Metal rustproof non-ignition anti-static wear-resistant and anti-impact floor material and preparation method thereof

A ground material and metal anti-rust technology, applied in the field of ground materials, can solve the problems of not having anti-static, poor impact resistance, poor impermeability, etc., and achieve the effects of good durability, high oil resistance and enhanced impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

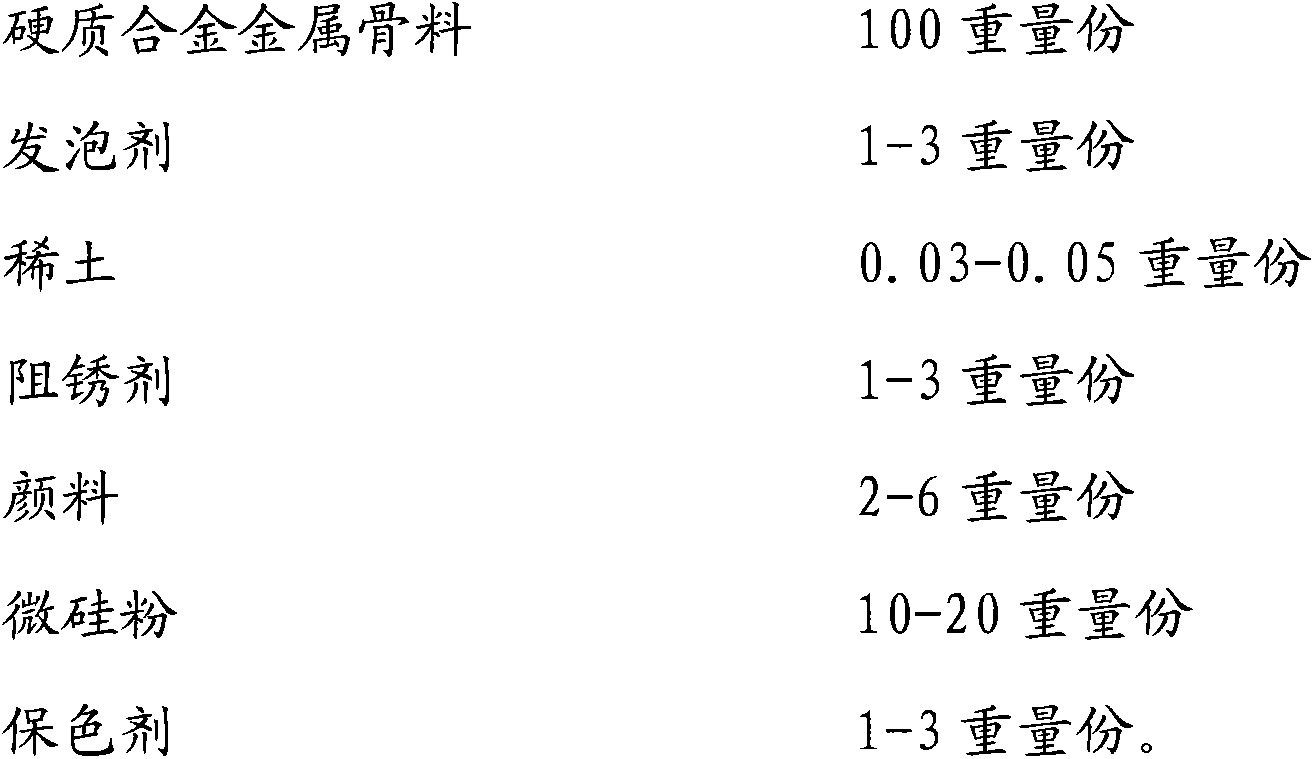

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of ground material of the present invention:

[0035] Sieve out impurities in 100 parts by weight of cemented carbide metal aggregates by manual sorting; crush the sorted cemented carbide metal aggregates with a rotary hammer mill to particles below -200 mesh, and then magnetically separate them with a magnetic separator , remove impurities, and then screen with a vibrating sieve to obtain cemented carbide metal aggregates of about -200 mesh; then put the obtained material into a sintering tank and send it to a high-temperature furnace to raise the temperature to 1300 ° C, and add 2 parts by weight of carbonic acid Silicon is roasted and foamed for 36 hours. When the roasted and foamed material is cooled to room temperature, it is pulverized into particles of about 120 mesh through a pulverizer. After foaming, the specific volume is controlled at 2.5T / m3; Soak in 7% sodium silicate solution for 30 minutes, carry out anti-rust treatment, the...

Embodiment 2

[0036] Embodiment 2: the preparation of ground material of the present invention:

[0037] Sieve out impurities in 100 parts by weight of cemented carbide metal aggregates by manual sorting; crush the sorted cemented carbide metal aggregates with a rotary hammer mill to particles below -200 mesh, and then magnetically separate them with a magnetic separator , remove impurities, and then use a vibrating sieve to screen to obtain cemented carbide metal aggregates of about -200 mesh; then the obtained materials are put into a sintering tank and sent to a high-temperature furnace to raise the temperature to 1400 ° C, and add 2.5 parts by weight of silicon carbonate to carry out Roasting and foaming for 36 hours. When the calcined and foamed material is cooled to room temperature, it is crushed into particles of about 120 mesh by a pulverizer. After foaming, the specific volume is controlled at 3T / m3; Soak in sodium silicate solution for 30 minutes, carry out anti-rust treatment, t...

Embodiment 3

[0038] Embodiment 3: the preparation of ground material of the present invention:

[0039] Sieve out impurities in 100 parts by weight of hard metals by manual sorting; crush the sorted hard metals with a rotary hammer mill to particles below -200 mesh, then magnetically separate them with a magnetic separator to remove impurities, and then use Vibrating sieves were used to screen to obtain -200 mesh hard metal materials; then the obtained materials were put into a sintering tank and sent to a high-temperature furnace to raise the temperature to 1400 ° C, and 3 parts by weight of silicon carbonate were added for roasting and foaming for 36 hours, and roasting and foaming When the final material is cooled to room temperature, it is pulverized into particles of about 120 mesh through a pulverizer, and the specific volume is controlled at 2.8T / m3 after foaming; then, the obtained particles are poured into a 7% sodium silicate solution and soaked for 30 minutes , carry out anti-ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com