Material level measuring device for steel ball coal mill and optimization and control method of powder-making process by bin type steel ball coal mill

A steel ball mill, material level measurement technology, applied in the direction of measurement device, program control, computer control, etc., can solve the problems of uneconomical operation, large environmental noise pollution, inability to measure, etc., achieve significant economic benefits, reduce labor intensity , the effect of good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The drawings show embodiments of the invention.

[0045] The content of the invention will be further explained below in conjunction with the accompanying drawings:

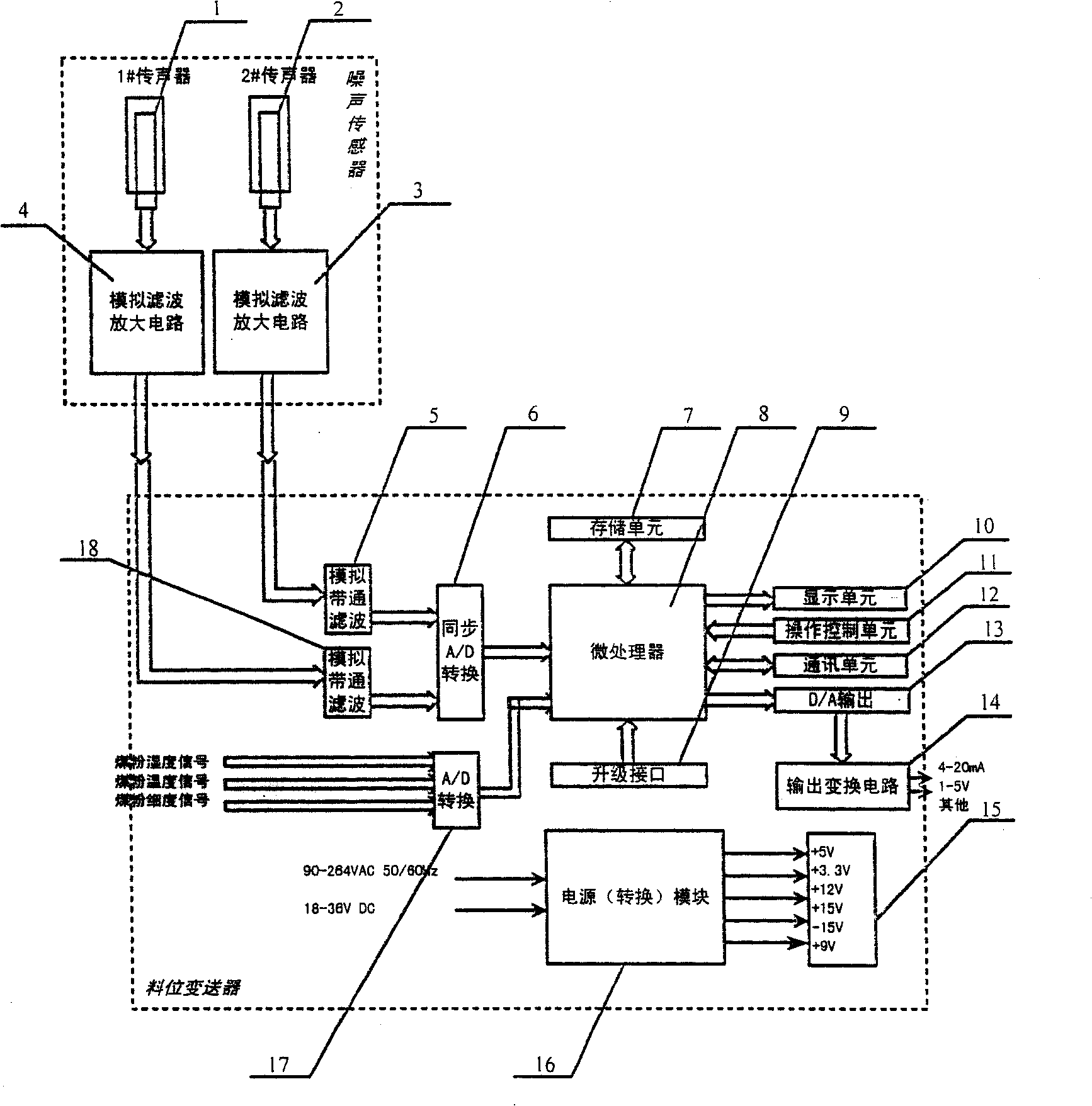

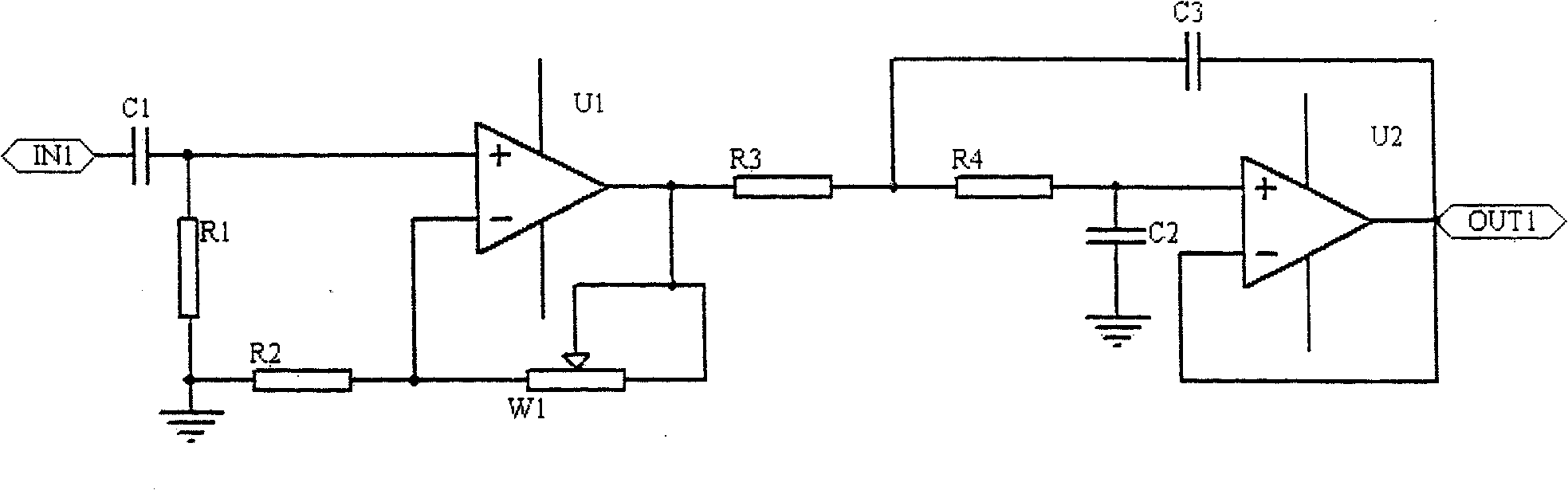

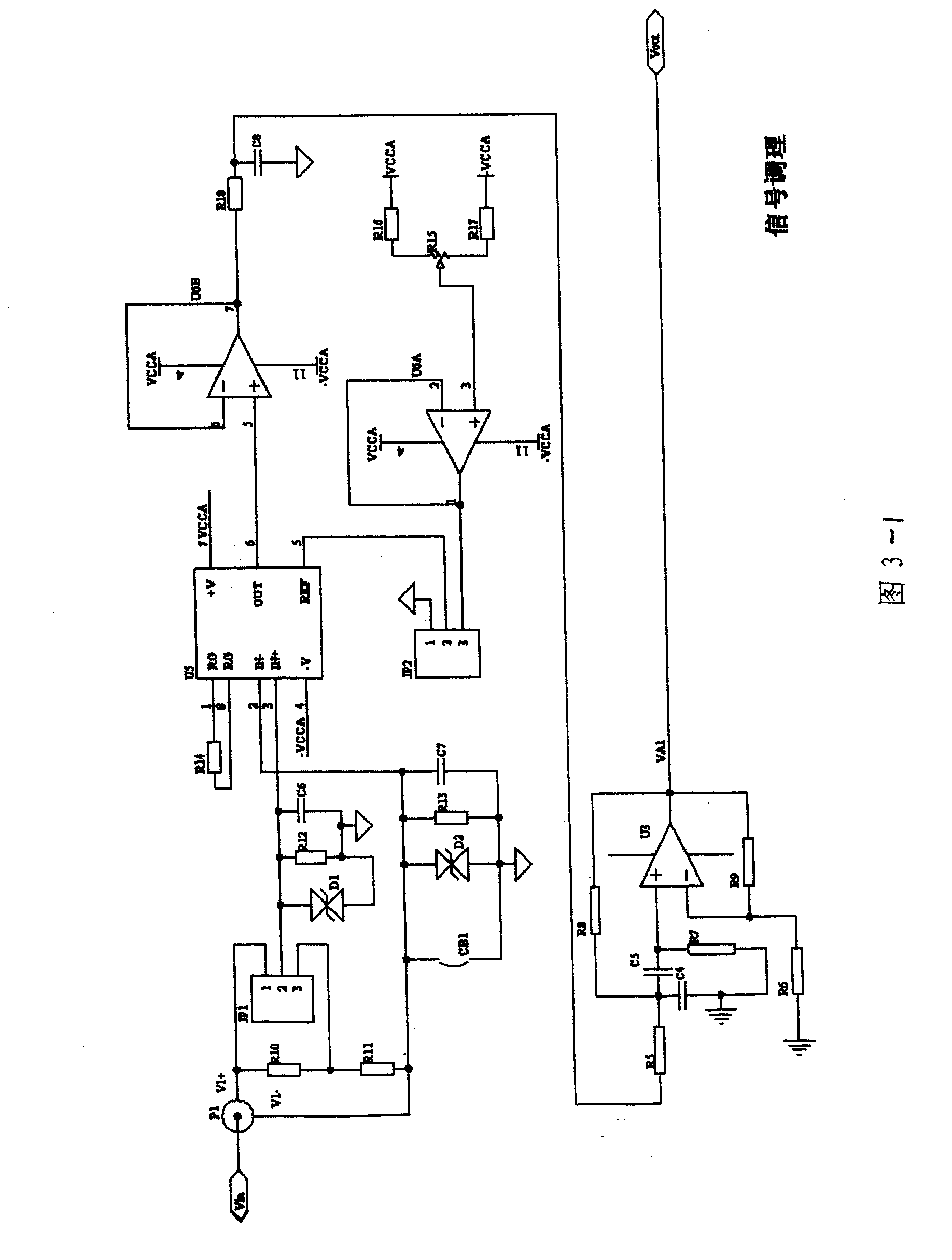

[0046] Refer to figure 1 As shown, a steel ball coal mill level measuring device is composed of a noise sensor and a level transmitter. The noise sensor is composed of single microphone 1 or dual microphones 1, 2. Microphone 1 is connected to an analog filter amplifier circuit 4, and microphone 2 is connected to an analog filter amplifier circuit 3. The other ends of the analog filter amplifier circuits 3 and 4 are connected to the analog One end of the band-pass filters 5 and 18 is connected, the other ends of the analog band-pass filters 5 and 18 are respectively connected to the synchronous A / D conversion circuit 6, and the other end of the synchronous A / D conversion circuit 6 is connected to the microprocessor 8. The device 8 is connected to the storage unit 7, the upgrade interface 9, the display unit 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com