Post-tensioned prestressing underground diaphragm wall and construction method

An underground diaphragm wall and post-tensioning prestressing technology, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the difficulty of concrete quality control, large concrete, deformation or displacement of prestressed steel bars, and influence on the force effect, etc. problems, to achieve the effects of reducing difficulty and risk, improving rigidity and crack resistance, and reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

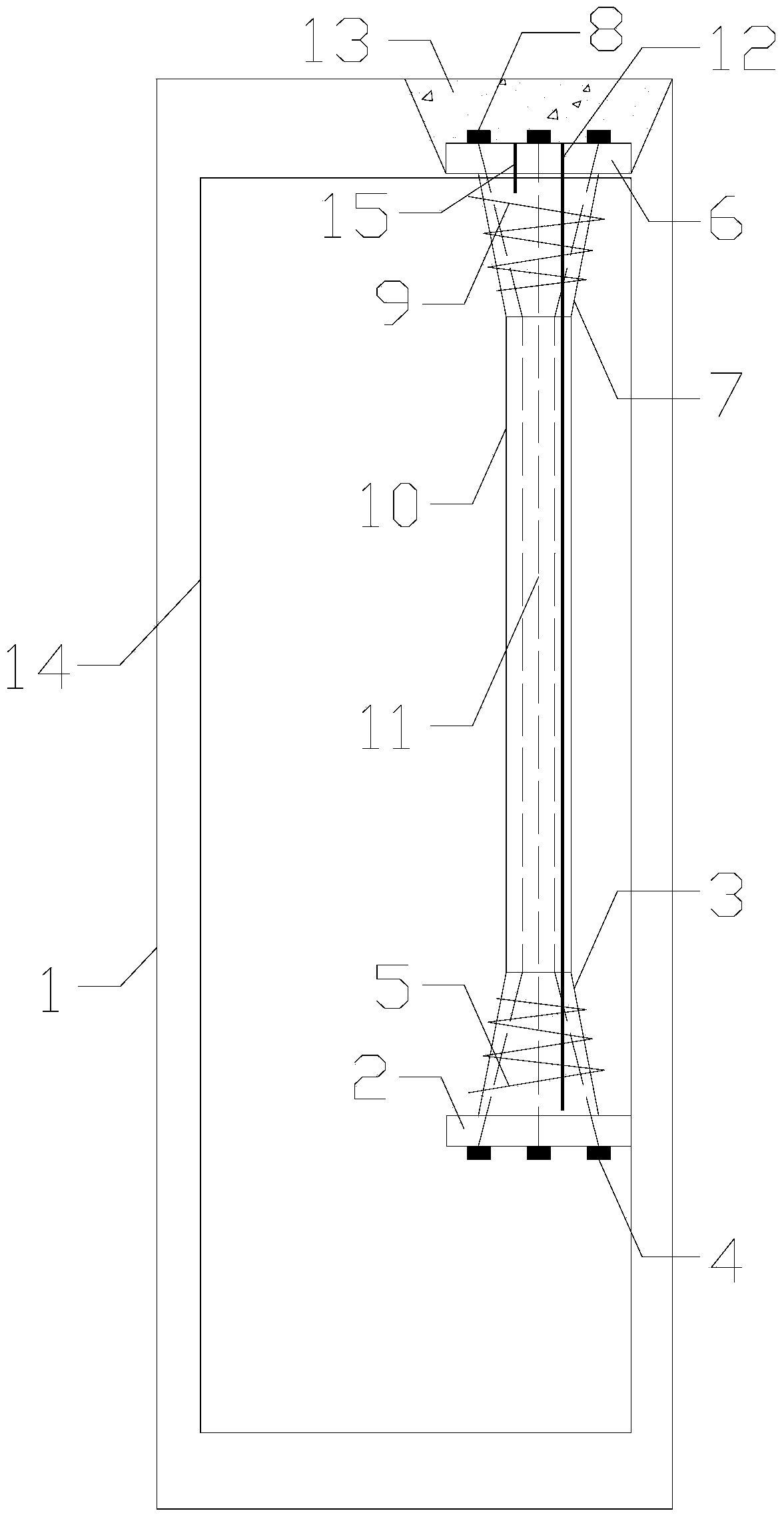

[0038] The post-tensioned prestressed underground diaphragm wall and construction method of the present invention will be further described below in conjunction with the accompanying drawings.

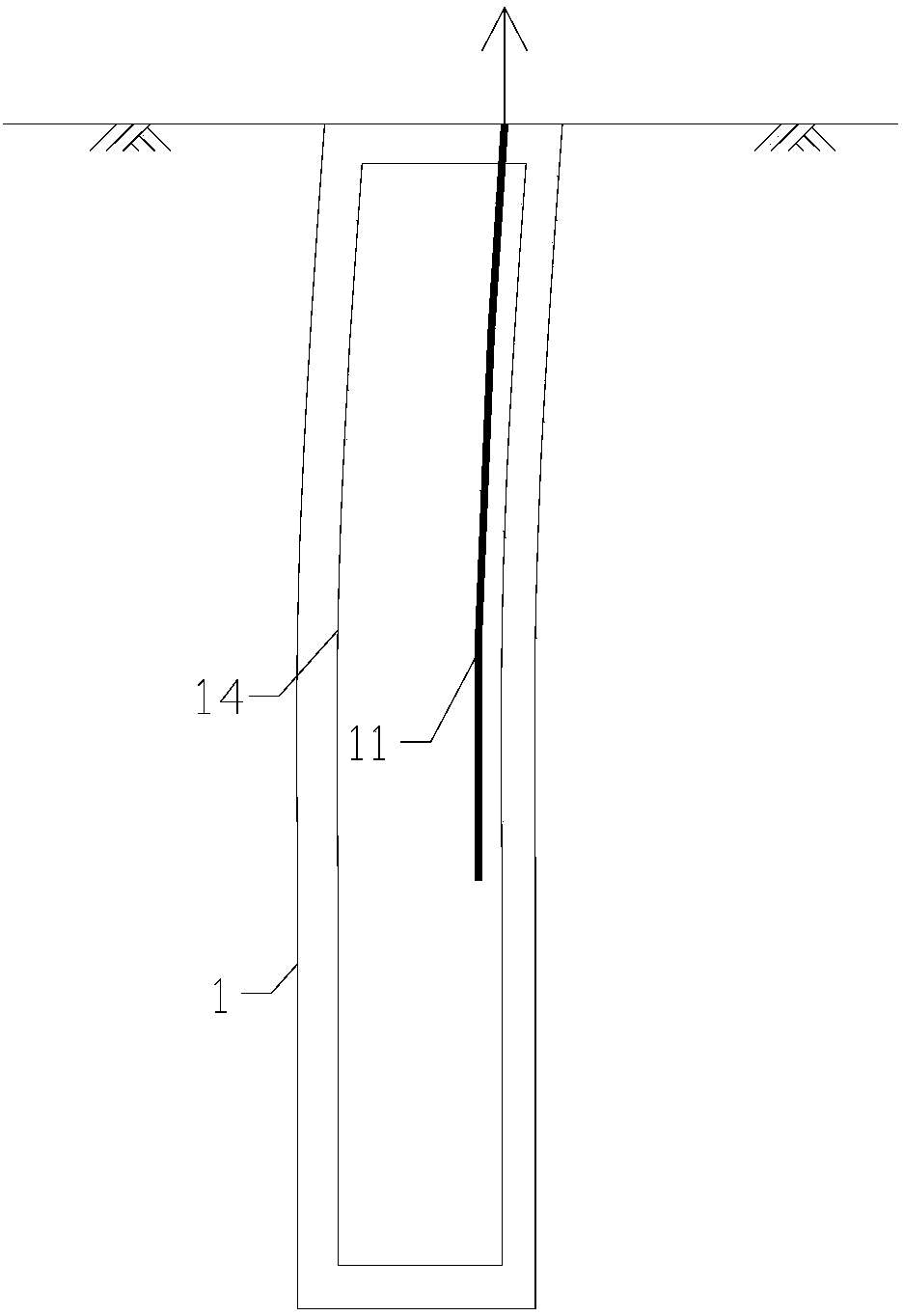

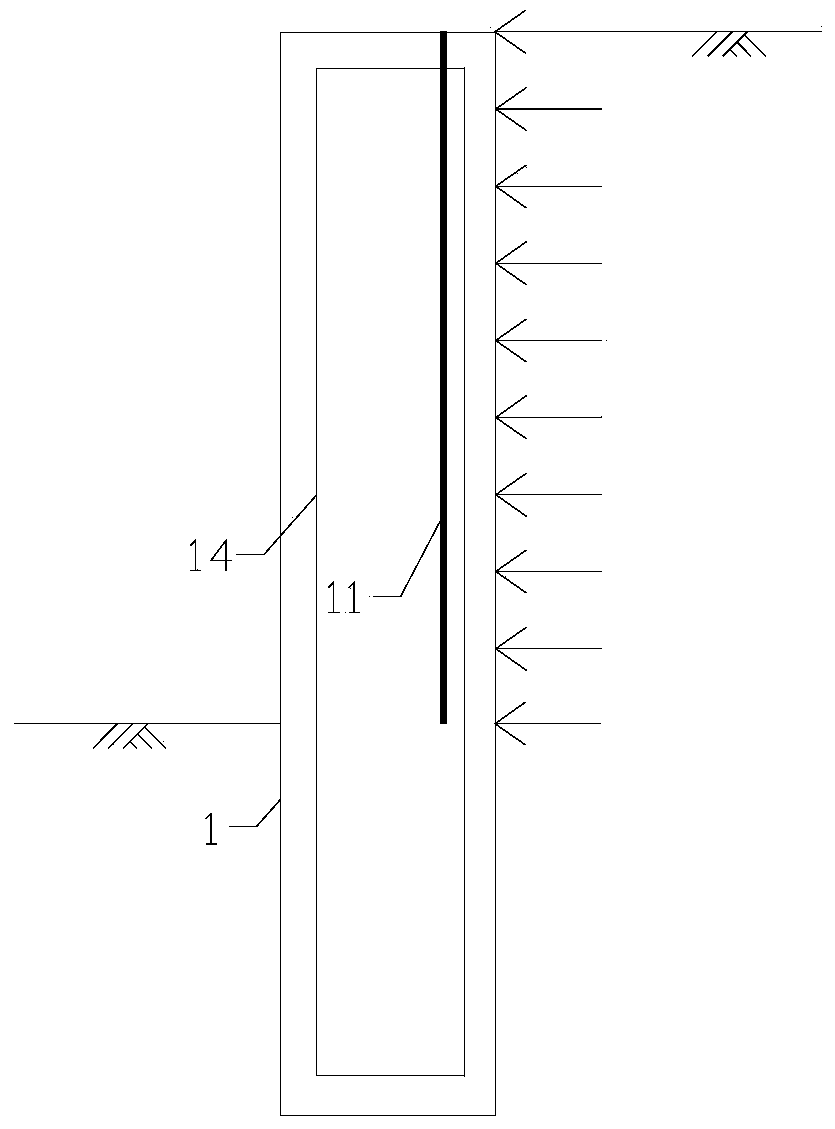

[0039]The design idea of the stress ground connection wall of the present invention is to apply the rebound reaction force of the prestressed steel bar to the ground connection wall concrete after stretching the prestressed steel bar in the tension area of the ground connection wall, so that the concrete is subjected to a pre-compression Stress, resulting in a certain compression deformation, such as figure 2 shown. When the member is stressed, the concrete in the tension area must first offset the previous compression deformation, and then the concrete is gradually stretched as the external force increases, thereby effectively improving the strength and stiffness of the ground connection wall and delaying the ground deformation. The time when the cracks appeared in the wall, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com