Patents

Literature

100results about How to "Reduce the amount of reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

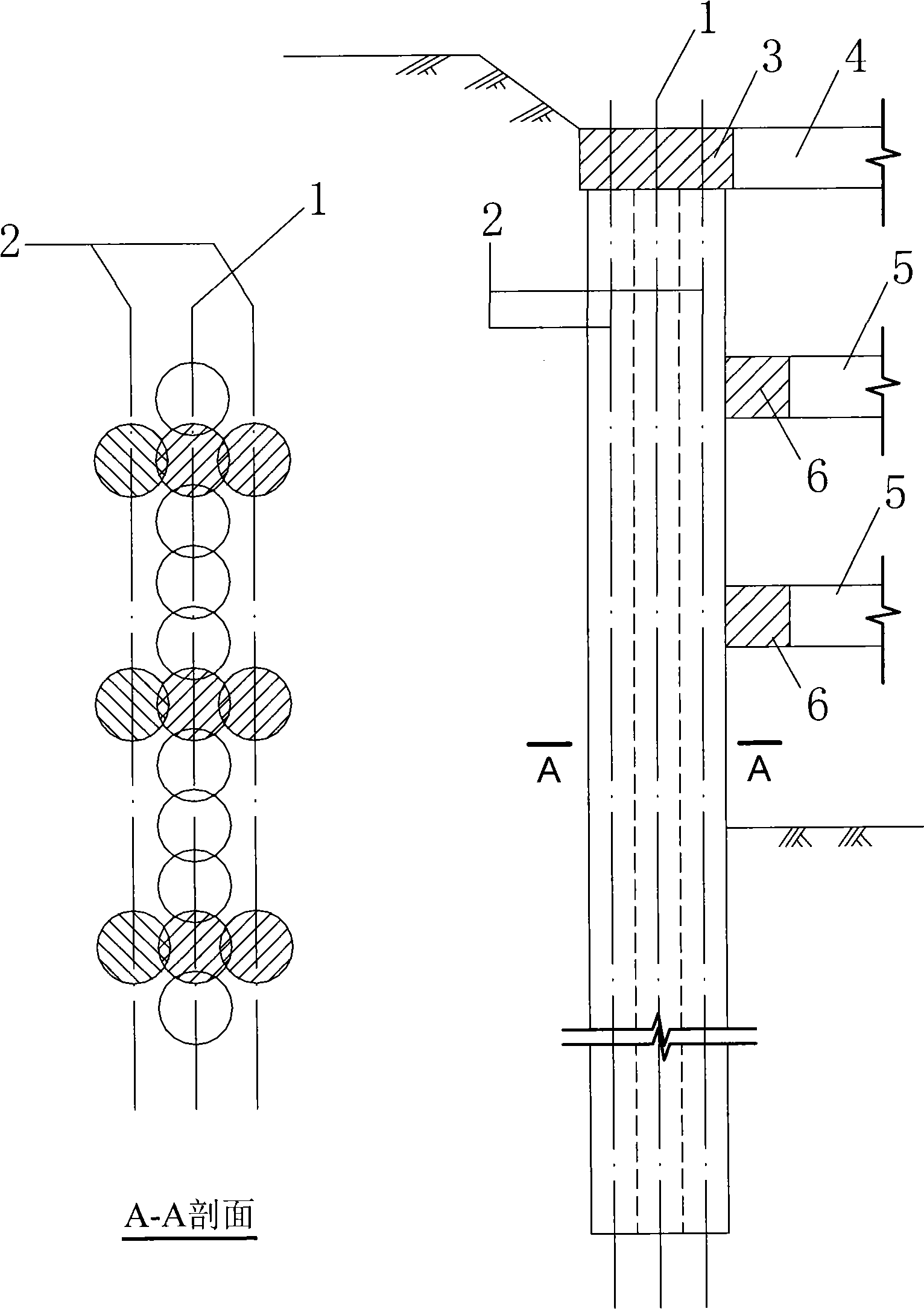

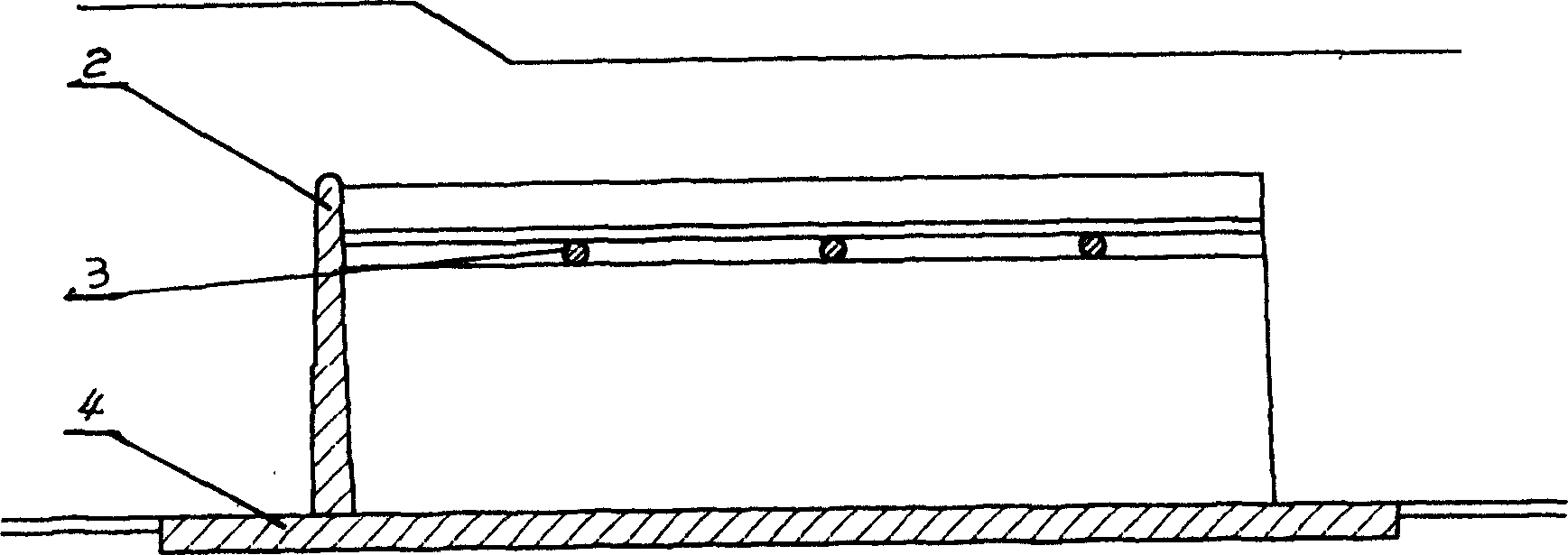

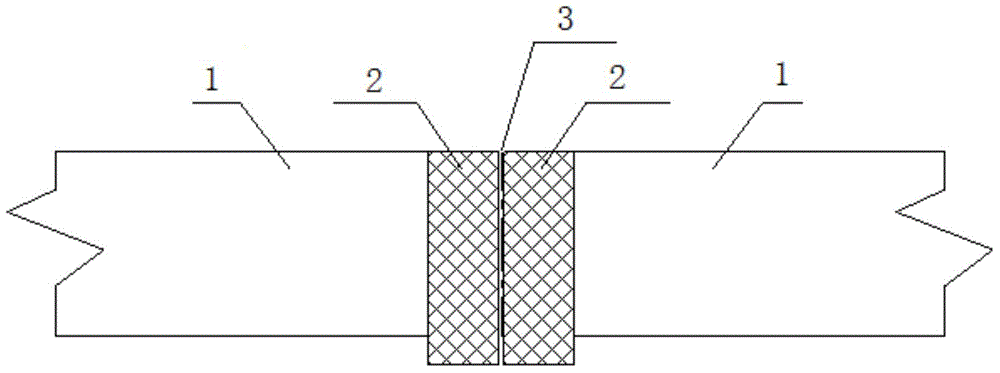

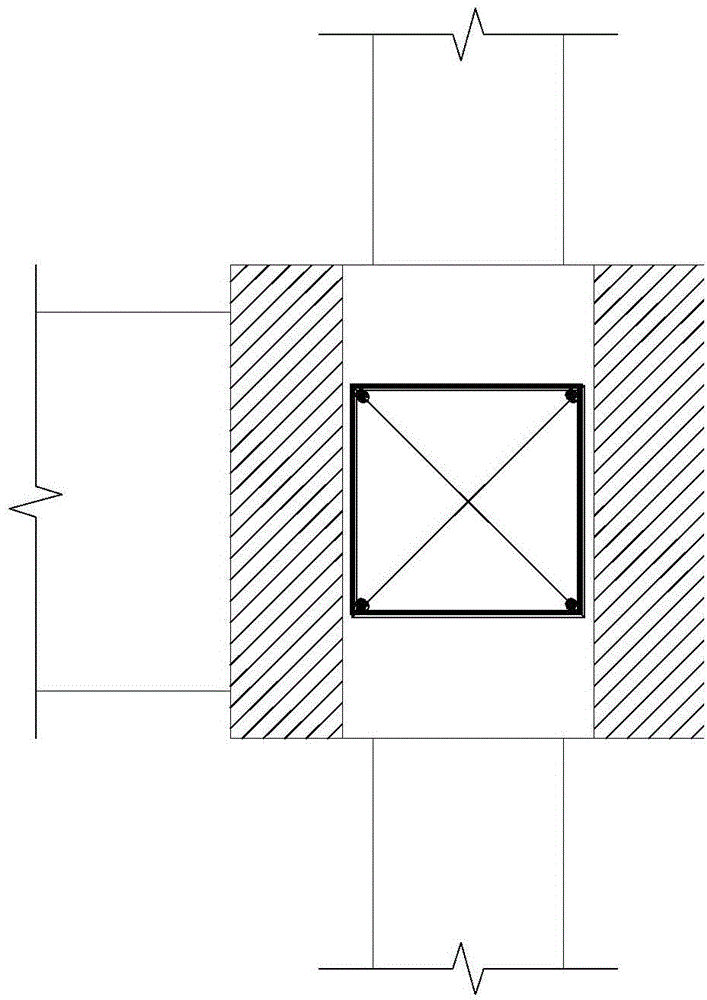

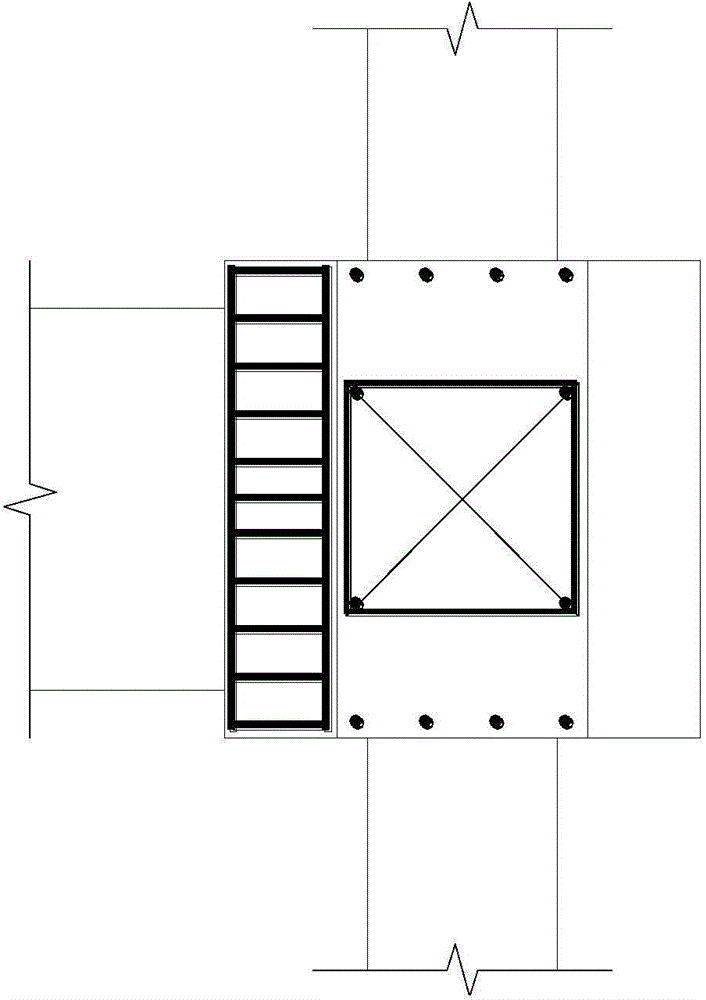

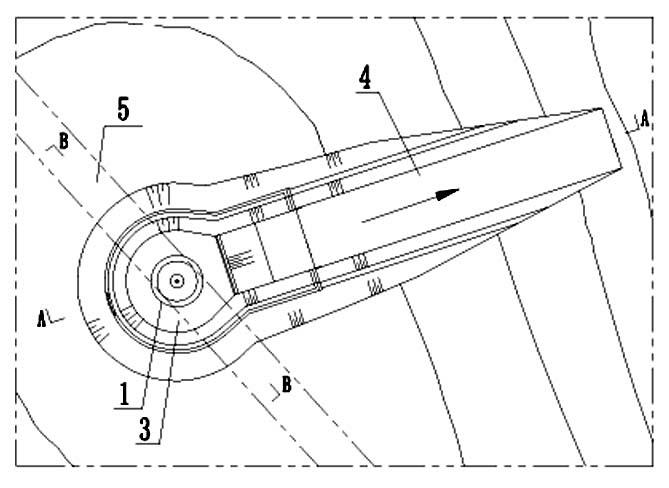

Method of using rotational multiaxial borehole pouring concrete occluding pile wall for enclosing deep foundation pit and slope protection project

The invention relates to a novel method for enclosing a deep foundation pit and a slope protection project, such as a multi-storey basement and a subway. A rotary multiaxial borehole pouring concrete occluding pile wall is combined with an internal supporting system or anchor rod to form an integral enclosing structure. The slope protection project can be enclosed by an cantilever pile wall without an internal supporting system and anchor rods inside. An enclosure wall adopting multiaxial borehole pouring concrete occluding piles can be constructed along the foundation pit enclosing axis; because the planes of the stressed multiaxial borehole pouring concrete occluding piles are rotated by 90 DEG at a fixed position, the long edges of the cross sections of the multiaxial borehole pouring concrete occluding piles are perpendicular to the foundation pit enclosing axis, so that the lateral resistant strength and the rigidity of the enclosure wall are improved, and the cost of the project is lowered. Compared with method of using the underground continuous wall for enclosing, the method is easy and rapid to implement with simple construction machines and the enclosure wall with strong rigidity, low manufacturing cost and the like. Calculation shows that the rigidity of the enclosure wall adopting conventional reinforcing steel bars can be improved by about six times, and the resistance to bending can be improved by about 2 times, and the amount of reinforcing steel bars used and the comprehensive manufacturing cost are all reduced by about half.

Owner:ZHEJIANG UNIV +2

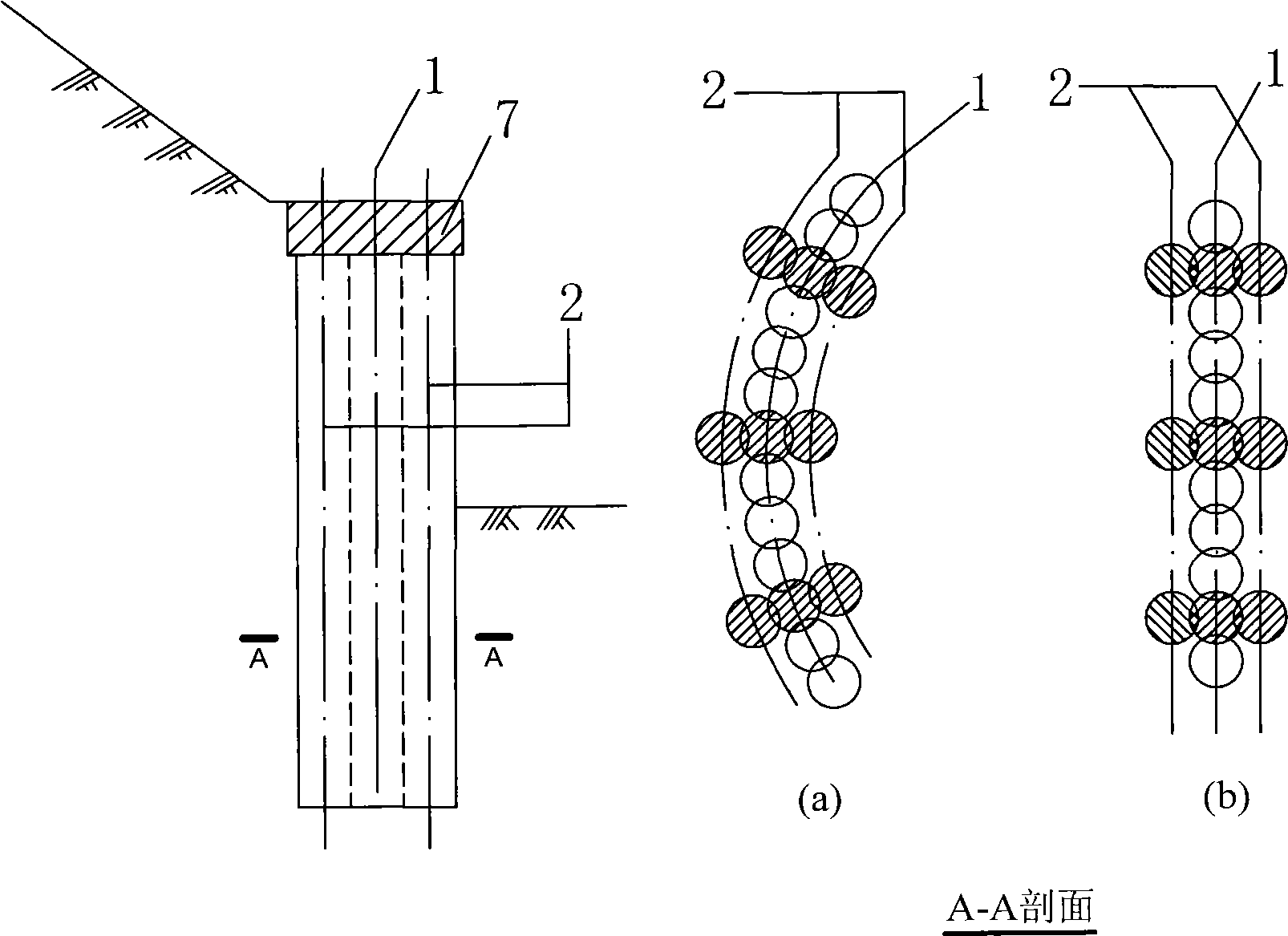

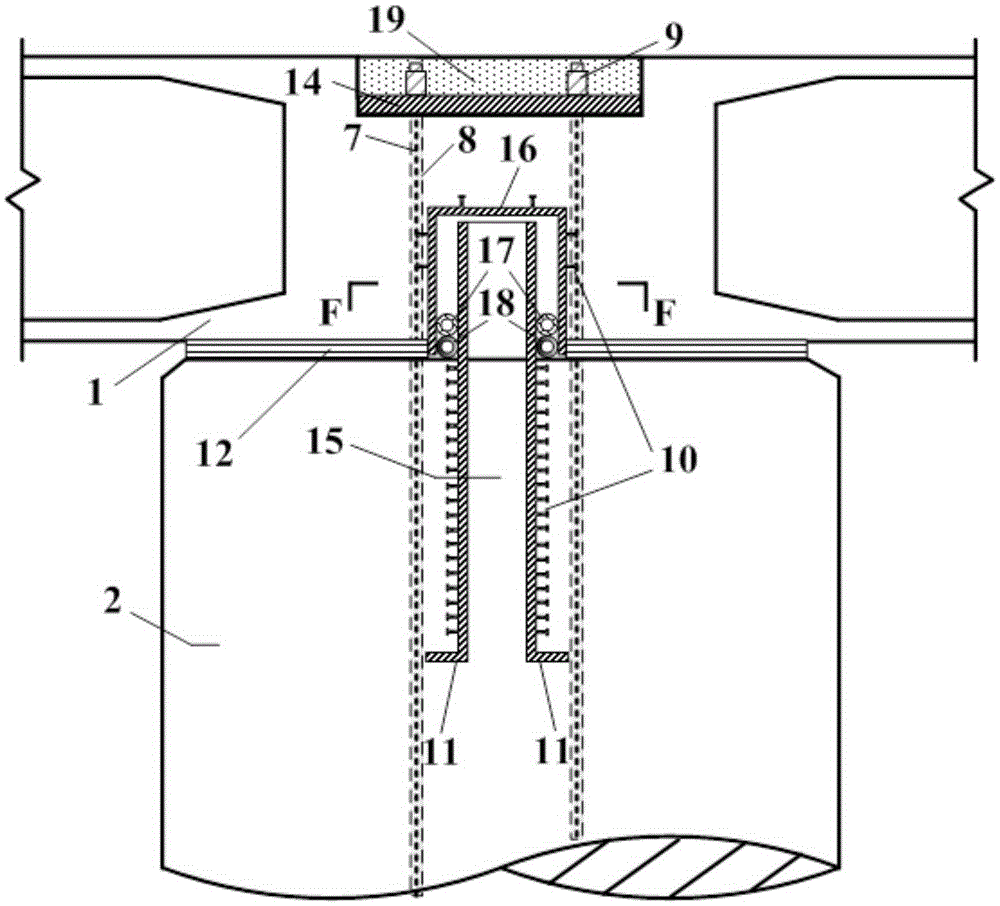

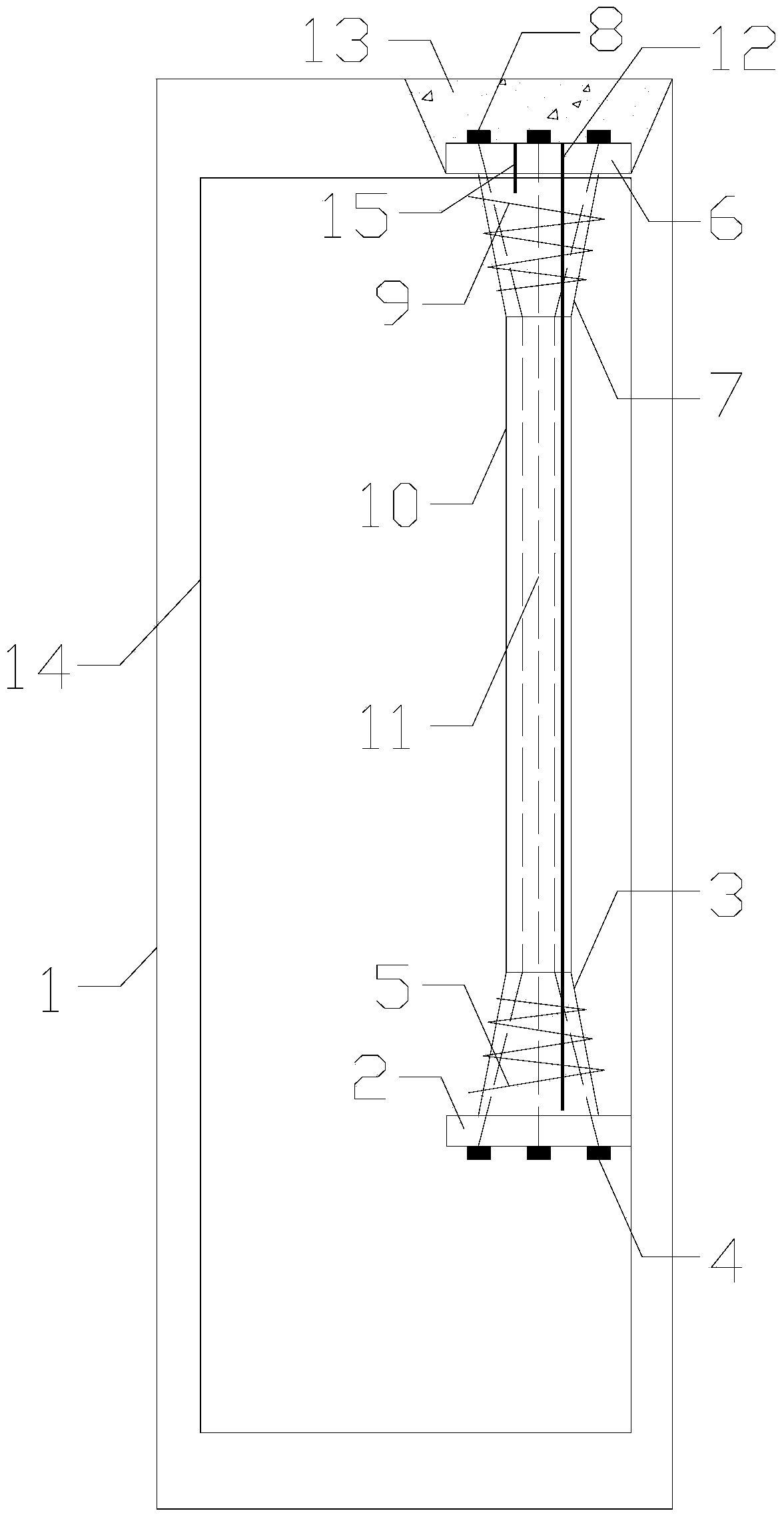

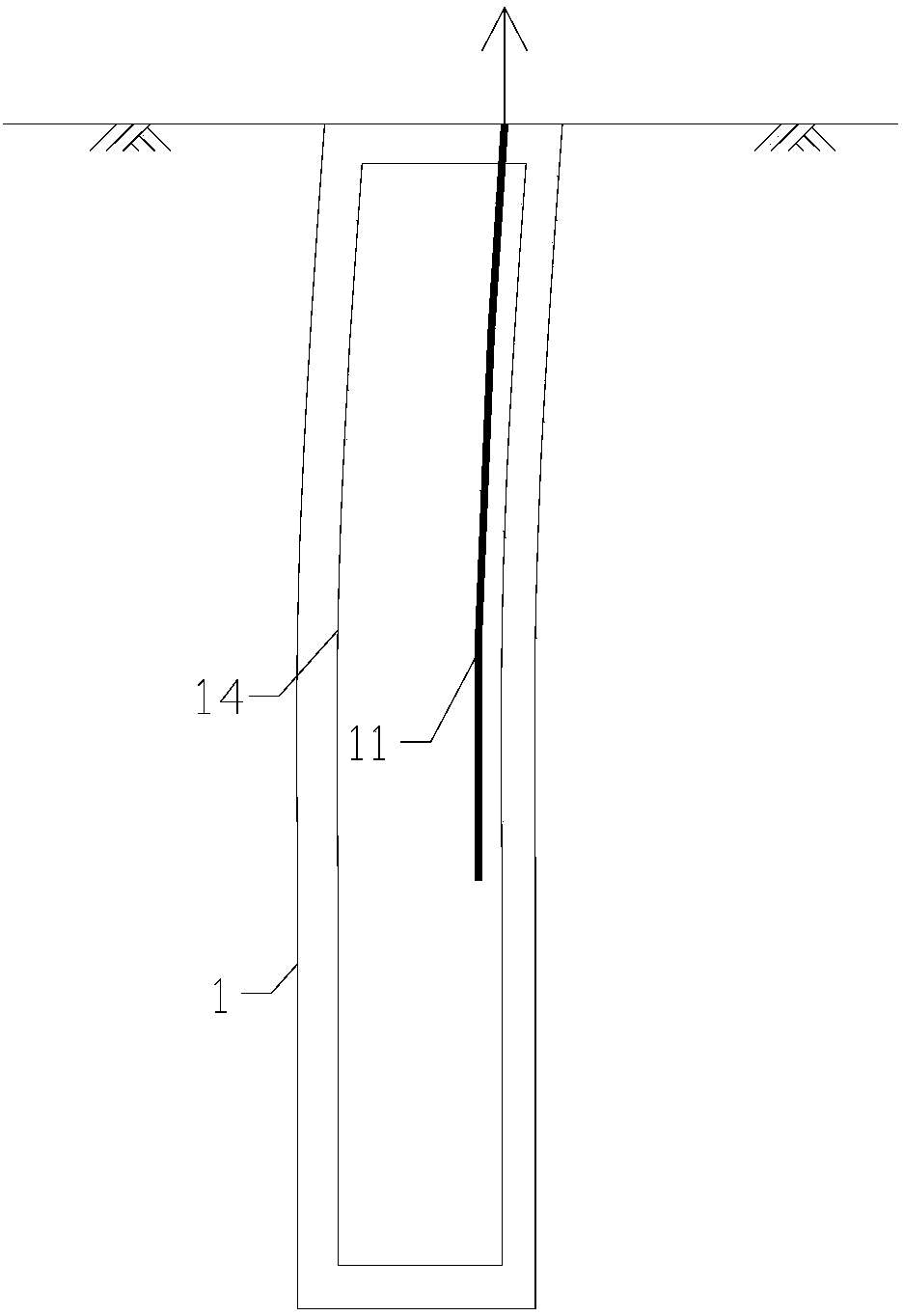

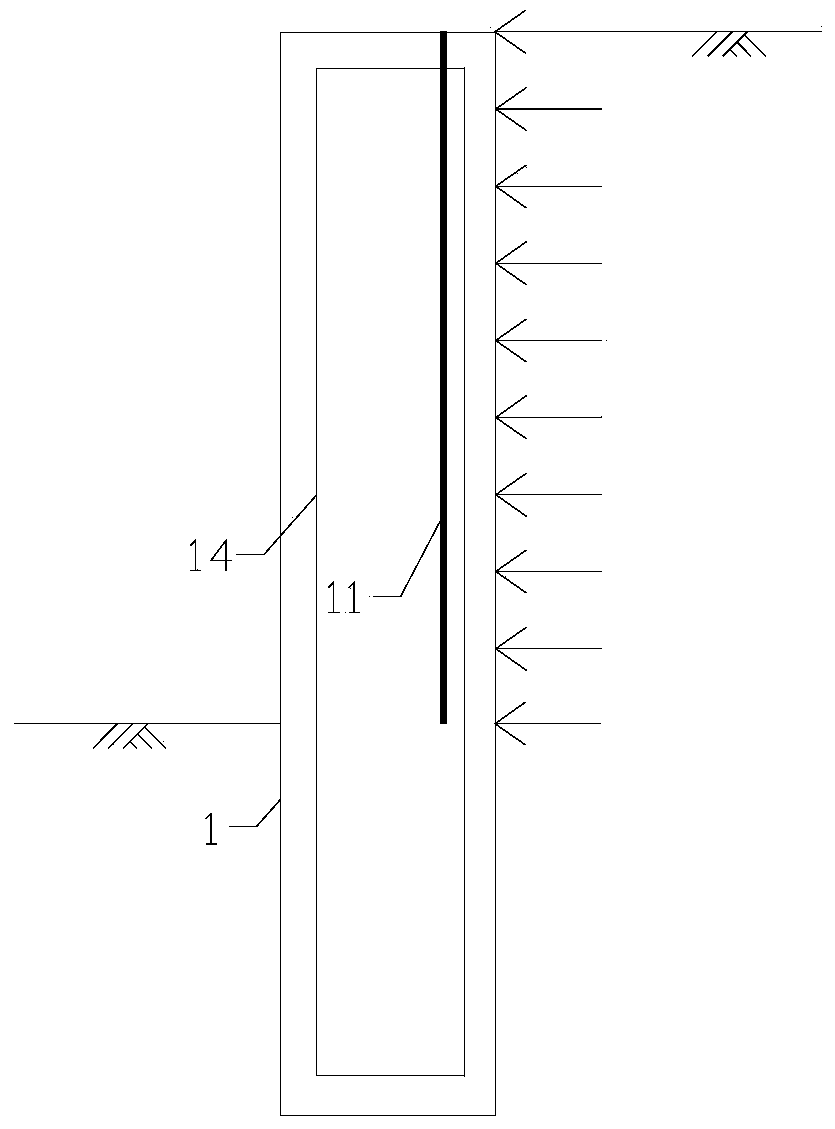

Construction method for vertical prestressed anchor rope friction pile slope-sliding prevention and treatment

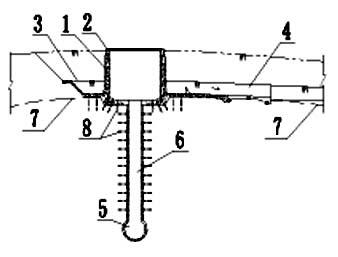

InactiveCN101230577AReduce the amount of reinforcementReduce bending moment deformationExcavationsBulkheads/pilesPre stressLandslide

A construction method for controlling the anti-slide pile and anti-landslide of a vertical prestressed anchor line, and the prior anti-slide pile is internally provided with the vertical prestressed anchor line, the construction of which is carried out according to the following steps: a vertical anti-slide pile hole is dug on the coast and the hole is dug into the deep of a stone head, and the pile hole is internally pre-buried with a steel tube or a PVC tube; a prestressed anchor eye is drilled downwards from the bottom of the pile hole; the anchor eye has the prestressed anchor line inside and carries out cement mortar perfusion; a steel reinforcement cage is put into the pile hole, and the concrete pouring of an anti-slide pile body is carried out; the prestressed anchor line is tensioned and the free perfusion above the sloping surface of the anti-slide pile is carried out; when the concrete initially coagulates, the prestressed anchor line is locked in an anti-tension way. The invention makes use of the advantages of the technology of prestressed anchorage and the structure of the anti-slide pile, thereby solving the problems of too long embedding and fixing section, overlarge cross section, poor antidumping performance and higher investment, etc. of the anti-slide pile of the prior large coast.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

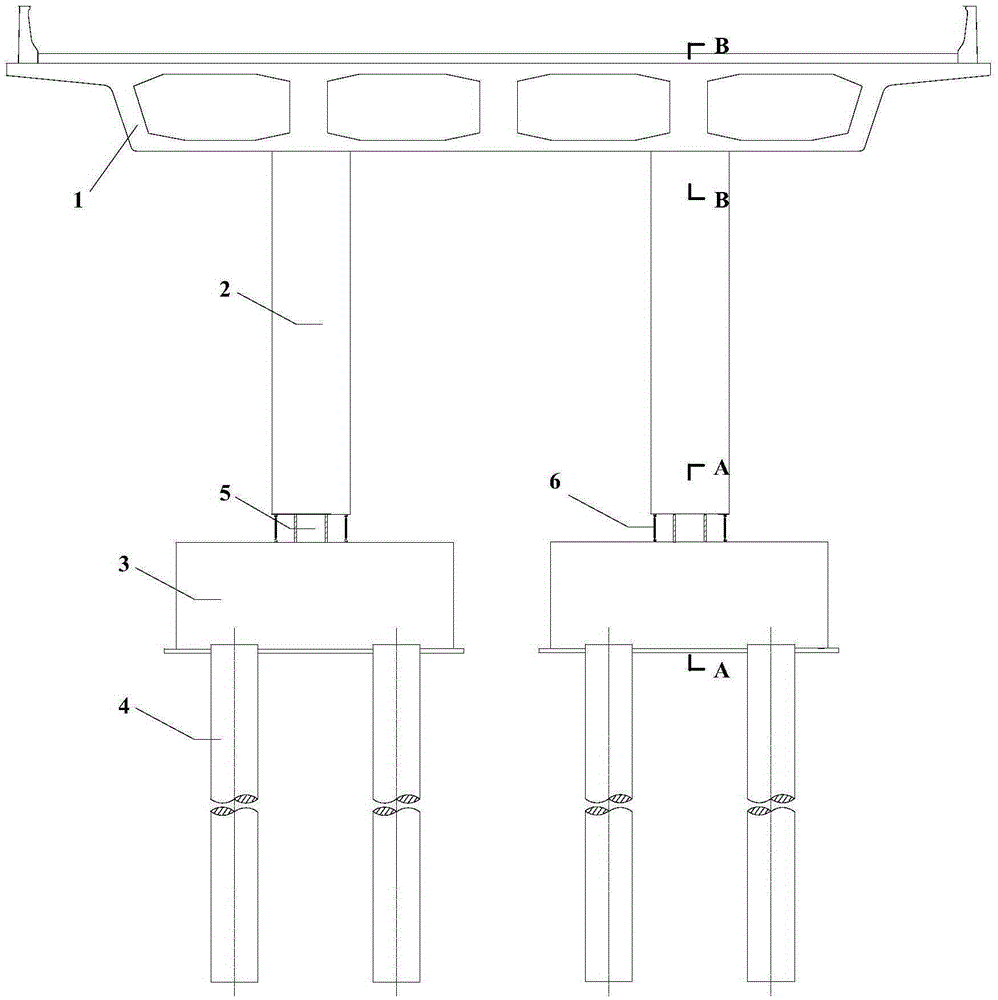

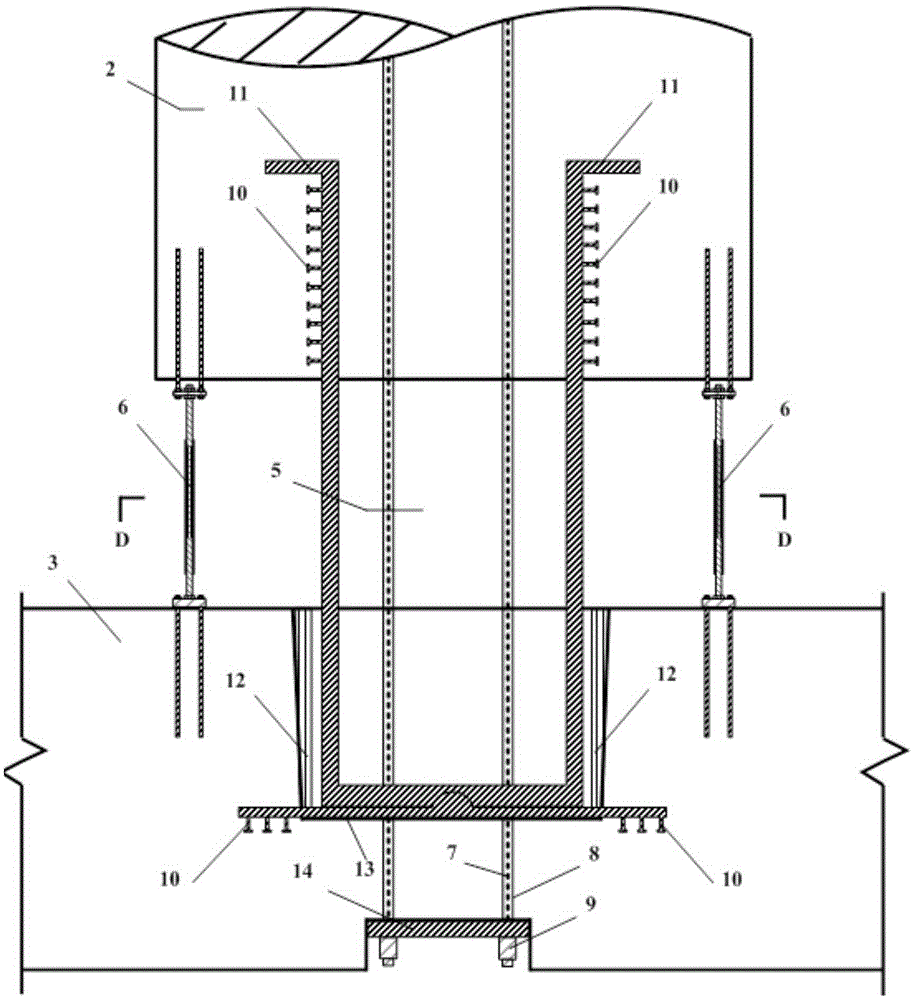

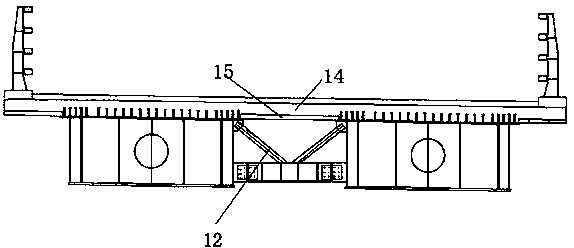

Double-column type swinging shock-insulation bridge pier structure system

ActiveCN105297617ARemarkable effect of shock absorption and isolationAvoid damageBridge structural detailsBridge engineeringResidual deformation

The invention provides a double-column type swinging shock-insulation bridge pier structure system and belongs to the field of bridge engineering. The structure system is mainly composed of an upper structure, a reinforced concrete bridge pier section and a steel pipe concrete bridge pier section, a bearing platform, a steel pipe concrete bolt pin, a non-binding pre-stress steel bar and the like. The steel pipe concrete bridge pier section is connected with the upper structure through the non-binding pre-stress steel bar; and with the help of an external energy consumption device and a metal annular object, the shock-insulation effect and the self-resetting capability of a bridge structure can be effectively provided. The structure system designed by the invention has a definite stress mechanism; under the condition of ensuring that the structure system has enough intensity and rigidity, the earthquake effect borne by the structure is reduced, and the effective energy consumption capability and self-resetting capability can be provided; and the problems of a traditional double-column type bridge pier structure system that a support is replaced in a life period and the system is seriously damaged and has large residual deformation after the earthquake effect can be solved.

Owner:BEIJING UNIV OF TECH

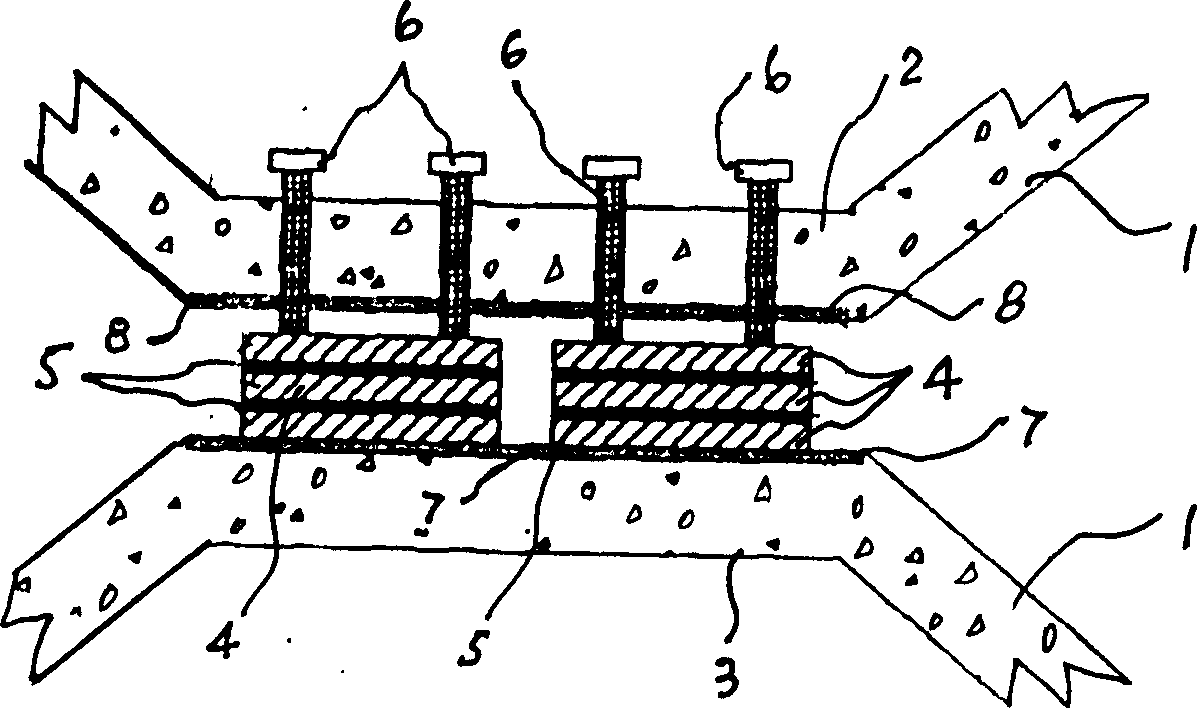

Post-tensioned prestressing underground diaphragm wall and construction method

ActiveCN103835311AHigh strengthIncrease stiffnessArtificial islandsUnderwater structuresSlurry wallPre stress

The invention provides a post-tensioned prestressing underground diaphragm wall. A fixed end anchor plate of a fixed end anchor tool of the underground diaphragm wall is provided with a taper hole and matched with a fixed end clamping piece. A prestressing steel bar is anchored through wedge caulking of the taper hole. A fixed end anchor plate lower stress member is jointly formed by a fixed end anchor backing plate and a fixed end spiral bar. A tension end anchor tool comprises a tension end anchor plate, a tension end anchor backing plate, a tension end clamping piece and a tension end spiral bar. The prestressing steel bar penetrates through a corrugated pipe to be laid and fixed to a steel bar cage, and then the two ends of the prestressing steel bar are fixed to the fixed end anchor tool and the tension end anchor tool respectively, the periphery of the steel bar cage and the periphery of the corrugated pipe are filled with concrete to form the post-tensioned prestressing underground diaphragm wall. Meanwhile, the invention provides a construction method of the post-tensioned prestressing underground diaphragm wall. The post-tensioned prestressing underground diaphragm wall and the construction method of the post-tensioned prestressing underground diaphragm wall have the advantages that the section of the post-tensioned prestressing underground diaphragm wall is reduced by 15 %, the antiknock performance is increased by 20 %, the steel bars are reduced by 30 %, the consumption of concrete is reduced by 15 %, and the post-tensioned prestressing underground diaphragm wall conforms to the development trend of the modern building structure.

Owner:CHINA COMM CONSTR FIRST HARBOR CONSULTANTS +1

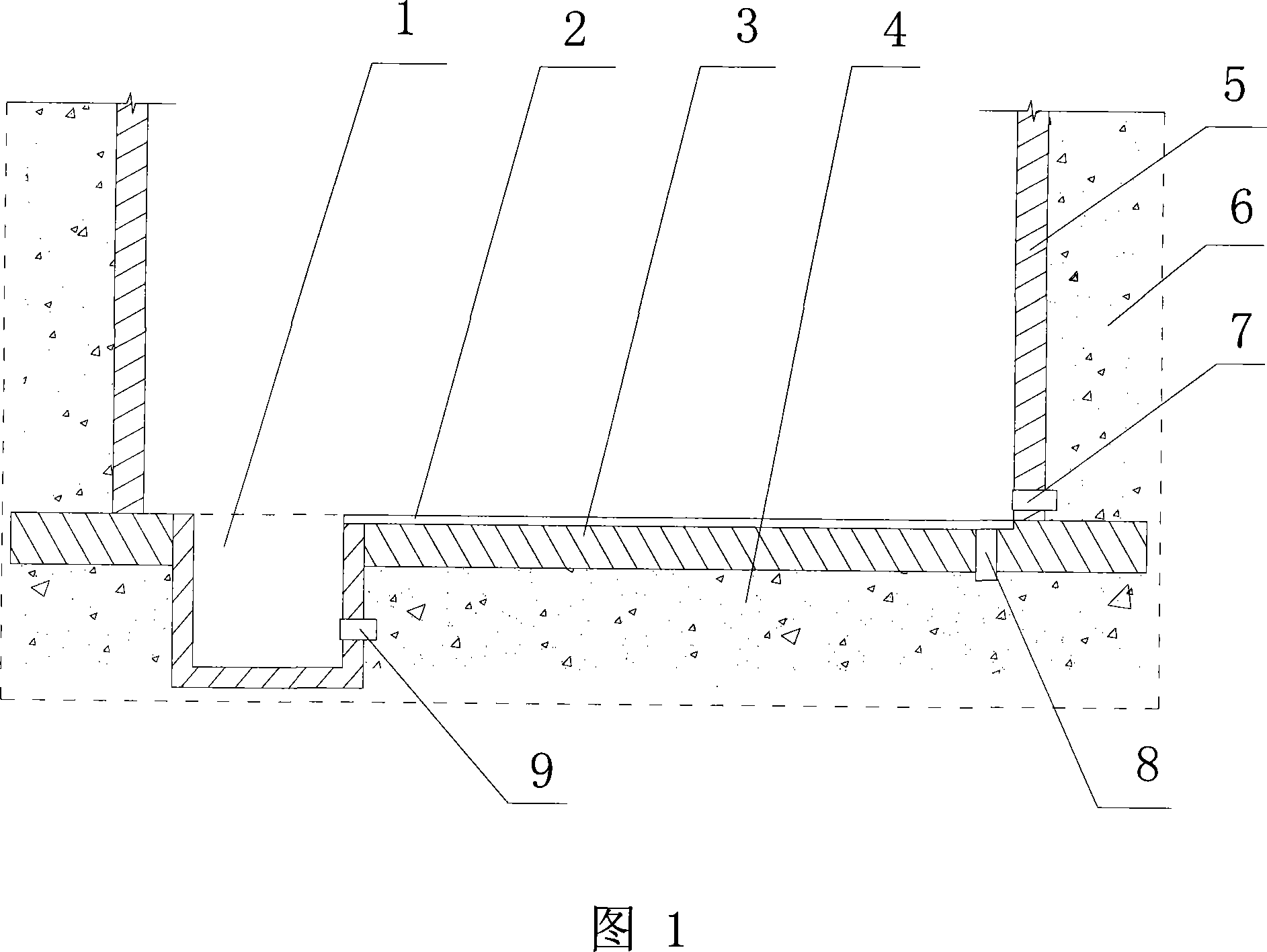

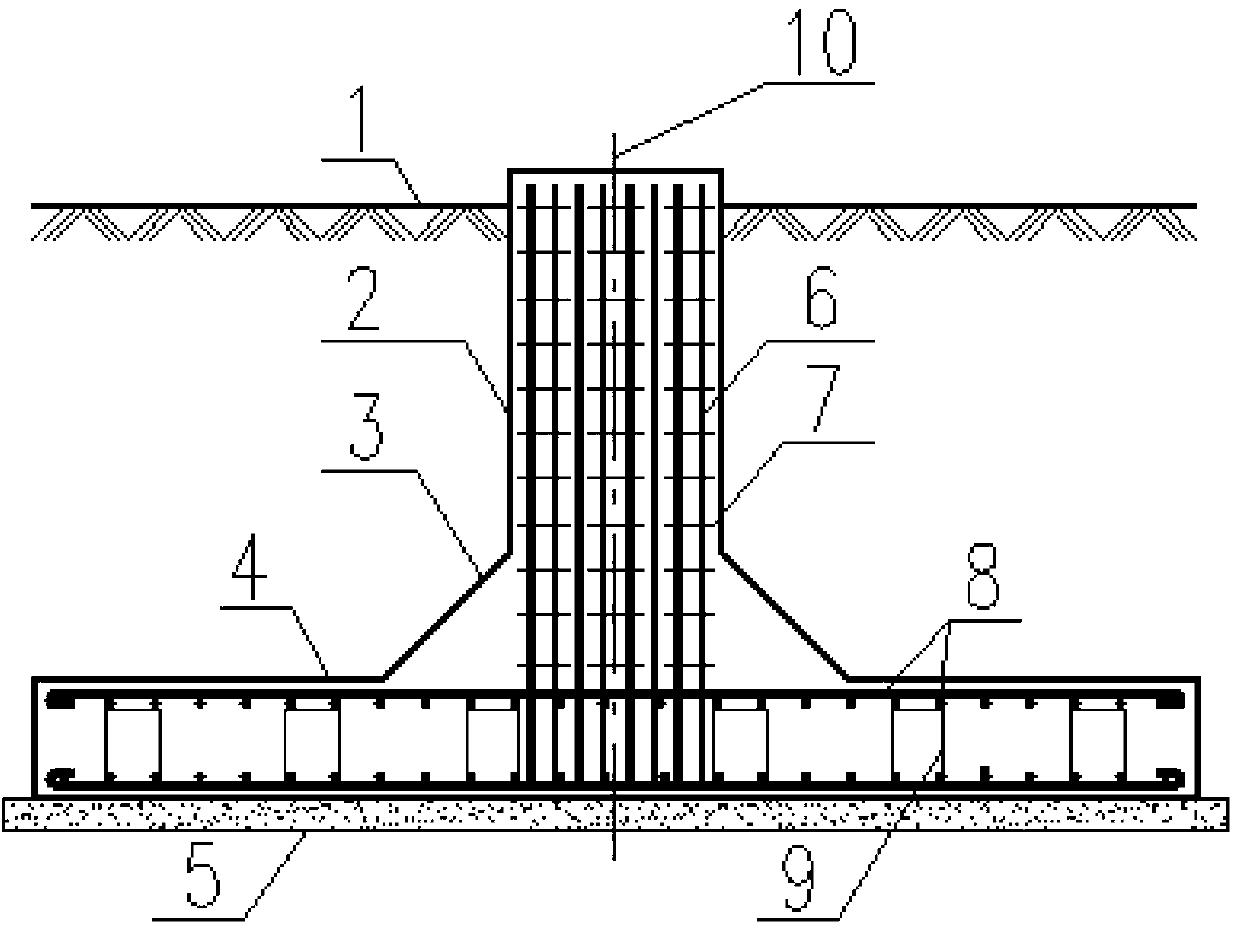

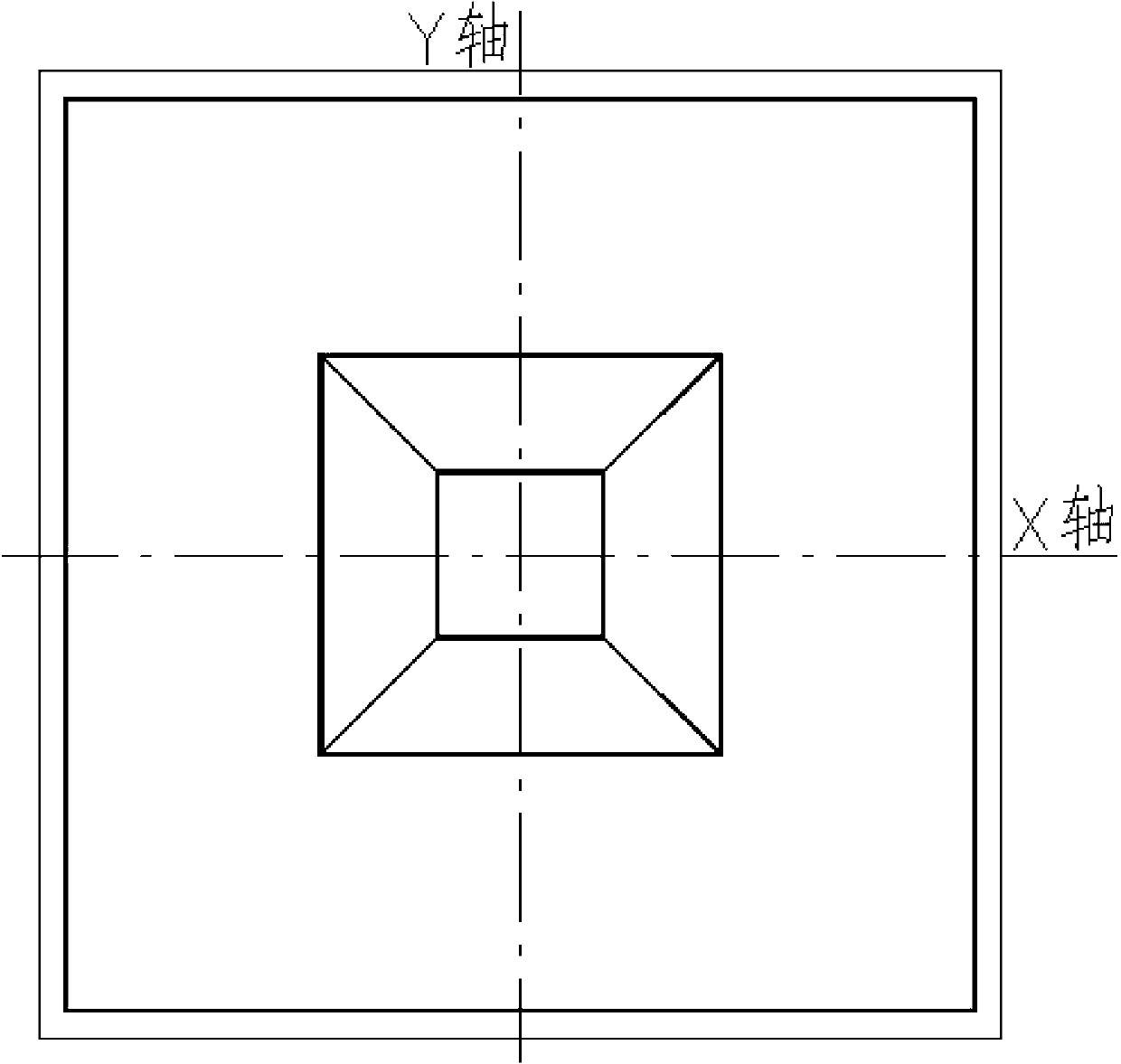

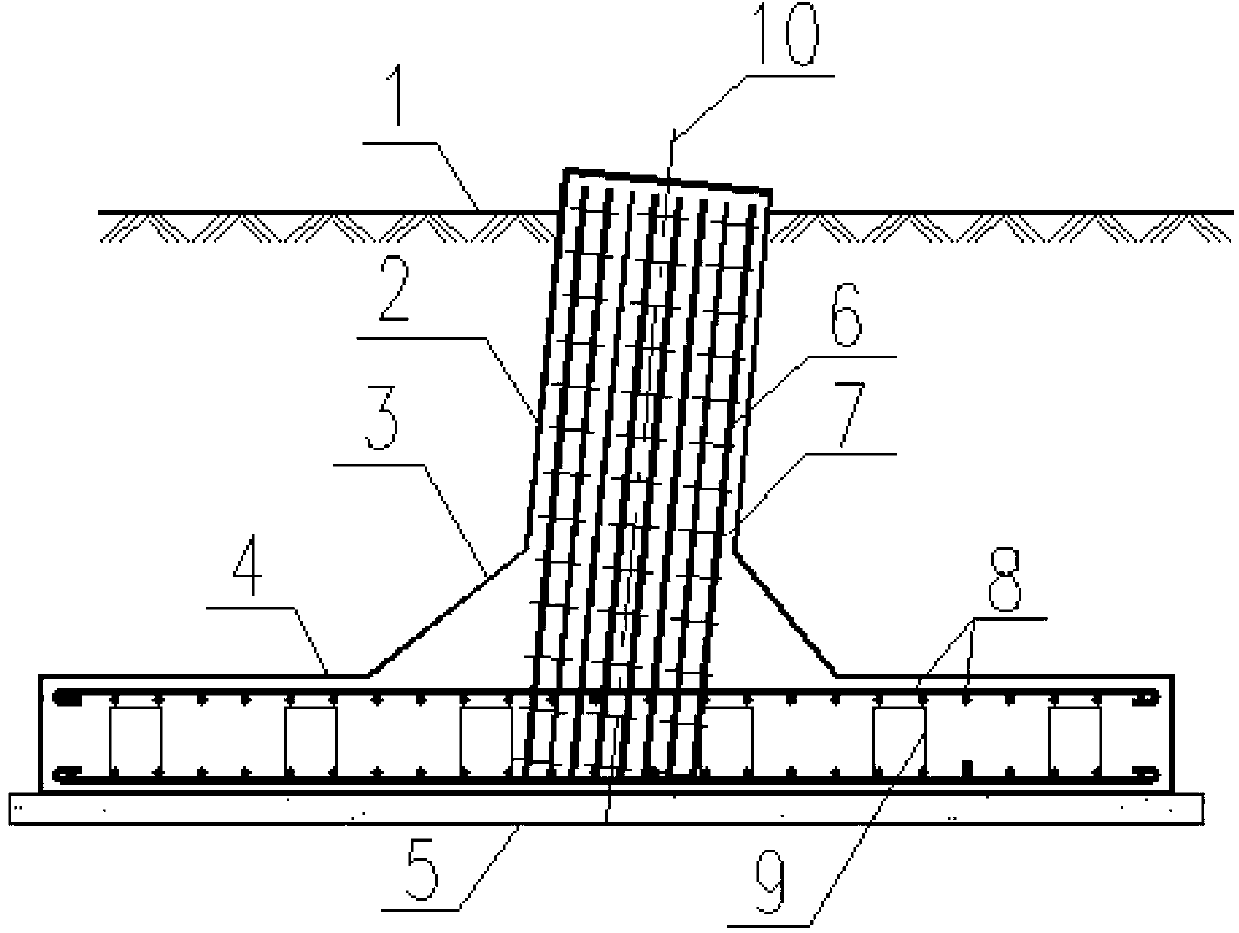

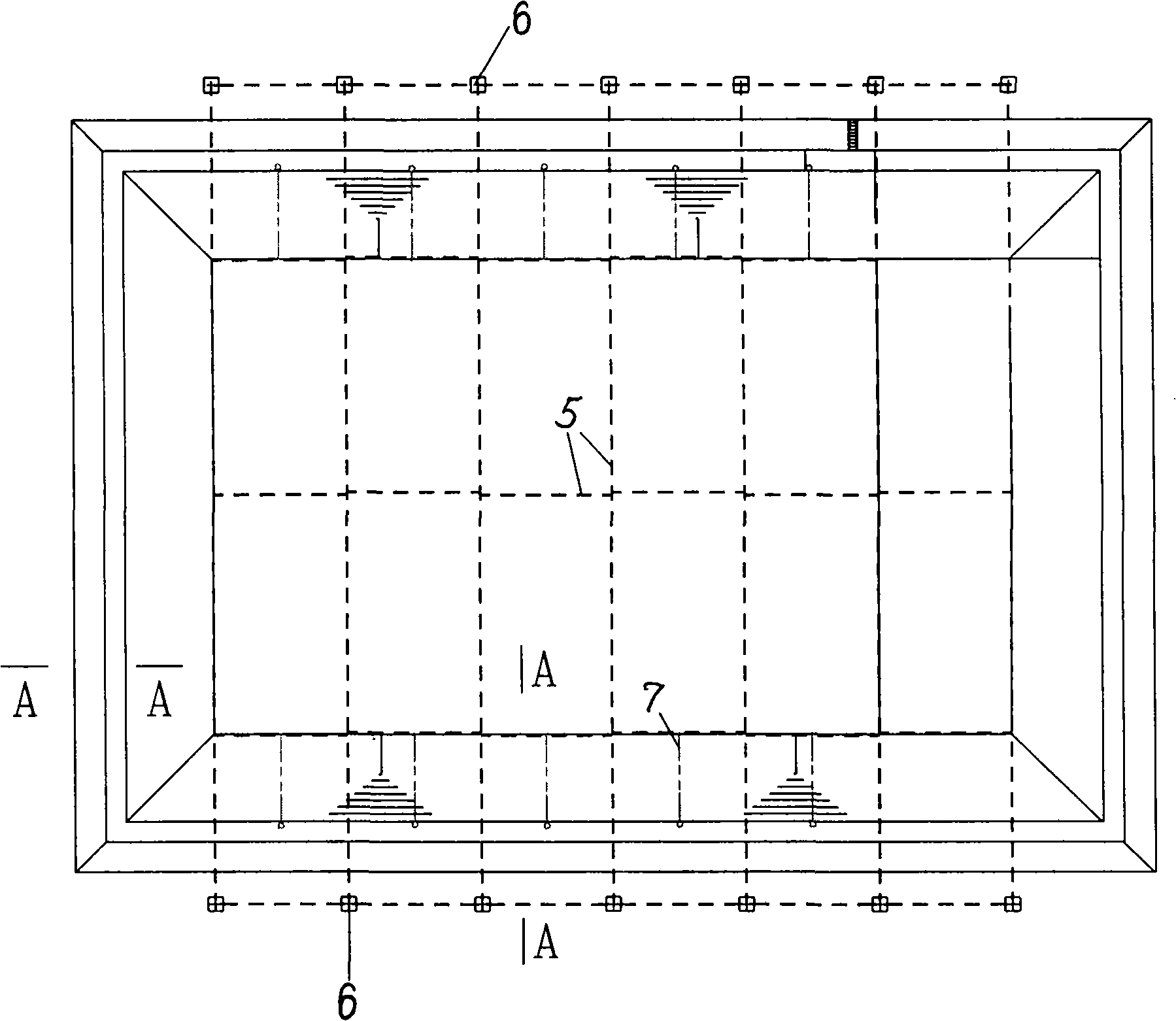

Method for anti-floating of underground building

ActiveCN101096852ANot to floatReduce buoyancyProtective foundationStructural engineeringCement paste

The invention discloses a method of underground structure against floating, which is characterized by the following: 1)adopting the following methods; a)arranging first drained hole (7)on lower of underground structure outside wall (5); b)arranging second drained hole (8)on underground structure bottom plate (3); c)arranging the first drained hole (7)on the lower of the underground structure outside wall (5); arranging the second drained hole on the underground structure bottom plate (3); 2)arranging drained tank (2)on the inner of the underground structure exterior wall; communicating with collecting well (1)in the underground structure; 3)discharging the water in the collecting well out of the underground structure; arranging third drained hole (9)on the wall of the collecting well (1); proceeding pressure poured cement paste under the underground structure bottom plate (3); change-filling backfill soil (6)of the underground structure outside wall (5)in the zone with big creep quantity. This invention possesses the advantages of simple and firm.

Owner:袁奕

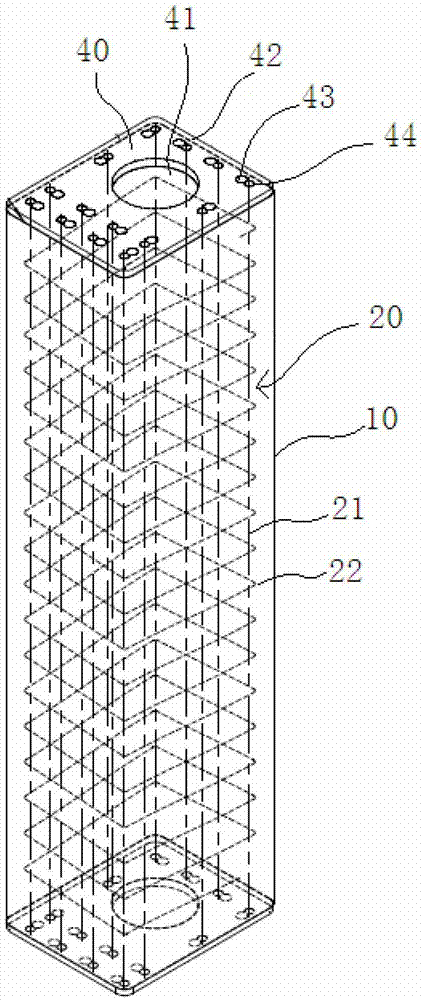

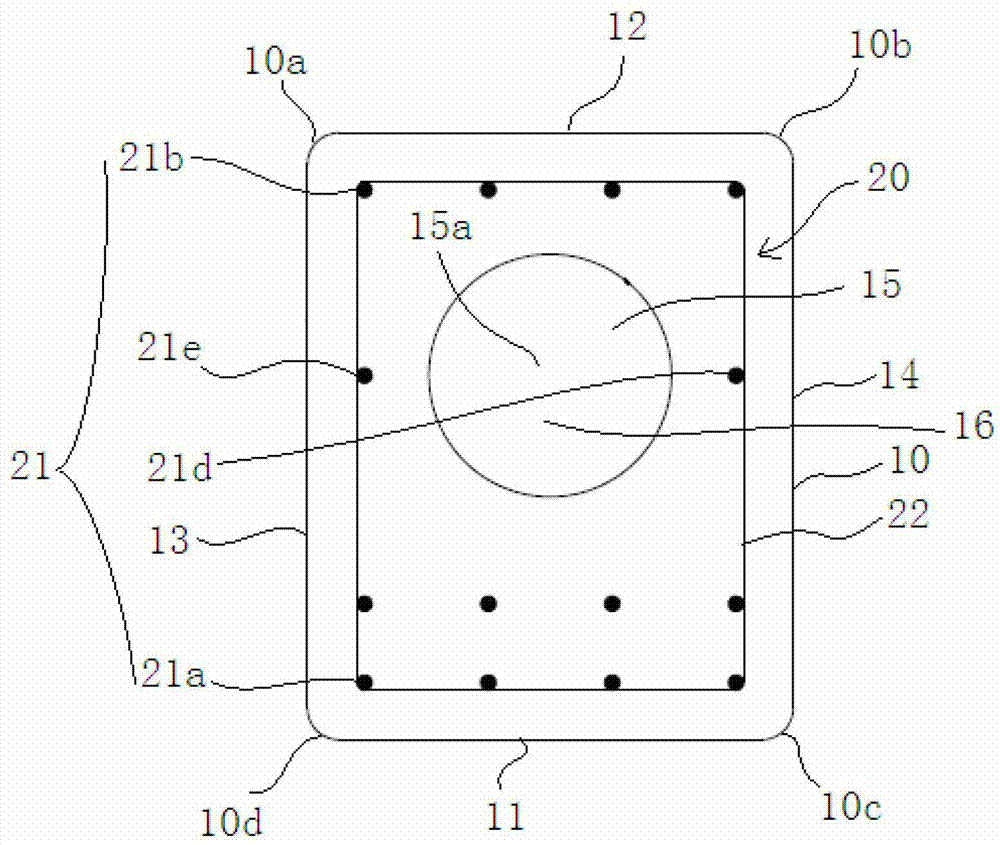

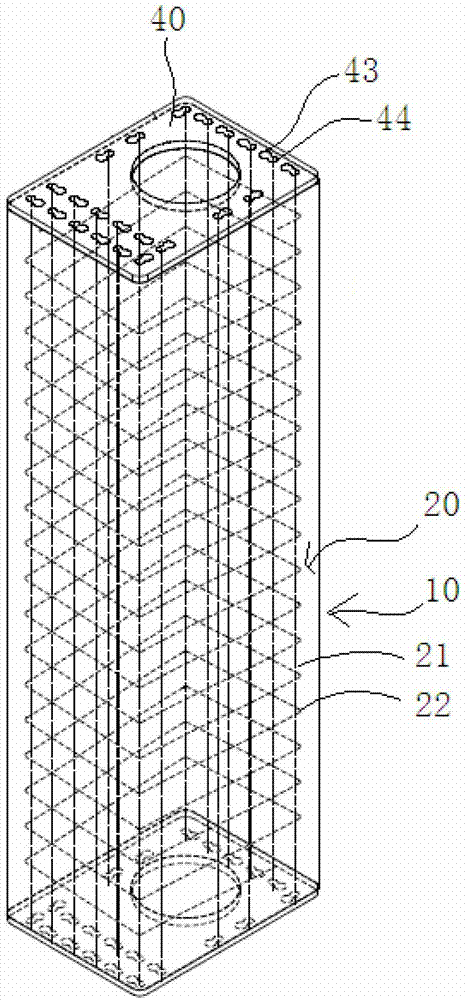

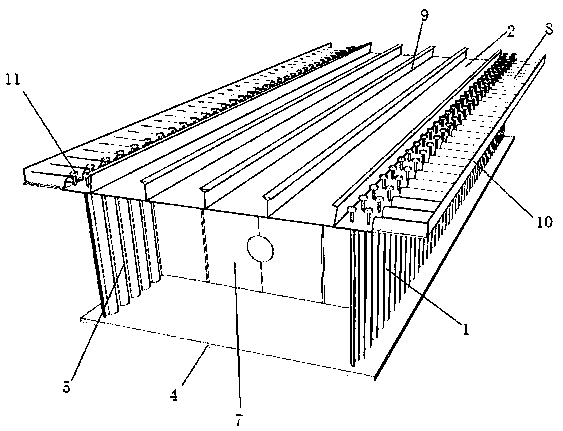

Non-uniform reinforcing bar prefabricated support pile as well as forming method and forming die thereof

InactiveCN102966093AReduce wall thicknessImprove the bending capacity of the sectionMouldsBulkheads/pilesRebarBearing capacity

The invention discloses a non-uniform reinforcing bar prefabricated support pile. The non-uniform reinforcing bar prefabricated support pile comprises a concrete pile body and a reinforcing bar cage arranged in the concrete along the axial direction of the pile body, wherein the reinforcing bar cage comprises a plurality of main steel reinforcing bars which are arranged in an axial parallel manner and are parallel to the axis of the pile body; the quantity of reinforcing bars on at least one side of the non-uniform reinforcing bar prefabricated support pile is greater than that of reinforcing bars on other sides of the non-uniform reinforcing bar prefabricated support pile; and the center of the non-uniform reinforcing bar prefabricated support pile is eccentric to the center of a pile body through hole. According to the non-uniform reinforcing bar prefabricated support pile disclosed by the invention, under the condition that the average reinforcement ratio of the section remains the same, the bent bearing capacity of the section can be improved; and the consumption of the reinforcing bars can be reduced when the bent bearing capacity of the section is same. The invention further discloses a method and a die for producing the non-uniform reinforcing bar prefabricated support pile.

Owner:SHANGHAI ZHONGJI PILE IND

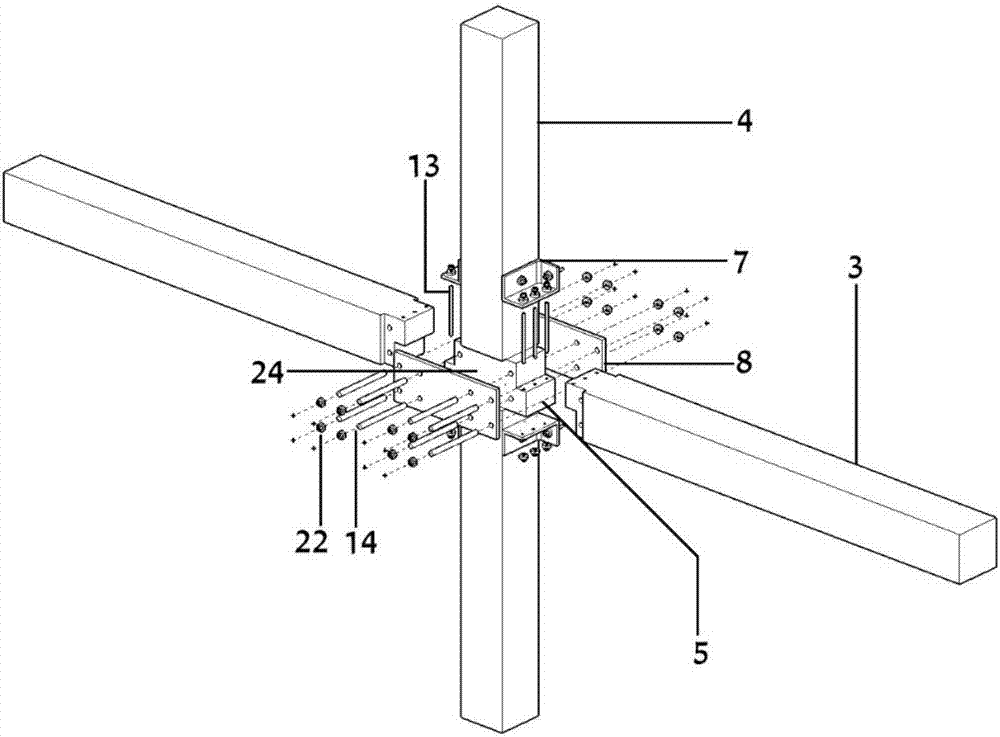

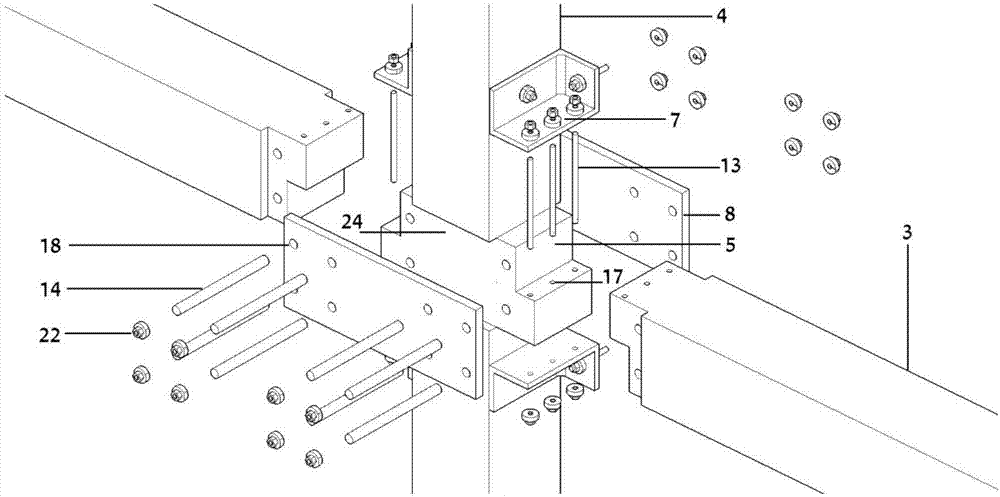

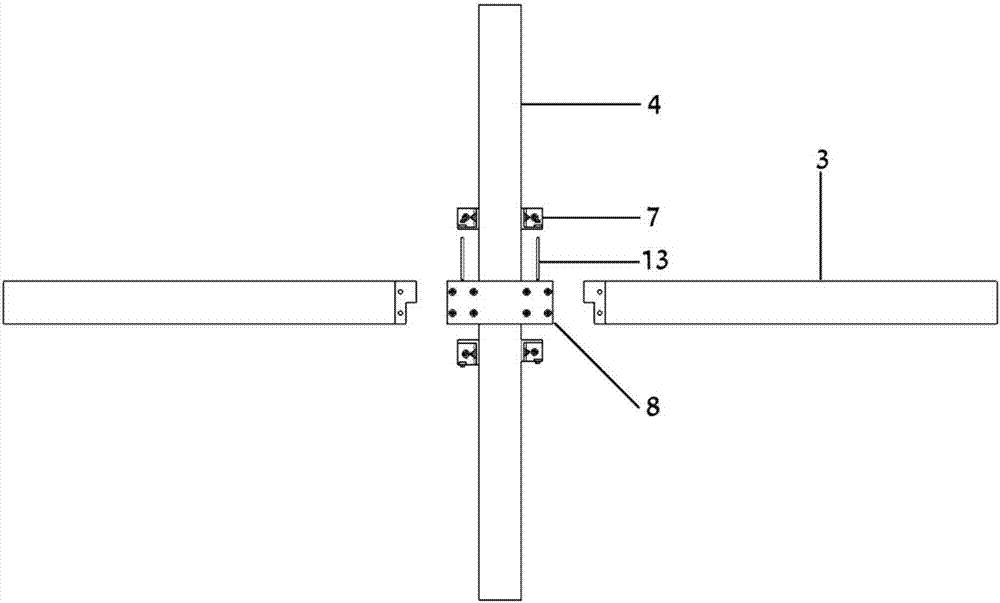

Novel controlled frame structural system with self-resetting energy dissipating brace

InactiveCN107806184ANo damageAvoid damageProtective buildings/sheltersShock proofingLateral stiffnessEngineering

The invention relates to a novel controlled swing frame system with self-resetting energy-dissipating supports, which belongs to the field of anti-seismic structural systems. It is mainly composed of frame columns, frame beams, self-resetting energy-dissipating supports, controlled beam-column nodes, controlled column foot nodes and foundations. The main controlled frame structure is subjected to vertical loads. When the structural system is subjected to an earthquake, the self-resetting energy-dissipating supports dissipate the seismic energy and provide lateral stiffness and restoring force to protect the main controlled frame structure from damage.

Owner:TONGJI UNIV

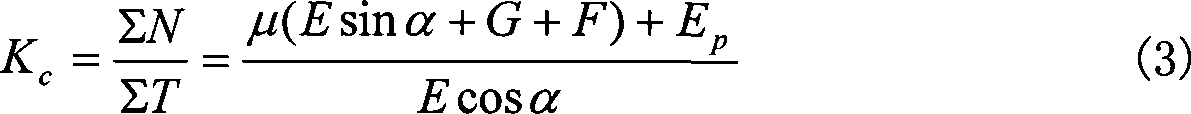

Foundation type for power transmission tower and bearing capacity calculation method for same

ActiveCN103343548AReduce dosageGood strengthFoundation engineeringTransmission towerReinforced concrete

The invention discloses a foundation type for a power transmission tower and a bearing capacity calculation method for the same. The foundation type comprises a reinforced concrete foundation pile partially buried below a design ground, concrete steps completely buried below the design ground, and a reinforced concrete bottom plate completely buried below the design ground, wherein the reinforced concrete foundation pile, the concrete steps and the reinforced concrete bottom plate are integrally poured, the concrete steps are cemented on the reinforced concrete bottom plate, the reinforced concrete foundation pile is cemented on the concrete steps, and the reinforced concrete foundation pile is connected with the concrete steps and the reinforced concrete bottom plate via foundation pile stressed steel bars; a concrete cushion is paved below the reinforced concrete bottom plate, a plurality of bottom plate stressed steel bars and a plurality of bottom plate stirrups are arranged in the reinforced concrete bottom plate, and the bottom plate stirrups are bound on the bottom plate stressed steel bars. According to the foundation type for the power transmission tower and the bearing capacity calculation method for the same disclosed by the invention, the dosages of foundation bottom plate concrete and steel bars are furthest saved on the premise of meeting requirements on the bearing capacity of the foundation, thus saving engineering cost and construction cost.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

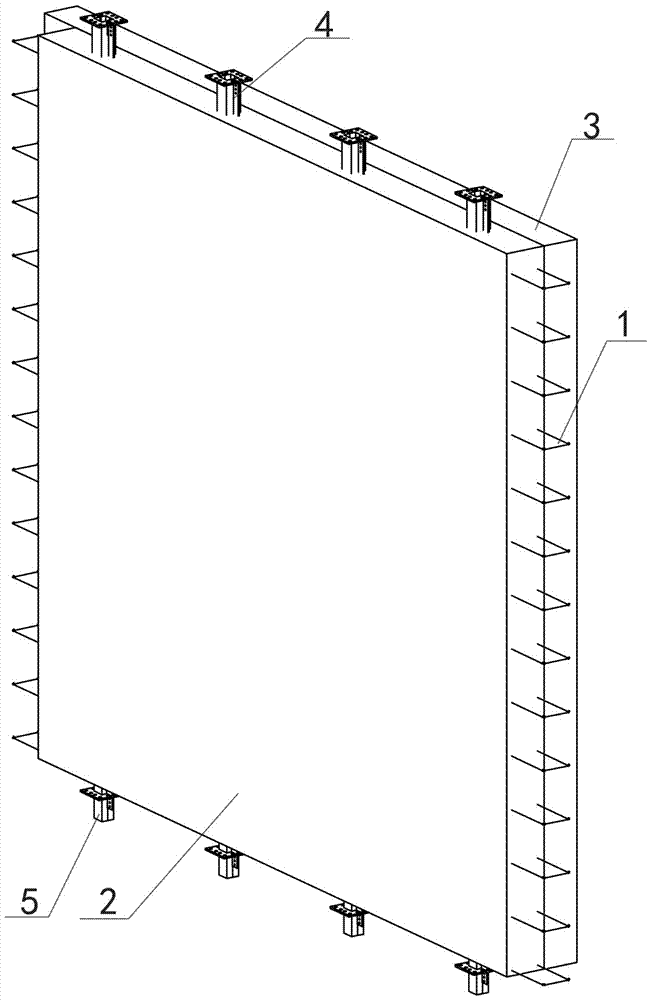

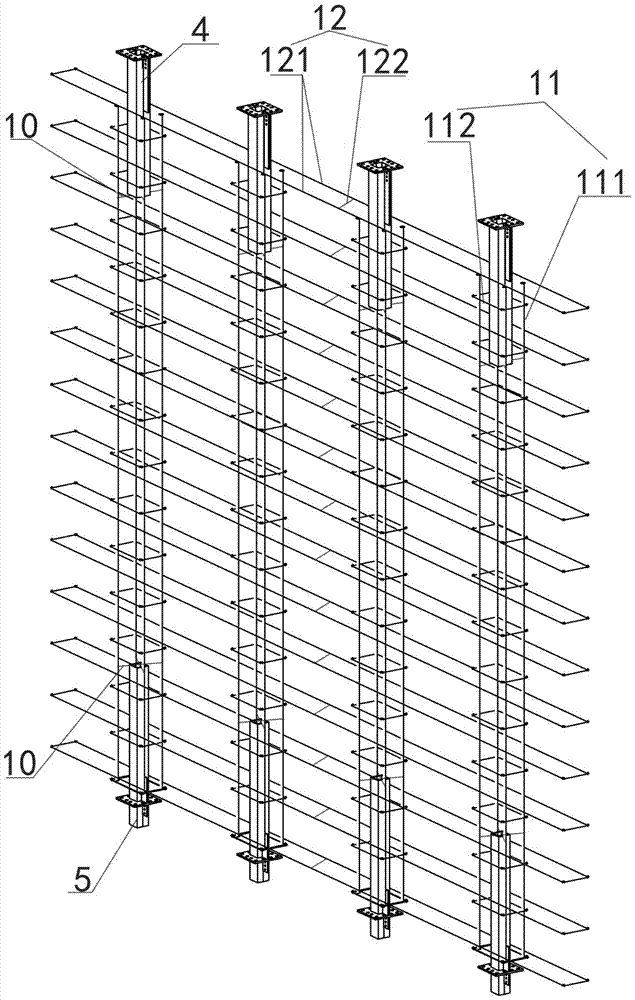

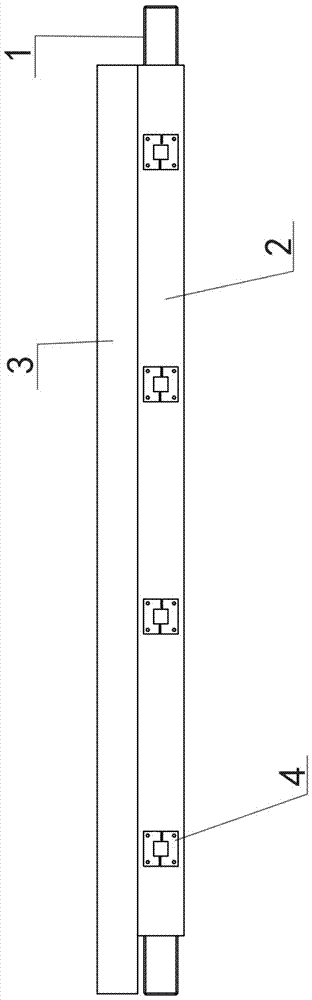

Prefabricated core column type self-insulating exterior wall plate, connecting structure and construction method thereof

PendingCN107386492AClear forceImprove ductilityWallsCeramic shaping apparatusFoam concreteReinforced concrete

The invention relates to a prefabricated core column type self-insulating exterior wall plate, a connecting structure and a construction method thereof. The exterior wall plate comprises a wall body and a connecting piece which is vertically connected with the wall; the wall is formed by combining a reinforced concrete structure layer and a foam concrete insulating layer; the reinforced concrete structure layer comprises a structure layer steel framework and structure layer concrete; the foam concrete insulating layer is made of foam concrete; the structure layer steel framework comprises a core column reinforcement cage and horizontal reinforcing steel bars; each horizontal reinforcing steel bar comprises two long reinforcing steel bars; a wall top connecting piece is inserted in the top of the core column reinforcement cage in an embedded manner; and a wall bottom connecting piece which is used with the wall top connecting piece is inserted in the bottom of the core column reinforcement cage in an embedded manner. By the prefabricated core column type self-insulating exterior wall plate, the degree of industrialization and assembling is improved effectively, the bearing ability, ductility and anti-seismic property of the wall are improved comprehensively, and purposes of integration of structure insulation, reliable connection between an upper wall body and a lower wall body and convenience in mounting are achieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

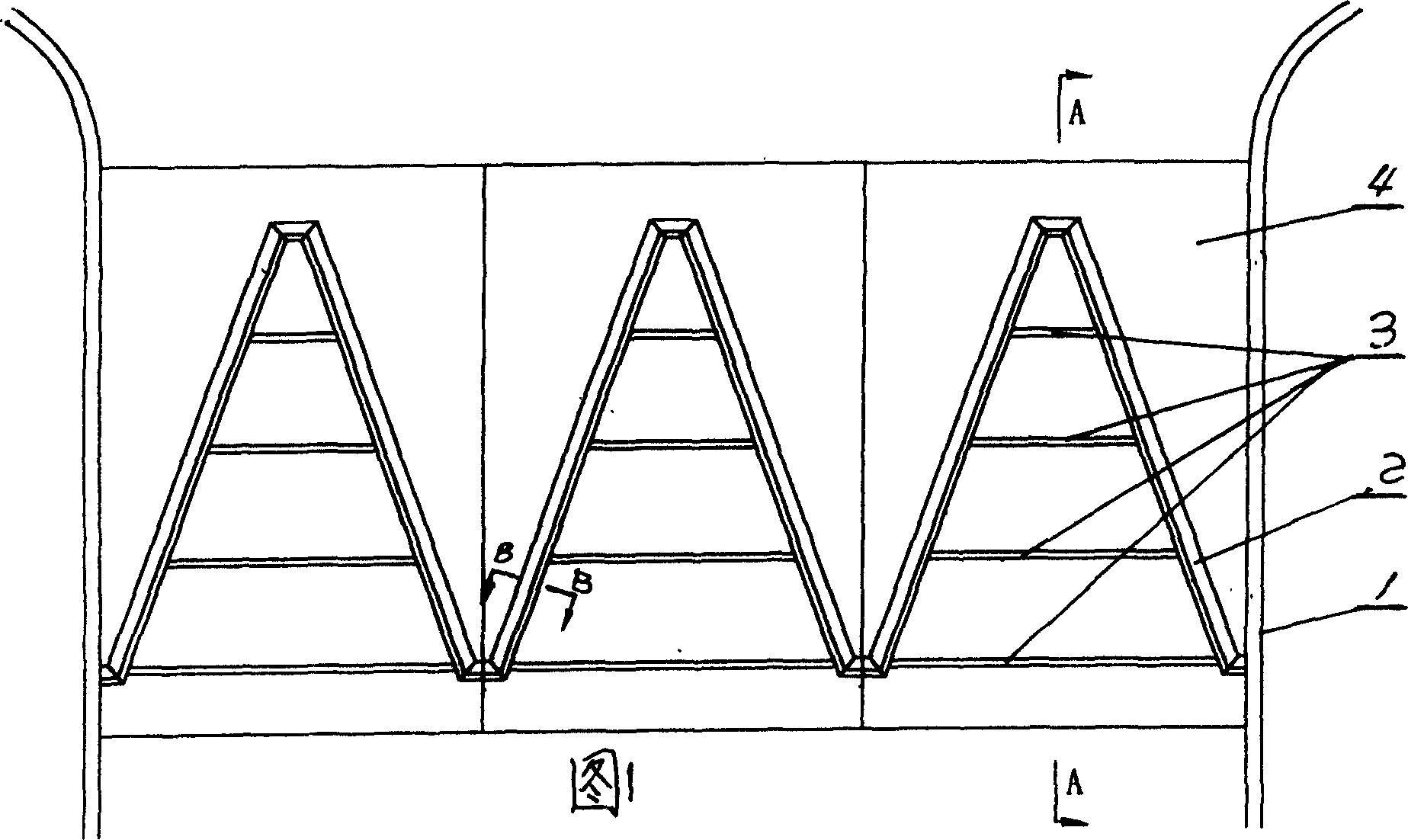

Supporting type labyrinth barrage

InactiveCN1558042AReduce section sizeReduce the amount of reinforcementBarrages/weirsEngineeringStressed state

The supporting labyrinth weir includes underplate and labyrinth weir walls, and features that in the upper part of two-to-two opposite weir walls, horizontal supporting beam is set and the outmost support beam is horizontal supporting beam or inclined supporting beam with upper end connected to the weir walls and the lower end to the underplate. Owing to the horizontal support beams in the equal distance and in the upper part of outside the weir walls, there are no cantilever beam stress state resulting in small size of weir wall and underplate cross section size, less reinforcing bars and low engineering cost.

Owner:贾树宝

Reinforced structure connected by steel angles and method for all-fabricated external attached frame

ActiveCN106988551AImprove the state of stressImproved Warp ModeBuilding repairsStressed stateEnergy consumption

The invention discloses a reinforced structure connected by steel angles and method for an all-fabricated external attached frame. The structure comprises a to-be-reinforced original frame structure and an external attached frame structure, the external attached frame structure comprises prefabricated beams and prefabricated columns, notches are formed in the ends of the prefabricated beams, and hidden brackets extend out of the two sides of joint core areas of the prefabricated columns; the ends, the hidden brackets and the joint core areas of the prefabricated beams are all partially weakened, and steel plates are embedded in the weakened areas; the ends of the prefabricated columns are weakened partially, and steel sleeves are embedded in the ends of the prefabricated columns; and three-side steel angles are arranged at the corners of connected joints of the prefabricated beams and the prefabricated columns, the prefabricated beams and the prefabricated columns are connected with the beams and the columns of the original frame structure through the steel angles, and the prefabricated columns at the lower ends are connected with the prefabricated columns at the upper ends through the steel sleeves and pull bolts. The external attached frame structure not only contributes to the anti-seismic capacity of the whole reinforced structure through the anti-seismic bearing capacity and the energy consumption capacity, but also can improve the stress state and deformation mode of the original structure, so that the structure forms a damage yield mechanism, and the anti-seismic capacity of the original structure is fully utilized.

Owner:SOUTHEAST UNIV

Fabricated light-weight energy consumption wall component of shear wall

InactiveCN103669644ASolve self-importanceSolve the problem of low prefabrication level of interior wallsWallsShock proofingReinforced concreteShearing deformation

The invention discloses a fabricated light-weight energy consumption wall component of a shear wall. The wall component comprises a reinforced concrete wallboard. Holes are arranged in the reinforced concrete wallboard, energy consumption parts are fixed in the holes and comprise hole pre-burying boards, connecting plates and yielding energy consumption steel plates, the hole pre-burying boards are pre-buried in the reinforced concrete wallboard, the connecting plates are vertically and medially connected to inner sides of the hole pre-burying boards, and the top and bottom of each yielding energy consumption steel plate are connected with the corresponding connecting plate. According to the wall component, the holes are arranged, so the weight of the component is lightened, earthquake force borne by the wall is reduced, the component can be conveniently transported, transportation cost is reduced, meanwhile hoisting pressure in the construction process is relieved, construction safety is guaranteed, and construction efficiency is improved; the steel plate shear wall type energy consumption parts are arranged in the holes, shear deformation of hole positions occurs under the action of shear force, energy consumption of the steel plates is achieved through buckling, damage to the concrete wallboard can be reduced, and safety of the shear wall under the earthquake action is effectively guaranteed.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

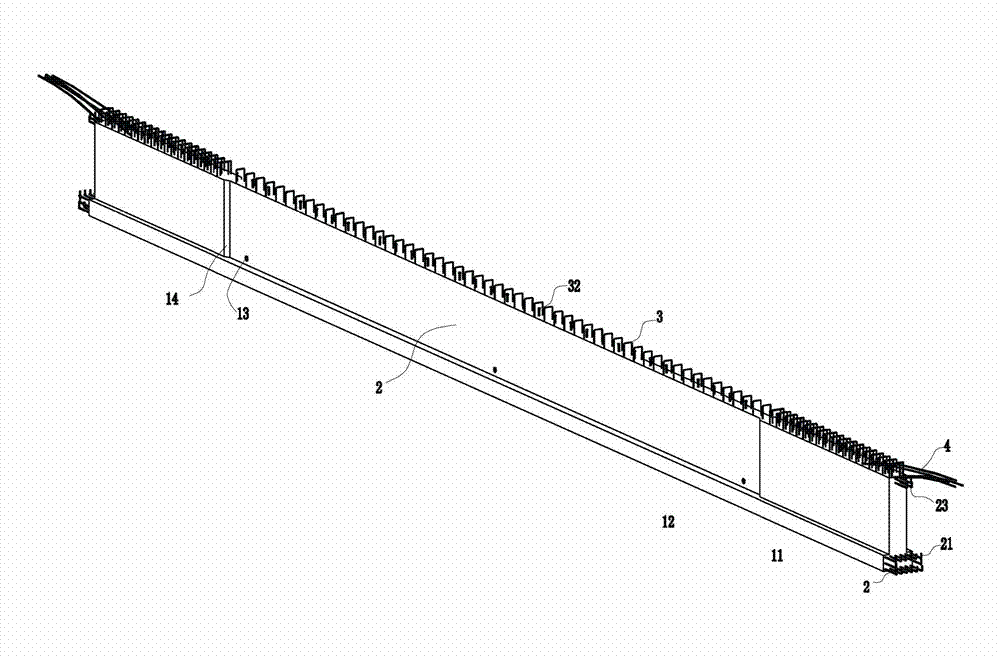

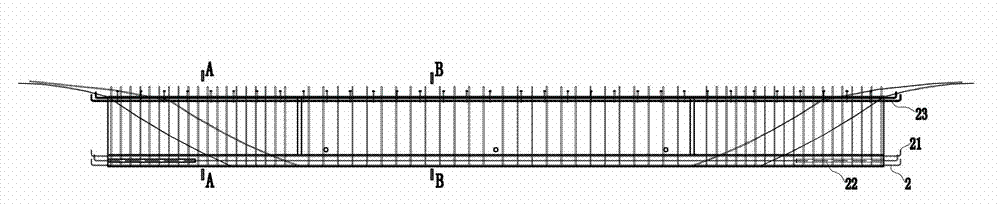

Assembly type corrugated steel web steel and concrete composite beam bridge and construction method

PendingCN110424242AAvoid fatigue damageLight weightBridge structural detailsBridge materialsBridge deckEngineering

The embodiment of the invention discloses an assembly type corrugated steel web steel and concrete composite beam bridge and a construction method. The assembly type corrugated steel web steel and concrete composite beam bridge comprises a steel box beam, a profiled steel plate arranged at the top of the steel box beam and a bridge deck slab arranged at the top of the profiled steel plate, whereinthe steel box beam comprises a steel bottom plate, corrugated steel webs, an upper wing plate and partition plates; the corrugated steel webs are welded on the steel bottom plate and are positioned on the two sides of the steel bottom plate; and the bottom edges of the partition plates are connected to the steel bottom plate, the two sides of the partition plates are connected with the corrugatedsteel web, and the upper wing plate is arranged at the top of the corrugated steel web plate. The assembly type corrugated steel web steel and concrete composite beam bridge is convenient to assembleand construct, and can guarantee the quality of bridge prefabricated members during transportation.

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +2

Straddle type monorail underground section rail wall structure and construction method thereof

The invention relates to the technical field of monorail traffic rails, in particular to a straddle type monorail underground section rail wall structure and a construction method thereof. The structure comprises an upper prefabricated wall, a lower cast-in-situ wall and a foundation structure, wherein the upper prefabricated wall is a prefabricated structure, and internal reinforcements downwards extend out ofthe lower surface of the prefabricated structure; and the lower cast-in-situ wall is a cast-in-situ structure, comprises the internal reinforcements of the upper prefabricated wall, extends into the foundation structure, and forms an integrated cast structure with the foundation structure. No buttresses need to be arranged at two sides of the structure; after the buttresses are omitted, the buttress occupation space under the traditional rail beam condition is omitted in the art; and the tunnel end surface is decreased.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

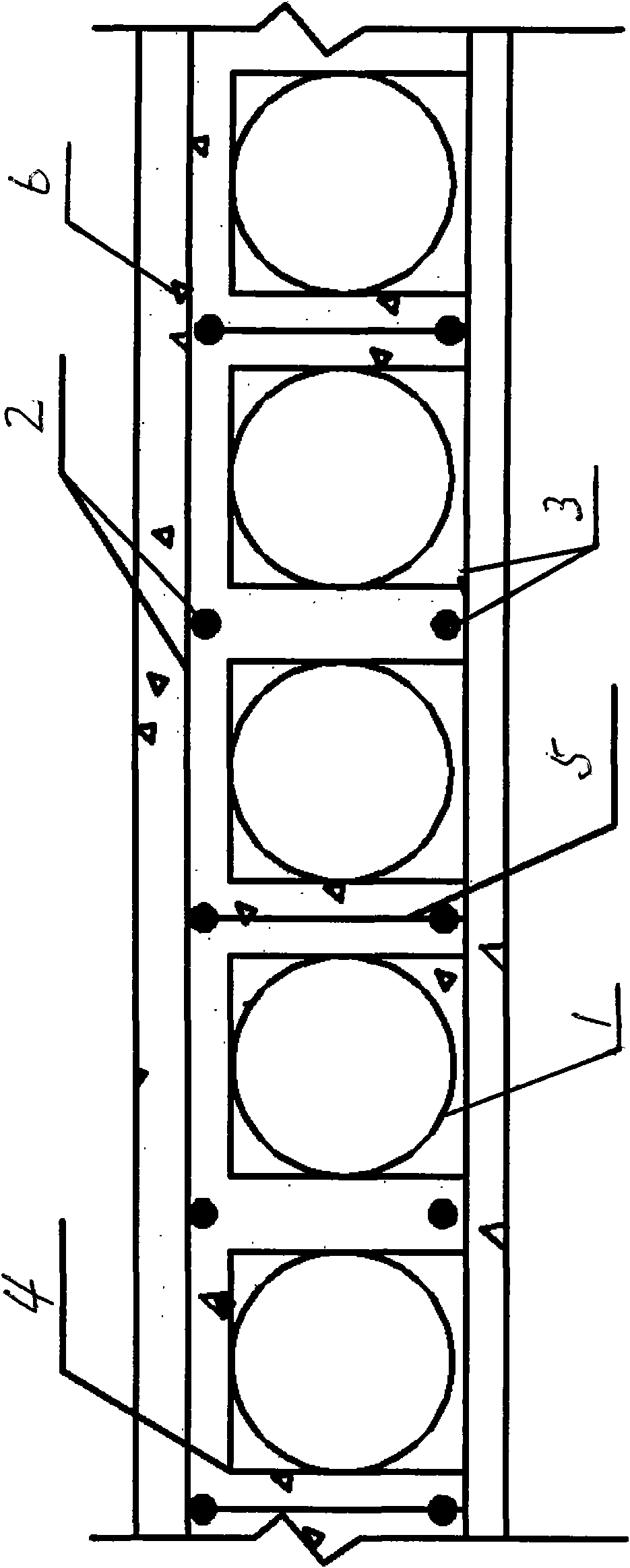

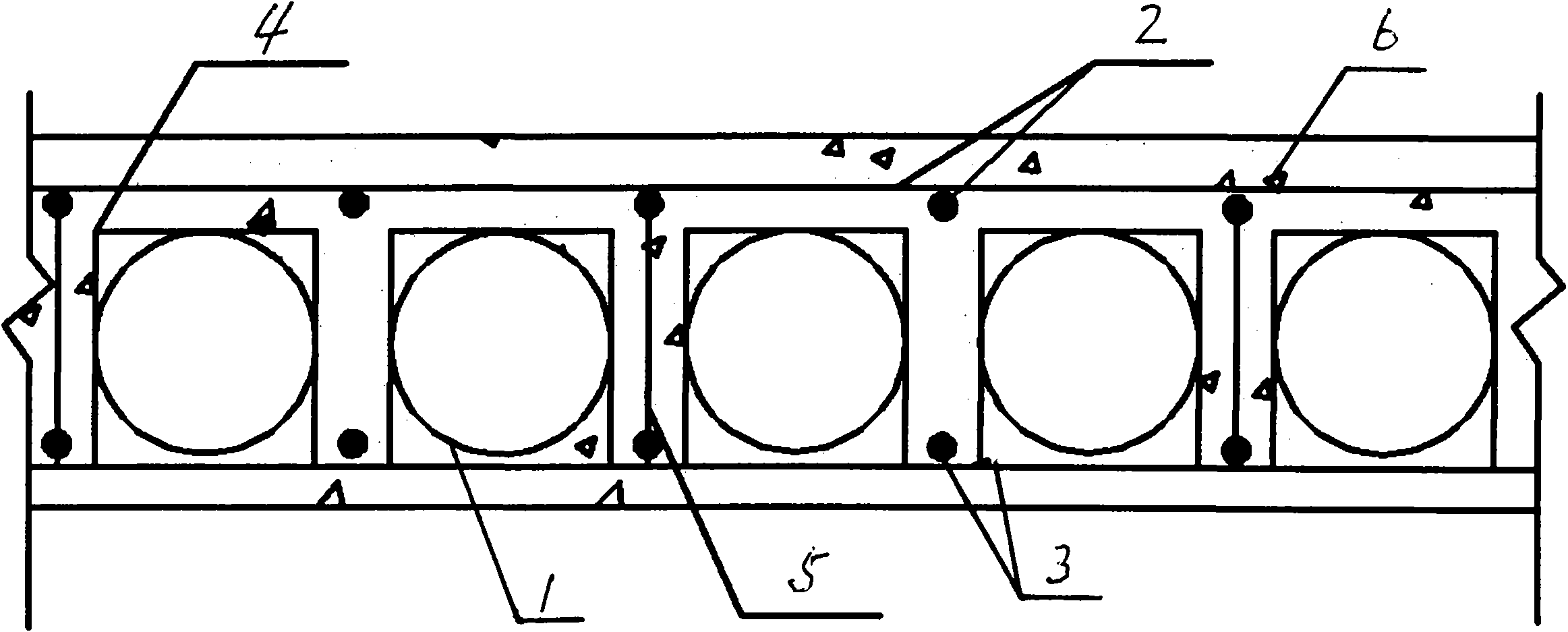

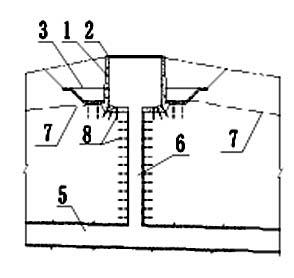

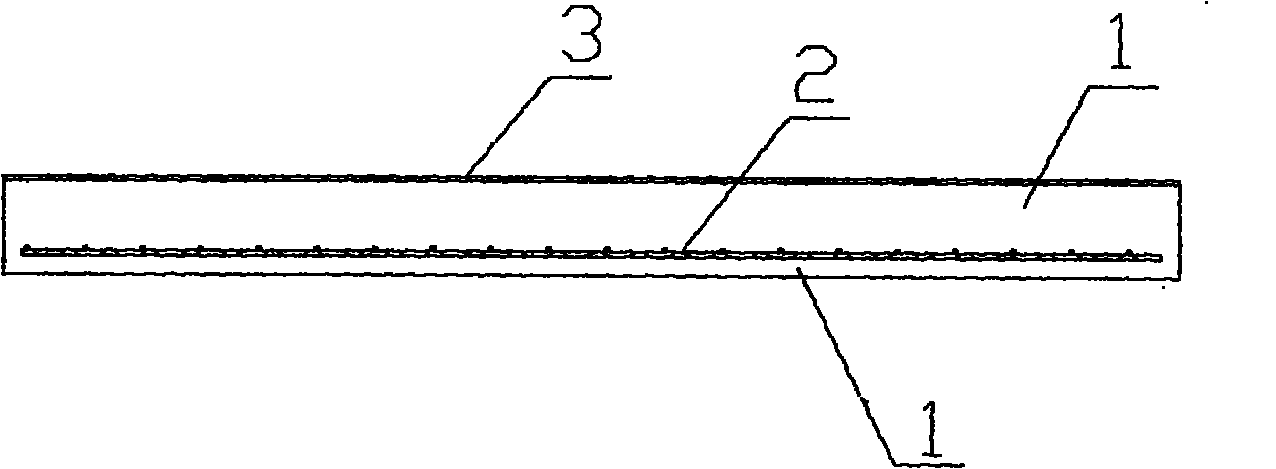

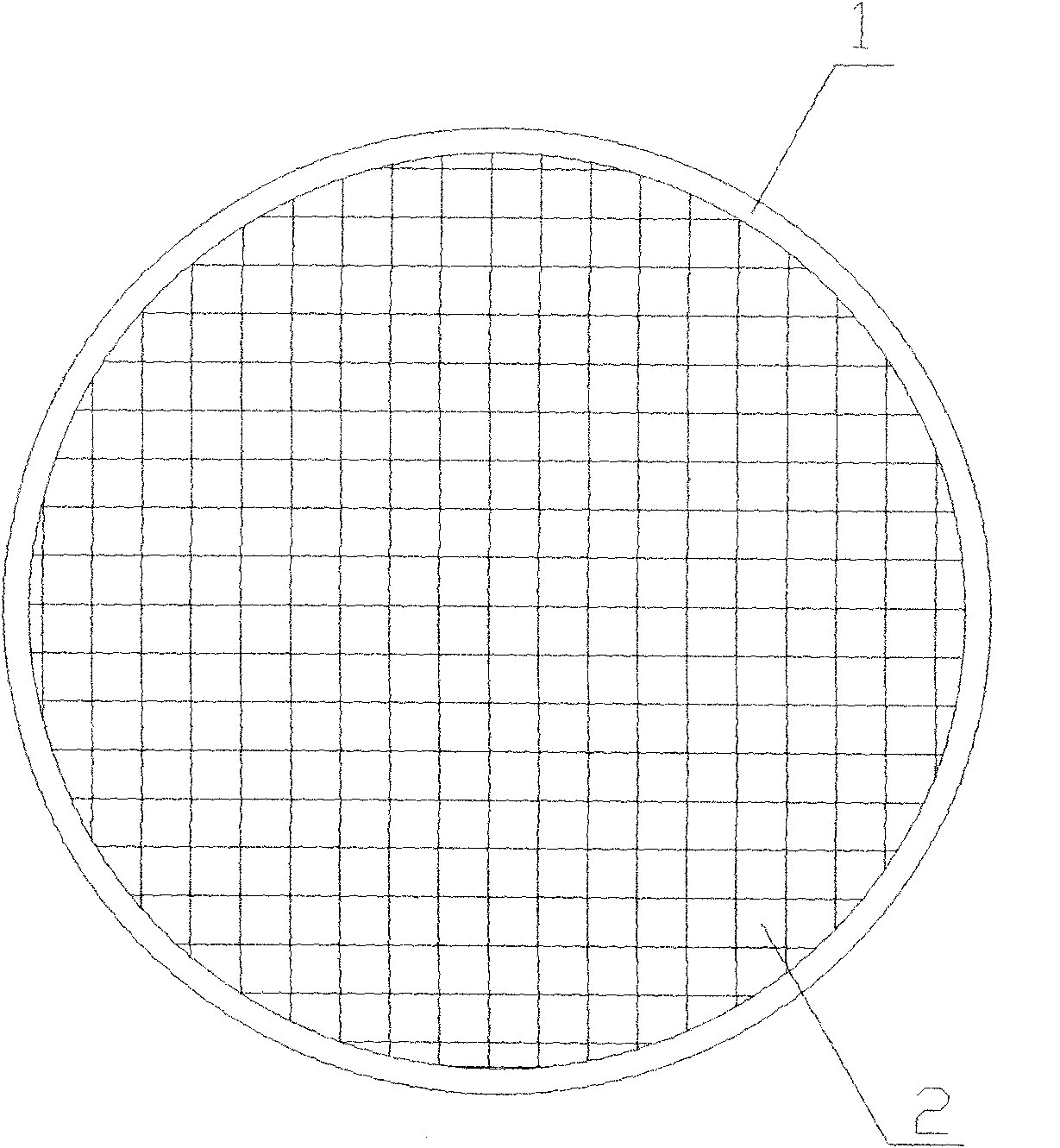

Thin-wall internal-mould large-thickness hollow floor plate

The invention discloses a thin-wall internal-mould large-thickness hollow floor plate comprising a layer of totally-closed core pipes in circular pipe shapes, reinforcing meshes and pouring concrete, wherein the reinforcing meshes are respectively arranged above and below the layer of core pipes; a pressure pipe reinforcing bar is tightly close to and surrounds each core pipe, and a row of vertical anti-floating reinforcing bars are arranged at intervals of every 2-4 core pipes; and the pouring concrete is filled among the core pipes, the reinforcing meshes and the pressure pipe reinforcing bars and on the upper surface of the upper reinforcing mesh. The thin-wall internal-mould large-thickness hollow floor plate is in a double-layer reinforcing bar structure, the core pipes are positioned in the middle of the pouring concrete to form a hollow structure so as to become a permanent core mould, and the problems of fixation and floating of the core pipes in the concrete pouring process are solved through the structure. The invention has the advantages of fast construction, convenient installation, heat insulation and good sound insulation performance, can effectively reduce the self weight, correspondingly decreases girders, columns and walls which support the floor plate and foundation loads and greatly reduces the quantity of reinforcing bars as structural members.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Low cost energy-consumption shock-dampening method, the related device and its usage method

InactiveCN1884756AReduced precision requirementsOn-site work is simple and easyShock proofingSteel platesReinforced concrete

The invention relates to a damping method with low cost and energy consumption, relative device and method, wherein the invention uses X-shape steel bar concrete rod as support element; uses steel plate clamp rubber sheet as friction energy consumer; connects four ends of steel bar concrete rod to the beam nodes of building frame; in said energy consumer, functions some fixing force on the steel plate of clamp rubber sheet, to generate stable friction between the rubber sheet and steel plate as the starting force of energy consumer that absorbs output kinetic energy; and adjusts the fixing force to adjust the starting force. The invention has low cost, high appearance, simple production and easy operation. Compared with traditional structure, the concrete and steel bar consumptions are reduced most.

Owner:KUNMING UNIV OF SCI & TECH

Irregular-shaped precast beam used for bridges

An irregular-shaped precast beam used for bridges comprises a reversed T-shaped beam body and a prestress steel strand which is embedded in the middle of the beam body and serves as a main reinforcing-bar. The beam body comprises a web, wherein a stirrup is arranged on a bottom flange web, and the stirrup extends out of the upper surface of the beam body. The irregular-shaped precast beam used for bridges is characterized in that through holes traversing partition board main reinforcing-bars are arranged on the lower portion of the beam body web along the longitudinal direction at intervals. The cross sections are simple in shape, and templates with single specifications and strong generality can be adopted to manufacture, thereby greatly lowering mold cost.

Owner:杨众 +1

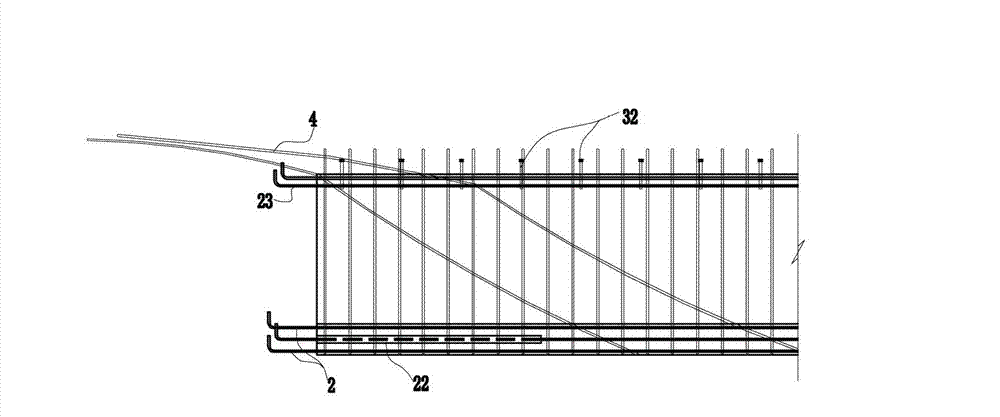

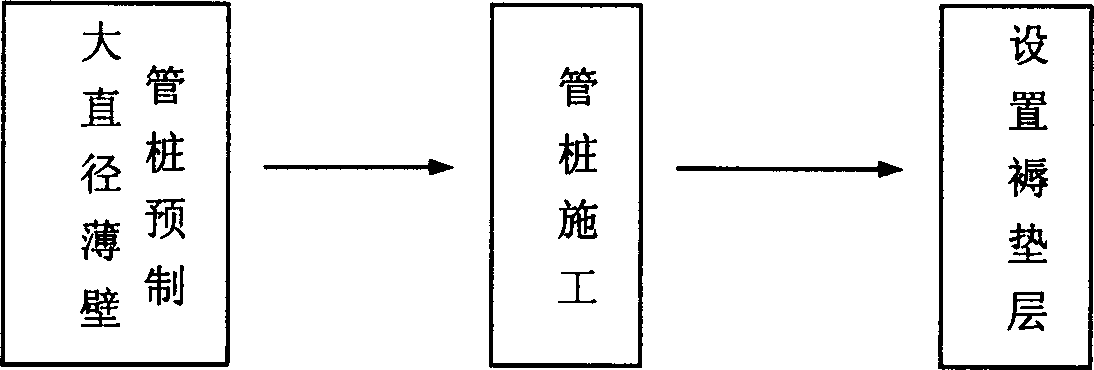

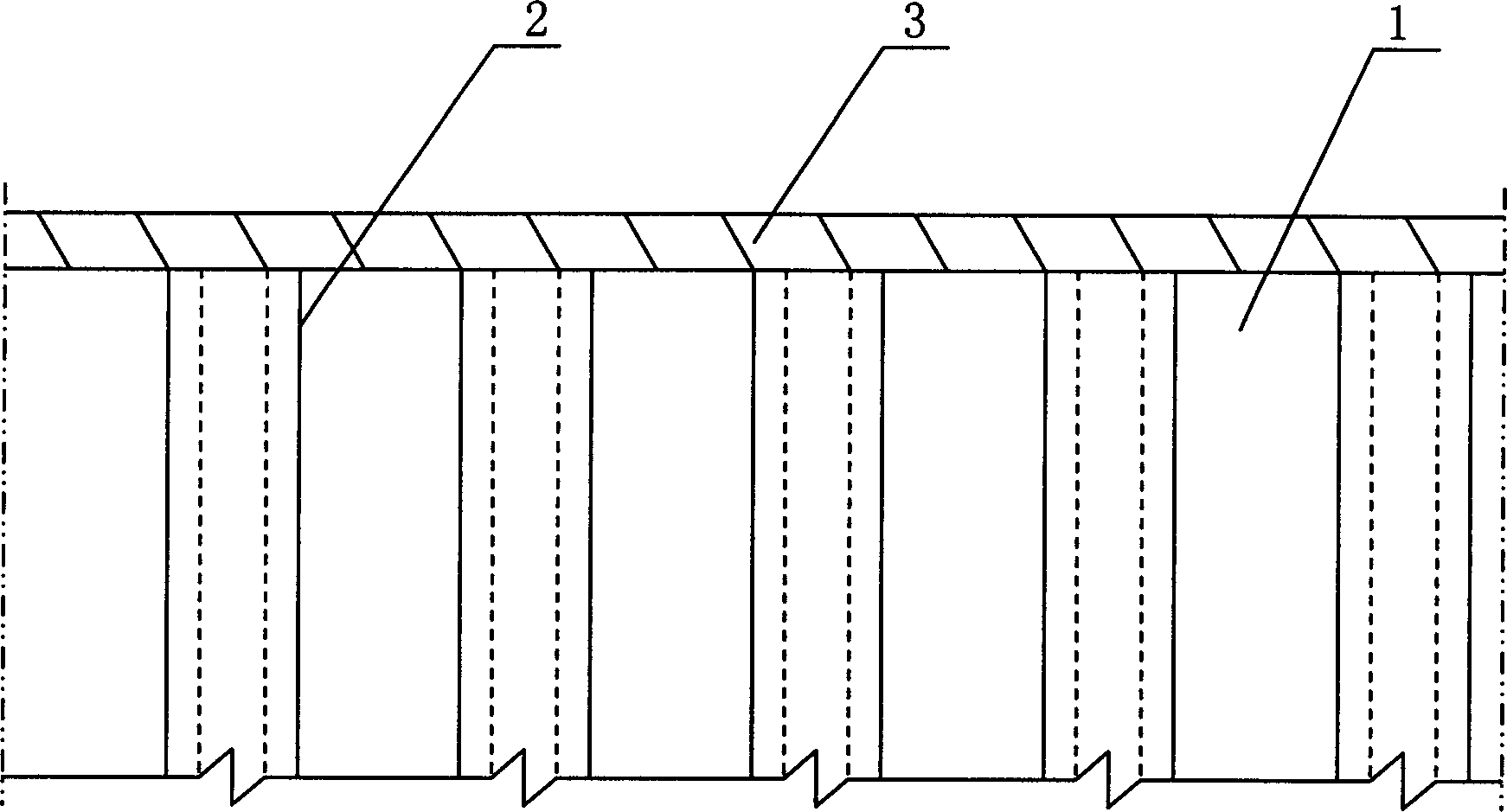

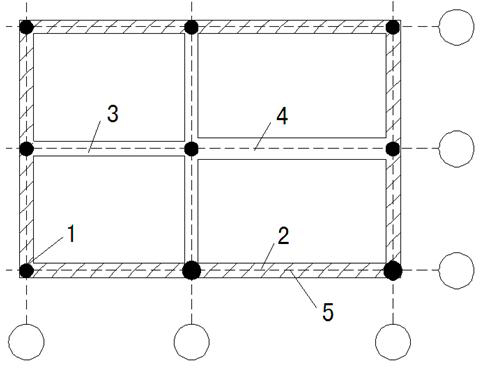

Method of reinforcing soft base using large diameter thin wall pipe pole composite ground

InactiveCN1556283AReduce penetration resistanceFast constructionBulkheads/pilesDistortionThin walled

The method includes following steps: (1) prefabricating big and thin wall pipe piles; (2) according to designed reinforcing requirement, punching or pressing the said prefabricated pipe piles into base of foundation in soft clay by using construction machinery; (3) setting mattress layer on top of pipe piles to assort with distortion and stress of pile ground. Advantages are convenient construction, low cost, fast, adjusting distortion of pile ground so as to ensure piling quality and suit reinforcing base of foundation in soft clay.

Owner:GUANGDONG PROVINCE HANGSHENG CONSTR GRP

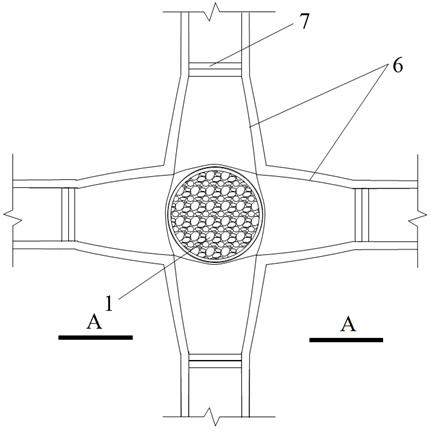

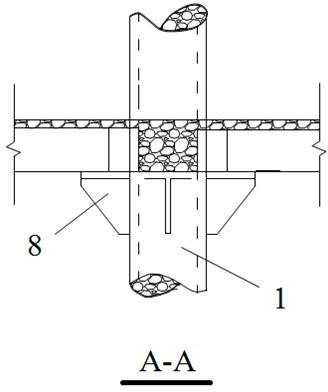

Steel pipe reactive powder concrete column-flat beam-shear wall structure system

The invention relates to a steel pipe reactive powder concrete column-flat beam-shear wall structure system, which comprises steel pipe concrete columns, reinforcing steel bar concrete beams and reinforcing steel bar concrete shear walls, wherein each steel pipe concrete column is a steel pipe reactive powder concrete column formed by pouring reactive powder concrete, and each reinforcing steel bar concrete beam is a flat beam, namely the width of each reinforcing steel bar concrete beam is larger than or equal to the height of the same. Since the compression strength of the reactive powder concrete (RPC) is 4-10 times of that of common concrete, the RPC and steel pipes are combined to form the steel pipe RPC columns, the section size of each column is greatly reduced, and the usable area of a building is increased. Additionally, the structure system has the advantages of a flat beam structure, such as capability of lowering story height, avoiding pipelines to penetrate through the beams and the like, thereby having extremely good comprehensive economic benefits and being suitable for large-scale popularization and application.

Owner:FUZHOU UNIVERSITY

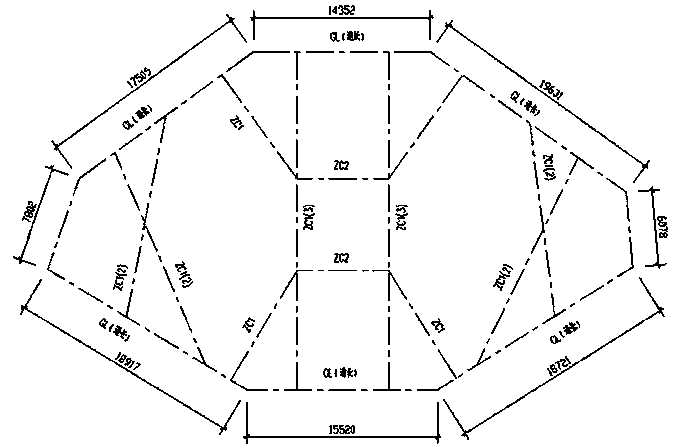

Method for laying rigid long piles and rigid short piles in deep foundation pit support engineering in thick-sludge soft soil area

The invention discloses a method for laying rigid long piles and rigid short piles in deep foundation pit support engineering in a thick-sludge soft soil area. The method comprises the following steps: A, collecting the building and structure construction drawings of the deep foundation pit support engineering to define the building elevation of an excavation surface; B, collecting the geologic reports of the deep foundation pit support engineering to learn the field description records and all physical and mechanical test indexes of the soil layers of a site within the range of influence of the deep excavation of a deep foundation pit; C, adopting analysis software to perform routine computation and analysis to all support sections to determine the diameters and lengths of the support piles and the reinforcing bars of pile bodies, and using a design method that the long piles and the short piles are arranged at intervals to perform check designing to section unit bodies. When the short piles are designed, the inserting depths and the reinforcing bars of the pile bodies as well as the diameters of the short piles are determined according to the local traditional experiences of a construction area. According to the method, not only the requirements of all the safety factors required by the computation of the support section unit bodies are met, but also the gaps between the long piles are filled with the short piles, so that the creep deformation of soil bodies between the support piles is controlled, the concrete consumption of the support piles and the consumption of the reinforcing bars of the pile bodies are reduced; the material cost is greatly lowered.

Owner:浙江天然工程勘察有限公司

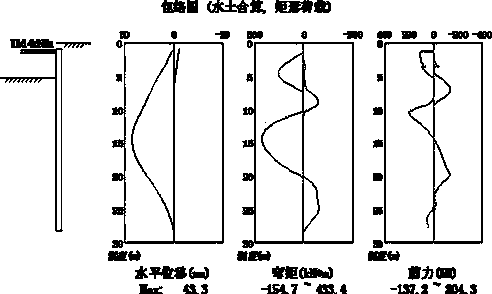

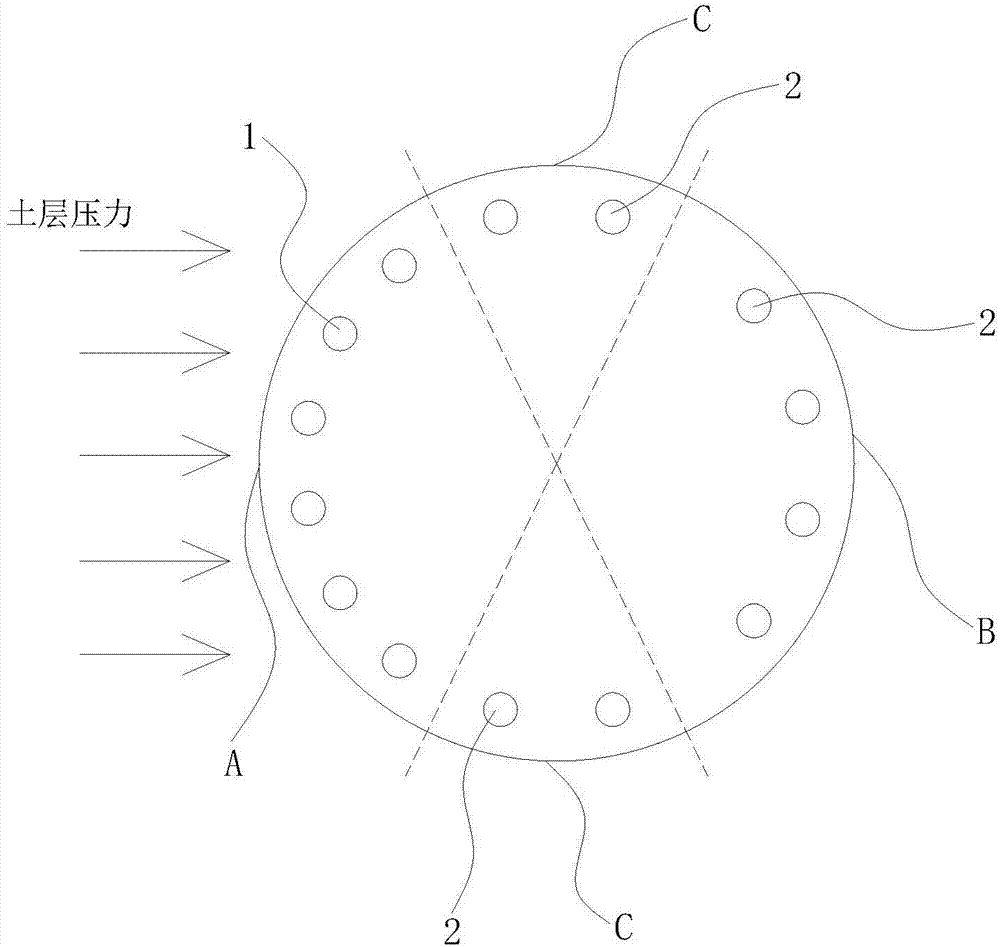

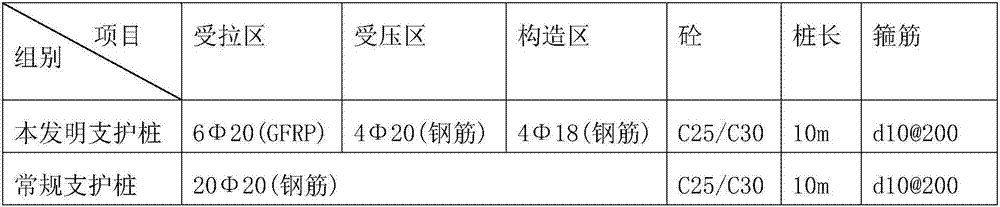

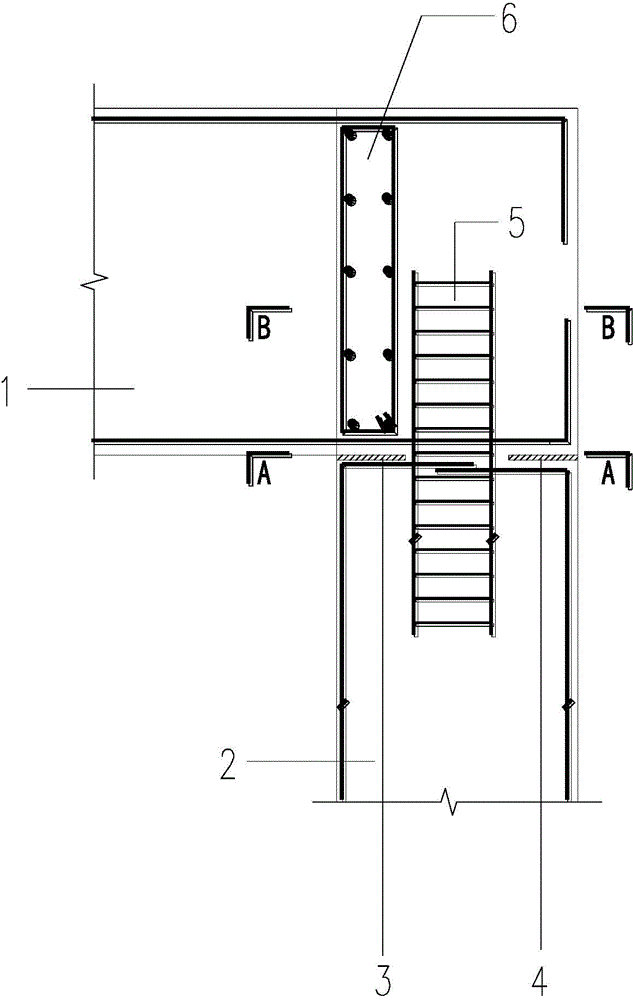

Non-symmetric composite reinforced concrete pouring supporting pile

InactiveCN107130589AReduce usageImprove corrosion resistanceExcavationsBulkheads/pilesGlass fiber reinforced polymerReinforced concrete

The invention relates to a non-symmetric composite reinforced concrete pouring supporting pile. The non-symmetric composite reinforced concrete pouring supporting pile comprises a tensile region and a compression zone, wherein the side surface of the tensile region is close to a soil layer; the side surface of the compression zone is away from the soil layer; reinforcement in the tensile region is formed by glass fiber-reinforced polymers arranged along a supporting pile in a circumferential direction at intervals or the glass fiber-reinforced polymers and steel bars alternately arranged along the supporting pile in a circumferential direction at intervals; the reinforcement in the compression zone is formed by steel bars arranged along the supporting pile in a circumferential direction at intervals; and the axial directions of the glass fiber-reinforced polymers and the steel bars are parallel to that of the supporting pile. According to the non-symmetric composite reinforced concrete pouring supporting pile disclosed by the invention, the usage quantity of the steel bars is greatly reduced through the reinforcement manner, so that steel materials are saved, and the non-symmetric composite reinforced concrete pouring supporting pile is energy-saving and environmentally-friendly; and besides, the corrosion resistance of the supporting pile is strengthened by the glass fiber-reinforced polymers, and the supporting pile is especially suitable for a seaside ground environment with a high content of chloride ions. According to the non-symmetric composite reinforced concrete pouring supporting pile disclosed by the invention, the utilization ratio of reinforcement materials is maximized, and particularly the adopted glass fiber-reinforced polymers are low in cost, so that the construction cost of the supporting pile is effectively reduced; and in addition, compared with the steel bars, the glass fiber-reinforced polymers are lighter, easier to transport, easier to hoist during production and manufacturing, and more convenient and quicker.

Owner:ANHUI INST OF BUILDING RES & DESIGN +1

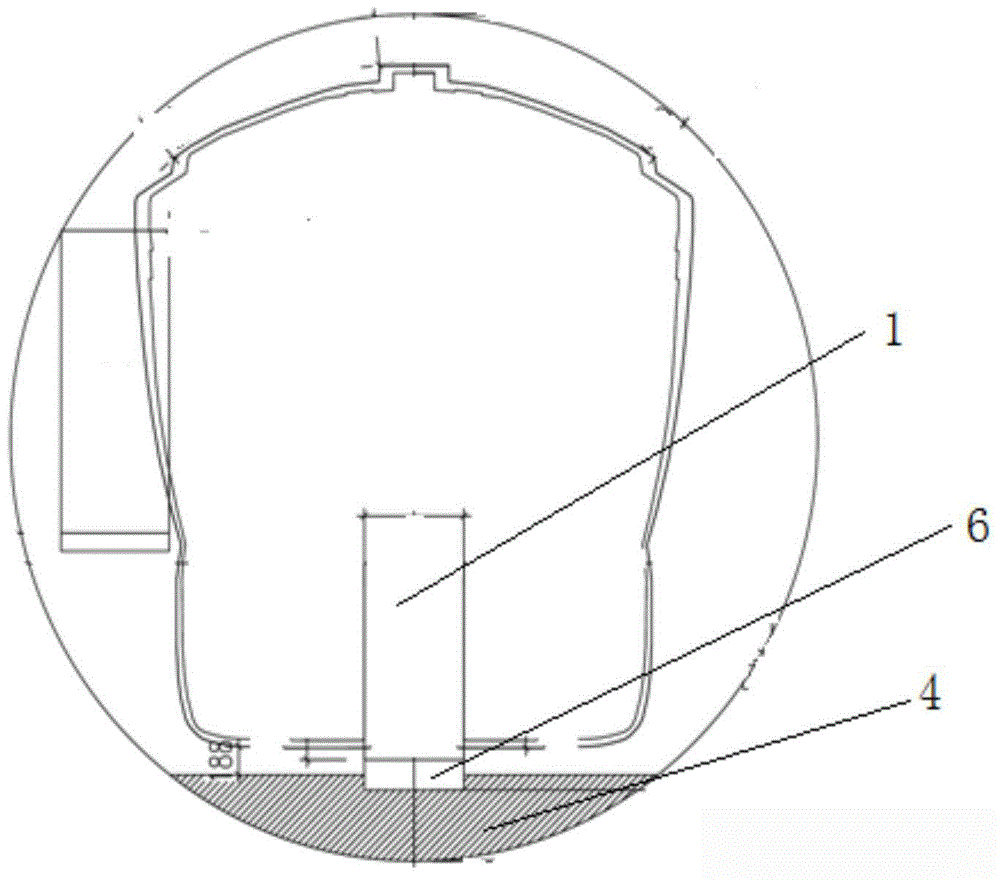

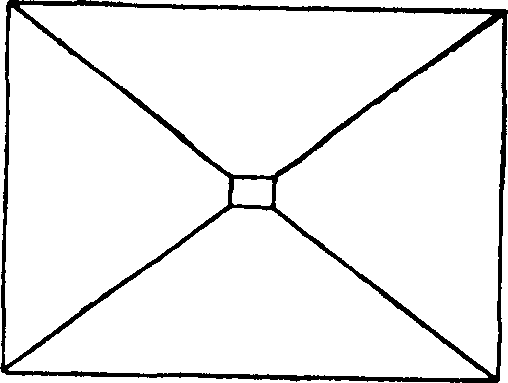

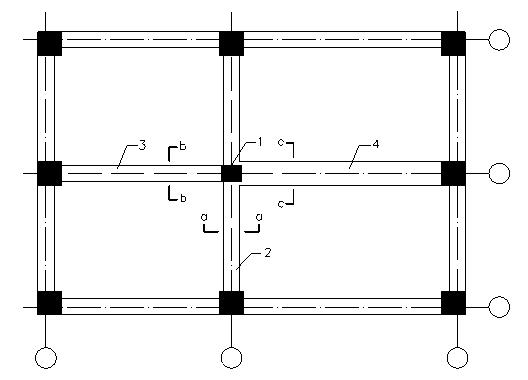

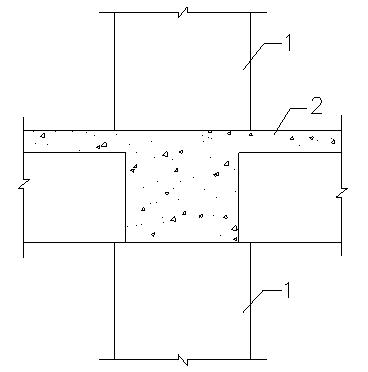

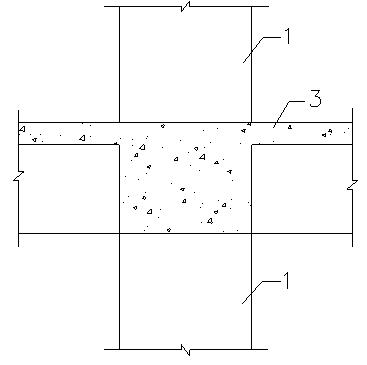

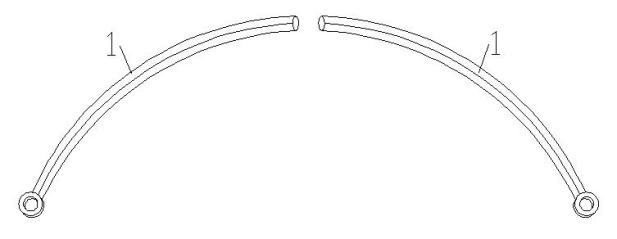

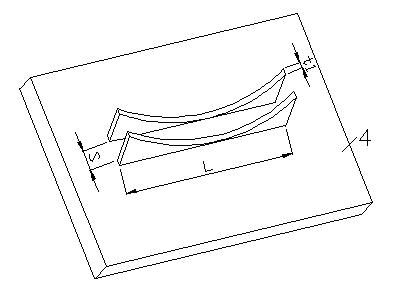

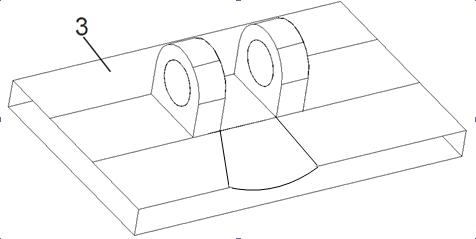

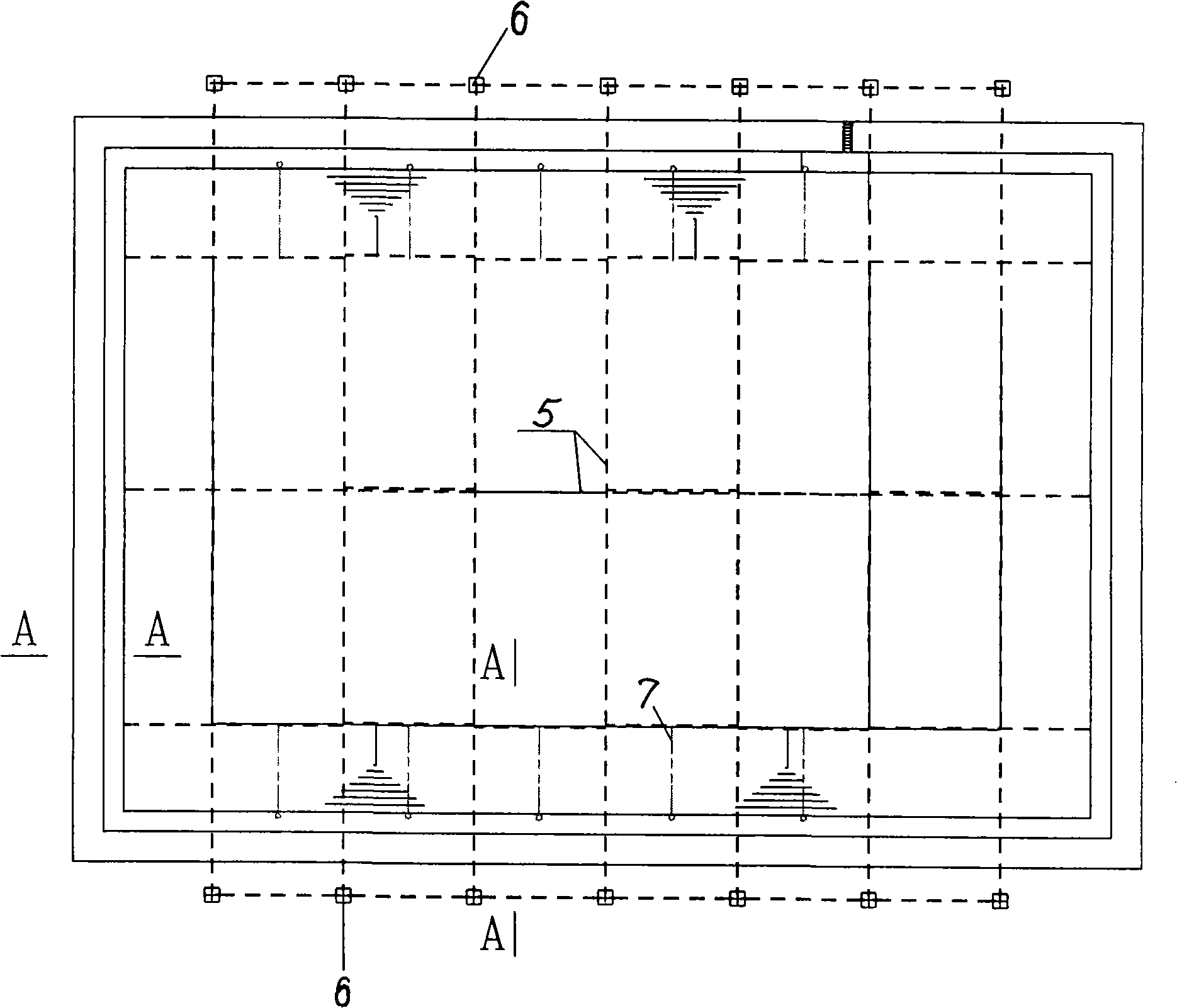

Hinging joint structure of large-span prestressed concrete framed girder

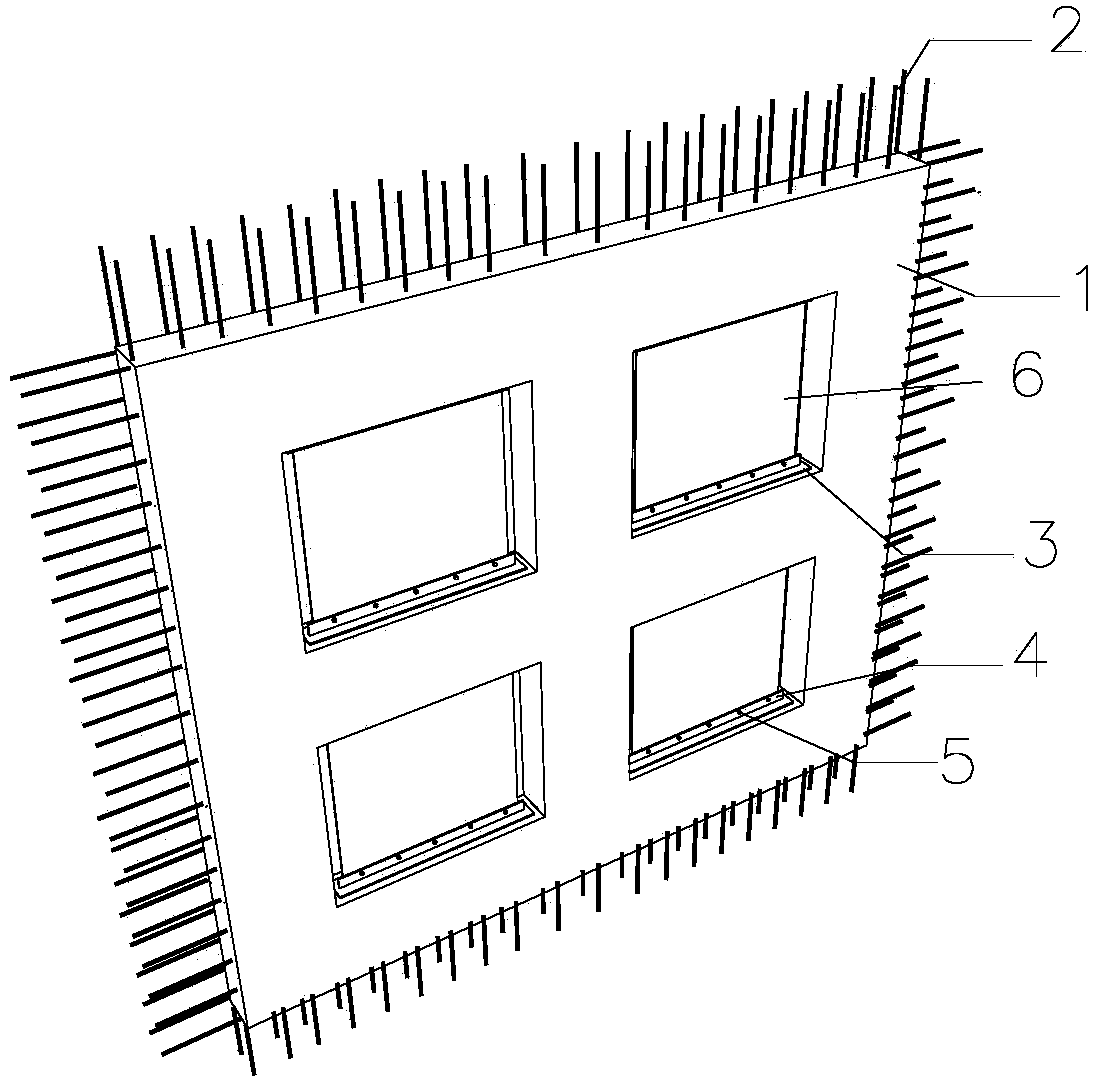

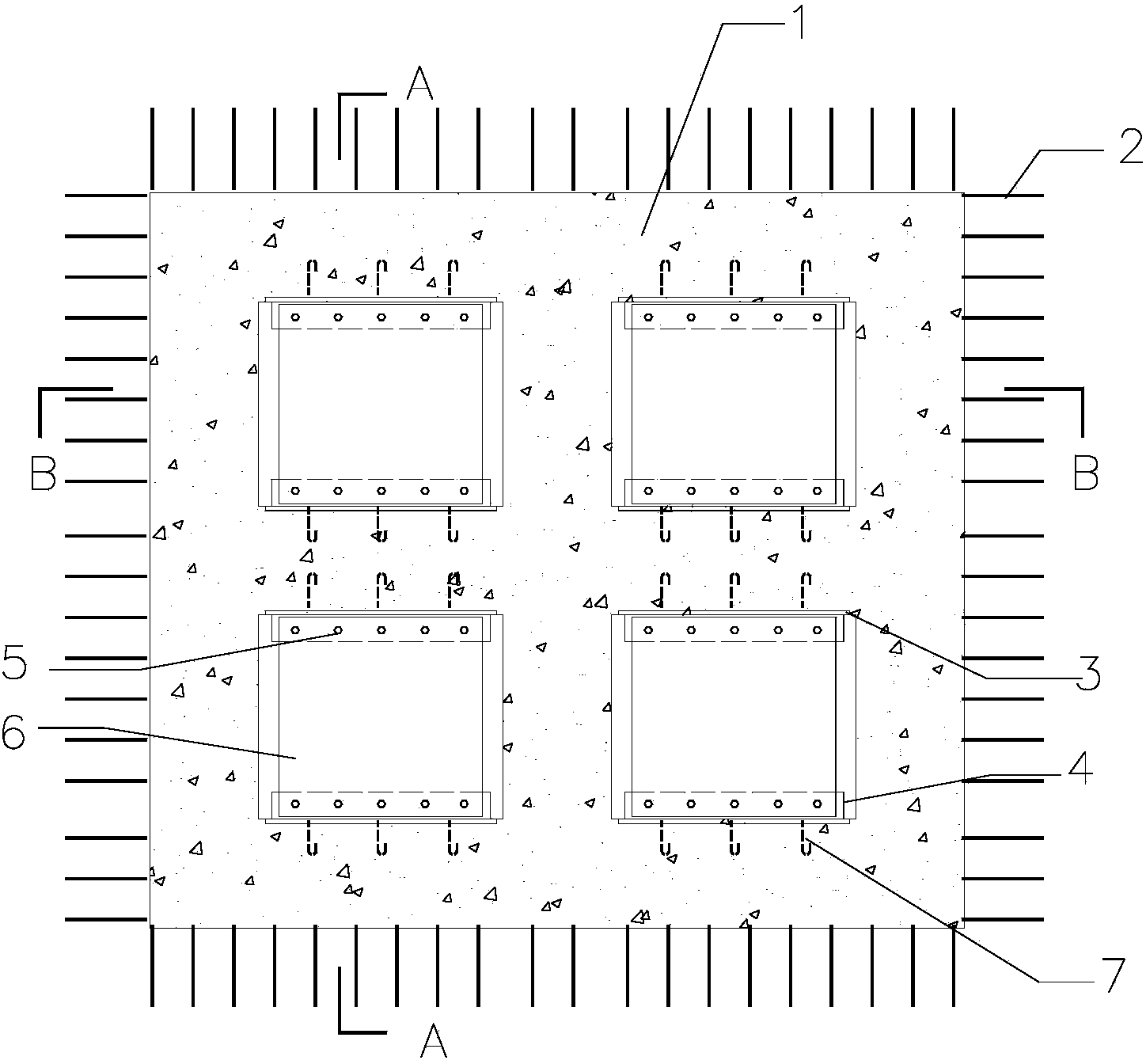

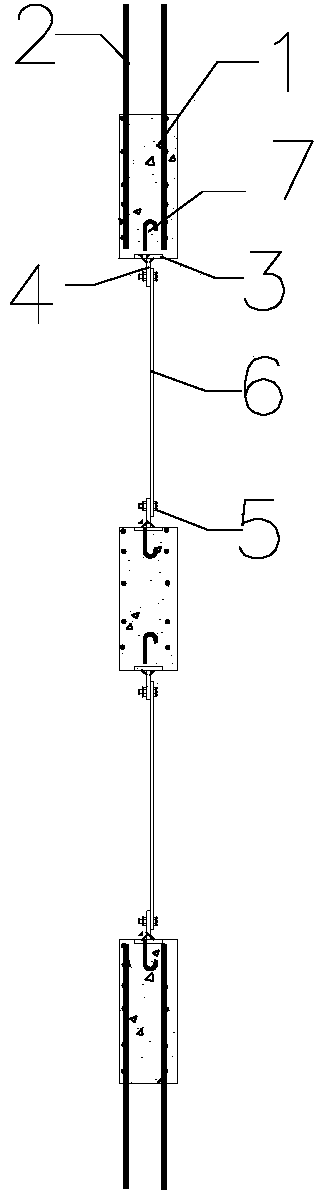

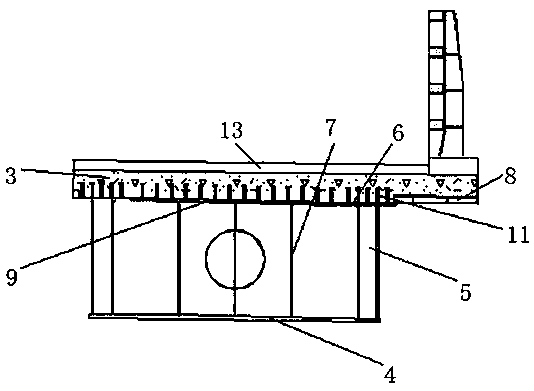

ActiveCN104389347AImprove mechanical performanceReduce the amount of reinforcementBuilding constructionsReinforced concretePre stress

The invention provides a hinging joint structure of a large-span prestressed concrete framed girder. The hinging joint structure comprises a framed girder (1) and a framed column (2) which are integrally connected to form a prestressed concrete frame structure. The hinging joint structure is characterized in that an inner side isolating layer (3) and an outer side isolating layer (4) are respectively arranged at the inner side and the outer side of a plane in which the bottom surface of the framed girder (1) is intersected with the top surface of the framed column (2); the framed girder (1) and the framed column (2) are connected through a reinforced concrete core column (5); a reinforced concrete girder pad (6) is arranged at one inner side of the framed girder (1), at the inner side plate isolating layer (3). According to the hinging joint structure, a side column of the large-span prestressed concrete frame of a roof is structured into a single hinging form, thus the bending moment transmitted by the large-span prestressed concrete framed girder can be released, the framed column at the side can be kept in a small-eccentric pressing state, and as a result, the quantity of reinforcement and the section dimension can be reduced, the bearing performance of the frame structure can be improved, and the large-space design requirement of a building is met.

Owner:上海建科预应力技术工程有限公司 +1

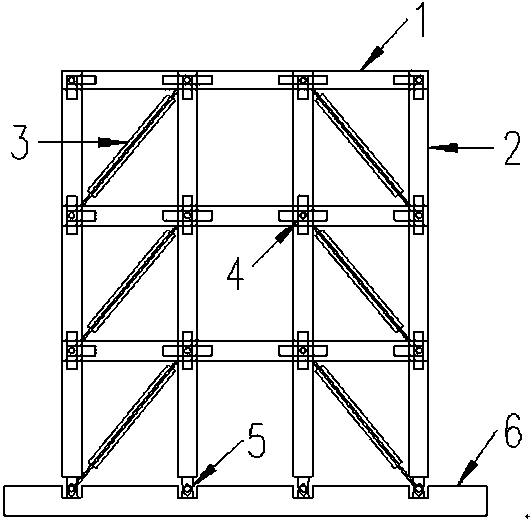

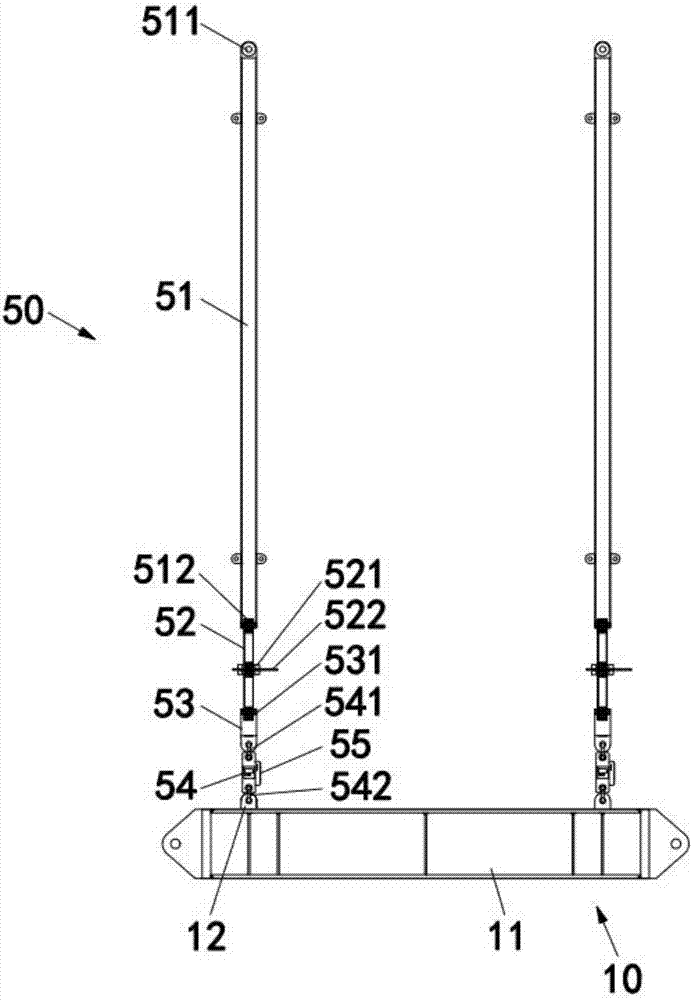

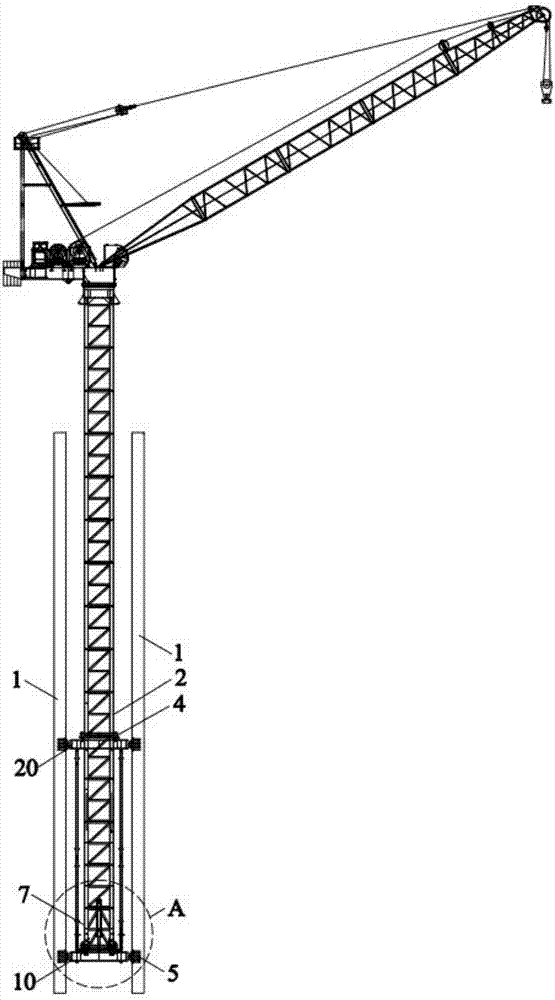

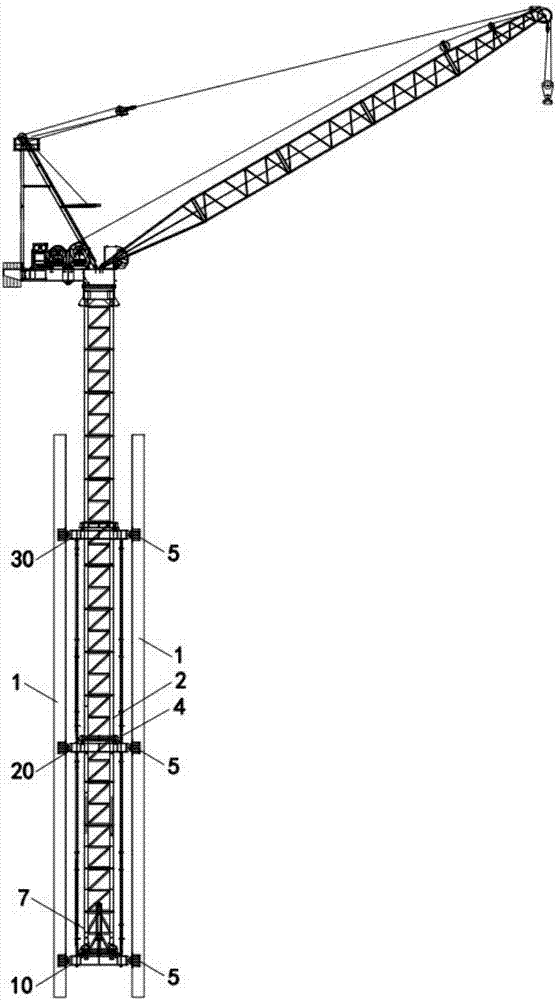

Moving arm tower crane climbing beam supporting system and using method thereof

PendingCN108002255AIncrease loading capacityReduce concentrated loadCranesSupporting systemBraced frame

The invention provides a moving arm tower crane climbing beam supporting system and a using method thereof and relates to the technical field of building construction. The system aims at the problemsthat when an ultrathin shear wall is reinforced in the prior art, economy is poor, the high-altitude construction difficulty is large, and the safety risks are high. The system comprises at least three supporting frameworks arranged in parallel and at intervals, and multiple adjustable pull rod assemblies connected between the two adjacent supporting frameworks. Each supporting framework is connected with an embedded part bolt. A self-climbing device of a moving arm tower crane is fixed to the bottom supporting framework. A tower body is connected with the top supporting framework. The multiple adjustable pull rod assemblies are uniformly distributed on the outer side of the tower body. When the moving arm tower crane climbs, the third supporting framework is connected with the tower body,the second supporting framework and the third supporting framework are connected through the adjustable pull rod assemblies, constraint between the tower crane and the first supporting framework is loosened, the moving arm tower crane climbs upwards to the position of the second supporting framework and is connected with the second supporting framework, and so forth, it is always kept that vertical loads are borne together by the two adjacent supporting frameworks and the adjustable pull rod assemblies connected between the adjacent supporting frameworks.

Owner:SHANGHAI NO 4 CONSTR

Reinforcement lightweight aggregate concrete flat beam structure

InactiveCN102425231AImprove punching resistanceSolve the problem of overcrowdingShock proofingSocial benefitsSteel bar

The invention relates to a reinforcement lightweight aggregate concrete flat beam structure which comprises a column, a beam and a plate, wherein the beam is a flat beam made of a reinforcing steel bar and lightweight aggregate concrete, the width of the flat beam is more than or equal to the height; and the column is a reinforcement lightweight aggregate concrete column. The reinforcement lightweight aggregate concrete flat beam structure provided by the invention also has better properties of light weight, energy saving, environment friendliness, good durability and the like of the lightweight aggregate concrete under the condition of the advantages of reducing floor height, avoiding pipeline beam crossing and the like, greatly reduces self gravity of the whole building structure and improves earthquake resistant behaviour of the structure while ensuring bearing capacity, and has remarkable economic and social benefits.

Owner:FUZHOU UNIV

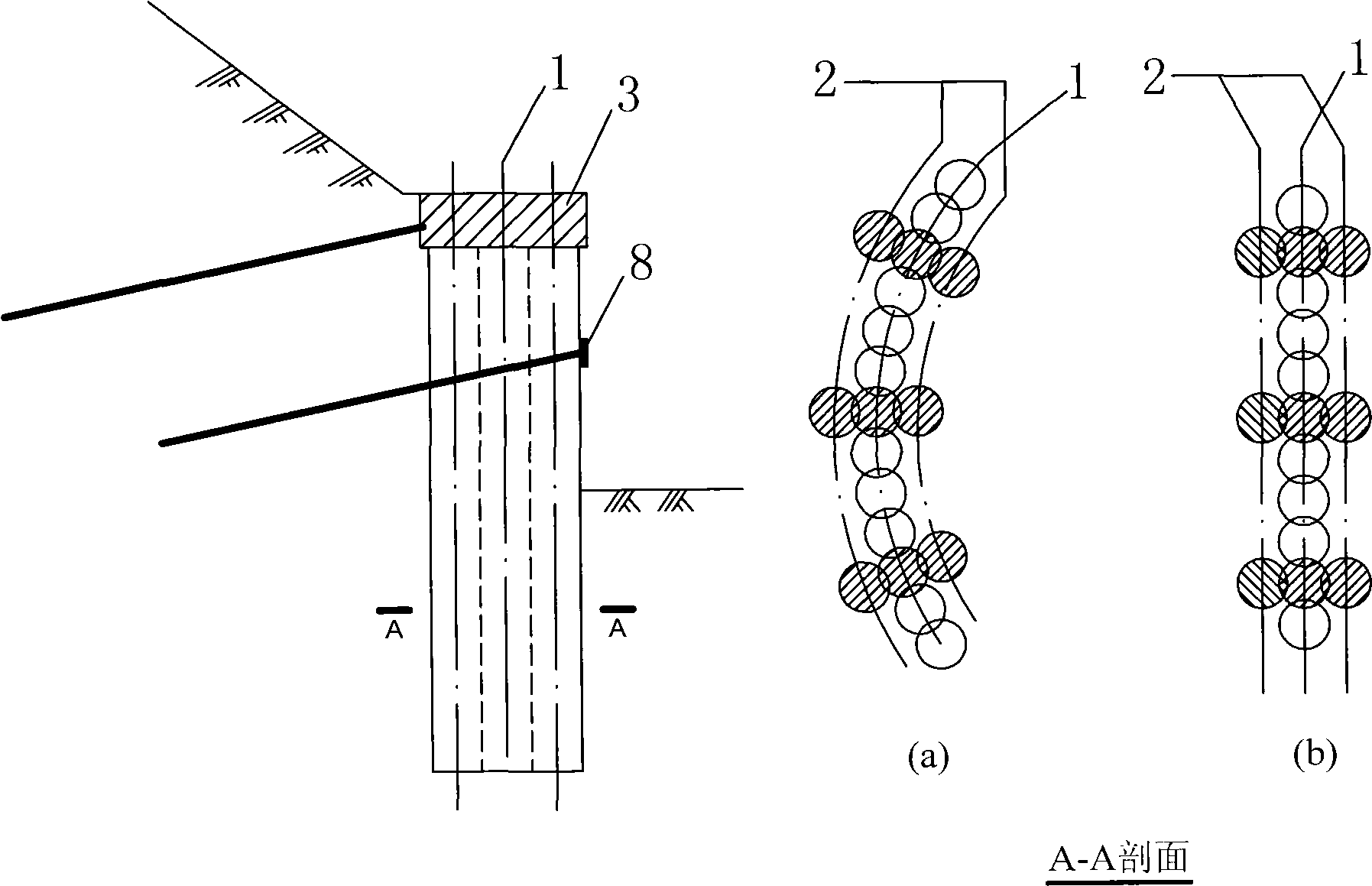

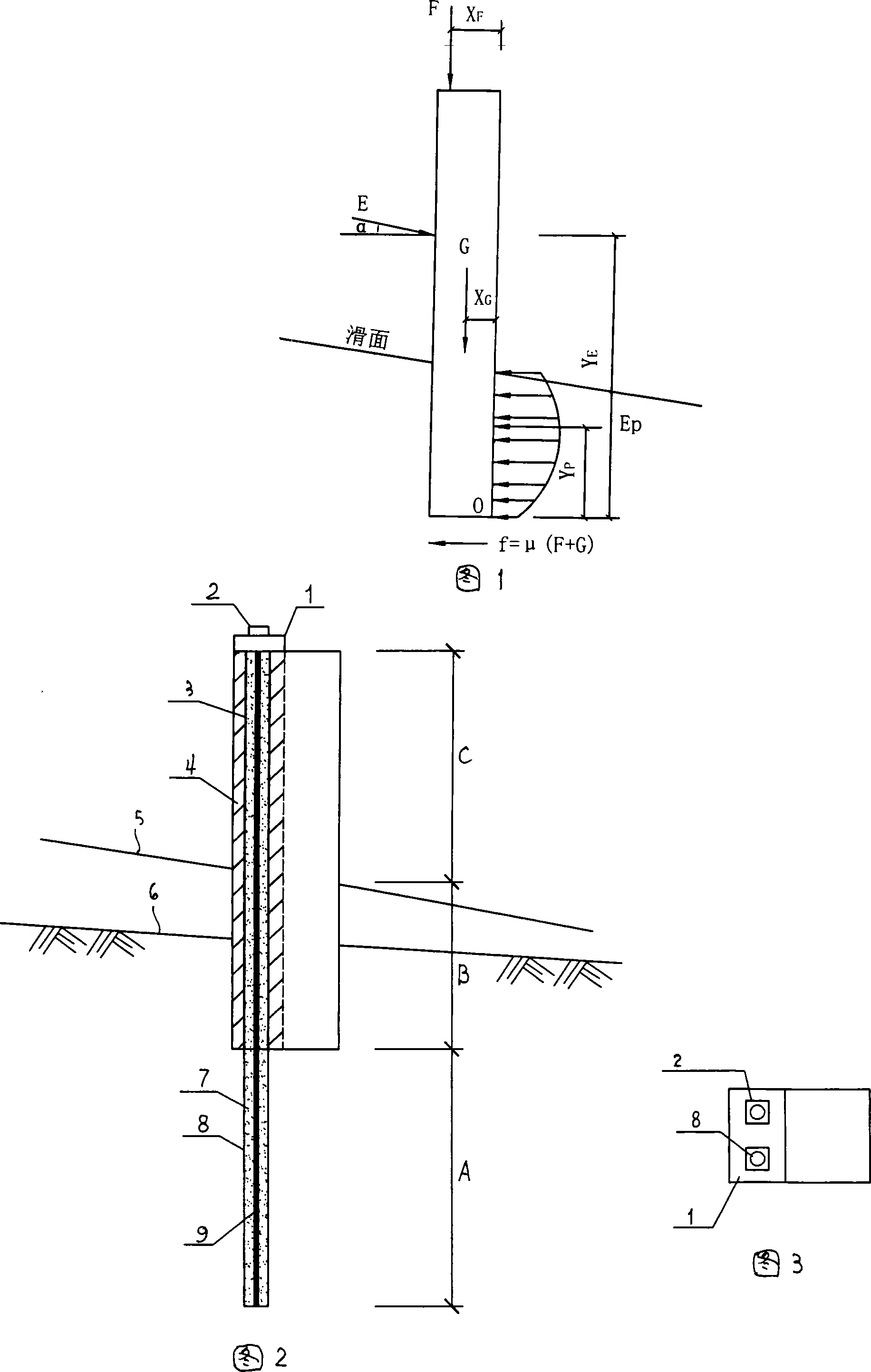

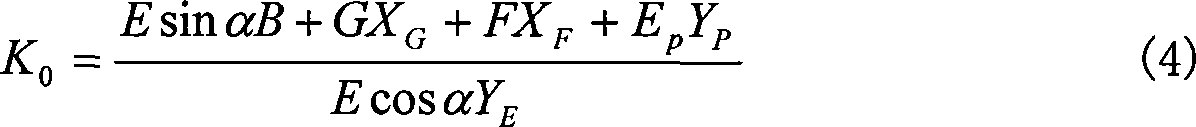

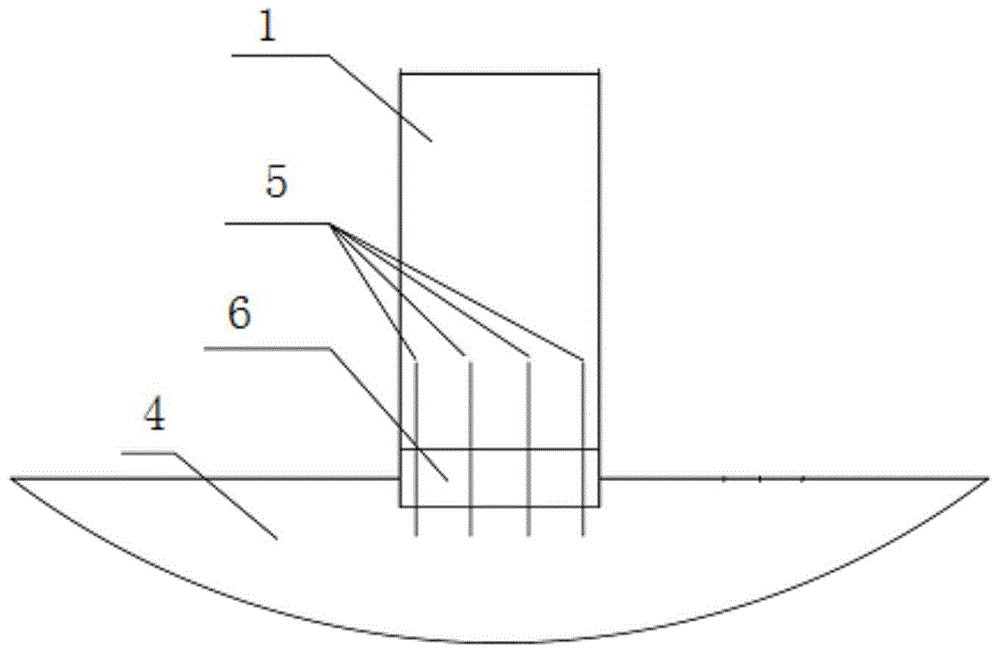

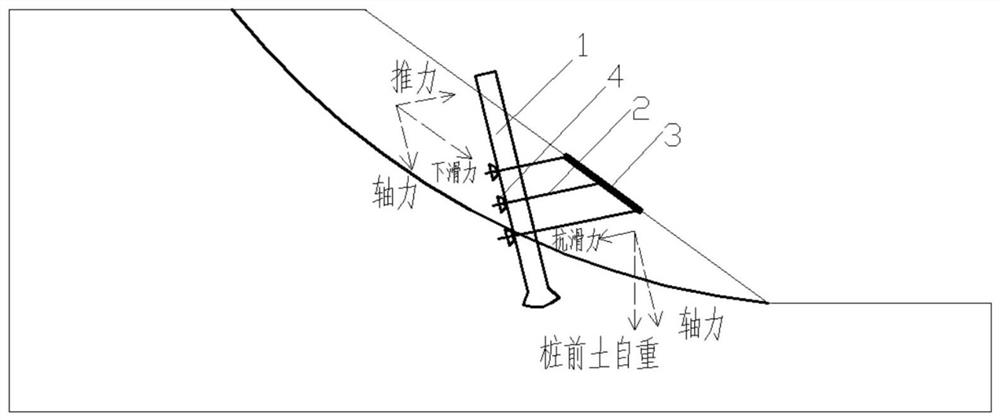

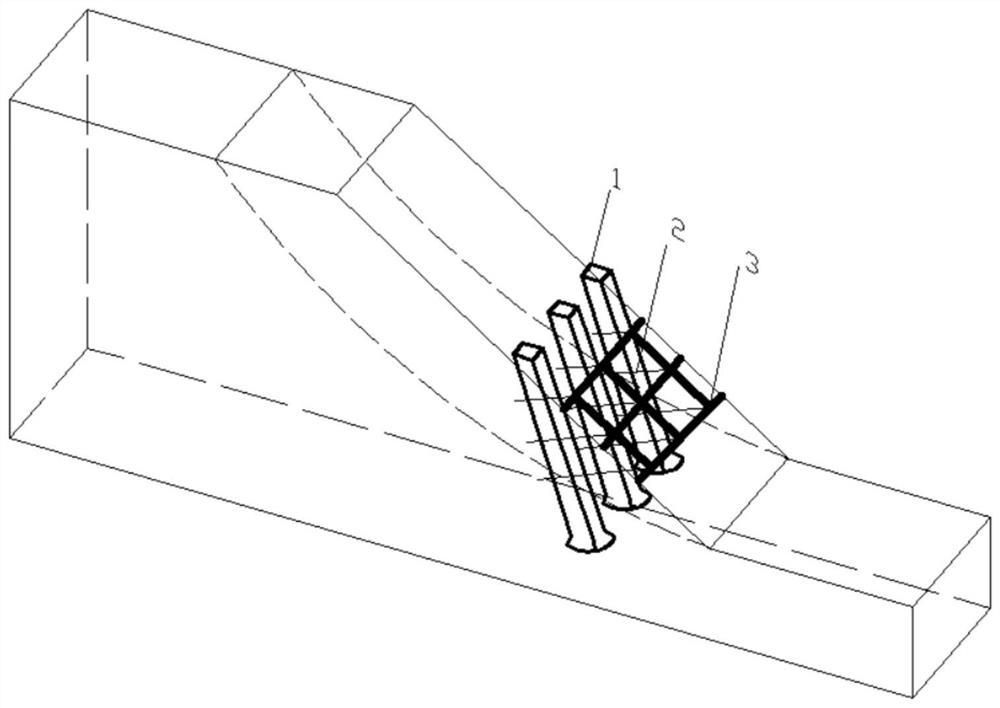

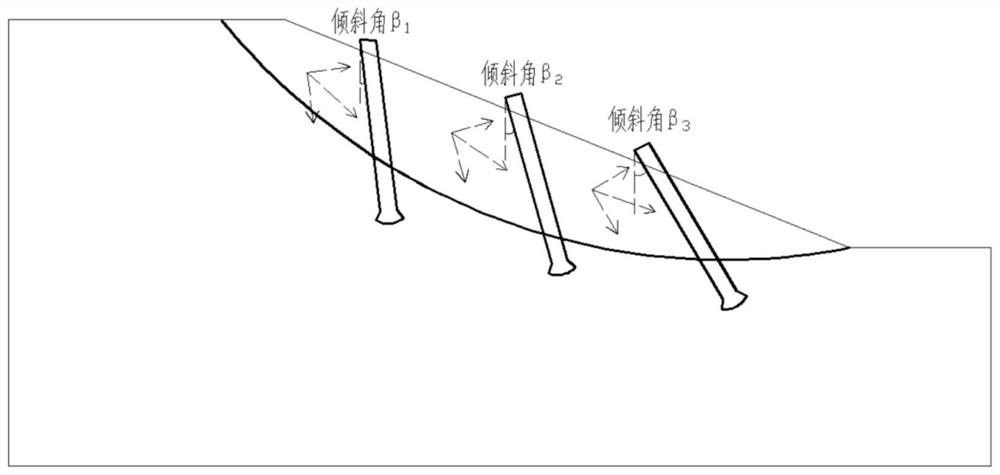

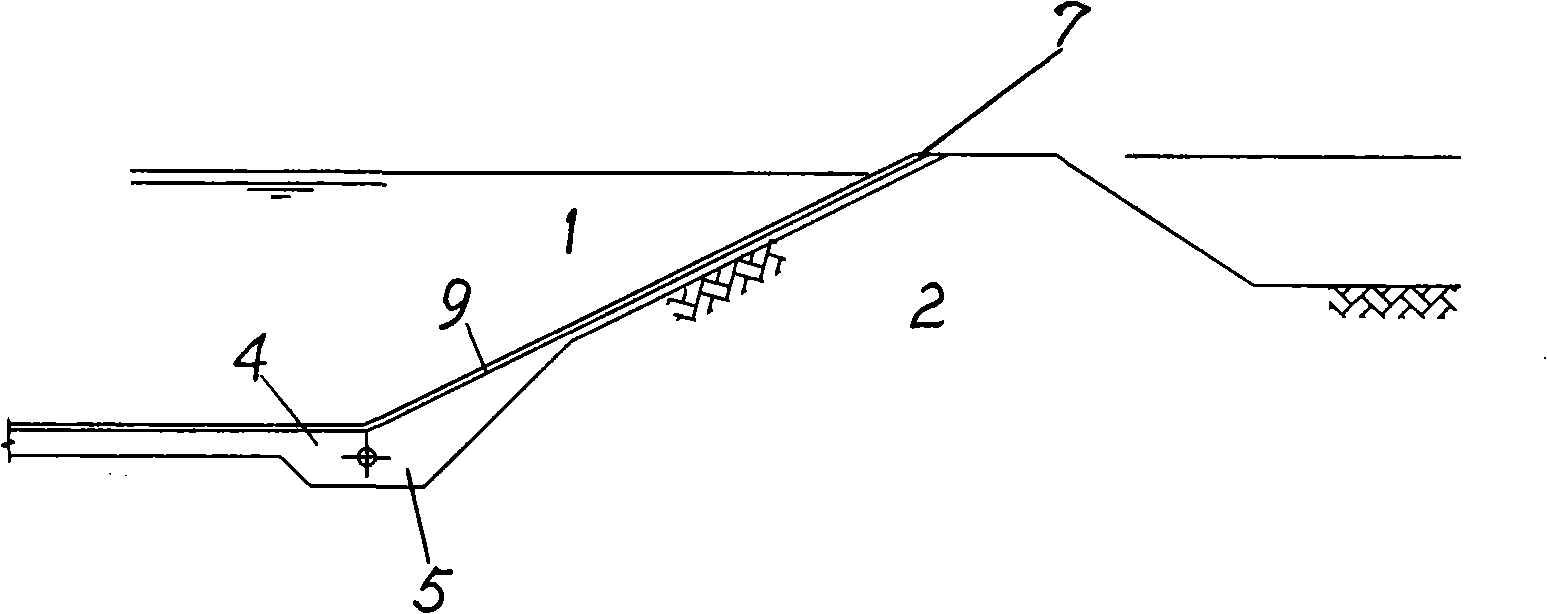

Landslide support system based on inclined anti-slide pile, landslide thrust calculation method, inclination angle optimization method and construction method

ActiveCN112982453AReduce shearMake good use of vertical bearing capacityGeometric CADExcavationsSupporting systemLandslide

The invention provides a landslide support system based on an inclined anti-slide pile. The landslide support system comprises an anti-slide pile (1), wherein a pile body of the anti-slide pile (1) is inclined towards a landslide surface, a plurality of anchor rods (2) are arranged on a soil body in front of the anti-slide pile (1), the anchor rods (2) penetrate through the anti-slide pile (1) and form a pile-post anchor head (4) behind the anti-slide pile (1), and all the anchor rods (2) which are located on the soil body in front of the pile are connected through frame beams (3). The invention further provides a landslide thrust calculation method, an inclination angle optimization method and a construction method of the landslide support system based on the inclined anti-slide pile. The support system gives full play to the vertical bearing capacity of an under-reamed bored pile, the bending moment and shearing force of the pile body are reduced, the use number of reinforcing bars of the anti-slide pile is reduced, the material cost is reduced, and the construction cost is reduced; and the calculation method is simple and easy to calculate, and a basis can be provided for the support design of the inclined anti-slide pile and the guidance of the construction of the inclined anti-slide pile.

Owner:HOHAI UNIV

Surge shaft construction method combining impedance with overflow

ActiveCN102644261ACompact layoutSimple structureBarrages/weirsWater-power plantsBedrockWater channel

The invention discloses a surge shaft construction method combining impedance with overflow, which includes that the height of a surge shaft body is determined based on reservoir water level and subjected to be higher than exceptional flood level, the inner diameter D of the shaft body is determined based on stable section area calculated by Thoma criterion, and the thickness of the shaft body wall is determined based on the meeting of concrete anti-crack requirements and axis force bearing requirements; the mouth edge at the top of the surge shaft is made into an arc-shaped overflow weir; an annular stilling pool is constructed around the surge shaft body, the width of the stilling pool is determined according to the nappe length Ld of falling water during the overflow of the surge shaft, the altitude of the stilling pool bottom is the altitude of complete bedrock, and lining protection is performed according to the depth of water in the stilling pool; a sluiceway communicated with the stilling pool is constructed on one side of the stilling pool, and the bottom of the stilling pool is excavated to the bedrock surface; a connecting pipe communicated with a water drawing dynamoelectric tunnel is excavated perpendicularly downwards at the bottom of the surge shaft, and consolidation grouting is performed on the periphery; and the diameter of the connecting pipe is determined based on the requirement of an impedance hole. The surge shaft construction method has the advantages that the structure is simple and compact, the project amount is small, and the investment is saved.

Owner:YELLOW RIVER ENG CONSULTING

Method for reinforcing polyester concrete and polyester concrete member provided with reinforcing material

The invention relates to a method for reinforcing polyester concrete and polyester concrete member provided with reinforcing material. The method for reinforcing polyester concrete includes that concrete combined material and resin adhesive as well as additive and filler are mixed into concrete mixture by ratio, and non metal structure frame or non metal reinforced net is adopted to be laid in the interior of concrete member when utilizing the mixture to process the concrete member. The polyester concrete member provided with reinforcing material is namely the concrete member made by adopting the method, and the member is in flat plate shape, or in tubular shape or in GONG (a Chinese character) shape. The invention adopts glass reinforcing rib or carbon fiber reinforcing rib to reinforce polyester concrete, and the obtained member has the following advantages: strength is high, hardness is four times higher than that of common concrete, toughness is higher than that of common steel bar, weight is light, and the member is anticorrosive, besides, glass fiber reinforced plastics is not conductive, has high safety, is resistant to water leaching and is adiabatic.

Owner:罗华德

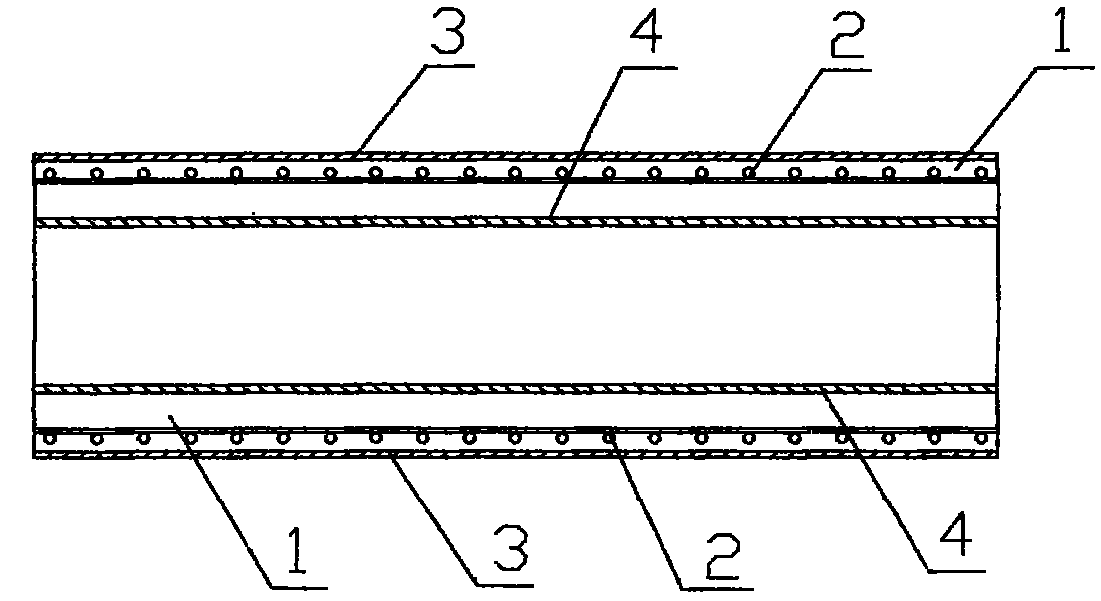

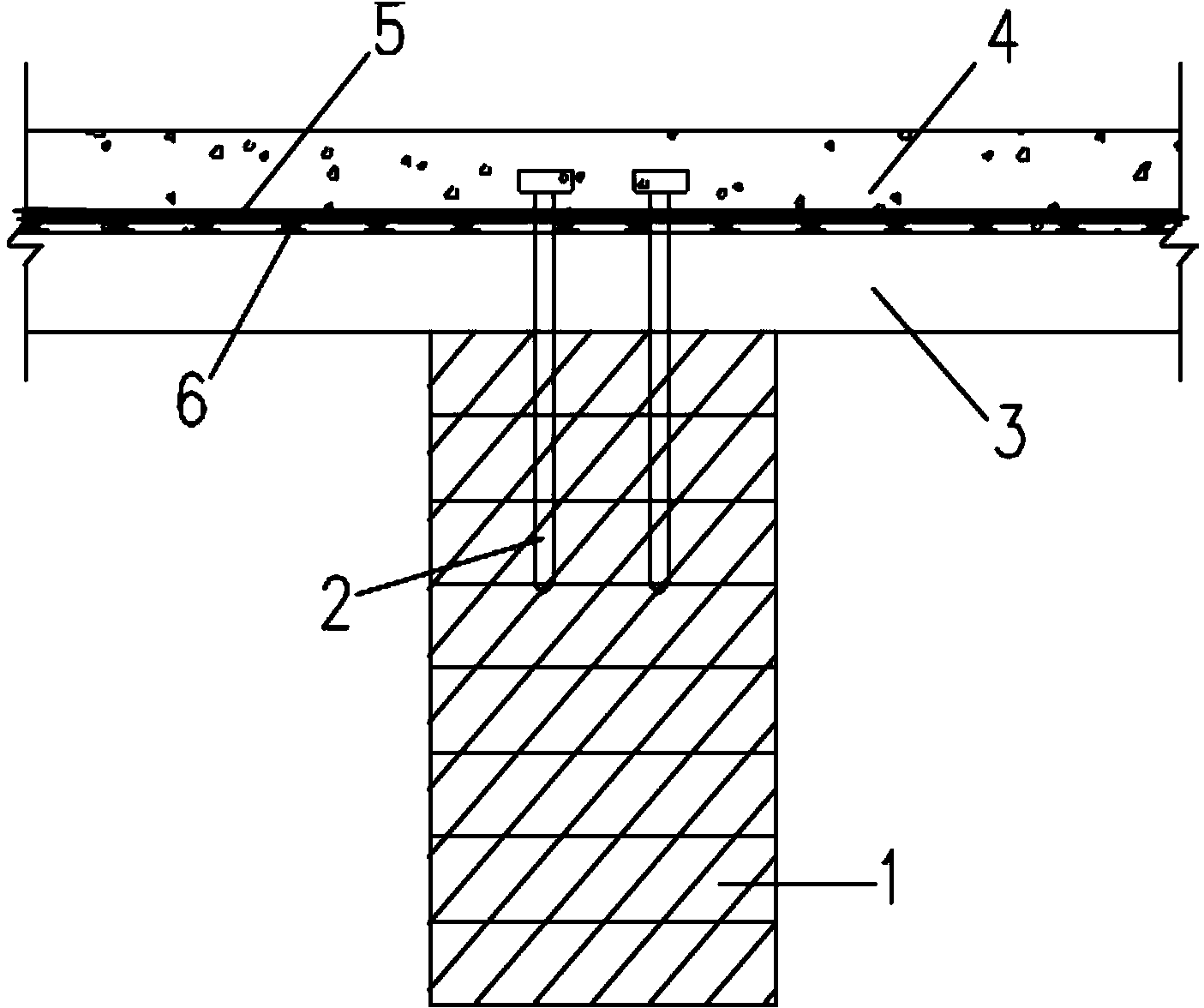

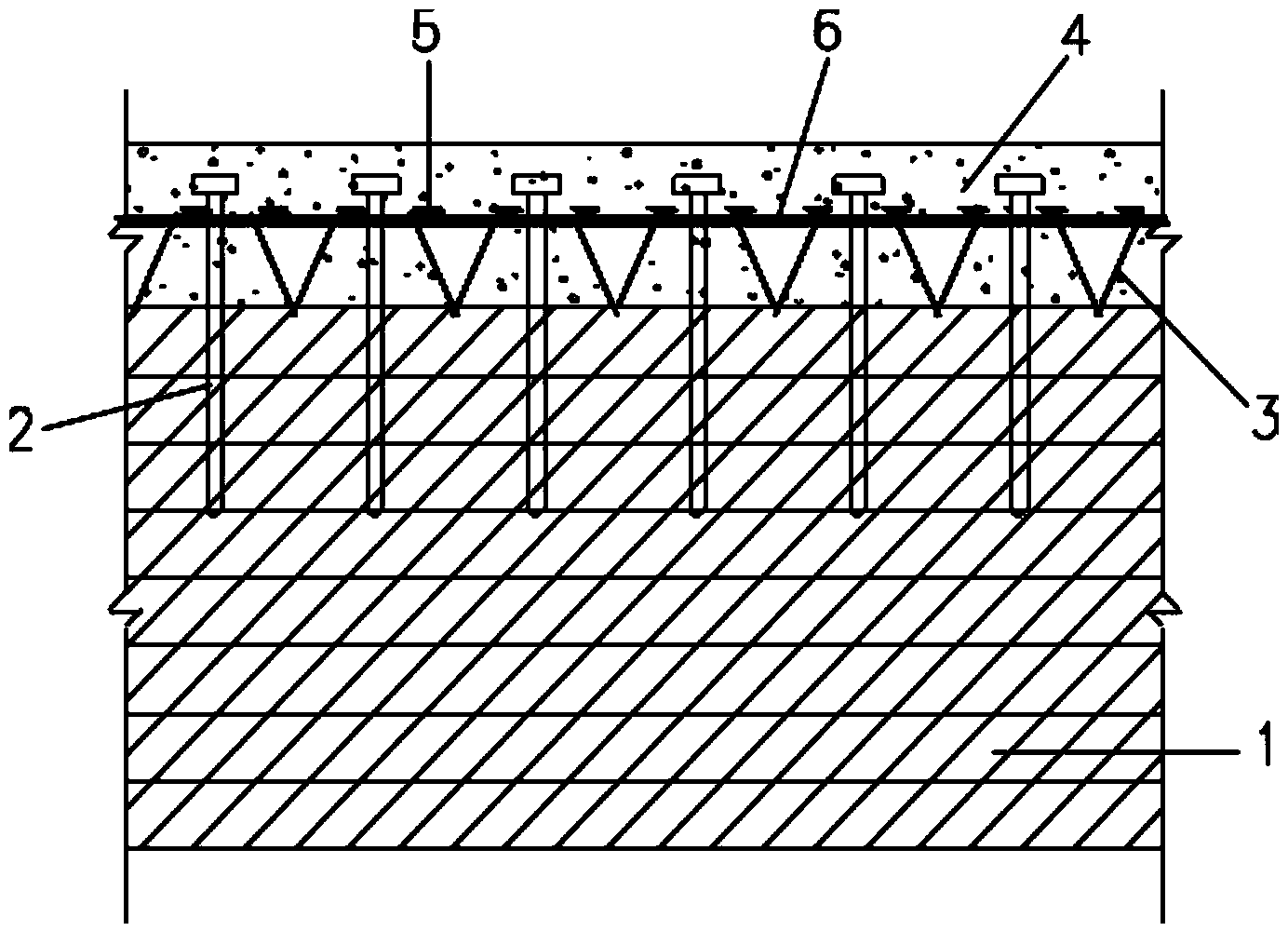

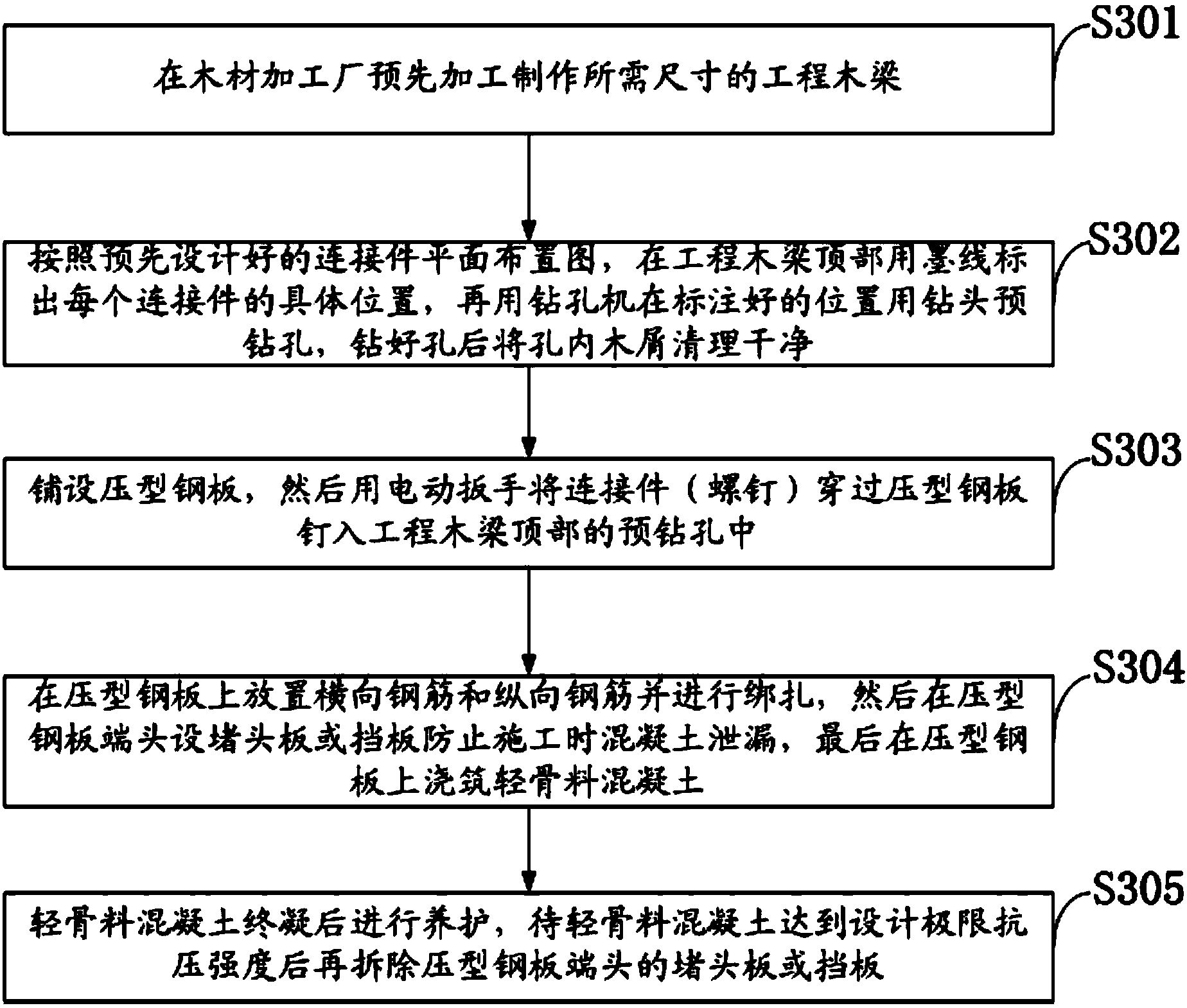

Combined beam of engineered wood, profiled steel sheet and light-weight aggregate concrete and production and installation method of combined beam

Owner:NANJING UNIV OF TECH

Supporting device for arched steel among beam columns

InactiveCN102691351AReduce section sizeReduce the amount of reinforcementArched structuresVaulted structuresEngineeringBeam column

Owner:SHANGHAI UNIV

Rubber reservoir

The invention relates to a rubber reservoir. The tank comprises a dam, a plurality of rubber liners and a bottom drainage system. The dam surrounds the reservoir. The rubber liners are respectively laid on inner surface of the reservoir. The bottom drainage system is arranged at the bottom of the reservoir, and comprises a plurality of sump pits, a filter layer and an exhaust system; the sump pits are arranged circlewise around the reservoir respectively. The filter layer is arranged at the bottom of the rubber liners and provided with a great amount of porous filter pipes which are classified into trunk pipes and branch pipes, two ends of the trunk pipes respectively extend to the sump pits. The exhaust system is arranged between the dam and the rubber liners around the reservoir, and conducts the filter layer and the atmosphere. The rubber reservoir has the following advantages and positive effects: 1. the rubber reservoir structure can effectively reduce construction cost; 2. a rubber reservoir structural system is easy for maintenance and management and convenient for quick emergency repair; and 3. the rubber reservoir is characterized by attractive appearance, simple construction and short construction period.

Owner:BAOSTEEL ENG & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com