Fiber-wrapped lightweight aggregateand method for inhibiting floating of lightweight aggregate

A lightweight aggregate and lightweight aggregate technology, applied in the field of concrete, can solve problems such as the influence of concrete construction performance, the floating of lightweight aggregate, and the impact on the service life of concrete structures and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

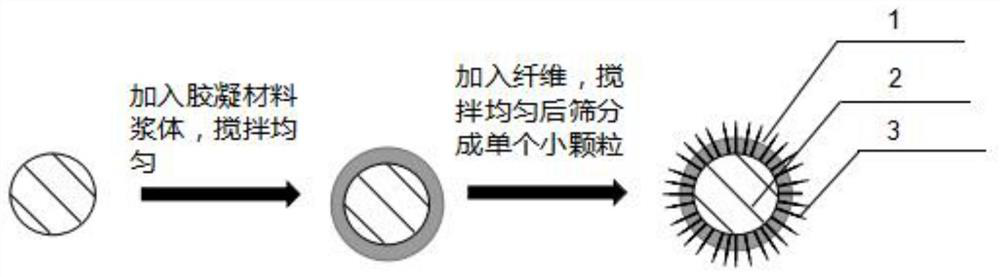

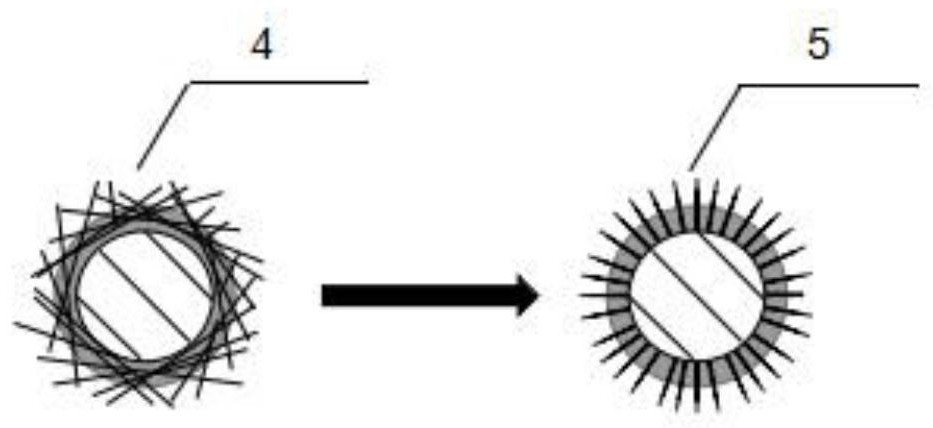

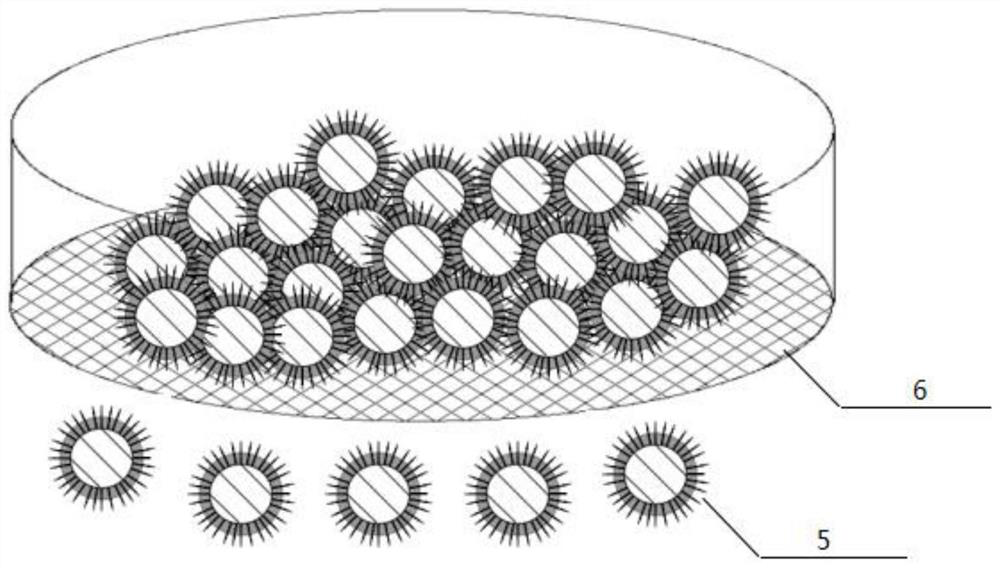

[0017] Such as figure 1 Shown, the preparation method of a kind of novel lightweight aggregate in the present invention has the following steps:

[0018] (1) Configuration of cementitious material slurry: the cementitious material slurry in the present invention is formed by mixing cementitious material, water, chemical additives and mineral admixtures in a certain proportion. The proportioning ratio is cementitious material: water: chemical additive: mineral admixture = 1: 0.45: 0.03: 0.7, wherein the cementitious material is made of ordinary Portland cement with a grade of 52.5; the mineral admixture is made of fly ash , granulated blast furnace slag, silica fume, etc., of which the fly ash is grade I fly ash, and the granulated blast furnace slag is S95 grade slag; the admixture is polycarboxylate high-performance water reducer with a concentration of 30%.

[0019] (2) Prepare a lightweight aggregate that inhibits floating: mix the pre-wet lightweight aggregate with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com