Patents

Literature

343results about How to "Anti-rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lipid type antirust oil with gaseous phase antirust function

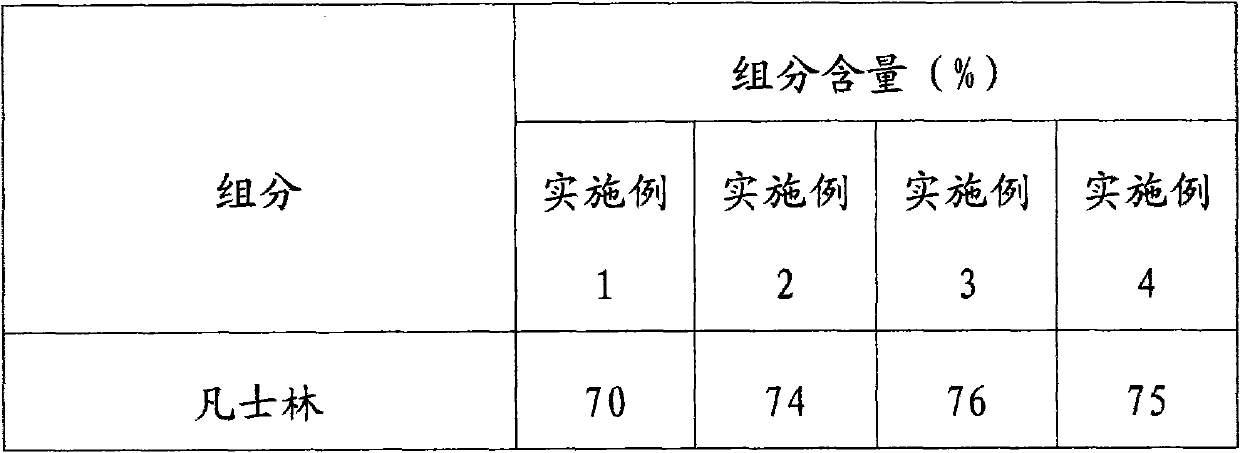

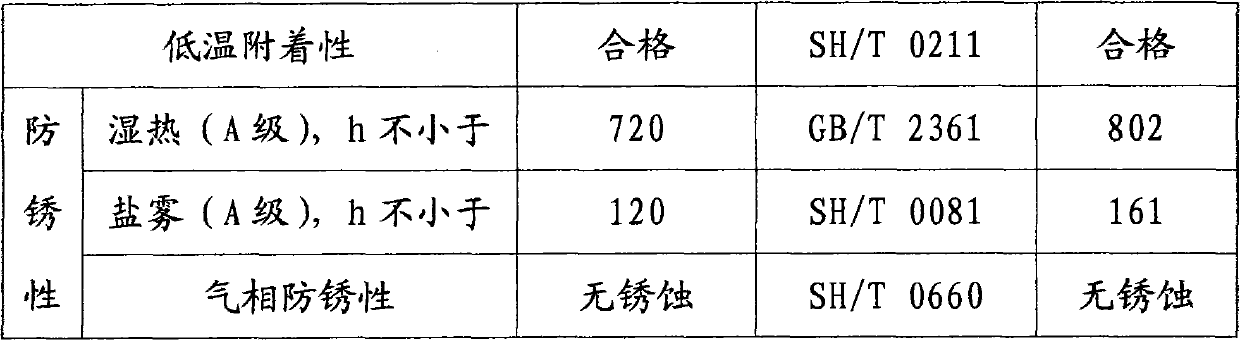

The invention discloses a lipid type antirust oil with gaseous phase antirust function; the composition of the lipid type antirust oil in weight percent is as follows: 70-90% of base lipid, 4-15% of antirust agent, 1-5% of gaseous phase antirust agent and 5-10% of oil film modifying agent; the inventive antirust oil has long protection period, sun and rain exposure resistance, non-leakage at hightemperature, non-cracking at low temperature, transparent and soft oil film, good paintability, and easy removal, and is mainly applied for antirusting for various metalwares, precise instruments, mechanical equipments, metal rotation sequence of workshops in machining industry, etc.

Owner:天津蓝星清洗有限公司

Environmental-friendly water-based antirust agent

The invention relates to an environmental-friendly water-based antirust agent, which mainly comprises boric acid, ethanolamine, a neutralizer, a corrosion inhibitor, an additive, water and the like. During use, the antirust agent is mixed with the water in a ratio of 1:5-1:20 to form antirust solution, and a steel workpiece is soaked in the antirust solution at the temperature of between 50 and 70 DEG C for 3 to 5 minutes and taken out; a continuous and compact thin film is formed on the surface of the soaked workpiece, so that oxygen and water vapor can be effectively prevented from contacting the surface of the workpiece, the primary color of the workpiece is kept unchanged, and the aim of rust prevention is fulfilled; and the treated workpiece can be directly subjected to the next process, so that the complex process of removing an antirust coating is reduced. The antirust agent does not contain poisonous and harmful substances such as nitrite, phosphate, bichromate and the like, cannot irritate and harm human bodies, and is an environmental-friendly water-based antirust agent.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

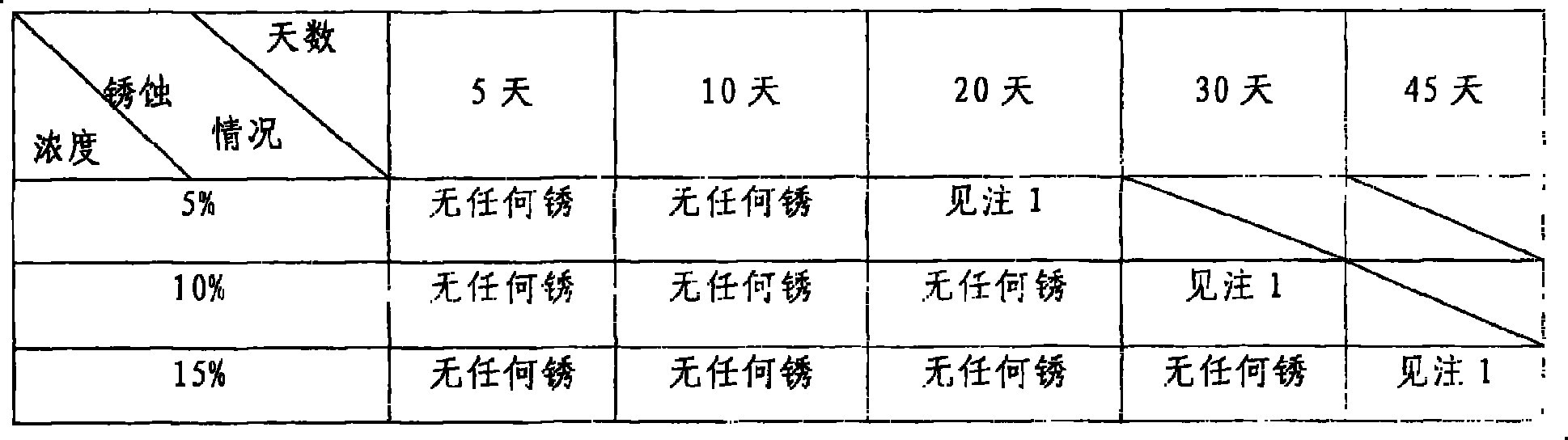

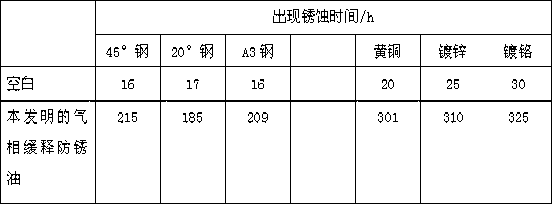

Ferrocene gas-phase slow-release rust preventive oil and preparation method thereof

The invention provides a ferrocene gas-phase slow-release rust preventive oil which is prepared from the following raw materials by weight: 150 parts of No. 120 solvent naphtha, 5 to 8 parts of rosin, 2 to 5 parts of zinc dust, 3 to 5 parts of sodium laureth sulfate, 15 to 18 parts of liquid paraffin, 3 to 5 parts of 3-aminopropyltrimethoxysilane, 10 to 15 parts of triethylenediamine, 10 to 13 parts of epoxidized soybean oil, 10 to 15 parts of xylene, 5 to 8 parts of a cross-linking agent TAIC, 1 to 2 parts of ferrocene, 3 to 5 parts of polyisobutylene, 1 to 2 parts of 4-amino-3,5-dimethyl-1,2,4-triazole, 1 to 2 parts of diethylhydroxylamine, 1 to 2 parts of 2-aminoethyl-heptadecenyl-imidazoline, 1 to 2 parts of diethanolamine, 1 to 2 parts of tri-n-octylamine, 2 to 3 parts of zinc dialkyl dithiophosphate, 5 to 8 parts of dimethicone, 1 to 2 parts of sodium dodecyl benzene sulfonate, 3 to 5 parts of acetyl tri(2-ethylhexyl) citrate, 5 to 6 parts of a film forming resin and 1 to 2 parts of modified attapulgite. The gas-phase rust preventive oil has good antirust performance and an excellent contact antirust effect, so the rust preventive oil can be widely applicable to antirust action on inner cavities or other contact or non-contact metal positions of mechanical equipment.

Owner:TONGLING RELY TECH

Corrosion inhibitor

The invention relates to a corrosion inhibitor, which is mainly used for corrosion inhibition in a continuous acid cleaning technology of a cold-rolled sheet. The corrosion inhibitor comprises the following components in percentage by weight: 10-25% of hexamine, 0-10% of vinylamine, 0-10% of ethanolamine, 0-3% of alkynol alkoxylate, 0-4% of oxalic acid, 2-5% of additive and 43%-88% of water. The corrosion inhibitor can effectively inhibit corrosion, improve the brightness of the surface of a sheet, prolong the use period of an acid liquid and has a certain rust-proof property.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Ammonium benzoate gas-phase slow-release rust preventive oil and preparation method thereof

The invention provides an ammonium benzoate gas-phase slow-release rust preventive oil which is prepared from the following raw materials by weight: 150 parts of No. 120 solvent naphtha, 5 to 8 parts of rosin, 2 to 5 parts of zinc dust, 3 to 5 parts of sodium laureth sulfate, 15 to 18 parts of liquid paraffin, 3 to 5 parts of 3-aminopropyltrimethoxysilane, 10 to 15 parts of triethylenediamine, 10 to 13 parts of epoxidized soybean oil, 10 to 15 parts of xylene, 5 to 8 parts of a cross-linking agent TAIC, 1 to 3 parts of ferrocene, 4 to 6 parts of polyisobutylene, 1 to 2 parts of ammonium benzoate, 1 to 2 parts of benzotriazol, 1 to 2 parts of 2-aminoethyl-heptadecenyl-imidazoline, 1 to 2 parts of triethanolamine, 2 to 4 parts of zinc dialkyl dithiophosphate, 1 to 2 parts of sodium dodecyl benzene sulfonate, 6 to 8 parts of dimethicone, 10 to 12 parts of epoxidized triglyceride, 5 to 6 parts of a film forming resin and 1 to 2 parts of modified attapulgite. The gas-phase rust preventive oil has good antirust performance and an excellent contact antirust effect, so the rust preventive oil can be widely applicable to antirust action on inner cavities or other contact or non-contact metal positions of mechanical equipment.

Owner:TONGLING RELY TECH

Multifunctional gaseous phase anti-rust oil

ActiveCN101638604AContact rust-proofWith gas phase corrosion inhibitor gas phase rust preventionAdditivesButanedioic acidGas phase

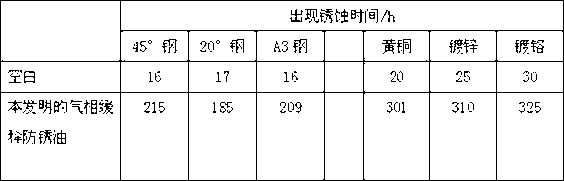

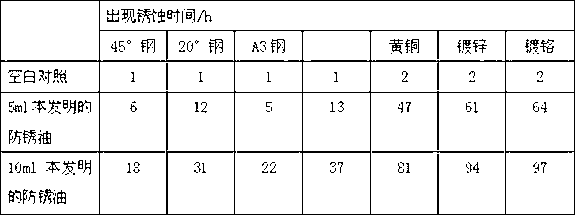

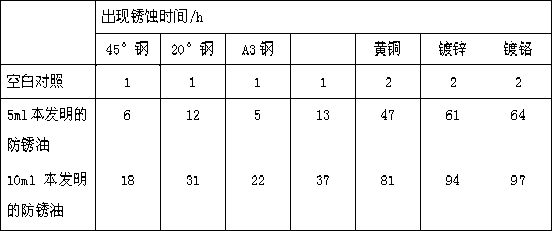

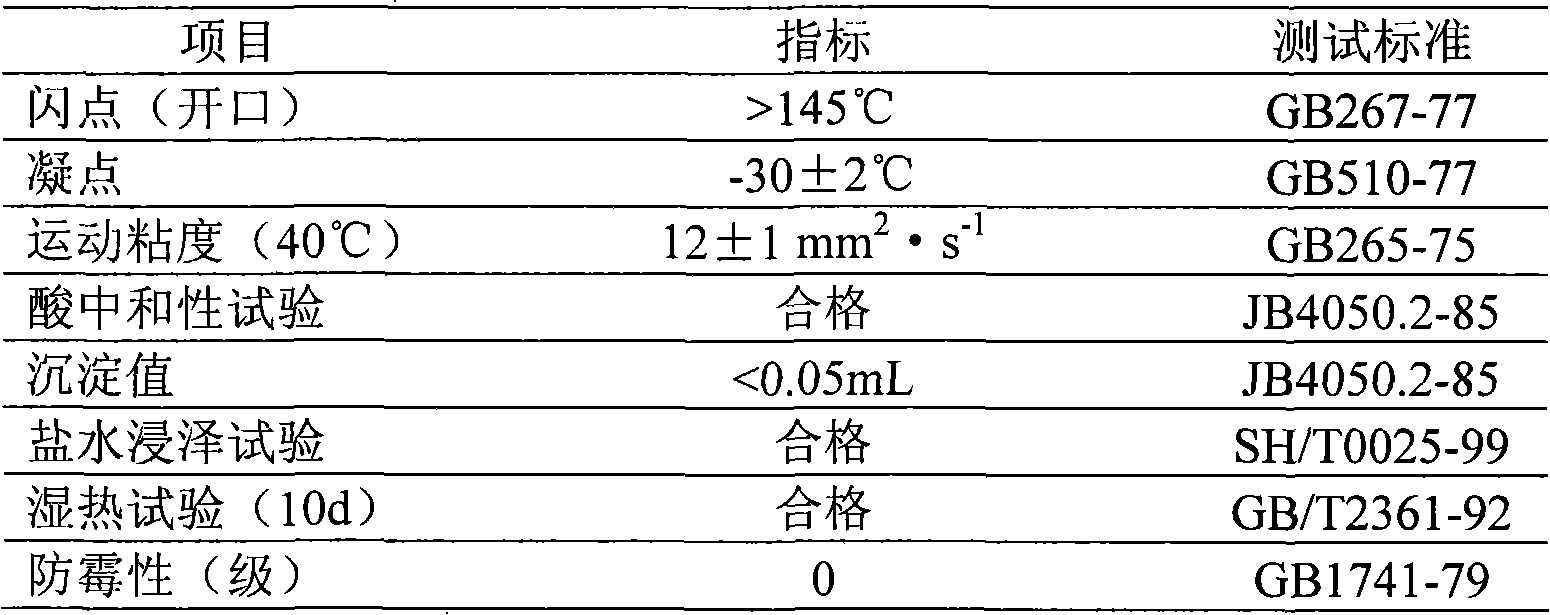

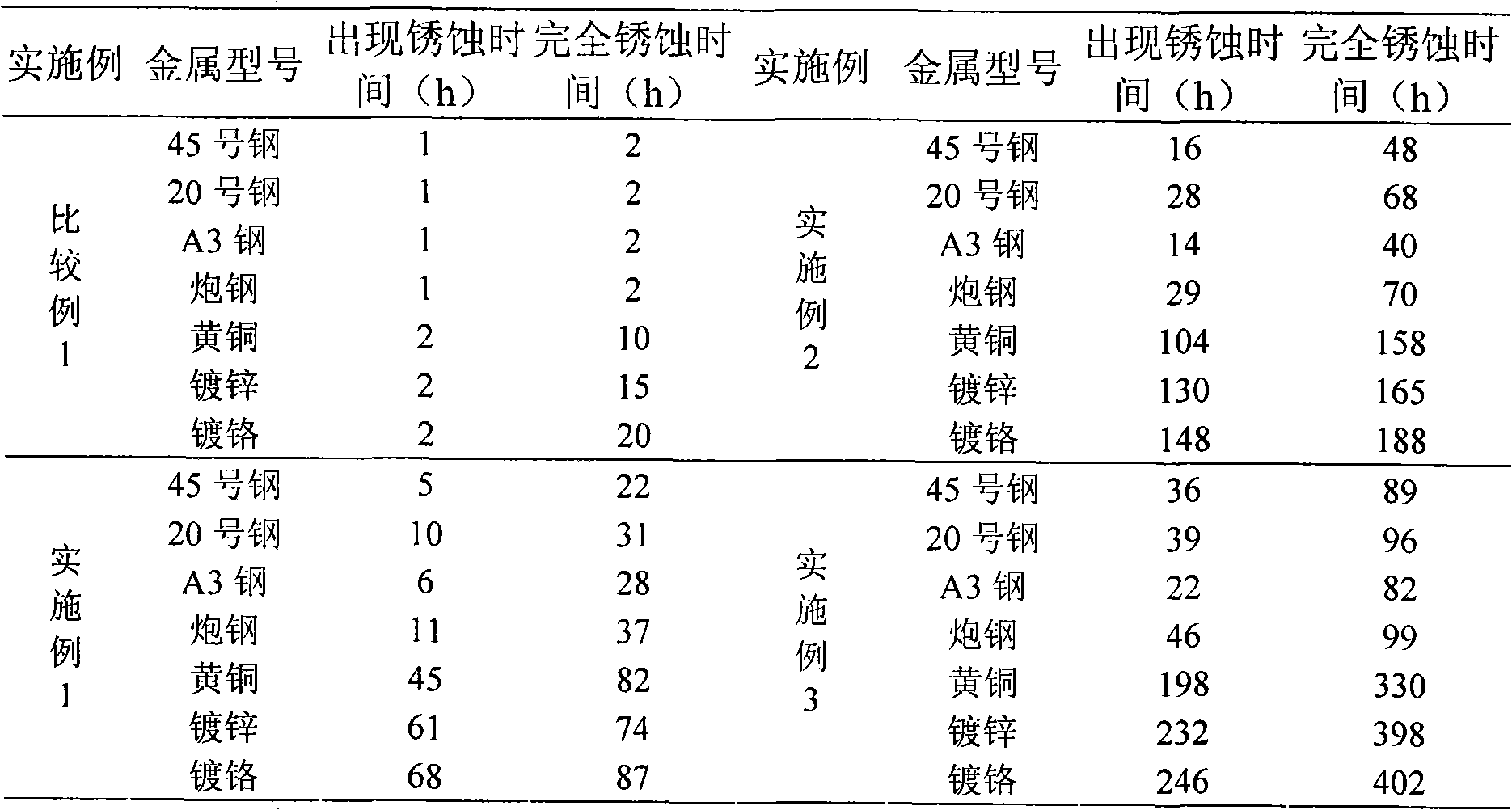

The invention discloses a multifunctional gaseous phase anti-rust oil which mainly comprises No. 25 transformer oil, oil-soluble vapor phase corrosion inhibitor, cosolvent dibutyl phthalate, defoamingagent polydimethylsiloxane, antioxidant zinc dialkyl dithiophosphate, mildewproof agent di-n-octyl-4-isothiazolin-3-ketone and the like; wherein the oil-soluble vapor phase corrosion inhibitor is prepared by mixing 10-40% of octadecyl butanedioic acid, 10-30% of 2-ethylamino heptadecenyl imidazoline, 2-20% of lanolin, 5-20% of zinc naphthenate and 15-30% of chromic acid tert-butyl ester. The gaseous phase anti-rust oil not only has the contact anti-rust property of the anti-rust oil, but also has the superior vapor phase anti-rust performance of the vapor phase corrosion inhibitor. The multifunctional gaseous phase anti-rust oil can be widely applied to long-term rust protection of military hardware and metal materials for civil use, more particularly, used for rust prevention of engines,large compressors, special gear boxes and the like, and mainly applicable to preventing a closed cavity system from rusting. The anti-rust oil not only can prevent black metal steel-made parts from rusting, but also has the function of rust prevention for multiple non-ferrous metal parts, thus effectively preventing metals such as steel, copper, zincification, chrome-plate and the like as well asalloy materials thereof from being corroded.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE +1

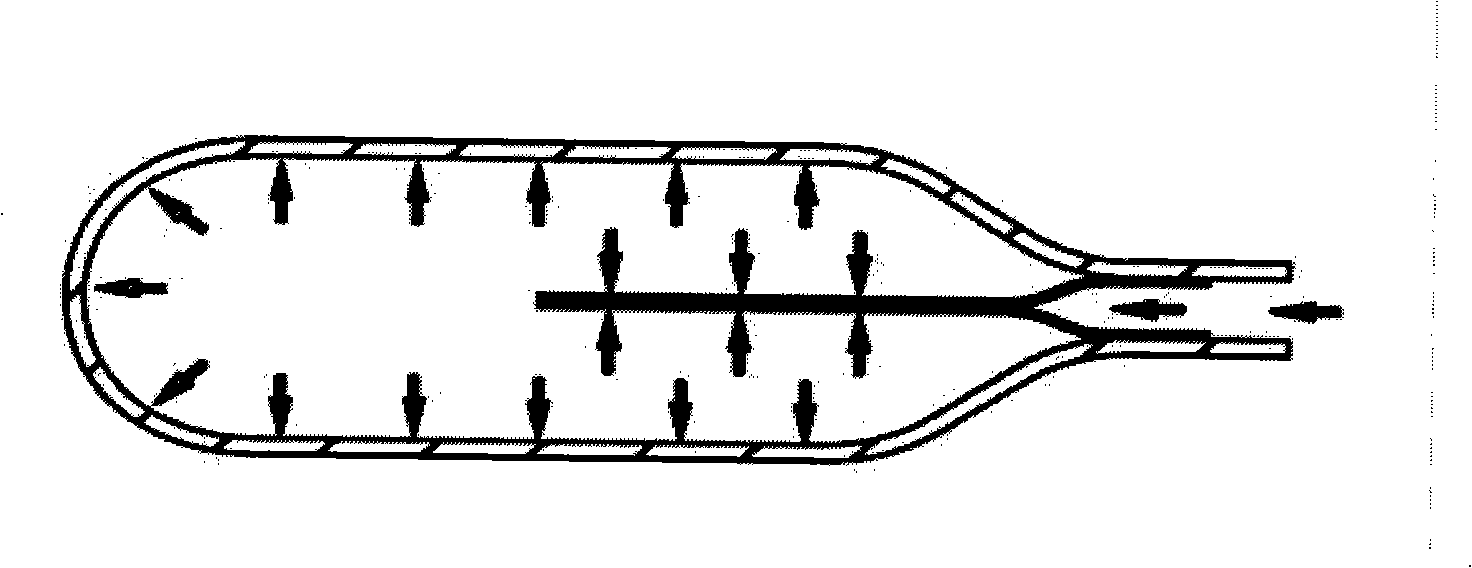

Hydroponic units and systems

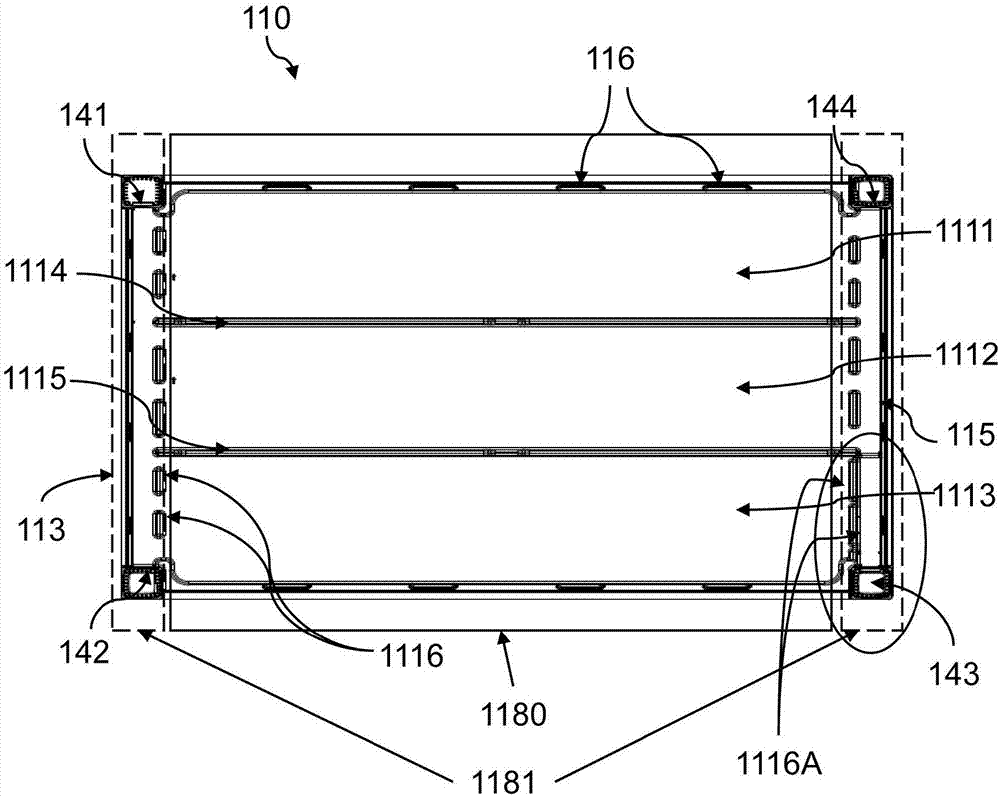

ActiveCN107072161AAcid resistantAlkali resistantAgriculture gas emission reductionCultivating equipmentsModularityNutrient solution

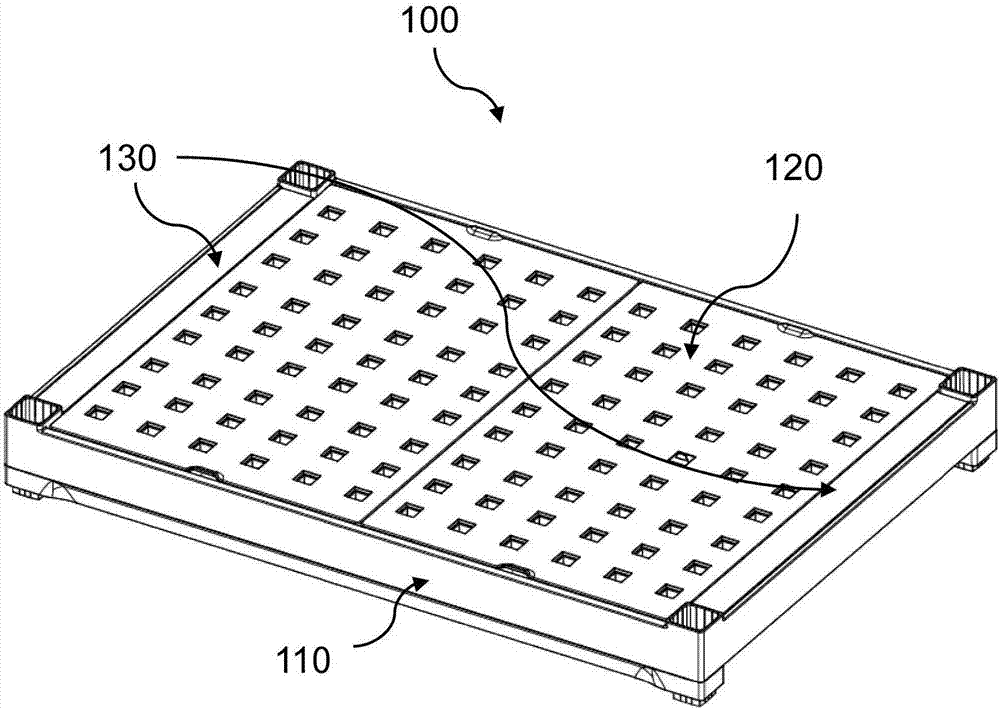

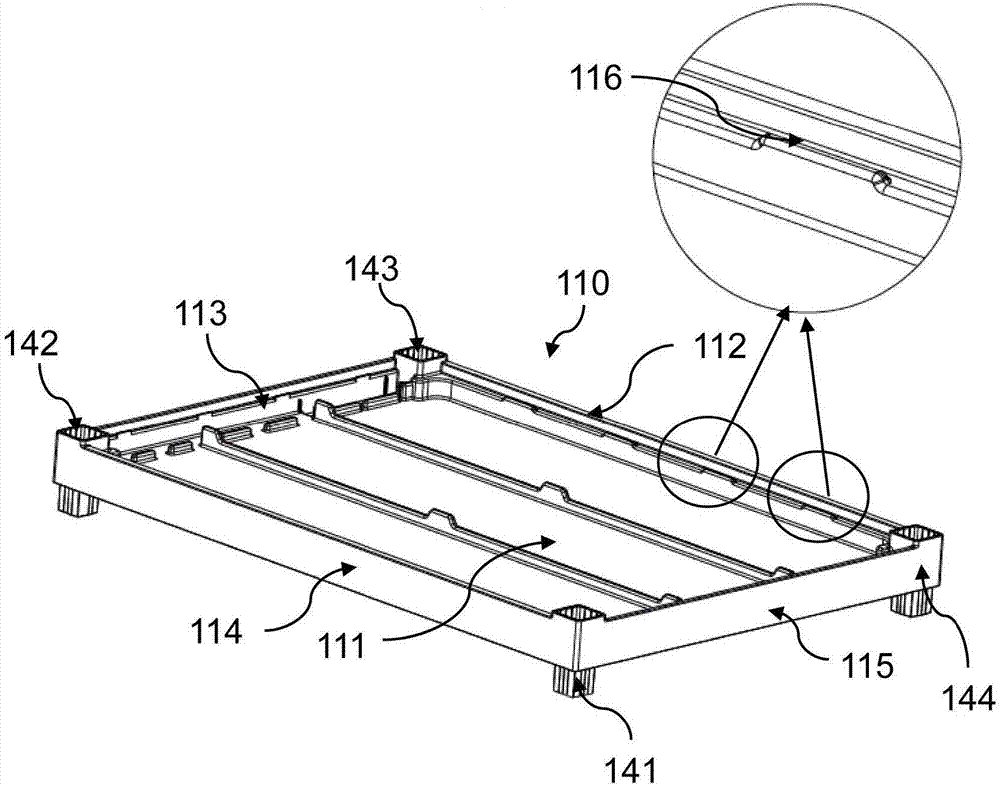

A configurable hydroponic unit and system are disclosed. The configurable hydroponic unit (100) comprises a water tank (110). The water tank includes at least one partition bar (1114, 1115) and at least one movable dam element (150). The at least one separation bar is provided at the bottom edge of the tank for separating the water tank into a plurality of groove areas. The at least one movable dam element is movably mounted within the tank to prevent nutrient flow. Said at least one divider bar and said at least one movable dam element forming a configurable channel in which the nutrient solution flows within the tank. Due to its modular characteristics, the configurable water culture unit can be stacked in turn to form a multi-layer hydroponic system which enables the vertical circulation of the nutrient solution.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

Concrete mold release agent

The invention discloses a concrete mold release agent, and belongs to the field of building materials. The concrete mold releasing agent disclosed by the invention comprises the following components in part by weight: 15 to 40 parts of polyvinyl alcohol, 10 to 15 parts of epoxy resin, 15 to 25 parts of microcrystalline wax, 1 to 10 parts of nonylphenol polyoxyethylene ether, 1 to 5 parts of rosin, 1 to 2 parts of tri-butyl-phosphate, 1 to 8 parts of sodium alginate, 1 to 6 parts of an anti-rust agent, and 200 to 800 parts of water. The concrete mold release agent has a good mold release effect; the concrete is smooth after a mold is released; the service life of a steel mold can be prolonged; the concrete mold release agent has an anti-rust performance.

Owner:栾晓健

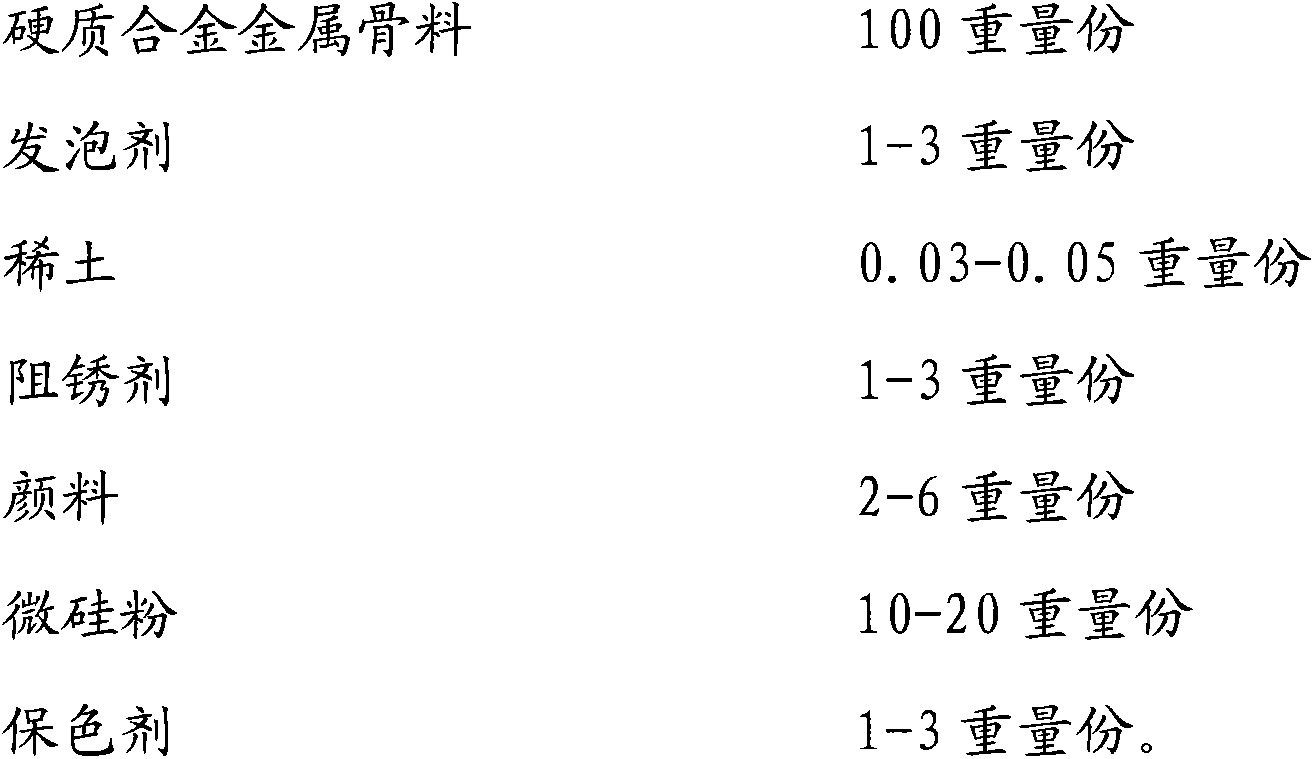

Metal rustproof non-ignition anti-static wear-resistant and anti-impact floor material and preparation method thereof

The invention relates to a metal rustproof non-ignition anti-static wear-resistant and anti-impact floor material and a preparation method thereof. The material is processed by mixing the following components: a hard alloy metal aggregate, rare earth, a foaming agent, a rust inhibitor, a pigment, micro-silicon powder and a color preserving agent. The floor material disclosed by the invention is uniformly mixed with ordinary portland cement, the mixture is sprinkled on the surface of concrete which is just built, the surface is leveled and maintained, and expansion joints are cut so as to obtain a metal rustproof non-ignition anti-static wear-resistant and anti-impact floor. The floor material is mainly applied to storage places for flammable and explosive chemicals, electronic computer rooms, army ammunition depots, regions using precision machinery in operation rooms, storage regions for petroleum and fuel oil, particularly wear-resistant and impact-resistant floors and places with particular requirements for anti-static and non-ignition effects; and simultaneously, the floor has the advantages of large surface density, good anti-seepage performance and rust protection, and can meet the floors with smooth to skid-proof requirements, perform synchronous construction with the concrete floors and shorten the construction period so as to reduce the construction cost.

Owner:曹洪生 +1

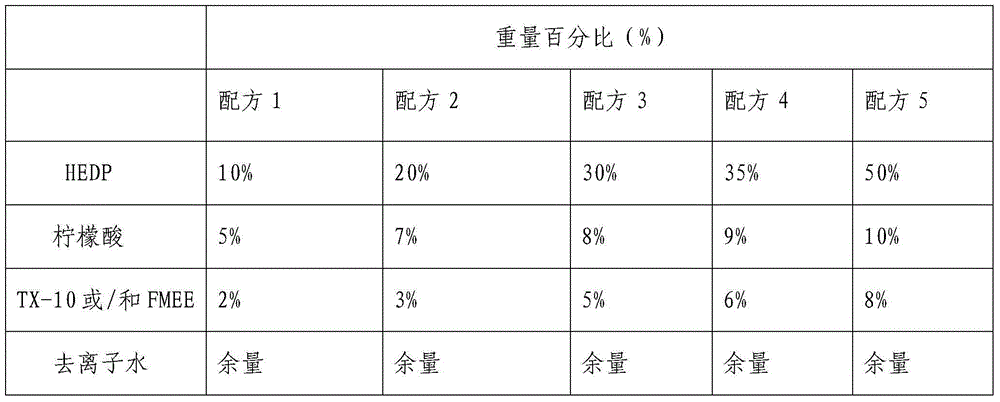

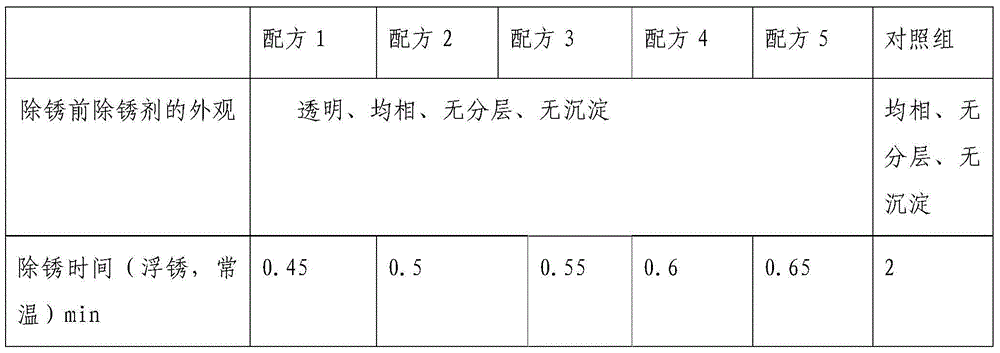

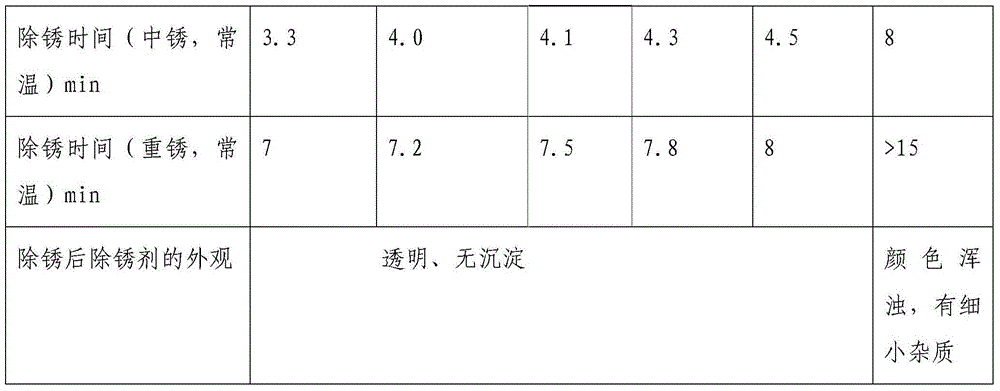

A steel environmental rust remover

The invention discloses a steel environmental rust remover. The rust remover comprises the following components by weight percentage: 10-50 % of organic phosphonic acid, 5-10 % of citric acid, and 3-5% of surfactant, with the balance being water. The surfactant is one of TX-10 and FMEE or a mixture of both. By adopting the technical solution of the invention, good rust removing effect can be achieved, the rust removing process is gentle and does not damage the surface of a steel article, and the use and manufacturing cost is low.

Owner:赵理奎

Alloy putty

InactiveCN1664038ALow shrinkageFast dryingFilling pastesPolyester coatingsFilling materialsAcrylonitrile

The invention relates to an alloy putty which comprises main body ash and curing agent by the weight ratio of 100:2, wherein the main body ash comprises (by weight ratio) unsaturated polyester resin 100, accelerating agent 2-4, epoxy resin 4-6, carboxyl-terminated butadiene-acrylonitrile 0.5-2, pigment 5-8, filling material 80-120, while the curing agent comprises (by weight ratio) initiating agent 100, pigment 2-4, filling material 4-6.

Owner:HARBIN INST OF TECH

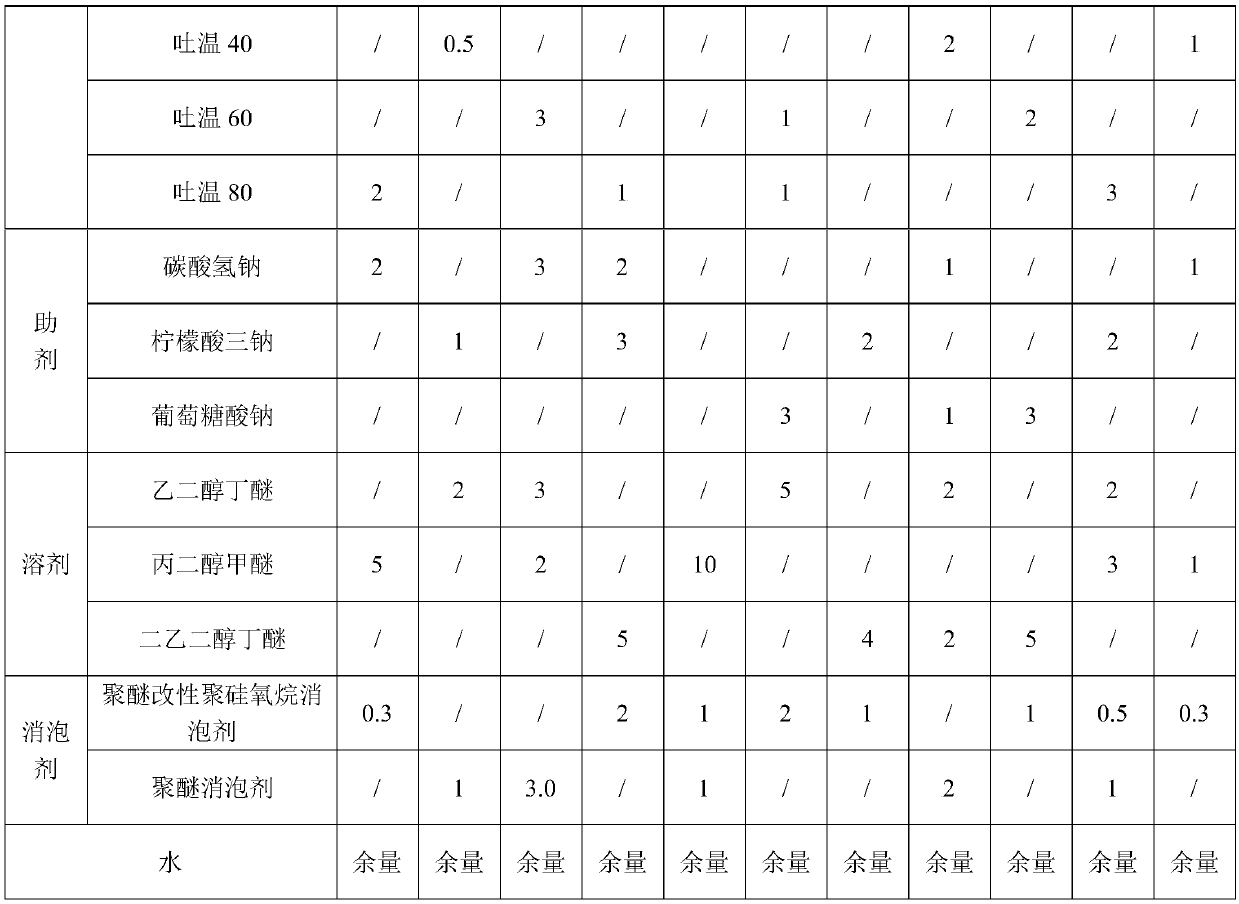

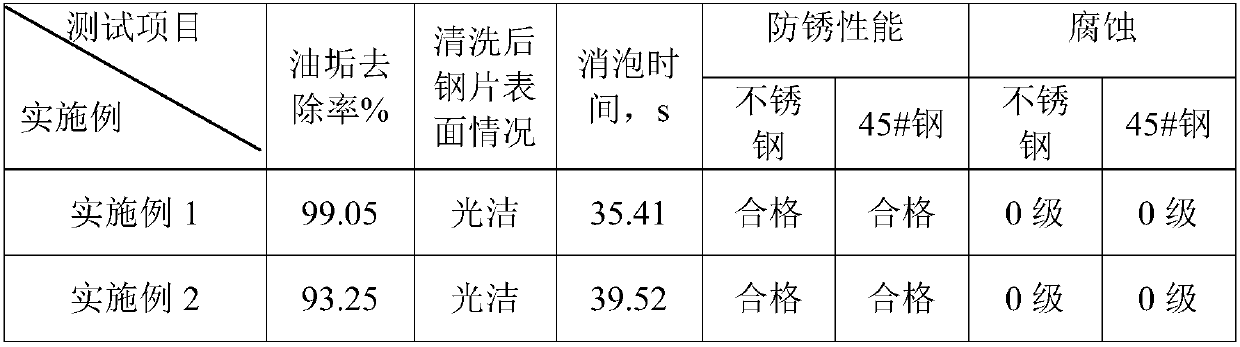

Environment-friendly neutral cleaning agent and preparation method and application thereof

The invention discloses an environment-friendly neutral cleaning agent. The environment-friendly neutral cleaning agent comprises, by mass percent, 2%-20% of a surface active agent, 1%-5% of an emulgator, 1%-5% of an auxiliary, 1%-10% of an organic solvent, 0.3%-4.0% of a defoaming agent and the balance deionized water. The surface active agent comprises at least one kind in fatty acid methyl ester ethoxylate and modified grease ethoxylate, at least one kind in alcohol alkoxylate and normal fatty alcohol polyoxyethylene ether, at least one kind in coconutt diethanol amide and laurel based amphiprotic sodium acetate and at least one kind in fatty alcohol glucoside and alkyl glycoside. Raw materials related to in the formula of the cleaning agent contain no phosphorus and are green and environment-friendly, the components are coordinated and cooperate with one another, the excellent properties of wetting, permeation, emulsification and dispersion are achieved, and grease and other dirt on the surfaces of stainless steel workpieces can be removed fast.

Owner:SHANGHAI FINE CHEM CO LTD

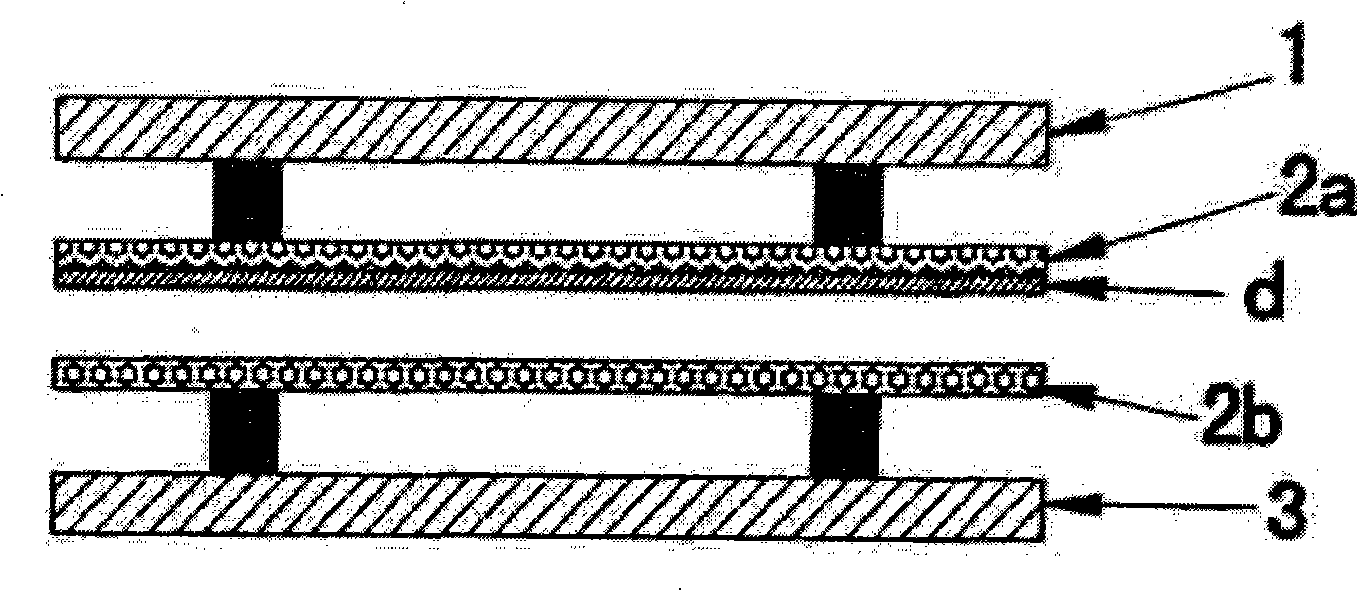

Gas phase anticorrosive thin film of thermal contraction

InactiveCN1796449AReduce weightAnti-rustSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

A gaseous rust resistant thermo shrinkable membrane consists of coupled inner and outer layer, within which the inner layer by weight comprises 60~80% low-density polyethylene, 5~20% linear low-density polyethylene, 5~15% metallocene polyethylene, 5~10% gaseous rust resistant agents and 0.2~1% organic pigments while the outer layer by weight comprises 75~95% low-density polyethylene and 5~25% high-density polyethylene. The gaseous rust resistant membrane in this invention is thermo shrinkable. When made into packages for packaging metallic products and components, the volume in the packages is greatly reduced by heating, which saves the spaces taken by packages, and meanwhile the rust resistant agents quickly spread to the whole space due to the heat and thus perform good rust resistant effects. The packages from the membrane in this invention are applicable in packaging precision instruments, metal tools, automobile components and electric and electronic devices.

Owner:李延明

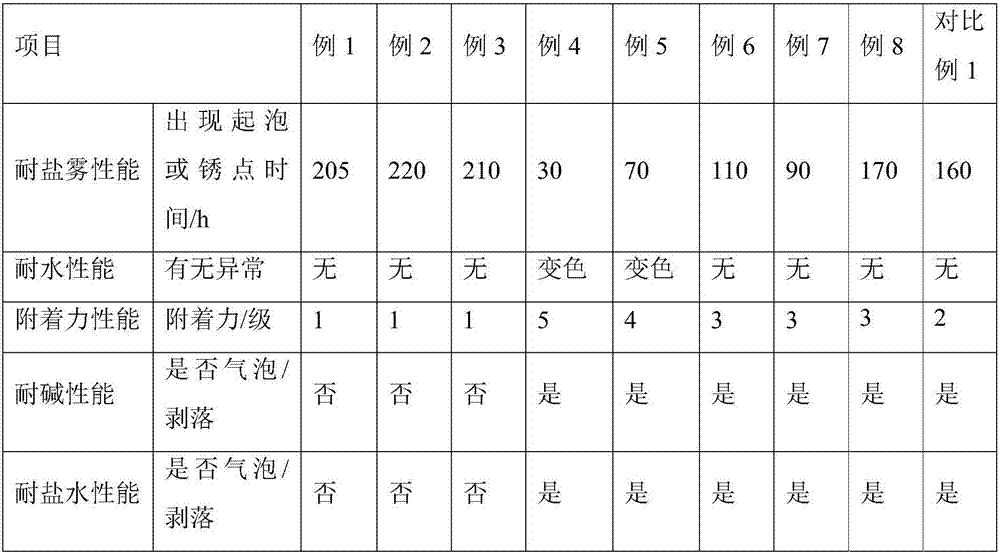

Waterborne rust conversion primer coating with rust and preparation method thereof

ActiveCN107987591AEnvironmentally friendlyImprove adhesionAnti-corrosive paintsEpoxy resin coatingsFungicideEmulsion

The invention provides waterborne rust conversion primer coating with rust and a preparation method thereof. The waterborne rust conversion primer coating with the rust is prepared by uniformly mixinga component A and a component B, wherein the component A is prepared from the following raw material components in parts by weight: 2 to 10 parts of a rust conversion agent, 2 to 5 parts of a rust conversion auxiliary agent, 5 to 8 parts of a stabilizer, 0.5 to 3 parts of a corrosion inhibitor, 2 to 4 parts of a film forming auxiliary agent, 0.1 to 0.3 part of a thickener, 0.3 to 0.6 part of a wetting dispersant, 0.2 to 0.5 part of a de-foaming agent, 0.05 to 0.2 part of fungicide, 30 to 50 parts of waterborne epoxy antirust emulsion and 15 to 25 parts of de-ionized water; the component B isan epoxy curing agent. Therefore, the primer coating has the characteristics of environment friendliness, good adhesive power, acid resistance, alkali resistance, salt spray corrosion resistance and long service life, can be coated with the rust and is convenient to construct.

Owner:宁波康曼丝涂料有限公司

Phosphorization liquid of manganese series containing calcium

InactiveCN1687484ASignificant advantagesSignificant beneficial effectMetallic material coating processesCalcium hydroxideCopper plating

The present invention relates to Mn series Ca containing phosphide solution in the domain of final chemical engineering. The main characteristic is its component and the ratio of its weight is: 20 - 31% H3PO4, 9 - 16% MnCO3, 0.5 - 4% HNO3, 0.3 - 3% CaOH and water it until 100%. The phosphating solution can make black, compact and twinkling phosphating film on the surface of metal, and there are also in the phosphating film. It also improved the capability of phosphating film. The experiment proves that: The phosphating film can enhance the wearable and anti-corrosive capability. The phosphating solution is steady and its component is suitable. It's easy to prepare the solution and cost little, and it's also passes over the process of copper-plates. It is the preparation of updates in phosphating solution belongs to manganese catalyst.

Owner:李长吉

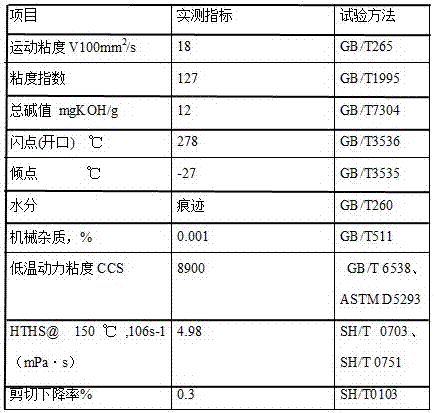

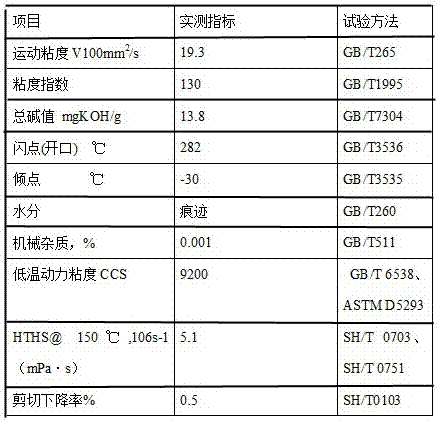

High-pressure-charging long-service-life diesel engine oil and manufacturing method thereof

The invention provides a high-pressure-charging long-service-life diesel engine oil which comprises the following components in percentage by weight: 80-90% of base oil and 10-20% of additive. The base oil comprises 72-80% of paraffin base Type II or Type III, 3-6% of high-viscosity poly-alpha-olefin of which the viscosity is 100-300 mm<2> / s at 100 DEG C and 1-3% of ester oil. The additive comprises 1-3% of hyperalkaline calcium sulfonate, 7-10% of polyisobutylene polysuccimide, 1-3% of sulfurized calcium alkyl phenate, 1-3% of sulfur / phosphorus bis octyl alkaline octyl salt, 0.001-0.005% of oil-soluble graphene, 0.3-1% of amine high-temperature antioxidant, 0.1-0.3% of pour-point depressant and 0.001-0.002% of composite defoaming agent. The diesel engine oil has the advantages of excellent high temperature detergency, excellent acid neutralizing capacity and rust resistance, is capable of effectively reducing high-temperature deposits on engine components and prolonging the oil change period, can inhibit the carbon deposits and paint film on the engine piston from generation, can form a complex micelle with a metallic detergent, has the characteristics of excellent consonance effect, excellent heat stability and outstanding abrasion resistance.

Owner:YANTAI HENGBANG CHEM

Heat-insulating powder for coating and preparation method thereof

InactiveCN101914314AGood heat insulationAnti-rustInorganic pigment treatmentPolyurea/polyurethane coatingsUltravioletVanadium oxide

The invention relates to heat-insulating powder for a heat-insulating coating in aspects of buildings, oil tanks, oil tubes and the like and a preparation method thereof. The heat-insulating powder is prepared by coating nano-titanium oxide, vanadium oxide, ferric oxide, rectorite powder and the like serving as a heat-insulating material with new nano-silicon oxide generated by reaction of sodiumsilicate and hydrochloric acid or sulfuric acid. The heat-insulating powder has the heat-insulating function of reflecting infrared rays and ultraviolet rays in sunlight, and the heat-insulating powder provided by the invention is a brand new heat-insulating material on the heat-insulating principle. In the heat-insulating powder, the nano-heat-insulating material is coated by the new nano-silicon oxide to enhance the heat-insulating effect of nanometer materials, avoid the agglomeration phenomenon and reduce the cost. In addition, the prepared heat-insulating material also has the multiple functions of rust prevention, corrosion prevention, sound insulation and the like.

Owner:SHANGHAI YUTANG INDAL

Fibrous unsaturated polyester putty

The fibrous unsaturated polyester putty is one kind of polymer putty. The fibrous unsaturated polyester putty consists of two parts, main fibrous unsaturated polyester putty and curing agent, in the weight ratio of 50. The main fibrous unsaturated polyester putty consists of unsaturated polyester resin 100 weight portions, promoter 2-4 weight portions, styrene 3-5 weight portions, fiber 0.3-0.5 weight portions, stuffing 100-120 weight portions, and pigment 3-5 weight portions. The curing agent consists of initiator 100 weight portions, pigment 3-5 weight portions, and stuffing 1-3 weight portions. The present invention has high strength, high attachment to metal material, convenient use, less shrinkage, fast drying speed, good air drying performance, high compatibility with paint, and fine and smooth film and makes it possible to fill hole as large as 10 mm in once operation.

Owner:HARBIN INST OF TECH

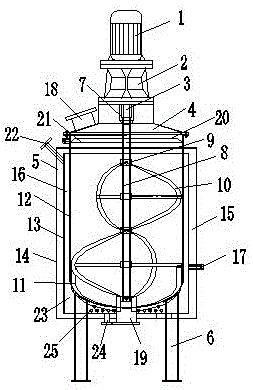

Biological fermentation tank

ActiveCN105886388AImprove wear resistanceImprove rust resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation

The invention relates to a biological fermentation tank which comprises a motor, a speed reducer, a stirring device, an upper cover, a fermentation bucket and a support. The upper cover is arranged at the upper end of the fermentation bucket and provided with a stirring opening, and the stirring device is arranged in the stirring opening and comprises a stirring shaft and stirring blades arranged on the stirring shaft. The stirring blades comprise the first stirring blade and the second stirring blade, the second stirring blade is arranged at the lower end of the stirring shaft, the first stirring blade is a flood dragon rotary blade, and the second stirring blade is a frame type stirring blade. Coatings are arranged on the outer sides of the stirring blades, the fermentation bucket is provided with an inner barrel body, an outer jacket and a shell in sequence from inside to outside, a heat preservation device is arranged between the outer jacket and the shell, a heating device is arranged between the inner barrel body and the outer jacket, and a sensor is arranged in the heat preservation device. The stirring blades are formed by combining the flood dragon rotary blade and the frame type stirring blade, therefore, reactants can be comprehensively stirred and can be effectively prevented from being pasted to the inner wall of the fermentation bucket, and the reaction rate is increased.

Owner:YANCHENG JIANFENG MACHINERY

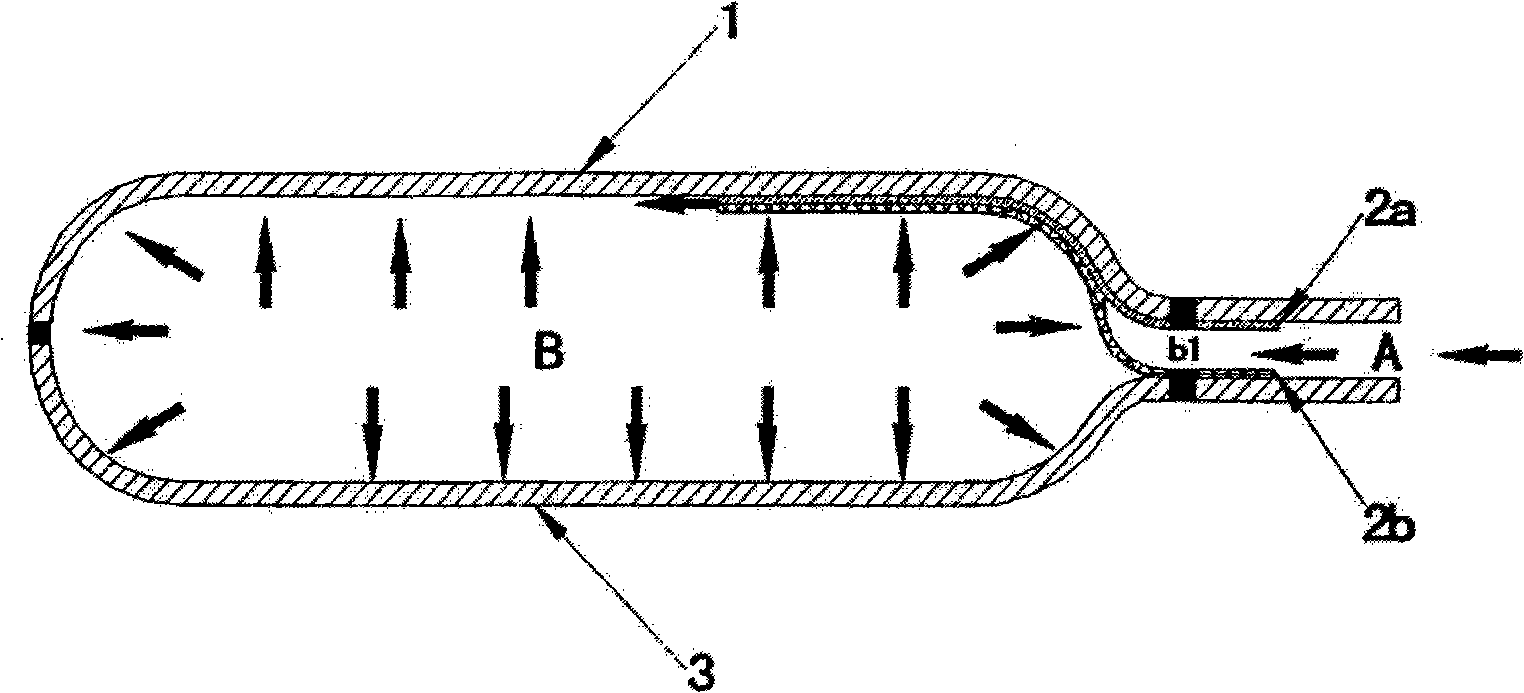

Function type cling-wrap one-way air blockage volumetric packaging material and preparation method thereof

InactiveCN101337609AEasy to useWear-resistantEnvelopes/bags making machineryLaminationImpressionabilityEngineering

The invention relates to a functional type self-adhesive film one-way air blocking three-dimensional packing material and a preparation method thereof. The three-dimensional packing material is formed by combing a plurality of layers of functional resin thin films, the functional resin thin films form a space used for storing the gaseous medium including air through hot sealing and folding, and the air and the thin films are combined into the functional type self-adhesive film one-way air blocking three-dimensional packing material. Compared with the prior art, the air three-dimensional packing material of the invention has excellent comprehensive protective properties of extrusion resistance, vibration resistance, falling prevention and buffering, and meanwhile, can be embodied with the functions of light prevention, moisture resistance, electrostatic prevention, electric conduction, wear-resistance, corrosion resistance, rust protection and impressionability, etc.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

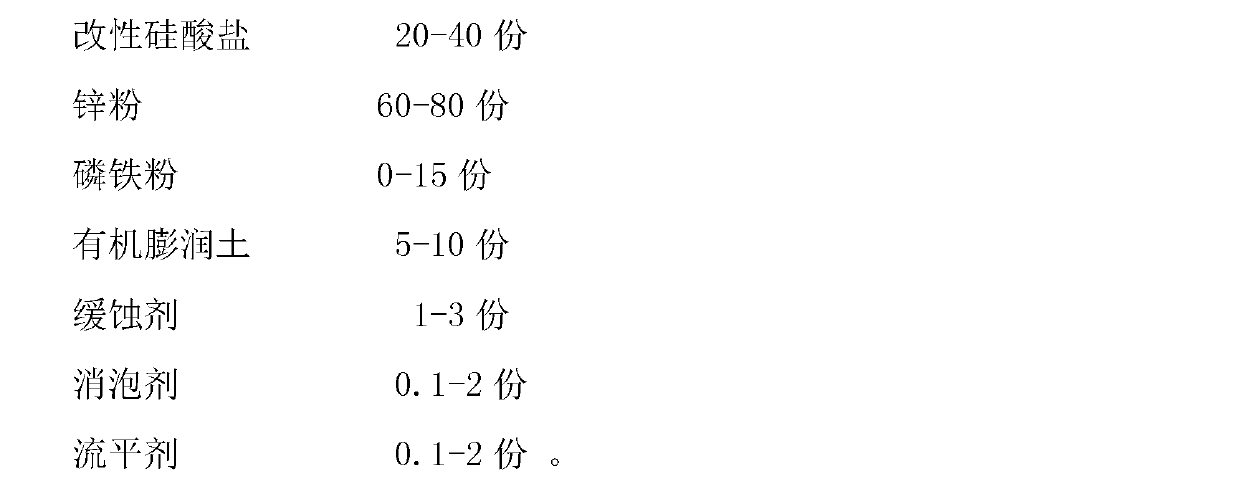

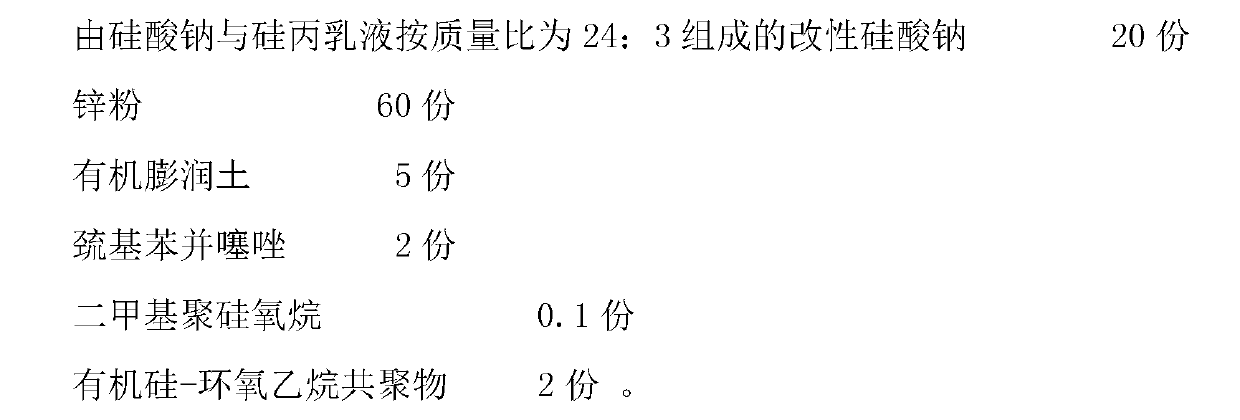

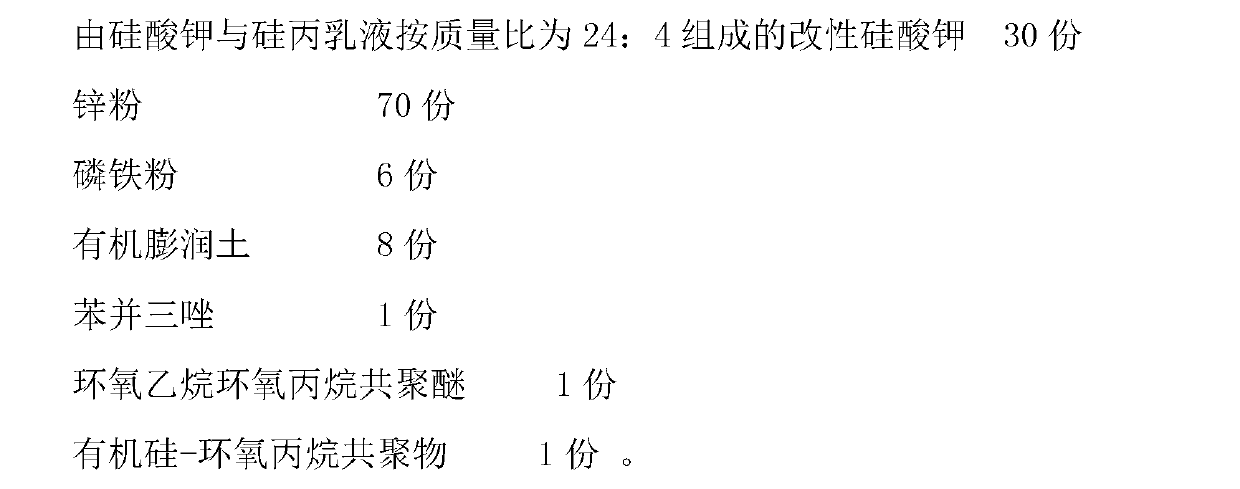

Inorganic zinc silicate workshop primer

InactiveCN103342908AImprove conductivityImprove thermal conductivityCoatingsIron powderSodium Bentonite

The invention provides an inorganic zinc silicate workshop primer. The Inorganic zinc silicate workshop primer is composed of modified silicate, zinc powder, ferro-phosphorus powder, organic bentonite, corrosion inhibitor, defoaming agents and flatting agents. The ferro-phosphorus powder replaces partial zinc powder in the workshop primer so as to reduce the usage amount of zinc powder, so that the production cost is reduced; meanwhile, a steel member painted with the primer reduces the production of zinc mist while welding or cutting, so that the working environment is improved, the body health of people is ensured, the cracking tendency of coatings can be greatly reduced, and the external smoothness and weather fastness of films are improved.

Owner:TIANCHANG JULONG TRAVEL PAINT

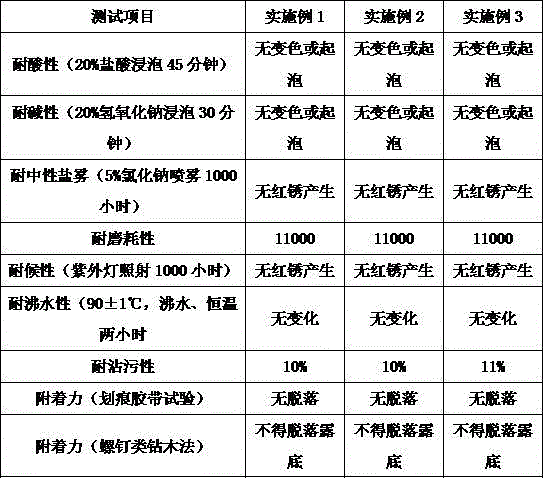

UV-curable resin composition for transparent colored coated steel sheet and steel sheet utilizing the same

ActiveCN102264850ACorrosion resistanceWith impact resistancePhotomechanical apparatusPolyurea/polyurethane coatingsSheet steelOligomer

The present invention relates to an ultraviolet curable resin composition comprising: 25 to 45 wt% modified epoxy acrylate oligomer; and 10 to 25 wt% urethane acrylate oligomer. The present invention can provide a metal sheet which is transparent, and which has corrosion resistance, impact resistance, scratch resistance, adhesion, anti-corrosion, and bendability (workability) by forming a coating film on the surface of metal materials such as steel materials, specifically steel sheets, using the ultraviolet curable resin composition of the present invention.

Owner:POSCO CO LTD

Lubricating grease for protecting aluminum-conductor steel-reinforced cables and preparation method of lubricating grease

InactiveCN104804809AMeet the needs of useGuaranteed Protection RequirementsLubricant compositionFatty amineWater resistant

The invention discloses lubricating grease for protecting aluminum-conductor steel-reinforced cables and a preparation method of the lubricating grease, and relates to the technical field of chemical engineering. The lubricating grease comprises the following components in percentage by weight: 50-90% of base oil, 1-5% of isocyanate, 1-5% of fatty amine, 1-6% of aromatic amine, 1-6% of a tackifier, 1-5% of a rust inhibitor, 0.25-0.8% of an anti-oxidant and 0.04-0.08% of a metal corrosion inhibitor, wherein the base oil is mineral oil or synthetic base oil of which the temperature is 40 DEG C and the kinematic viscosity is 120-500 mm<2> / s. The lubricating grease has the advantages that the normal operation of the aluminum-conductor steel-reinforced cables in a seriously corroded offshore industry area can be guaranteed, the service lives of the aluminum-conductor steel-reinforced cables in the seriously corroded offshore industry area can be effectively prolonged, the water-resistant, rustproof and anti-corrosive functions can be realized, and the protecting requirements for the aluminum-conductor steel-reinforced cables can be ensured.

Owner:TIANJIN JINHAILI GREASE CO LTD

Aqueous antirust paint for ship cabin

InactiveCN103725068AStrong adhesionEasy to apply multiple timesAnti-corrosive paintsSolventChemistry

The invention discloses aqueous antirust paint for a ship cabin. 30-48 parts of solid acrylic acid is used as a base material and added with the following raw materials, including 15-25 parts of modified resin, 0-10 parts of dye, 10-30 parts of filler, 1-5 parts of a flashrust inhibitor, 5-15 parts of an additive and 10-20 parts of deionized water, to prepare the aqueous antirust paint,. The aqueous antirust paint, namely the acrylic acid aqueous paint for the ship cabin, has the advantages of weather resistance, light protection, color protection, rust resistance and corrosion resistance, meanwhile has excellent adhesion force, corrosion resistance and oil contamination resistance, and not only satisfies the requirements of the ship cabin on semi-gloss and sub-gloss antirust paint, but also is easy to coat for many times, difficult in moisture volatilization, stronger in adhesion force and free in flash rust.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Coating solution used on tire bead steel wire surface and preparation method of coating solution

ActiveCN105131777AImprove adhesionPlay the role of anti-rustAnti-corrosive paintsPolysulfide rubberSulfur

The invention provides a coating solution used on a tire bead steel wire surface and a preparation method of the coating solution. The coating solution is prepared from, by weight, 9-16 parts of methyl methacrylate grafted natural rubber, 2-5 parts of liquid polysulfide rubber, 3-7 parts of coumarone resin, 2-8 parts of terpene resin, 1-3 parts of auxiliary crosslinking agents PDM, 530-600 parts of methylbenzene and 360-440 parts of acetone. By means of a coating formed by applying the coating solution to a tire bead steel wire, the performance of the tire bead steel wire for bonding with tire bead glue can be effectively improved, and a certain antirust effect is achieved.

Owner:JIANGSU XINGDA STEEL TYPE CORD

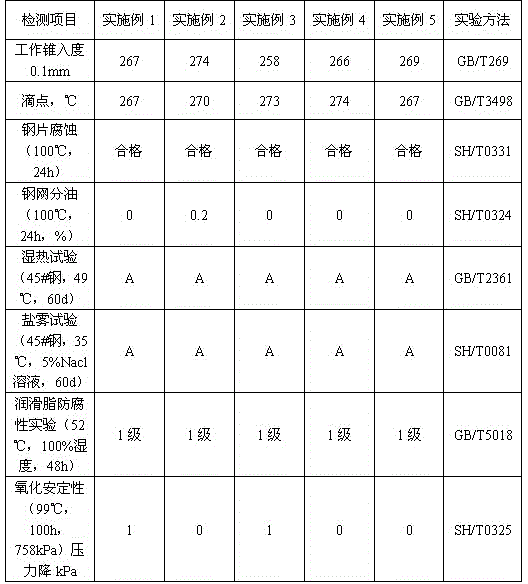

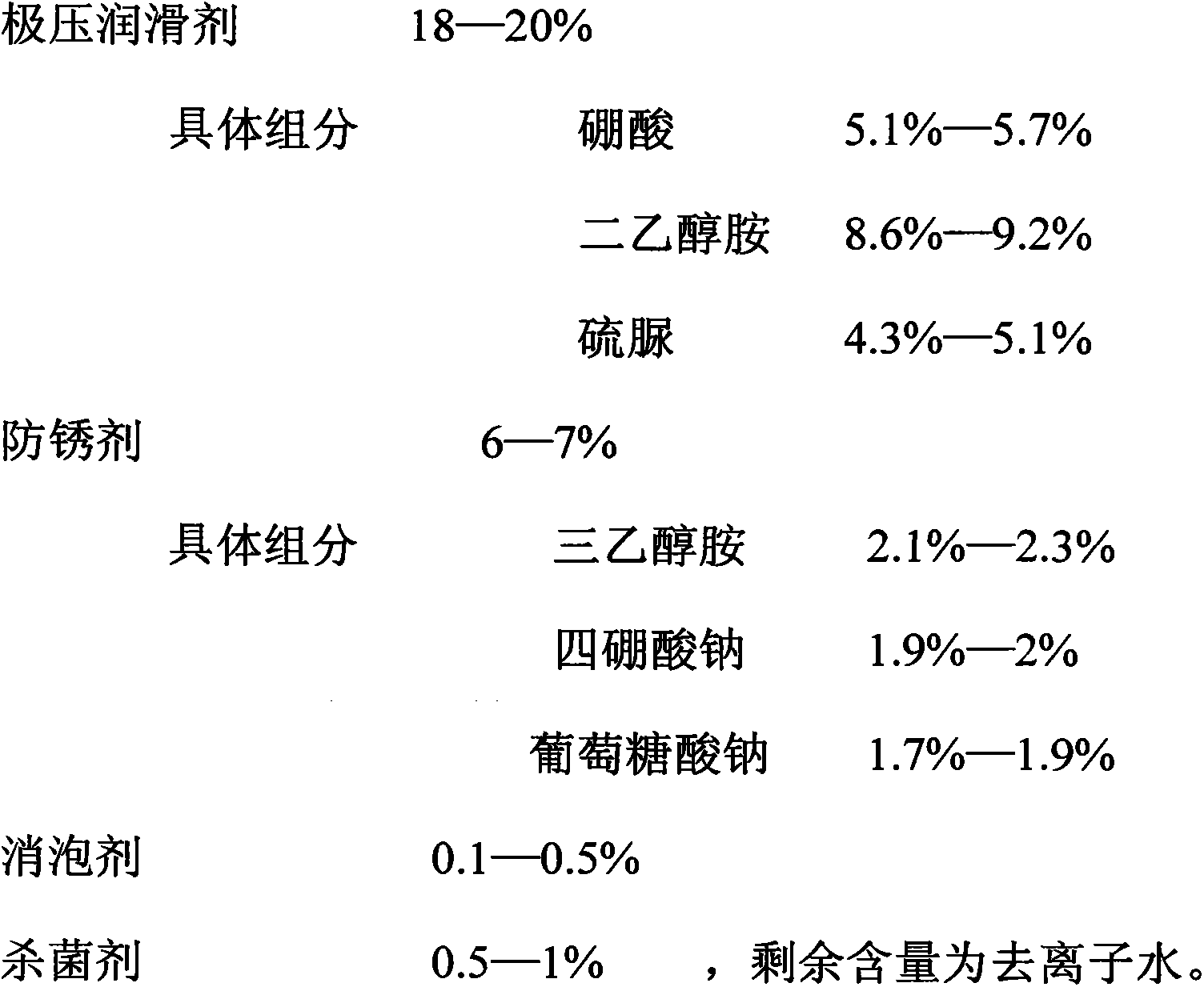

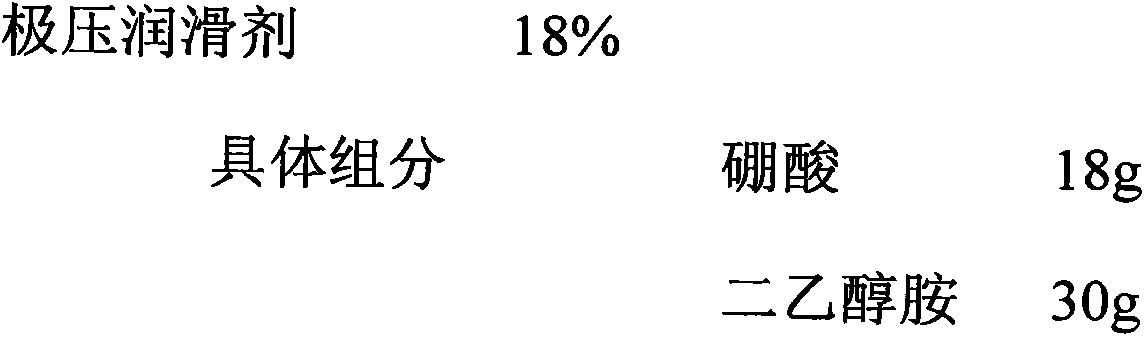

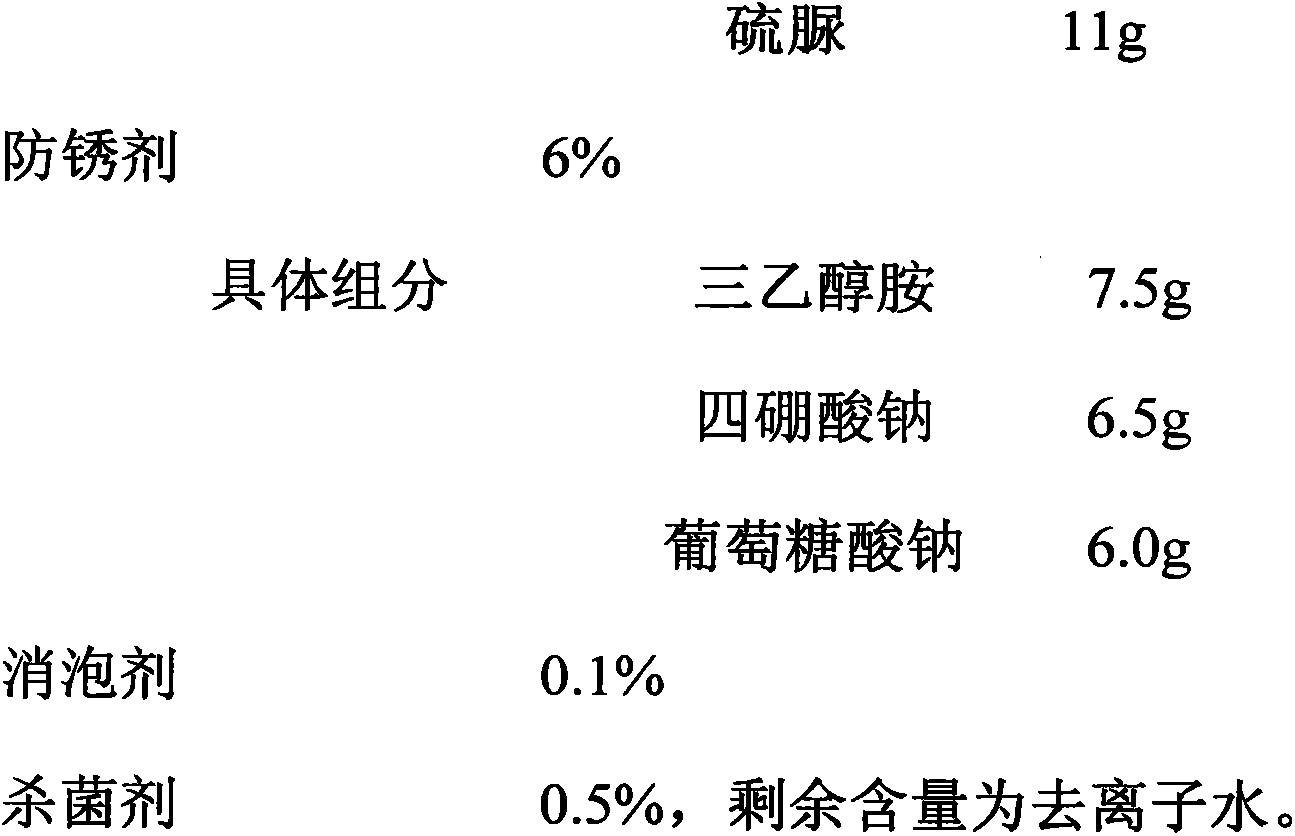

Full-synthetic metal cutting liquid

InactiveCN103820197ASimple preparation processImprove performanceLubricant compositionThioureaPerformance index

A full-synthetic metal cutting liquid comprises the following components in percentage by weight: 18-20% of an extreme-pressure lubricant, 6-7% of an antirusting agent, 0.1-0.5% of a defoaming agent, 0.5-1% of a bactericide and the balance of deionized water, wherein the extreme-pressure lubricant comprises 5.1-5.7% of boric acid, 8.6-9.2% of diethanol amine and 4.3-5.1% of thiourea, and the antirusting agent comprises 2.1-2.3% of triethanolamine, 1.9-2% of sodium tetraborate and 1.7-1.9% of sodium gluconate. A method for preparing the metal cutting liquid comprises the following steps: (1) synthetizing organic boric acid ester; (2) synthetizing the extreme-pressure lubricant; (3) preparing the antirusting agent; (4) preparing the full-synthetic metal cutting liquid. Proven by the results, the prepared metal cutting liquid is transparent and stable, is high in extrusion resistance, wear resistance and rust resistance, can be used for processing various materials such as aluminium alloy, cast iron, carbon steel and copper, is equal to foreign similar high-grade products in performance indexes, and achieves the effects of environmental protection, energy conservation and consumption reduction.

Owner:SOUTHWEST UNIVERSITY

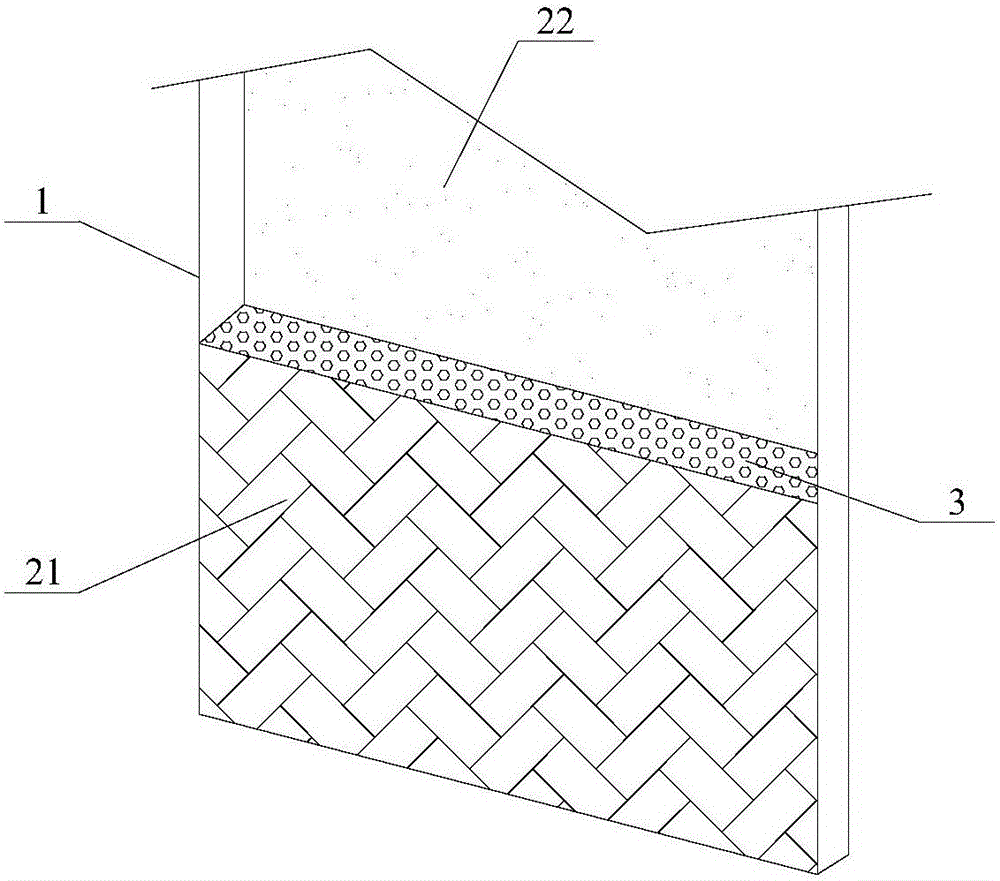

Light non-dismantling self-thermal-insulation cast-in-place wall and preparation method of filling material thereof

InactiveCN106284763AEliminate seam thermal bridgesReduce steel consumptionWallsHeat proofingMicron scaleKeel

The invention discloses a light non-dismantling self-thermal-insulation cast-in-place wall and a preparation method of filling material thereof. The preparation of the filling materials comprises the steps that micro-scale or micron-scale microcellular foam is prepared; the microcellular foam and inorganic compound gelatinization matrixes containing silicate are blended, microcellular slurry is formed through puffing foaming, and a light porous fire-resistant inorganic framework is prepared; the light porous fire-resistant inorganic framework is filled with organic lightweight aggregate, and mixed slurry is made; and the mixed slurry is solidified and formed. The light non-dismantling self-insulation cast-in-place wall comprises a keel frame, a non-dismantling wall plate fixed to the keel frame and the filling material. According to the light non-dismantling self-thermal-insulation cast-in-place wall and the preparation method of the filling materials thereof, no additional mould is supported, a pipeline can be embedded, construction is simplified greatly, cost is reduced greatly; in the casting process, plate expanding, template bursting and hollowing do not occur; the fireproof and self-insulation purposes are achieved, and thus no external thermal insulation needs to be conducted; seamless connection is achieved, and thus amount of steel used is reduced; weather resistance, the freezing and thawing resistance cycle and no crack are achieved, so that the service life of the wall is the same with that of a building; and no corrosion occurs, and thus a rust-proof role is played on a steel structure, and the service life of the steel structure is prolonged.

Owner:南京依科国特新材料科技有限公司

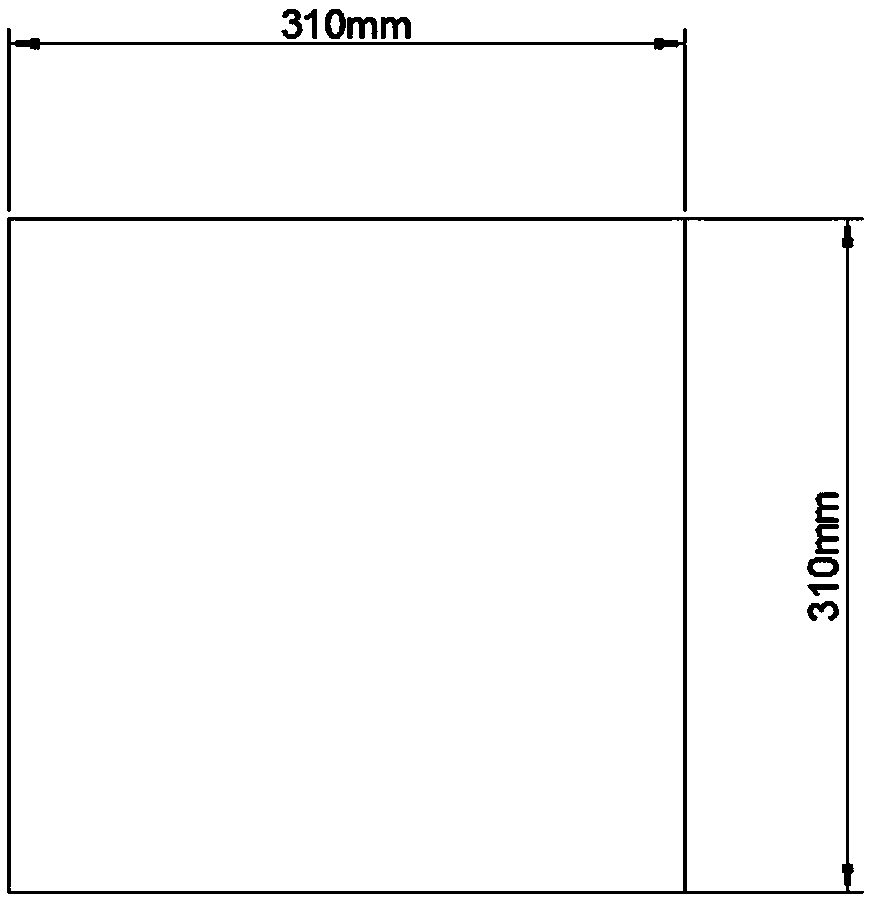

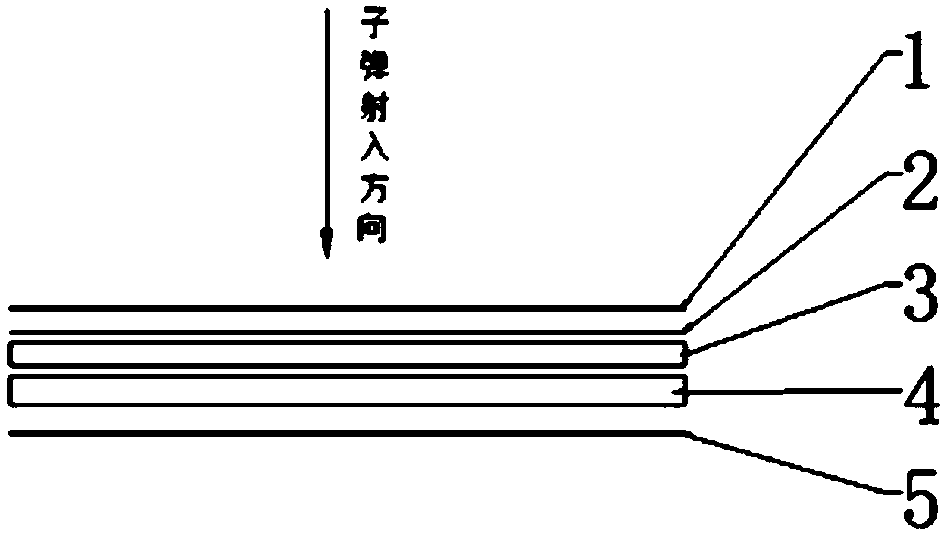

Ceramic-based composite material capable of defensing 12.7mm armor piercing incendiary

InactiveCN108859357AWear-resistantWaterproofProtective equipmentSynthetic resin layered productsInter layerAramid

The invention provides a ceramic-based composite material capable of defensing 12.7mm armor piercing incendiary. The material comprises a polyurea layer, an aramid fiber layer, a ceramic layer and a PE layer, wherein the aramid fiber layer, the ceramic layer and the PE layer are sequentially arranged from top to bottom and are bonded together through a bonding agent to form a middle layer; the polyurea layer is sprayed and coated at the upper surface and the lower surface of the middle layer; the thickness of the polyurea layer is 0.5mm; the thickness of the aramid fiber layer is 1mm; the thickness of the ceramic layer is 15mm; the thickness of the PE layer is 18mm.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

Rust-proof cutting fluid suitable for processing air valves

InactiveCN101597540AImprove rust resistanceExcellent cutting lubrication performanceAdditivesBase-materialsHydrogen phosphatePolyethylene glycol

The invention relates to rust-proof cutting fluid suitable for processing air valves, which is a water solution prepared by using monoethanolamine benzoate as a main rust-proof agent and sodium alkylsulfonylglycinate as a main cutting lubricant, and adding other ingredients. The weight ratios of the materials of the cutting solution are: 1-2.2% of monoethanolamine benzoate; 0.2-0.8% of sodium hydrogen phosphate; 0.1-0.9% of glycerin; 0.5-2.0% of sodium alkylsulfonylglycinate; 0.1-0.5% of polyethylene glycol with the molecular weight of 400-600; the balance of deionized water. The rust-proof cutting fluid suitable for processing the air valves can meet the cutting processing requirement and the rust-proof requirement of the air valve, and is safe and non-toxic.

Owner:SOUTH CHINA UNIV OF TECH

Carbon remover for heat-conducting oil and removing method

InactiveCN107033986APlay the role of flocculationImprove settlement performanceFuel additivesHeat conductingSurface-active agents

The invention relates to the technical field of carbon removal, particularly provides a carbon remover for heat-conducting oil and a removing method, and aims to solve the problem that carbon deposits of a heat-conducting oil system are difficultly cleaned. The carbon remover comprises, by weight, 20-30 parts of basic water, 27-37 parts of anionic surface active agents, 22-32 parts of non-ionic surface active agents and 10-20 parts of complex agents. The removing method of the heat-conducting oil includes the steps: treating the heat-conducting oil by the aid of the carbon remover; adding the complex agents and process water into the heat-conducting oil to uniformly mix and stir; circularly heating to remove carbon deposits in the heat-conducting oil. Removing efficiency of the carbon deposits reaches 98% or more, influence of the carbon deposits to heat-conducting oil performances is reduced, the service life of the heat-conducting oil is prolonged, operating cost is reduced, and heat utilization rate is high.

Owner:SHANDONG ENKLI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com