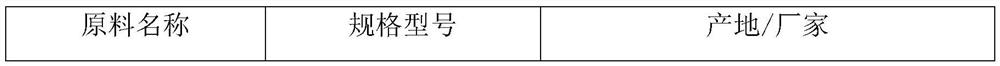

Patents

Literature

59results about How to "Stop floating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

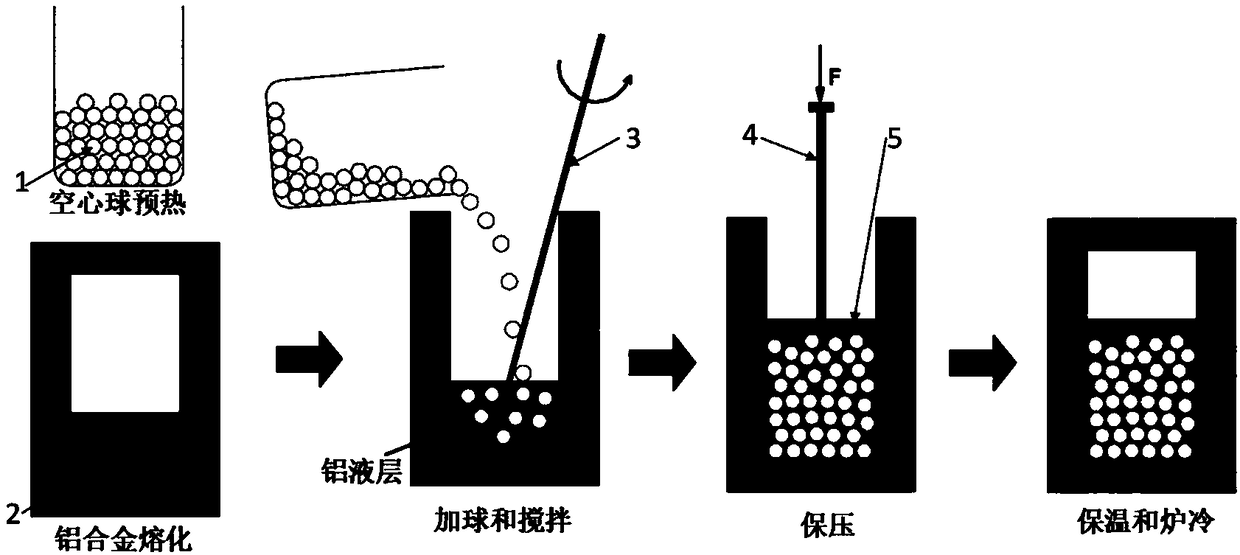

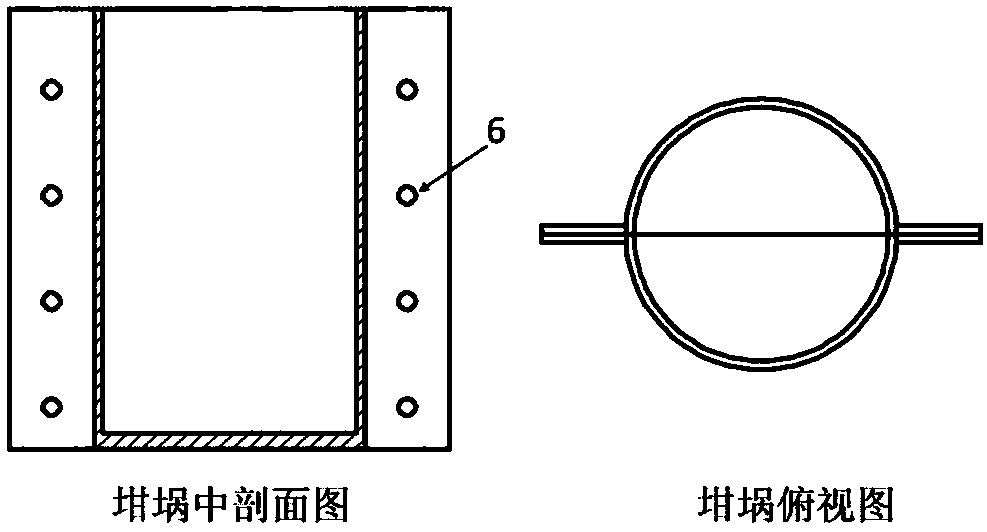

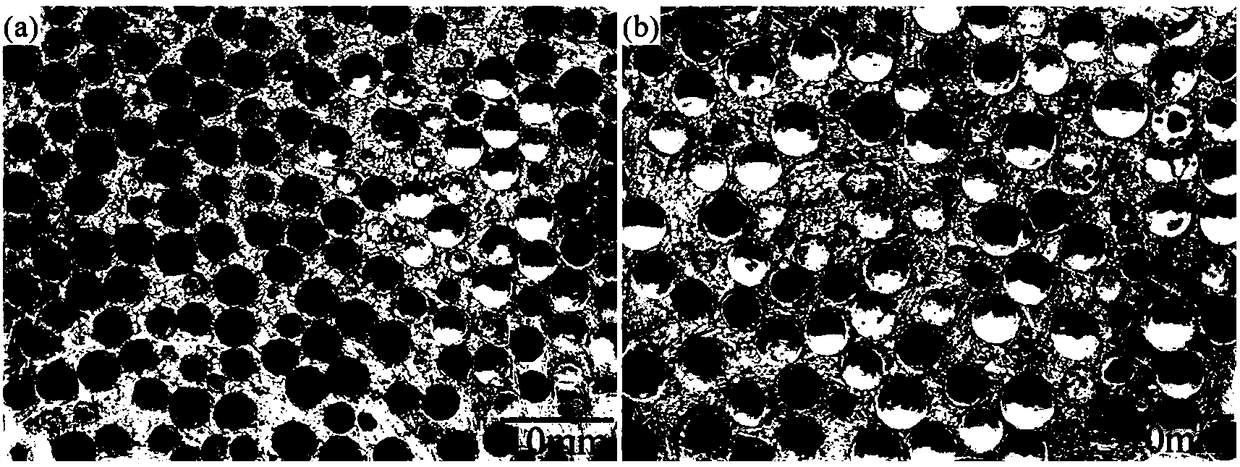

Metal-based hollow-ball composite foam material and preparation method thereof

The invention relates to a metal-based hollow-ball composite foam material and a preparation method thereof. The composite foam material comprises a metal matrix and ceramic hollow balls, wherein theceramic hollow balls are uniformly distributed in the metal matrix. The preparation method has the advantages of simple operation and low cost. In the prepared aluminum-based / aluminum oxide hollow-ball composite foam material, the interface bonding of an aluminum matrix and the hollow balls is good, the grain size of the hollow balls is larger, and the volume fraction of the hollow balls is larger. The plateau stress in a compressive stress-strain curve can reach 46MPa, the plateau phase is flat and long, and the prepared aluminum-based / aluminum oxide hollow-ball composite foam material is anexcellent light energy absorbing material. Under impulse load, the plateau stress of the composite foam can be increased to about 60MPa. The composite foam material has a significant advantage and a good application prospect in the field of shock resistance and explosion protection.

Owner:TSINGHUA UNIV

Method for preparing SiC particle reinforced foamed aluminium radical composite material

The invention relates to a preparing method for a SiC particle reinforced foam aluminum based composite, which comprises the following procedures: taking by mass among the total alloy amount 1-3% Mg, 6-8% Si and remainder Al, heating 10-20% SiC particles to melt into molten aluminum alloy, carrying out electromagnetic agitating evenly; adding 1-3% foaming agent by mass, after agitating evenly the foaming agent, keeping temperature and foaming 3-5 minutes; cooling after the molten aluminum grows steadily so as to cool and solidify the molten aluminum alloy foam, then getting SiC particle reinforced foam aluminum based composite with even hole structure and high porosity. The method adds molten aluminum alloy SiCp, which on one hand increases the viscosity of the molten alloy so as to prevent the bubbles dissolved from the foaming agent from floating upward and prolong the lives of the bubbles, on another hand, SiCp can also improve the strength of the foam aluminum. These bubbles take SiCp as a core and grow, then are cooled concurrently in all directions, this can overcome any shortcoming in solidifying and get foam aluminum of high porosity and even hole structure. By using electromagnetic agitating, the burning loss in the agitating blade can be avoided, this is useful for controlling the chemical components of the alloy.

Owner:SHANGHAI UNIV

Environment-friendly shield construction single-liquid synchronous grouting slurry

ActiveCN101935198AHigh energy consumptionSolve the problem of occupying a lot of landSolid waste managementHigh energySlurry

The invention relates to materials applicable to underground engineering construction, in particular to environment-friendly shield construction single-liquid synchronous grouting slurry. The slurry comprises the following materials in percentage by weight: 55 to 70 percent of sand, 10 to 20 percent of desulphurization gypsum, 10 to 20 percent of fly ash and the balance of additive and water, wherein the additive is a water-soluble high-molecular polymer thickening agent and / or a high-performance polycarboxylic water reducing agent; the water-soluble high-molecular polymer thickening agent is 0.5 to 1.0 percent of the total weight of the desulphurization gypsum and the fly ash; and the high-performance polycarboxylic water reducing agent is 0.75 to 1.25 percent of the total weight of the desulphurization gypsum and the fly ash. Compared with the conventional single-liquid synchronous grouting, the grouting slurry has the advantages of substituting the lime powder with high energy consumption and high pollution for waste desulphurization gypsum, along with the same performance. The grouting slurry solves the problems of a large amount of land occupied by the desulphurization gypsum and serious environmental pollution, also avoids the use of the lime powder with high energy consumption and high pollution and fulfills the aims of energy conservation and environmental protection. Meanwhile, a new way is found for the application of the desulphurization gypsum.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

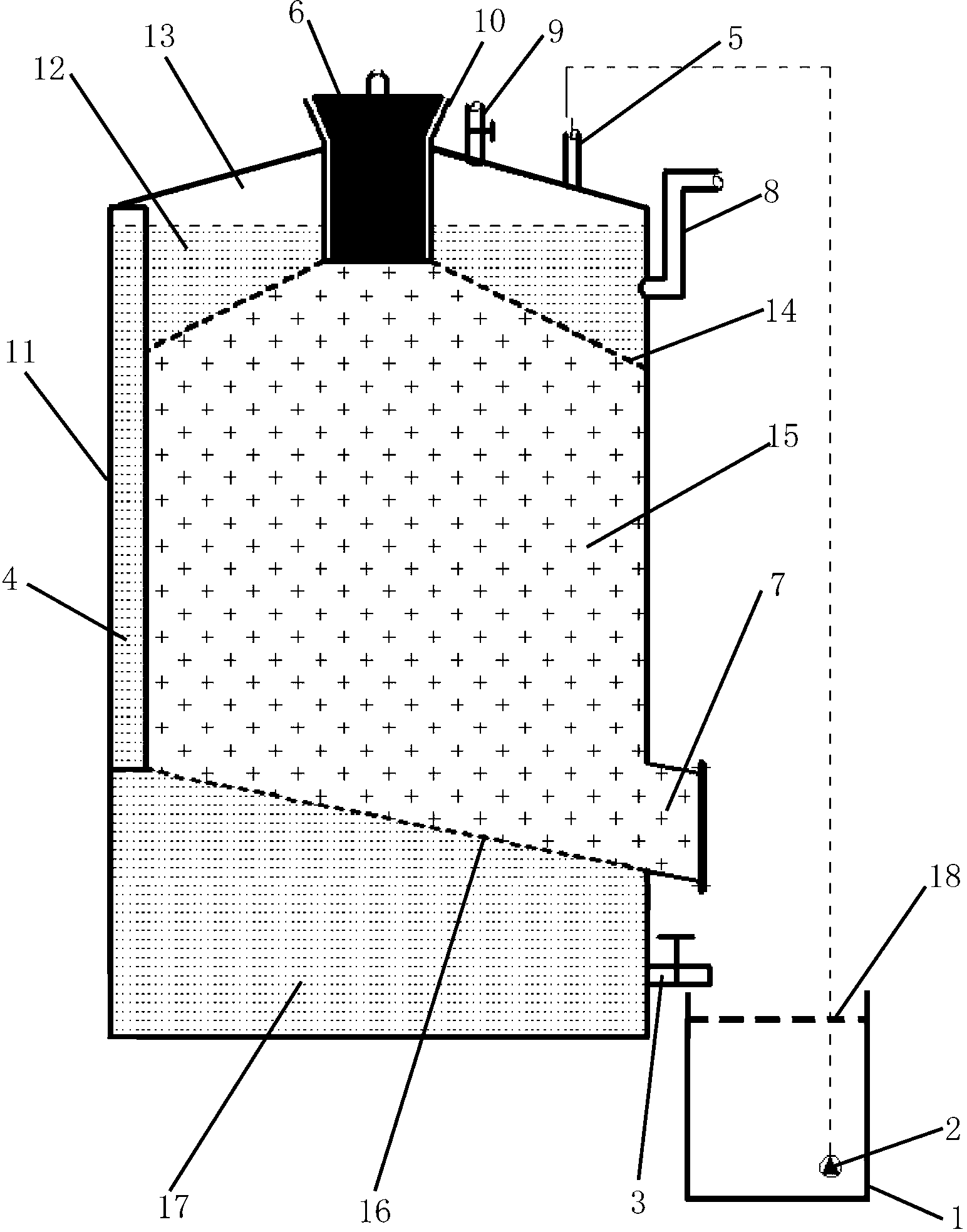

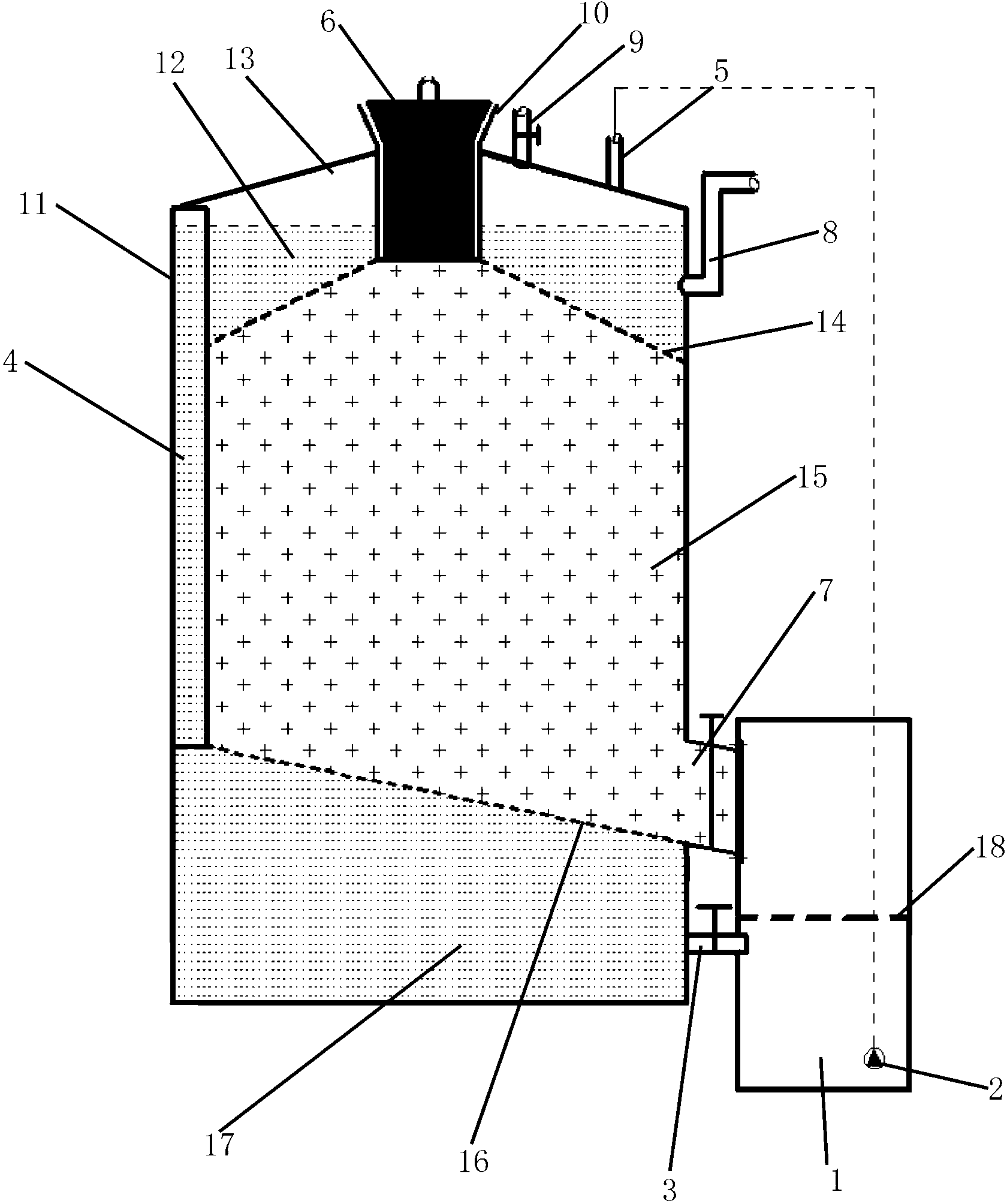

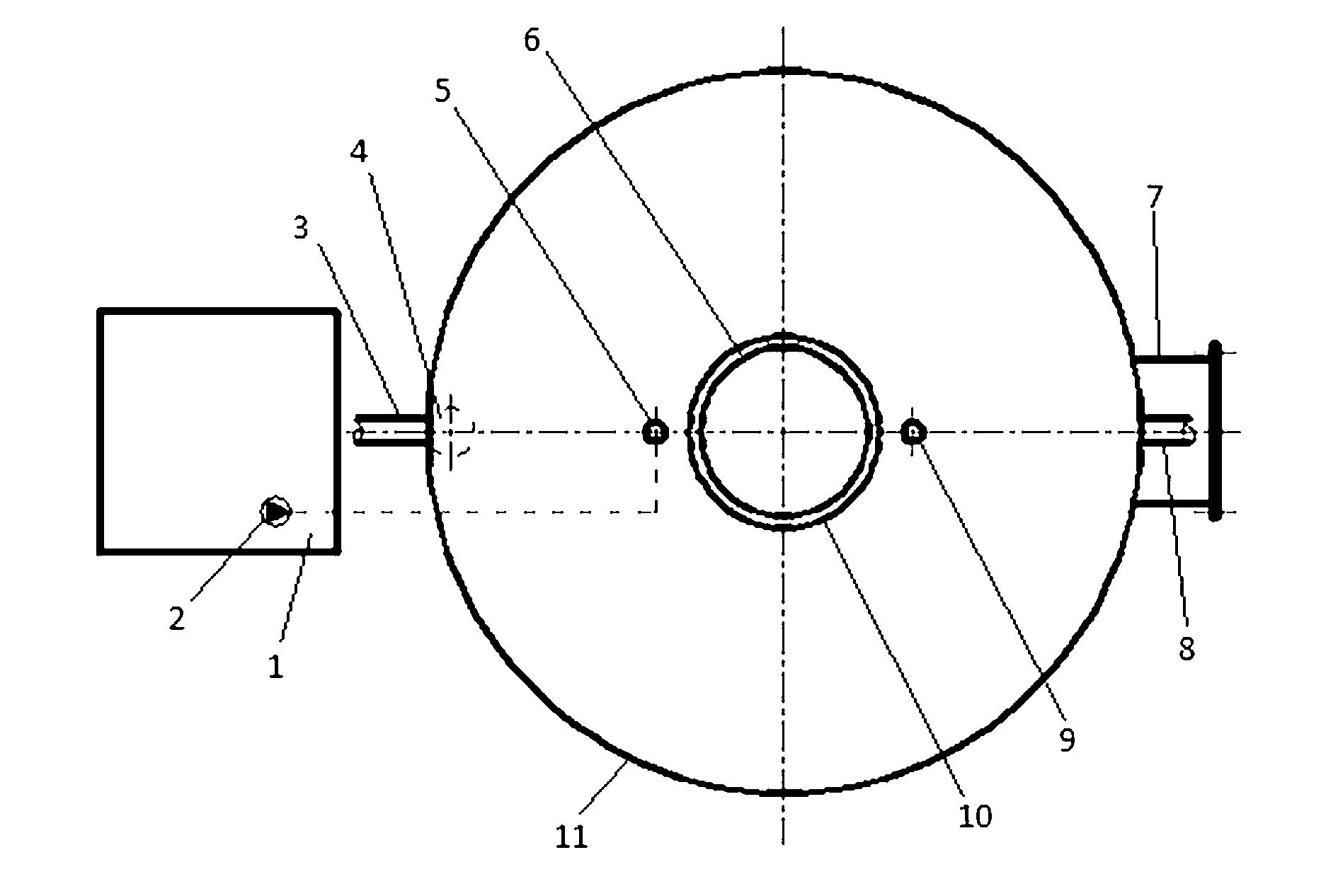

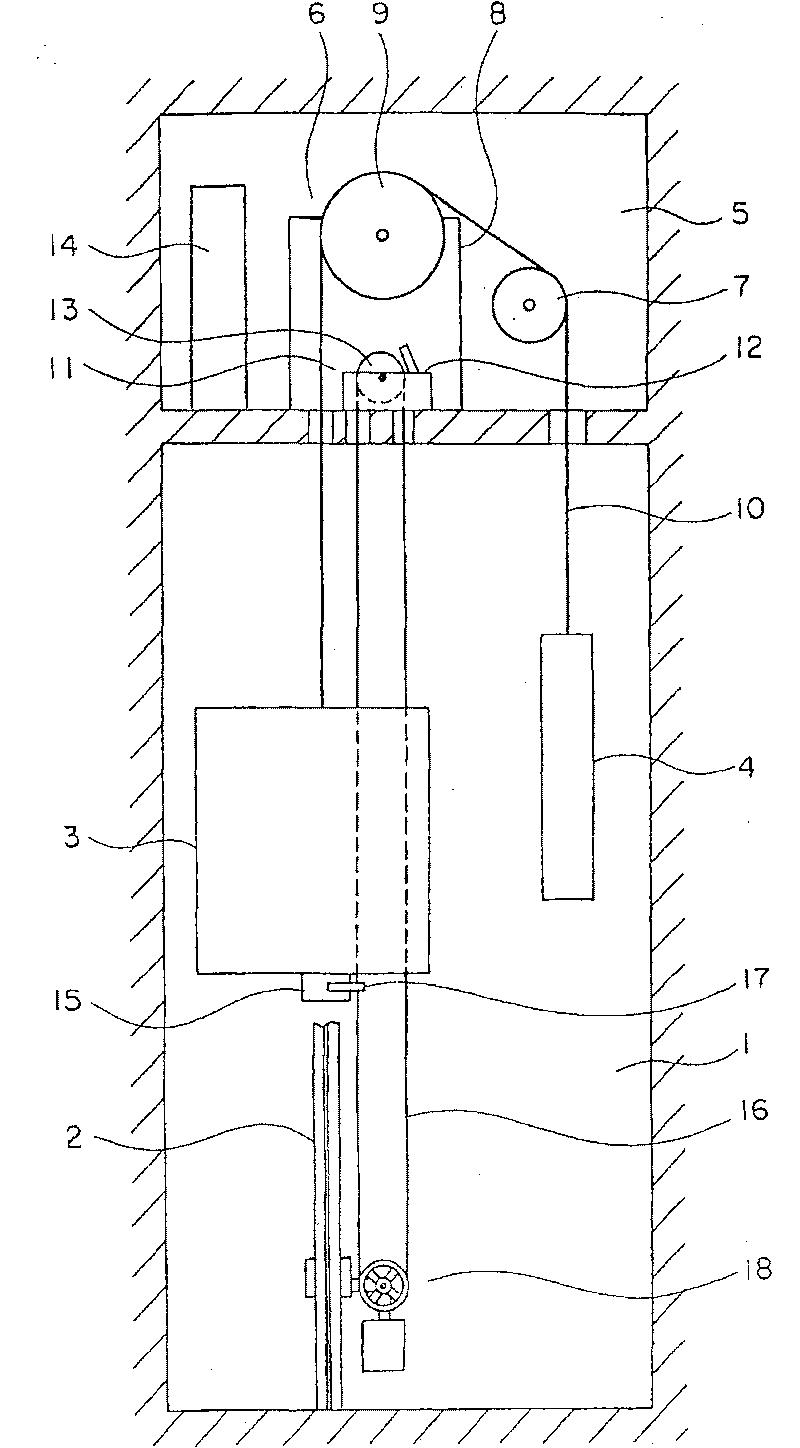

Large granular straw biogas fermentation device

ActiveCN103060179APrevent floating crustsIncrease concentrationGas production bioreactorsWaste based fuelLiquid slagFermentation

The invention belongs to a large granular straw biogas fermentation device in the field of an energy source. The large granular straw biogas fermentation device is composed of a fermentation tank (11) and a liquid storage unit (1), wherein a feeding pipe (10) and a biogas pipe orifice (9) are arranged at the top part of the tank body; a slag discharge hole (7) is arranged at the bottom part of the tank body; a gravity pusher (6) is arranged inside the feeding pipe (10); the gravity pusher (6) seals the feeding pipe (10); a circular table slag baffle ring plate (14) is arranged at the upper part inside the tank body; the upper end of the slag baffle ring plate (14) is connected with the outlet of the feeding pipe (10); the lower end of the slag baffle ring plate (14) is connected with the inner wall of the tank body; a sieve hole is arranged on the ring plate; a liquid slag separating plate (16) is arranged at the lower part inside the tank body; the periphery is connected with the inner wall of the tank body; a bleeder tube (3) is arranged at the bottom part of the fermentation tank (11), and a sieve plate (18) or / and a porous slag frame are arranged in the liquid storage unit (1). The large granular straw biogas fermentation device provided by the invention can directly digest the large granular straw, is low in energy consumption and low in input-output ratio, and can smoothly feed and discharge.

Owner:BIOGAS SCI RES INST MIN OF AGRI

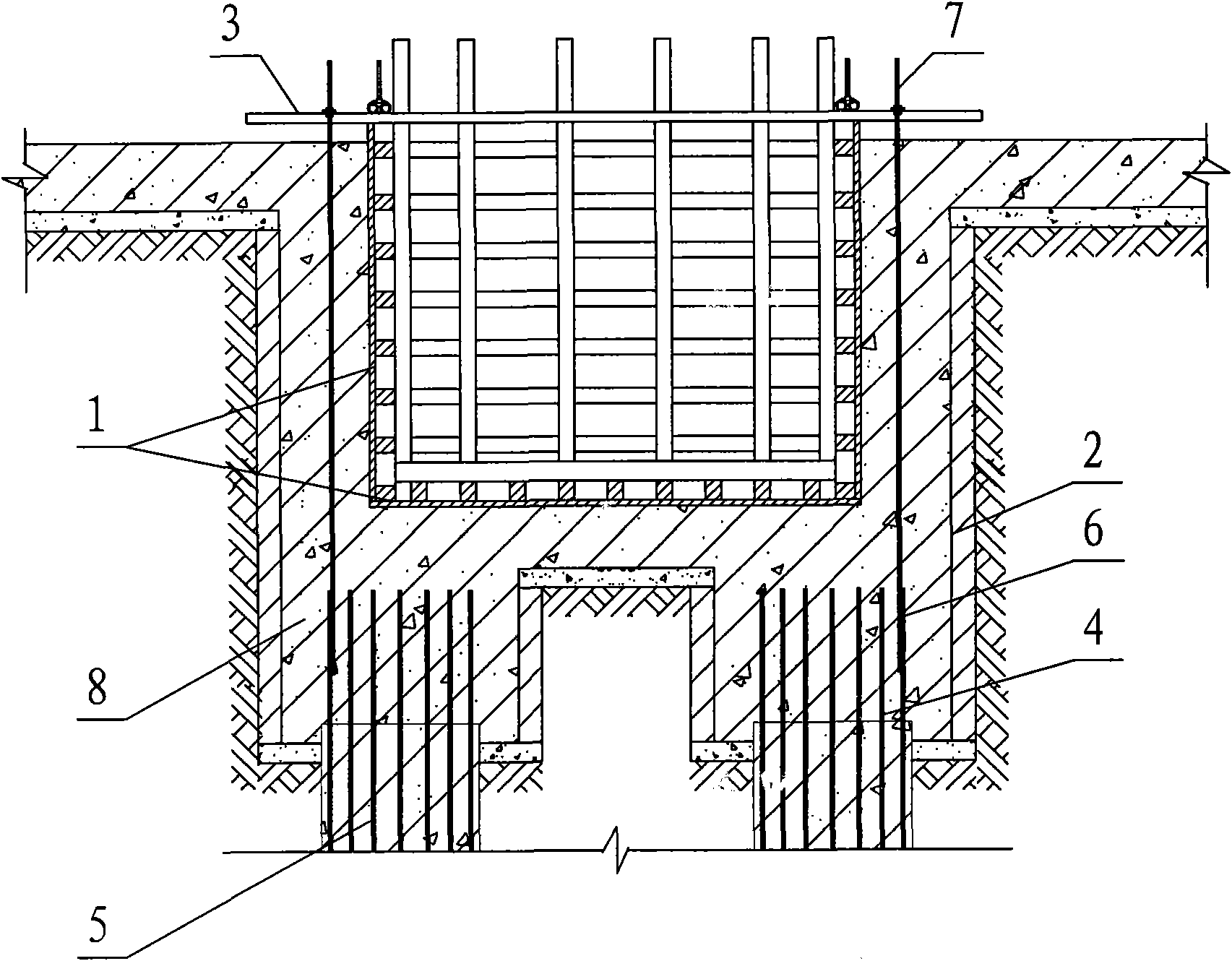

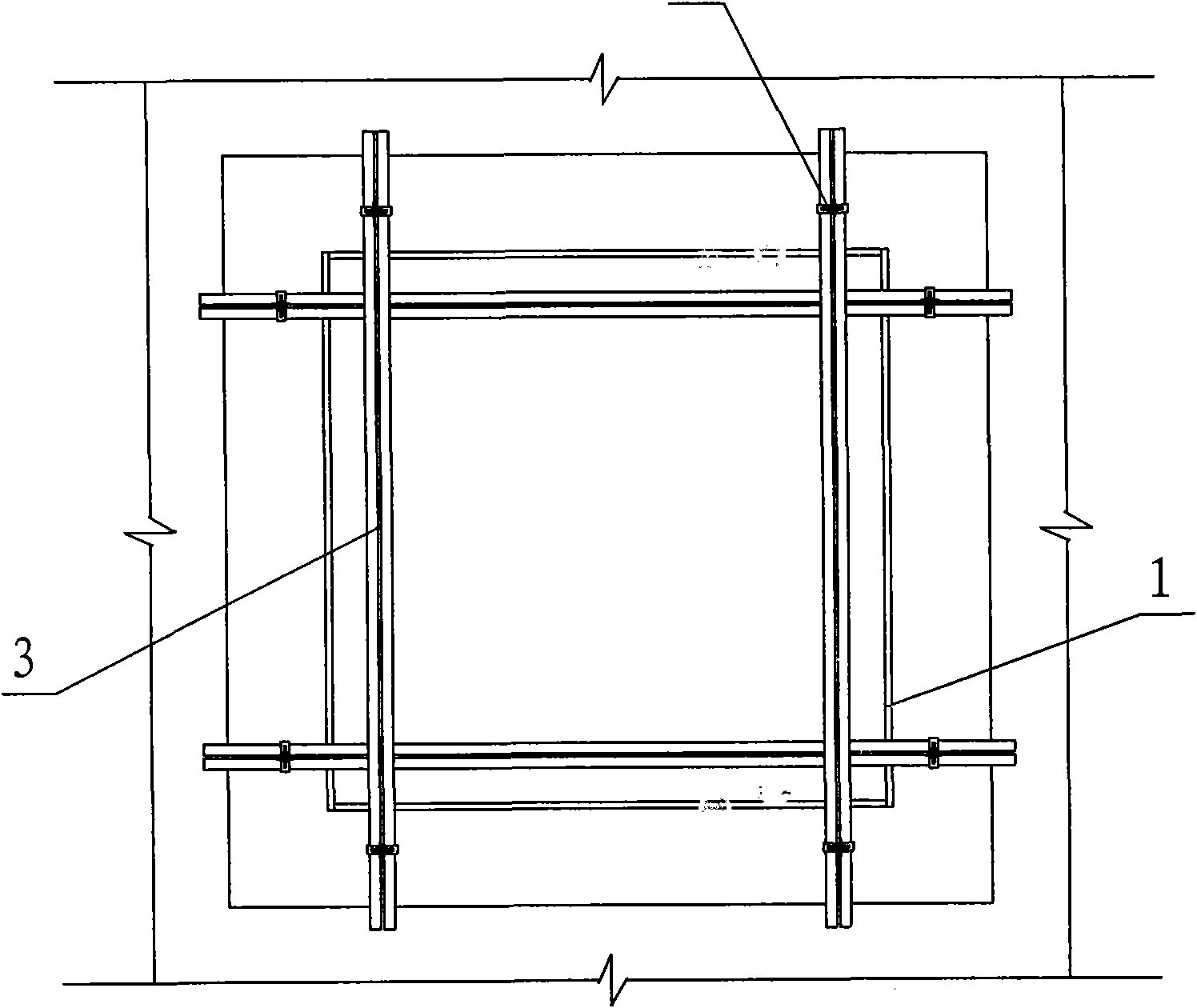

Construction method for resisting uplift in internal mold of concrete box

The invention provides a construction method for resisting the uplift in the internal mold of a concrete box. The method comprises the following steps: welding the longitudinal reinforcing steel bars on the box wall of the concrete box to be cast with the main reinforcing steel bars of a pile foundation at the bottom of a foundation pit; embedding an internal mold in the foundation pit and arranging a batten or a support tube at the top of the internal mold; tensioning the longitudinal reinforcing steel bars of the box wall, which are welded with the main reinforcing steel bars of the pile foundation, and then, fixedly connecting the upper ends of the longitudinal reinforcing steel bars of the box wall with the batten or the support tube; and casting the concrete and resisting the buoyant force of the concrete applying on the bottom plate of the box mold by the reaction force generated by the welded longitudinal reinforcing steel bars of the box wall and the batten or the support tube, so that the internal mold can be pressed by the support tube to prevent the internal mold from going up. The invention is suitable for resisting the buoyant force in the internal mold of a small-size concrete box and has the characteristics of reliable buoyancy resistance and easily guaranteed construction quality; and compared with the conventional method, the invention does not need secondary transport with high labor consumption, economizes on human resources and improves the production efficiency.

Owner:HUNAN SUNPEAK CONSTR

Alumina-silica drainage agent and preparation method thereof

ActiveCN104493150AImprove performanceNo pollution in the processMelt-holding vesselsCinnabarSteelmaking

The invention provides an alumina-silica drainage agent and a preparation method thereof and belongs to the field of amorphous surface fireproofing materials for steelmaking industries. According to the technical scheme, the alumina-silica drainage agent is prepared from pottery cinnabar with the granularity of 0.5-1.2mm, desert silica sand with the granularity of 0.3-0.9mm, flake graphite with the granularity smaller than or equal to 75 mu m, and an adhesive. The preparation method includes first drying the pottery cinnabar and the desert silica sand, adding the flake graphite and the adhesive, and performing stirring in a barrel type stirrer to prepare the alumina-silica drainage agent. The alumina-silica drainage agent is clean, environmentally friendly, and capable of effectively increasing a pouring rate of a product to above 98%, meanwhile substantially reducing product costs, effectively reducing discharge of exhaust gases and dust, and meeting requirements for product qualities, prices and steel liquid purity degrees in present steel industries.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

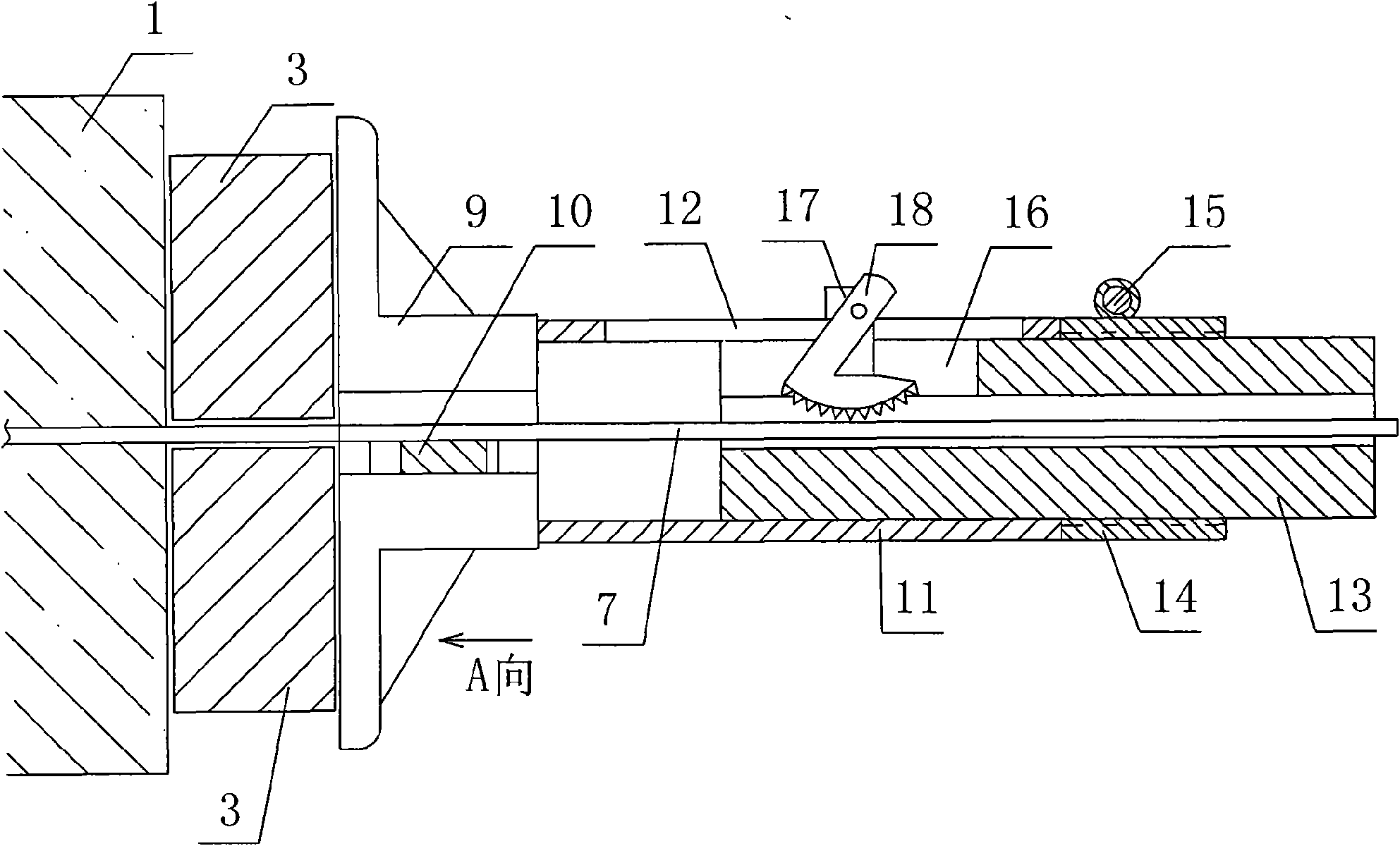

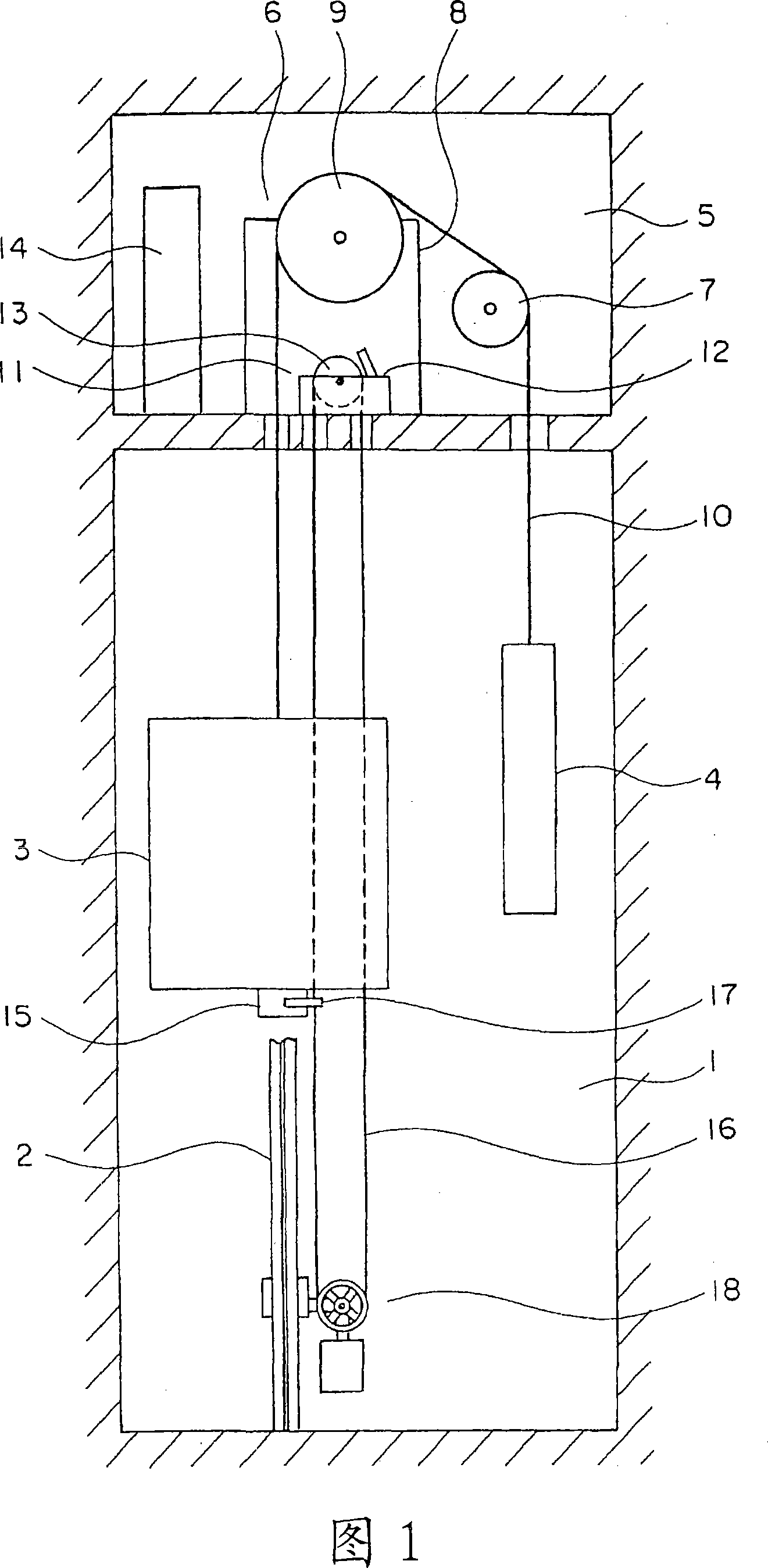

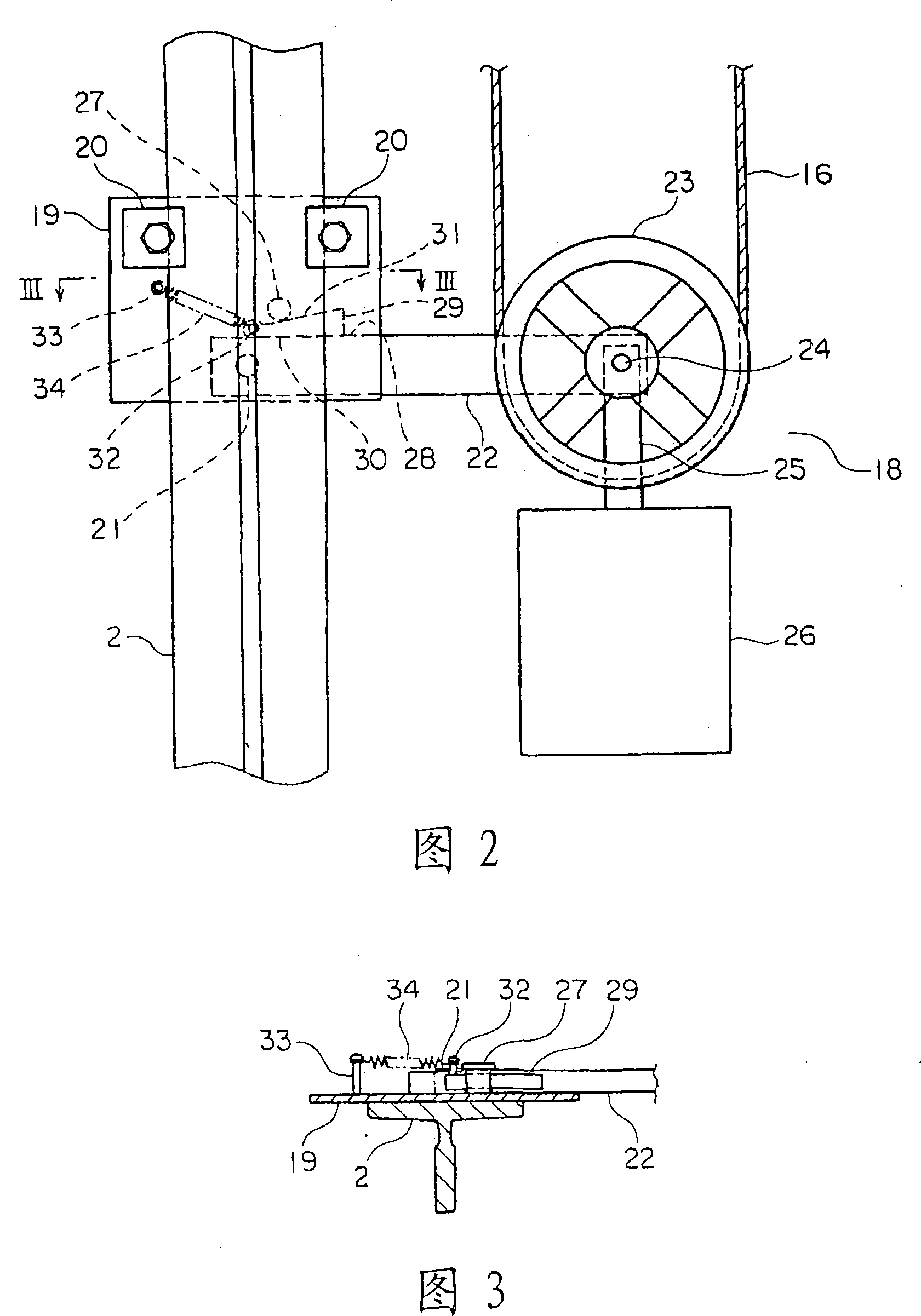

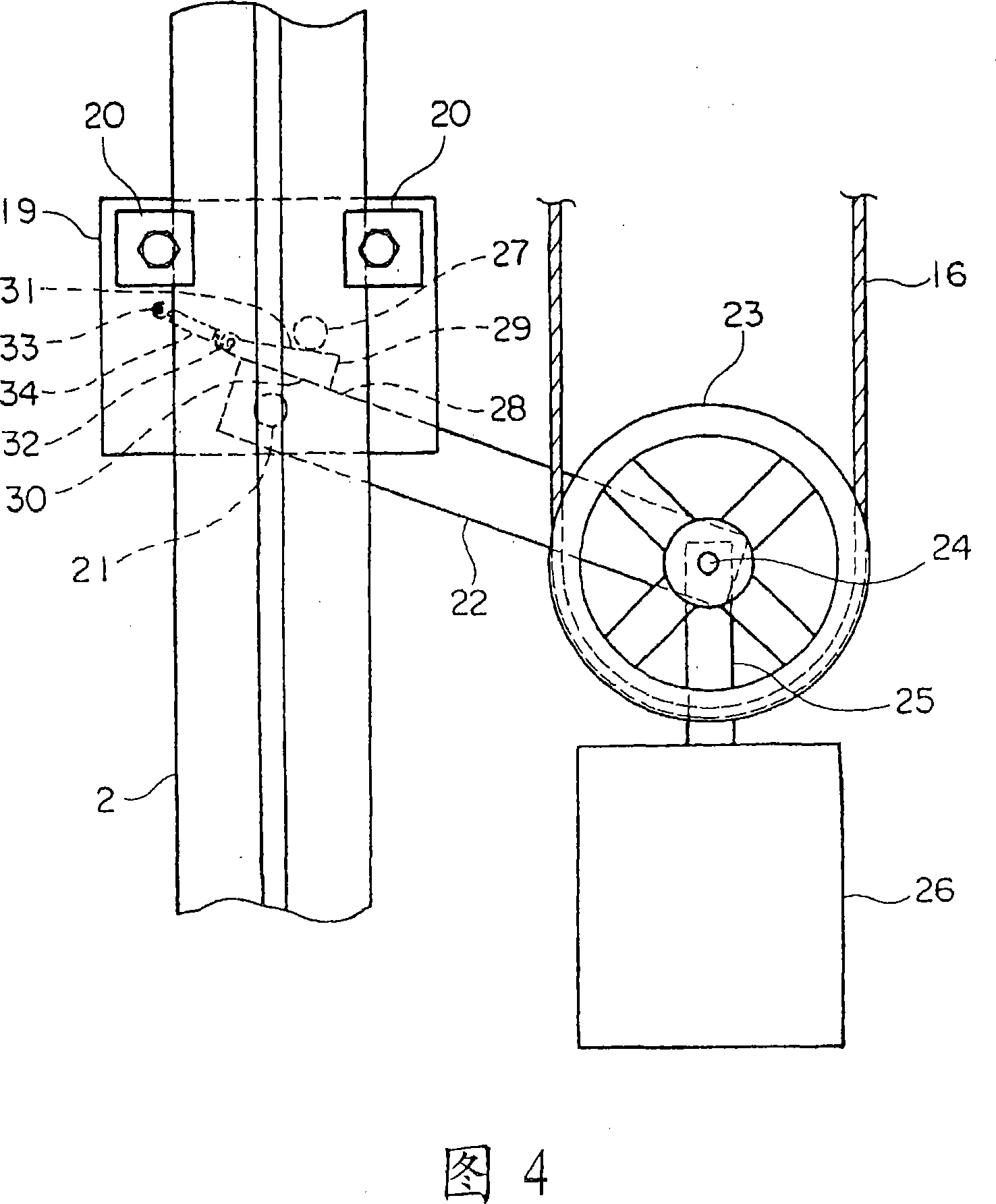

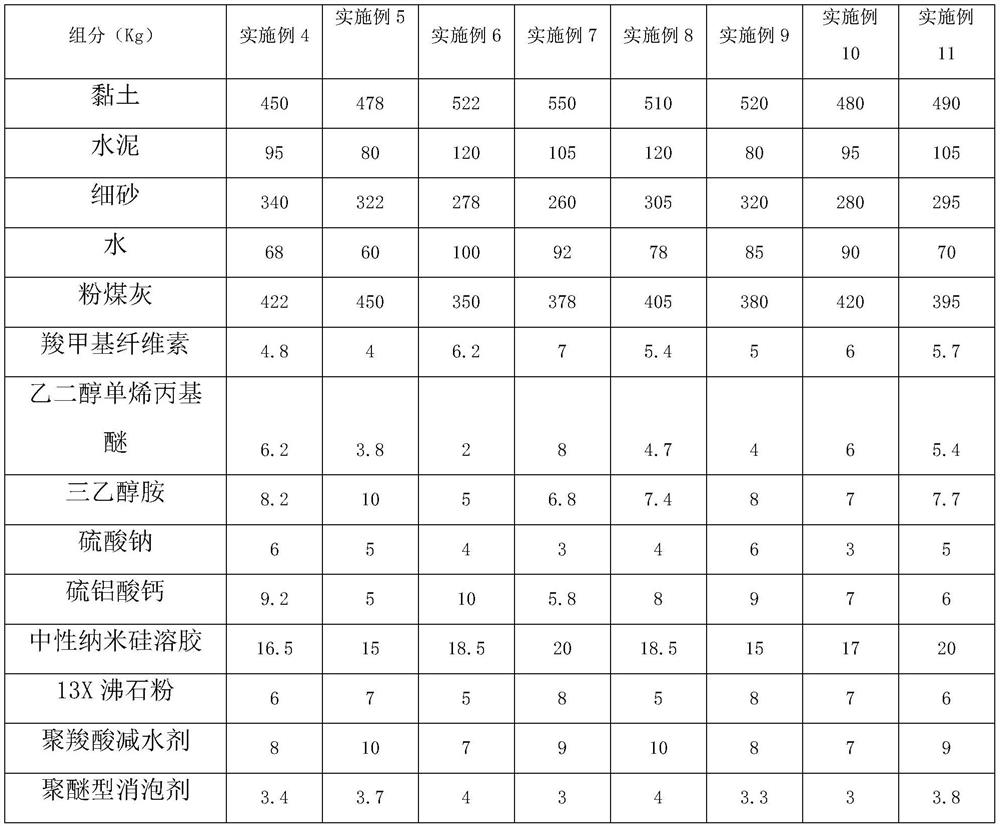

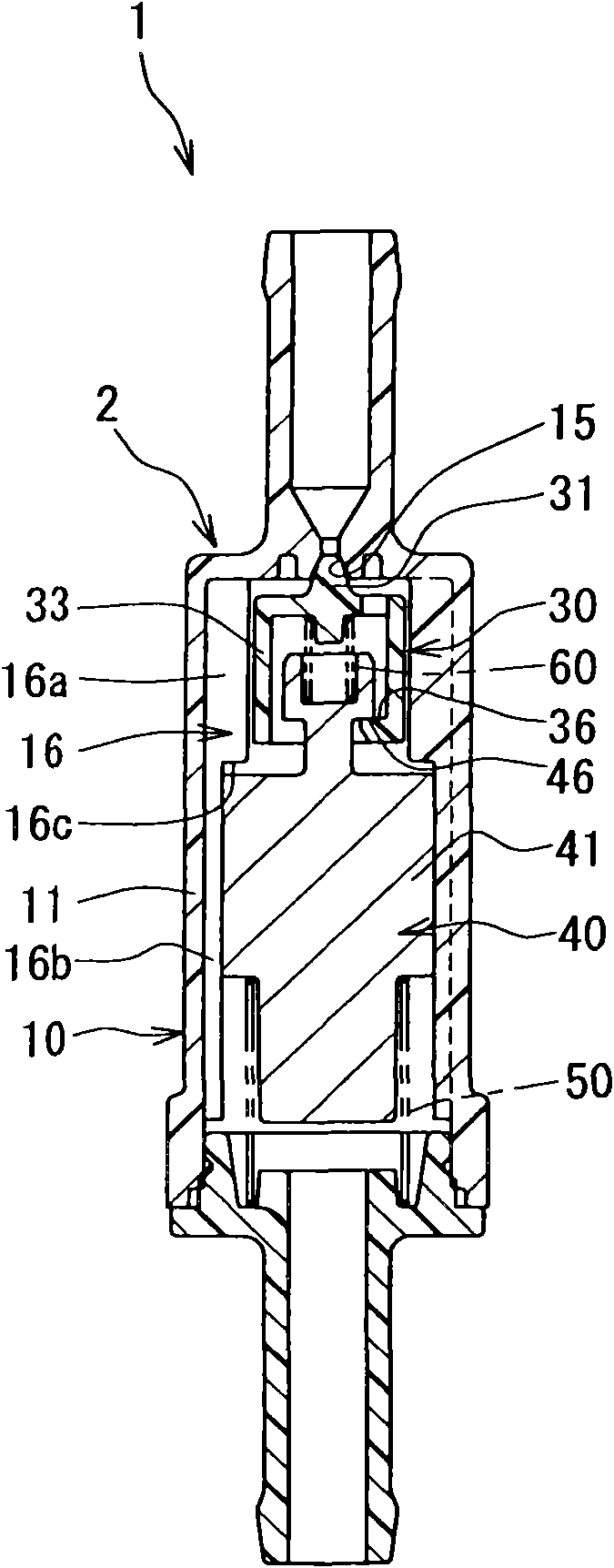

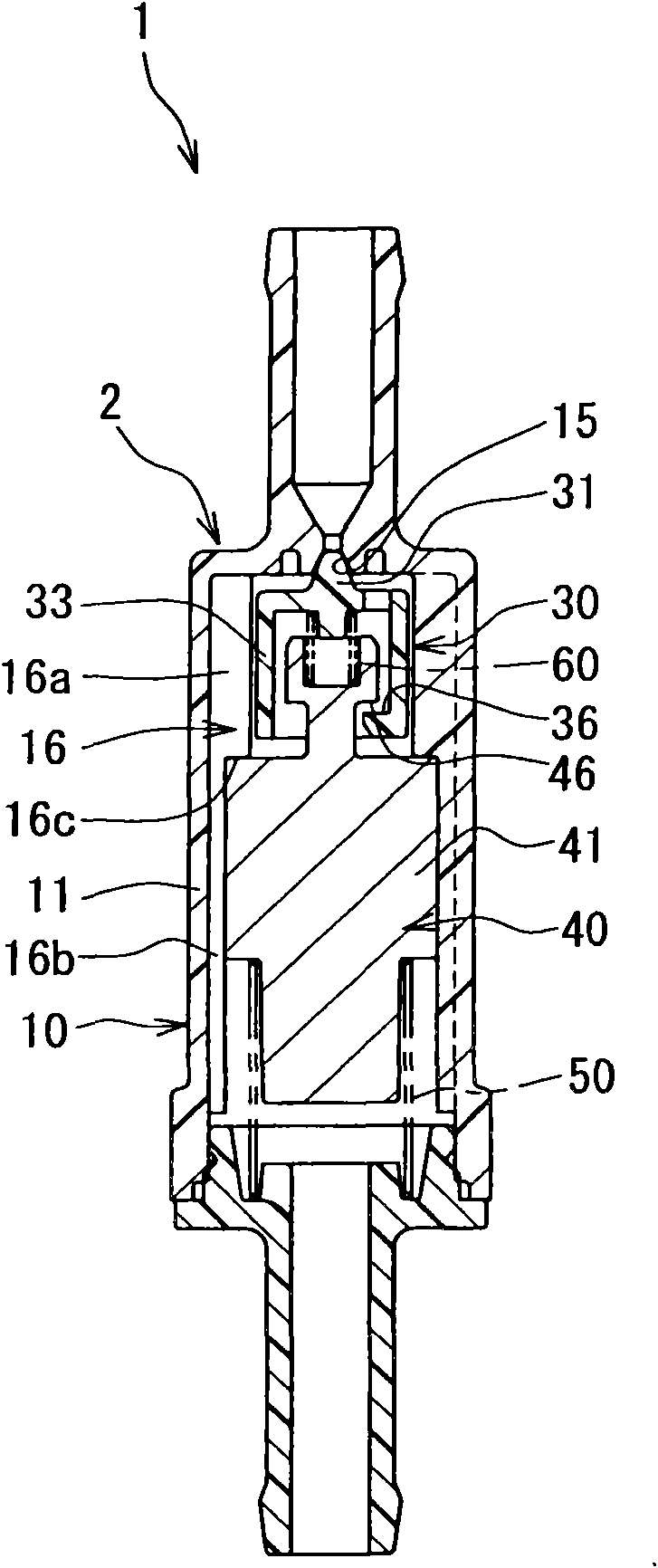

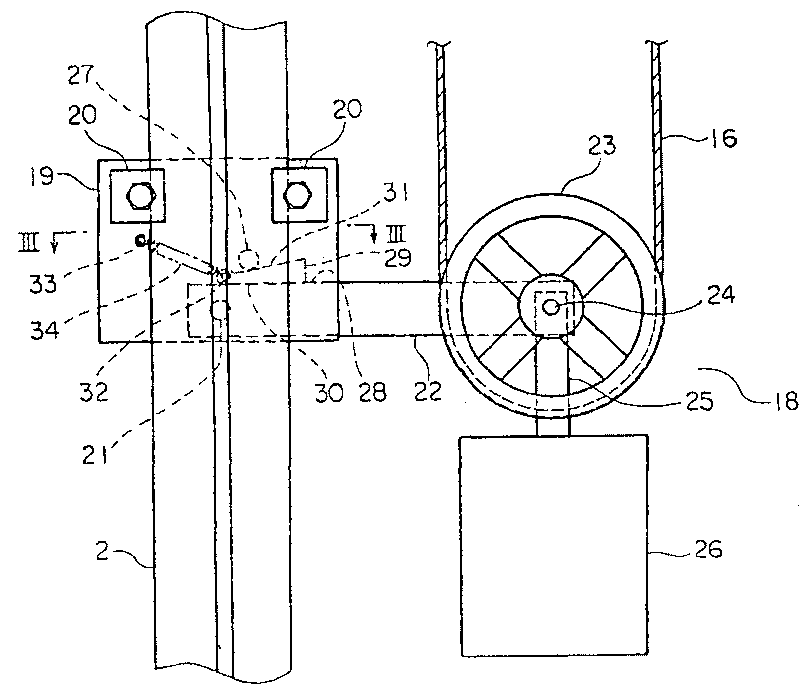

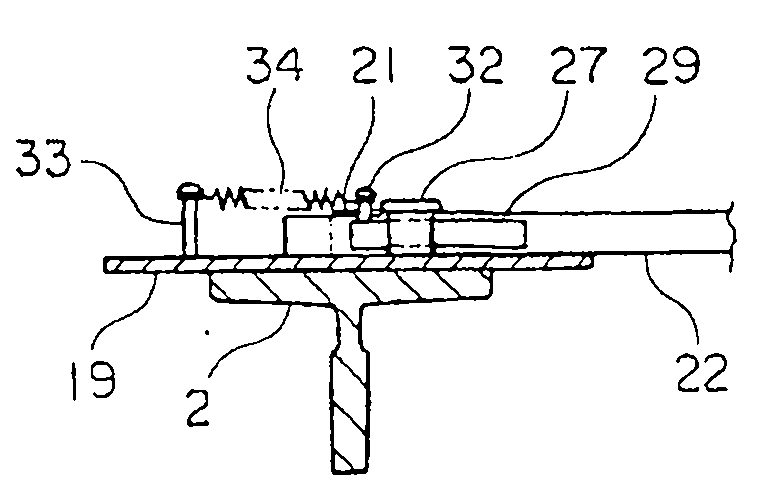

Tensioner apparatus for overspeed governor of elevator

The invention provides a tension pulley device for an elevator governor rope has a tension pulley suspended by the governor rope, a pivoting member rotated by a vertical displacement of the tension pulley, a restraining member whose distance from the pivoting member is reduced when the pivoting member is pivoted into the direction in which the tension pulley is displaced upward, a wedge inserted between the pivoting member and the restraining member, and an urging member for urging the wedge into the direction in which the wedge pushes and spreads the distance between the pivoting member and the restraining member. A supporting member is provided in a hoistway, and the pivoting member and the restraining member are disposed on the supporting member. The wedge has a first contact surface coming into contact with the pivoting member and a second contact surface inclined relative to the first contact surface and coming into contact with the restraining member. Pushing of the wedge into the gap between the pivoting member and the restraining member prevents the tension pulley from being displaced upward.

Owner:MITSUBISHI ELECTRIC CORP

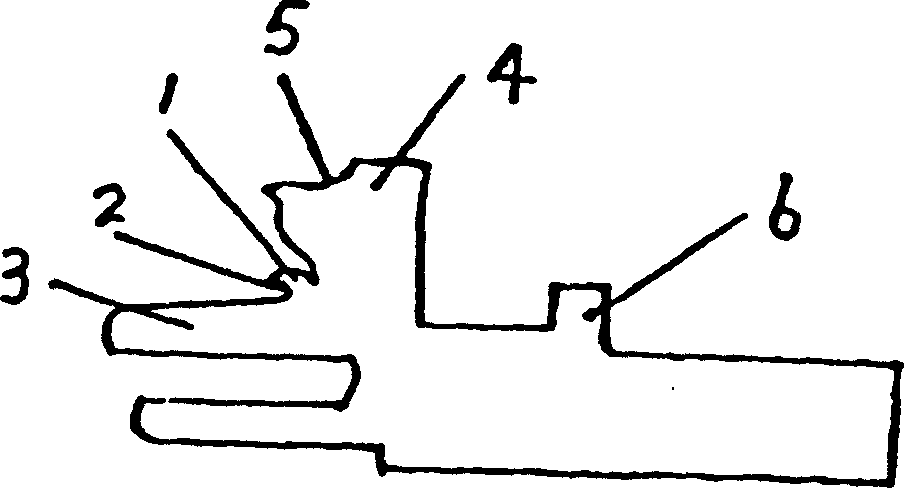

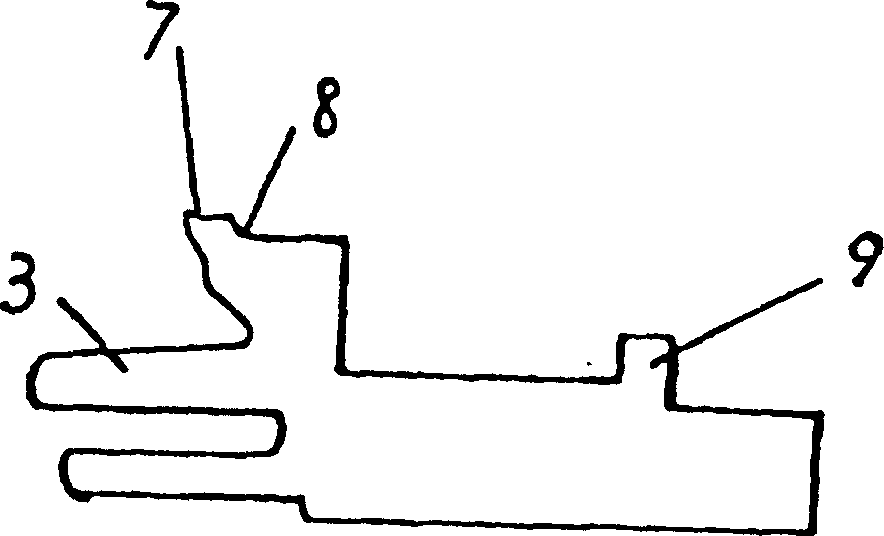

Sinker for loop cutting

The invention provides the terry sinker used for weaving terry cloth on single cylinder knitting machine. The sinker is a couple of sinkers which are composed of a higher sinker and a lower one. There two are inserted into the same tongue-and-groove. There is a blade, facing the center of syringe, which has been grinded smoothly to an arch on the top of the higher sinker, and the lower one is against. The two face-to-face blades form a semicircular concave, and as a supporting side of plush yarn, these blades cling to each other and are controlled by each sinker to move radial to form stitch and cut stitch. With this kind of sinker, knitting terry gelatin suede cover directly on the machine, it replaces the napping technology, solves the problem of depilation of gelatin suede cover and improves the quality of printed matter.

Owner:唐欢利

Heave deformation resisting construction method for foundation pit excavation above existing tunnel

The invention discloses a heave deformation resisting construction method for foundation pit excavation above an existing tunnel. The heave deformation resisting construction method comprises the following steps that grouting pre-reinforcing is conducted on bottom layers around the existing tunnel and overlaying soil layers of the existing tunnel; primary slope putting and soil nailing shotcrete anchor supporting are constructed from the vertical upper part of the existing tunnel; primary slope putting and soil nailing shotcrete anchor supporting are constructed from the periphery of a foundation pit; foundation pit enclosure is constructed, and an internal support are erected; secondary slope putting and soil nailing shotcrete anchor supporting are constructed from reserved core soil; connecting grooves are dug; a grouting pipe curtain is constructed; and the reserved core soil is excavated segment by segment in a groove skipping mode. The heave deformation resisting construction method adopts the mode of combining formation pre-reinforcing with the grouting pipe curtain, the formation stiffness can be effectively increased, the formation is prevented from floating, thus the deformation value of the existing tunnel structure is controlled, long-term stable operation of the tunnel is ensured, and the application range is wide; and a method of reserving original core soil abovethe tunnel is adopted, it can be ensured that the overlaying gravity of the tunnel continuously exists, and interference to the stability of an underground structure is small.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

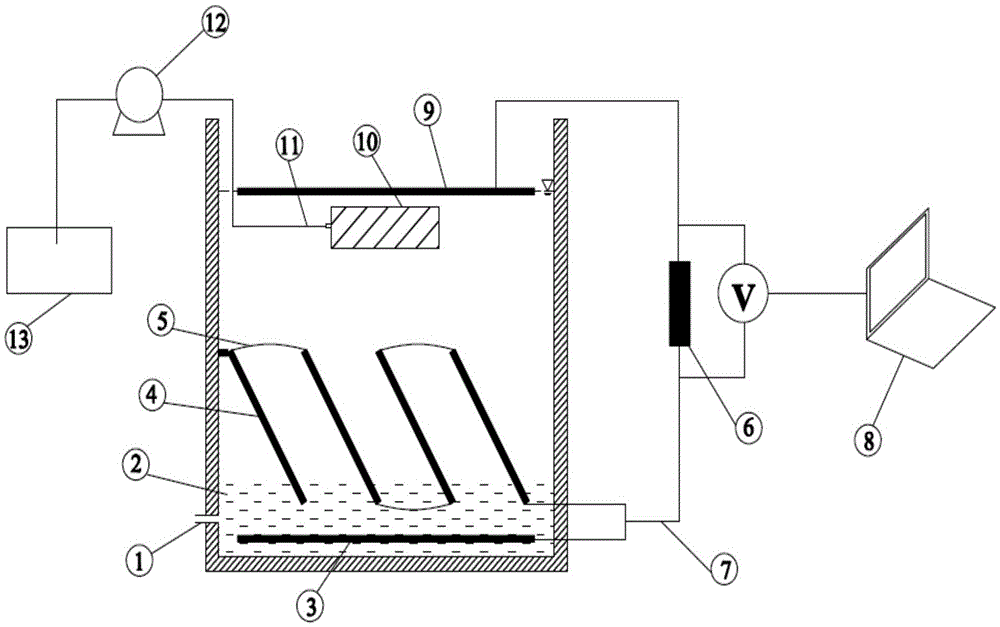

Apparatus for realizing surplus sludge disposal and membrane filtration through coupled single-chamber inclined-plate multi-positive-electrode microbial fuel cell

InactiveCN105609847AReduce extra powerReduce pollutionFinal product manufactureTreatment with anaerobic digestion processesElectrical batteryFiltration

The invention provides an apparatus for realizing surplus sludge disposal and membrane filtration through a coupled single-chamber inclined-plate multi-positive-electrode microbial fuel cell, and belongs to the technical field of environmental engineering. Anaerobic zone sludge is arranged at the bottom of the apparatus; a carbon felt positive electrode is arranged in the anaerobic zone sludge; inclined-plate positive electrodes are arranged in the middle part; the carbon felt positive electrode and the inclined-plate positive electrodes are connected through wires to form the multiple positive electrodes; a carbon felt negative electrode is suspended in a supernatant liquor; the upper layer is exposed in the air to be used as an air negative electrode; the positive electrodes and the air negative electrode are connected through an external electric wire, and are connected with an external resistor; and a hollow fiber membrane module is arranged in the supernatant liquor close to the position of the negative electrode. Due to the additional inclined-plate positive electrodes of the cell, the positive electrode area can be enlarged, so that rich organic matters in the middle of a sedimentation basin can be fully utilized to improve power generation efficiency, effectively prevent sludge from floating upwardly, and slow down membrane pollution; positive-electrode electricity-generating bacteria can utilize the organic matters in the middle and at the bottom of the sedimentation basin, so that the surplus sludge in the sedimentation basin can be reduced while extra electric energy can be generated as well; and therefore, the cost for disposing, conveying and landfilling of the surplus sludge can be lowered, and the generated electric energy can be stored and utilized.

Owner:DALIAN UNIV OF TECH

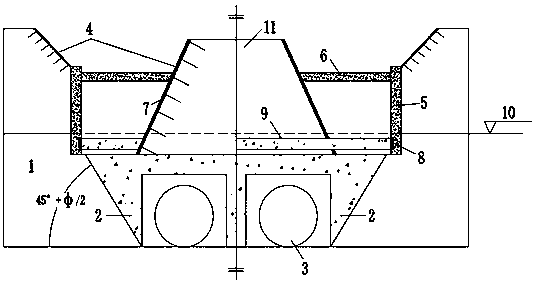

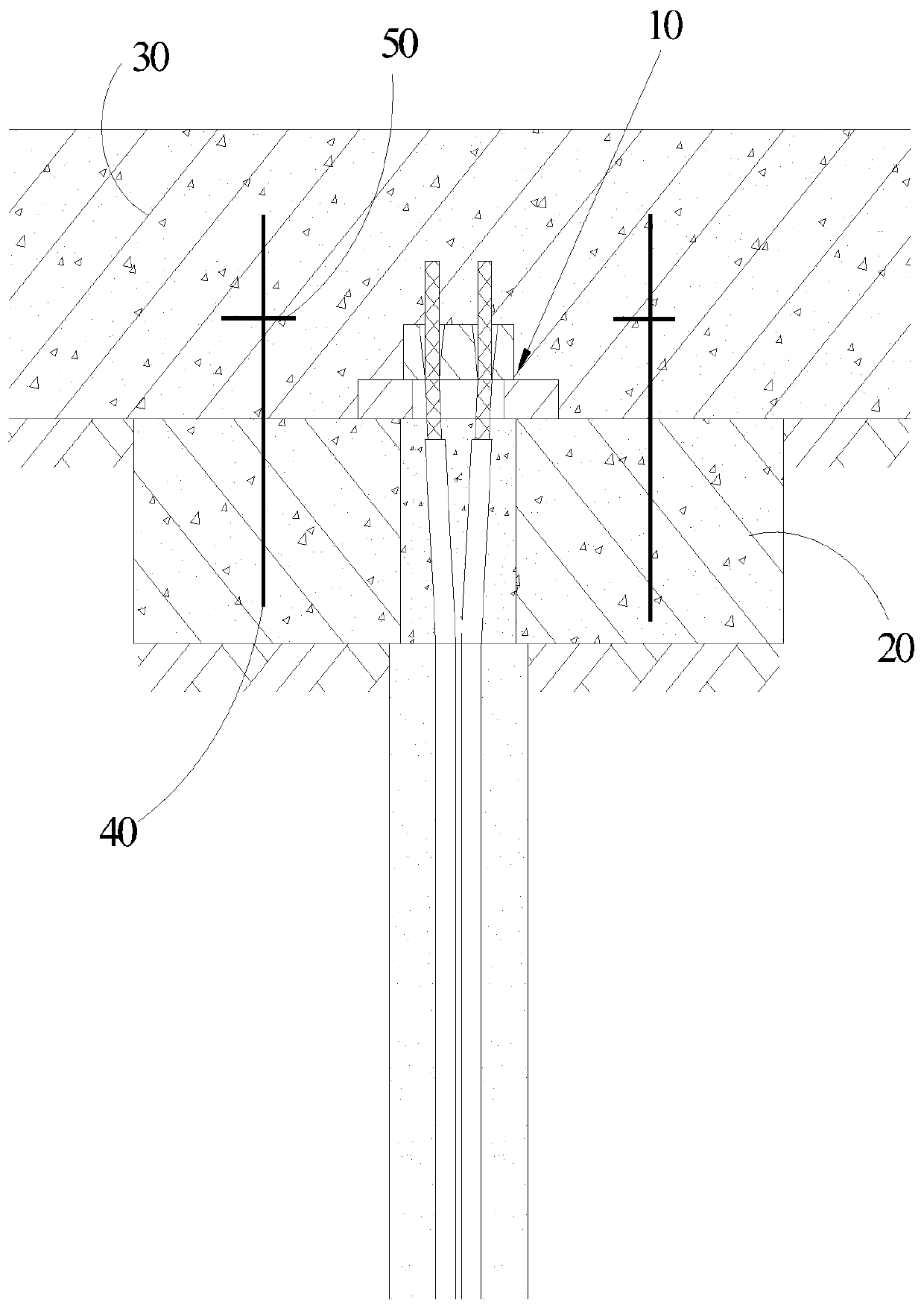

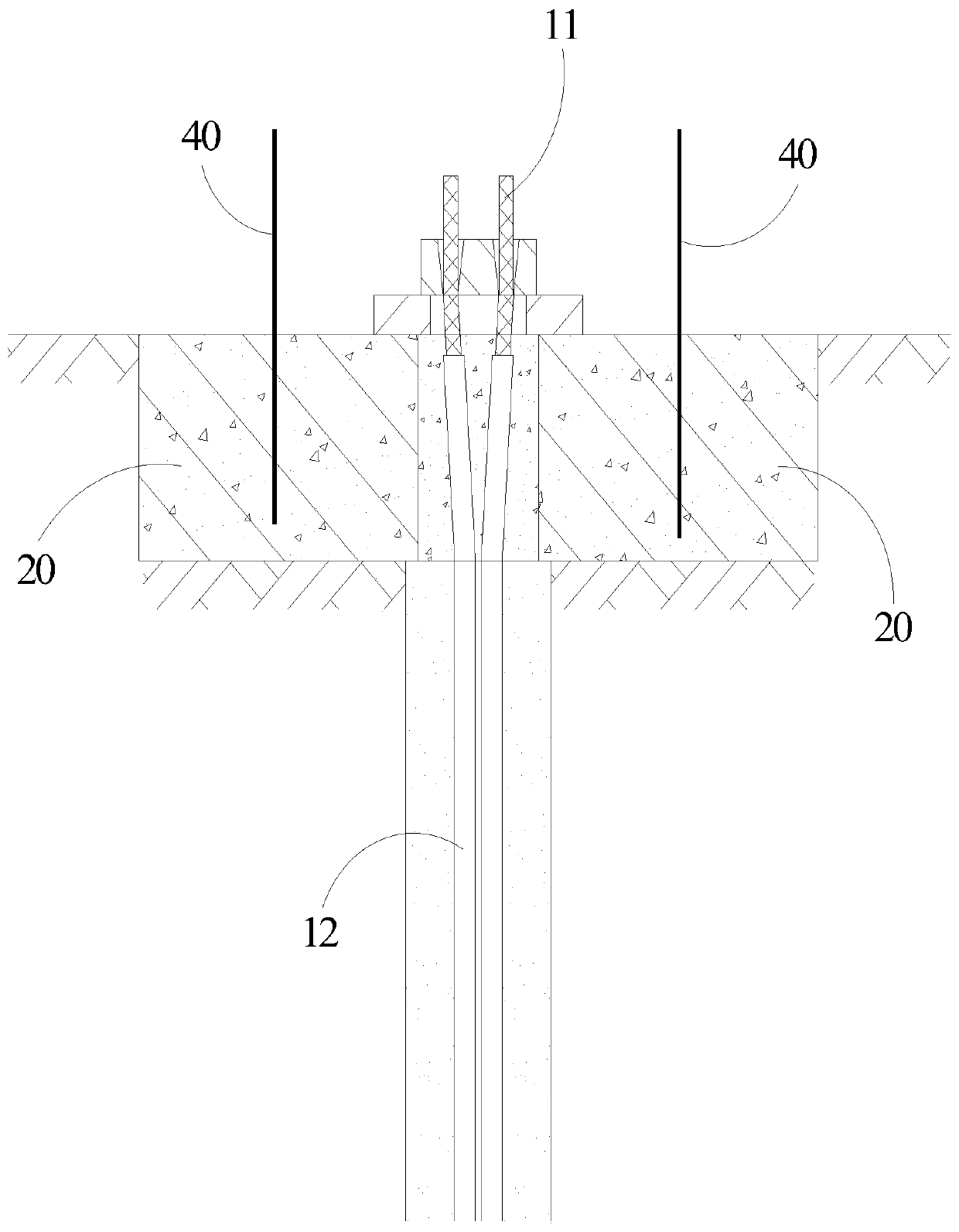

Pre-tensioned and post-anchored prestressed anti-floating anchor rod construction method

InactiveCN109811804ATension lock for easyPrevent floating deformationProtective foundationBulkheads/pilesReinforced concretePre stress

The invention relates to the technical field of prestressed anti-floating anchor rod construction, and discloses a pre-tensioned and post-anchored prestressed anti-floating anchor rod construction method. The pre-tensioned and post-anchored prestressed anti-floating anchor rod construction method comprises the following steps: 1) performing prestressed anchor rod construction; and forming a drilling hole in a soil body by construction, lowering a prestressed anchor rod to drill a hole, and pouring mud in the drilled hole after the prestressed anchor rod is lowered, wherein the prestressed anchor rod comprises an anchor head and a rod body; 2) enabling the anchor head to be positioned out of the drilled hole, and enabling the rod body to be located in the drilled hole; excavating along theperiphery of the anchor head to form a construction groove, and performing reinforced concrete construction in the construction groove to form an anchor pier; 3) tensioning and locking the prestressedanchor rod; and 4) constructing an underground structure above the soil body, and anchoring the anchor head into the underground structure. Therefore, prestressed anchor rod construction, anchor pierconstruction and underground structure construction are not interfered with one other, and construction management is facilitated; tensioning and locking are facilitated, and construction steps are simplified; and moreover, restraining force is generated on the underground structure to prevent the underground structure from floating upwards, and the underground structure is prevented from floating upwards and deforming, so that an anti-floating effect is enhanced.

Owner:SHENZHEN INST OF GEOLOGICAL ENVIRONMENT CO LTD

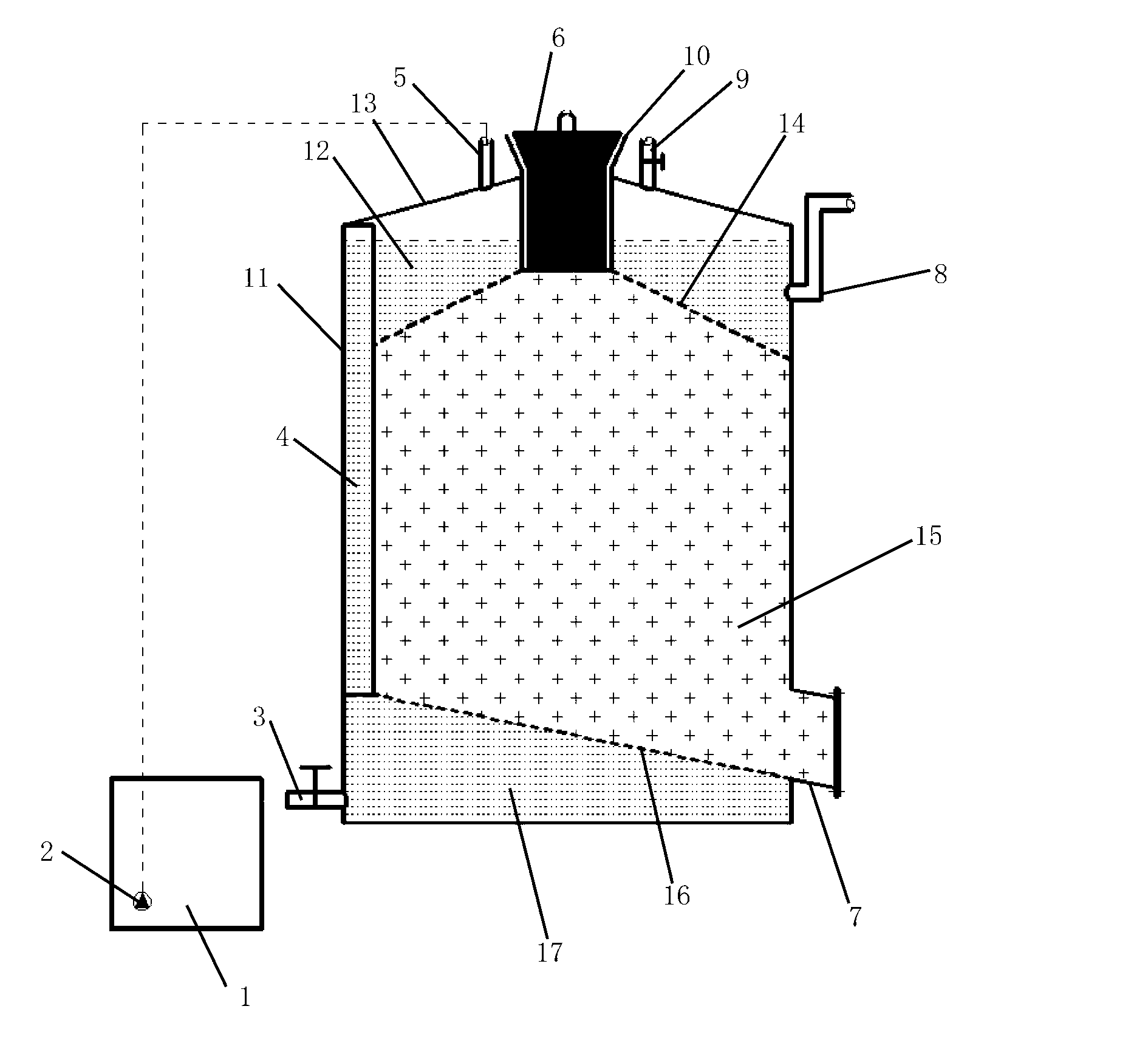

High-concentration straw methane fermentation equipment

ActiveCN103074208APrevent floating crustsIncrease concentrationBiological substance pretreatmentsGas production bioreactorsHigh concentrationLiquid slag

The invention belongs to the field of energy sources and relates to high-concentration straw methane fermentation equipment which comprises a fermentation tank (11) and a liquid storage unit (1), wherein a feed pipe (10) and a methane pipe orifice (9) are arranged at the top of a tank body; a slag discharge port (7) is formed at the bottom of the tank body; the feed pipe (10) is internally provided with a gravity material pusher (6); a circular-table-shaped slag blocking ring plate (14) is mounted at the upper part in the tank body; the upper end of the slag blocking ring plate (14) is connected with an outlet of the feed pipe (10) and the lower end thereof is connected with an internal wall of the tank body; sieve pores are formed in the ring plate; a liquid-slag separation plate (16) is mounted at the lower part in the tank body; sieve pores are formed in the liquid-slag separation plate (16); the periphery of the liquid-slag separation plate (16) is connected with the internal wall of the tank body; a liquid discharge pipe (3) is arranged at the bottom of the fermentation tank (11); and an outlet of the liquid discharge pipe (3) corresponds to or is connected with the liquid storage unit (1). The high-concentration straw methane fermentation equipment can directly consume bulky-grain straw, is low in energy consumption, smooth in feeding and discharging, and low in input-output ratio.

Owner:BIOGAS SCI RES INST MIN OF AGRI

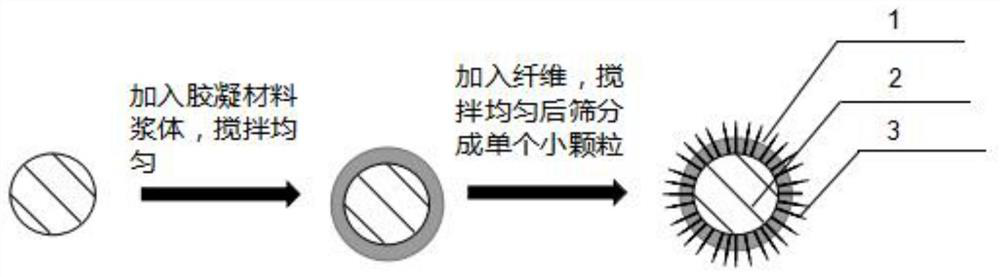

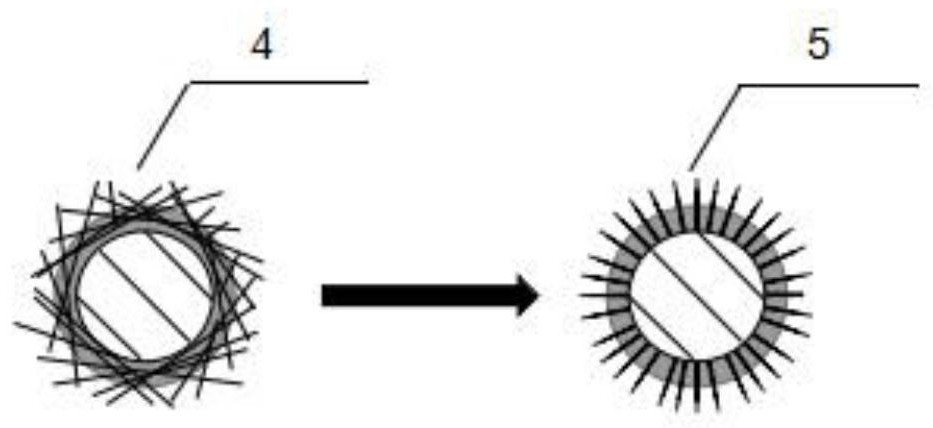

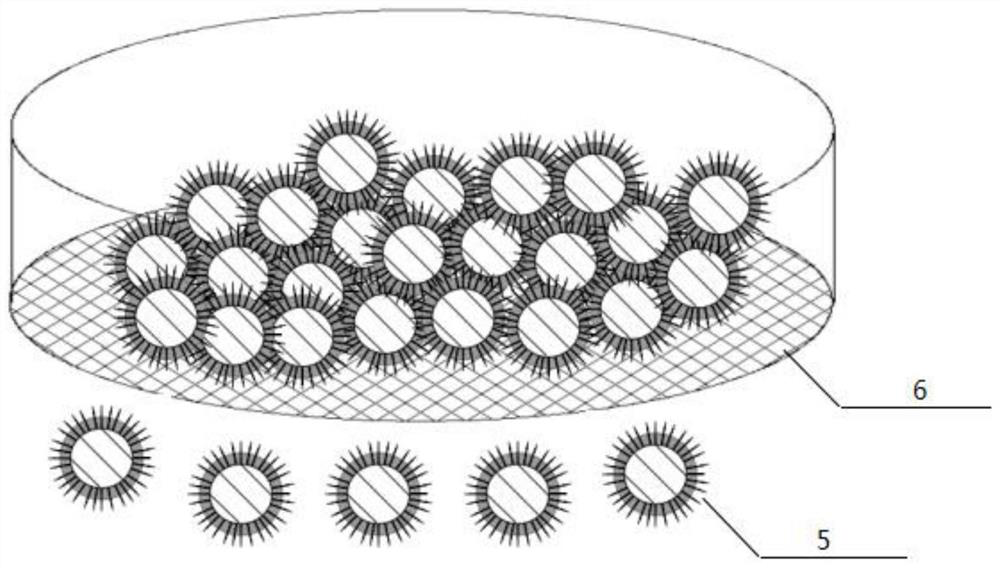

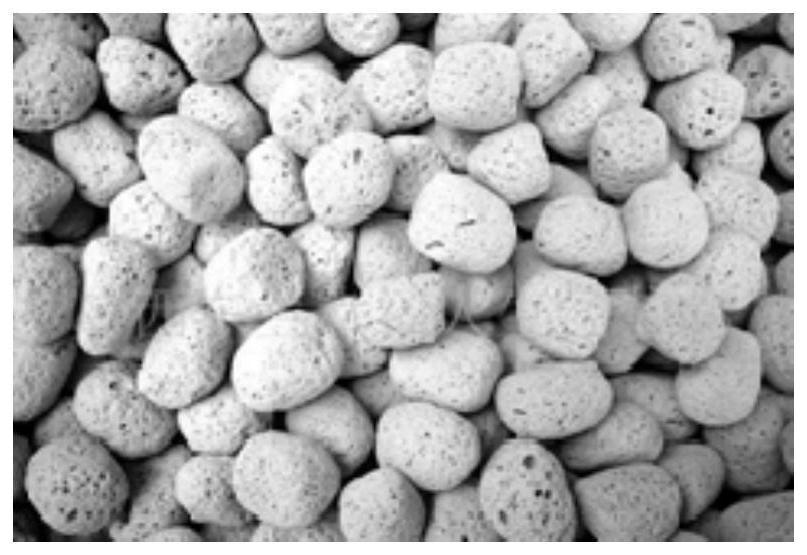

Fiber-wrapped lightweight aggregateand method for inhibiting floating of lightweight aggregate

The invention discloses a fiber-wrapped lightweight aggregate and a method for inhibiting floating of the lightweight aggregate. Pre-wetted lightweight aggregate and fiber are connected into a whole through a small amount of cementing material slurry, a cementing material slurry thin layer with the fiber is formed on the surface of the lightweight aggregate, and the hair-like lightweight aggregate with the fiber is prepared after coagulation and hardening. The lightweight aggregate is used as a novel coarse aggregate to prepare lightweight concrete. Therefore, the floating problem of the lightweight aggregate is effectively solved, and the homogeneity of a test piece is ensured; one end of the fiber on the surface of the lightweight aggregate is embedded and fixed in the thin layer of the cementing material coating the surface of the aggregate, and the other end of the fiber on the surface of the lightweight aggregate is embedded and fixed in concrete slurry, so that the contact area between the aggregate and the cement slurry is increased. Compared with a method of directly adding fibers, the method has the advantages that prepared concrete has larger tensile strength and larger interface bonding strength with the aggregate and cement paste, so that the lightweight aggregate is more effectively prevented from floating upwards.

Owner:BEIJING UNIV OF TECH

Production method of complete movable denture with biological adsorbability

The invention relates to a production method of a complete movable denture with biological adsorbability. The whole edge of a denture base support is effectively closed by virtue of a movable mucous membrane, and a temporary negative pressure is generated during swallowing and chewing, so that the up-floatation of the denture during the speaking is prevented, and the retention and stabilization ofthe denture in the functional movement process are improved. According to the production method, the problems that a finished product is poor in adsorption capacity, a mandibular arch relation is notcoordinated, the jaw relation is instable, residual alveolar crests are seriously absorbed, the range of a bearing region cannot be determined, and the appearance is not sufficiently attractive in and after the production processing process of a traditional complete denture are solved, so that the fatal disadvantages that the adsorption capacity of the common denture is insufficient, a biting jawis difficult to adjust, and the like are improved.

Owner:沈阳市佳艺义齿加工厂

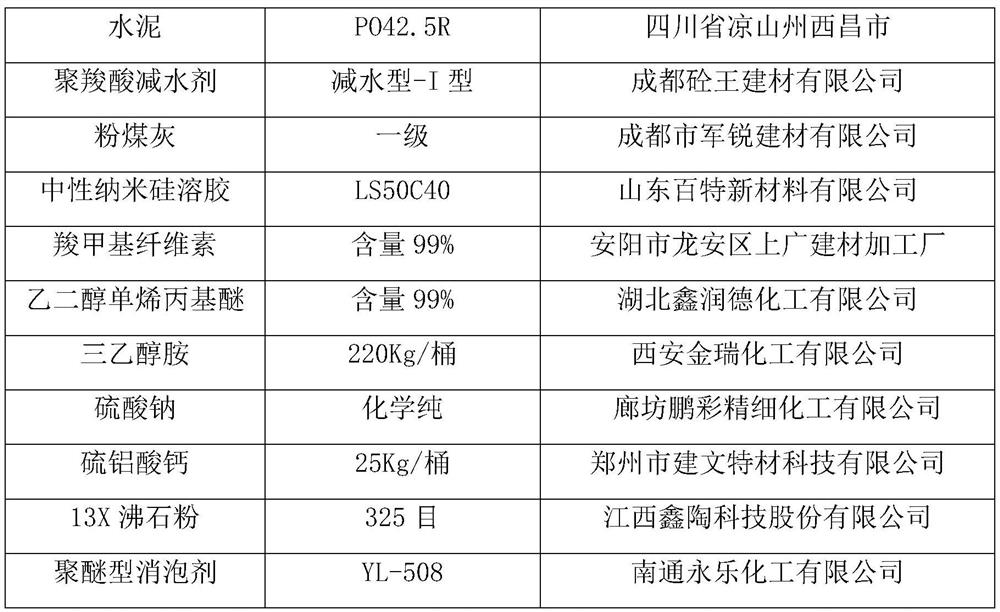

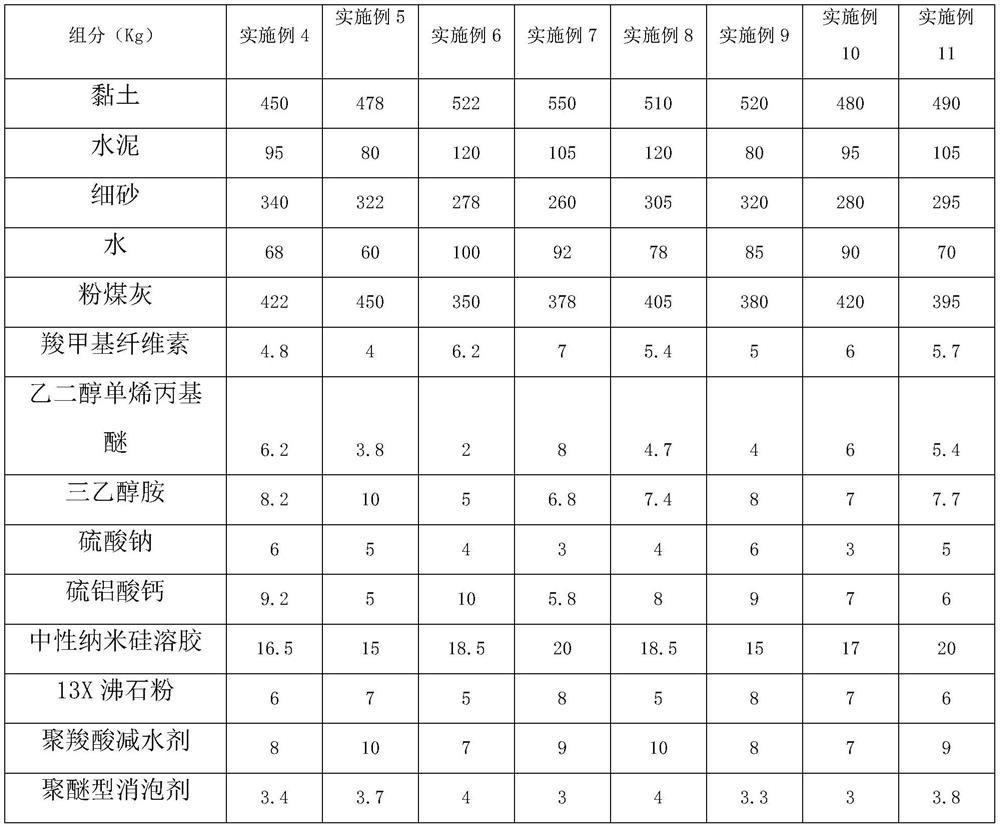

Premixed flow-state solidified soil slurry for composite pile and preparation method of premixed flow-state solidified soil slurry

The invention discloses premixed flow-state solidified soil slurry for a composite pile and a preparation method of the premixed flow-state solidified soil slurry, and relates to the technical field of preparation of building materials. The invention discloses premixed flow-state solidified soil slurry for a composite pile. The premixed flow-state solidified soil slurry is mainly prepared from thefollowing solidified soil slurry raw materials in parts by weight: 450-550 parts of clay, 80-120 parts of cement, 260-340 parts of fine sand, 60-100 parts of water and 350-450 parts of coal ash. Thesolidified soil slurry further comprises a modifier, and the modifier comprises the following modifier raw materials in parts by weight: 4-7 parts of carboxymethyl cellulose and 2-8 parts of ethyleneglycol monoallyl ether. The solidified soil slurry raw material further comprises an excitant. The premixed flow-state solidified soil slurry of the composite pile has the advantage of high safety. The preparation method of the premixed flow-state solidified soil slurry for the composite pile comprises the following steps: preparation of the modifier, preparation of the excitant, preparation of the flow-state solidified soil slurry and the like. The preparation method of the premixed flow-state solidified soil slurry for the composite pile has the advantage that the product safety can be improved conveniently.

Owner:四川东成建设有限公司

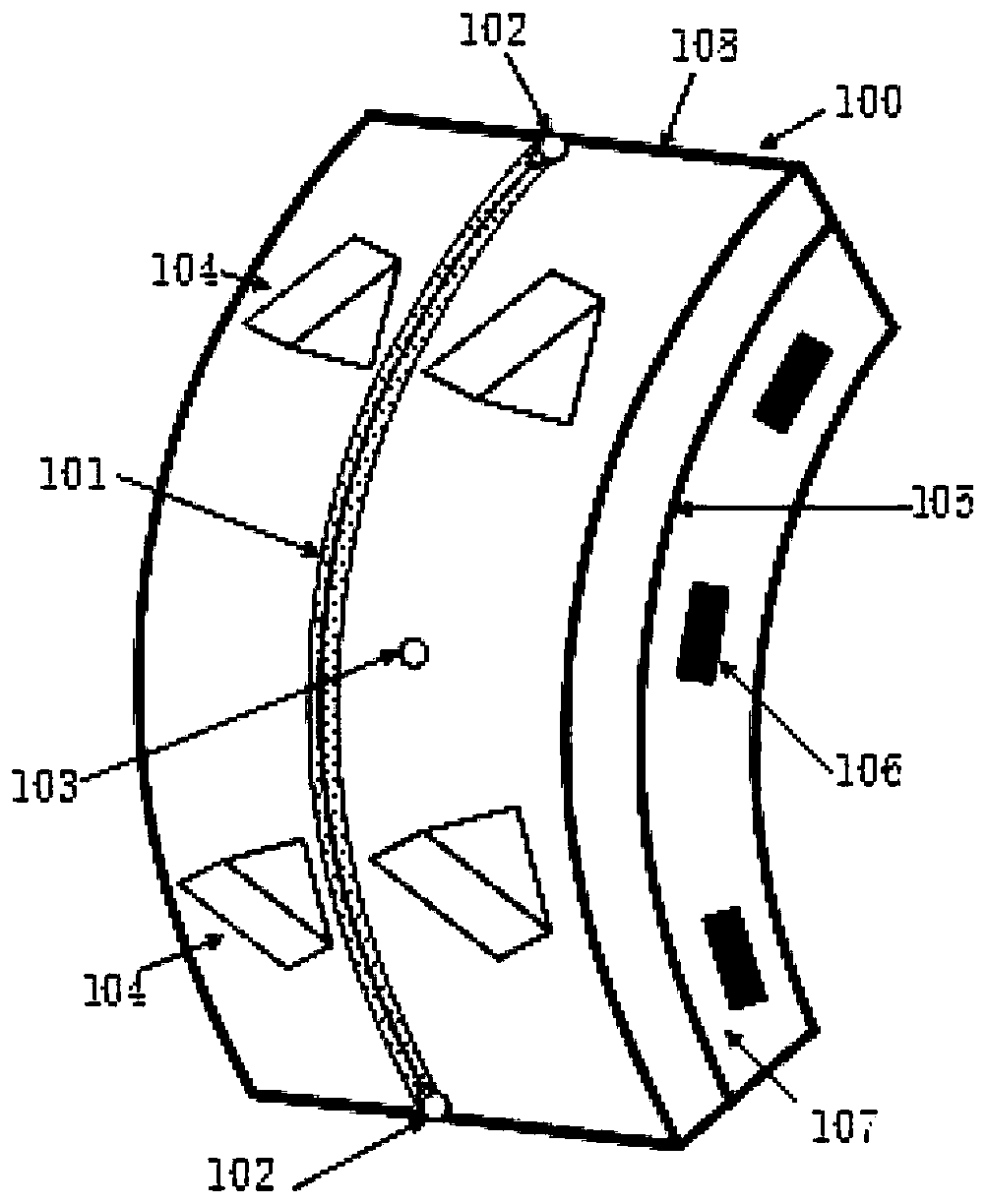

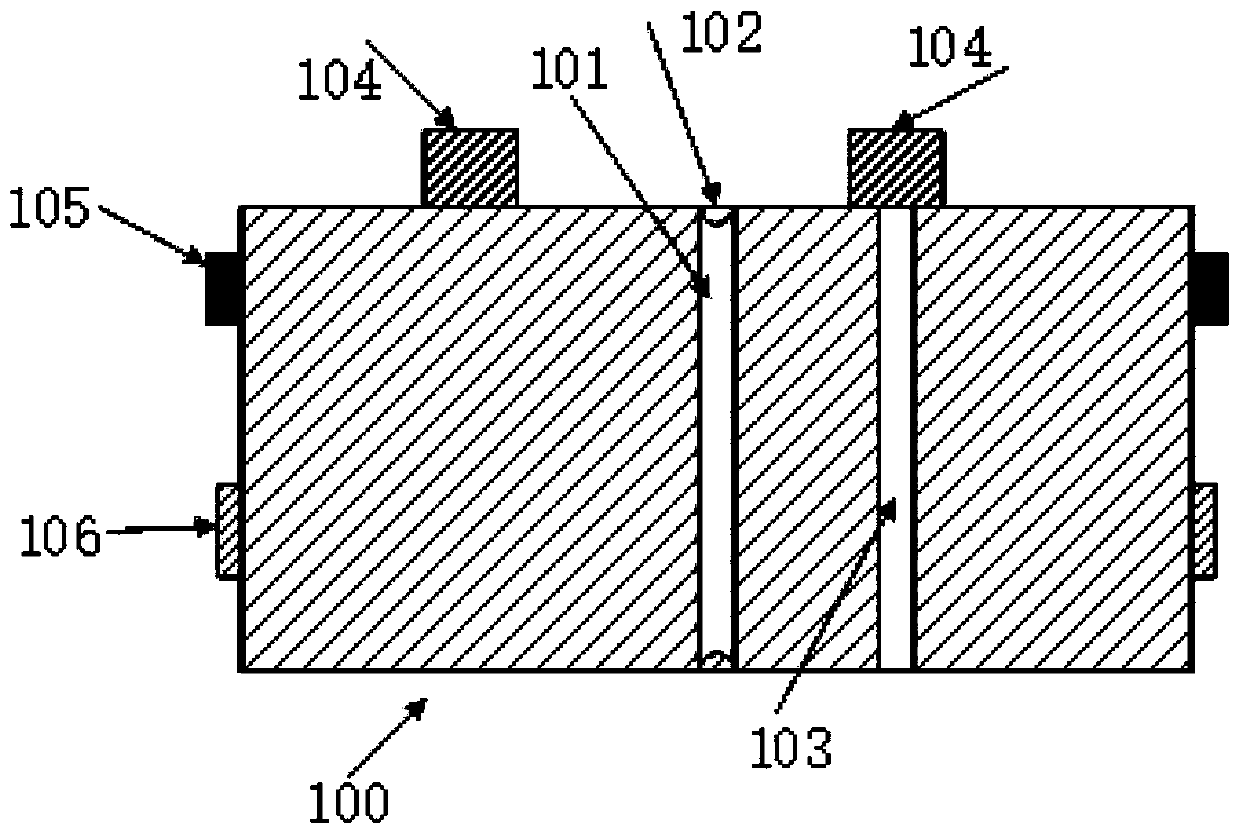

Roll-over safety valve

InactiveCN102140980AControl deformationReduce shock loadNon-fuel substance addition to fuelEqualizing valvesEngineeringSafety valve

A roll-over safety valve (1) comprises a counterweight part (40, 140, 240, 340, 440) located in a housing (2) and a valve element (30, 130, 230, 330, 430). The counterweight part is heavier than the valve element. The valve element comprises a first surface (36, 136, 236, 336, 436) facing a first end part in an axis direction, and the counterweight part comprises a second surface (46, 146, 246, 346, 446) facing a second end part in the axis direction. The second surface is positioned to be closer to the first end part than the first surface. When the valve element is separated from a valve seat, the first surface and the second surface are engaged with each other.

Owner:KYOSAN DENKI KABUSHIKI KAISHA

Ecological pit-type treatment method for black and odorous water body

InactiveCN109607988AImprove black and odor phenomenonImprove metabolic environmentWater treatment parameter controlWater cleaningIn situ degradationBiological oxidation

The invention discloses an ecological pit-type treatment method for a black and odorous water body. Firstly, exogenous solid-liquid contaminants are prevented from entering the polluted black and odorous water body, the solid contaminants in the water body are primarily removed through manual operation or mechanical fishing, a mud-water separating material is added into the black and odorous waterbody of a lake to improve the transparency of the water body, and illumination energy is provided for growth and propagation of microorganisms; then, porous biological carriers are put into a bottomsludge layer of the water body through the modes of pit digging, net pipe arranging or bottom mud structures, and biological oxidation materials are added and injected in the targeting direction of the bottom sludge layer to activate the microorganism metabolism environment of the bottom mud. The ecological pit-type treatment method is mainly applied to treatment on the black and odorous water body, can rapidly improve the water body and the black and odorous phenomenon of the bottom mud, optimizes the microorganism metabolism environment of the bottom mud, realizes in-situ degradation withoutsludge removal, effectively stops the bottom mud from floating, and promotes biological degradation of COD / NH3-N / TP.

Owner:合肥市东方美捷分子材料技术有限公司 +1

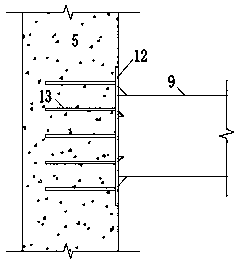

Active drainage anti-floating segment and lining structure

The invention belongs to the field of building construction, and particularly relates to an active drainage anti-floating segment and a lining structure. A main structure of the active drainage anti-floating segment comprises a segment body, a drainage pipe, drainage holes, a grouting hole, corner blocks, a water stop strip, anti-collision strips, a curved side end surface and a rectangular side end surface; through the active drainage holes, after slurry is hardened, the excess slurry existing between the segment and surrounding rock is bled and drained out, and then grouting is carried out again through the grouting hole until the position, between the segment and the surrounding rock, is all filled with hardened concrete, the filling rate of the slurry is improved, and the phenomenon that only the upper part of the segment is filled with water due to the shrinkage of the hardened volume of the slurry is eliminated, the anti-floating ability of the segment is greatly increased, through the triangular corner blocks composed of reinforced concrete, the contact between the segment and the surrounding rock is more tight, action points of the triangle corner blocks on both sides of the segment transfer to the depth of the surrounding rock to form a stress arch, and the segment is effectively prevented from floating up.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

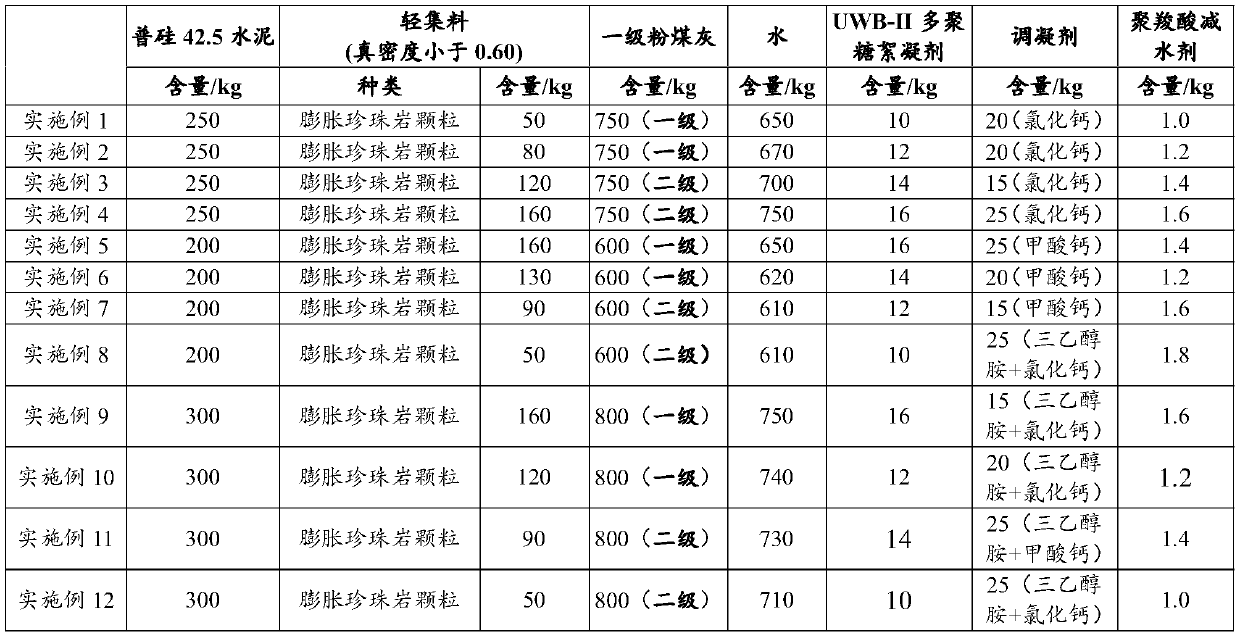

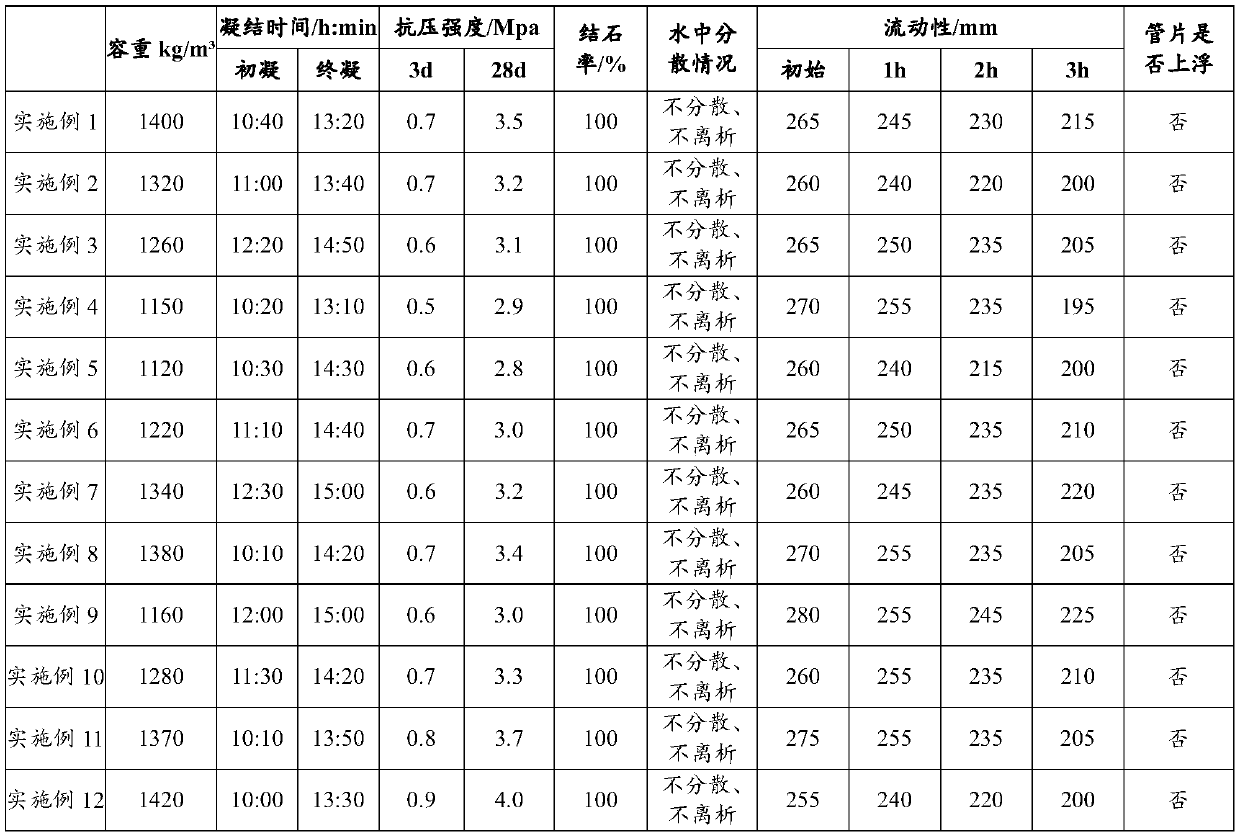

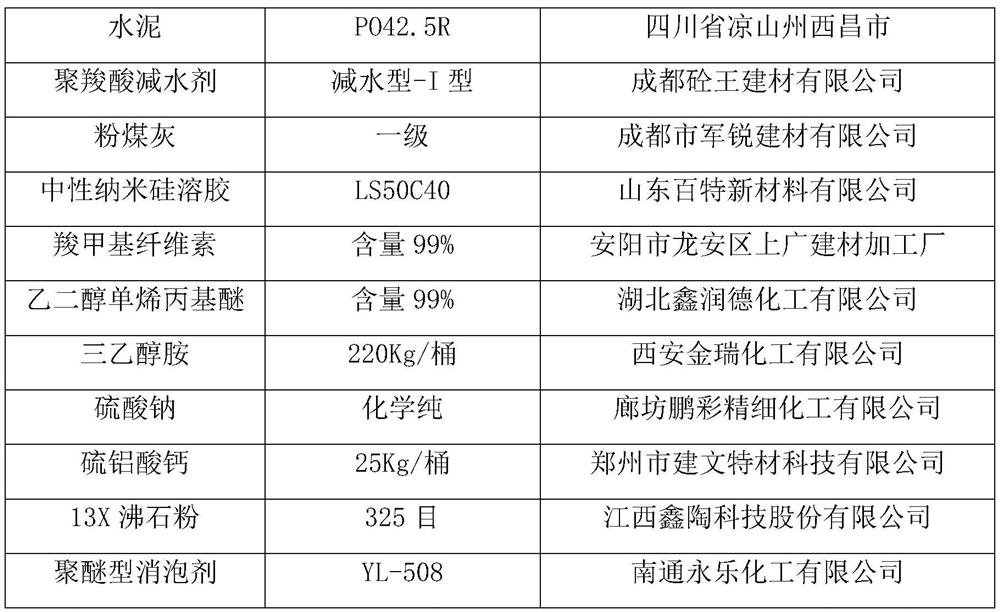

Light slurry for shield synchronous grouting

The invention discloses light slurry for shield synchronous grouting. The light slurry comprises the following components in parts by weight: 200 to 300 parts of cement, 50 to 160 parts of light aggregate, 600 to 800 parts of fly ash, 1.0 to 1.6 parts of a water reducing agent, 10 to 16 parts of a flocculating agent, 15 to 25 parts of a thickening time control agent and 600 to 750 parts of water.Compared with the prior art, the volume weight of the light slurry for shield synchronous grouting is 1.0-1.4 kg / m<3>; the volume weight is far less than that of existing synchronous mortar, the lightslurry cannot will not quickly sink to a bottom cushion supporting pipe sheet or be taken away by the circulating slurry at the slurry discharge port below, thereby greatly reducing the loss amount after the synchronous slurry is injected, obviously improving the shield synchronous grouting effect, and effectively preventing the pipe sheets from floating upwards in the shield construction in a water-rich section. Besides, the light slurry for shield synchronous grouting is not dispersed in water, the 3d compressive strength in water can reach 0.5 MPa or above, the final setting time is shorter than 15 h, the light slurry is particularly suitable for filling building gaps between pipe sheets and surrounding rock in tunnel synchronous shield tunneling construction, and the engineering quality can be better guaranteed.

Owner:中广核工程有限公司 +2

A kind of aluminum silicon draining agent and preparation method thereof

ActiveCN104493150BImprove performanceNo pollution in the processMelt-holding vesselsSteelmakingEnvironmental resistance

The invention provides an aluminum-silicon drainage agent and a preparation method thereof, belonging to the field of unshaped surface refractory materials used in the steelmaking industry. The technical solution of the present invention is: an aluminum-silicon drainage agent, which is composed of ceramic bead sand with a particle size of 0.5-1.2 mm, desert quartz sand with a particle size of 0.3-0.9 mm, phosphorus flake graphite with a particle size of ≤75 μm, and an adhesive It is made by first drying ceramic bead sand and desert quartz sand, then adding phosphorus flake graphite and binder, and stirring in a cylinder mixer to make it. The aluminum-silicon drainage agent of the present invention can effectively increase the casting rate of the product, so that the casting rate of the product can reach more than 98%, and at the same time greatly reduce the cost of the product, effectively reduce the emission of waste gas and dust, clean and environmentally friendly, and adapt to the current steel industry's requirements for product quality, Price and purity requirements of molten steel.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

A kind of composite pile ready-mixed fluid solidified soil slurry and preparation method thereof

The invention discloses a composite pile pre-mixed fluid solidified soil slurry and a preparation method thereof, and relates to the technical field of building material preparation; a composite pile pre-mixed fluid solidified soil slurry mainly consists of the following solidified soil slurry in parts by weight Raw materials are obtained: 450-550 parts of clay, 80-120 parts of cement, 260-340 parts of fine sand, 60-100 parts of water, and 350-450 parts of fly ash; The modifier includes the following modifier raw materials in parts by weight: 4-7 parts of carboxymethyl cellulose, and 2-8 parts of ethylene glycol monoallyl ether; the solidified soil slurry raw material also includes an activator. The ready-mixed fluid solidified soil slurry for composite piles has the advantage of high safety. The preparation method of the composite pile ready-mixed fluid-state solidified soil slurry comprises the following steps: preparation of a modifier, preparation of an activator, preparation of a fluid-state solidified soil slurry, and the like. The preparation method of the composite pile ready-mixed fluid solidification soil slurry has the advantage of being convenient to improve product safety.

Owner:四川东成建设有限公司

Smoke dust inhibitor as well as preparation method and application thereof

PendingCN112877033AImprove flame retardant performanceFlame retardantOther chemical processesCarbonationBrown iron oxide

The invention provides a smoke dust inhibitor which comprises the following components in percentage by mass: 46-54% of aluminosilicate, 19-22% of a phosphoric acid compound, 13-17% of a carbonic acid compound and 13-17% of chloride. The smoke dust inhibitor is prepared by taking aluminosilicate, a phosphoric acid compound, a carbonic acid compound and chloride as raw materials, and the dosage of each component is controlled, so that iron oxide in the smoke dust can be completely decomposed, nitrogen oxide can be completely volatilized, and the floating of graphite can be prevented, thereby realizing the effective inhibition on the smoke dust. Results of the embodiment show that the smoke dust inhibitor provided by the invention has the smoke dust covering performance of 100%, the flame retardant performance of 100%, the floating prevention performance of 100% and the decomposition performance of 100%.

Owner:巩义市科正冶金材料有限公司

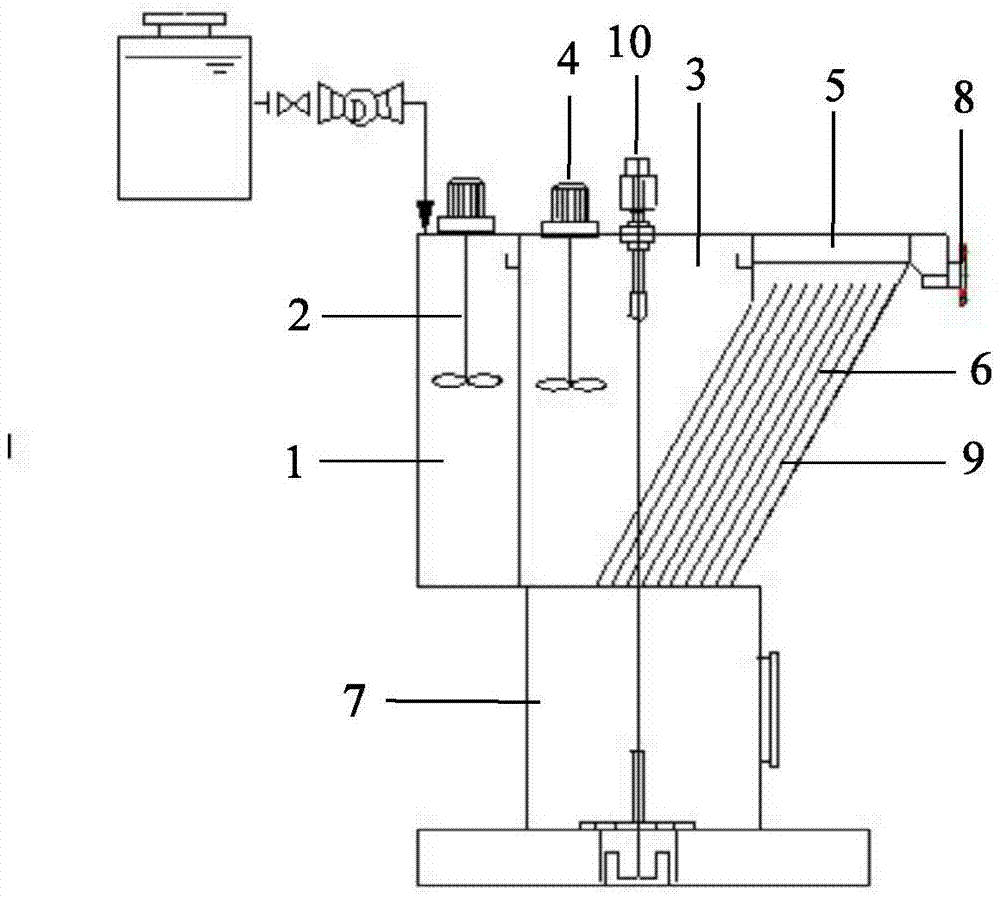

Efficient and energy-saving paint-water separation device

InactiveCN103663660AReduce paint slag contentHigh slag removal efficiencyWater/sewage treatment by flocculation/precipitationSlagPrecipitation

The invention provides an efficient and energy-saving paint-water separation device, which comprises a rapid mixing tank (1), a slow mixing tank (3) and a precipitation tank (5), wherein a stirrer (2) is arranged in the rapid mixing tank (1); the rapid mixing tank (1) is communicated with a liquid inlet pipeline; the slow mixing tank (3) has a cavity shell structure; a stirrer (4) is arranged in the slow mixing tank (3); the slow mixing tank (3) is communicated with the rapid mixing tank (1) through a middle penetration hole; the precipitation tank (5) comprises a sloping plate precipitation area (6) and a paint slag bucket (7) positioned below the sloping plate precipitation area (6); the sloping plate precipitation area (6) is completely communicated with the paint slag bucket (7); a water outlet (8) is formed in the top of the rear end of the precipitation tank (5); the precipitation tank (5) is communicated with the slow mixing tank (3); a paint slag outlet is formed in one side of the paint slag bucket (7); the tops of the rapid mixing tank (1), the slow mixing tank (3) and the precipitation tank (5) are positioned on the same horizontal plane; a chemical feeding system is unidirectionally communicated with the rapid mixing tank (1), the slow mixing tank (3) and the precipitation tank (5).

Owner:江苏佳有环保科技有限公司

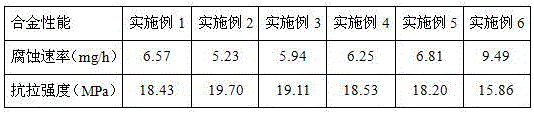

A positive electrode grid alloy for maintenance-free lead-acid batteries

The invention provides positive electrode grid alloy for a maintenance-free lead-acid storage battery and a preparing method of positive electrode grid alloy. The alloy is prepared from, by weight, 0.02%-0.15% of barium, 0.002%-0.01% of silver, 0.04%-0.15% of calcium, 0.25%-1.80% of tin, 0.02%-0.20% of rare earth elements and the balance lead. The strength of the alloy is improved, the corrosion resistance of the alloy is improved, and accordingly the high-temperature floating life and the deep cycle life of the battery are prolonged.

Owner:CAMEL GRP HUAZHONG BATTERY

Tensioner apparatus for overspeed governor of elevator

The invention provides a tension pulley device for an elevator governor rope has a tension pulley suspended by the governor rope, a pivoting member rotated by a vertical displacement of the tension pulley, a restraining member whose distance from the pivoting member is reduced when the pivoting member is pivoted into the direction in which the tension pulley is displaced upward, a wedge inserted between the pivoting member and the restraining member, and an urging member for urging the wedge into the direction in which the wedge pushes and spreads the distance between the pivoting member and the restraining member. A supporting member is provided in a hoistway, and the pivoting member and the restraining member are disposed on the supporting member. The wedge has a first contact surface coming into contact with the pivoting member and a second contact surface inclined relative to the first contact surface and coming into contact with the restraining member. Pushing of the wedge into the gap between the pivoting member and the restraining member prevents the tension pulley from being displaced upward.

Owner:MITSUBISHI ELECTRIC CORP

Hollow glass bead-elastic resin compound grains and production method and application thereof

ActiveCN109852019AStop floatingImprove performanceAbrasion apparatusGrinding devicesHeavy particleWater soluble

The invention discloses hollow glass bead-elastic resin compound grains and a production method and application thereof. Elastic resin is used as a matrix of the compound grains, hollow glass beads are evenly distributed in the matrix, and the volume of the hollow glass beads accounts for 30-70% of the total volume of the compound grains. According to the hollow glass bead-elastic resin compound grains, the grain size of the compound grains is large, and the large-area lipophilic elastic resin is on the surfaces of the compound grains, is conducive to preventing compound grain floatation in aliquid polishing wheel mixture, and plays a part in obstructing sedimentation of heavy particles at the same time, so that the homogeneity of the liquid mixture is improved, existing water-soluble salt is replaced, and the technical performance of a polishing wheel is improved; and the produced polishing wheel plays a part in vibration absorption and noise reduction due to the hollow glass beads in the polishing wheel, so that high-decibel noise occurs during polishing is greatly reduced.

Owner:天津佐源新材料科技有限公司

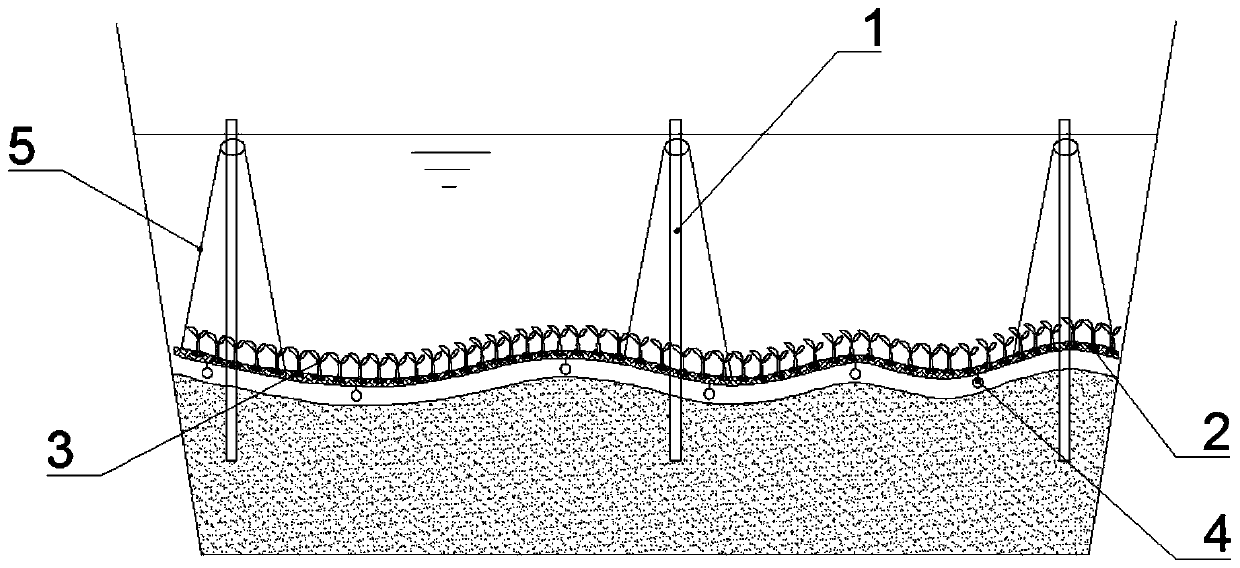

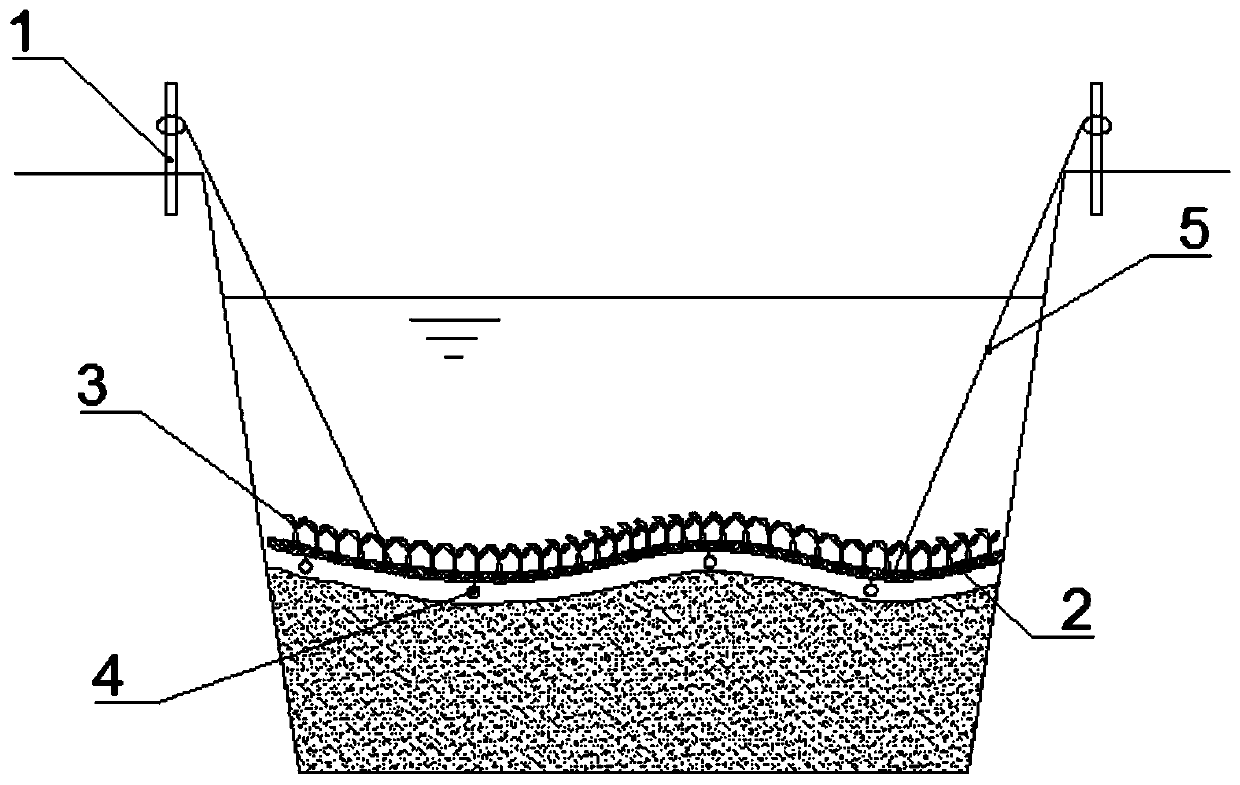

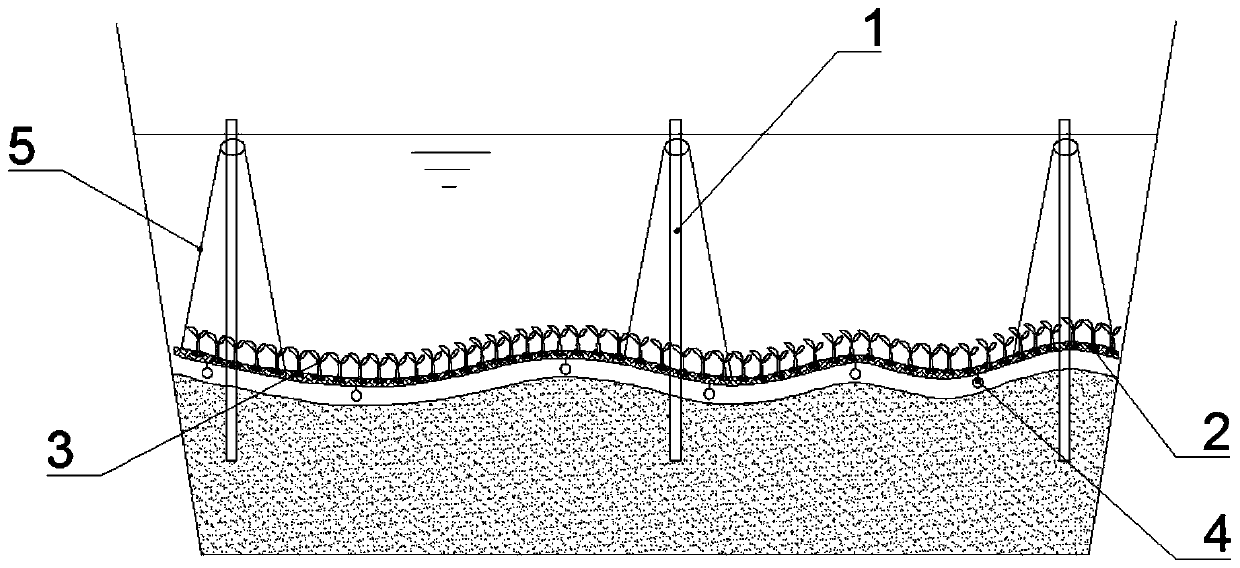

System and method for ecologically processing black and odorous water body

PendingCN109970206AStop floatingPromotes fast digestionBiological sludge treatmentBiological water/sewage treatmentEngineeringRiver bed

The invention provides a system and method for ecologically processing a black and odorous water body, and belongs to the technical field of water treatment. The system comprises a fixed pile and braided straws, submerged plants with strong roots are planted in braided straws; the bottom of the braided straws is fixedly connected to a plurality of balancing weights through connection ropes; the top of the braided straws is fixedly connected to one end of a limiting rope, the other end of the limiting rope is fixed on the fixed pile; when the system is used, the braided straws are slowly soakedinto the water, after the water above the braided straws becomes clear, the braided straws are precipitated until the submerged plants can be seen, and the steps are repeated until the braided strawscover the bottom mud of the river bed. The water body is purified by an ecological means such as microbes, submerge plants, and the like; the bottom mud is decomposed and absorbed, the submerge plants can be harvested periodically, the water body is purified, the bottom mud is degraded, the cost is low, and the method is simple and effective.

Owner:以农环境工程有限公司

Concrete with pumice waste residues as aggregates and preparation method of concrete

The invention discloses concrete with pumice waste residues as aggregates and a preparation method of the concrete. The concrete comprises the following components: 350-550 kg / m<3> of cement, 90-100 kg / m<3> of fly ash, 30-50 kg / m<3> of silica fume, 900-1000 kg / m<3> of the pumice waste residues, 170-250 kg / m<3> of water and 15-80 kg / m<3> of an additive, wherein the additive comprises the followingcomponents in percentage by mass: 4%-5% of a water reducing component, 0.8%-1.2% of a water retaining component, 0.8%-1.2% of a slump retaining component, 1.0%-1.5% of a thickening component and 92%-93% of a lubricating component. The surfaces of the pumice waste residues do not need to be treated at all, particle size screening of the pumice waste residues is not needed either, and direct application of the pumice waste residues can be achieved.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

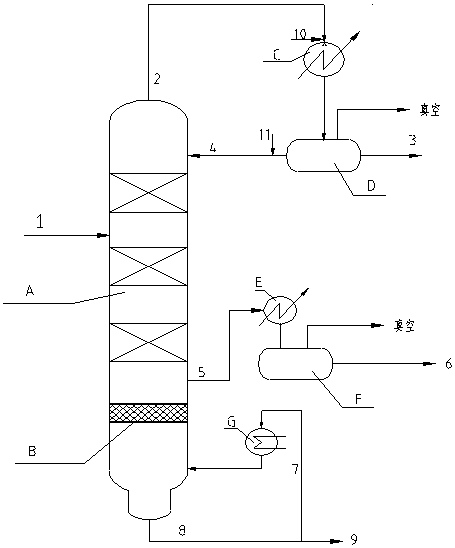

A post-processing method and post-processing device for a 3-methylthiopropionaldehyde reaction mixture

ActiveCN105968034BStop floatingReduce lossesOrganic chemistryOrganic compound preparationProcess engineeringTower

The invention provides a post-treatment method for a 3-methylthio-propylaldehyde reaction mixture. The post-treatment method comprises feeding, tower top discharging of a rectification tower, tower bottom discharging of the rectification tower and feeding of a polymerization inhibitor. The invention further provides a post-treatment device for the 3-methylthio-propylaldehyde reaction mixture; the device is characterized by comprising the rectification tower, a lateral line discharging hole and a polymerization inhibitor feeding hole; the inner structure of the rectification tower comprises a packing section and a de-foaming device; the packing section is located at the upper end of the rectification tower; the de-foaming device is located at the lower end of the rectification tower. The post-treatment process provided by the invention has the following beneficial effects that a rectification process of 3-methylthio-propylaldehyde is simplified and the cost of equipment is reduced; leftovers generated by product polymerization in a rectification process are reduced, the rectification yield is improved, the material loss is reduced, the yield of the product reaches 99.2 percent and the purity of the product is 99.9 percent; one-step rectification adopted so that the energy consumption is reduced and the production cost is reduced.

Owner:SHANDONG XINHECHENG AMINO ACID

A preparation method of cast graphene/aluminum alloy composite material and cast graphene/aluminum alloy composite material

ActiveCN107502772BOvercome the disadvantage of poor interfacial wettabilityPrevent oxidationHeat resistanceAlloy composite

Owner:WUXI JCNANO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com