Thin-wall internal-mould large-thickness hollow floor plate

A technology with hollow floor slab and large thickness, which is applied in the direction of floor slab, structural elements, building components, etc., to achieve the effects of fast speed, weakened earthquake force, and reduced structure weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

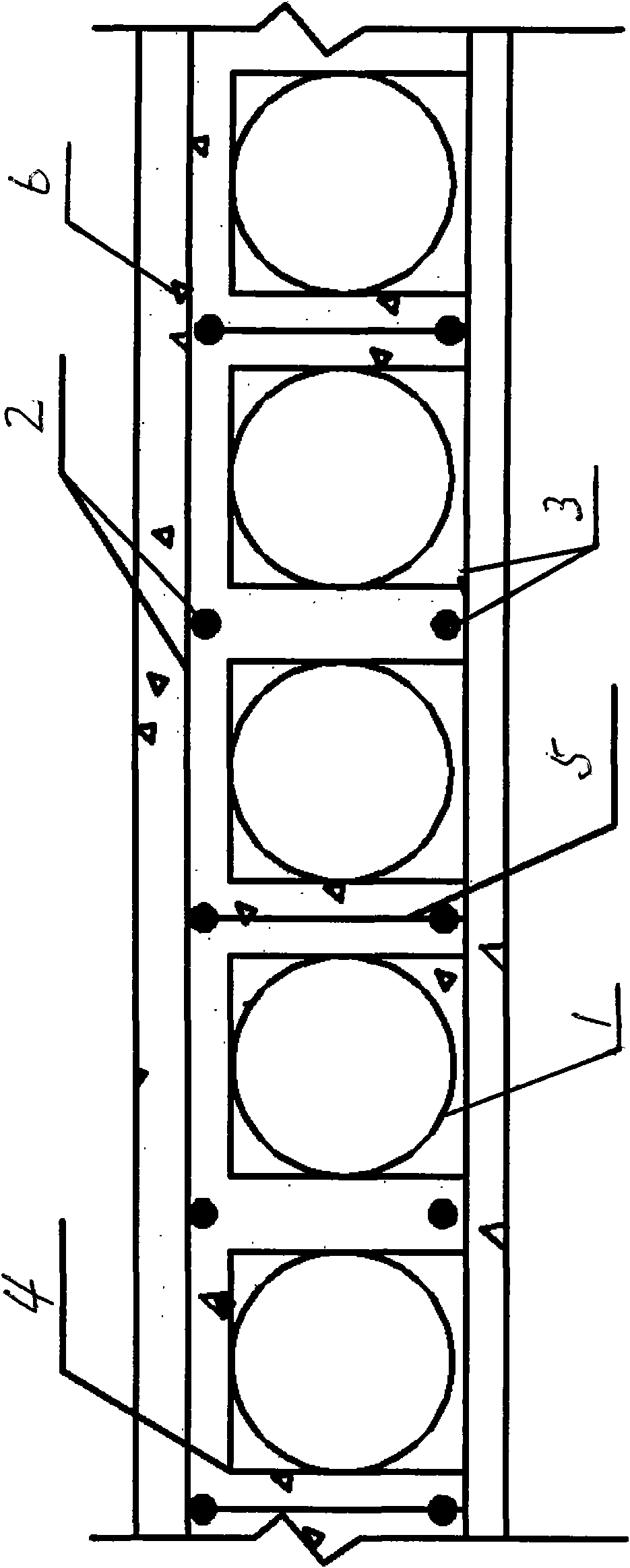

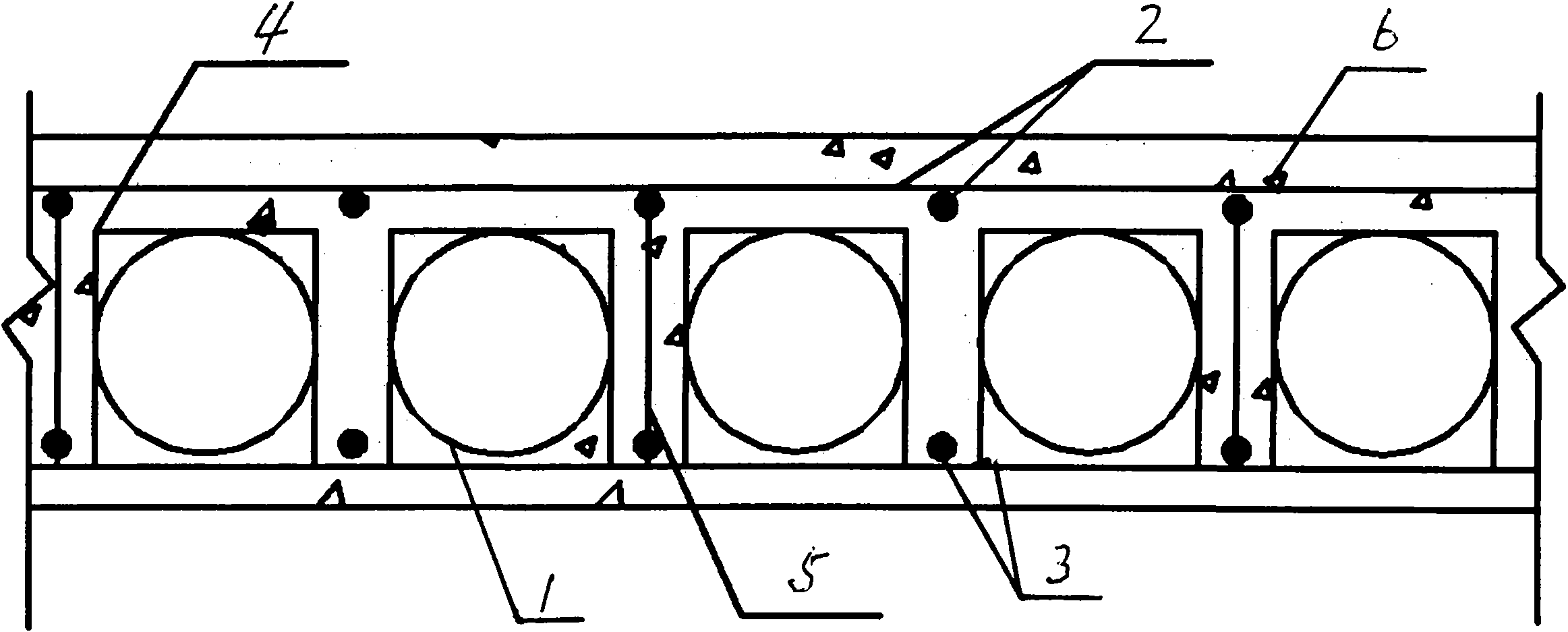

[0008] Attached below figure 1 Give an example: as figure 1 As shown, the large-thickness hollow floor of the thin-walled internal formwork is a double-layer reinforced structure, and the core tube 1 in the shape of a fully enclosed circular tube with a diameter of 450 cm is embedded in the middle of the concrete structure to form a hollow structure and become a permanent core. mold. The upper and lower sides of the core pipe 1 are provided with reinforcement meshes 2 and 3 respectively. Each core tube 1 is tightly wound with a pressure tube steel bar 4 , and the two ends of the pressure tube steel bar 4 are fixedly connected with the lower reinforcement mesh 3 . A row of vertical anti-floating reinforcing bars 5 is arranged every two core tubes 1, and the upper and lower ends of the anti-floating reinforcing bars 5 are fixedly connected with the upper and lower reinforcing meshes 2 and 3 respectively.

[0009] like figure 1 As shown, pouring concrete 6 is filled between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com