Integrated construction method for artificial dug pile and steel pipe concrete column

A technology of steel pipe concrete columns and artificial excavated piles, which is applied to the survey of foundation soil on site, columns, pier columns, etc., can solve the problems of separation and disjoint, achieve the effects of reducing steel consumption, overcoming separation and disjoint, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention are described in detail below. The present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the scope of application of the present invention is not limited to the following embodiments.

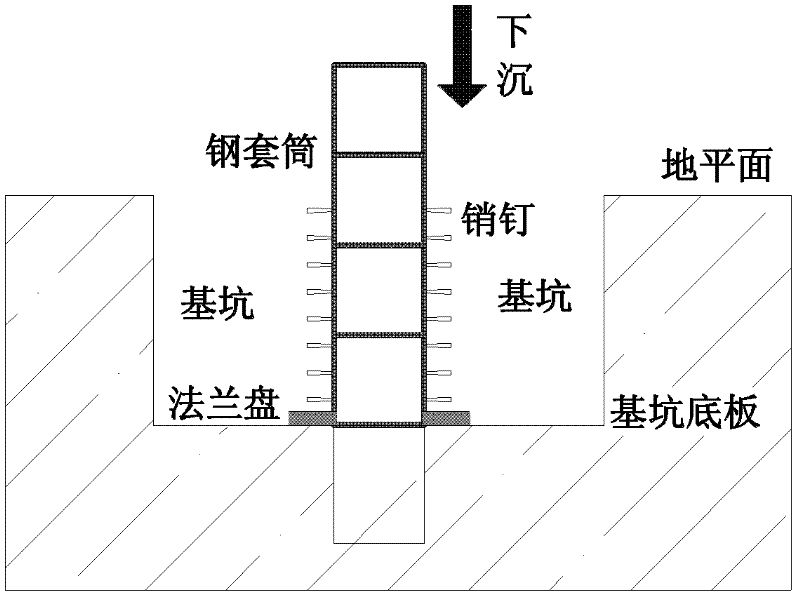

[0039] A subway station is planned to be built in a certain site, and the design excavation depth of the station is 15m. Figure 5 As shown, the specific construction steps are briefly described as follows:

[0040]Step 1: On-site geological exploration: The static penetration method is used to explore the layers of the stratum on the site, and the specific data such as sand content, permeability, acidity, etc. are determined. Make a relationship diagram for the penetration resistance and pore water pressure of the static penetration test to determine the depth of the affected area of the site in this construction example. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com