Light non-dismantling self-thermal-insulation cast-in-place wall and preparation method of filling material thereof

A technology of cast-in-place walls and filling materials, which is applied in the direction of heat preservation, walls, and building components. The effect of the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] like figure 1 As shown, the preparation method of the filling material of the non-dismantling lightweight self-insulation cast-in-place wall provided by the invention may further comprise the steps:

[0029] Preparation of nano- or micro-scale microcellular foam;

[0030] The microporous foam is fused with the inorganic composite gel matrix containing silicate, expanded and foamed to form a microporous slurry, and nano- or micron-sized closed cells are formed in the microporous slurry to make a lightweight porous refractory inorganic framework ;

[0031] Then use organic lightweight aggregate to fill the lightweight porous refractory inorganic framework to make a mixed slurry;

[0032] The mixed slurry is solidified and formed.

[0033] Preferably, the silicate includes calcium silicate and aluminum silicate, as an inorganic composite gelling matrix, which has high strength after curing and is suitable for building materials.

[0034] Preferably, polystyrene foam pa...

Embodiment 1

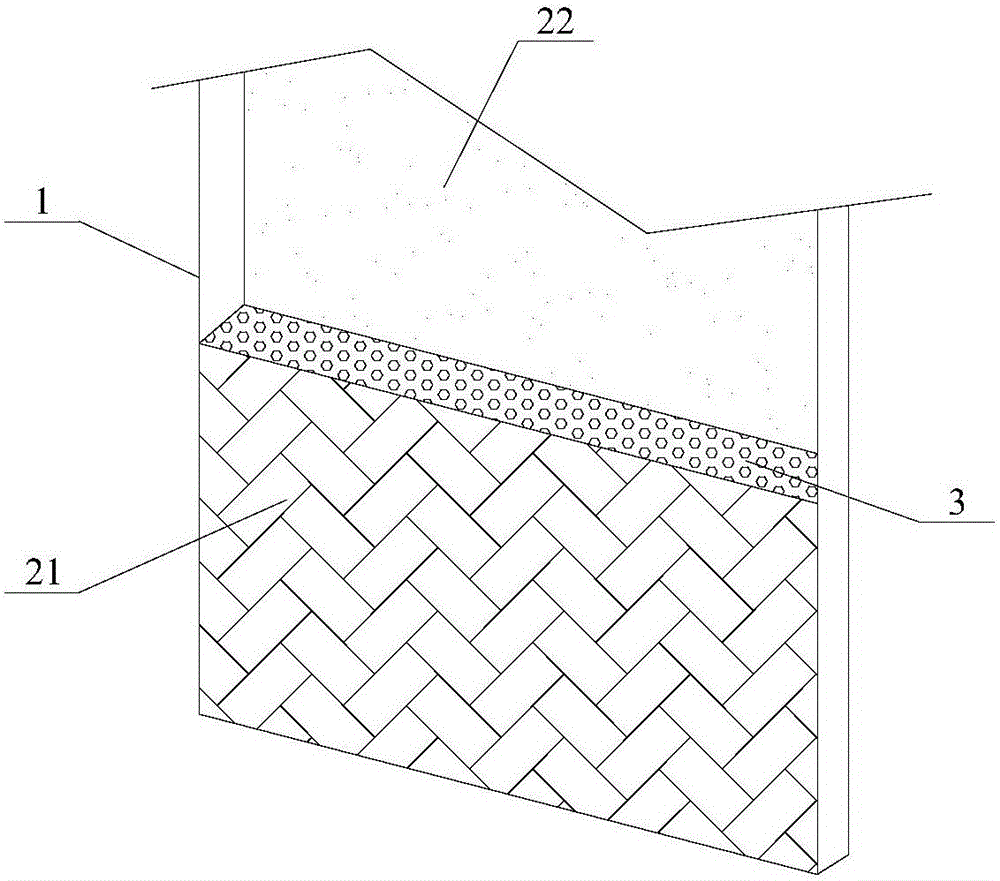

[0045] The keel frame 1 adopts C-shaped steel keel with a steel structure of 13cm, the outer wall panel 21 adopts 10mm thick Ozon board, the inner wall panel 22 adopts 12mm thick paper-faced gypsum board, and the wire pipes and wire boxes are pre-installed on the outer wall panel 21 and the filling space of the inner wallboard 22, and then pouring mixed slurry in the filling space, the mold does not expand and does not leak, and the mixed slurry solidifies to form a self-insulating wall.

Embodiment 2

[0047] The keel frame 1 adopts a 16cm I-shaped steel keel, the outer wall panel 21 adopts an 80mm thick aerated panel, the inner wall panel 22 adopts a 12mm thick GRC board, and the wire pipes and wire boxes are preset in the filling space. Install a reinforcing rib at the center of the pouring, and then pour the mixed slurry in the filling space, without expansion and no leakage of the slurry, and the self-insulating wall will be formed after the mixed slurry solidifies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com