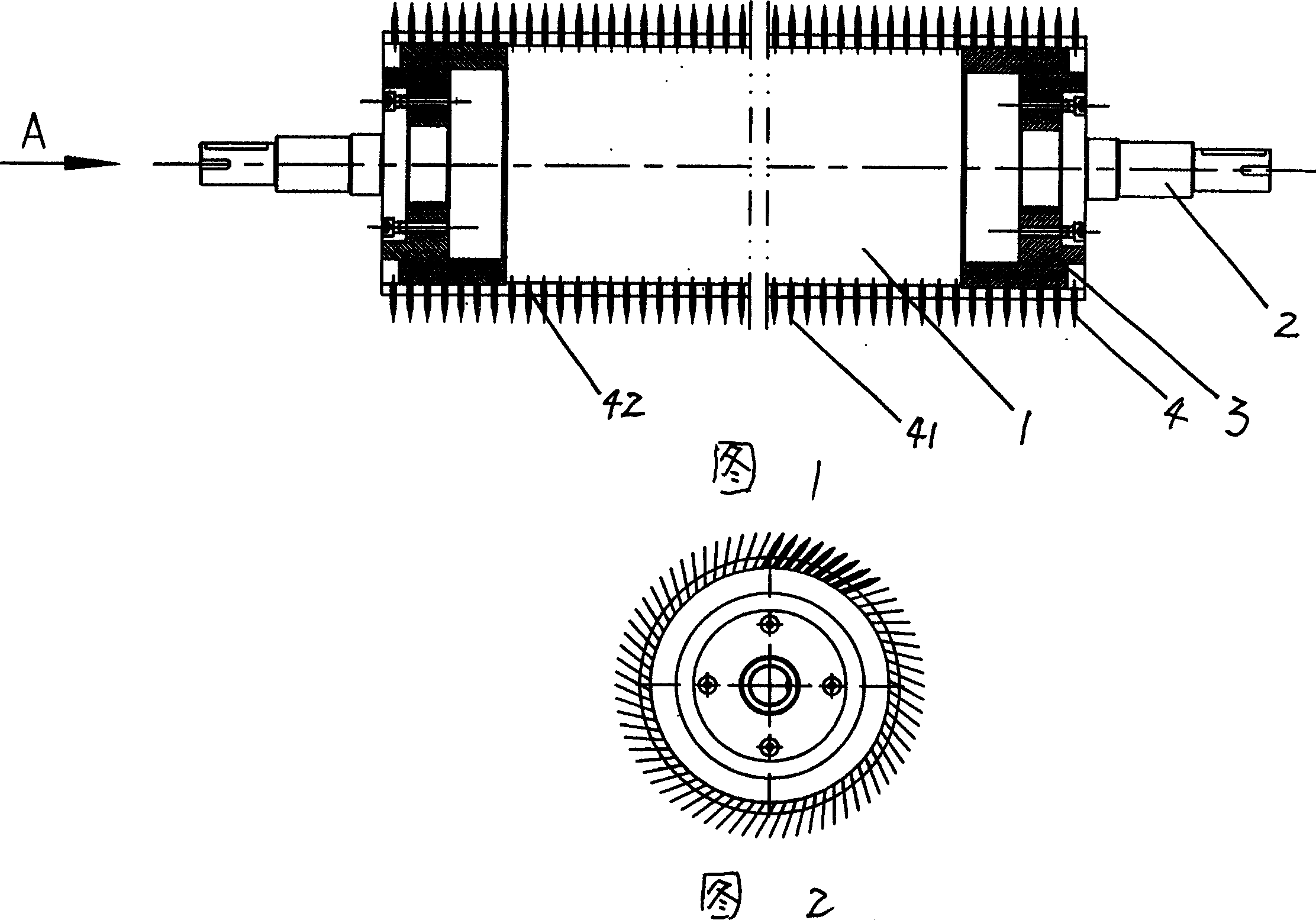

[0009] Needle roller for carding machine, including aluminum alloy tube 1 and central shaft 2, both ends of aluminum alloy tube 1 are closed by flange 3, aluminum holes are opened on the wall of aluminum alloy tube 1, and steel needles are planted in the aluminum holes 4. The steel needle is composed of a needle point 41 and a needle column 42. The steel needle made of carbon steel has been subjected to surface treatment, that is, the carbon steel needle is quenched and tempered to make the steel needle hardness 48-55 degrees, and then the steel needle is The surface is coated with nickel, the diameter of the aluminum hole is greater than or equal to 2-4 wires than the diameter of the steel needle, and the steel needle 4 pins implanted in the aluminum alloy tube hole are bonded and closed with the aluminum alloy tube 1 by superglue.

[0010] The preparation method of the needle roller for the carding machine is as follows: inject superglue into the hole of the perforated alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com